Composite magnetic powder and chip coil component using same

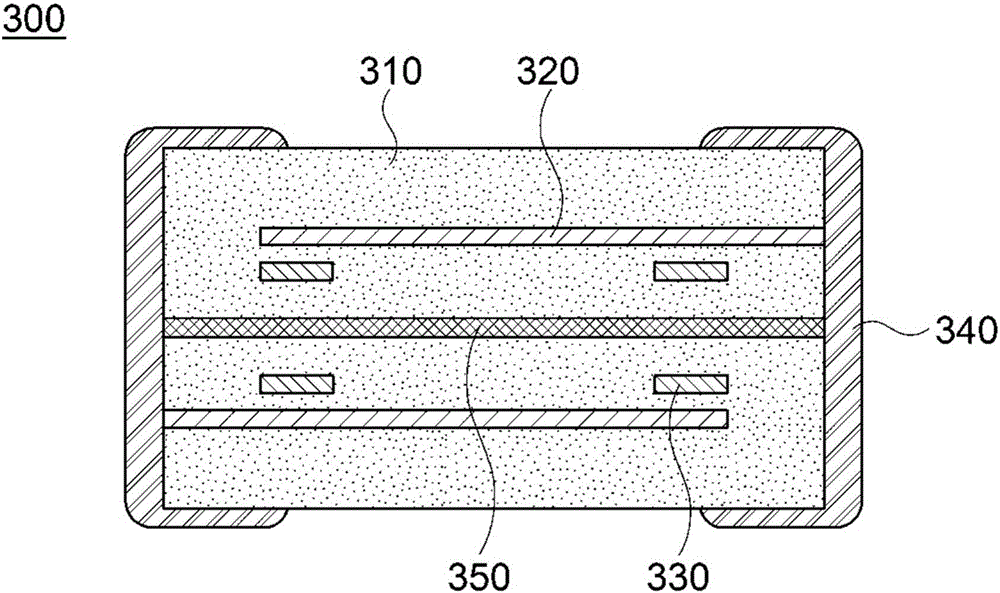

A technology of composite magnetic powder and coil components, which is applied in the direction of loop antennas with ferromagnetic material cores, magnetic materials, magnetic objects, etc., can solve problems such as parasitic capacitance degradation, reduce magnetic permeability loss, increase magnetic The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

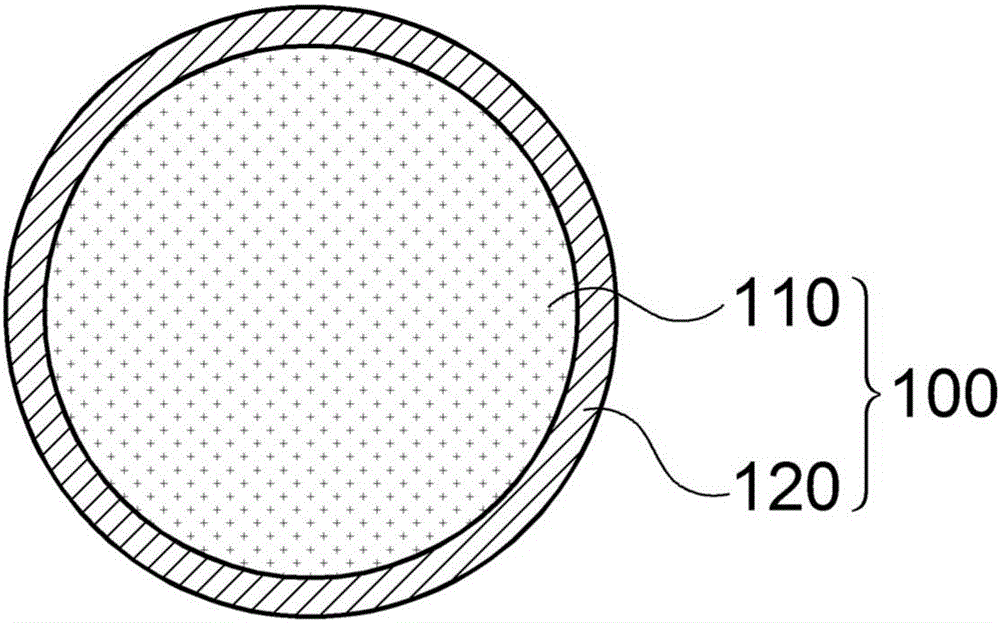

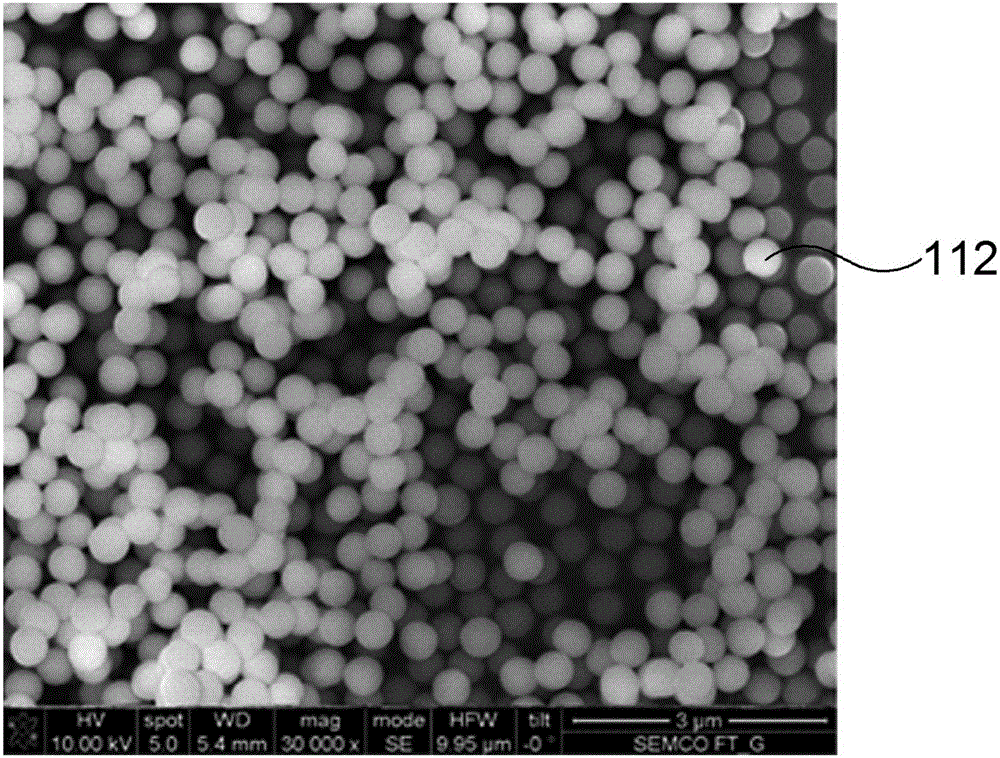

[0102] To manufacture a sample for measurement, 3 g of composite magnetic powder (SiO 2 -BaFe 12 o 19 ) was mixed with 0.3 g of epoxy adhesive, dried in an oven maintained at a temperature of 150° C., and manufactured in a standard ring shape suitable for network analyzer measurement.

[0103] At this time, the composite magnetic powder (SiO 2 -BaFe 12 o 19 ); the ferrite powder (BaFe 12 o 19 ) coated on SiO with a thickness of 50nm 2 on the surface of the powder.

Embodiment 2

[0105] It is the same as Example 1 except that the average particle diameter is 400 nm.

Embodiment 3

[0107] Except that the thickness of the ferrite coating is 10nm, the rest is the same as the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com