Ehaust device of cartridge heater of injection machine

A technology of injection molding machine and exhaust device, applied in the field of exhaust device, can solve problems such as moisture and gas condensation, and achieve the effects of good suction, easy cleaning and easy configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

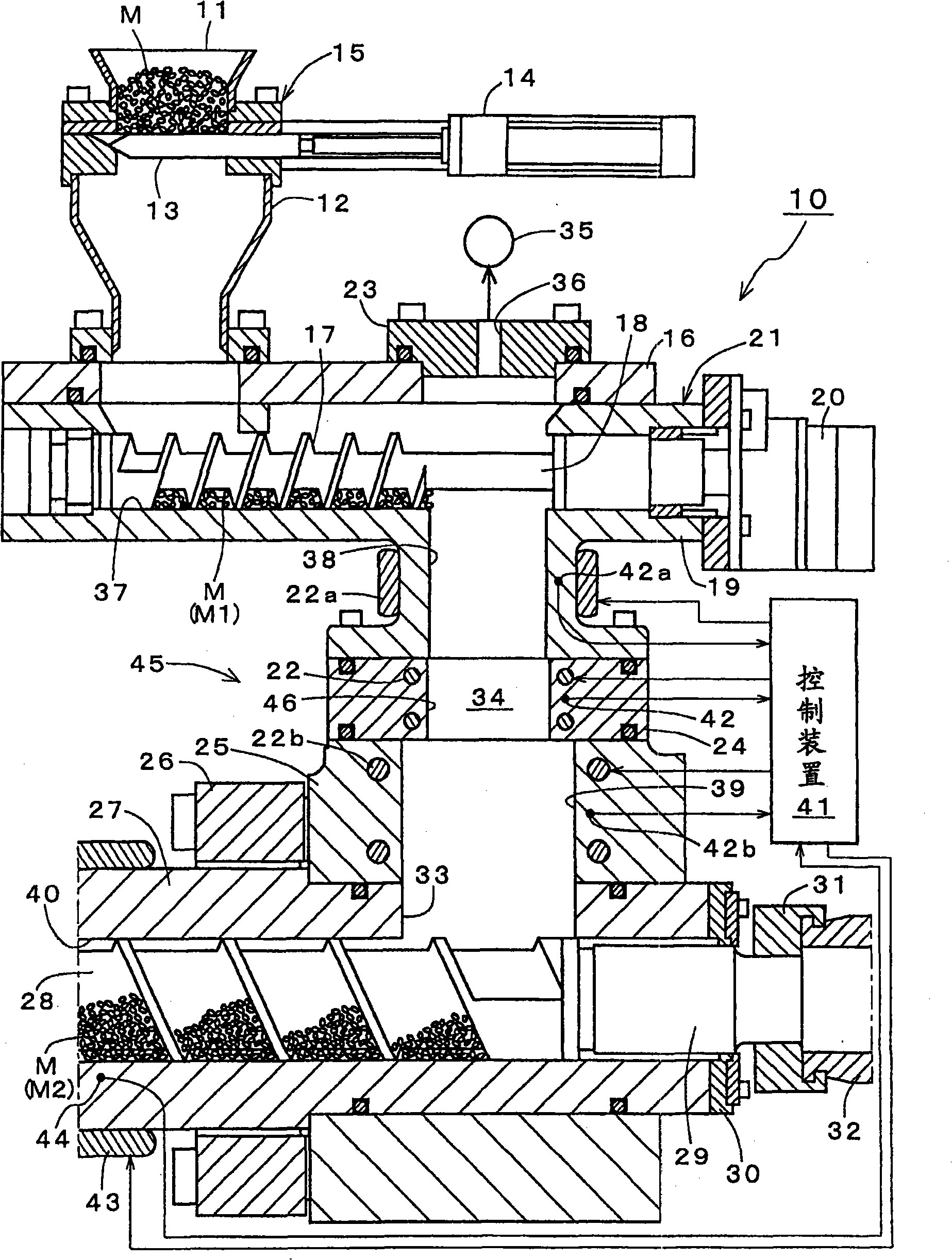

[0030] Embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a longitudinal sectional view showing main parts of an exhaust device of an injection molding machine embodying the present invention.

[0031] exist figure 1 In the injection molding machine 10 shown, the molding raw material M put into the raw material supply device 15 is supplied to the raw material conveying device 21 while maintaining the depressurized state in the raw material supply device 15, and the molding raw material M after adjusting the conveyed amount by the raw material conveying device 21 is M (M1) is supplied to the heating cylinder 27 through the raw material drop passage 34 and the upper opening 33, and passes through the heating cylinder 27 and the screw 28 that is inserted into the inner hole 40 in a reciprocating manner and rotates under the action of the screw driving device 32 , the molding raw material M (M2) can be plasticized to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com