Patents

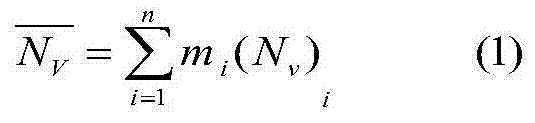

Literature

311results about How to "Not easy to generate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

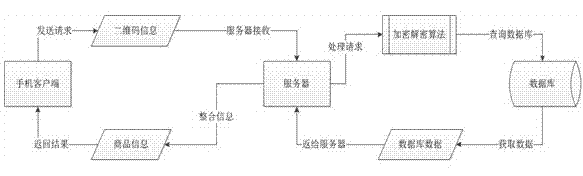

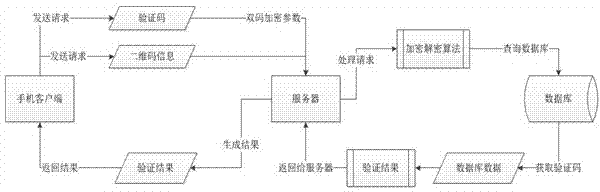

Commodity double-layer anti-fake method based on technologies of internet of things

Provided is a commodity double-layer anti-fake method based on technologies of internet of things. The commodity double-layer anti-fake method based on the technologies of the internet of things comprises a plain code layer, a code layer, a mobile terminal, a server and a database. The plain code layer only contains inquiry codes which are used for inquiry of commodity information. A user obtains an inquiry code through the mobile terminal, and the inquiry code is automatically sent to the server. The server obtains a commodity information code through a decipherment algorithm, inquires corresponding commodity information from the database, and then sends the commodity information back to the mobile terminal. The code layer only contains verification codes which are used for verification of authenticity of a commodity, wherein a verification code and a corresponding inquiry code are a pair of rule codes which are bound in a one-to-one correspondence mode. The user obtains the verification code through the mobile terminal which is provided with identification software of two-dimension codes, bar codes or digital codes, and the verification code is automaticlly sent to the server. The server matches the verification code and the inquiry code, and sends a matching result back to the mobile terminal. The commodity double-layer anti-fake method based on the technologies of the internet of things has the advantages of being good in anti-fake performance, providing convenience, and being high in encryption performance, rapid, not prone to being forged, and beneficial for protecting rights and interests of consumers and enterprises.

Owner:HUNAN IOT ONLINE TECH

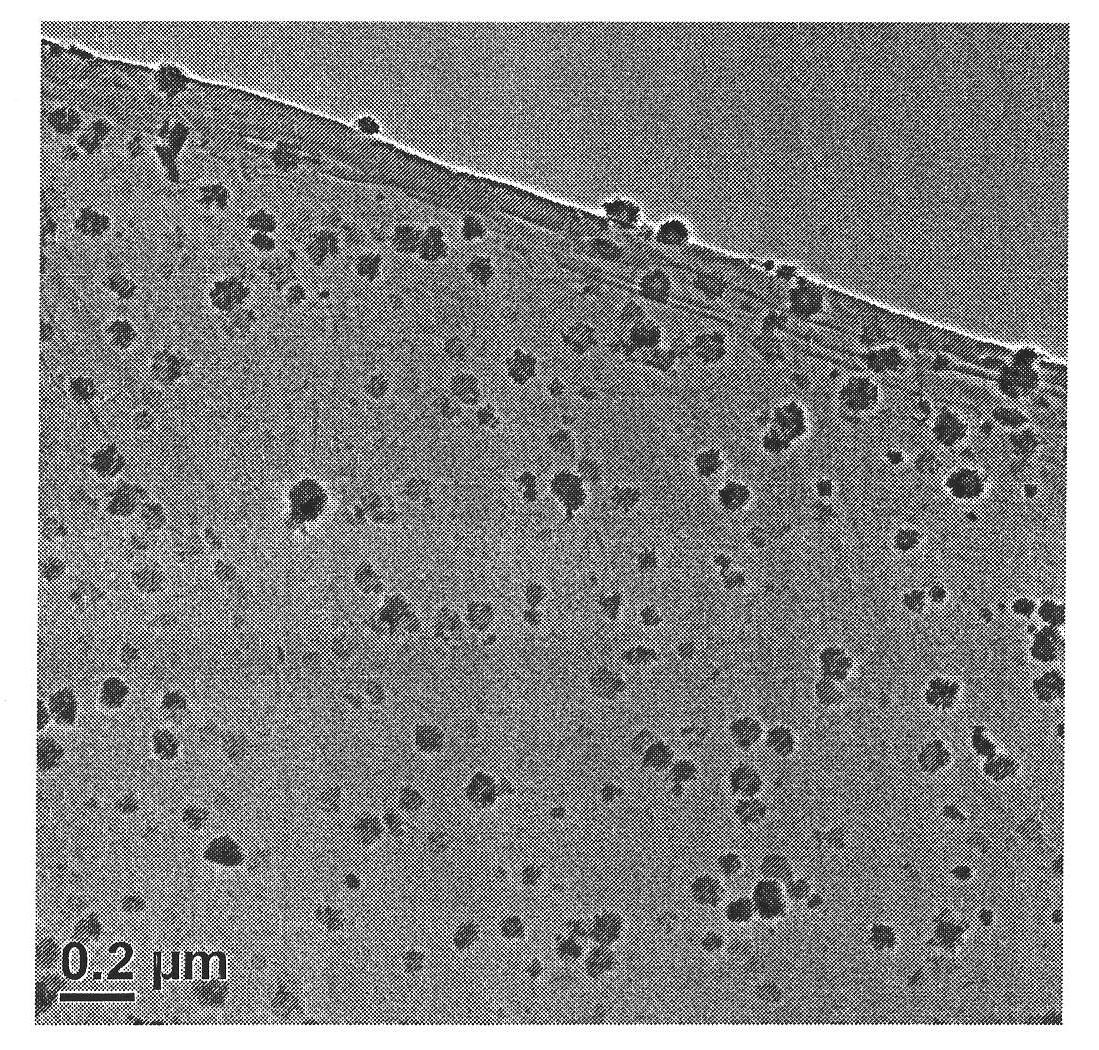

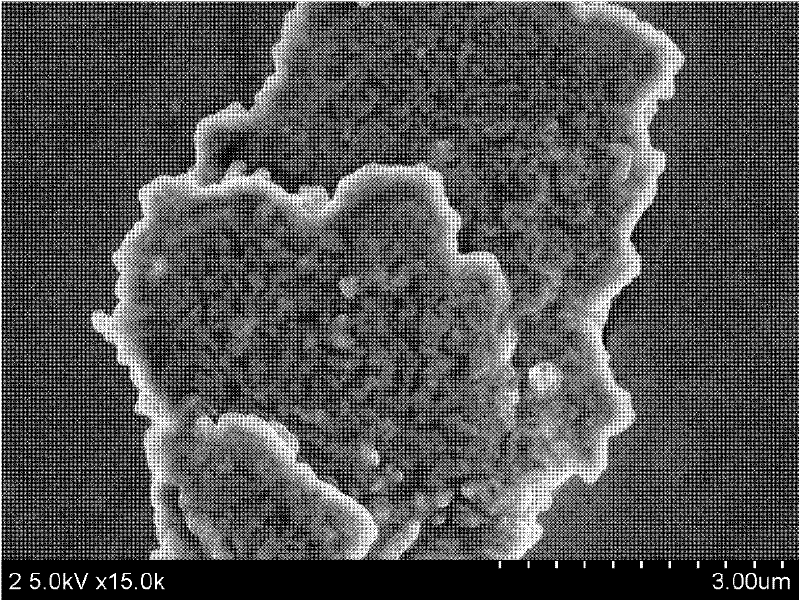

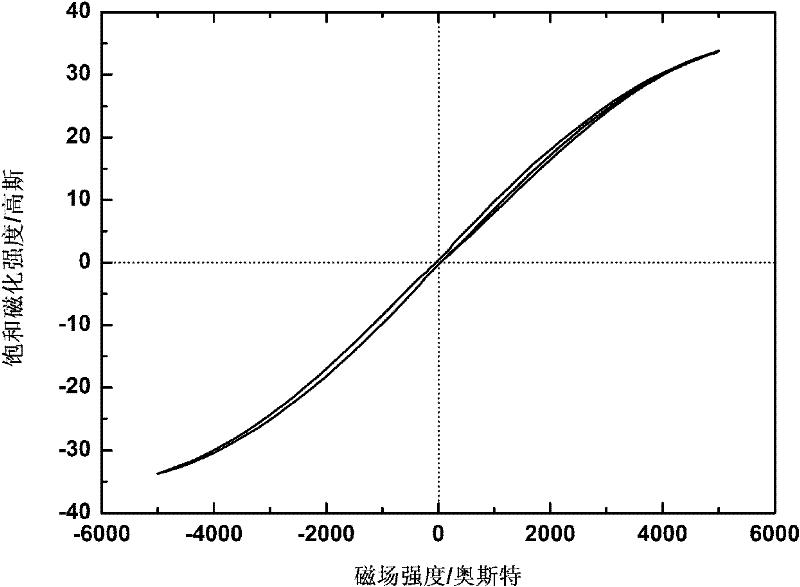

Method for preparing graphene/Fe3O4 composite powder by alcohol thermal method

InactiveCN101837971AEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesAlcoholPolyethylene glycol

The invention relates to a method for preparing graphene / Fe3O4 composite powder by an alcohol thermal method, which comprises the following steps of: (1) weighing oxidated graphite and ferric salt at room temperature, dispersing into a glycol solution, adding polyethylene glycol after dissolving completely, then adding anhydrous sodium acetate, stirring and forming reaction liquid; (2) putting into a reaction kettle, heating to the temperature of 180 to 220 DEG C and reacting for 8 to 16h; and (3) cooling to the room temperature, collecting a product by using a magnet, washing the product by deionized water and drying so as to obtain the graphene / Fe3O4 composite powder. In the invention, the preparation method is simple and is easy for industrialized production; and Fe3O4 in the prepared graphene / Fe3O4 composite powder has pure crystalline phase, little possibility of agglomeration, favorable compounding with graphene and good dispersibility at the surface of the graphene and in the layer of the graphene, and the composite powder has small resistivity and high magnetization intensity.

Owner:DONGHUA UNIV

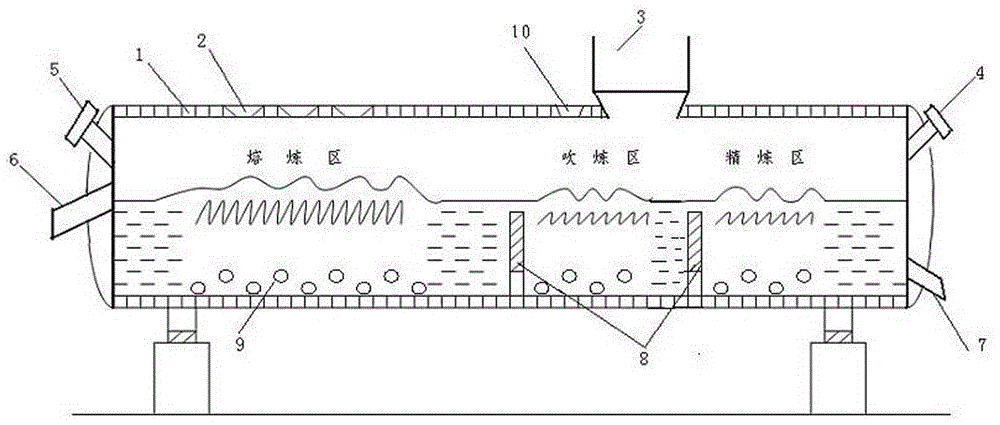

Copper smelting device and process

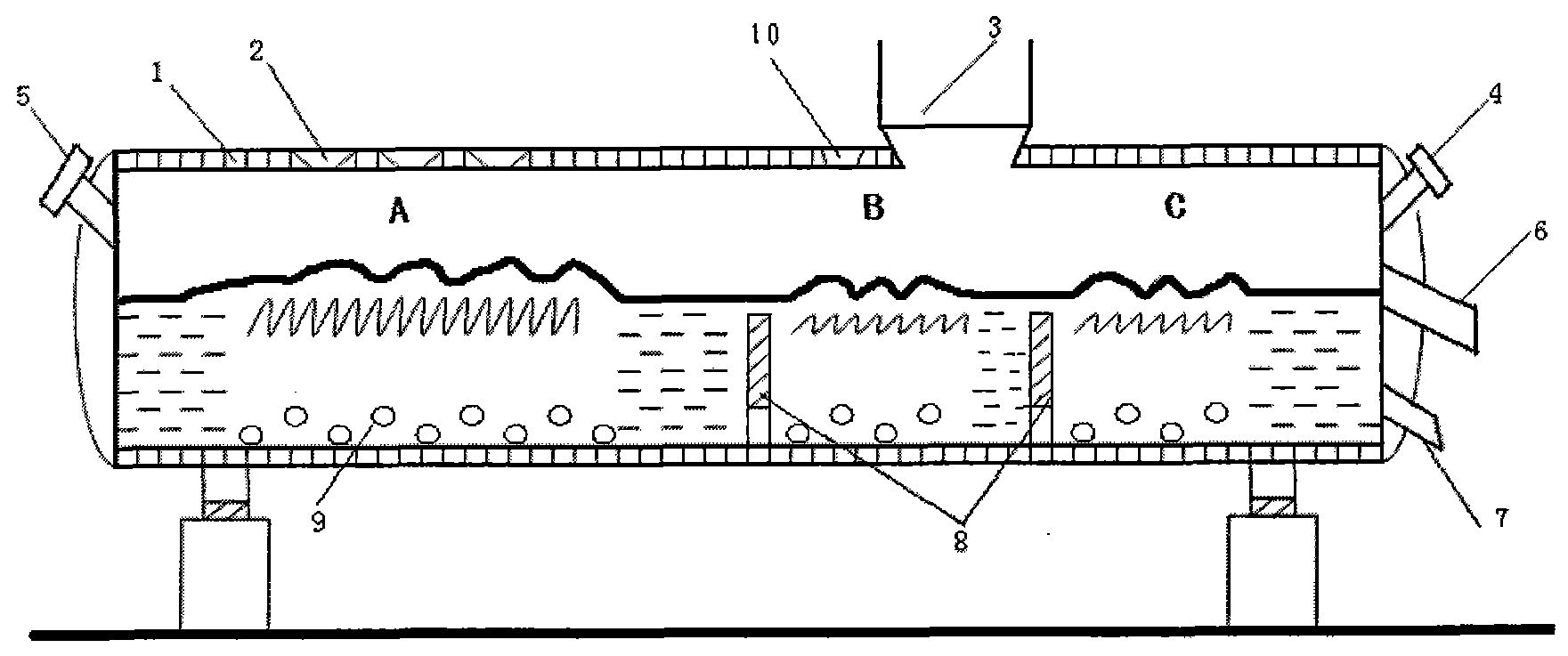

InactiveCN102181661AAchieve positive resultsReduce bad luckRotary drum furnacesCrucible furnacesBrickSmelting process

The invention provides a copper smelting device and a copper smelting process. In the device, a shell of a rotary horizontal type cylindrical furnace body is made of a steel plate; an inner liner is made of a refractory material; the furnace body passes through two supporting rings and is supported on a foundation through four supporting rollers; one side of the furnace body is provided with a transmission mechanism; a motor is used for driving a speed reducer to drive the furnace body to rotate along a central shaft through a gear and a gear ring on a cylinder; the furnace body is partitioned into a smelting area, a blowing area and a refining area by a refractory brick retaining wall; a gap is formed at the bottom of the retaining wall; the bottoms of all areas are provided with a spray gun respectively; a charging hole is formed above the smelting area; a flue hole and a fluxing agent hole are formed above the blowing area; a main burner nozzle and an auxiliary burner nozzle are arranged on the shell of the furnace body end close to the two sides of the smelting area and the refining area respectively; and a slagging hole and a copper discharging hole are formed on the shell of the furnace body end on one side of the auxiliary burner nozzle. The device has a simple structure, a reasonable design and extremely good popularization value and application value and is energy-saving and environment-friendly.

