Patents

Literature

30results about How to "Reduce bad luck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

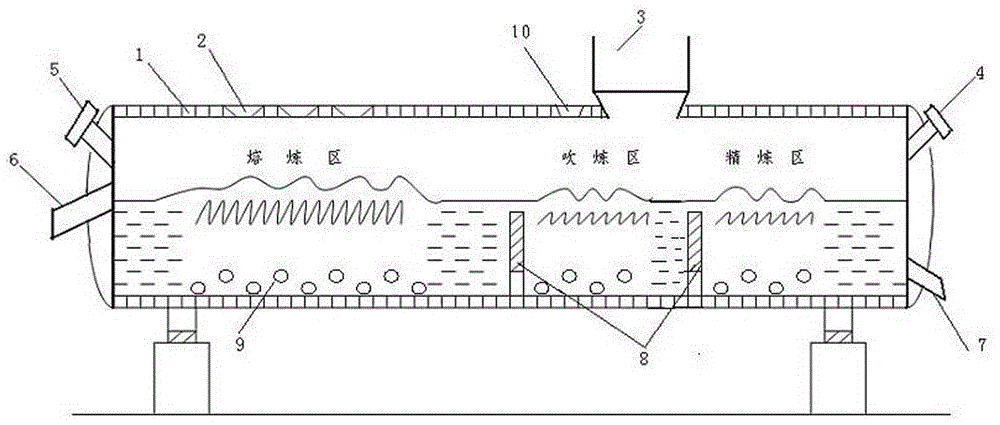

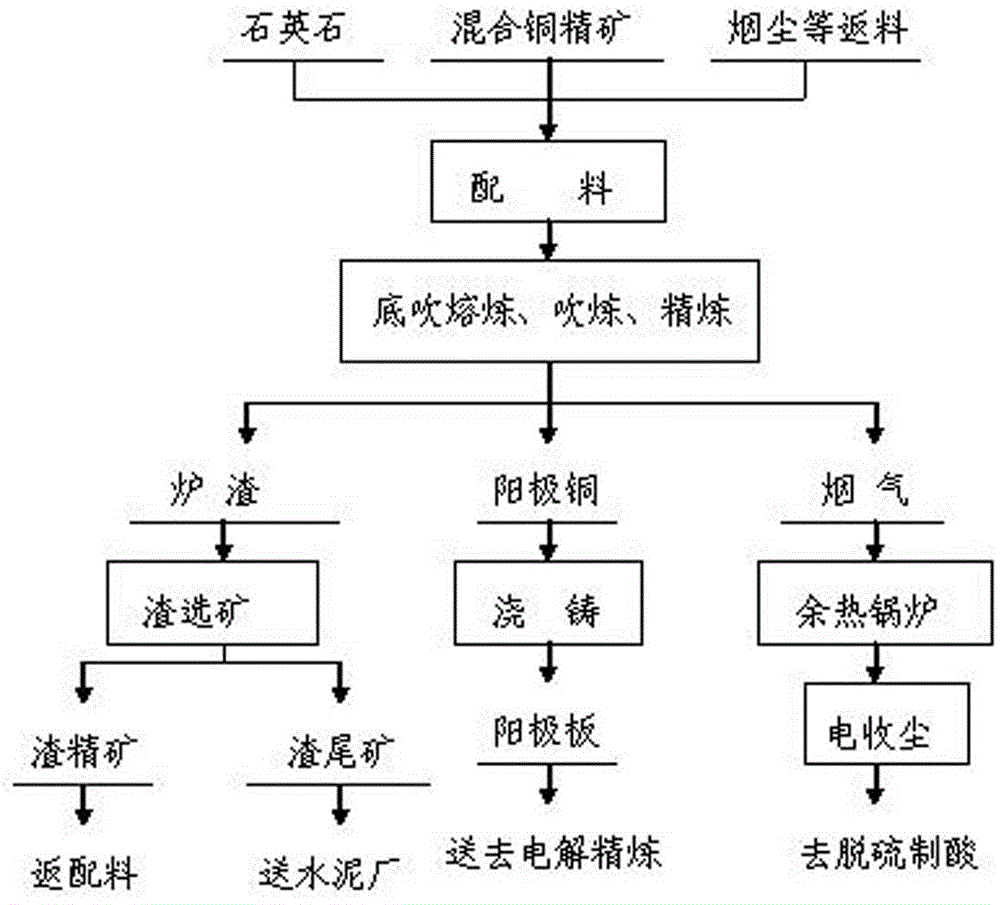

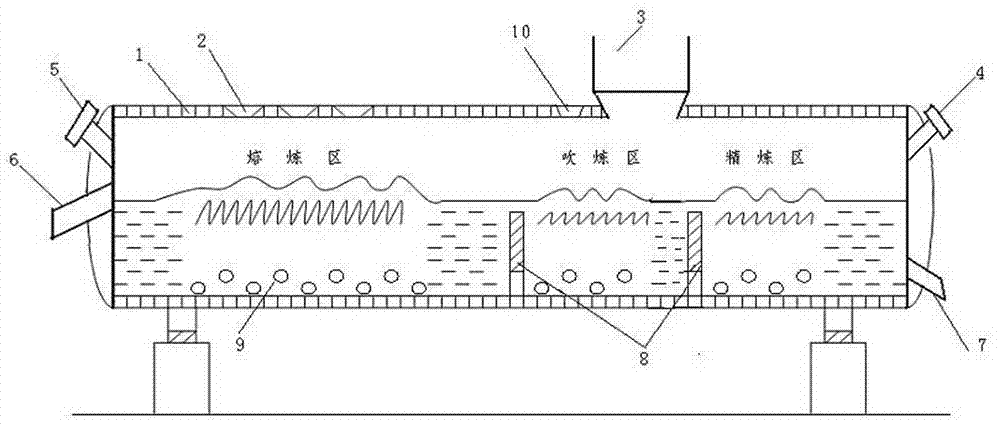

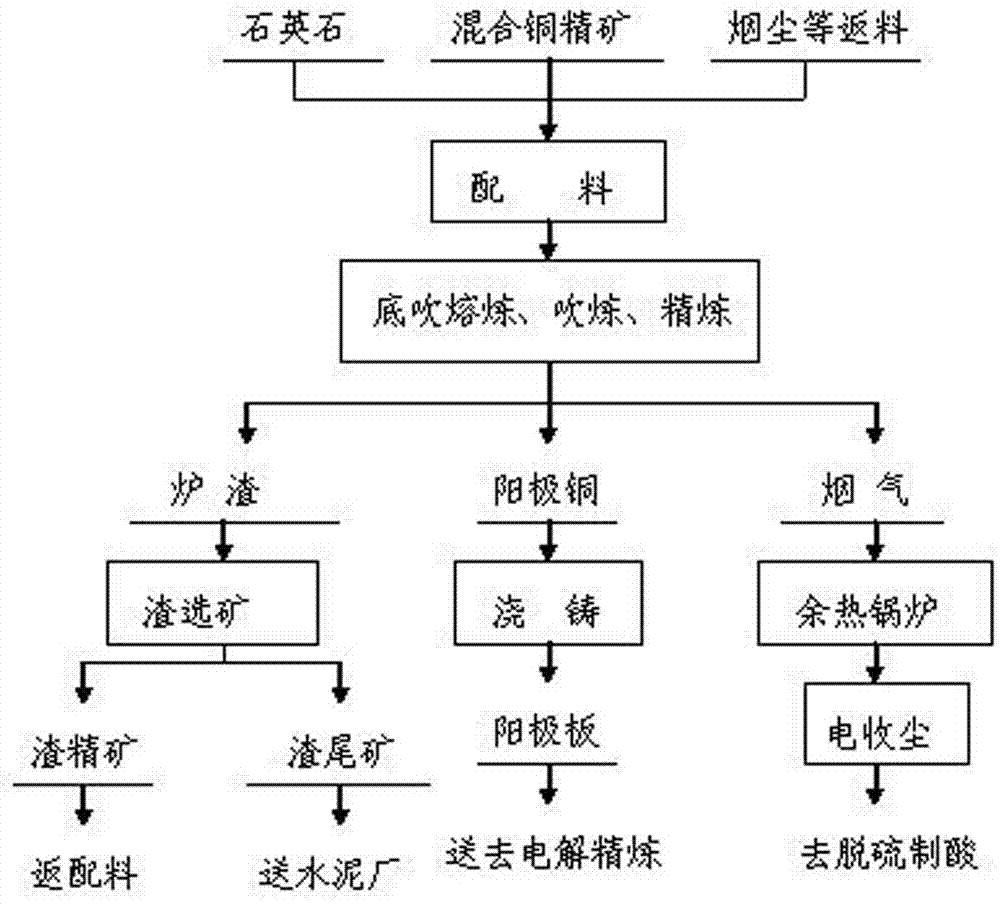

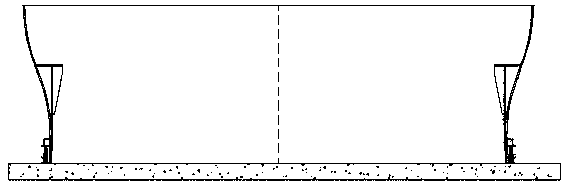

One-step copper smelting technology and device thereof

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

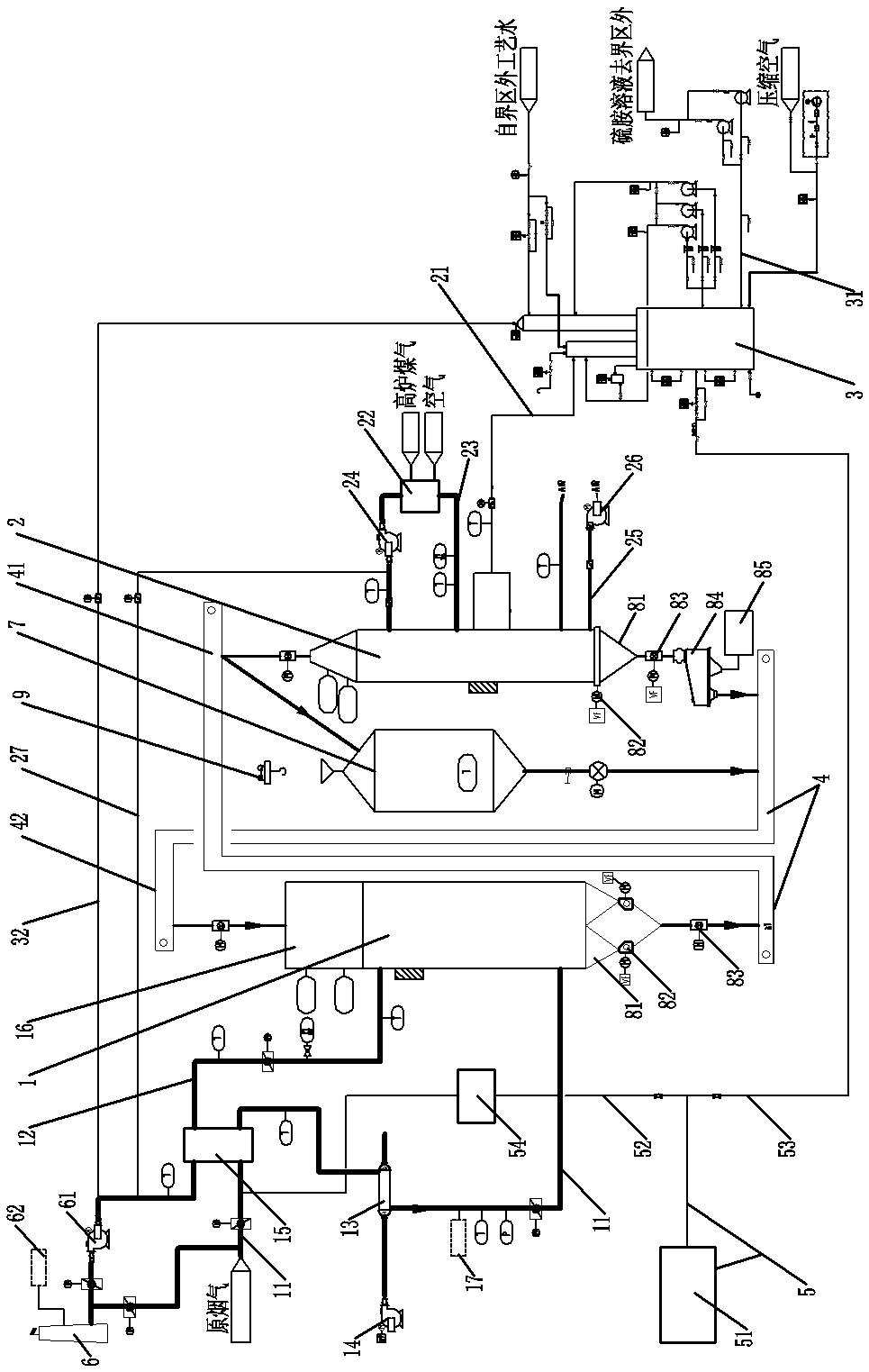

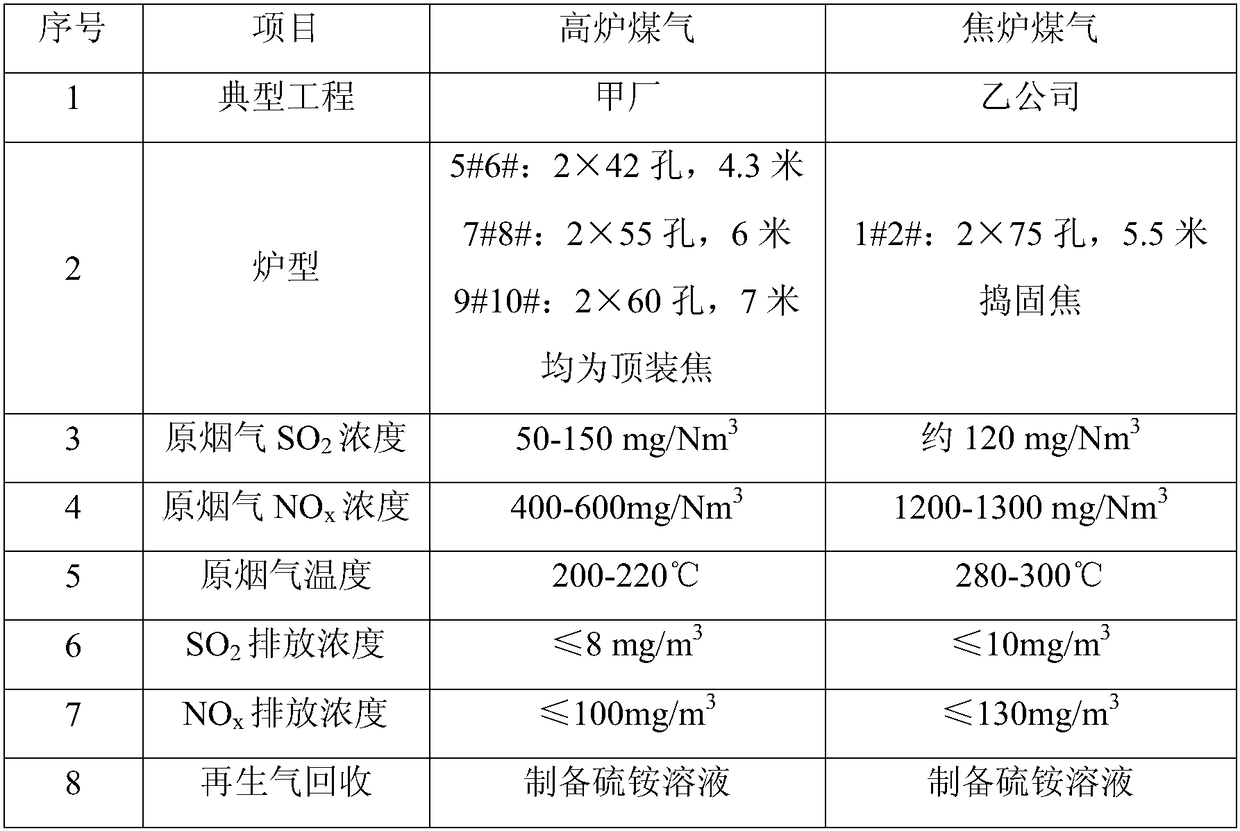

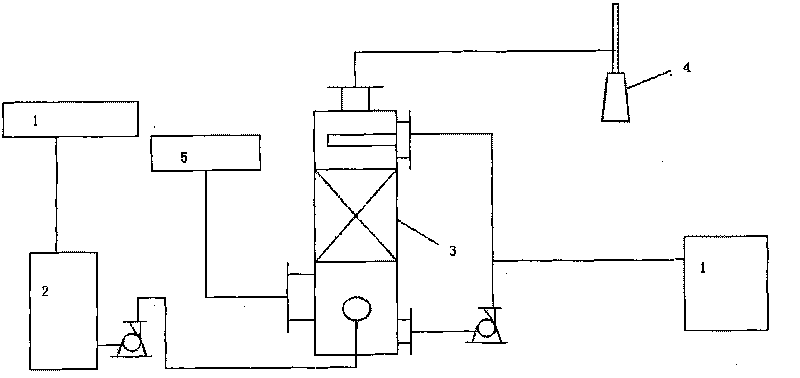

Activated carbon/coke-based coke oven flue gas desulfurization and denitration system and activated carbon/coke-based coke oven flue gas desulfurization and denitration method

PendingCN108380041AReduce escapeWell mixedGas treatmentDispersed particle separationEngineeringAmmonium sulfate

The invention discloses an activated carbon / coke-based coke oven flue gas desulfurization and denitration system and an activated carbon / coke-based coke oven flue gas desulfurization and denitration method. The flue gas desulfurization and denitration system comprises an activated carbon / coke flue gas purification tower, an activated carbon / coke regeneration tower, a chimney, an ammonia water injection system and an absorption tower, wherein an activated carbon / coke conveyor is arranged between the purification tower and the regeneration tower; the regeneration tower is connected with a high temperature heating system and a regenerated gas pipeline; the ammonia water injection system comprises an ammonia water container; the ammonia water container is connected with a first ammonia water pipeline and a second ammonia water pipeline which are arranged in parallel; the first ammonia water pipeline and the second ammonia water pipeline are respectively communicated with the interiors of aflue gas inlet pipeline and the absorption tower; the bottom of the absorption tower is connected with an ammonium sulfate solution pipeline, and the top of the absorption tower is connected with a waste gas exhaust pipeline; the regenerated gas pipeline is communicated with the interior of the absorption tower; a purified gas exhaust pipeline and the waste gas exhaust pipeline are communicated with the chimney; the activated carbon / coke conveyor comprises an old material conveyor used for conveying activated carbon / coke at the bottom of the purification tower onto the top of the regenerationtower, and a new material conveyor used for conveying activated carbon / coke at the bottom of the regeneration tower onto the top of the purification tower.

