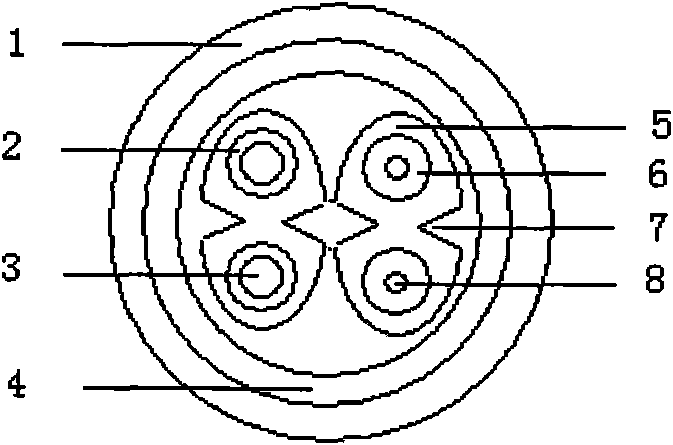

Patents

Literature

38results about How to "Simplify logistics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

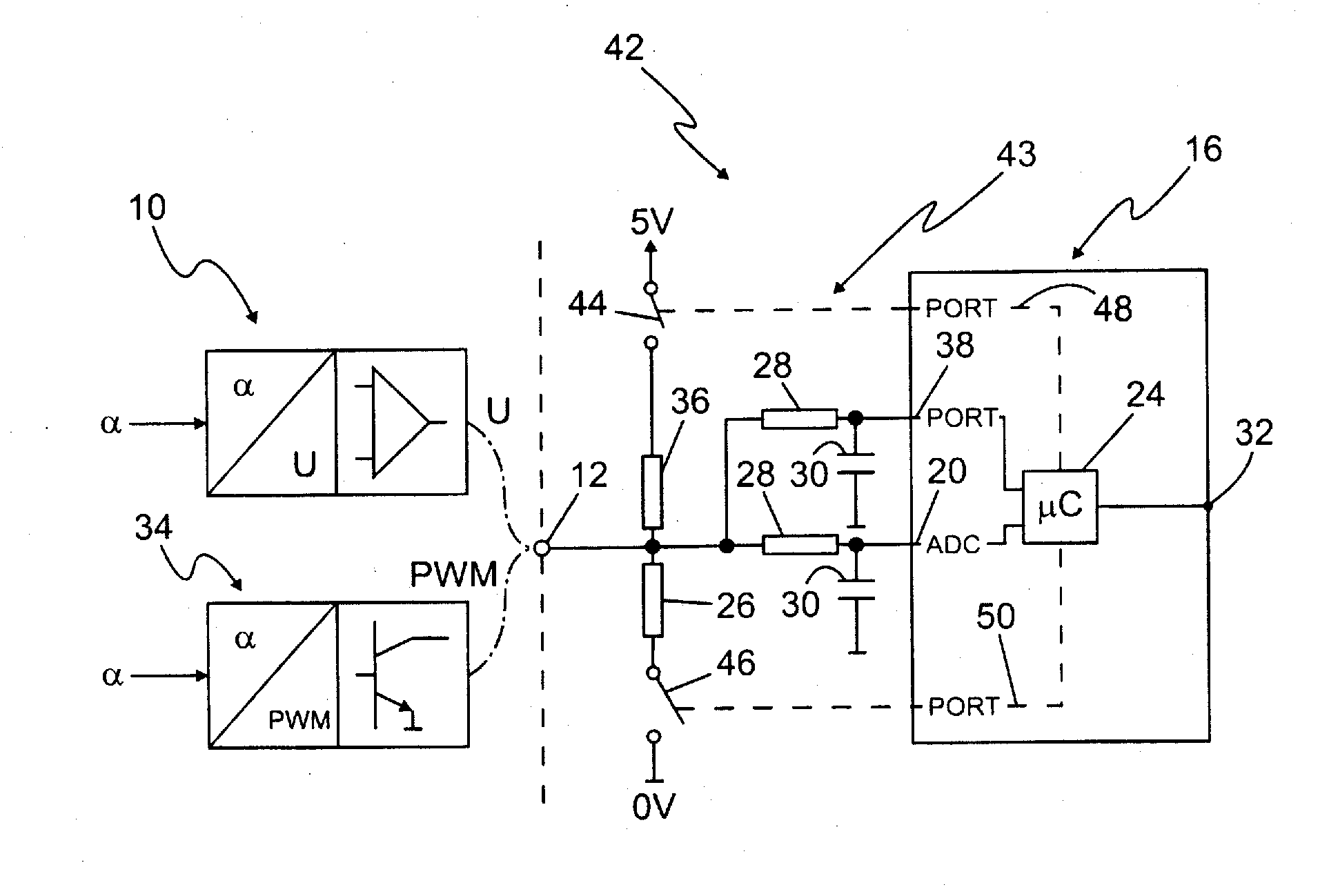

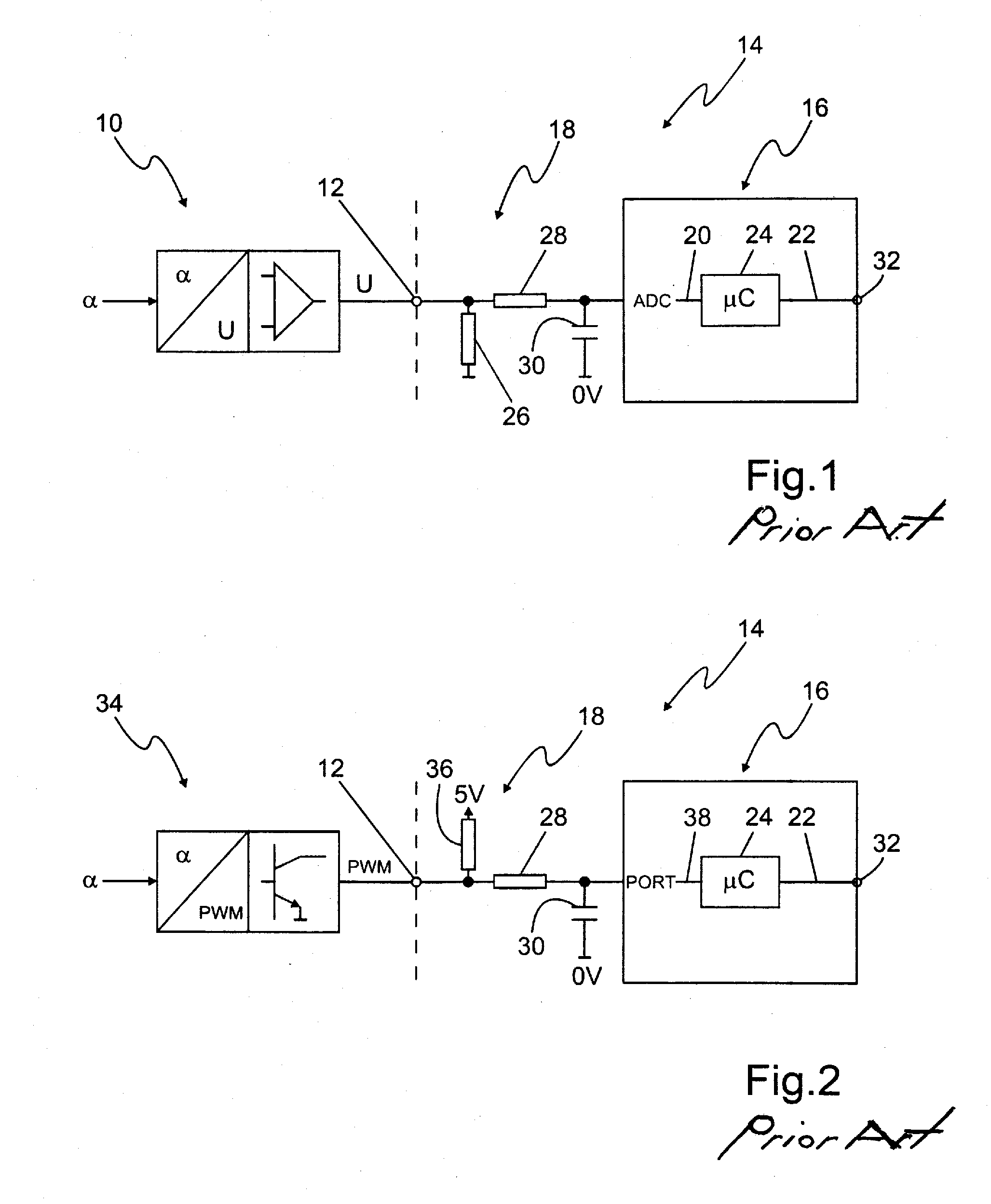

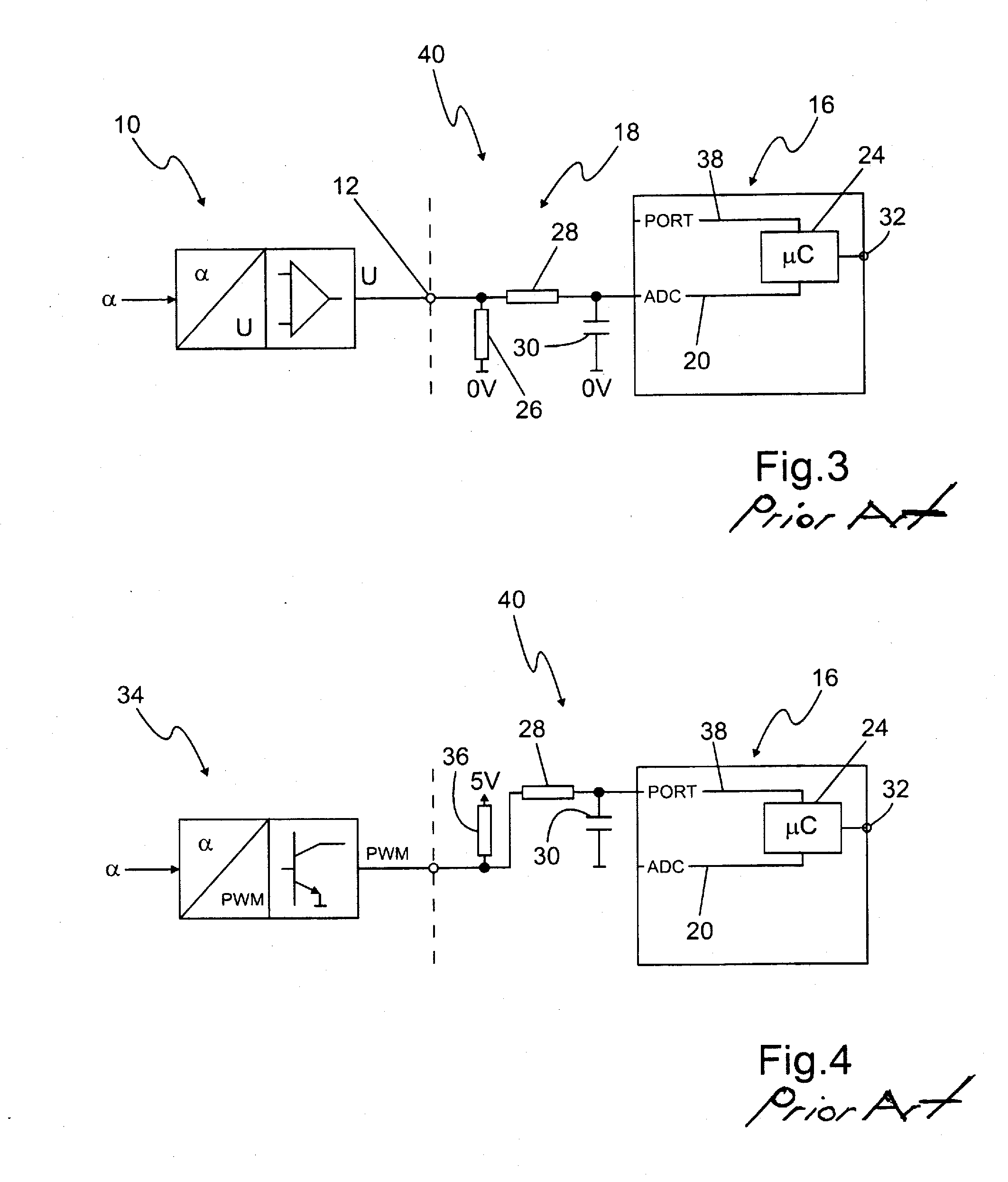

Control device for a motor vehicle having an input equipped for processing signals of different types of sensors

A control device (42) for use in a motor vehicle includes at least one input that has an input port (12), at least one input channel (20, 38), and an input circuitry (43) and receives signals from a sensor (10, 34) via the input port (12) and sends the signals via the input circuitry (43) to the input channel (20, 38). The input port (12) is connected to a defined voltage via a resistor. The input circuitry (43) has a pull-up switch (44) that can be actuated by the control device (42), which controls connection of the input port (12) to a high voltage, and a pull-down switch (46) that can be actuated by the control device (42), which controls connection of the input port (12) to a low voltage. A method adapts the control device (42) to the sensor (10, 34), which is connected to the control device (42).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

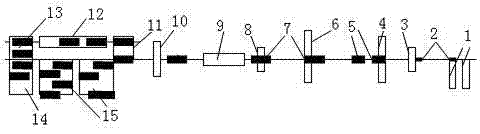

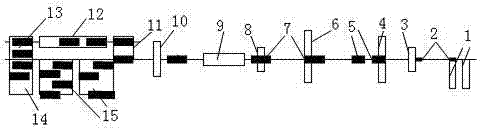

Production process of high-toughness and ultra-high strength steel and production system thereof

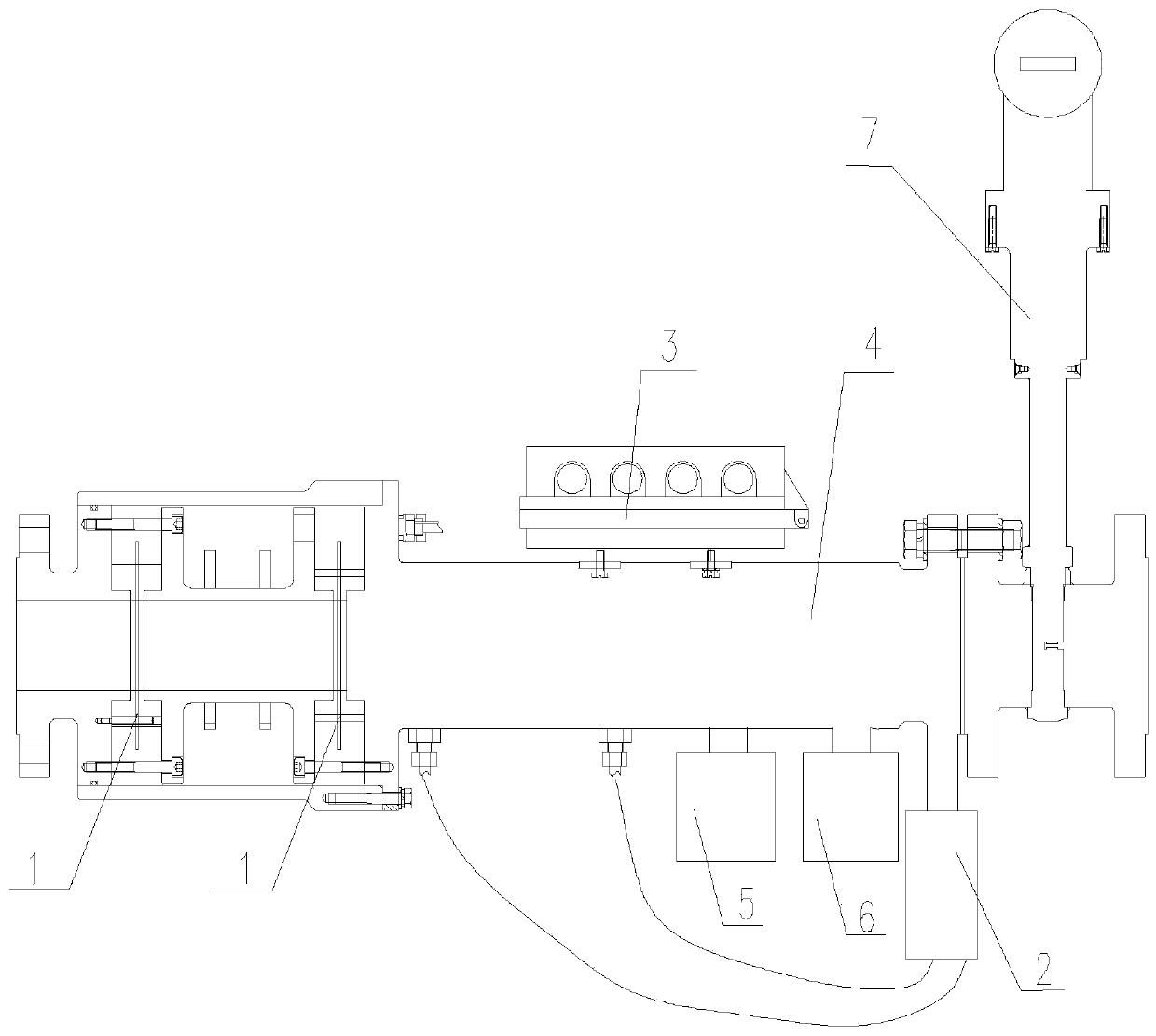

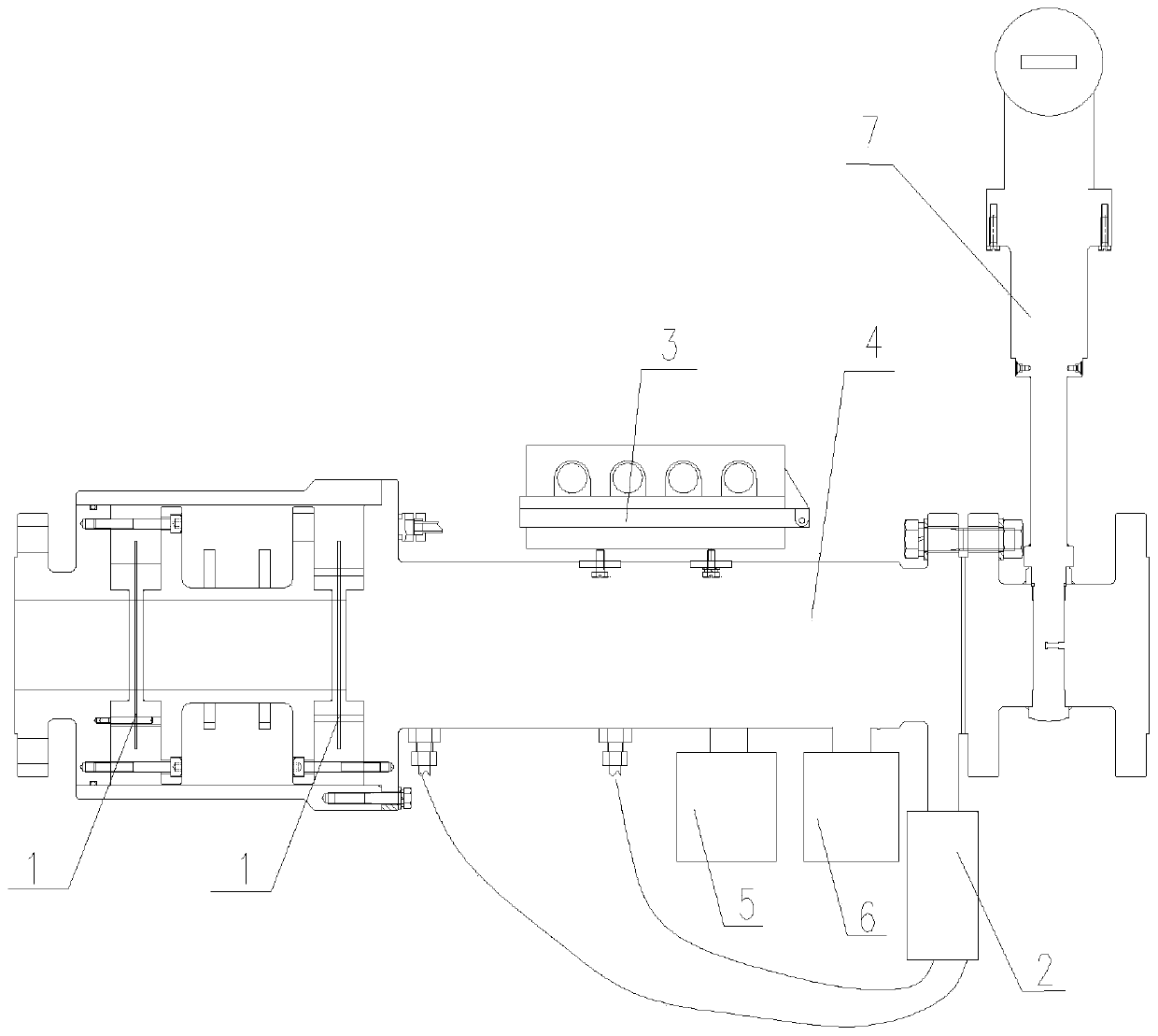

The invention relates to a production process of high-toughness and ultra-high strength steel and a production system thereof. The production system comprises a descaling box, a roughing mill, a temperature waiting roller table, a finishing mill, an ultra-fast cooling system, a thermal straightening machine, steel splitting racks and an open flame tempering furnace. The production process comprises the following steps of: fully heating a plate blank, discharging the plate blank from a furnace, descaling the plate blank, sequentially performing rough rolling, temperature waiting, finish rolling, on-line ultra-fast quenching and fast thermal straightening, separating the plate blank from a main production line through the steel splitting racks, fast sending a steel plate into the open flame tempering furnace for heat insulation, performing carbon distribution at PT (carbon distribution temperature), discharging the steel plate from the furnace, and then performing air cooling. The sequential arrangement of equipment of the production line is as follows: the heating furnace, the plate blank, the descaling box, the roughing mill, an intermediate blank, the finishing mill, a pre-straightening machine, an ultra-fast cooling unit, the thermal straightening machine, the first steel splitting rack, the open flame tempering furnace, the second steel splitting rack, a thick plate cooling bed and an intermediate plate cooling bed.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

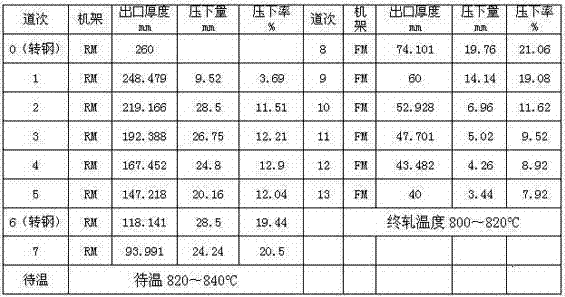

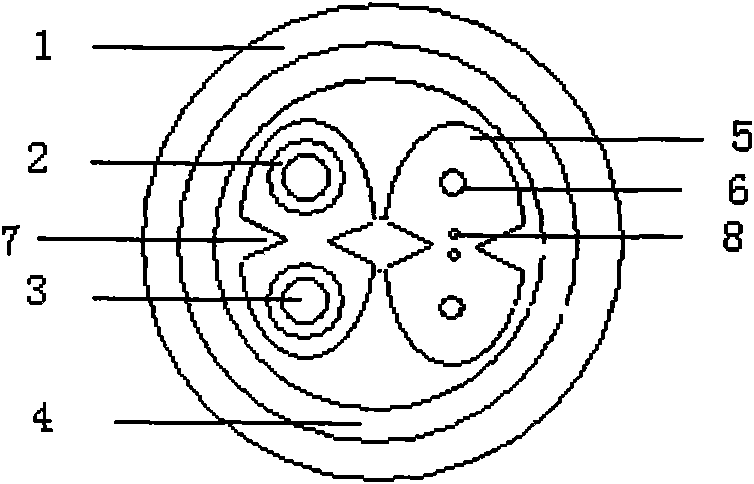

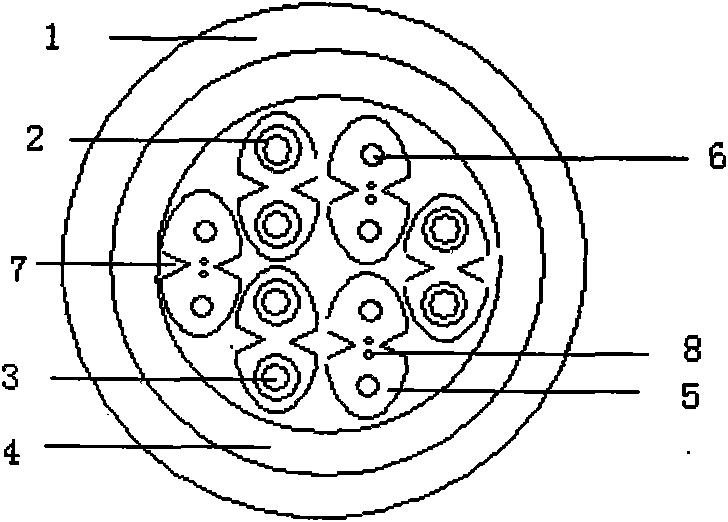

Fiber-to-tower-top photoelectric compound cable

ActiveCN101894630AReduce deployment workloadReduce occupancyCommunication cablesFiberElectrical conductor

The invention discloses a fiber-to-tower-top photoelectric compound cable, and relates to a compound cable which integrates fibers and a power line and has the function of grounding. The compound cable is mainly used for fiber-to-tower-top (FTTT) arrangement. The operator is directly connected with three sectors through the compound cable, thereby reducing the tower or roof load, simplifying the wiring process and lowering the installation cost. The compound cable comprises a compound cable outer sheath, conductor sheaths, conductor cores, a corrugated aluminum pipe, optical unit sheaths, reinforcing members, tearing slots, and tight coated fibers or bare fibers, wherein the tight coated fibers or bare fibers, the reinforcing member and the optical unit sheath constitute an optical unit; the conductor core and the conductor sheath constitute an electric unit; a plurality of optical units and electric units are wrapped in the corrugated aluminum pipe to form a photoelectric compound cable core; the compound cable outer sheath is extruded outside the photoelectric compound cable core to finally form the complete fiber compound cable; and each optical unit and electric unit are provided with the tearing slot.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

Housing with a bottom section and a cover

InactiveCN103057821ASimple structureEasy to operateClosed casingsLidsEngineeringMechanical engineering