Owner:DONGYING LUFANG METAL MATERIAL

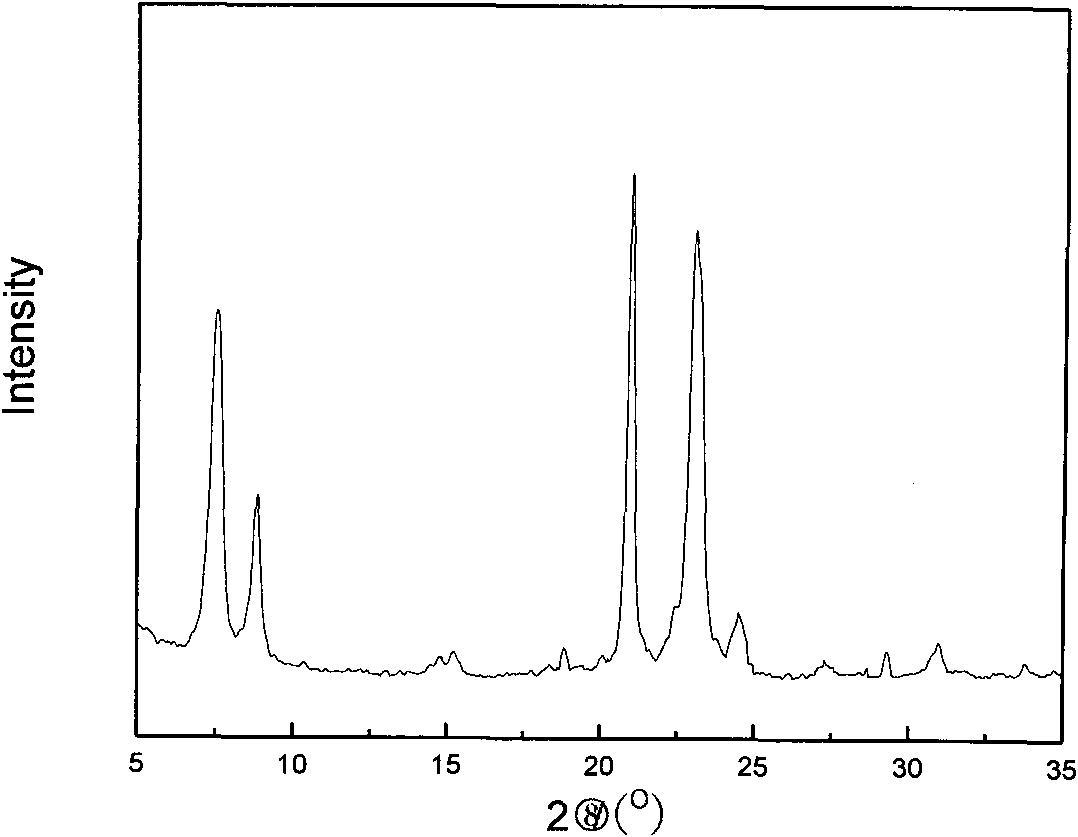

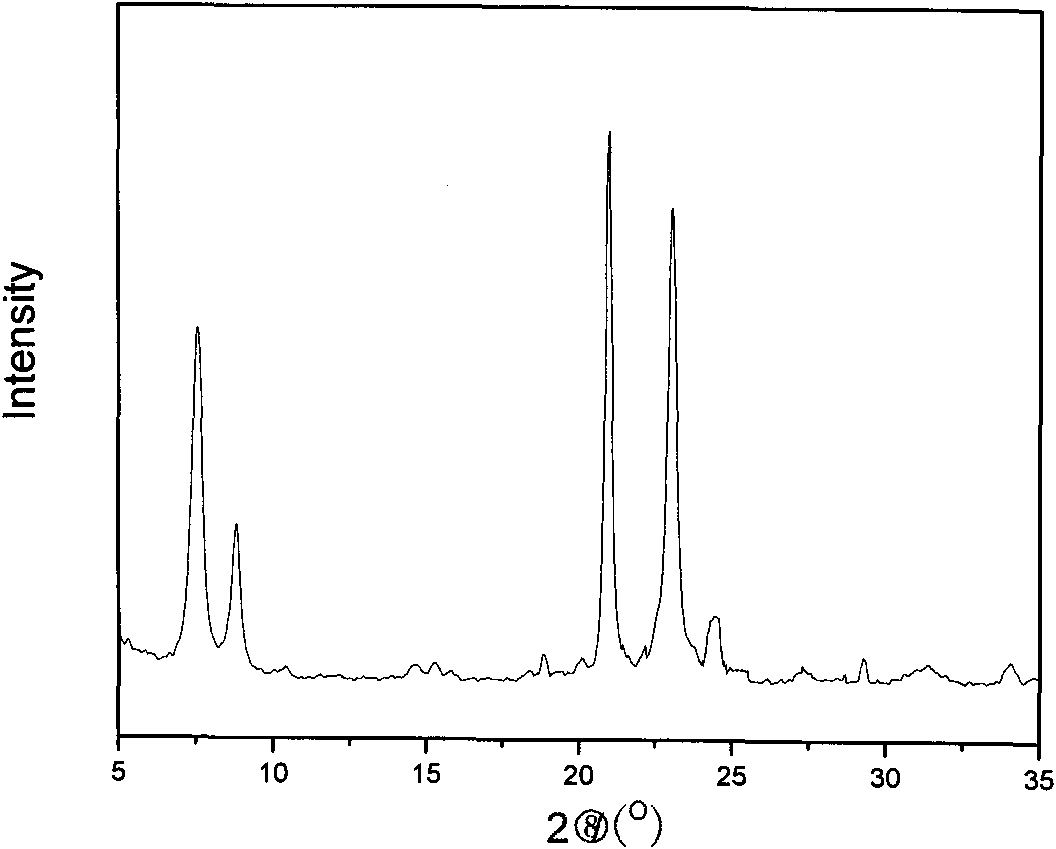

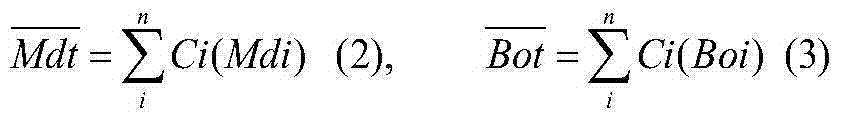

Method for synthesizing zeolite ZSM-48

The invention provides a method for synthesizing zeolite ZSM-48, belonging to the technical field of inorganic chemistry and catalytic chemistry. The invention is characterized in that the method comprises the steps of mixing silicon source, aluminium source, alkali metal (M) source, structure guiding agent (R) N, N-dimethyl hexamethyleneimine quaternary ammonium base and water to prepare a reaction mixture with molar ratios that SiO2 / Al2O3 is equal to 60-2000, H2O / SiO2 is equal to 10-100, OH<-> / SiO2 is equal to 0.1-2.0, M / SiO2 is equal to 0.05-1.0 and R / SiO2 is equal to 0.05-1.0, carrying out hydrothermal crystallization on the reaction mixture at the temperature of 120-180 DEG C for 1-15 days, washing and drying products after crystallization is completed, thus obtaining the zeolite ZSM-48. By adopting the method provided by the invention, zeolite ZSM-48 with the ratio of silicate to aluminium being less than 150 can be synthesized.

