Patents

Literature

41results about How to "Density unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

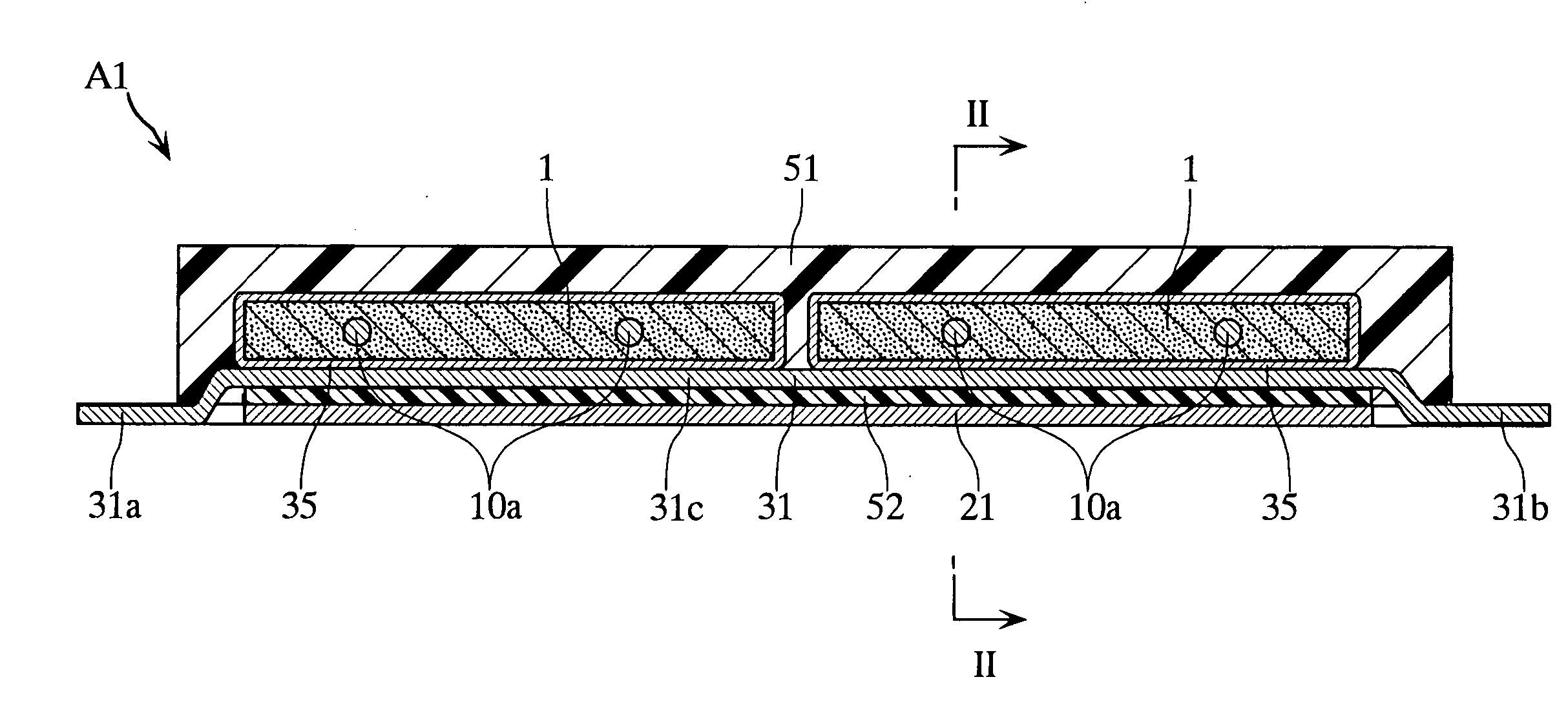

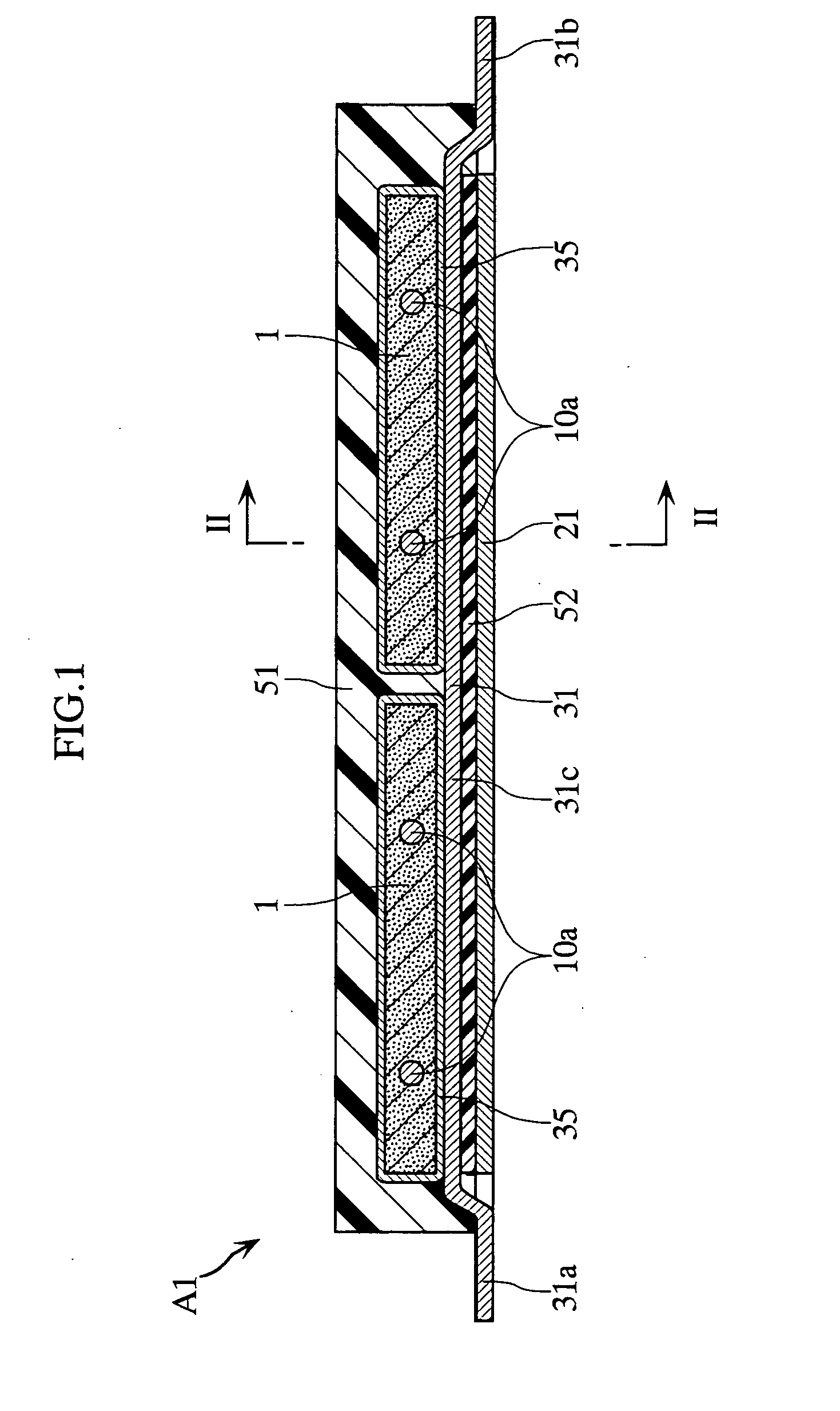

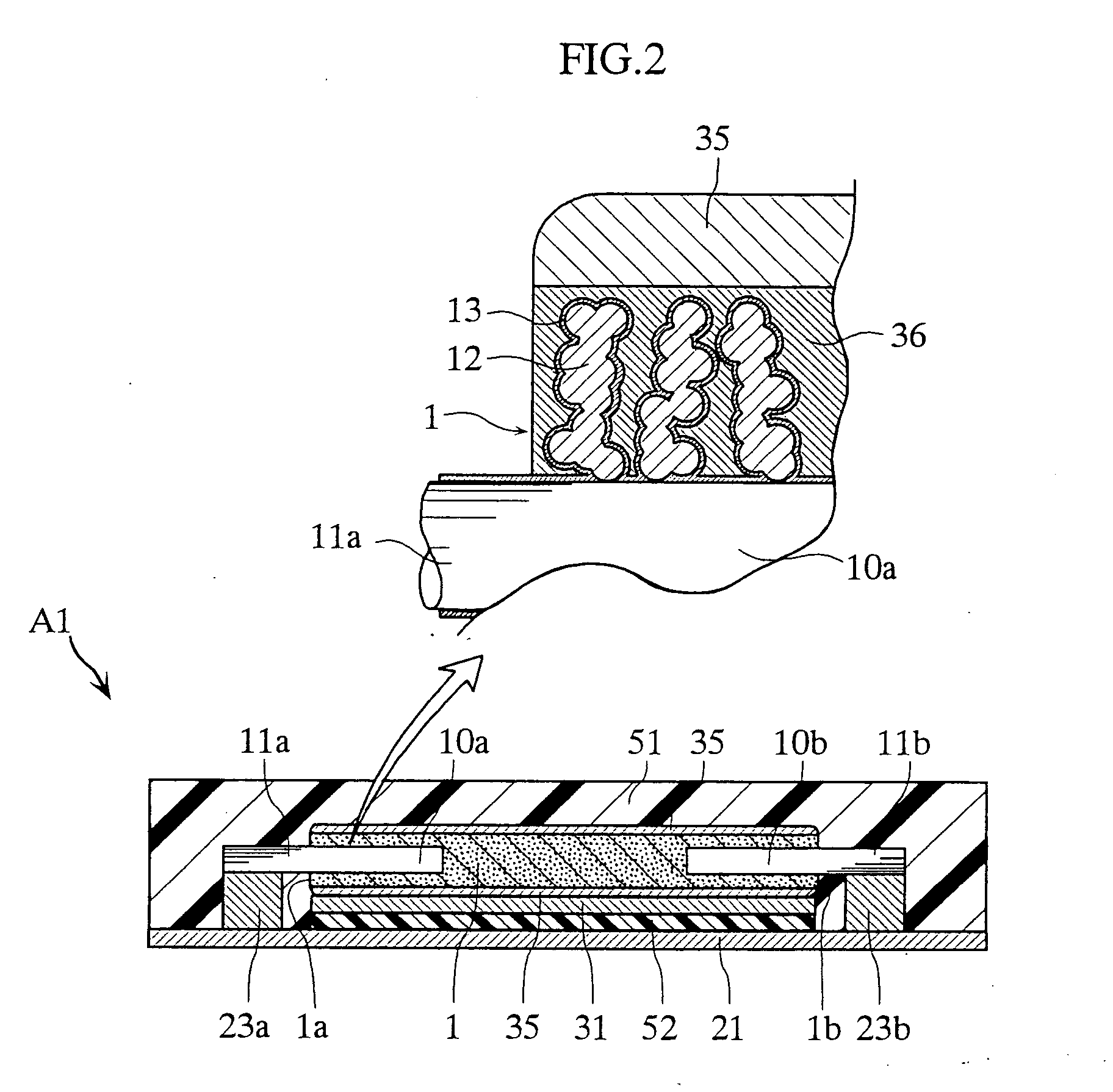

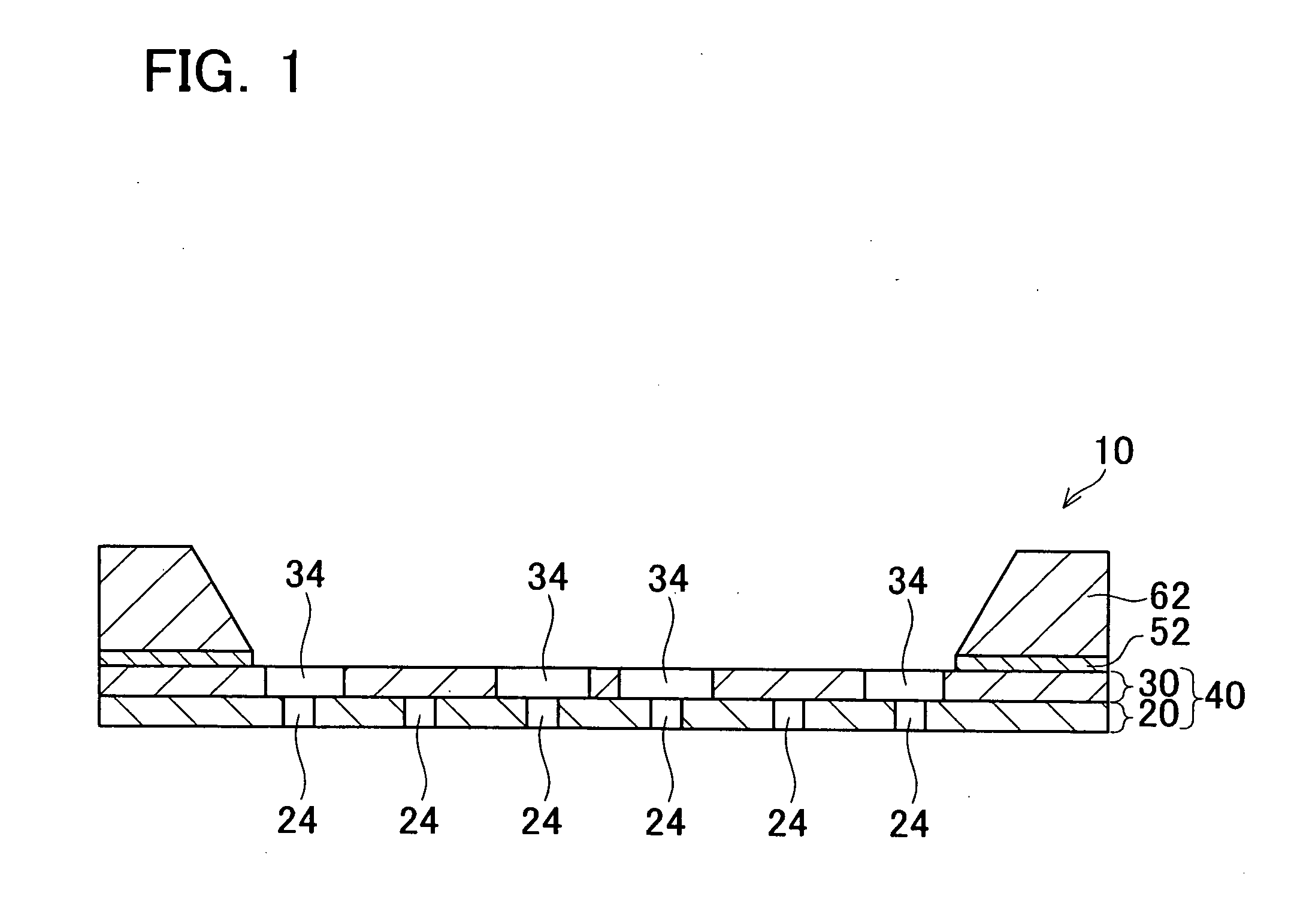

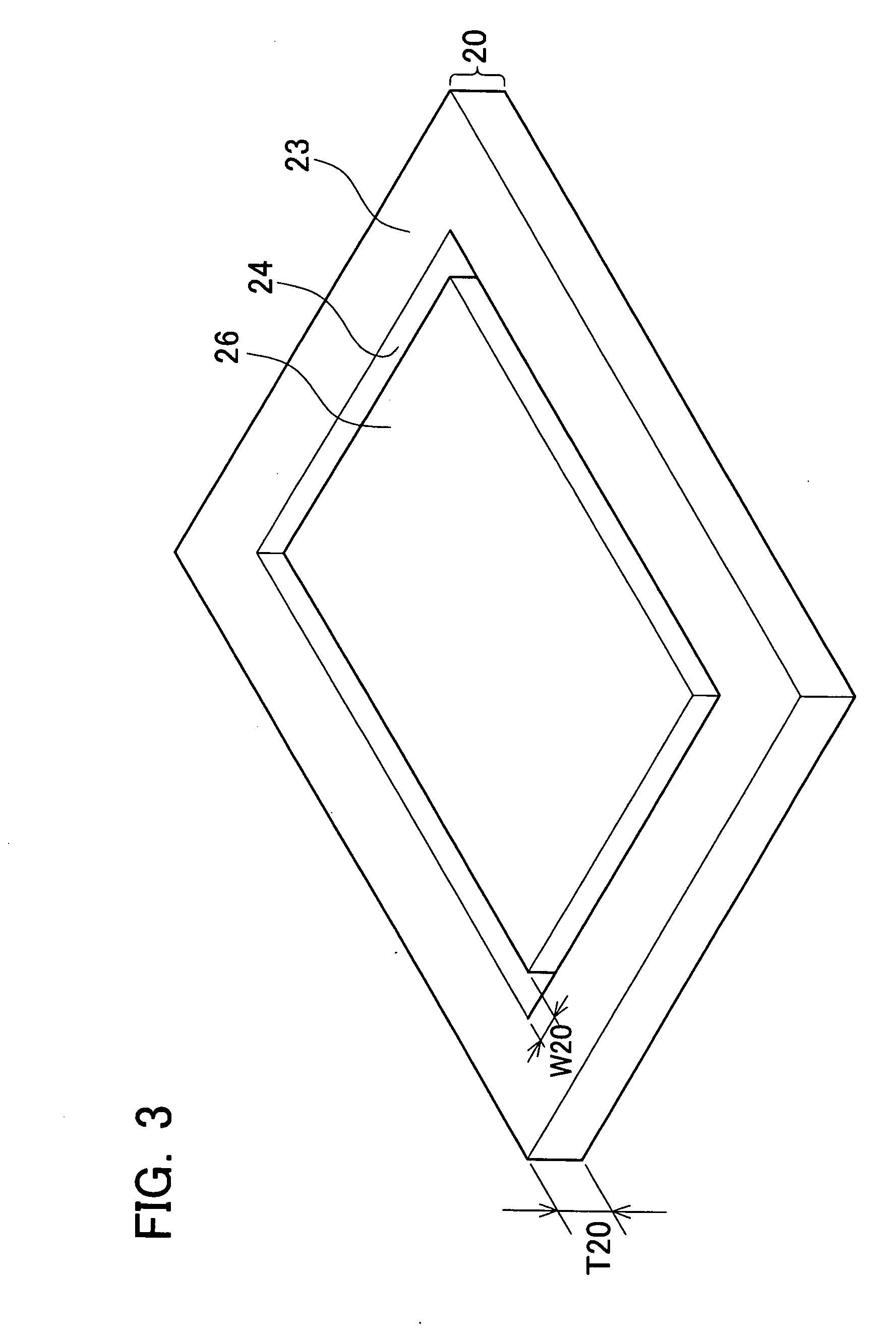

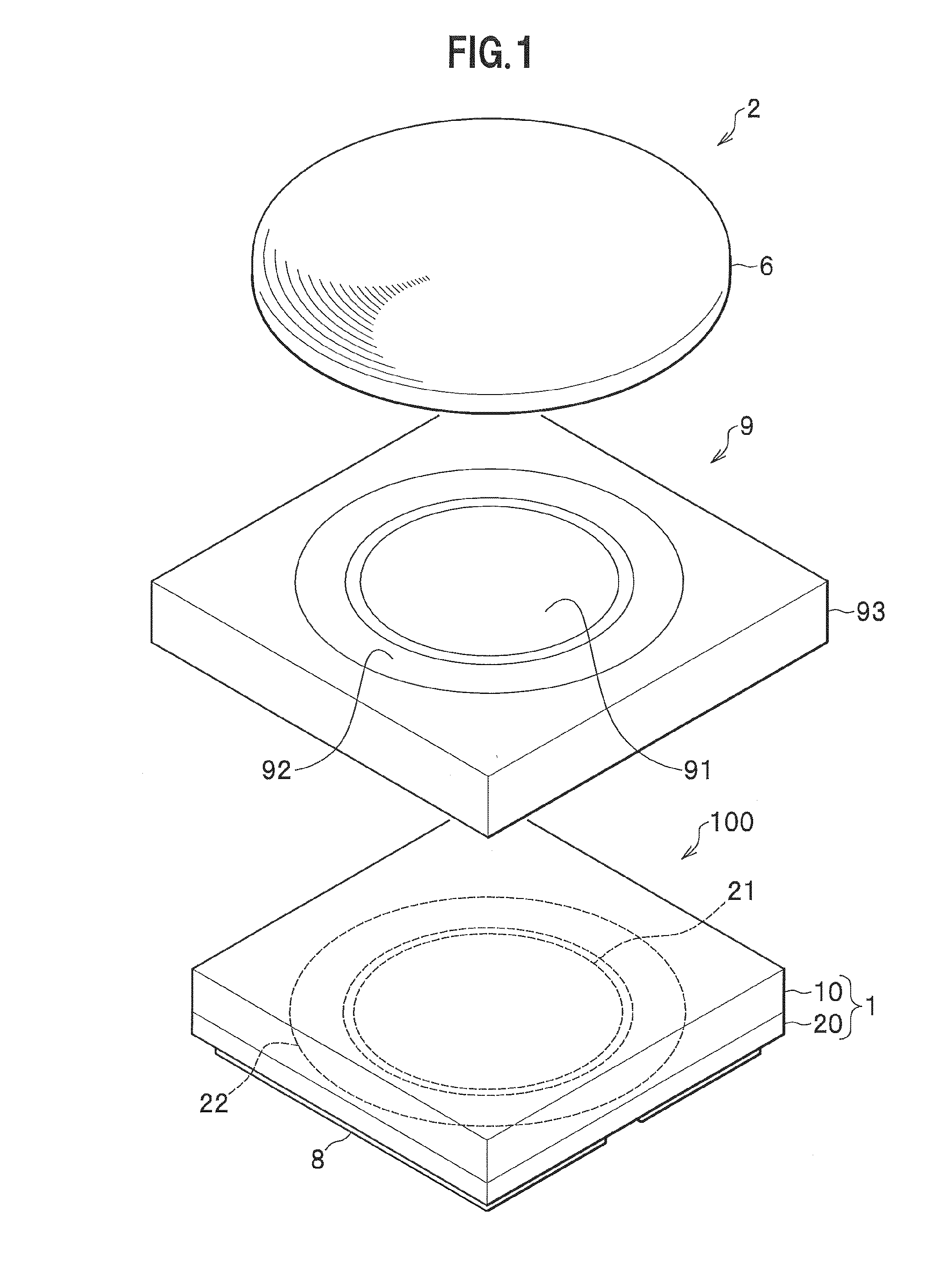

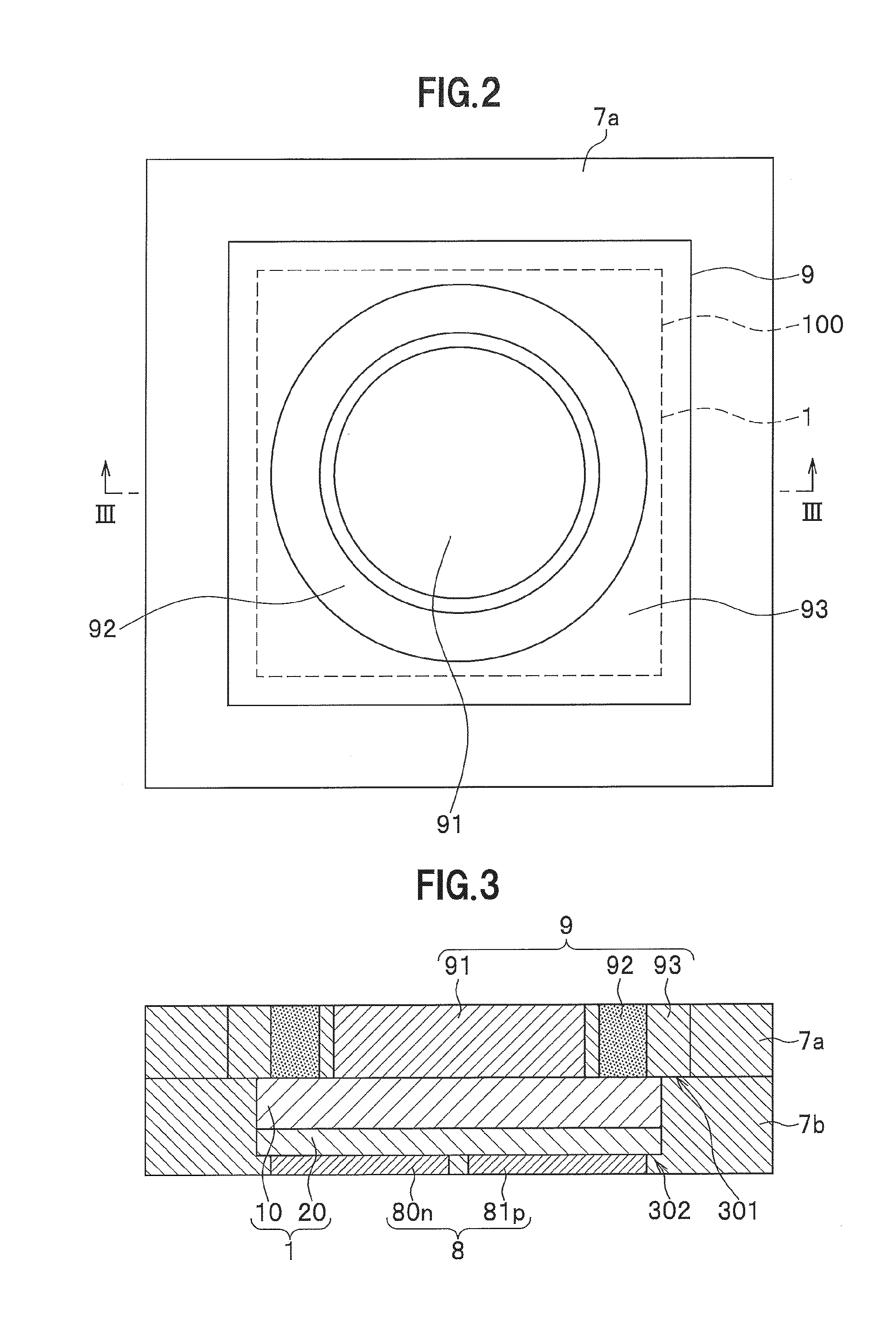

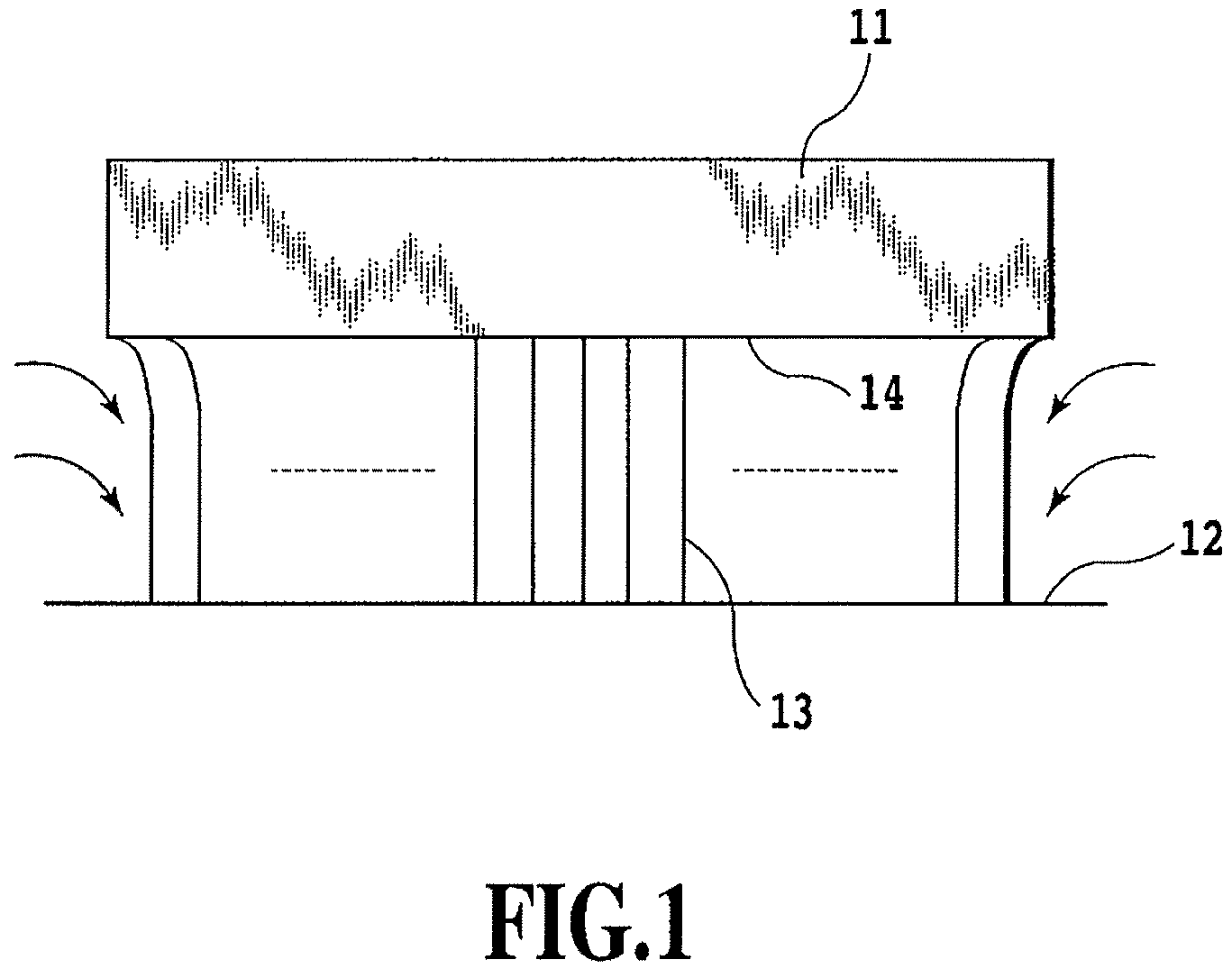

Solid electrolytic capacitor

InactiveUS7551424B2Sufficient contact pressureIncrease resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

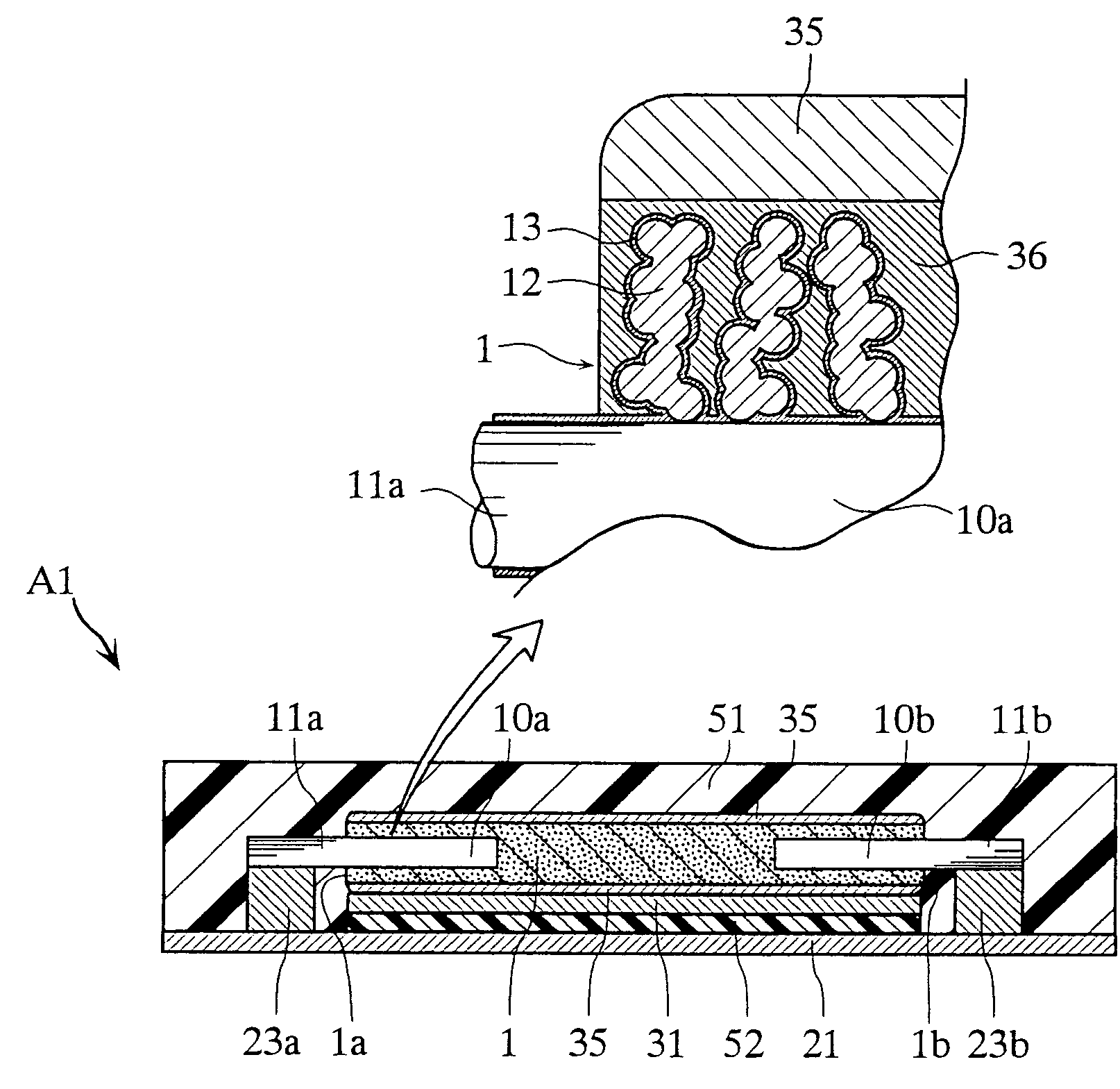

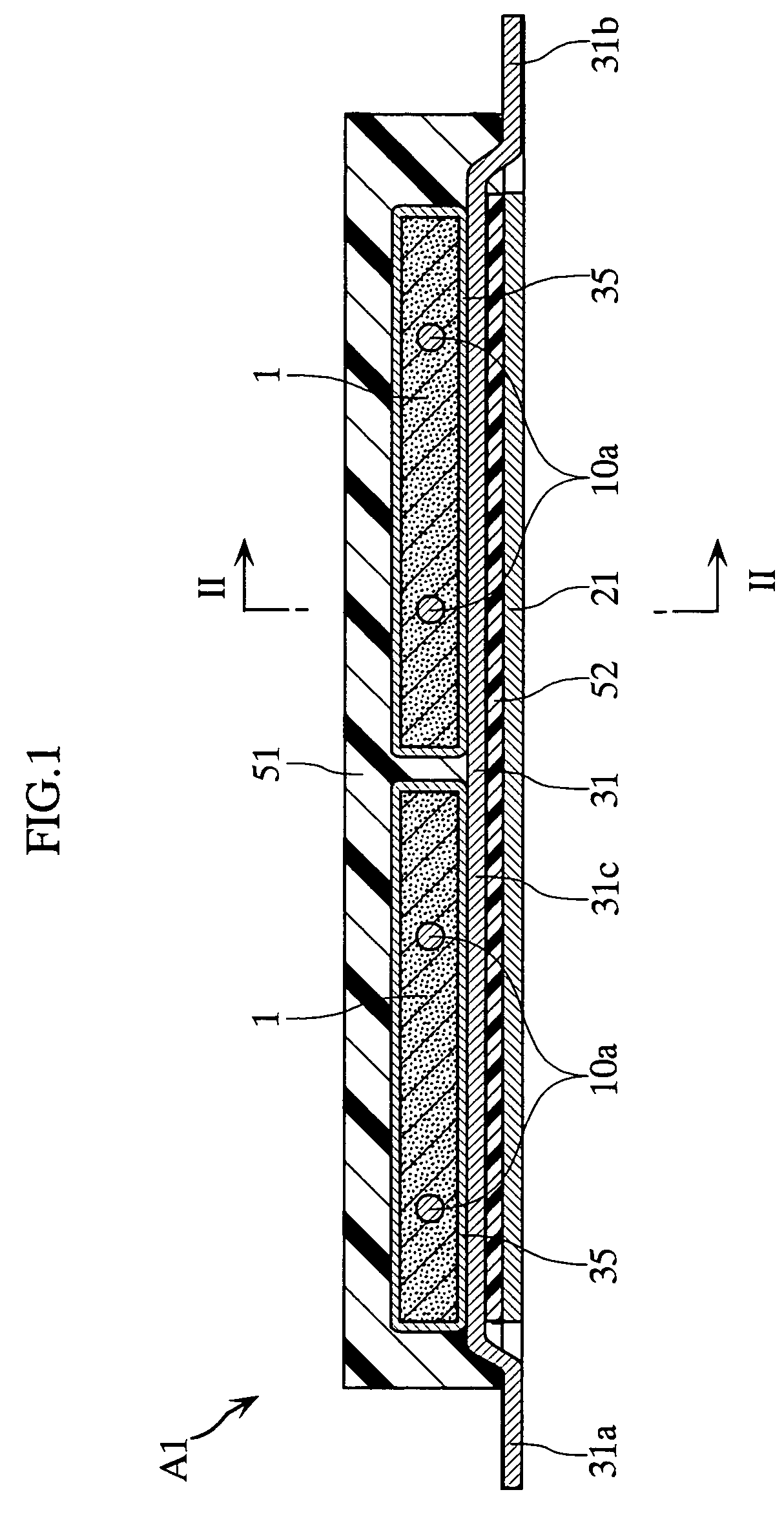

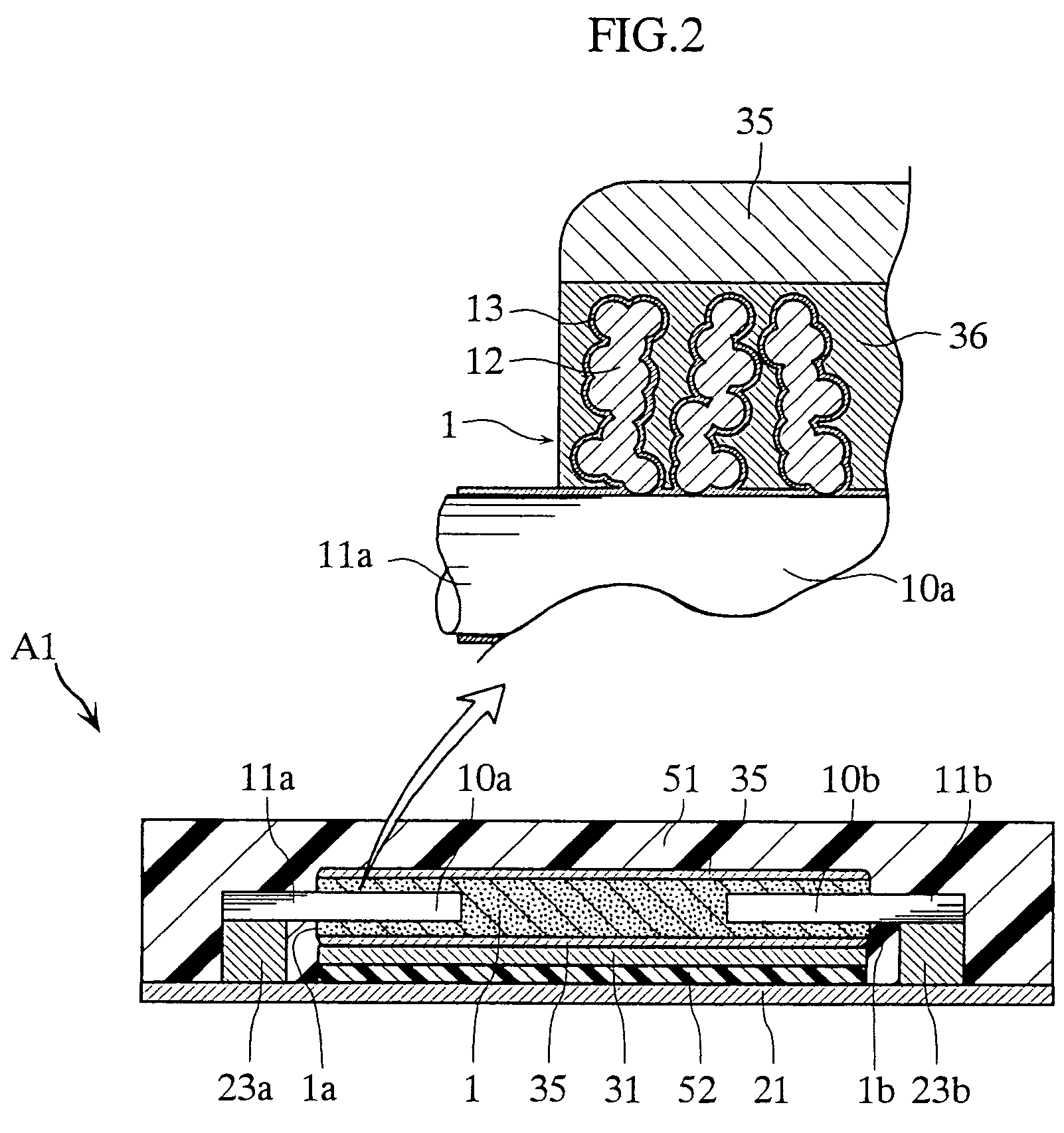

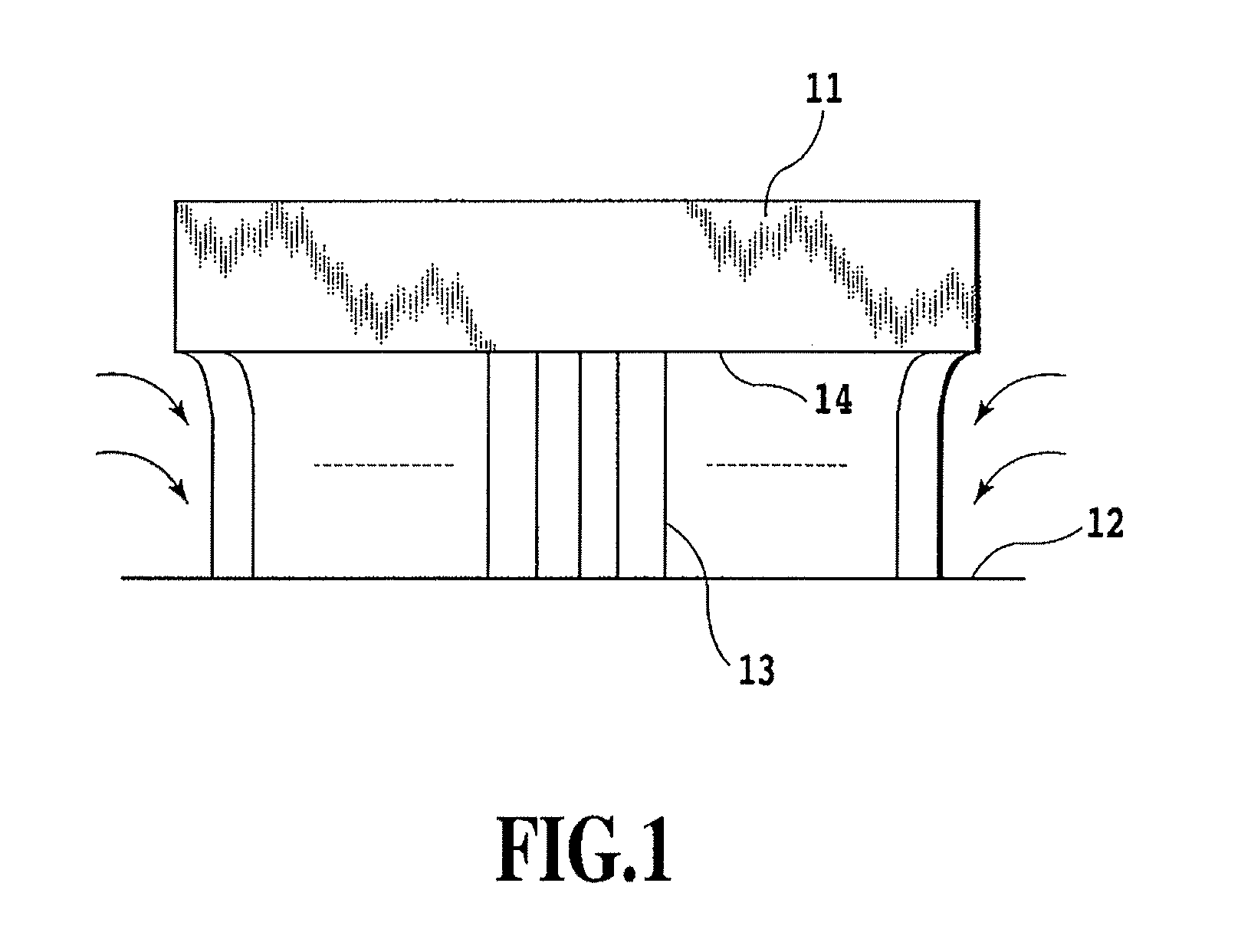

A solid electrolytic capacitor (A1) includes a first and a second porous sintered bodies (1). Each sintered body (1) is flat, with its thickness being small relative to the width or the length. The first and the second sintered bodies (1) are spaced from each other in the widthwise or lengthwise direction.

