Machine frame for high-pressure roller press

A high-pressure roller and frame technology, used in presses, presses using rotating pressure components, grain processing, etc., can solve problems such as no function, high space requirements for bridge frames, etc., and achieve the effect of avoiding breaking points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

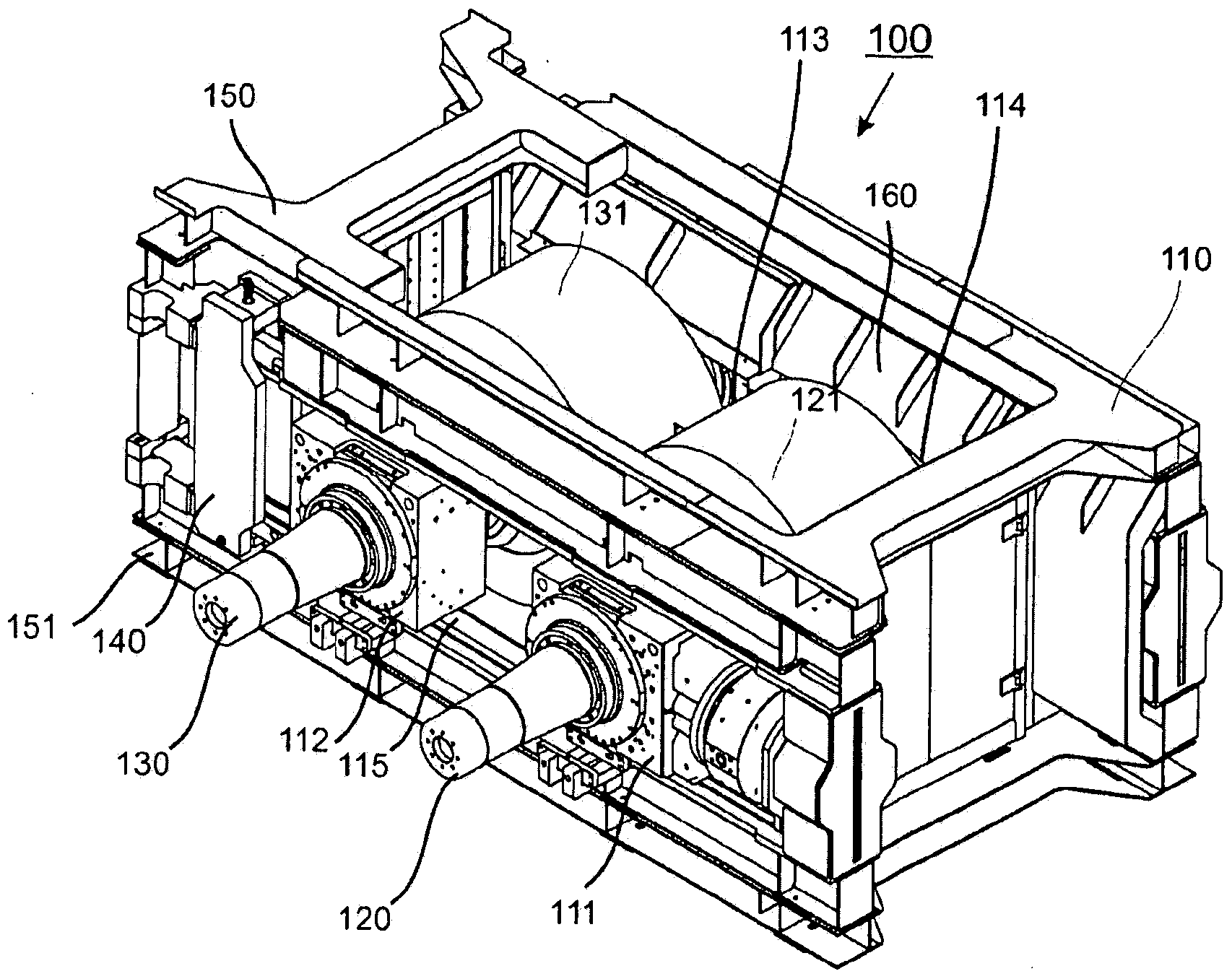

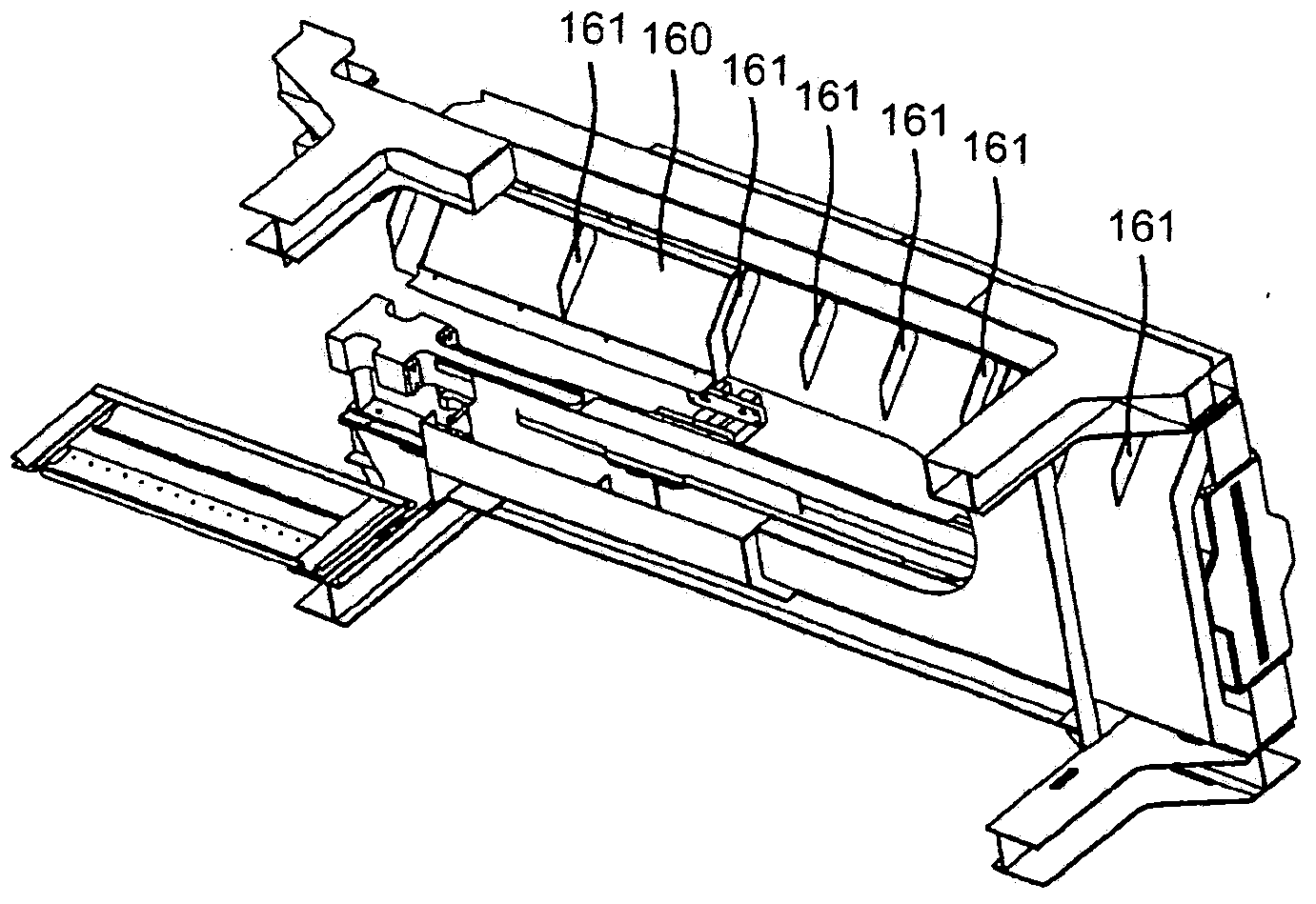

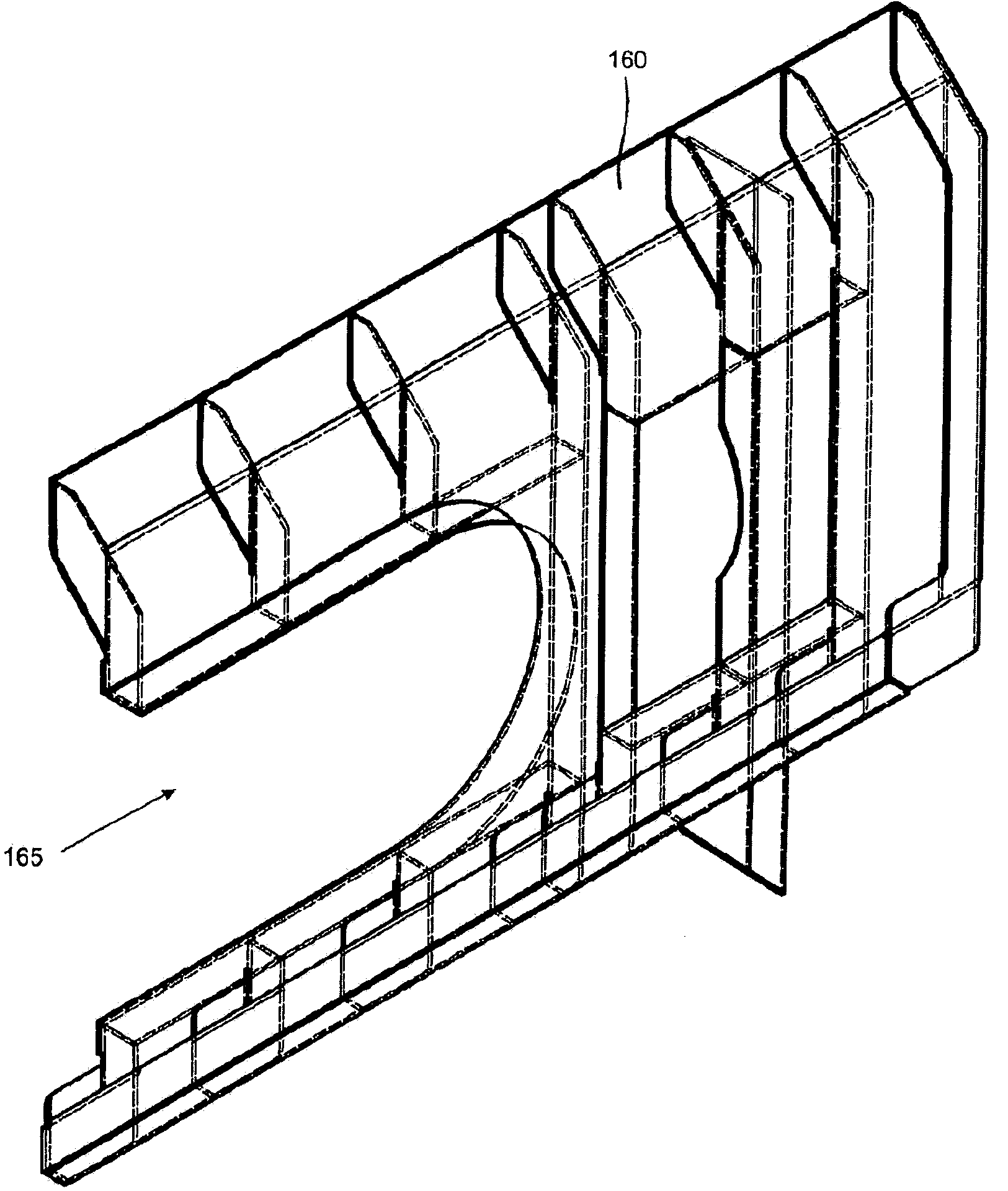

[0013] exist figure 1 A high-pressure roller press 100 with a stand 110 according to the invention is depicted in FIG. Bearing brackets 111 , 112 , 113 and (not visible) 114 sliding on mounts are accommodated in frame 110 , only the front mount 115 is visible in this view. A corresponding bearing is received in each bearing bracket, each bearing rotatably supporting the shafts 120 and 130 of the grinding rollers 121 and 131 .

[0014] In order to remove the grinding rollers 121 and 131 from the frame 110, it is provided in this design that the locking device 140 is taken out of the frame 110 in order to thereby open the machine on the side of the frame pointing backwards from the paper. shelf. The grinding rollers 121 and 131 with their bearings and bearing brackets 111, 112, 113 and 114 are then pushed out of the frame backwards with respect to the paper. The sub-elements or belt structures 150 and 151 remain after the grinding roller has been dismantled and form open open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com