Owner:SHANXI DATONG UNIV

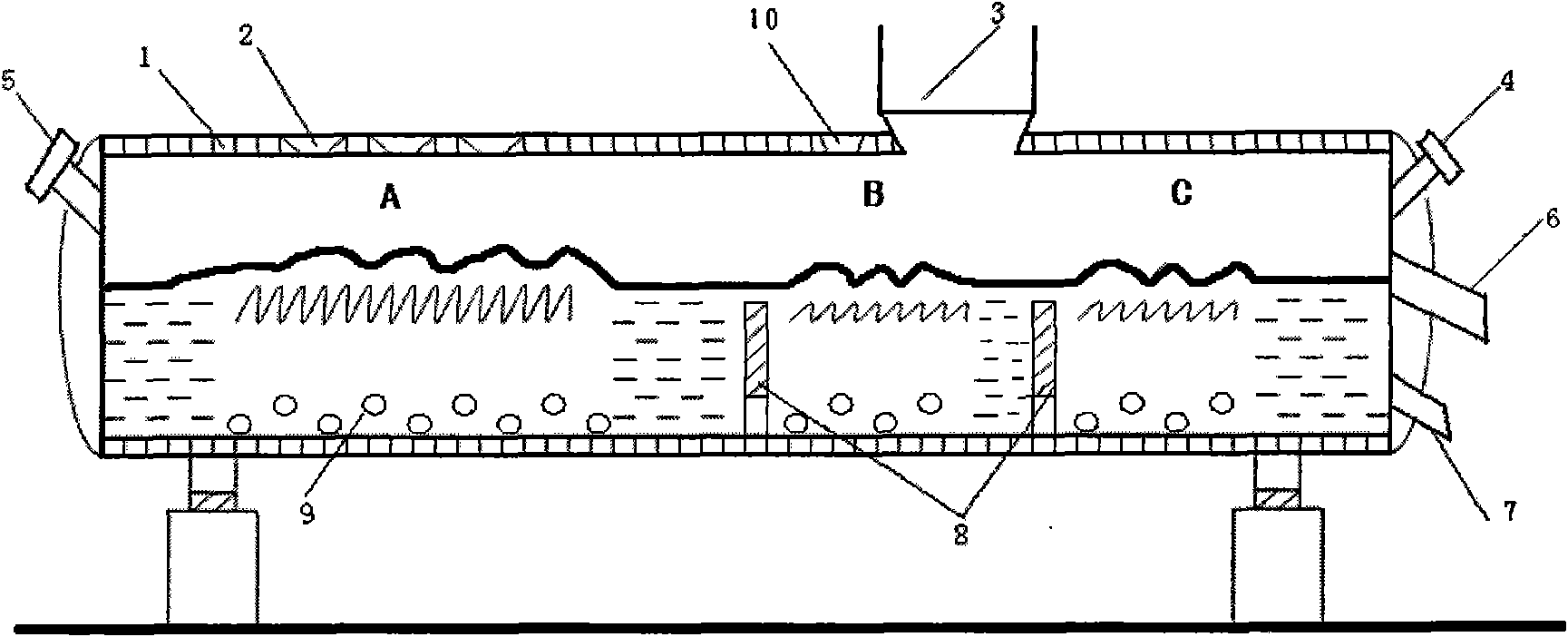

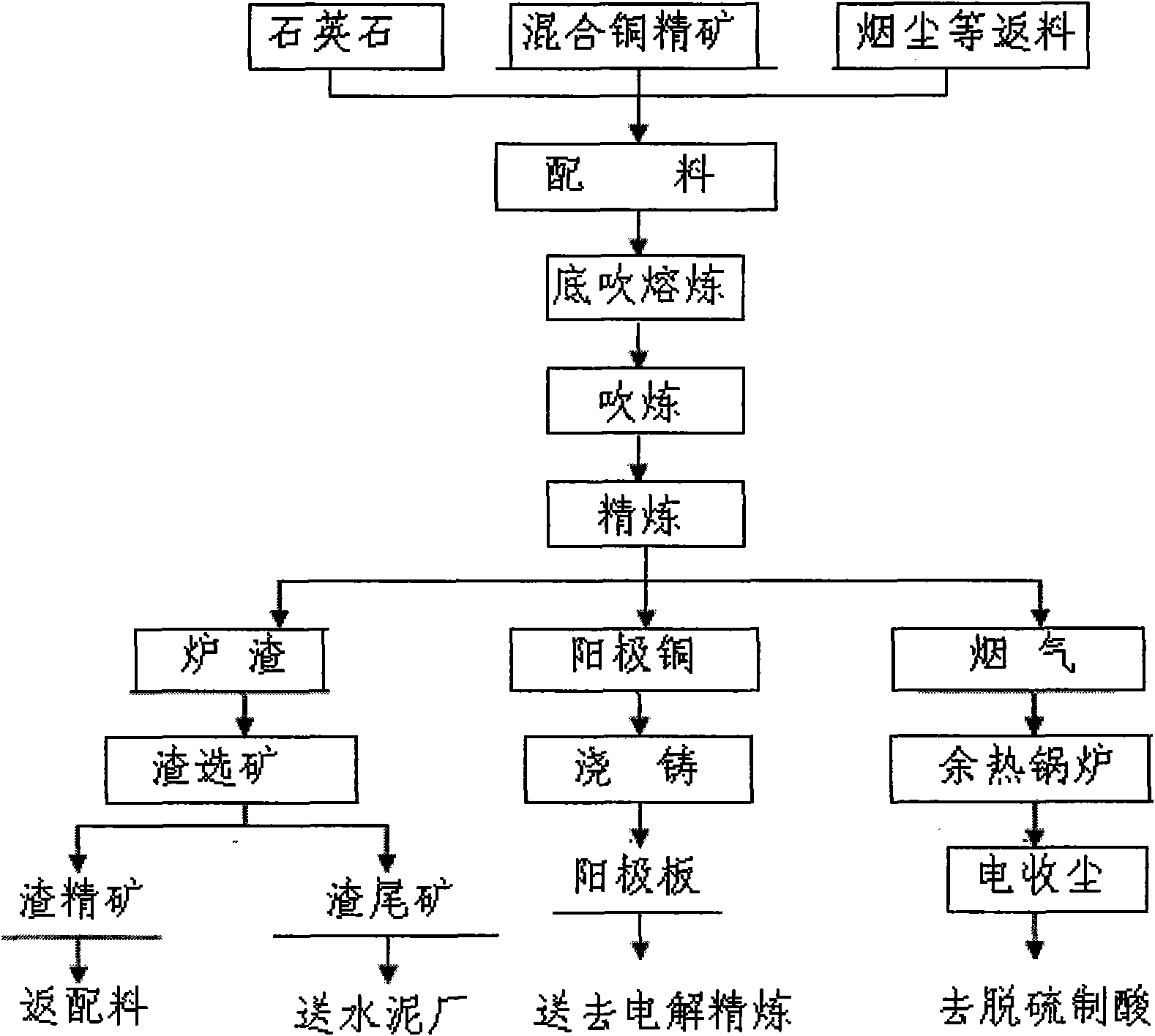

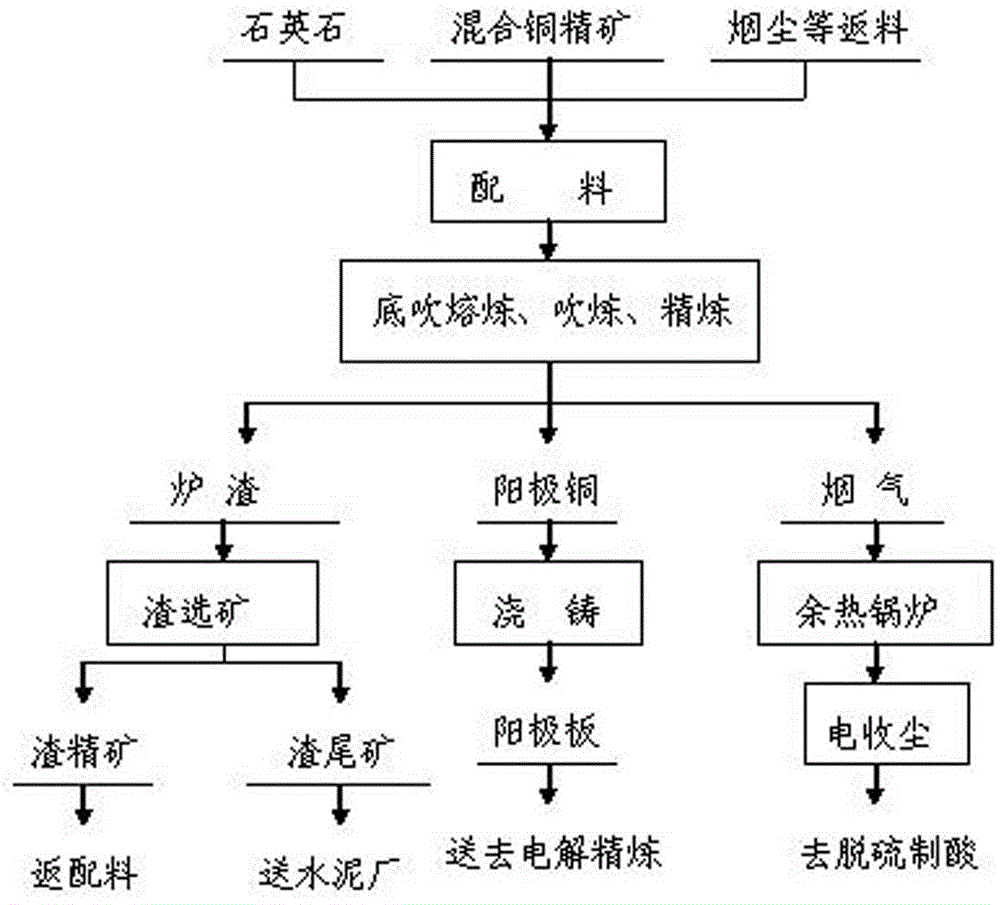

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

Supported catalyst for preparing aldehyde by olefin hydroformylation

InactiveCN1736602AIncreased space-time yieldSimple compositionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionMolecular sieveTetrafluoroborate

Disclosed is a supported catalyst mainly containing sulfonated triphenylphosphine- rhodium complex and is used for preparing aldehyde by hydroformylation of olefin, and relates to an ionic liquid catalyst. It contains solid oxide, sulfonated triphenylphosphine- rhodium complex, sulfonated triphenylphosphine ligand and ionic liquid. The solid oxide is one from hole molecular sieve, SiO2, TiO2, gamma- Al2O3; sulfonated triphenylphosphine- rhodium complex is single-sulfonated triphenylphosphine- rhodium complex, di- sulfonated triphenylphosphine- rhodium complex and tri- sulfonated triphenylphosphine- rhodium complex; and the ionic liquid is 1, 1, 3, 3, - tetramethyl guanidine lactate, 1- butyl- 3- methyl imidazolium tetrafluorborate and 1- butyl- 3- methyl imidazolium hexafluorophosphate. By mass ratio, the solid oxide is among 50%- 90%, the ionic liquid 8%- 49%, and rhodium 0.05%- 2%, and by molecular ratio phosphine to rhodium is 3- 200.

Owner:XIAMEN UNIV

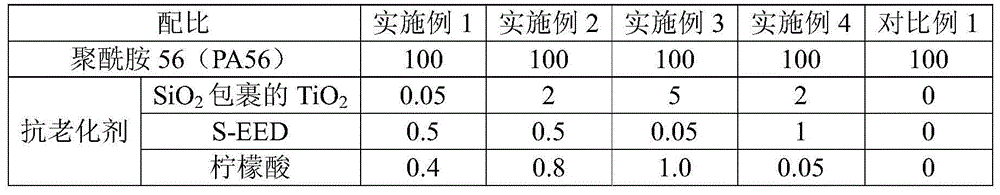

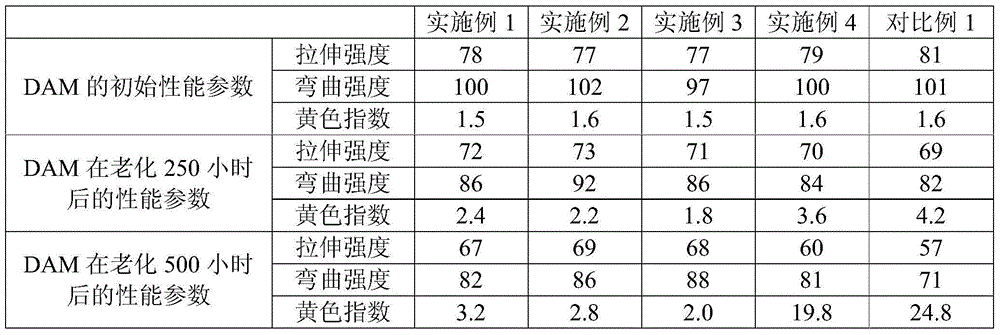

Anti-yellowing polyamide composition and preparation method of anti-yellowing polyamide

The invention provides an anti-yellowing polyamide composition and a preparation method of anti-yellowing polyamide; the yellowing polyamide composition includes polyamide 56 and anti-aging agents, wherein the anti-aging agents include a heat stabilizer, a light stabilizer and an amino functional group end-capping agent. The preparation method of the anti-yellowing polyamide comprises that the components of the anti-yellowing polyamide composition are subjected to melt mixing, and thus the anti-yellowing polyamide is obtained. The anti-yellowing polyamide not only has durable anti-yellowing property, but also has excellent mechanical properties and processability.

Owner:CATHAY R&D CENT CO LTD

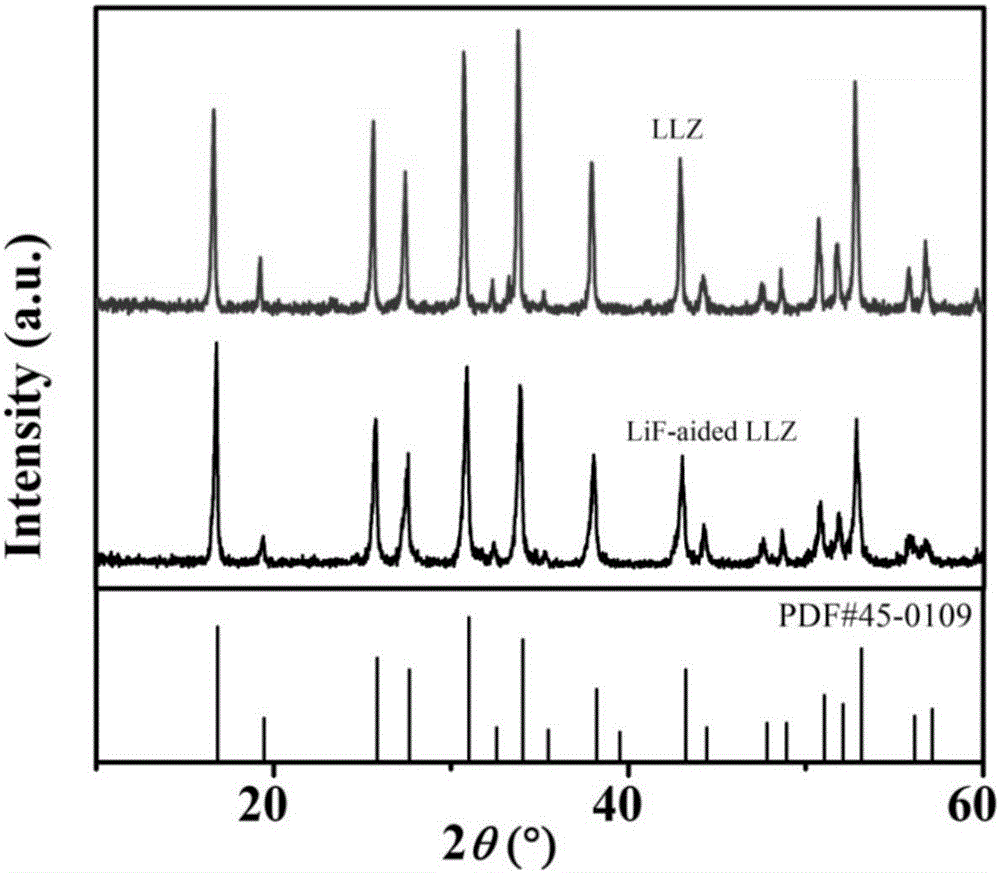

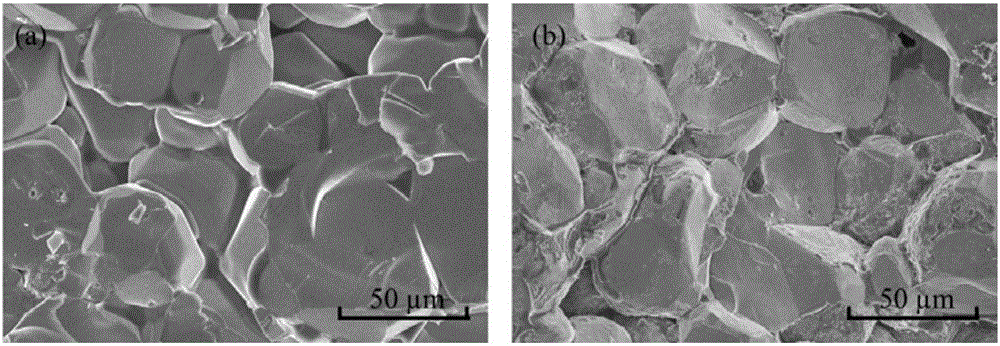

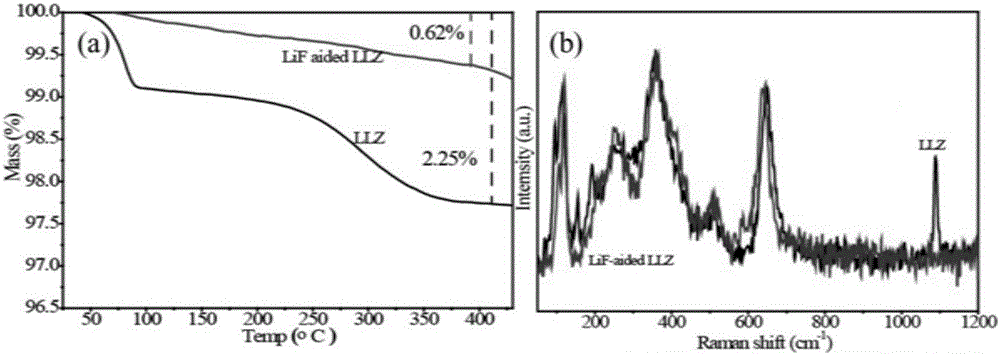

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

Anti-wrinkle tidying method for pure cotton fabric

InactiveCN101942750AImprove wrinkle resistanceImprove flatnessSucessive textile treatmentsFibre treatmentOrganic acidBrute force

The invention relates to an anti-wrinkle tidying method for a pure cotton fabric, sequentially comprising the following processes: shell fabric preparation, pre-limbering, resin padding, curing, rinsing, post-limbering and preshrinking. The method has the main technical characteristic that the padding formula used in the resin padding process comprises the following components by concentration: 80-120g / L of 2D resin, 80-100g / L of oxalaldehyde resin, 40g / L of 1,3-Dimethylurea, 40g / L of magnesium chloride activated by organic acid, 20-40g / L of brute-force protective agent, 1-2g / L of penetrating agent and the balance of water. The invention has reasonable design, and fully utilizes the advantages of two types of the resins and catalysts; the tidied pure cotton fabric has the characteristics of higher planeness, higher brute force, favorable abrasive resistance, lower formaldehyde content and the like; and the garment made of the tidied pure cotton fabric has the characteristics of comfortable wearing, beautiful appearance and strong durability.