Owner:宝培拉机箱系统有限公司

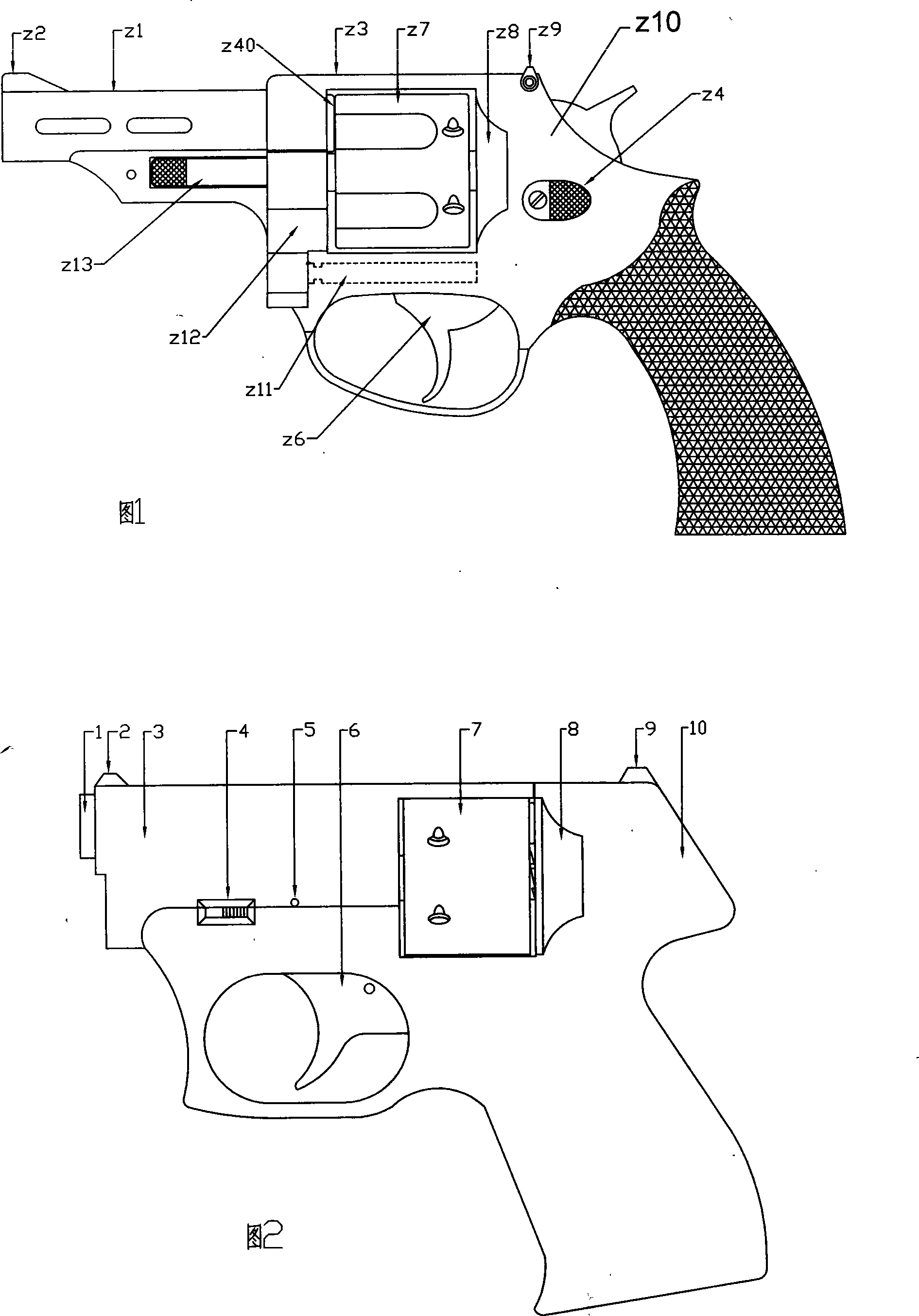

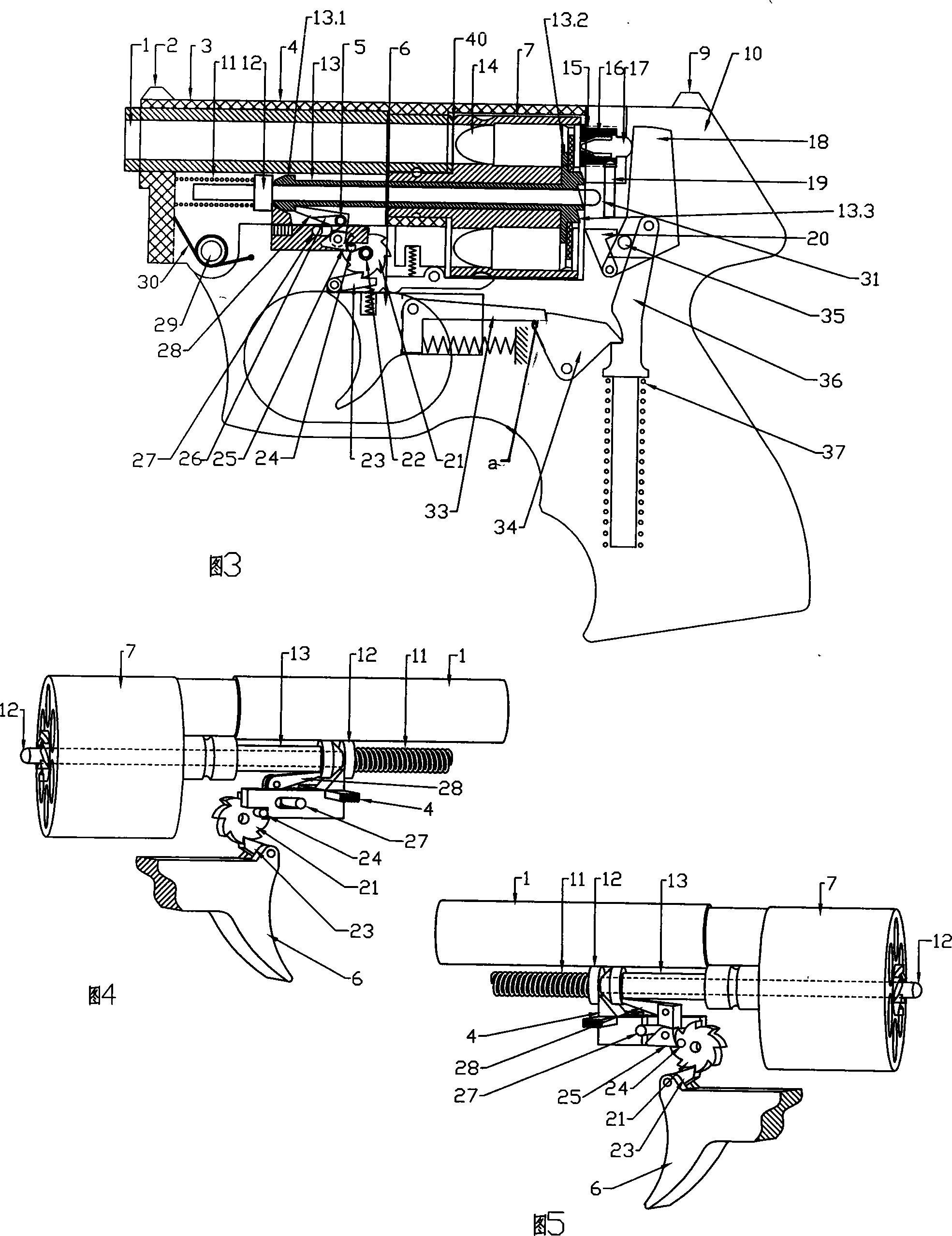

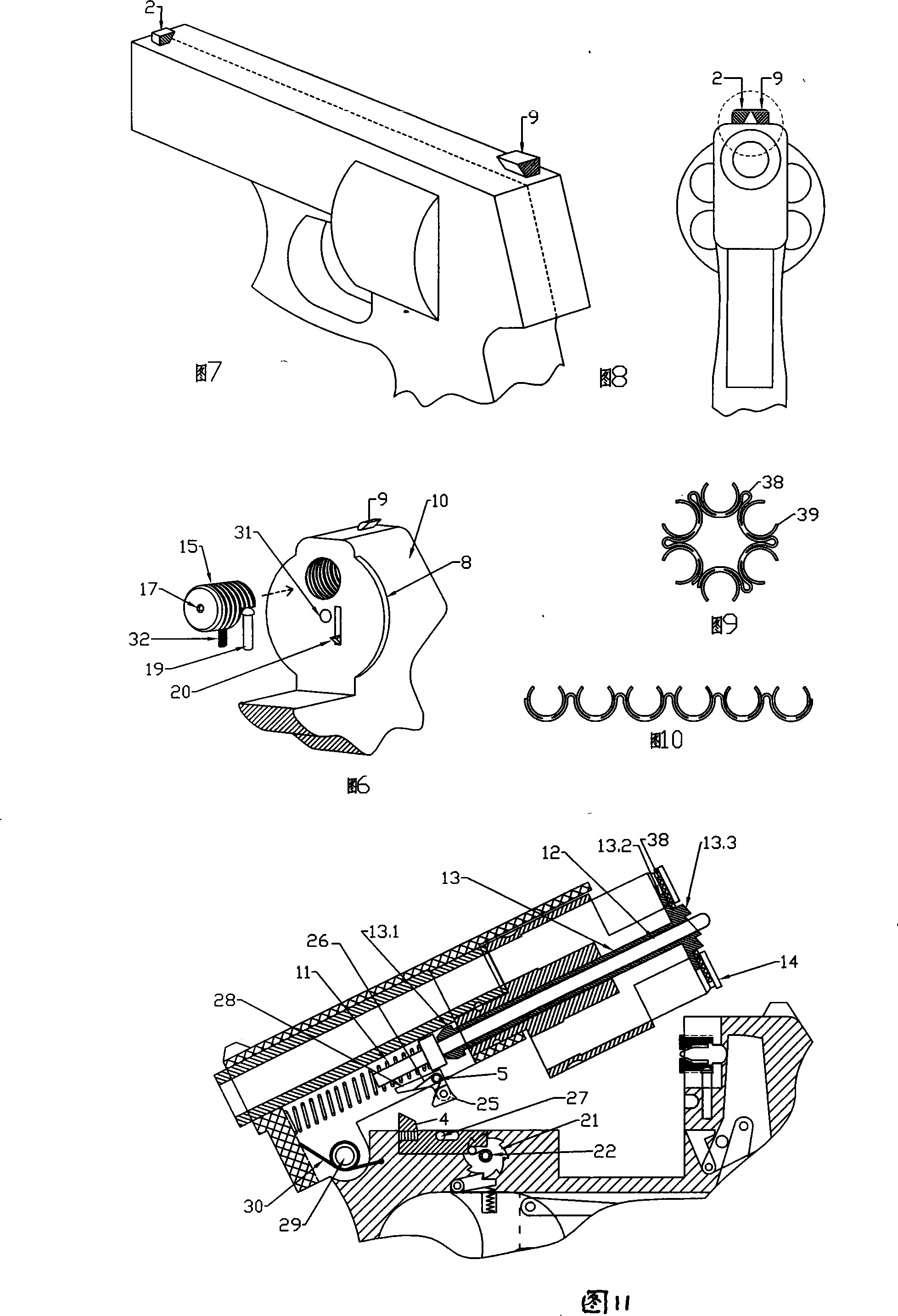

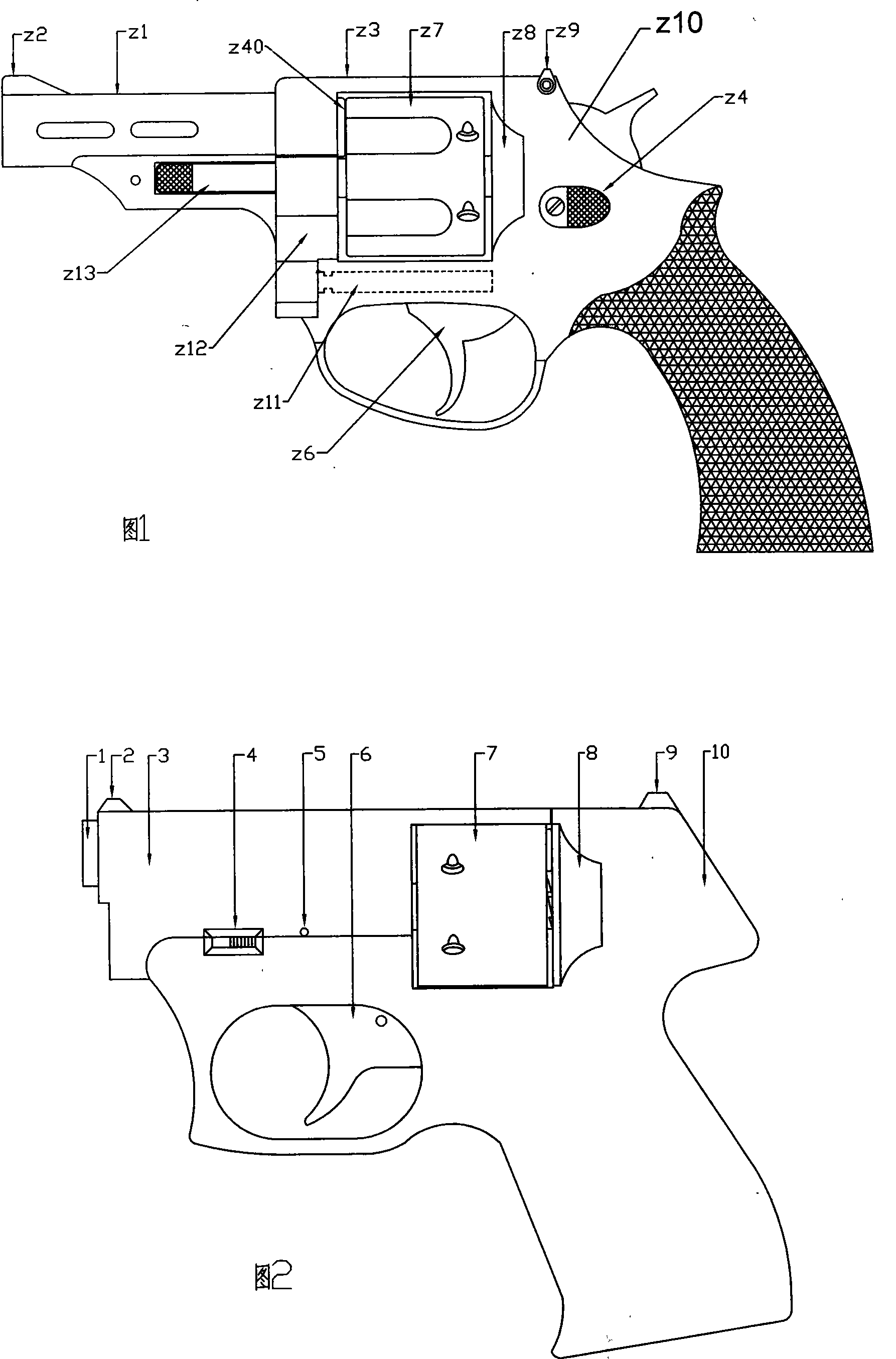

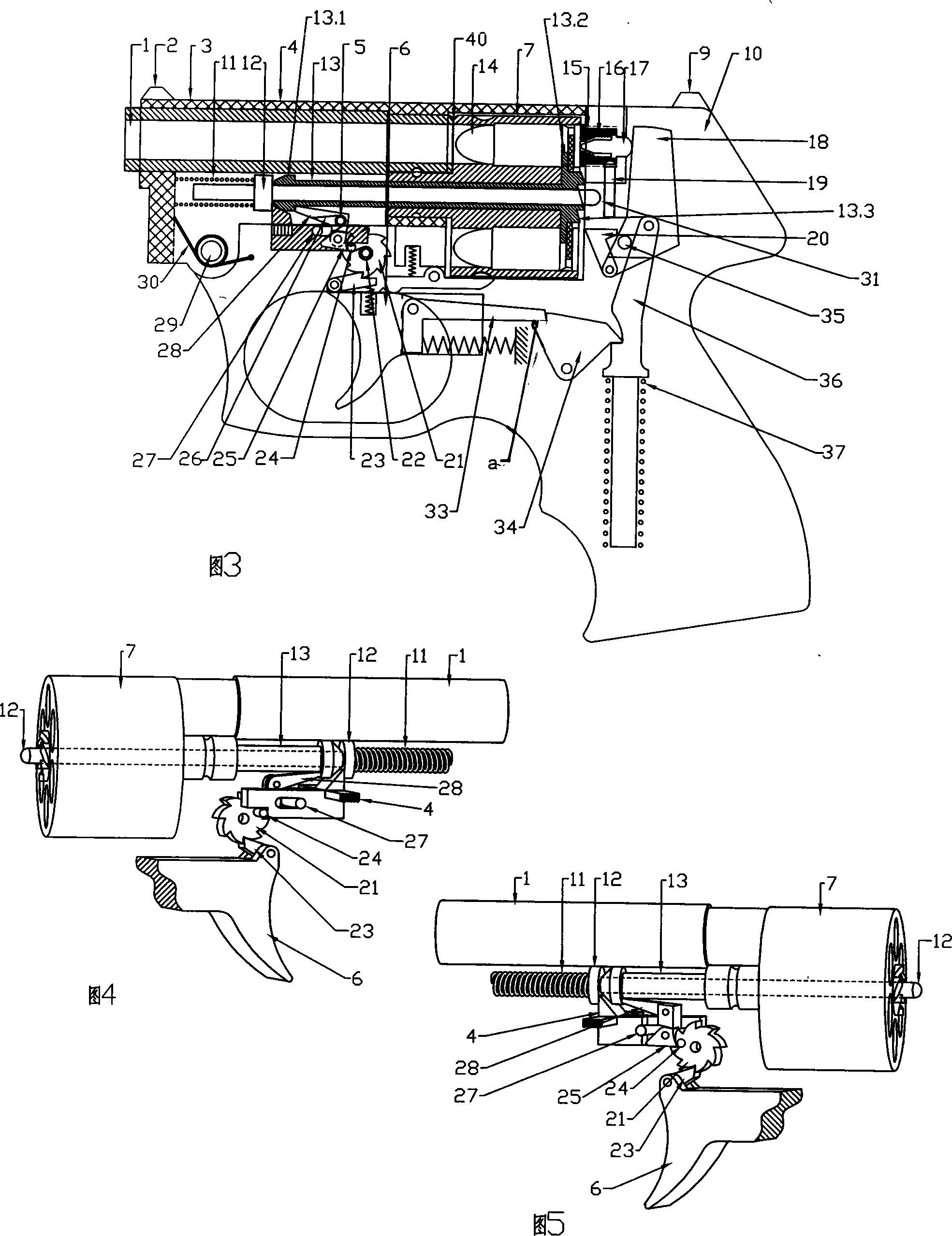

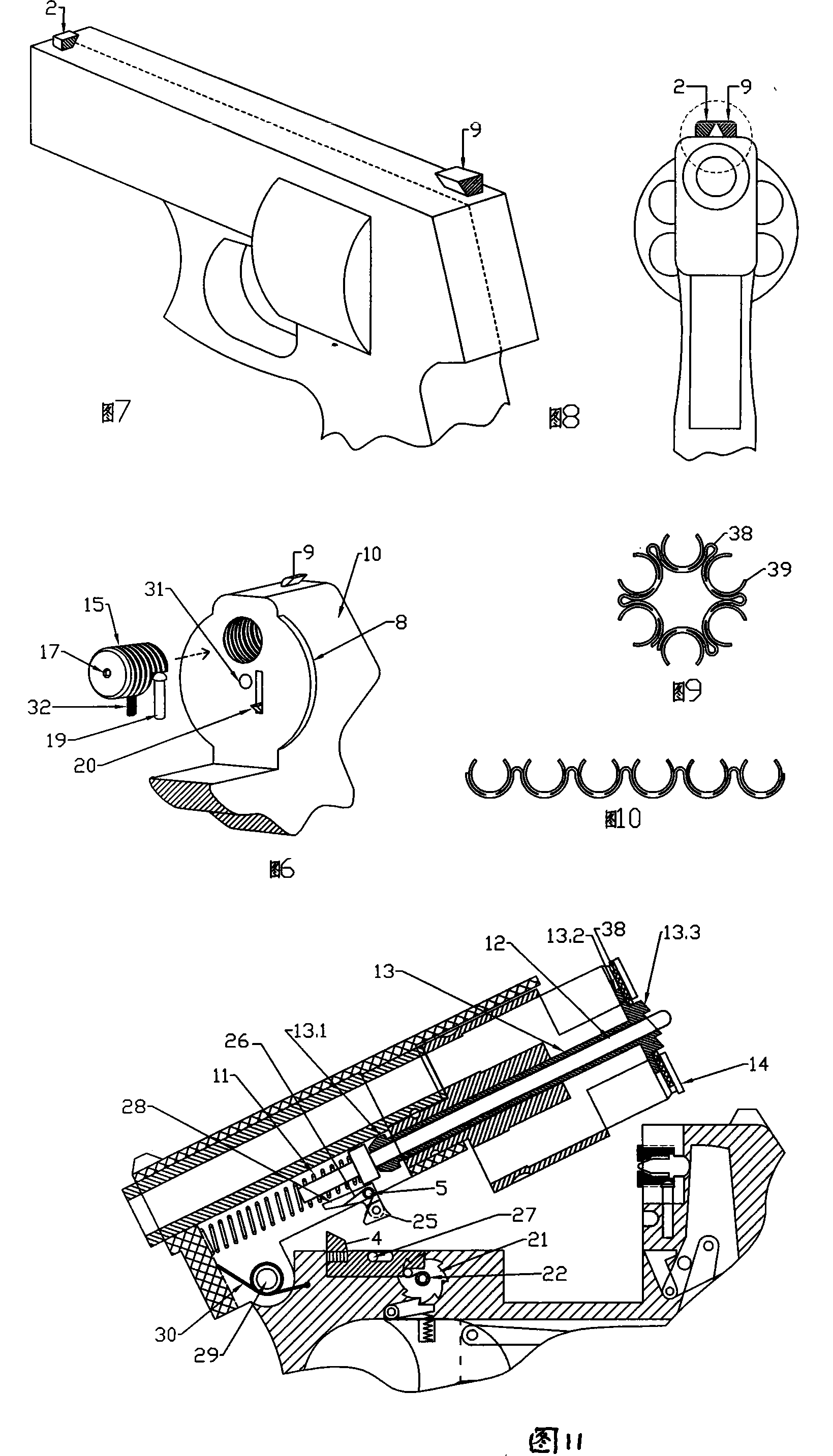

Rotary wheel pistol

A revolver, which refers to small arms. The prior art revolvers have the following disadvantages: complex structure and large size, the runner can only be swung out from the left side of the gun body, the loading speed is slow, the gap between the runner and the barrel cannot be closed, and the sight is inconvenient for quick aiming, etc. . The upper casing of the present invention is provided with an automatic shell ejection mechanism linked with the trigger, the screw hole of the gun body is screwed with a closed chamber device, and the cross-sections of the front sight and the rear sight are symmetrical to each other. Tilted at an angle, the tips of the two front sights are on the centerline of the barrel. The spring magazine clip is connected with 6 holding clips on the detachable elastic bending magazine clip at both ends, and can use ordinary bottomless pistol bullets. The present invention is a "revolver pistol" with simple structure, compact layout, small volume, automatic shell ejection, fast loading, closed bullet chamber, unique aiming device, completely symmetrical structure, and convenient operation by both left and right hands. ".