Owner:ROHM CO LTD

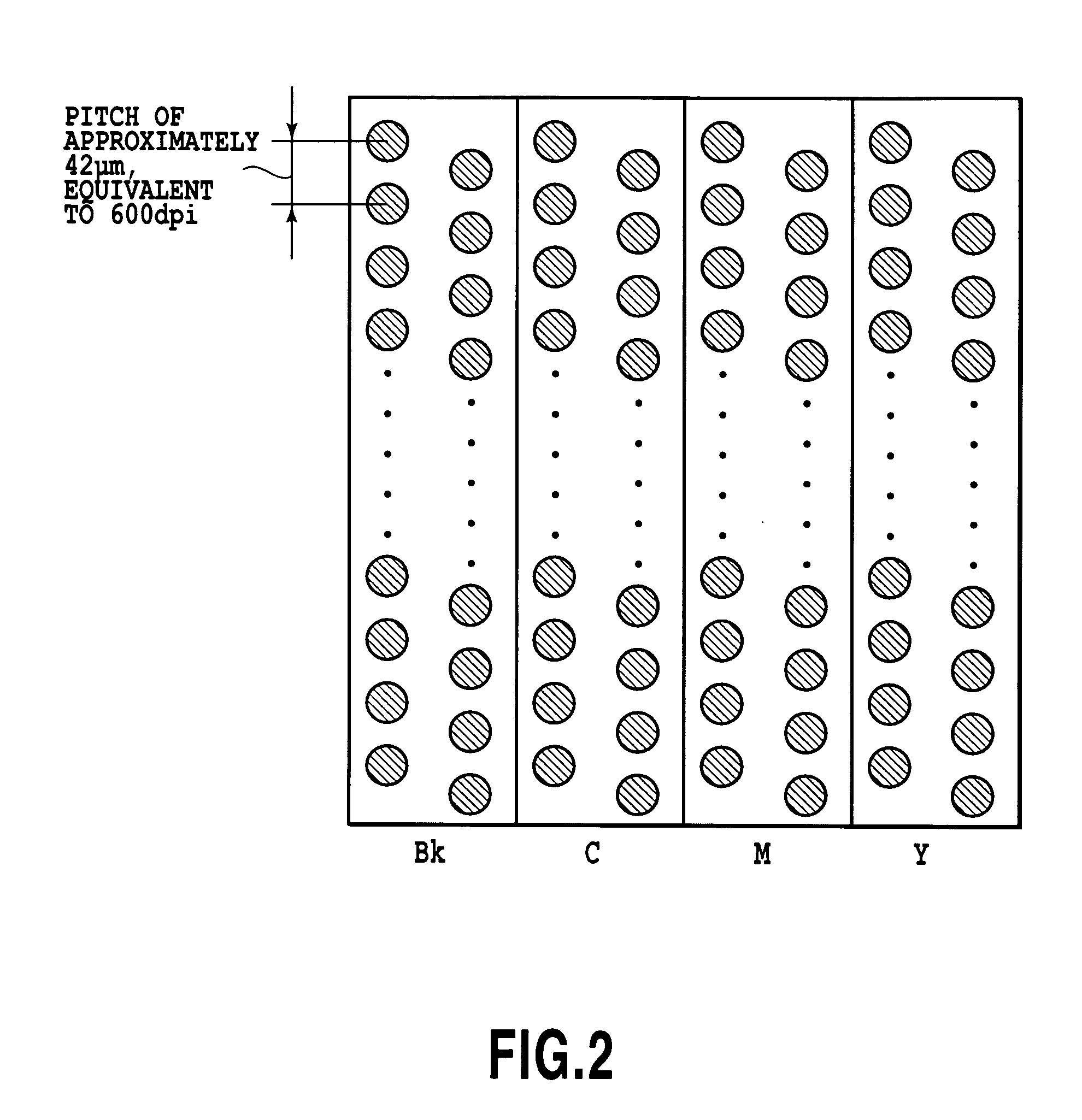

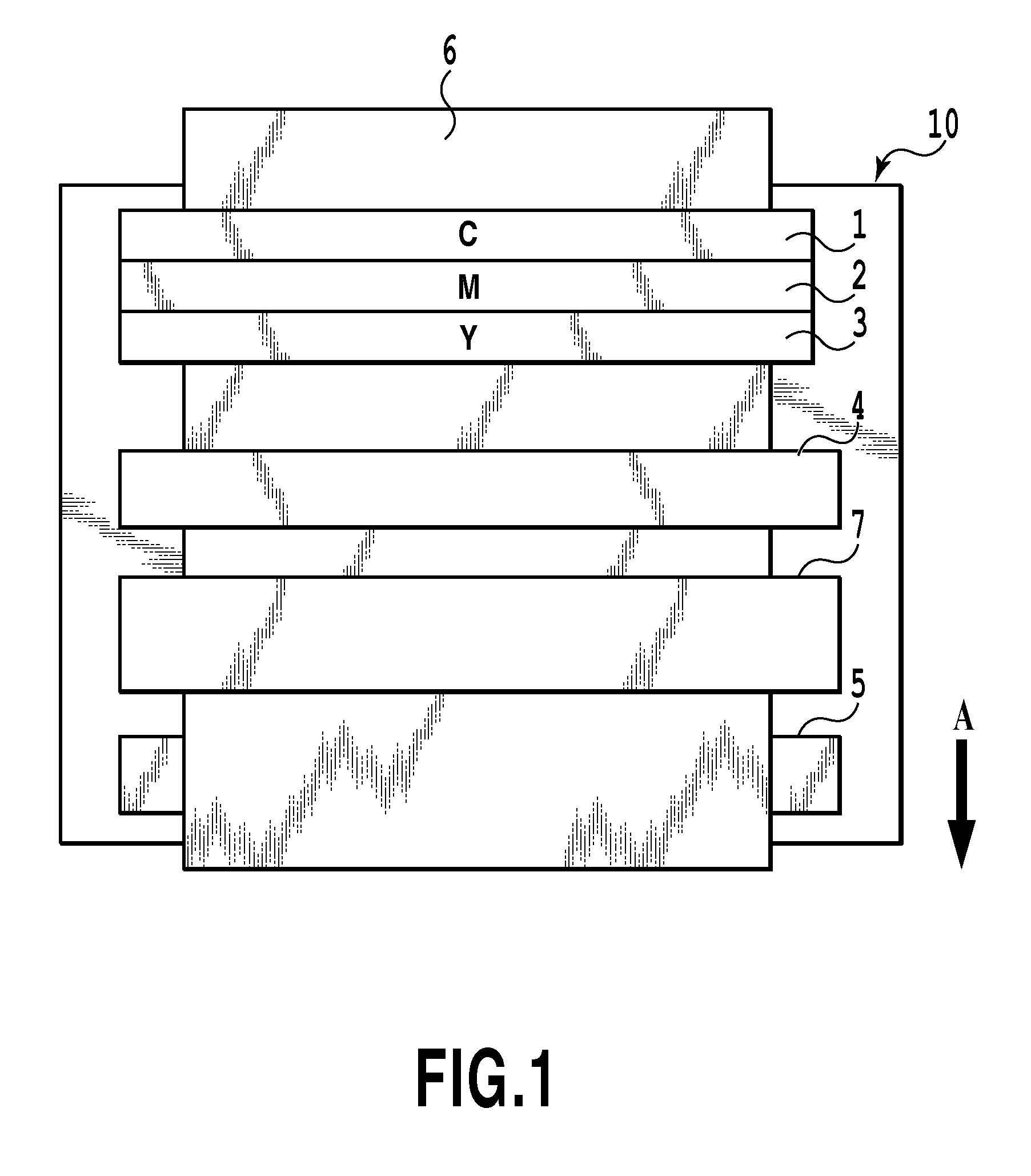

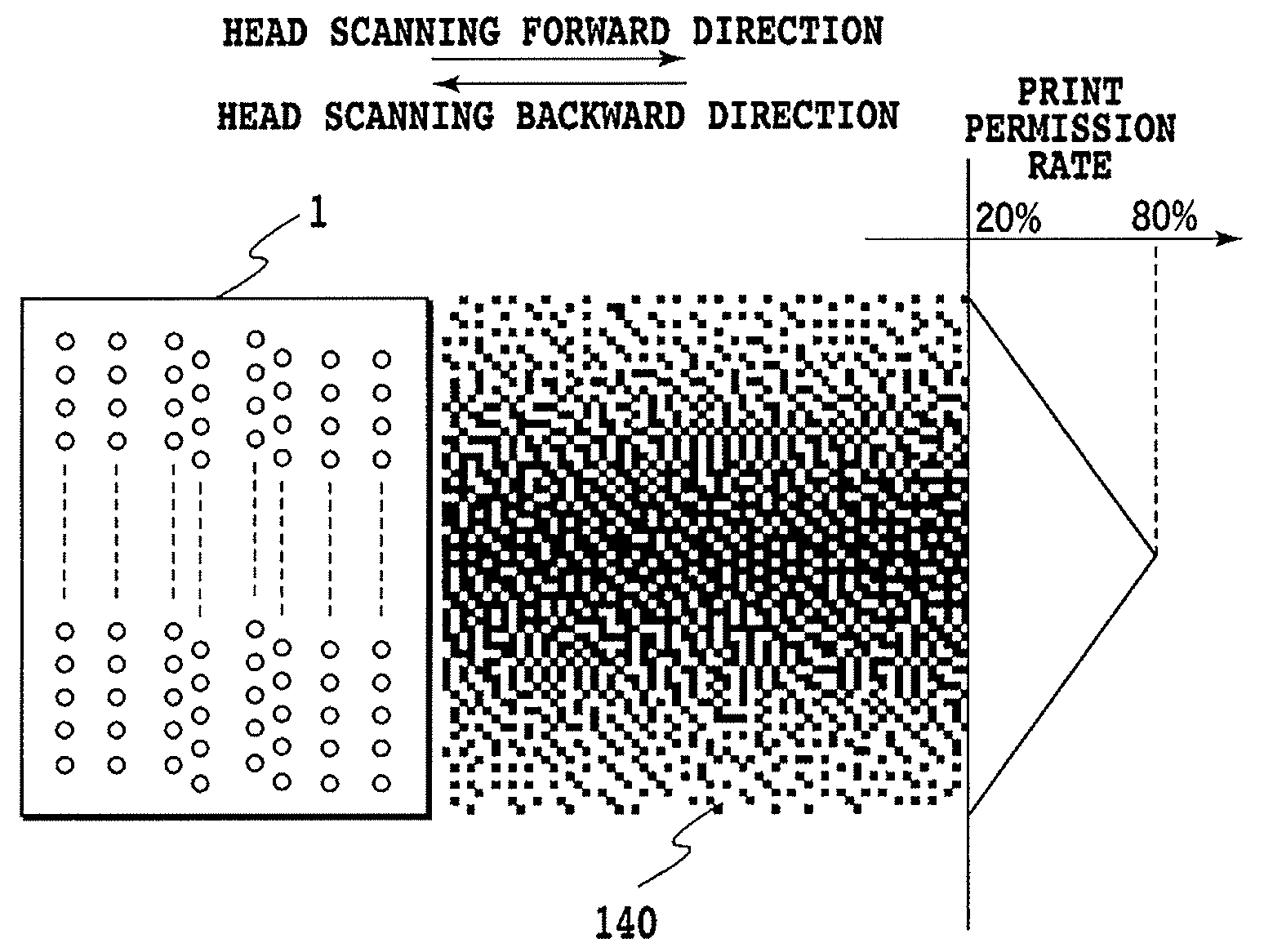

Inkjet printer and inkjet printing method

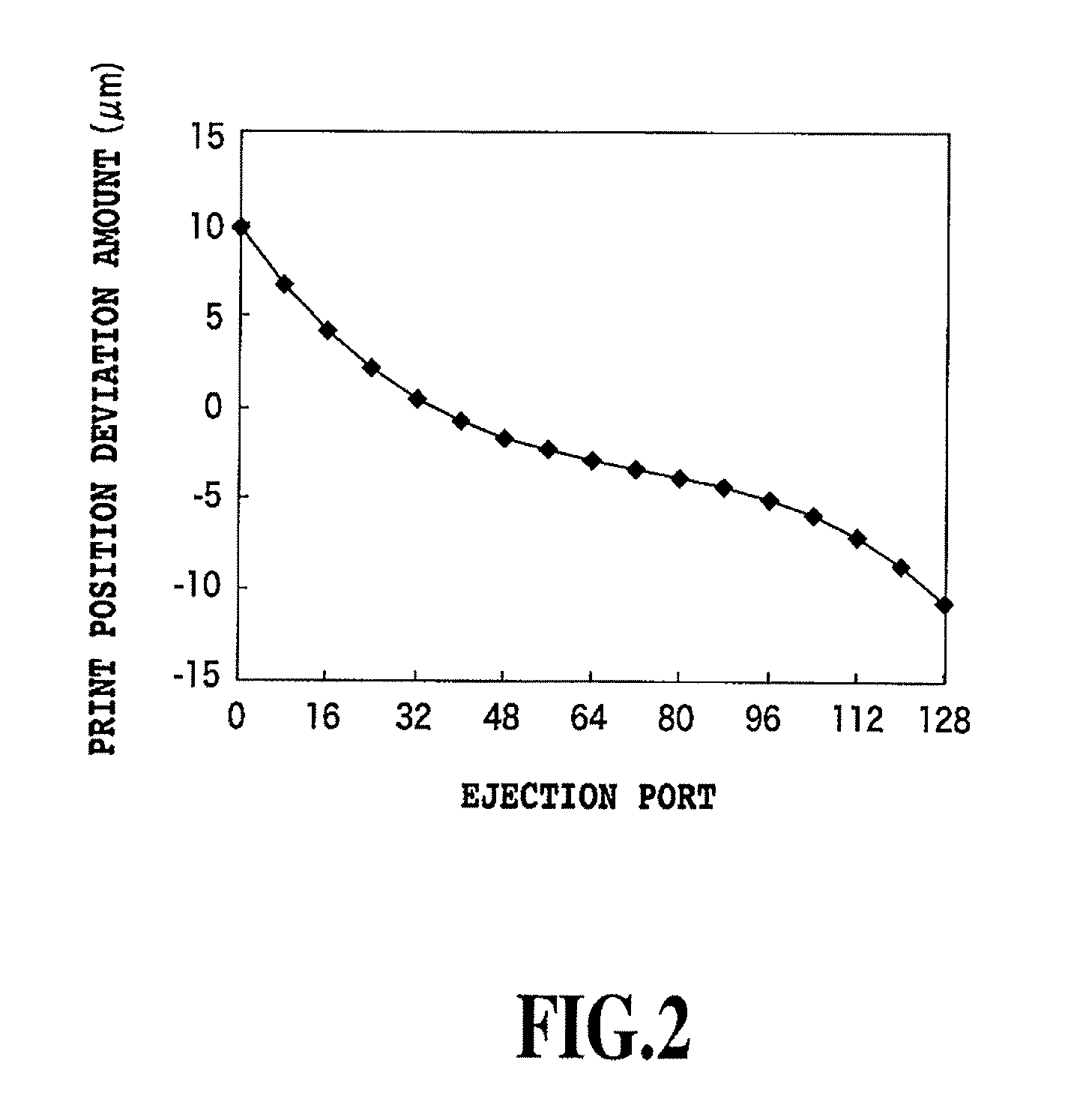

InactiveUS20070285451A1Quality improvementDensity unevennessOther printing apparatusSmall dropletComputer printing

An image is output, the image having high quality in which density unevenness due to an end-deviation is excellently reduced in all colors in forming an image with use of a bidirectional inkjet printing head provided with ejection port arrays of a plurality of colors for small droplets of ink. Thereby, distributions of print permission rates of mask patterns to be used in performing a multi-pass printing are made different from each other in accordance with a distance between the two ejection port arrays for the same kind of ink. Thus, the degree of the end-deviation depending on the distance between the two ejection port arrays can be suppressed for every ejection port array.

Owner:CANON KK

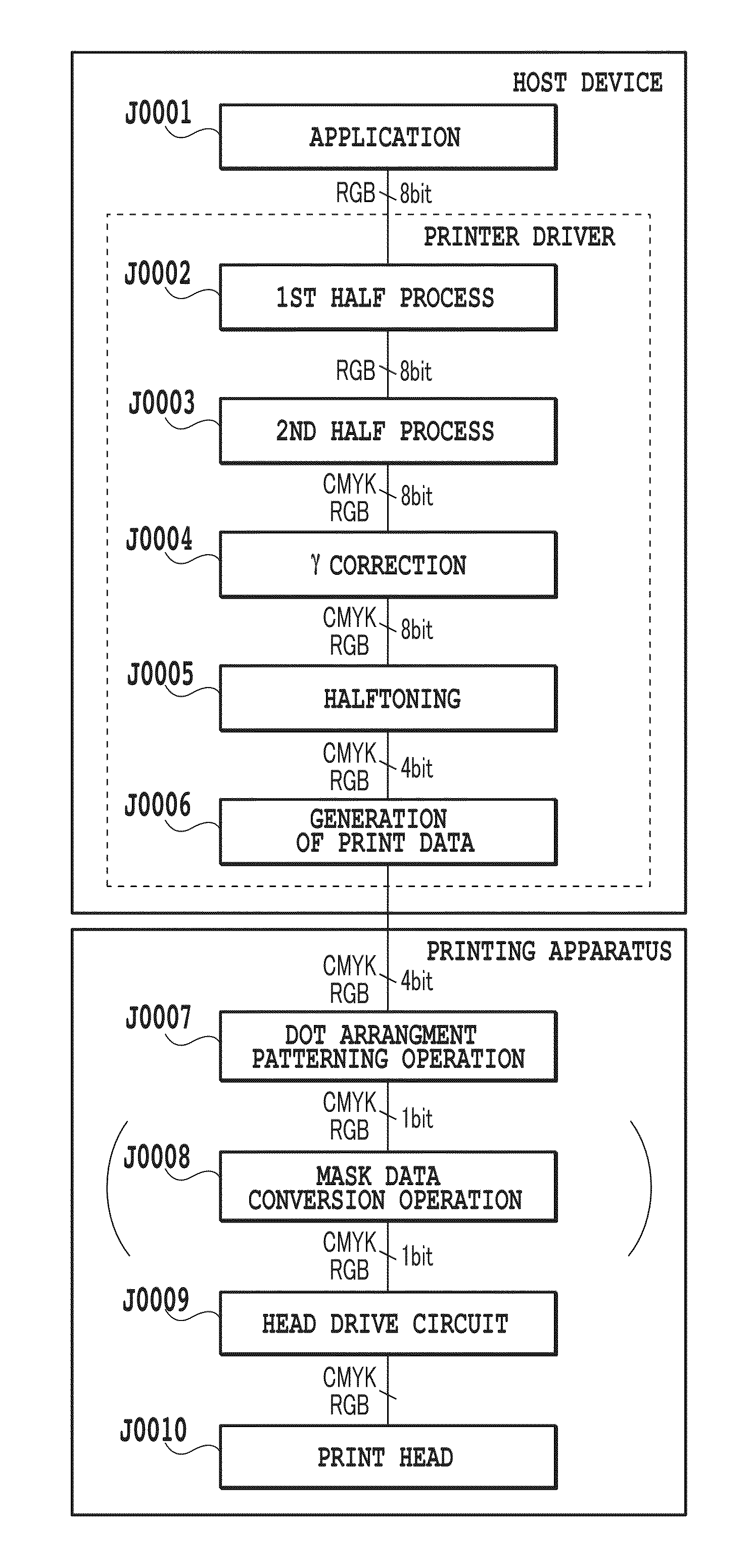

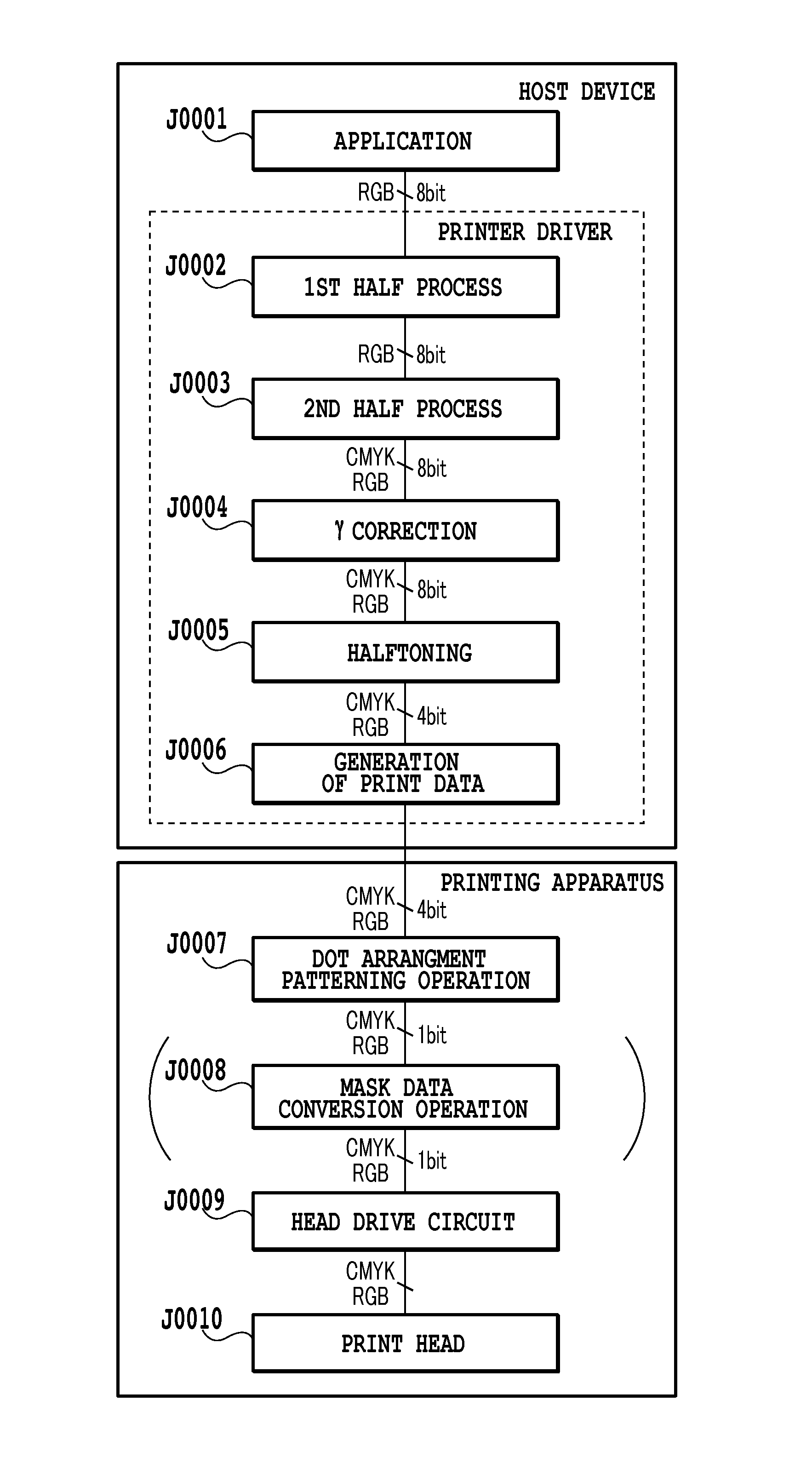

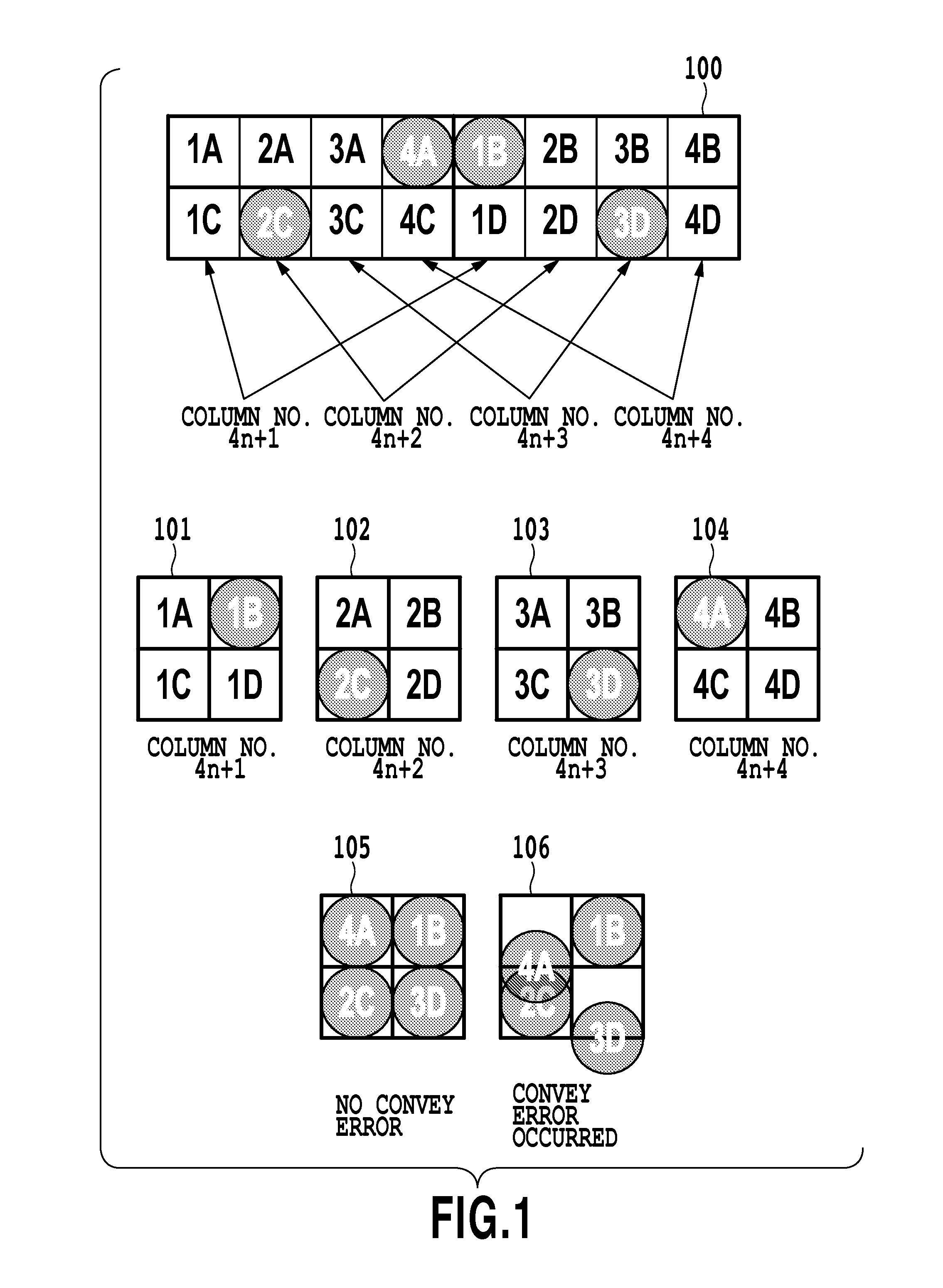

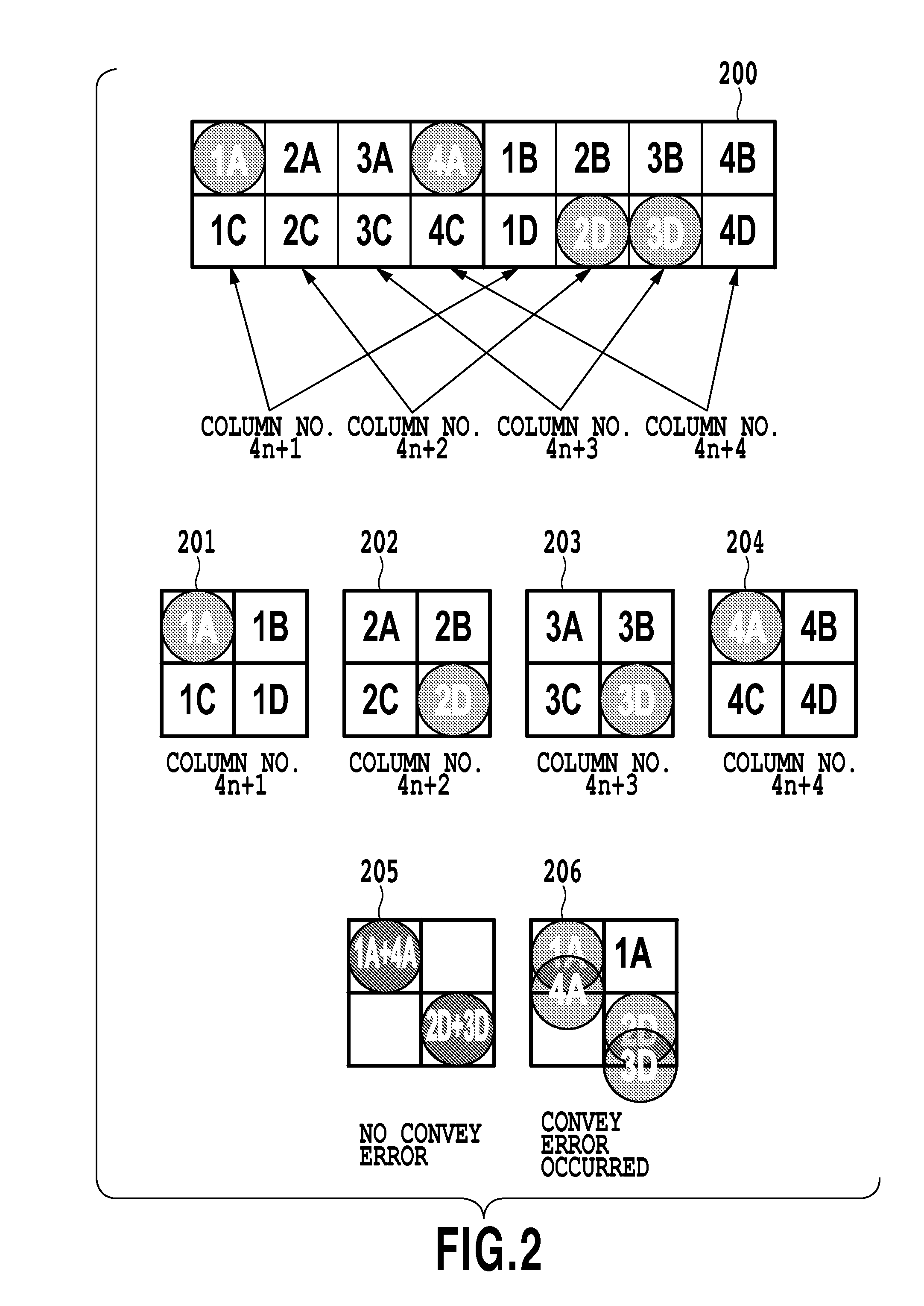

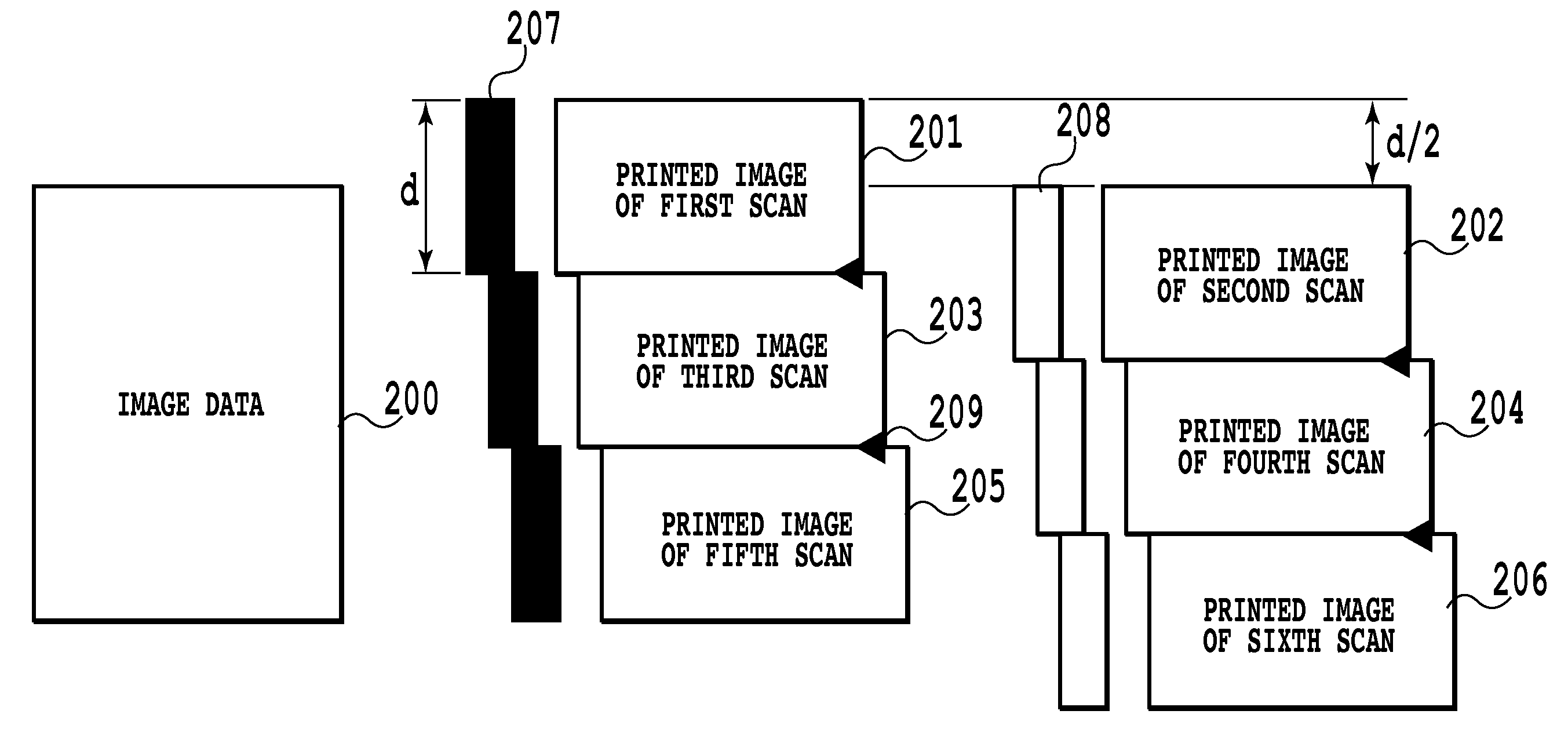

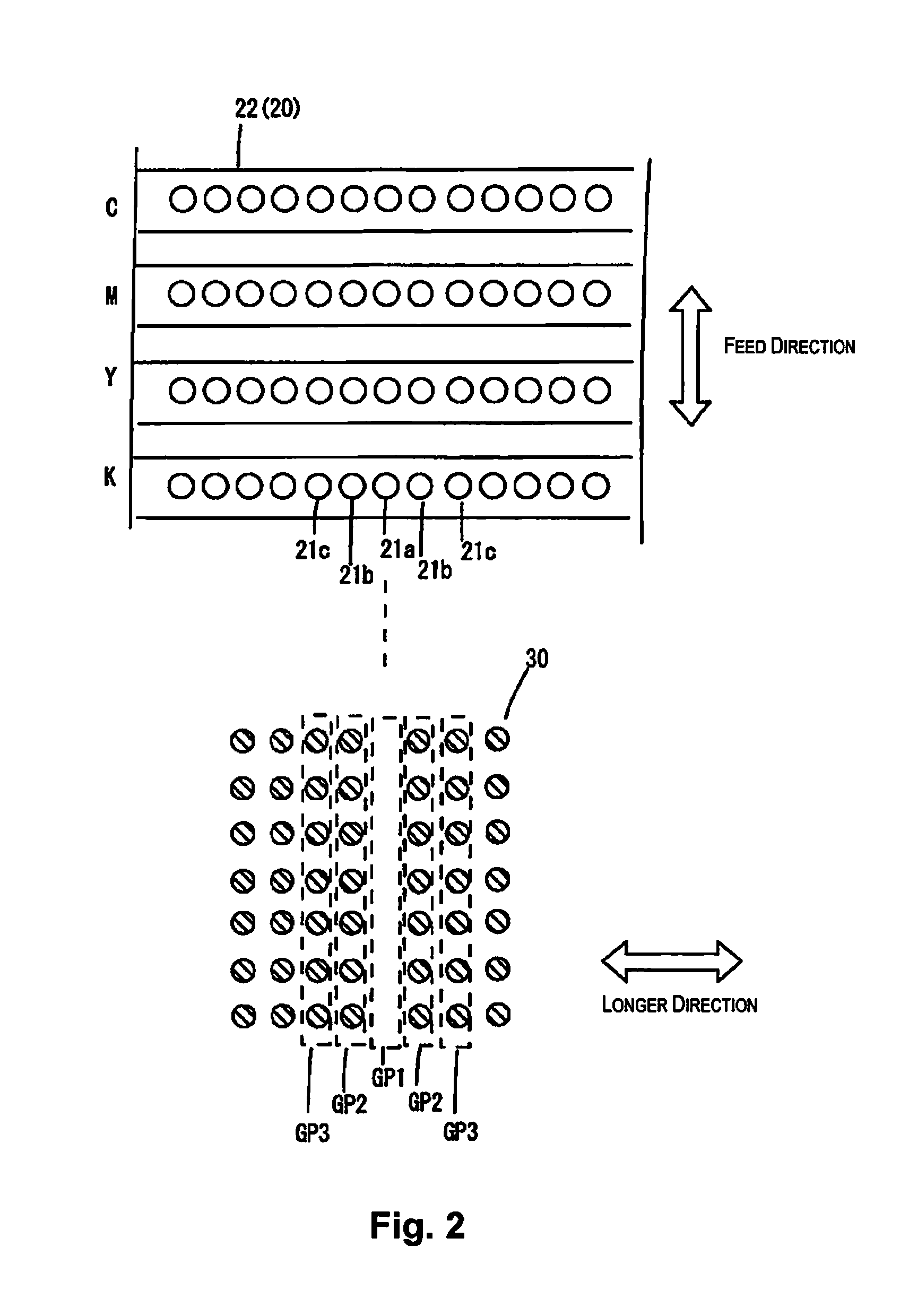

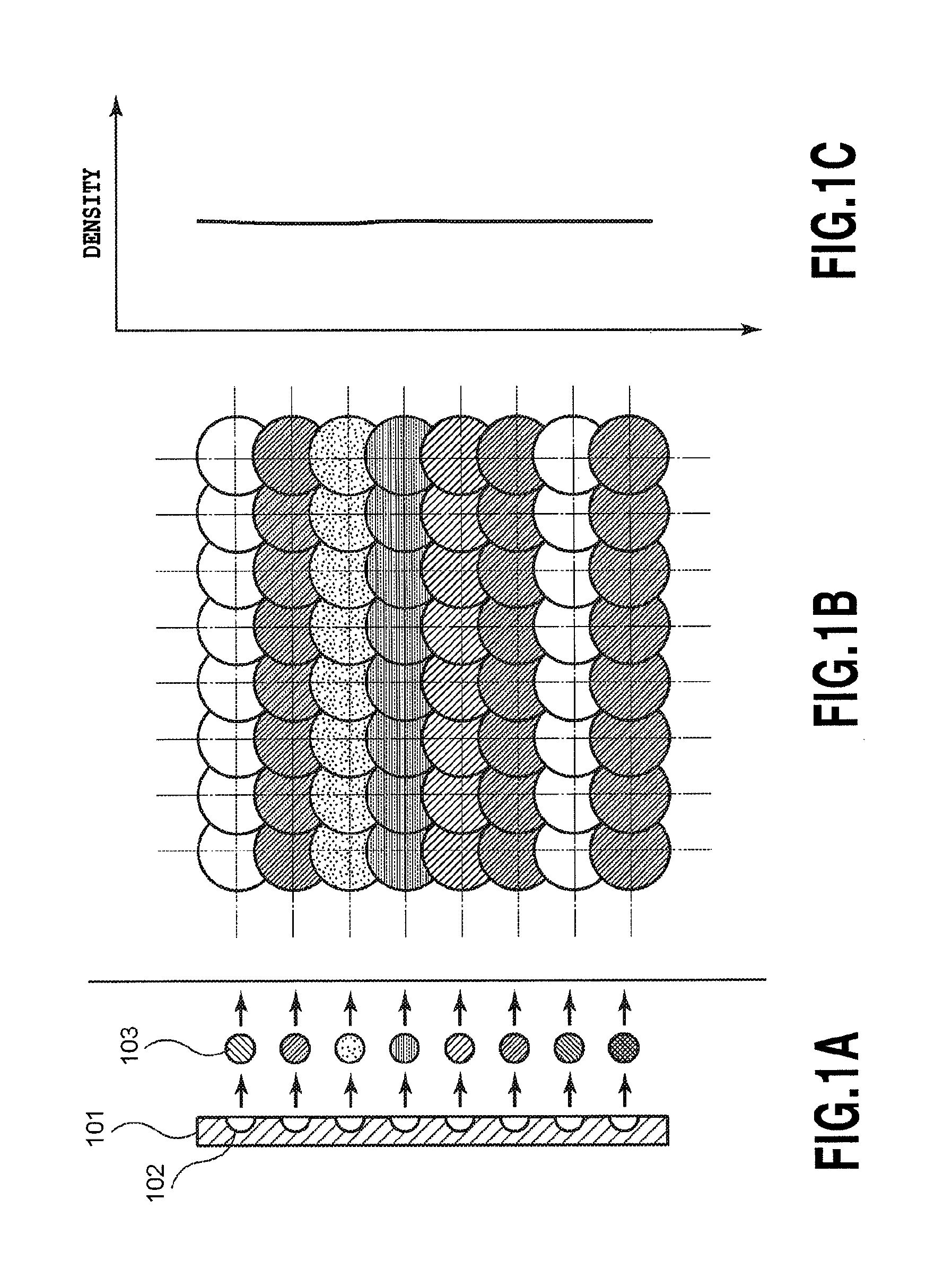

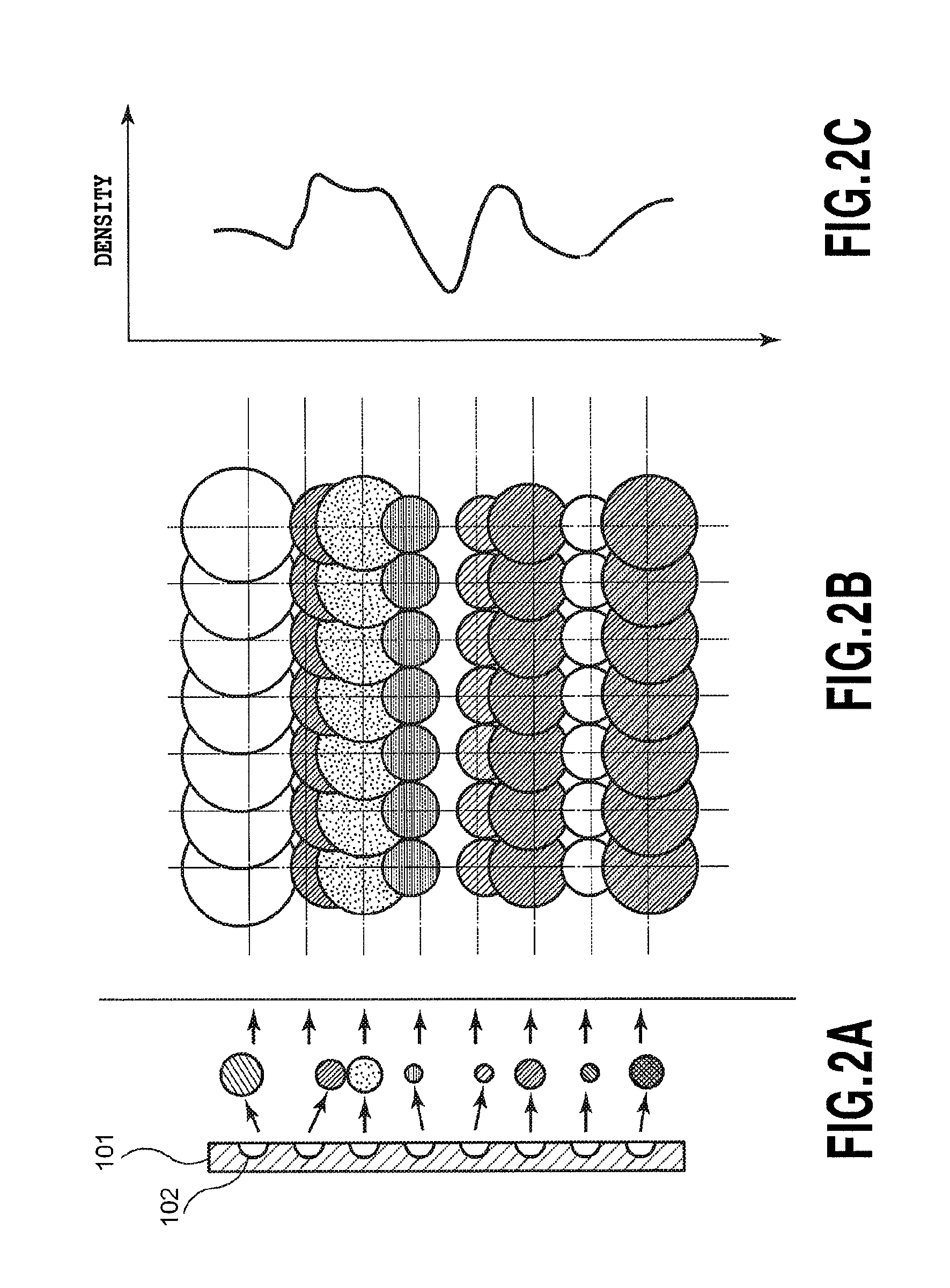

Printing apparatus, printing method and image processor

ActiveUS8287074B2Minimize changesDensity unevennessVisual presentationPrintingArea ratioImaging data