Owner:TIANJIN TIANGE TEXTILE

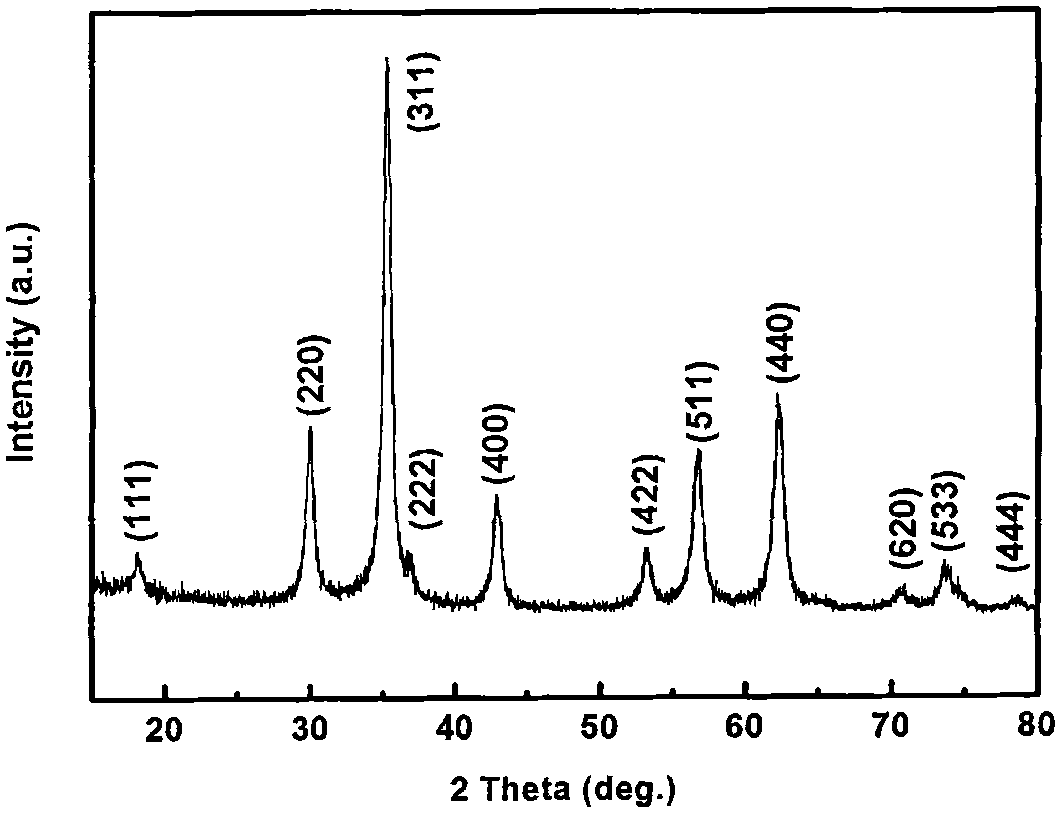

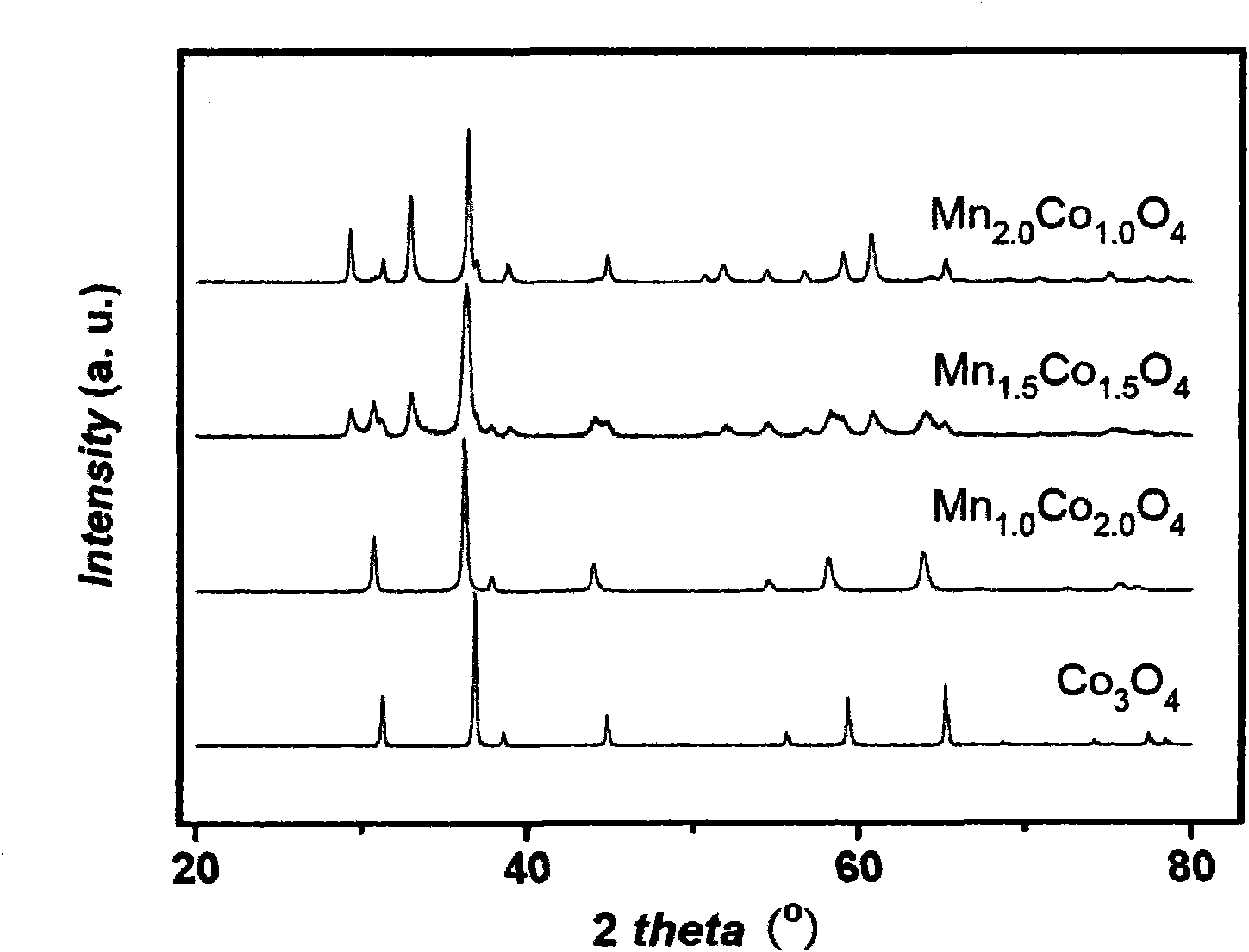

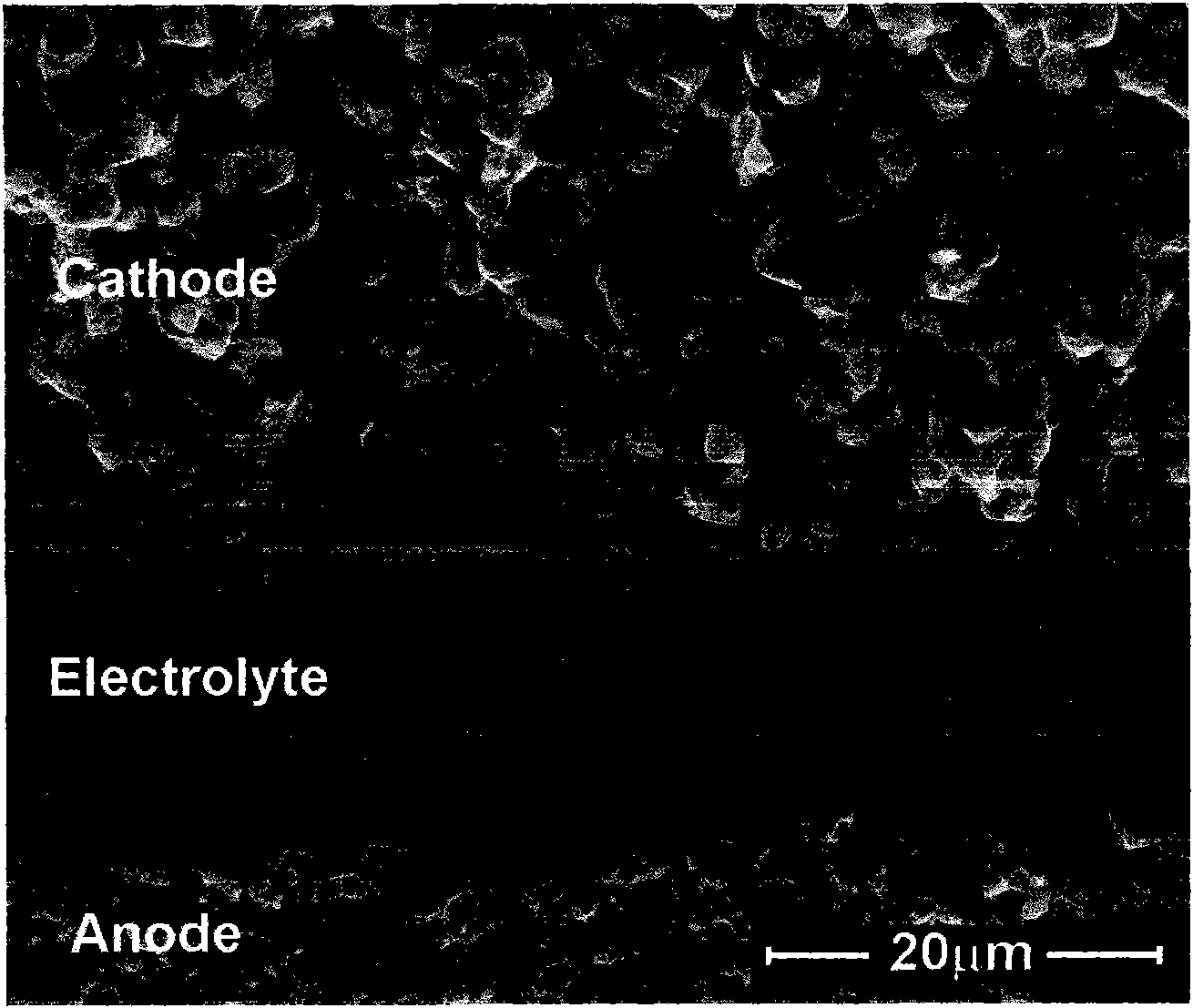

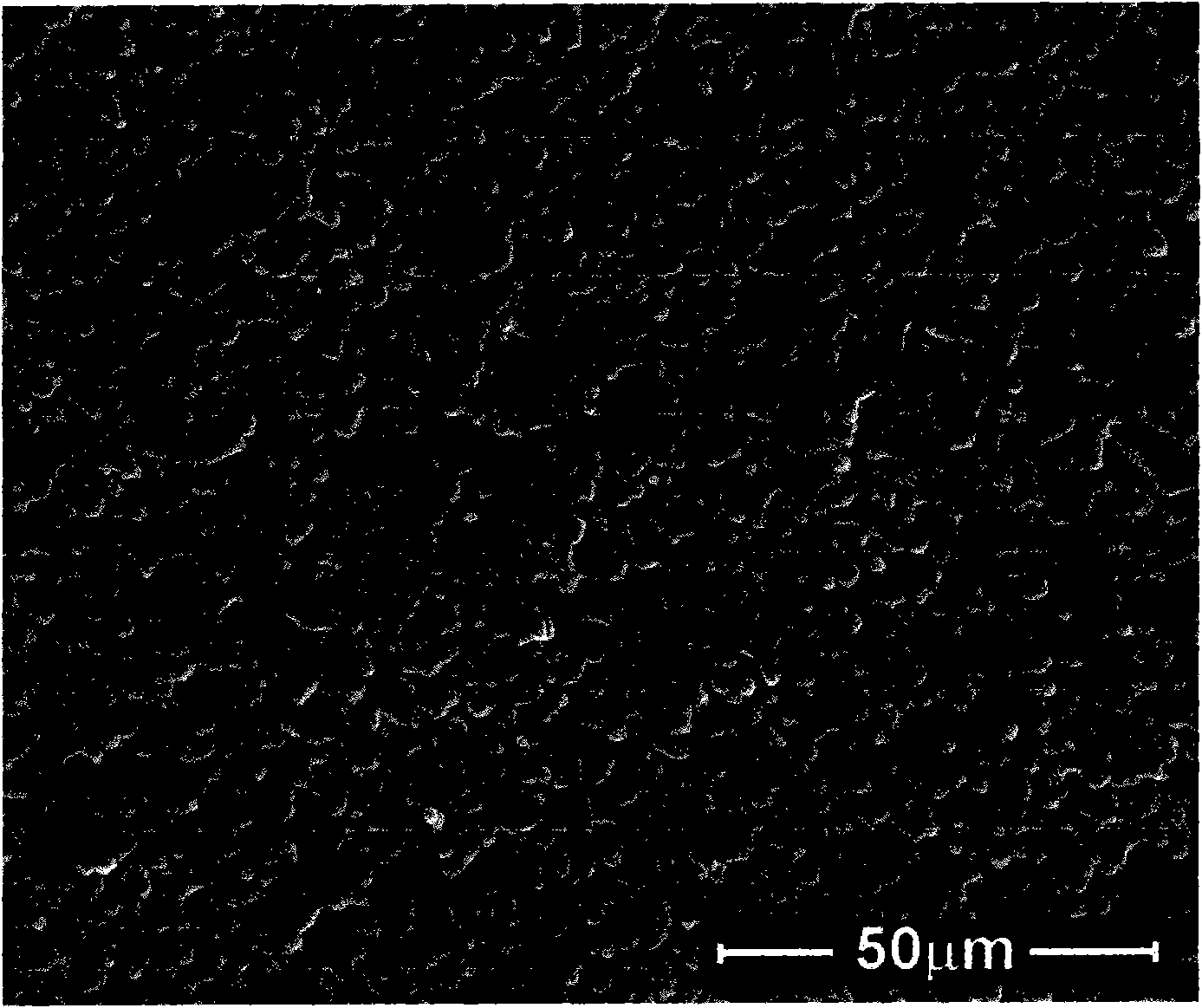

Cathode material of solid oxide fuel cell and preparation method thereof

The invention relates to a cathode material of a solid oxide fuel cell, comprising spinel type oxide material powder and oxygen conductive material powder, wherein, the weight of the spinel type oxide material powder accounts for 10-100 % of the total weigh of the cathode material, and the oxygen conductive material powder is the rest. The preparation method of the cathode material comprises the following steps: first, preparing the spinel type oxide material powder and oxygen conductive material powder; then, mixing the spinel type oxide material powder and oxygen conductive material powder, grinding, and preparing into electrode paste; and finally, scratching the electrode paste onto the electrolyte layers, drying, roasting for 2-5 h at the temperature of 900-1150 DEG C to obtain the cathode material of the solid oxide fuel cell. The cathode material has high conductive capability in low temperature area, and has good catalytic activity to oxygen reduction reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