Owner:太原阿瑞斯精密机械科技有限公司

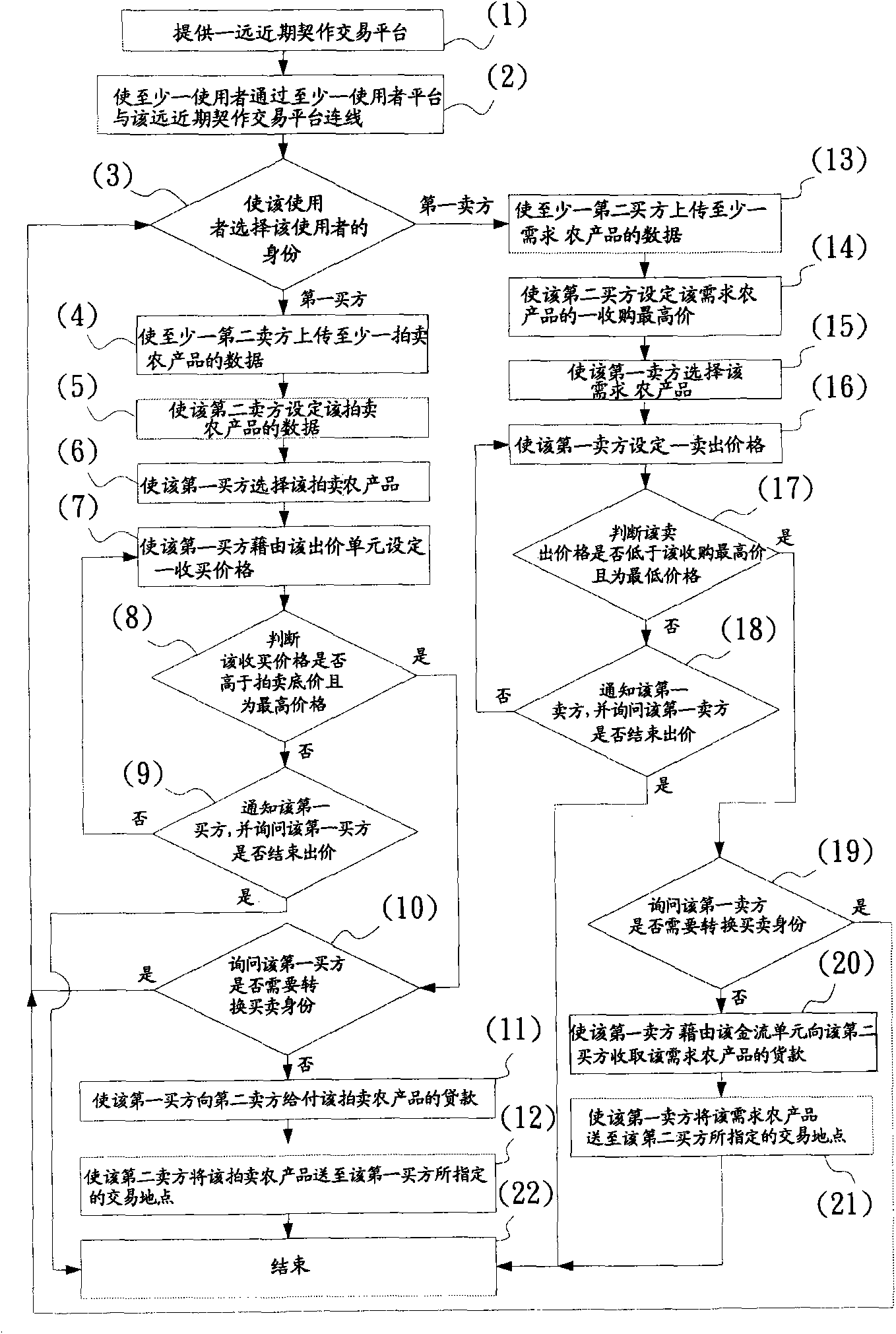

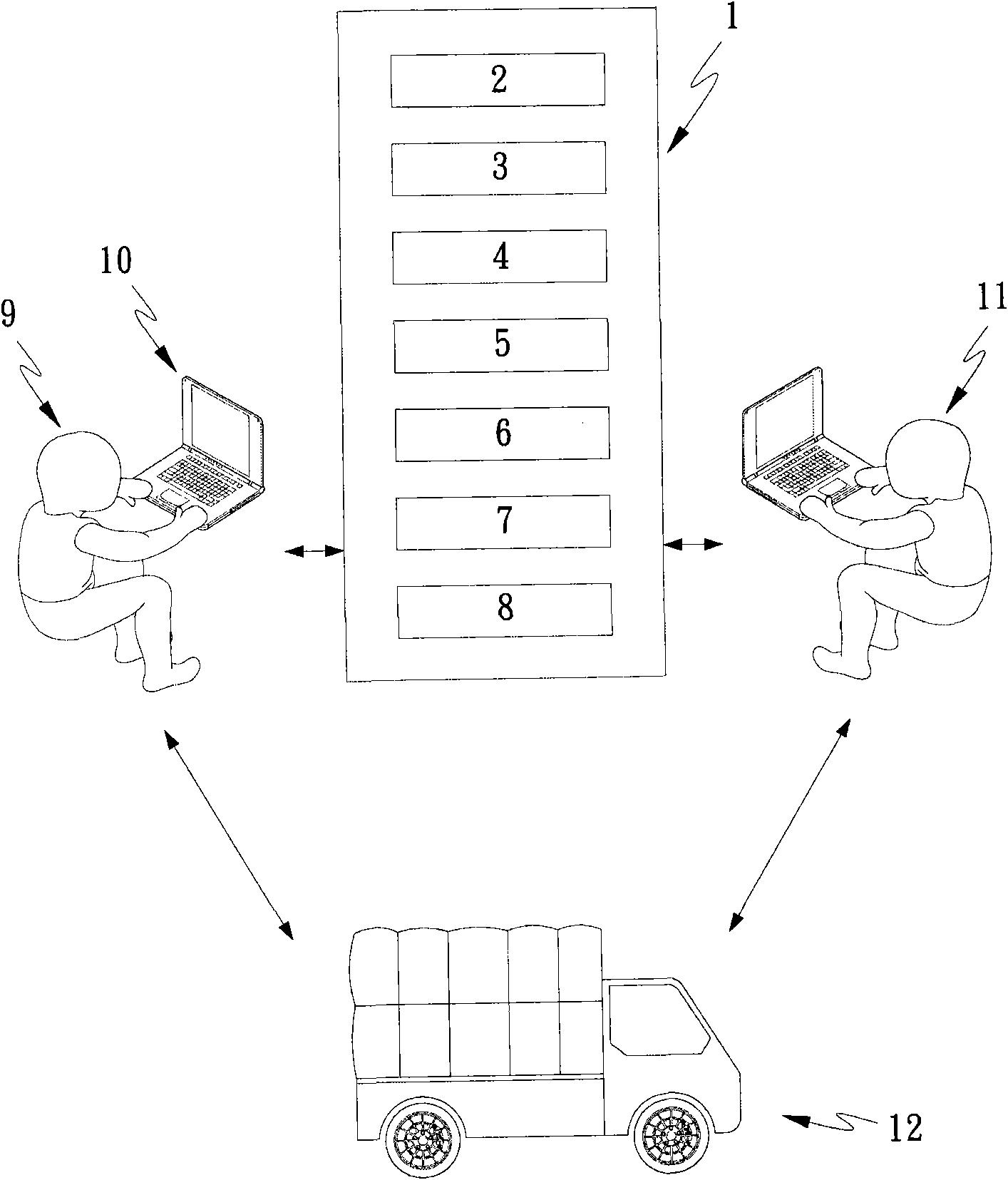

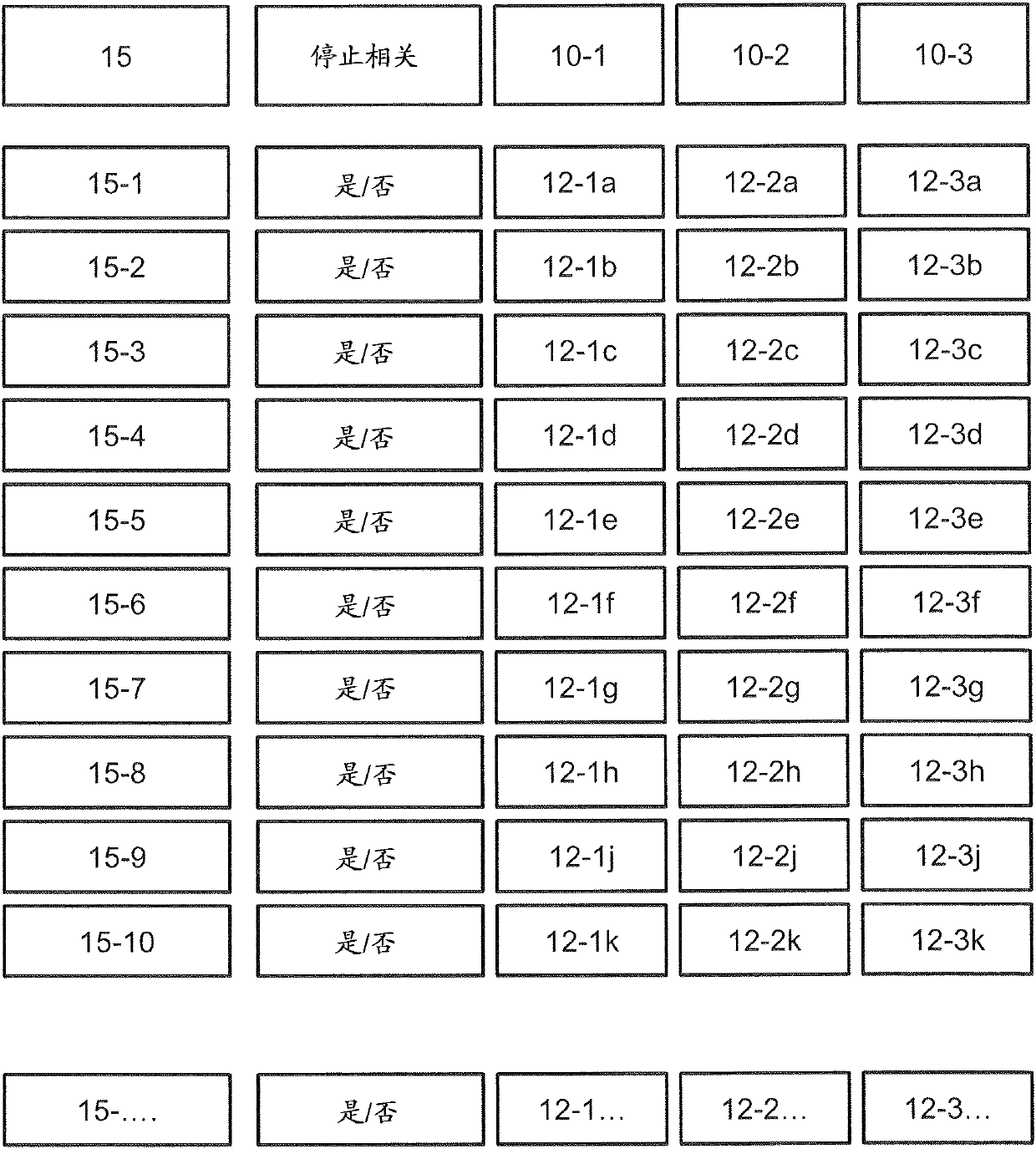

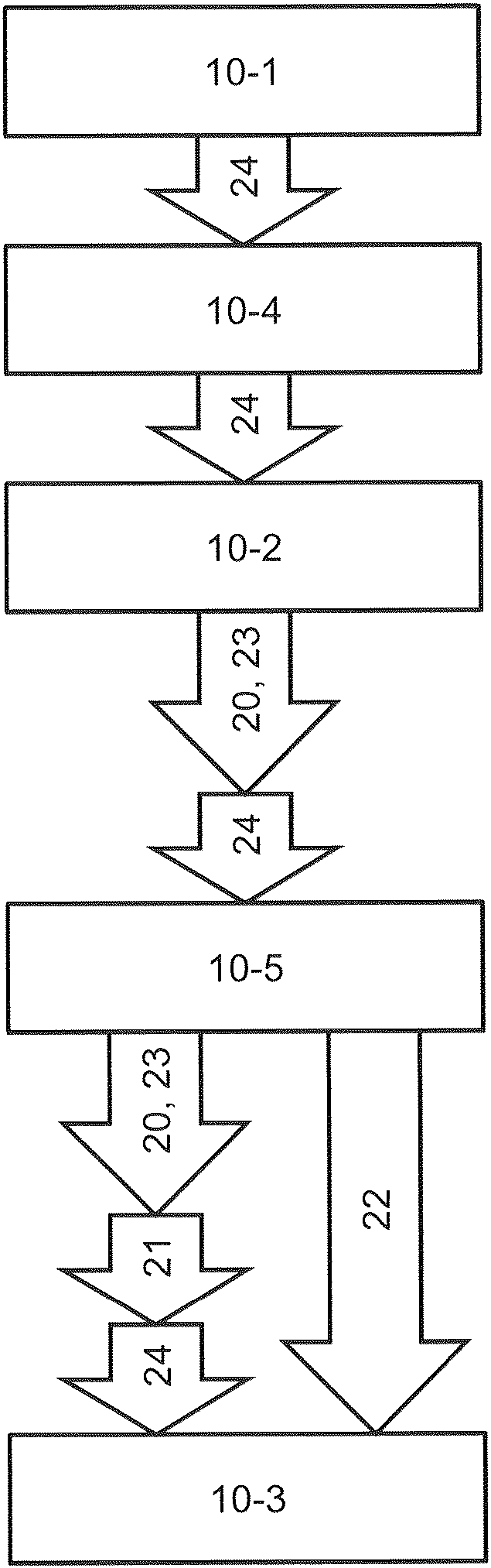

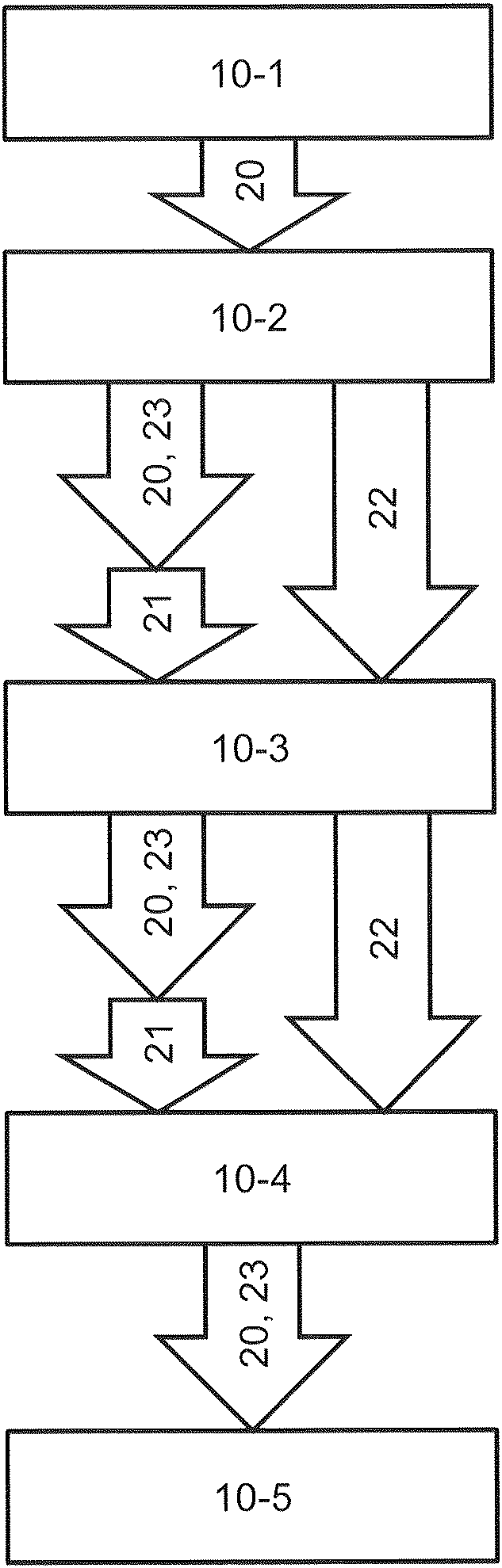

Method for transacting agricultural products by long-term and short-term combined transaction platform

The invention relates to a method for transacting agricultural products by a long-term and short-term combined transaction platform, which comprises the following steps: a long-term and short-term combined transaction platform is provided, so that at least one seller and at least one buyer are connected on line by at least one user platform and the long-term and short-term combined transaction platform; after the transaction is completed, the identifications of the seller and the buyer can be changed according to the conditions, and the agricultural products are put on shelves for the subsequent auction. Thus, the risk of the cultivators can be shared by the market; the output forecast and the regulation of supply and demand can reduce the risk of the unsalable agricultural products; the transportation distance for the agricultural products can be shortened; the transaction of the agricultural products can be advanced prior to the cultivation so as to realize the transaction in advance; the agricultural products can be transacted many times; and the economic scale can be enlarged.

Owner:陈 淑玲

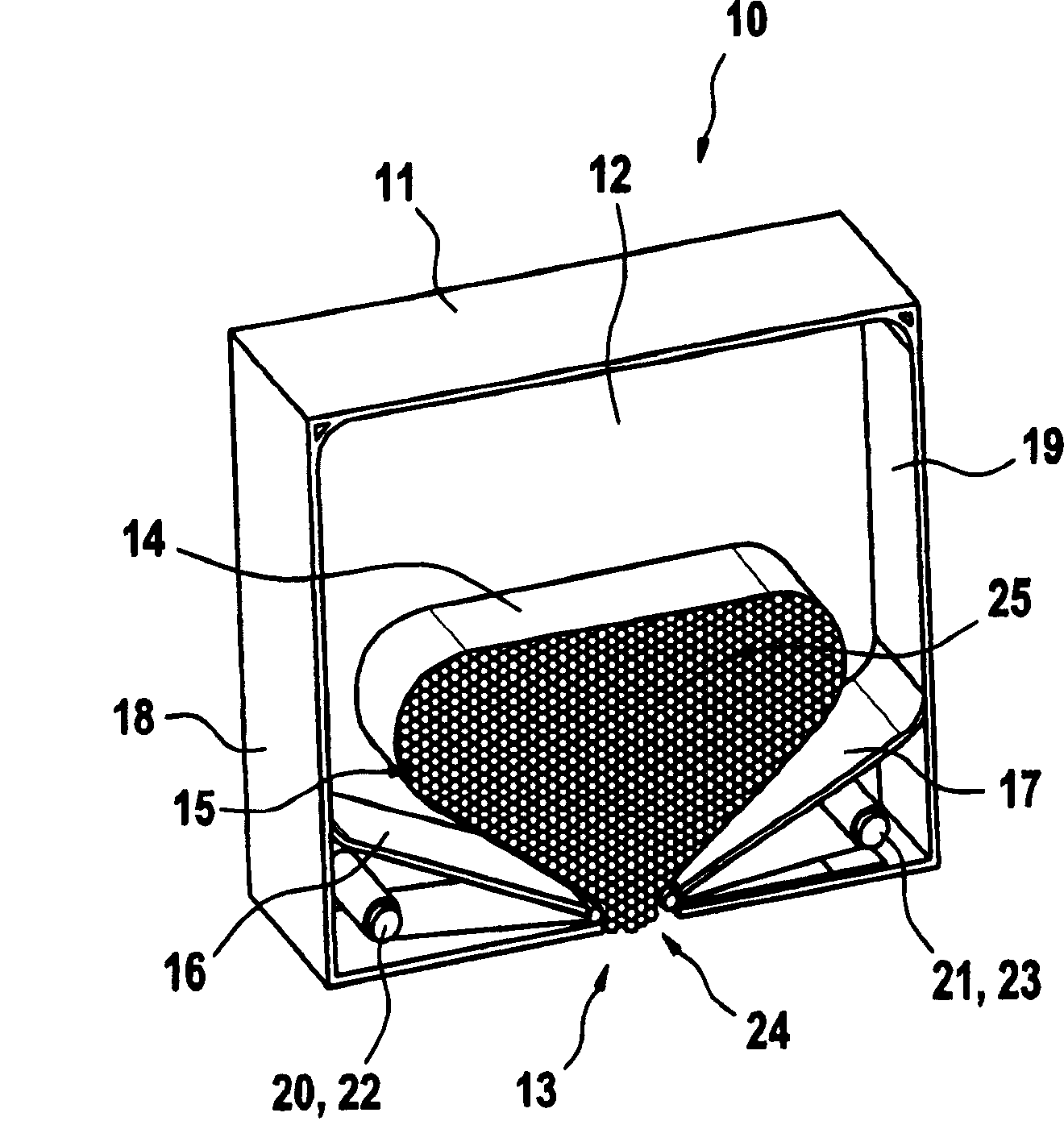

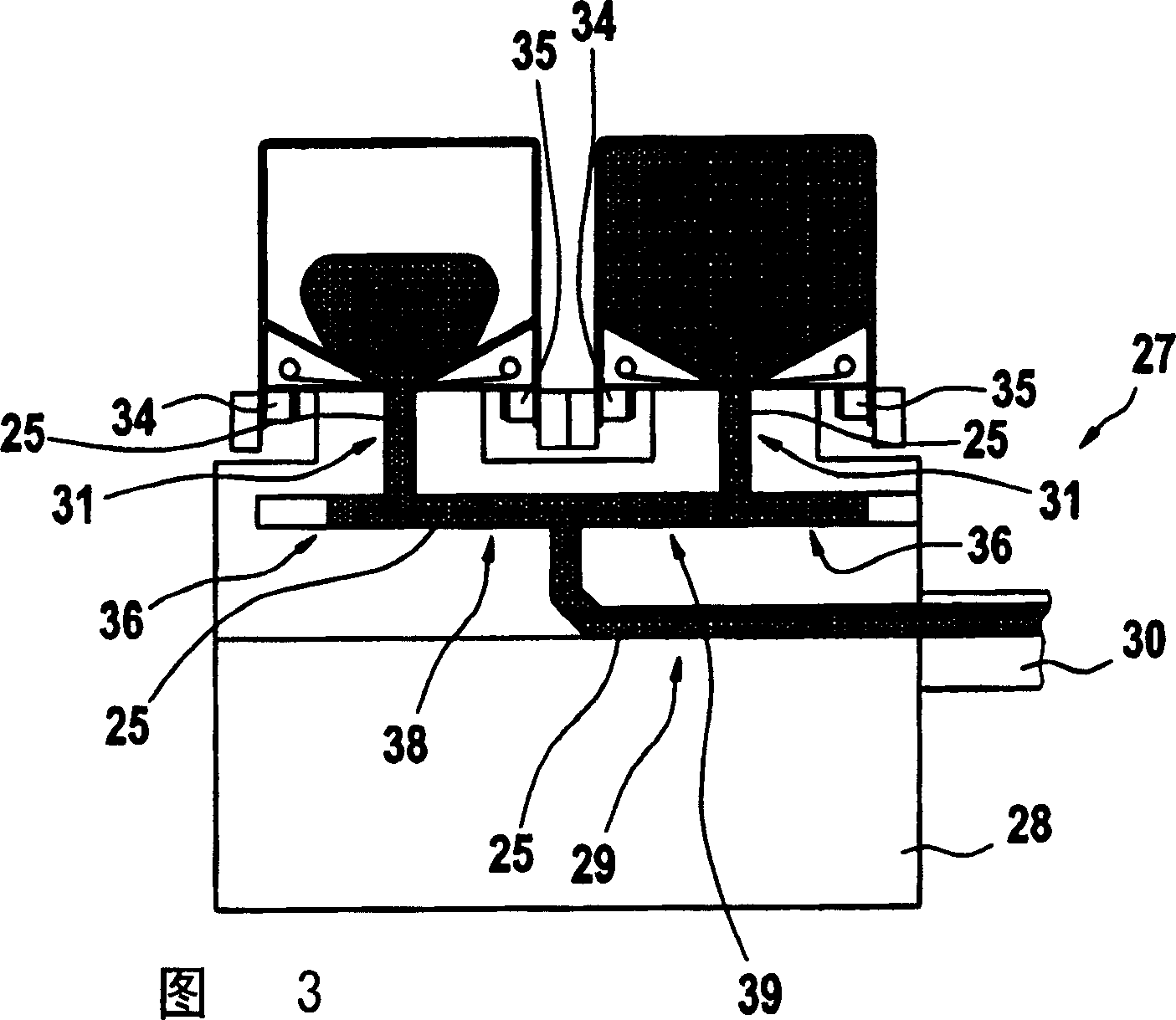

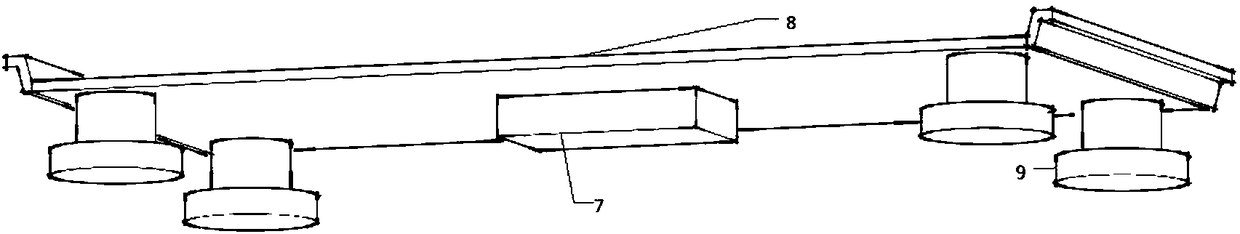

Storing apparatus for rod-shaped articles and apparatus and method for filling storing apparatuses

InactiveCN1899933AIncrease capacityReduce loadCigarette manufactureLarge containersEngineeringMechanical engineering

The invention concerns a storage apparatus for rod-shaped articles, including a housing with a closable opening for filling and emptying the storage apparatus, wherein within the housing is arranged a flexible belt element which is designed for variable adjustment of a storage space depending on the fill level, which is distinguished in that the storage apparatus is designed for filling with a multi-layer, disorderly mass flow. Furthermore, the invention concerns an apparatus and a method for filling a corresponding storage apparatus.

Owner:HAUNI MASCHINENBAU AG

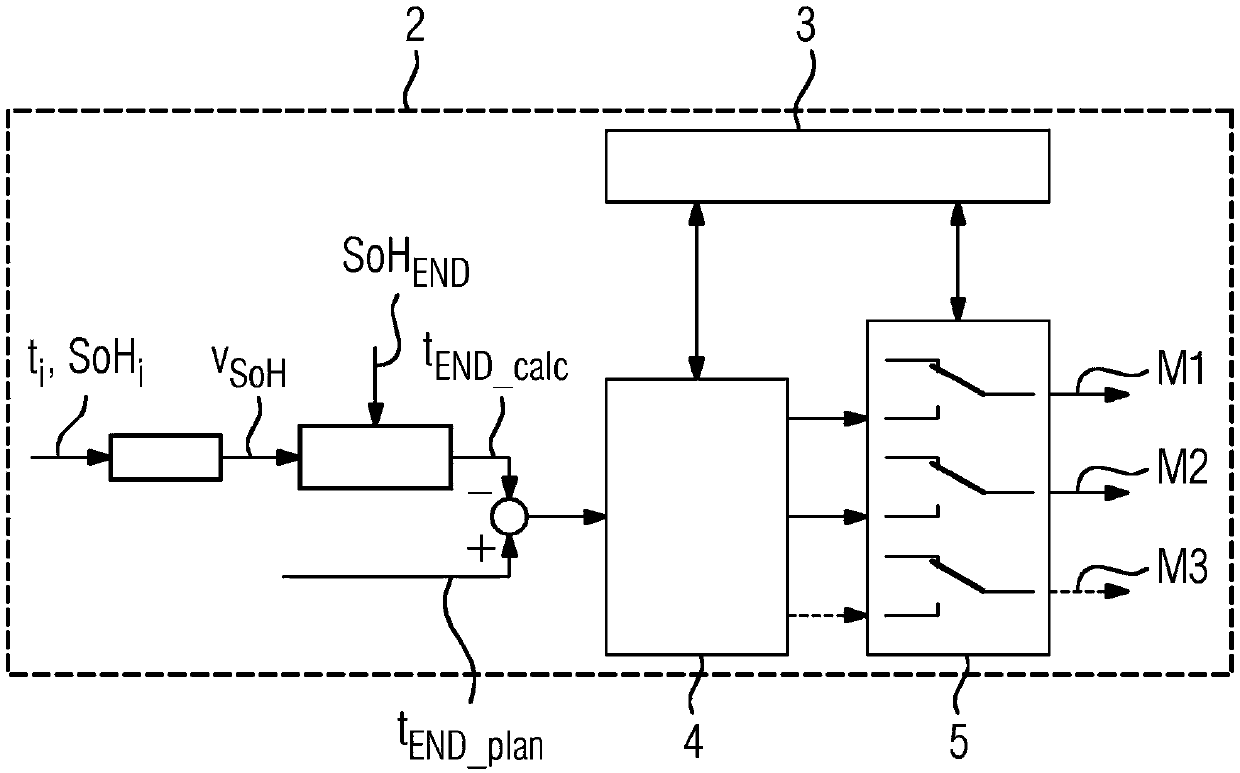

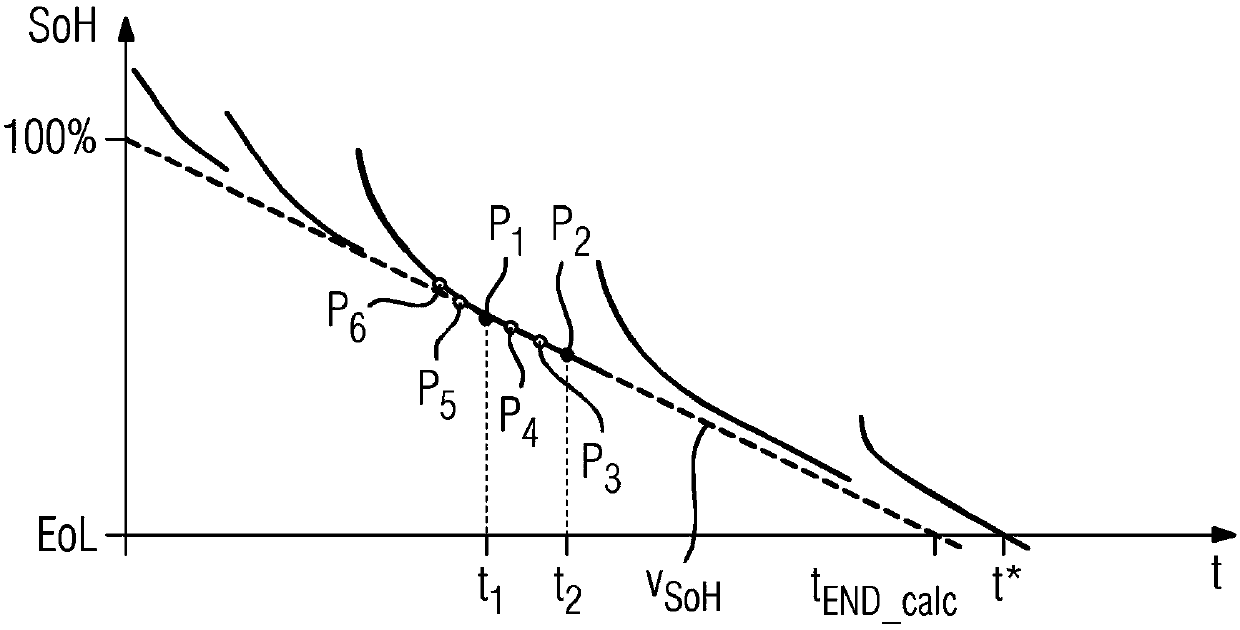

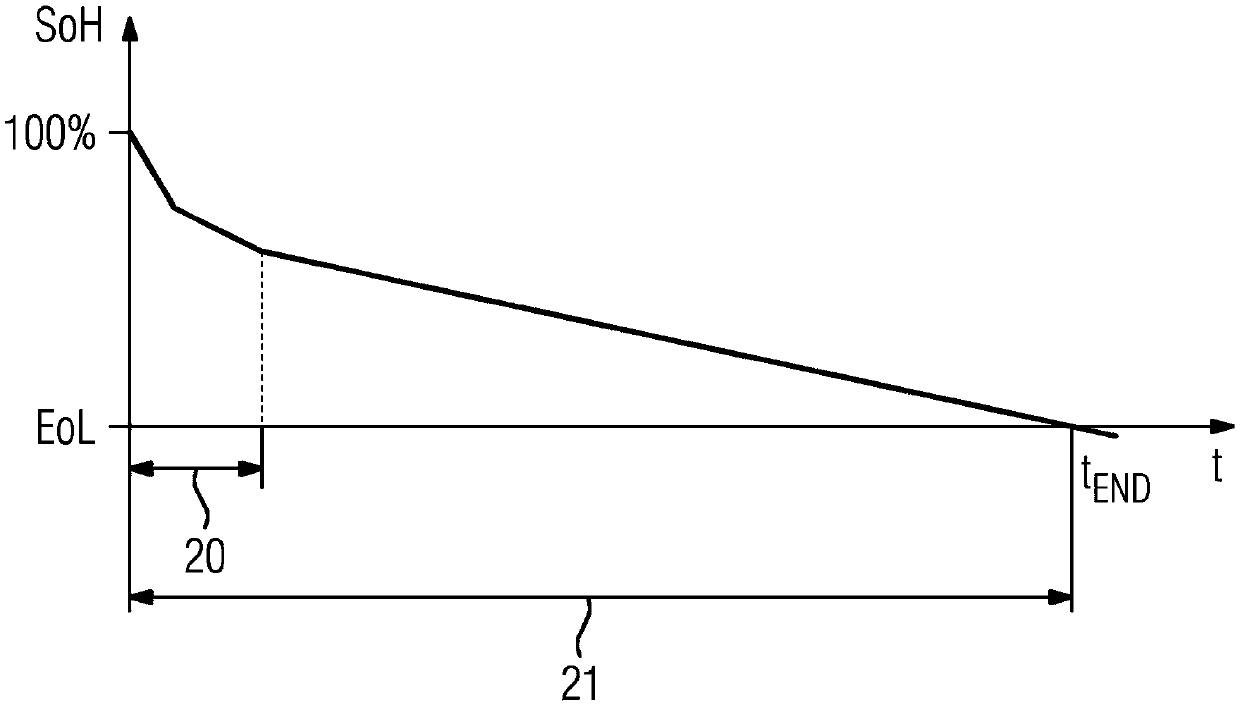

Service life control for energy stores

InactiveCN108701873AExtend your lifeAchieve normal operationHybrid vehiclesElectric devicesState of healthEmergency medicine