A printing apparatus and a printing method are provided which, even if a print position misalignment occurs between a plurality of print scans during a multipass printing, can minimize density variations in a unit area reliably and stably, thus producing an image without density unevenness. For this purpose, multi-grayscale-level image data is converted into a plurality of dot arrangement patterns that determine individual subpixels either to be printed or not to be printed with a dot. Then, these dot arrangement patterns are printed overlappingly on a print medium in different print scans of the print head. At this time, the plurality of dot arrangement patterns are so arranged that, if these dot arrangement patterns are shifted from one another, a change in the dot-overlapping area ratio will be smaller than when the dots are arranged separately so that they do not overlap one another.

Owner:CANON KK

Solid electrolytic capacitor

InactiveUS20070177336A1Good effectHigh electrical resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

A solid electrolytic capacitor (A1) includes a first and a second porous sintered bodies (1). Each sintered body (1) is flat, with its thickness being small relative to the width or the length. The first and the second sintered bodies (1) are spaced from each other in the widthwise or lengthwise direction.

Owner:ROHM CO LTD

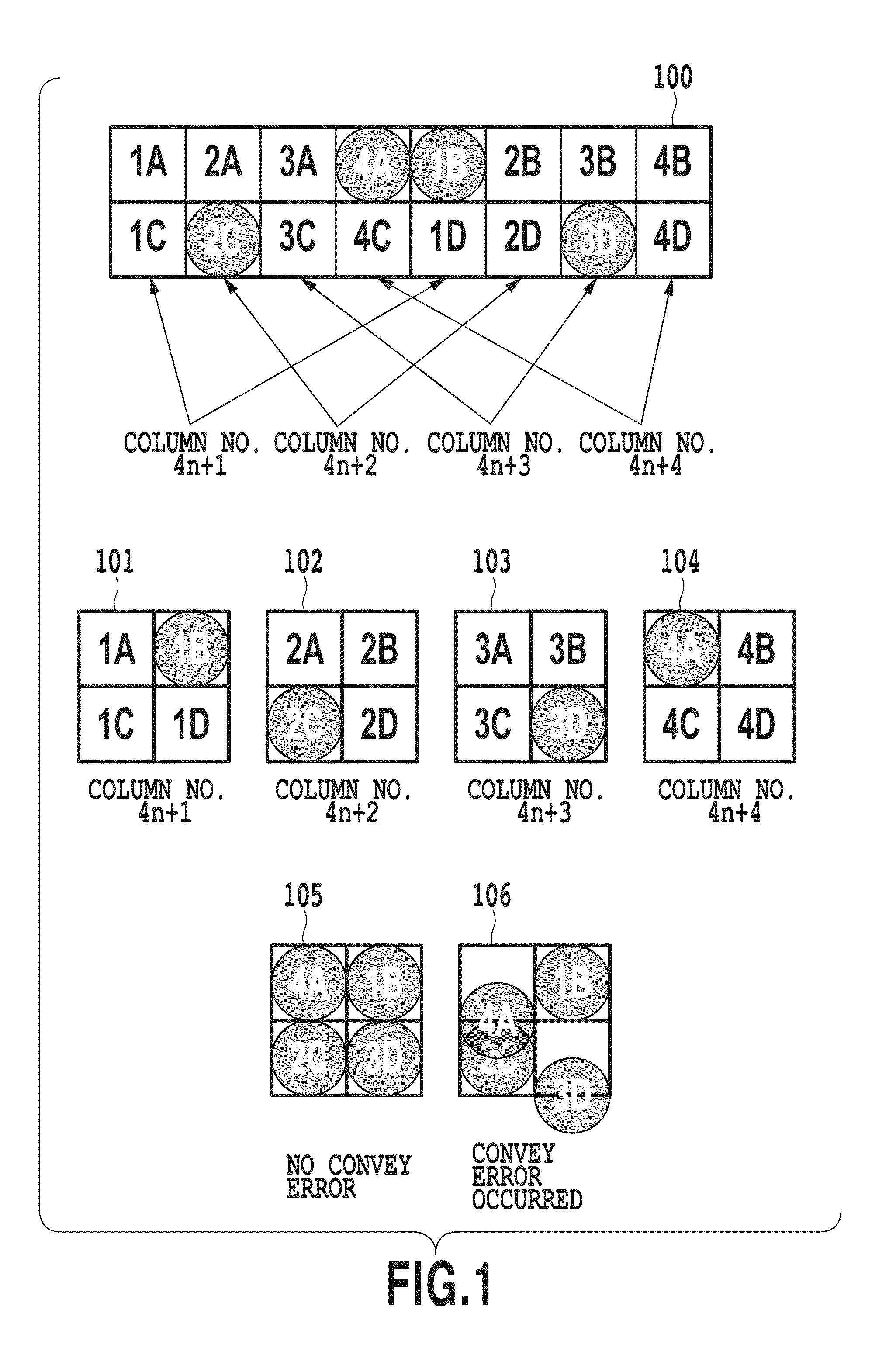

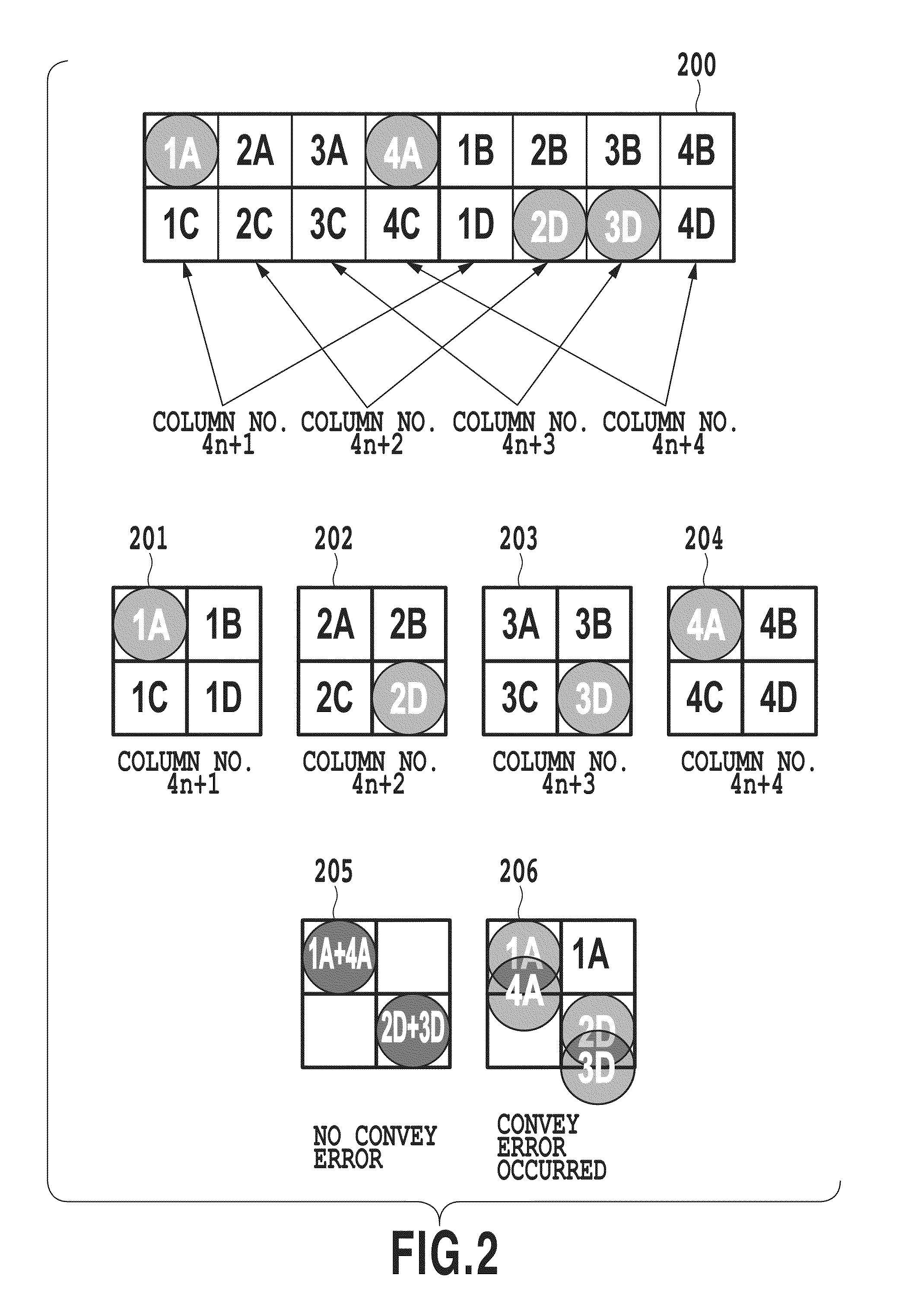

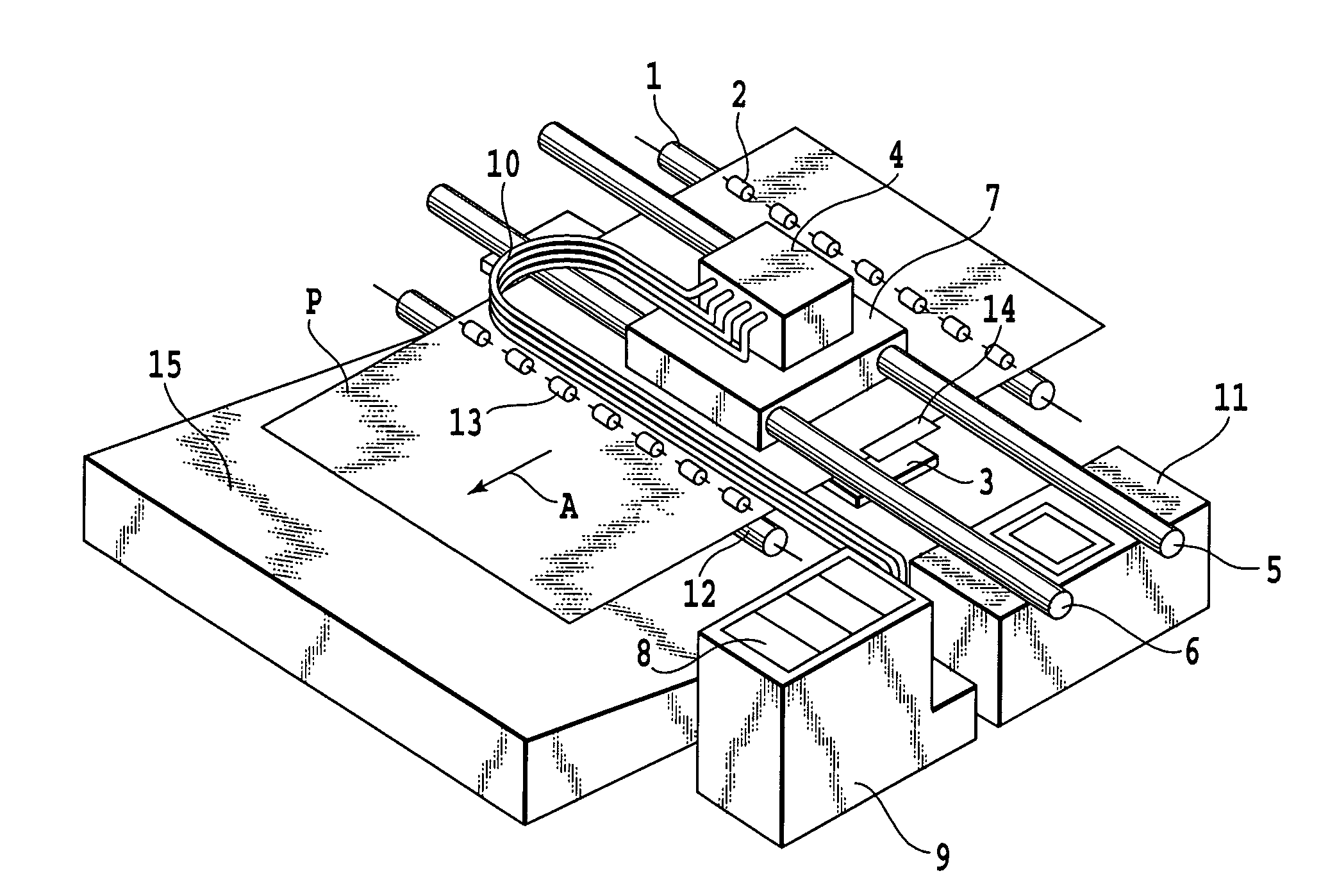

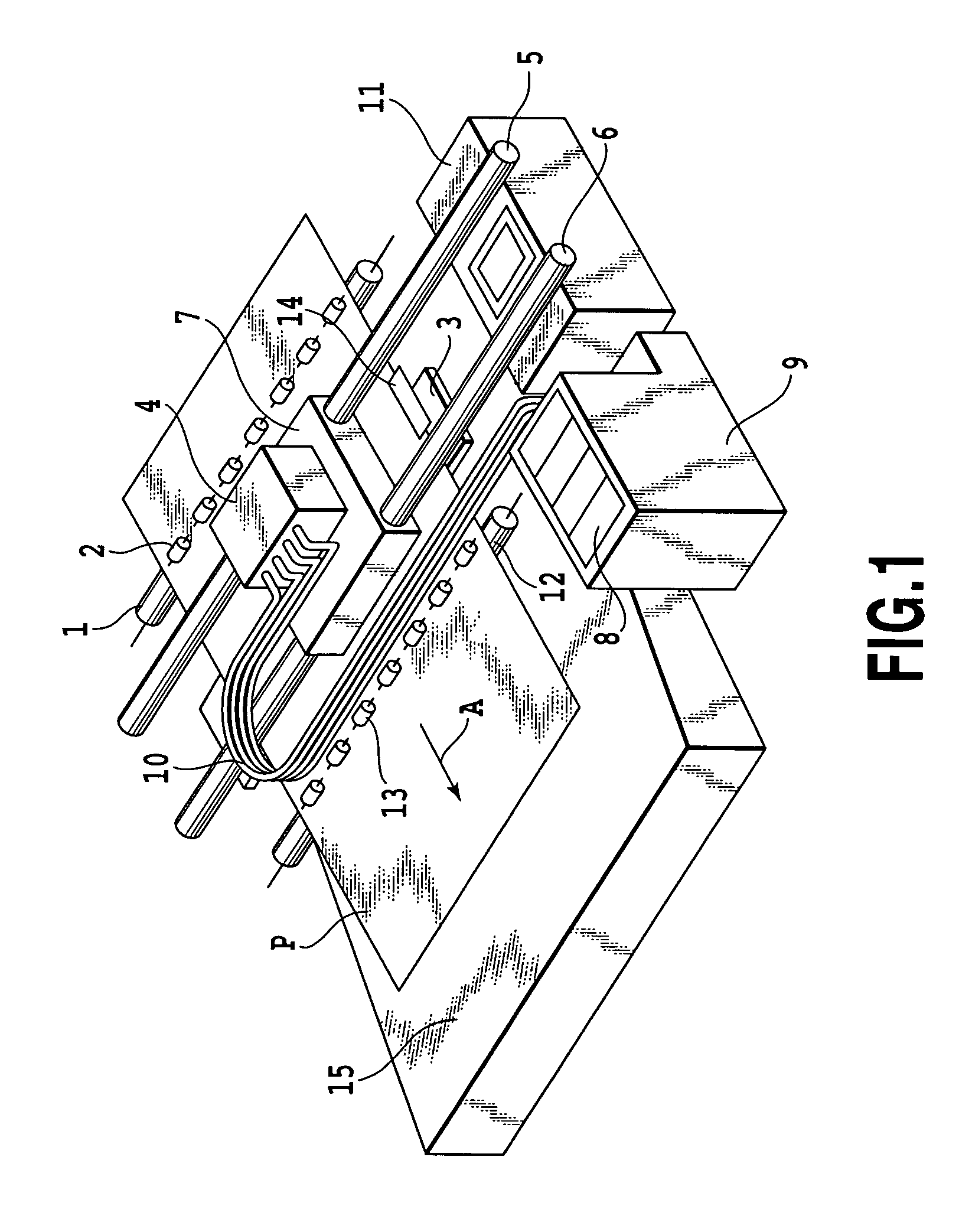

Inkjet printing apparatus and inkjet printing method

InactiveUS20080284808A1Reduce density unevennessReduce distanceOther printing apparatusEngineeringBrightness perception

Provided is an inkjet printing apparatus for performing a printing with a first nozzle array for ejecting a first color ink and a second nozzle array for ejecting a second color ink. The apparatus reduces density unevenness stemming from a sudden error in conveyance of a printing medium. When the apparatus performs a scan with respect to the printing medium for printing in which using ranges of nozzles in the first and second nozzle arrays are restricted to parts thereof, the restricted using ranges of the first and second nozzle arrays are shifted from each other. Thereby, the density unevenness stemming from the error in conveyance occur in positions which are different between the first and second colors, Thus, it possible to make the overall density unevenness less obvious by making gradients of variations in brightness and chroma of an image smaller.

Owner:CANON KK

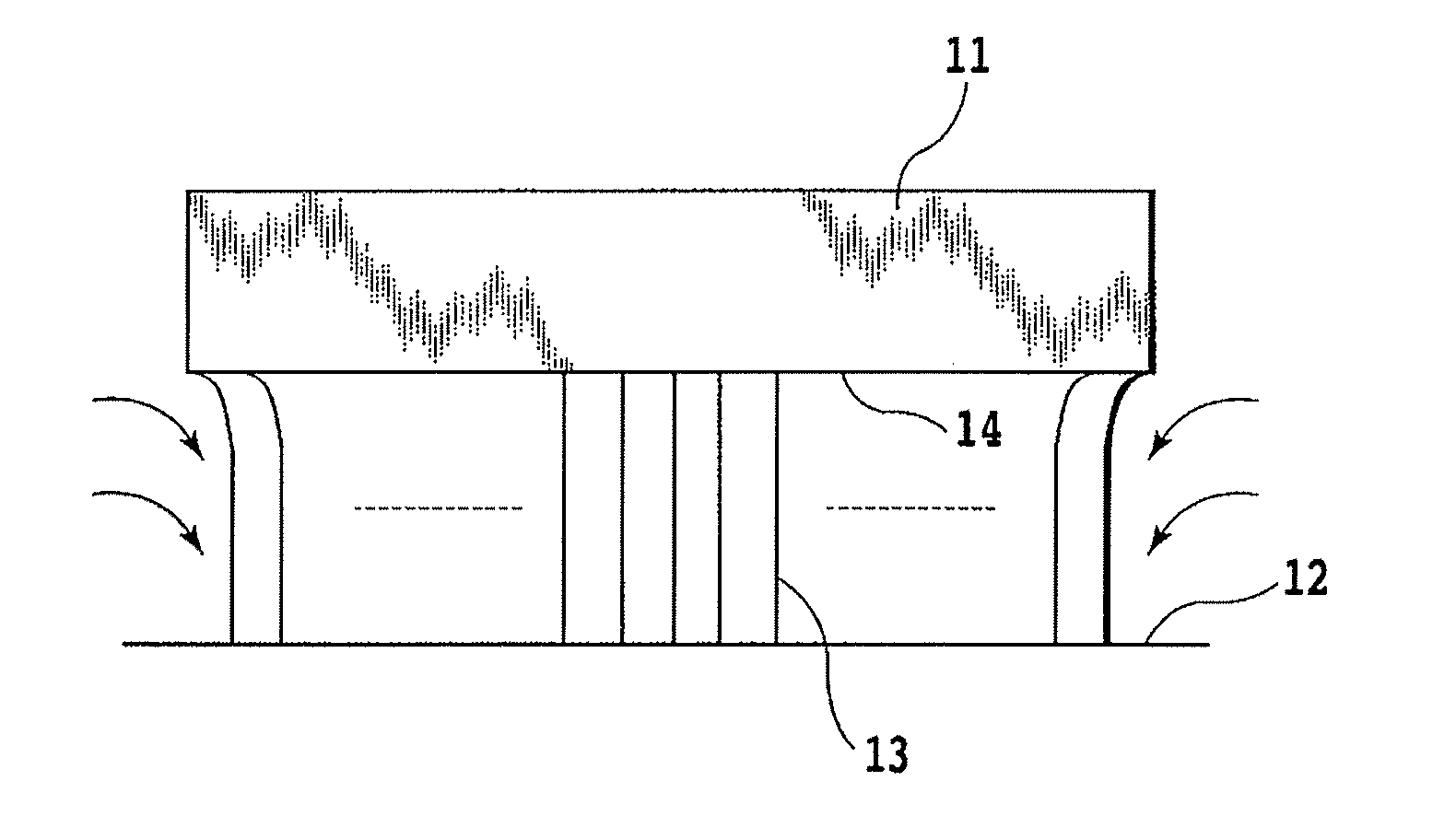

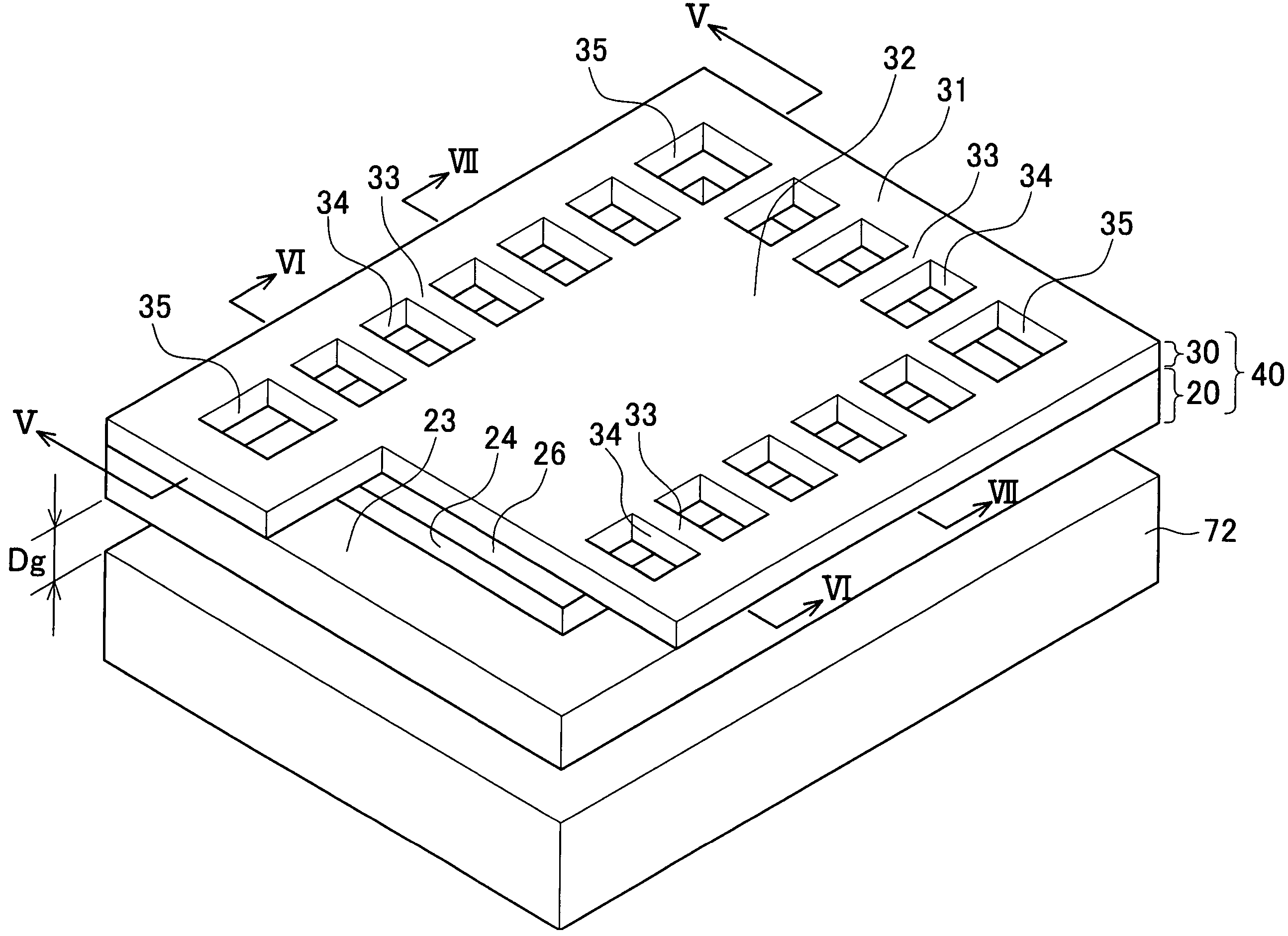

Stencil masks, method of manufacturing stencil masks, and method of using stencil masks

InactiveUS20070077501A1Easy to manufactureEfficient use ofElectric discharge tubesNanoinformaticsSurface patternElectrical conductor

The present invention presents a stencil mask in which various surface patterns can be formed, and in which deformation is suppressed when charged particles are introduced. A stencil mask of the present invention is provided with a semiconductor stack. A first penetrating hole corresponding to an ion introducing area is formed in a first semiconductor layer of the semiconductor stack, and second penetrating holes are formed in a second semiconductor layer, these second penetrating holes having a width greater than the width of the first penetrating hole. The first penetrating hole and the second penetrating holes communicate and pass through the semiconductor stack. Beam members extending between adjacent second penetrating holes connect portions of the first semiconductor layer separated by the first penetrating hole.