Owner:南京泽众环保科技有限公司

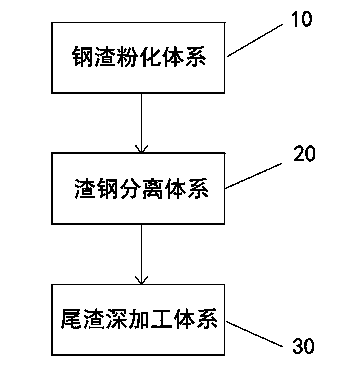

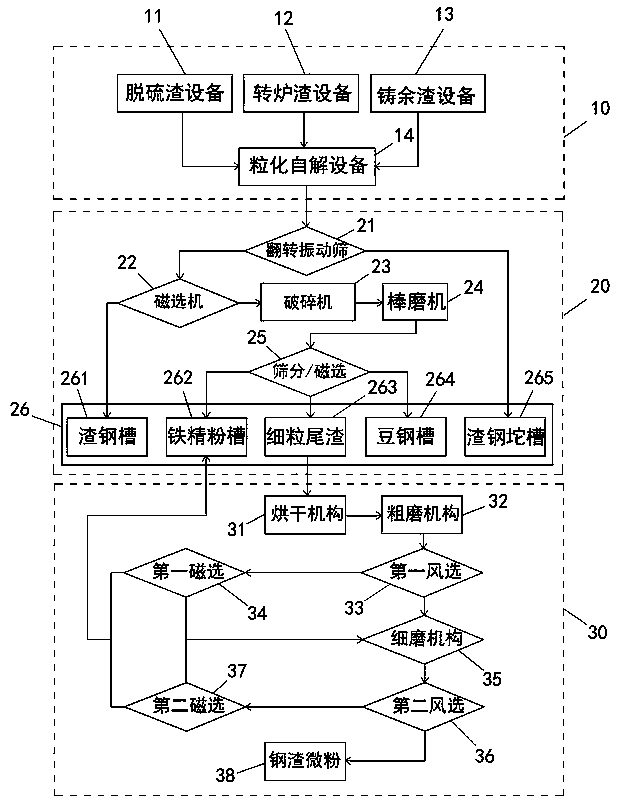

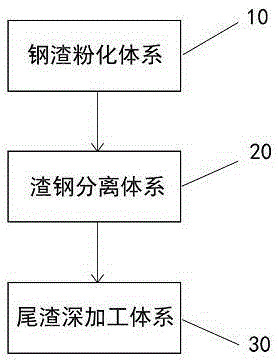

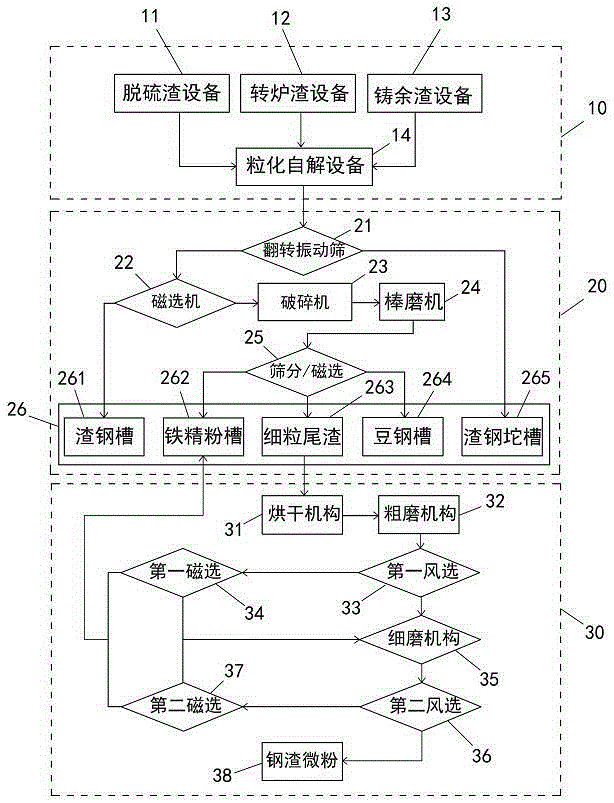

System and method for converting steel slag into renewable resources

ActiveCN103555867AEfficient use ofShort processRecycling and recovery technologiesProcess efficiency improvementSlagMagnetic separator

The invention discloses a system and a method for converting steel slag into renewable resources. The system comprises a steel slag powdering system, a steel slag separating system and a tail slag deep processing system, wherein the steel slag powdering system comprises desulphurization slag equipment, converter slag equipment, casting residue equipment and granulation self-extracting equipment which is communicated with the desulphurization slag equipment, the converter slag equipment and the casting residue equipment respectively; the steel slag separating system is connected with the granulation self-extracting equipment and comprises overturn vibration equipment, a magnetic separator, a crushing machine, a rod mill, screening / magnetic separation equipment and material storage equipment, wherein the overturn vibration equipment, the magnetic separator, the crushing machine, the rod mill, and the screening / magnetic separation equipment are led to the material storage equipment; the tail slag deep processing system is connected with a fine tail slag device and comprises a drying mechanism, a coarse grinding mechanism, a fine grinding mechanism, a first winnowing mechanism, a second winnowing mechanism, a first magnetic separation mechanism, a second magnetic separation mechanism and a steel slag fine powder groove. By the combination of the structures of the system, the design construction of the system for converting the steel slag into the renewable resources, which is clean and environment-friendly and reduces occupation space, is realized.

Owner:WISDRI ENG & RES INC LTD

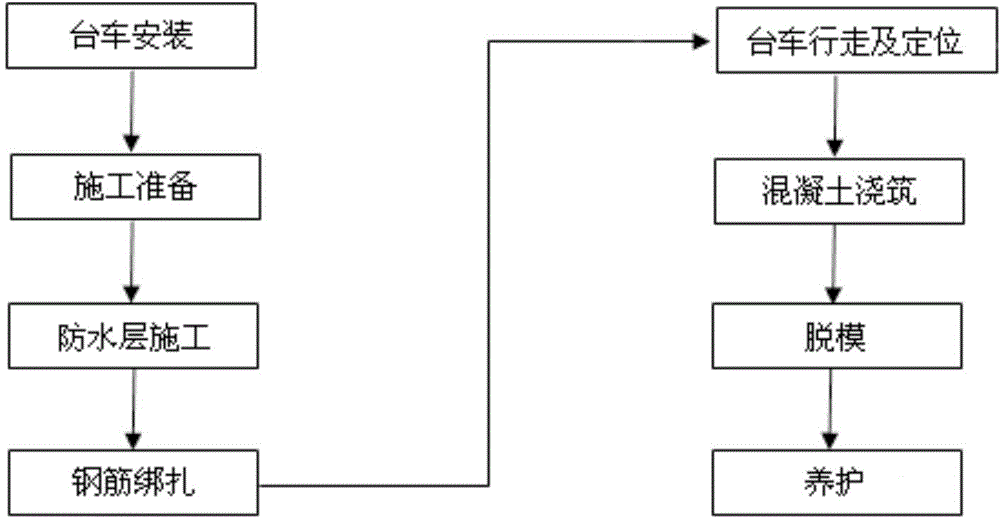

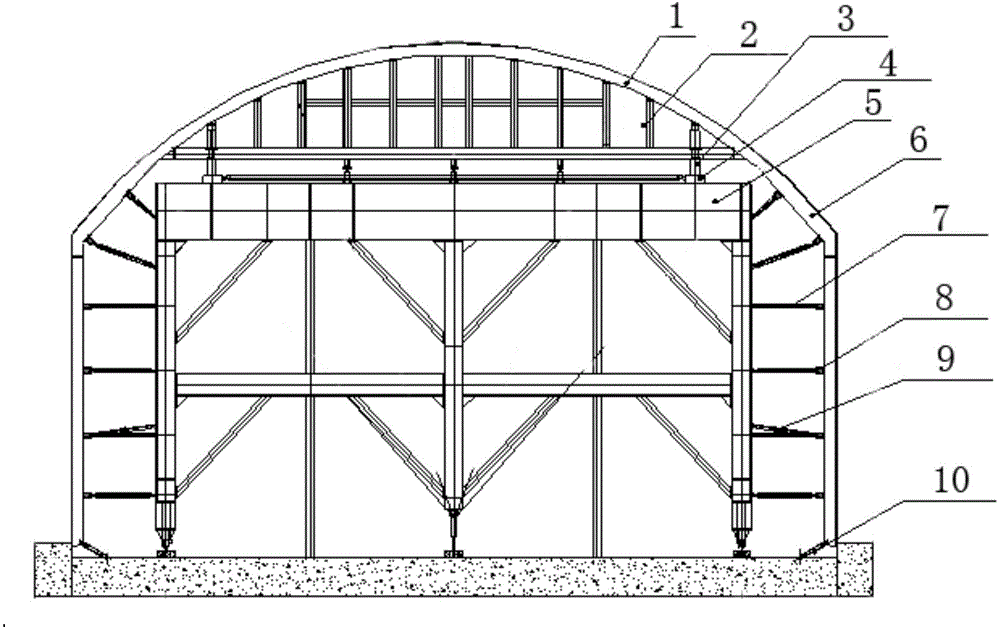

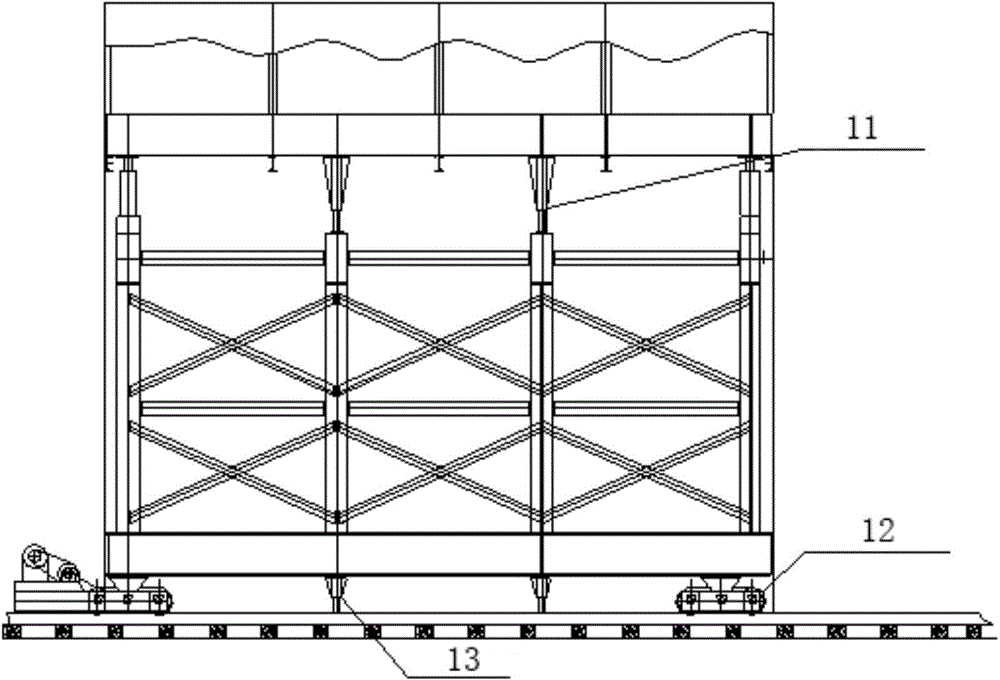

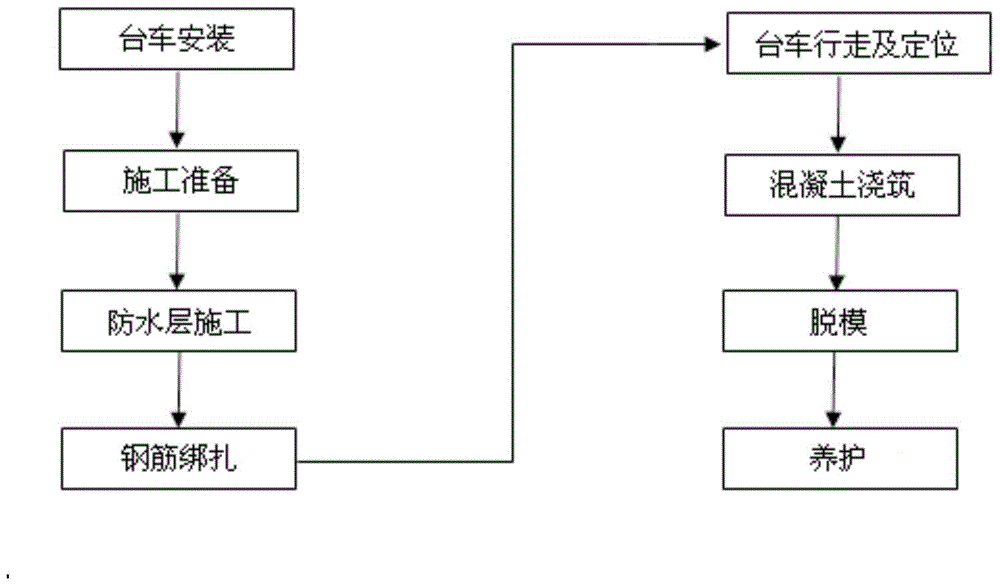

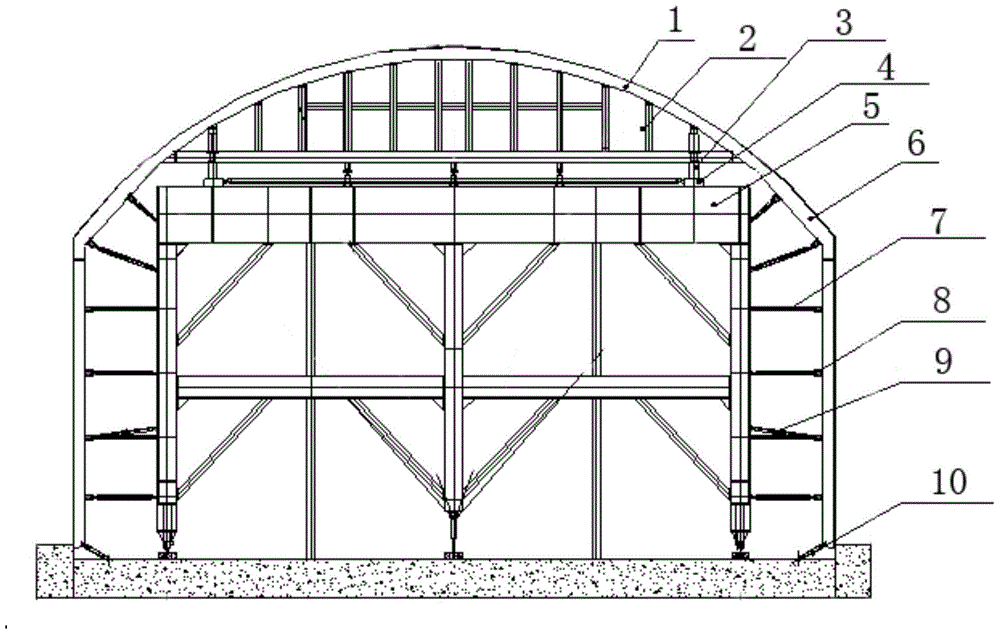

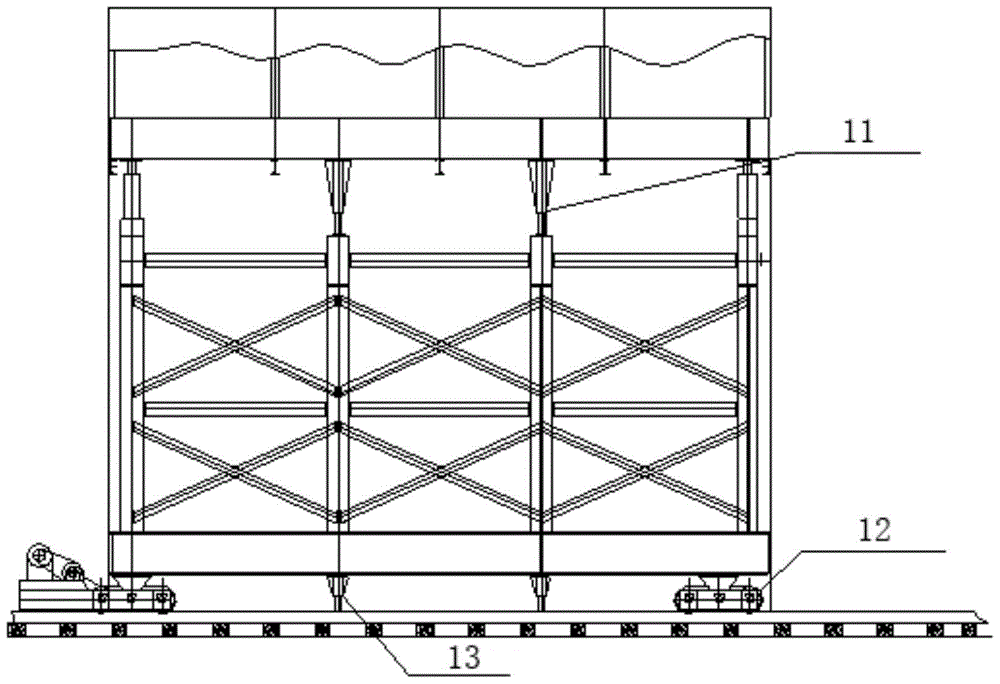

Super-large section chamber reinforced concrete modelling construction method

ActiveCN104533456AMove fastFast positioningUnderground chambersTunnel liningReinforced concreteMotor drive

