Patents

Literature

150results about How to "Suppress disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device

InactiveUS7795619B2Inhibit deteriorationPrevent short-circuitingSemiconductor/solid-state device detailsSolid-state devicesTransistorPhysics

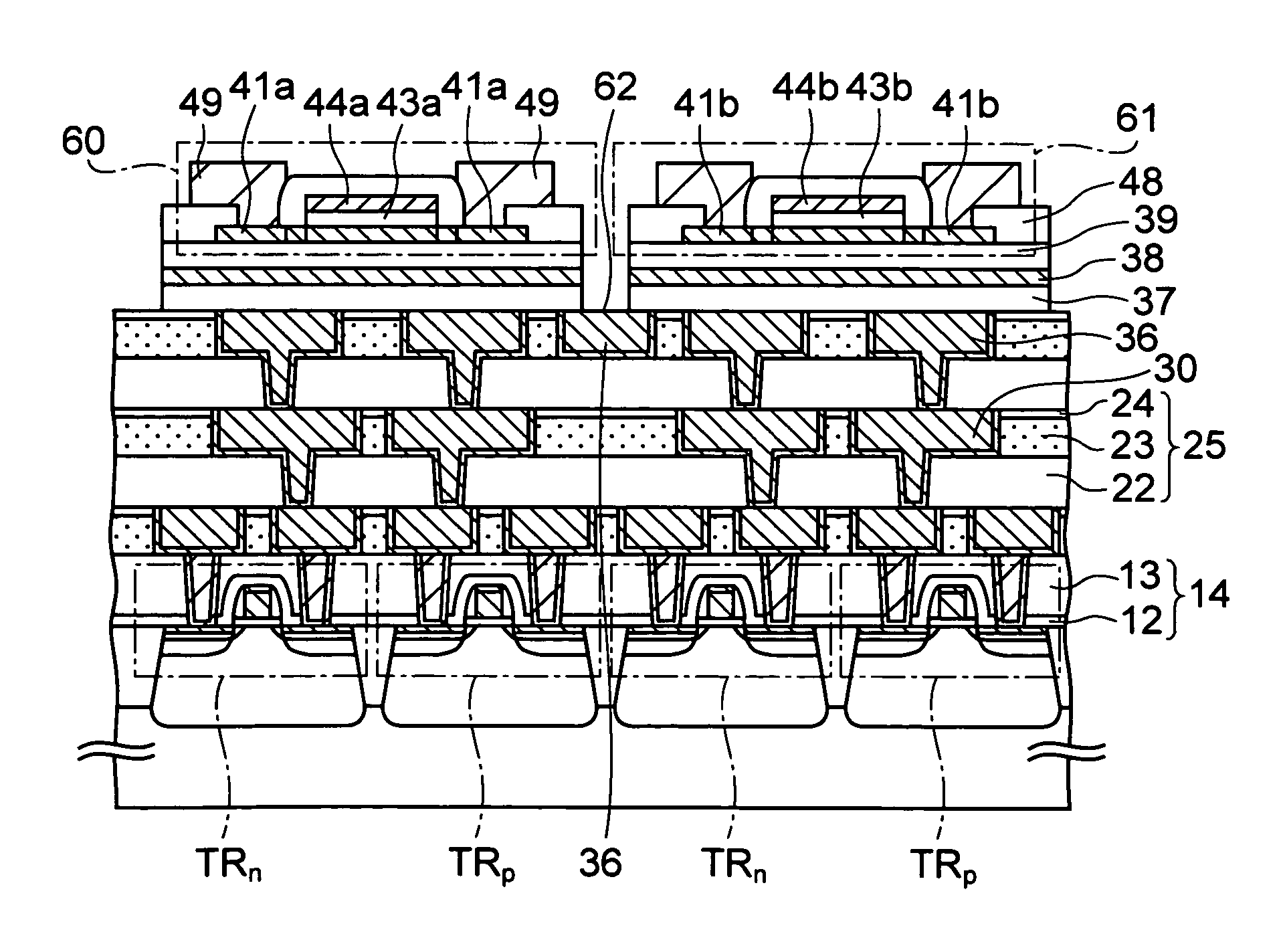

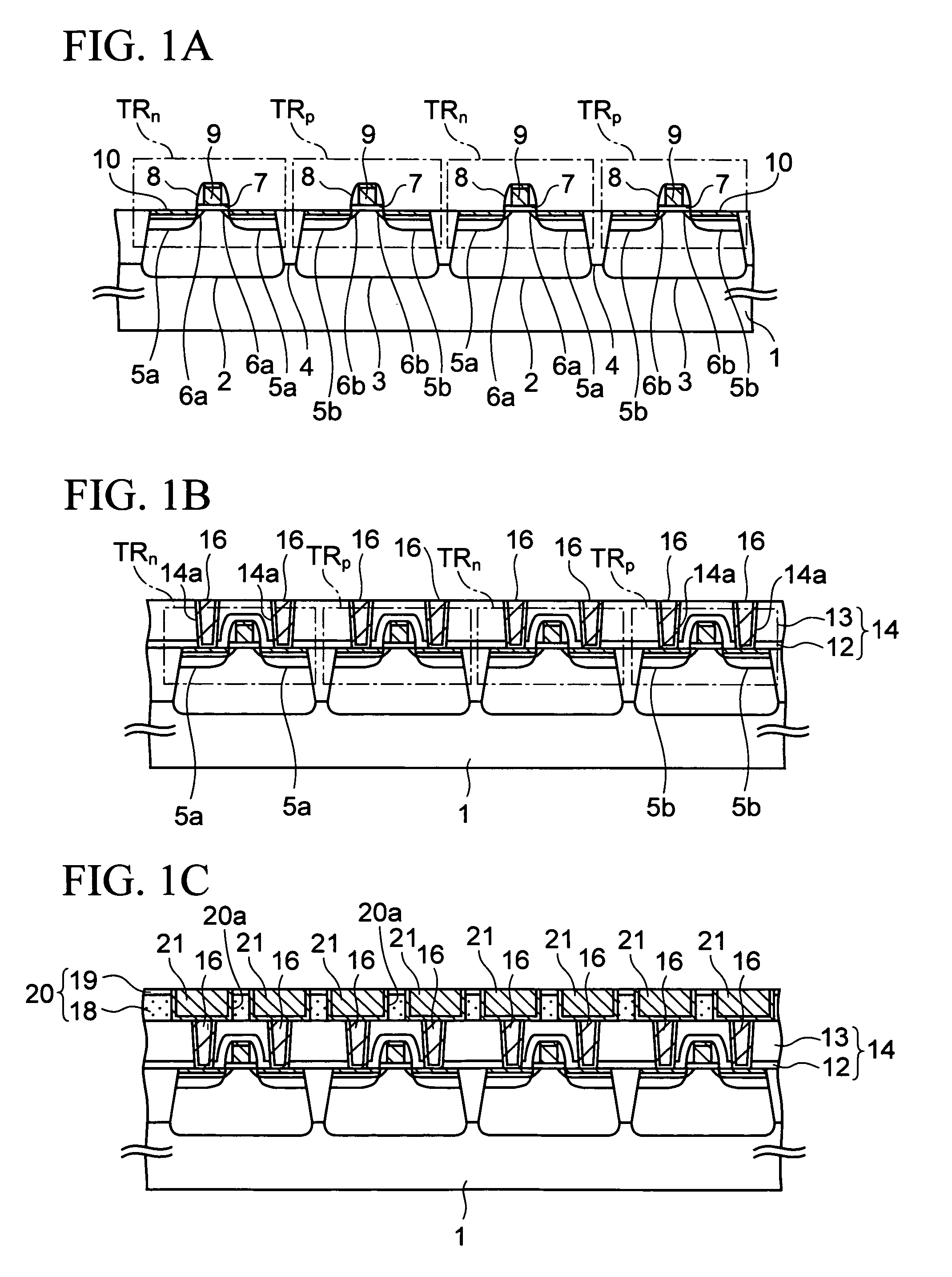

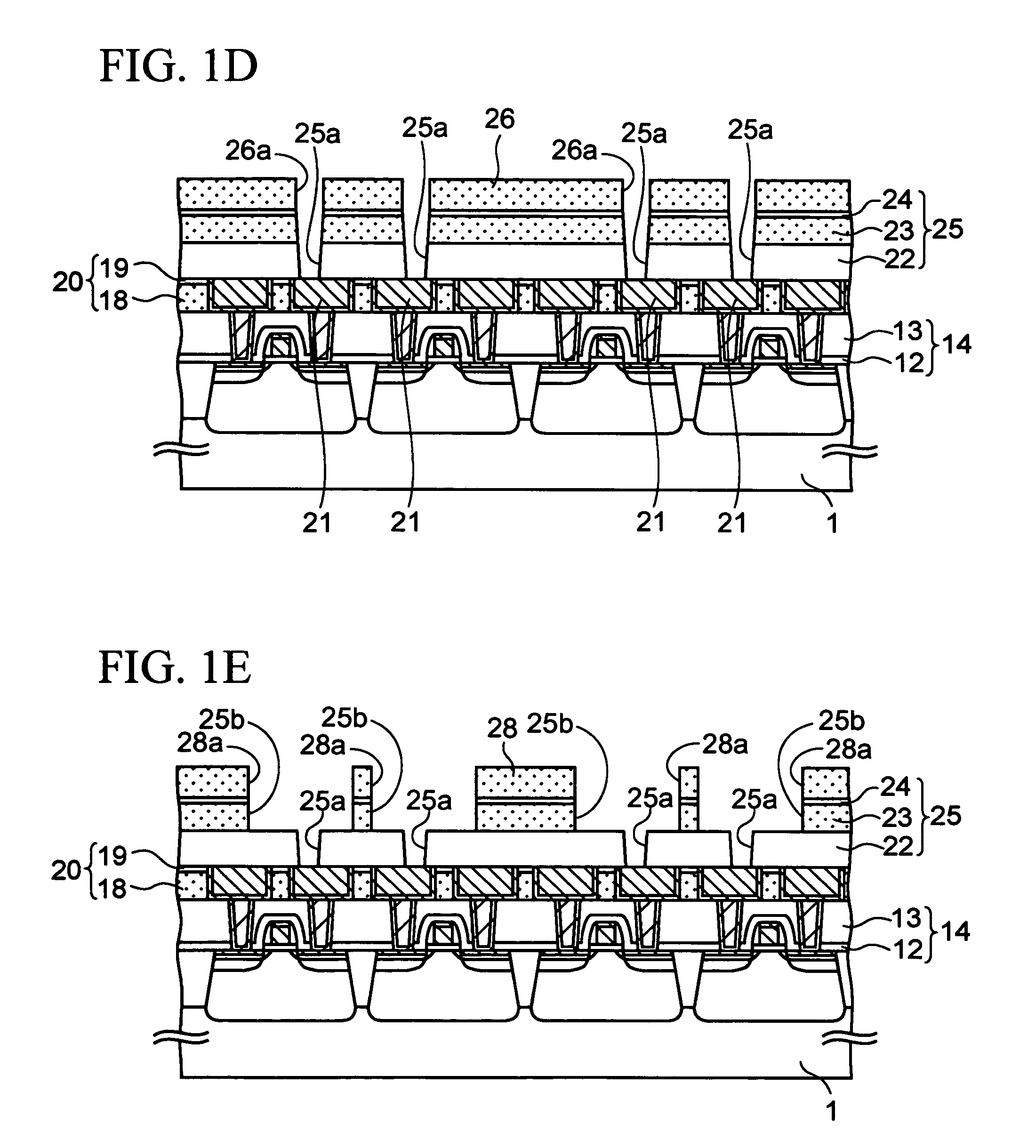

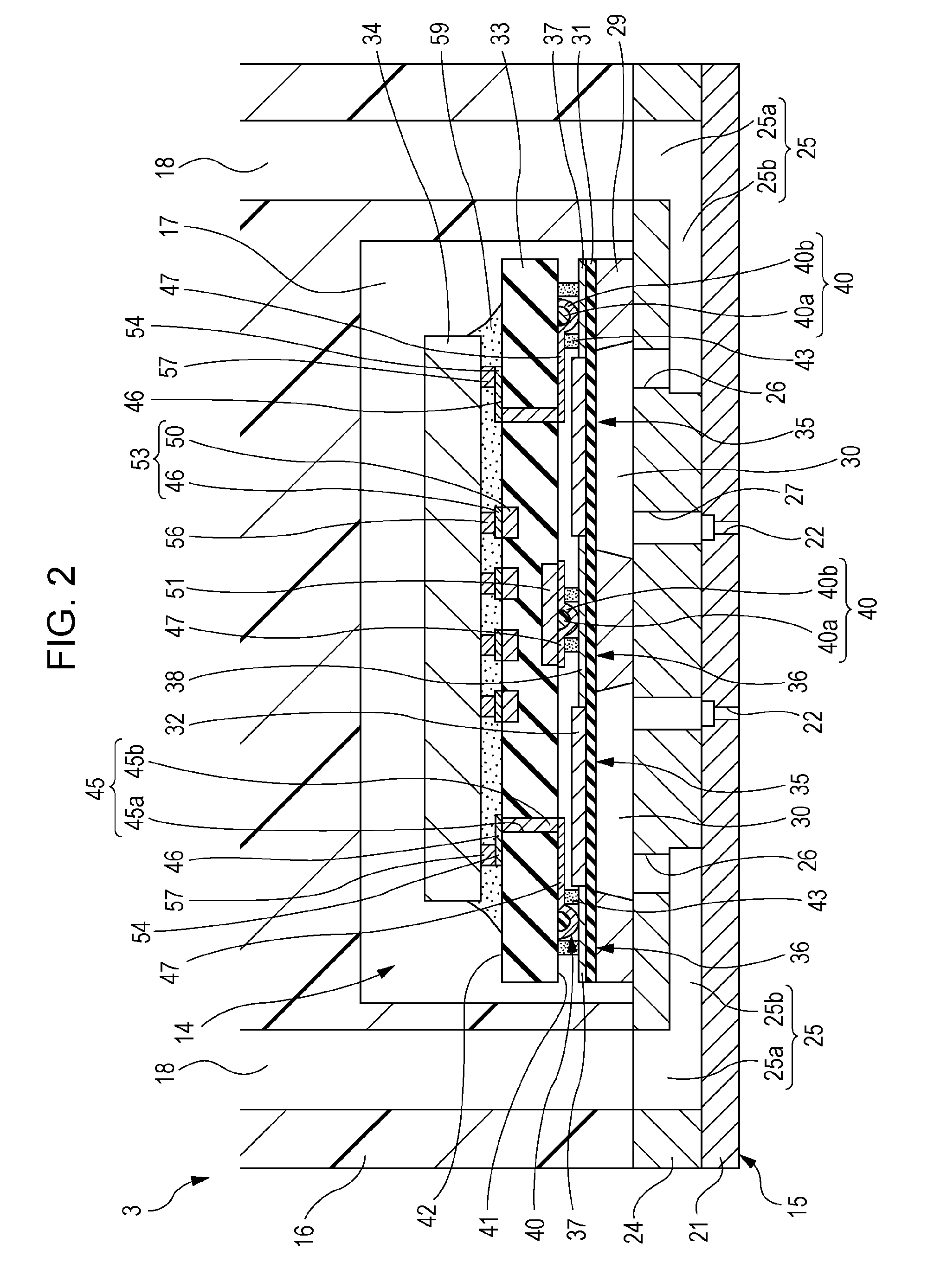

A method for manufacturing a semiconductor device, including the steps of: forming a shielding film 38 on a first insulating film 37; sequentially forming a second insulating film 39 and an amorphous semiconductor film 40 on the shielding film 38; melting the amorphous semiconductor film 40 at least in portions to be channels of thin-film transistors by irradiating an energy beam onto the amorphous semiconductor film 40, and converting the amorphous semiconductor film 40 into a polycrystalline semiconductor film 41; sequentially forming a gate insulating film 43a and a gate electrode 44a on the polycrystalline semiconductor film 41 on the channels; and forming source and drain regions 41a in the polycrystalline semiconductor film 41 on sides of the gate electrode 44a, and forming a TFT 60 by use of the source and drain regions 41a, the gate insulating film 43a, and the gate electrode 44a.