Owner:TOYOTA JIDOSHA KK

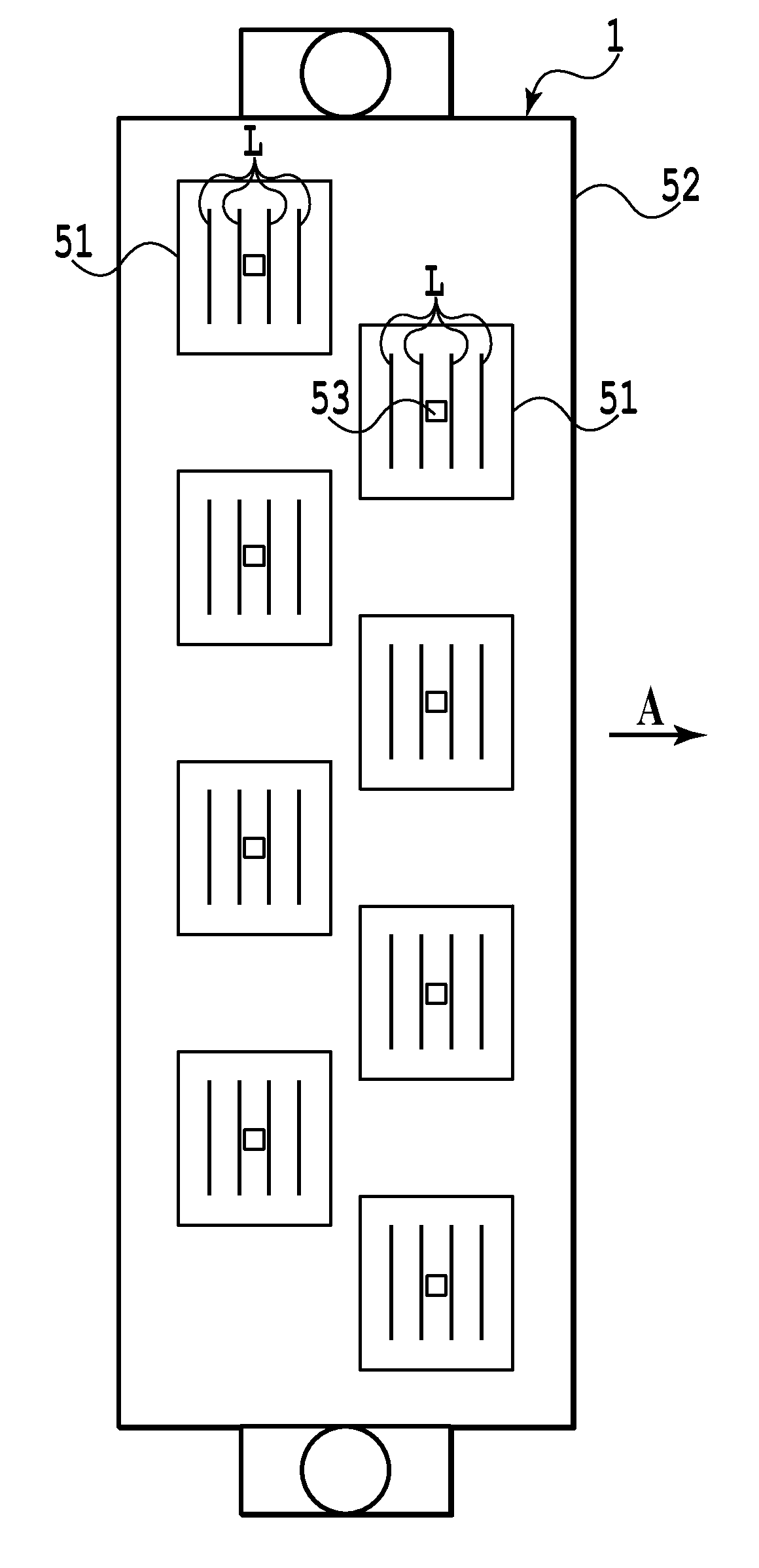

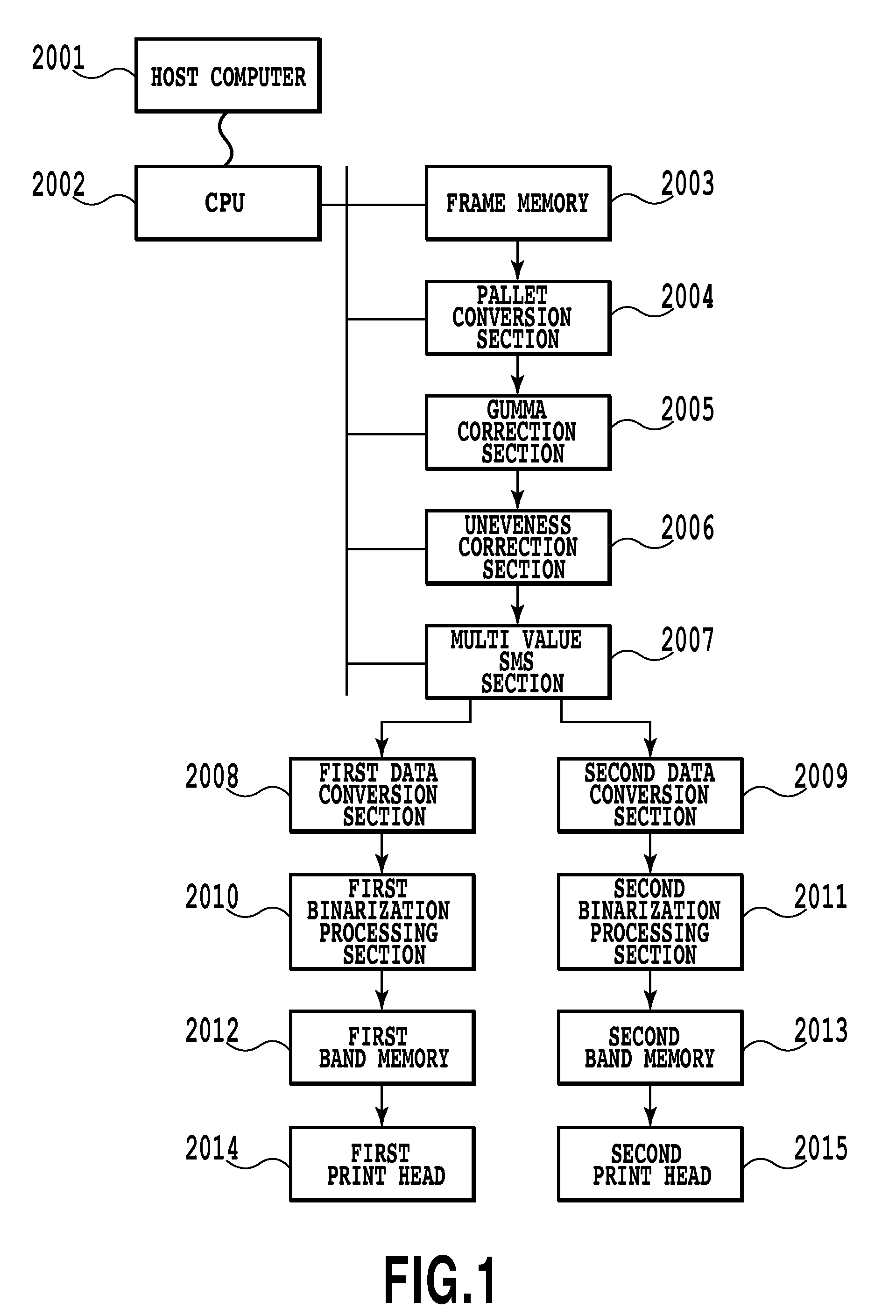

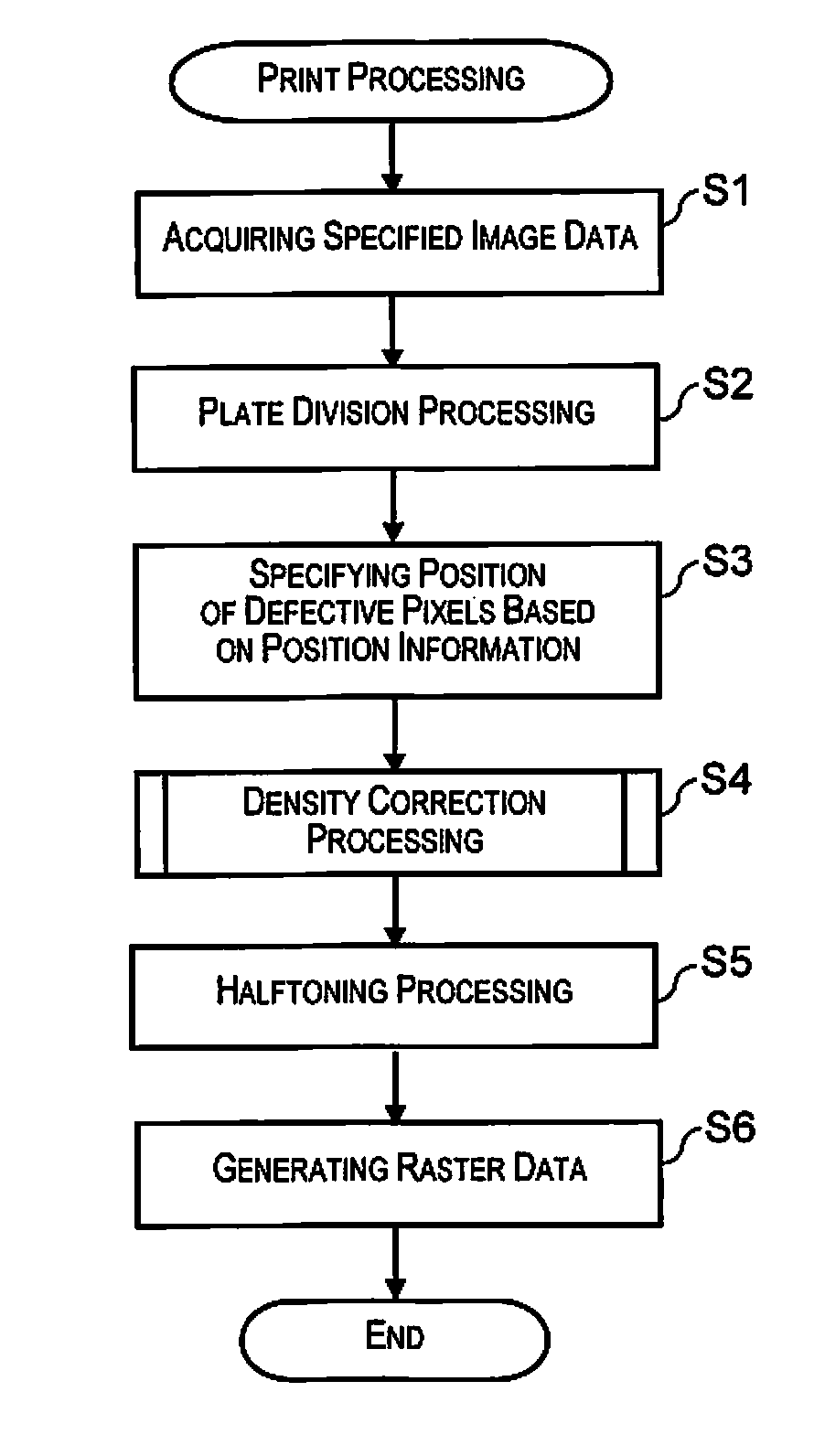

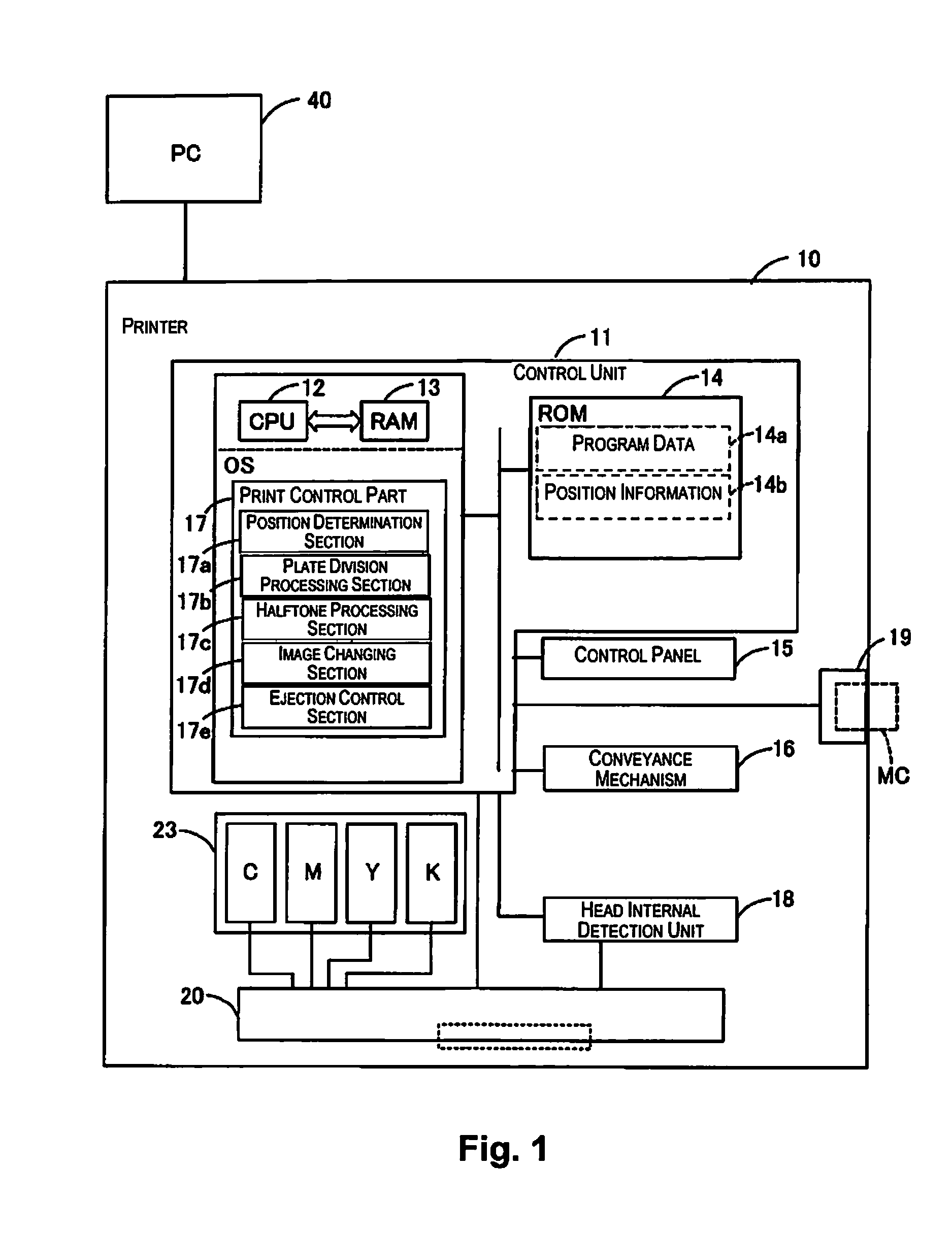

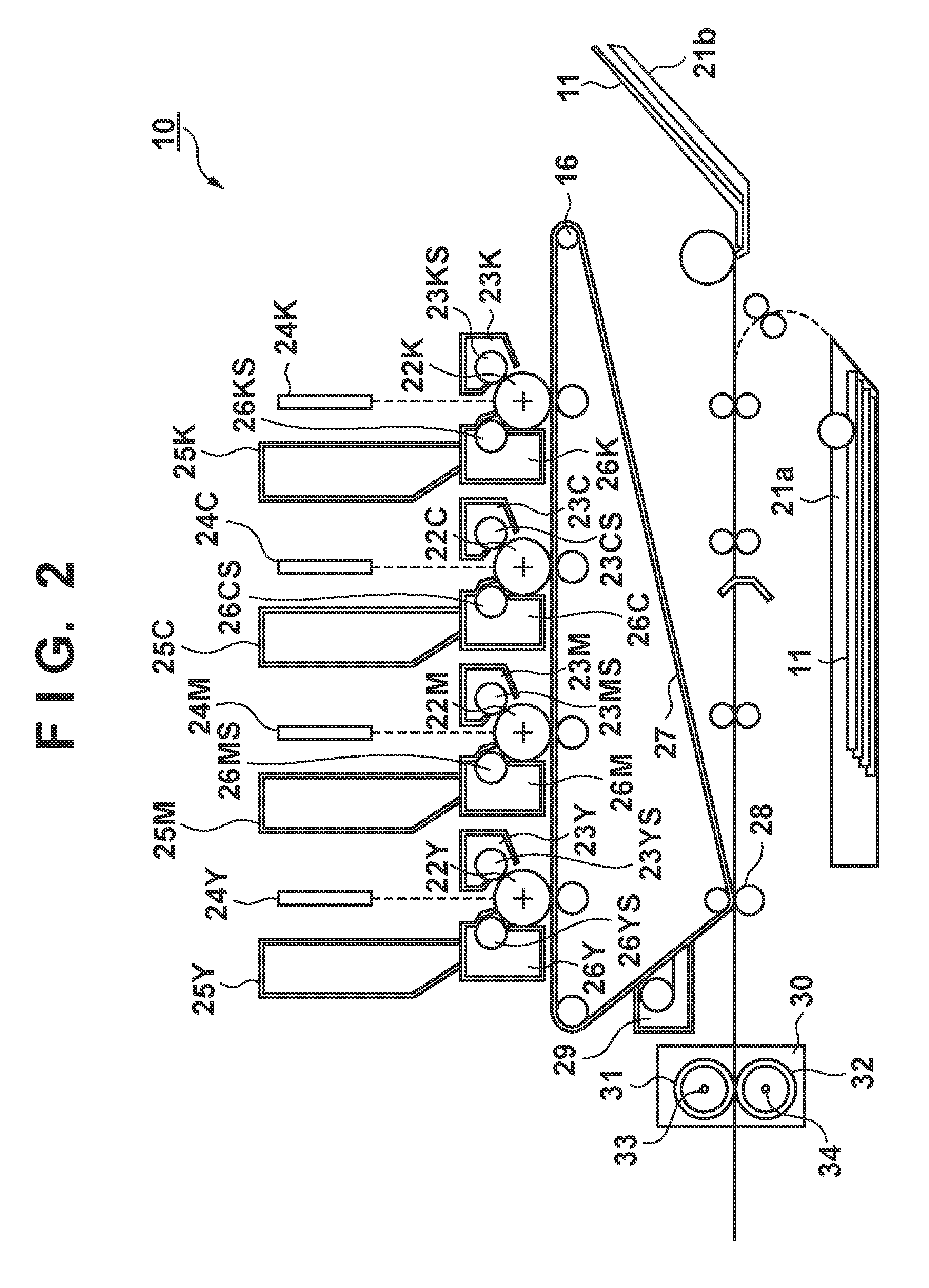

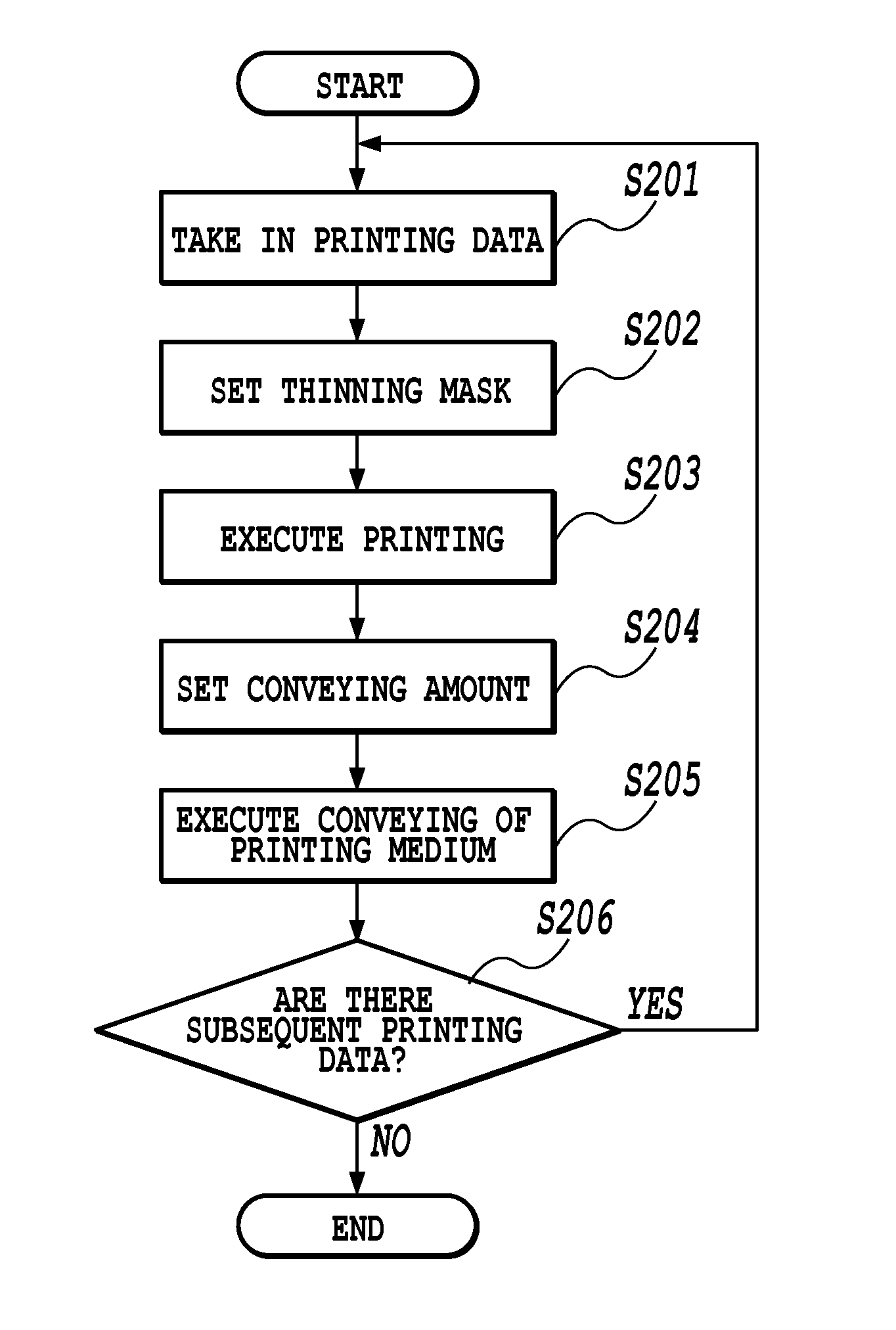

Printing apparatus and method for controlling printing apparatus

InactiveUS20120069067A1Reduce the number of processing stepsDensity unevennessDigitally marking record carriersVisual presentation using printersVolumetric Mass DensityEngineering

According to the present invention, each printing head includes chips wherein a plurality of nozzles are prepared. The density of dots formed by ejecting ink from the nozzles is detected for each chip, and when a density difference between the chips is smaller than a predetermined value, print data are corrected, and the number of dots is adjusted so as to reduce the density difference. When the density difference is equal to or greater than the predetermined value, first, a drive pulse for the nozzles is modulated and the volume of ink to be ejected for one dot is adjusted so as to reduce the density difference. Thereafter, the print data is corrected, and the number of dots to be formed is controlled so as to reduce the density difference.

Owner:CANON KK

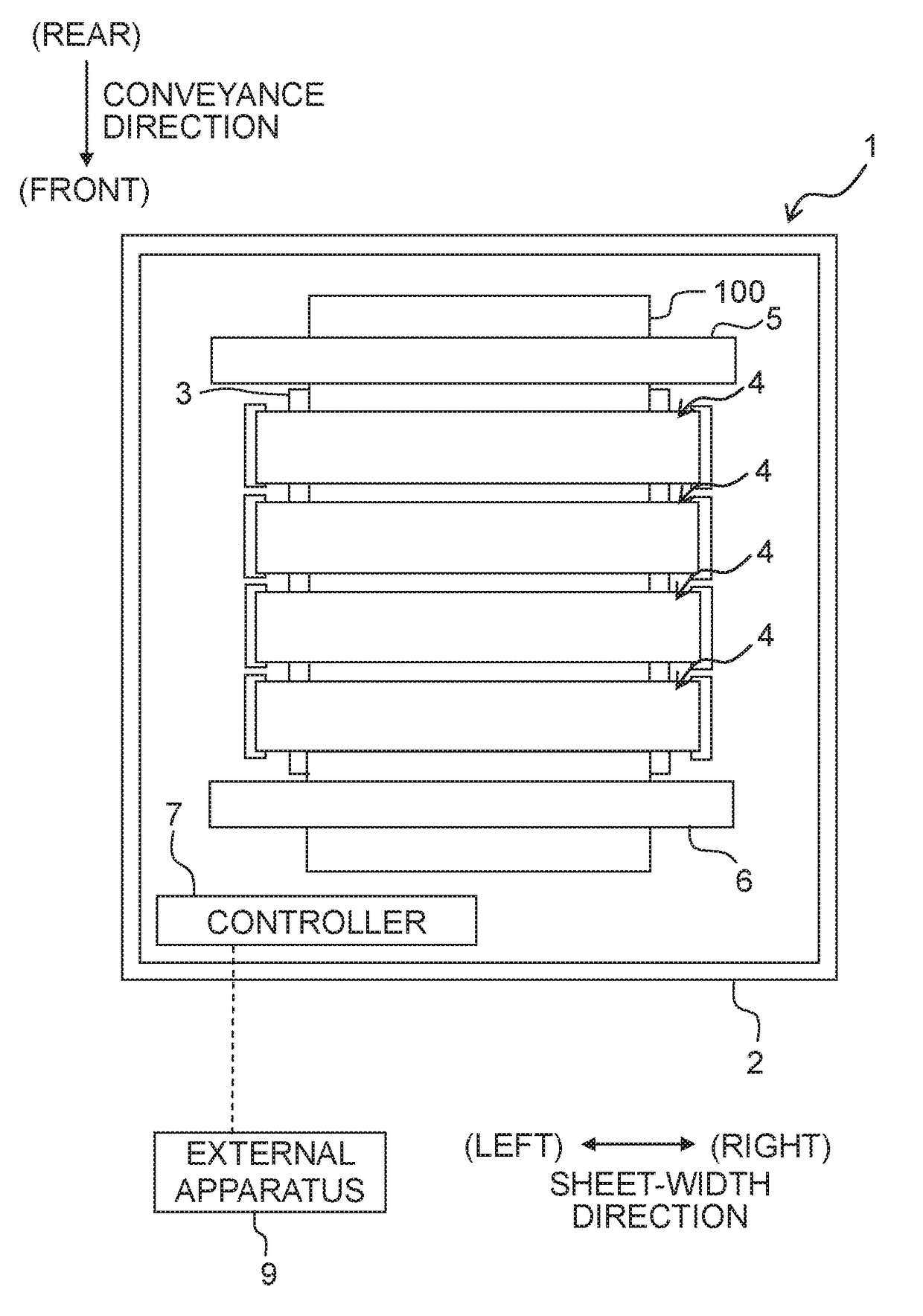

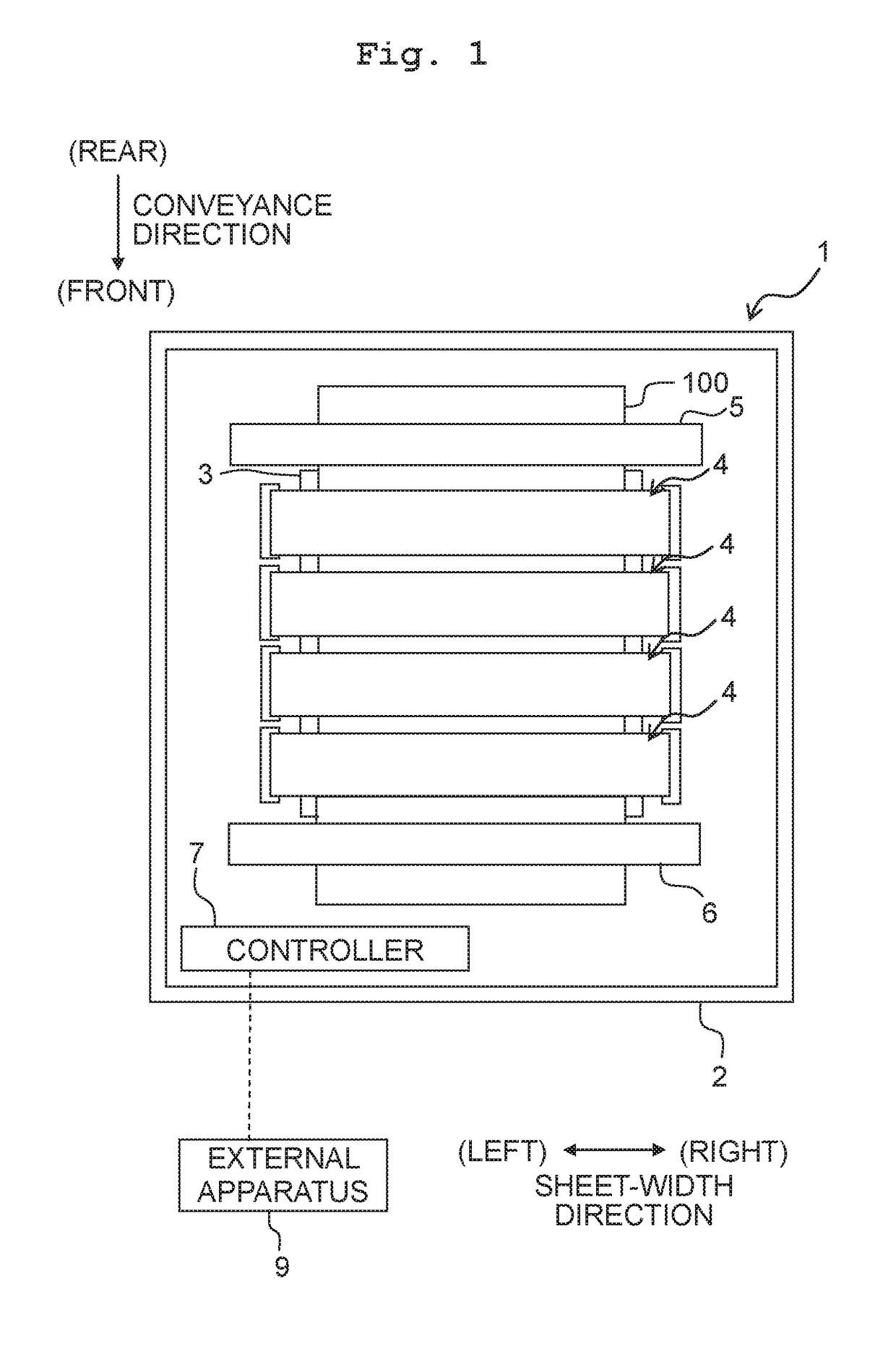

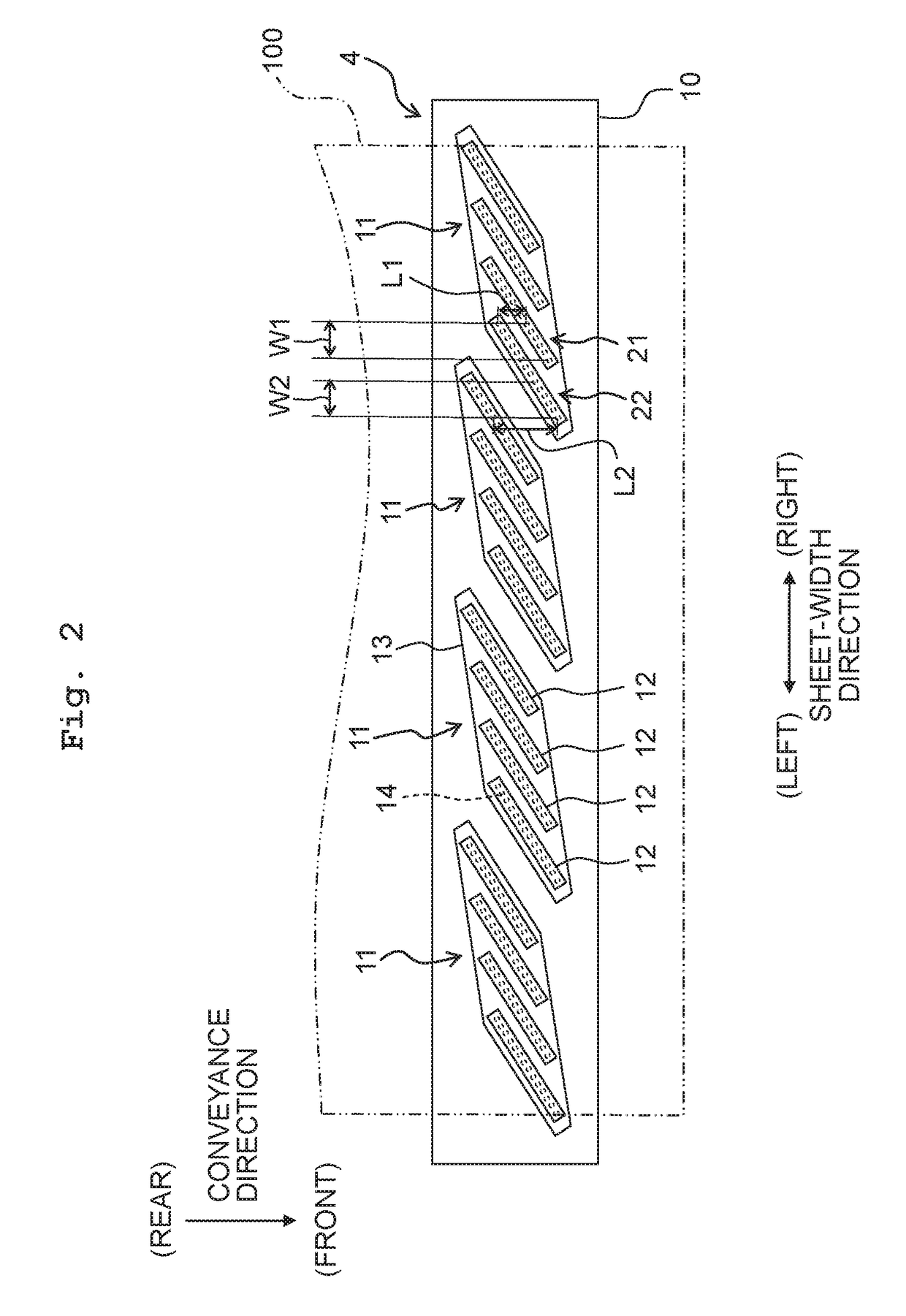

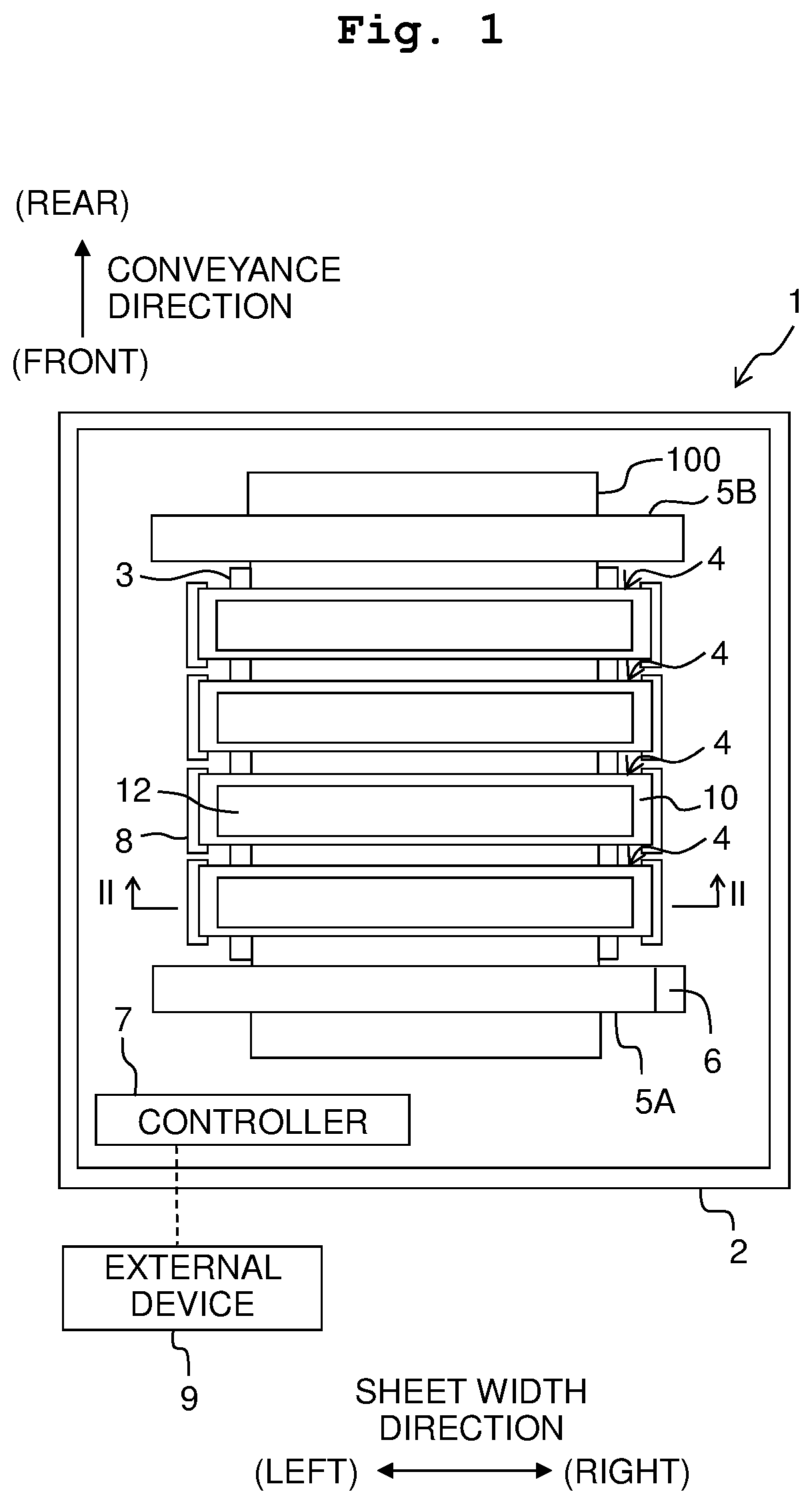

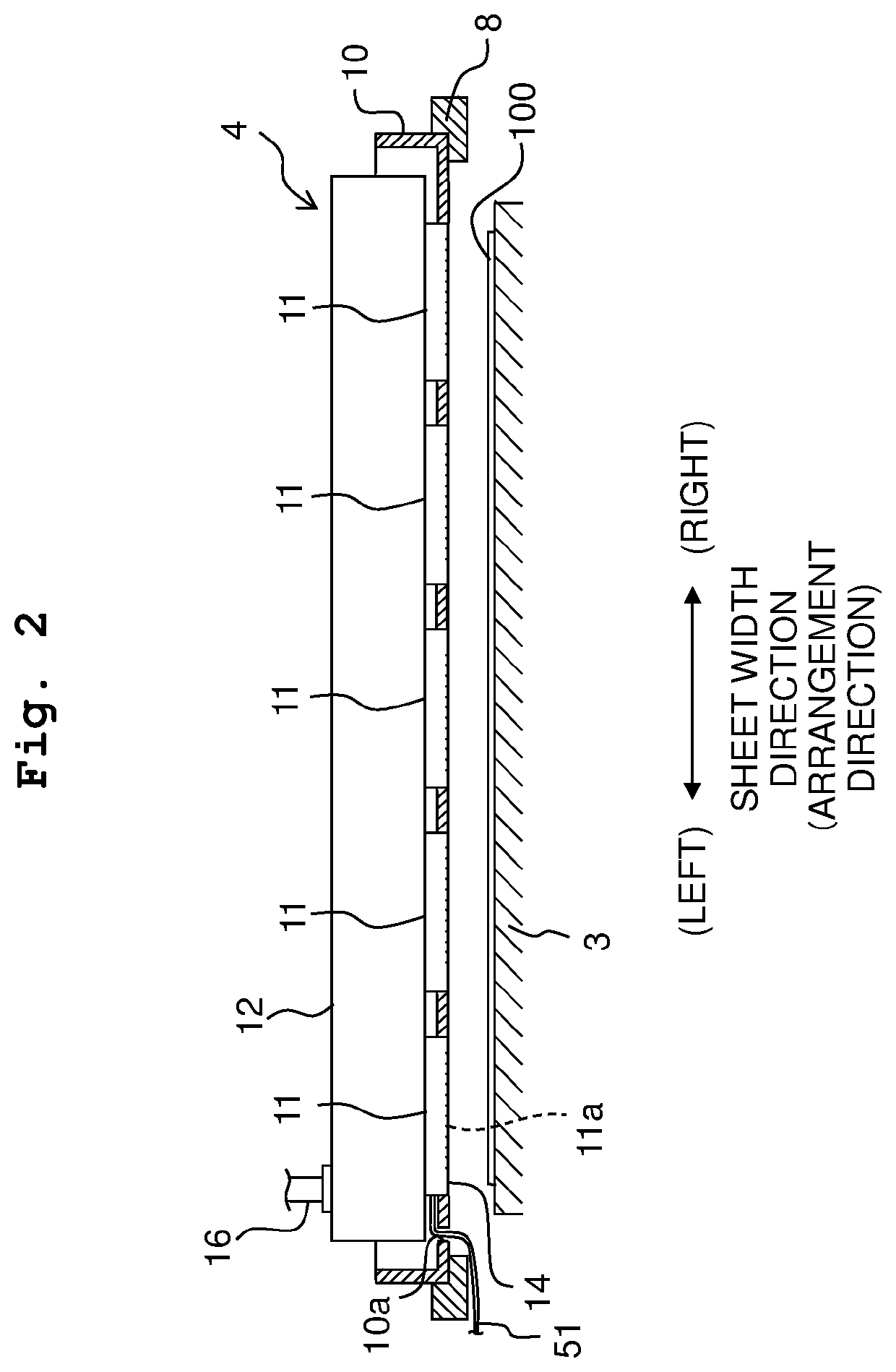

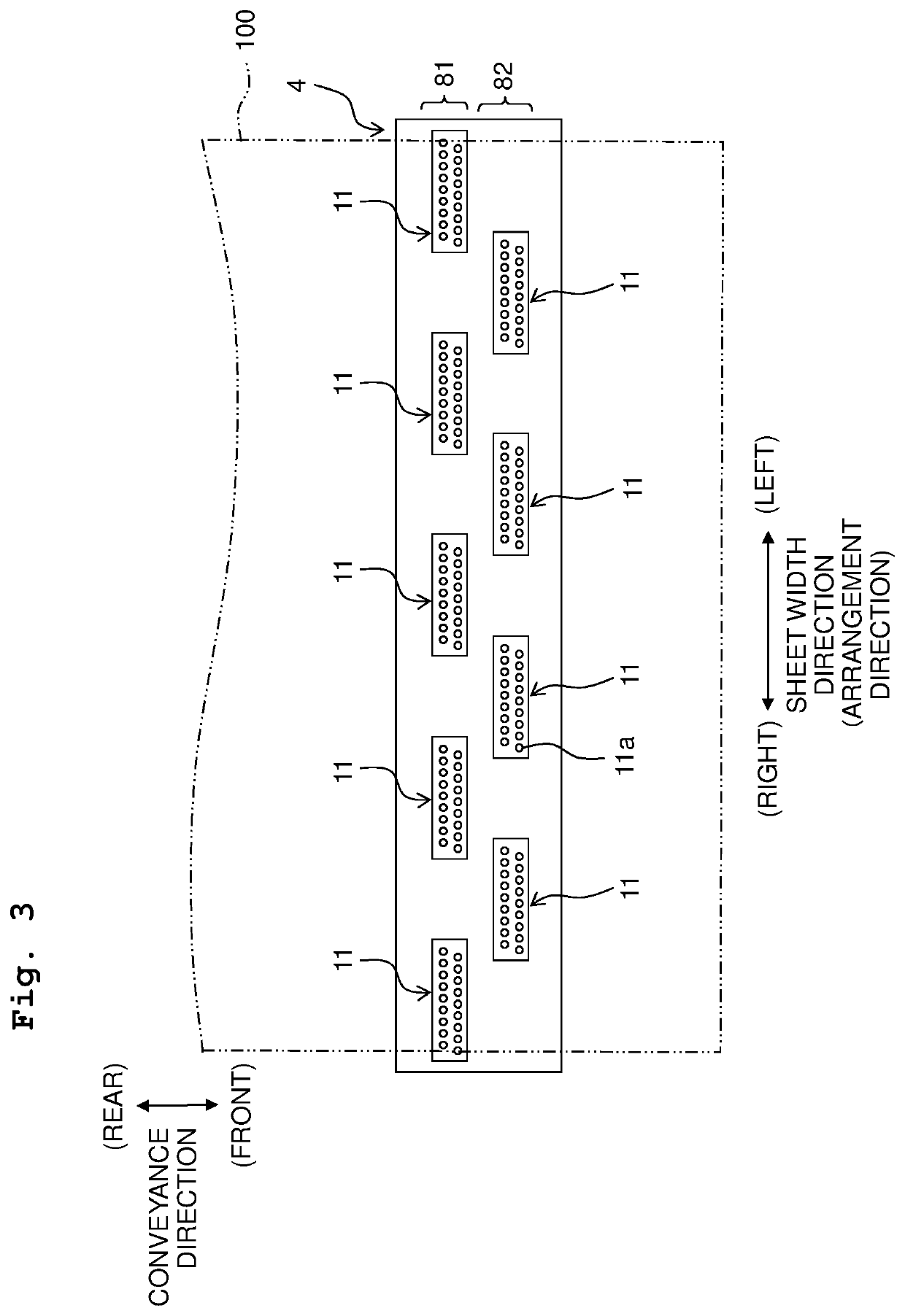

Liquid jetting apparatus

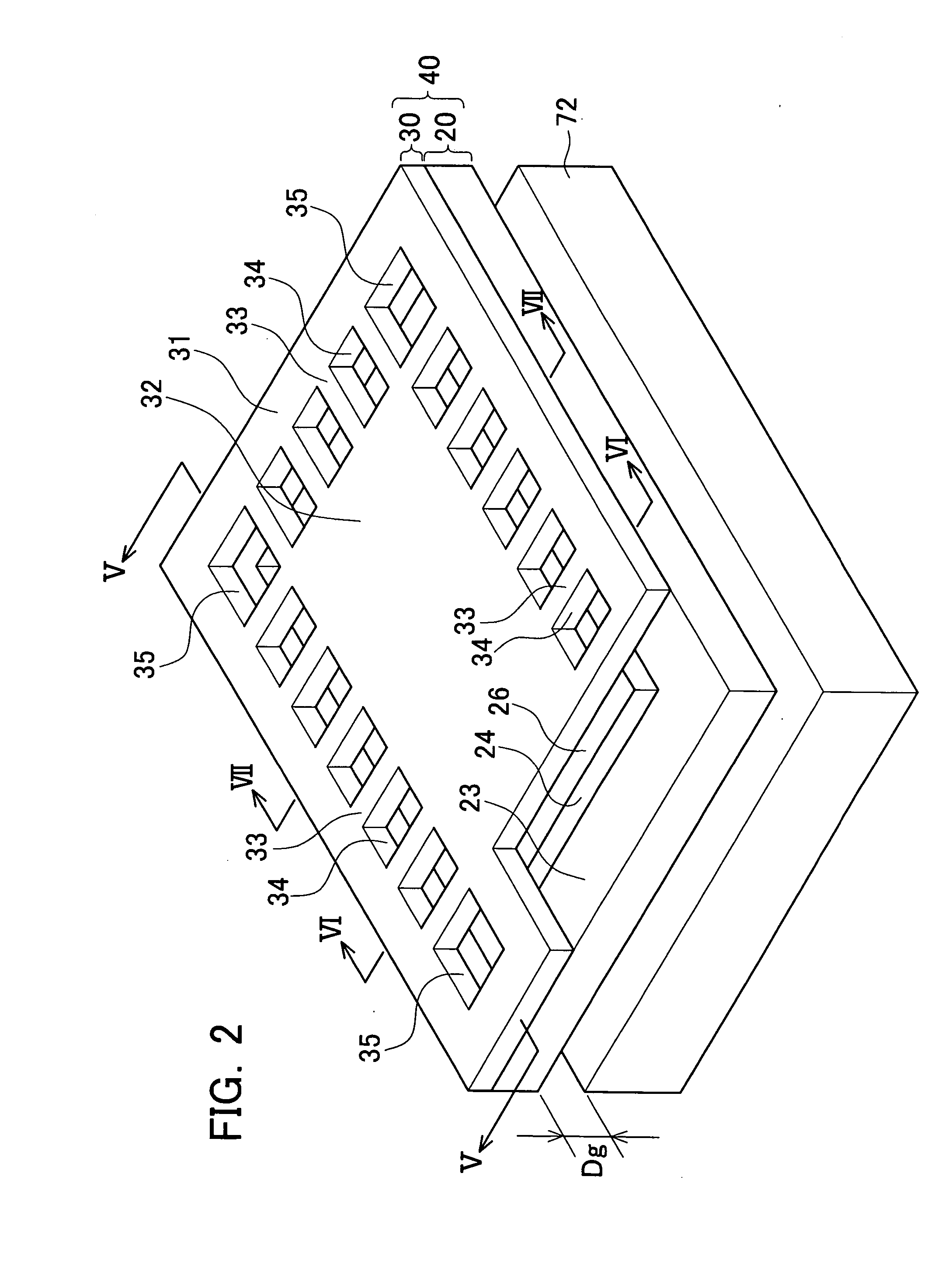

ActiveUS20170282562A1Unevenness in density can be lessUneven inhibitory concentrationInking apparatusLiquid jetEngineering

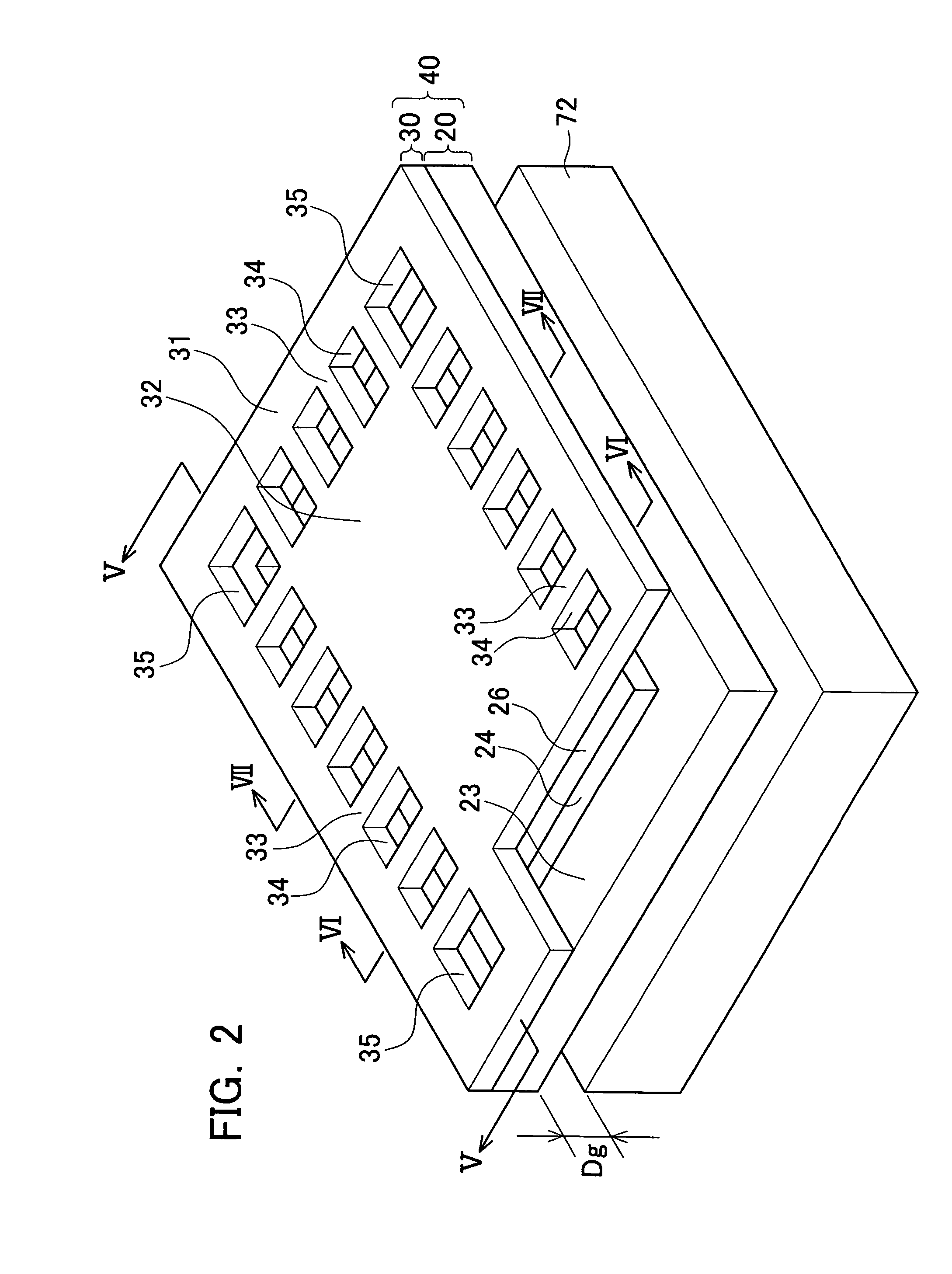

A liquid jetting apparatus jetting a liquid onto a recording medium conveyed in a first direction includes head units arranged in a second direction orthogonal to the first direction. One head unit includes nozzle chips; one nozzle chip has a nozzle arrangement area wherein nozzles are aligned in a third direction crossing the first and second directions. The nozzle chip is arranged to be shifted relative to another nozzle chip in a direction crossing the first and second directions and different from the third direction. The head unit has a first overlapping portion wherein nozzle arrangement areas of first and second nozzle chips included in the nozzle chips partially overlap with each other in the first direction. The liquid jetting apparatus has a second overlapping portion wherein nozzle arrangement areas of third and fourth nozzle chips included in the head units partially overlap with each other in the first direction.

