Patents

Literature

42results about How to "Good inductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

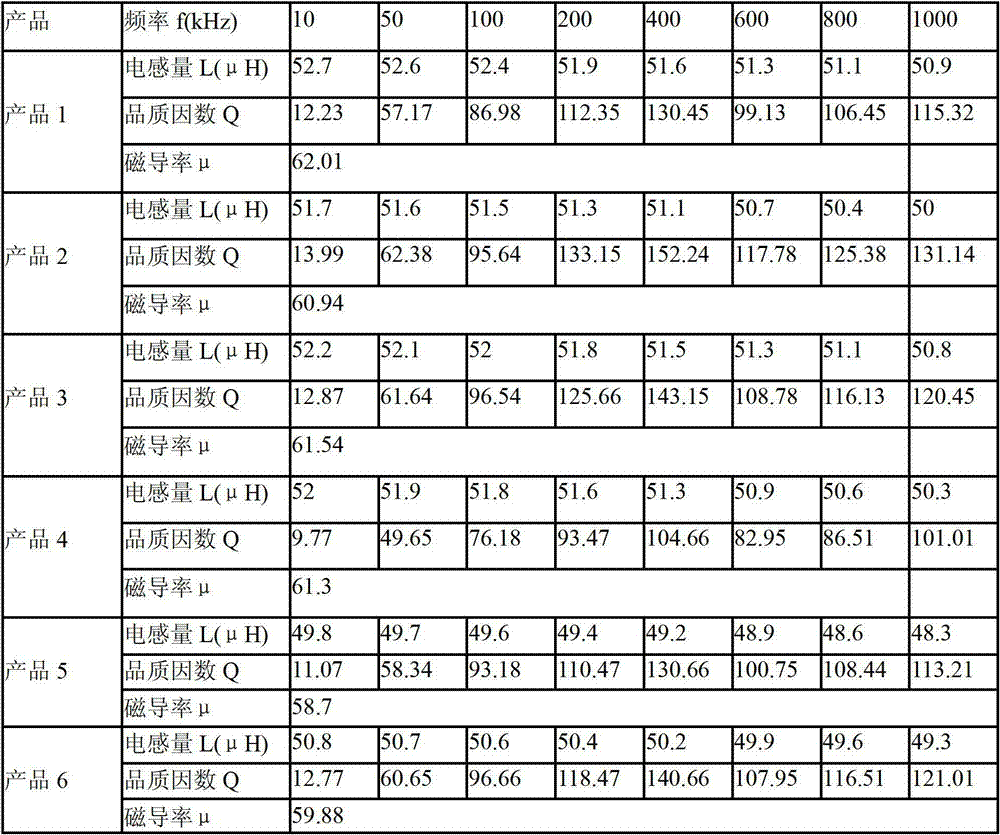

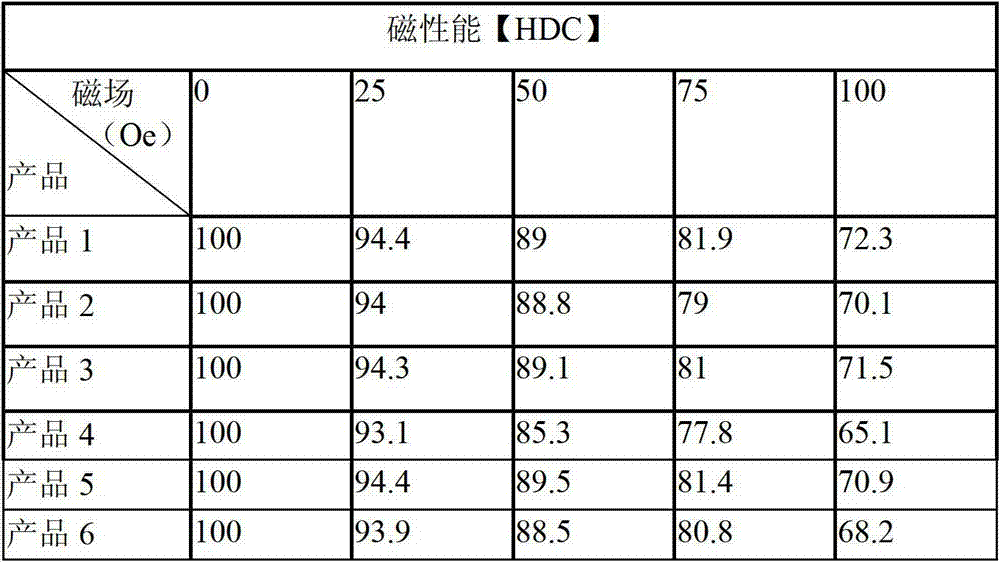

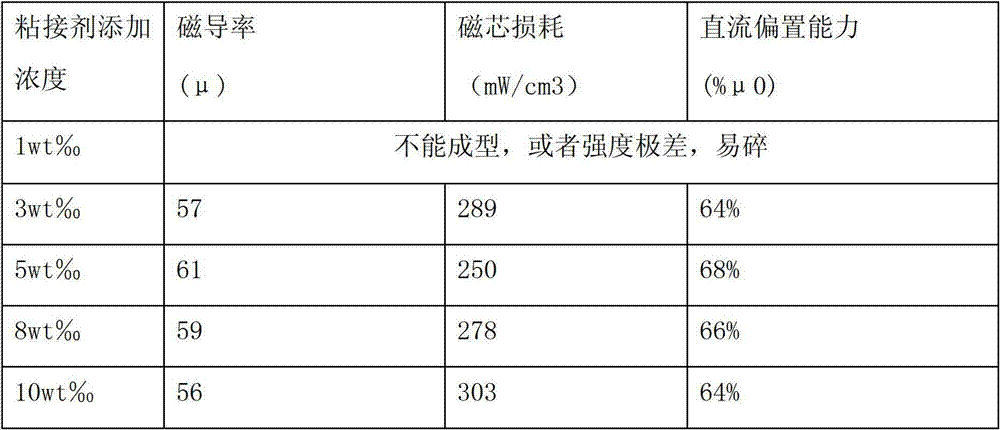

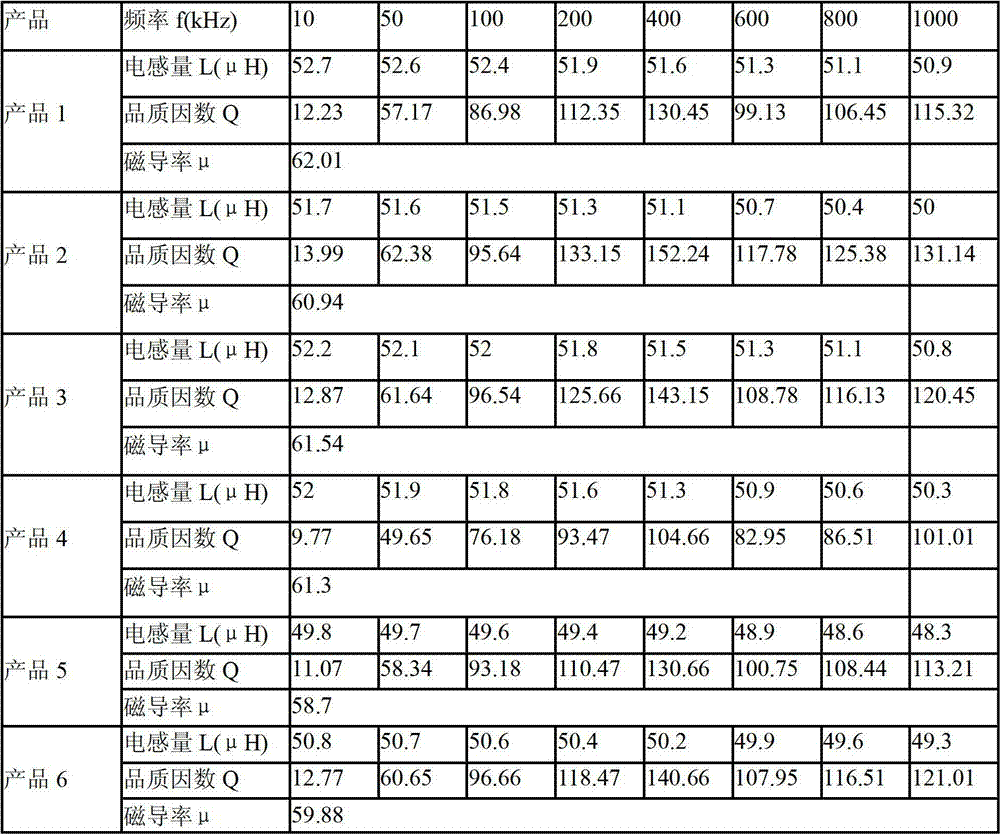

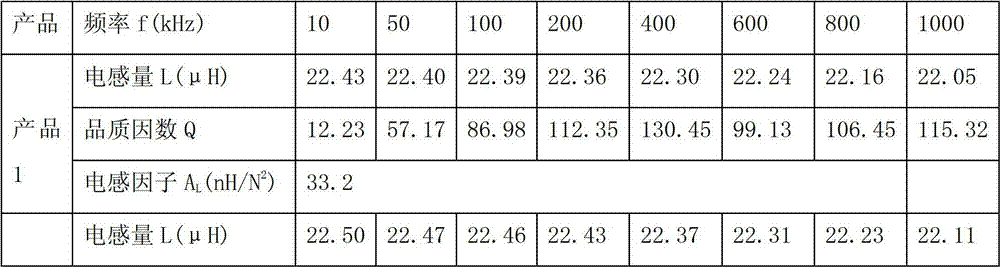

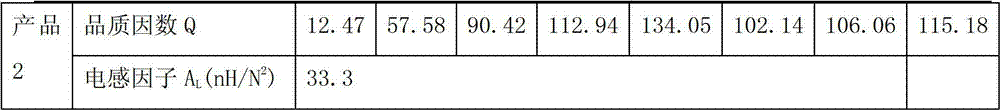

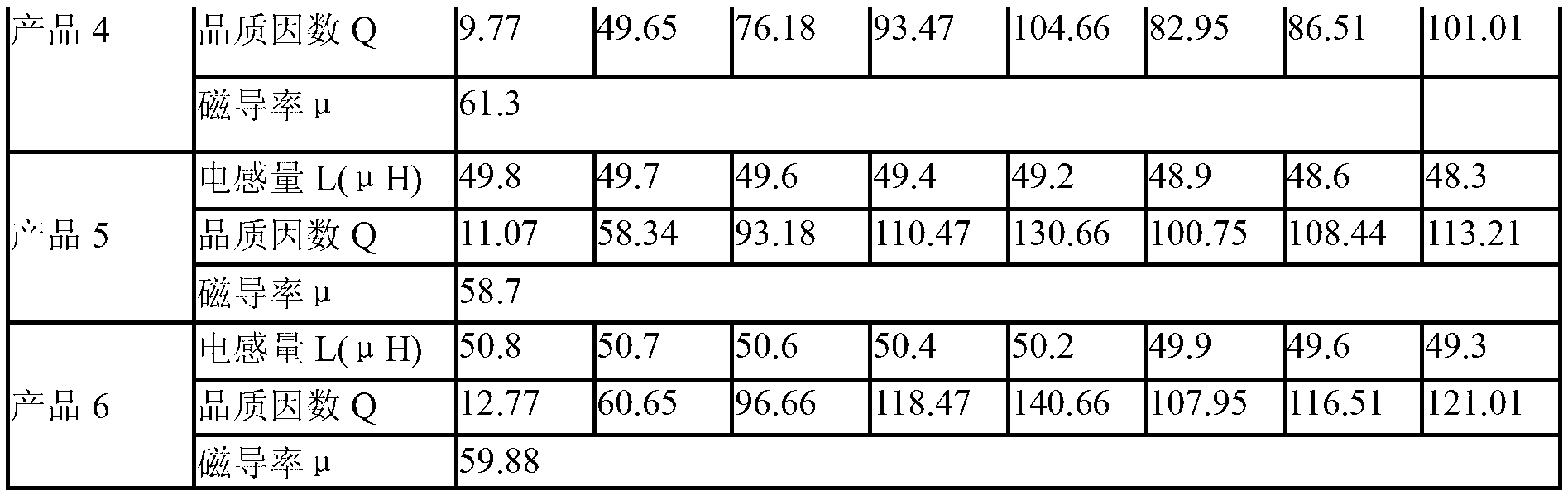

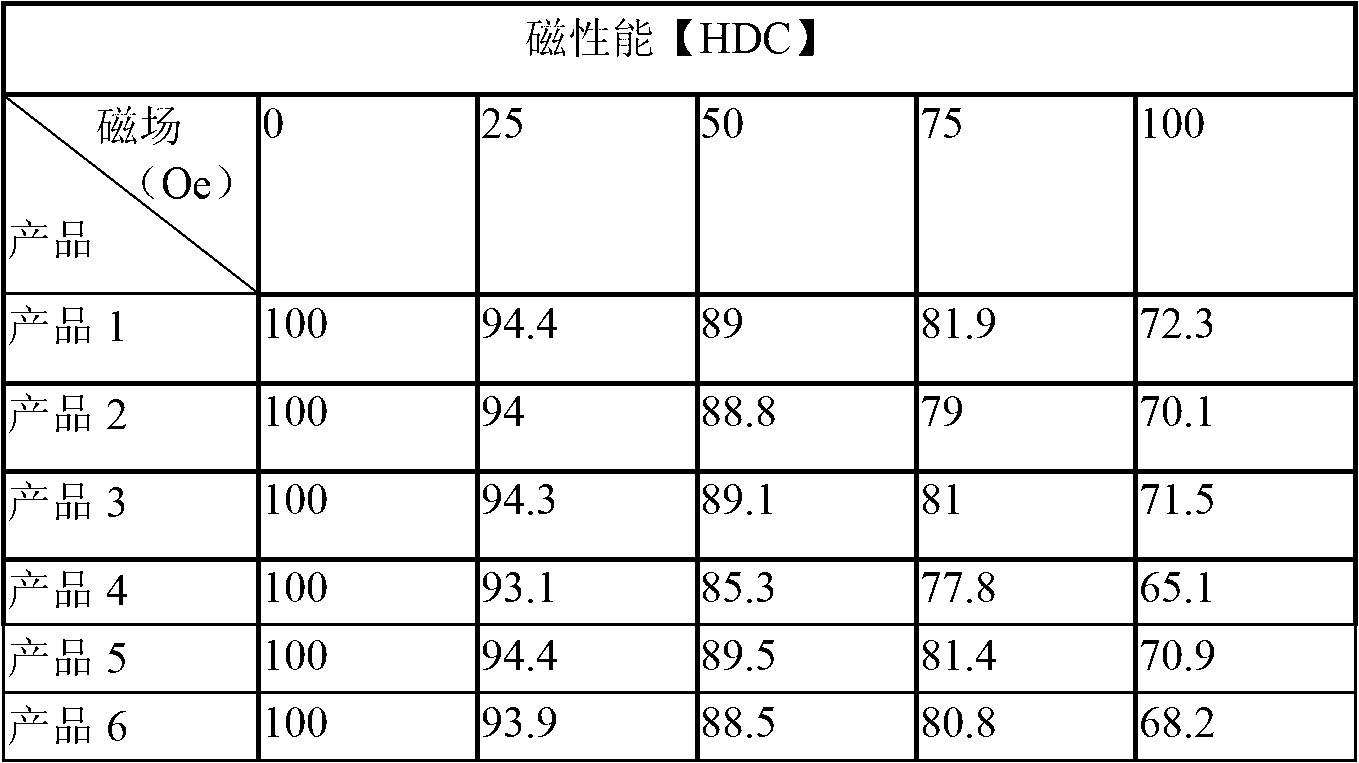

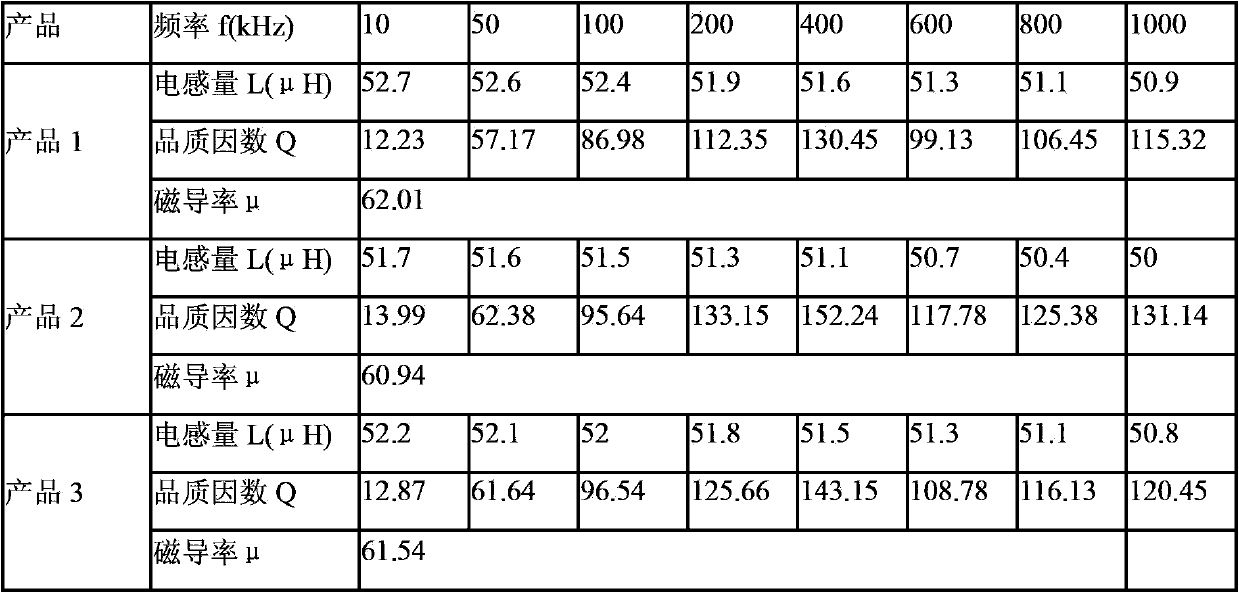

Preparation method of nanometer crystal magnetic powder core with magnetic conductivity mum of 60

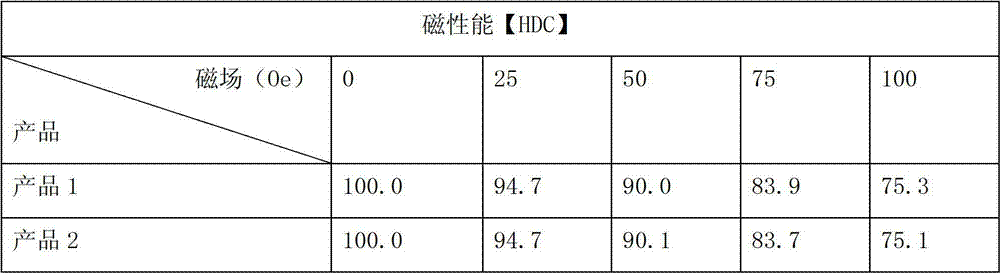

InactiveCN102737799AGood inductanceHigh quality factorInorganic material magnetismInductances/transformers/magnets manufactureNano crystallineMetal powder

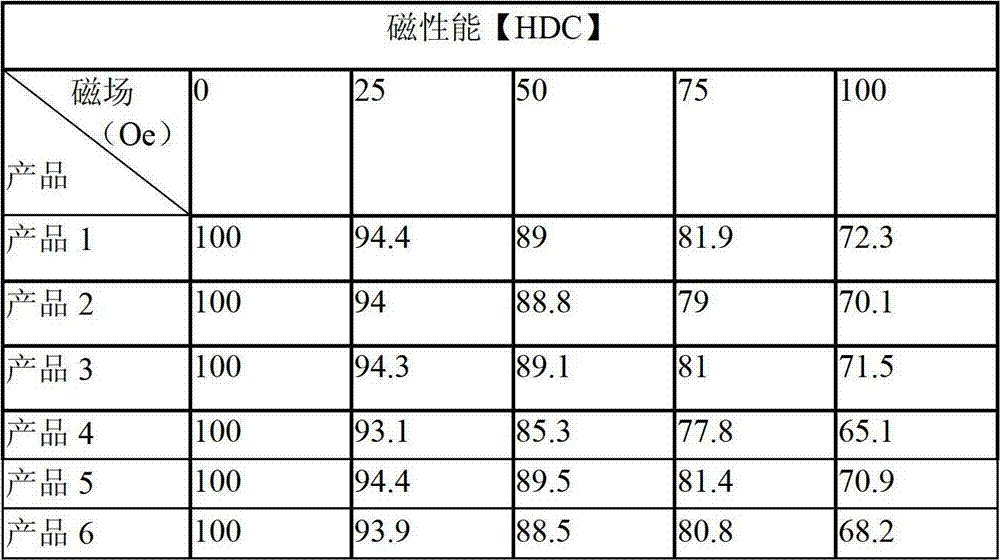

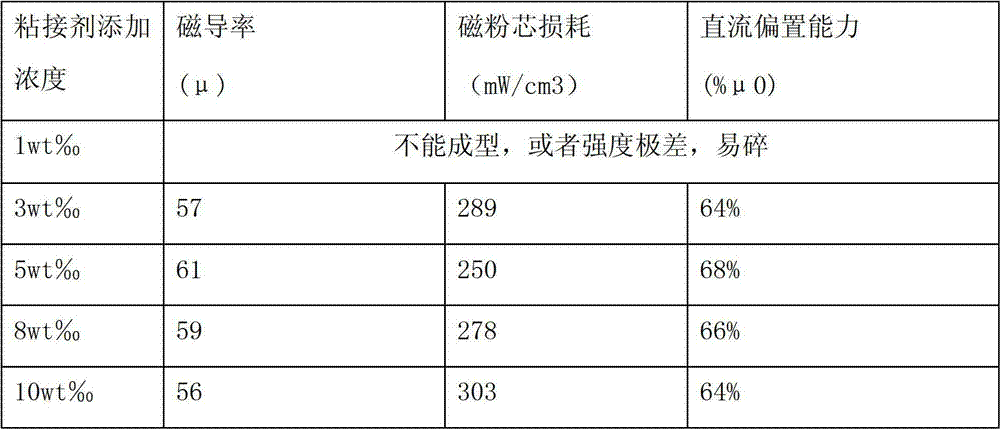

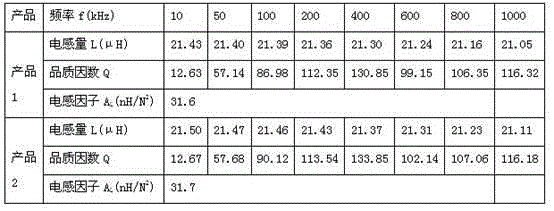

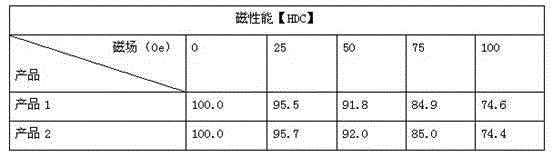

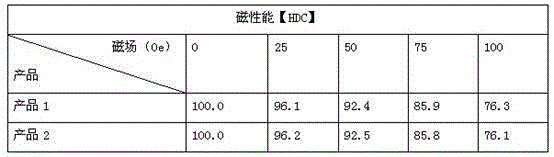

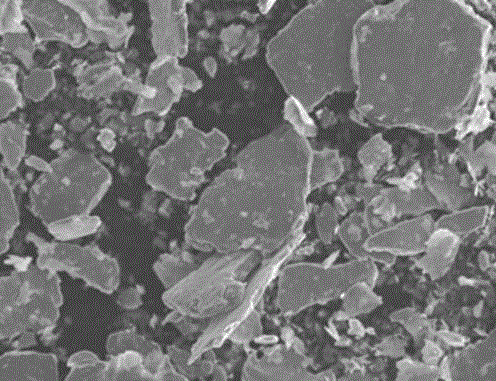

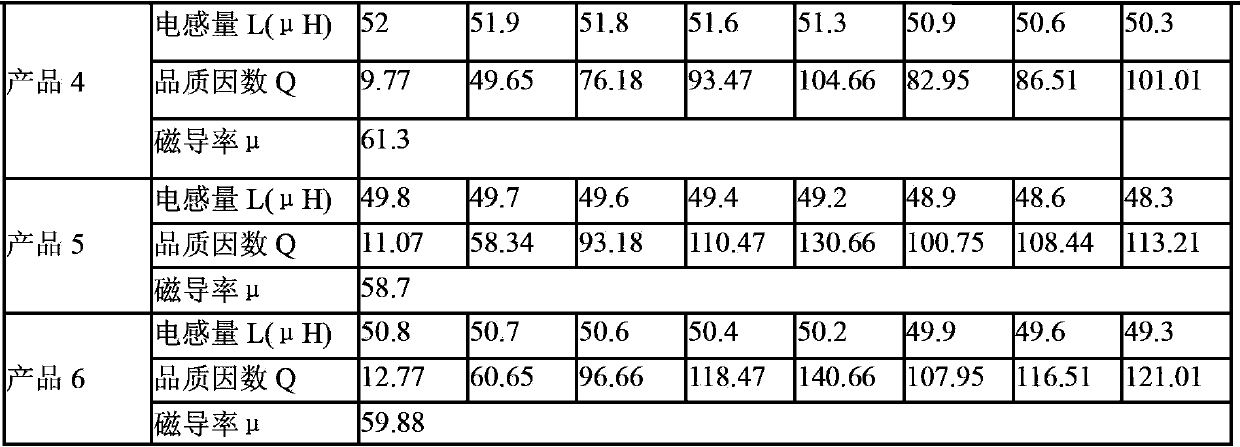

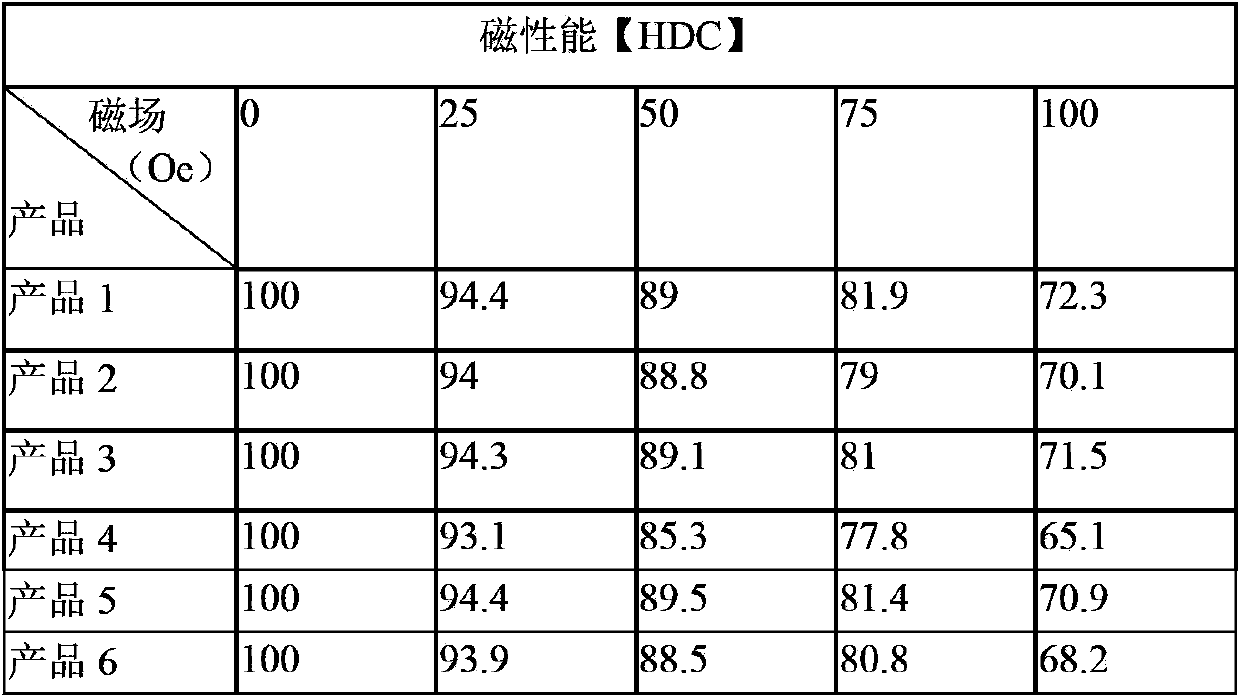

The invention discloses a preparation method of a nanometer crystal magnetic powder core with a magnetic conductivity mumof 60. The method comprises the following steps: thermally treating an iron-based amorphous thin ribbon prepared by a rapid cooling method into a nano-crystalline ribbon, wherein the iron-based amorphous thin ribbon has the following components by weight: 3-15% of Ni, 1-10% of Si, 1-4% of B, 1-9% of Al and the balance of Fe; crushing the nano-crystalline ribbon to obtain nano-crystalline metal powders; conducting ball-milling and shaping the nano-crystalline metal powders; screening the nano-crystalline metal powders, and mixing the nano-crystalline metal powders into powder particle consisting of 90%-98% of first powder screened by a -200-mesh sieve and 2%-10% of second powder screened by a (-150)-(+200)-mesh sieve for distribution; mixing the mixed nano-crystalline metal powders with a bonding agent, and pressing to form the magnetic core; and annealing the formed magnetic core, and then, coating the magnetic core with insulating resin. According to the technical scheme, the magnetic powder core has stable magnetic conductivity, a loss value and direct-current bias ability.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