Owner:FUJITSU SEMICON LTD

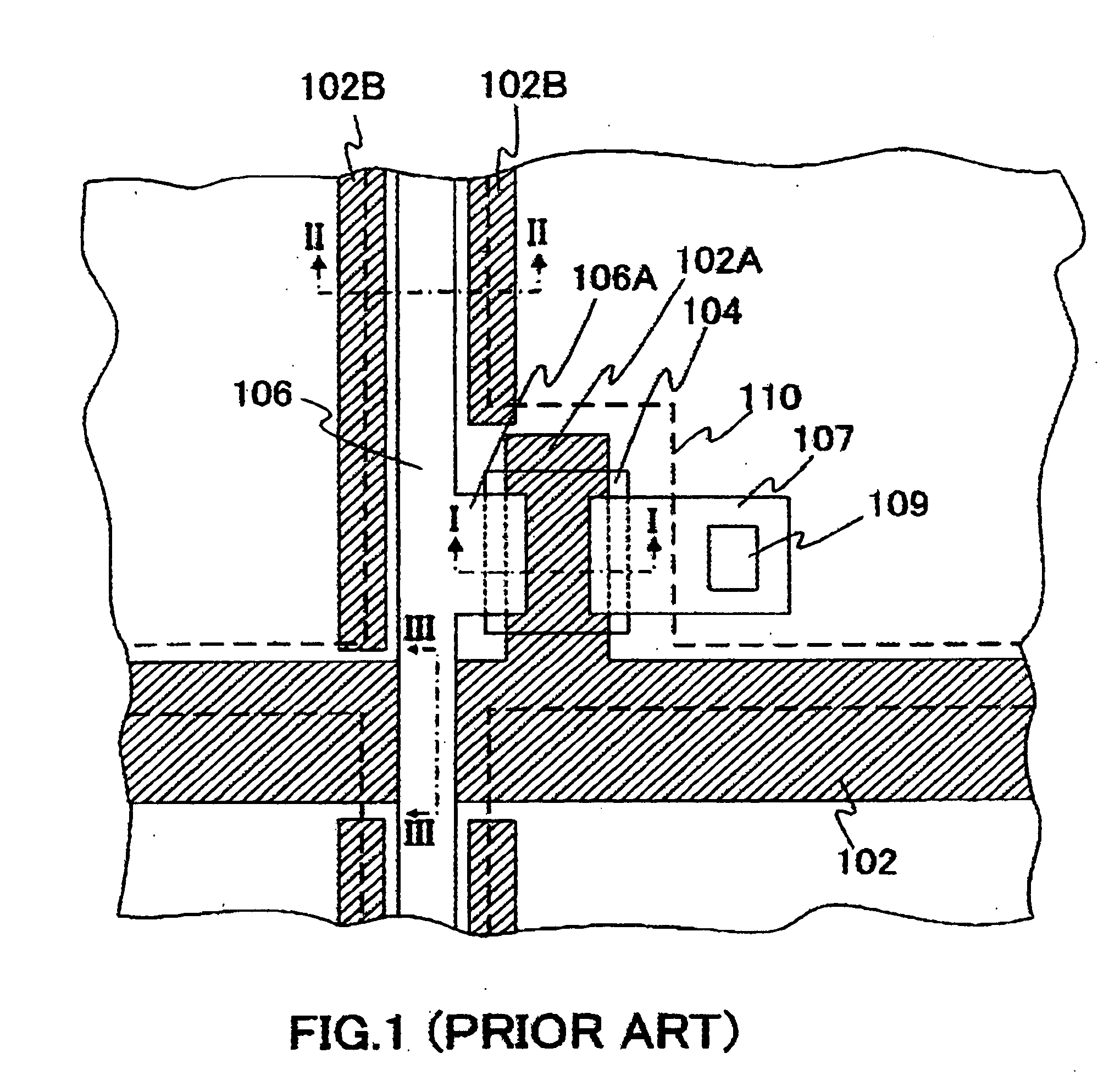

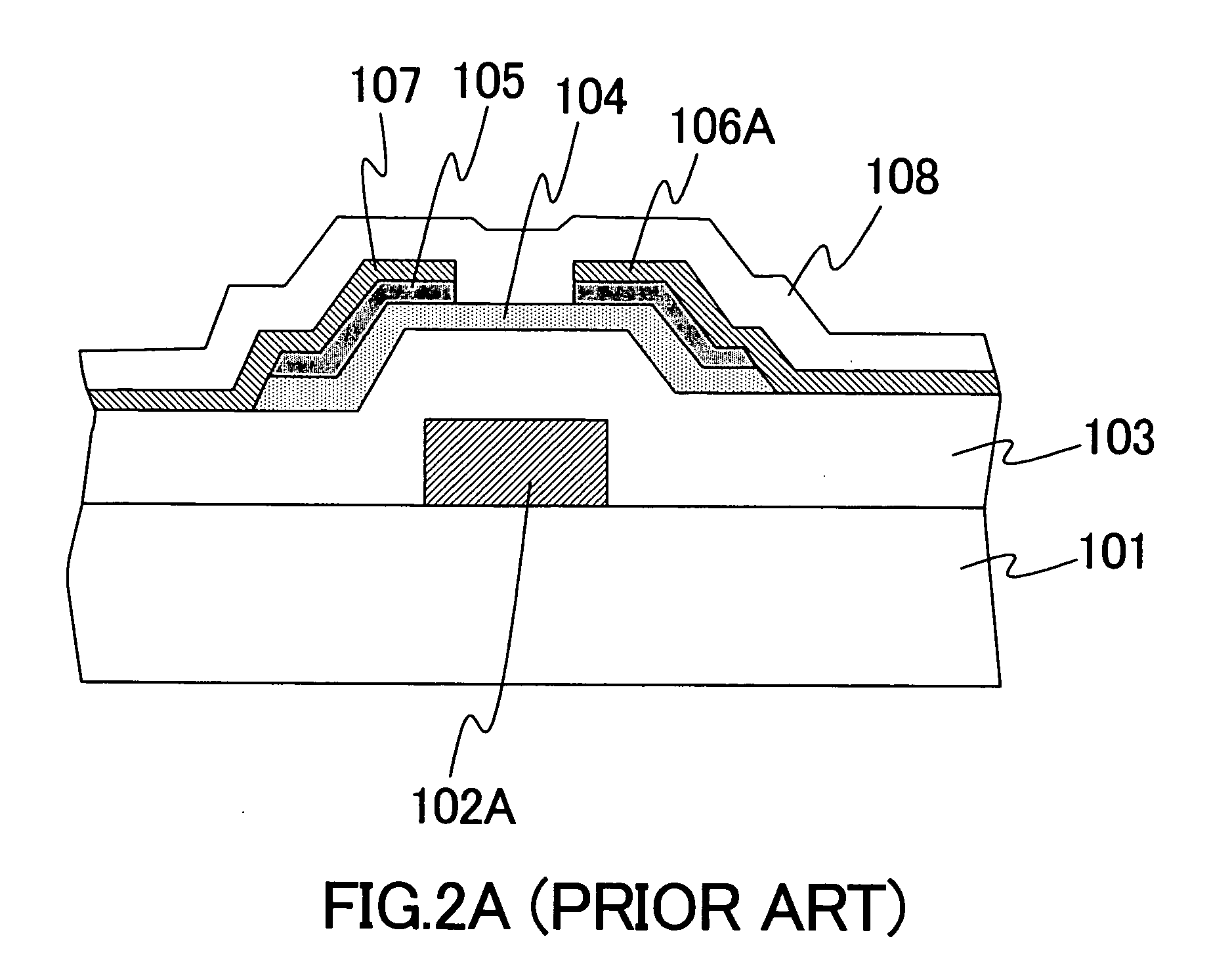

Liquid crystal display device and manufacturing method of the same

InactiveUS20060209222A1Small sizeHigh densitySolid-state devicesNon-linear opticsHigh densityLiquid-crystal display

