Automatic weight measuring system and method for warp knitting fabrics

A warp knitting and grey fabric technology, applied in the field of grey fabric weighing equipment, can solve the problems of unsmooth logistics process, waste of space, complicated procedures, etc., and achieve the effect of simplifying the logistics in the factory, facilitating later marking, and reducing labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

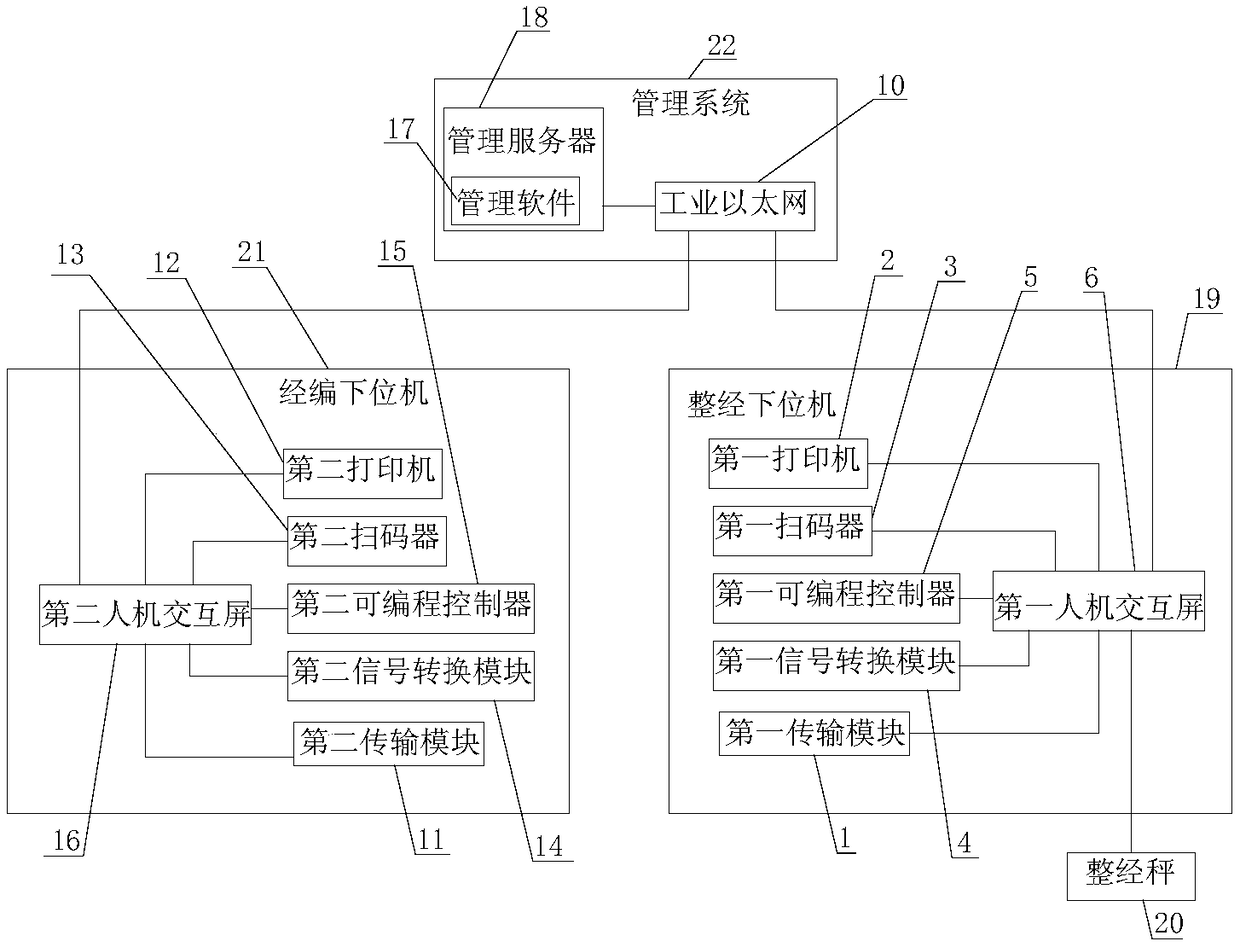

[0034] Such as Figure 1-3 As shown, an automatic weighing system for warp knitting gray cloth includes a warping scale 20 , a warping lower computer 19 , a warp knitting lower computer 21 and a management system 22 . The warping scale 20 is used to weigh the warping head before and after winding. The warping lower machine 19 acquires the information of the number of the pan head, the length of the yarn, and the number of grains. The warp knitting lower computer 21 reads and calculates the length of the gray cloth when it falls. The warping scale 20 is connected to the warping lower computer 19 , and both the warping lower computer 19 and the warp knitting lower computer 21 are connected to the management system 22 . When in use, the management system 22 receives and stores the data provided by the warping scale 20, the warping lower computer 19 and the warp knitting lower computer 21, and calculates the weight of each piece of cloth.