Owner:SIEMENS AG

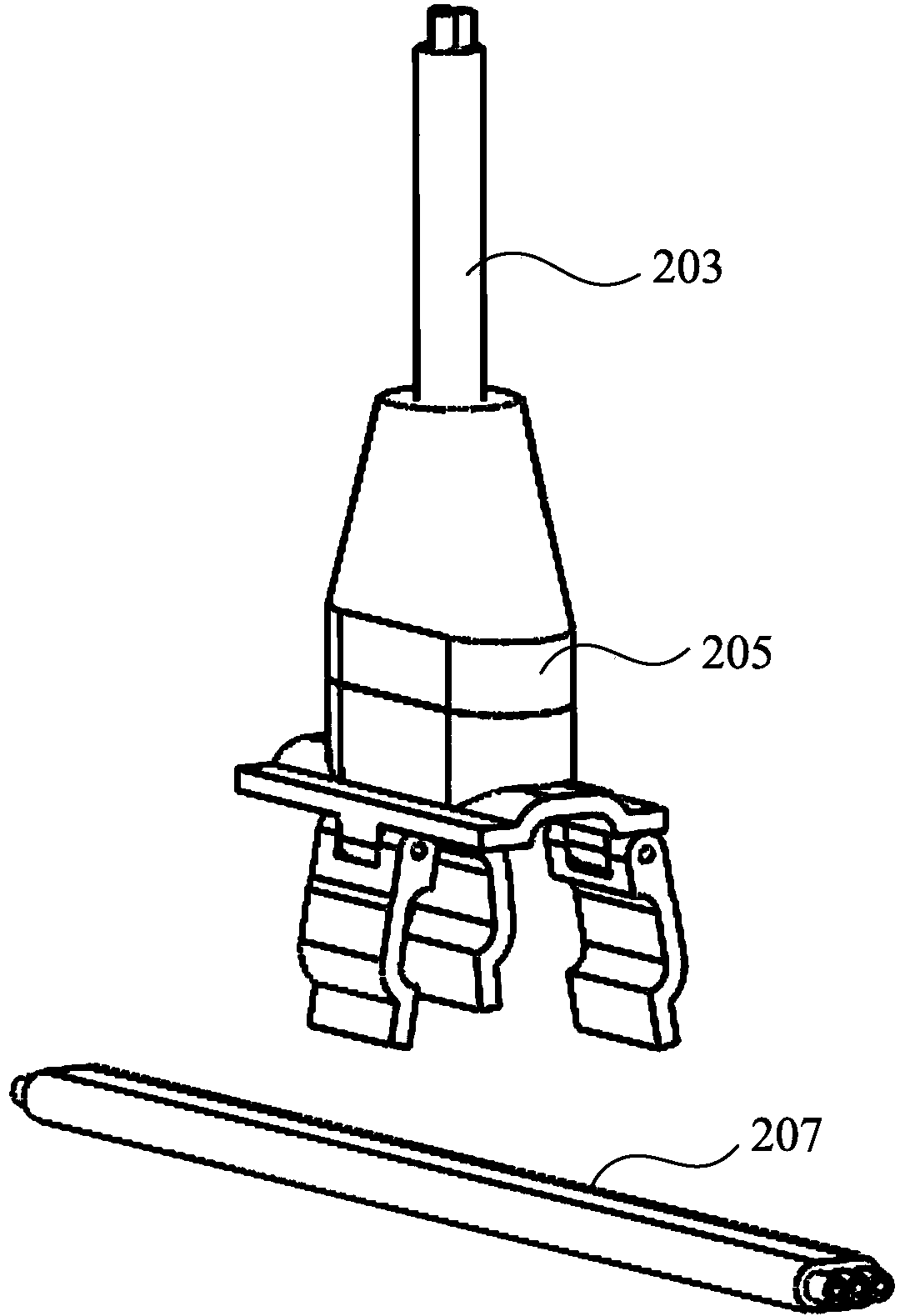

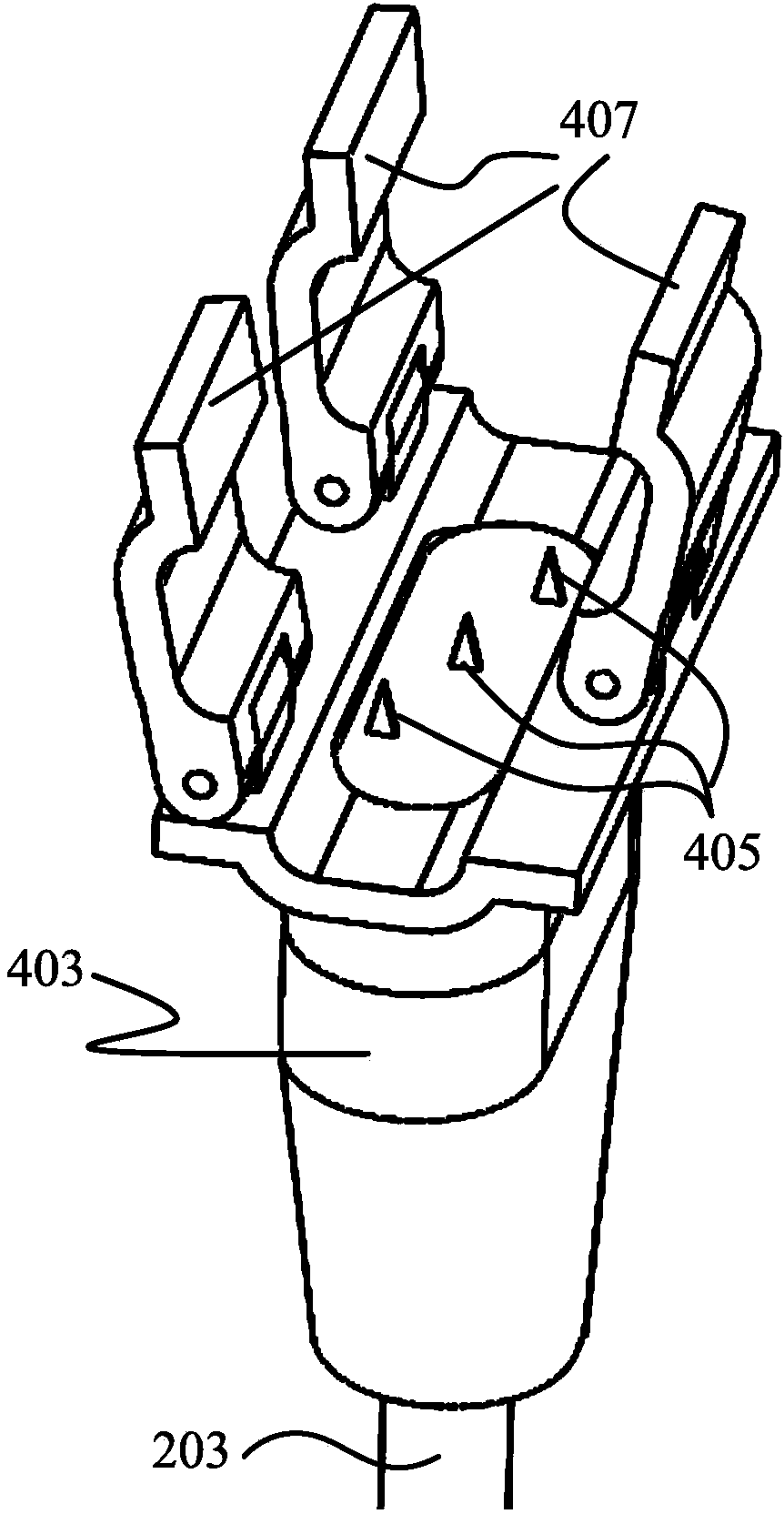

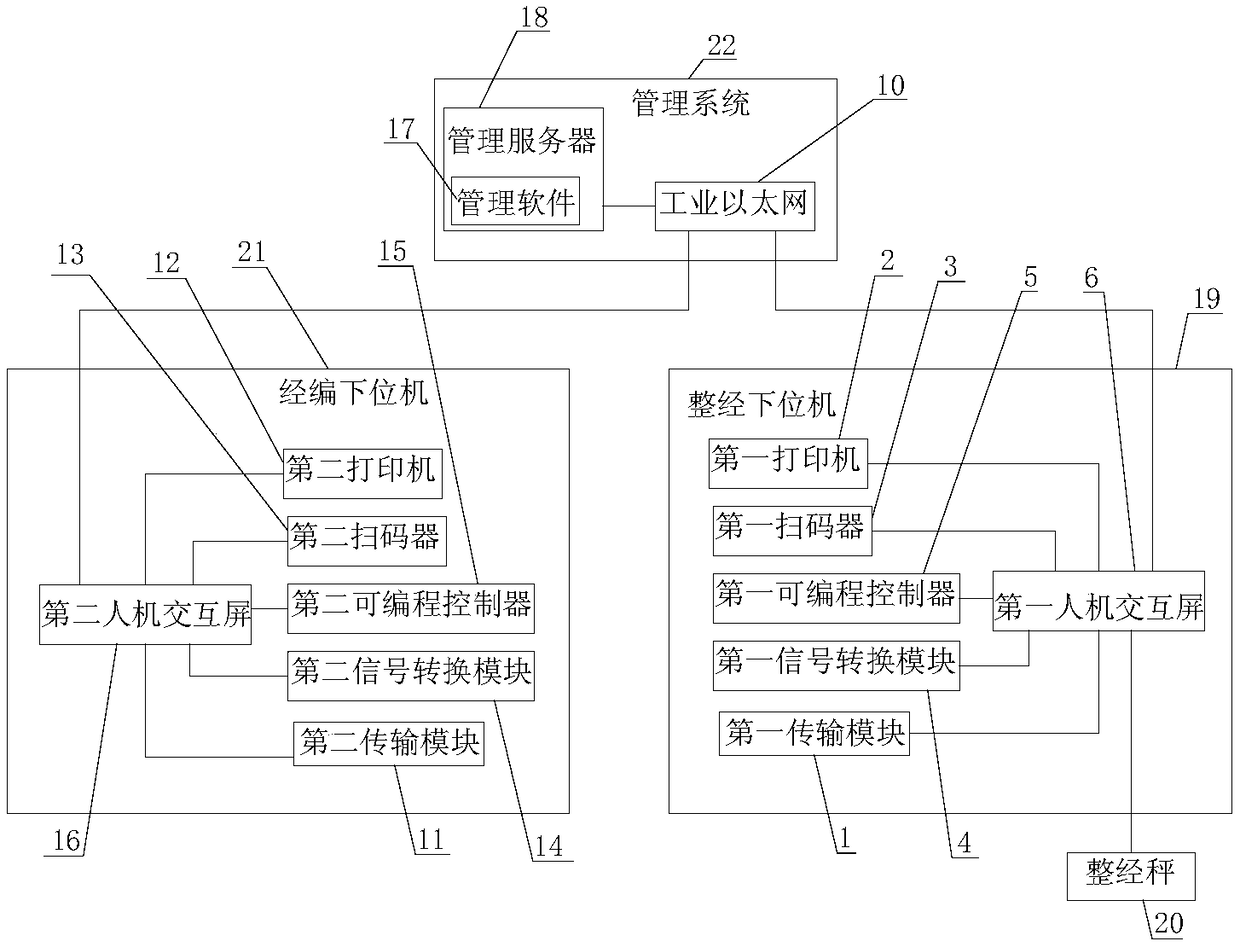

Cable connector suitable for being connected with distributed power source

ActiveCN103779685ASimple designSimplify logisticsCoupling contact membersContact members penetrating/cutting insulation/cable strandsElectrical conductorEngineering

The invention provides a cable connector suitable for being connected with a distributed power source. One end of the cable connector is connected with a branch cable connected with the distributed power source, and the other end of the cable connector is in T-type connection with a total cable used for receiving alternating currents output by multiple distributed power sources connected in parallel. The cable connector comprises a main body part and a clamping part. The tail of the main body part is connected with the branch cable, a plurality of puncturing components are arranged at the head of the main body part in a protruding mode and are electric conductors, the root portions of the puncturing components are correspondingly connected with multiple inner conductors of the branch cable respectively, the pointed portions of the puncturing components are used for penetrating through the outer skin of the total cable and correspondingly connected with multiple inner core conductors in the total cable respectively, and the clamping part is connected with the head of the main body part and used for fixing the total cable and the main body part to keep the total cable in stable contact with the branch cable. According to the cable connector, a socket and a plug are eliminated in connection of the branch cable and the total cable, cost is reduced, the installation flexibility is improved, and the original risk that connection of the socket and the plug loses efficacy is further eliminated.

Owner:ALTENERGY POWER SYST

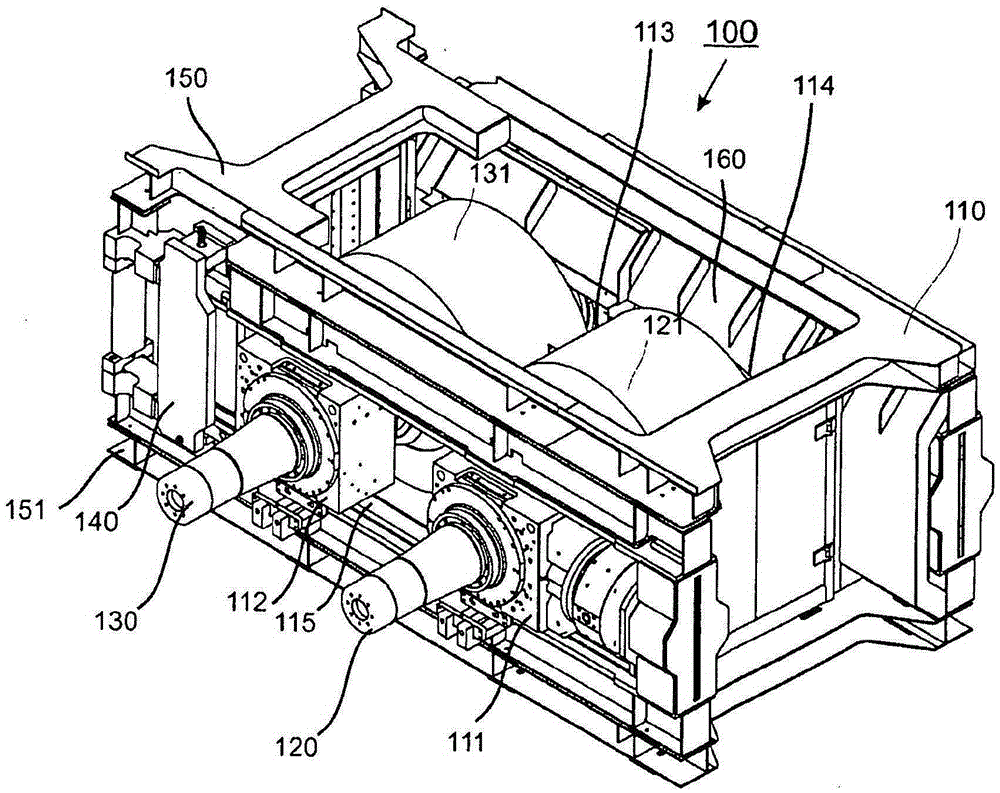

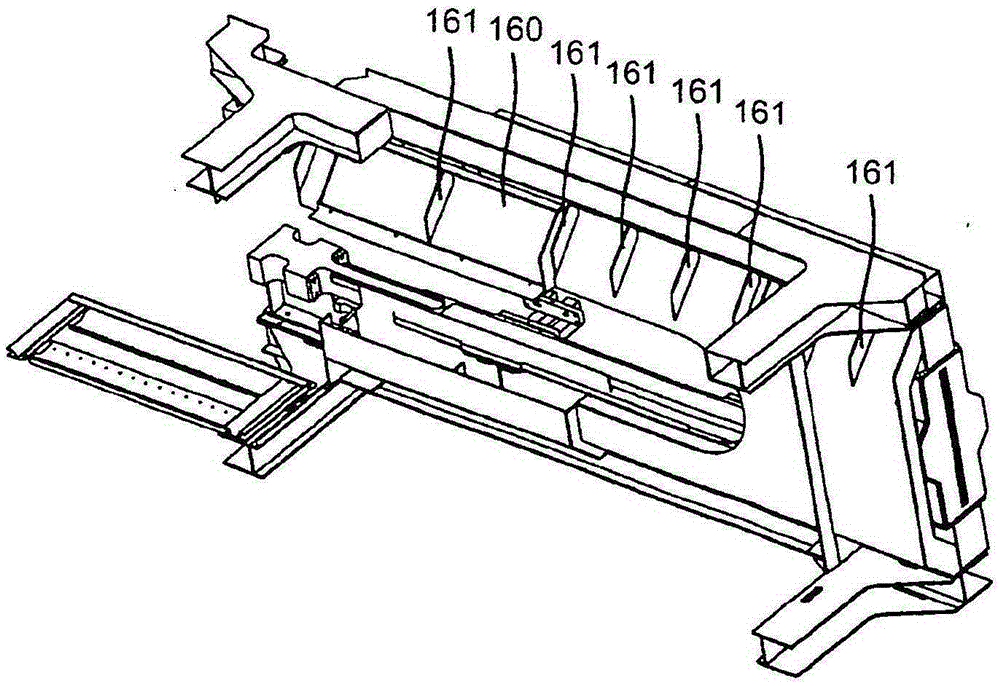

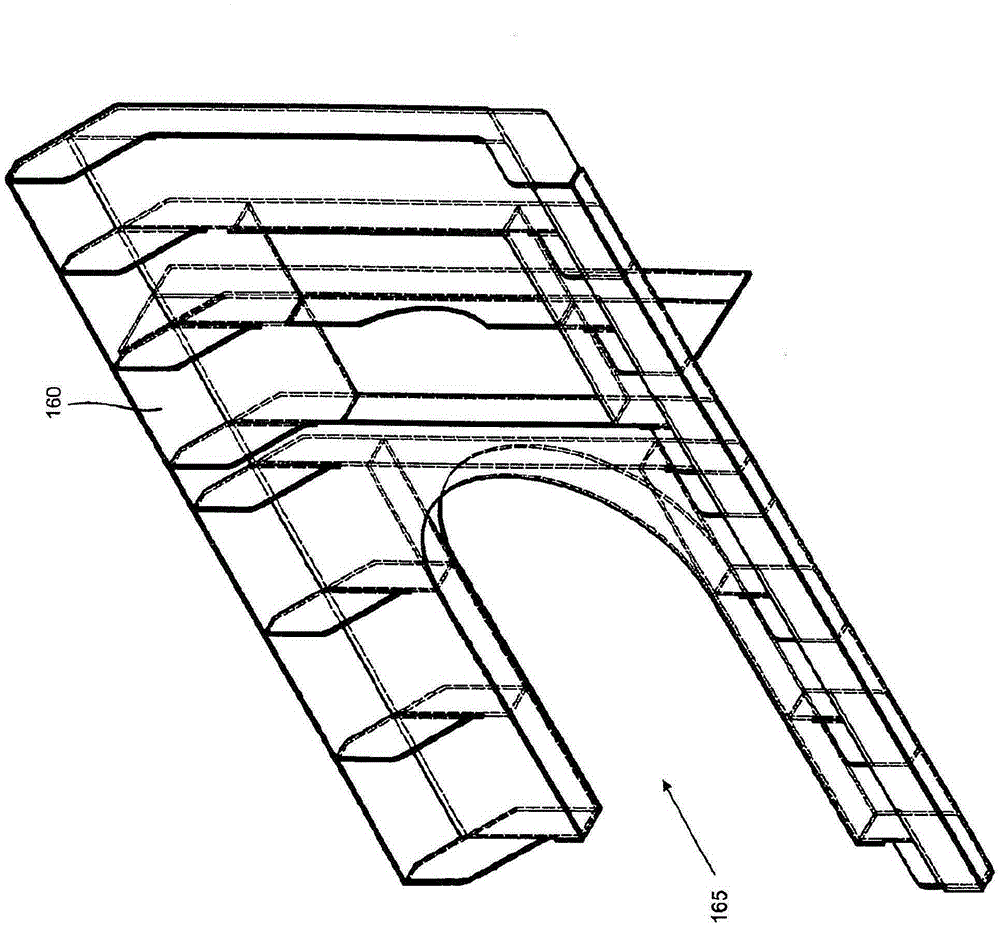

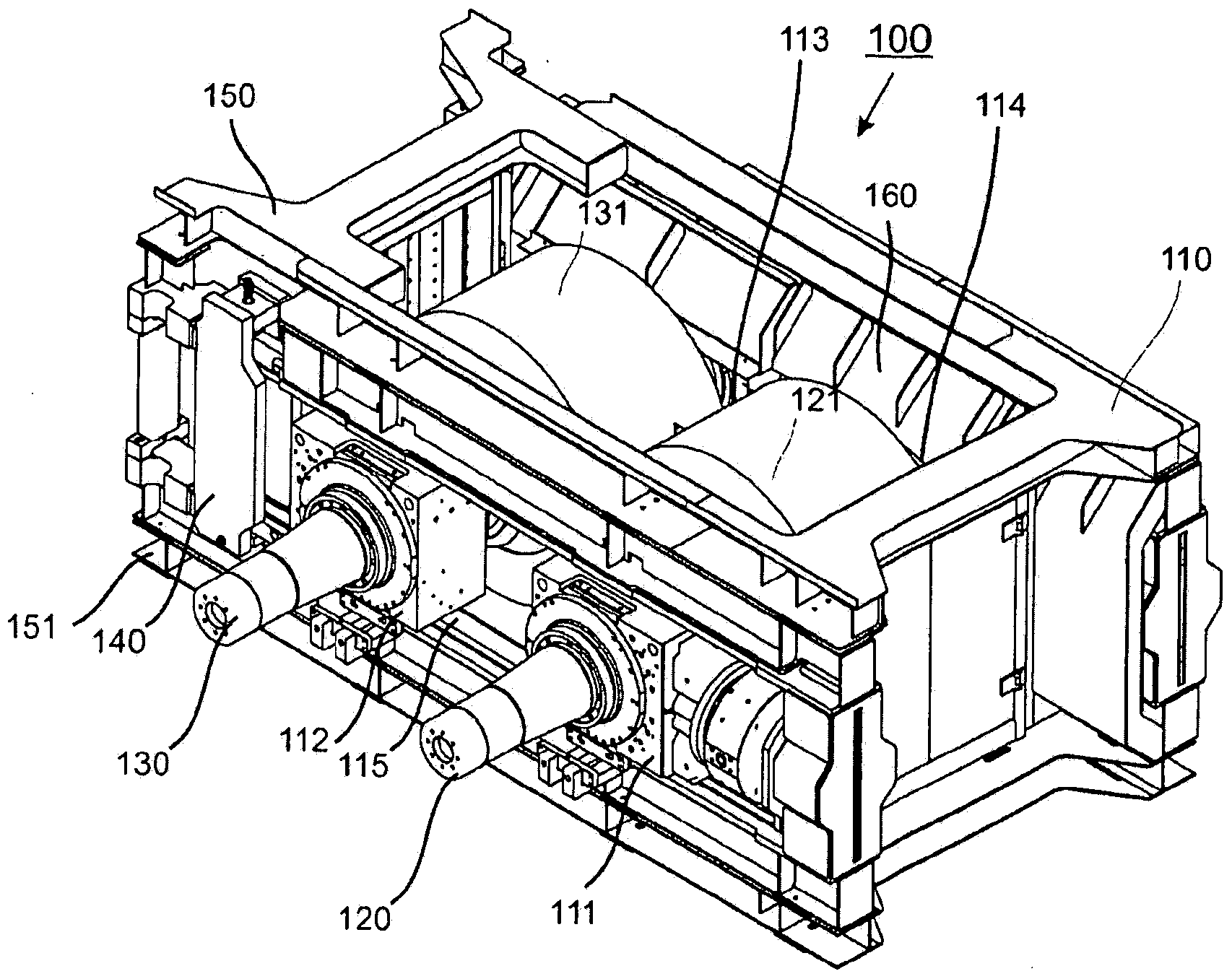

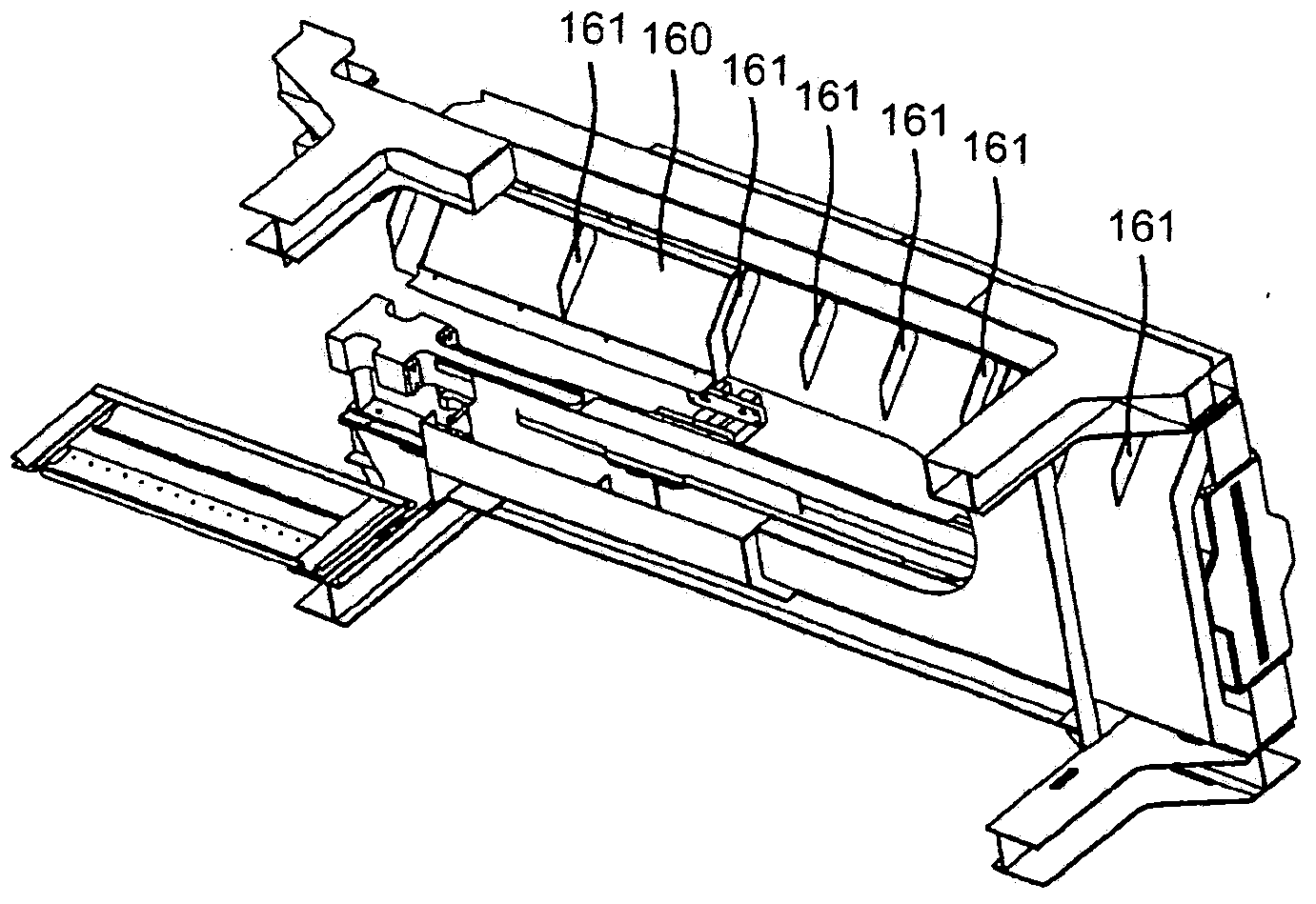

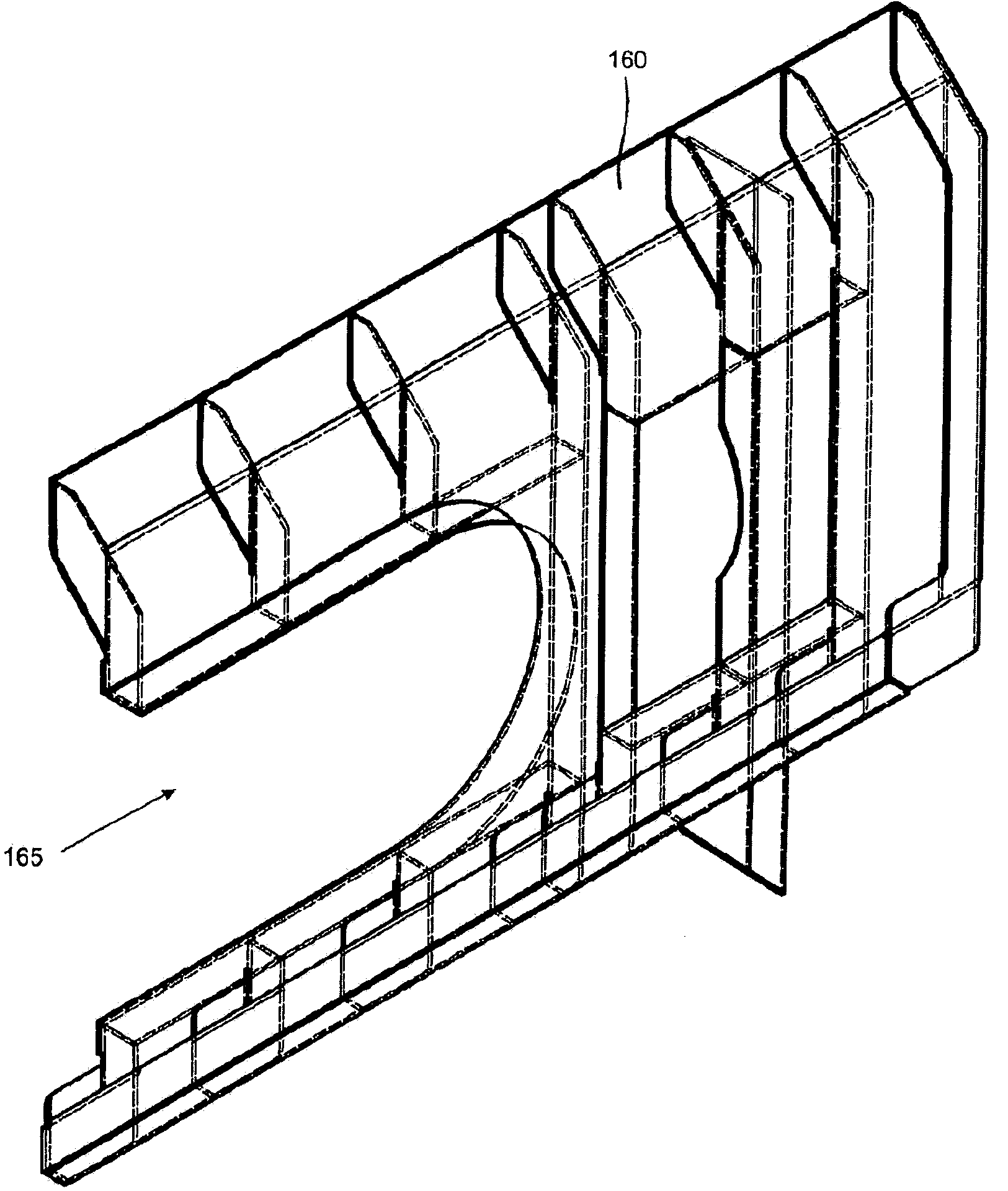

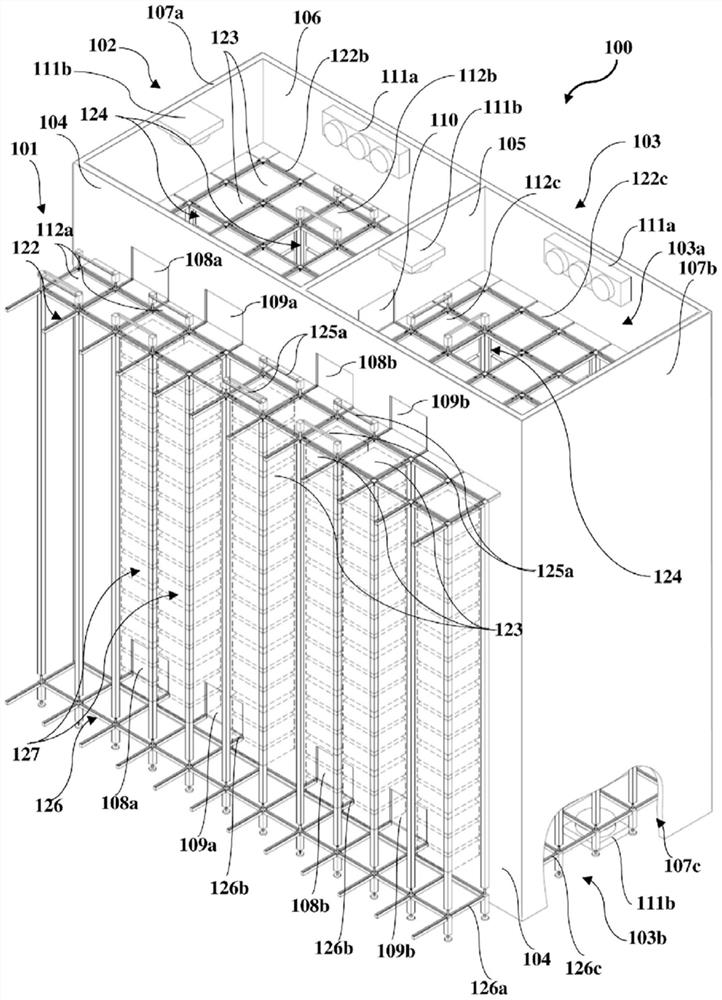

Frames for high pressure roller presses

ActiveCN103987461BReduce weightSimplify logisticsGrain treatmentsRotary pressEngineeringHigh pressure

The invention relates to a machine frame (110) for a high-pressure roller press (100) which must be opened for disassembly. The invention states that opposing belts (150, 151) in the machine frame (110) are connected by a side wall (160). Because of the side wall, bridge supports for stabilising the machine frame during disassembly are not required.