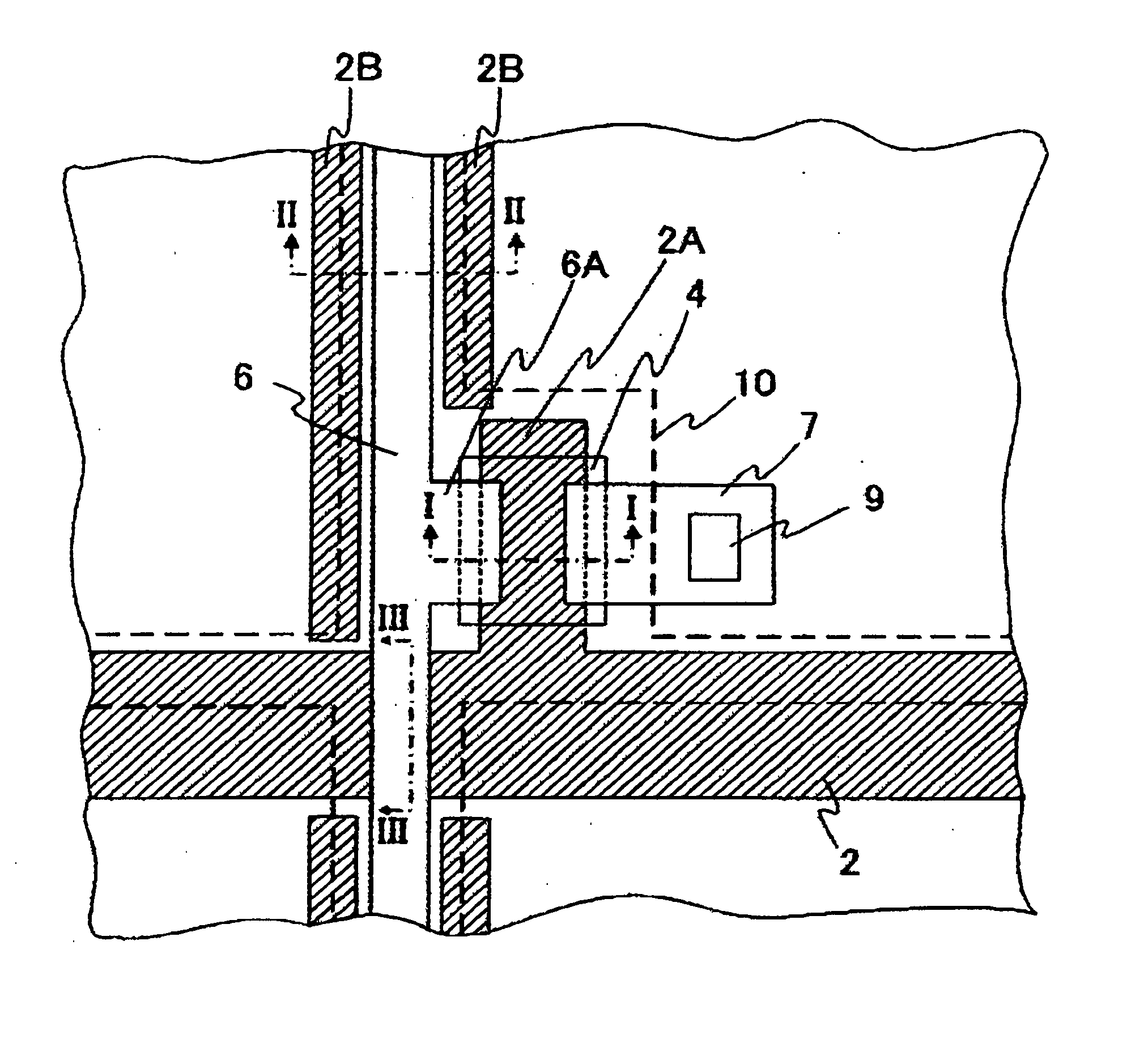

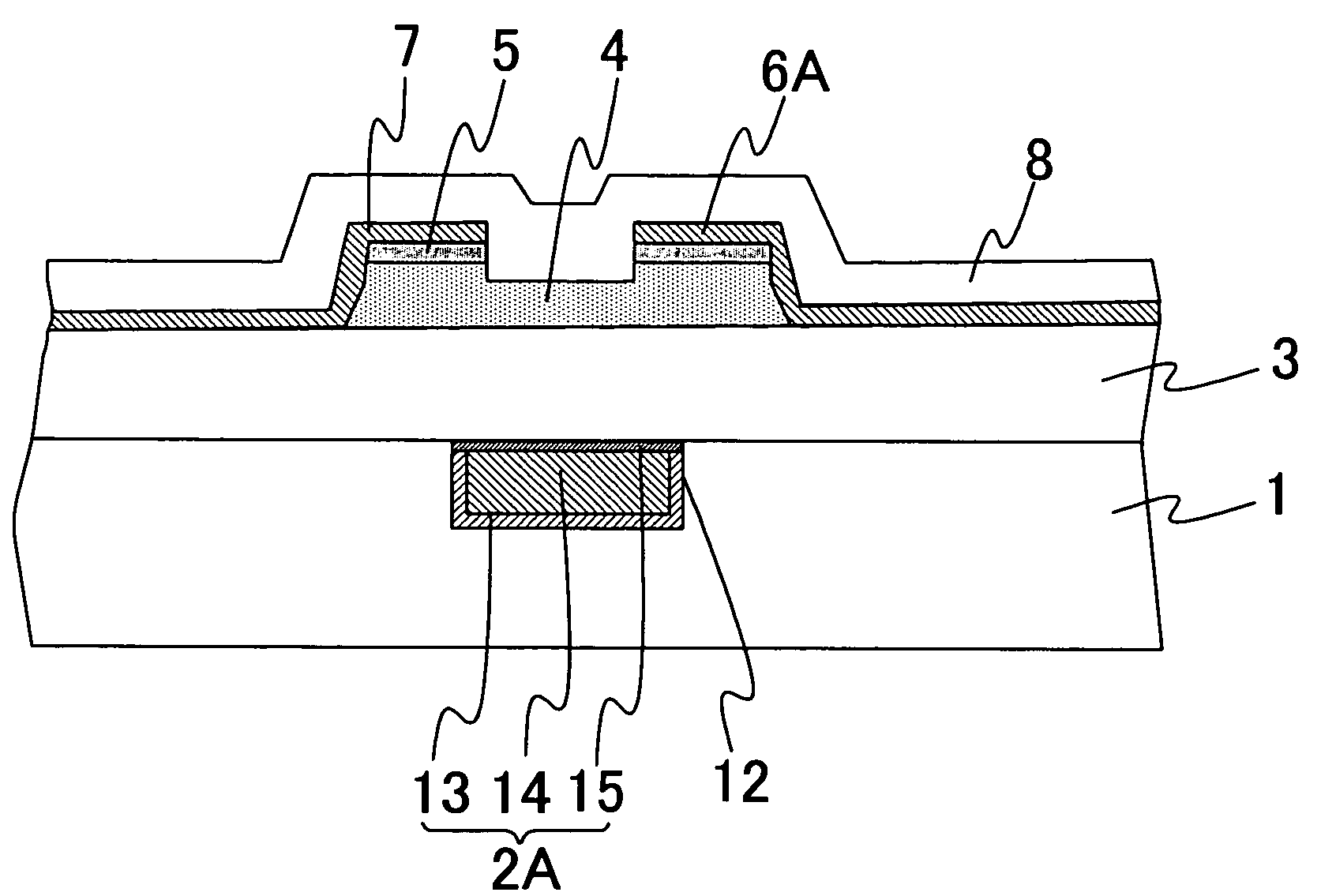

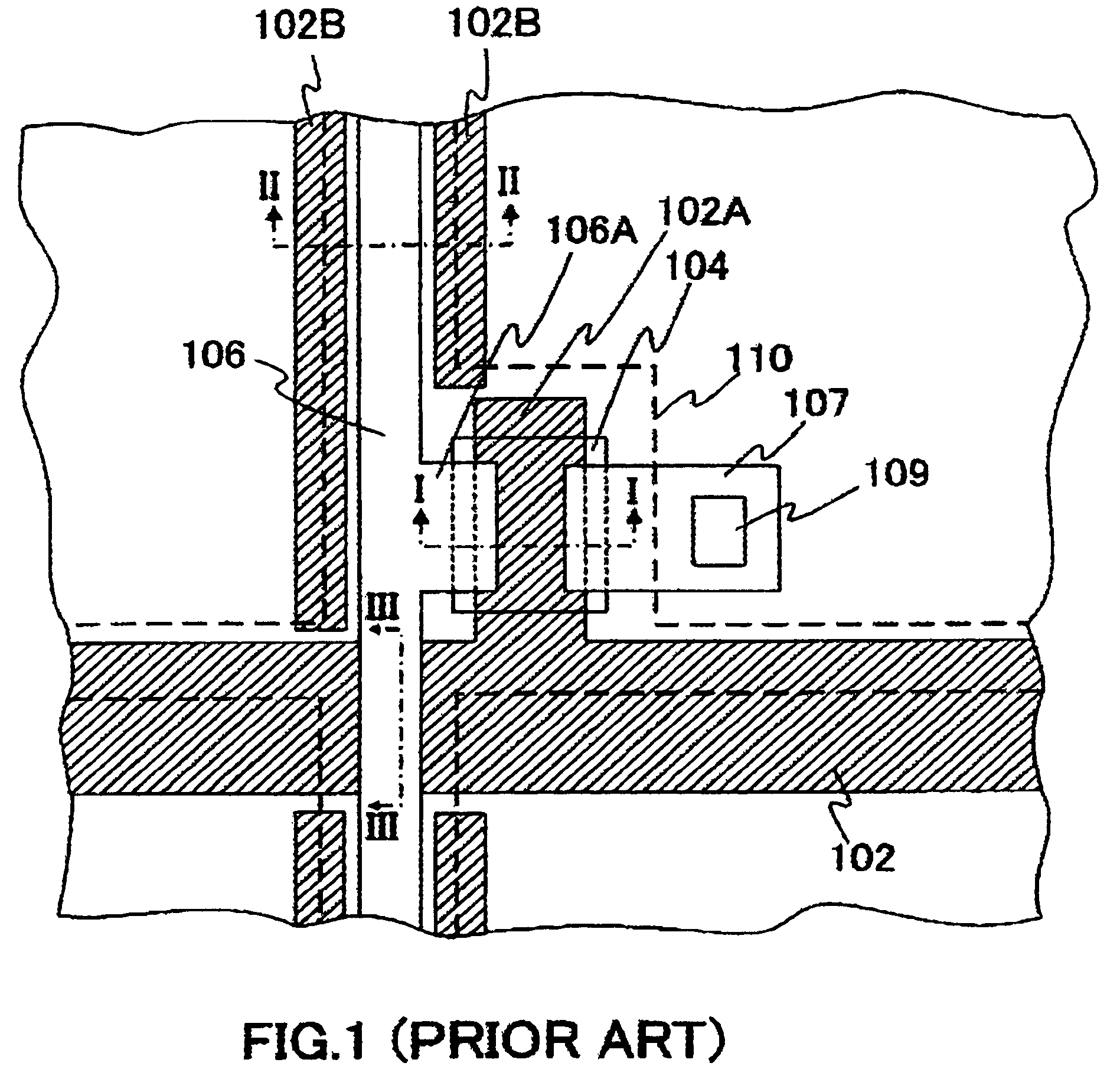

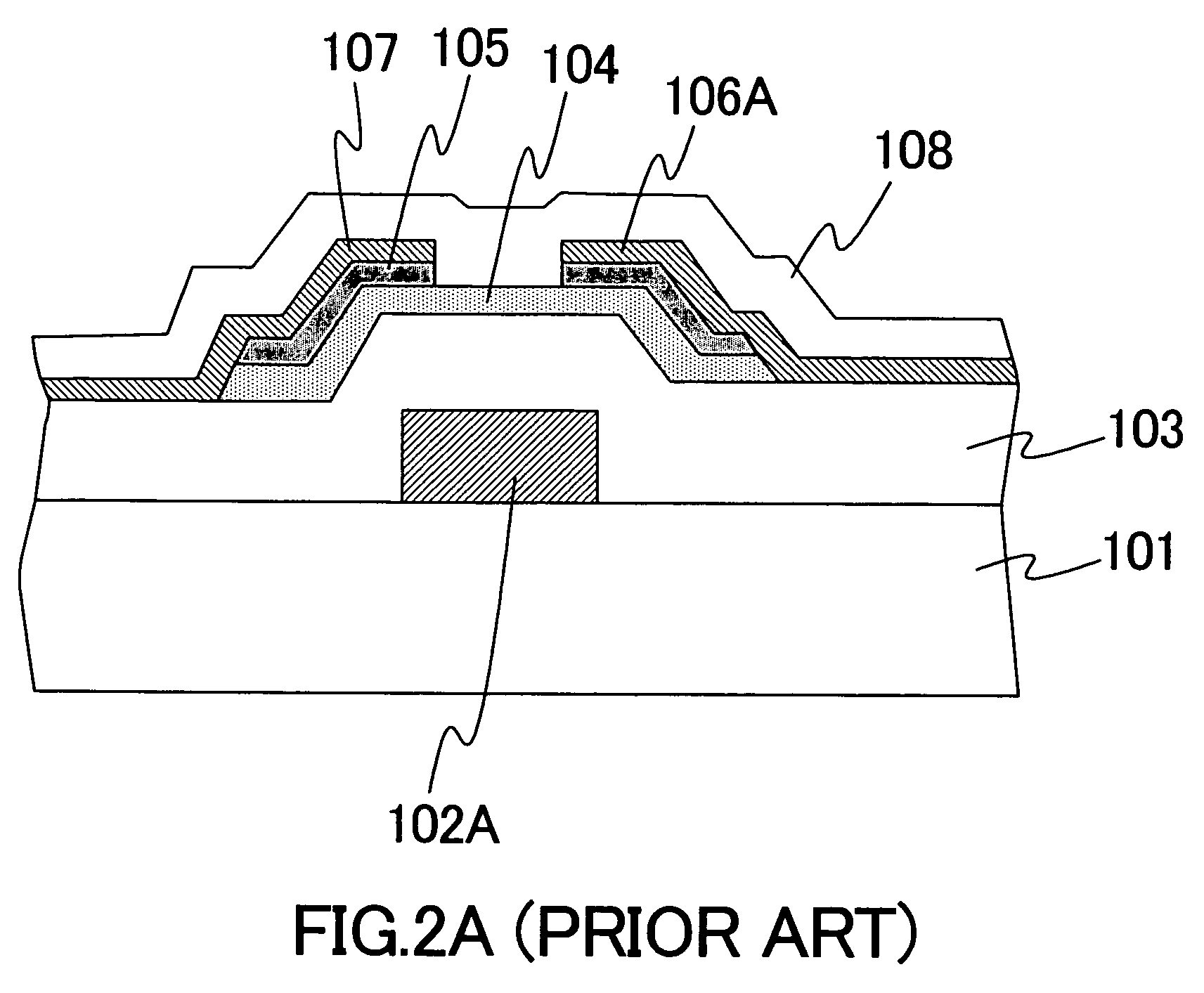

An active matrix substrate or TFT substrate is provided with a lower layer wiring with a groove wiring structure covering surroundings of a copper layer with a barrier metal film is formed by forming a groove at an insulating substrate and depositing the barrier metal film and the copper layer in this groove. This groove wiring structure is used for a TFT substrate of a liquid crystal display (LCD) device. It is possible to manufacture an LCD device with large size, high density, a large aperture ratio and in which the disclination defects originating from a different in level of the lower layer wiring and an occurrence of disconnection failures in an upper layer wiring are suppressed.