Owner:BROTHER KOGYO KK

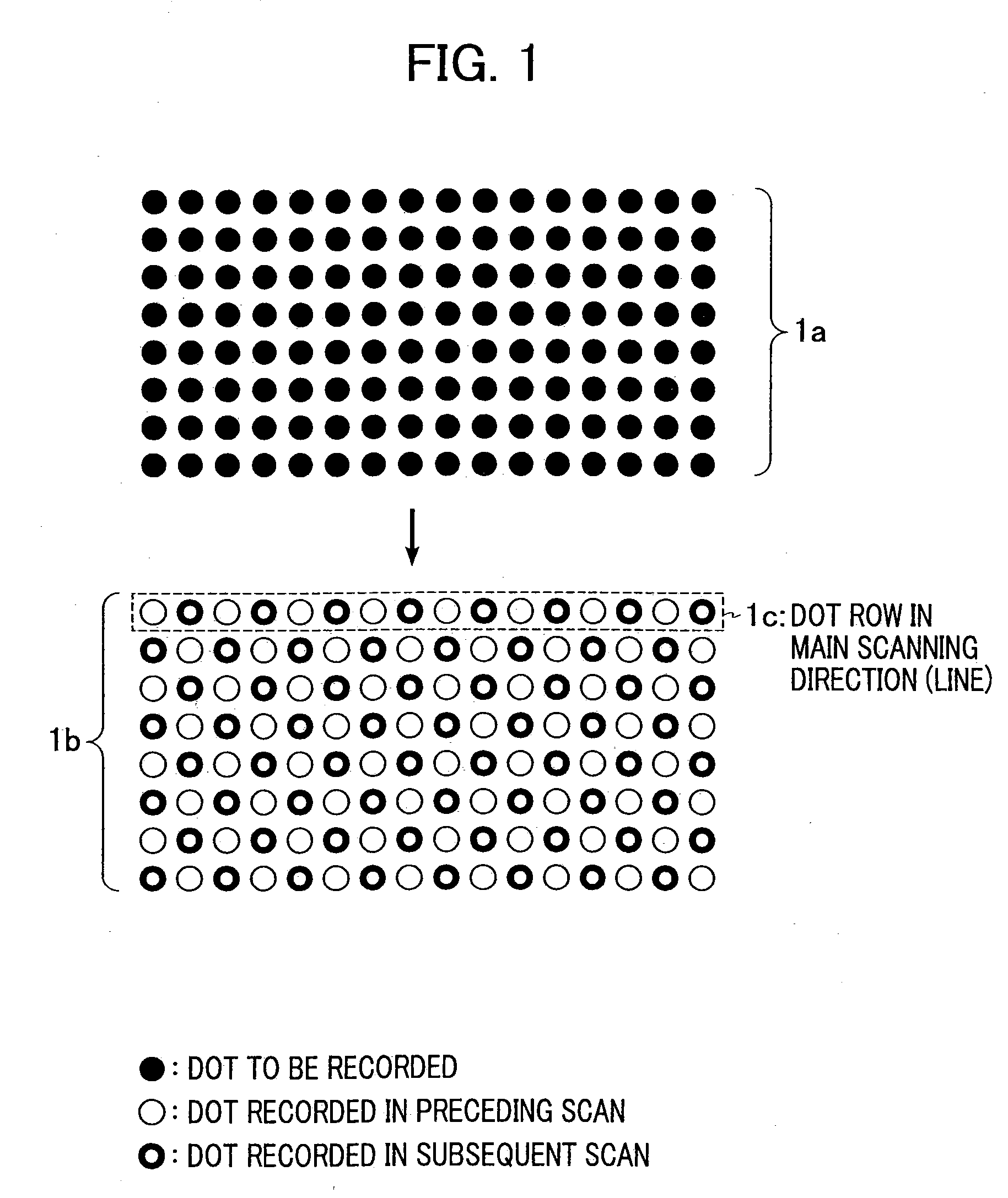

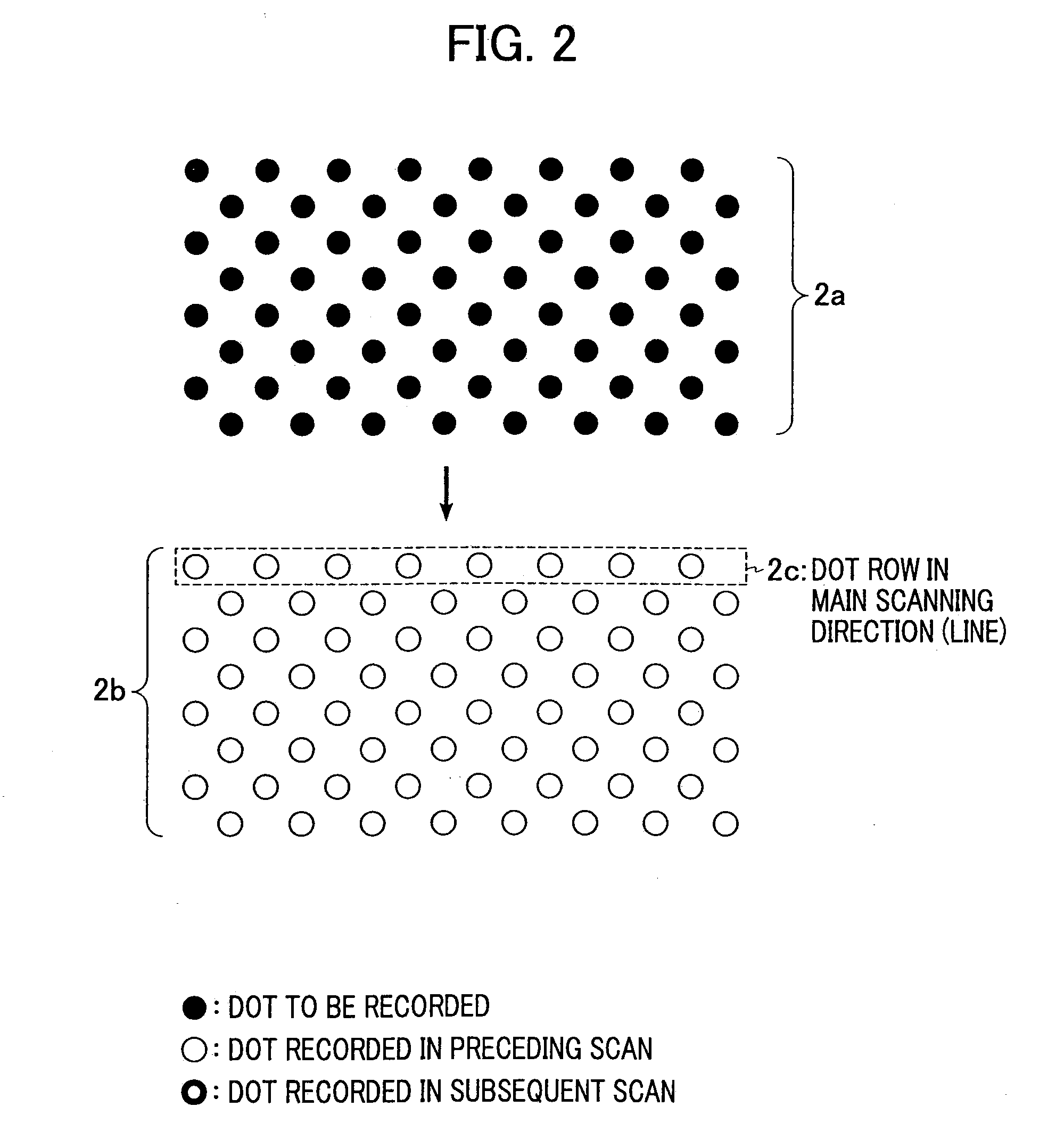

Printing apparatus, printing method and image processor

ActiveUS20100245445A1Minimize changesDensity unevennessVisual presentationPrintingEngineeringVolumetric Mass Density

A printing apparatus and a printing method are provided which, even if a print position misalignment occurs between a plurality of print scans during a multipass printing, can minimize density variations in a unit area reliably and stably, thus producing an image without density unevenness. For this purpose, multi-grayscale-level image data is converted into a plurality of dot arrangement patterns that determine individual subpixels either to be printed or not to be printed with a dot. Then, these dot arrangement patterns are printed overlappingly on a print medium in different print scans of the print head. At this time, the plurality of dot arrangement patterns are so arranged that, if these dot arrangement patterns are shifted from one another, a change in the dot-overlapping area ratio will be smaller than when the dots are arranged separately so that they do not overlap one another.

Owner:CANON KK

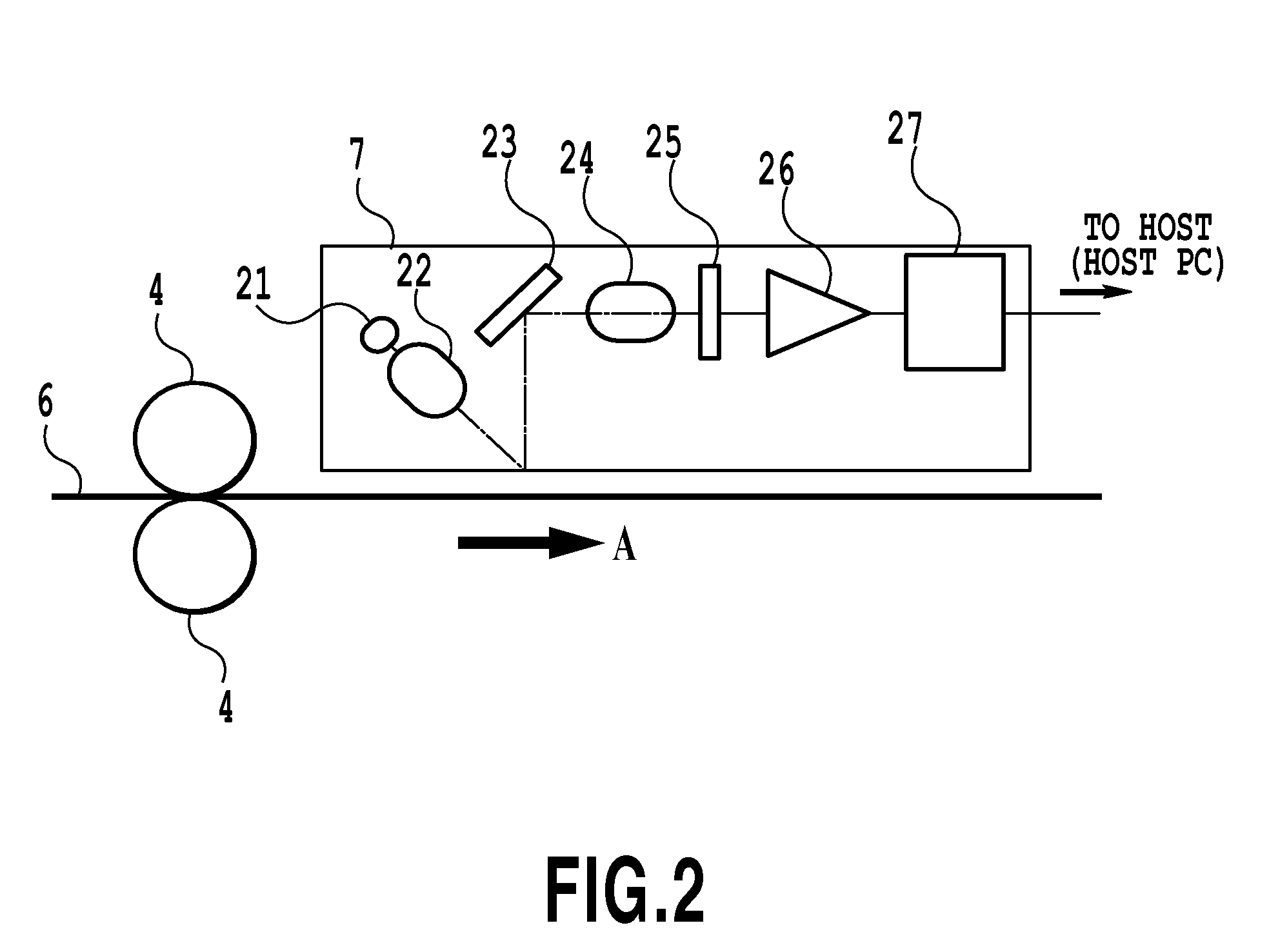

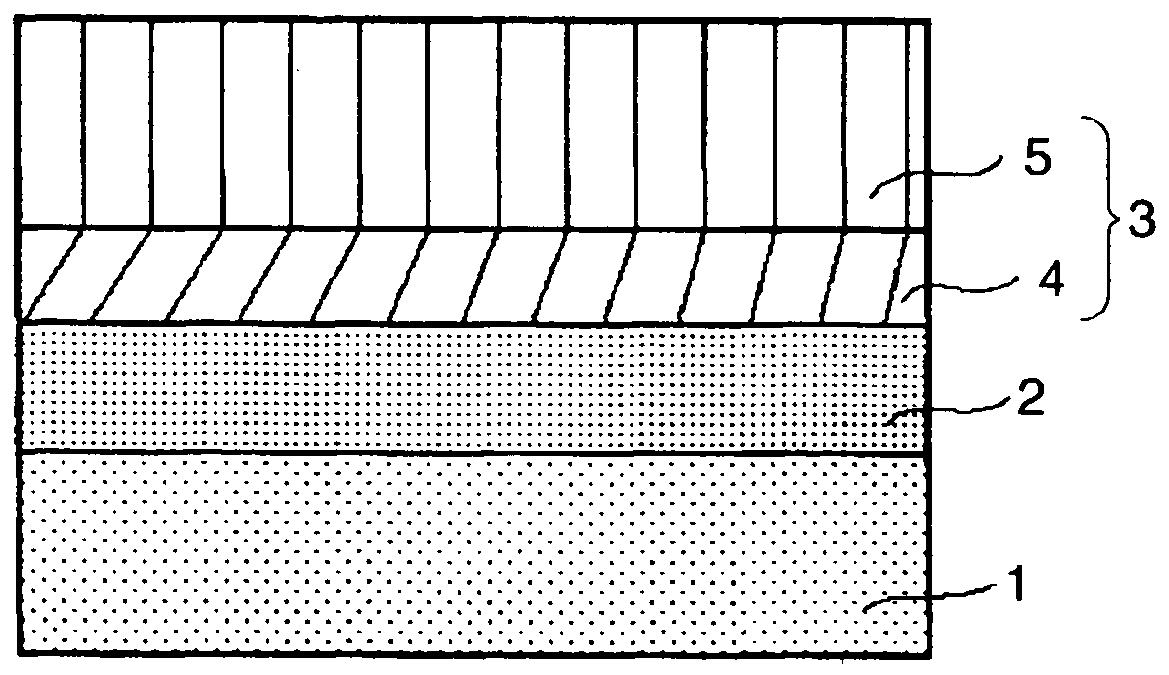

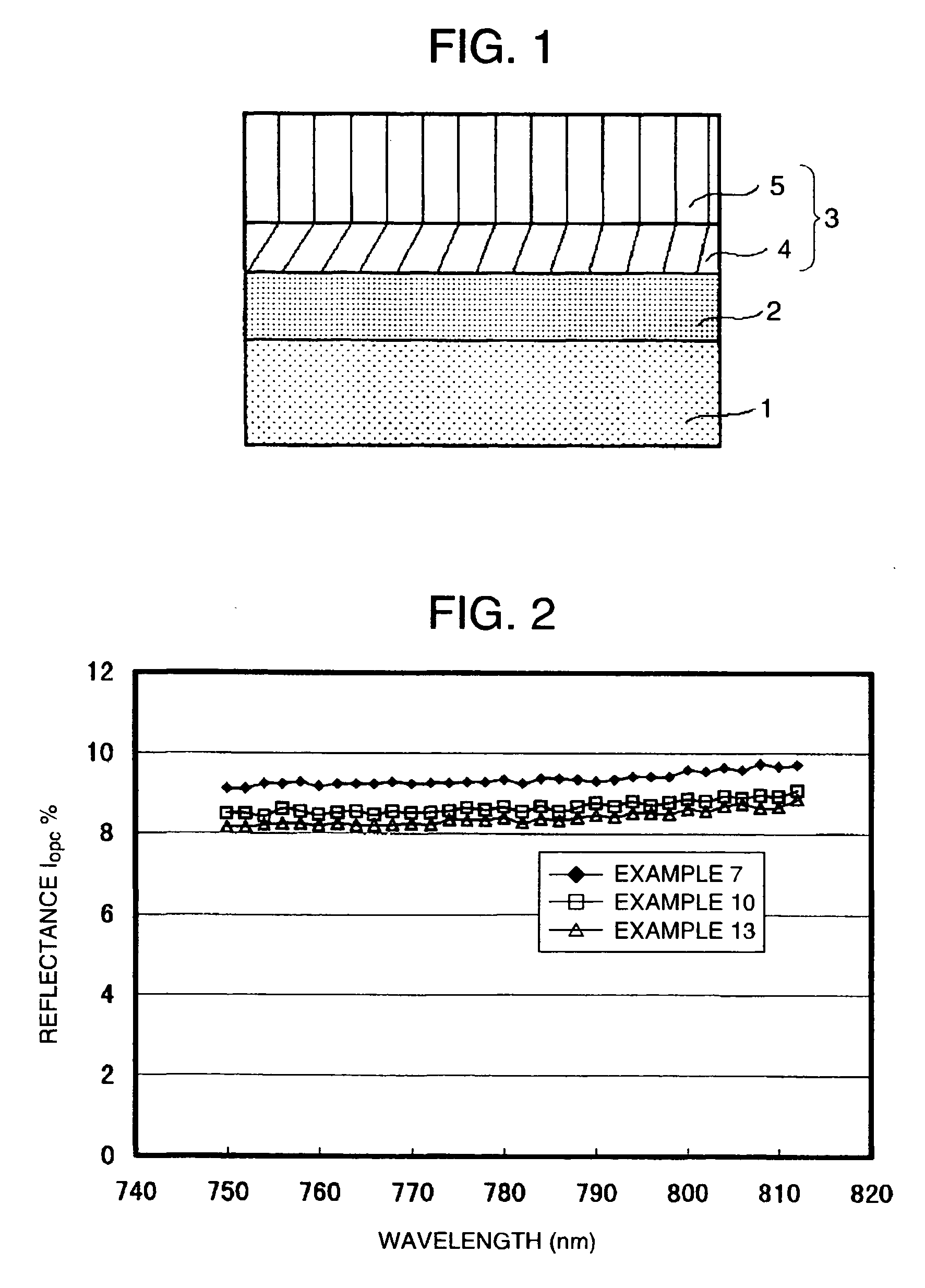

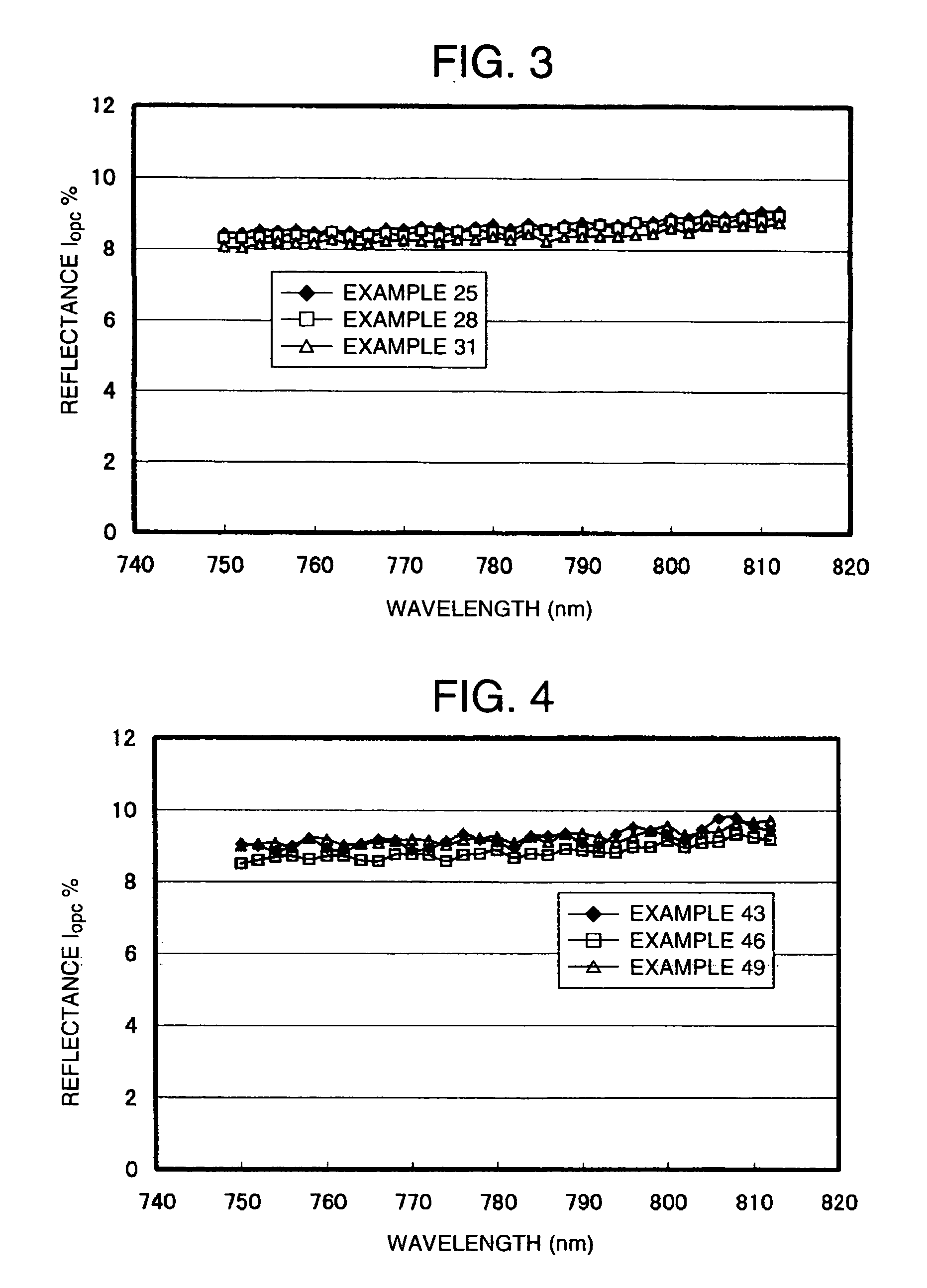

Electrophotographic photosensitive member and judging method for interference fringes caused by electrophotographic photosensitive member

In an electrophotographic apparatus (e.g., a photocopier or laser printer), an electrophotographic photosensitive member (image-forming part) has a metal substrate roughened on its surface, a metal oxide-containing undercoat layer on the substrate, and an organic photosensitive layer over the undercoat. A coherent light source (e.g., laser) can cause interference fringes that degrade the printed image. Interference fringes are judged (or predicted) as follows: The surface reflectance is measured at intervals over the spectral width of the light source. The measured surface reflectance is corrected, using a mirror-surface conductive substrate as a reference, to obtain a reflectance of the photosensitive member. The reflectance is subjected to a discrete Fourier transformation, which generates a power spectrum, over the spectral width of the light source, from the reflectance as a function of the wavelength. Interference fringes are judged from the maximum peak value in the power spectrum, as compared to a predetermined value.

Owner:FUJI ELECTRIC CO LTD

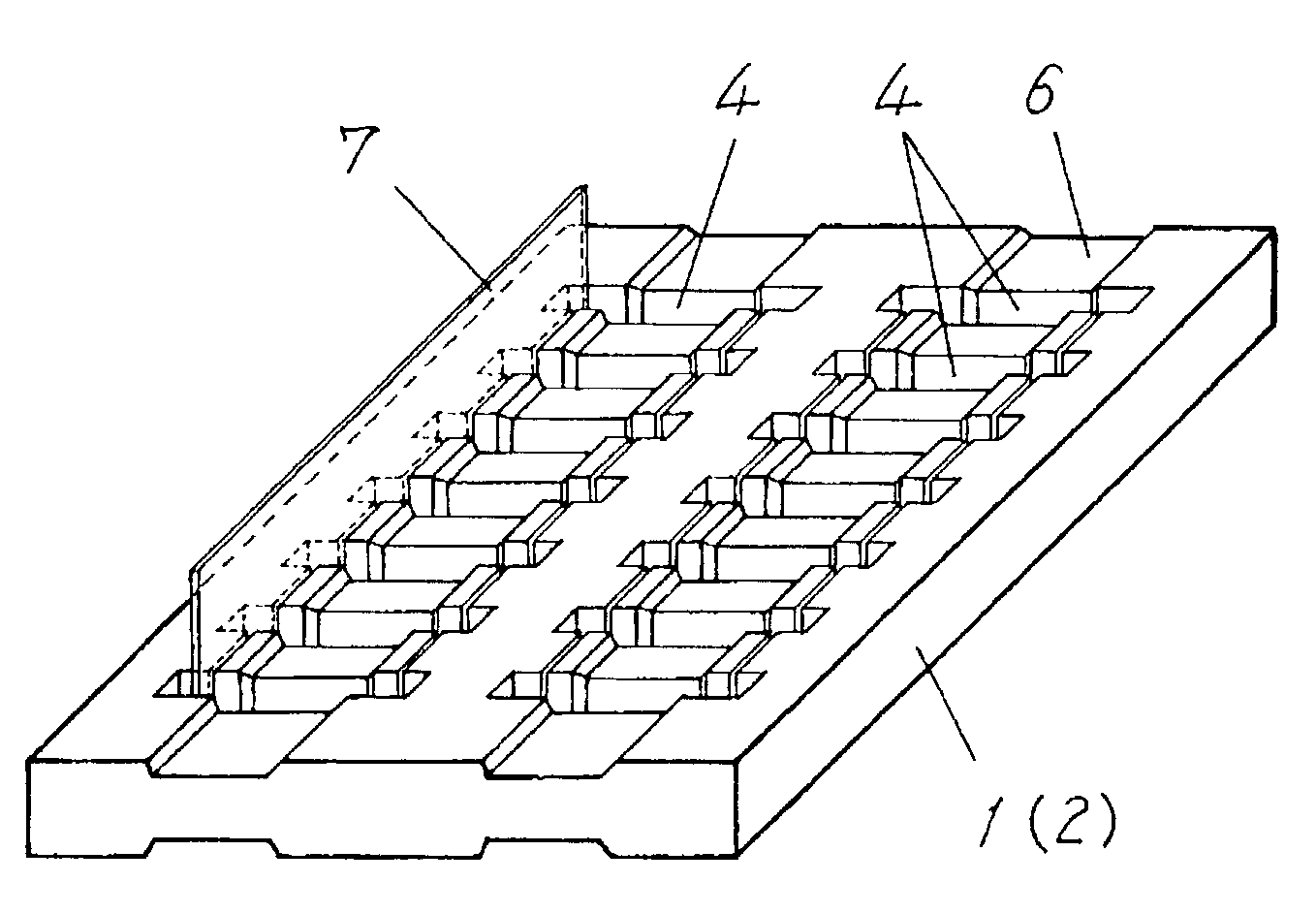

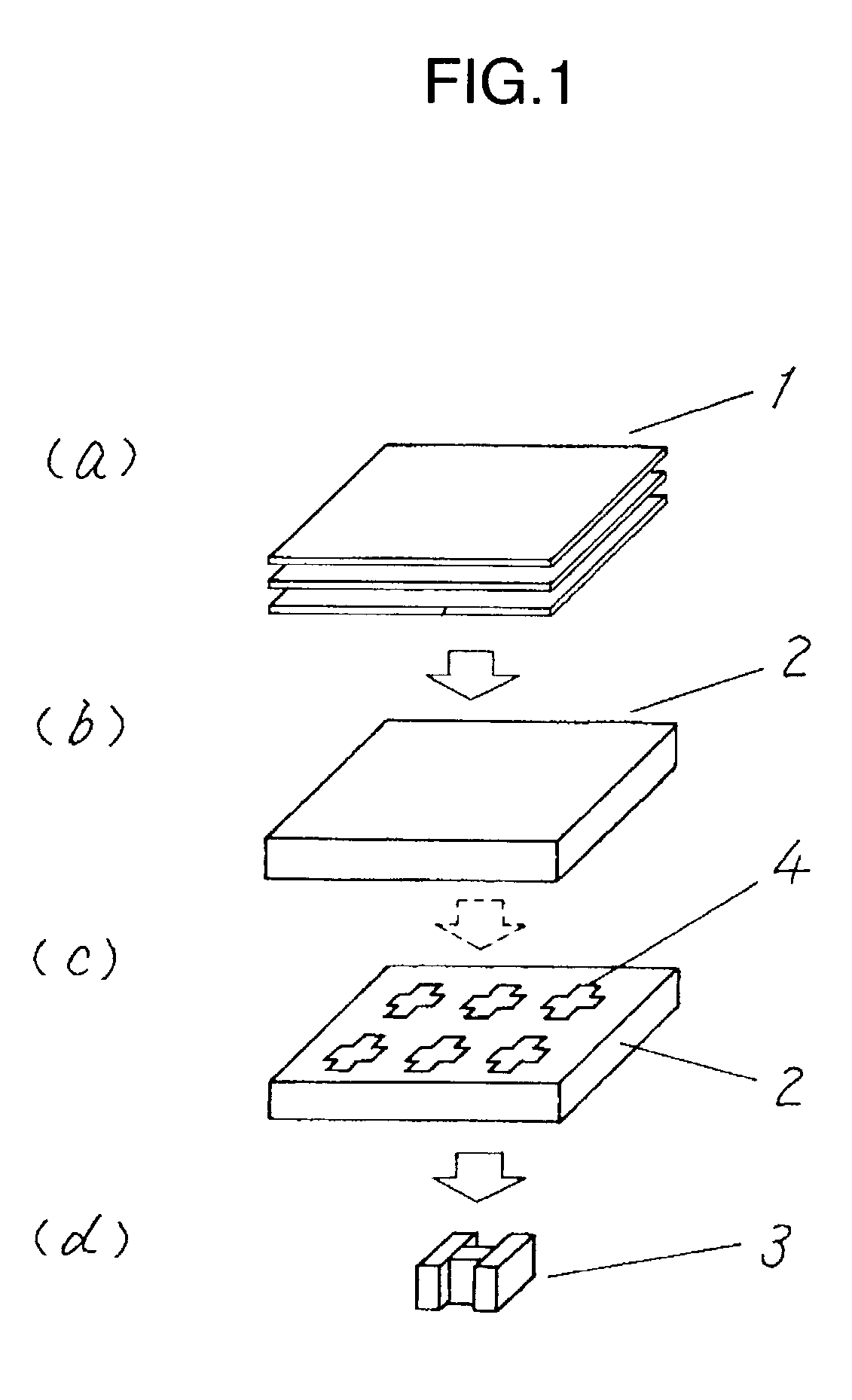

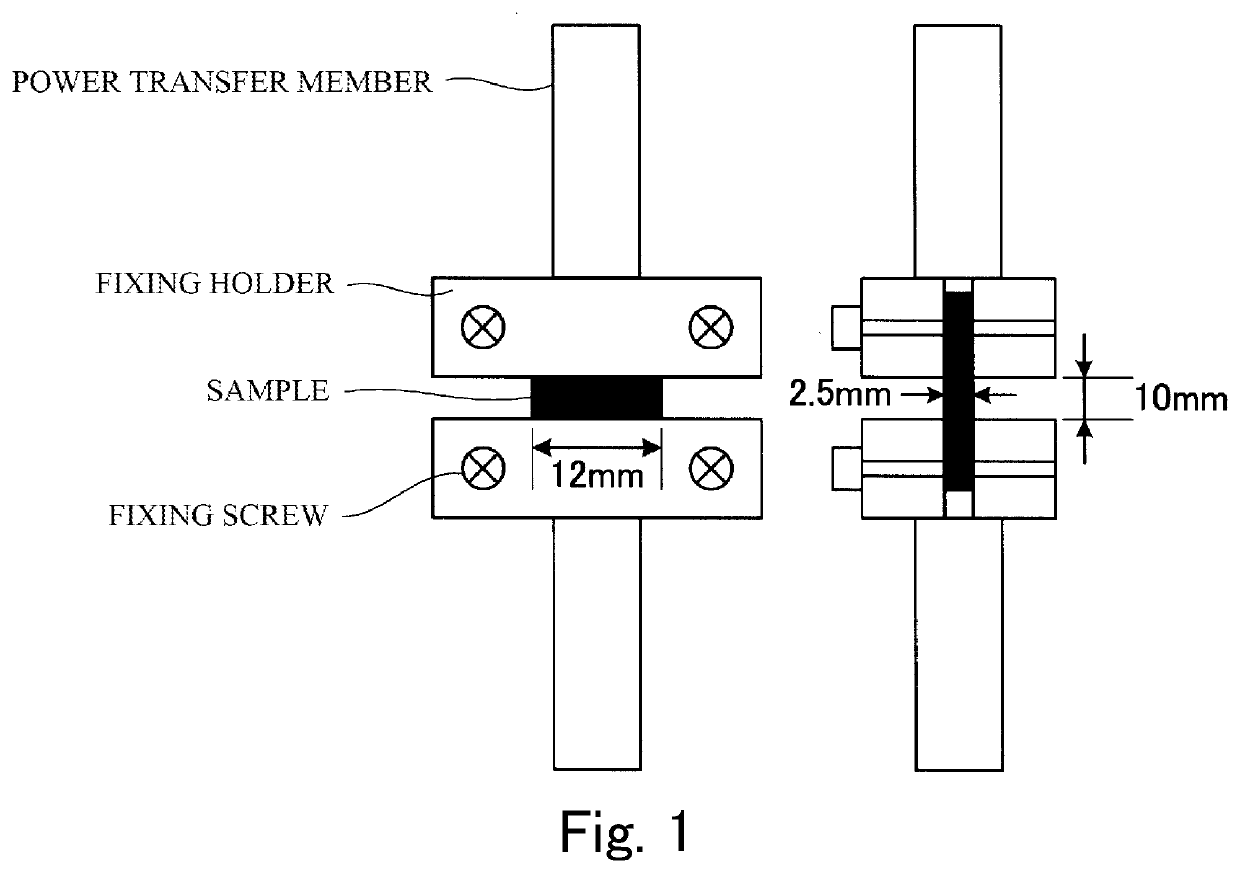

Method of manufacturing ceramic material body

InactiveUS7390449B2Low costDensity unevennessButtonsTransformers/inductances casingsMetallurgyVolumetric Mass Density

A method of manufacturing ceramic bodies comprising the steps of: preparing a ceramic sheet; forming through holes in the ceramic sheet, each of the through hole forming at least one part of the contour of each ceramic bodies; and cutting the ceramic sheet into pieces of ceramic bodies. The ceramic sheet can be a single ceramic sheet or a laminate of ceramic sheets. The method of manufacturing ceramic bodies further comprises a step of forming a recess in the ceramic sheet, or pressure molding or partially removing of the ceramic body, as required. The manufacturing method provides inexpensive production of small ceramic elements having a complicated shape and extremely smooth surfaces with less uneven filling and nonuniform density.

Owner:PANASONIC CORP

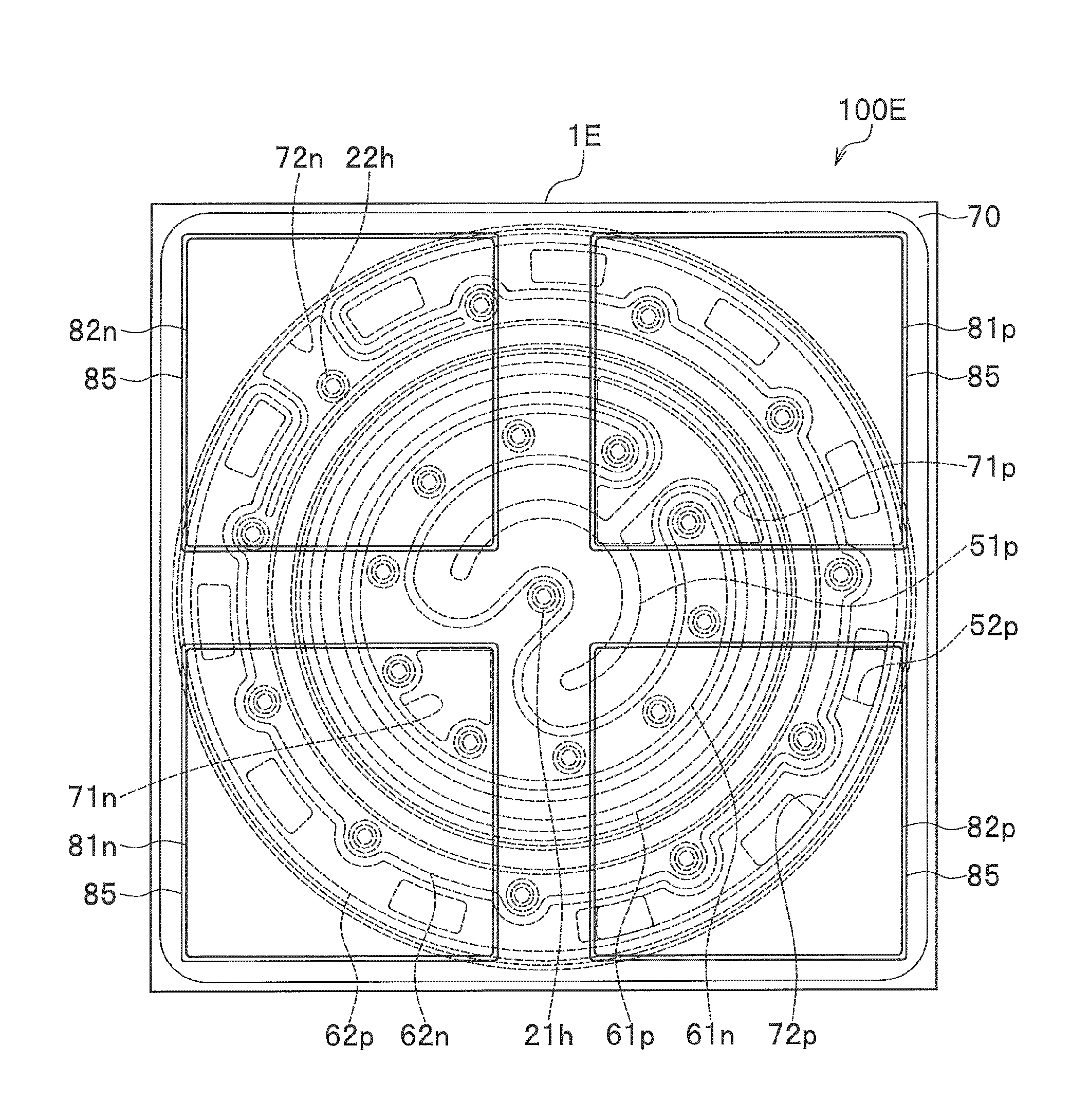

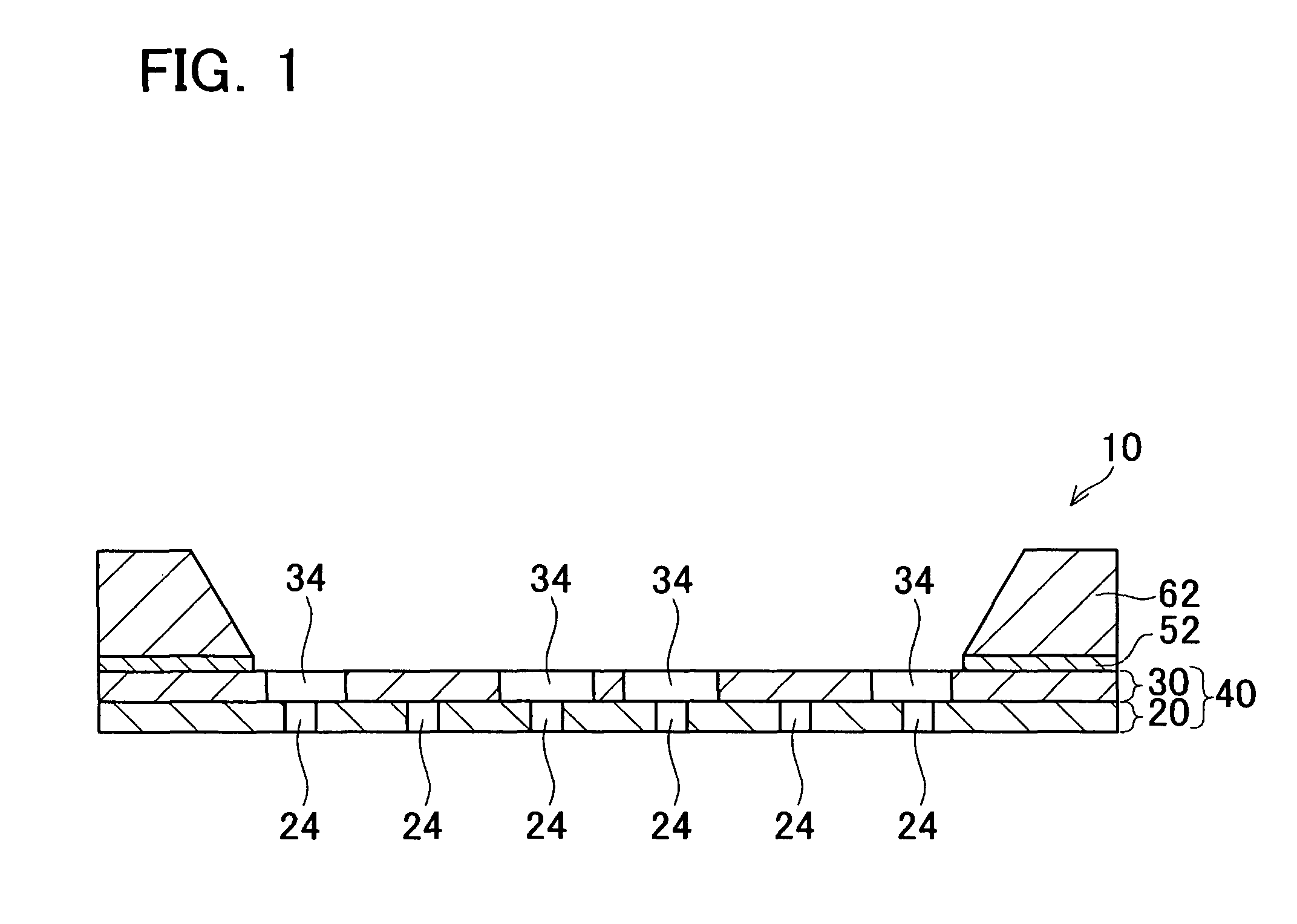

Light emitting element and light emitting device

ActiveUS20170018694A1Reduce unevennessImprove light emission intensity distributionSemiconductor devicesPhysicsExternal connection

Provided are a light emitting element and a light emitting device with improved light emission intensity distribution. A light emitting element includes a light-transmissive substrate, an n-type semiconductor layer, a first p-type semiconductor layer, a first p-side electrode, a first n-side electrode, a second p-type semiconductor layer, a second p-side electrode, and a second n-side electrode. A light emitting device includes the light emitting element, and an external connection electrode provided at the light emitting element on a side opposite to the light-transmissive substrate. The external connection electrode includes an n-side external connection electrode connected to the first n-side electrode and the second n-side electrode, a first p-side external connection electrode connected to the first p-side electrode, and a second p-side external connection electrode connected to the second p-side electrode.

