Laminated coil component

A technology of stacking coils and devices, applied in coil manufacturing, transformer/inductor components, inductors, etc., can solve the problems of inner conductor layer thickness, inner conductor layer disconnection, and outer electrode peeling, etc., to achieve less characteristic deviation, The effect of preventing disconnection and high impedance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

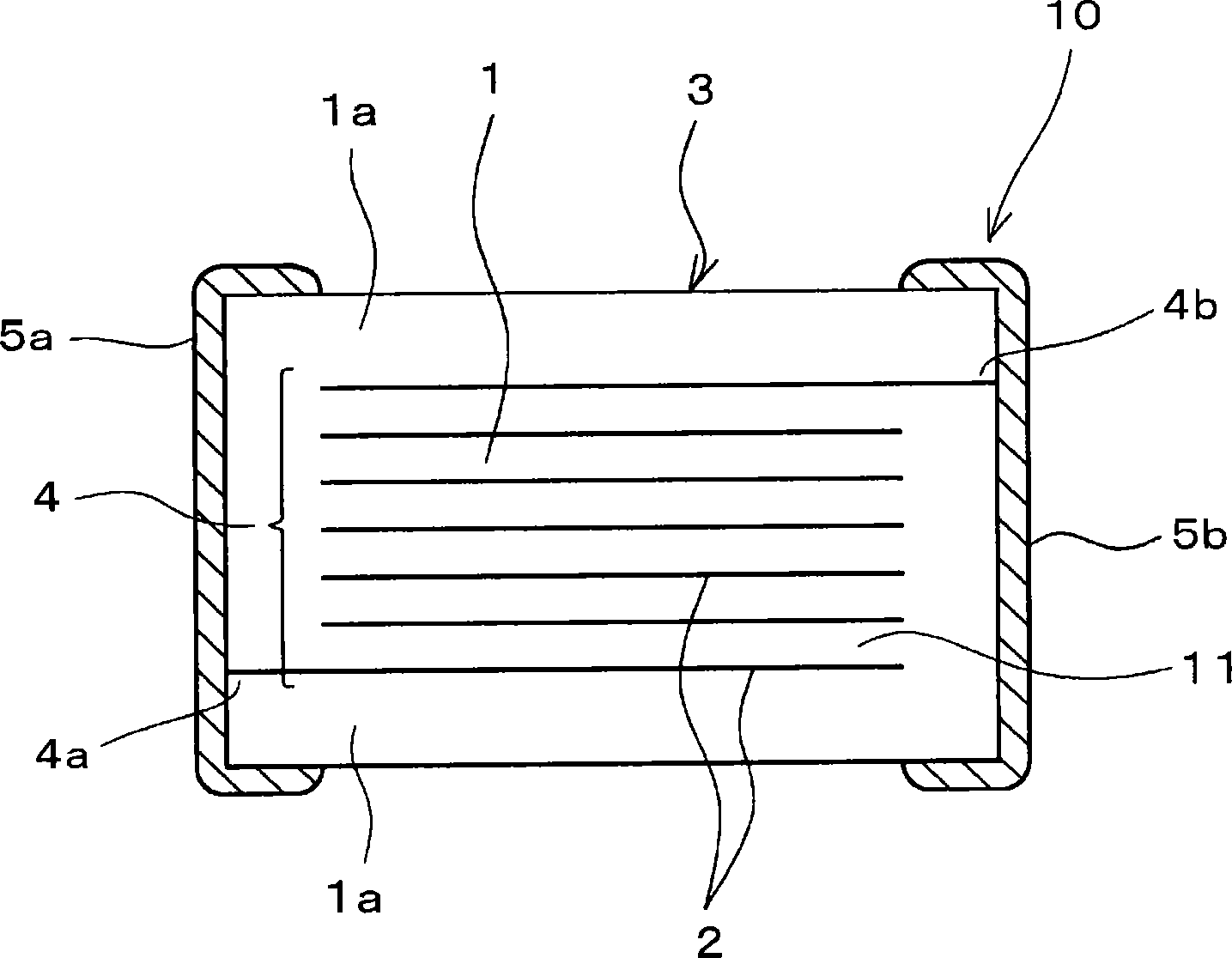

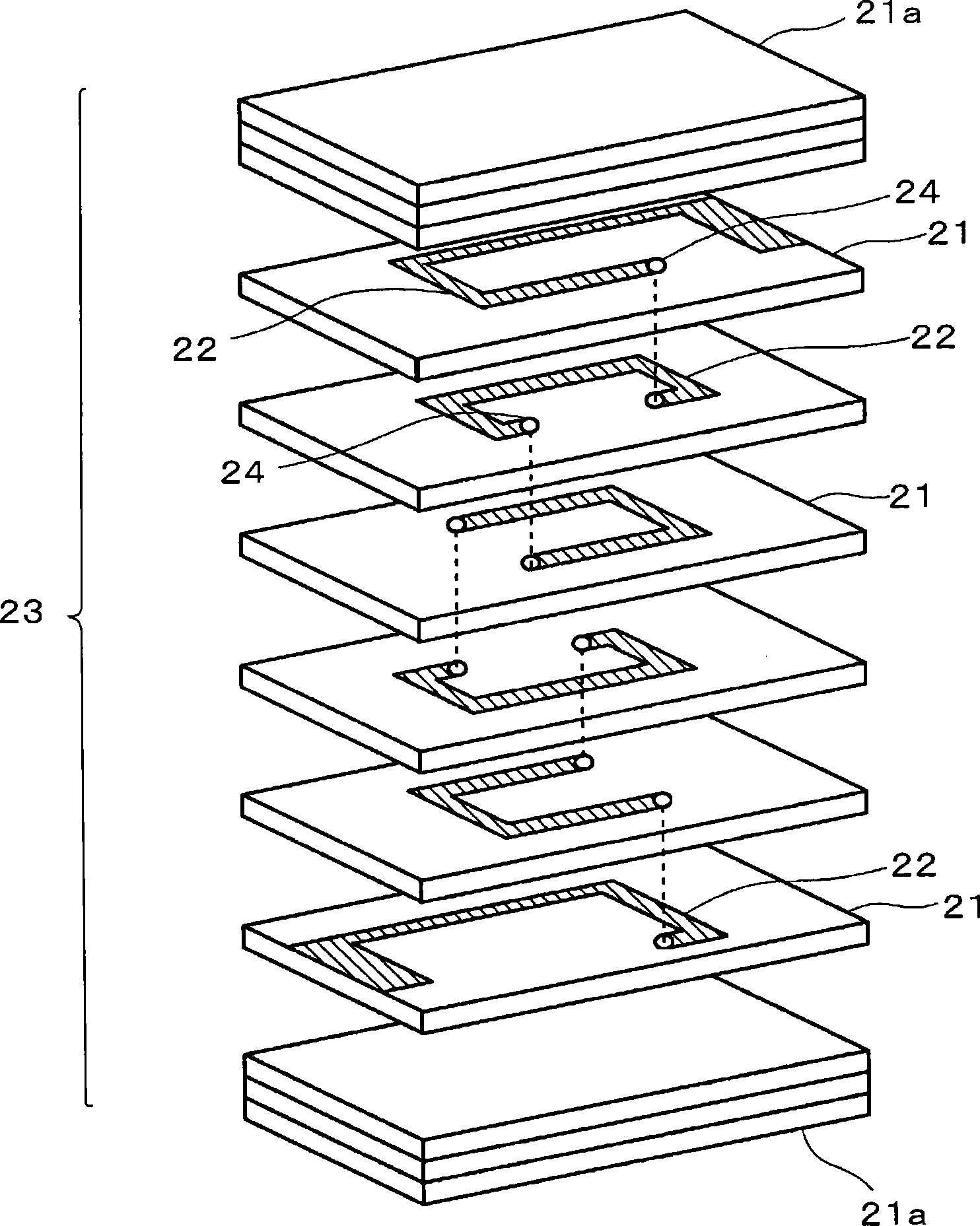

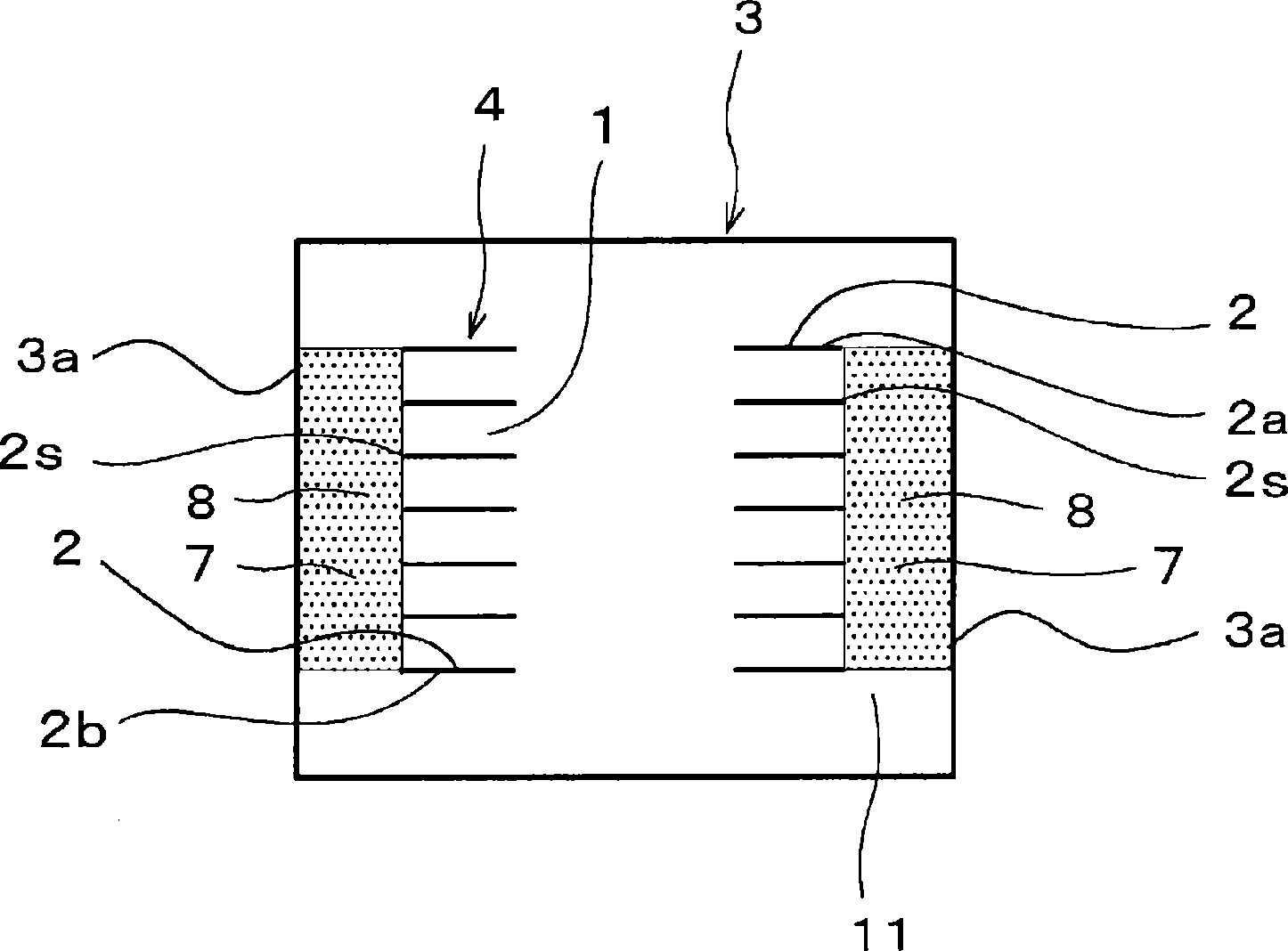

[0070] figure 1 It is a front cross-sectional view showing the structure of a laminated coil device (in this embodiment 1, a laminated impedance element) according to an embodiment (Example 1) of the present invention, figure 2 is an exploded perspective view showing its manufacturing method, image 3 yes figure 1 Side cross-sectional view of the structure of a laminated coil device.

[0071] Such as Figure 1 ~ Figure 3 As shown, this laminated coil device 10 is manufactured through the process of firing a laminate obtained by laminating a ferrite layer 1 and a coil-forming internal conductor 2 mainly composed of Ag. The element 3 is provided with a helical coil 4 inside.