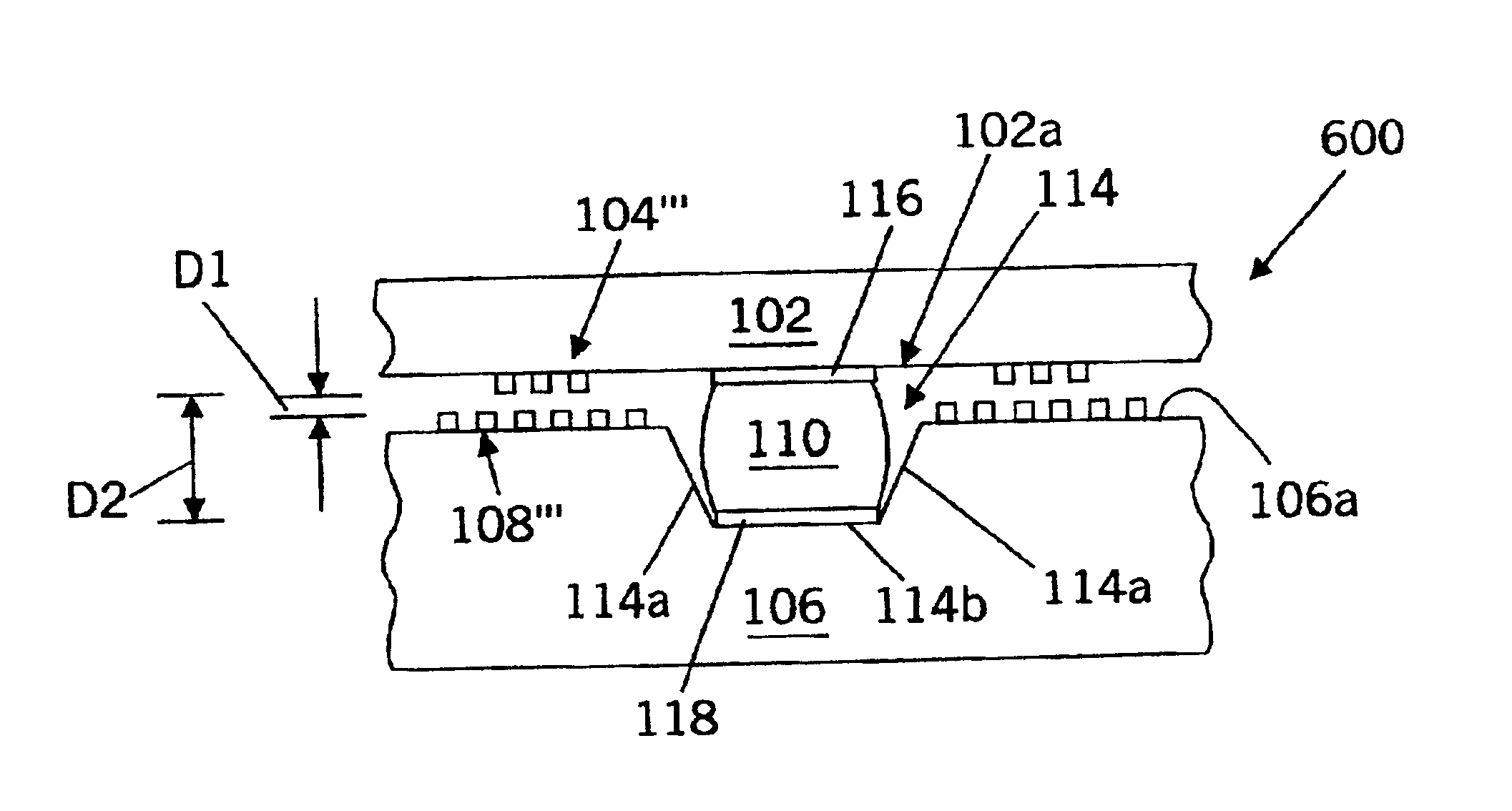

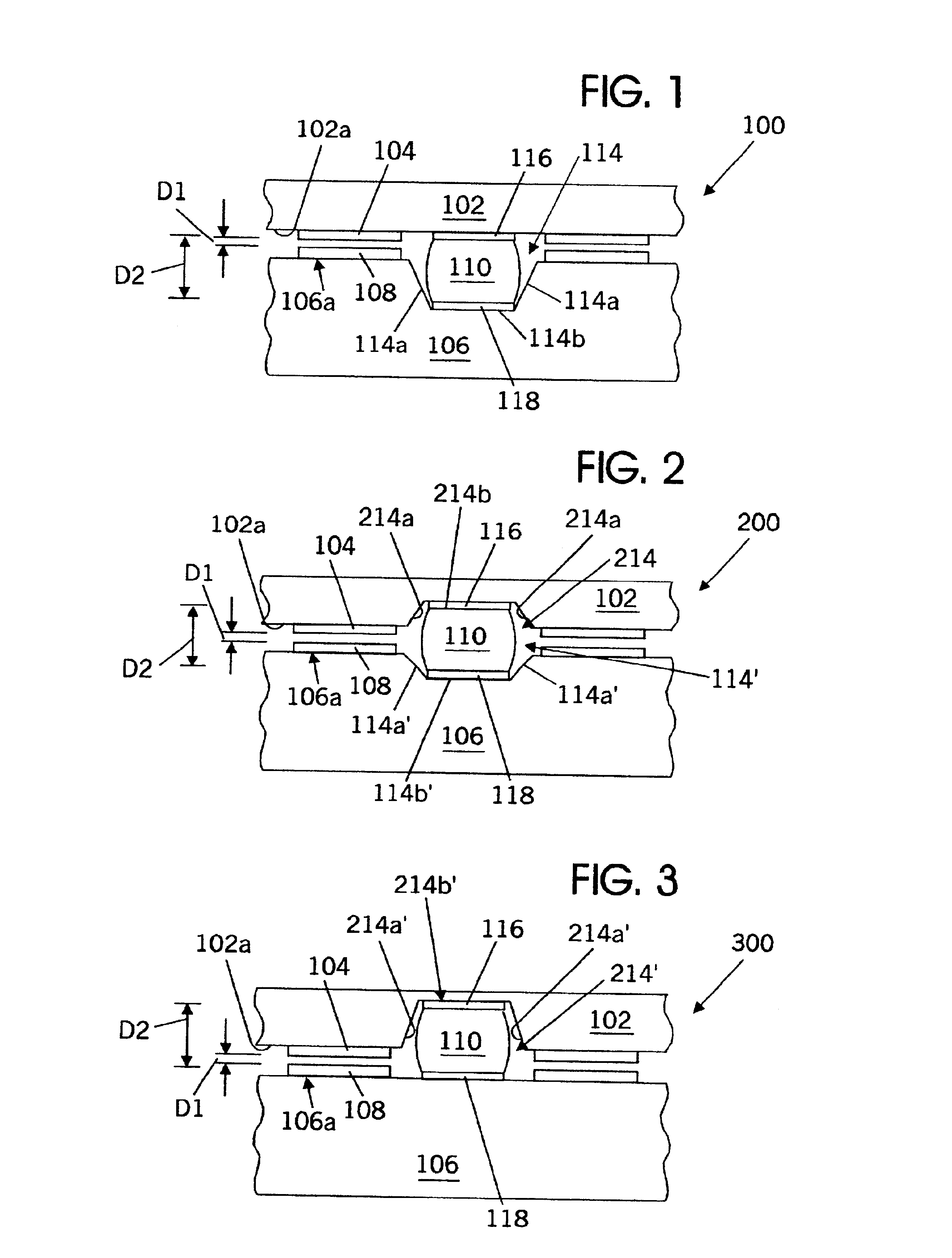

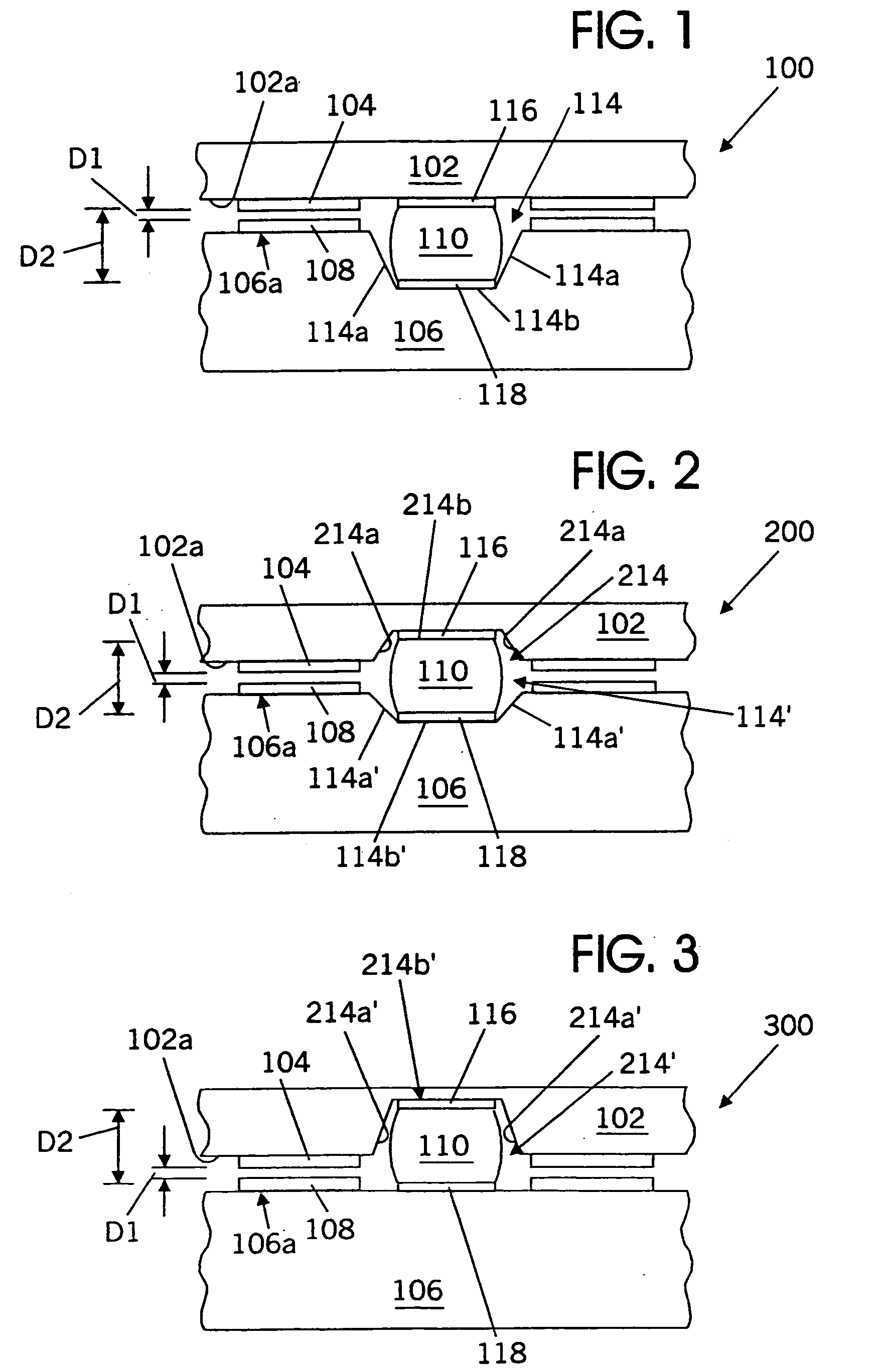

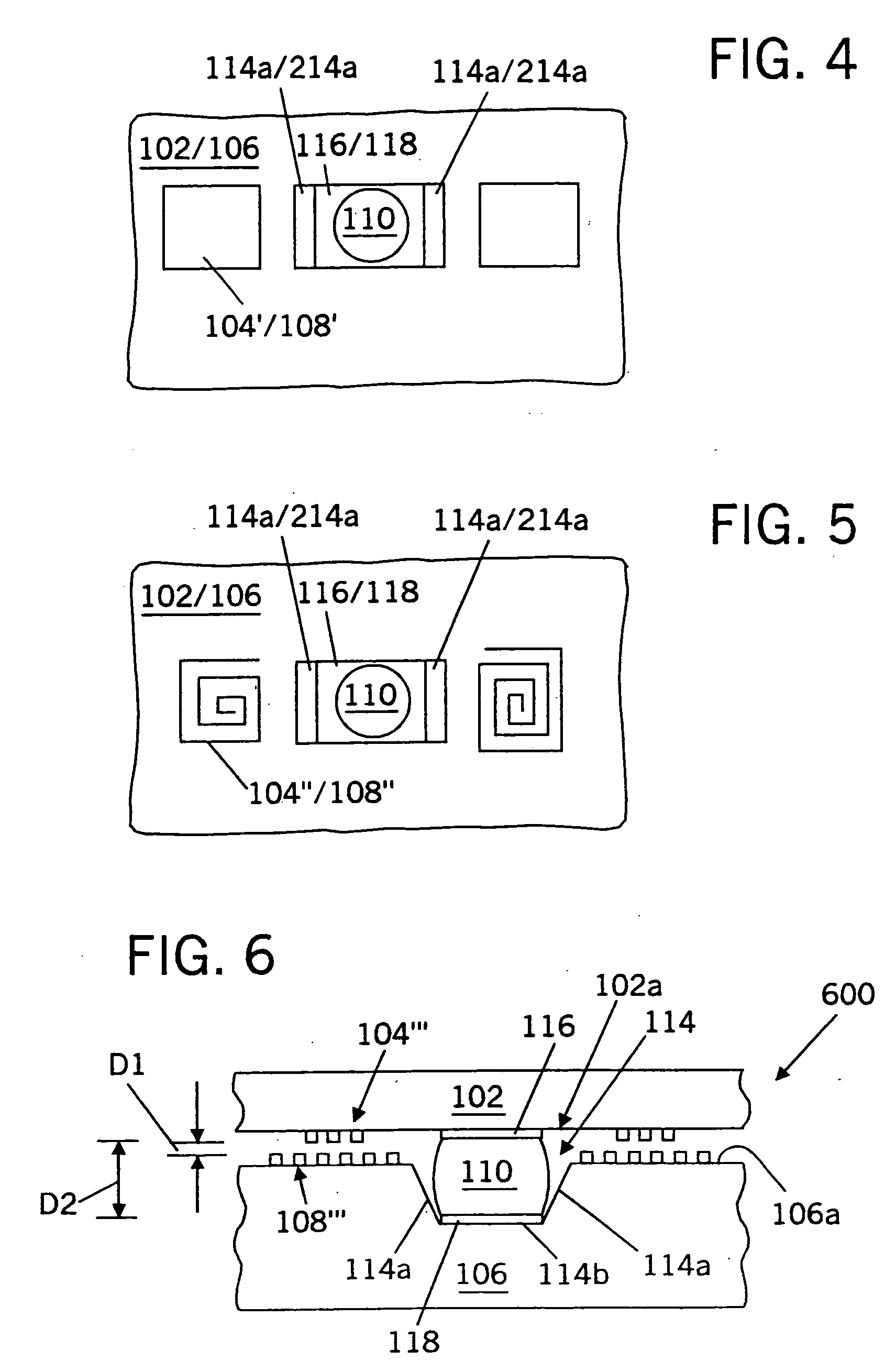

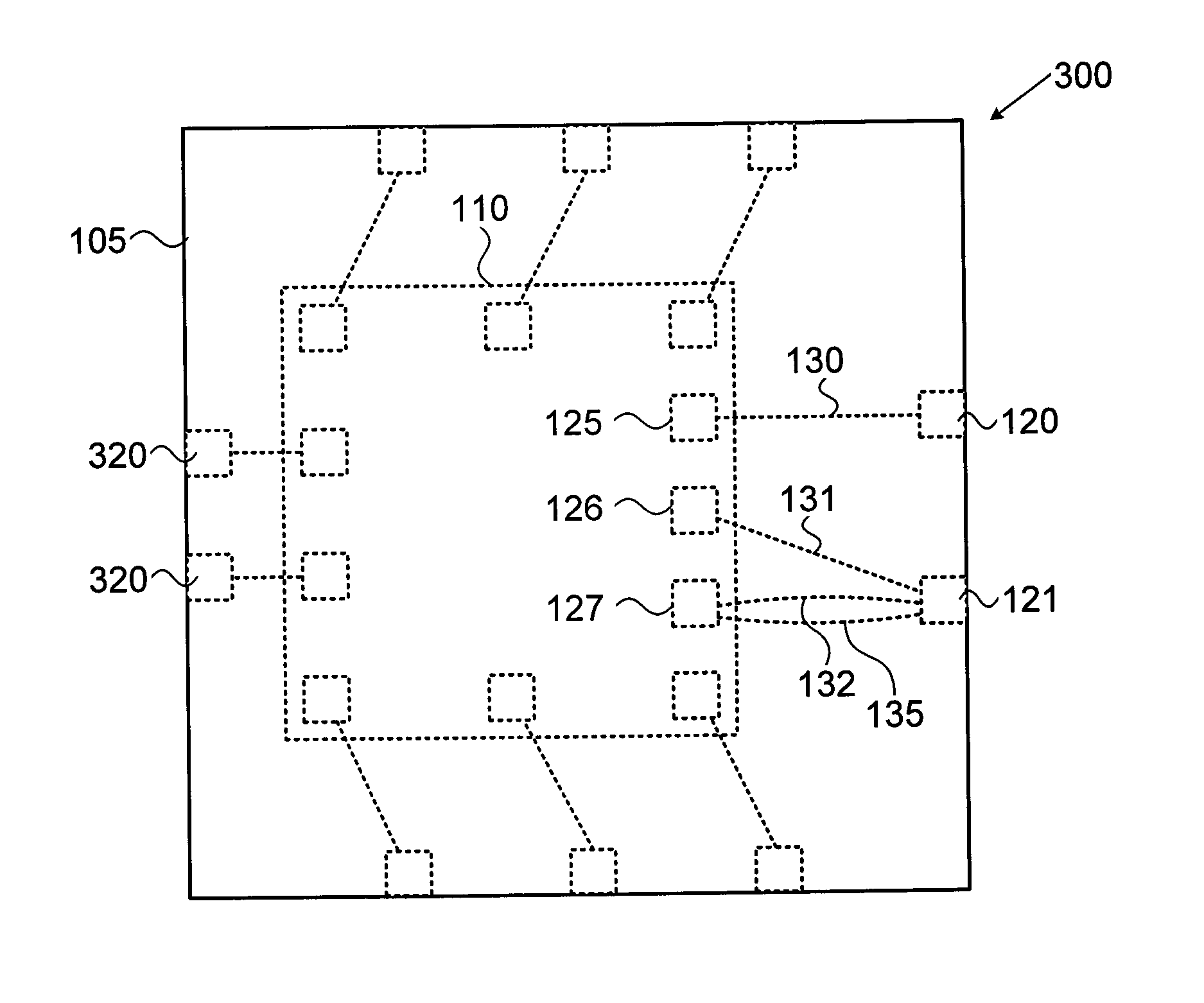

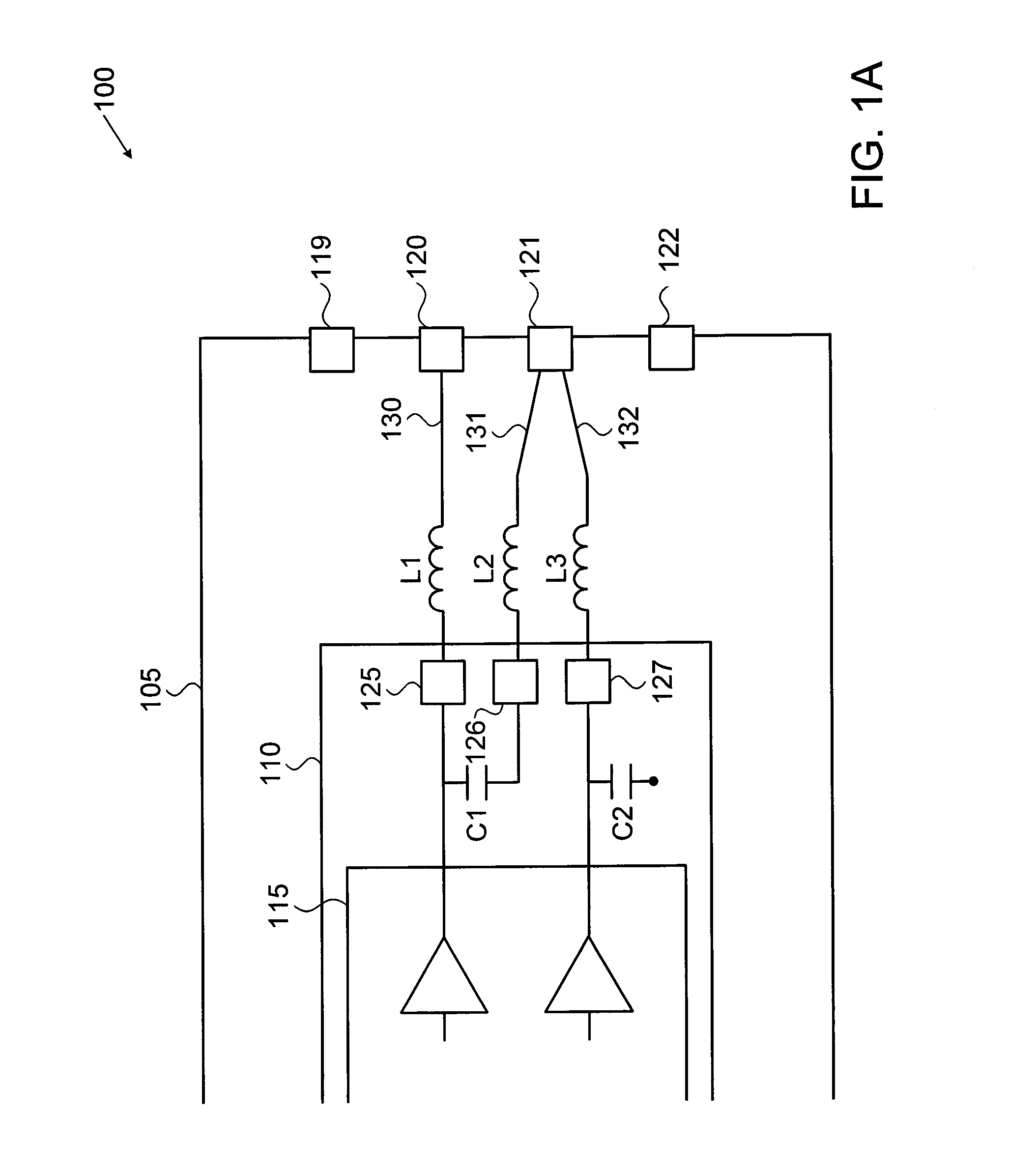

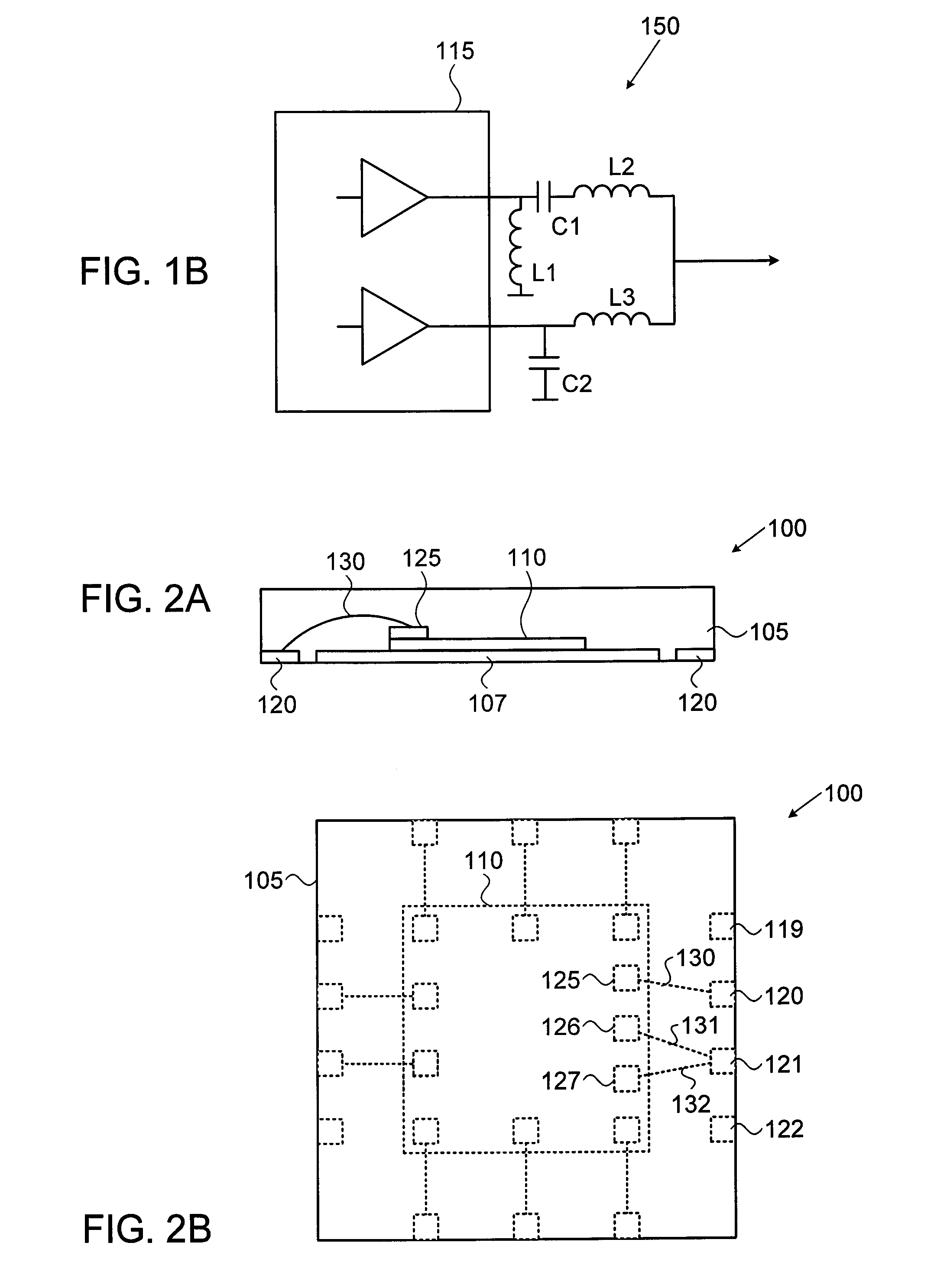

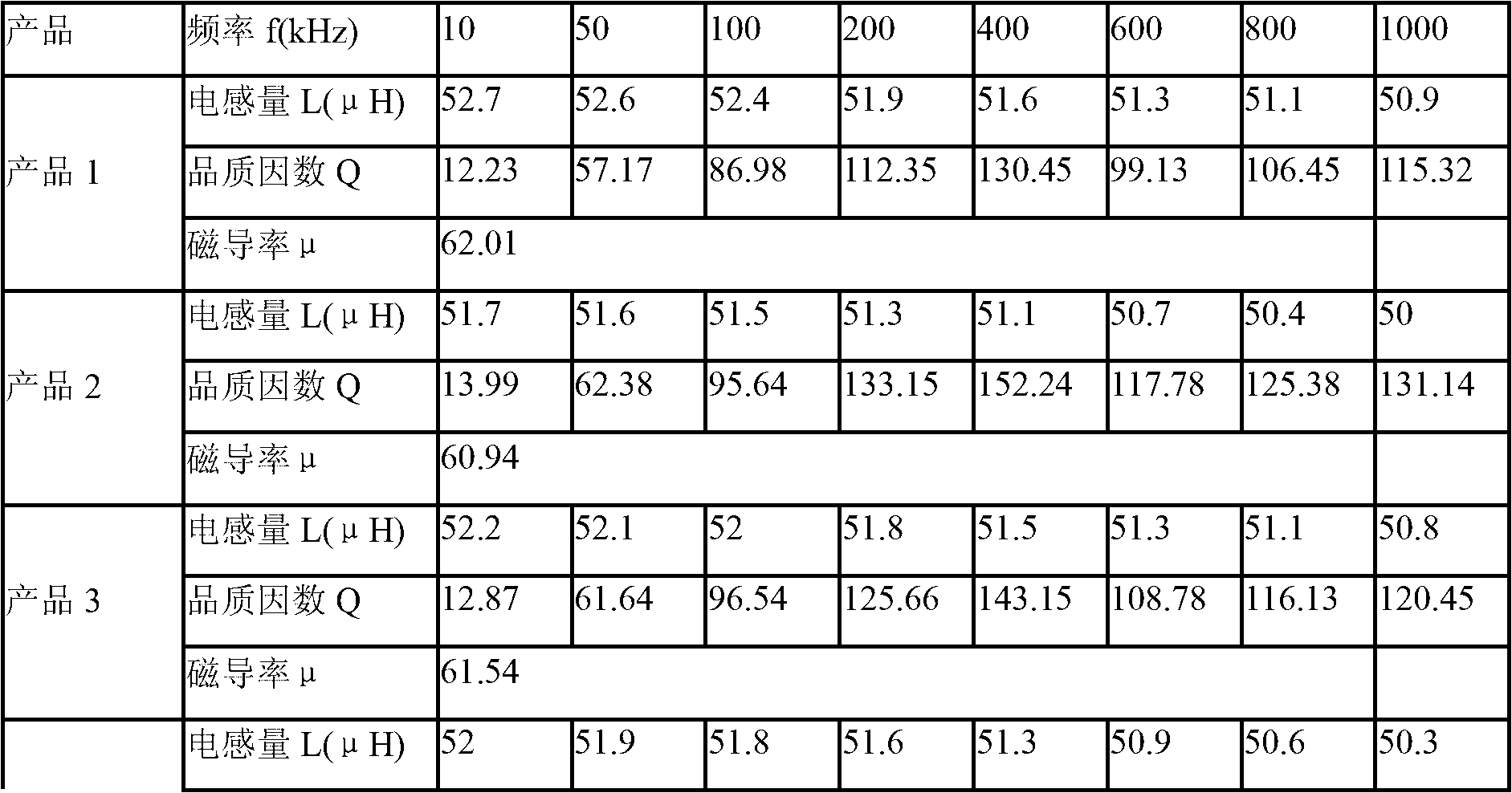

Inductively coupled electrical connectors

InactiveUS6885090B2Sufficient complianceAvoid excessive distancePrinted circuit assemblingSemiconductor/solid-state device detailsElectricityInductor

Microelectronic packages include a first microelectronic substrate having a first face and a first AC-coupled interconnect element on the first face. A second microelectronic substrate includes a second face and a second AC-coupled interconnect element on the second face. A buried solder bump extends between the first and second faces, and is at least partially buried beneath the first and / or second faces, to maintain the first and second AC-coupled interconnect elements in closely spaced apart relation. The buried solder bump also may couple DC power between the first and second substrates. Other technologies also may be used to maintain the AC-coupled interconnect elements in closely spaced apart relation and to couple DC power between the substrates. The first and second AC-coupled interconnect elements may be first and second capacitor plates, first and second inductors and / or first and second combined inductive and capacitive elements.

Owner:NORTH CAROLINA STATE UNIV

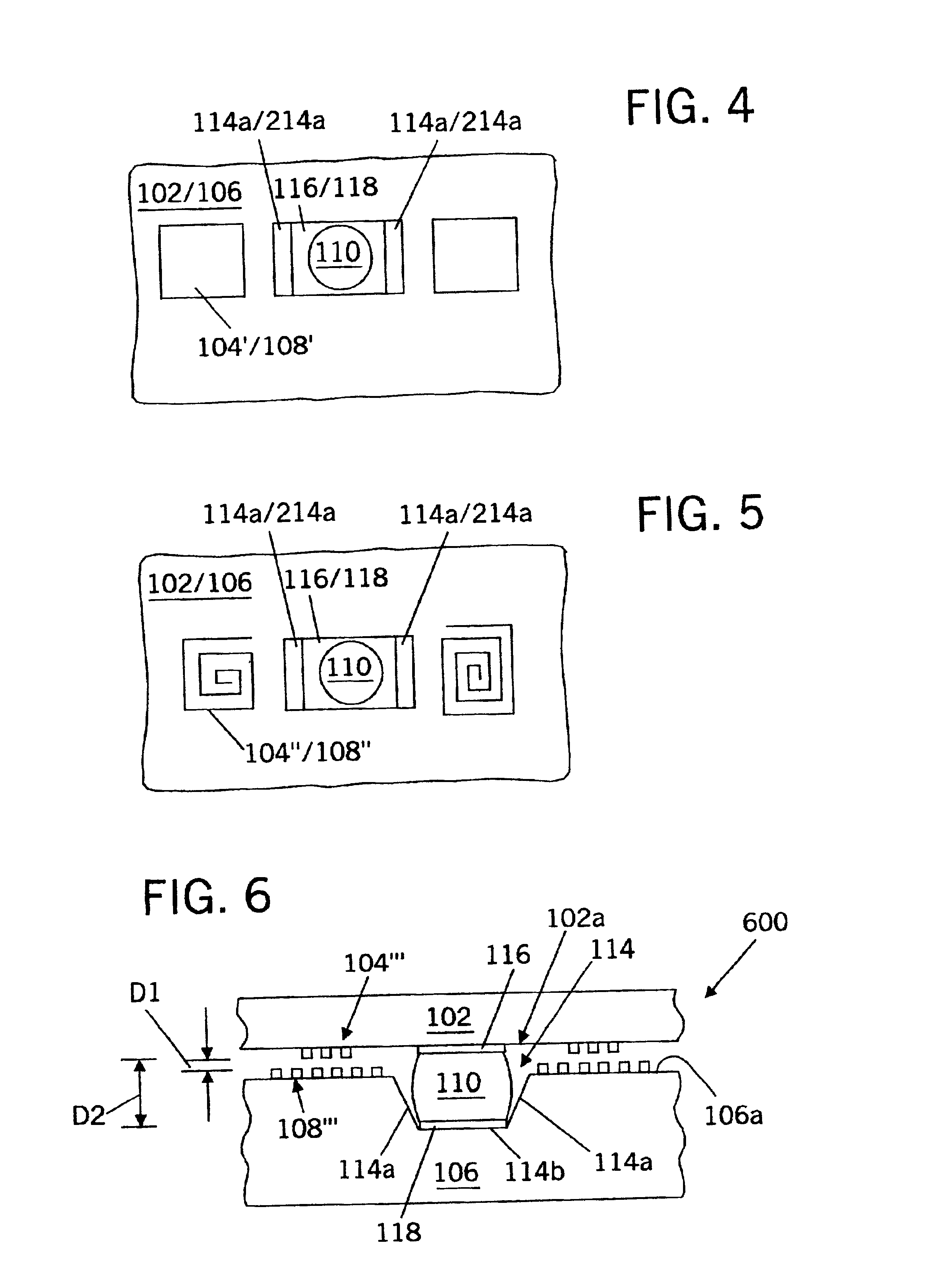

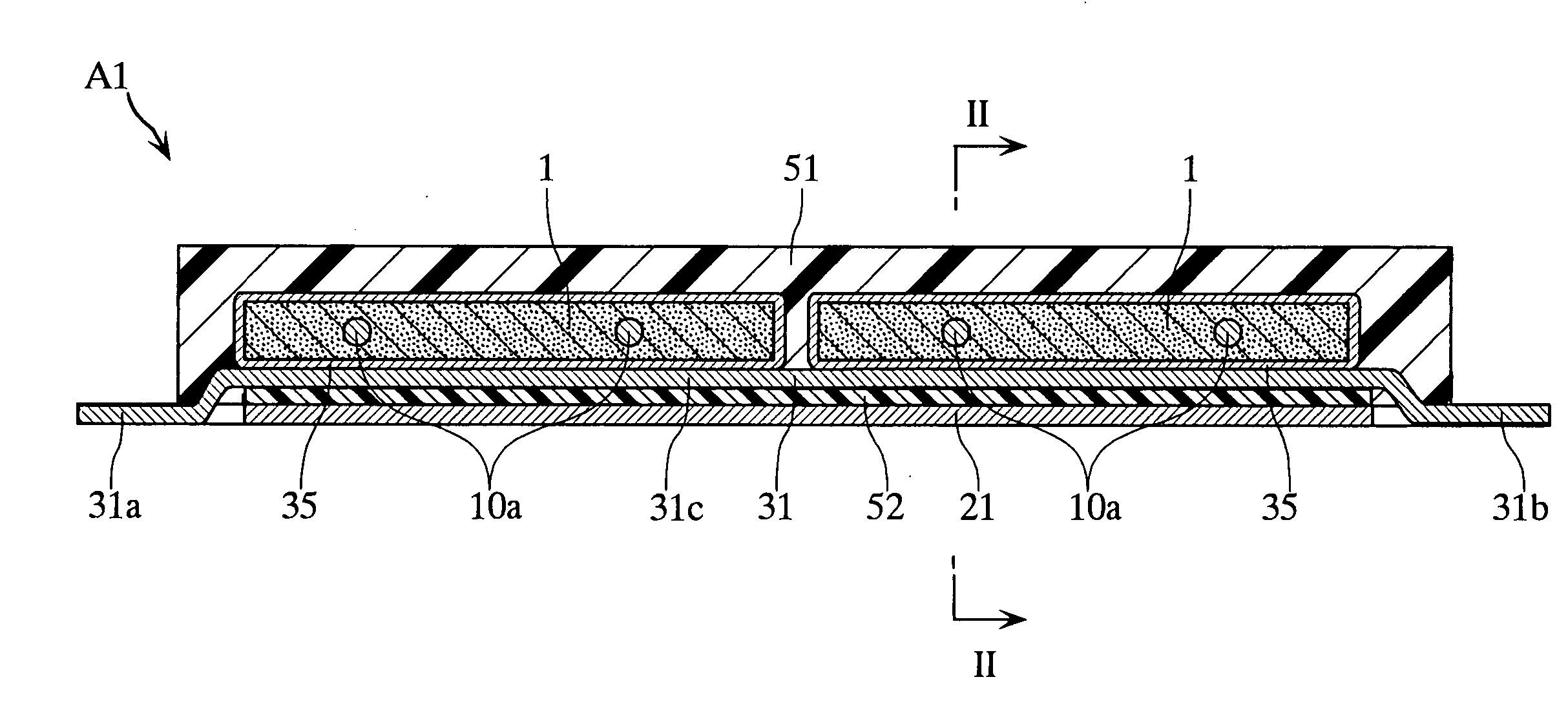

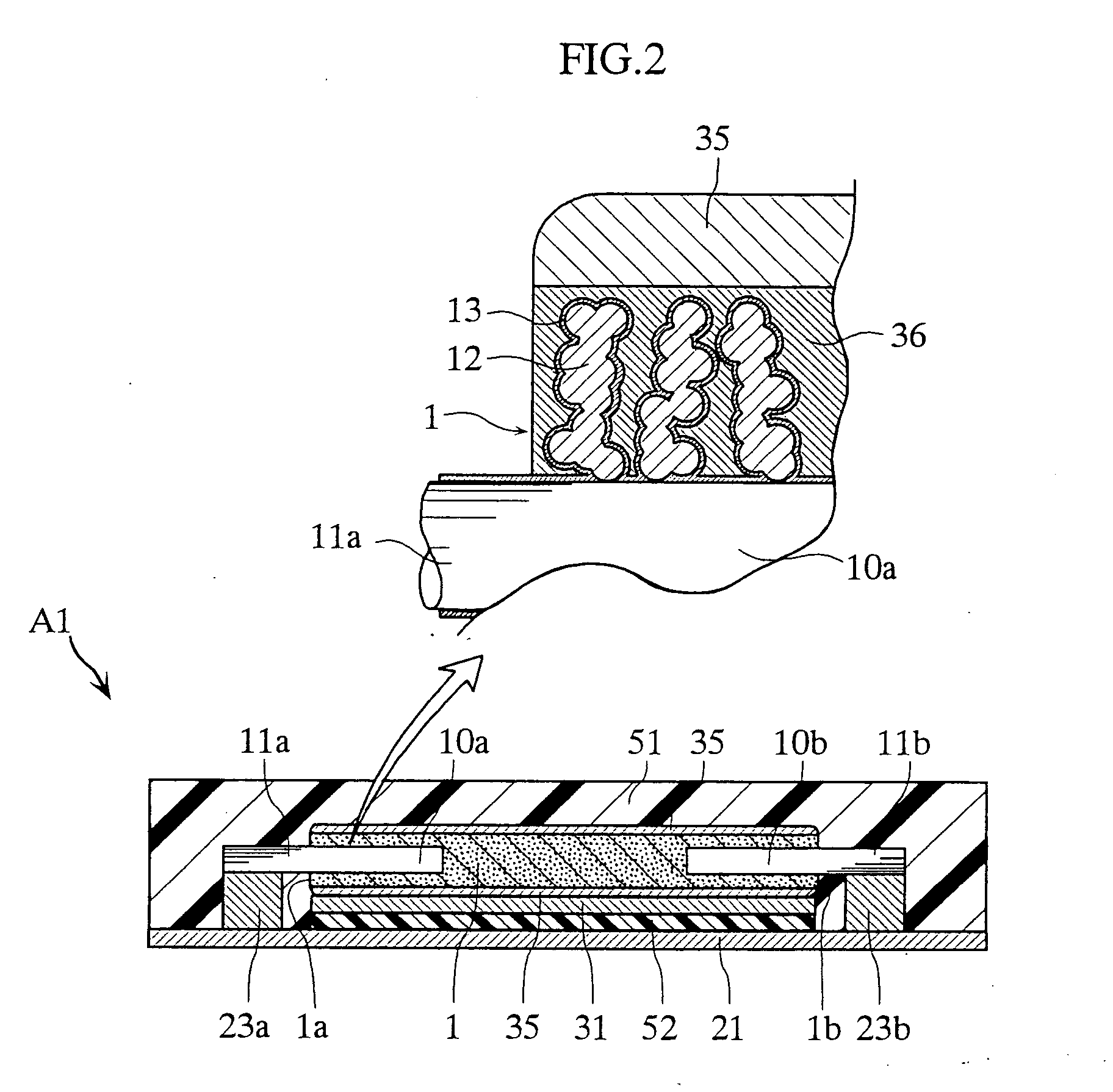

Solid electrolytic capacitor

InactiveUS20070177336A1Good effectHigh electrical resistanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisElectrolytic capacitor

