Multi-area automatic warehousing system

A warehousing system and multi-area technology, applied in the field of multi-area automatic warehousing system and automatic introduction process, can solve problems including material handling equipment, achieve easy real-time monitoring, predictable operation, and improve storage and fetching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0174] Embodiments of various aspects of the present invention may be a system of components and / or structures, a method, and / or a non-transitory computer-readable storage medium storing one or more computer-readable program codes.

[0175] Accordingly, various embodiments of the invention may take the form of a combination of hardware and software embodiments, including mechanical structures as well as electronics, computing elements, circuits, microcode, firmware, software, and the like.

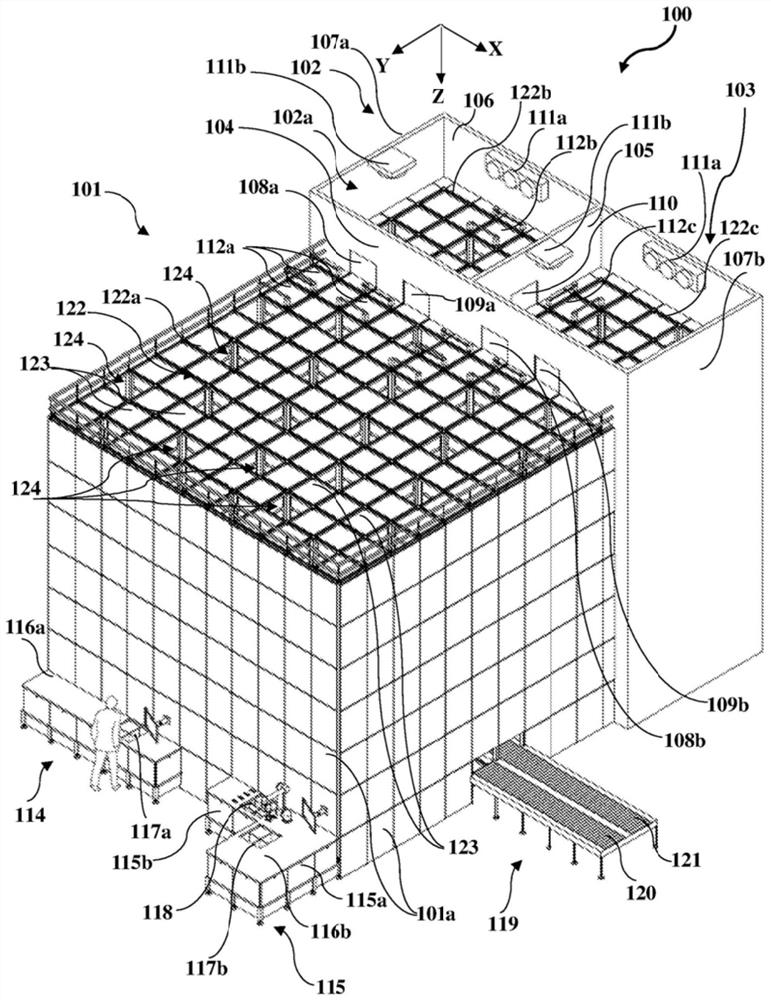

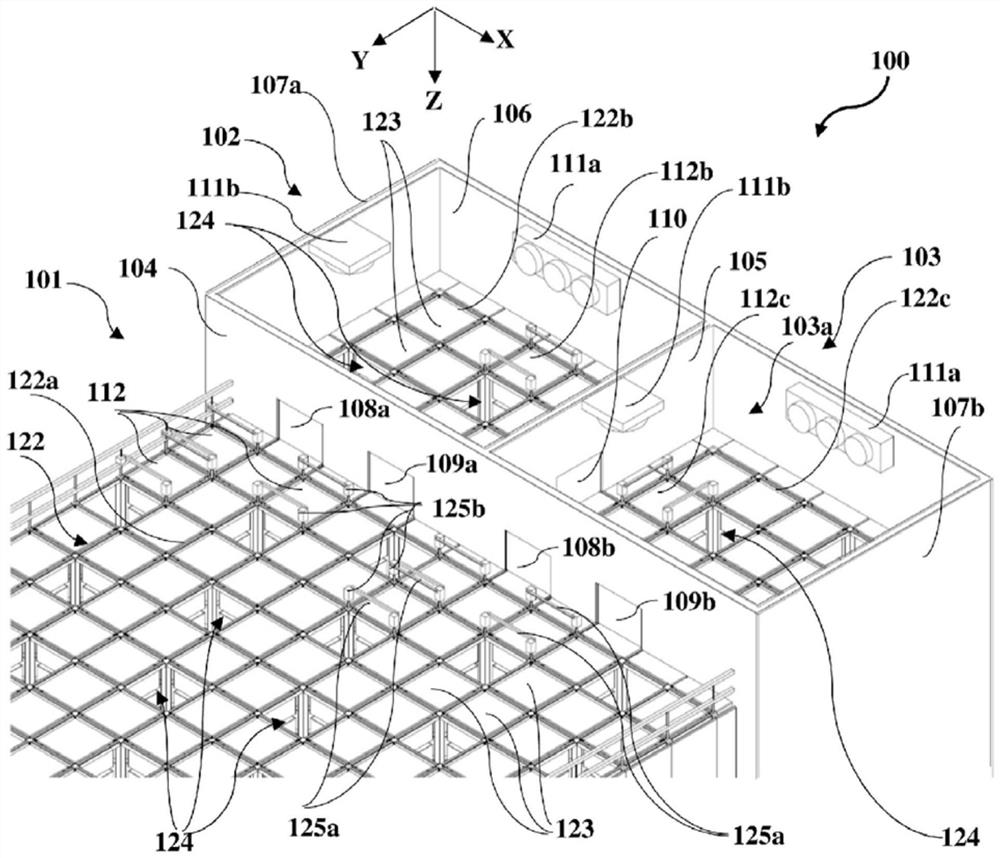

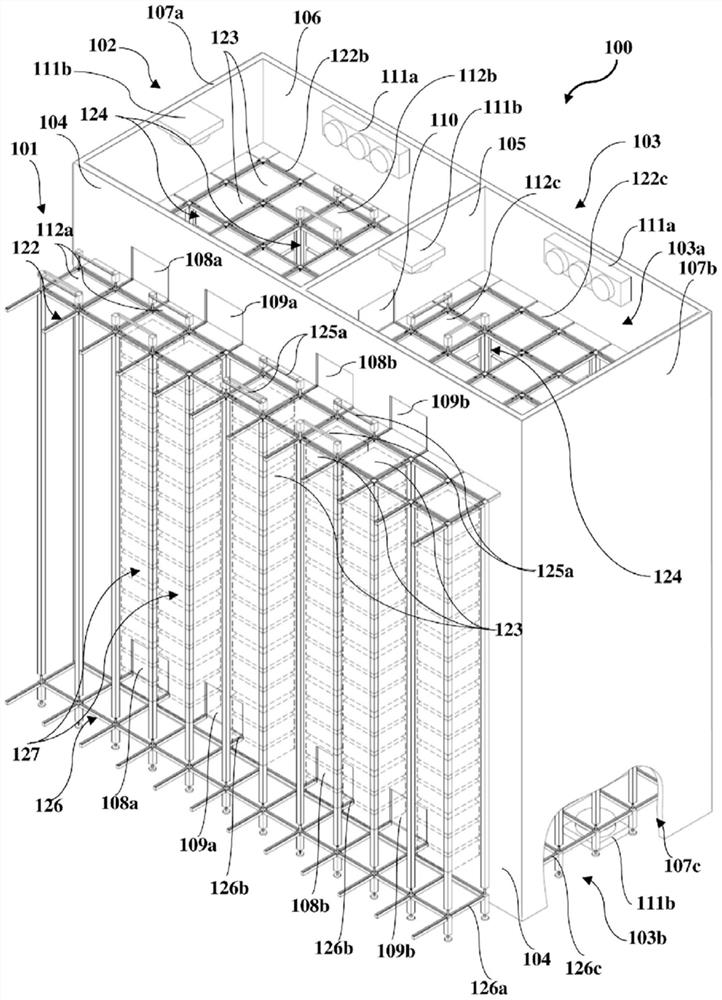

[0176] figure 1 It is a top perspective view of a multi-zone automated storage system (ASRS) 100 according to an embodiment herein, showing an upper rail structure 122 of a three-dimensional (3D) grid storage structure adopted by the multi-zone ASRS 100 .

[0177] In one embodiment, the multi-region ASRS 100 disclosed herein employs Figure 4 The illustrated 3D grid storage structure 100a.

[0178] The multi-zone ASRS 100 disclosed herein includes multiple storage locations configured to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com