Preparation method of film-coated soft magnetic flaky FeNi alloy

A soft magnetic and flake technology, applied in the field of FeNi alloy, can solve the problems of lower production cost, high electrical conductivity, poor impedance matching, etc., and achieve the effect of lower production cost, high quality factor and good inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

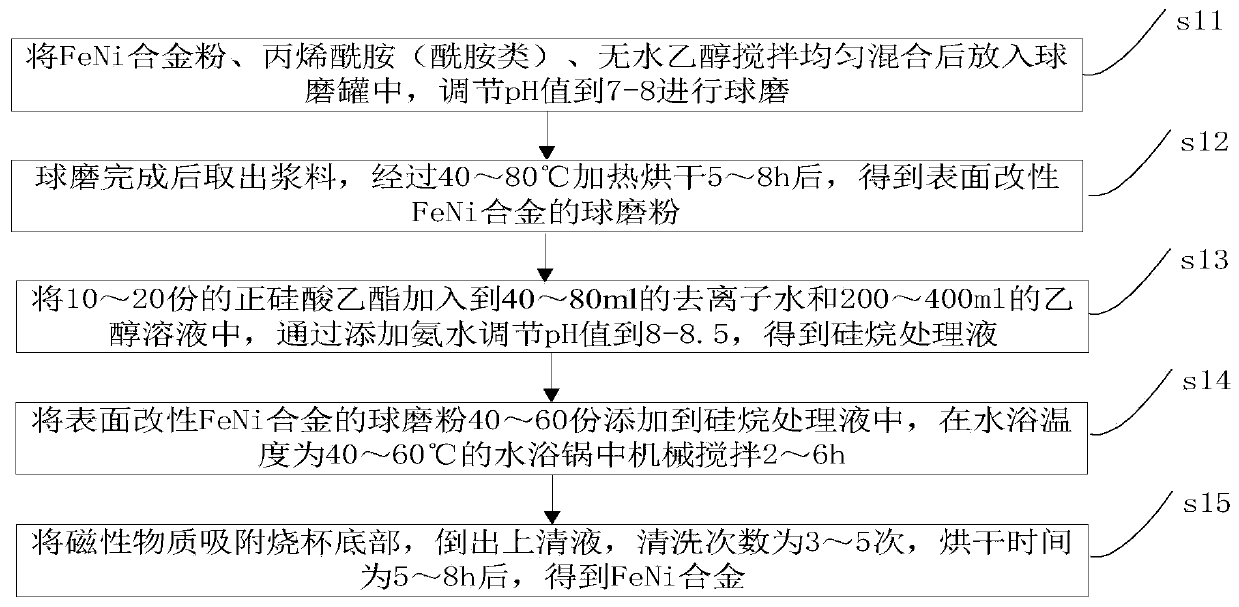

Method used

Image

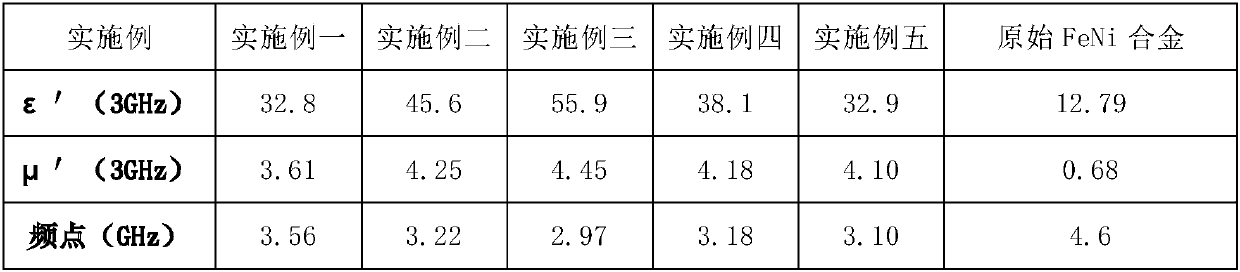

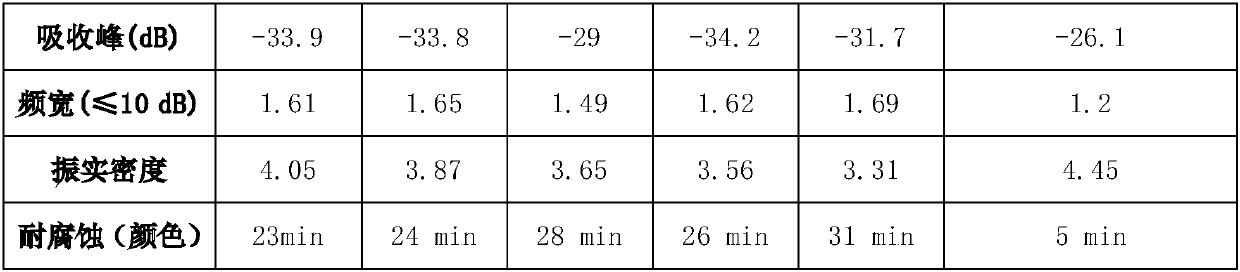

Examples

Embodiment 1

[0024] (1) Stir and mix the purchased FeNi alloy powder, acrylamide (amides), and absolute ethanol evenly and then put them into a ball mill tank for wet milling. Ball mill in a horizontal planetary ball mill with a ball mill speed of 300r / min. For 8h; wherein the content of FeNi alloy powder, acrylamide (amides) and dehydrated alcohol is 200g: 10mL: 800mL respectively, the ball material content of agate beads and FeNi alloy powder is 5: 1, agate beads are made of diameter 10mm, 6mm, 3mm large, medium and small three kinds of agate beads, the mass ratio of the large, medium and small three kinds of agate beads is 2:25:50, and the total weight of the three is 2.5Kg. After the ball milling is completed, the slurry is taken out, heated and dried at 80° C. for 6 hours, and the ball milled powder of the surface-modified FeNi alloy is obtained.

[0025] (2) Add 10 parts of tetraethyl orthosilicate to 40ml of deionized water and 200ml of ethanol solution, then adjust the pH value to ...

Embodiment 2