Owner:VISTA PEAK VENTURES LLC

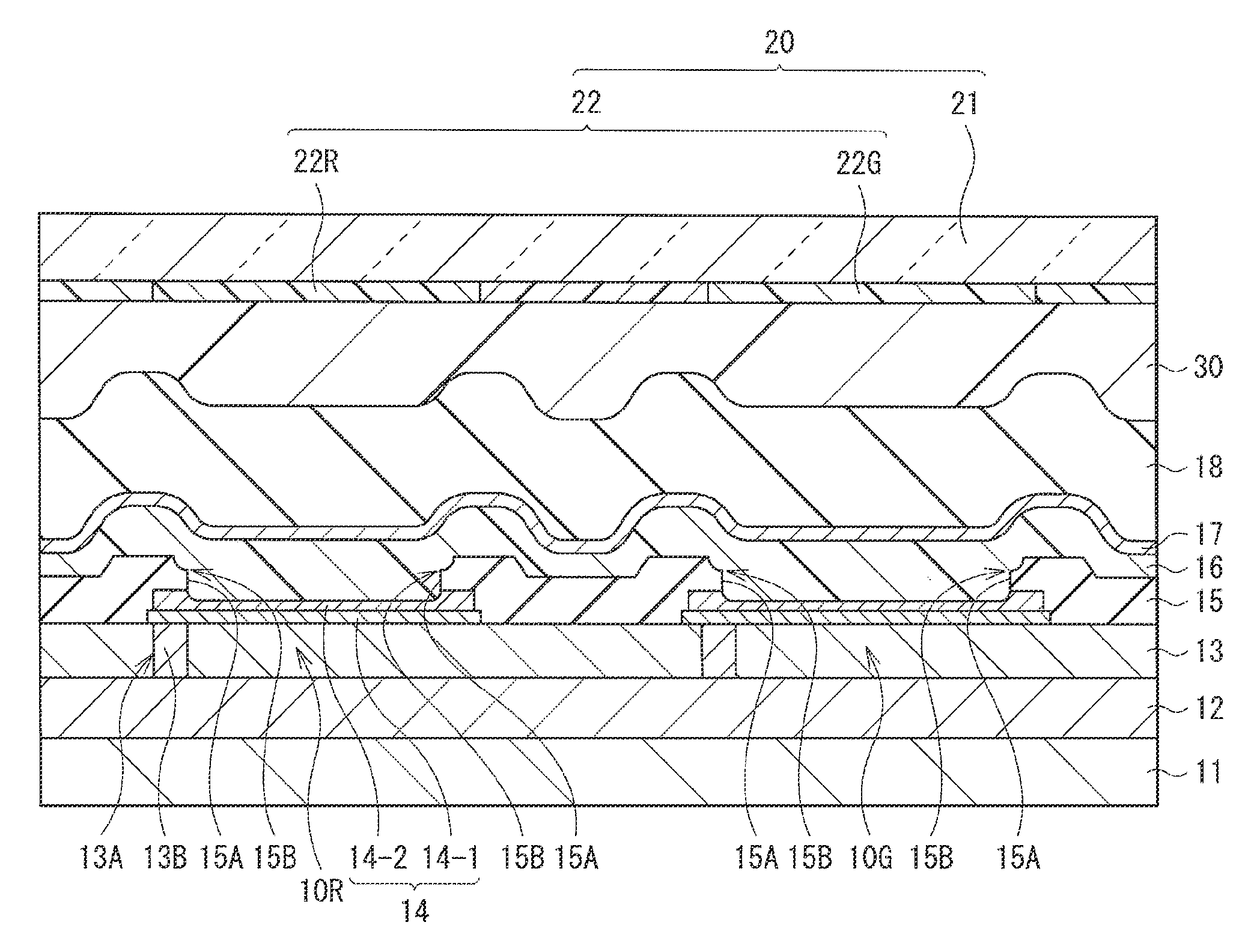

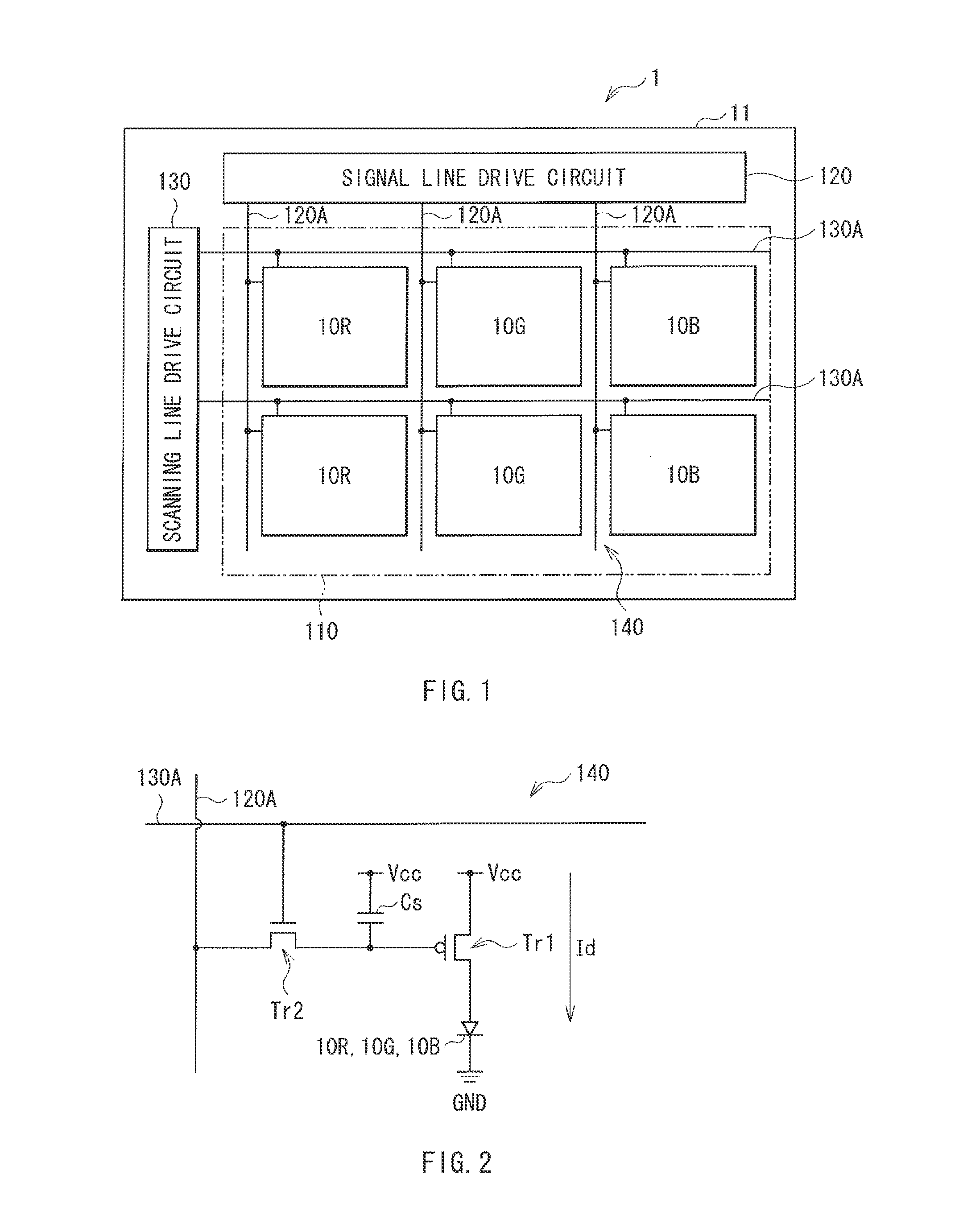

Organic light emitting device and display unit including the same

ActiveUS20120248467A1Deterioration of characteristicIncrease the aperture ratioSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceOrganic layer

An organic light emitting device includes a first electrode and a second electrode, an organic layer including a light emitting layer between the first electrode and the second electrode, and an insulating film covering a rim of the first electrode from a surface thereof to a side surface thereof, and having an internal wall surface being in contact with the organic layer, and one or more corner sections in the internal wall surface with a ridge line thereof in parallel with the surface of the first electrode.