Owner:KHD HUMBOLDT WEDAG GMBH

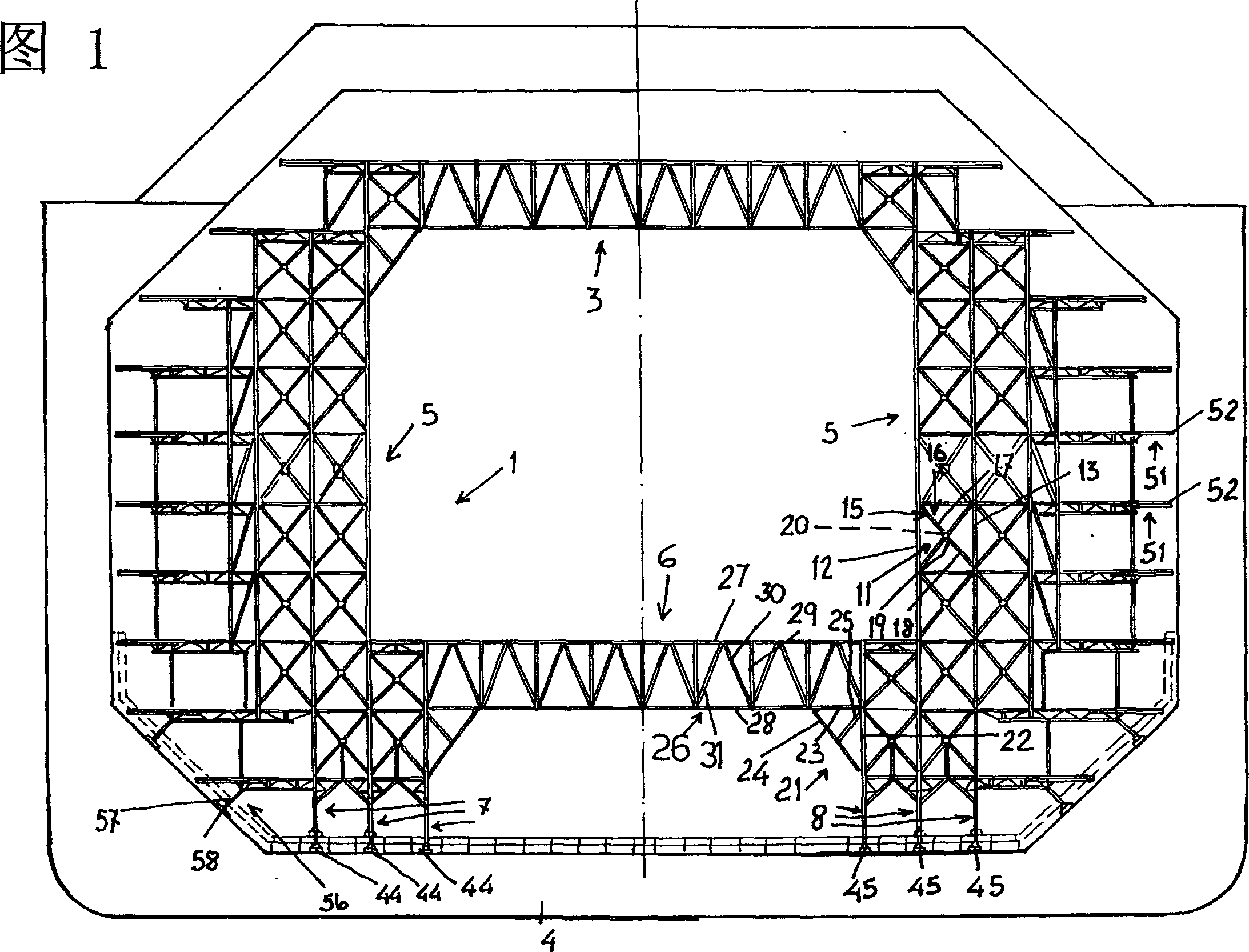

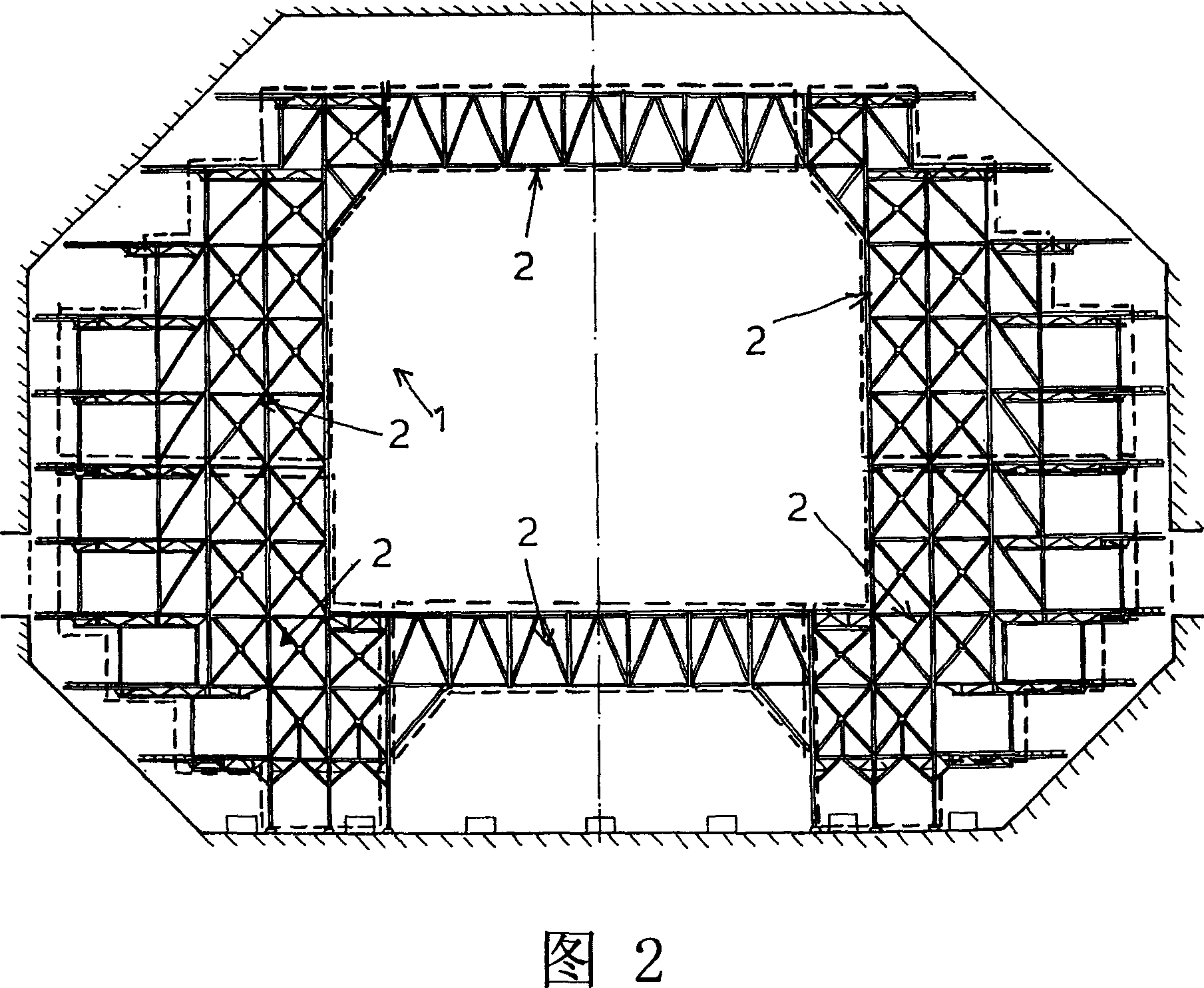

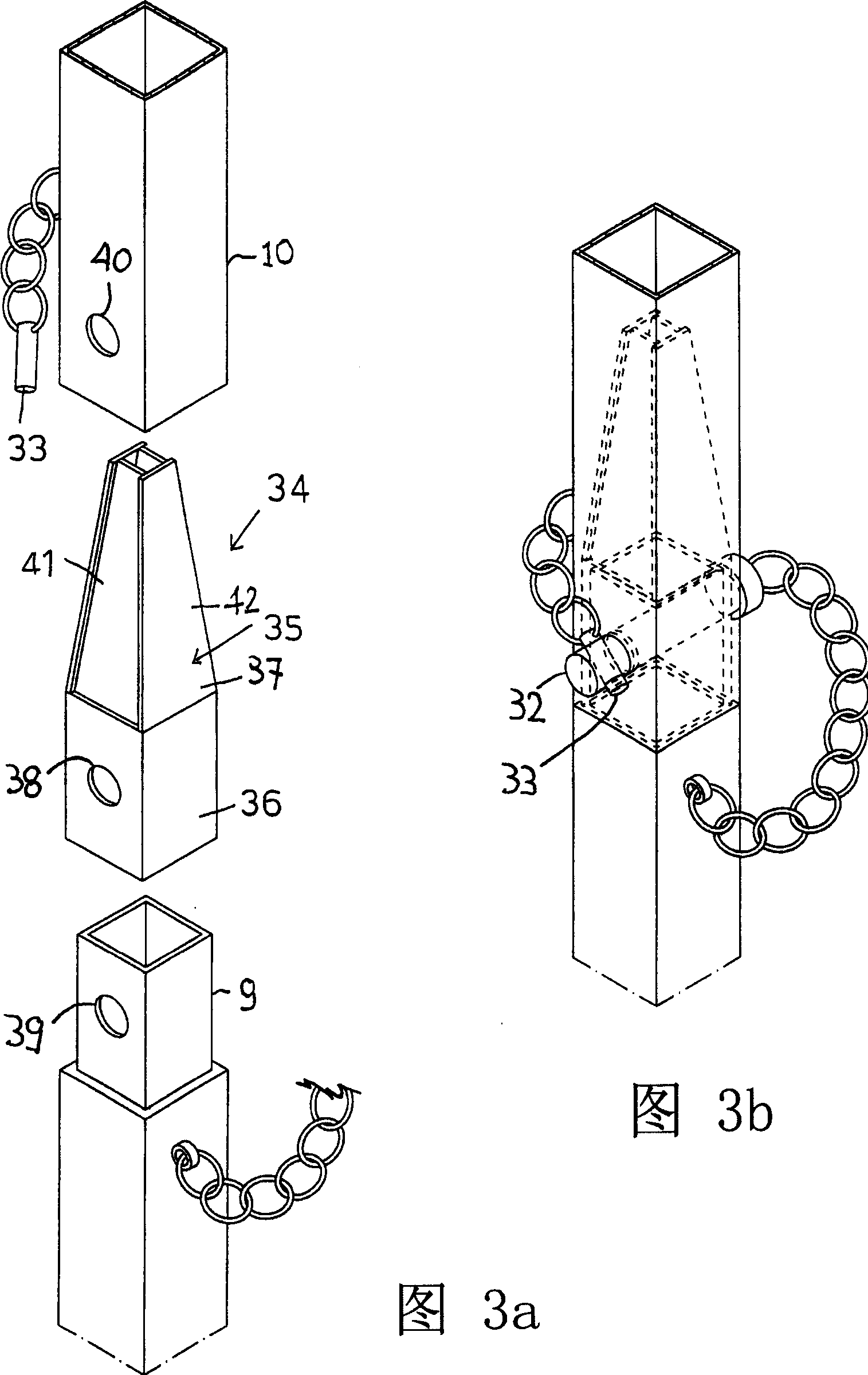

Scaffolding framework mounting process and related scaffolding framework

InactiveCN1922374ASimplify the assembly processSimplify the shipping processTank vesselsDry-dockingFalseworkEngineering

In the process for the assembly of a scaffolding structure for the laying of the coating of the hold of a ship for the transportation of liquefied natural gas, polygonal modules of the structure are assembled in blocks outside of the hold, and then the blocks are assembled together inside the hold.

Owner:马尔切加利亚建材有限公司

Method for optimizing the production sequence

InactiveCN105512953AHigh automatic classification utilizationIncrease staffing needsData processing applicationsVisual presentationIndustrial engineeringRelief printing

A method for optimising the production sequences of a plurality of printing orders assigned to a printing system is provided. When multiple printing orders are assigned to a specific printing system, each printing order on its own can be economically produced on the specific printing system, but economically optimal processing of the entirety of the printing jobs to be processed in a defined time interval is not thereby ensured. To increase the efficiency of the processing of a plurality of printing orders, the printing orders assigned to the printing system are arranged in their order and thus their sequence of processing in an automated manner, such that the printing orders assigned to the printing system can be produced in an optimised manner at least with regard to at least one sorting criterion. The method is applicable for sorting printing orders both for print form variable printing methods, as well as for non-print form variable printing methods and also for sheet-fed and / or reel-fed printing systems.

Owner:MANROLAND WEB SYST

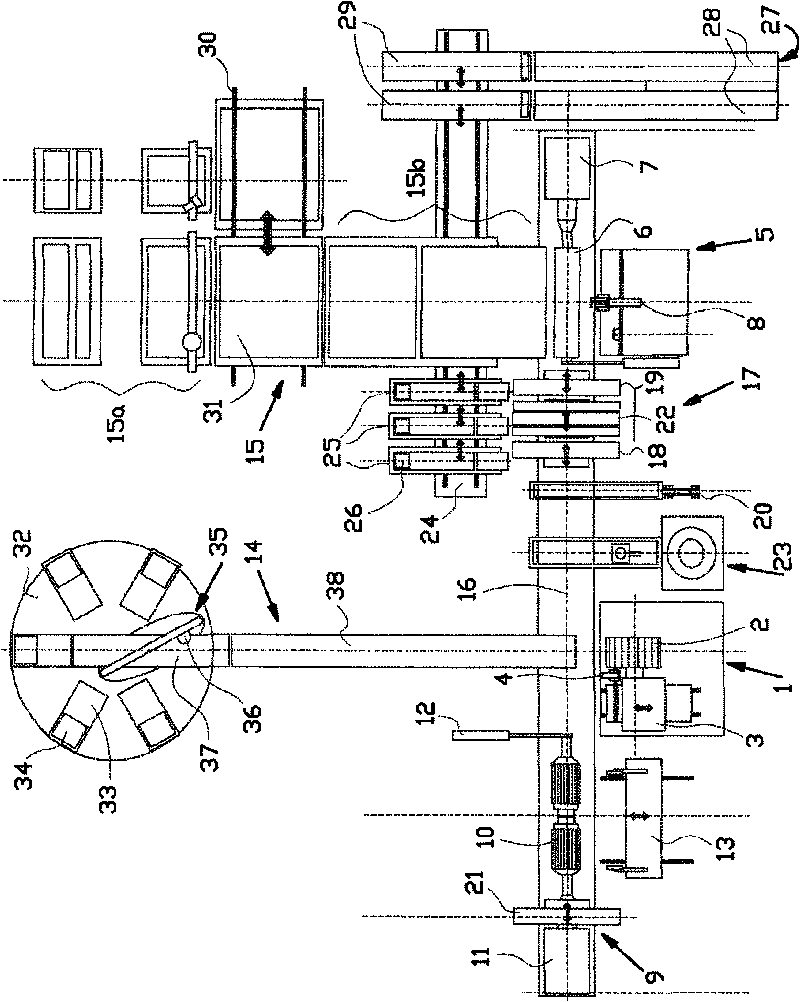

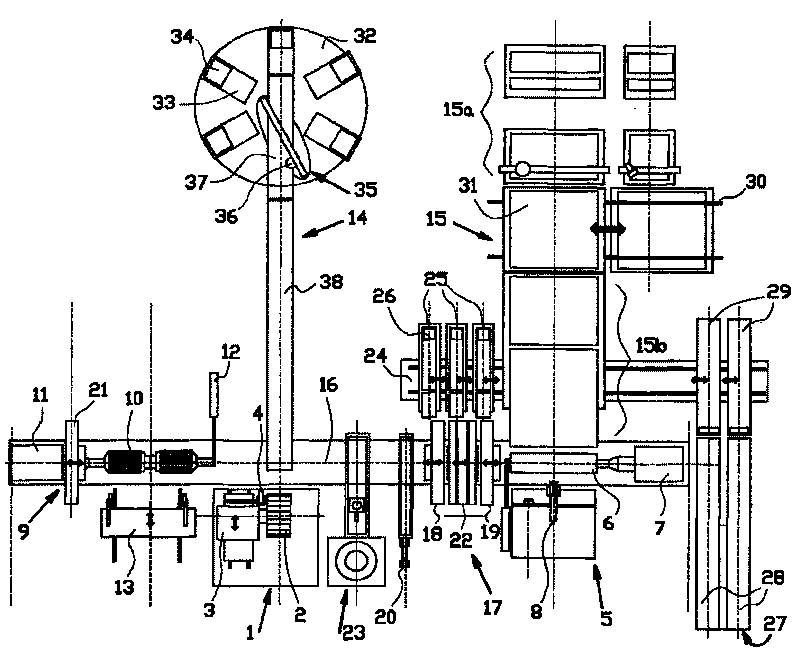

Assembly of units for building an unvulcanised or green tyre for vehicles

Assembly of units for building a vehicle tyre. The assembly has a first unit (1) having a breaker building drum (2), a second unit (5) having a carcass building drum (6), a third unit (9) having a shaping drum (10), a breaker ply supply unit (14) for supplying breaker plies to the breaker building drum (2), a carcass material supply unit (15) for supplying carcass material to the carcass drum (6), a first transportation rail (16) which, considered in vertical direction, is placed below the shaping drum (10) and the carcass building drum (6), a unit (17) for retaining and positioning beads, a first breaker transfer ring (21) and a second carcass transfer ring (22) movably placed on the transportation rail (16). The assembly further comprises a second transportation rail (24) extending spaced apart from and parallel to the first transportation rail (16) and placed adjacent to the carcass building drum (6), a number of arrangement units (25) for arranging rubber material, wound on a roll(26), on the carcass building drum (6), wherein the arrangement units (25) can be moved over the second transportation rail (24).

Owner:VMI HOLLAND BV

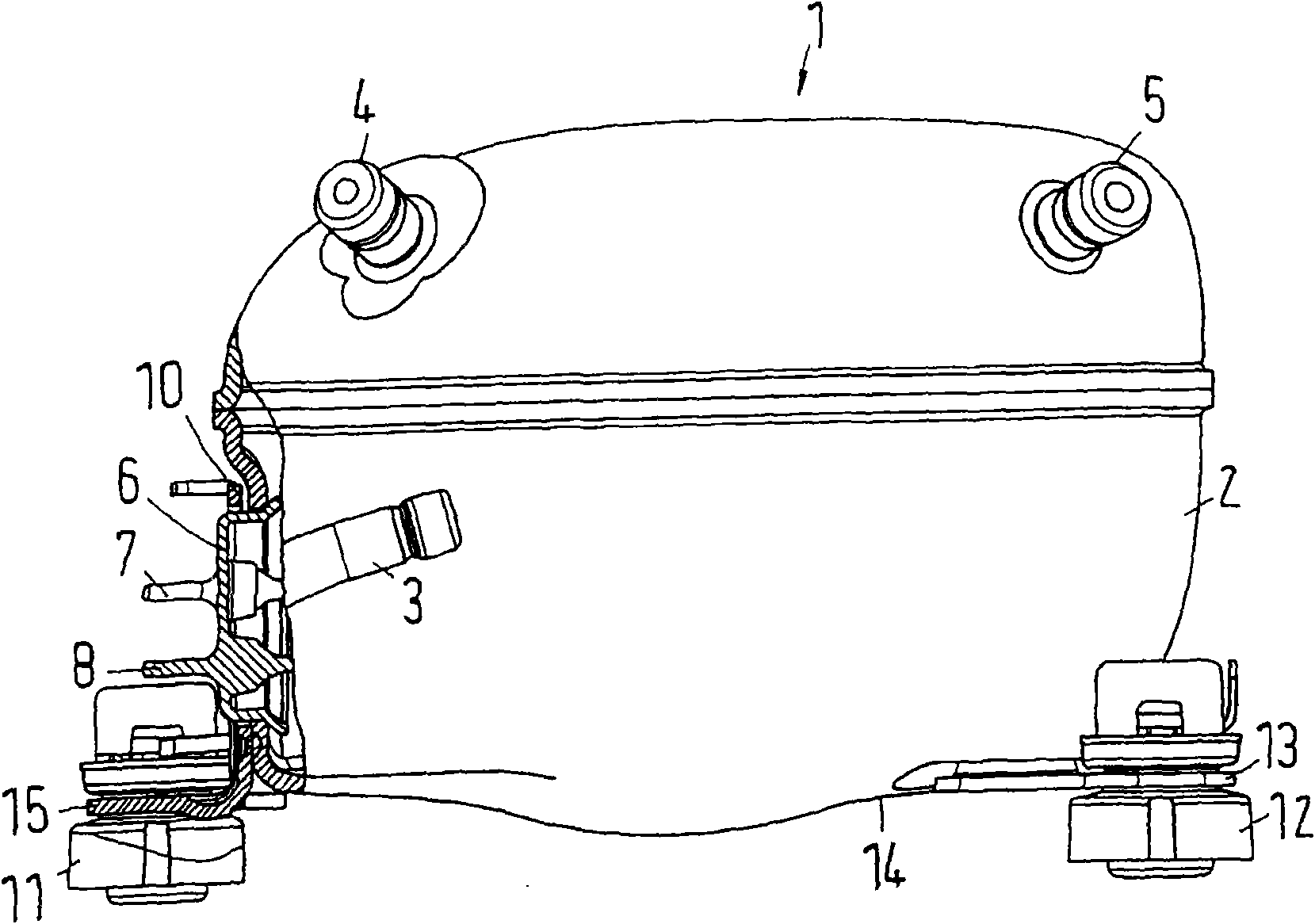

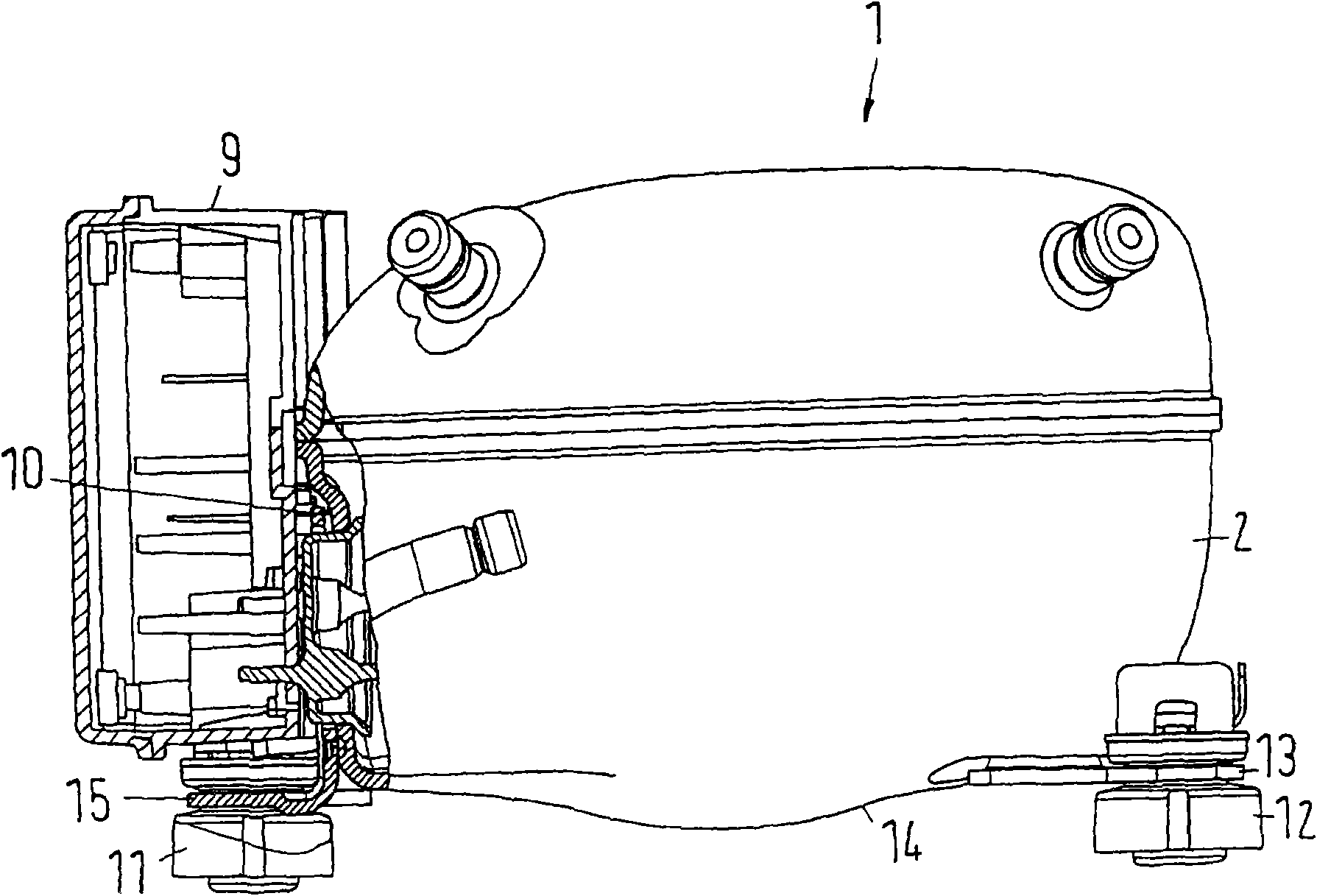

Hermetically enclosed refrigerant compressor

ActiveCN101629564AReduce manufacturing costEffective installationPositive displacement pump componentsPositive-displacement liquid enginesElectricityEngineering

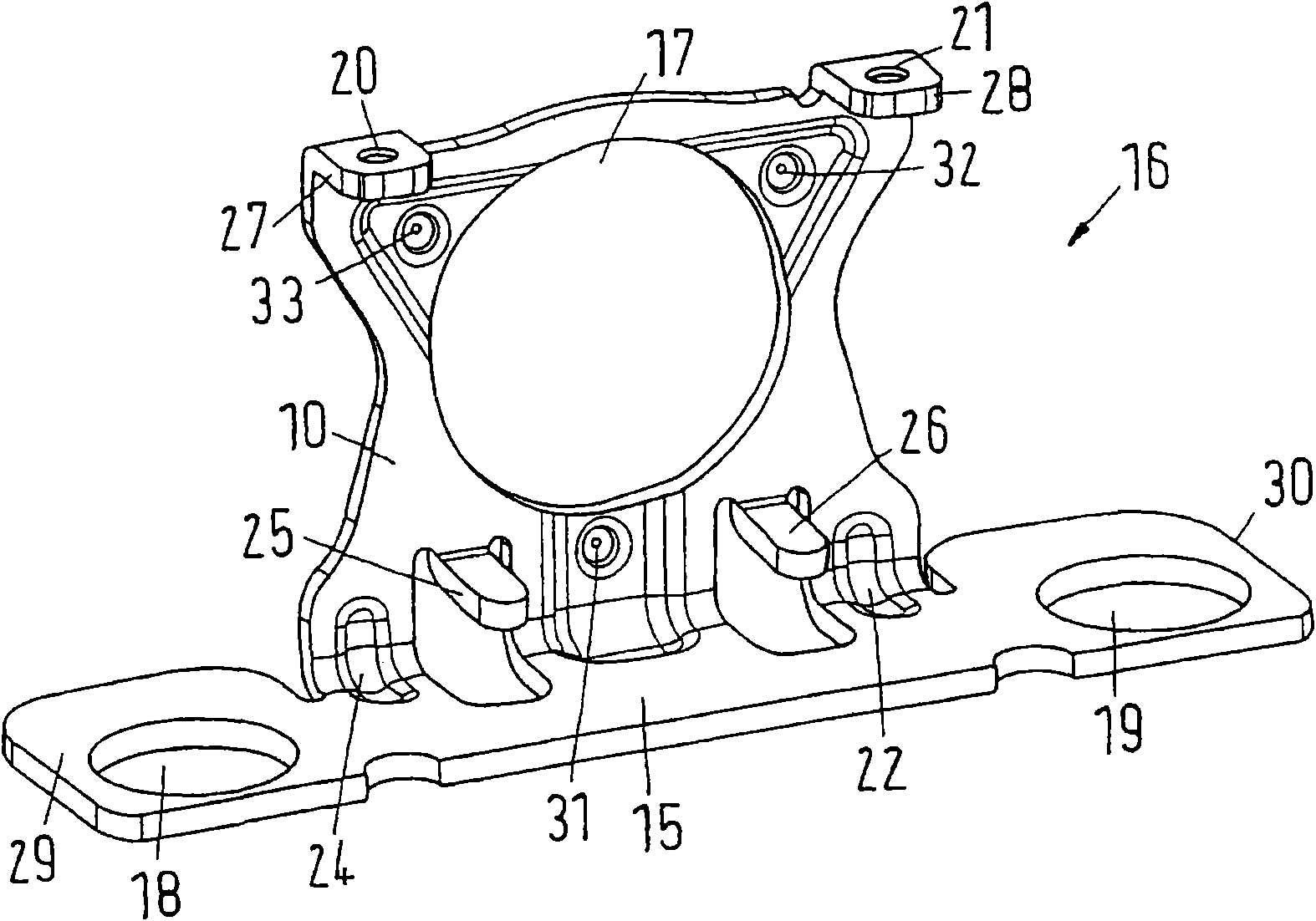

The invention relates to a hermetically enclosed refrigerant compressor with a housing comprising an electrical feed-through, a connection plate (10) arranged outside the housing in the area of the electrical feed-through, and a base plate (15) supporting the bottom of the housing in the gravity direction. The invention attempts to obtain low manufacturing cost. For this purpose, the connection plate (10) and the base plate (15) are made together as one part (16).

Owner:丹佛斯家用压缩机有限责任公司

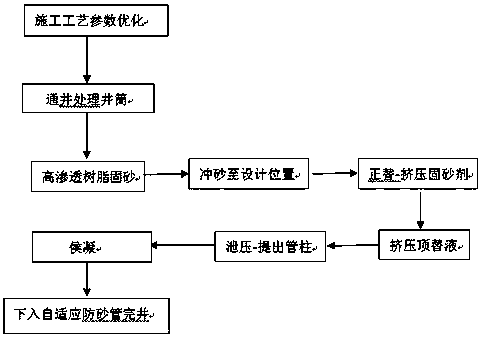

Non-filling self-adapting sand prevention technology method

ActiveCN111577217AIncrease fluid productionReduce mixFluid removalFlushingMining engineeringWellbore

The invention provides a non-filling self-adapting sand prevention technology method. The non-filling self-adapting sand prevention technology method comprises the following steps of step1 according to data including oil reservoir physical properties, geological structures, reservoir sand granularmetric analysis, numerical simulation and the like, performing technology parameter optimizing; step 2, processing a wellhole for drafting; step 3, performing sand fixing with high-infiltration resins: firstly, washing the sand to a position according to design requirements, arranging a construction pipe column according to design requirements, performing preprocessing on the oil layer, then selecting a high-infiltration resin type sand fixing dose, extruding the resin type sand fixing dose and replacement liquid, after pressure is naturally proliferated, slowly raising the construction pipe column for coagulation; and step 4, arranging a self-adapting sand prevention inflation sand preventionpipe column. The non-filling self-adapting sand prevention technology method disclosed by the invention has the main advantages that a filling operation is not needed, so that the construction technology is simplified, the cost is low, and no risk is generated; the quick sand is fixed by the high-infiltration resins, and the fluid naturally passes, so that sand is prevented, and oil is not prevented; and self-adapting classified expanding materials allow sand of which the diameter is less than 40 microns to pass, and preferable sand prevention is really performed through sand passing.

Owner:CHINA PETROCHEMICAL CORP +3

Machining technology of cross-country vehicle steering knuckle

InactiveCN113084469AReduce production cost inputReduce blindnessSteering linkagesNumerical controlLogistics management

The invention relates to a machining technology of a cross-country vehicle steering knuckle, the machining technology is characterized by comprising the following steps of: S1, a main pin hole, a bracket surface, a gear opening surface, a central hole and a branch pin hole of the cross-country vehicle steering knuckle are roughly machined by adopting a first horizontal machining center with an exchangeable workbench; S2, a numerical control turning and milling composite machine tool is adopted for machining all stages of journal machining surfaces, disc surface threads and journal end surfaces at a time; and S3, a second horizontal machining center with an exchangeable workbench is adopted for conducting finish machining on the main pin hole, the bracket surface, the gear opening surface, the central hole and the branch pin hole through journal positioning machined in the step S2. The machining technology has the beneficial effects that the production cost input is low, and the blindness of equipment investment can be reduced through the relatively concentrated technology mode; and logistics links among procedures are greatly simplified, investment is conducted on a production line in batches according to types of production parts and capacity requirements, and investment risks are reduced.