The invention relates to the technical field of construction, in particular to a reinforced concrete modelling construction method which is applicable to a large section chamber. According to the super-large section chamber reinforced concrete modelling construction method, a multi-vertical-rod type lining trolley is adopted to control the integral rigidity of a rack, a motor drives a walking mechanism to drive the trolley to move, formwork in place and tunnel reinforced concrete forming of closing mold are adjusted through a hydraulic oil cylinder and a screw jack, the multi-rod type lining trolley adopts a method of pouring the side wall and the arc portion together or separately pouring the arc wall according to the size, the construction period and the concrete supply conditions of the tunnel section. According to the reinforced concrete modelling construction method, the multi-rod type lining trolley is adopted, the side wall and the arc portion can be poured separately and simultaneously, the construction period and costs are saved, the splicing time and material reshipment are reduced, the trolley movement and positioning speed is rapid, and personnel operation is facilitated; the multi-rod trolley adopts full-hydraulic vertical closing mold, the motor driving is matched with walking of the rail, accurate positioning is easy, braking is convenient, movement safety risks are small, and the structure is reasonable.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

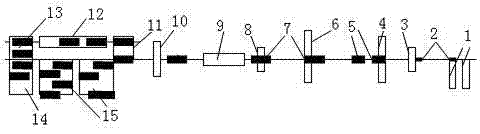

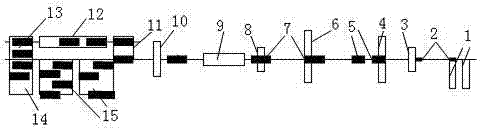

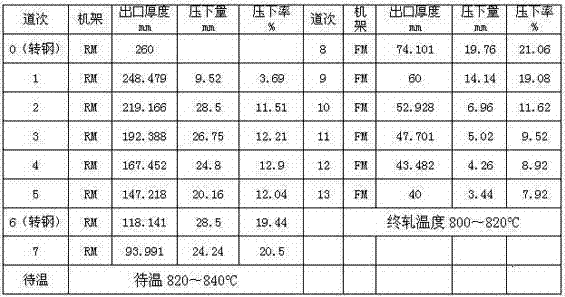

Production process of high-toughness and ultra-high strength steel and production system thereof

The invention relates to a production process of high-toughness and ultra-high strength steel and a production system thereof. The production system comprises a descaling box, a roughing mill, a temperature waiting roller table, a finishing mill, an ultra-fast cooling system, a thermal straightening machine, steel splitting racks and an open flame tempering furnace. The production process comprises the following steps of: fully heating a plate blank, discharging the plate blank from a furnace, descaling the plate blank, sequentially performing rough rolling, temperature waiting, finish rolling, on-line ultra-fast quenching and fast thermal straightening, separating the plate blank from a main production line through the steel splitting racks, fast sending a steel plate into the open flame tempering furnace for heat insulation, performing carbon distribution at PT (carbon distribution temperature), discharging the steel plate from the furnace, and then performing air cooling. The sequential arrangement of equipment of the production line is as follows: the heating furnace, the plate blank, the descaling box, the roughing mill, an intermediate blank, the finishing mill, a pre-straightening machine, an ultra-fast cooling unit, the thermal straightening machine, the first steel splitting rack, the open flame tempering furnace, the second steel splitting rack, a thick plate cooling bed and an intermediate plate cooling bed.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

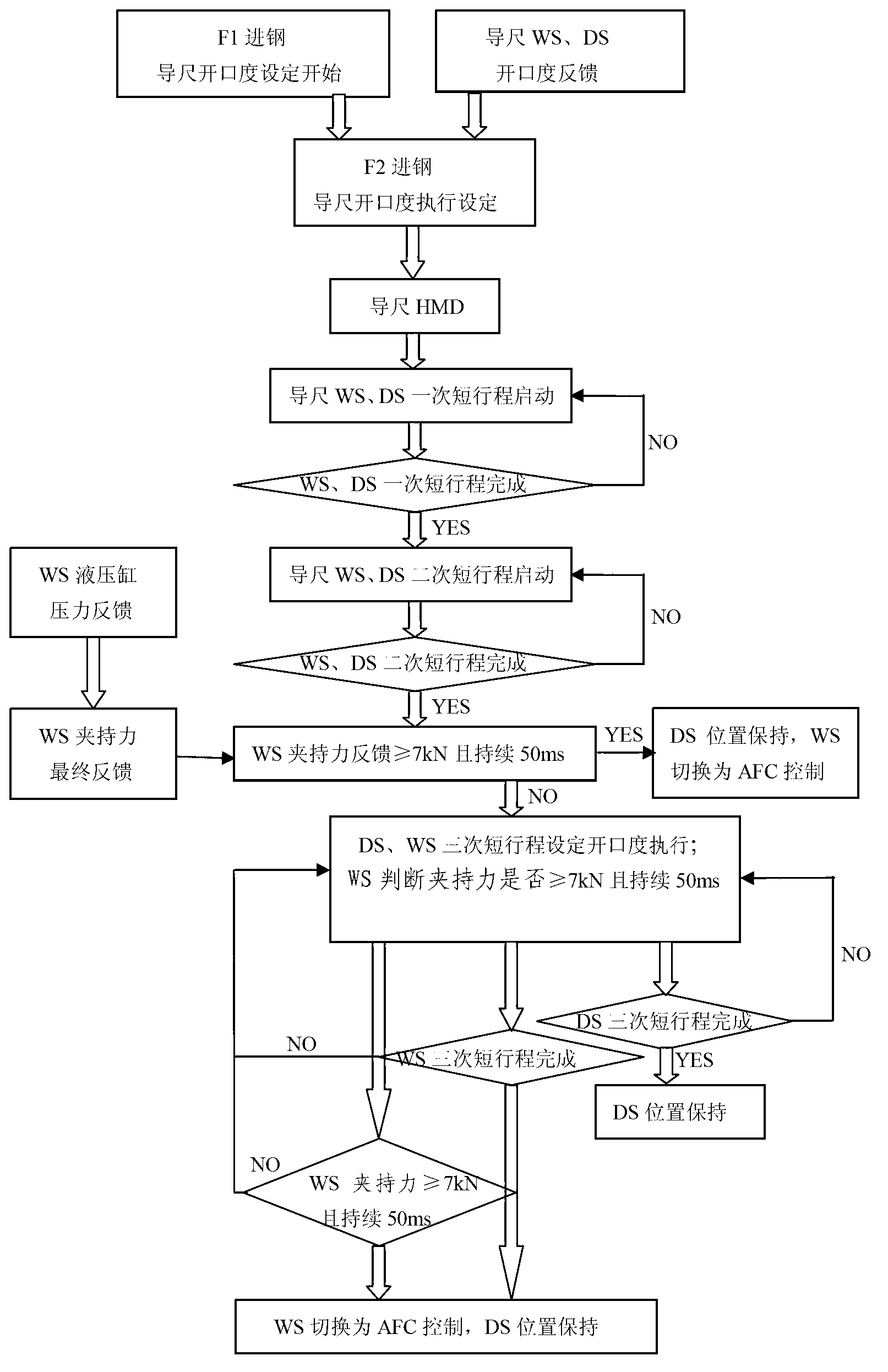

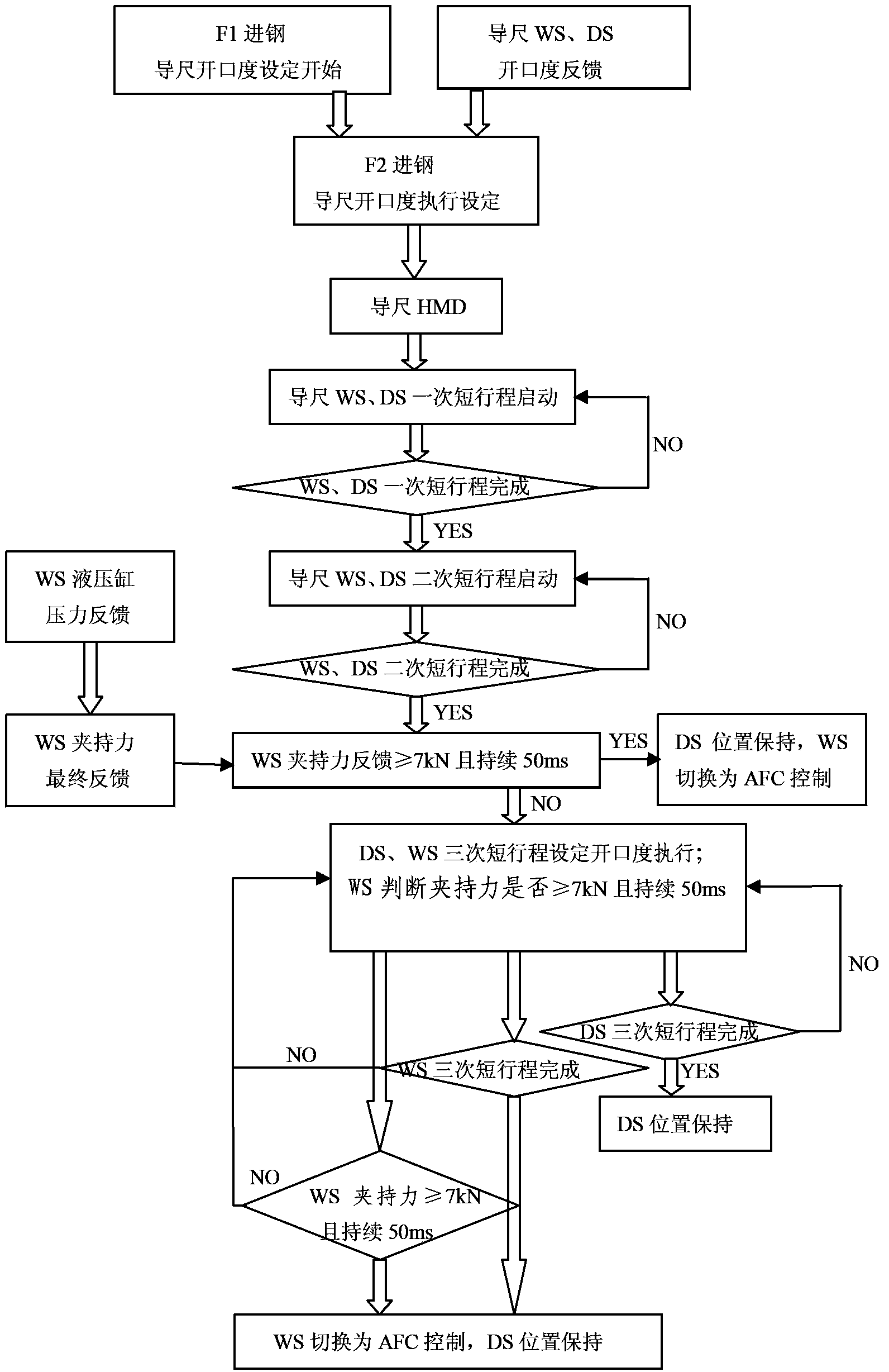

Thin material threading control method for guide rulers of hot rolling coiler

ActiveCN103008359AEliminate the "inner tower" phenomenonQuality improvementRoll mill control devicesMetal rolling arrangementsAutomatic controlControl manner

The invention provides a thin material threading control method for guide rulers of a hot rolling coiler. The method comprises the following steps of: additionally arranging a pressure sensor, and additionally arranging an analog quantity input plate and a corresponding program in a PLC (Programmable Logic Controller); when steel is fed through a second frame, setting the opening degrees of the guide rulers by using a secondary computer: when the head part of a steel strip arrives at the middle position of each guide ruler, controlling to start up a primary short stroke and a second short stroke in sequence on the working sides and transmission sides of the guide rulers by using the PLC; judging whether the WS clamping force feedback on the working sides of the guide rulers is more than or equal to 7KN and can last for 50 milliseconds or not at the moment after, and if so, directly switching to a guide ruler working side pressure automatic control way; otherwise, setting a third short stroke: if the working sides of the guide rulers never meet a switching condition, directly switching to an AFC (Automatic Frequency Control) way after the third short strokes of the working sides of the guide rulers are completed. Due to the adoption of the method, the 'inner tower' phenomenon and head cutting loss of a steel coil can be eliminated, the total sealing rate is controlled to be below 1.8 percent, the hot rolling coiling quality is improved greatly, and rolling yield is increased greatly, and the recoiling quantity of sub-coils is reduced by over 30 percent.

Owner:ANGANG STEEL CO LTD

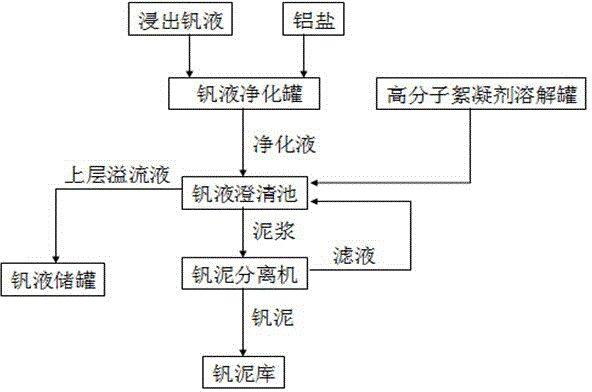

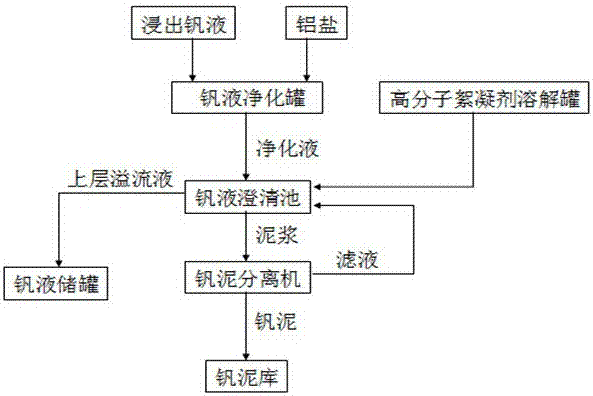

Settlement method of vanadium mud in leached vanadium liquid

ActiveCN104129838ASettling fastImprove purification efficiencyProcess efficiency improvementWater/sewage treatment by flocculation/precipitationAluminium sulfateSilicon

The invention discloses a settlement method of vanadium mud in a leached vanadium liquid. The settlement method comprises the following steps of adding an aluminum salt into a leached vanadium liquid for purification, adding a polymer flocculant solution into the purified vanadium liquid, carrying out mixing to obtain a uniform mixture, and carrying out standing for solid-liquid separation so that a clear vanadium liquid and vanadium mud are obtained. The leached liquid is added with the aluminum salt for purification and then is added with the polymer flocculant solution so that the vanadium mud can be fast deposited. Therefore, the settlement method effectively improves a vanadium mud sedimentation rate, shortens vanadium sedimentation time and effectively improves vanadium liquid purification efficiency so that the whole production process connection is more smooth, vanadium sedimentation time of the vanadium sedimentation process is shortened to about 100min from 250min and production efficiency is improved. The settlement method effectively reduces silicon and phosphor impurity content of the vanadium liquid, reduces a vanadium concentration of the supernatant, effectively reduces unit consumption of aluminum sulfate as a purification agent, reduces system vanadium loss, improves vanadium mud separation efficiency, reduces transport amount of a turbid vanadium liquid and reduces energy consumption.

