Liquid filter and volume compensation element for liquid filter

A technology of liquid filter and volume compensation, which is applied in the direction of membrane filter, fixed filter element filter, filtration separation, etc., and can solve the problem of damage to the liquid filter shell and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

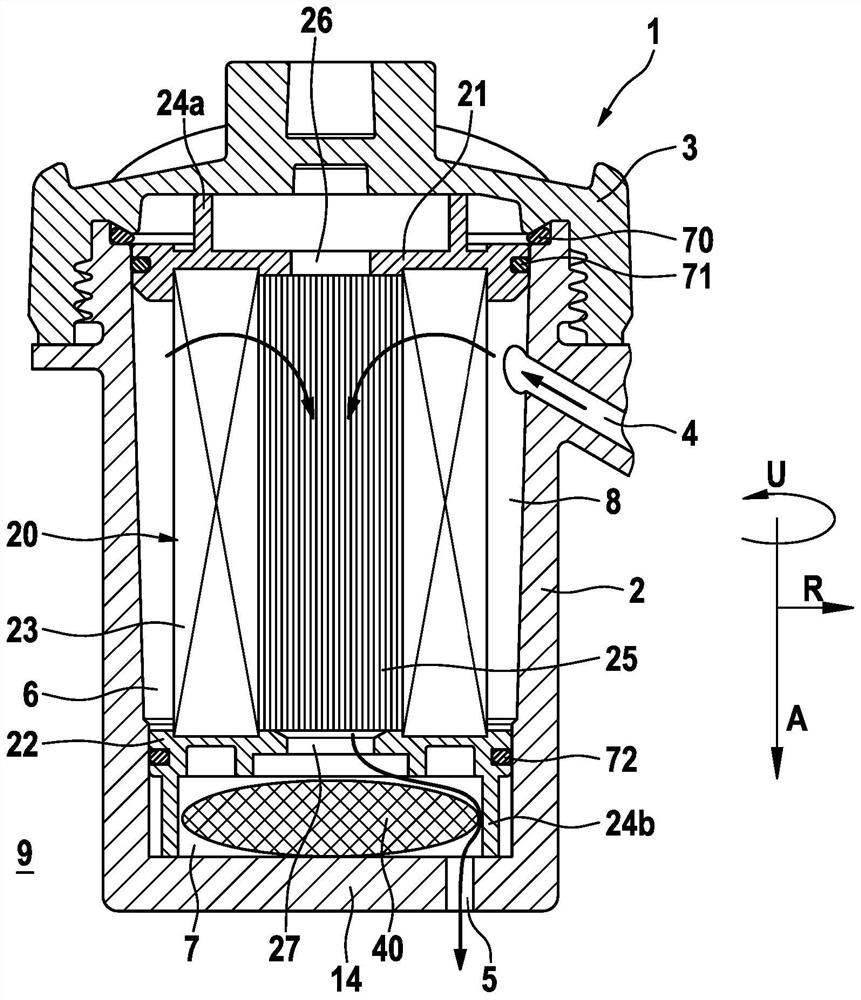

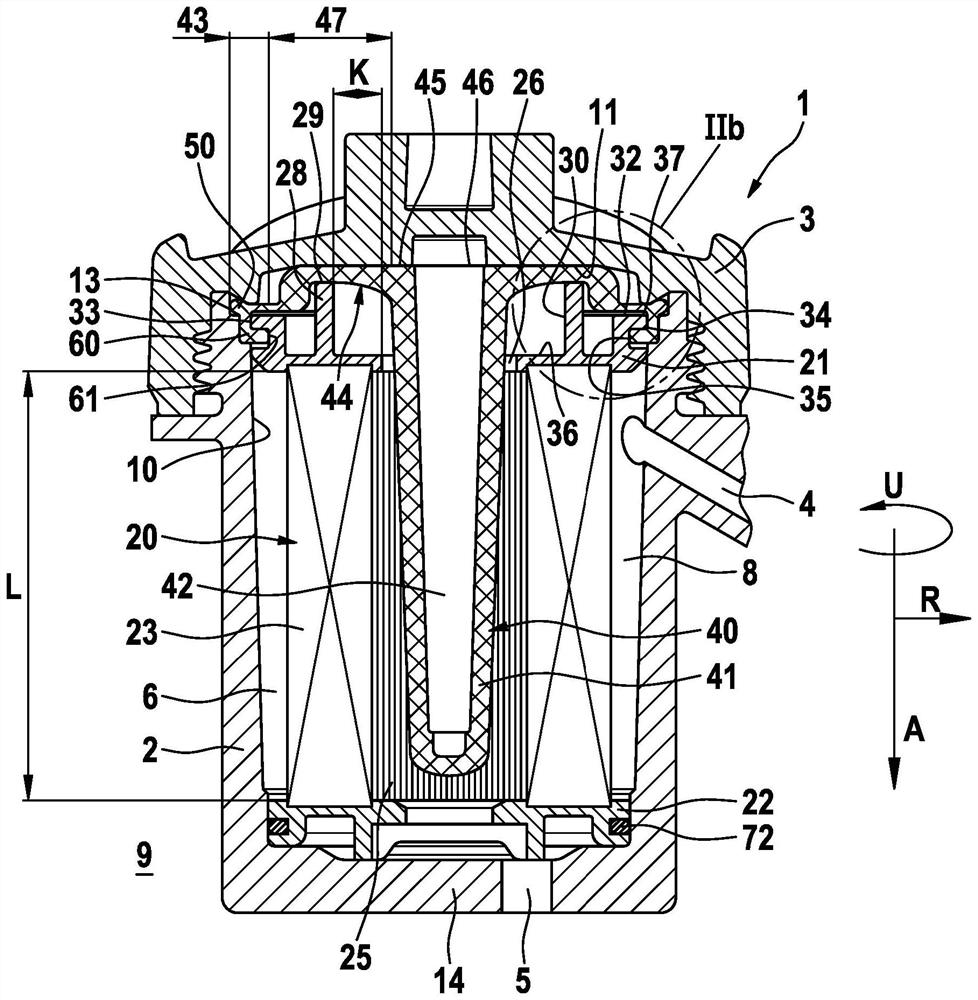

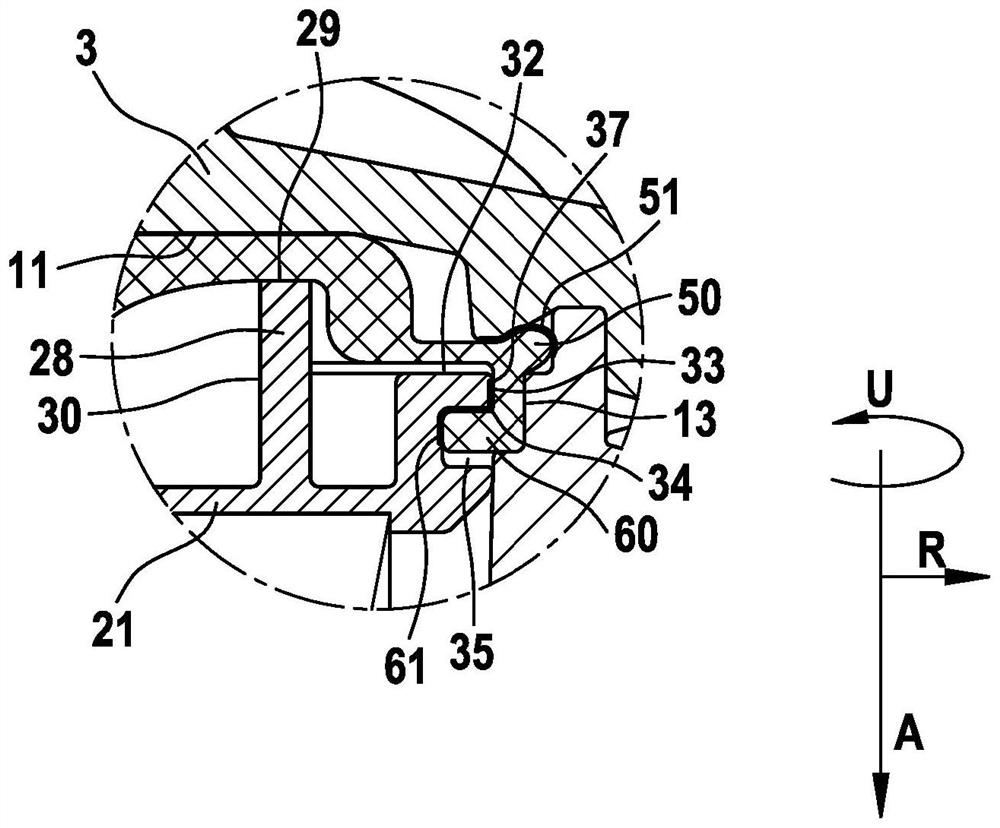

[0081] Figure 1 shows a schematic cross-section of a liquid filter 1 of the prior art.

[0082] The liquid filter 1 includes a housing 2 having a cover 3 , a liquid inflow port 4 , a liquid outflow port 5 , and a filter element 20 . The filter element 20 is arranged in the interior 6 of the housing 2 and has a first end cap 21 , a second end cap 22 facing the cover 3 and a filter medium 23 arranged in the axial direction A between the two end caps 21 , 22 . The second end cap 22 here faces towards the bottom 14 of the housing 2 , which is constructed here in the form of a cup. The direction of gravity can be directed from the cover 3 to the base 14 , for example. The filter element 20 separates the clean side 7 (on which the filtered liquid is present) from the raw side 8 (on which the liquid to be filtered lies). The first end cap 21 has a channel-shaped first opening 26 . The second end cap 22 has a channel-shaped second opening 27 . The filter insert 20 is here formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com