Method for optimizing the production sequence

A technology of sequence and production parameters, applied in data processing applications, devices for permanent visual display, input/output process of data processing, etc., to achieve the effect of simplifying logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following exemplary embodiments are shown in each case on the basis of a variable-stamp printing system with an integrated folding device and an immutable-stamp printing system, wherein it is expressly stated in this connection that it can be transferred to a printing system for processing paper with corresponding adaptations superior.

[0040]The stamp-variable printing system is implemented in the form as described in documents EP2308681A2 or DE102012103729A1.

[0041] Cylinder printing systems with an immutable stamp, such as cylinder offset printing presses, cylinder gravure printing presses or, for example, cylinder flexographic printing presses, have long been known to those skilled in the art from the prior art.

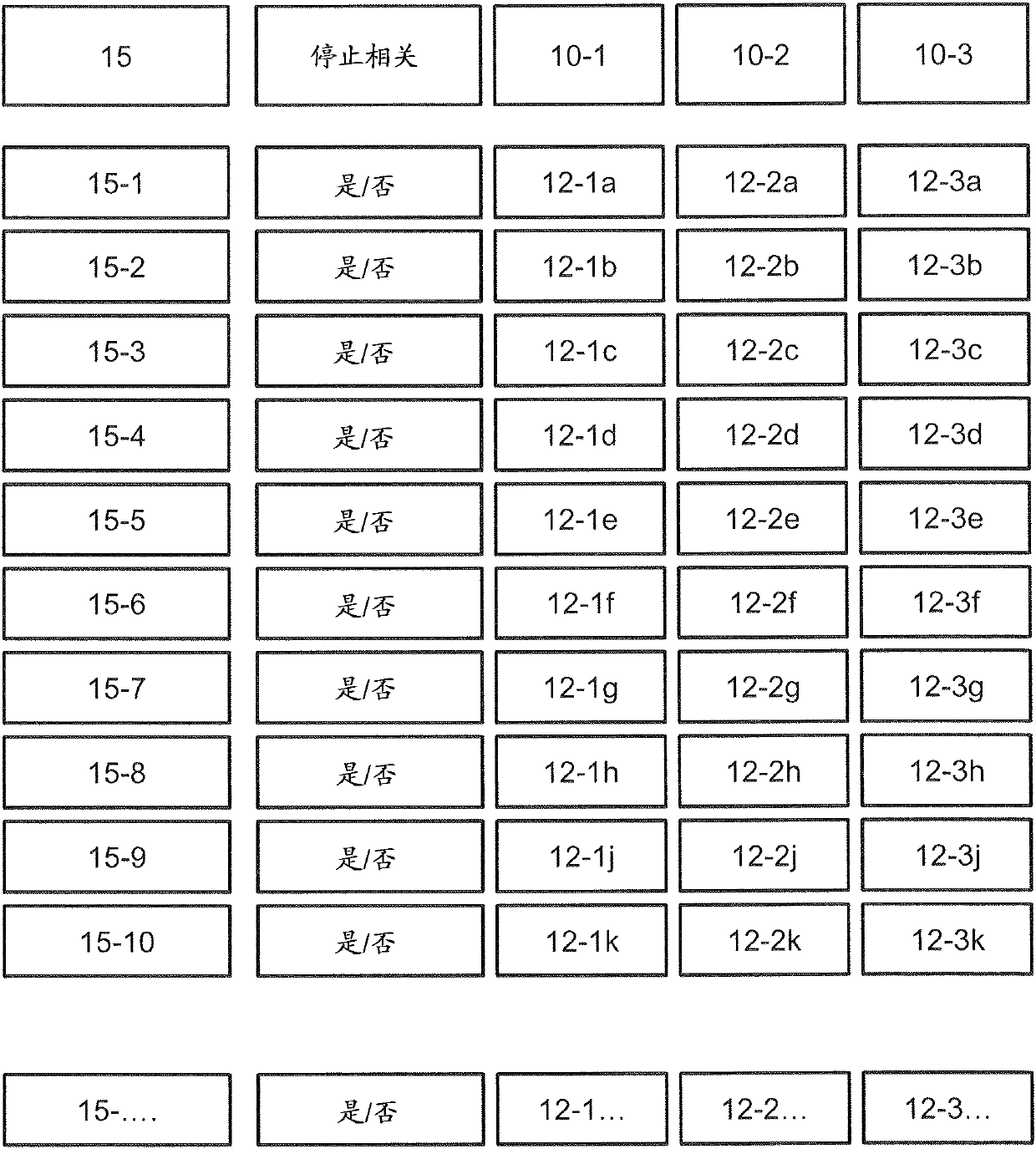

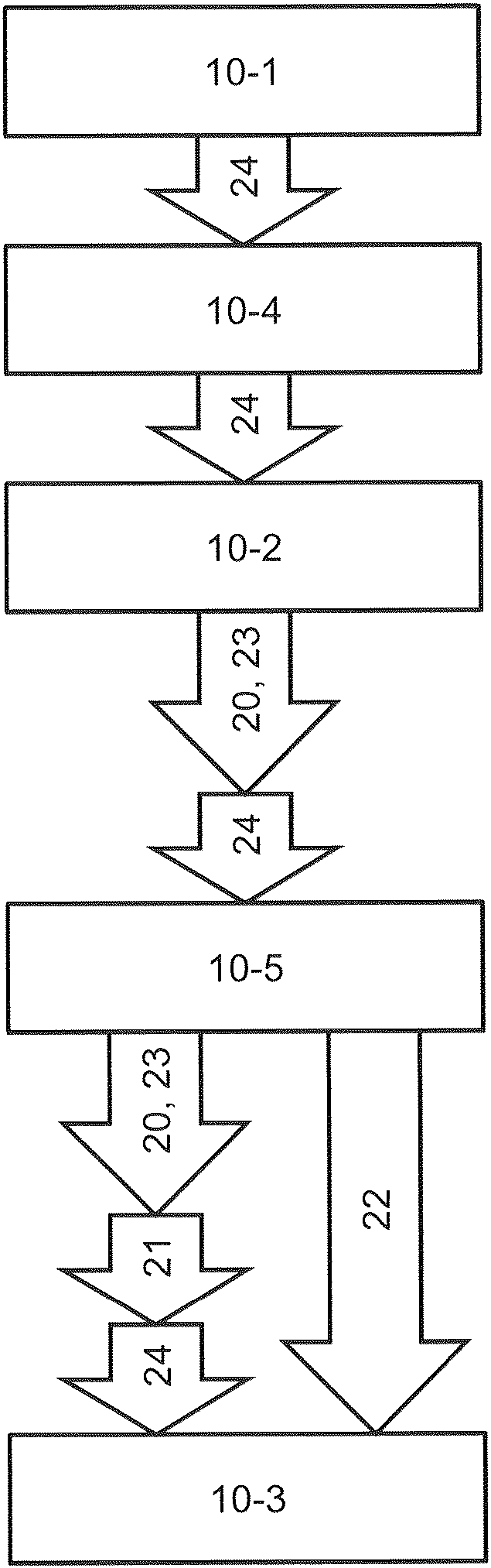

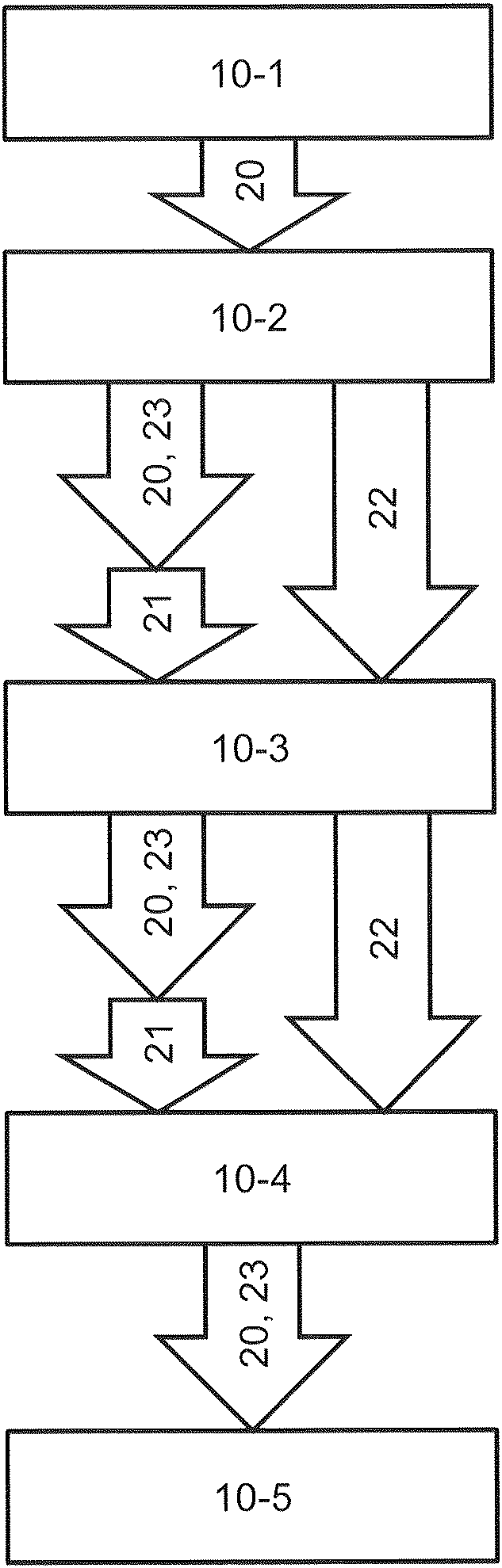

[0042] For reasons of simplicity, the method is explained below using the example of five printing jobs with a correspondingly predictable number of production parameters that are taken into account for the classification. Obviously, with the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com