Owner:HEBEI IRON AND STEEL

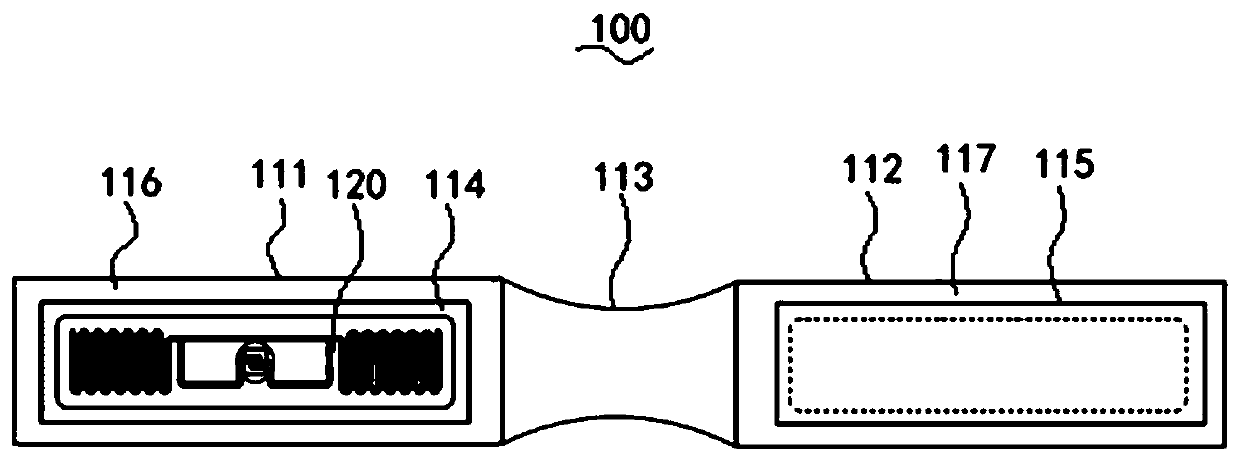

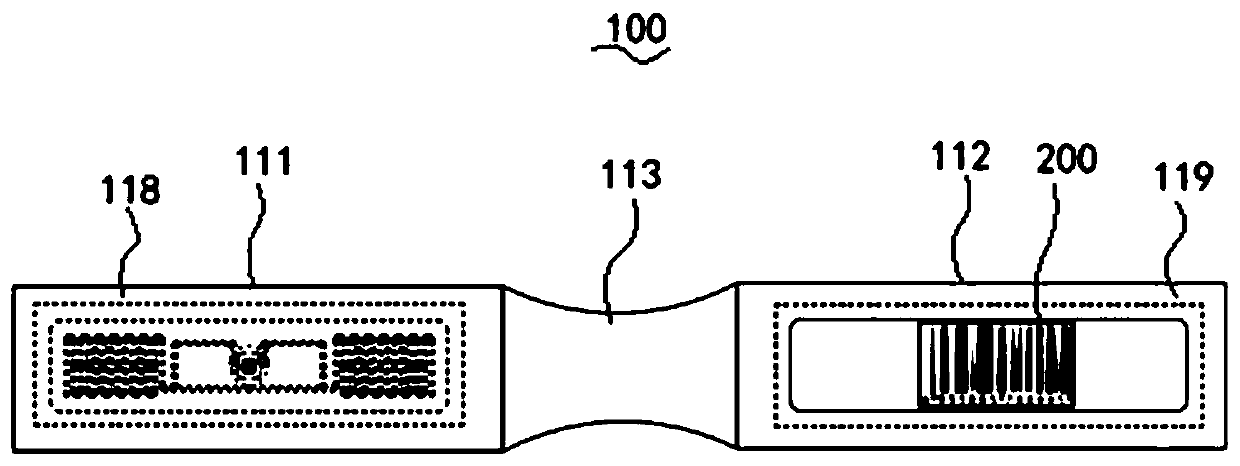

Aviation printing luggage RFID tag

PendingCN110674911AReduce viscosityEasy to printMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesAviationLogistics management

The invention discloses an aviation printing luggage RFID tag comprising a tag body and an RFID chip component, wherein the RFID chip component is arranged in the tag body; the tag body comprises a first portion, a second portion and a connection portion; the first portion is connected with the second portion through the connection portion; the first surface of the first portion is provided with afirst pair of adhesive layers; the first surface of the second portion is provided with a second pair of adhesive layers; and the first portion can be matched with the second pair of adhesive layerson the second portion through the first pair of adhesive layers on the first portion to form a relative bonding structure with the second portion. According to the scheme, the self-adhesive glue is extremely low in viscosity at normal temperature, so that required characters and patterns can be conveniently printed in airports or in the logistics industry; and the target luggage can be automatically identified by using the radio frequency signal, and a plurality of luggage objects moving at a high speed can be simultaneously identified without manual intervention, so that the operation is quick and convenient.

Owner:SHANGHAI INESA TOPLABEL INFORMATION TECH CO LTD

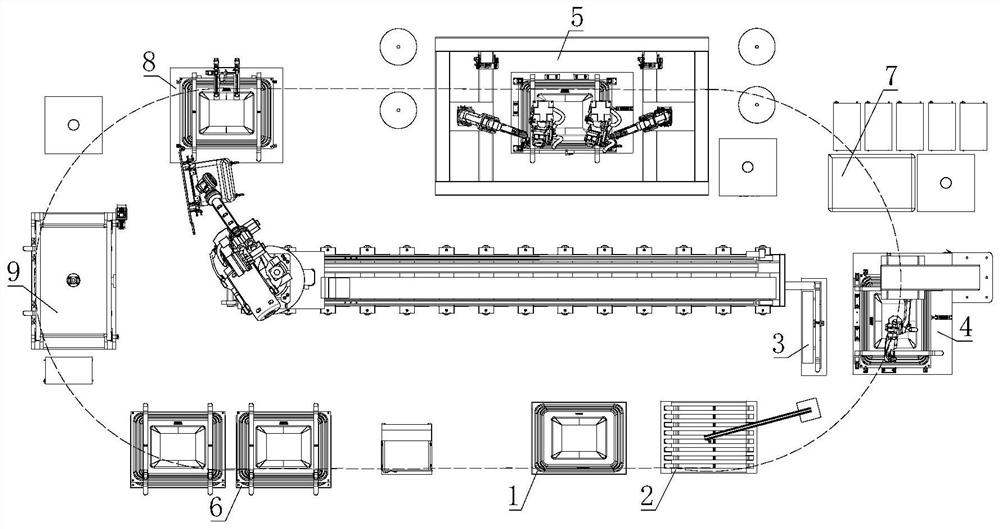

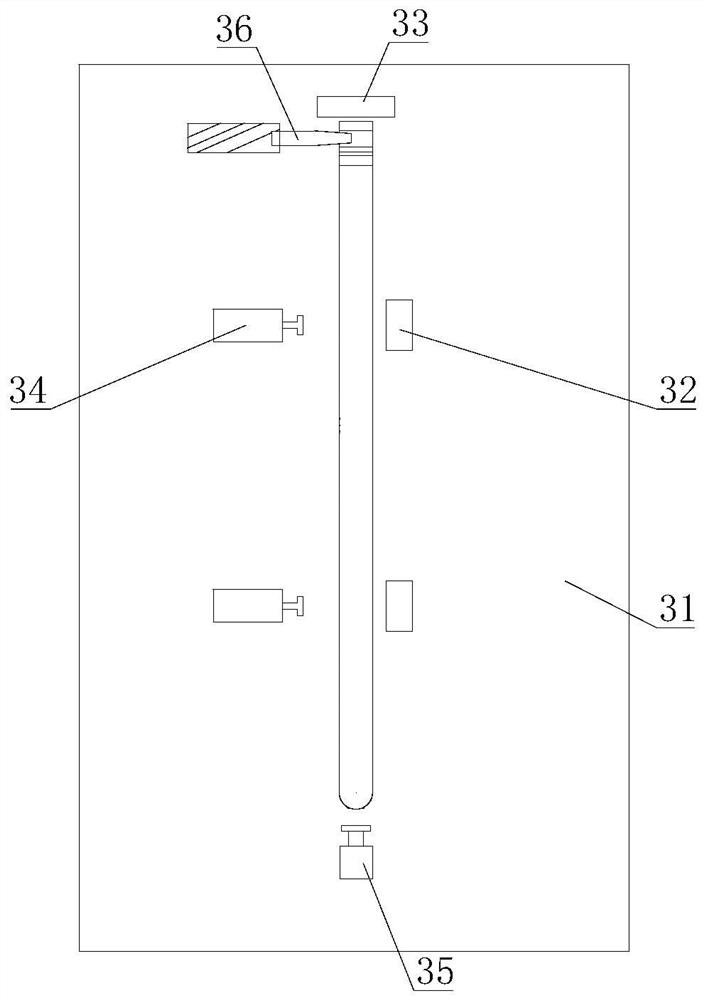

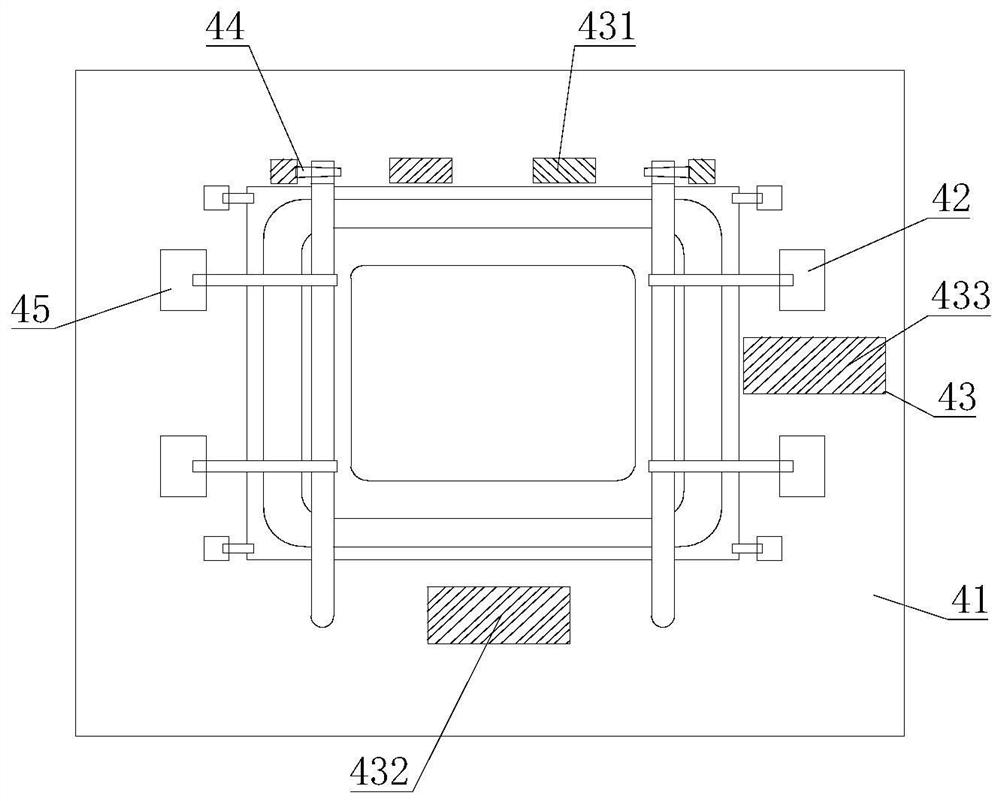

Automatic production system for railway wagon lower side door assembly

InactiveCN112809252AReduce bad luckIncrease the level of automationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

The invention belongs to the technical field of lower side door production systems, and particularly relates to an automatic production system for a railway wagon lower side door assembly. According to the technical scheme, the automatic production system for the railway wagon lower side door assembly comprises a door plate feeding area, a hinge feeding area, a hinge pre-positioning device, a resistance spot welding device, an automatic welding device and a stacking area which are sequentially arranged, and welding manipulators are installed on the resistance spot welding device and the automatic welding device; the automatic production system further comprises a track, and a plurality of transfer robots for transferring materials are mounted on the track; the hinge pre-positioning device comprises a pre-positioning platform, and a plurality of hinge fixing and positioning check blocks used for positioning hinges and a plurality of hinge clamping air cylinders used for clamping the hinges are installed on the pre-positioning platform. The automatic production system for the railway wagon lower side door assembly can ensure that the hinges are accurately positioned on the resistance spot welding device.

Owner:CRRC MEISHAN

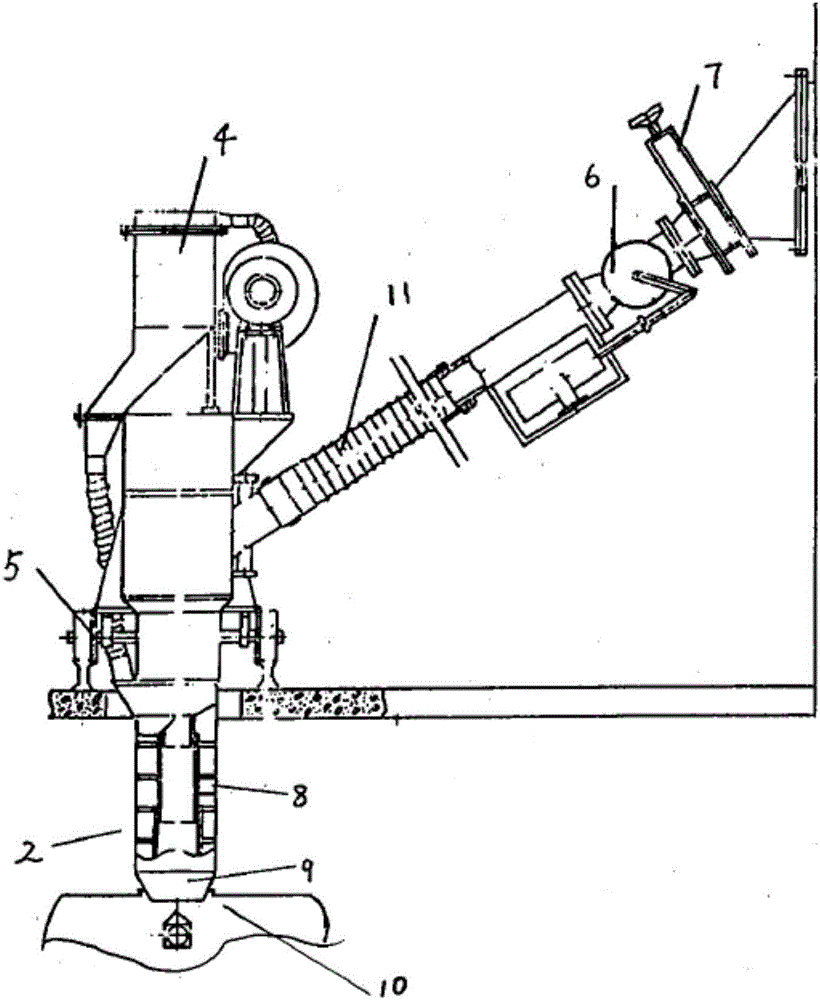

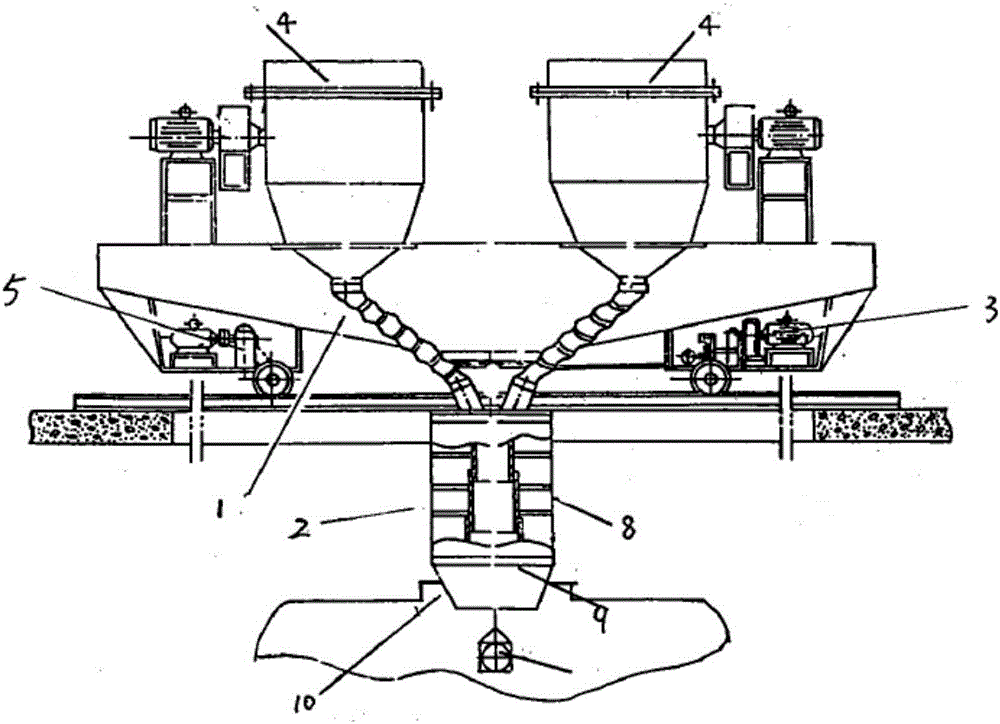

Mobile type bulk dust-free car loader

InactiveCN106276335ASolve the sealing problemReduce bad luckConveyorsLoading/unloadingAutomatic controlEngineering

The invention discloses a mobile type bulk dust-free car loader which comprises a machine head of the car loader, a bulk head, a bulk head hoisting mechanism, a dust collecting device, a metering and automatic control device, a machine head travelling mechanism and a cement conveying pipeline; the cement conveying pipeline is flexibly connected with a steel framework rubber hose; and the dust collecting device is fixedly arranged on the machine body, and can move along with the machine body. The mobile type bulk dust-free car loader solves the sealing problem, and also reduce dust-collected reverse-transportation equipment and dust collecting pipelines.