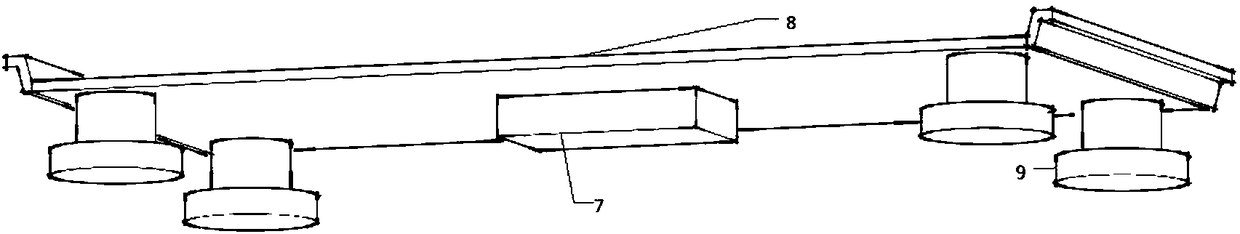

[0035] Such as figure 2 As mentione...

Embodiment 2

[0045] The present embodiment is the using method of embodiment 1, i.e. warp knitted gray cloth automatic weighing method, comprises the following steps:

[0046] (A) Weighing link: the warping scale 20 weighs the front and back of the winding yarn on the pan head respectively and transmits the weight information to the warping lower computer 19;

[0047] In this step, the weight of the empty pan head is weighed in advance, the weight of the full pan head is weighed during the production process, and the difference is calculated in the management system 22 to obtain the yarn weight required for calculating the yarn density.

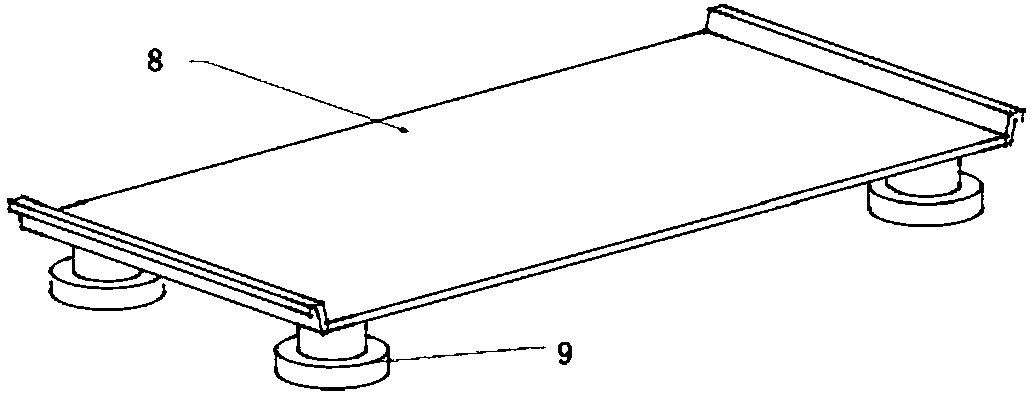

[0048] It is necessary to provide a warping scale with stable dimensions and stable measurement at the warping head roller station, so as to realize the weight of the empty head and the full head;

[0049] (B) Warping process: the warping lower computer 19 obtains the serial number of each head, and tracks each head; the warping lower computer 19 obtains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com