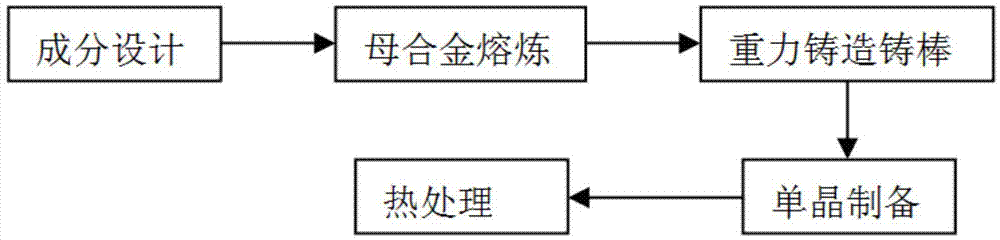

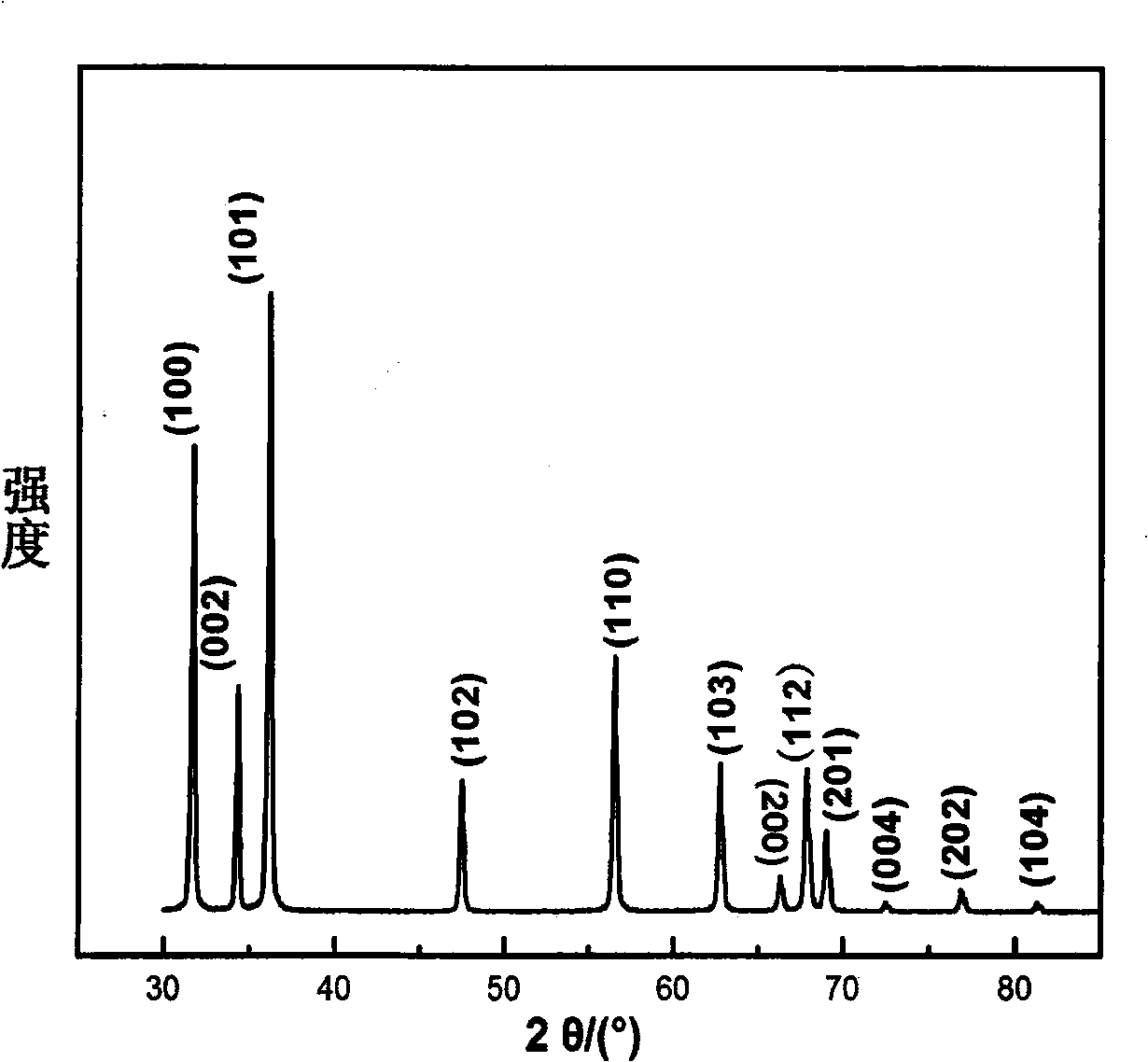

Low rhenium and nickel-based single crystal high-temperature alloy and preparation method thereof

InactiveCN103866392ARaise the initial melting temperatureWide melting temperature rangePolycrystalline material growthFrom frozen solutionsRheniumSingle crystal superalloy

The invention discloses low rhenium and nickel-based single crystal high-temperature alloy and a preparation method thereof. The alloy comprises the following raw materials by mass percent: 6.75-7.25% of Cr, 7.25-7.75% of Co, 1.3-1.7% of Mo, 5.8-6.2% of W, 5.8-6.2% of Ta, 0.85-1.15% of Re, 5.9-6.1% of Al, 1.3-1.7% of Ti, 0.12-0.18% of Hf, 0.04-0.06% of C, 0.003-0.005% of B, 0.010-0.020% of Y, and the balance of nickel. The method comprises the following preparation steps: smelting master alloy by using a vacuum induction furnace; preparing a master alloy rod by gravity casting; preparing a single-crystal test rod by adopting a seed crystal method through a Bridgeman directional solidification technology; carrying out thermal treatment on single crystal high-temperature alloy. The alloy disclosed by the invention is high in incipient melting temperature, wide in melting temperature range, small in solidification interval, low in alloy density, high in strength, good in oxidation resistance, good in phase stability and low in cost; a harmful phase is not easy to generate in long-term aging.

Owner:NANJING UNIV OF SCI & TECH +3

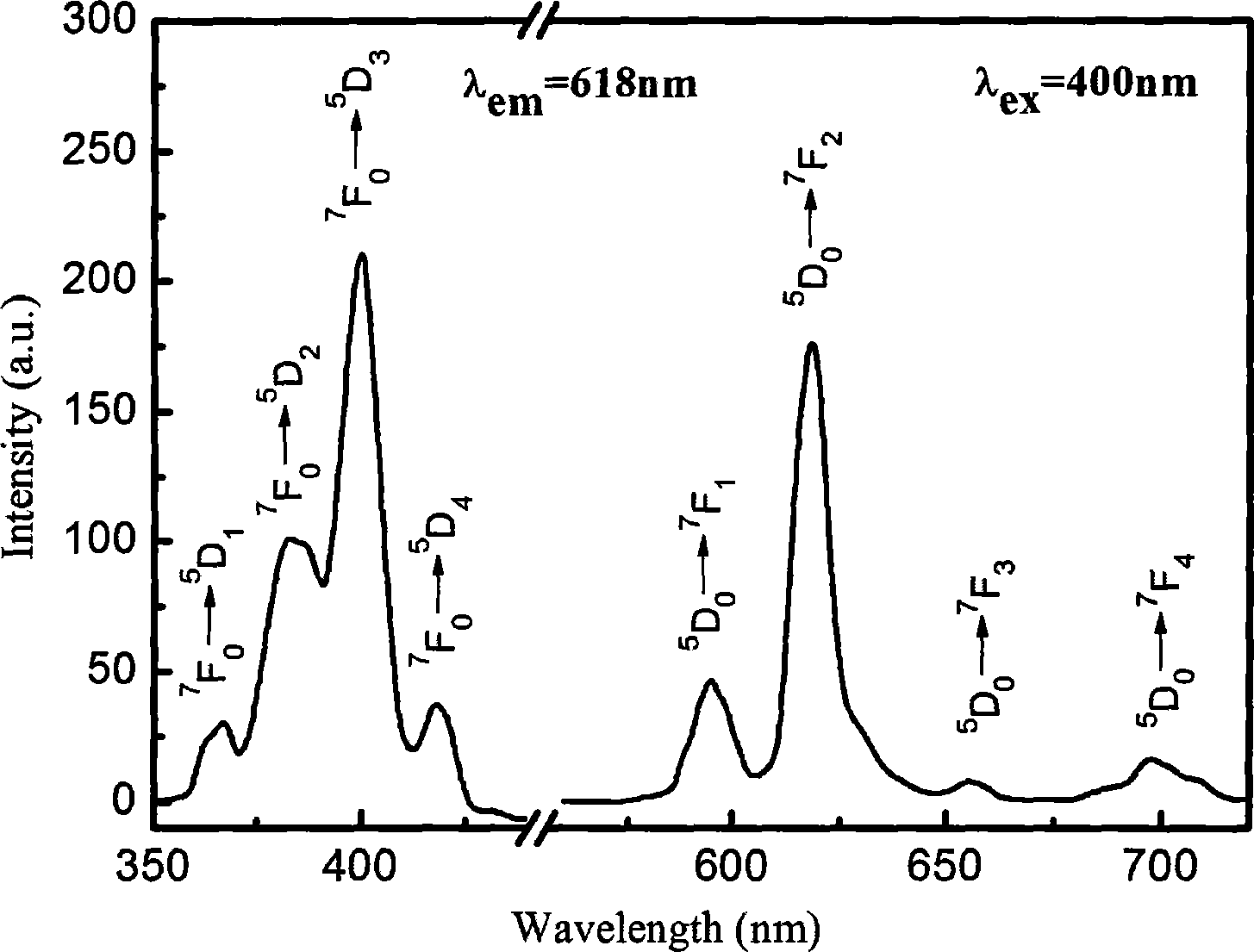

Preparation of doped calcium titanate (CaTiO3: Eu3+) fluorescent powder

InactiveCN101376523AGood chemical stabilitySmall grain sizeTitanium compoundsLuminescent compositionsAlcoholDissolution

The invention relates to a preparation method of Eu-doping calcium titanate CaTiO3:Eu<3+> fluorescent powders, which comprises the steps as follows: a soluble europium salt, a calcium salt and Ti(OC4H9)4 are weighed according to the mole ratio that is 1:49:50 to 1:4:5 among Eu<3plus>, Ca<2plus> and Ti<4plus>, and are respectively dissolved in absolute ethyl alcohol, and the confected solution is stirred for ample dissolution; (2) a mixed ethanol solution of the europium salt and the calcium salt is added in an ethanol solution of Ti(OC4H9)4, and a sol is obtained through stirring; (3) the sol is placed at the temperature ranging from 0 to 50 DEG C to obtain a wet gel which is put in a baking box for drying; (4) the dried gel is milled into powders, the obtained powders are calcined for 2 to 8 hours to obtain the CaTiO3:Eu<3plus> fluorescent powders. In the preparation method, the prepared CaTiO3:Eu<3plus> fluorescent powders have high chemical durability, small grain size, pure crystalling phase and low calcination temperature; the preparation method has simple technology, and is easy for industrialized production.

Owner:DONGHUA UNIV

Method for preparing zinc oxide (ZnO) nanorods

InactiveCN101514029AUniform sizePromote generationZinc oxides/hydroxidesEthylenediamineReaction temperature

The invention relates to a method for preparing zinc oxide (ZnO) nanorods, and the method comprises: (1) soluble zinc salt and hydroxide with the molar ratio of 1:2-1:4 are weighed at room temperature and added in deionized water, then a mixed solvent of ethylenediamine and ethanolamine with the volume ratio of 1:5-5:1 is added, and the mechanical stirring is carried out for 20-40 minutes for obtaining clear reaction solution, wherein, the volume ratio of the added mixed solvent to the deionized water is 1:6-1:1; (2) the reaction solution in step (1) is added in a reaction kettle for carrying out the solvent thermal reaction, the reaction temperature is 110-150 DEG C, the reaction is carried out for 6-12h, and the natural cooling is carried out to the room temperature; (3) products are centrifugally separated, washed and dried at 40-60 DEG C for 5-12h, thereby obtaining the ZnO nanorods. The preparation method is simple and easy to control, and the prepared zinc oxide nanorods have even size; in addition, nano-particles are more stable in the organic phase and difficult to generate the impurity phase.

Owner:DONGHUA UNIV

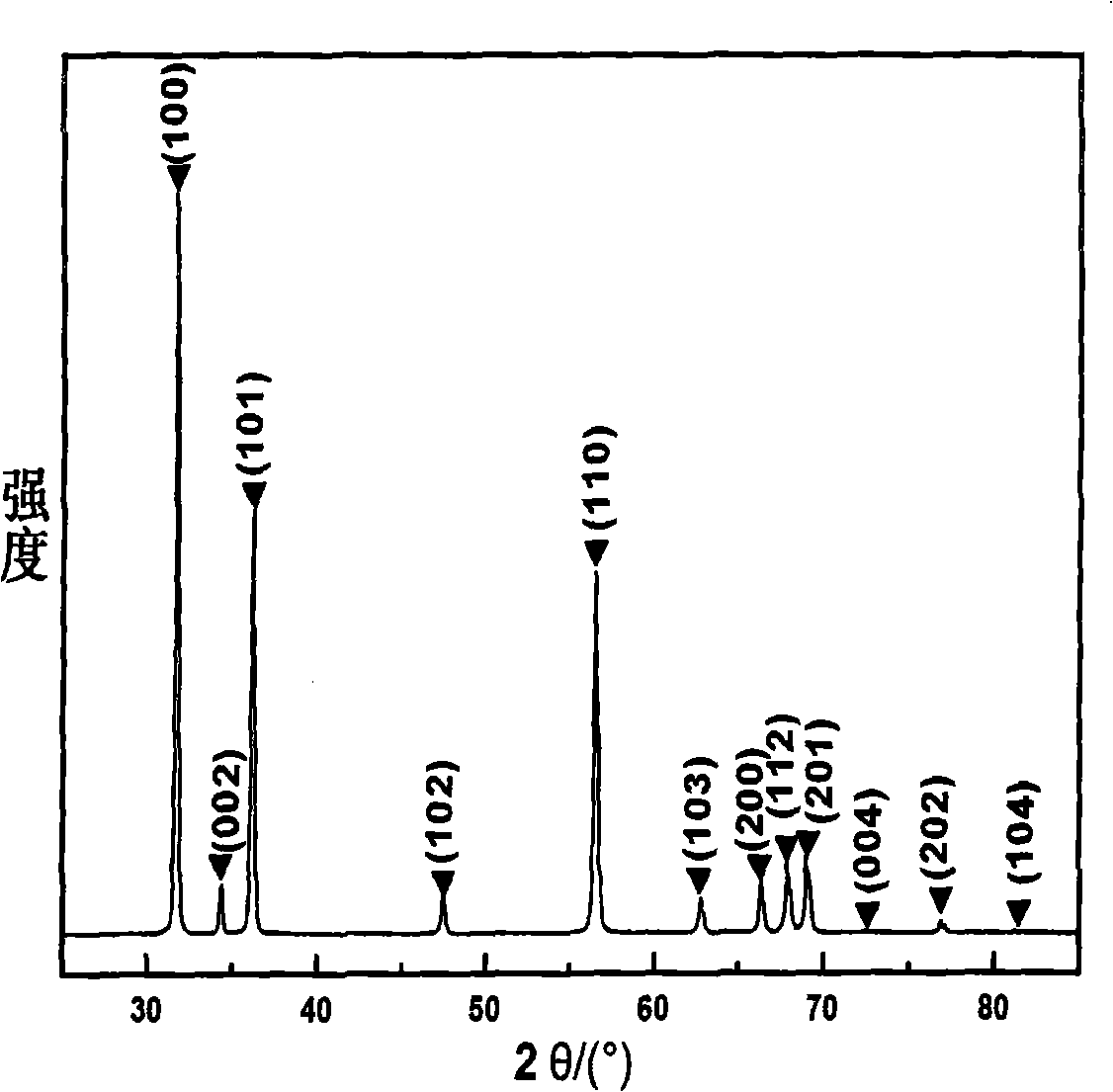

Non-rhenium nickel base single crystal superalloy and preparation method thereof

ActiveCN103436740ARaise the initial melting temperatureWide melting temperature rangePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses non-rhenium nickel base single crystal superalloy and a preparation method thereof. The non-rhenium nickel base single crystal superalloy comprises the following components in percentage by weight: 7.25-7.75% of Cr, 4.8-5.2% of Co, 1.8-2.2% of Mo, 7.8-8.2% of W, 6.3-6.7% of Ta, 6.0-6.2% of Al, 0.12-0.18% of Hf, 0.04-0.06% of C, 0.003-0.005% of B, 0.010-0.030% of Y, and the balance of Ni. The preparation method for the non-rhenium nickel base single crystal superalloy comprises the steps as follows: adopting a vacuum induction furnace to smelt the raw material into mother alloy, and preparing a mother alloy casting rod through gravity casting; adopting a seed crystal method to prepare a single crystal test bar within the temperature gradient of 150-250 K / cm and the withdrawing rate of 5-100 micron / s through a Bridgeman directional solidification technology; performing solution treatment on the single crystal superalloy for 2-4 h within the temperature range of 1,295-1,305 DEG C and performing air cooling, then performing high-temperature aging treatment on the single crystal superalloy for 2-4 h within the temperature range of 1,090-1,310 DEG C and performing air cooling; performing low-temperature aging treatment on the single crystal superalloy for 16-24 h within the temperature range of 850-890 DEG C and performing air cooling.