Owner:JIANGSU GREEN LEAVES MACHINERY

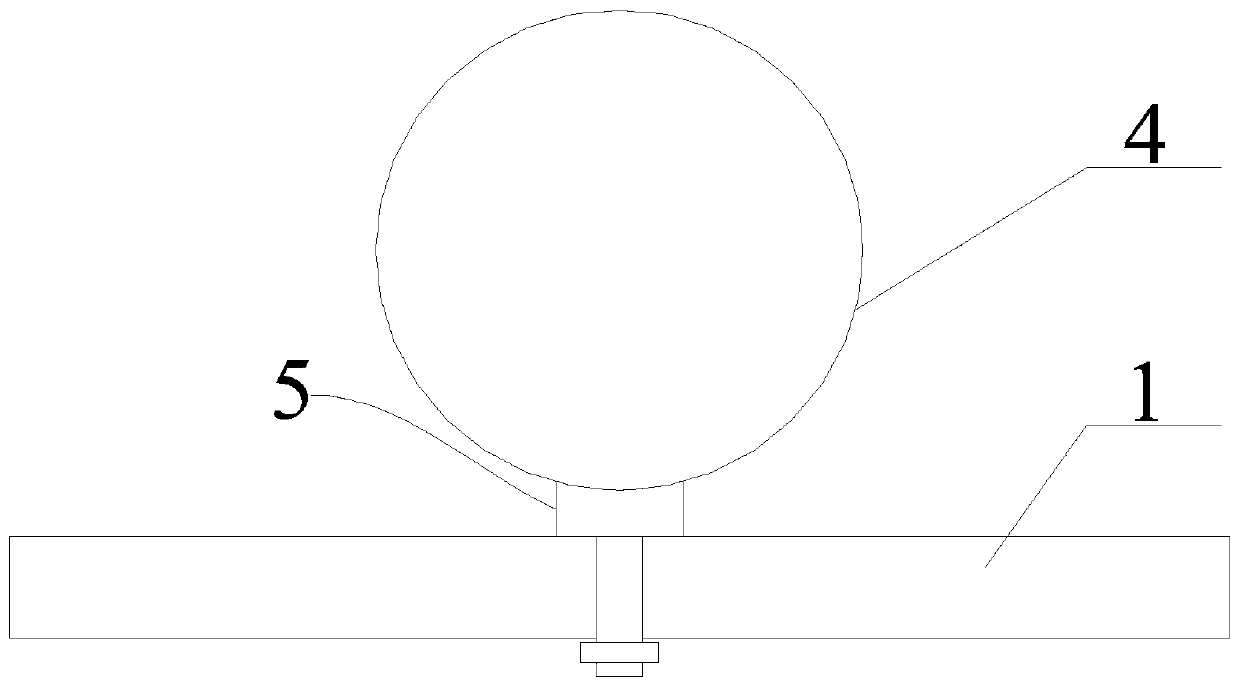

Large-inclination-angle climbing type tubular belt conveyor

The invention relates to the technical field of conveying equipment, and provides a large-inclination-angle climbing type tubular belt conveyor. The large-inclination-angle climbing type tubular beltconveyor comprises a plurality of storage mechanisms uniformly arranged on a belt in the conveying direction; the storage mechanisms are used for dividing the belt into a plurality of chambers after the belt rolls up to form a circular pipe; and the storage mechanisms are arranged on the belt through fixing assemblies. According to the conveyor, the storage mechanisms are arranged on the belt, theplurality of independent chambers are formed after the belt rolls into a cylindrical shape, and materials are separated into the chambers. When the tubular belt conveyor performs large-inclination-angle lifting or vertical lifting, each section of the material is supported by a storage mechanism, so that the weight of the materials is supported and is prevented from sliding down, and the liftingoperation is realized. According to the conveyor, the advantages of an existing tubular belt conveyor are kept, and the large-inclination-angle lifting capability is achieved, the use of lifting equipment is canceled, the material transportation is reduced, the conveying efficiency and the conveying quality are improved, and the conveying cost is reduced.

Owner:闫冰

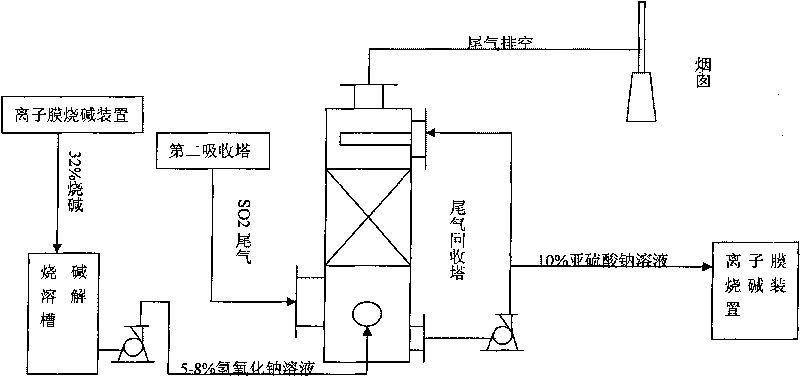

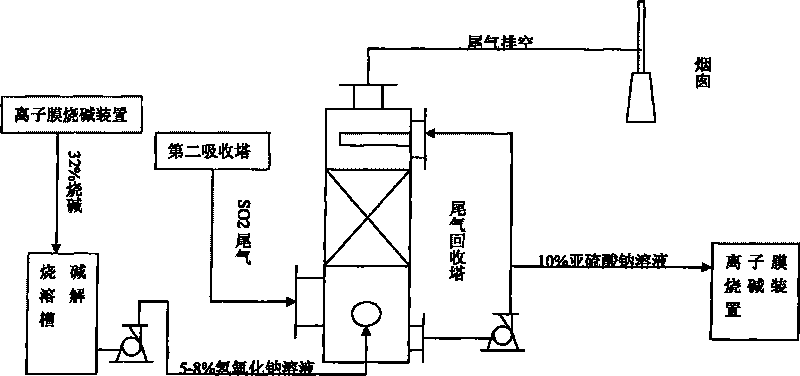

Process and apparatus for preparing sodium sulfite in production of ion-film caustic soda

InactiveCN101759203AReduce manufacturing costReduce pollutionAlkali metal sulfite preparationSodium sulfiteIon

The invention relates to a process and an apparatus for preparing sodium sulfite in the production of ion-film caustic soda, and belongs to the technical field of chemical processes. In the process, part of caustic soda in an ion-film caustic soda device is delivered to a caustic soda dissolving tank by utilizing the apparatus so as to prepare a sodium hydroxide solution with a certain concentration; the sodium hydroxide solution is delivered to a tail gas recovery tower to react with the delivered sulfur dioxide tail gas, thereby producing a sodium sulfite solution with the mass concentration of 10%; and the sodium sulfite solution is delivered to the ion-film caustic soda device for later use. The process of the invention greatly reduces the production cost, saves the energy, reduces the consumption and reduces the pollution.

Owner:聊城鲁西氯甲烷化工有限公司

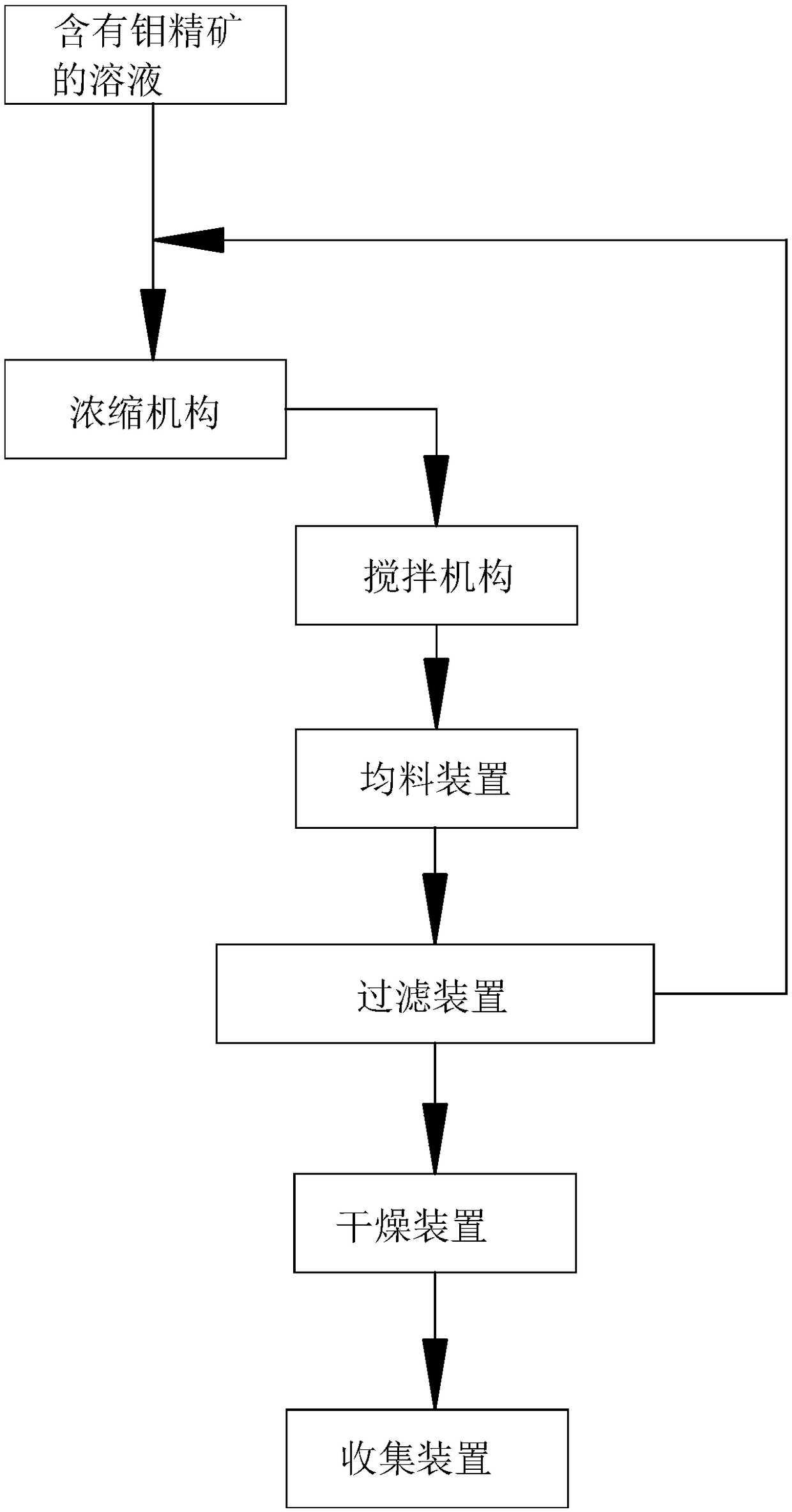

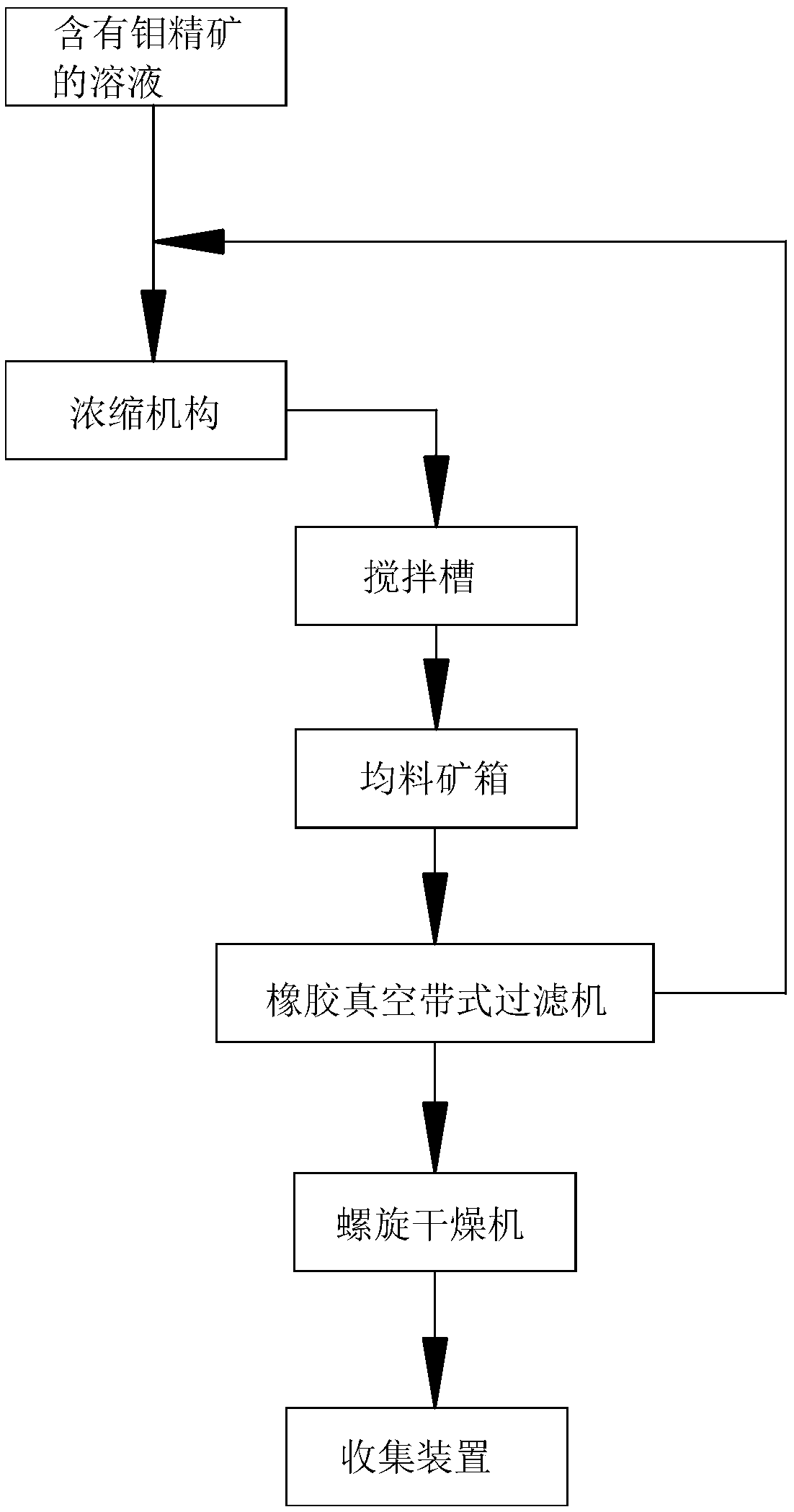

Molybdenum concentrate dewatering method

InactiveCN108714331AEfficient recyclingAchieve seamless connectionFiltration circuitsMineralogyFilter cake

The invention discloses a molybdenum concentrate dewatering method. The molybdenum concentrate dewatering method comprises the following steps: S1, concentrating an ore pulp solution containing molybdenum concentrate to a set concentration by a concentration device; S2, filtering the ore pulp solution at the set concentration by a filtering device, separating out the filter cake and the filtrate,and enabling the filtrate to flow back to the concentration device, wherein the filtering device is used for filtering in the process of transporting the ore pulp solution; and S3, drying the filter cake separated by the filtering device by a drying device, wherein the drying device is used for drying in the process of transporting the filter cake. According to the molybdenum concentrate dewatering method disclosed by the embodiment of the invention, the integrated process and configuration of operations for filtering, drying and transporting the materials are realized, the intermediate transportation, reshipment and storage links are reduced, and the dewatering efficiency is greatly improved. In addition, the loss of fine fraction molybdenum concentrate due to filtration is reduced, and the molybdenum concentrate can be effectively recovered.