Owner:RUIAN LIANZHONG AUTO PARTS

A filling-free self-adaptive sand control method

ActiveCN111577217BIncrease fluid productionReduce mixFluid removalFlushingSelf adaptiveParticle Size Analyzer

Owner:CHINA PETROCHEMICAL CORP +3

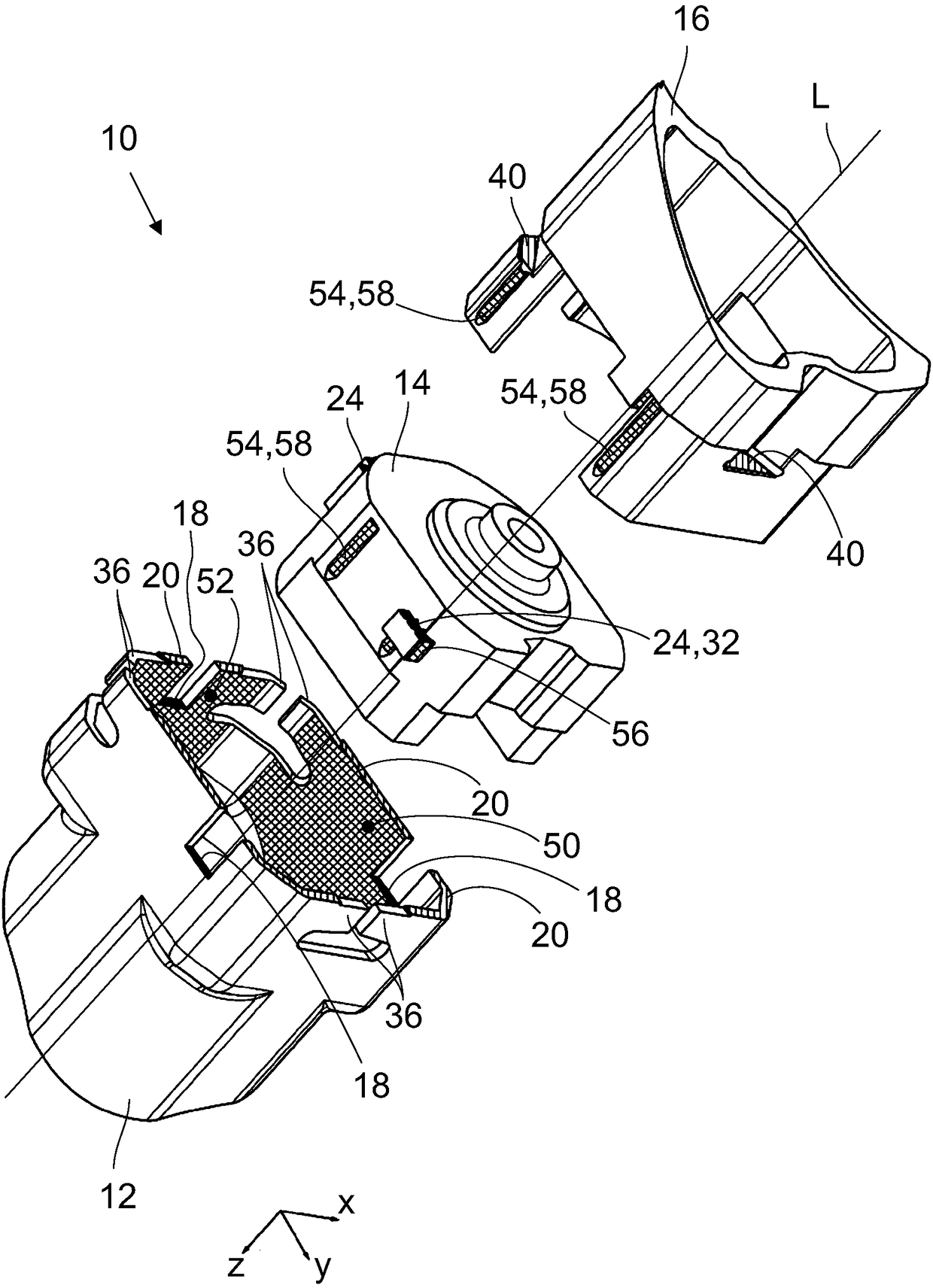

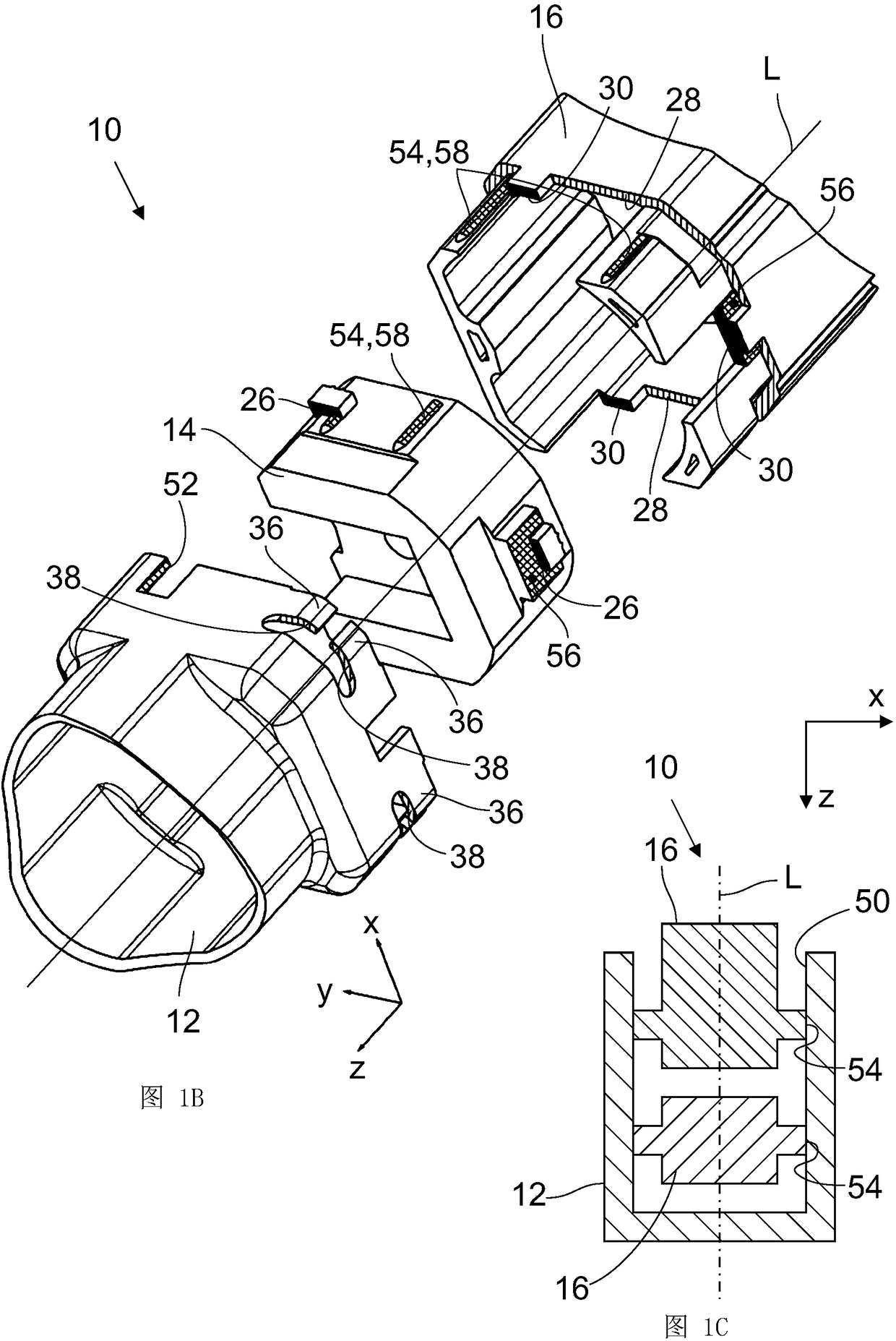

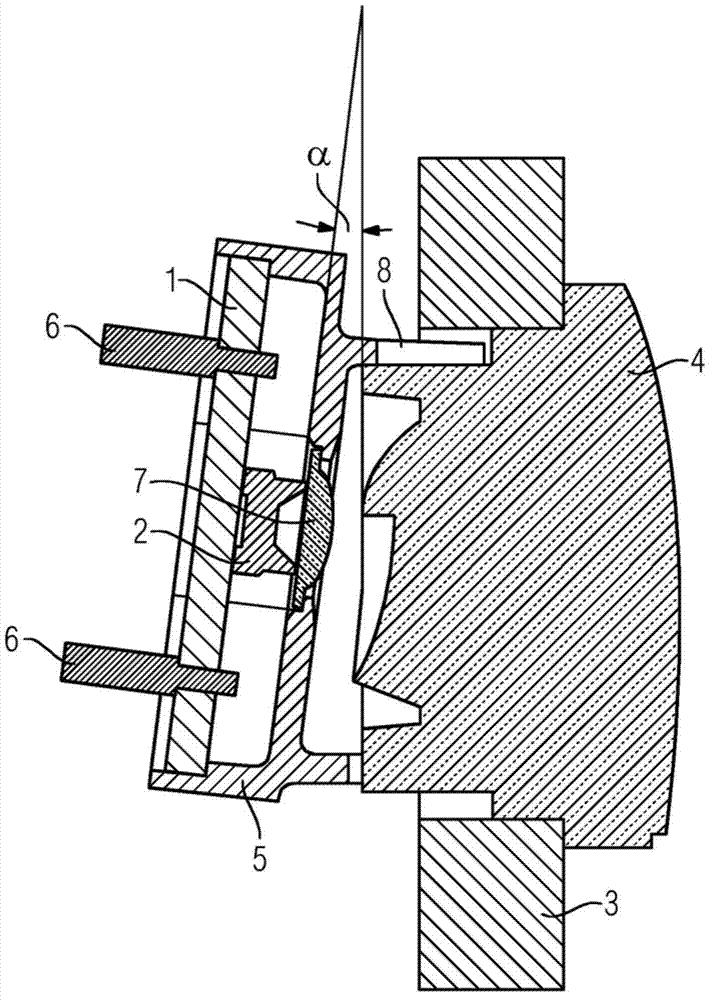

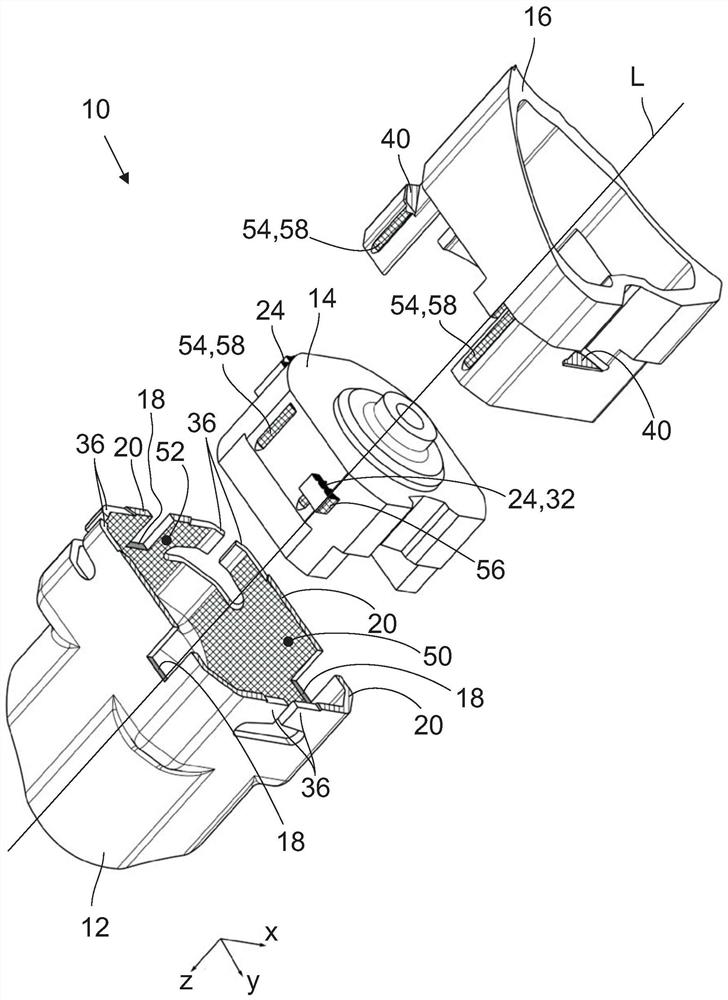

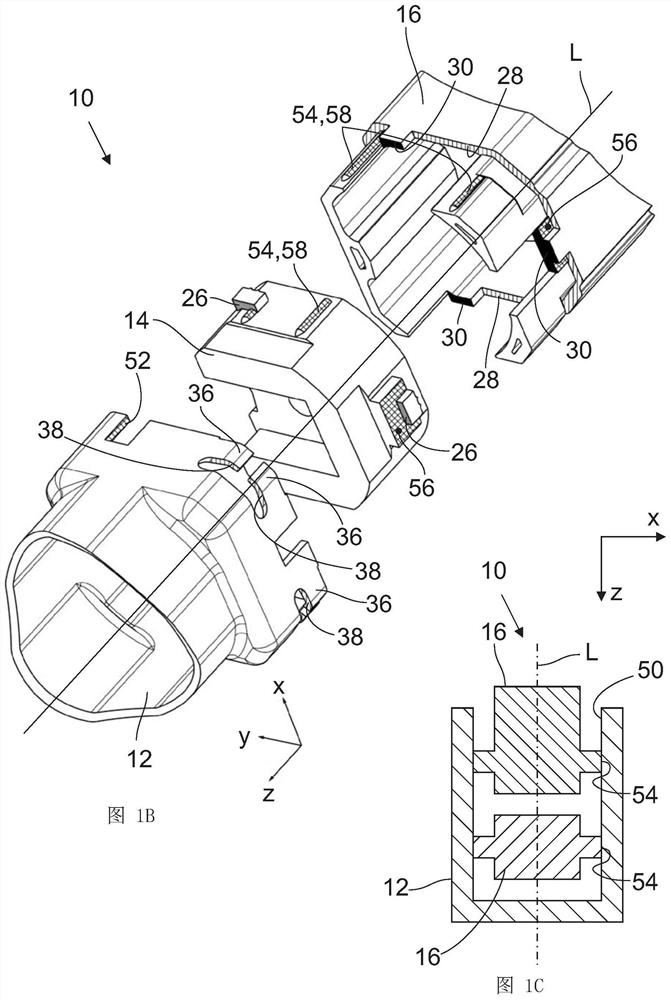

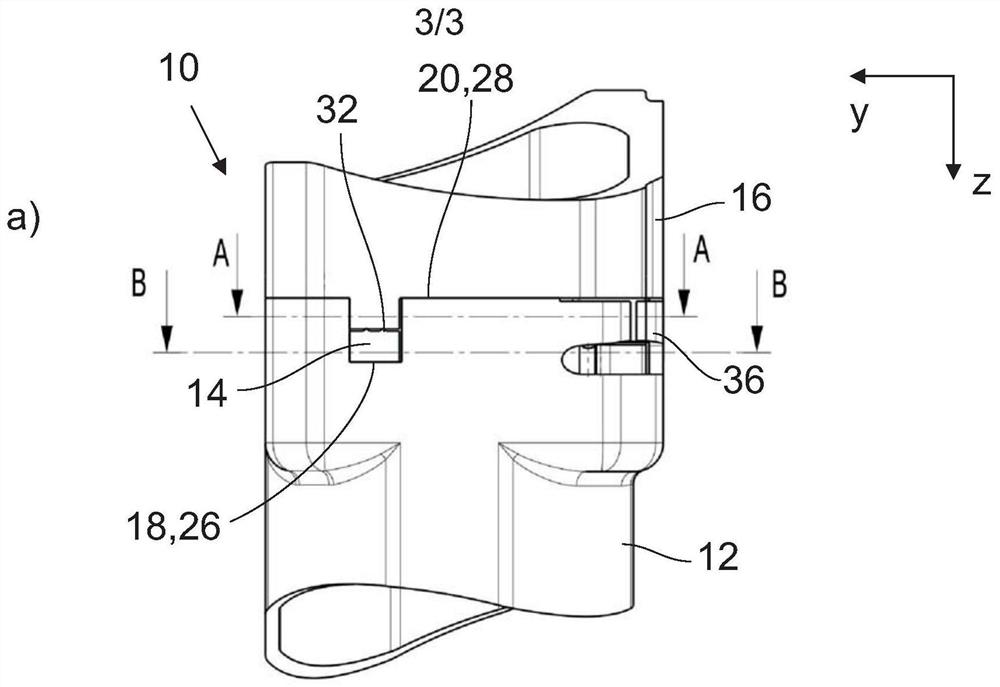

Motor-transmission connection assembly, particularly for use in motor vehicles

ActiveCN108928232AOvercome manufacturing tolerancesReduce modificationRotary current collectorMechanical energy handlingIn vehicleSunroof

The present invention relates to a motor-transmission connection assembly, in particular for use in vehicles, comprising a motor pot (12) for receiving an electric motor, a brush holder (14) for holding brushes of the electric motor, and a transmission housing (16) for receiving a gearbox , wherein the motor pot (12), the brush holder (14) and the transmission housing (16) are plugged into each other for connection, and the motor pot (12) has a plurality of centering surfaces (50,52), whereby the motor pot with respectively one of the centering surfaces (50,52) comes into contact both with thebrush holder (14) as well as with the transmission housing (16), when the motor pot (12), the brush holder (14) and the transmission housing (16) are plugged into one another, and whereby the brush holder (14) and the transmission housing ( 16) are aligned concentrically with the motor pot (12). In addition, the invention relates to a sunroof for a vehicle with such motor-transmission connectionassembly (10) and a vehicle with such motor-transmission connection assembly (10).

Owner:IMS GEAR SE & CO KGAA

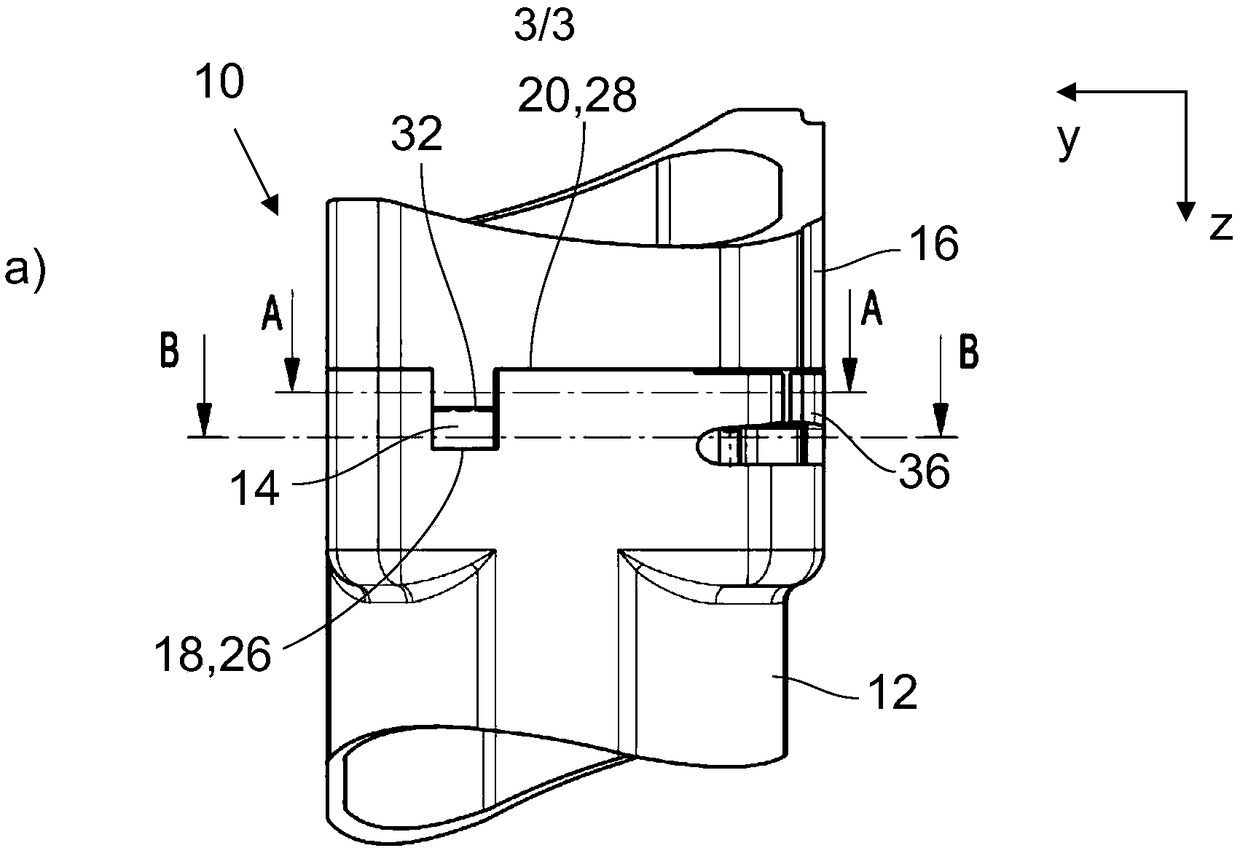

Automatic weight measuring system and method for warp knitting fabrics

ActiveCN108593068ADensity is accurateReduce handlingWeighing apparatus for materials with special property/formEngineeringWeight measure

The invention relates to the field of gray fabric weight measuring equipment, and particularly discloses an automatic weight measuring system and method for warp knitting fabrics. The automatic weightmeasuring system comprises a warping scale, a warping lower computer, a warp knitting lower computer and a management system, wherein the warping scale is used for weighing the weight of pan heads before and after winding; the warping lower computer acquires the number of the pan heads, yarn length and head grain number information; the warp knitting lower computer reads and calculates the lengthof gray fabrics during doffing; the warping scale is connected with the warping lower computer; the warping lower computer and the warp knitting lower computer are connected with the management system; and the management system receives and stores data which are provided by the warping scale, the warp knitting lower computer and the warp knitting lower computer and calculates the weight of everypiece of cloth. The automatic weight measuring system is simple in structure and high in weight calculation accuracy, requires less components, is simple to operate, and occupies little site and space, and human labor capacity is reduced.

Owner:杭州执信智控技术有限公司

Machine frame for high-pressure roller press

ActiveCN103987461AReduce thicknessAvoid threaded holesGrain treatmentsRotary pressEngineeringHigh pressure

The invention relates to a machine frame (110) for a high-pressure roller press (100) which can be opened for disassembly. According to the suggestions of the invention, opposing belts (150, 151) in the machine frame (110) are connected by a side wall (160). Because of the side wall, bridge supports for stabilizing the machine frame during disassembly are not required.