Owner:NICHIA CORP

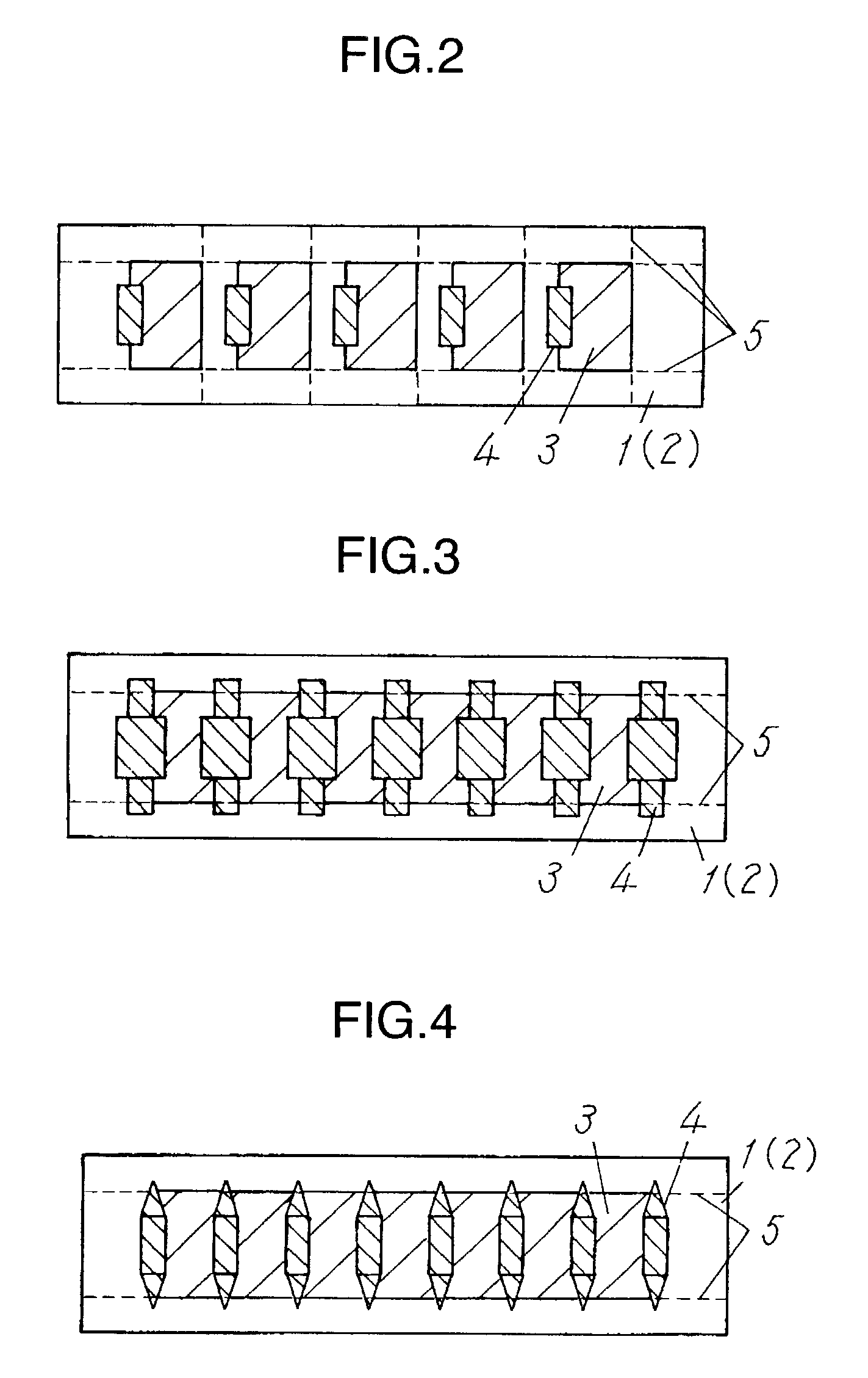

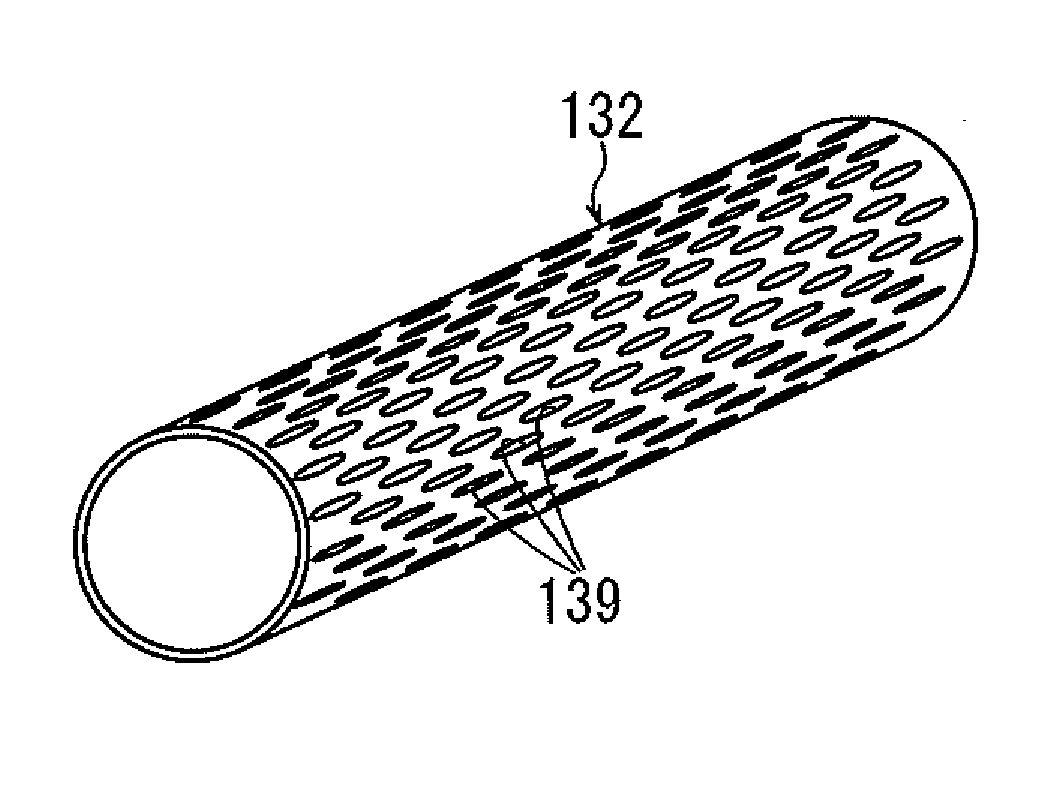

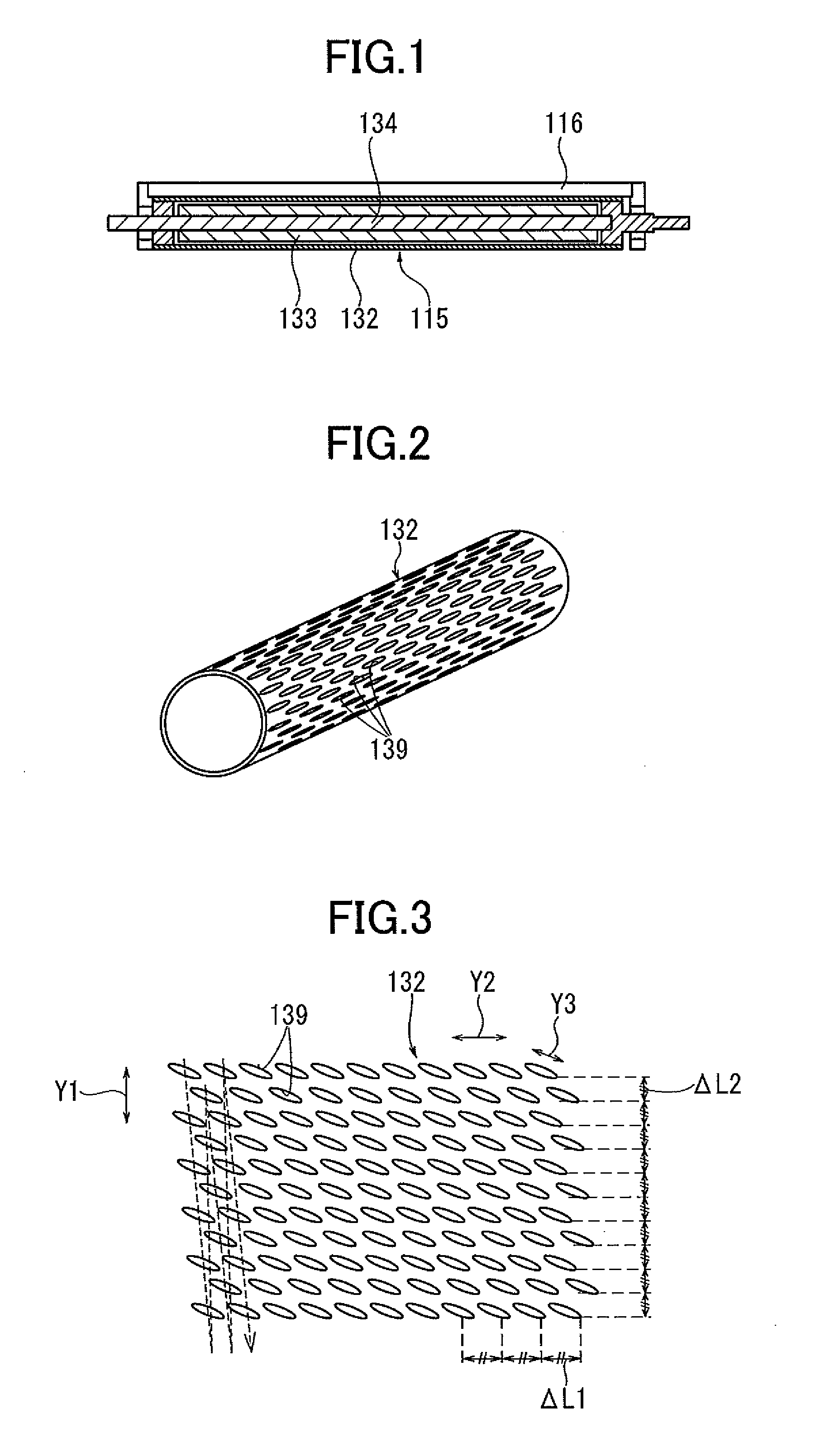

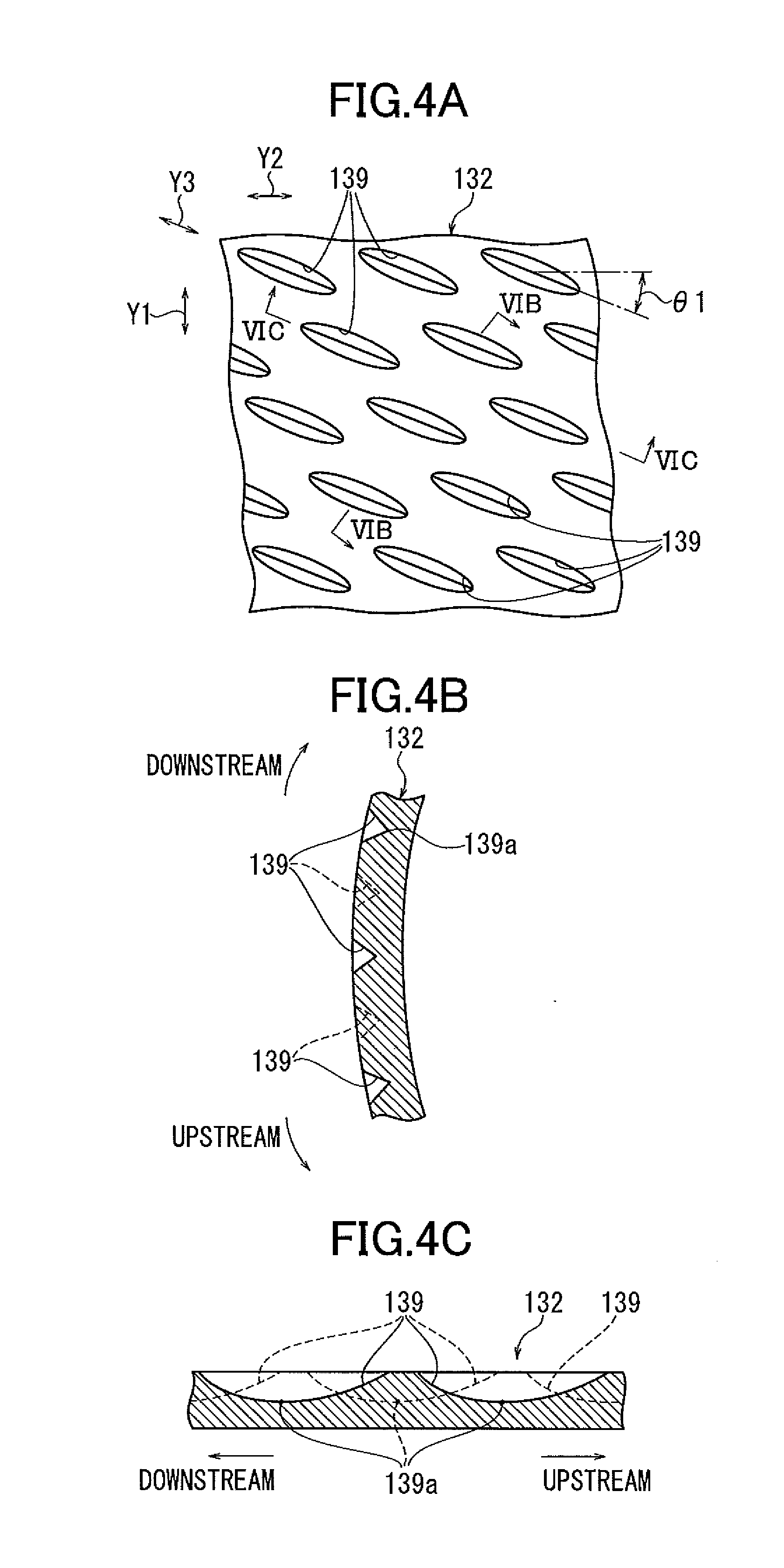

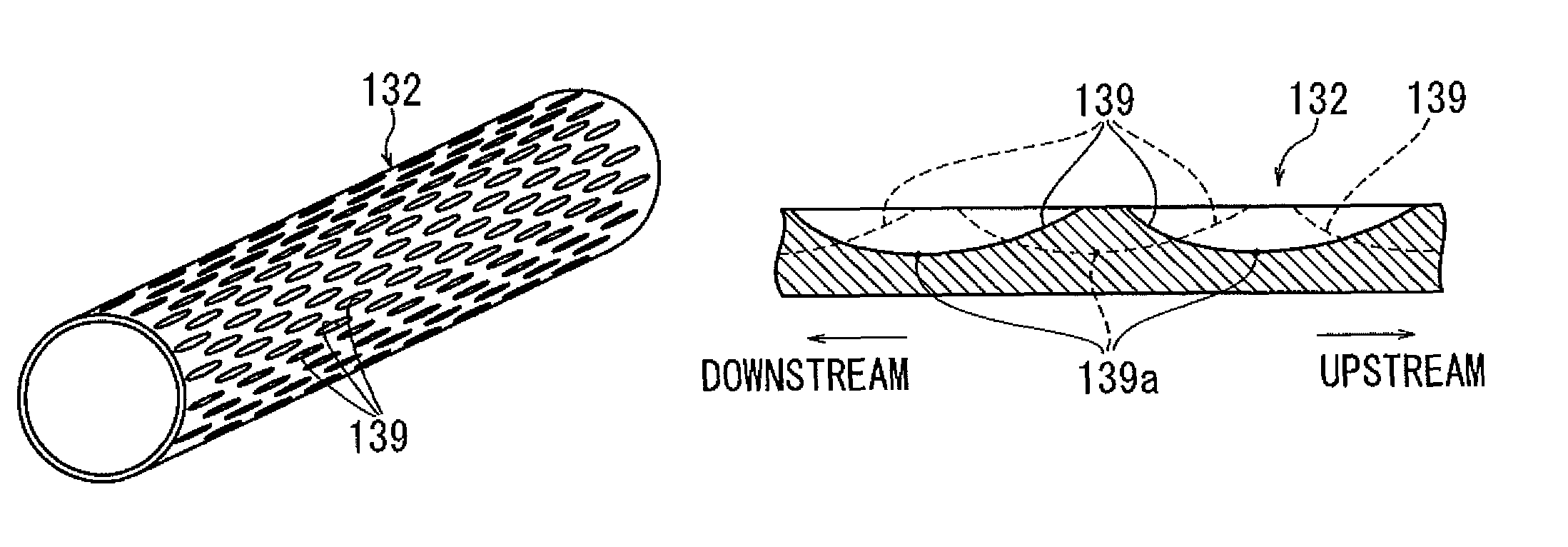

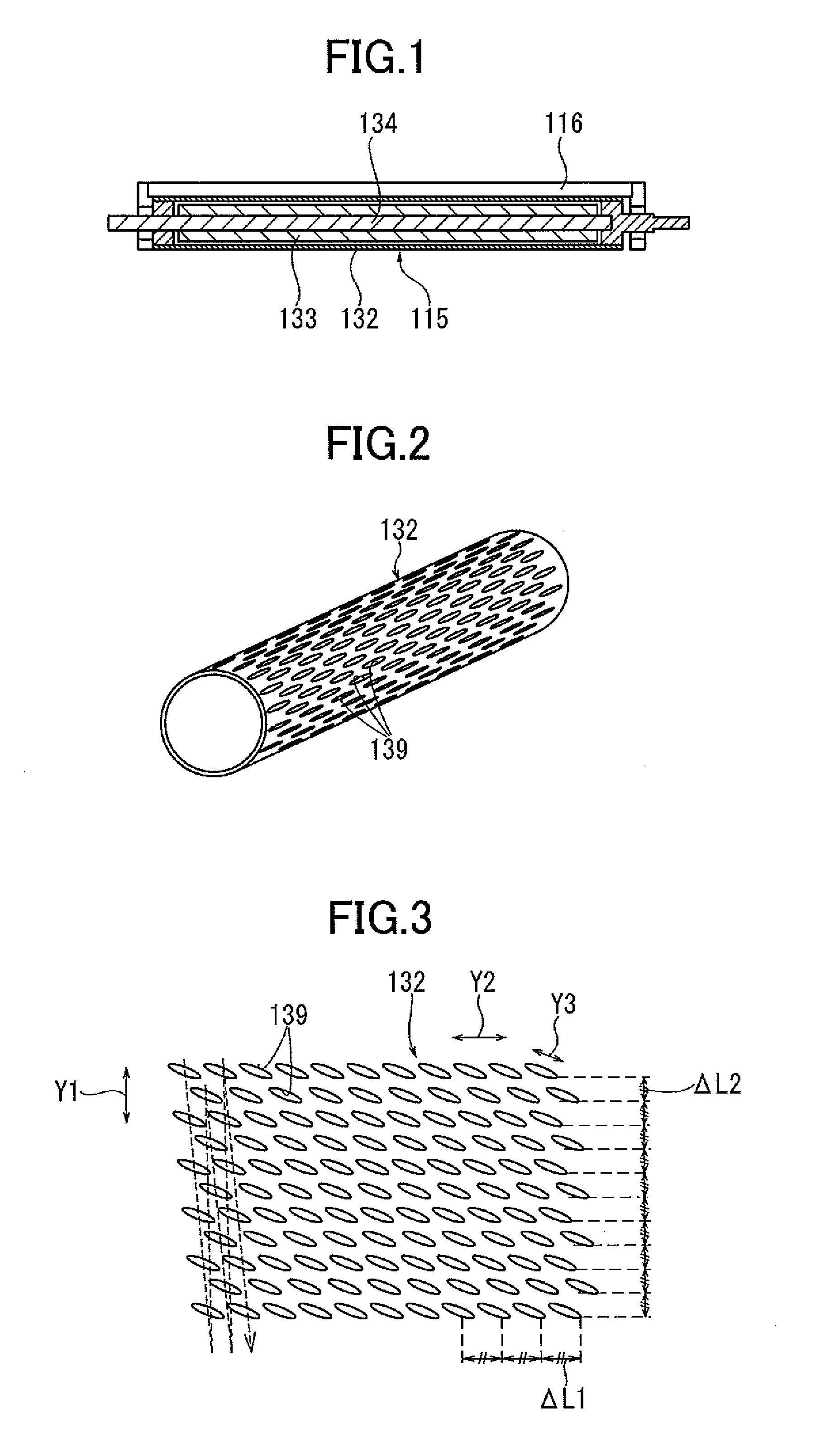

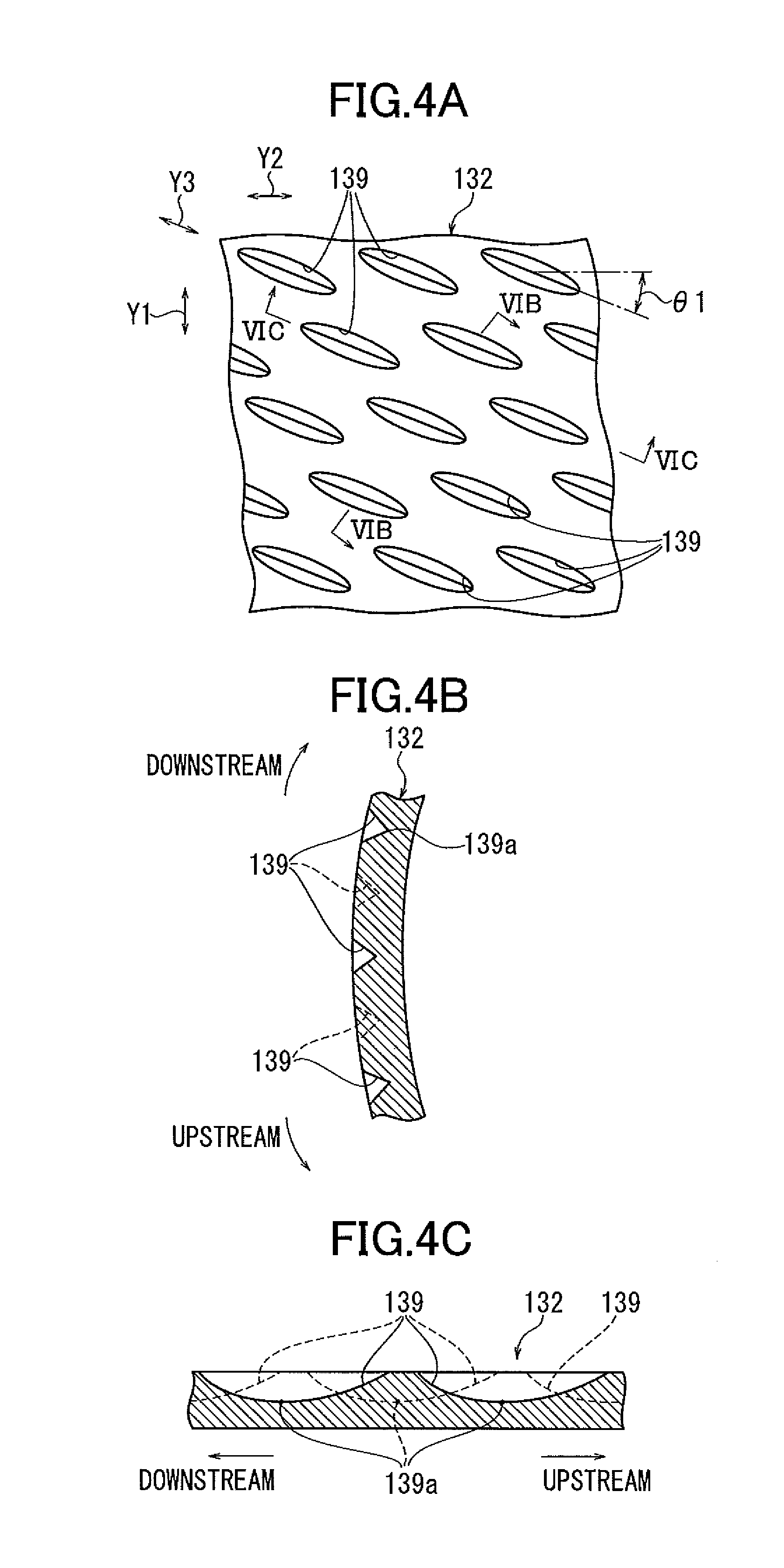

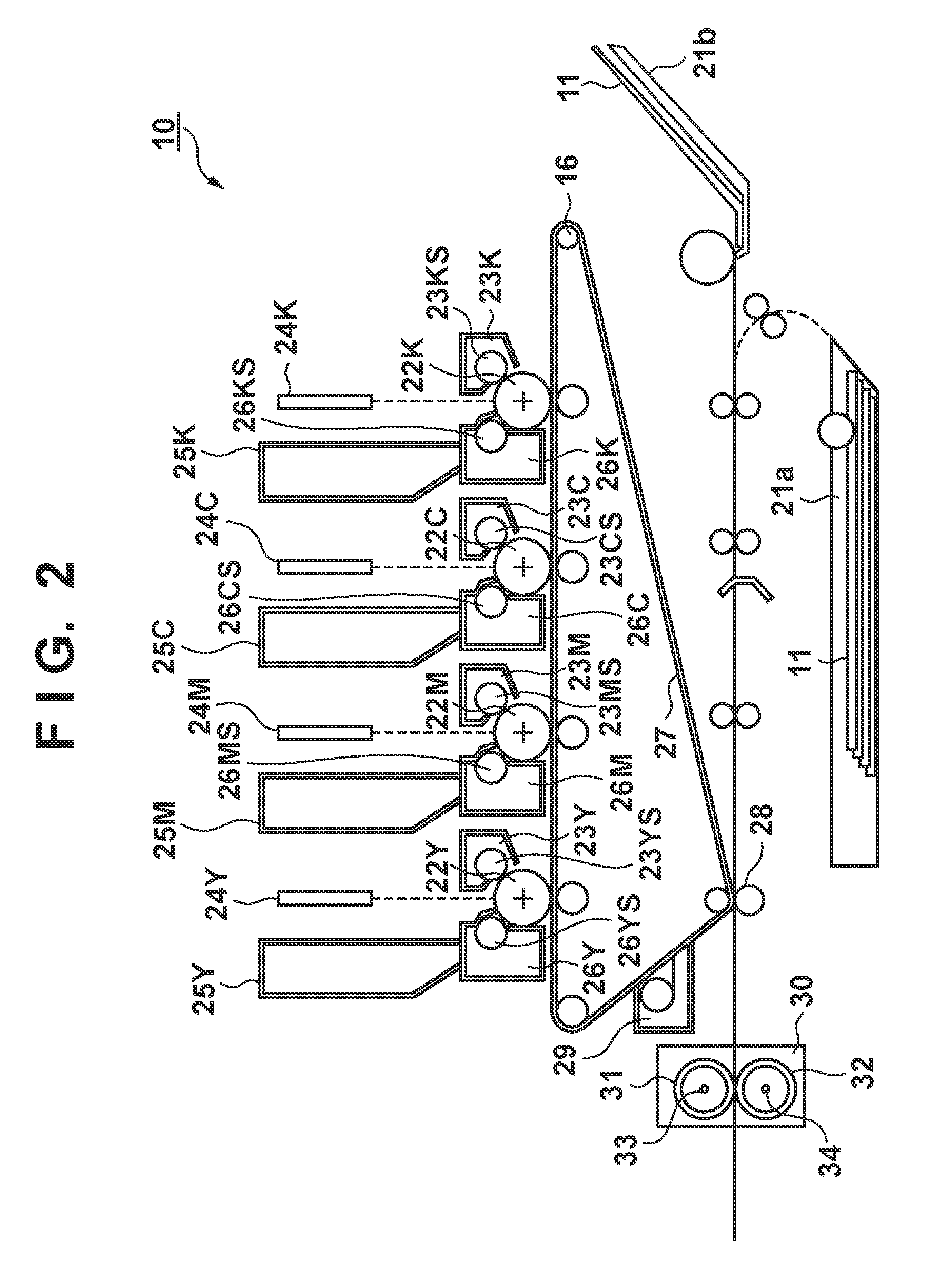

Develop roller, develop unit, process cartridge, and image forming apparatus

InactiveUS20110274471A1Inhibition amountDensity unevennessElectrographic process apparatusMagnetic tension forceEngineering

A develop roller includes a magnet roller, and a develop sleeve containing the magnet roller and comprising a plurality of depressions in an elliptic shape regularly arranged with an interval in a longitudinal direction on a surface onto which developer is attracted by a magnetic force of the magnet roller, wherein the depressions are arranged such that a longitudinal direction of the depressions is intersected with the longitudinal direction of the develop sleeve, and a downstream side of the depressions are formed to be deeper than an upstream side in a rotary direction of the develop sleeve.

Owner:RICOH KK

Image processing apparatus, printing apparatus, and image processing method

InactiveUS20100188678A1Reduce processReduce errorsVisual presentationPictoral communicationImaging processingVolumetric Mass Density

When executing the gradation lowering processing to a data area in the lower side in multi-valued print data 403, an error generated by executing the gradation lowering processing to the data area in the lower side is stored in an information storage area 901B. On the other hand, the error thus distributed and stored is used for executing the gradation lowering processing to the data area “J” (Jth line) in multi-valued print data 404 relating to the next scan. In this way the error generated when executing the gradation lowering processing to the multi-valued print data is stored, which is used at the time of executing the gradation lowering processing to the multi-valued print data relating to the next scan. Therefore, the density is stored by receiving and delivering the error between the multi-valued print data in a scan unit.

Owner:CANON KK

Inkjet printer and inkjet printing method

InactiveUS7798604B2Quality improvementDensity unevennessOther printing apparatusSmall dropletEngineering

An image is output, the image having high quality in which density unevenness due to an end-deviation is excellently reduced in all colors in forming an image with use of a bidirectional inkjet printing head provided with ejection port arrays of a plurality of colors for small droplets of ink. Thereby, distributions of print permission rates of mask patterns to be used in performing a multi-pass printing are made different from each other in accordance with a distance between the two ejection port arrays for the same kind of ink. Thus, the degree of the end-deviation depending on the distance between the two ejection port arrays can be suppressed for every ejection port array.

Owner:CANON KK

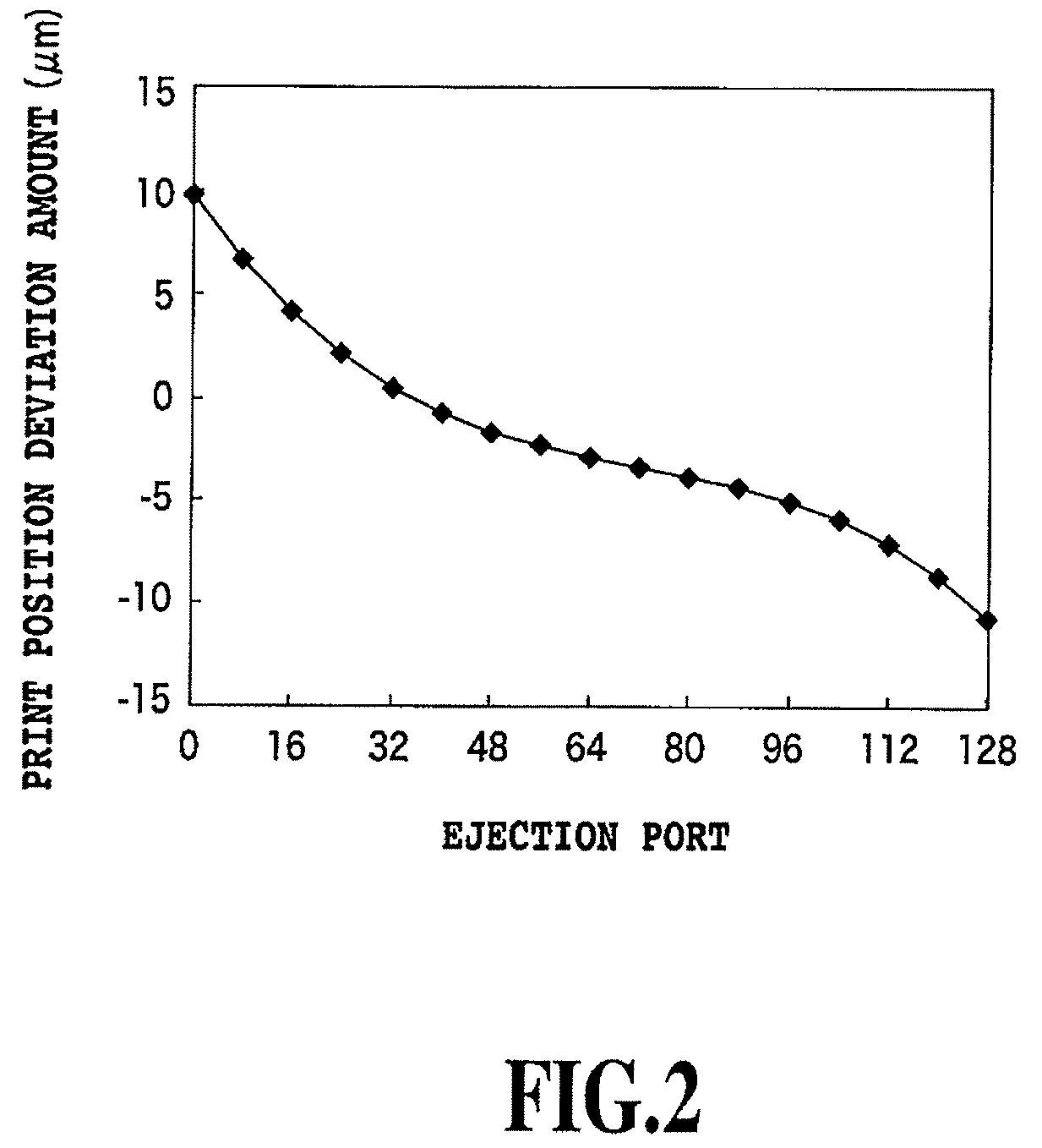

Inkjet printer and printing method

An inkjet printer includes a print head, a nozzle position and a print control section. The print head includes a plurality of nozzles to eject ink. The nozzle position specifying section is configured to specify a position of a first nozzle of the plurality of nozzles that exhibits defective ejection of the ink. The print control section is configured to eject the ink from the plurality of nozzles based on image data. The print control section is configured to determine a density of second pixels, which are positioned adjacent to first pixels to be printed by the first nozzle that was specified, and a density of third pixels, which are positioned adjacent to the second pixels except the first pixels, based on the image data, and to correct to increase the density of the second pixels and to reduce the density of the third pixels.