Owner:CHINA ENFI ENGINEERING CORPORATION

Rapid assembling method for enlarged zone stove shell and lining structure of dome-combustion hot stove

The invention relates to the field of construction of dome-combustion hot stoves and particularly relates to a rapid assembling method for an enlarged zone stove shell and a lining structure of a dome-combustion hot stove. The method is characterized by comprising the following steps: S-bend lower-part straight-section stove shell assembling, S-bend enlarged zone stove shell assembling, tile bearing plate-stud plate locating paying-off, inner container slotting, inner container hoisted-to-S-bend-interior assembling, tile bearing plate-stud plate upper-half welding, S-bend and straight-sectionstove shell jacking, tile bearing plate-stud plate rest lower-half welding and tile bearing plate mounting. According to the rapid assembling method, the problem during the assembly of an S-bend enlarged zone stove shell of the dome-combustion hot stove that the requirements on site space are high is effectively solved, meanwhile, secondary hoisting transportation can also be reduced, then, the assembling speed is accelerated, the approach time of large hoists is retarded, the machine shift of cranes is reduced, and the efficiency of construction is increased.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

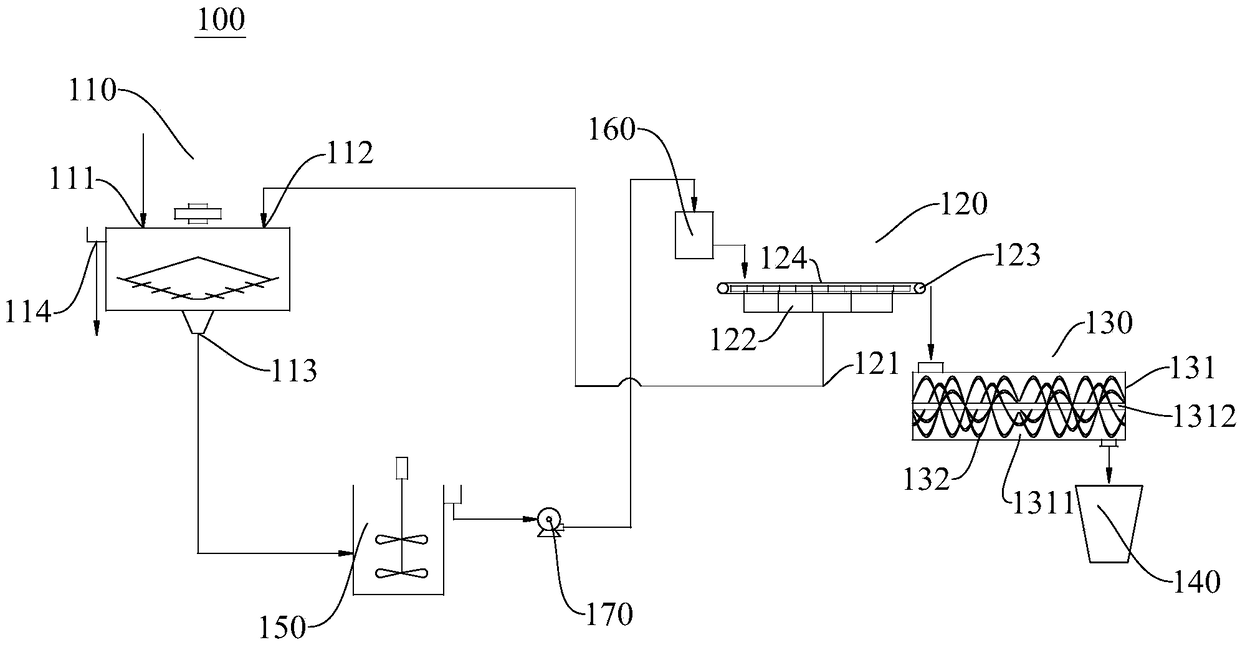

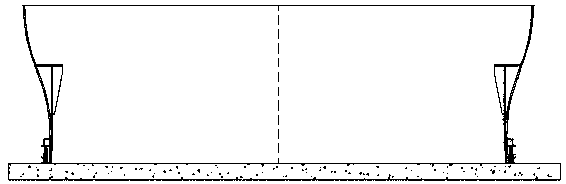

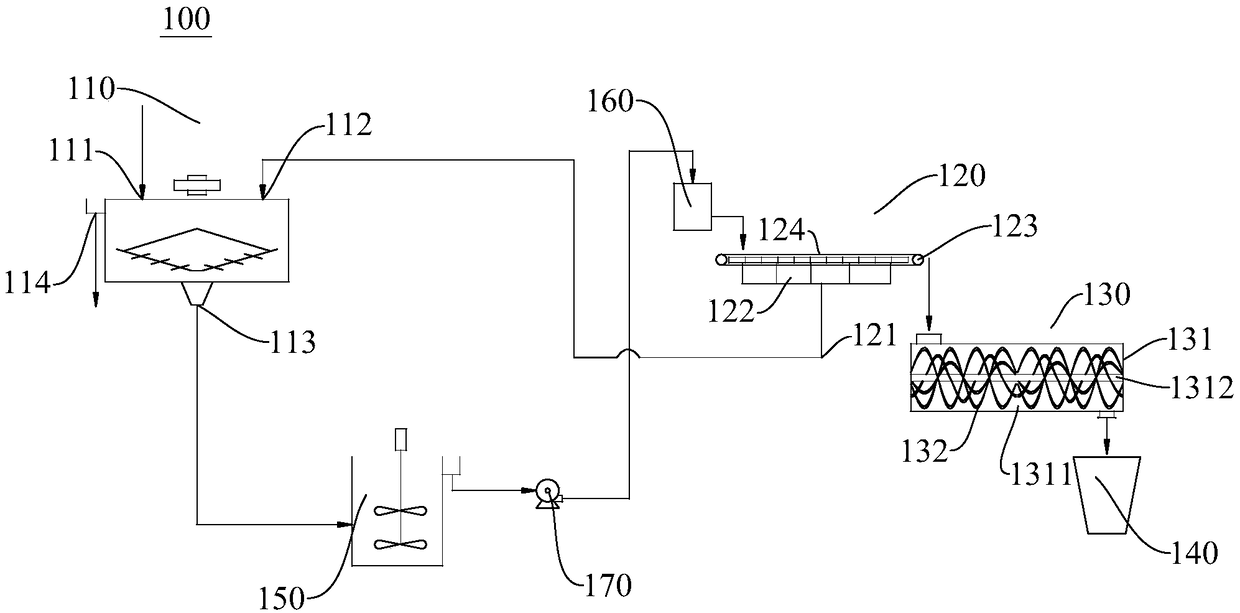

Molybdenum concentrate dewatering system

PendingCN108714332AEfficient recyclingAchieve seamless connectionFiltration circuitsEngineeringFilter cake

The invention discloses a molybdenum concentrate dewatering system. The molybdenum concentrate dewatering system comprises a concentration device, a filtering device, a drying device and a collectiondevice, wherein the concentration device is used for concentrating an ore pulp solution containing molybdenum concentrate to set concentration; the filtering device is connected with the concentrationdevice; the filtering device is used for filtering the ore pulp solution at the set concentration and separating out the filter cake and the filtrate; the filtering device comprises a return pipe used for returning the filtrate to the concentration device; the drying device is connected with the filtering device; the drying device is used for receiving the filter cake separated by the filtering device and drying the filter cake; and the collection device is connected with the drying device so as to collect the dried filter cake, According to the molybdenum concentrate dewatering system disclosed by the embodiment of the invention, the integrated process and configuration of operations for filtering, drying and transporting the materials are realized, the intermediate transportation, reshipment and storage links are reduced, and the dewatering efficiency is greatly improved. In addition, the loss of fine fraction molybdenum concentrate due to filtration is reduced, and the molybdenum concentrate can be effectively recovered.

Owner:CHINA ENFI ENGINEERING CORPORATION

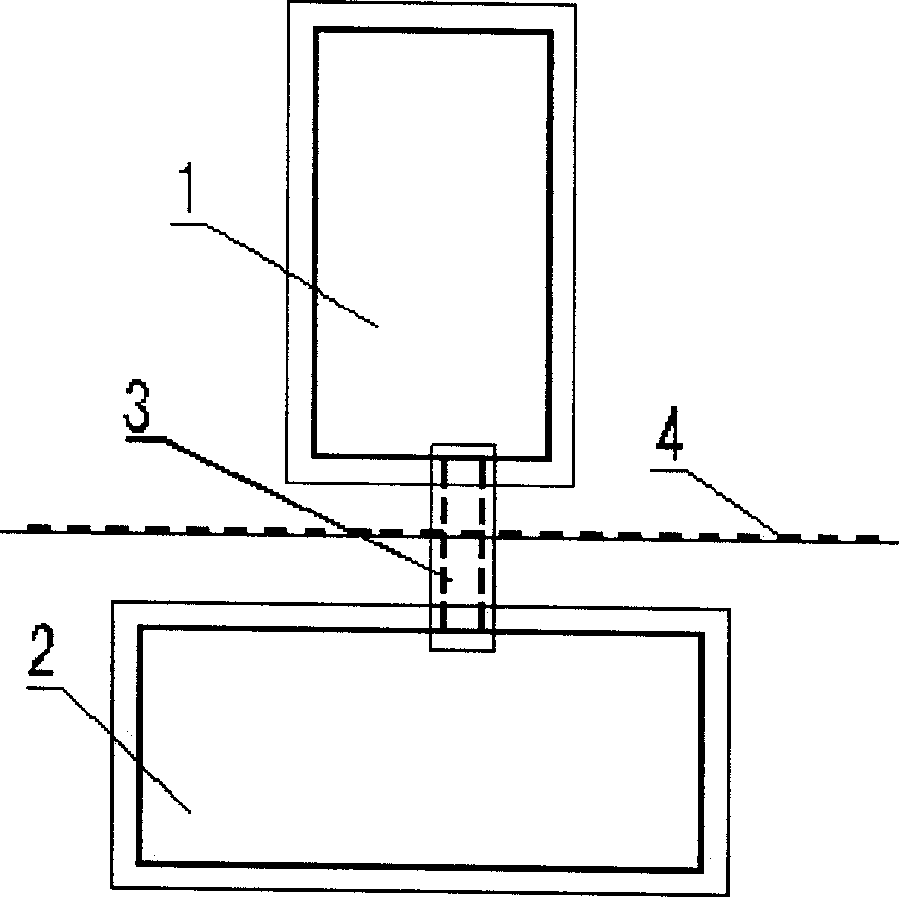

Arrangement structure of carbon block transferring station and anode assembling shop in anode factory

InactiveCN1844468AReduce bad luckCompact layoutIndustrial buildingsOperational costsAgricultural engineering

This invention discloses an assembly structure of anode charcoal block transfer station and anode assembly workshop, which includes: charcoal block transfer station (1) and anode assembly workshop (2), wherein the space between the charcoal block transfer station (1) and anode assembly workshop (2) connects with earthing transfer tunnel (3) which is to transfer anode charcoal; and the charcoal transfer station (1)'s height is higher than that of the anode assembly workshop (2). According to the practice, in the condition of hill area and complex landform, using this invention can reduce land using area and reduce transfer vehicles.

Owner:GUIYANG AL-MG DESIGN & RES INST

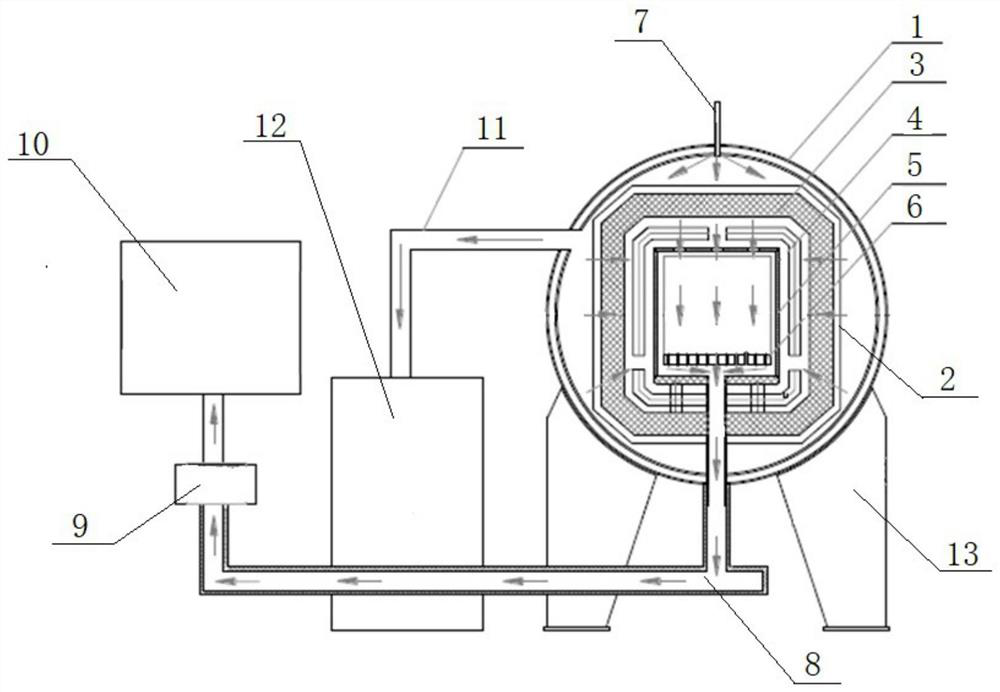

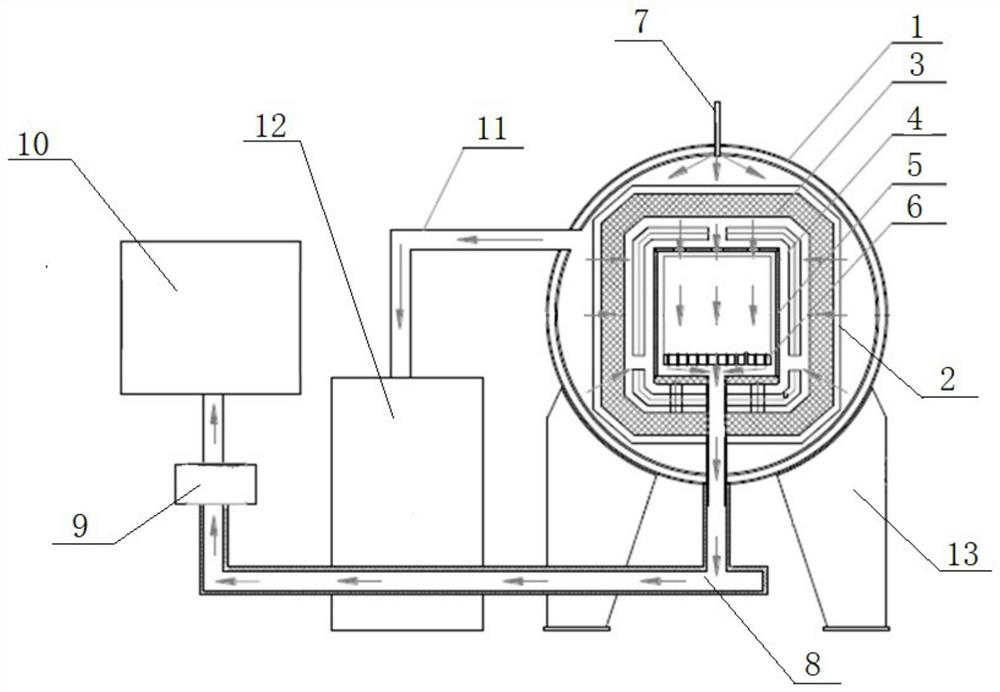

Equipment and method for continuous heat treatment of spherical fuel elements

ActiveCN112708749BReduce bad luckIncrease productivityFurnace typesProcess efficiency improvementCombustion systemTemperature control

The invention relates to a continuous heat treatment equipment and method for spherical fuel elements, including a furnace body, a heating and heat preservation system, a temperature control system, a loading and unloading system, a vacuum system, a waste discharge system, a process gas system, a pneumatic system, a water system, and an exhaust gas system. Combustion system and electrical control system to realize the continuous heat treatment of low temperature carbonization and high temperature purification of spherical fuel elements in the same equipment. The equipment and method can not only be used for continuous heat treatment of spherical fuel element green bodies, but also can be used for the preparation of matrix graphite ball products, realizing low-temperature carbonization and high-temperature purification in the same equipment, reducing material reversing, and the heat treatment time of spherical fuel elements is reduced by About 90 hours of original separate and separate processing is shortened to about 50 hours of continuous heat treatment, which can increase the production efficiency by 44.4%.

