Integration Method and Structure of Transformer and Inductor

A technology for transformers and transformer windings, applied in the field of transformers, can solve problems such as affecting efficiency, magnetic loss of common magnetic cores, and inconvenience for producers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

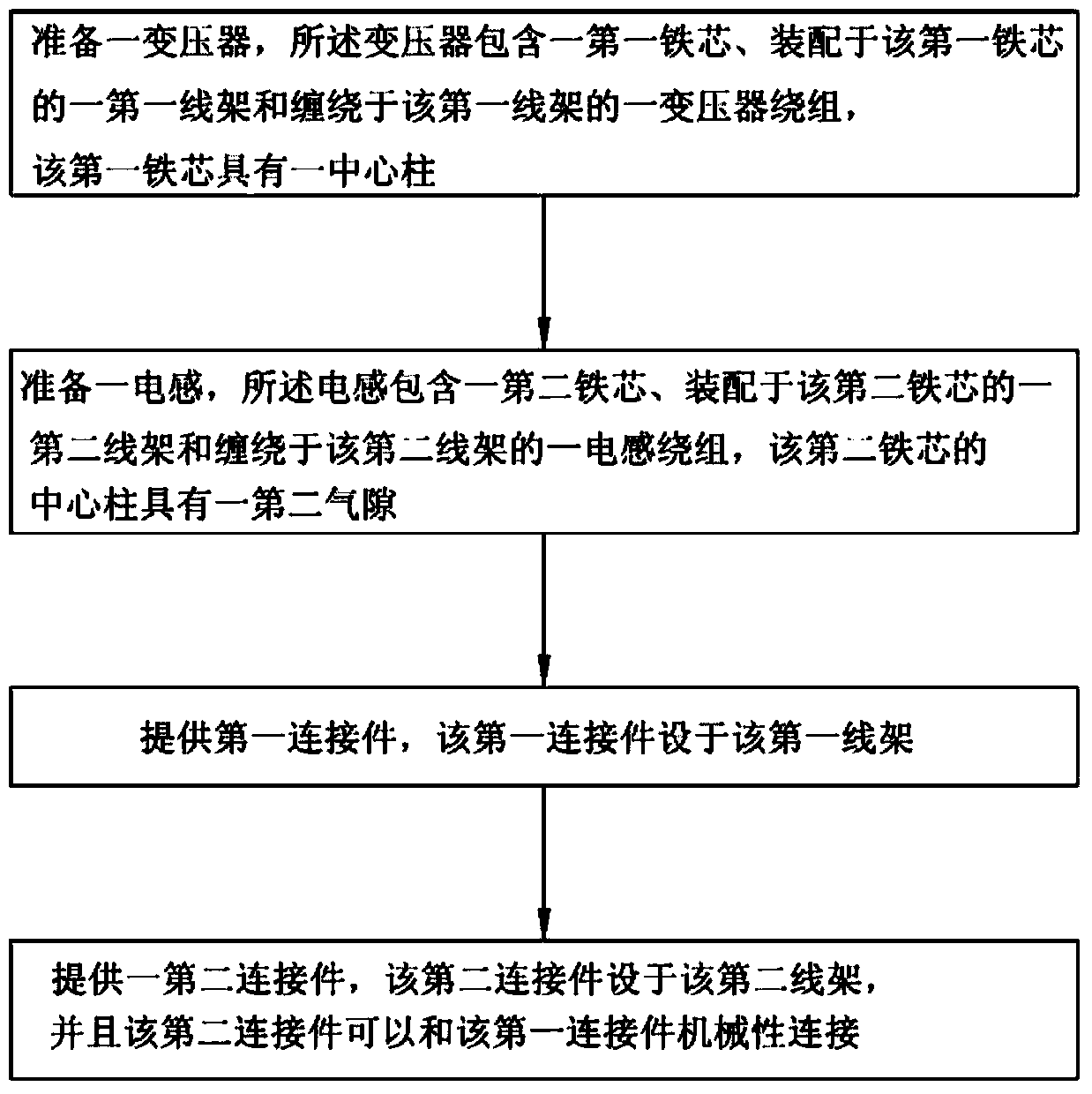

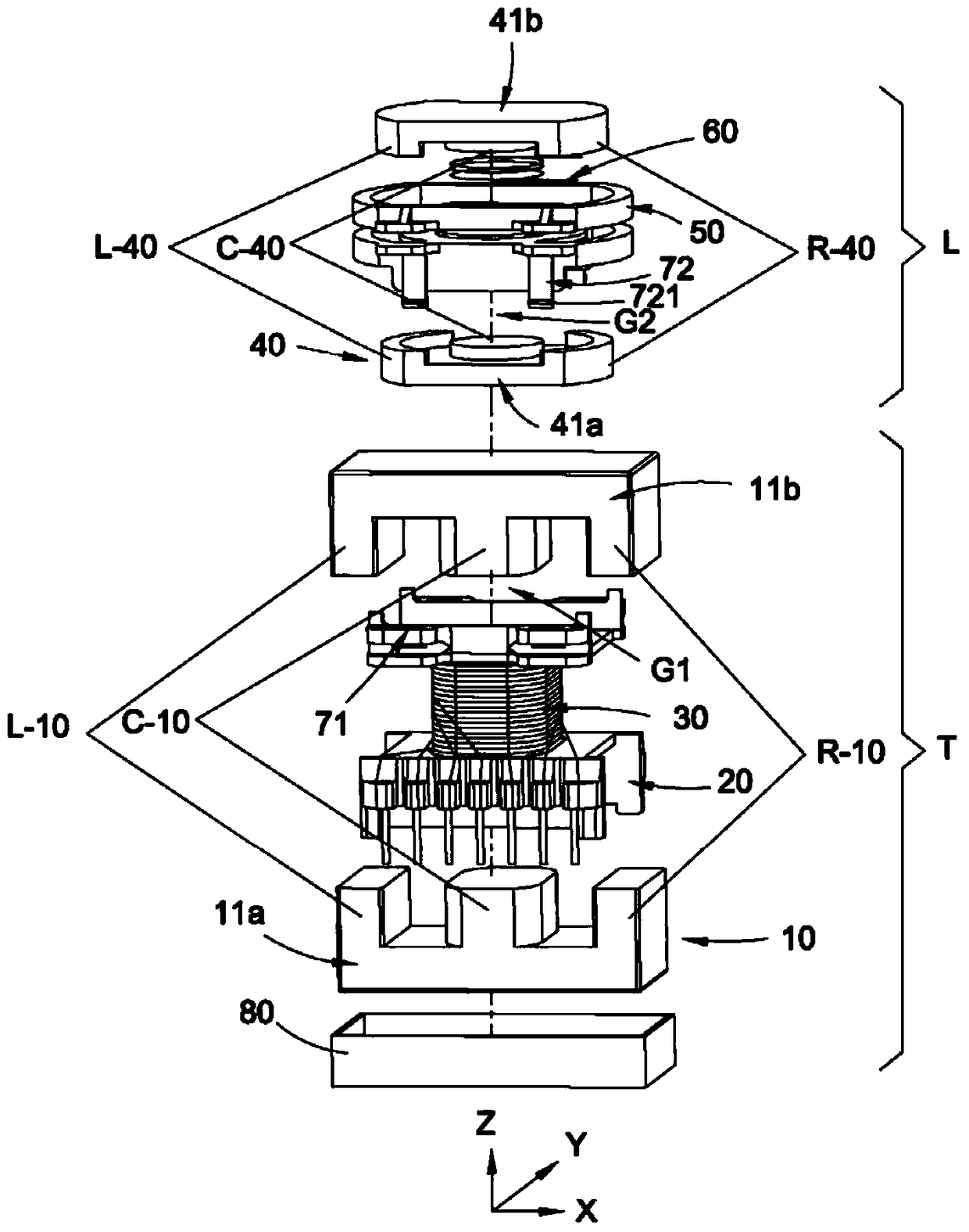

[0052] See first Figure 1 to Figure 4 It is a flow chart of the steps of an embodiment of the method for integrating transformers and inductors of the present invention. An embodiment of the method for integrating transformers and inductors proposed by the present invention includes:

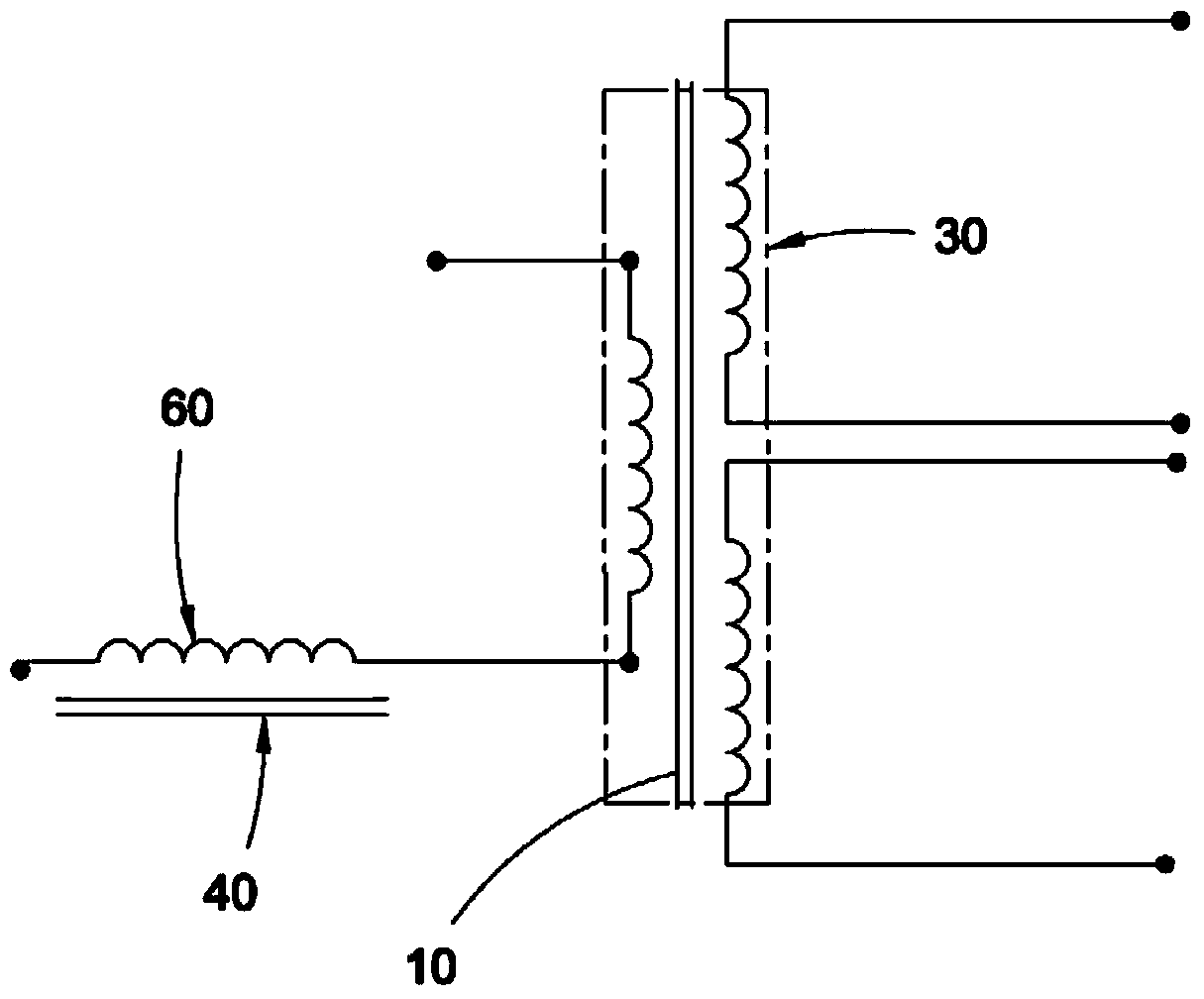

[0053] Prepare a transformer T, the transformer T includes a first iron core 10 (see image 3 structure of an embodiment), a first bobbin 20 assembled on the first iron core 10 and a transformer winding 30 wound on the first bobbin 20, the center column C-10 of the first iron core has a first an air gap G1, or alternatively the central column C-10 of the first core is designed without incorporating an air gap;

[0054] Prepare an inductance L, the inductance L comprises a second iron core 40, a second wire frame 50 assembled on the second iron core 40 and an inductance winding 60 wound on the second wire frame 50, the central column of the second iron core C-40 has a second air gap G2;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com