Owner:SEIKO EPSON CORP

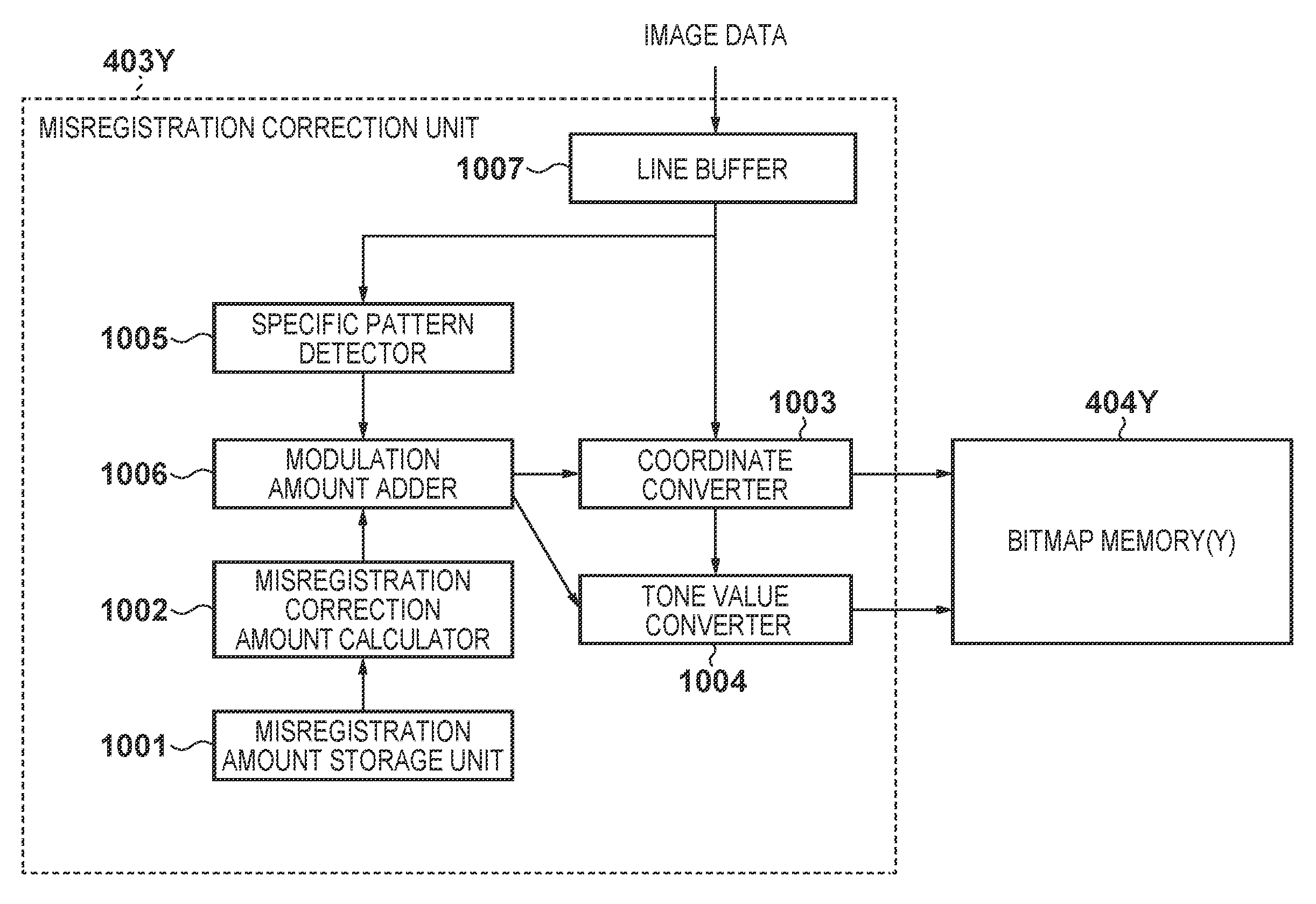

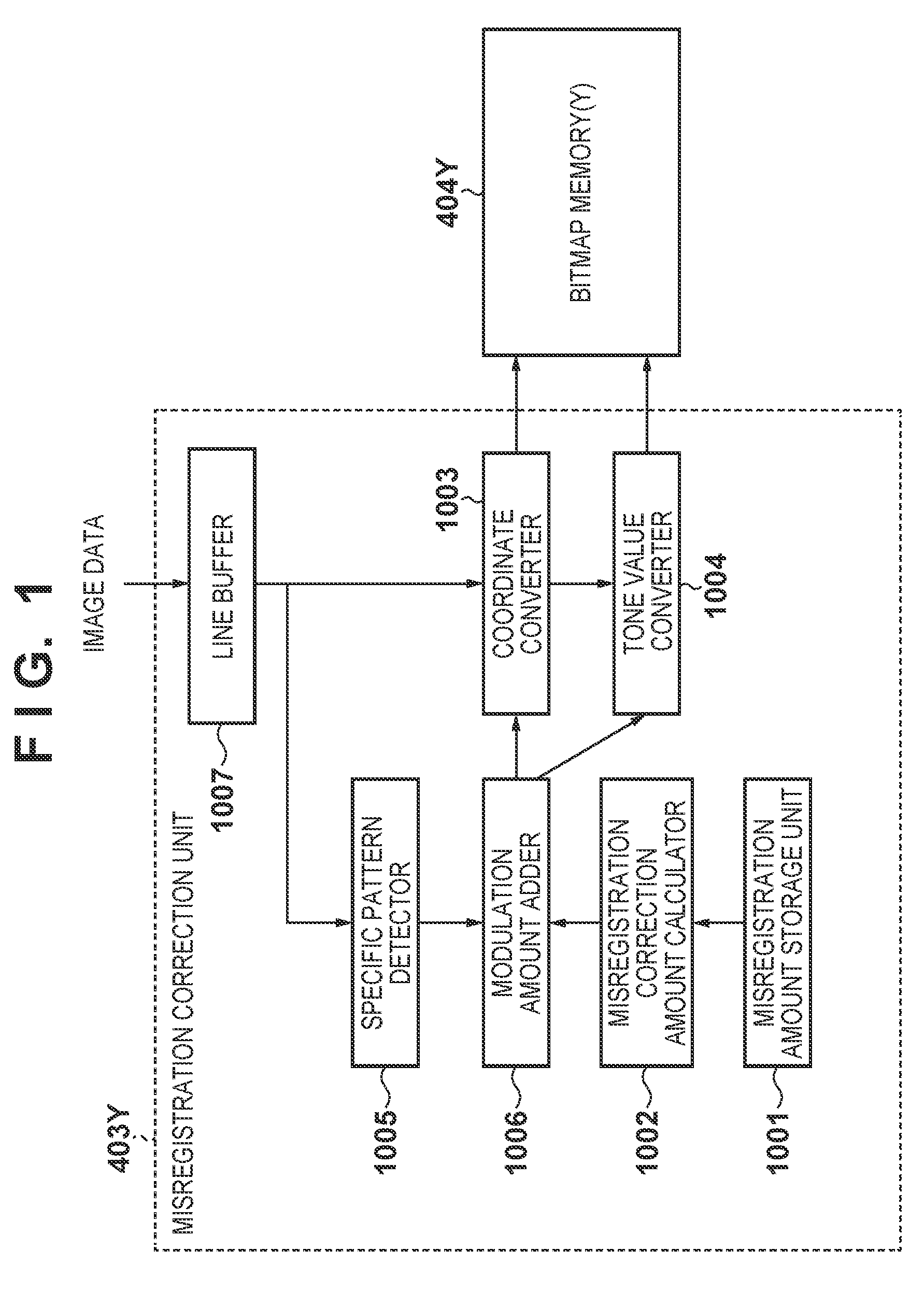

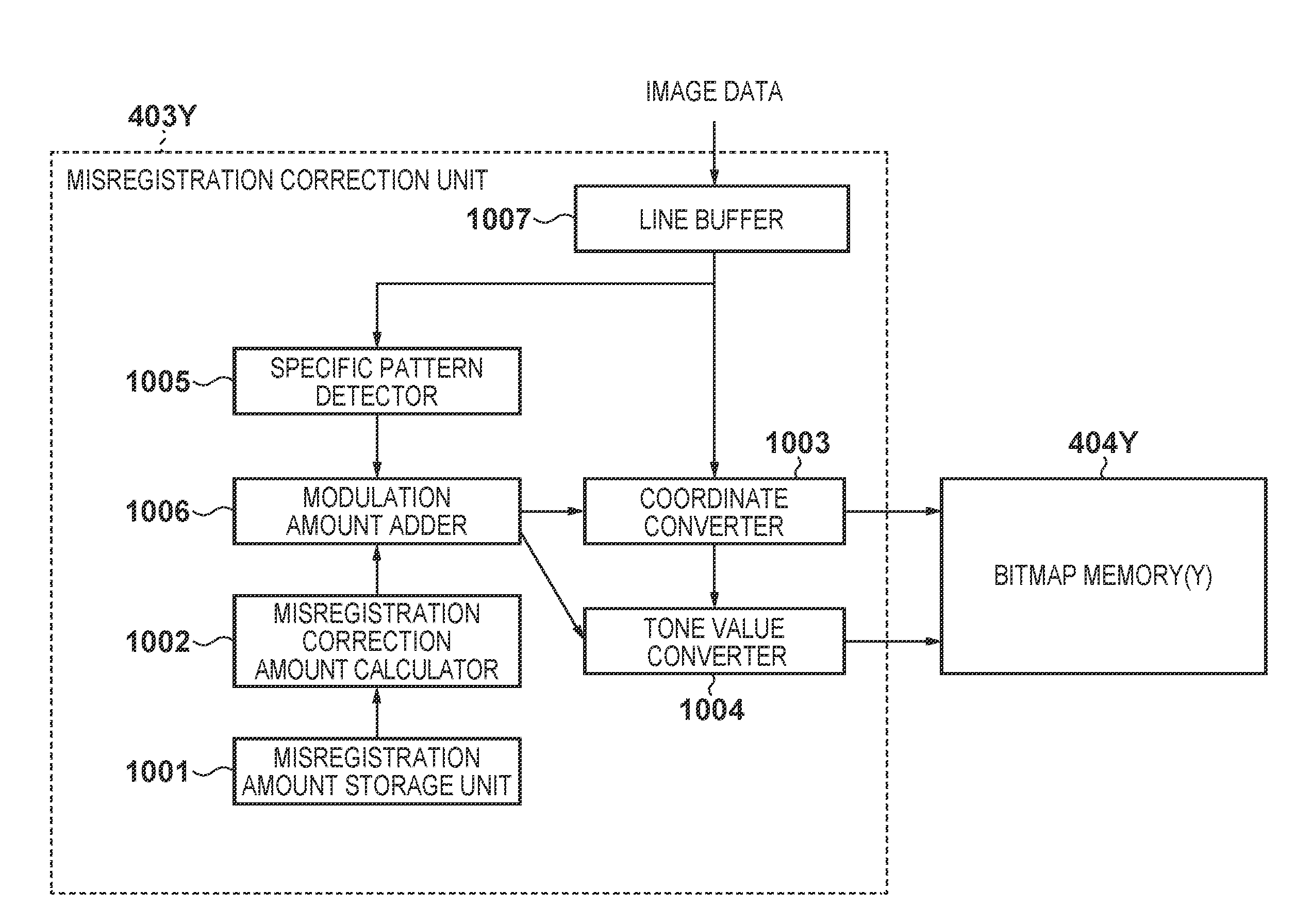

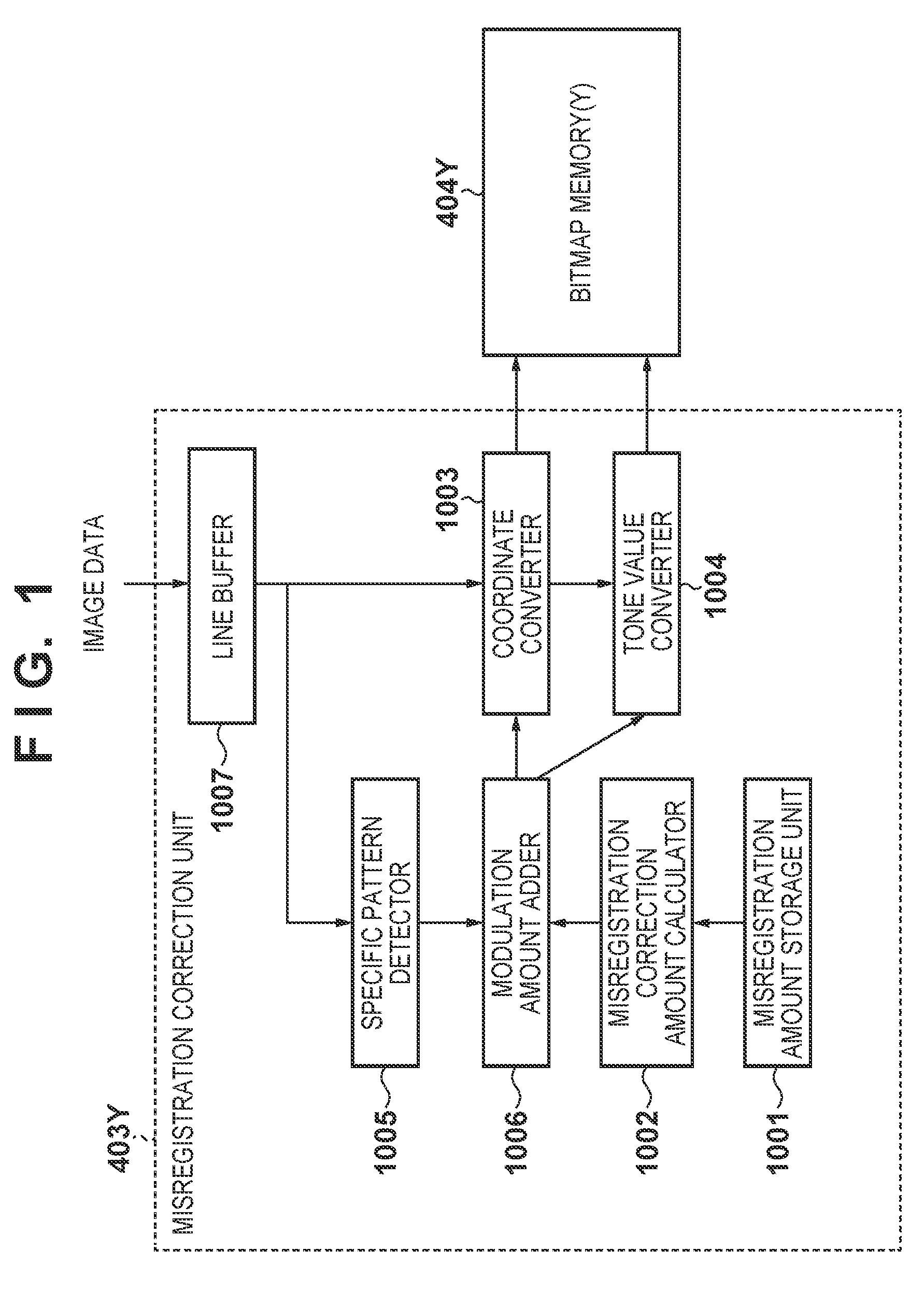

Image processing apparatus, control method of image processing apparatus, image forming apparatus, and storage medium

InactiveUS20130265613A1Density unevennessVisual presentationElectrographic process apparatusImaging processingImage formation

When an image processing apparatus of one aspect of this invention corrects input image data using correction values (misregistration correction amounts Δy), it determines whether or not image data to be corrected using amounts Δy includes a specific pattern which may cause density unevenness in an image to be formed. When the image processing apparatus determines that the image data includes the specific pattern, it modifies amounts Δy corresponding to pixels including the specific pattern of the amounts Δy using any of a plurality of different predetermined modulation amounts (modification values). Furthermore, the image processing apparatus corrects the image data for respective pixels using either the amounts Δy before modification, or the modified amounts Δy when the modification is done.

Owner:CANON KK

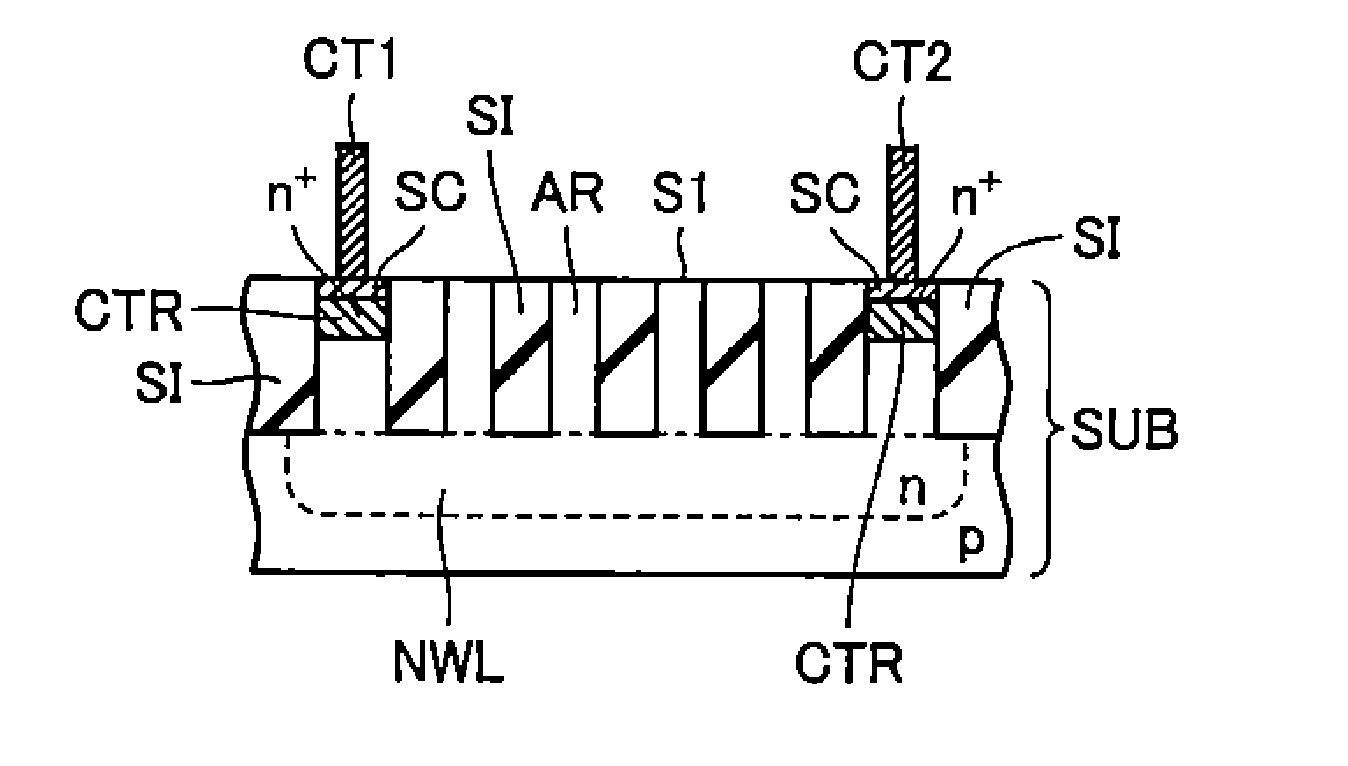

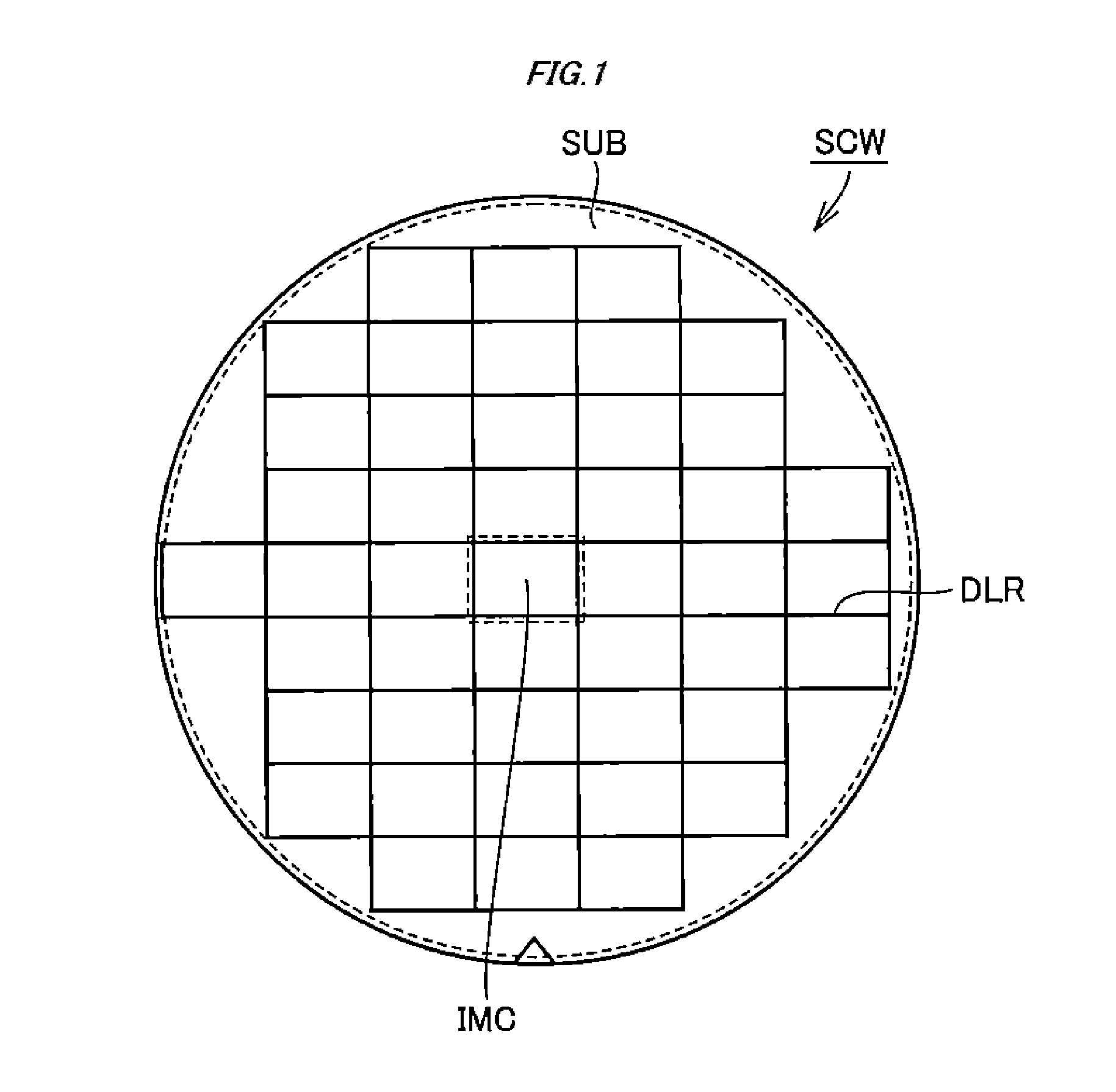

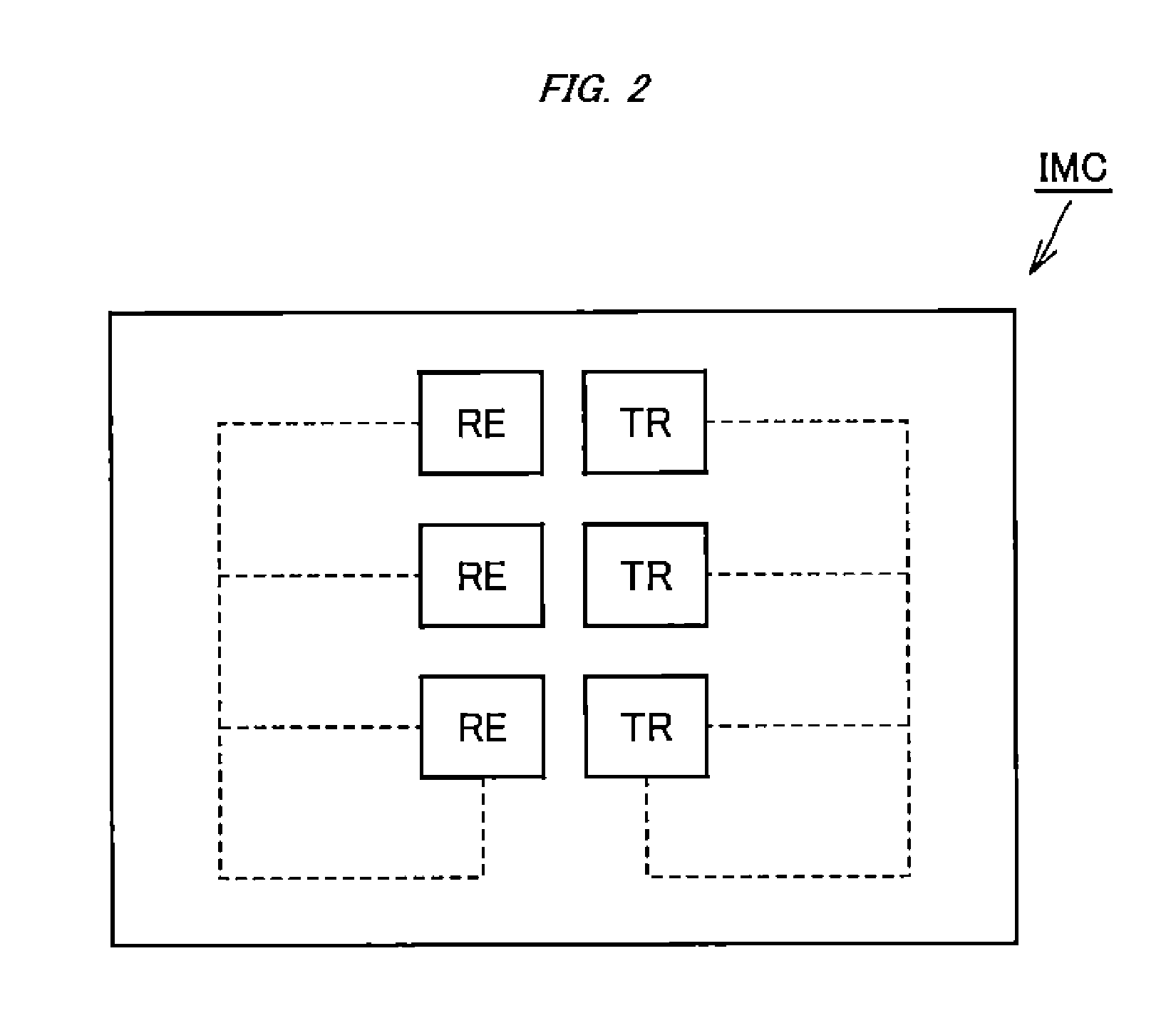

Semiconductor device and method of manufacturing the same

ActiveUS20160049470A1Improve accuracyReduce withstand voltageTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device including a well resistance element of high accuracy and high withstand voltage and a method of manufacturing the semiconductor device are provided.The semiconductor device includes a semiconductor substrate, a well region, an input terminal, an output terminal, a separation insulating film, and an active region. The input terminal and the output terminal are electrically coupled to the well region. The separation insulating film is arranged to be in contact with the upper surface of the well region in an intermediate region between the input terminal and the output terminal. The active region is arranged to be in contact with the upper surface of the well region. The separation insulating film and the active region in the intermediate region have an elongated shape in plan view. In the intermediate region, a plurality of separation insulating films and a plurality of active regions are alternately and repeatedly arranged.

Owner:RENESAS ELECTRONICS CORP

Stencil masks, method of manufacturing stencil masks, and method of using stencil masks

InactiveUS7824825B2Reduce rigidityIncrease the amount of deformationElectric discharge tubesNanoinformaticsEngineering physicsSemiconductor

The present invention presents a stencil mask in which various surface patterns can be formed, and in which deformation is suppressed when charged particles are introduced. A stencil mask of the present invention is provided with a semiconductor stack. A first penetrating hole corresponding to an ion introducing area is formed in a first semiconductor layer of the semiconductor stack, and second penetrating holes are formed in a second semiconductor layer, these second penetrating holes having a width greater than the width of the first penetrating hole. The first penetrating hole and the second penetrating holes communicate and pass through the semiconductor stack. Beam members extending between adjacent second penetrating holes connect portions of the first semiconductor layer separated by the first penetrating hole.

Owner:TOYOTA JIDOSHA KK

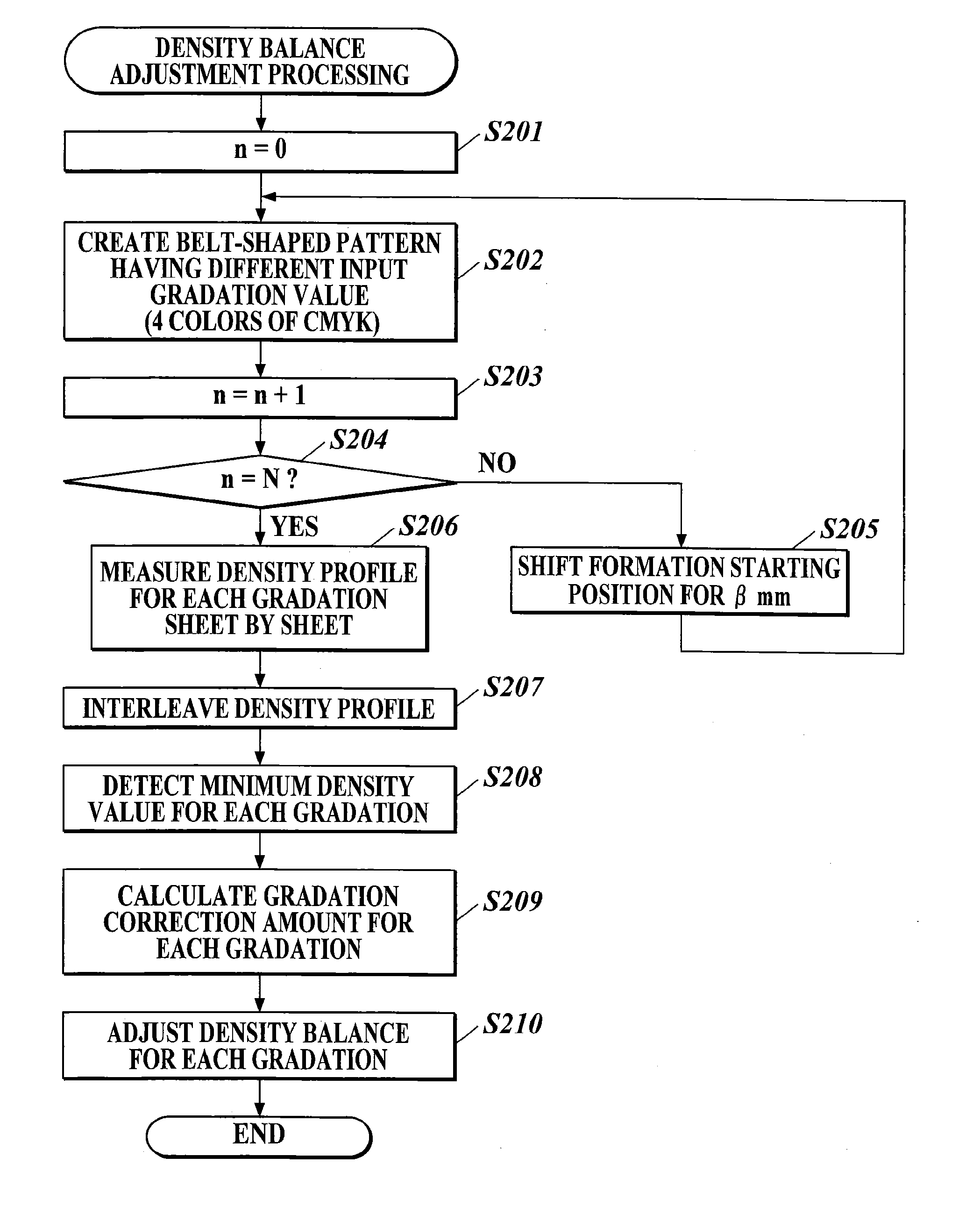

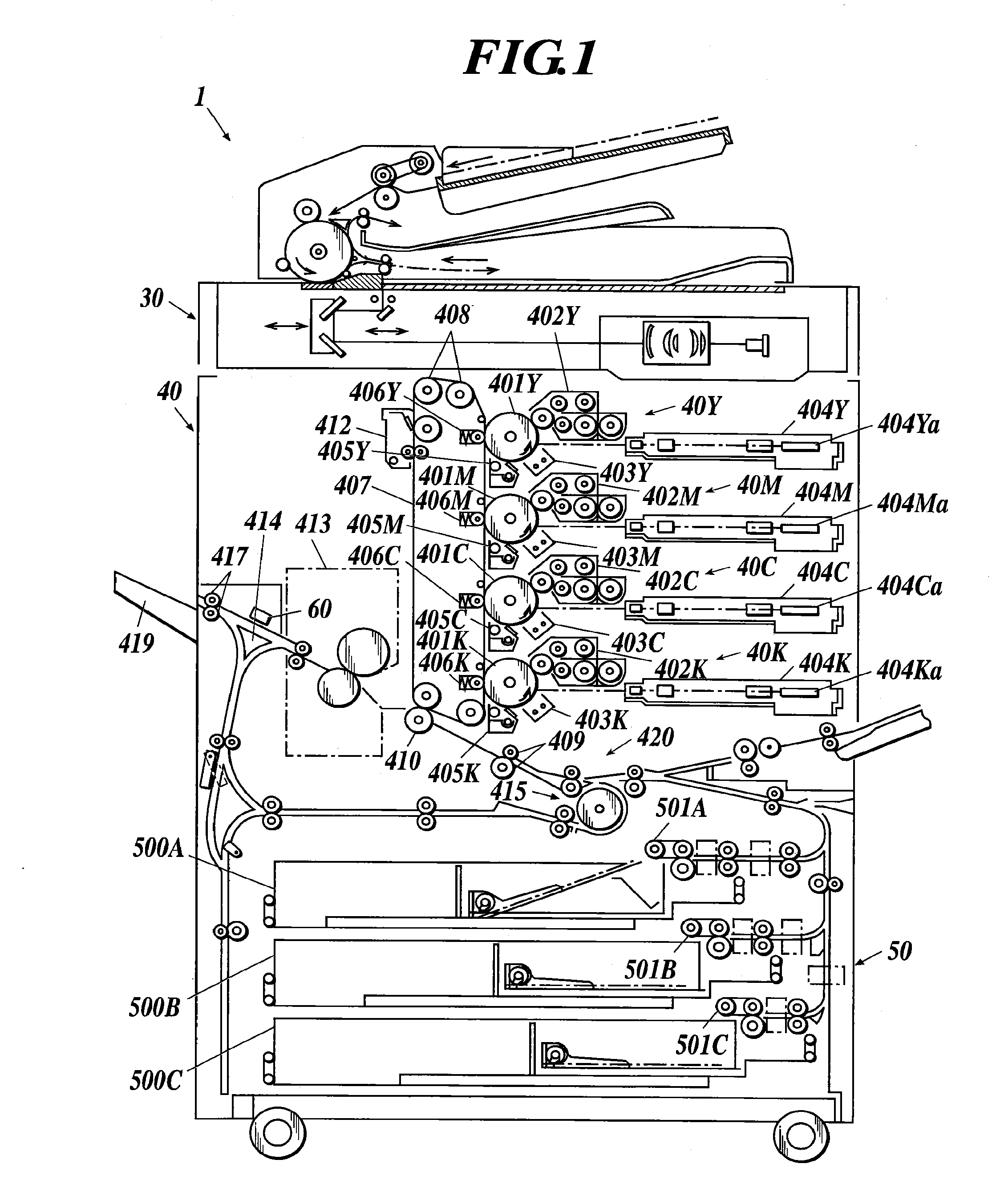

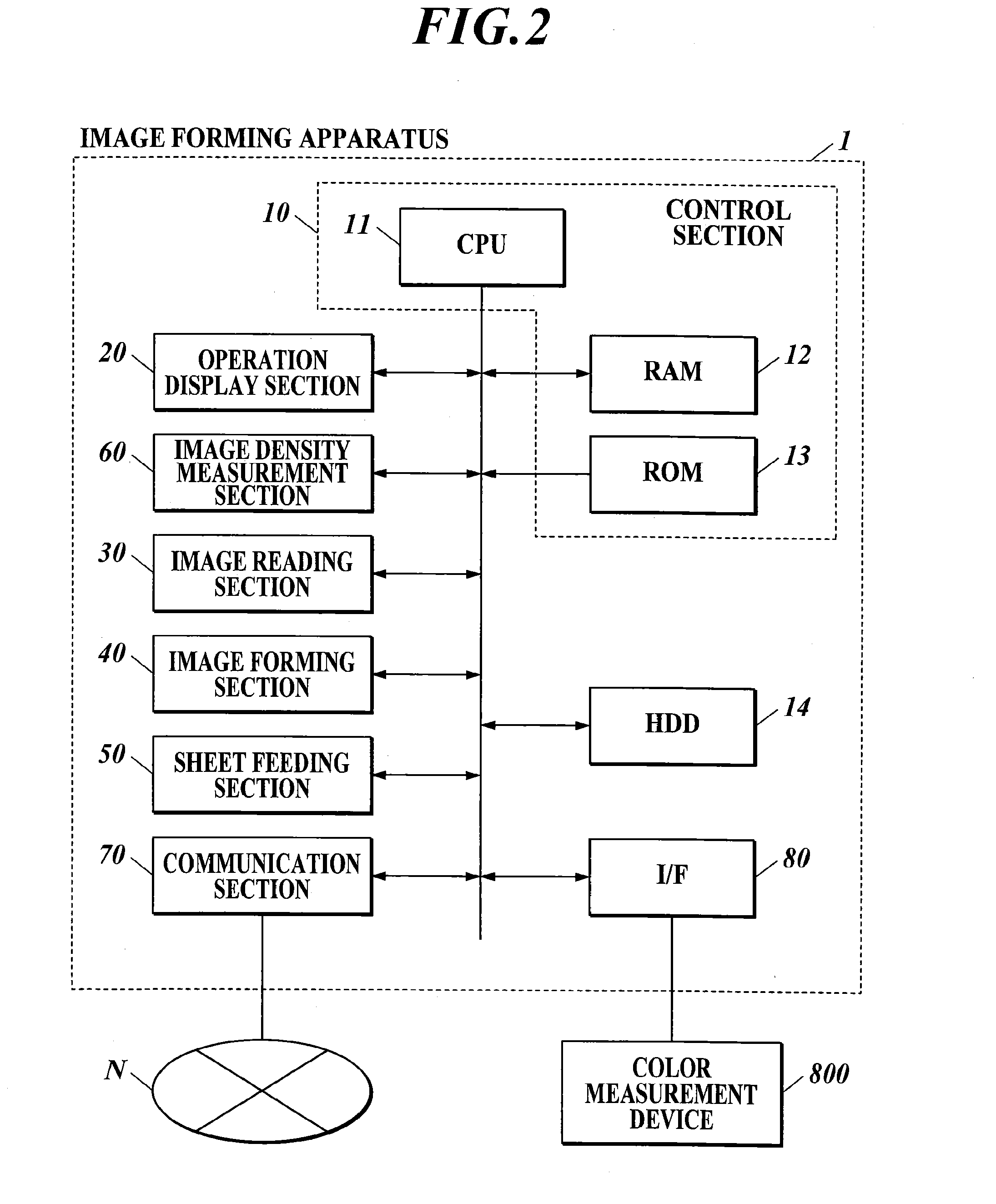

Image forming apparatus, image forming system, and image density adjustment method

InactiveUS20110222868A1Corrects density unevennessDensity unevennessElectrographic process apparatusImage formationImage density

An image forming apparatus including: an image forming section; and a control section allowing the image forming section to form a belt-shaped pattern on sheets in such a way that a formation starting position of the belt-shaped pattern is shifted for a distance, obtained by dividing a measurement-distance by a number of sheets to be used, in a main-scanning direction sheet by sheet; collecting, sheet by sheet, pieces of density information each of which indicates the density of the belt-shaped pattern at a measurement position of measurement positions; creating data in which the pieces of density information respectively correspond to the measurement positions arranged in the main-scanning direction on each of the sheets; and correcting density unevenness of image data in the main-scanning direction based on the created data, wherein the image forming section forms an image based on the image data of which the density unevenness is corrected.

Owner:KONICA MINOLTA BUSINESS TECH INC

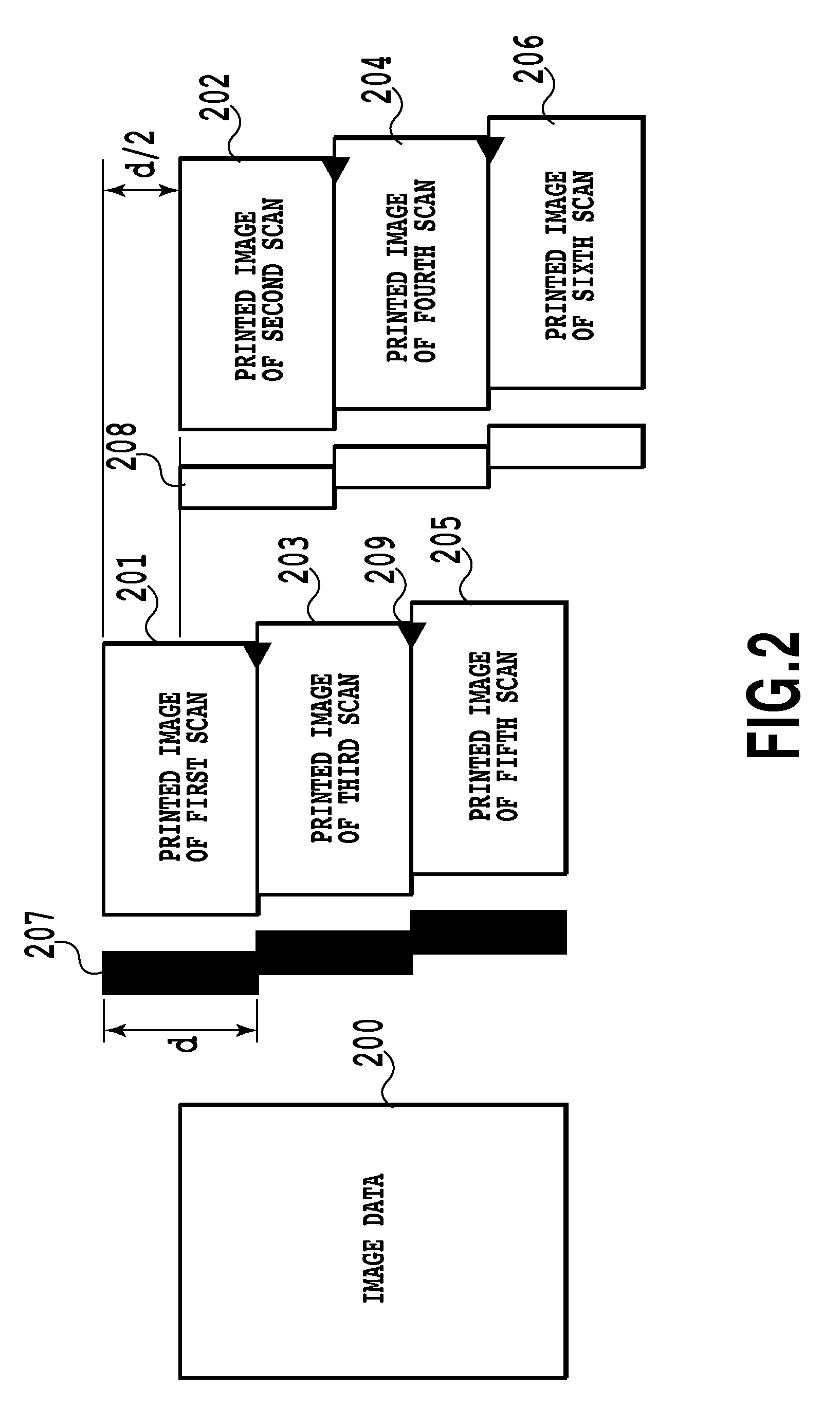

Inkjet printing apparatus and inkjet printing method

ActiveUS8070249B2Density unevennessImprove image qualitySpacing mechanismsOther printing apparatusVolumetric Mass DensityEngineering

After a first scan in a forward direction, conveying corresponding to one nozzle block is performed, and then in a second scan in a backward direction, printing of a “printing area 1,” which is a unit area, is completed. Then after completion of printing of the unit area, conveying corresponding to 14 nozzle blocks is performed. Then by reciprocal third and fourth scans, printing of a “printing area 2” is completed in a likewise manner. Subsequently, two scans in a reciprocal manner are performed in a likewise manner to perform printing of each unit area. In any unit area, printing time intervals between scans are such that, at a same position in a scan direction, the time interval is the same. Consequently, differences in density between unit areas that are adjacent in a conveying direction of a printing medium, that is, between-band unevenness becomes more difficult to recognize.