Owner:TSINGHUA UNIV

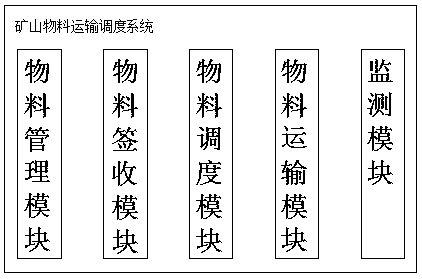

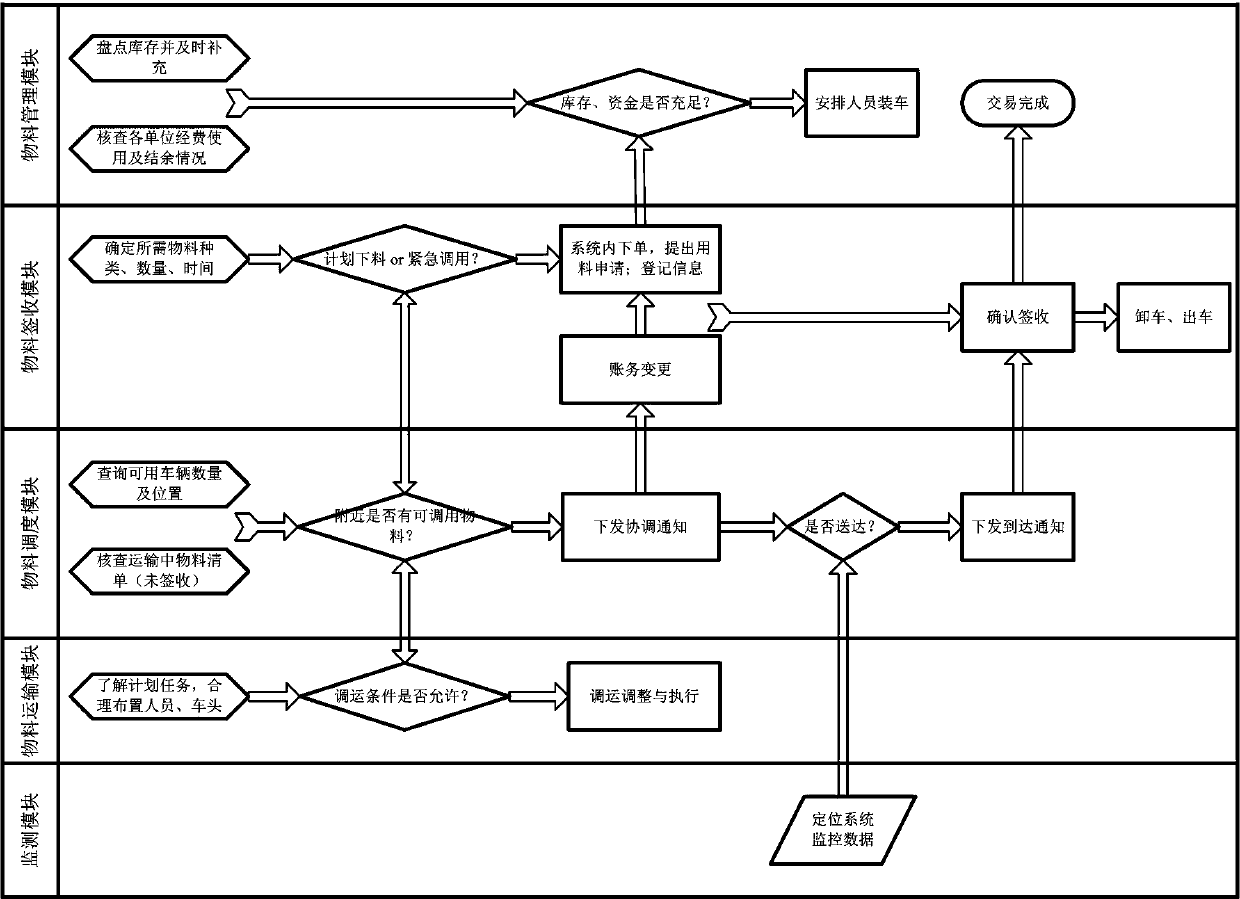

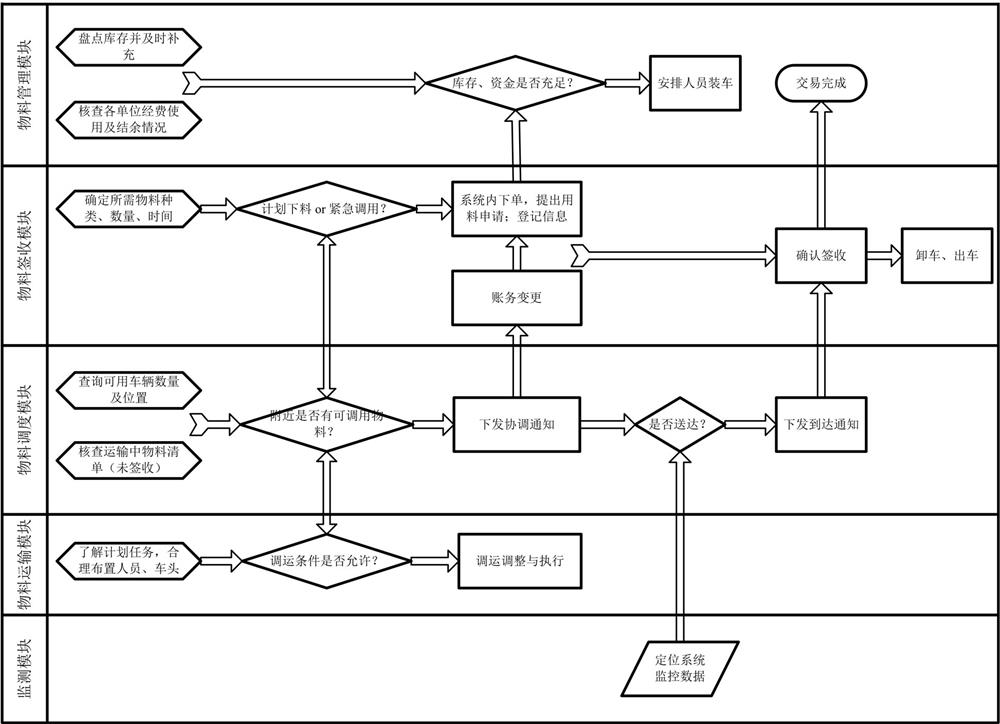

Mine material transportation dispatching system and method

ActiveCN109850465AAvoid resource vacancy situationsAvoid tight inventoryStorage devicesTruckMaterials management

The invention discloses a mine material transportation dispatching system and method. The mine material transportation dispatching system comprises a material management module, a material sign-off module, a material dispatching module and a material transporting module; the material management module is used for receiving a material using application proposed by the material sign-off module and sending an instruction for assigning personnel for truck loading to a material dispatching department; the material sign-off module is used for determining the type and quantity of required materials and the time, proposing the material using application to the material management module after selecting a material dispatching mode, conducting financial changing according to the proposed material using application, conducting confirmation sign-off after receiving an issuing reaching notification emitted by the material dispatching module, and assigning the personnel for truck unloading and dispatching after confirmation sign-off; and the material transporting module is used for obtaining a scheduled task and reasonably assigning the personnel and trucks. The phenomenon that mining company material transportation dispatching work is chaotic and low in efficiency can be solved fundamentally, and thus the mining company auxiliary transport link is orderly, fast and efficient.

Owner:STATE GRID CORP OF CHINA +1

A mine material transportation scheduling system and method

ActiveCN109850465BReasonable arrangementReduce occupancyStorage devicesTransportation schedulingMaterial transport

Owner:STATE GRID CORP OF CHINA +1

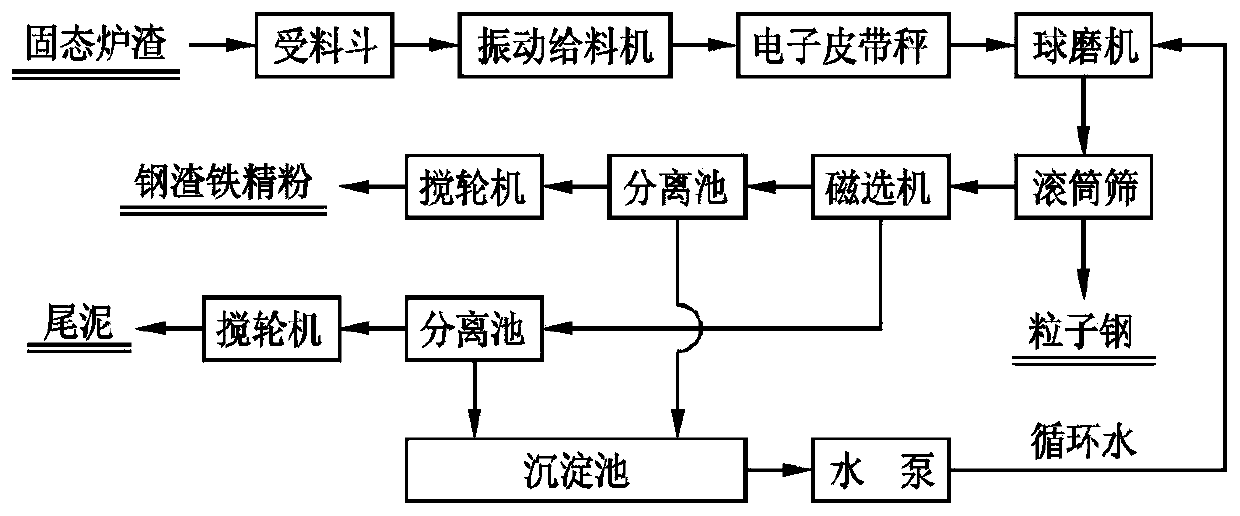

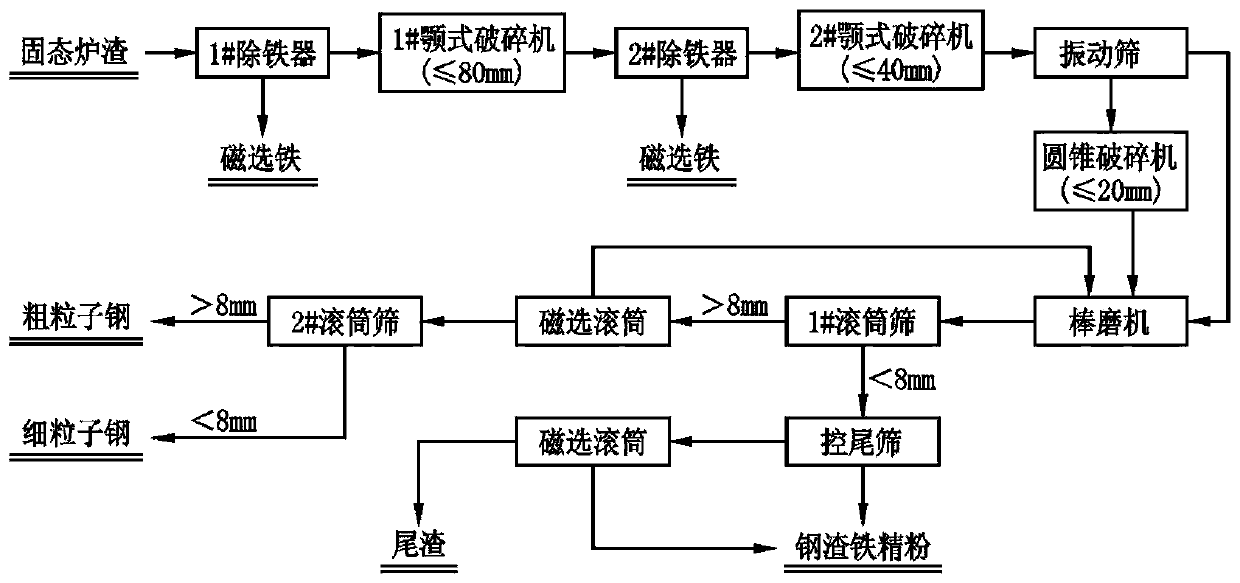

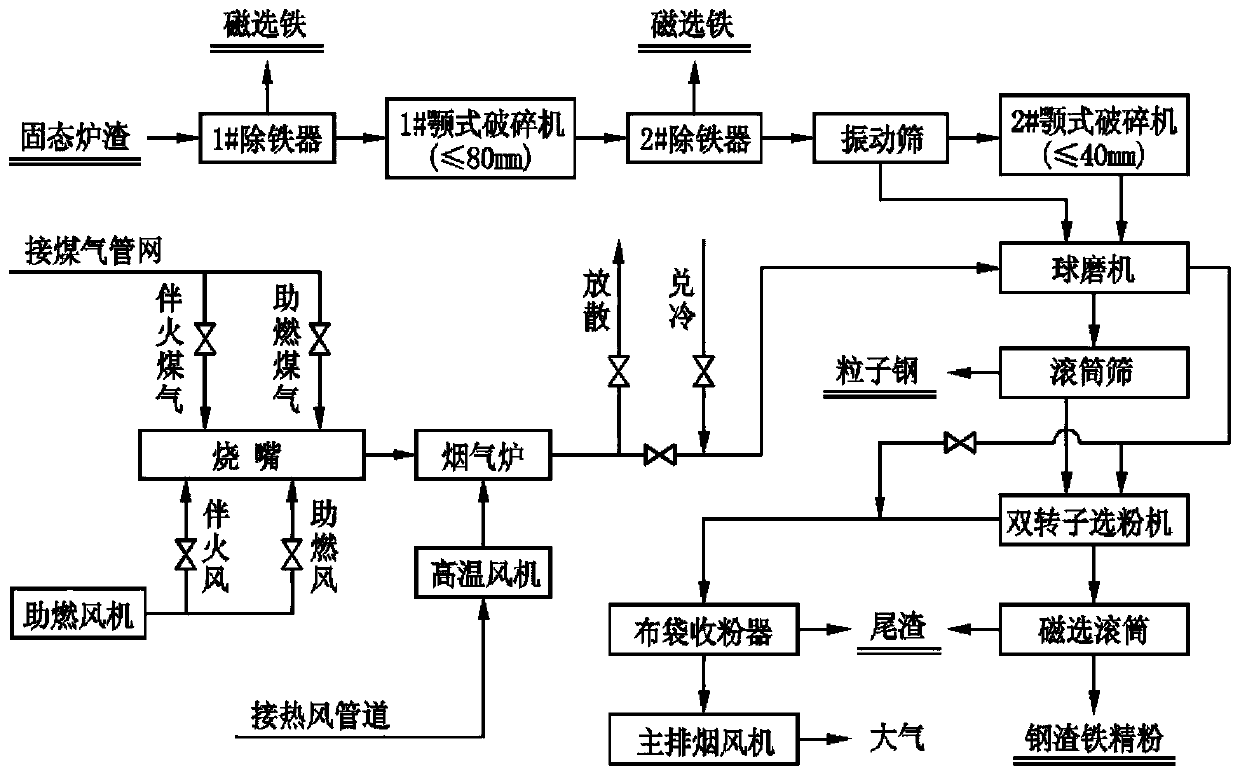

A kind of steel slag iron fine powder production process

ActiveCN108380360BIncrease total iron contentRaise the gradeMagnetic separationGrain treatmentsSteelmakingIron powder

The invention discloses a high-quality steel slag iron powder production process. Solid slag is subjected to magnetic separation, rough smashing, magnetic separation and fine smashing, then the solidslag enters a ball mill to be ground, ground products pass through a rotary screen, and particle steel and slag powder are separated out; the particle steel is a final product, the slag powder passesthrough a birotor powder concentrator, tailings and rough middlings are separated out, and the tailings are final products; the rough powder passes through a magnetic separation roller, and tailings and steel slag iron powder are separated out; low-temperature smoke introduced through a high-temperature draught fan and high-temperature smoke are mixed in a smoke furnace, then enter the ball mill and serve as a drying agent for drying the solid slag and a carrier for conveying part of the tailings; gas-solid separation is achieved in a bag dust collector, gas is exhausted to the air through a main smoke exhaust fan, and solid is tailings. According to the high-quality steel slag iron powder production process, except for a smashing procedure, the negative pressure control technology is adopted in the whole process, and the beneficial effects of generating no circulating sewage or dust, being free of weather influence on production, effectively improving the grade of steel slag iron powder, reducing steel smelting production cost and the like are achieved.

Owner:XINING SPECIAL STEEL

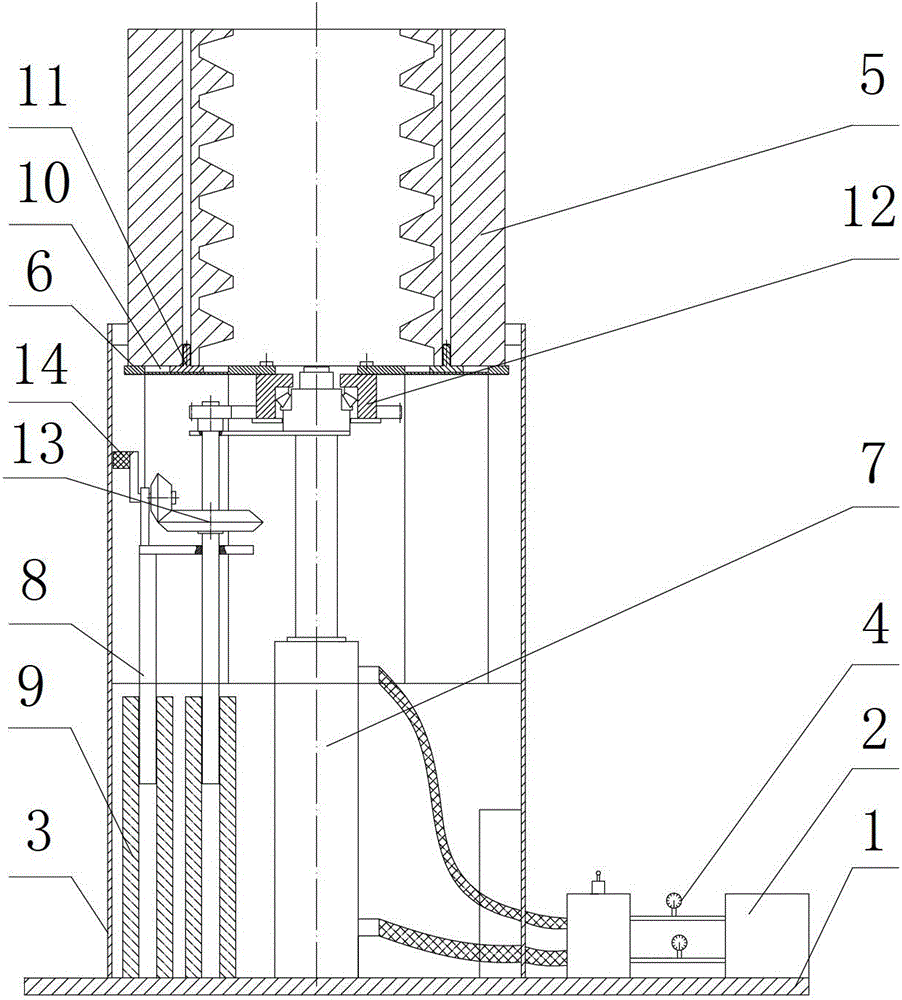

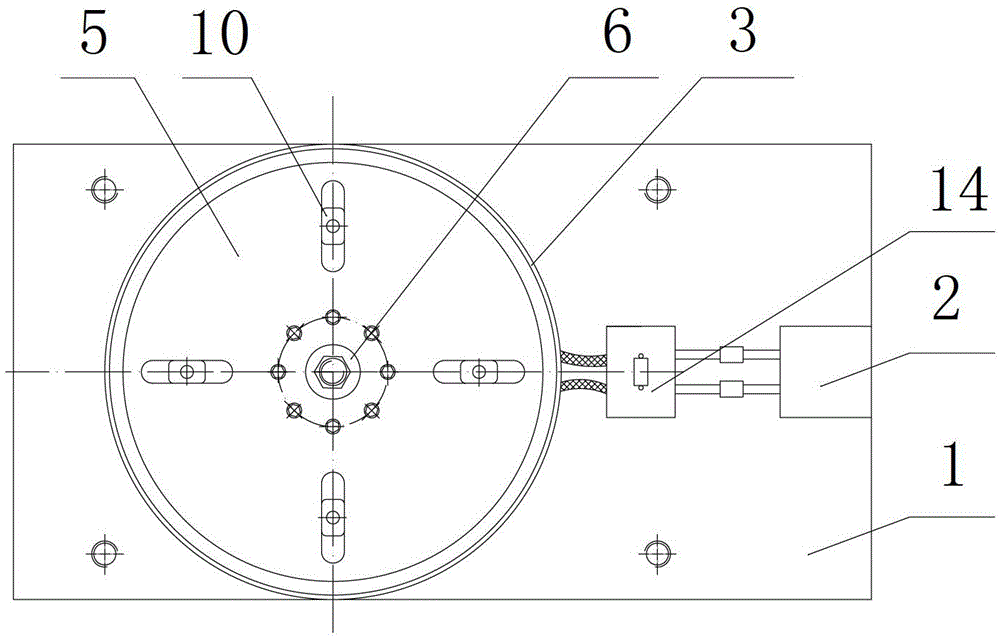

Down-pressing nut replacement system

ActiveCN102847719BGuaranteed stabilityEnsure safetyMetal rolling stand detailsMetal rolling arrangementsEngineeringOperation safety

The invention discloses a down-pressing nut replacement system which comprises an execution device and a control device, wherein the execution device is used for bearing and positioning a down-pressing nut when the down-pressing nut is replaced; and the control device is used for adjusting the up-and-down position of the execution device for bearing the down-pressing nut when the down-pressing nut is replaced. According to the down-pressing nut replacement system, through the cooperation of a guide rod and a guide sleeve, a bearing platform runs steadily; a throttling valve controls the running speed, so that the running speed can be adjusted in real time; the down-pressing nut replacement system is simple in structure and is operated safely and conveniently; reverse operation of the down-pressing nut is reduced; and the replacement time of the down-pressing nut is shortened from 2 to 3 days to 12 hours or so. The labor amount is reduced; and the stability, the safety and the accuracy of the down-pressing nut replacement process are fully guaranteed.