A solid electrolytic capacitor (A1) includes a first and a second porous sintered bodies (1). Each sintered body (1) is flat, with its thickness being small relative to the width or the length. The first and the second sintered bodies (1) are spaced from each other in the widthwise or lengthwise direction.

Owner:ROHM CO LTD

High-frequency vertical spring probe card structure

InactiveCN102608364AContact stabilityImprove flatnessMeasurement leads/probesElastomerElectrical conductor

Owner:PLEADER YAMAICHI

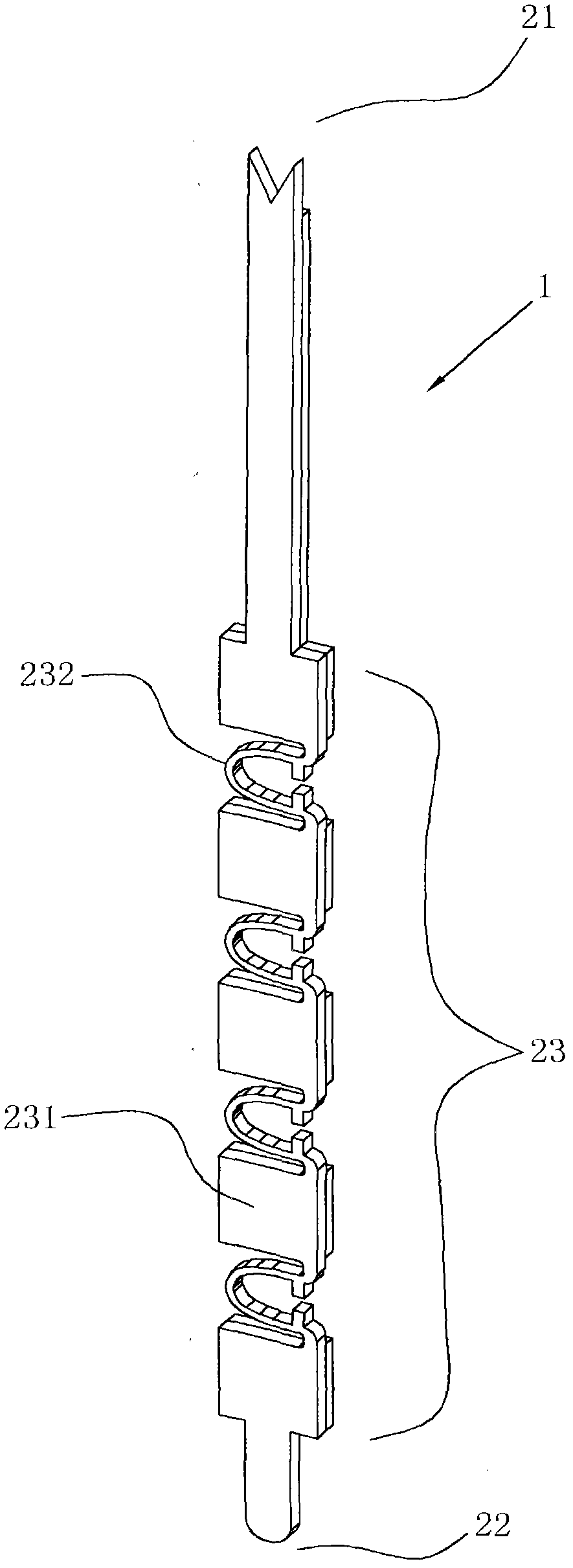

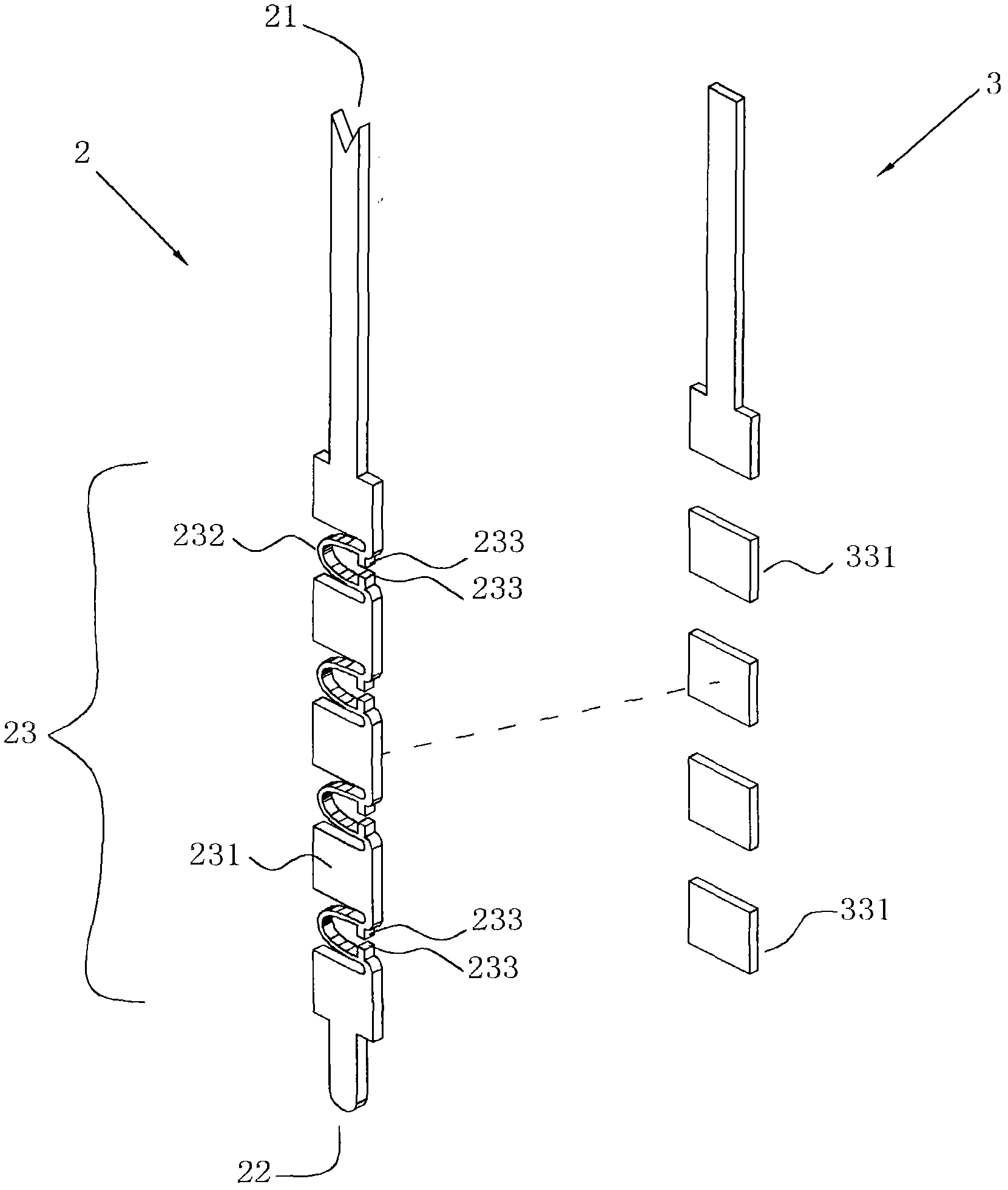

Thin film inductor and power supply conversion circuit

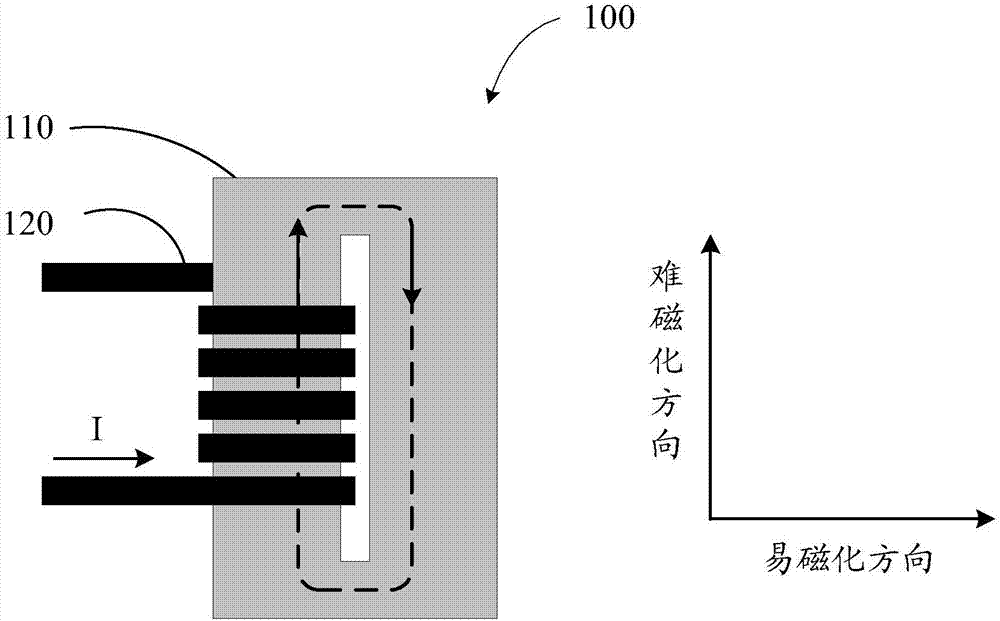

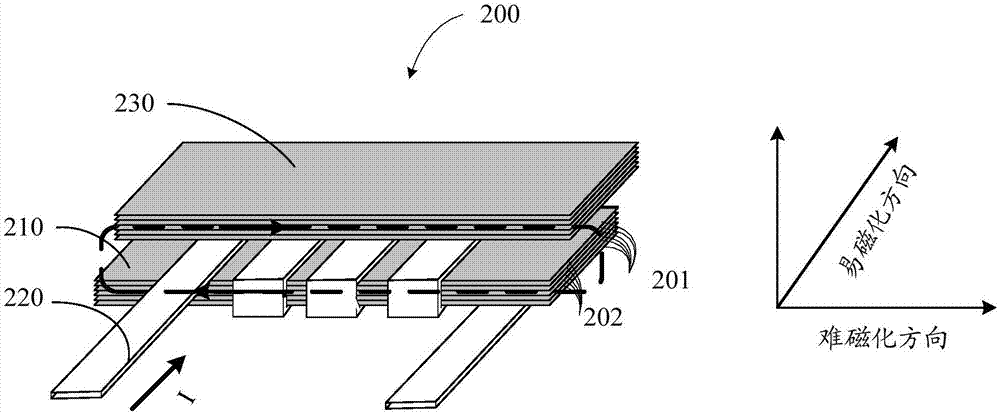

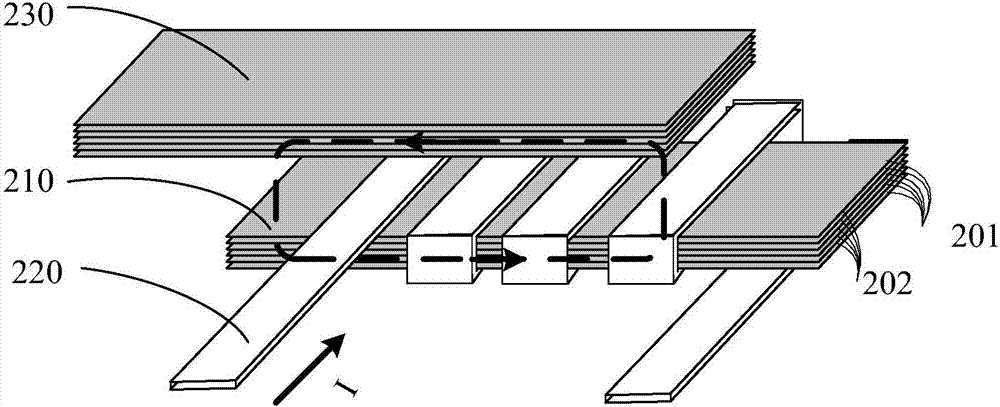

ActiveCN106910602AReduce satietyReduce riskTransformers/inductances coils/windings/connectionsDc-dc conversionMagnetizationInductor

The embodiment of the invention provides a thin film inductor. The thin film inductor comprises a first thin film magnetic core and at least one second thin film magnetic core (230); at least one winding (220) is wound on the first thin film magnetic core (210) in the hard magnetization direction of the first thin film magnetic core (210); no winding is wound on the second thin film magnetic cores (230), each second thin film magnetic core (230) is not in the same plane with the first thin film magnetic core (210), the hard magnetization direction of each second thin film magnetic core (230) is same as that of the first thin film magnetic core (210), and projections, on a second plane, of the second thin film magnetic cores (230) and the first thin film magnetic core (210) are at least partially overlapped. The risk that magnetic flow is easily saturated in the easy magnetization direction can be reduced, and better inductance can be produced.