Owner:NANJING UNIV OF SCI & TECH

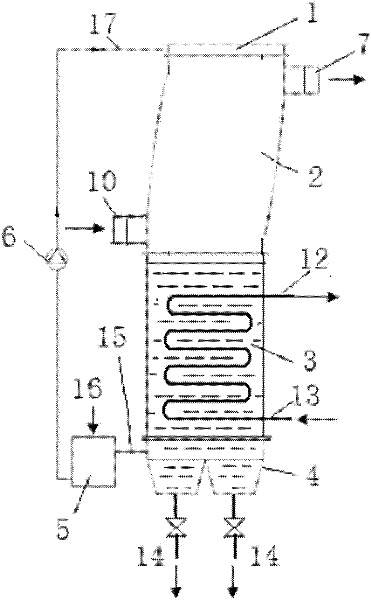

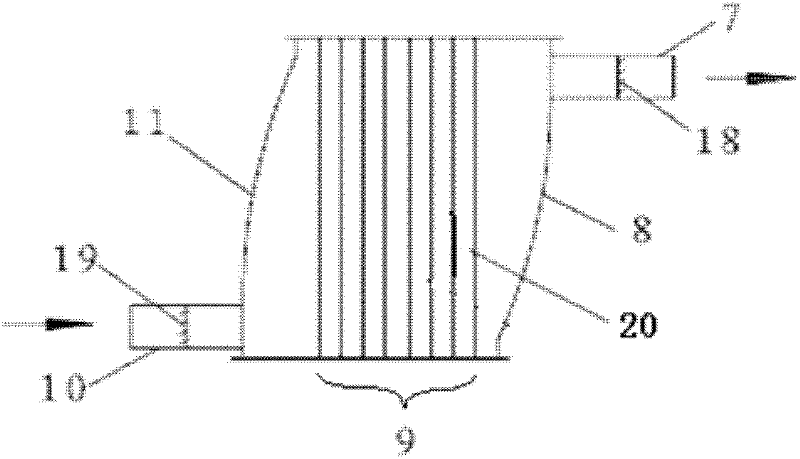

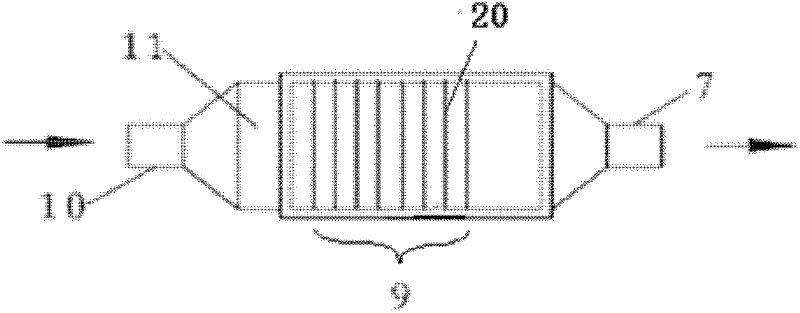

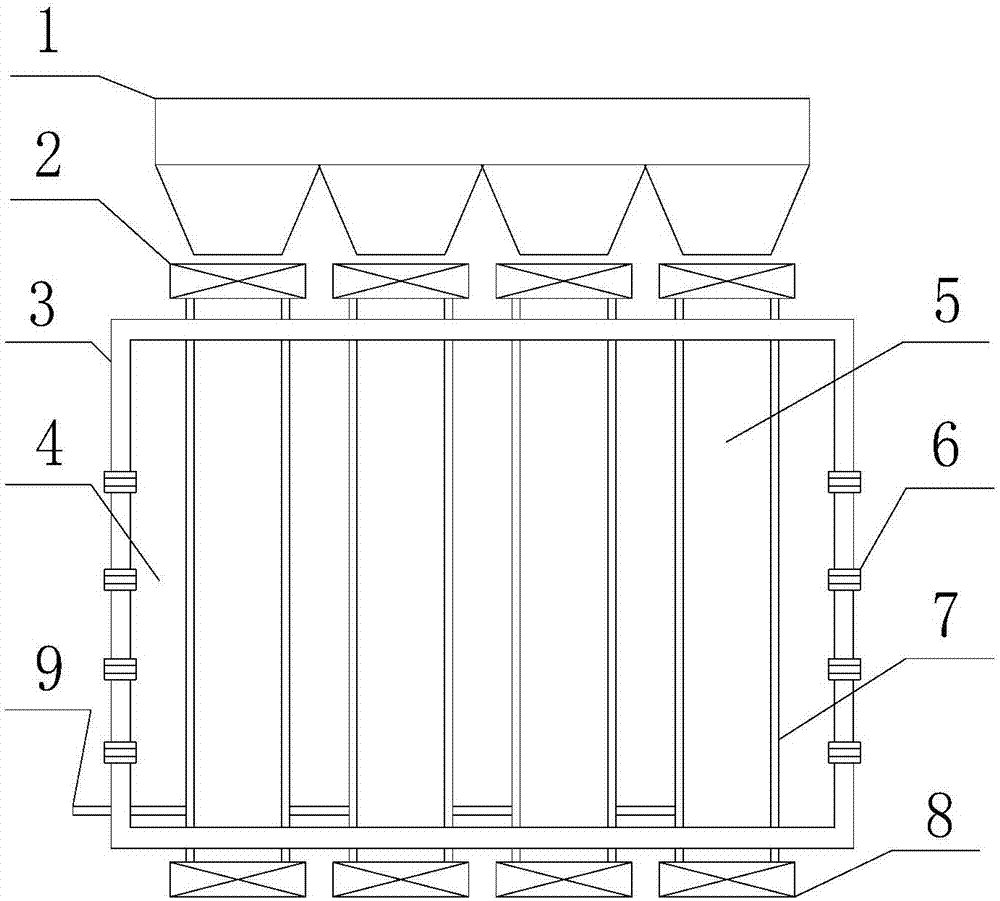

Composite equipment for flue gas waste heat recovery and dust cleaning

ActiveCN102407070AIncrease surface areaIncrease contact heat exchange areaCombination devicesWaste heat recovery unitPlate heat exchanger

The invention relates to composite equipment for flue gas waste heat recovery and dust cleaning, belonging to the technical field of flue gas waste heat recovery and dust cleaning. The equipment comprises a heat exchange and absorption compound device, a recuperative heat exchanger, a precipitate collection and pollutant discharge device, a solution pool and a liquid pump, wherein a liquid distributor is arranged at the top of the heat exchange and absorption compound device, the recuperative heat exchanger is located at the lower part of the heat exchange and absorption compound device, and the precipitate collection and pollutant discharge device is arranged at the lower part of the heat exchange and absorption compound device; the heat exchange and absorption compound device comprises a flue gas inlet section, a flue gas inlet diversion section, a heat exchange and absorption section, a flue gas outlet liquid baffle diversion section and a flue gas inlet section, and a liquid mesh type liquid membrane distribution net is arranged inside the heat exchange and absorption section. Waste heat recovery and purification treatment are integrated, sensible heat and latent heat of exhausted flue can be recovered, the composite equipment also have the actions of corrosion prevention, dust removal, scale prevention, purification treatment and the like, flow resistance and energy consumption of fans and water pumps are also reduced, the cost of products is lowered, and the deep recovery of flue gas waste heat is achieved.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE +1

Electrolytic cathode containing titanium boride-carbon coating, and preparation method thereof

The invention discloses an electrolytic cathode containing a titanium boride-carbon coating, and a preparation method thereof. The electrolytic cathode is characterized in that: a coating is coated on the surface of the electrolytic cathode, wherein the coating comprises components of, by mass: 20 to 22% of TiB2, 15 to 20% of epoxy resin, 24 to 27% of diethylene triamine, 0.3 to 0.8% of carbon fiber, and balance of graphite powder. The preparation method of the aluminum electrolytic cathode comprises steps that: the materials are sufficiently mixed and uniformly coated on the surface of the electrolytic cathode; the coating is heated from normal temperature to 150 DEG C, such that the coating is cured, and the electrolytic cathode containing the titanium boride-carbon coating is obtained.According to the invention, good wettability of aluminum liquid and the electrolytic cathode is utilized, such that aluminum oxide deposition is not easy to be left on the surface of the electrolyticcathode. Therefore, deposition or crusting is not easy to occur, current is uniformly distributed, disturbance of magnetic fields to the aluminum liquid is reduced, current efficiency is improved, energy consumption is reduced, the service life of an electrolyte tank is prolonged, and aluminum liquid level and polar pitch can be appropriately reduced. With the electrolytic cathode provided by theinvention, an average working voltage and a secondary reaction probability of the aluminum electrolyte tank are reduced, aluminum electrolytic production is improved, and the quality of aluminum products is improved.

Owner:YUNNAN RUNXIN ALUMINUM

Pyrolyzing and melting kiln and method for preparing ceramics and fuel oil by pyrolyzing garbage

ActiveCN102966954AEasy to recycleNot easy to generateLiquid hydrocarbon mixture productionIncinerator apparatusThermal energyTunnel kiln

The invention provides a pyrolyzing and melting kiln and a method for preparing ceramics and fuel oil by pyrolyzing garbage, belonging to the fields of environment-friendly technical devices, biomass energy and novel ceramic materials. The pyrolyzing and melting kiln is formed by communicating equal-temperature sections of a pyrolyzing furnace cavity and a tunnel kiln cavity. In the method, the pyrolyzing and melting kiln provided by the invention is used, a pyrolyzing barrel is taken as a combustion chamber I while the tunnel kiln cavity is taken as a combustion chamber II for burning mixed garbage, garbage pyrolysis and clinker melting are realized synchronously by using heat energy of the garbage, and ceramic and fuel oil products with high added values are prepared directly. An overall economic, efficient and environment-friendly solution is provided for the pyrolysis of materials such as garbage as well as clinker treatment and utilization.

Owner:佛山市骏鹰环境能源装备有限公司

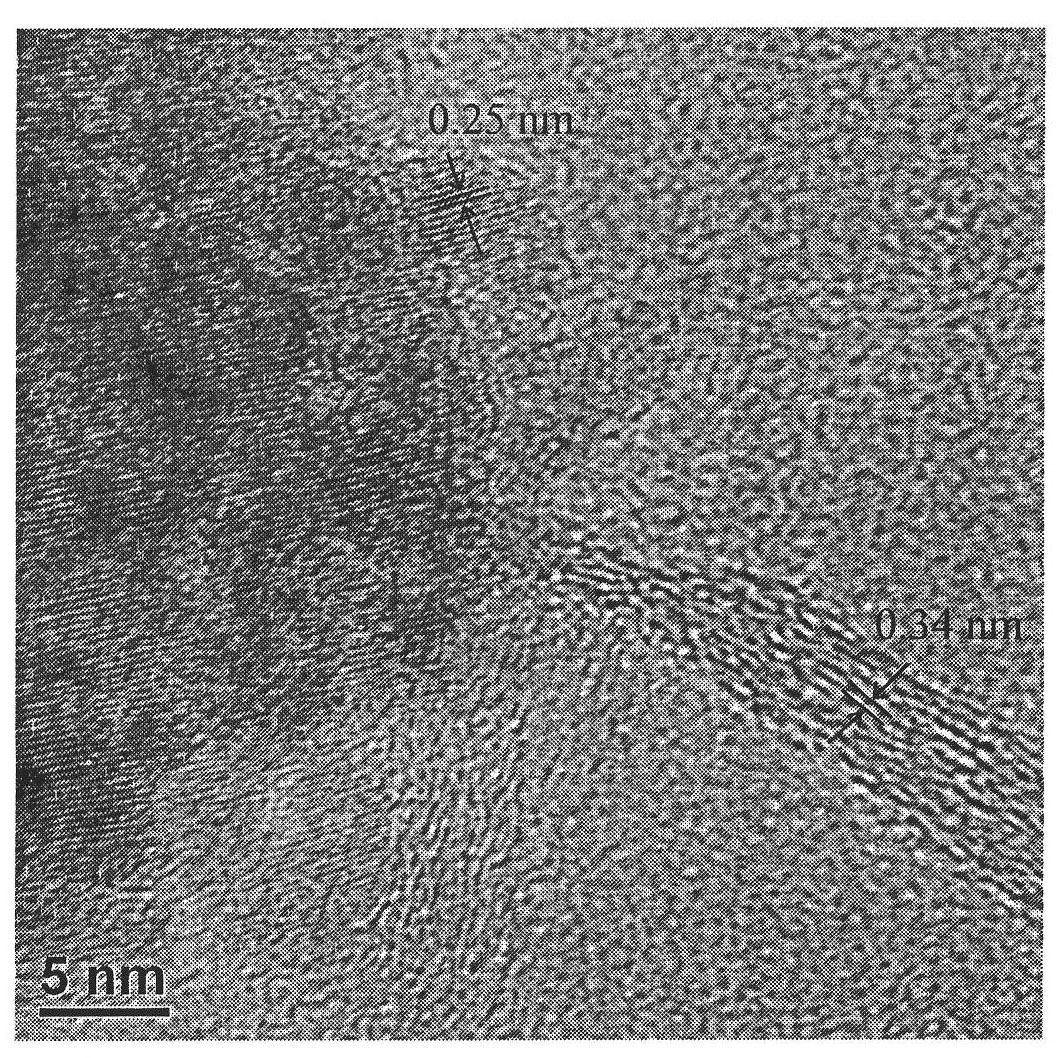

Method for preparing MWCNTs/Co1-xZnxFe2O4 magnetic nanocomposite material

InactiveCN101800105ASimple preparation processProduction equipment requirements are simpleInorganic material magnetismIron compoundsSodium acetatePolyethylene glycol

The invention relates to a method for preparing a multiwall carbon nano-tube (MWCNTs) / cobalt zinc ferrite (Co1-xZnxFe2O4) magnetic nanocomposite material, which comprises the following steps of: (1) mixing a strong oxidizing acid and MWCNTs in a mass ratio of 1:200-1:400 and reflowing the solution in an oil bath after ultrasonic dispersion; and (2) dispersing the acidized MWCNTs into solution of ethylene glycol at room temperature, weighing a ferric salt, a zinc salt and a cobalt salt, dissolving the salts into the solution, adding polyethylene glycol and anhydrous sodium acetate after the added salts are fully dissolved, mechanically stirring the mixture, putting the mixture into a high-pressure reaction kettle for reaction after polyethylene glycol and anhydrous sodium acetate are fully dissolved, cooling the mixture to room temperature, and washing, collecting and drying a product. The magnetic nanocomposite material prepared by the method has the advantages of pure crystalline phase, high dispersibility, difficult agglomeration, high magnetization intensity and high magnetic induction sensitivity; and the method has the advantages of simple preparation process, relatively lower requirements on production equipment and easy industrial production.

