Novel polycrystalline silicon production preheating method and novel polycrystalline silicon production preheating device

A new technology of polysilicon, applied in furnace control devices, chemical instruments and methods, silicon compounds, etc., can solve the problems of reduced microwave heating efficiency, high production costs, and large safety hazards, and achieve shortened heating time, easy operation, and improved The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

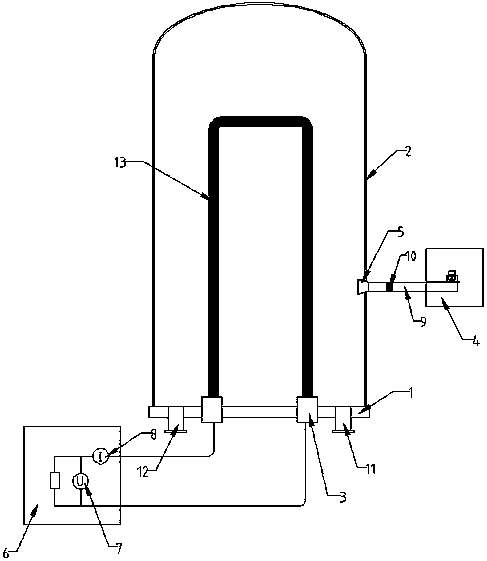

[0036] This embodiment, as a basic embodiment of the present invention, discloses a reduction furnace for preheating a new type of polysilicon production, and its specific structure is as follows: figure 1 Said, including chassis 1 and furnace cover 2, described chassis 1 is connected with furnace cover 2 to form an airtight space, described chassis 1 is provided with electrode 3, and one end of electrode 3 extends into furnace cover 2 through chassis 1 In the airtight space formed with the chassis 1, the other end of the electrode 3 protrudes out of the airtight space formed by the chassis 1 and the furnace cover 2, and this section of the electrode 3 is connected to the electric heating power supply 6; the furnace cover 2 is also provided with The microwave feed port 5 is connected to the microwave generator 4, and the chassis 1 is respectively provided with an air inlet and an exhaust port for passing in and discharging the protective gas.

Embodiment 2

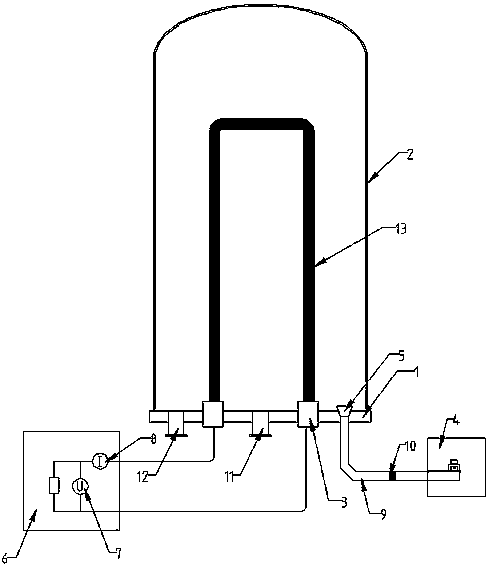

[0038] This embodiment is another preferred embodiment of the present invention, which discloses a new polysilicon production preheating reduction furnace, the specific structure is as follows figure 2 As shown, it includes a chassis 1 and a furnace cover 2 connected to each other, and the furnace cover 2 is connected with the chassis 1 to form a closed space. The chassis 1 is provided with an electrode 3, and one end of the electrode 3 extends through the chassis 1 into the In the closed space formed by the furnace cover 2 and the chassis 1, the other end of the electrode 3 extends out of the closed space formed by the chassis 1 and the furnace cover 2, and this section of the electrode 3 is connected to the electric heating power supply 6, and the electric heating power supply 6 A voltage detection device 7 for detecting the voltage at both ends of the silicon core 13 and a current detection device 8 for detecting the current at both ends of the silicon core 13 are arranged ...

Embodiment 3

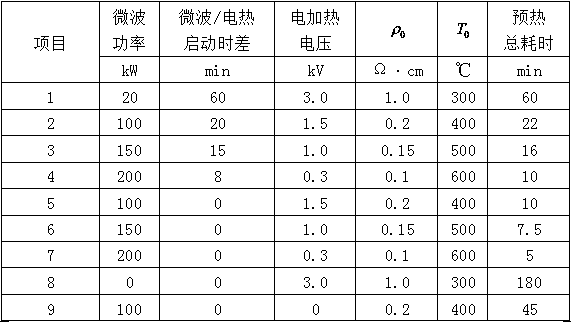

[0040] This embodiment, as a preferred embodiment of the present invention, discloses a novel polysilicon production preheating method, comprising the following steps:

[0041] A. Make a single silicon core into a U shape or connect multiple silicon cores in series to form a U shape, then connect the two ends of the U-shaped silicon core to the two electrodes on the chassis, and then connect the chassis to the furnace cover in a sealed manner;

[0042] B. Open the air inlet and exhaust port, and pass nitrogen through the air inlet, completely replace the air in the furnace cover, and then close the air inlet and exhaust port;

[0043] C, start microwave generator, carry out microwave irradiation to silicon core, microwave power is 20kW;

[0044] D. After 60 minutes of microwave irradiation, start the electric heating power supply, energize the two electrodes on the chassis, and the energizing voltage is 3kV, read the energizing voltage and current through the voltage detection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com