An engine-transmission connection assembly

A technology for connecting components and transmissions, applied in the direction of electric components, connections, transmission parts, etc., can solve problems such as space shortage, and achieve the effect of avoiding manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

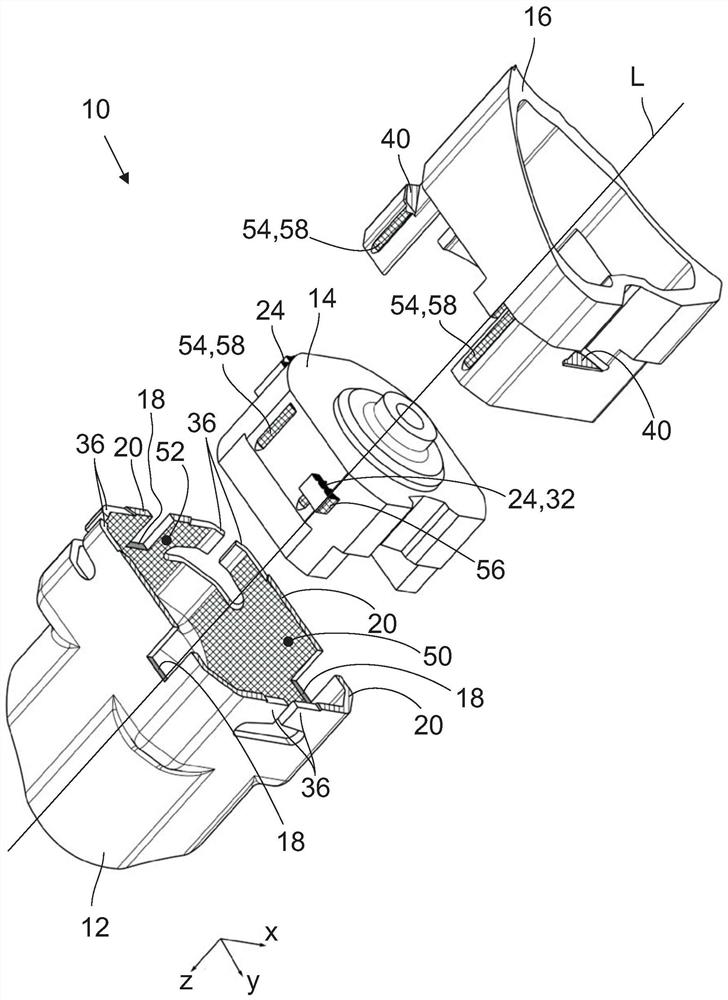

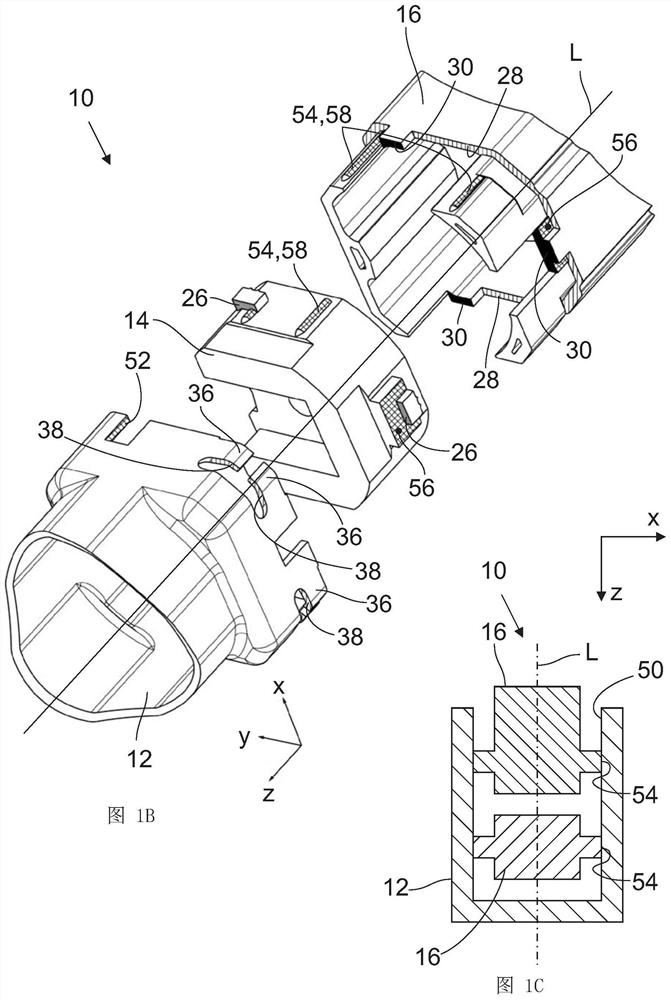

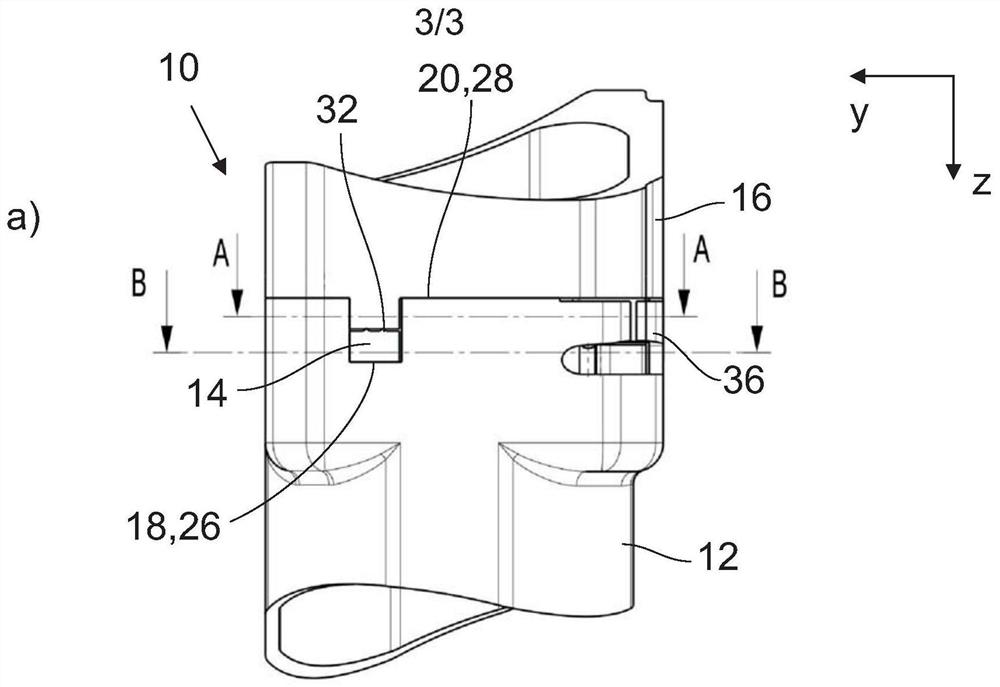

[0029] exist Figure 1A to Figure 2C An exemplary embodiment of an engine-transmission connection assembly 10 according to the present invention is shown in FIG. The engine-transmission connection assembly 10 includes: an engine compartment 12 for accommodating an electric motor, not shown; a brush holder 14, with which brushes, not shown, for the electric motor are held; and a transmission case 16, Used to accommodate drives, also not shown.

[0030] The nacelle 12 includes a first contact surface 18 by which the nacelle 12 comes into contact with the brush holder 14 when the brush holder 14 is inserted into the nacelle 12 . Furthermore, the nacelle 12 has a second contact surface 20 via which the nacelle 12 comes into contact with the transmission housing 16 when the transmission housing 16 is inserted into the nacelle 12 .

[0031] In addition, the brush holder 14 has a third contact surface 24 through which the brush holder 14 comes into contact with the transmission hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com