Owner:DONGHUA UNIV

Production method of tower type prilling slow release fertilizer

ActiveCN101475414ALess investmentThe granulation temperature is loweredAgriculture gas emission reductionFertiliser formsExothermic reactionChemistry

The invention relates to a method for making a slow-release fertilizer through tower granulation, which comprises: heating and mixing solid urea or a urea solution and a formaldehyde solution to form mixed slurry, wherein the mol ratio of the urea to formaldehyde is 1-8:1, and the temperature of the mixed slurry is between 40 and 80 DEG C; mixing a phosphorus fertilizer preheated to a temperature of between 50 and 80 DEG C, one or more selected from a nitrogenous fertilizer, a potassium fertilizer or solid filler, and a urea-formaldehyde solution; and adding a small amount of dilute sulfuric acid solution into the mixed slurry, spraying the mixed slurry from the top of a tower, and making the granular compound fertilizer. The method utilizes the principle that condensation reaction of the urea and the formaldehyde in an acid solution is exothermic reaction to achieve the aim of flash evaporation of moisture, reduces the height of the granulation tower, simultaneously reduces the temperature of the mixed slurry, and can produce composite fertilizers with various formulas. The compound fertilizer is slowly released and difficult to agglomerate.

Owner:SHANGHAI RES INST OF CHEM IND

Combustion-supporting, desulfurization and coal-saving additive used for boiler fire coal

InactiveCN101230301AHigh thermal efficiencyPrevent coking accidentsSolid fuelsFuel additivesCombustionPotassium dichromate

The invention provides a combustion-supporting desulfurating coal-saving additive which is used in the burning coal in boiler, the preparation of which is composed of 24-35 percent combustion improvers of methanol, aether, tween-80; 32-38 percent oxidants of potassium permanganate, potassium chlorate and potassium dichromate; 4-28 percent desulfurizer in which quicklime, potassium permanganate, potassium chlorate and potassium dichromate take part in; 18-22 percent anti-coking agent which contains potassium dichromate and quicklime; the rest is water, which complement the total volume of the additive to be 100 percent. The additive is prepared by adding water in the quicklime to produce lime cream; heating the water for acting as solution, after potassium permanganate, potassium chlorate and potassium dichromate are added into the solution and are stirred evenly; adding and mixing the methanol and tween-80 into the solution evenly, and then adding and mixing the lime cream into the solution evenly; finally adding and mixing the aether into the solution evenly; and preserving the heat for 1 hour. The invention can improve the desulfurization rate by 40 percent, improve the coal saving rate by 25 percent, and improve the thermal efficiency of the boiler by up to 5-10 percent; and can prevent the occurrence of boiler coking accident.

Owner:周兴泽

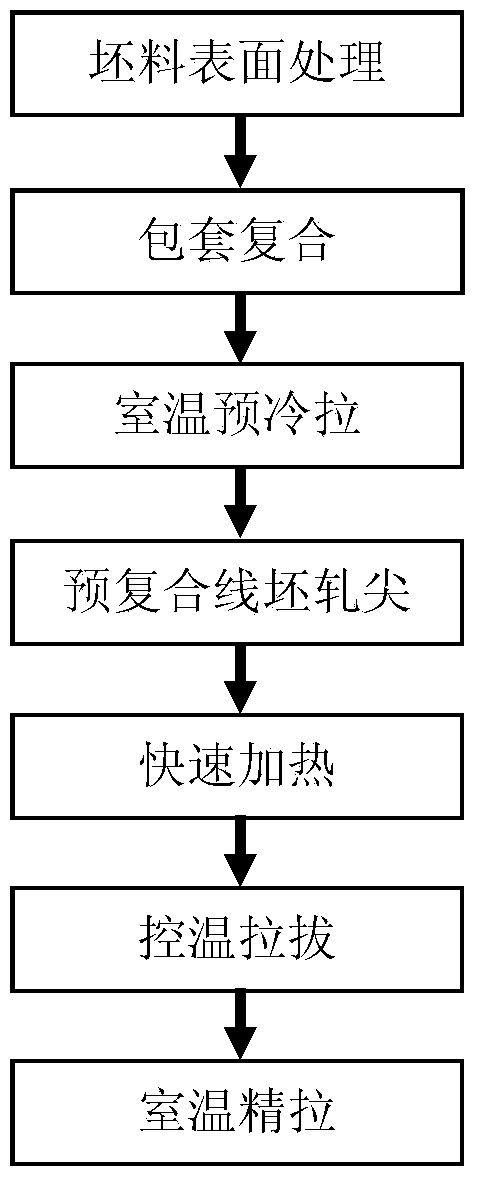

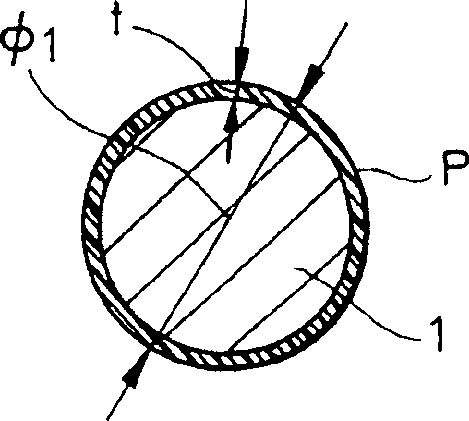

Drawing forming method of two-metal layered composite wire

ActiveCN104138923AHigh degree of freedom of combinationHigh bonding strengthDissimilar metalManufactured material

The invention relates to a drawing forming method of a two-metal layered composite wire, which belongs to the technical field of the preparation of a two-metal layered composite wire. The drawing forming method is characterized by comprising the following steps: cladding a metal pipe blank with a heterogeneous rod, drawing and pre-compounding the metal pipe blank with the heterogeneous rod at a room temperature in a single manner, rapidly heating, treating by adopting the combination of drawing and metallurgically compounding under a condition of controlling the temperature and finely drawing at the room temperature to prepare a high-quality two-metal layered composite wire. The drawing forming method has the advantages that the combination strength of a compounded interface of the two-layer layered composite wire is high, a dispersion layer is thin, composite metal is uniformly distributed along the circumferential direction and the longitudinal direction, a cladding ratio is easy to precisely control, the drawing intermediate annealing is not required, the product specification is flexible, raw materials can be freely combined, the product quality and performance are excellent, and the micro two-metal layered composite wire with the diameter of less than 1mm is easy to prepare. The drawing forming method is particularly suitable for preparing the two-metal layered composite wire with an inter-metal compound being easy to generate on the compounded interface and the two-metal layered composite wire which is difficult to process.

Owner:UNIV OF SCI & TECH BEIJING

Non-damage self-diverting acid and preparation method and application

ActiveCN103820098AImprove abilitiesWon't happenFluid removalDrilling compositionAcid fracturingMagnesium salt

The invention relates to a non-damage self-diverting acid and its preparation method and an application thereof. Components of the self-diverting acid contain 3-10% of a hydroxyl sulfonate ampholytic surfactant, 1-5% of a polybasic carboxylic acid chelating agent,?10-28% of acid and the balance water. The preparation method comprises the following steps: uniformly mixing acid and water, adding the hydroxyl sulfonate ampholytic surfactant and the polybasic carboxylic acid chelating agent and uniformly mixing. The non-damage self-diverting acid provided by the invention is used in acidification, acid fracturing and production increasing of carbonate reservoir and sandstone reservoir. The self-diverting acid is not easy to generate insoluble calcium and magnesium salts, is harmless to stratum, has good product liquidity, and is convenient to construct.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

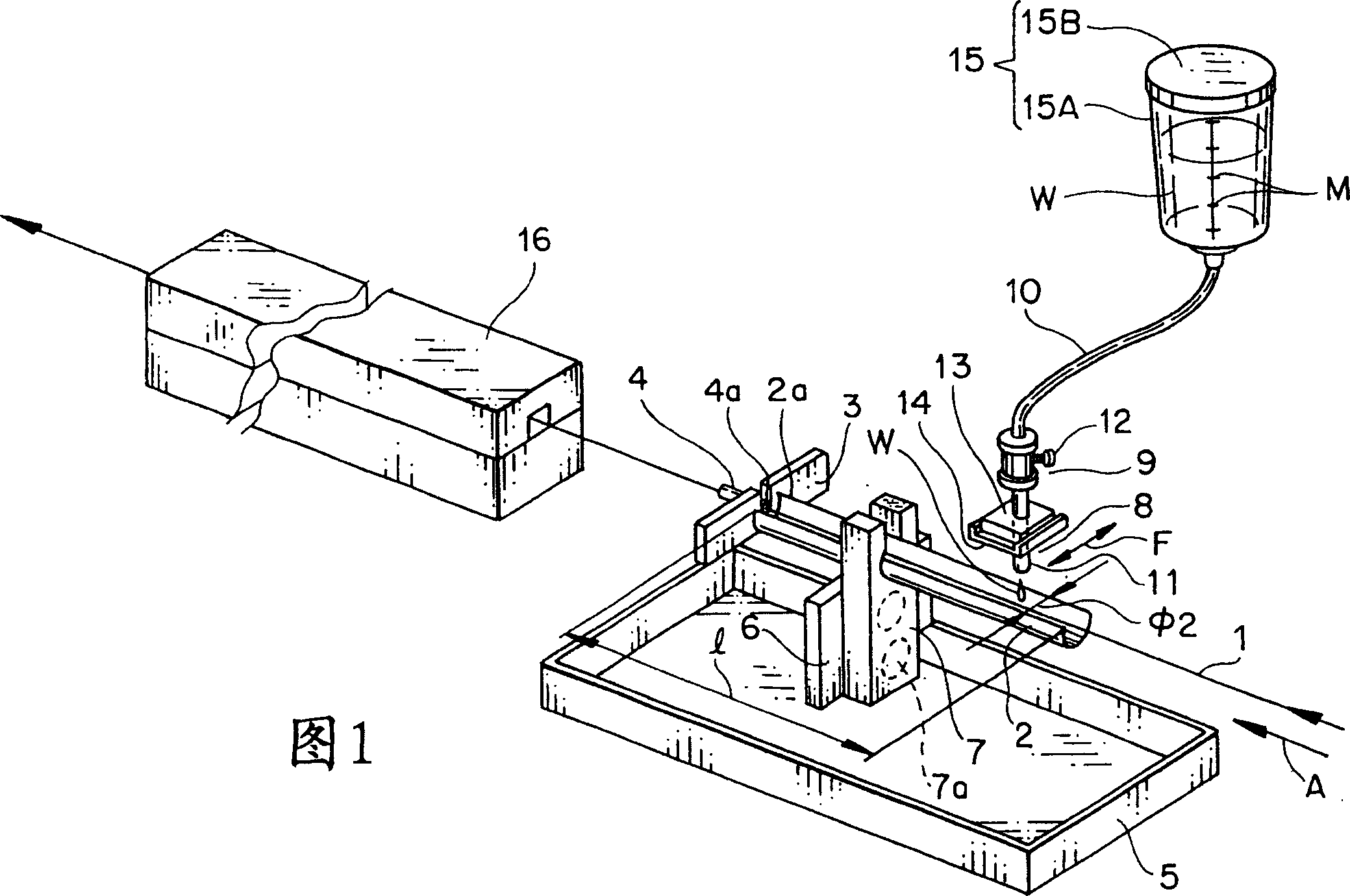

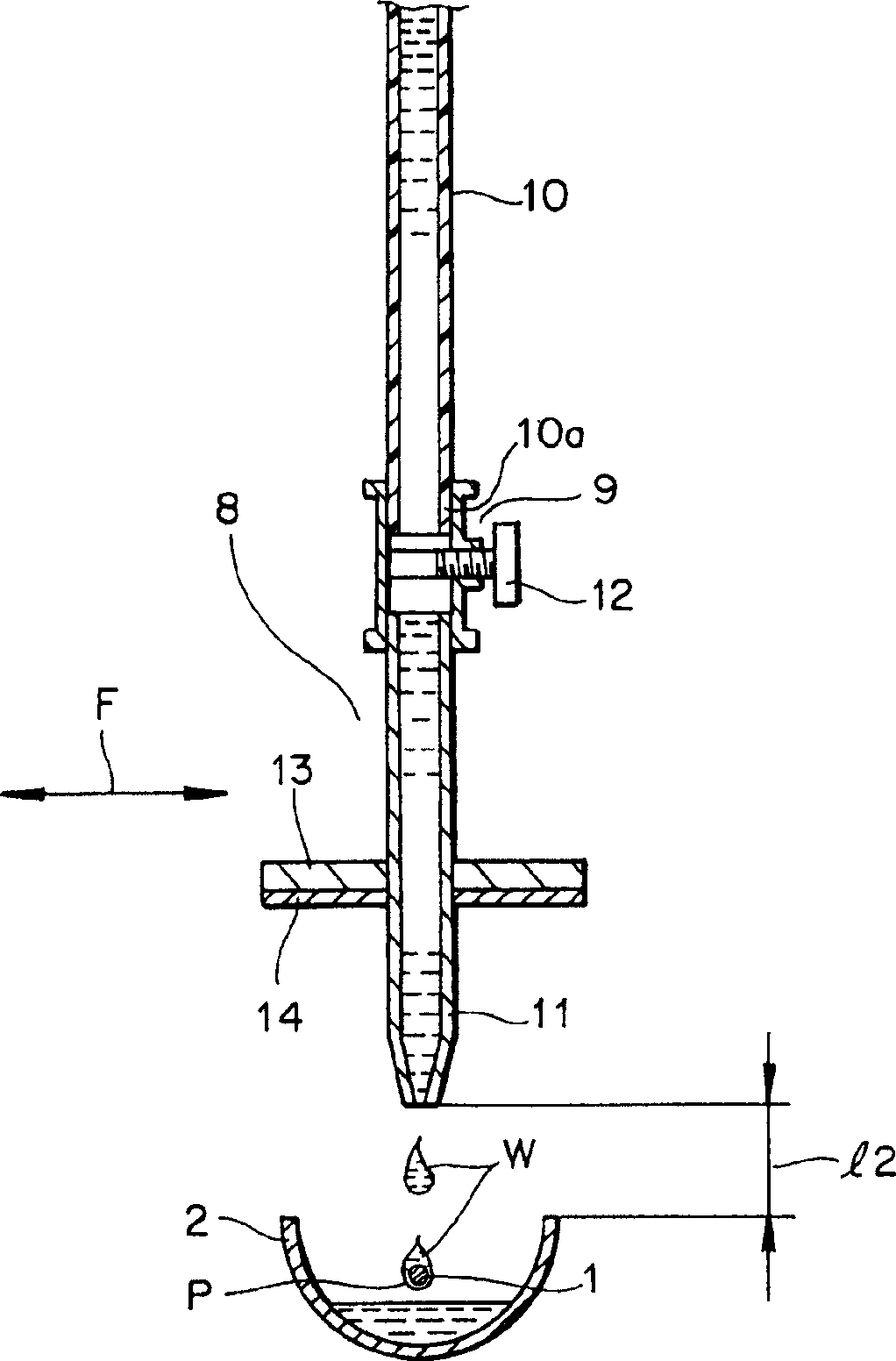

Device for applying varnish to electric wire and method of applying varnish

InactiveCN1577641ANot easy to generateMaintain varnish qualityLiquid surface applicatorsInsulated cablesVarnishElectric wire

An electric wire 1 is moved in a moving direction at a desired speed. An insulating layer of varnish is formed on the outer surface of the electric wire 1 by a device for applying the varnish. The device includes a rough-like container 2 and dropping means 8. The rough-like container 2 is located below the electric wire 1 in the moving direction. The dropping means 8 is located for the electric wire above the container. Adesired quantity of varnish is dropped from the dropping means 8 toward the outer surface of the electric wire 1 through a flow rate adjusting portion. The flow rate of the varnish is adjusted by the flow rate adjusting portion 9.