[0072] In addition, a pair of external electrodes 5 a , 5 b are arranged at both end portions of the ferrite element 3 so as to conduct with both end portions 4 a , 4 b of the helical coil 4 .

[0073] In addition, in this laminated coil device 10, there is no gap at the interface between the interna...

Embodiment 2

[0154] In addition to using a 0.2 mol / L aqueous solution of gluconolactone (manufactured by Nacalai Tesque), to replace the complexing agent solution (citric acid-hydrate 0.2 mol / L aqueous solution), to immerse the laminated impedance element (sample) in the gluconolactone 0.2mol / L aqueous solution for 3, 6, 12, 24 hours, except for stress relaxation treatment, all use the above-mentioned implementation In the same manner as in Example 1, a laminated impedance element (sample) was fabricated.

[0155] In addition, in this example, although 0.2 mol / L aqueous solution of gluconolactone was used as the complexing agent solution, the concentration is not limited thereto, and it can be set to an appropriate concentration in consideration of various conditions. In addition, it is not limited to water solubility, and a solution obtained by dissolving a complexing agent in a solvent other than water can also be used.

[0156] Next, for the manufactured multilayer impedance element, the...

Embodiment 3

[0164] In order to investigate the effect of the pore area ratio of the side gap on the stress relaxation effect, the firing temperature of (6) in Example 1 was changed in the range of 840-900°C, so that the pore area ratio of the side gap was produced 26-3% laminated impedance element (sample), and use citric acid-hydrate 0.2mol / L aqueous solution as a complexing agent solution for stress relaxation treatment. In addition, in other respects, the same method and conditions as in Example 1 above were set.

[0165] Next, the Cu segregation rate, impedance (|Z| at 100 MHz), flexural strength, and pore area ratio of the side gap were examined in the same manner as in Example 1 above.

[0166] The results are shown in Table 4.

[0167] [Table 4]

[0168]

[0169] As shown in Table 4, it has been confirmed that when the sample is sintered at 855-885°C, the pore area ratio of the side gap is in the range of 6-20%, and the Cu segregation rate is 5% or less (1.5-1.8% ), it is pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com