Owner:BEIJING SHOUGANG CO LTD

A system and method for converting steel slag into renewable resources

ActiveCN103555867BEfficient use ofShort processRecycling and recovery technologiesProcess efficiency improvementSlagMagnetic separator

The invention discloses a system and a method for converting steel slag into renewable resources. The system comprises a steel slag powdering system, a steel slag separating system and a tail slag deep processing system, wherein the steel slag powdering system comprises desulphurization slag equipment, converter slag equipment, casting residue equipment and granulation self-extracting equipment which is communicated with the desulphurization slag equipment, the converter slag equipment and the casting residue equipment respectively; the steel slag separating system is connected with the granulation self-extracting equipment and comprises overturn vibration equipment, a magnetic separator, a crushing machine, a rod mill, screening / magnetic separation equipment and material storage equipment, wherein the overturn vibration equipment, the magnetic separator, the crushing machine, the rod mill, and the screening / magnetic separation equipment are led to the material storage equipment; the tail slag deep processing system is connected with a fine tail slag device and comprises a drying mechanism, a coarse grinding mechanism, a fine grinding mechanism, a first winnowing mechanism, a second winnowing mechanism, a first magnetic separation mechanism, a second magnetic separation mechanism and a steel slag fine powder groove. By the combination of the structures of the system, the design construction of the system for converting the steel slag into the renewable resources, which is clean and environment-friendly and reduces occupation space, is realized.

Owner:WISDRI ENG & RES INC LTD

A Construction Method of Reinforced Concrete Formwork for Super Large Section Chamber

ActiveCN104533456BEasy to move and accuratePrecise positioningUnderground chambersTunnel liningReinforced concreteMotor drive

The invention relates to the technical field of construction, in particular to a reinforced concrete modelling construction method which is applicable to a large section chamber. According to the super-large section chamber reinforced concrete modelling construction method, a multi-vertical-rod type lining trolley is adopted to control the integral rigidity of a rack, a motor drives a walking mechanism to drive the trolley to move, formwork in place and tunnel reinforced concrete forming of closing mold are adjusted through a hydraulic oil cylinder and a screw jack, the multi-rod type lining trolley adopts a method of pouring the side wall and the arc portion together or separately pouring the arc wall according to the size, the construction period and the concrete supply conditions of the tunnel section. According to the reinforced concrete modelling construction method, the multi-rod type lining trolley is adopted, the side wall and the arc portion can be poured separately and simultaneously, the construction period and costs are saved, the splicing time and material reshipment are reduced, the trolley movement and positioning speed is rapid, and personnel operation is facilitated; the multi-rod trolley adopts full-hydraulic vertical closing mold, the motor driving is matched with walking of the rail, accurate positioning is easy, braking is convenient, movement safety risks are small, and the structure is reasonable.

Owner:SHANGHAI CIVIL ENG GRP CO LTD OF CREC +1

One-step copper smelting process and its device

ActiveCN103952571BReduce bad luckReduce lossesMetal recyclingProcess efficiency improvementThermal energySlag

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

Rapid assembly method of enlarged furnace shell and lining structure of top-combustion hot blast stove

The invention relates to the field of construction of dome-combustion hot stoves and particularly relates to a rapid assembling method for an enlarged zone stove shell and a lining structure of a dome-combustion hot stove. The method is characterized by comprising the following steps: S-bend lower-part straight-section stove shell assembling, S-bend enlarged zone stove shell assembling, tile bearing plate-stud plate locating paying-off, inner container slotting, inner container hoisted-to-S-bend-interior assembling, tile bearing plate-stud plate upper-half welding, S-bend and straight-sectionstove shell jacking, tile bearing plate-stud plate rest lower-half welding and tile bearing plate mounting. According to the rapid assembling method, the problem during the assembly of an S-bend enlarged zone stove shell of the dome-combustion hot stove that the requirements on site space are high is effectively solved, meanwhile, secondary hoisting transportation can also be reduced, then, the assembling speed is accelerated, the approach time of large hoists is retarded, the machine shift of cranes is reduced, and the efficiency of construction is increased.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Spherical fuel element continuous heat treatment equipment and method

ActiveCN112708749AReduce bad luckIncrease productivityFurnace typesProcess efficiency improvementCombustion systemTemperature control

The invention relates to spherical fuel element continuous heat treatment equipment and method. The equipment comprises a furnace body, a heating and heat preservation system, a temperature control system, a loading and unloading system, a vacuum system, a waste discharge system, a process gas path system, a pneumatic system, a water path system, a tail gas combustion system and an electrical control system. Continuous heat treatment of low-temperature carbonization and high-temperature purification of the spherical fuel element in the same equipment is realized. The equipment and the method not only can be used for continuous heat treatment of spherical fuel element green bodies, but also can be used for preparation of matrix graphite nodule products, low-temperature carbonization and high-temperature purification are continuously performed in the same equipment, material transfer is reduced, the heat treatment time of the spherical fuel element is shortened to about 50 hours of continuous heat treatment from about 90 hours which are originally performed separately and independently, and the production efficiency can be improved by 44.4%.

Owner:TSINGHUA UNIV

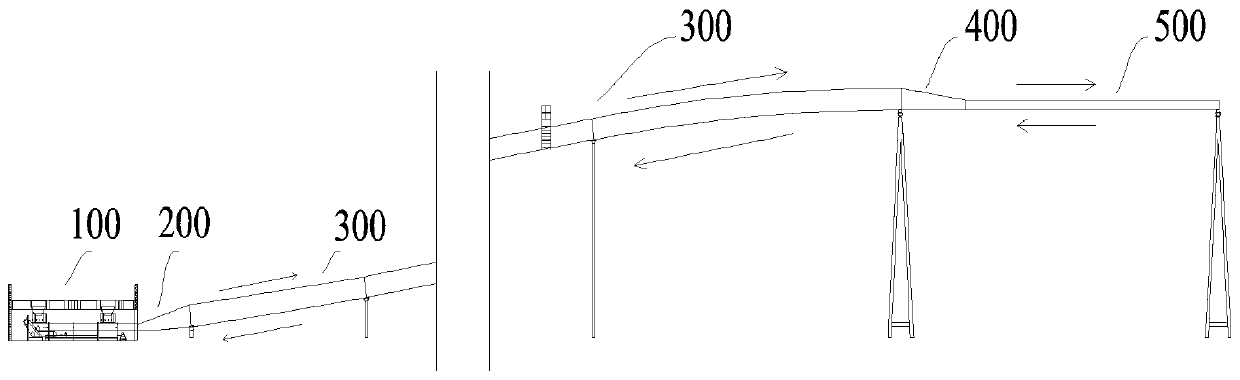

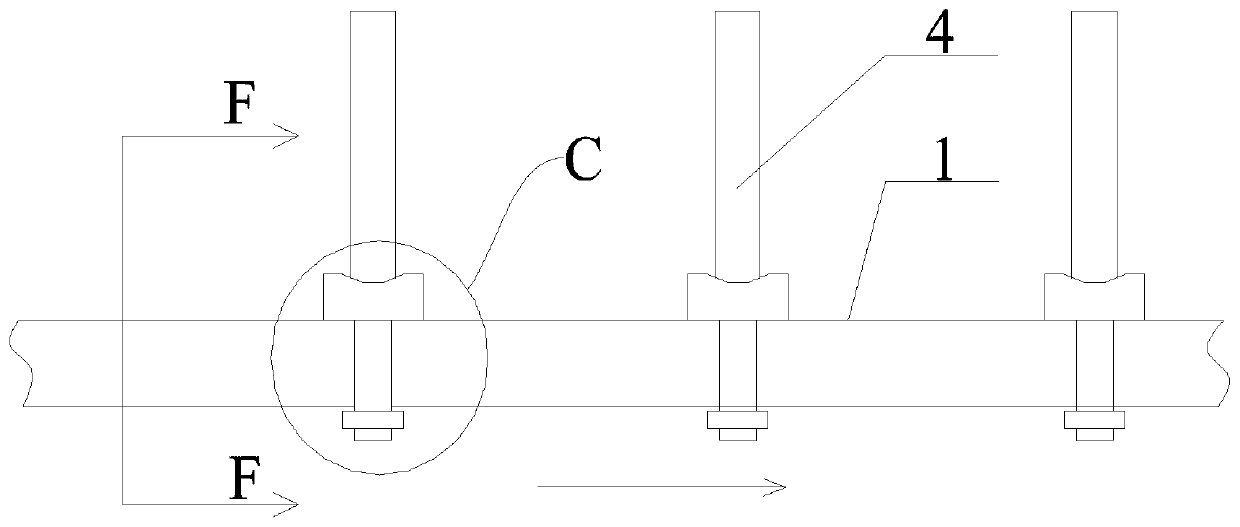

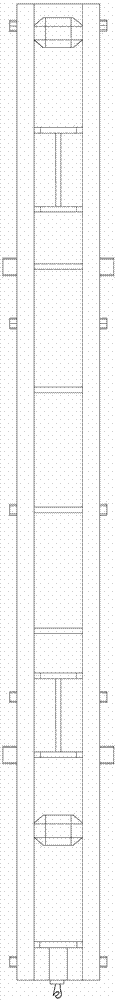

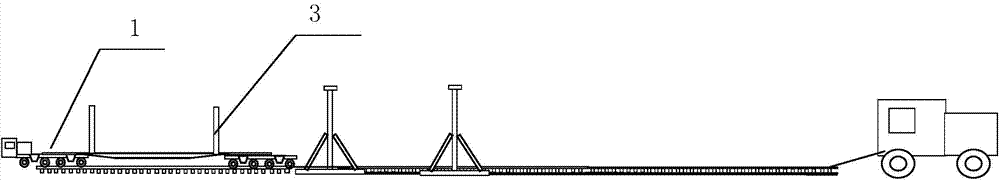

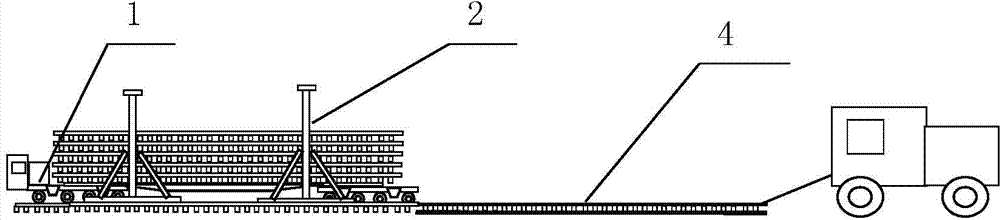

Track laying machine and track laying method

ActiveCN103469705BPillow spacing specificationReduce bad luckRailway track constructionTerrainPortal frame

The invention discloses a track layering machine for track panels and a track layering method of the track layering machine, which are applied to track layering construction of railways. A track layering flat car is provided with a track layering portal frame support, and a track layering portal frame can be erected on the track layering portal frame support and moves along with the track layering flat car. In a track panel layering procedure, the track layering flat car runs to a tool track panel, and puts down and levels up the track layering portal frame, and the track layering portal frame is used for lifting the track panels on the track layering flat car for layering; in a reverse track panel layering procedure, the track layering flat car conveys the track panels to a reverse portal frame, the reverse portal frame lifts up the track panels, and the track layering flat car returns to the place of the reverse portal frame and receives the track panels. According to the track layering machine for the track panels and the track layering method of the track layering machine, which are disclosed by the invention, the tool track panel is used for assisting in the track layering flat car to move forwards, so that the operation efficiency is greatly improved, the tool track panel can be repeatedly utilized, the investment of main labors and circulation materials is reduced, the safety, the quality and the efficiency of construction are improved, and the track layering cost is reduced; the body of the track layering flat car and the tool track panel can be separated, so that the road transportation is convenient, the terrain limitation of the transportation is small, and the limitation of track transportation does not exist.

Owner:中铁二十二局集团第二工程有限公司 +1

Construction method of foundation prefabrication for transmission line engineering

ActiveCN108149703BReduce field construction proceduresReduce the amount of field construction workCeramic shaping apparatusFoundation engineeringTerrainMovable type

Owner:POWER CHINA HENAN ENG CO LTD

Settling method of vanadium mud in leaching vanadium liquid

ActiveCN104129838BSettling fastImprove purification efficiencyProcess efficiency improvementWater/sewage treatment by flocculation/precipitationAluminium sulfateEnergy consumption

The invention discloses a settlement method of vanadium mud in a leached vanadium liquid. The settlement method comprises the following steps of adding an aluminum salt into a leached vanadium liquid for purification, adding a polymer flocculant solution into the purified vanadium liquid, carrying out mixing to obtain a uniform mixture, and carrying out standing for solid-liquid separation so that a clear vanadium liquid and vanadium mud are obtained. The leached liquid is added with the aluminum salt for purification and then is added with the polymer flocculant solution so that the vanadium mud can be fast deposited. Therefore, the settlement method effectively improves a vanadium mud sedimentation rate, shortens vanadium sedimentation time and effectively improves vanadium liquid purification efficiency so that the whole production process connection is more smooth, vanadium sedimentation time of the vanadium sedimentation process is shortened to about 100min from 250min and production efficiency is improved. The settlement method effectively reduces silicon and phosphor impurity content of the vanadium liquid, reduces a vanadium concentration of the supernatant, effectively reduces unit consumption of aluminum sulfate as a purification agent, reduces system vanadium loss, improves vanadium mud separation efficiency, reduces transport amount of a turbid vanadium liquid and reduces energy consumption.

Owner:HEBEI IRON AND STEEL

Thin material threading control method for guide rulers of hot rolling coiler

ActiveCN103008359BEliminate the "inner tower" phenomenonQuality improvementRoll mill control devicesMetal rolling arrangementsAutomatic controlControl manner

The invention provides a thin material threading control method for guide rulers of a hot rolling coiler. The method comprises the following steps of: additionally arranging a pressure sensor, and additionally arranging an analog quantity input plate and a corresponding program in a PLC (Programmable Logic Controller); when steel is fed through a second frame, setting the opening degrees of the guide rulers by using a secondary computer: when the head part of a steel strip arrives at the middle position of each guide ruler, controlling to start up a primary short stroke and a second short stroke in sequence on the working sides and transmission sides of the guide rulers by using the PLC; judging whether the WS clamping force feedback on the working sides of the guide rulers is more than or equal to 7KN and can last for 50 milliseconds or not at the moment after, and if so, directly switching to a guide ruler working side pressure automatic control way; otherwise, setting a third short stroke: if the working sides of the guide rulers never meet a switching condition, directly switching to an AFC (Automatic Frequency Control) way after the third short strokes of the working sides of the guide rulers are completed. Due to the adoption of the method, the 'inner tower' phenomenon and head cutting loss of a steel coil can be eliminated, the total sealing rate is controlled to be below 1.8 percent, the hot rolling coiling quality is improved greatly, and rolling yield is increased greatly, and the recoiling quantity of sub-coils is reduced by over 30 percent.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com