Owner:CANON KK

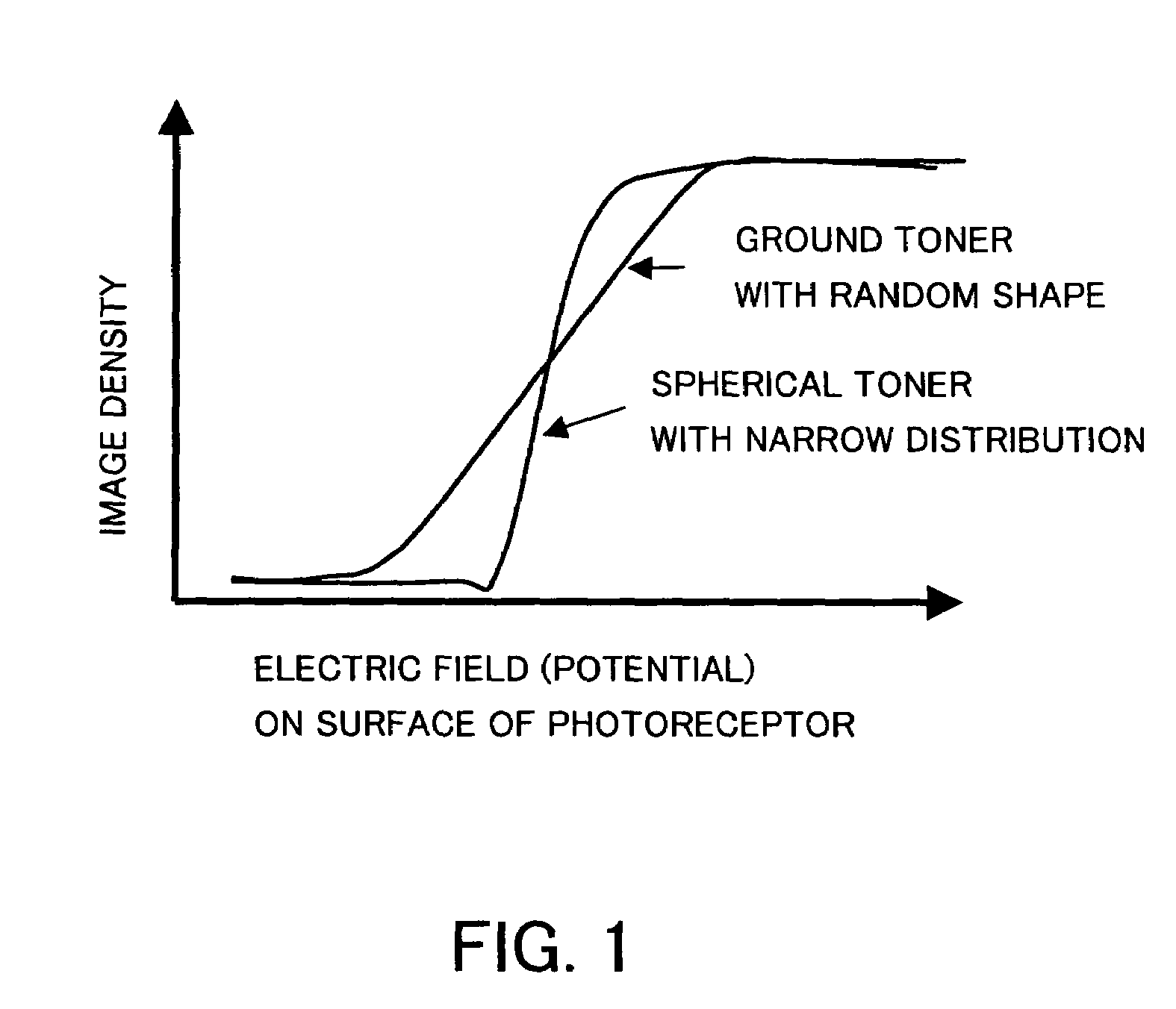

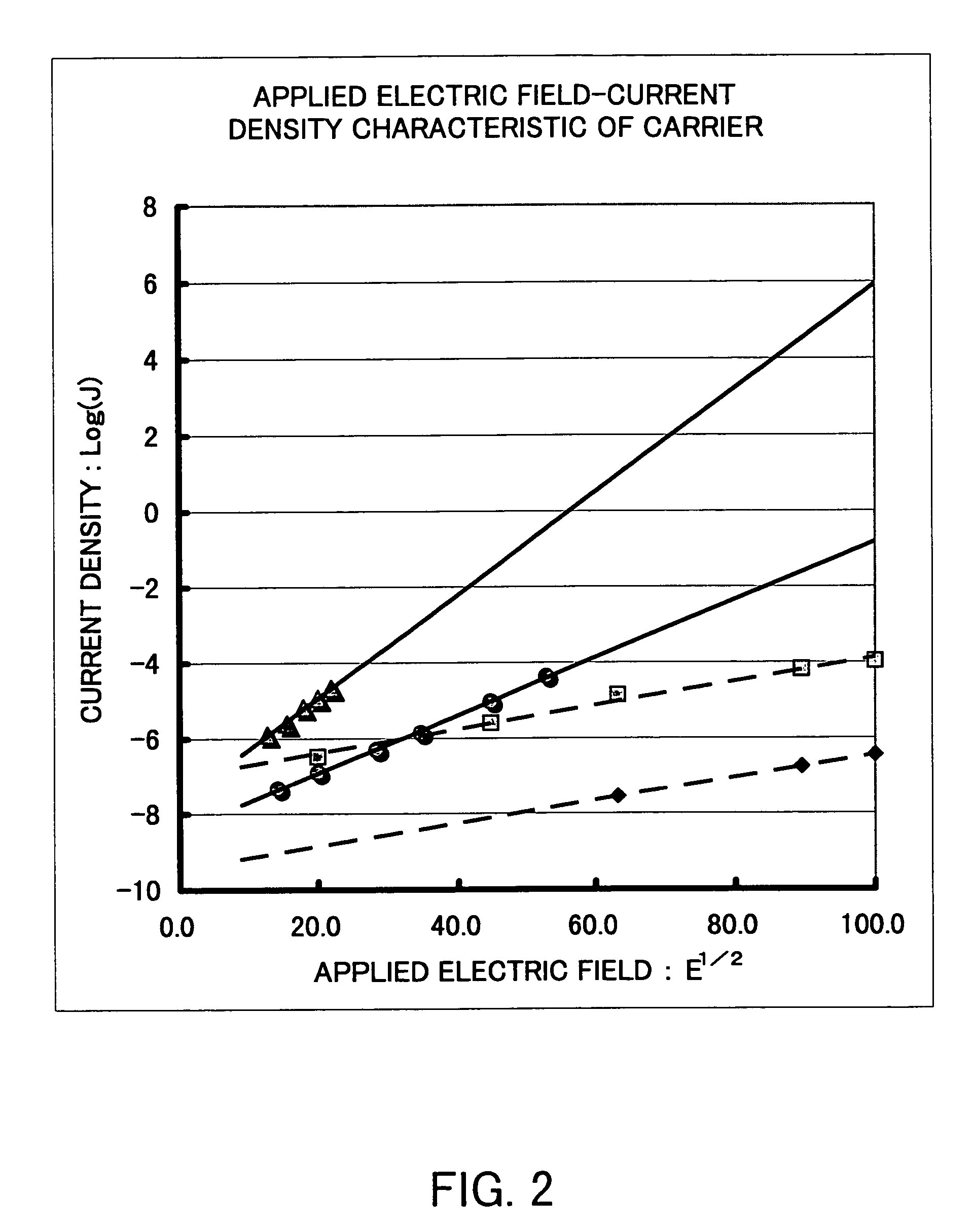

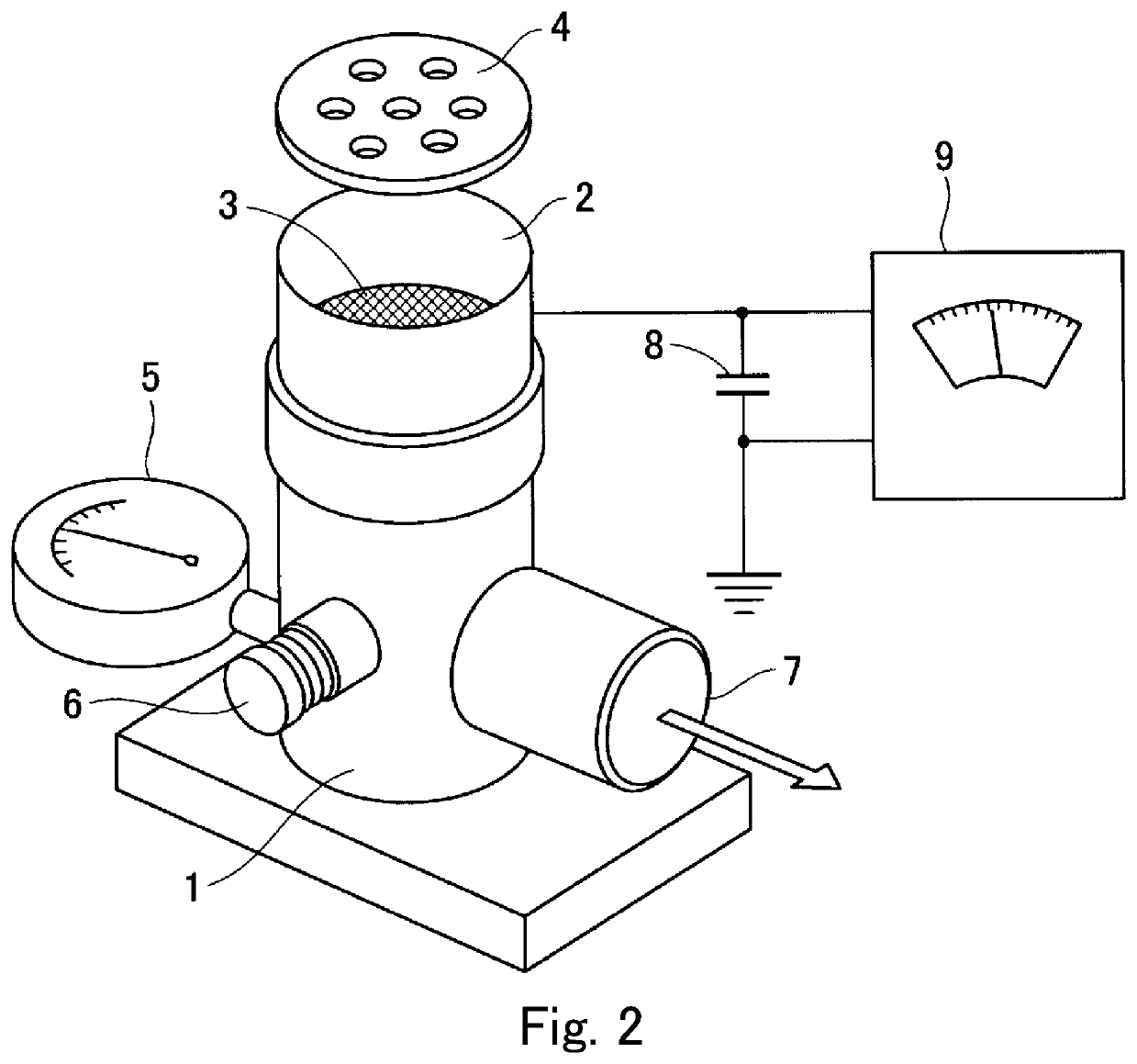

Electrostatic latent image developer, image forming method, and image forming apparatus

InactiveUS7070899B2Eliminating reproduction deficiencyImage qualityDevelopersElectrographic process apparatusLatent imageImage formation

An electrophotographic developer is provided for realizing high-quality images and superior reproducibility of laser dots in a low coverage region and reduced unevenness of color in halftone solid images. The electrophotographic developer includes a toner and a carrier. The toner has a shape factor of 140 or less and a volume average particle size distribution GSDv of 1.3 or less. The carrier has a coat resin layer on a core material, the coat resin layer containing a conductive powder. The core material has a dynamic electric resistivity of 1 Ω·cm or less under an electric field of 104 V / cm in a form of a magnetic brush. The conductive powder has an electric resistivity of 101 Ω·cm or greater and 106 Ω·cm or less. The carrier has an electric resistivity in a range between 10 and 1×108 Ω·cm. An image forming method is also provided wherein the electrophotographic developer is used for development in a developing stage.

Owner:FUJIFILM BUSINESS INNOVATION CORP

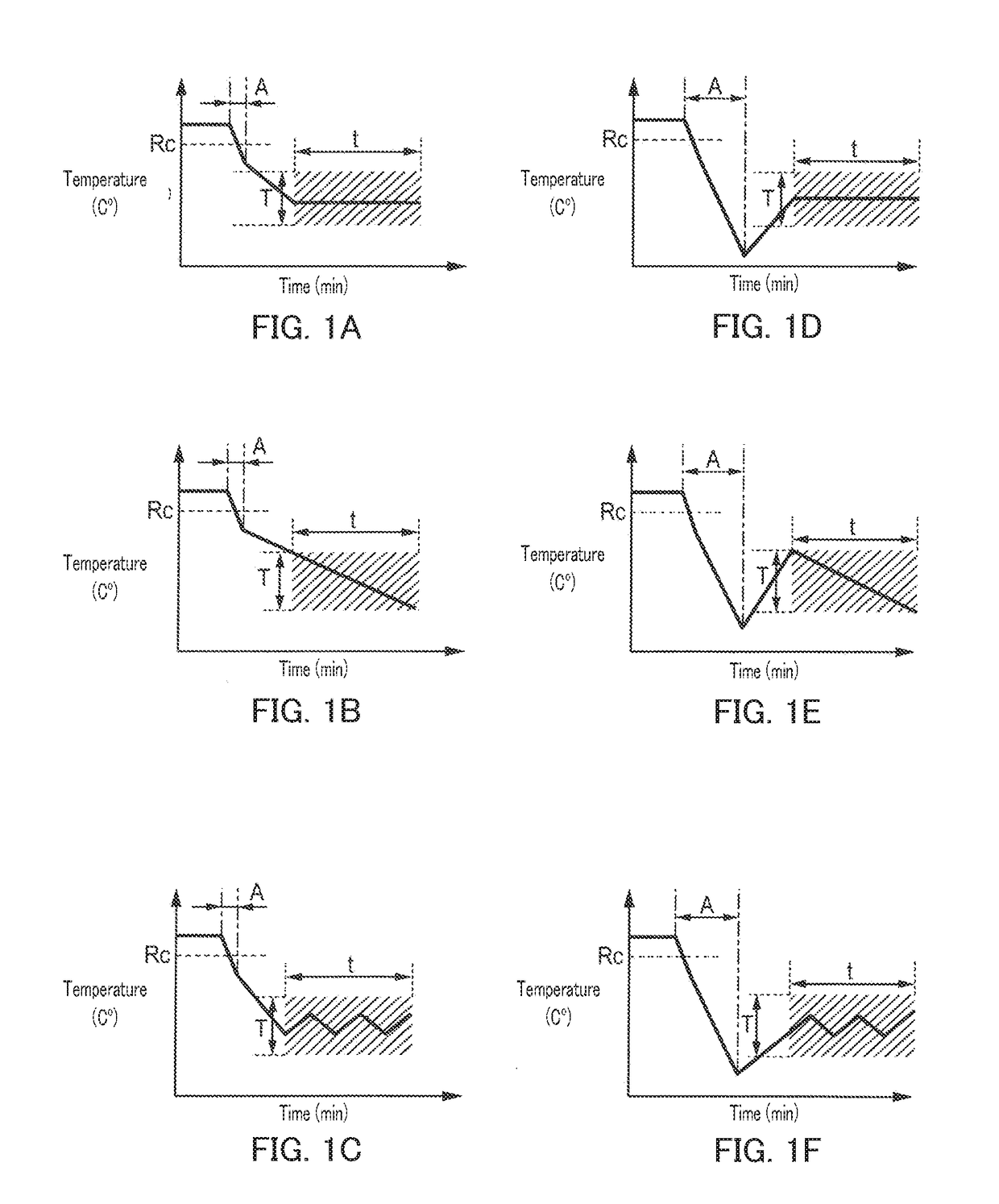

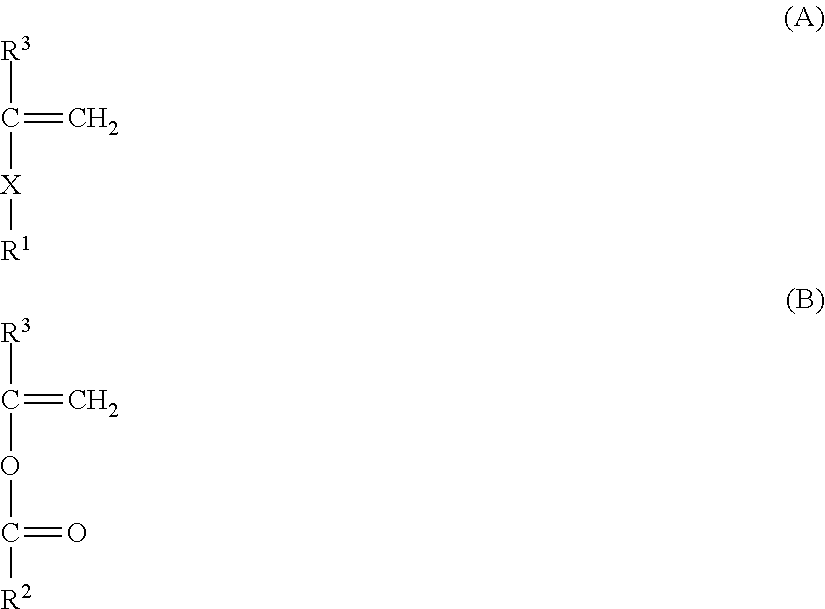

Process for producing a toner

A process for producing a toner of the present invention includes: a first step of heating a dispersion containing an aqueous medium and a binder resin containing a crystalline resin to a temperature higher than or equal to a melting point of the crystalline resin; and a second step of maintaining the dispersion at temperature T (° C.) for 30 minutes or longer in a state where a pH of the dispersion is maintained at 5.5 or higher and 9.0 or lower, in which the temperature T satisfies the following expression, Rc−25≦T≦Rc−5, where the Rc represents a recrystallization temperature (° C.) of the crystalline resin.

Owner:KONICA MINOLTA INC

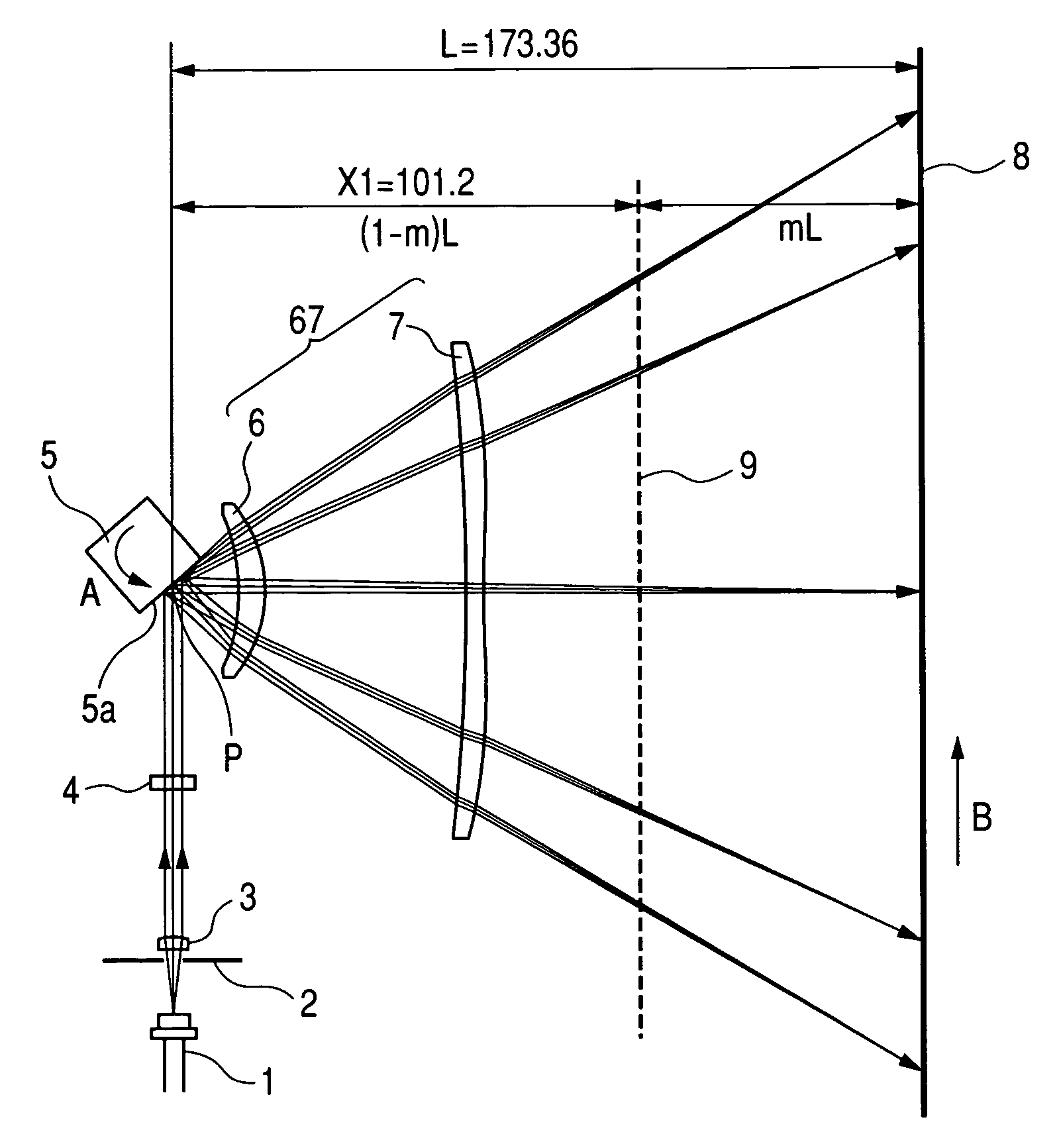

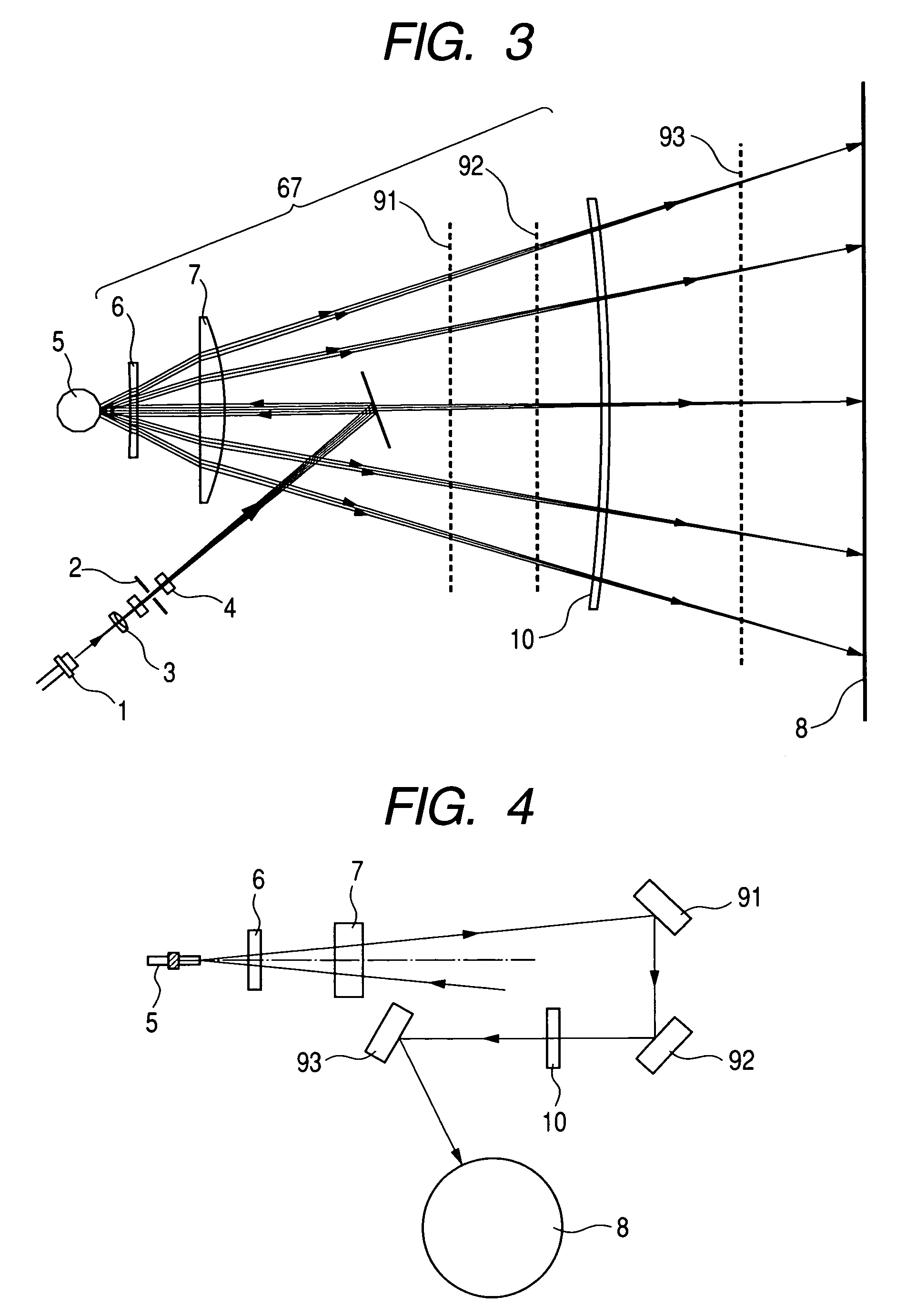

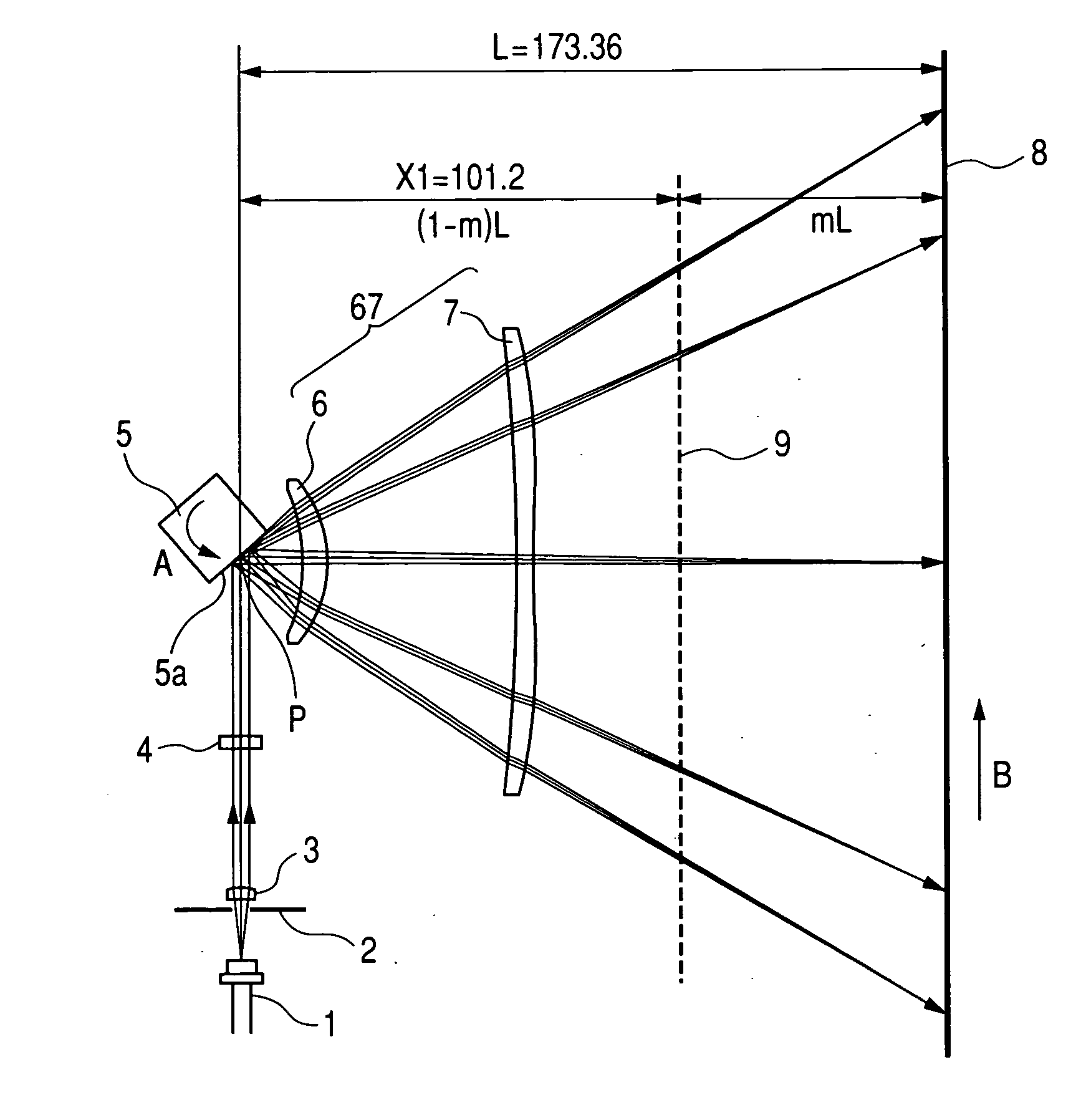

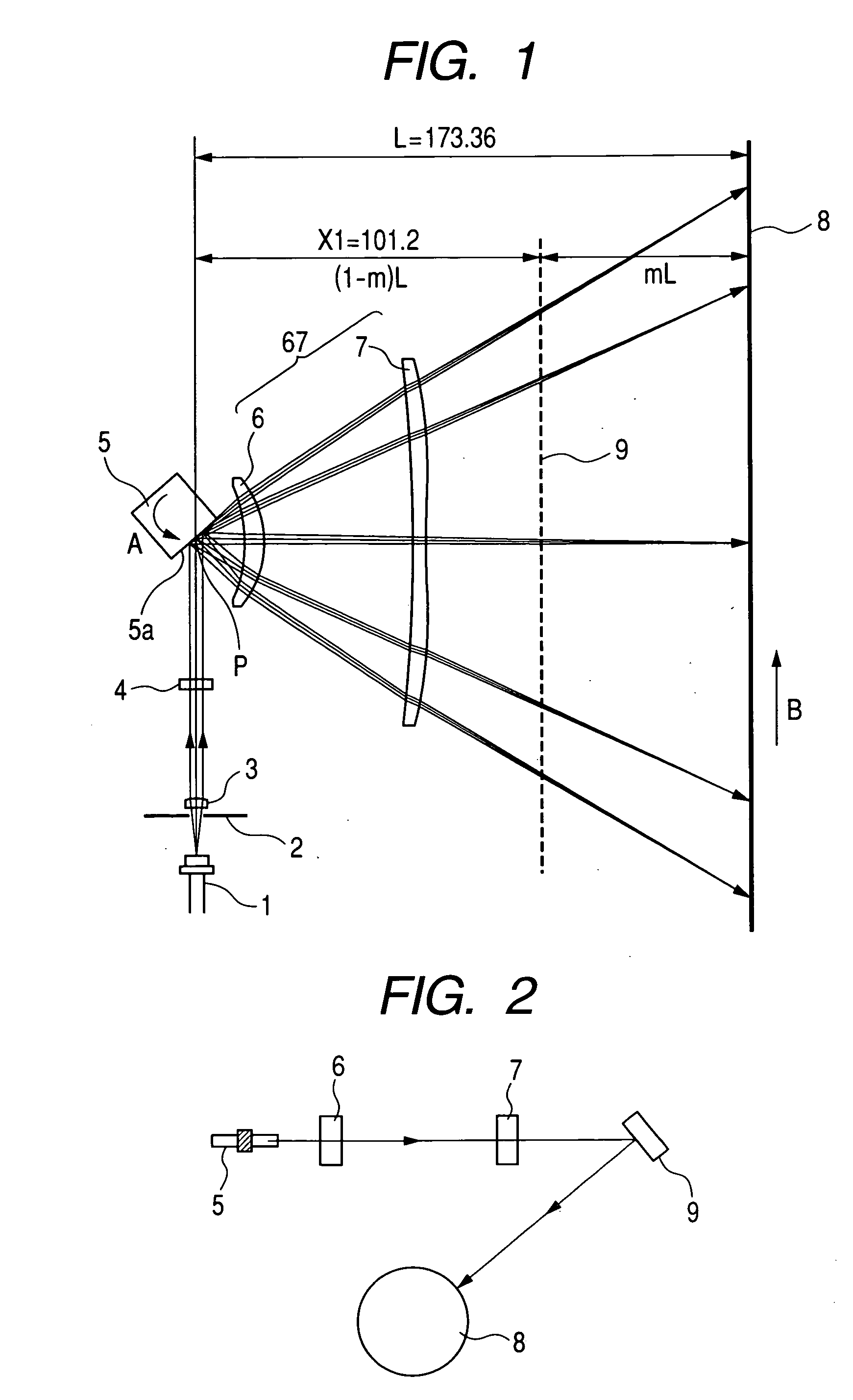

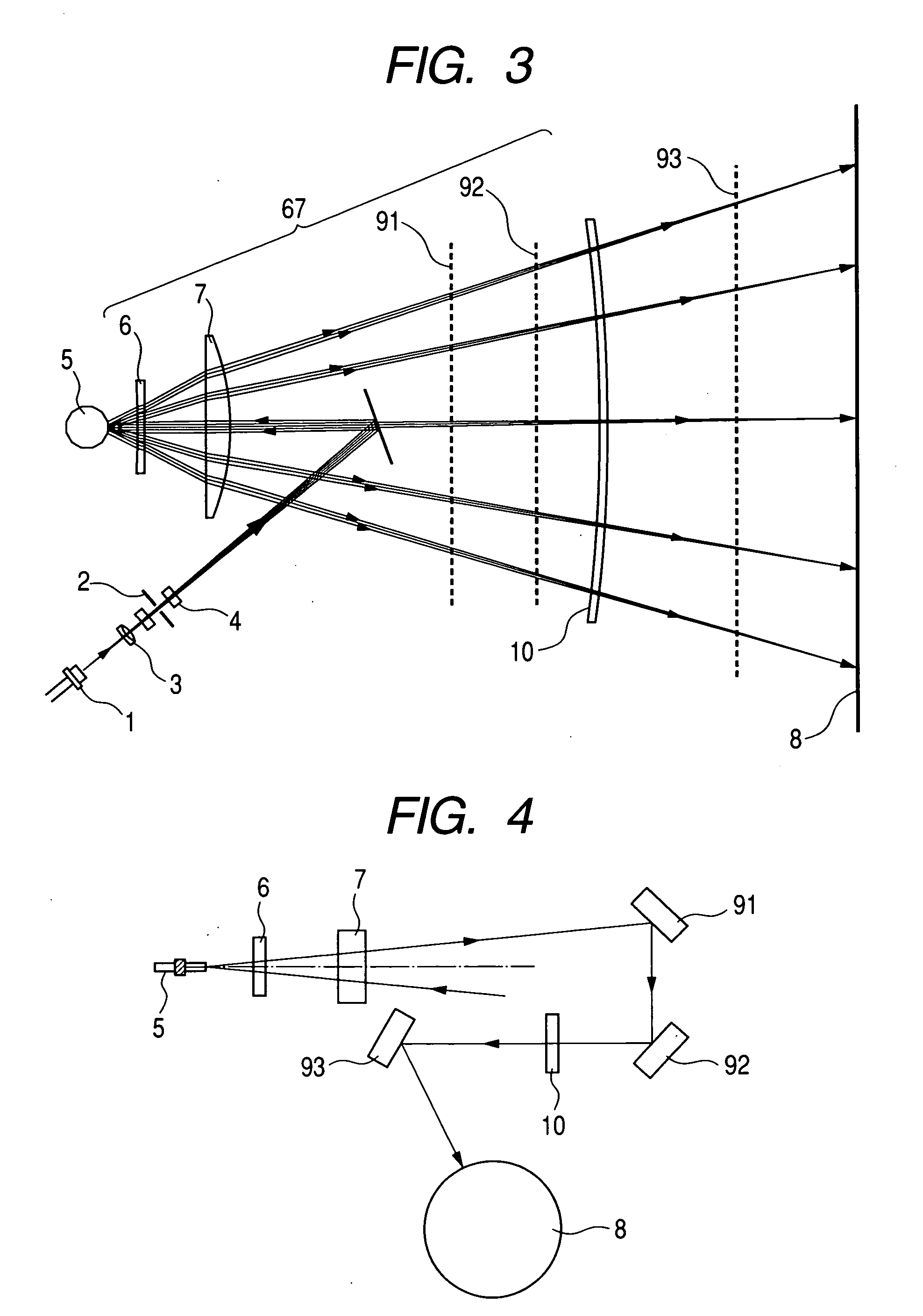

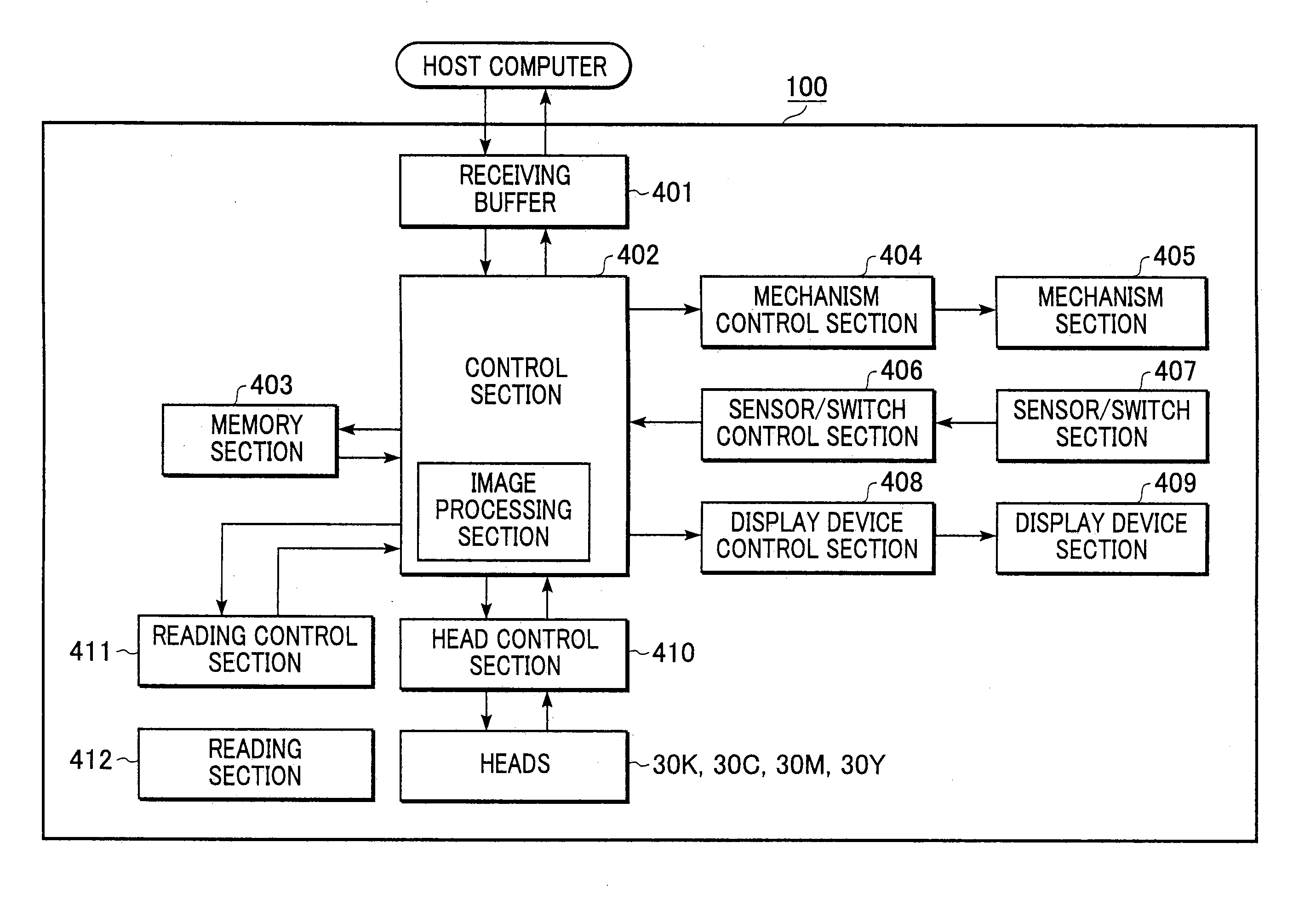

Optical scanning apparatus and image forming apparatus equipped with the same

InactiveUS7218434B2Reduce streaksEnhance the imageInking apparatusBeam/ray focussing/reflecting arrangementsOptical axisImage formation

An optical scanning apparatus in which streaks in an image or unevenness in density of an image caused by influences of dust, scratches and toner etc. on the surface of a reflecting member are unlikely to occur and excellent images can be always obtained and an image forming apparatus equipped with such an optical scanning apparatus are to be achieved. The apparatus comprises a first optical system for guiding a light beam emitted from light source unit to deflecting unit, the deflecting unit for reflecting and deflecting the light beam from the first optical system, a second optical system for guiding the light beam reflected and deflected by the deflecting unit onto a surface to be scanned through reflecting unit including n (n is an integer equal to or larger than 1) reflecting members. The apparatus satisfies the following conditions for the F-number Fnomain (mm) with respect to a main scanning cross section of an exit side of the second optical system and the smallest beam area Smin (mm2) among beam areas on reflecting surfaces of the n reflecting members on which a light beam is reflected during traveling on the optical axis of the second optical system: 70<FNOmain, and (0.004 / Smin)xn<0.03.

Owner:CANON KK

Develop roller, develop unit, process cartridge, and image forming apparatus

InactiveUS8731444B2Inhibition amountDensity unevennessAgricultural rollersElectrographic process apparatusMagnetic tension forceImaging equipment

Owner:RICOH KK

Optical scanning apparatus and image fomring apparatus equipped with the same

InactiveUS20050269493A1Reduce streaksExcellent imageInking apparatusBeam/ray focussing/reflecting arrangementsLight sourceOptical axis

An optical scanning apparatus in which streaks in an image or unevenness in density of an image caused by influences of dusts, scratches and toner etc on the surface of a reflecting member are unlikely to occur and excellent images can be always obtained and an image forming apparatus equipped with such an optical scanning apparatus are to be achieved. The apparatus comprises a first optical system for guiding a light beam emitted from light source unit to deflecting unit, the deflecting unit for reflecting and deflecting the light beam from the first optical system, a second optical system for guiding the light beam reflected and deflected by the deflecting unit onto a surface to be scanned through reflecting unit including n (n is an integer equal to or larger than 1) reflecting members. The apparatus satisfies the following conditions for the F-number Fnomain (mm) with respect to a main scanning cross section of an exit side of the second optical system and the smallest beam area Smin (mm2) among beam areas on reflecting surfaces of the n reflecting members on which a light beam is reflected during traveling on the optical axis of the second optical system: 70<Fnomain, and (0.004 / Smin)×n<0.03.

Owner:CANON KK

Recording method and recording apparatus capable of reducing streaks and unevenness in image density

InactiveUS20070013730A1Eliminate image defectDensity unevennessOther printing apparatusComputer hardwareImage density

A recording method for use in a recording system for completing an image by multiple scans of a recording head includes the steps of reading an image recorded by a predetermined number of scans among the multiple scans of the recording head except at least the last scan, and correcting, based on a result of reading the image in the reading step, data for an image to be recorded by one or more scans subsequent to the predetermined number of scans. An image is correctively recorded by performing one or more scans subsequent to the predetermined number of scans in accordance with the corrected data.

Owner:CANON KK

Image processing apparatus, control method of image processing apparatus, image forming apparatus, and storage medium

InactiveUS8786907B2Density unevennessTelevision system detailsDigitally marking record carriersPattern recognitionImaging processing

When an image processing apparatus of one aspect of this invention corrects input image data using correction values (misregistration correction amounts Δy), it determines whether or not image data to be corrected using amounts Δy includes a specific pattern which may cause density unevenness in an image to be formed. When the image processing apparatus determines that the image data includes the specific pattern, it modifies amounts Δy corresponding to pixels including the specific pattern of the amounts Δy using any of a plurality of different predetermined modulation amounts (modification values). Furthermore, the image processing apparatus corrects the image data for respective pixels using either the amounts Δy before modification, or the modified amounts Δy when the modification is done.

Owner:CANON KK

Printing apparatus and printing method

ActiveUS11338580B2Constant jetting speed of dropletsDensity unevennessOther printing apparatusEngineeringPower circuits

A printing apparatus has a conveyance roller configured to convey a sheet in a first direction, an encoder provided at the conveyance roller, a head having a plurality of nozzles aligned in a second direction intersecting with the first direction and being configured to jet liquid to the sheet which is conveyed in the first direction by the conveyance roller and a controller having a power circuit configured to apply voltage to the head for jetting the liquid. The controller is configured to: determine a jetting frequency for the head based on a signal outputted from the encoder; and change an output voltage of the power circuit depending on the determined jetting frequency.

Owner:BROTHER KOGYO KK

Toner

ActiveUS20210055667A1Hot offset resistanceDensity unevennessDevelopersComposite materialPolymer chemistry

A toner comprising a resin that contains an amorphous segment and a crystalline segment as a binder resin, wherein a proportion of a tetrahydrofuran-insoluble matter of a resin component is from 40% by mass to 80% by mass; in differential scanning calorimeter measurement of the tetrahydrofuran-insoluble matter, where a temperature of a maximum endothermic peak is denoted by Tm [° C.] and an endothermic quantity is denoted by H(I) [J / g], the following formulas (1) and (2) are satisfied:55.0≤Tm≤80.0 (1)10.0≤H(I)≤80.0 (2).

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com