Owner:KHD HUMBOLDT WEDAG GMBH

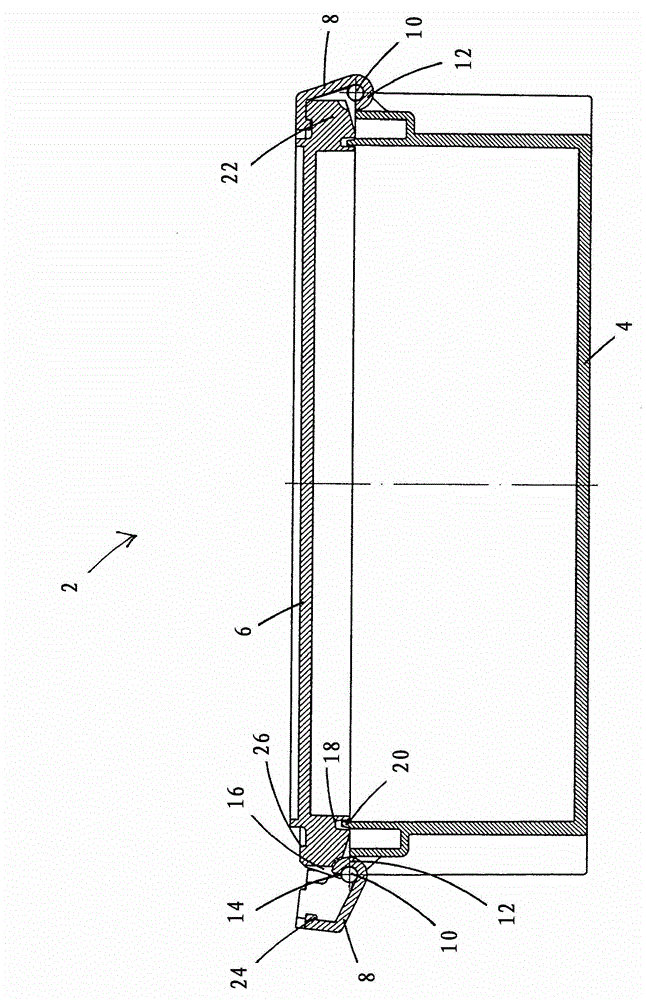

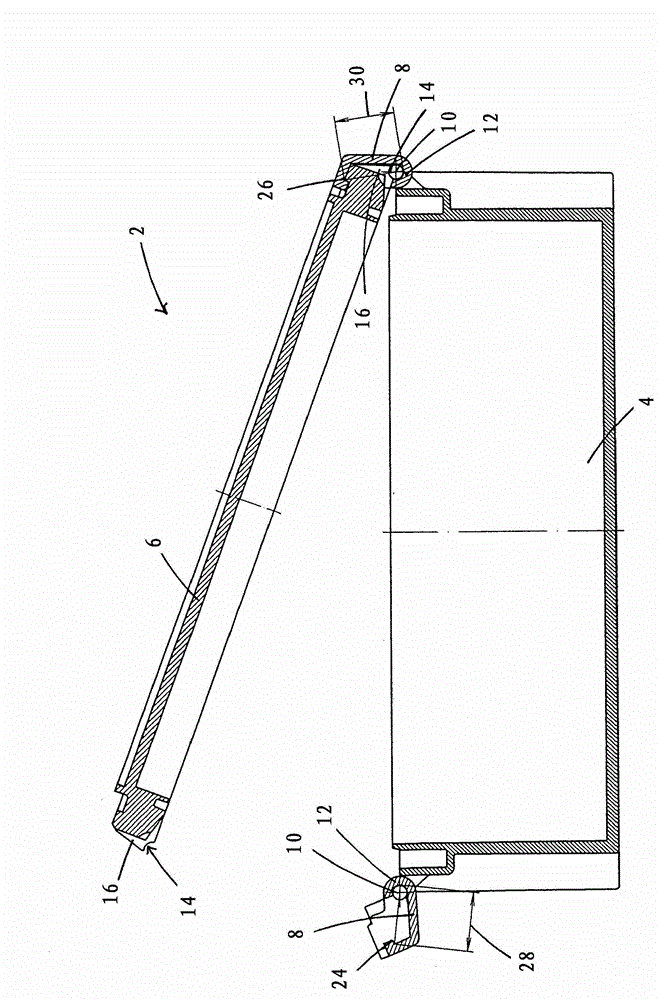

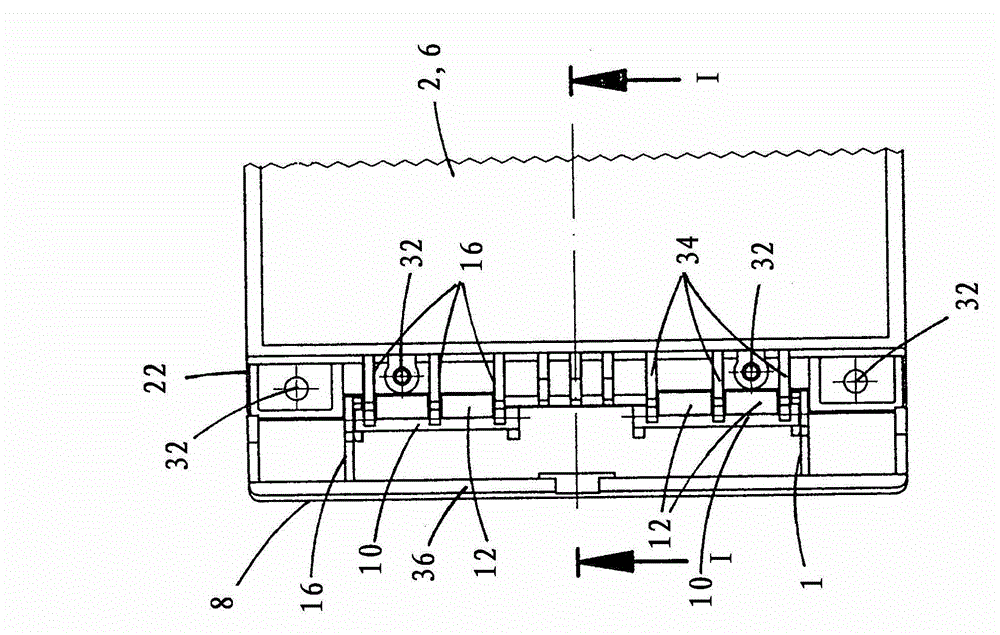

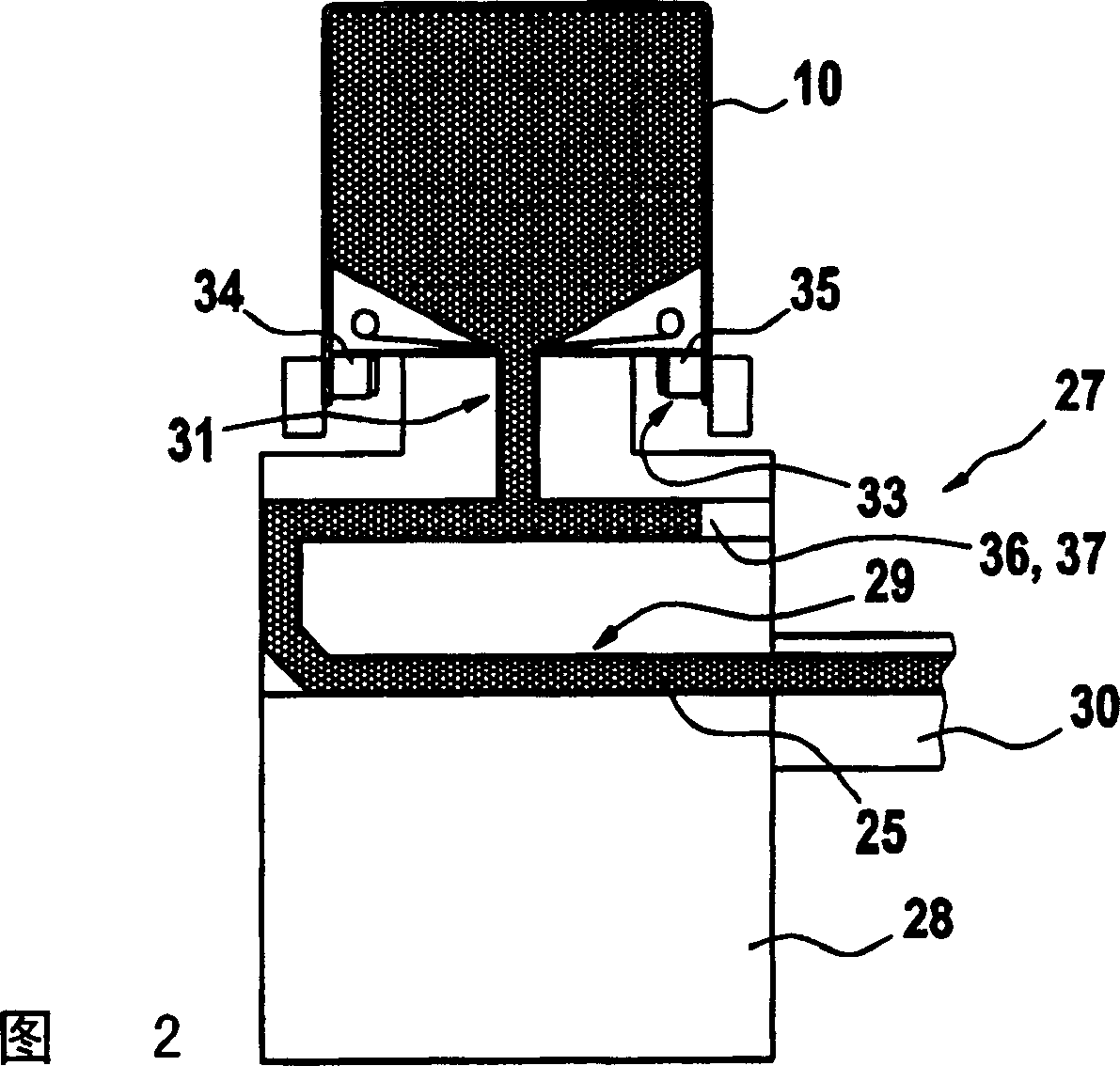

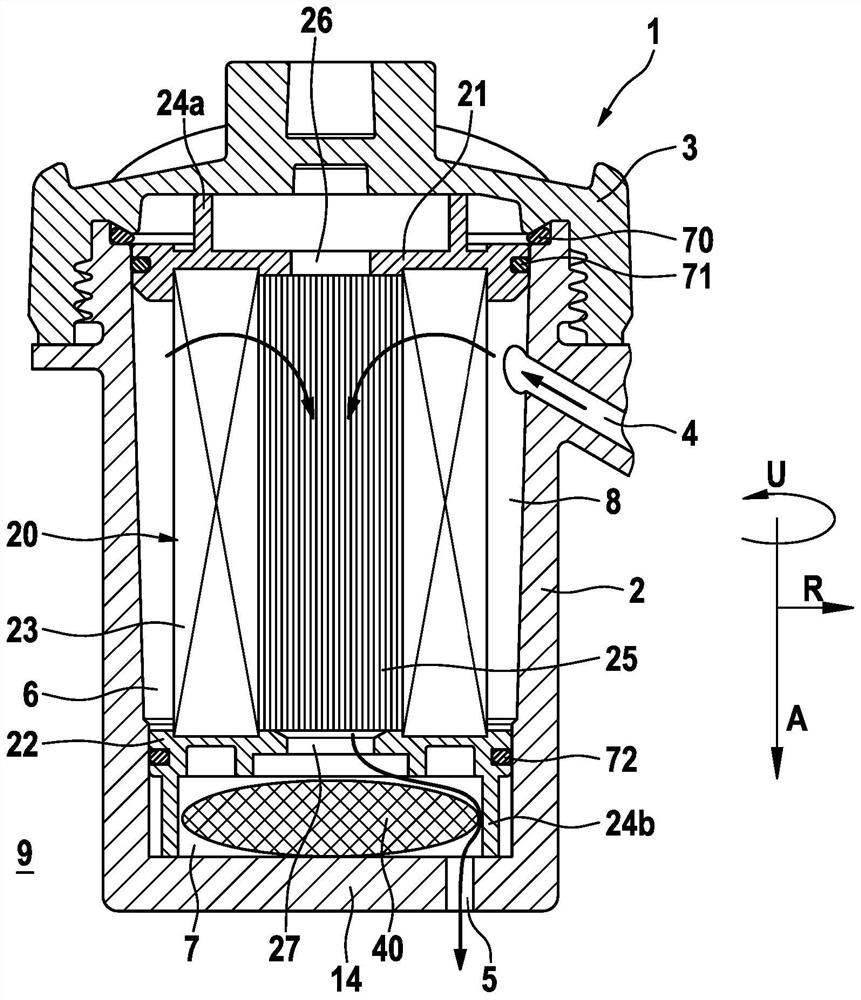

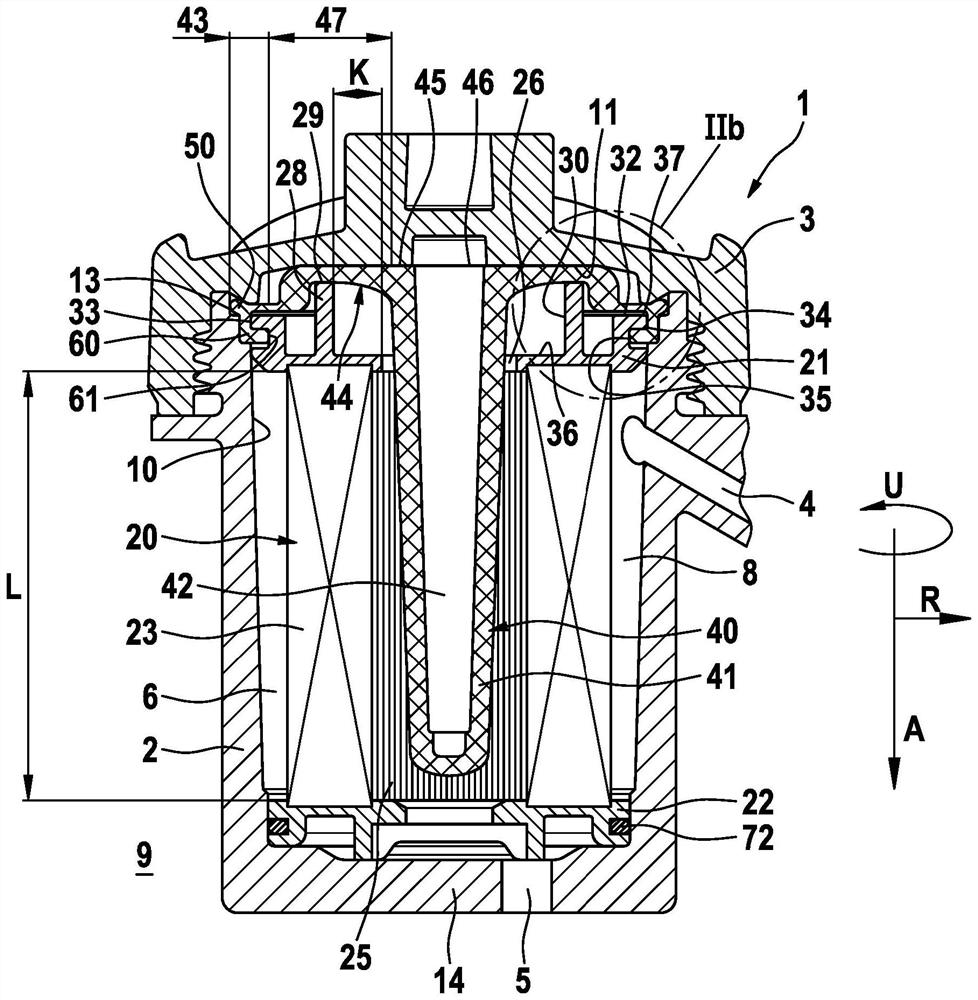

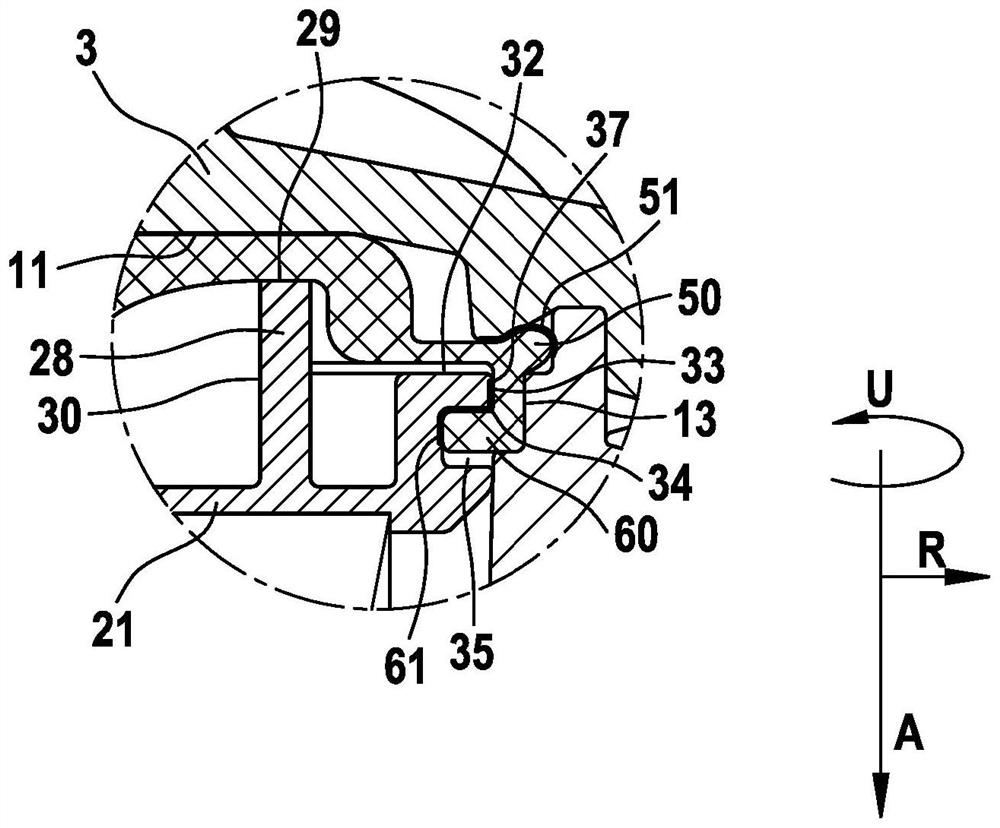

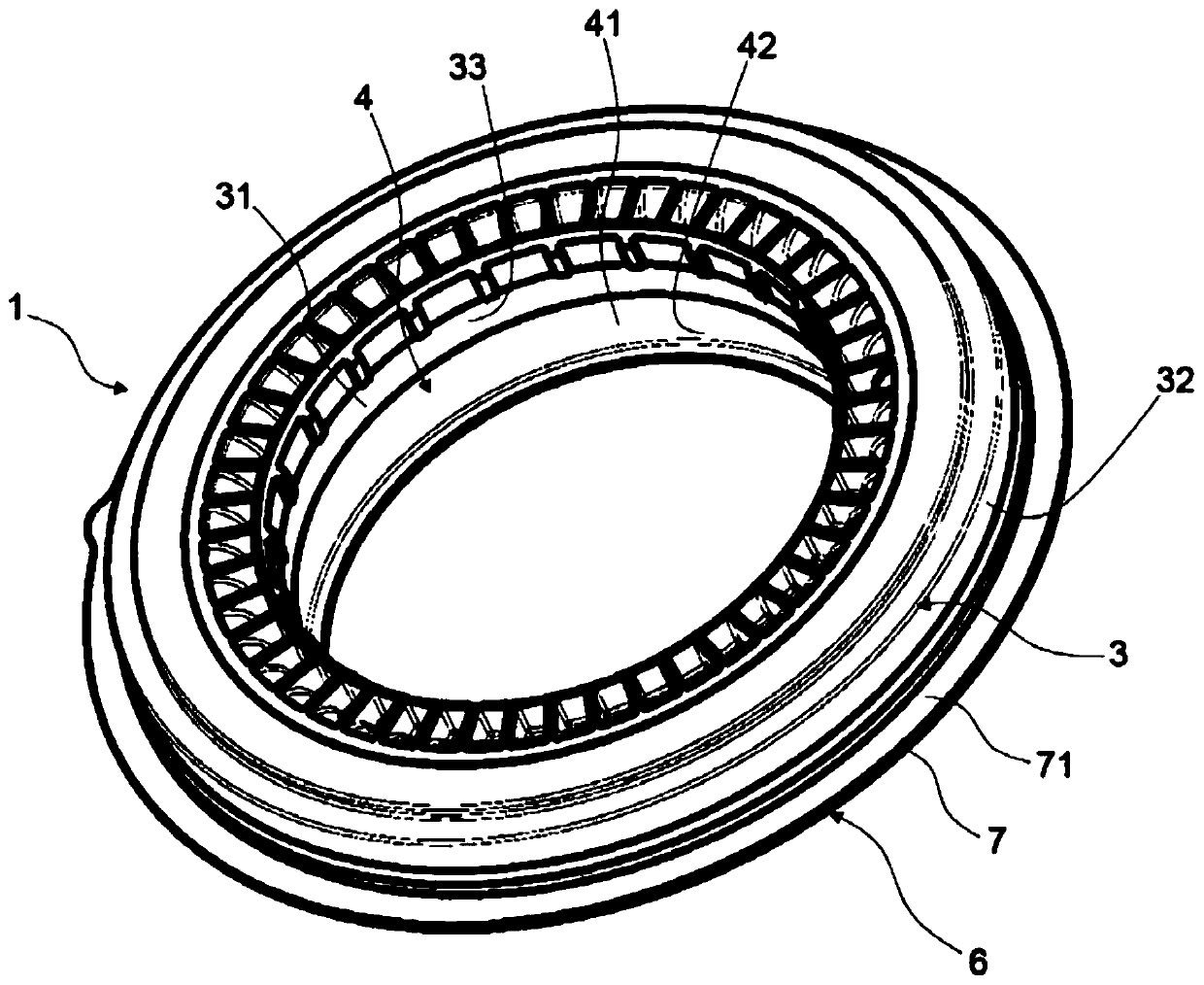

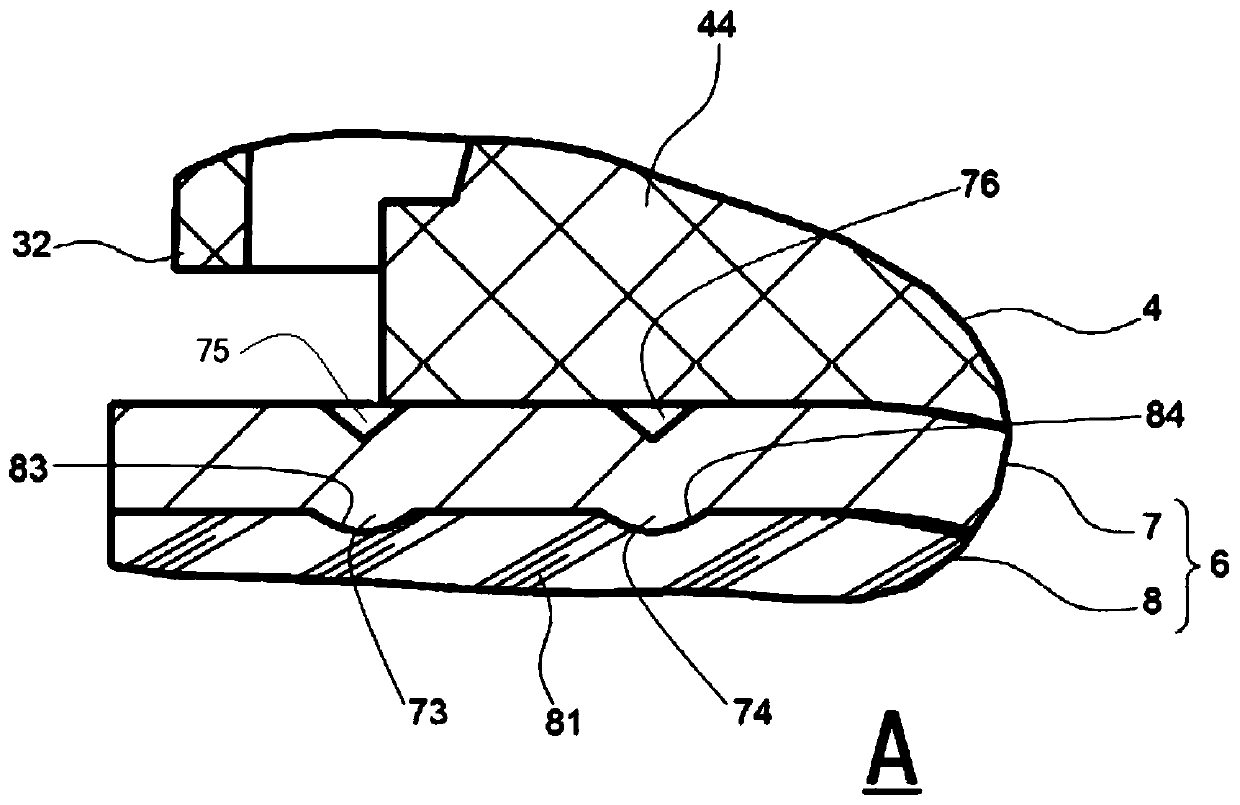

Liquid filter and volume compensation element for liquid filter

PendingCN114746161AExtended optimizationRepeat and fine-tuneMembrane filtersStationary filtering element filtersInterior spaceFilter media

The invention relates to a liquid filter. The invention relates to a liquid filter having: a housing (2) comprising a cover (3); and a liquid inlet (4) and a liquid outlet (5); and a filter insert (20) which is arranged in the interior (6) of the housing (2) and has a first end shield (21) facing the cover (3), a second end shield (22) and a filter medium (23) which is arranged in the axial direction (A) between the two end shields (21, 22), the filter insert (20) separating the clean side (7) from the original side (8). Furthermore, the liquid filter has a volume compensation element (40) comprising an elastically reversibly compressible central body (41) having a central body interior (42), the central body interior (42) enclosing the initial volume in an uncompressed state and enclosing the final volume in a compressed state, the volume difference between the final volume and the initial volume corresponds to at least 35% of the maximum volume change of the liquid in the liquid filter (1) at normal pressure in a temperature range between + 90 DEG C and-40 DEG C. Here, the volume compensation element (40) has a first sealing region (50) surrounding the central body (41), the first sealing region (50) being designed to interact with the housing (2) and the cover part (2) in the fully assembled state of the liquid filter (1) such that the interior (6) of the housing is sealed in a fluid-tight manner from the exterior space (9) of the liquid filter (1). Here, the volume compensation element (40) has a second sealing region (60) surrounding the central body (41), the second sealing region (60) being designed to prevent a fluid short circuit between the clean side (7) and the original side (8).

Owner:ROBERT BOSCH GMBH

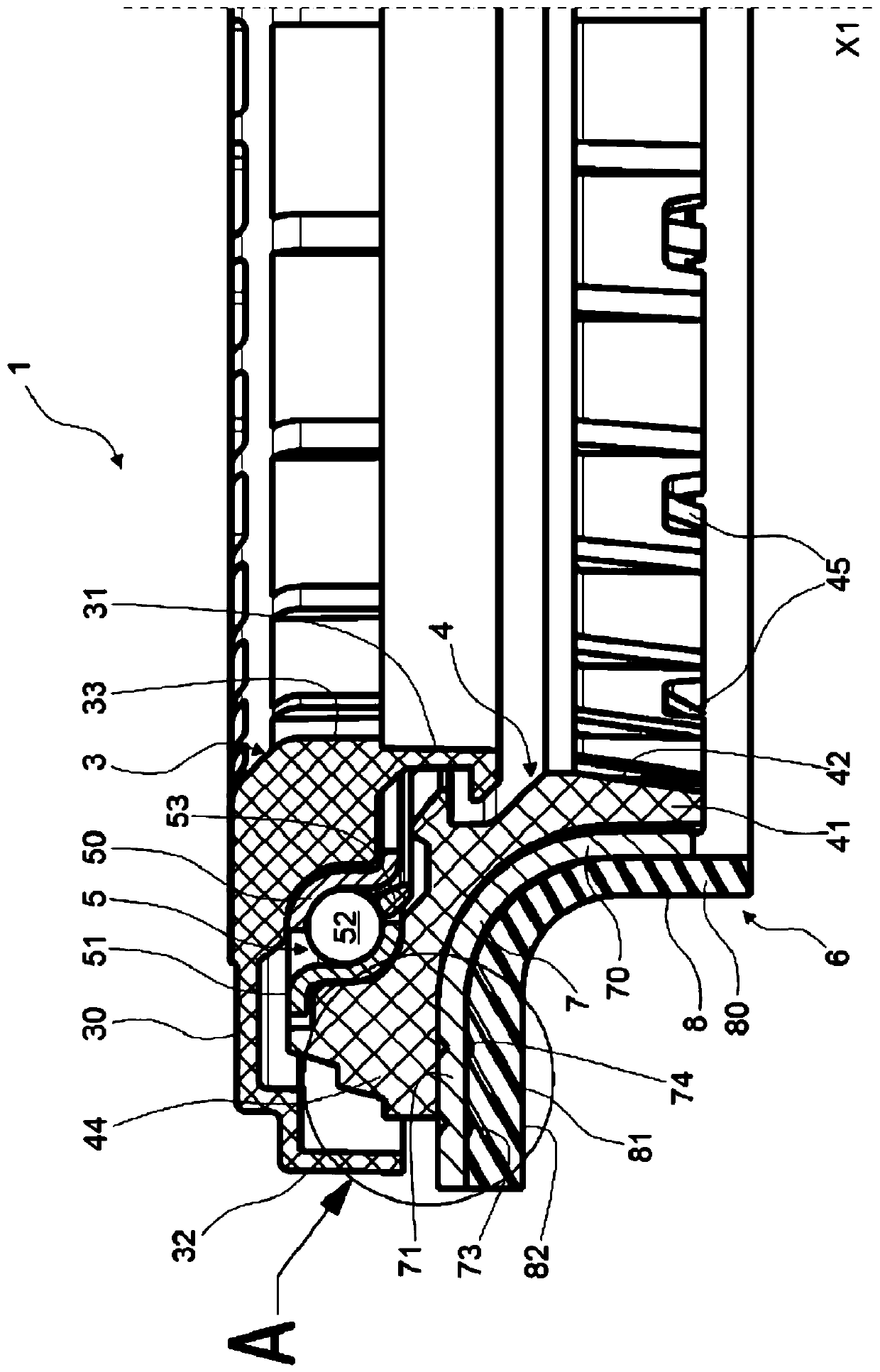

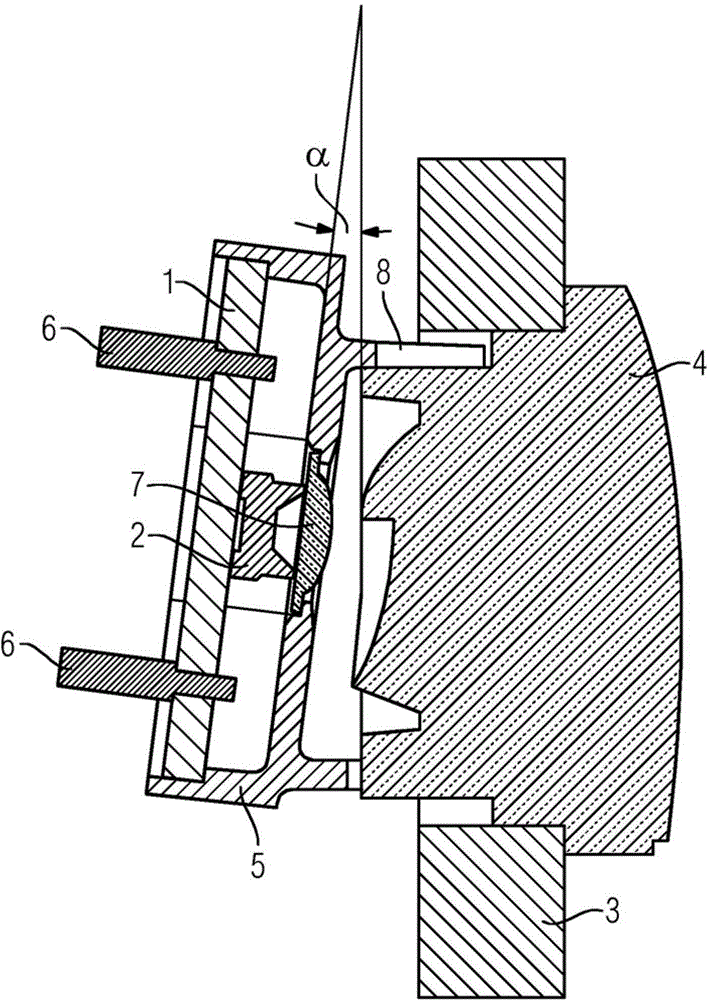

Suspension thrust bearing unit

ActiveCN110360220AAvoid displacementGuaranteed positionRolling contact bearingsResilient suspensionsRolling-element bearingThrust bearing

The invention relates to a suspension thrust bearing unit (1) for use in an automotive suspension assembly having an upper annular cap and a lower annular cap (4) rotatable with respect to the upper annular cap (3), the upper annular cap and the lower annular cap delimiting together an annular chamber that houses a rolling bearing (5). The lower annular cap comprises a subassembly (6) for dampingvibrations and distributing stress and is provided with a lower support surface (82) that axially supports an upper end of a suspension spring. The subassembly includes an annular stiffening cup (7) made from a metal material and mounted to the lower cap, and an annular damping device (8) made from a resilient material and mounted to the stiffening cup. The stiffening cup having at least one protruding portion (73, 74) formed by stamping and that extends towards the damping device, the damping device being locally deformed by the protruding portion and forming a recess (83, 84) to receive theprotruding portion (73, 74).