Owner:HUAWEI MACHINERY

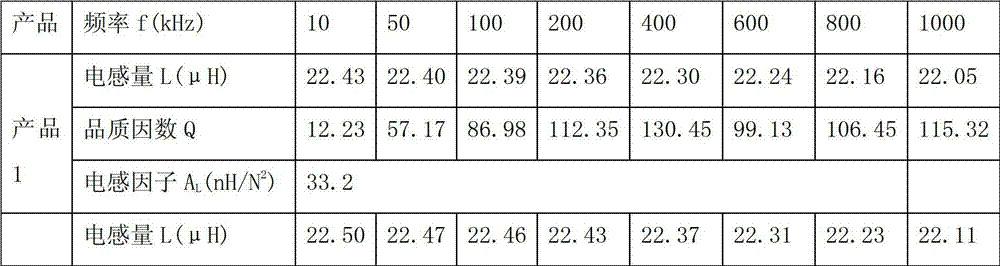

Nano-crystalline magnetic powder core with magnetic conductivity of mu=60

ActiveCN102969107AImprove permeabilityStable DC bias capabilityInorganic material magnetismMetal powderNano crystalline

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

Low-permeability, low-power consumption Fe-Si-Al soft magnetic material and production method thereof

The invention relates to a production method for a magnetic material, in particular to a low-permeability, low-power consumption Fe-Si-Al soft magnetic material and a production method thereof. The production method for the low-permeability, low-power consumption Fe-Si-Al soft magnetic material includes the following steps: (1) In the process of producing Fe-Si-Al powder, a melt-spinning machine rapid cooling method is adopted to produce a strip, and flat Fe-Si-Al powder is produced by atmosphere-protected mechanical crushing; (2) when the produced Fe-Si-Al powder is roasted until the temperature reaches 80 DEG C to 120 DEG C, phosphoric acid diluent is added for surface treatment, and the Fe-Si-Al powder then continues to be roasted to become dry; (3) the Fe-Si-Al alloy soft magnetic powder is pressed to be shaped; (4) in heat treatment, hydrogen or nitrogen is filled into a heat treatment furnace; (5) epoxy resin paint is applied on the surface of the soft magnetic material. The invention has the advantages that: the oxygen content of the powder is greatly decreased, the grain size of the product is reduced, consequently, the loss of the Fe-Si-Al product is reduced, and the properties of the product are enhanced.

Owner:德清鑫晨新材料有限公司

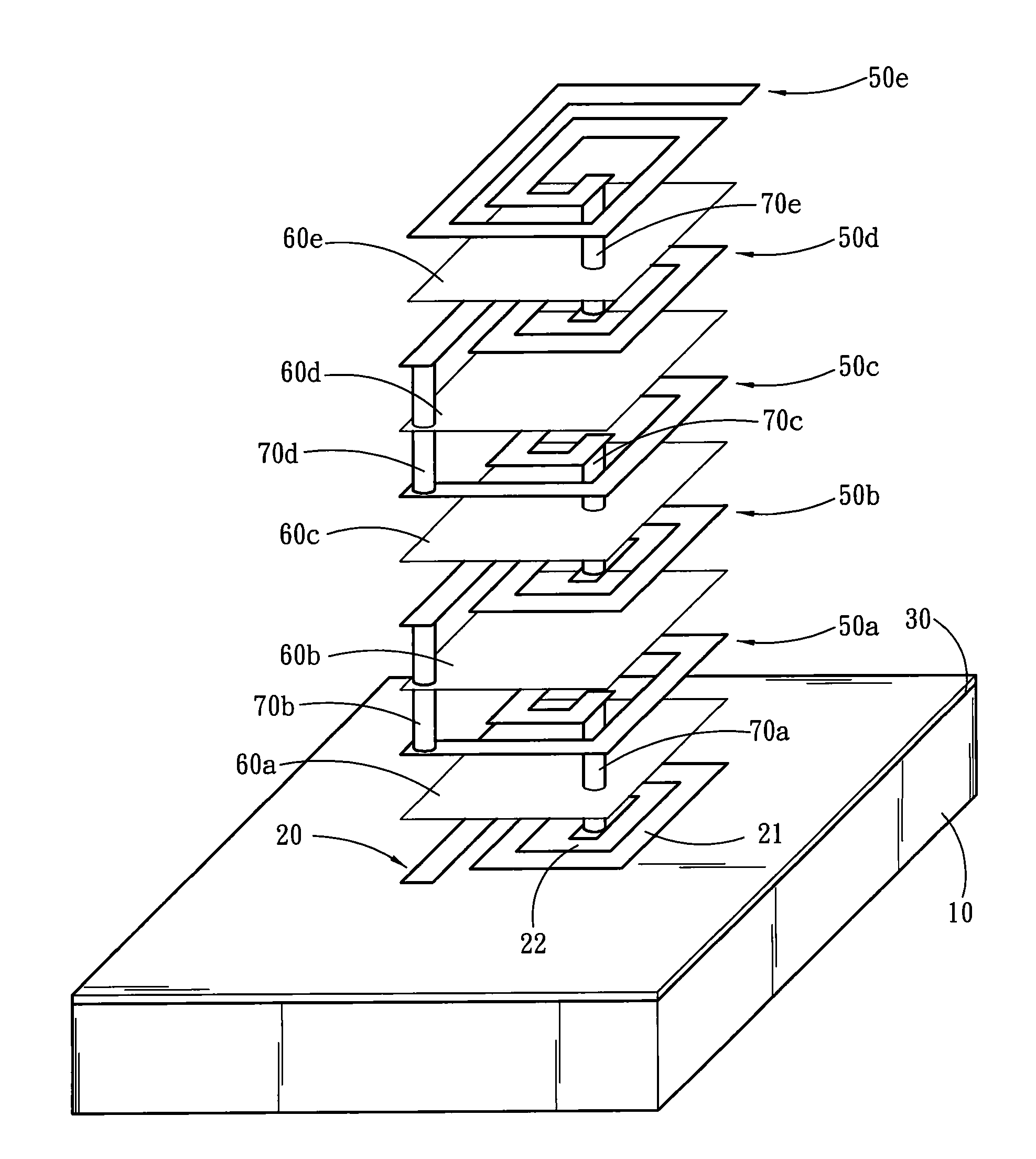

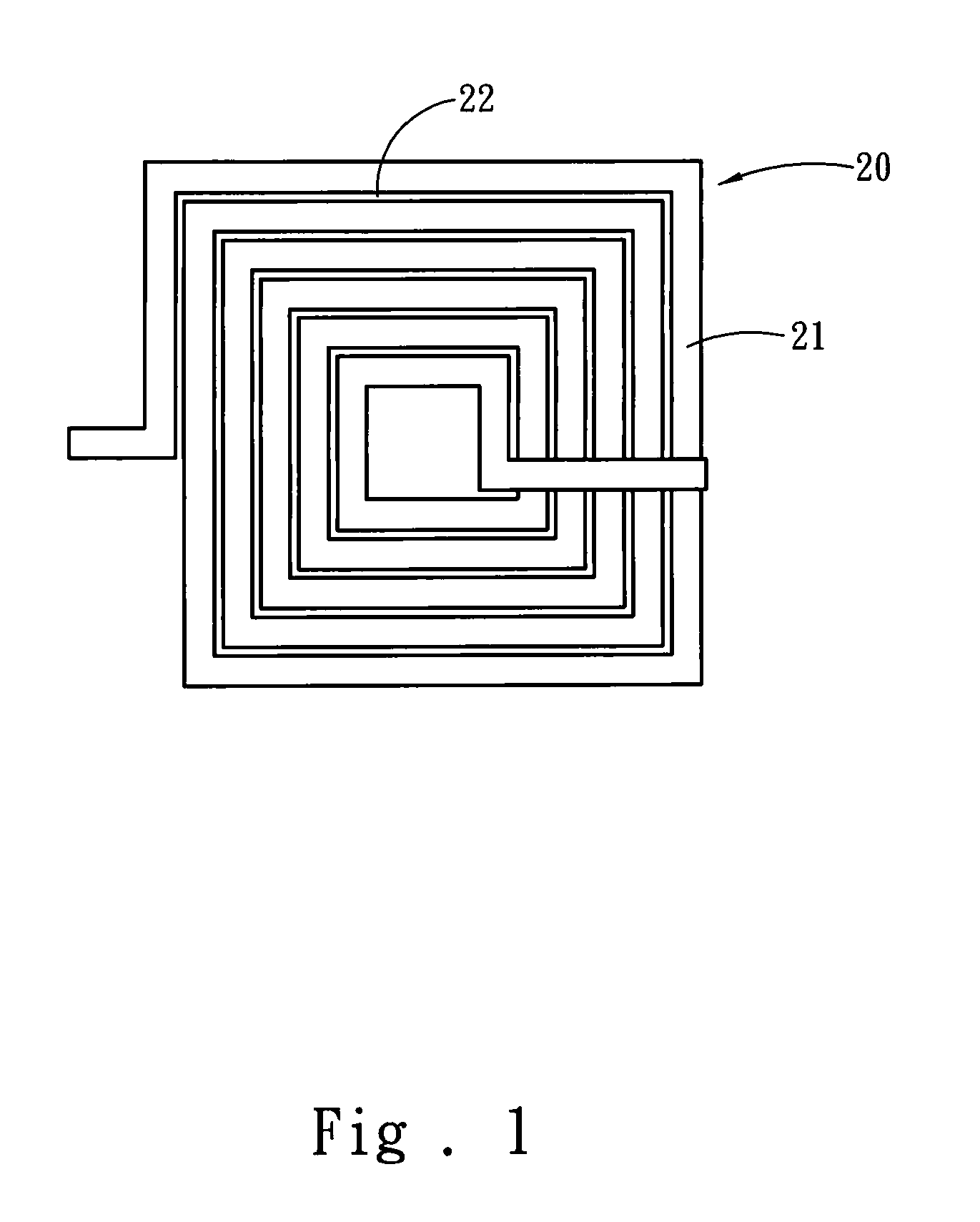

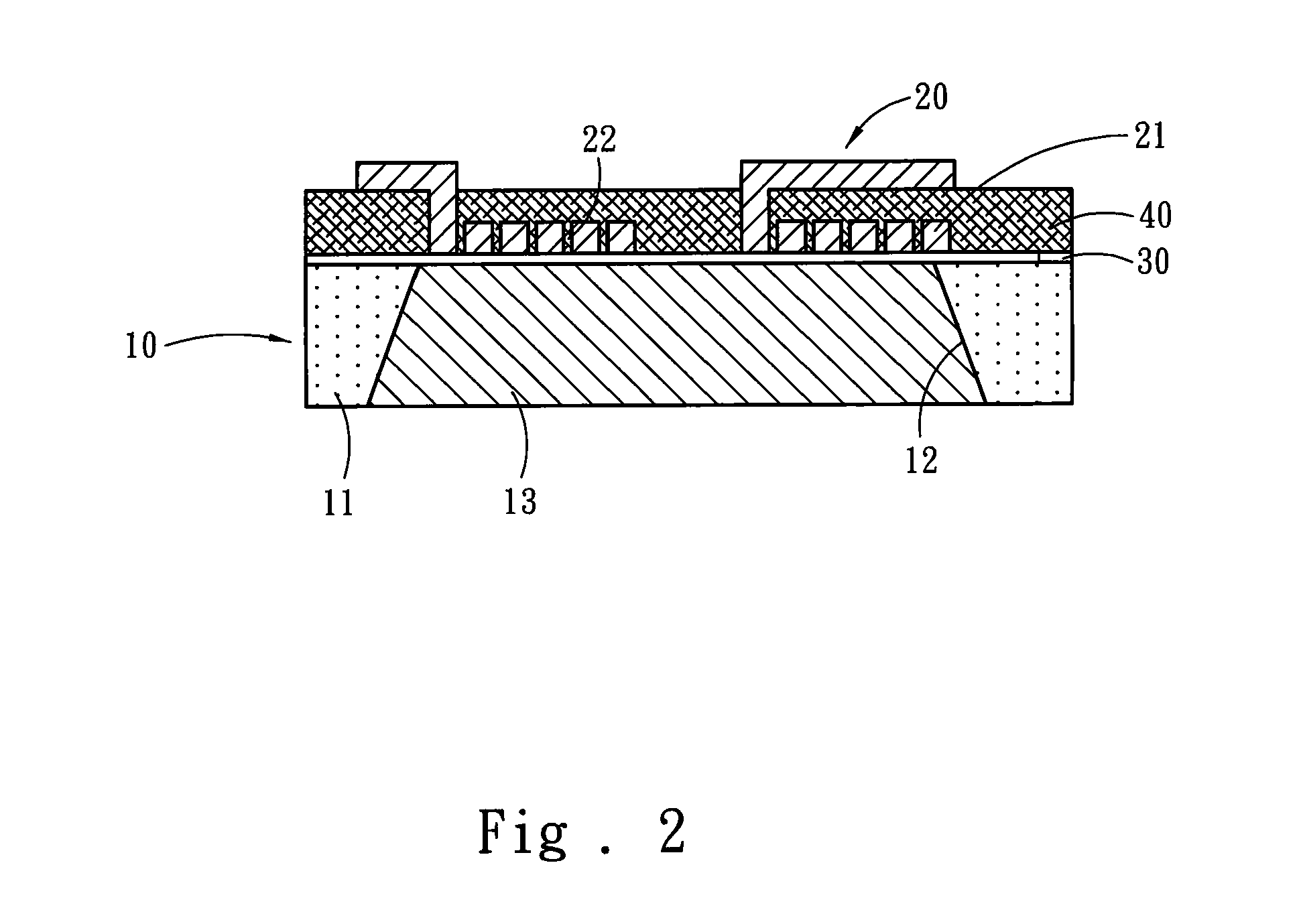

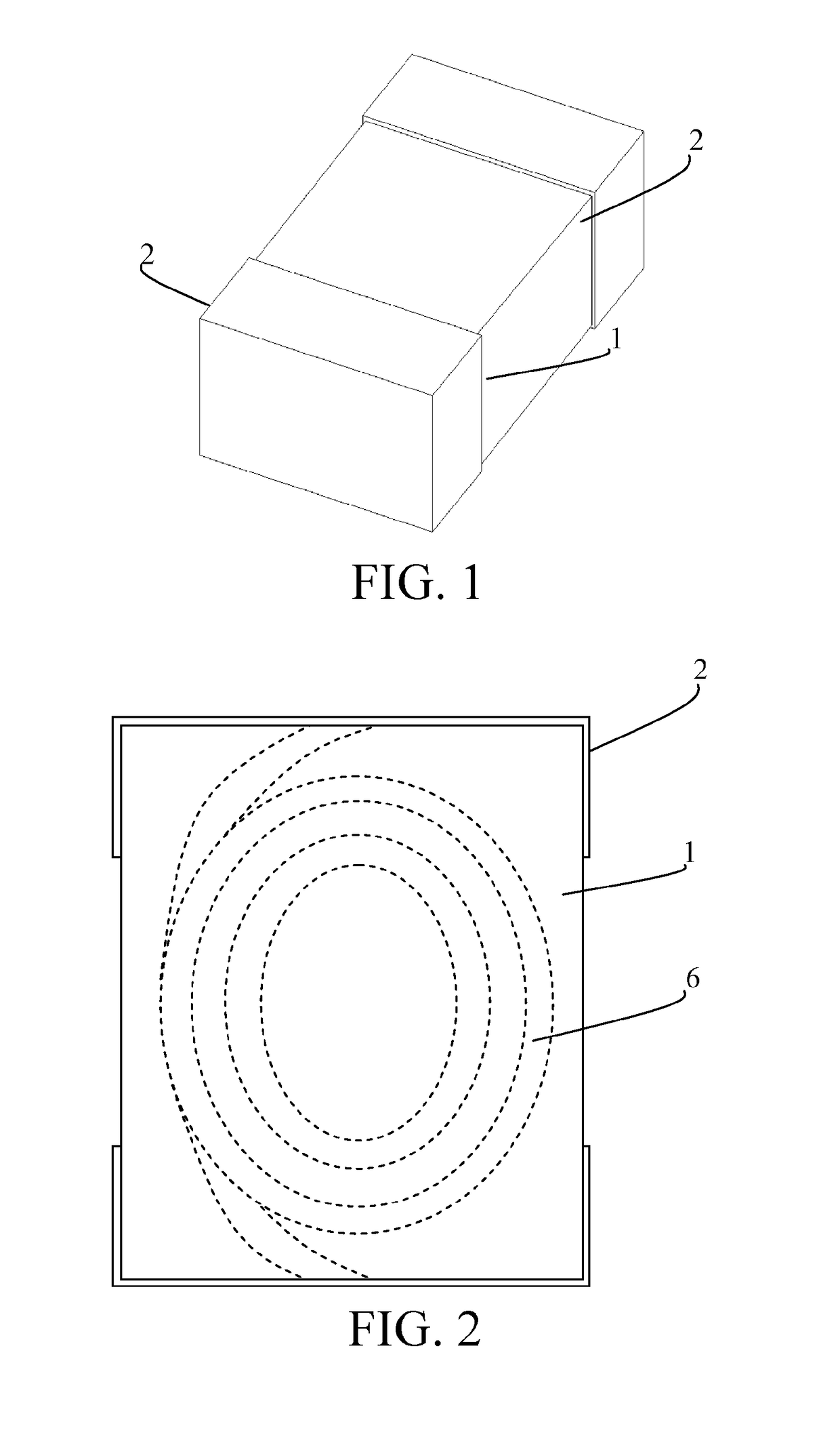

Inductor structure

InactiveUS20110109415A1Enhance mutual inductionIncrease inductanceCoilsFixed signal inductancesEngineeringInductor

The present invention discloses an improved inductor structure, which applies to the semiconductor field, particularly to a system-on-chip, and which comprises a substrate, a first conductive patterned film, and a first insulating layer formed between the substrate and the first conductive patterned film. The substrate has a base and an accommodation portion formed in the base. A magnetic material is filled into the accommodation portion to form a magnetic region. The accommodation portion is fabricated via etching the base or drilling a through-hole in the base. A plurality of conductive wires is arranged in a spiral way to form the first conductive patterned film. A protective layer covers the surface of the first conductive patterned film and isolates the contact of the first conductive patterned film and moisture.