Owner:SONY CORP

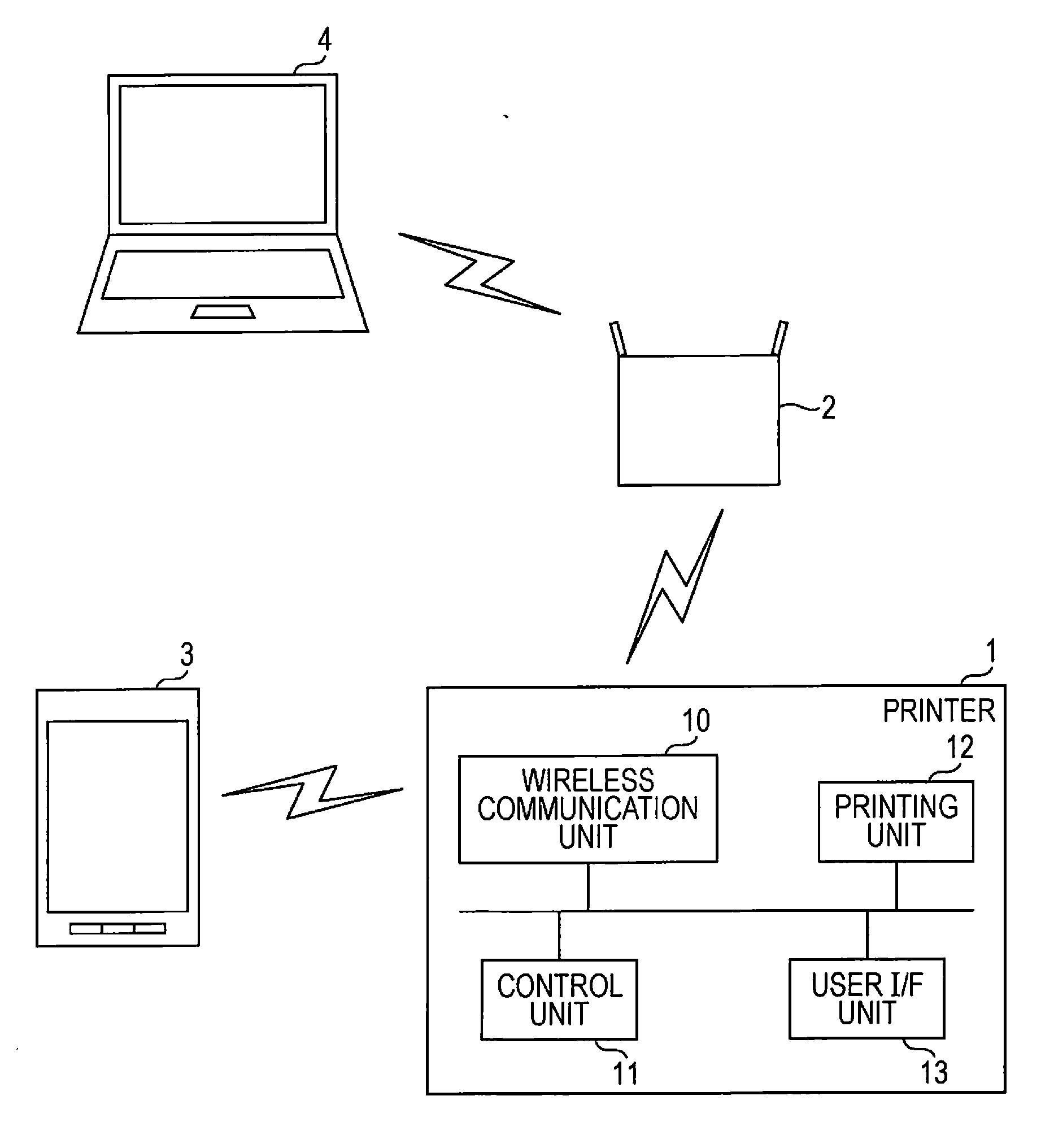

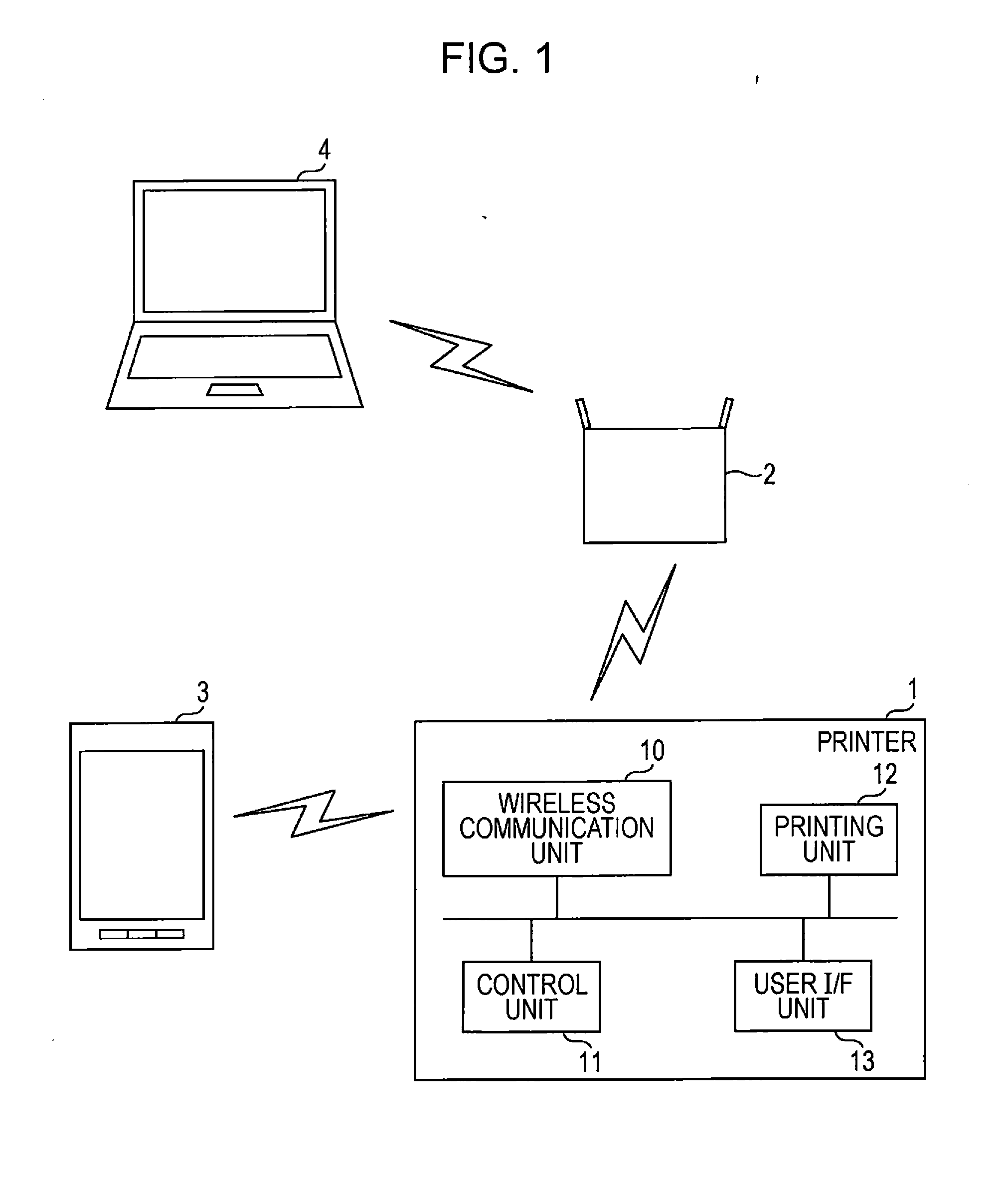

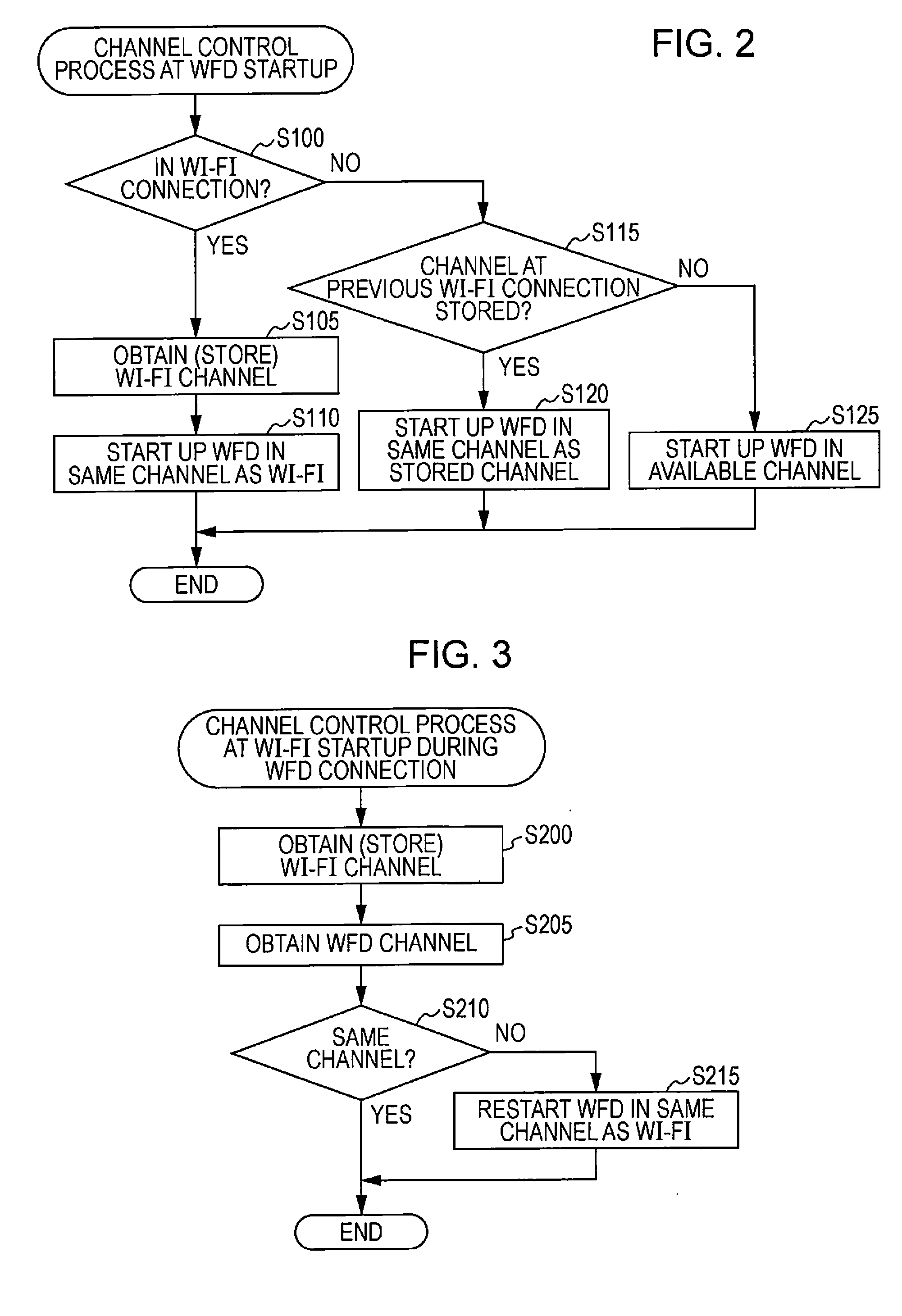

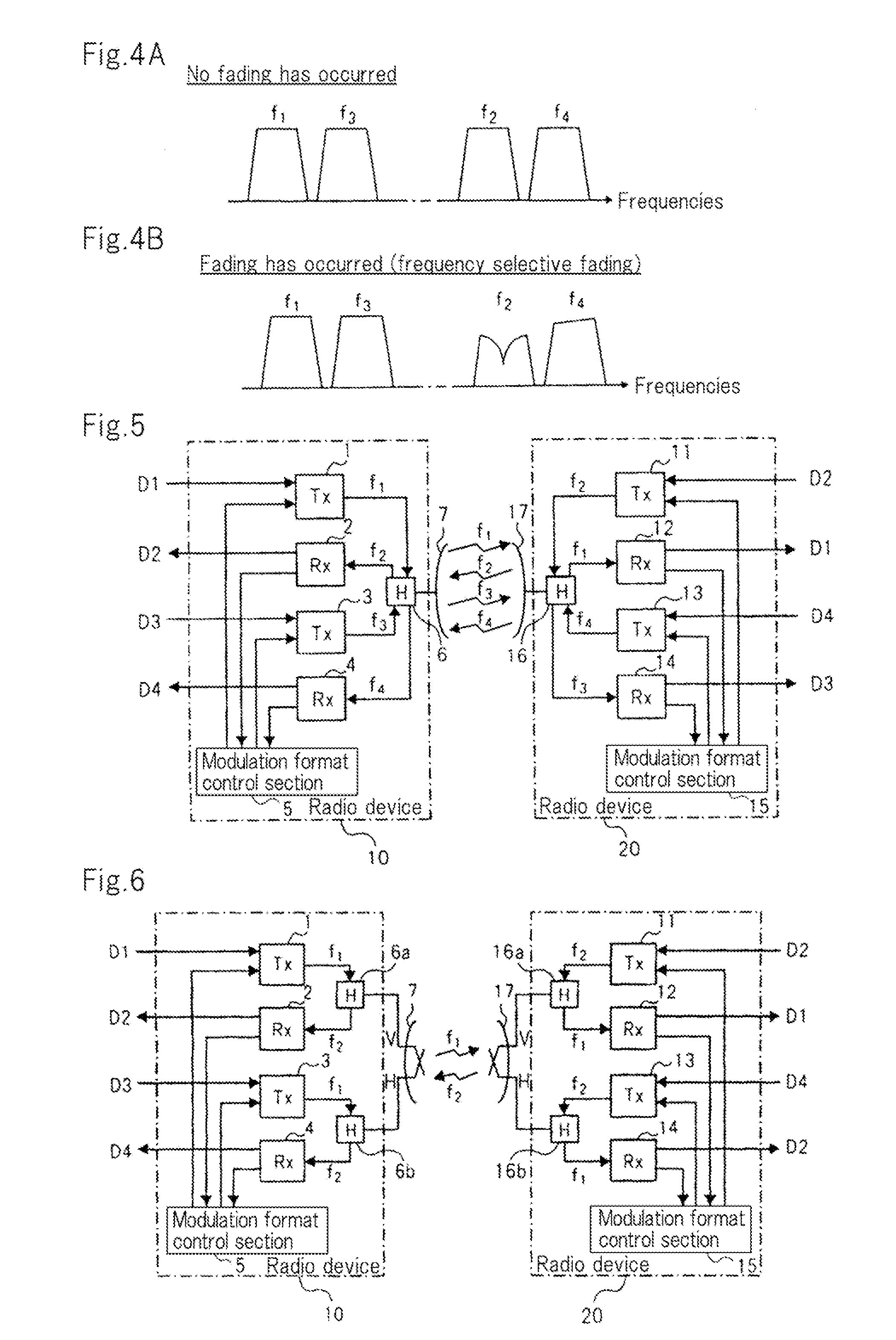

Wireless communication device and wireless communication method

ActiveUS20160066361A1Reduce transfer speedAvoid disconnectionFrequency-division multiplex detailsTime-division multiplexCommunication unitTelecommunications

A wireless communication device includes a wireless communication unit that performs a plurality of wireless communications using different channels by switching the wireless communications by performing time division multiplexing, and a control unit that causes the wireless communication unit to perform a first wireless communication for wirelessly communicating via a relay device and a second wireless communication for wirelessly communicating with a wireless terminal through a Peer to Peer system. The control unit controls the wireless communication unit to use the same channel as a channel to be used in the first wireless communication and perform the second wireless communication.