[0027] (1) Stir and mix the purchased FeNi alloy powder, acrylamide (amides), and absolute ethanol evenly and then put them into a ball mill tank for wet milling. Ball mill in a horizontal planetary ball mill with a ball mill speed of 50r / min. It is 10h; Wherein the content of FeNi alloy powder, acrylamide (amides) and dehydrated alcohol is 300g: 15mL: 900mL respectively, the spherical material content of agate bead and FeNi alloy powder is 6: 1, and agate bead is made of diameter 10mm, 6mm, 3mm large, medium and small three kinds of agate beads, the mass ratio of the large, medium and small three kinds of agate beads is 4:30:50, and the total weight of the three is 2.5Kg. After the ball milling is completed, the slurry is taken out, heated and dried at 80° C. for 6 hours, and the ball milled powder of the surface-modified FeNi alloy is obtained.

[0028] (2) Add 10 parts of tetraethyl orthosilicate to 40ml of deionized water and 200ml of ethanol solution, then adjust the pH v...

Embodiment 3

[0030](1) Stir and mix the purchased FeNi alloy powder, acrylamide (amides), and absolute ethanol evenly and then put them into a ball mill tank for wet milling. Ball mill in a horizontal planetary ball mill with a ball mill speed of 450r / min. 12h; the contents of FeNi alloy powder, acrylamide (amides) and absolute ethanol are respectively 600g: 20mL: 1000mL, and the pH value is adjusted to 8. The ball material content of agate beads and FeNi alloy powder is 8:1. The agate beads are composed of three types of agate beads with diameters of 10mm, 6mm, and 3mm. The mass ratio of the large, medium, and small agate beads is 5: 40:70, the total weight of the three is 2.5Kg. After the ball milling is completed, the slurry is taken out, heated and dried at 80° C. for 6 hours, and the ball milled powder of the surface-modified FeNi alloy is obtained.

[0031] (2) Add 10 parts of tetraethyl orthosilicate to 60ml of deionized water and 300ml of ethanol solution, then adjust the pH value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com