Owner:NATIONAL TSING HUA UNIVERSITY

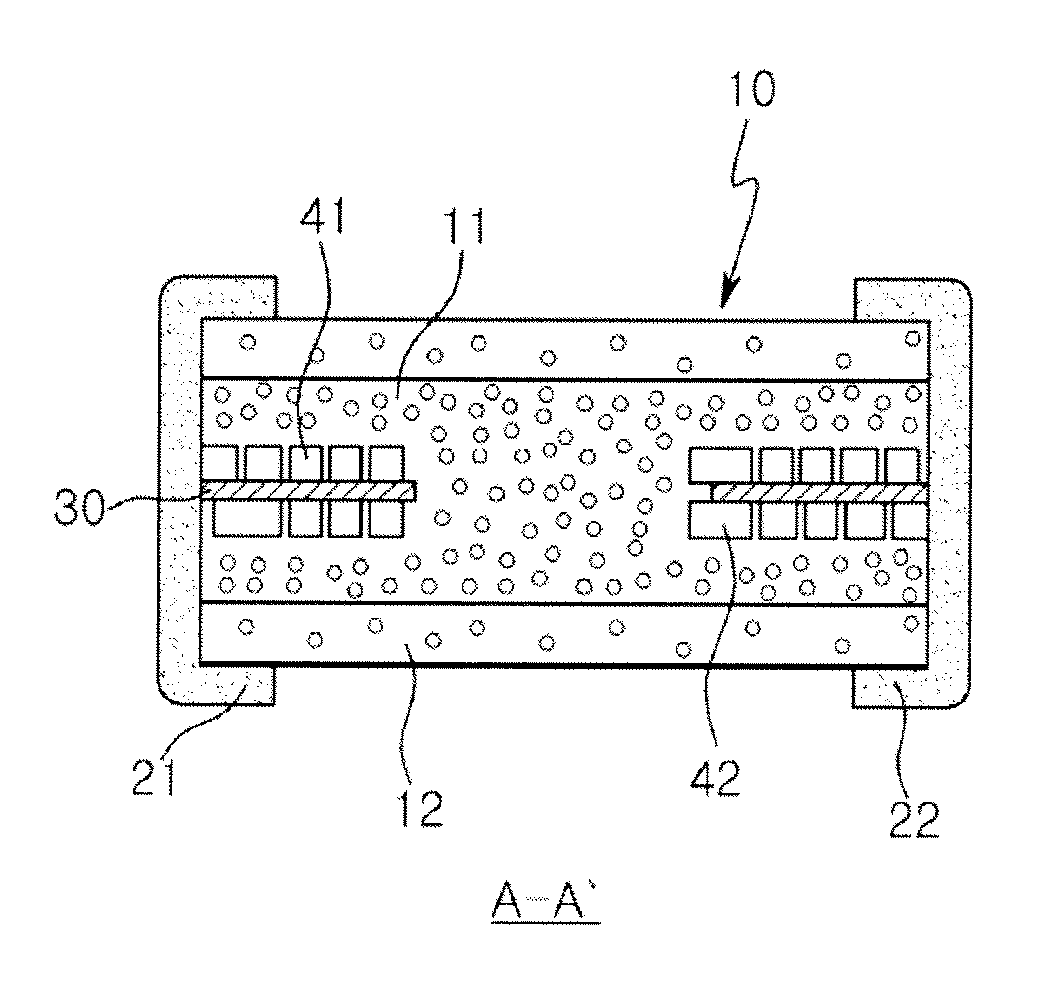

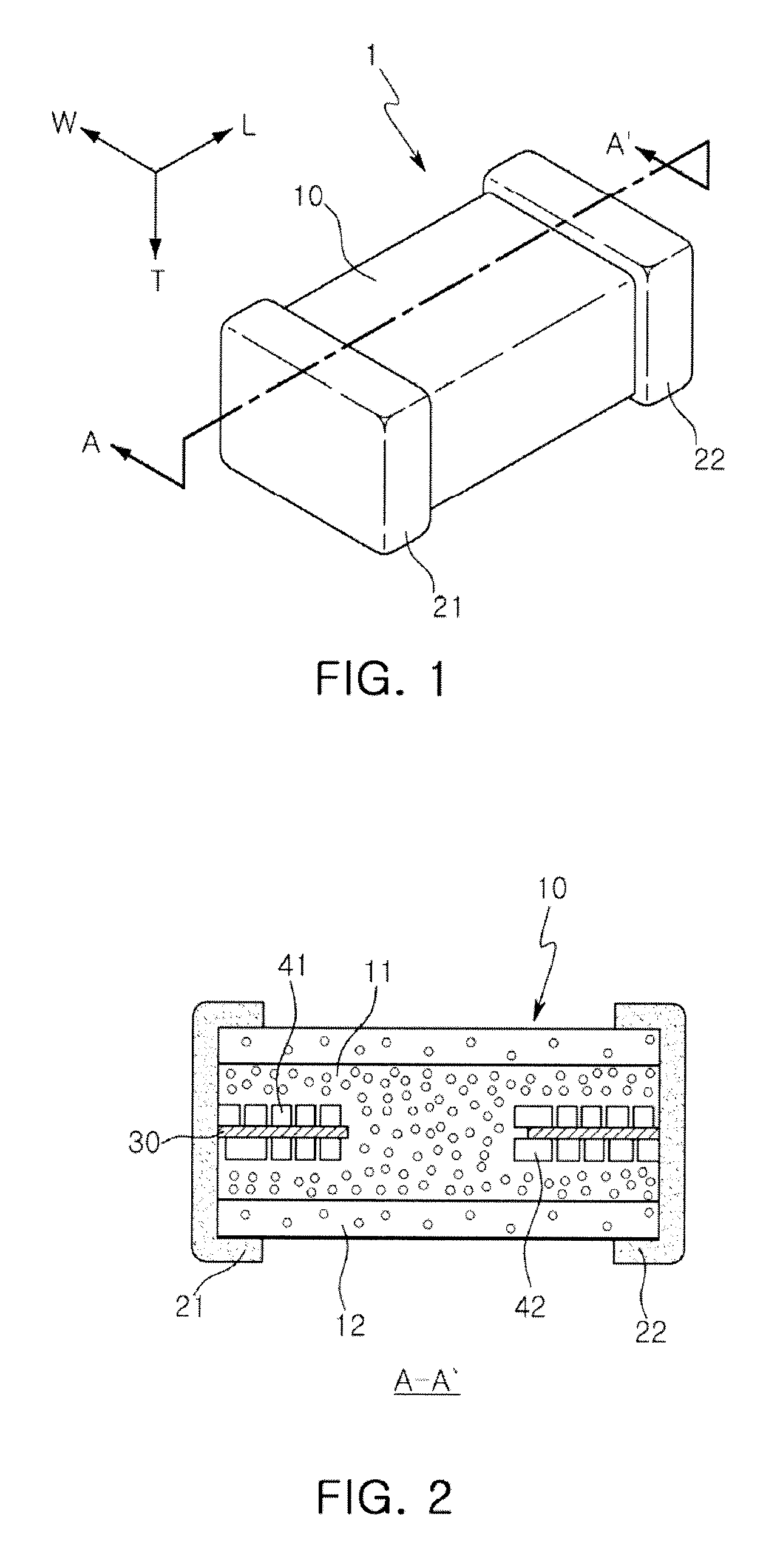

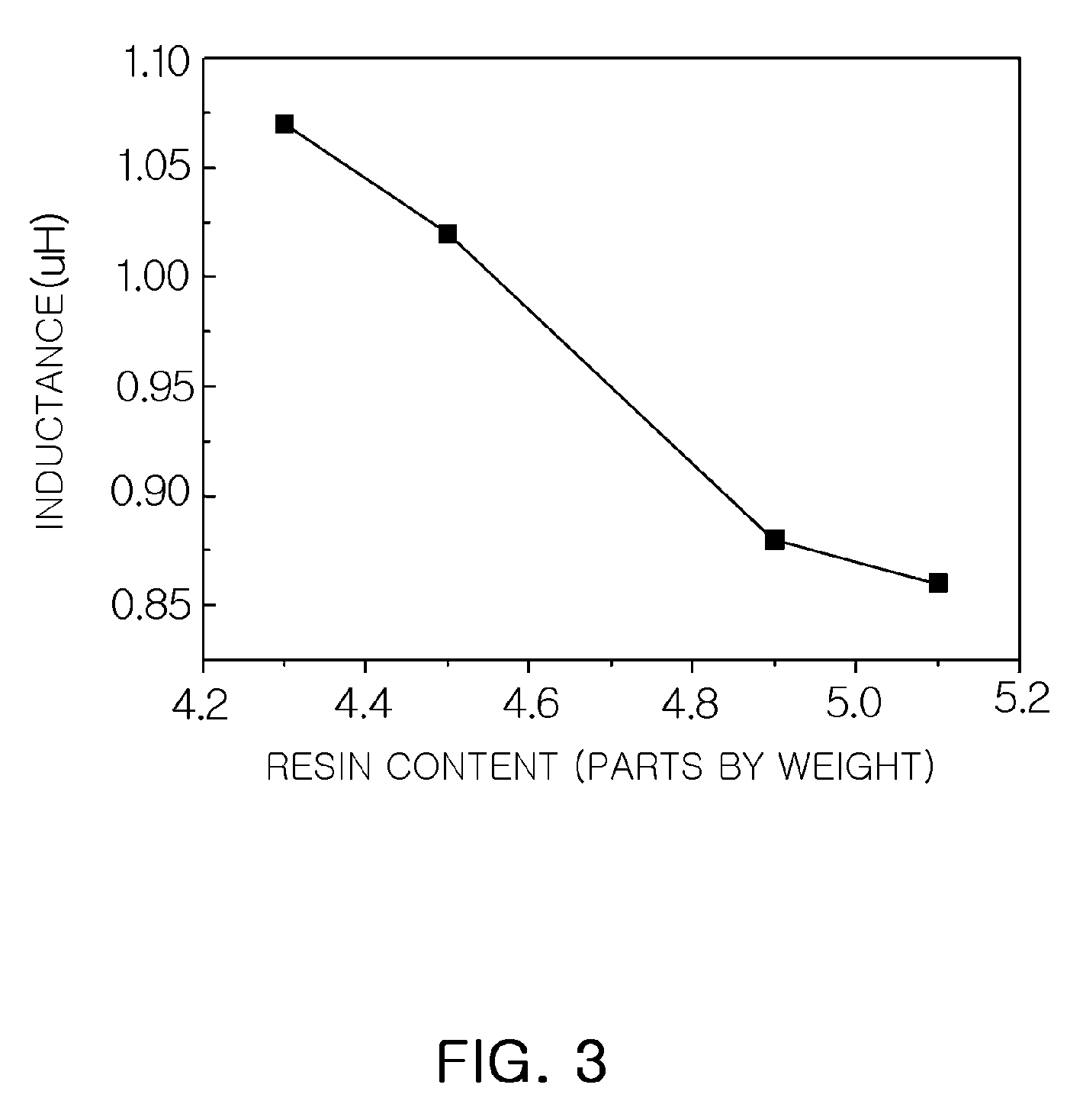

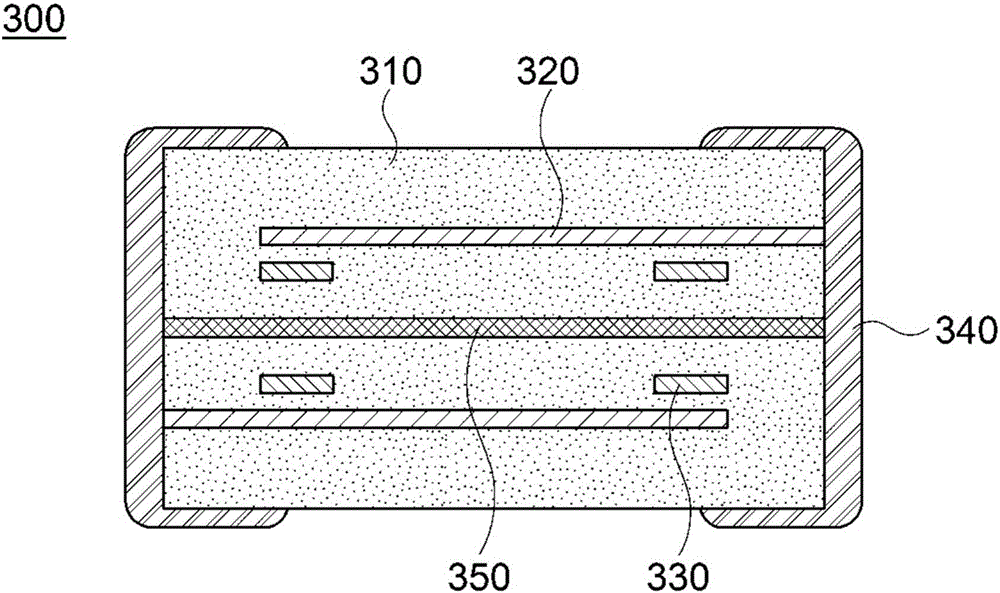

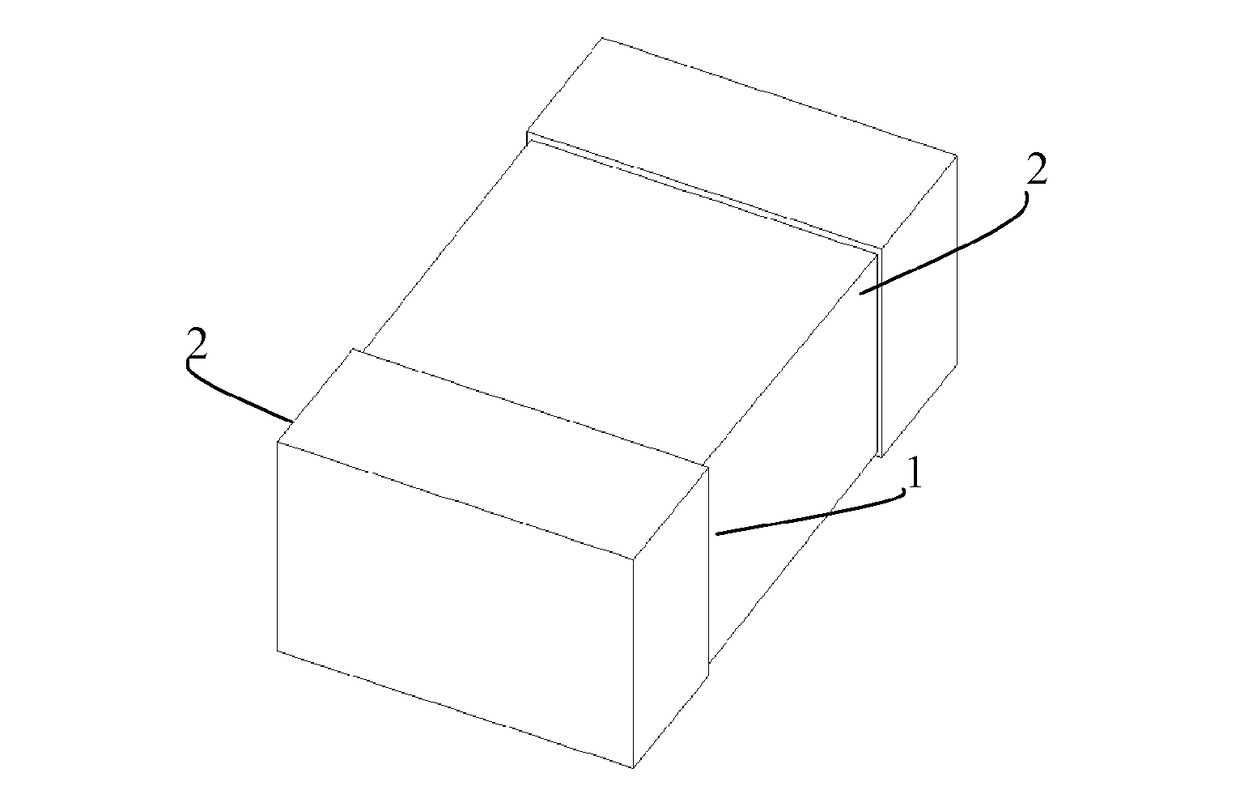

Power inductor and method of manufacturing the same

ActiveUS9269486B2Good inductanceImprove reliabilityTransformers/inductances casingsTransformers/inductances magnetic coresInductorEngineering

There is provided a power inductor, including a magnetic body including a substrate having coils formed thereon, a first metal-polymer complex layer formed on upper and lower surfaces of the substrate, and a second metal-polymer complex layer formed on upper and lower surfaces of the first metal-polymer complex layer and including a higher content of a polymer than that included in the first metal-polymer layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

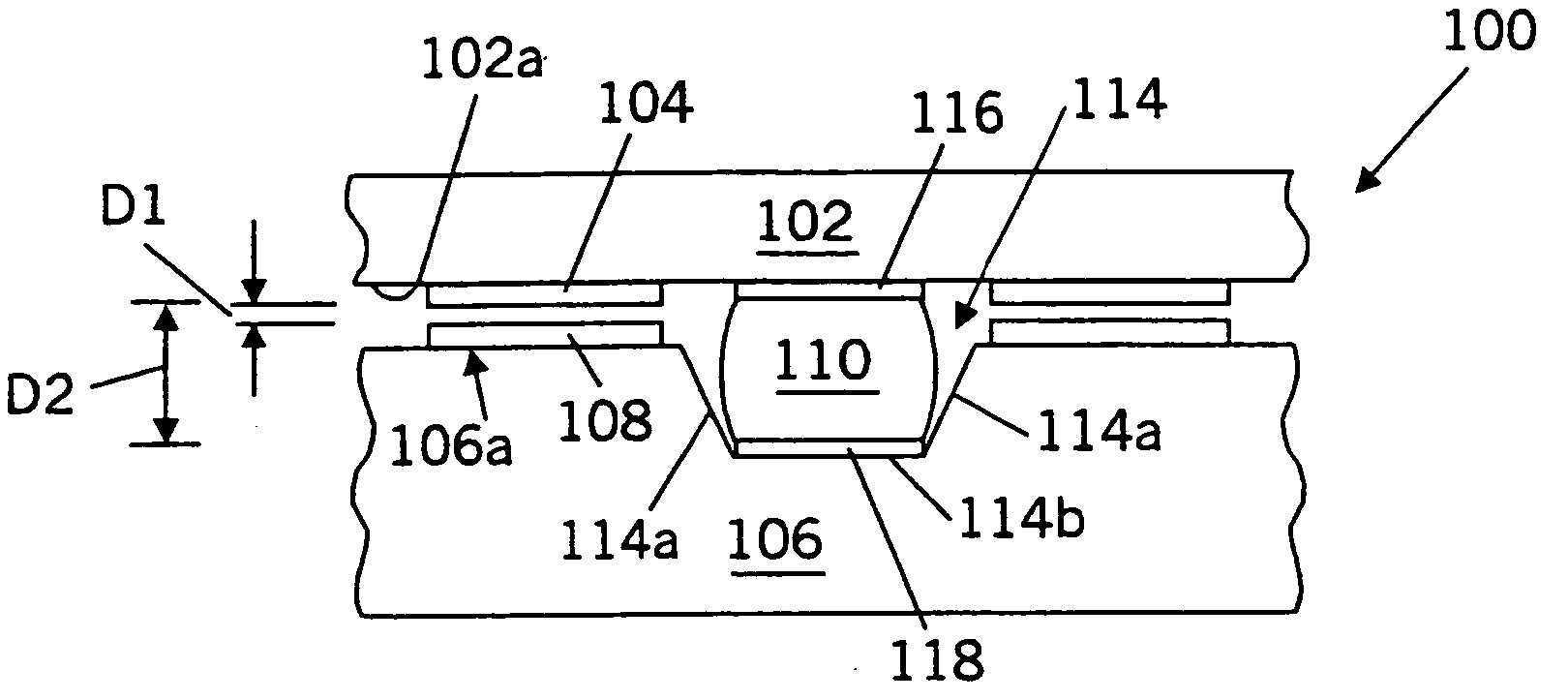

Buried solder bumps for AC-coupled microelectronic interconnects

InactiveUS20050046037A1Sufficient complianceAvoid excessive distancePrinted circuit assemblingSemiconductor/solid-state device testing/measurementCapacitanceEngineering

Microelectronic packages include a first microelectronic substrate having a first face and a first AC-coupled interconnect element on the first face. A second microelectronic substrate includes a second face and a second AC-coupled interconnect element on the second face. A buried solder bump extends between the first and second faces, and is at least partially buried beneath the first and / or second faces, to maintain the first and second AC-coupled interconnect elements in closely spaced apart relation. The buried solder bump also may couple DC power between the first and second substrates. Other technologies also may be used to maintain the AC-coupled interconnect elements in closely spaced apart relation and to couple DC power between the substrates. The first and second AC-coupled interconnect elements may be first and second capacitor plates, first and second inductors and / or first and second combined inductive and capacitive elements.

Owner:NORTH CAROLINA STATE UNIV

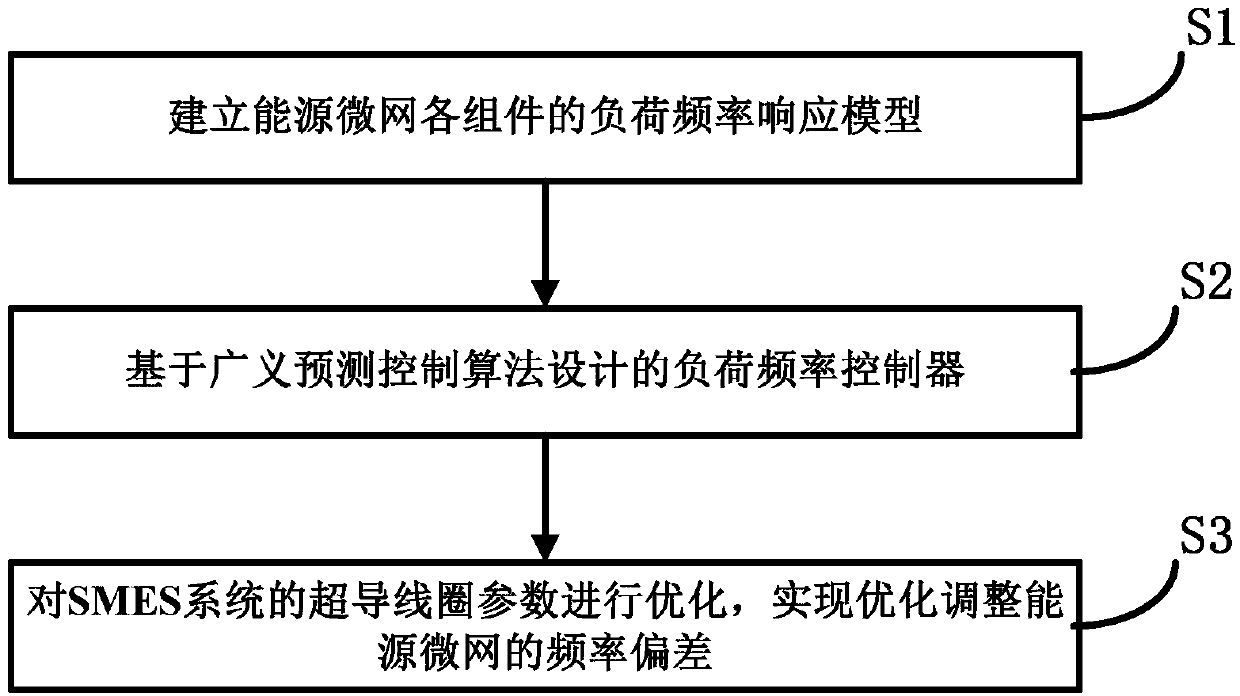

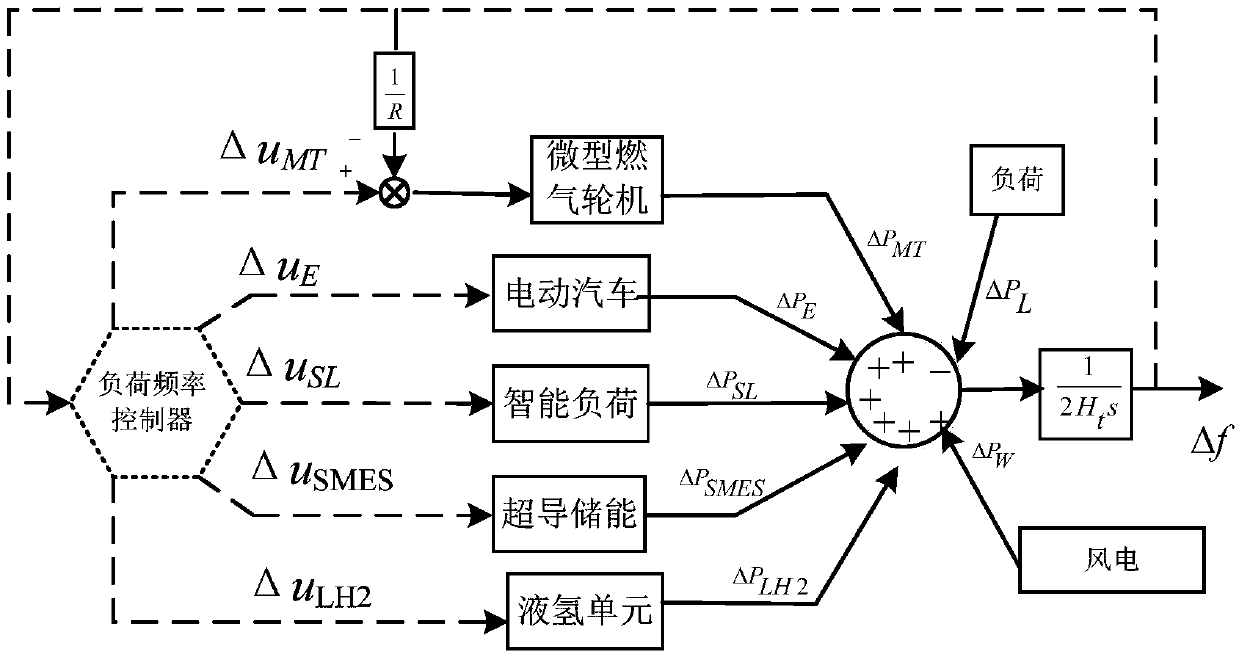

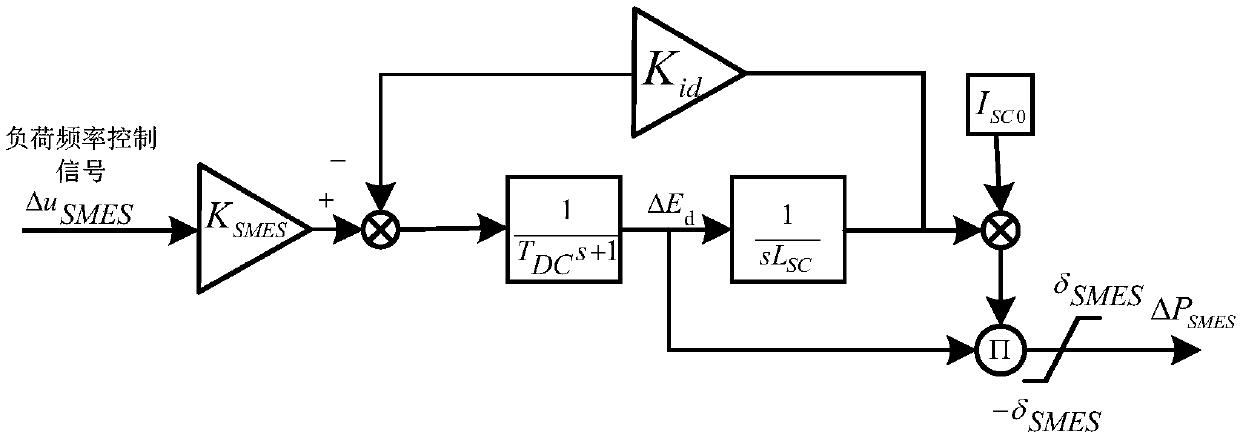

Energy microgrid load frequency control method and system and related products

ActiveCN111478344AFrequency stabilityImprove frequency qualityFlexible AC transmissionPower oscillations reduction/preventionFrequency stabilizationPrediction algorithms

The invention discloses an energy microgrid load frequency control method, an energy microgrid load frequency control system and related products. The method comprises the following steps of establishing a load frequency response model of each component of an energy microgrid; designing a load frequency controller based on a generalized predictive control algorithm; and optimizing the superconducting coil parameters of an SMES system to optimize and adjust the frequency deviation of the energy microgrid, wherein each assembly of the energy microgrid comprises an LIQHYSMES device, a micro gas turbine, an electric vehicle charging station and an intelligent load. The invention provides a high-robustness coordinated load frequency controller based on a generalized prediction algorithm, wherein the controller is applied to load frequency control of an energy microgrid containing a liquid hydrogen superconducting energy storage device, and can effectively maintain the frequency stability ofthe energy microgrid; and the invention provides an optimization design of superconducting coil parameters, wherein the optimization design comprises: optimizing initial current, inductance and initial storage energy so as to obtain a good frequency control effect.

Owner:STATE GRID ENERGY RES INST +2

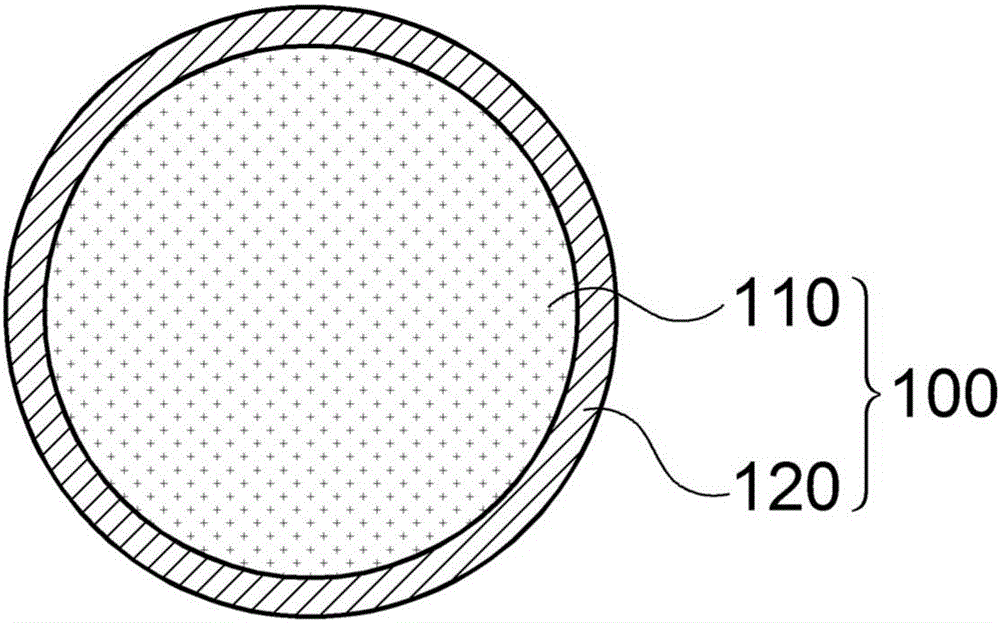

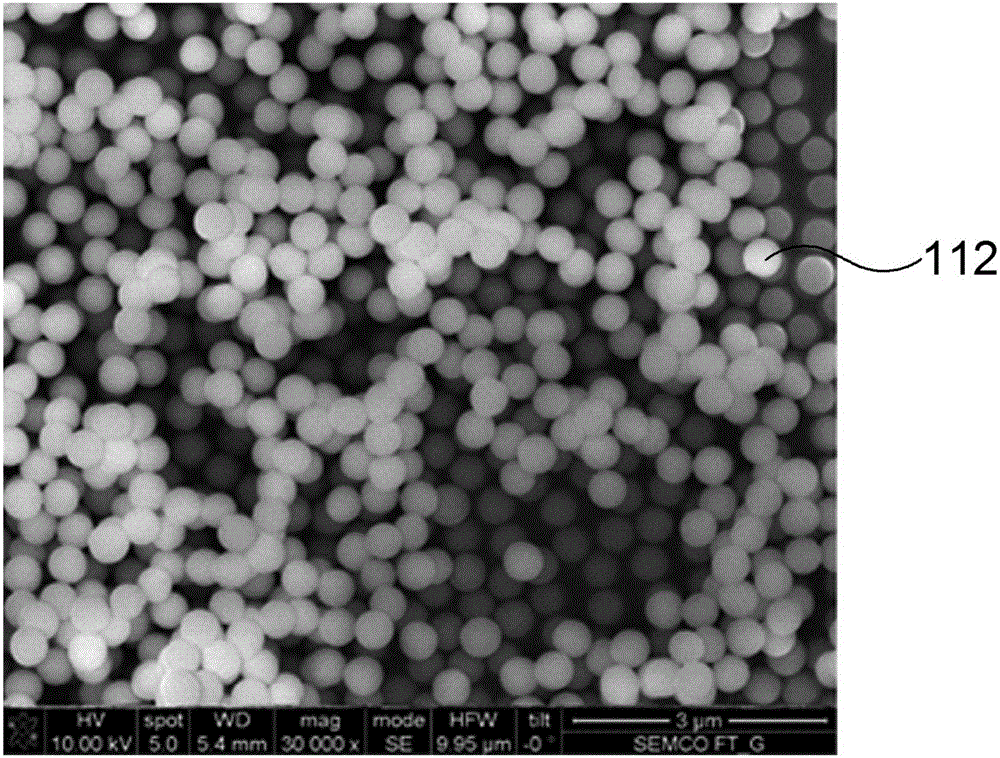

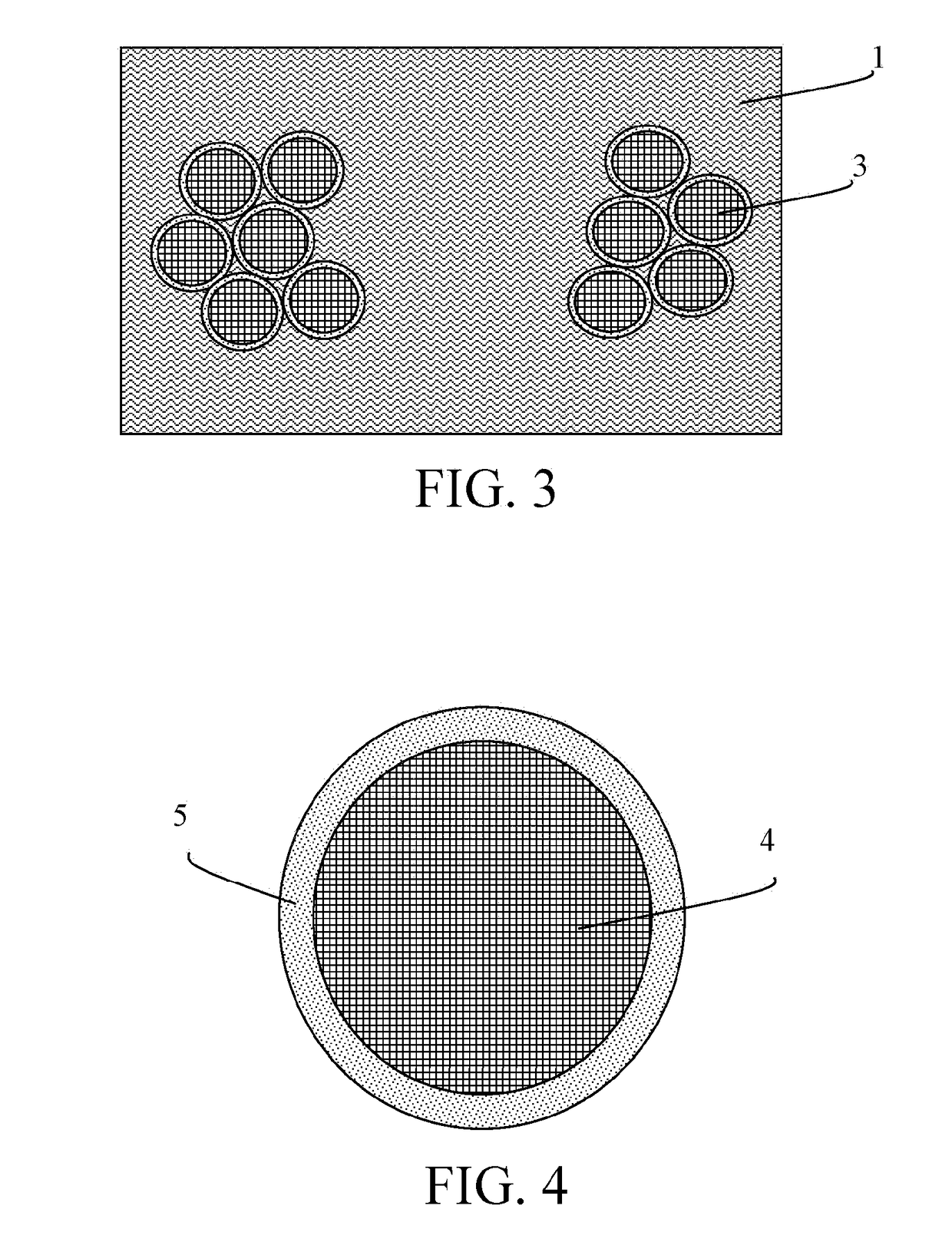

Composite magnetic powder and chip coil component using same

InactiveCN105321670AReduced permeability lossImprove permeabilityLoop antennas with ferromagnetic coreTransformers/inductances coils/windings/connectionsFerrite powderSilicon dioxide

