Housing with a bottom section and a cover

A technology of a shell and a protruding part is applied in the field of shells, which can solve the problems of high cost, and achieve the effects of low cost, material saving and material cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

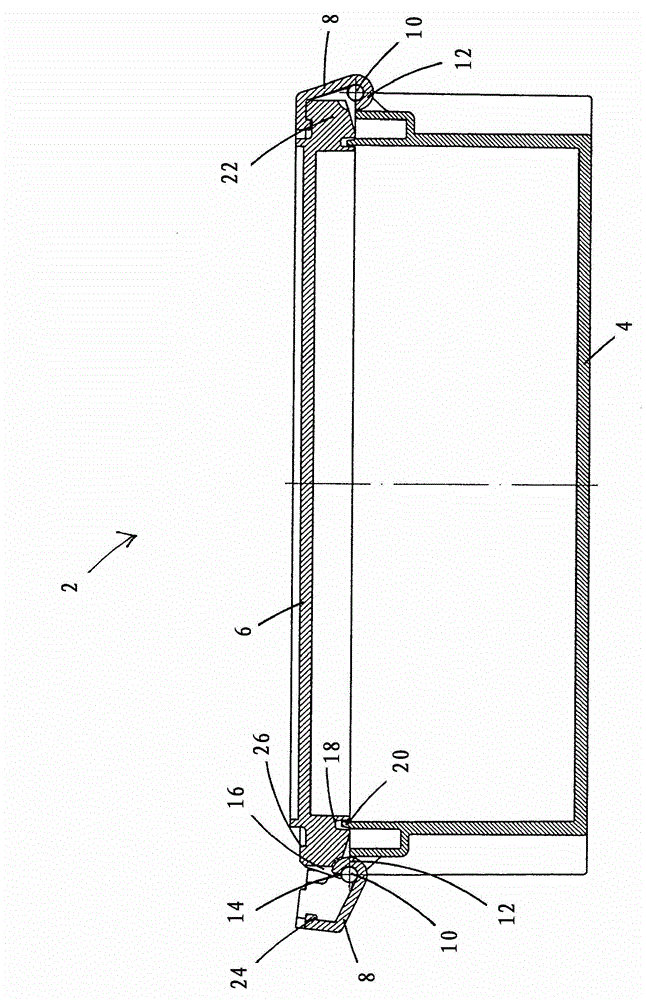

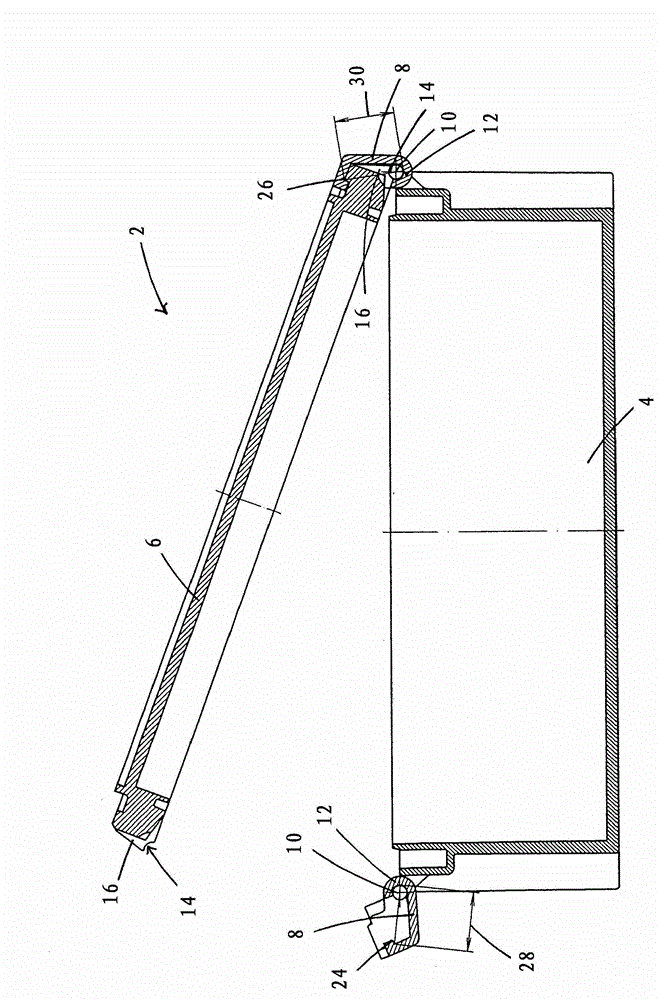

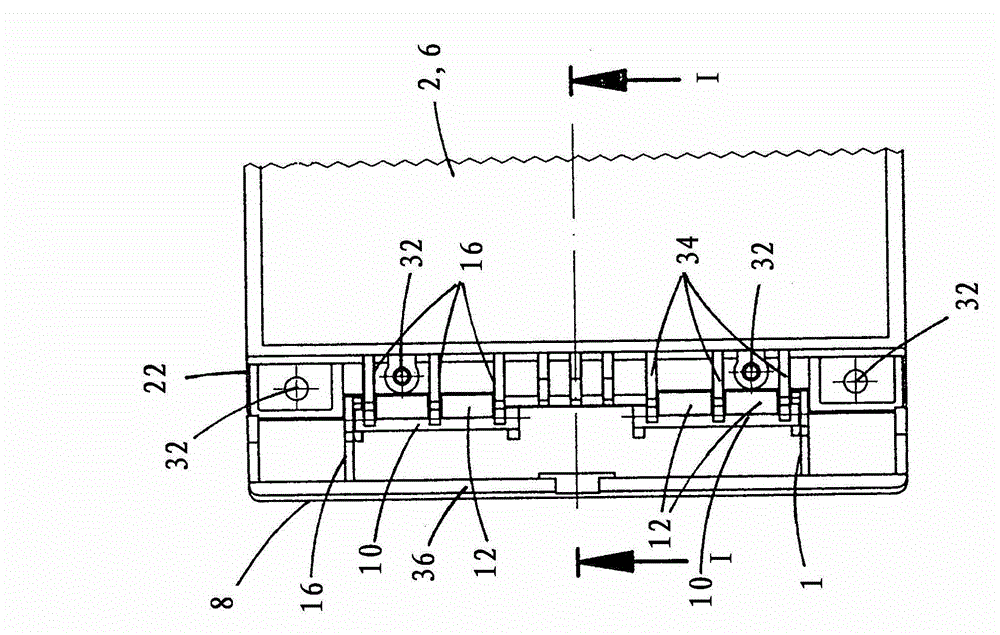

[0025] exist figure 1 The housing 2 is shown in a cross-sectional view. The housing 2 comprises a lower part 4 onto which a cover 6 is mounted. The lower part 4 and the cover 6 are first and second housing members, respectively. The housing components can be connected to one another via tensioning elements 8 . exist figure 1 The right-hand tensioning element 8 is shown in the snapped position, while the left-hand tensioning element 8 is shown in the open position. The tensioning element 8 has a web 12 which surrounds a fastening shaft 10 which is fixedly connected to the lower part 4 . The web 12 can be removed from the fastening shaft 10 in the deflected position of the tensioning element 8 when the tensioning element 8 needs to be completely removed from the respective housing component 4 , 6 .

[0026]A bearing surface 14 is formed on the cover 6 , by means of which the cover 6 is supported on the corresponding fastening shaft 10 . In the exemplary embodiment, the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com