Production process of high-toughness and ultra-high strength steel and production system thereof

A technology of ultra-high-strength steel and production technology, which is applied in the field of steelmaking, can solve the problems of low straight line rate of steel plate, cumbersome production management, and reduce production cost, and achieve the effects of facilitating production management, reducing production cost, and improving straight line rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: 260X2080X3450 slab rolling to produce 30X3200XL ultra-high strength steel plate.

[0033] Its process steps are as follows:

[0034] a. Slab heating, the heating temperature is 1230-1250°C, the heating coefficient is 9-10min / cm, and the furnace temperature is 1150-1160°C;

[0035] b. The slab is fully descaled and the surface oxide scale is removed;

[0036] c. The rolling start temperature is 1050-1070°C. After the slab is widened, the rough rolling is guaranteed to have more than two passes and the reduction rate is greater than 15%, so as to realize slow rolling under high temperature and high pressure. The rough rolling finish rolling temperature is 950- 970°C, the intermediate billet is controlled to 103mm;

[0037] d. Wait for the temperature of the roller table to reach 830-850°C;

[0038] e. The starting temperature of finish rolling is 830-850°C, and the finishing rolling temperature is 810-830°C. After the steel plate is rolled, it enters the pre...

Embodiment 2

[0047] Example 2: 260X2080X3450 slab rolling to produce 40X3500XL ultra-high strength steel plate.

[0048] Its process steps are as follows:

[0049] a. Slab heating, the heating temperature is 1150-1250°C, the heating coefficient is 9-10min / cm, and the furnace temperature is 1130-1150°C;

[0050] b. The slab is fully descaled and the surface oxide scale is removed;

[0051] c. The rolling start temperature is 1050-1080°C, ensuring that there are more than two passes of rough rolling, and the reduction rate is greater than 15%, realizing slow rolling under high temperature and high pressure. ;

[0052] d. The temperature of the roller table is 820 ~ 840 ℃;

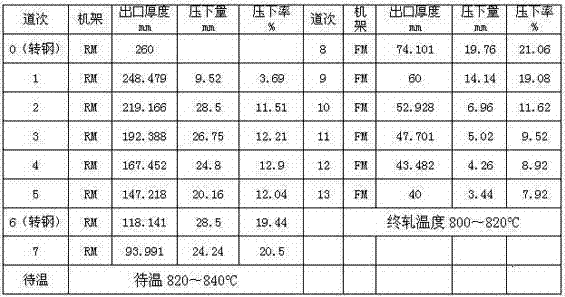

[0053] e. The start rolling temperature of finish rolling is 820-840°C, the finish rolling temperature is 800-820°C, and the steel plate enters the pre-leveler for straightening after rolling. The rolling process parameters are shown in Table 2;

[0054] Table 2 The main parameters involved in the rolling process of Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com