The invention relates to composite magnetic powder and a chip coil component using the same. According to the invention, the chip coil component comprises coil patterns stacked on a ceramic layer or wound on a ceramic core, wherein the ceramic layer or the ceramic core includes powder with a core-shell structure, the powder with the core-shell structure is made of SiO2 powder, and the shell is made of ferrite powder.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

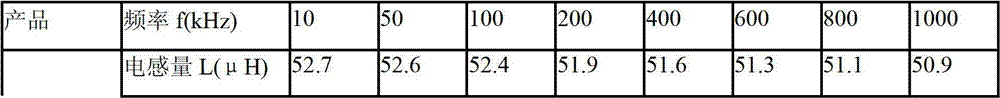

Low-power Si-Al alloy material with magnetic permeability μ=26 and its preparation method

ActiveCN102543345BGood inductanceHigh quality factorInductances/transformers/magnets manufactureMagnetic materialsCompression moldingUltimate tensile strength

The invention relates to a preparation method of a magnetic material, in particular to a low power consumption Fe-Si-Al alloy material with magnetic conductivity mu=26 and a preparation method thereof. The Fe-Si-Al alloy soft magnetic material is prepared from Fe-Si-Al alloy powder through surface treatment, compression molding and thermal treatment. The weight content of Si in the Fe-Si-Al alloy powder is 8.5-10%, the weight content of Al is 5-6%, the weight content of Ni is 0.5-1%, the weight content of Cr is 0.5-1%, and the balance weight is Fe. The invention has the following advantages: (1) the manufacturing process is simple, and used equipment is simple; (2) the product manufactured by using the method has improved saturation induction density while good inductance and high quality factor are maintained; (3) and the DC offset capability is increased, and the loss value is reduced.

Owner:德清鑫晨新材料有限公司

A kind of preparation method of iron silicon nickel magnetic powder core

ActiveCN104036903BSimple preparation processEasy to useInorganic material magnetismShielding gasLubrication

The invention discloses a Fe-Si-Ni magnetic powder core and a preparation method thereof.The method comprises the following steps of: 1) smelting a Fe-Si-Ni alloy cast ingot with a vacuum induction furnace, 2) mechanically crushing the alloy cast ingot and ball-milling into powder for annealing treatment in an argon shield atmosphere, 3) taking Fe-Si-Ni powder for particle size distribution in a certain proportion, 4) adding a passivating agent into the prepared Fe-Si-Ni powder for passivating treatment, 5) adding magnetic particle glue and an insulating agent diluted by acetone, and uniformly stirring for insulating adhesion and coating, 6) then adding a lubrication releasing agent, mixing uniformly, and conducting pressure forming, and 7) placing a compression molding sample in a shielding gas atmosphere for annealing treatment, furnace cooling and spraying, and obtaining a target product.According to the method, a Ni content in the alloy powder is lower, so that the cost is lower; the packing density can be maximized by the reasonable particle size distribution of the alloy powder; the saturation induction density of the magnetic powder core is improved; and power loss of the magnetic powder core is reduced.

Owner:ZHEJIANG UNIV

Integrated circuit including a differential power amplifier with a single ended output and an integrated balun

InactiveUS20130127010A1Convenient lengthGood inductanceHigh frequency amplifiersSemiconductor/solid-state device detailsInductorEngineering

An integrated circuit, including, a die with an electronic circuit embedded thereon; wherein the electronic circuit includes a differential power amplifier and pads to electronically interface with the electronic circuit; a packaging encasing the die with contact pins to connect between the integrated circuit and external elements; wires connecting between the pads and the contact pins; a converter that includes capacitors and inductors to combine the outputs from the differential power amplifier to form a single ended output at one of the contact pins; wherein inherent inductance of some of the wires serve as the inductors of the converter.

Owner:DSP GROUP

Metal powder for preparing nanocrystalline magnetic core

The invention discloses metal powder for preparing a nanocrystalline magnetic core. The metal powder is prepared according to the following steps: conducting heat treatment on a Fe-based amorphous thin belt obtained according to a rapid cooling method, so as to convert the Fe-based amorphous thin belt into a nanocrystalline thin belt, wherein the Fe-based amorphous thin belt comprises the following ingredients by weight: 3 to 15 percent of Ni, 1 to 10 percent of Si, 1 to 4 percent of B, 1 to 9 percent of Al, and Fe in balancing amount; crushing the nanocrystalline thin belt to obtain nanocrystalline metal powder; conducting ball milling shaping on the nanocrystalline metal powder; and screening the nanocrystalline metal powder, and mixing to obtain powder granules containing 90 to 98 percent of first powder penetrating a -200 mesh and 2 to 10 percent of second powder penetrating a -150 to +200 mesh. The magnetic core prepared according to the technical scheme has stable magnetic permeability, loss value and DC offset capability.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

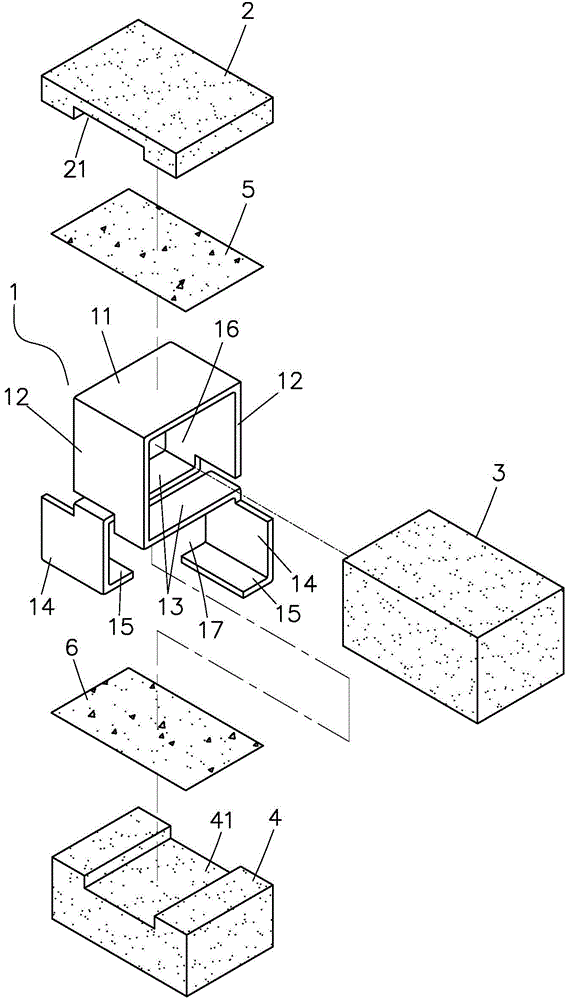

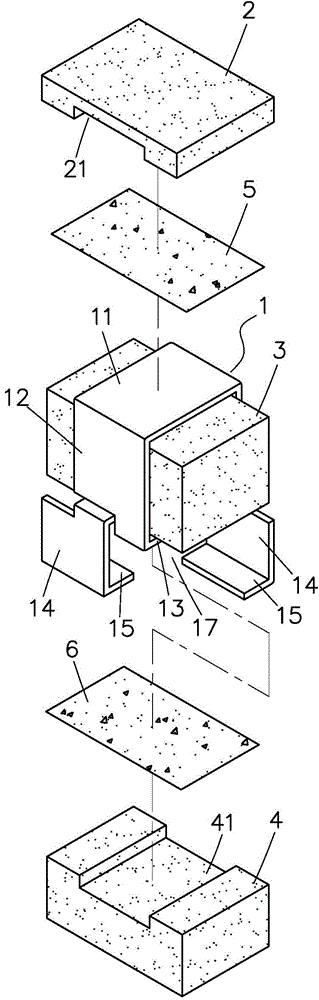

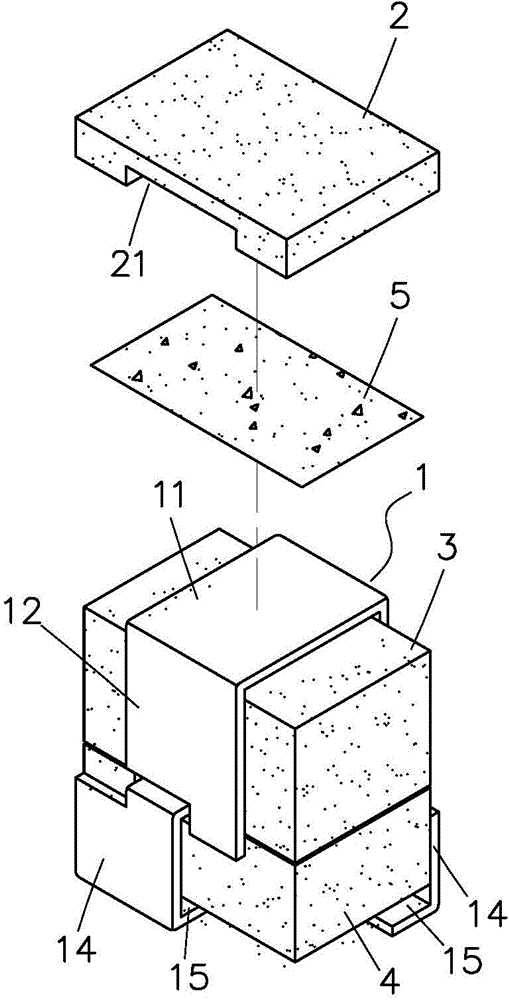

Assembled stacked inductor device

InactiveCN105097227AEffective adjustment of inductanceGood inductanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorEngineering

The invention provides an assembled stacked inductor device, and particularly relates to a power-type inductor. The assembled stacked inductor device comprises an approximately 8-shaped sheet metal coil formed through stamping, three iron core bodies and two sheet bodies; after the iron core bodies are assembled in the upper, middle and lower spaces of the approximately 8-shaped sheet metal coil, the assembled stacked inductor device of two or three inductance coils is formed on the periphery of the iron core bodies. The inductor device of the structure can realize promotion of the inductance value and adjusts the size of the inductance value by means of the control for the gaps of the iron core bodies, so that flexible combination of various inductance characteristics is achieved.

Owner:ALLIANCE MAGNETICS H K

Low-permeability, low-power consumption Fe-Si-Al soft magnetic material and production method thereof

The invention relates to a production method for a magnetic material, in particular to a low-permeability, low-power consumption Fe-Si-Al soft magnetic material and a production method thereof. The production method for the low-permeability, low-power consumption Fe-Si-Al soft magnetic material includes the following steps: (1) In the process of producing Fe-Si-Al powder, a melt-spinning machine rapid cooling method is adopted to produce a strip, and flat Fe-Si-Al powder is produced by atmosphere-protected mechanical crushing; (2) when the produced Fe-Si-Al powder is roasted until the temperature reaches 80 DEG C to 120 DEG C, phosphoric acid diluent is added for surface treatment, and the Fe-Si-Al powder then continues to be roasted to become dry; (3) the Fe-Si-Al alloy soft magnetic powder is pressed to be shaped; (4) in heat treatment, hydrogen or nitrogen is filled into a heat treatment furnace; (5) epoxy resin paint is applied on the surface of the soft magnetic material. The invention has the advantages that: the oxygen content of the powder is greatly decreased, the grain size of the product is reduced, consequently, the loss of the Fe-Si-Al product is reduced, and the properties of the product are enhanced.

Owner:德清鑫晨新材料有限公司

Metal powder used for preparing nanometer crystal magnetic core

The invention discloses metal powder used for preparing a nanometer crystal magnetic core. The metal powder is prepared by the following steps: carrying out heat treatment on an iron base amorphous thin belt made by using a rapid cooling method, so that the iron base amorphous thin belt is converted into a nanometer crystal thin belt; crushing the nanometer crystal thin belt so as to obtain nanometer crystal metal powder; carrying out ball mill to shaping the nanometer crystal metal powder; and screening the nanometer crystal metal powder, mixing the screened nanometer crystal metal powder composed of 90%-98% of first powder capable of passing through a -200-mesh sieve and 2%-10% of second powder capable of passing through a -150- +200-mesh sieve. The magnetic core prepared from the metal powder has stable magnetic permeance rate, loss value and direct current biasing ability.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

Low-permeability, low-power consumption Fe-Si-Al powder material and production method thereof

InactiveCN102969114AReduce oxygen contentReduce lossInorganic material magnetismMechanical crushingOxygen content

The invention relates to a production method for a magnetic material, in particular to a low-permeability, low-power consumption Fe-Si-Al powder material and a production method thereof. In the process of producing Fe-Si-Al powder, a melt-spinning machine rapid cooling method is adopted to produce a strip, and the cooling speed is 104 DEG C / second to 106 DEG C / second; and moreover, the flat Fe-Si-Al powder is produced by atmosphere-protected mechanical crushing. The invention has the advantages that: the oxygen content of the powder is greatly decreased, the grain size of the product is reduced, consequently, the loss of the Fe-Si-Al product is reduced, and the properties of the product are enhanced.

Owner:德清鑫晨新材料有限公司

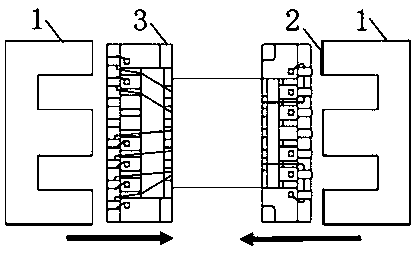

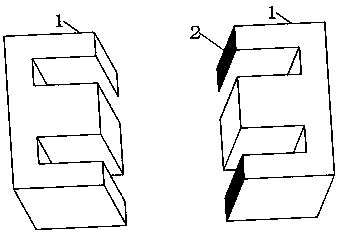

Magnetic core fixing method

InactiveCN110942907AQuick fixGood effectEncapsulation/impregnationCoils manufactureAdhesiveTransformer

The invention provides a magnetic core fixing method. The transformer comprises two E-shaped magnetic cores with the same structure, the contact end faces of the two sides of an E-shaped magnetic coreare coated with a layer of little anaerobic adhesive. Penetrating the E-shaped magnetic core coated with the anaerobic adhesive and the other E-shaped magnetic core not coated with the anaerobic adhesive into the transformer coil from the left side and the right side of the transformer coil; the two E-shaped magnetic cores are pinched with hands, it is guaranteed that no air exists between the contact end faces of the two E-shaped magnetic cores, standing is conducted for two minutes, the anaerobic adhesive can be cured, and then operation of the next paint dipping procedure is conducted. According to the method, the magnetic core can be quickly fixed. Meanwhile, it can be guaranteed that insulating paint does not enter the contact end faces of the magnetic core in the paint dipping process, the product inductance percent of pass can be effectively increased, and meanwhile the production cost can be reduced.