Owner:AB SKF

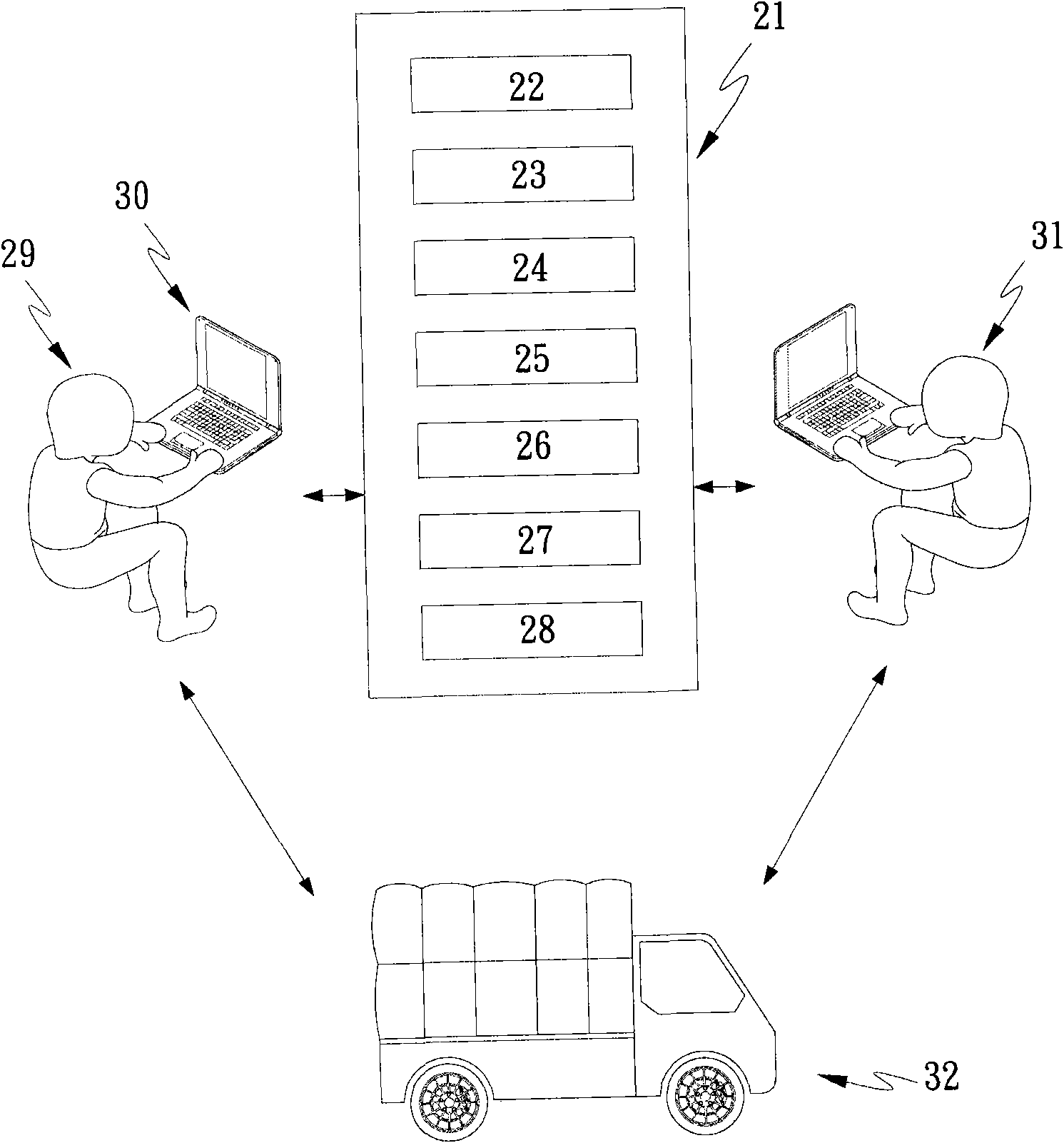

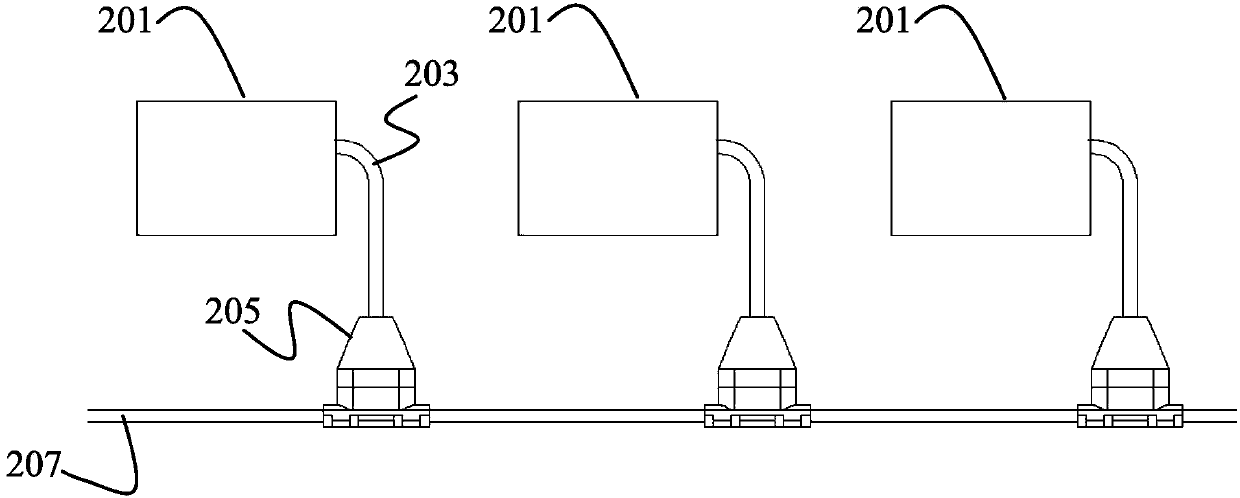

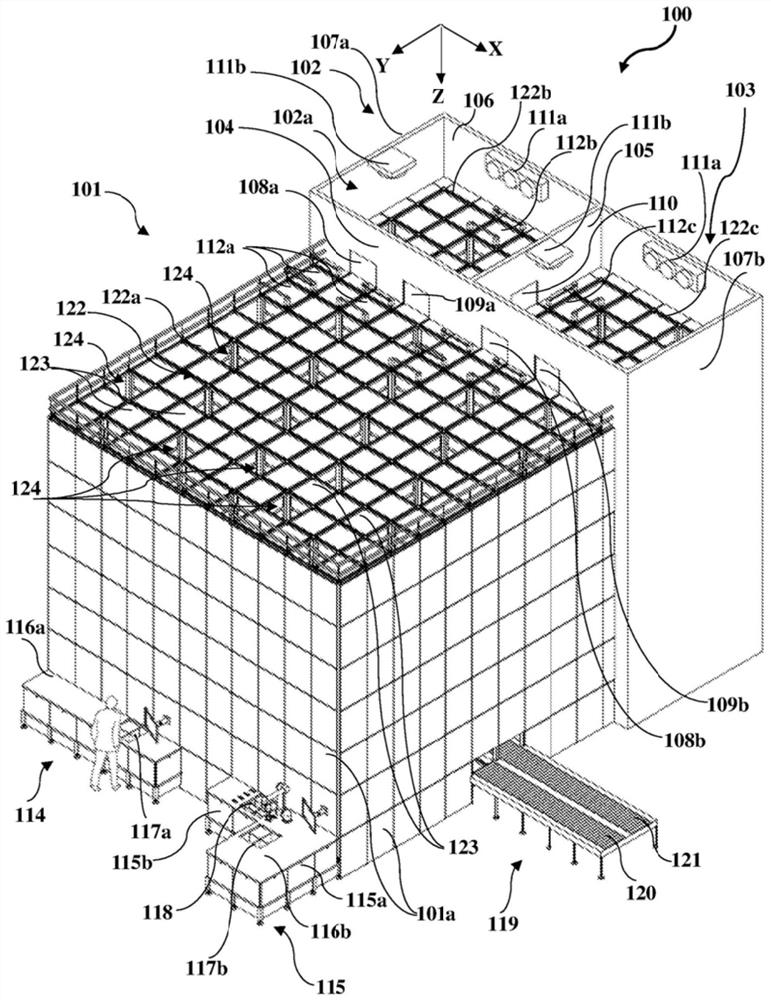

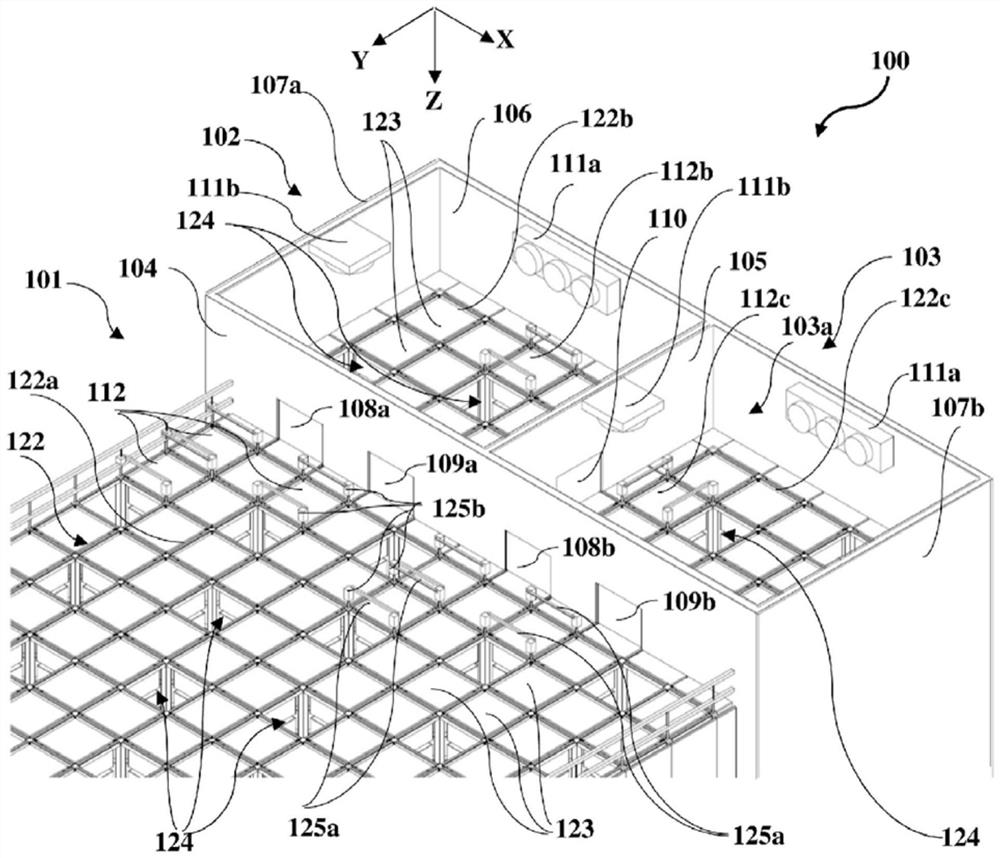

Multi-area automatic warehousing system

PendingCN114269663AEasy to transportSimplify logisticsLighting and heating apparatusStationary refrigeration devicesMemory cellTrackway

A multi-zone automated storage system (ASRS) and a method for controlling the operation of a machine storage vehicle (RSRV) in the system are provided. The multi-zone ASRS includes first and second memory zones separated by at least one resistive wall, and includes first and second groups of memory locations for receiving memory cells. The multi-zone ASRS includes one or more entrances that open resistance walls between the storage zones and at least one track structure. The track structure comprises a first track area, a second track area and one or more connecting track sections, the first track area and the second track area are located in the first storage area and the second storage area respectively, and the connecting track sections are connected with the first track area and the second track area through the inlets. The RSRV stores and retrieves the storage units at the storage locations and travels over the first and second track zones through the connecting track segments to enter and exit first and second groups of the storage locations from the first and second track zones, respectively.

Owner:ATTABOTICS INC

Symbol indicator

InactiveCN102770896AAvoid security impactReduce in quantityIlluminated signsIdentification meansDisplay deviceEngineering

The invention relates to a symbol indicator, in particular for rail-bound traffic routes, comprising LED modules (1) for the pixelated far and near field representation of the symbol, and optical elements which are associated with the LED modules (1) which are arranged on a front plate (3). The aim of the invention is to produce different symbols using only a few optical and mechanical elements and to effectively protect against incident extraneous light on said indicator, such that the LED modules (1) respectively comprise an LED (2) and that the optical elements are embodied as collimator lenses (4) having a first spherical surface for the far field representation of the indicator and a second spherical surface for the near field representation of the indicator. The entire surface of the front plate (3) is provided with collimator lenses (4) and symbol-specific required pixels are produced by the LED modules (1).

Owner:SIEMENS AG

Rotary wheel pistol

InactiveCN101169314BMake up for deficienciesQuick compositionPistolsEngineeringStructural engineering

The invention discloses a rotating wheel handgun, which relates to the field of light weapon. The bulldog of the prior art has the disadvantages of complicated structure, big volume and slow loading speed, and the rotating wheel just can be put out from the lift side of the gun body and the gap between the rotating wheel and the gun barrel can not be sealed so that the aiming tool is inconvenient to aim. An upper machine box of the invention is provided with an automatic shell throwing mechanism inside which is linked with the trigger; a screw hole of the gun body is screwed with a chest closing device inside; the cross sections of the front and the rear posts symmetrically and mutually incline to form a certain angle; the points of the two posts are arranged on the central line of the gun barrel. A spring bullet clip is connected with 6 bullet hoops at the elastic bent bullet clip with two separable ends so as to use the common handgun bullet without bottom edge. The invention has the advantages of simple structure, compact distribution, automatic shell throwing, rapid bullet loading, sealing the bullet chest, unique aiming device and completely symmetric structure. The rotating wheel handgun of the invention can be conveniently operated by the left hand and the right hand.

Owner:太原阿瑞斯精密机械科技有限公司

An engine-transmission connection assembly

ActiveCN108928232BOvercome manufacturing tolerancesPrecise layoutRotary current collectorMechanical energy handlingNacelleBrush

The invention relates to an engine-transmission connection assembly, especially for use in a vehicle, comprising: an engine compartment (12) for housing an electric motor; a brush holder (14) for holding the brushes of said electric motor; and a transmission a housing (16) for accommodating a transmission, whereby the engine compartment (12), the brush holder (14) and the transmission housing (16) can be inserted into each other for connection, and the engine compartment (12) has a plurality of centering surfaces (50, 52), whereby when the engine compartment (12), the brush holder (14) and the transmission housing (16) are inserted into each other, the The nacelle (12) comes into contact with the brush holder (14) and the transmission housing (16) using a respective one of the centering surfaces (50, 52), whereby the brush holder (14 ) and the transmission housing (16) are oriented concentrically with the nacelle (12). The invention also relates to a sunroof for a vehicle having such an engine-transmission connection assembly (10) and a vehicle having such an engine-transmission connection assembly (10).

Owner:IMS GEAR SE & CO KGAA

symbol display

InactiveCN102770896BAvoid security impactReduce in quantityIlluminated signsIdentification meansDisplay deviceEngineering

The invention relates to a symbol indicator, in particular for rail-bound traffic routes, comprising LED modules (1) for the pixelated far and near field representation of the symbol, and optical elements which are associated with the LED modules (1) which are arranged on a front plate (3). The aim of the invention is to produce different symbols using only a few optical and mechanical elements and to effectively protect against incident extraneous light on said indicator, such that the LED modules (1) respectively comprise an LED (2) and that the optical elements are embodied as collimator lenses (4) having a first spherical surface for the far field representation of the indicator and a second spherical surface for the near field representation of the indicator. The entire surface of the front plate (3) is provided with collimator lenses (4) and symbol-specific required pixels are produced by the LED modules (1).

Owner:SIEMENS AG

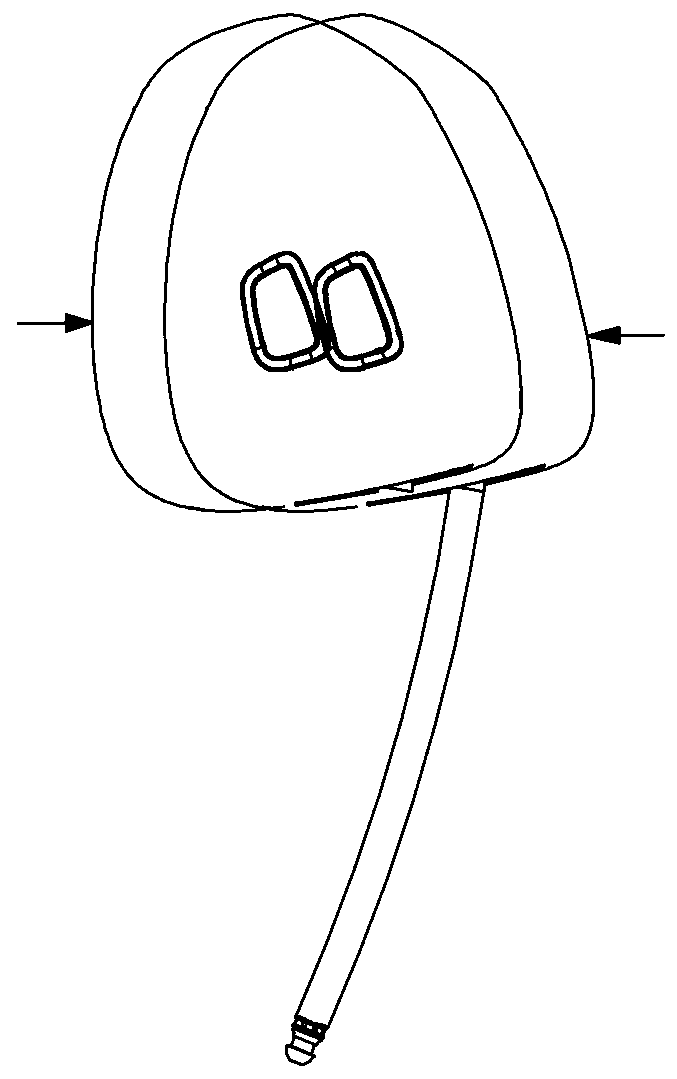

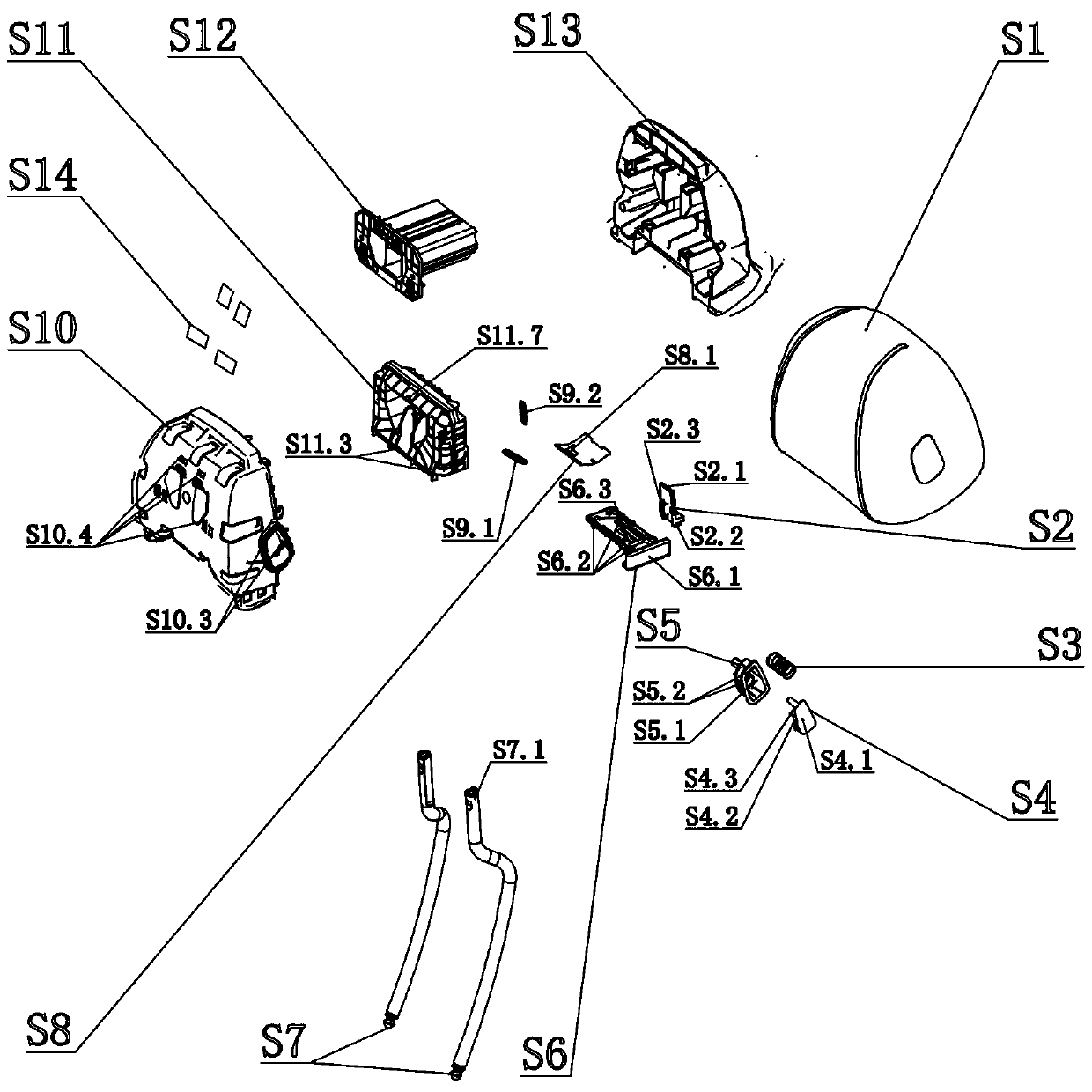

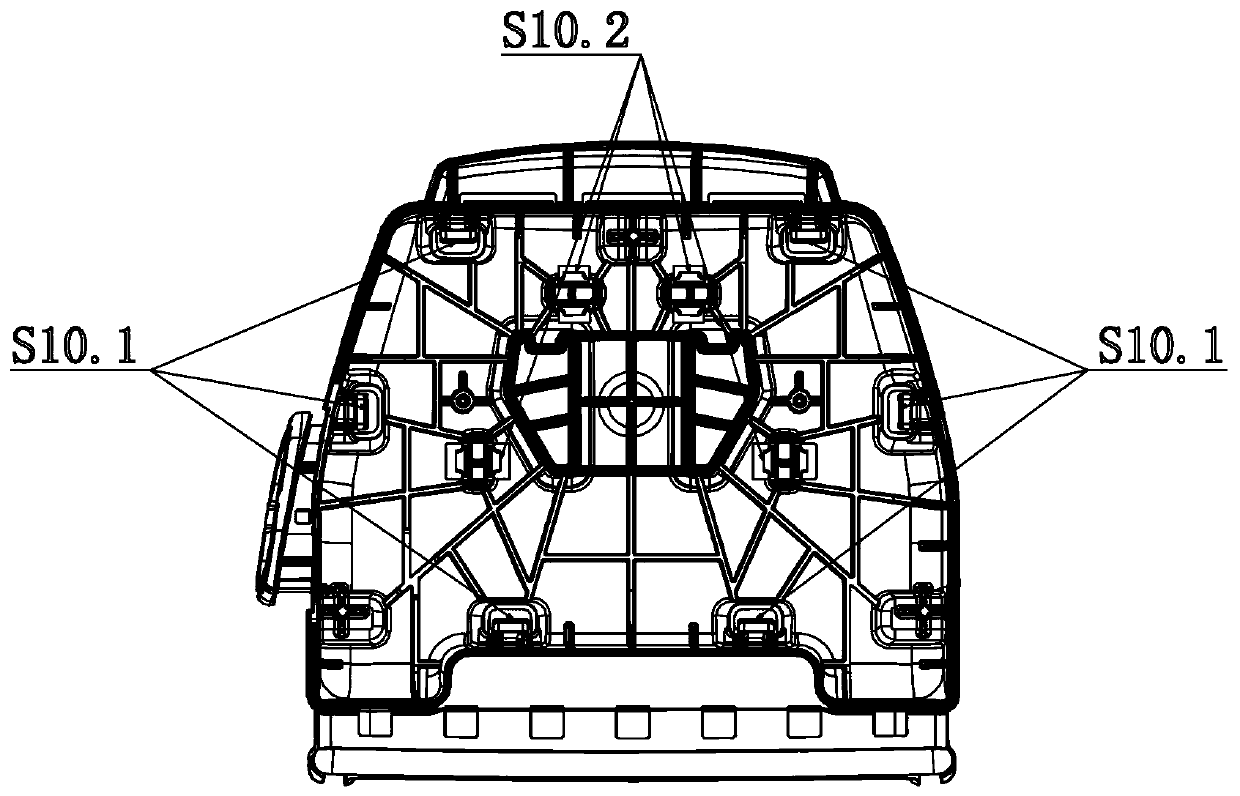

Novel multifunctional automobile seat headrest wrapped by polyurethane through injection molding

The invention relates to a novel multifunctional automobile seat headrest wrapped by polyurethane through injection molding. A headrest body is mainly formed by buckling a front housing and a rear housing. A carrier piece and a sliding piece are arranged in a cavity formed by buckling the front housing and the rear housing. The upper end of a headrest rod is fixedly connected with the carrier piece, the buckled front housing and rear housing are connected with the sliding piece, and the sliding piece slides forwards and backwards in a sliding cavity of the carrier piece through a locking mechanism to drive the headrest to move forwards and backwards. A modified polyurethane layer is injection-molded on the outer side of the headrest body of which the front housing and the rear housing arematched to form a headrest assembly. According to the seat headrest, a secondary injection molding process mode is adopted, and the outer layer of a headrest functional module with a sealing effect iscoated with a modified polyurethane material in a melting mode. The design, production and subsequent assembly processes of foaming products and skin products are directly replaced, so that the development difficulty of the product is greatly reduced, the verification period of the product is shortened, the production process of the product is simplified, and the cost is saved.

Owner:沈阳金杯李尔汽车座椅有限公司

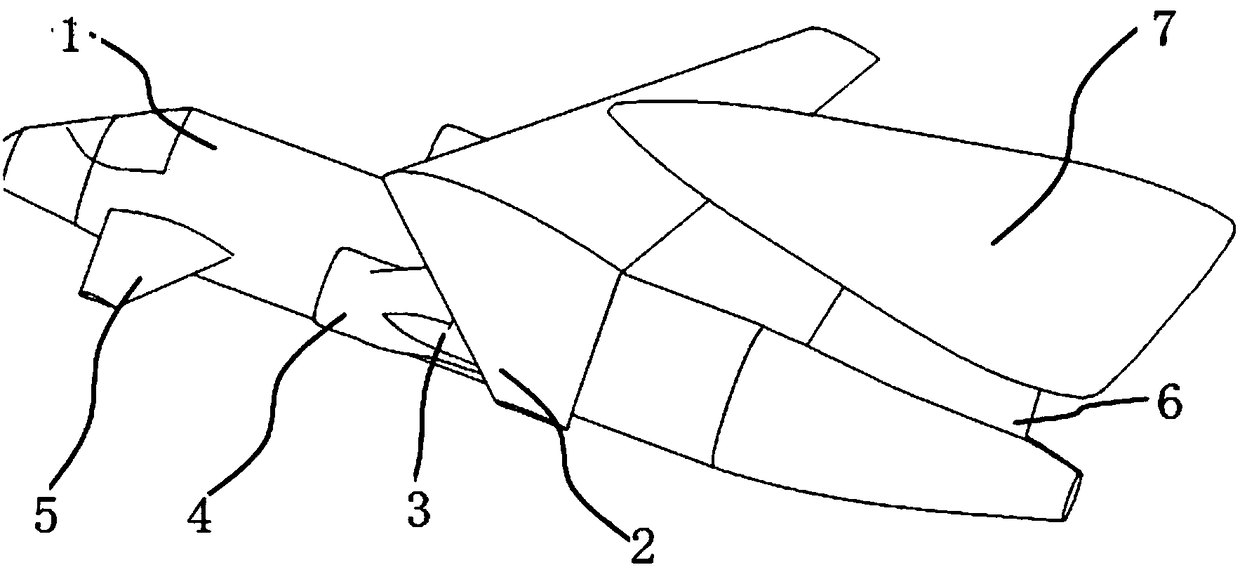

Multifunctional airplane

The invention discloses a multifunctional airplane which comprises an airplane body, wings, additional devices, engine nacelles, front wings, a vertical fin and an early warning radar, wherein the wings and the vertical fin are arranged on the airplane body; the wings are high span-chord ratio trapezoid wings; the additional devices are arranged on the wings; the early warning radar is mounted onthe vertical fin; the two engine nacelles are both arranged on the wings; the wingspan of each of the high span-chord ratio trapezoid wings is 17-25m; the span-chord ratio is 6-10; the length of a tipchord is 1.0-1.5m; the length of a root chord is 3.6-4.1m; the wing root mounting angle is 2-5 degrees; the wing tip mounting angle is 0-2 degrees; the dihedral angle of the wings is 2-6 degrees; thesweepback angle of a leading edge is 15-25 degrees; the sweepforward angle of a trailing edge is 7-12 degrees. According to the multifunctional airplane disclosed by the application, an early warningfunction can be achieved, and the additional devices can be loaded with fuel tanks or missiles, so that the purpose of fighting or refueling is achieved; the airplane body has a transportation function, so that the multifunction of the airplane is achieved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

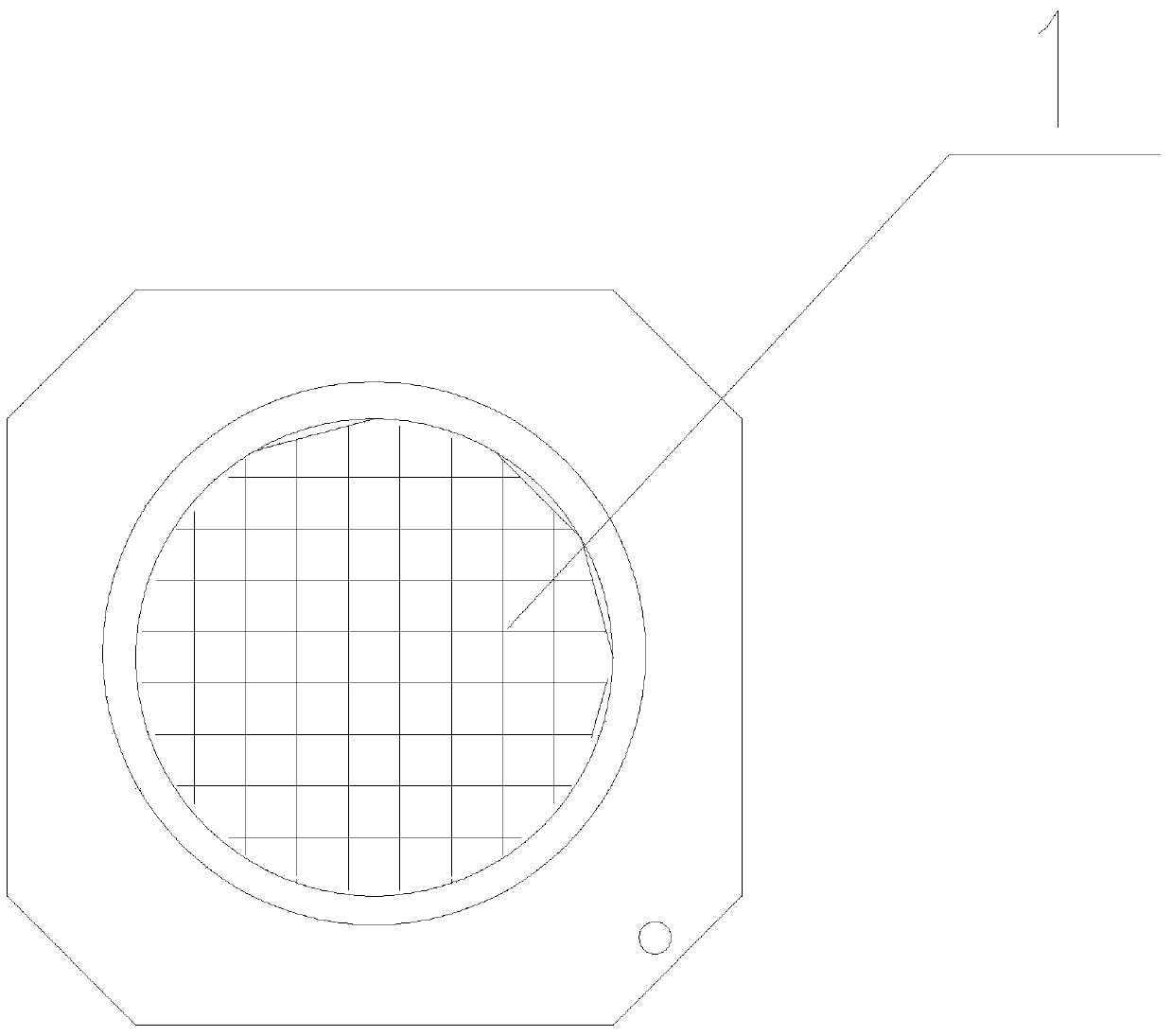

A multiphase flow non-separation on-line measuring device and its measuring method

ActiveCN105806424BAvoid harmAvoid radioactive contaminationVolume/mass flow by differential pressureCapacitanceComputer module

The invention discloses a multi-phase flow nondisjunction online measuring device and a measuring method thereof. The device comprises a sensor module and a data acquisition processor. The sensor module comprises two or more grid capacitive sensors arranged in a fluid pipeline. The grid capacitive sensors are composed of multiple exciting electrodes and multiple detecting electrodes, all of which are not connected, and the grid capacitive sensors are used for measuring the oil-gas-water phase volume fraction and speed. The data acquisition processor is connected with the sensor module. By means of the device and the measuring method thereof, various kinds of data of fluid can be accurately measured in real time, the application range is wide, the device is simple, no manual intervention is needed during measurement, and the whole measuring process is clean and environmentally friendly.

Owner:CHENGDU ZHONGYOU YILONG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com