Owner:GOTO DENISH CO LTD

Ecological organic biofertilizer and its preparation method and use

ActiveCN105367164AHigh activityImprove physical fertilityFertilizer mixturesMicroorganismDecomposition

The invention discloses ecological organic biofertilizer and its preparation method and use. The ecological organic biofertilizer comprises, by weight, 10-15 parts of a mixture of nitrogenous fertilizer, phosphate fertilizer and potash fertilizer, 20-50 parts of an organic material subjected to fermentation decomposition, 15-30 parts of calcium-magnesium-silicon-potassium fertilizer and a nitrogen-fixing microorganism agent and / or a phosphate-solubilizing microorganism agent, wherein a ratio of the nitrogen-fixing microorganism agent and / or the phosphate-solubilizing microorganism agent to the ecological organic biofertilizer is in a range of 0.2-5.0%. The ecological organic biofertilizer can improve soil physical and chemical properties, improves a soil loosening degree after use and improves drought resistance and water retention capacities.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

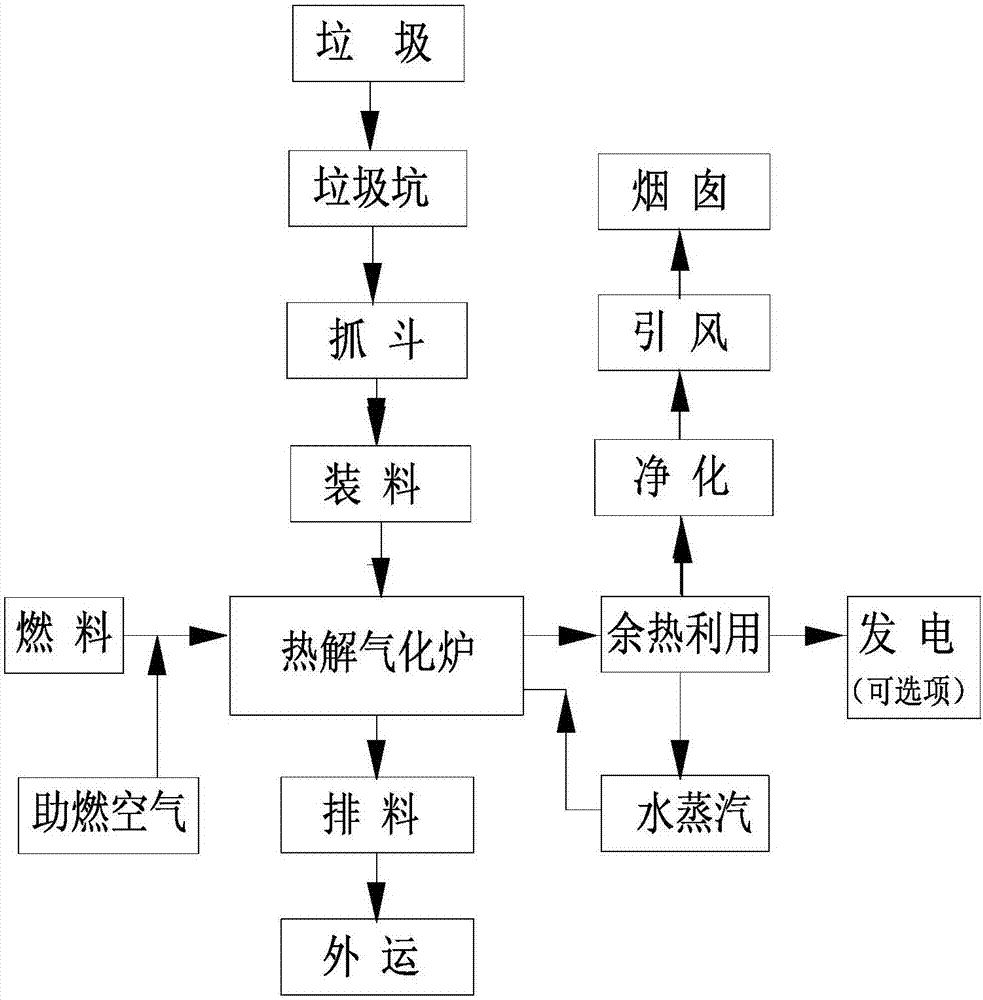

Large-scale domestic garbage pyrolysis and gasification technology

InactiveCN107490008AAdaptableSimple loading processIncinerator apparatusCombined combustion mitigationCombustion chamberPyrolysis

The invention relates to a large-scale domestic garbage pyrolysis and gasification technology. The large-scale domestic garbage pyrolysis and gasification technology includes the following steps that after domestic garbage is transported to a garbage pit, a grab bucket is used for grabbing the domestic garbage to the top of a pyrolysis and gasification furnace and loading the domestic garbage into a pyrolysis and gasification tank in the pyrolysis and gasification furnace through a loading device. Pyrolysis and gasification of the domestic garbage are completed in the tank, and ash obtained after pyrolysis and gasification is loaded into an ash tank through a discharging device and then is transported outwards. Heat needed by the pyrolysis and gasification tank is transmitted in from a combustion chamber in the pyrolysis and gasification furnace through a partition wall, and high-temperature flue gas in the combustion chamber passes through waste heat utilizing and purifying devices and other devices and then is discharged into the air. Compared with existing domestic garbage incineration, pyrolysis and gasification melting technologies and other technologies, the large-scale domestic garbage pyrolysis and gasification technology has the obvious beneficial effects that the domestic garbage adaptability is high, large-scale production is achieved, environment friendliness is good, cost is low, and the investment is small.

Owner:许志英

Graphite composite fire resistant material

The invention relates to a graphite composite fire resistant material which comprises the following components in parts by weight: 2-30 parts of surface coated graphite, 65-95 parts of a fire resistant aggregate and 2.5-5 parts of a binder. The fire resistant aggregate is one or more of magnesite, aluminum oxide corundum, zirconium oxide, magnesium aluminate spinel and silicon carbide. The binder is phenolic resin or furfural resin. According to the graphite composite fire resistant material provided by the invention, the surface of graphite is coated with an antioxidant, so that the antioxidant effect is remarkable. The antioxidant is separated from the fire resistant aggregate and is not directly contacted with the fire resistant aggregate, so that low-melting-point products cannot be produced easily at high temperatures, so that the high temperature resistance of the fire resistant material is improved.

Owner:江苏苏嘉集团新材料有限公司

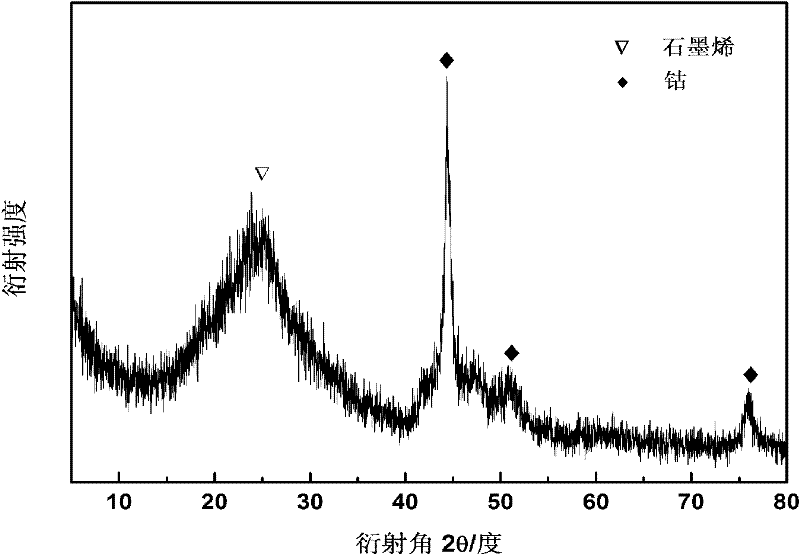

Method for preparing cobalt/graphene composite material by alcohol thermal method

InactiveCN102229425ASimple processLow requirements for production equipmentMaterial nanotechnologyAlcoholMagnetization

The invention relates to a method for preparing a cobalt / graphene composite material by an alcohol thermal method. The method comprises the following steps of: (1) dispersing graphite oxide into glycol solution at room temperature to obtain mixed solution with concentration of 0.5 to 2 mg / mL, ultrasonically dispersing the mixed solution for 30 to 60 minutes, adding cobalt salt, anhydrous sodium acetate and polyethylene glycol, and stirring for 1 to 2 hours to obtain reaction solution; and (2) adding the reaction solution into a reaction kettle, heating the reaction kettle to 180 to 210 DEG C,reacting for 8 to 16 hours, cooling the obtained product to room temperature, centrifugally collecting the product, washing the product with deionized water and absolute ethanol, and drying to obtainthe cobalt / graphene composite material. The method is simple in process and suitable for industrialized production. The prepared cobalt / graphene composite material has a pure cobalt crystalline phase, high complex property with graphene, high dispersibility on the surface of the graphene and in the layer, low resistivity, high magnetization intensity and a good application prospect.

Owner:DONGHUA UNIV

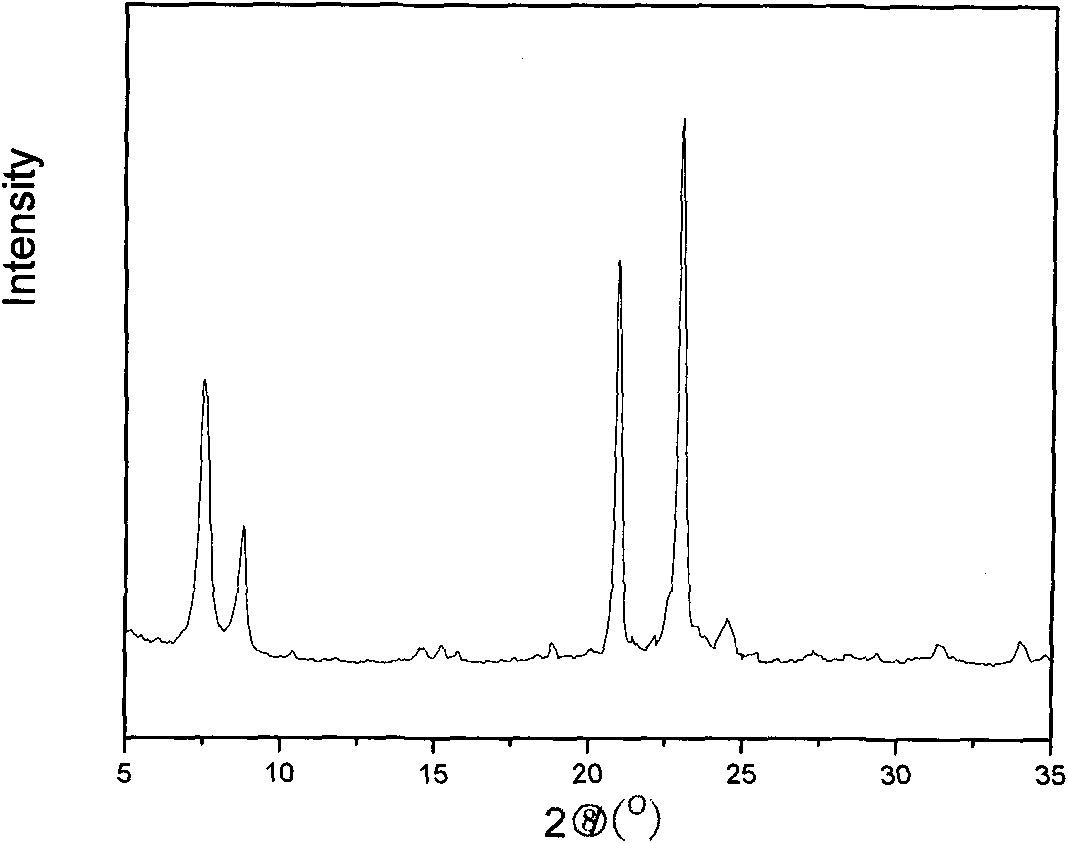

Synthesis method of Ti-Beta molecular sieve

InactiveCN103395798APromote generationSilicon-titanium ratioCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention discloses a synthesis method of a Ti-Beta molecular sieve. The method includes: taking N, N-diethylpiperidine quaternary ammonium base as a structure directing agent, mixing a silicon source, a titanium source, a fluorine anion (F<->) source with N, N-diethylpiperidine quaternary ammonium base (R) and water, then subjecting the reaction mixture to hydrothermal crystallization for 3-25 days at 120-180DEG C, then washing, drying and roasting the product, thus obtaining the Ti-Beta molecular sieve. During synthesis of the invention, the range of the gel Si-Ti ratio is wide, and the synthesized Ti-Beta molecular sieve has a wide Si-Ti ratio. No miscellaneous crystal is generated, and the synthesized Ti-Beta molecular sieve does not contain aluminum and non-framework titanium. Especially, the Ti-Beta molecular sieve with a higher framework titanium content can be synthesized, thus being conducive to enhancing the catalytic activity.

Owner:SHANXI DATONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com