Owner:TIANJIN HUIGAO MAGNETICS

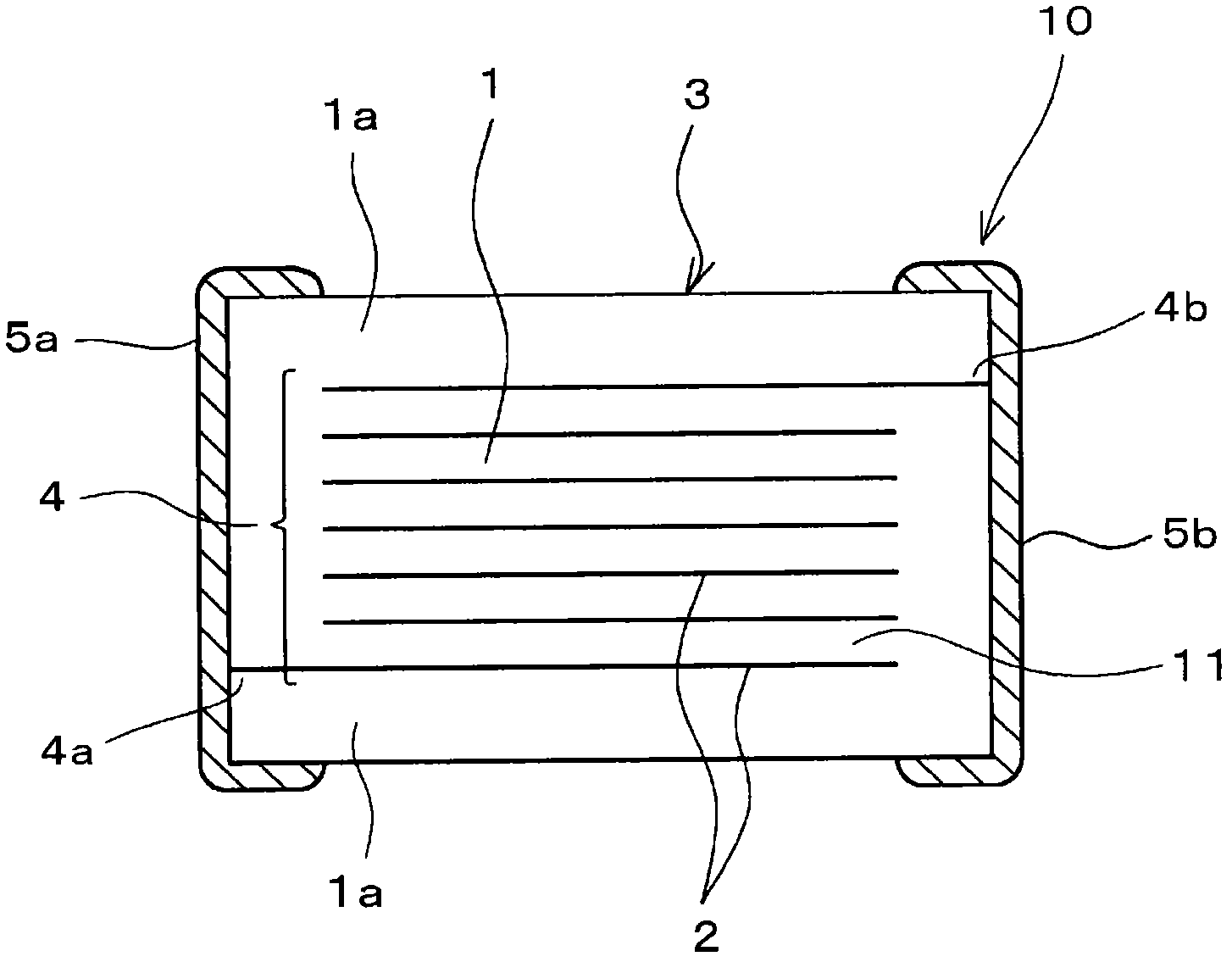

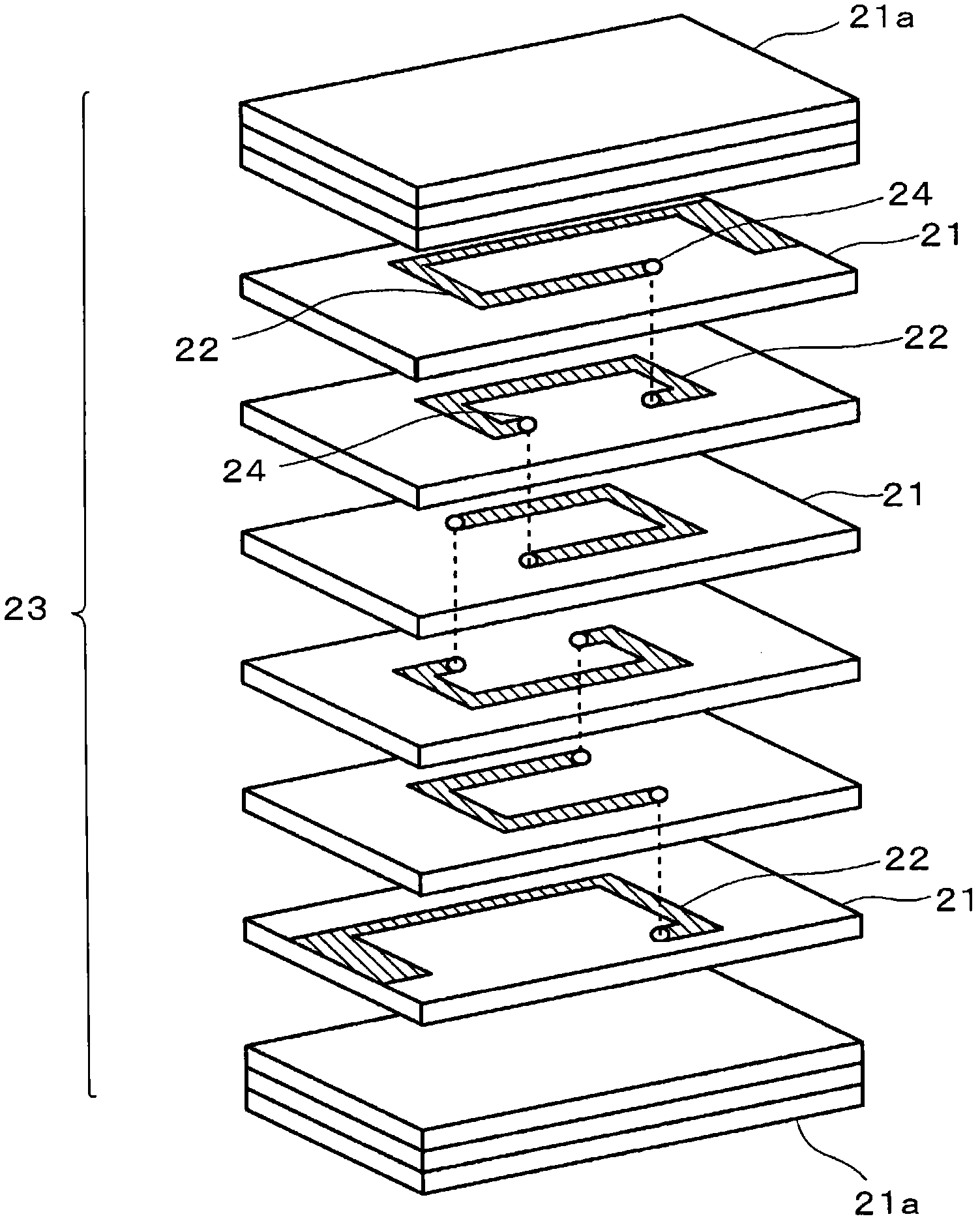

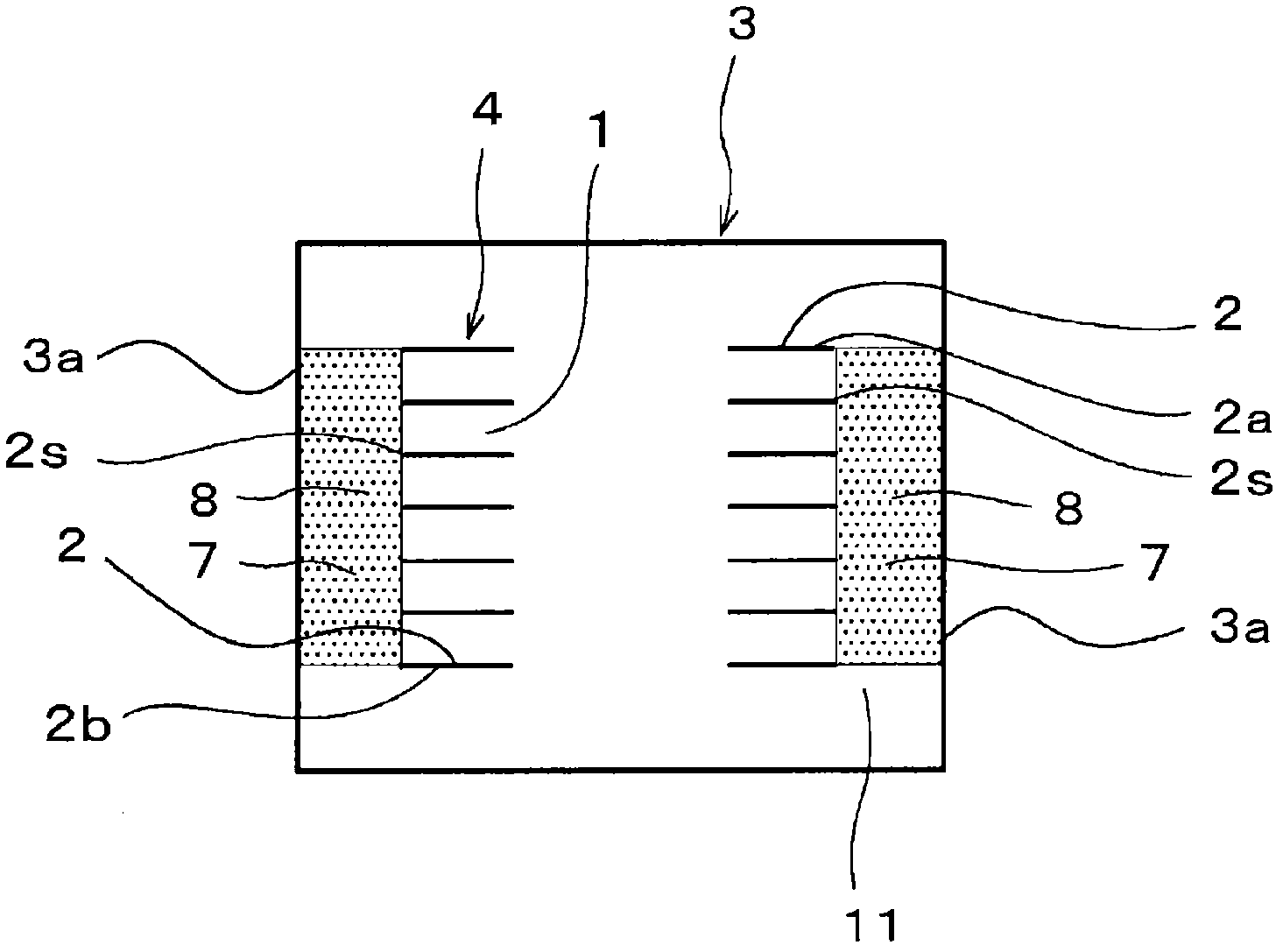

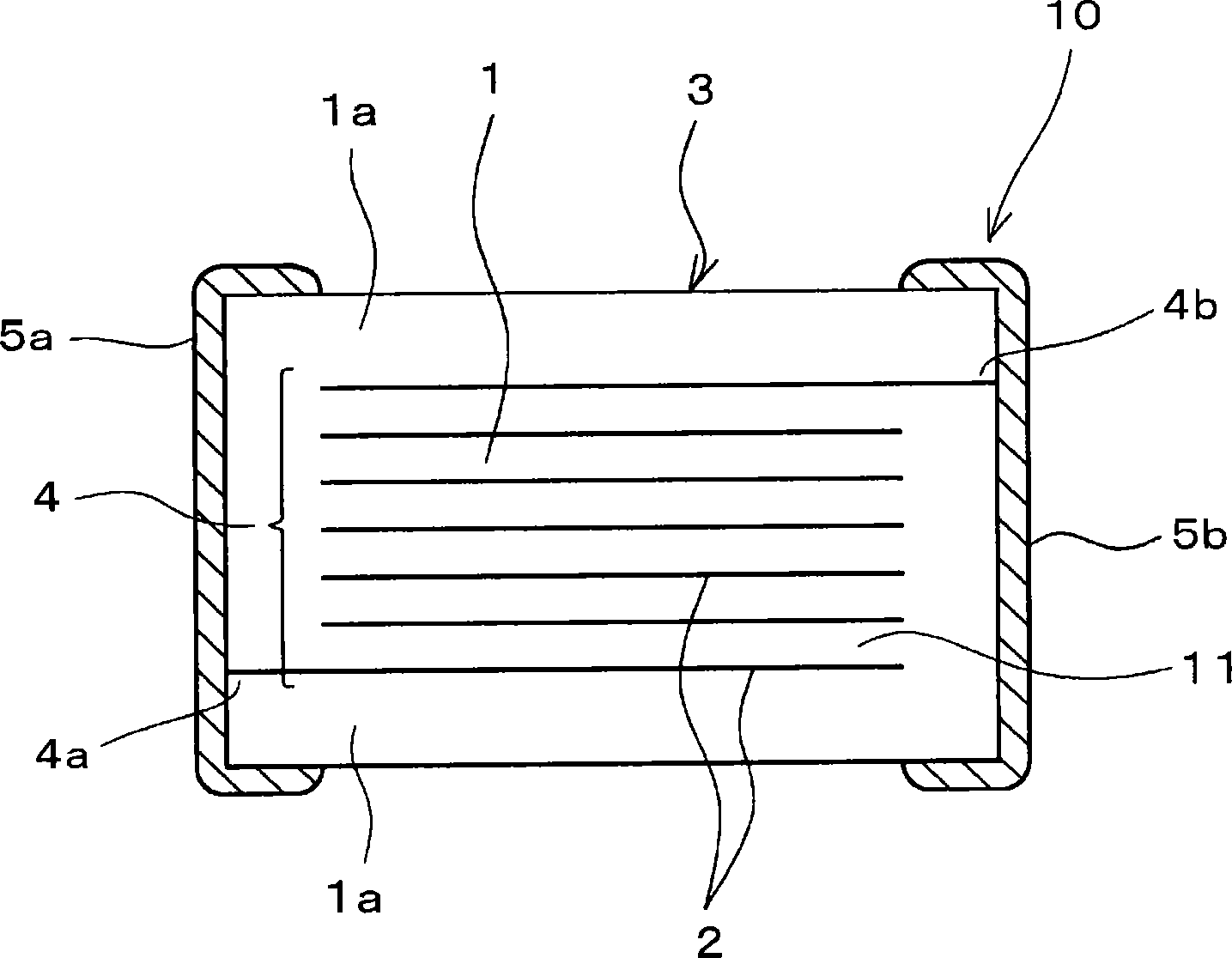

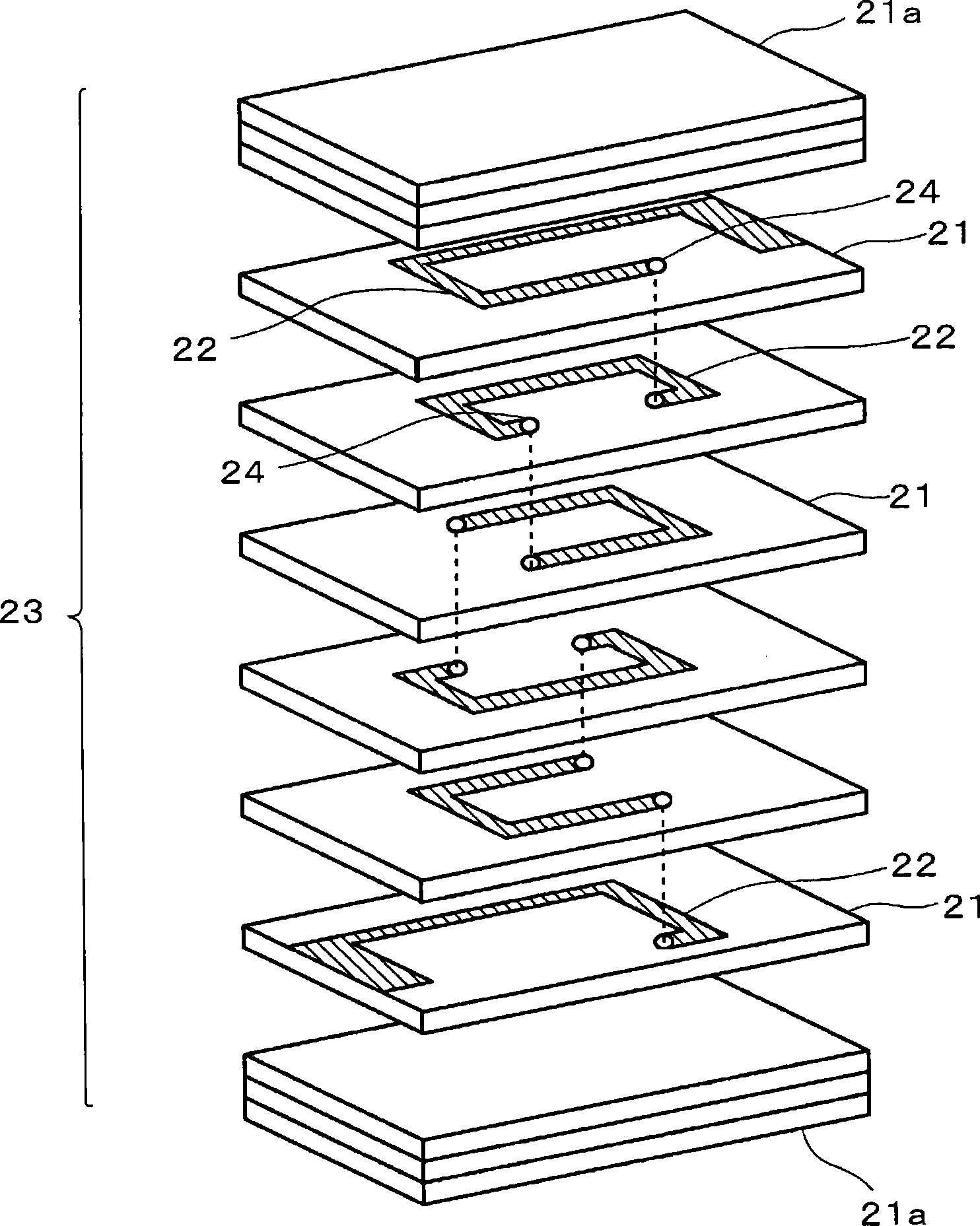

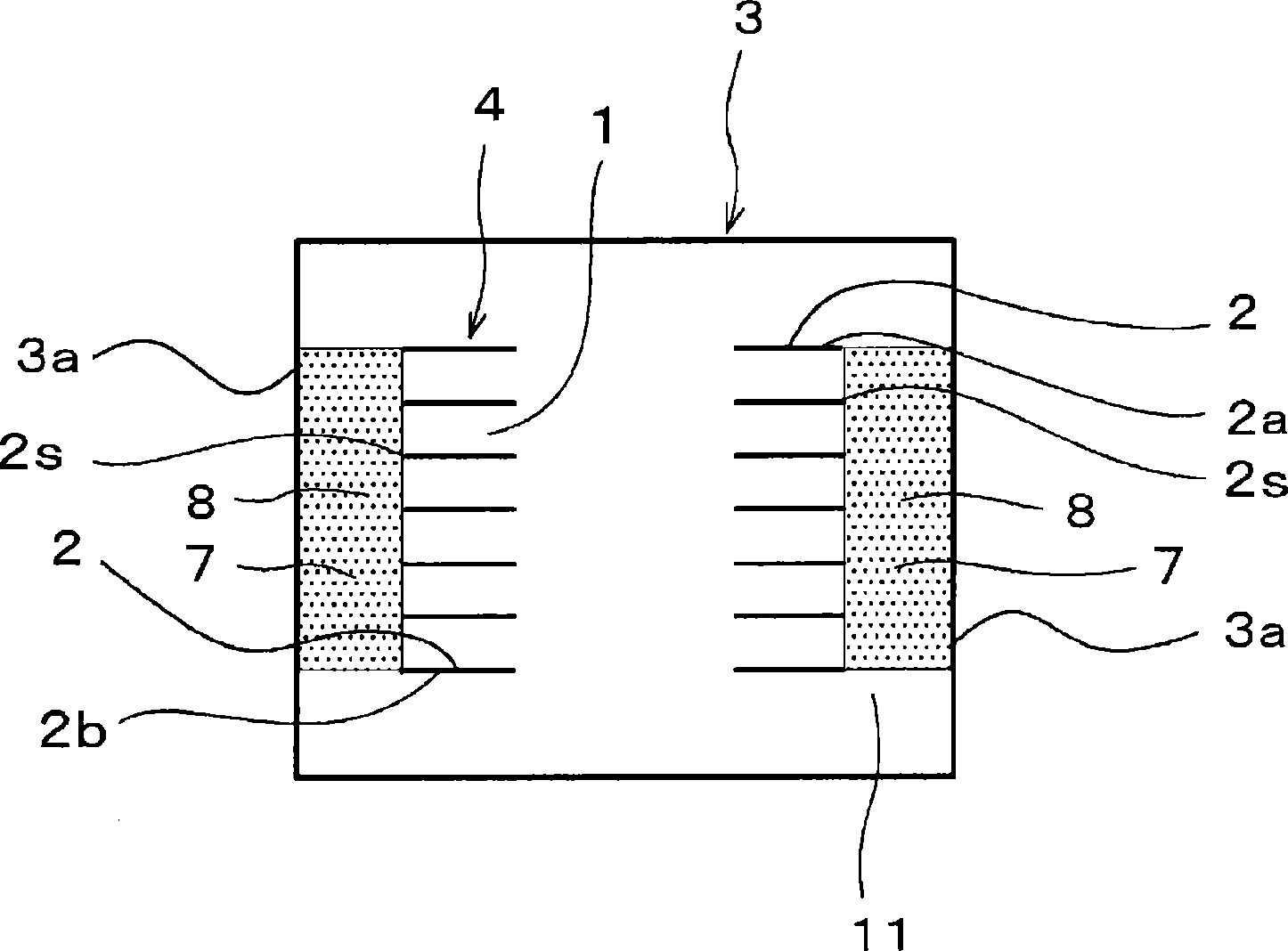

Laminated coil component

ActiveCN102741949AImprove reliabilityHigh impedance valueTransformers/inductances detailsCoils manufactureFerrite layerThermal expansion

Provided is a highly reliable laminated coil component which does not require an opening to be formed between a ferrite layer and an internal conducting layer as conventionally, and enables alleviation of the internal stress between the ferrite layer and internal conducting layer caused by the difference between the firing shrinkage behavior and thermal expansion coefficient. A process is prepared for dissociating the boundary between the internal conductor (2) and the surrounding ferrite (11). This is done by enabling a complexing agent solution to reach a boundary between an internal conductor and ferrite (11) surrounding it by passing it from a side surface (3a) of a ferrite element (3) containing a spiral-shaped coil (4) and then through a side gap part (8). As the complexing agent solution, a solution is used that includes at least one substance selected from a group comprising aminocarboxylic acid and its salt, oxycarboxylic acid and its salt, amine, phosphoric acid and its salt and a lactone compound.

Owner:MURATA MFG CO LTD

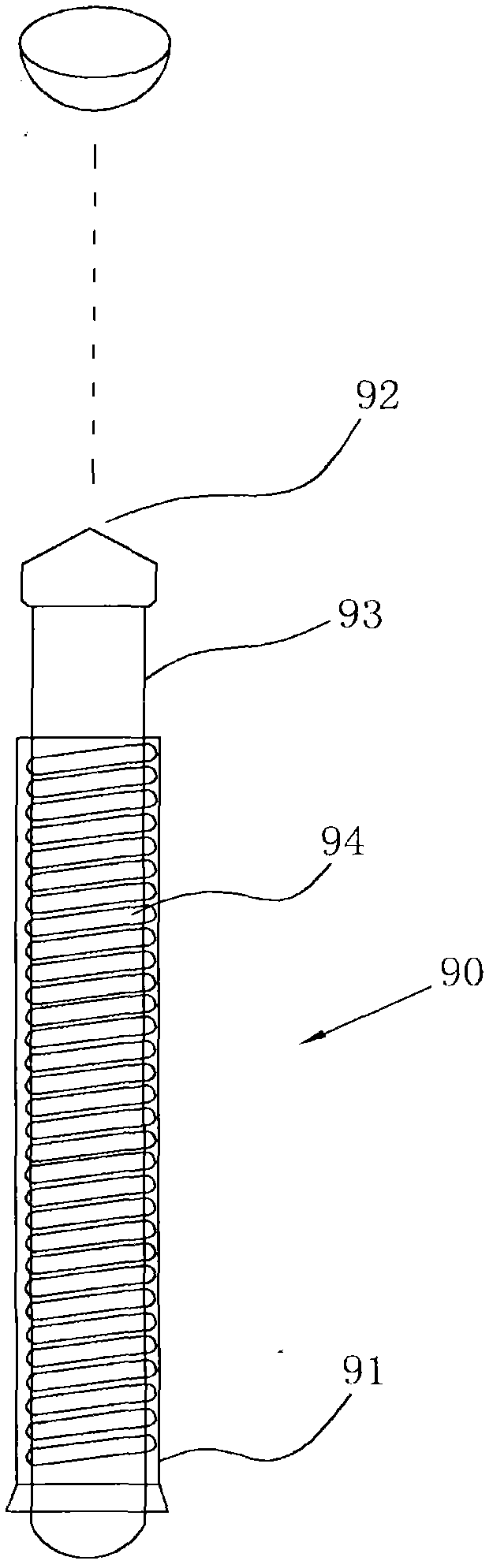

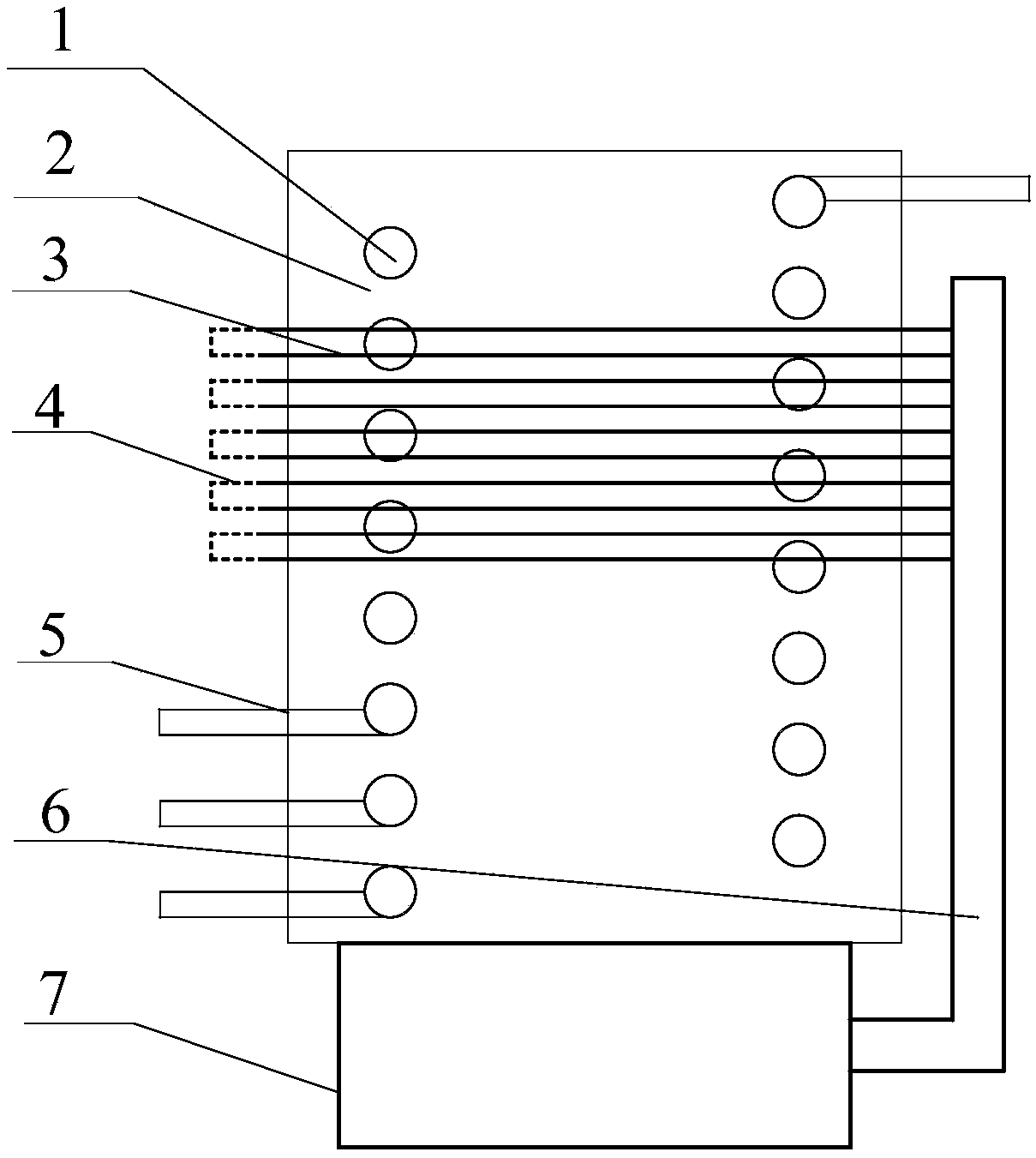

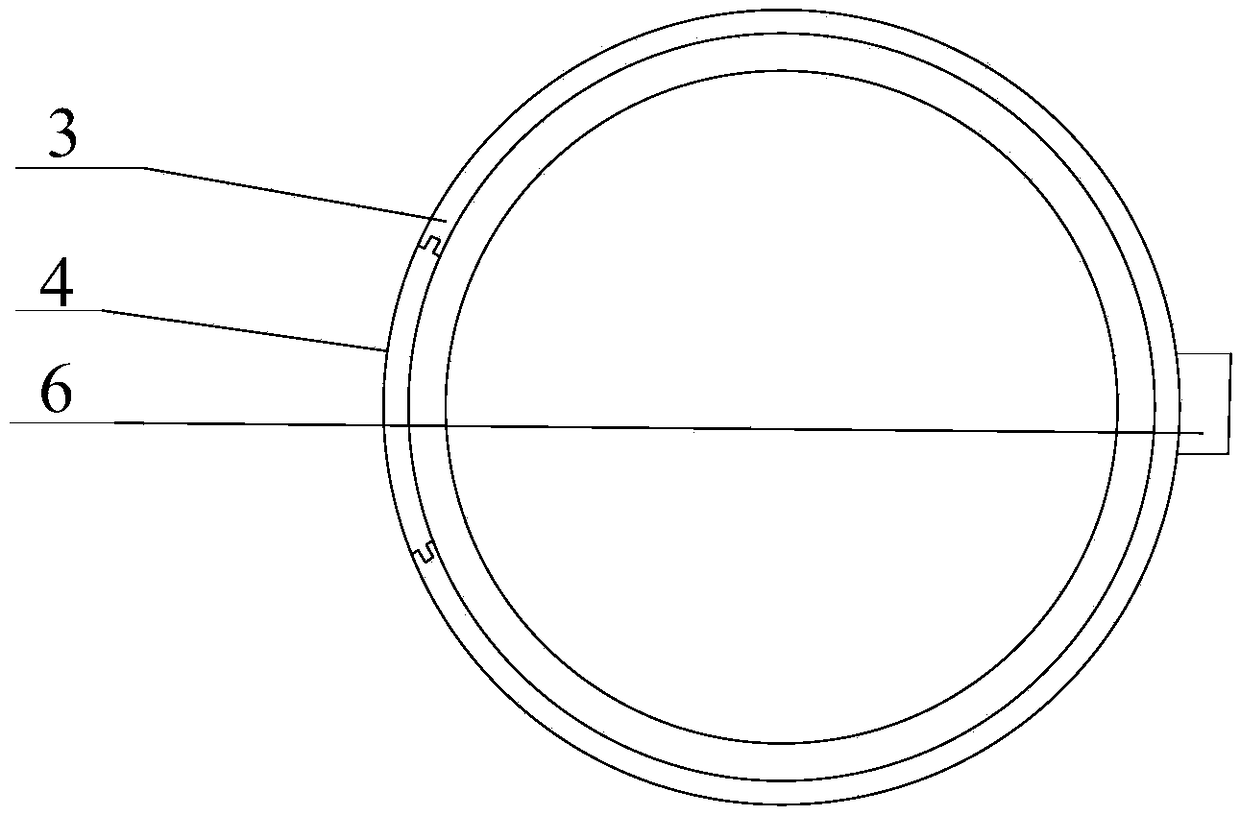

An inductor for current formation in a high-voltage impulse circuit

ActiveCN109215939AInductance adjustmentReduce magnetic field strengthTransformers/inductances coils/windings/connectionsDiscontinuously variable inductances/transformersInsulation layerInductor

The invention discloses an inductor for current formation in a high-voltage impulse circuit, which comprises a metal coil, an epoxy insulating layer, an unclosed induction coil, a detachable closure device, a multi-stage lead-out sheet, a coil support and a base; the metal coil comprises a metal coil, an epoxy insulating layer, an unclosed induction coil, a detachable closure device, a multi-stagelead-out sheet and a base. An epoxy insulating layer is coated with a metal coil to form an inductor housing, A metal coil first end is connected with a lead-out tab, a second end is connected with aplurality of stage lead-out tab, a cylindrical shell made of epoxy insulation layer is arranged at that center of the base, a plurality of non-closed induction coils are fixedly connected with a coilsupport on the base, and a detachable closure device is selectively installed on the non-closed induction coils according to a test current condition, and the metal coil first end is connected with alead-out tab, the epoxy insulation layer is arranged at the center of the base. The inductor of the invention has a plurality of inductance value selections, realizes the fine adjustment of the current waveform in the high-voltage impulse circuit, obtains the selection of the optimum inductance value of the specific working loop, realizes the inductance value change by changing the connecting length of the metal coil and the magnitude of the magnetic field established by the coil, is safe and reliable in use, and is suitable for the working condition of large current.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing metal powder of nanocrystalline magnetic cores with magnetic permeability mu of 60

InactiveCN102728840AGood inductanceHigh quality factorInorganic material magnetismInductances/transformers/magnets manufactureAmorphous ribbonParticle composition

The invention discloses a method for preparing metal powder of nanocrystalline magnetic cores with magnetic permeability mu of 60. The method comprises the steps that: heat treatment for iron-based amorphous ribbons is carried out to produce nanocrystalline ribbons, wherein the iron-based amorphous ribbons are prepared with a rapid cooling method; the iron-based amorphous ribbons consist of, on a mass basis, 3-15% of Ni, 1-10% of Si, 1-4% of B, 1-9% of Al, and the balance being of Fe; the nanocrystalline ribbons are broken to obtain nanocrystalline metal powder; ball milling shaping of the nanocrystalline metal powder is carried out; the nanocrystalline metal powder is screened; and powder particle composition comprises 90%-98% of the first powder which is screened by using a sieve with a size of -200 meshes and 2%-10% of second powder is screened by using a sieve with a size of -150-+200 meshes. According to the technical scheme, nanocrystalline magnetic cores with magnetic permeability mu of 60 are prepared; magnetic permeability, loss value and direct current bias capability of the magnetic cores are stable.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

Laminated coil component

ActiveCN102741949BImprove reliabilityHigh impedance valueTransformers/inductances detailsCoils manufactureFerrite layerElectrical conductor

Owner:MURATA MFG CO LTD

Preparation method of metal powder for nanocrystalline magnetic core

ActiveCN102699336BImprove permeabilityGood inductanceInorganic material magnetismFurnace typesBoronMetal powder

The invention discloses a preparation method of a metal powder for a nanocrystalline magnetic core. The preparation method comprises the following steps of: carrying out heat treatment on an iron-based amorphous thin ribbon made by using a rapid cooling method; converting the iron-based amorphous thin ribbon into a nanocrystalline thin ribbon, wherein the iron-based amorphous thin ribbon comprises the following components in percentage by mass: 3-15% of Ni, 1-10% of Si (Silicon), 1-4% of B (Boron), 1-9% of Al (Aluminum) and the balance of Fe (Ferrum); crushing the nanocrystalline thin ribbon to obtain nanocrystalline metal powder; ball-milling and shaping the nanocrystalline metal powder; screening the nanocrystalline metal powder; and then mixing the nanocrystalline metal powder to achieve powder particle distribution, wherein the powder particle distribution is formed by 90-98% of first powder passing through -200 meshes and 2-10% of second powder passing through (-150)-(+200) meshes. According to the technical scheme, the preparation method is used for preparing the nanocrystalline magnetic core with magnetic permeability mu of 26-90; and the magnetic core has the advantages of stable magnetic permeability, stable dissipation value and stable direct current biasing capacity.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

Inductor and method for manufacturing the same

InactiveUS20180130588A1Good inductanceLower average currentTransformers/inductances coils/windings/connectionsCoils manufactureElectrical resistance and conductanceElectrical conductor

An inductor and a method for manufacturing the same are disclosed. The inductor includes a magnetic body and a conductor coil, where the conductor coil is inside the magnetic body; and further includes an inorganic insulation layer, where the inorganic insulation layer is wrapped on a surface of the conductor coil, and the inorganic insulation layer is inside the magnetic body. According to the present application, an inductor having a higher inductance or an inductor having a lower direct current resistance may be manufactured.

Owner:SHENZHEN SUNLORD ELECTRONICS

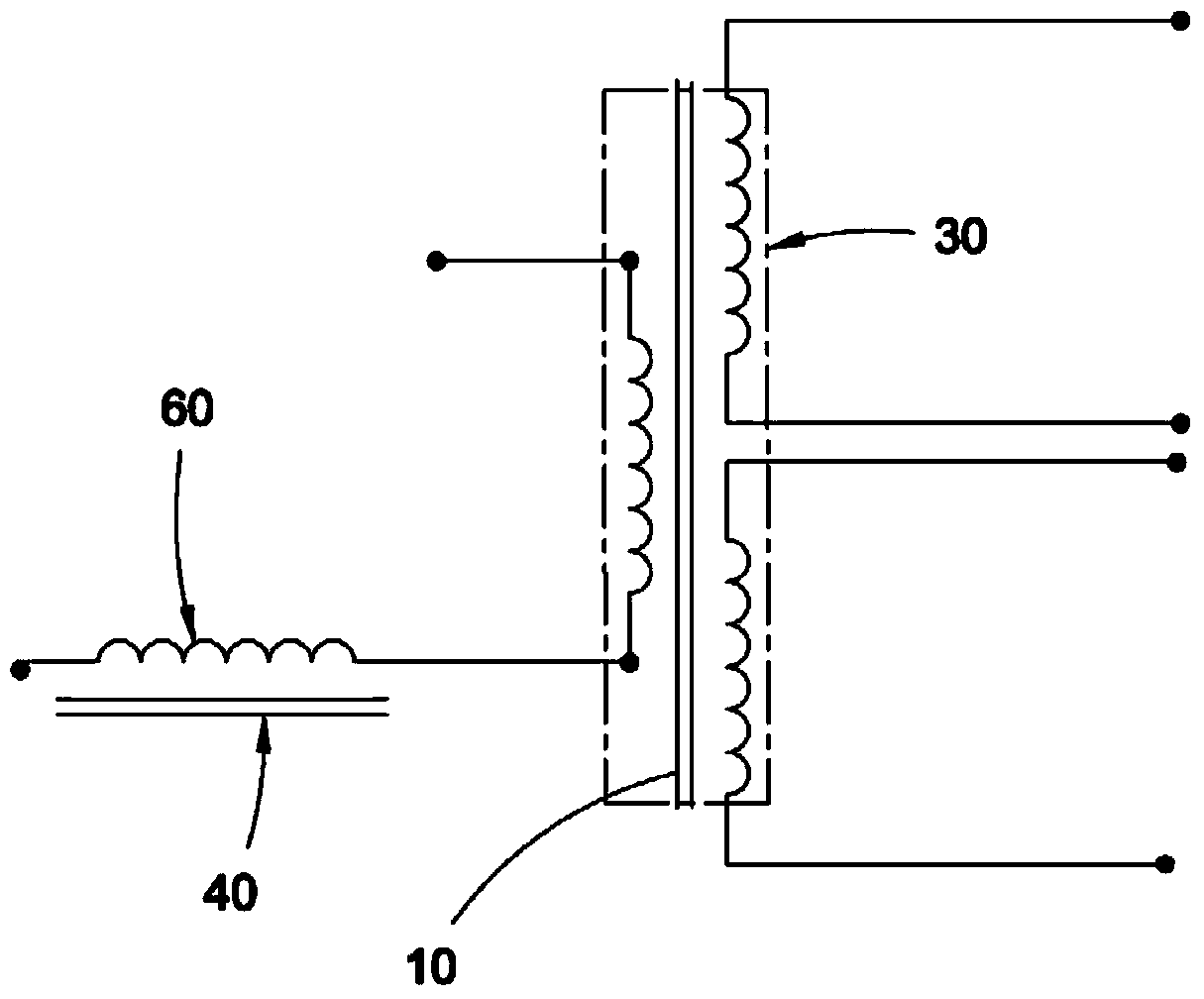

DC-DC converter and electronic device using same

PendingCN112751486AImprove performanceGood inductanceTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsConvertersTransformer

The invention provides a DC-DC converter and an electronic device using the same. The DC-DC converter comprises a transformer, a first inductor and a second inductor, wherein the transformer comprises a plurality of first voltage transformation modules, a second voltage transformation module and two first magnetic cores; wherein each first voltage transformation module comprises a primary winding and a secondary winding; the second voltage transformation module comprises a primary winding; the second voltage transformation module and the plurality of first voltage transformation modules are sequentially sleeved between the two first magnetic cores; the first inductor and the second inductor are arranged on the two sides of the transformer; the first inductor comprises a first winding, and the first winding is connected with the plurality of primary windings; and the second inductor comprises a second winding, and the second winding is connected with the secondary winding. The DC-DC converter provided by the invention is better in performance and better in inductance value, withstand voltage value and safety value.

Owner:SHENZHEN JINGQUANHUA ELECTRONICS

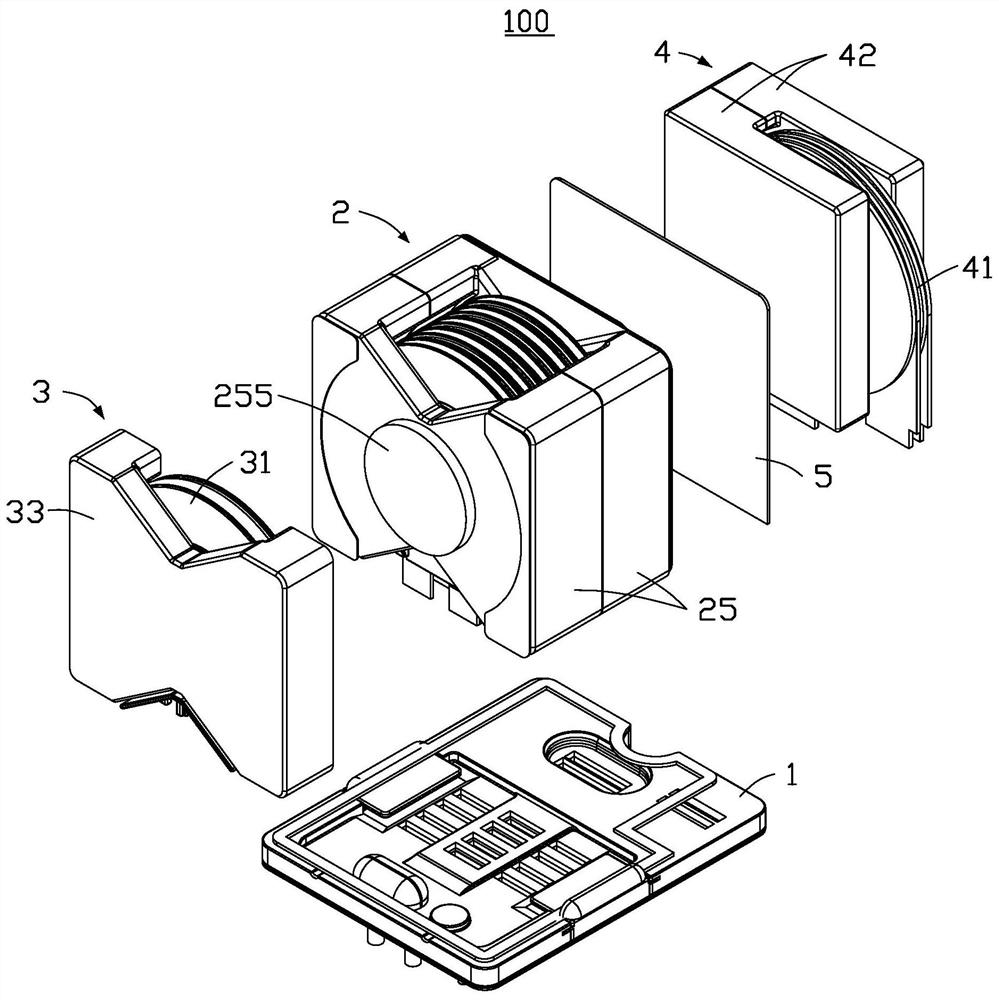

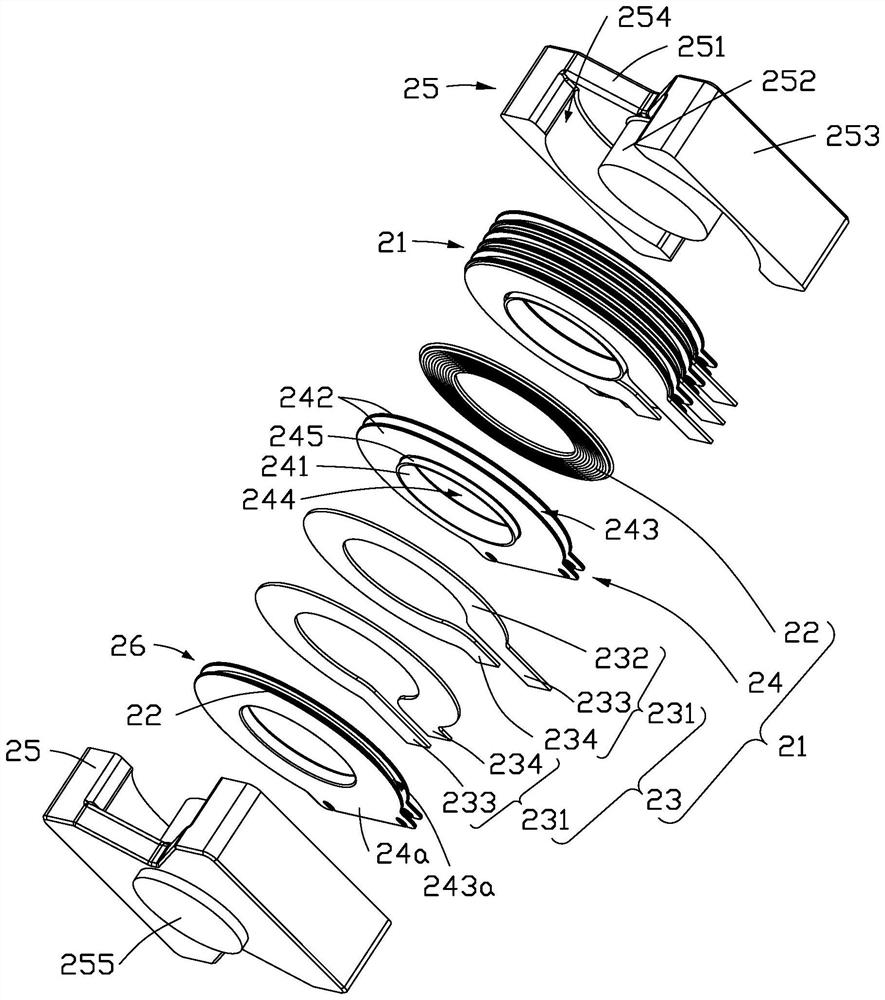

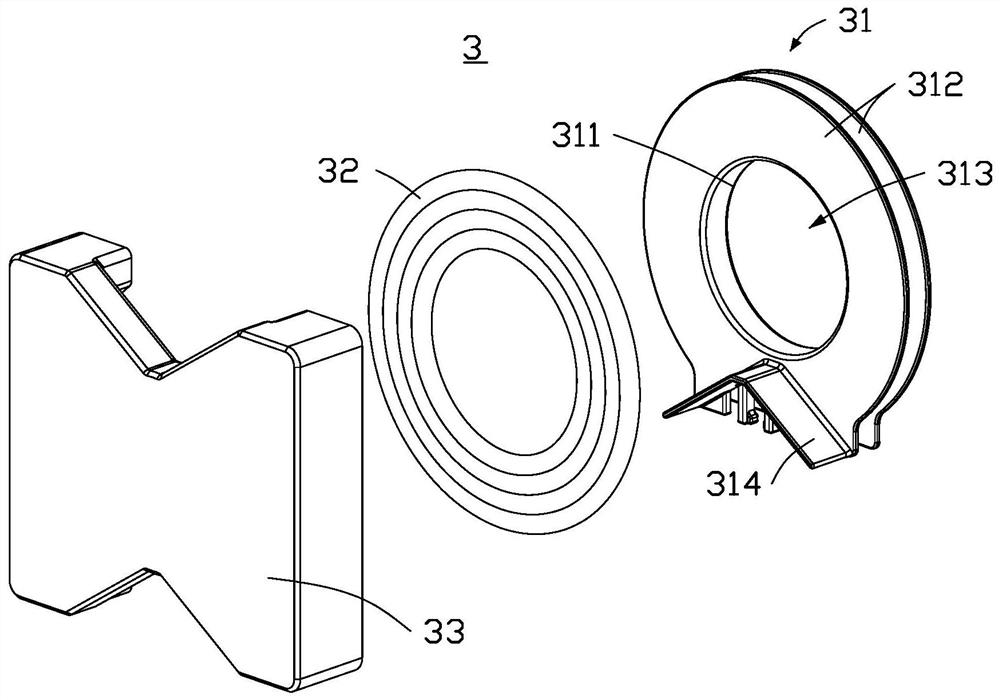

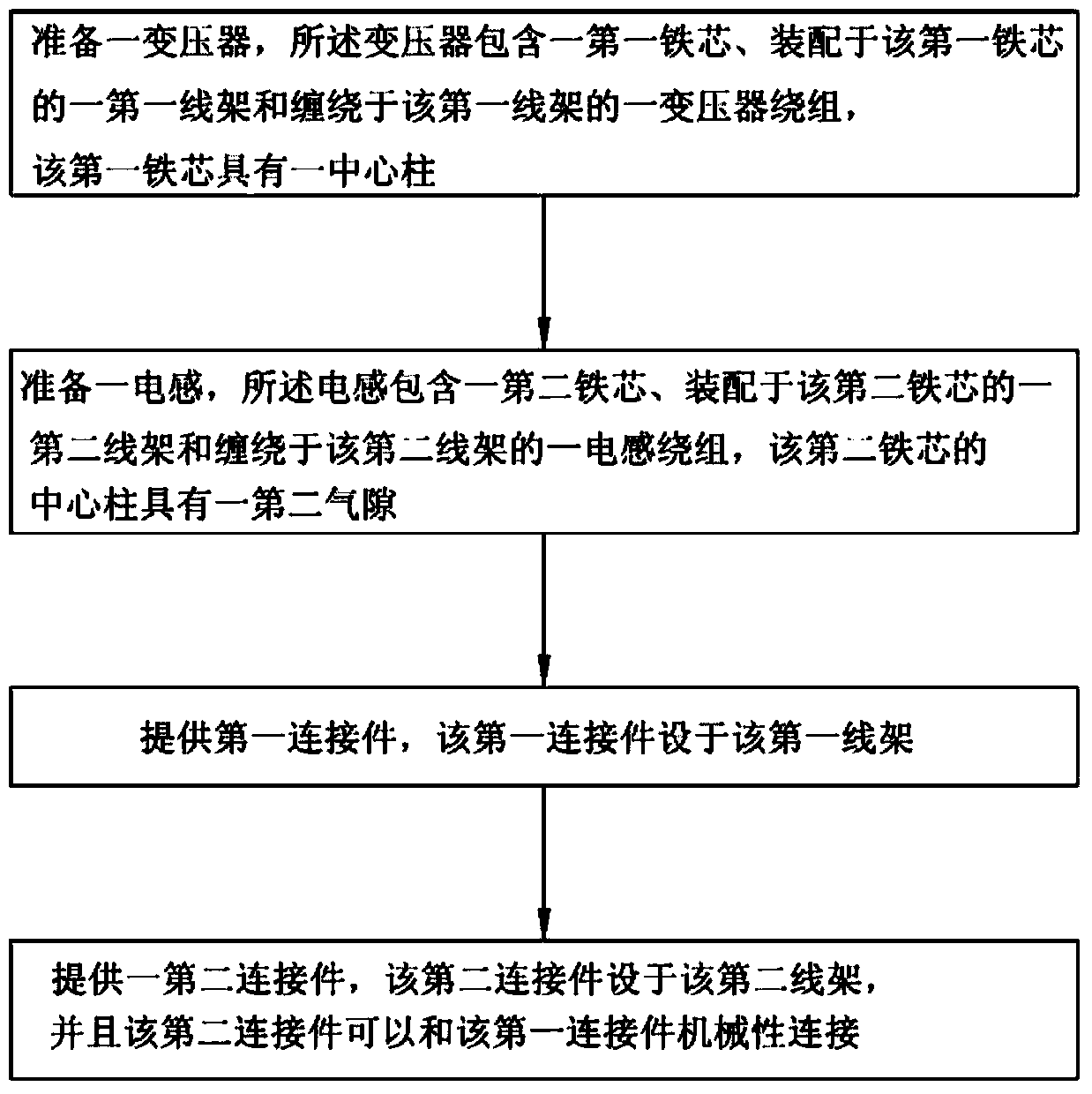

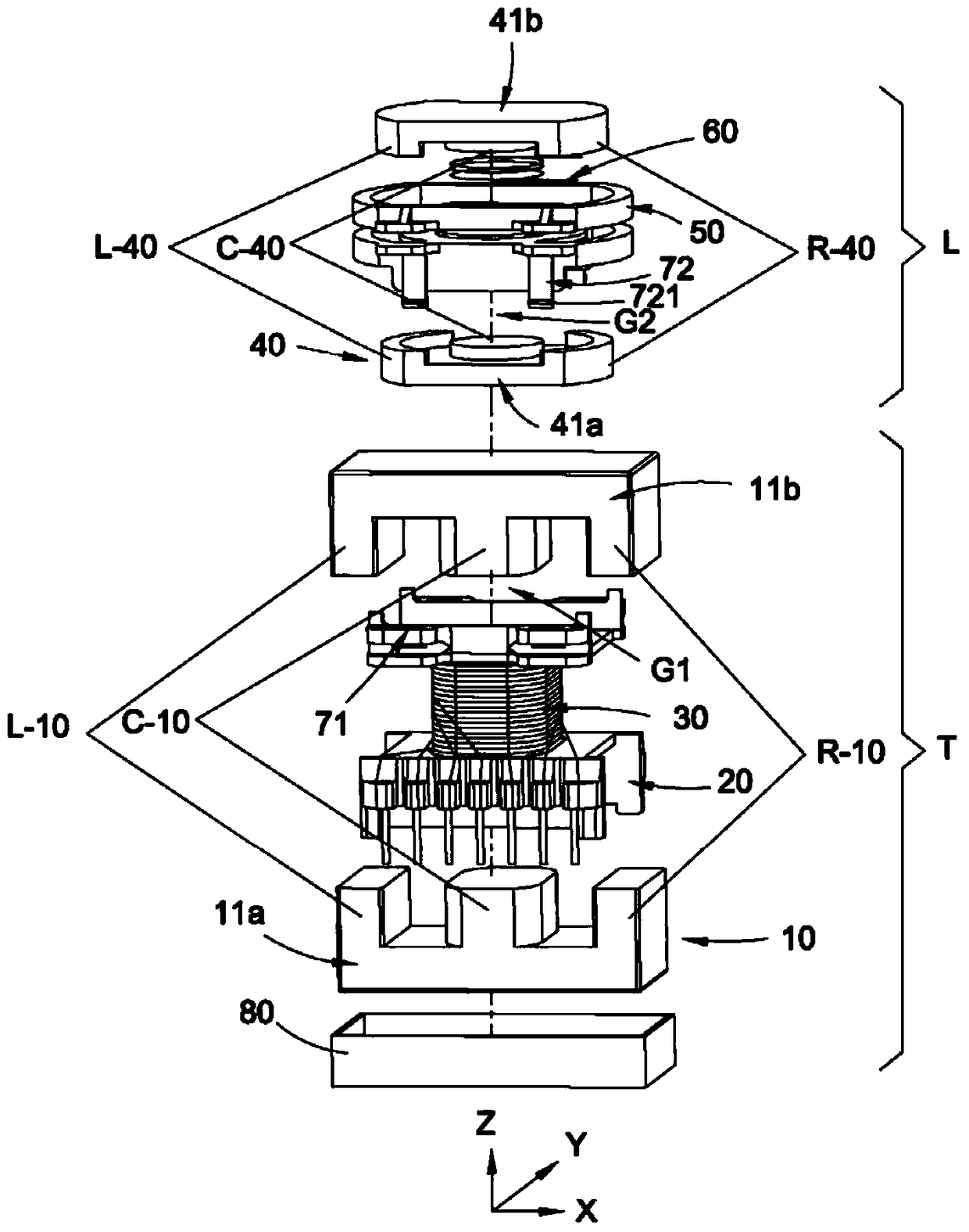

Integration Method and Structure of Transformer and Inductor

ActiveCN105375739BEasy to integrateGood inductanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductor windingsWhole body

The invention provides a combining method and a combining structure of a transformer and an inductor. The combining structure comprises a first iron core, a first coil holder assembled on the first iron core, a second iron core, and a second coil holder assembled on the second iron core. The first iron core comprises two first open iron cores. The second iron core comprises two second open iron cores. A first transformer winding is wound around the first coil holder, and an inductor winding is wound around the second coil holder. A central column of the first iron core has a first air gap or is designed to have no combination air gap. A central column of the second iron core has a second air gap. The first coil holder is provided with a first connecting member. The second coil holder is provided with a second connecting member, which can be mechanically connected to the first connecting member. The advantages are that the inductor and the transformer can be conveniently combined to form a whole body by means of the first connecting member and the second connecting member, inductors and transformers different in inductance or dimension can be flexibly selected and combined, inductors different in inductance can be easily combined and modulated, and the combining structure is convenient to produce.

Owner:SUPER FLOWER COMP +1

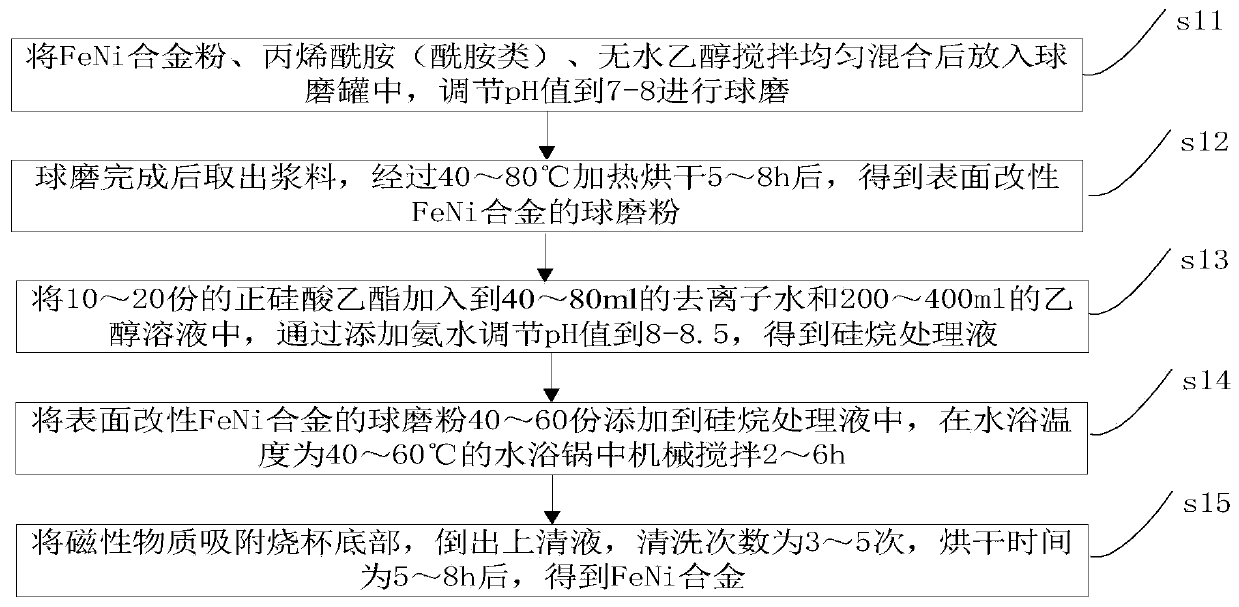

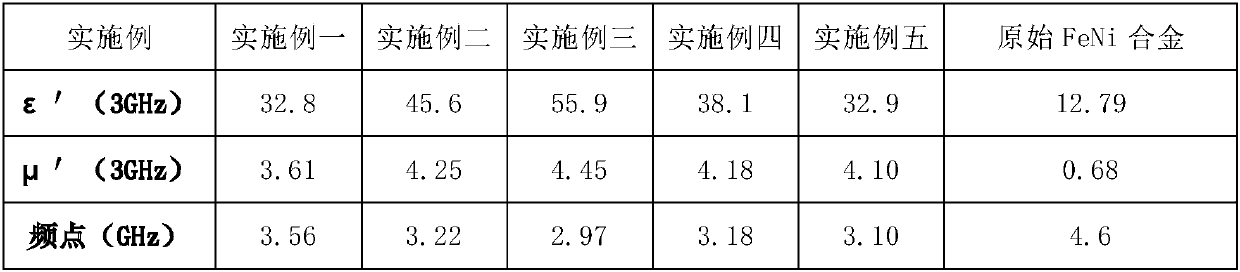

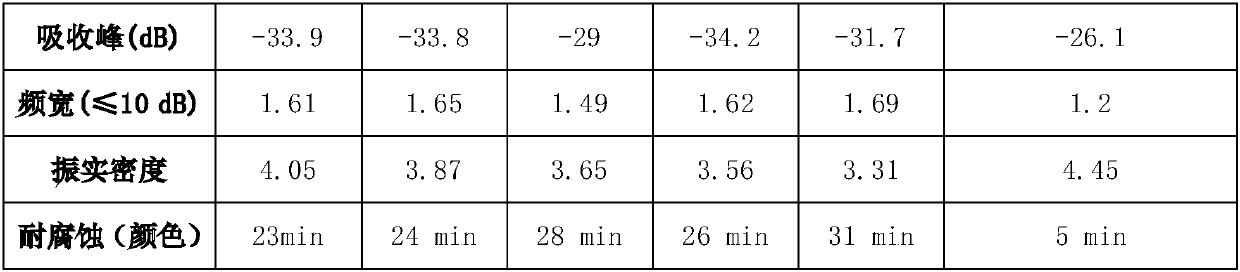

Preparation method of film-coated soft magnetic flaky FeNi alloy

ActiveCN111375756AEasy to useReduce manufacturing costTransportation and packagingMetal-working apparatusAlcoholSilicic acid

The invention provides a preparation method of a film-coated soft magnetic flaky FeNi alloy. The preparation method comprises the following steps that FeNi alloy powder, a surface modifier and absolute ethyl alcohol are put into a ball milling tank for ball milling; after the ball milling is completed, a slurry is taken out and heated and dried, and ball-milled powder of the surface modified FeNialloy is obtained; 10-20 parts of tetraethoxysilane are added into a 200-400ml ethanol solution, and the pH value is adjusted to 8, and a silane treatment solution is obtained; 40-60 parts of ball-milled powder of the surface modified FeNi alloy is added into the silane treatment solution, reaction is carried out for 0.5-5 hours at the water bath temperature of 40-60 DEG C, and the coated flaky FeNi alloy is obtained after cleaning and drying are finished. The manufacturing cost is low, the process is simple, and different comprehensive performance requirements in various industrial fields such as telecommunication, computers and printed circuit boards can be met.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com