Owner:SEIKO EPSON CORP

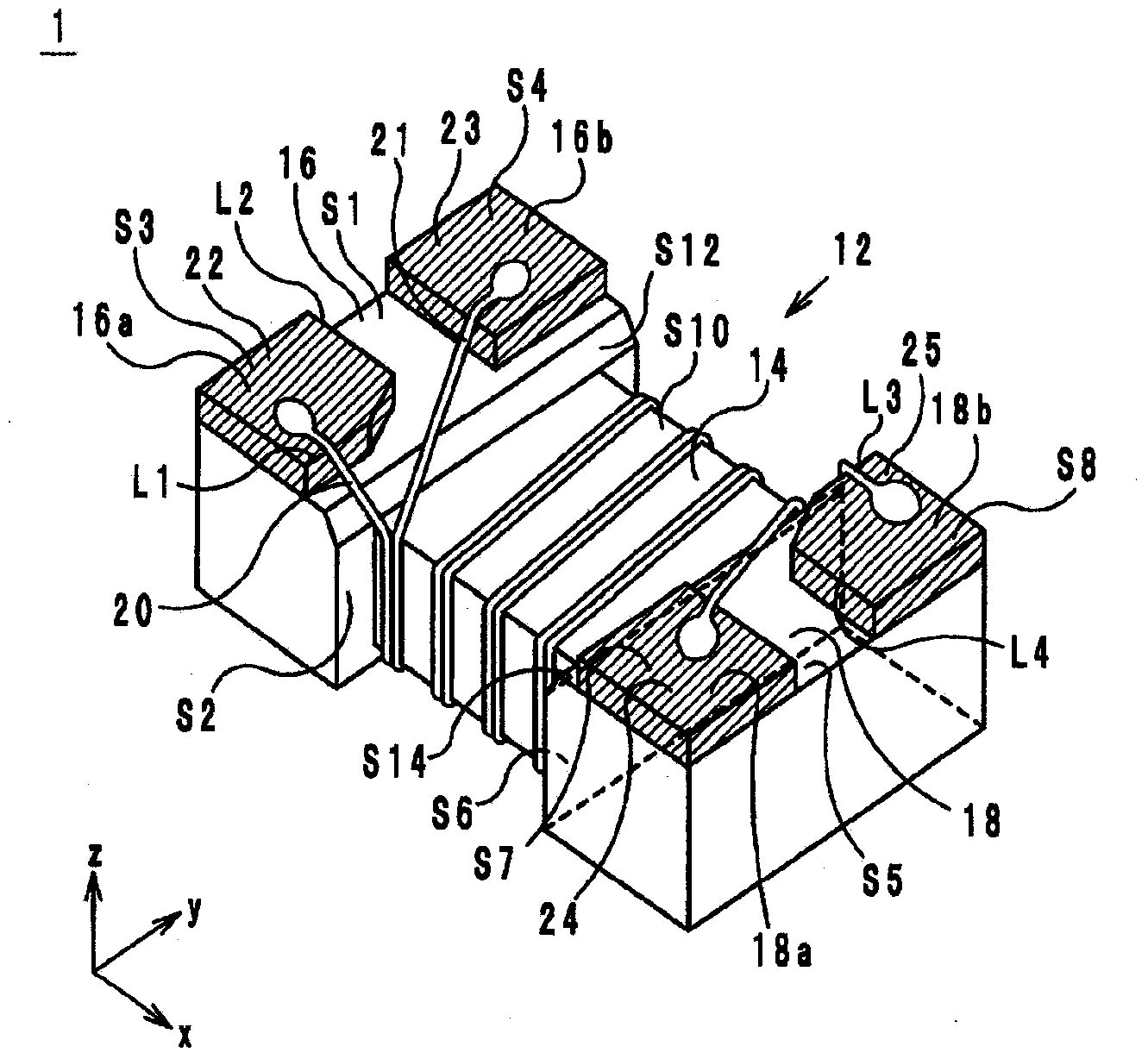

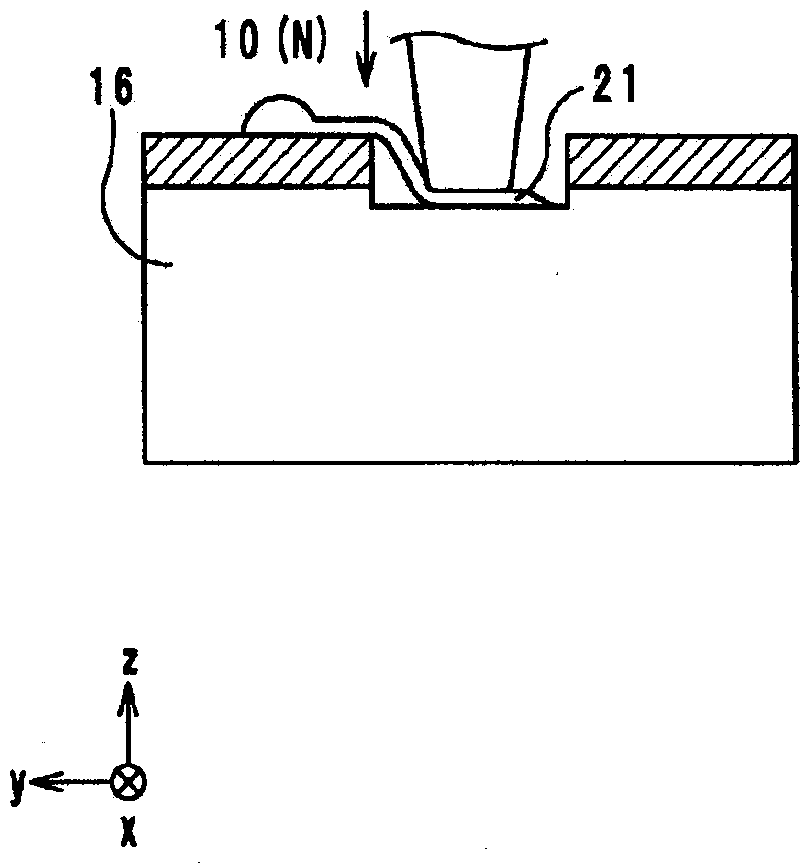

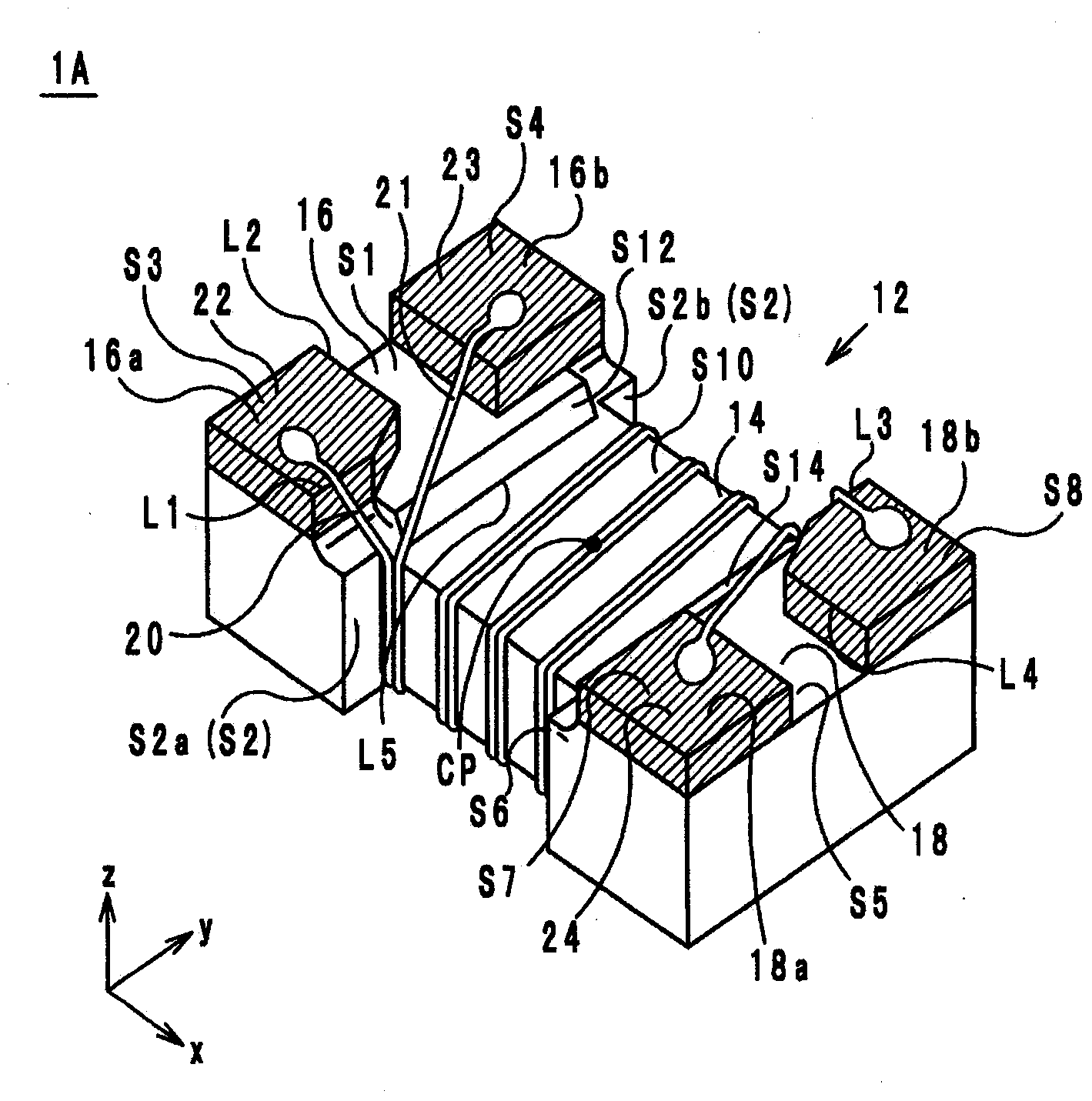

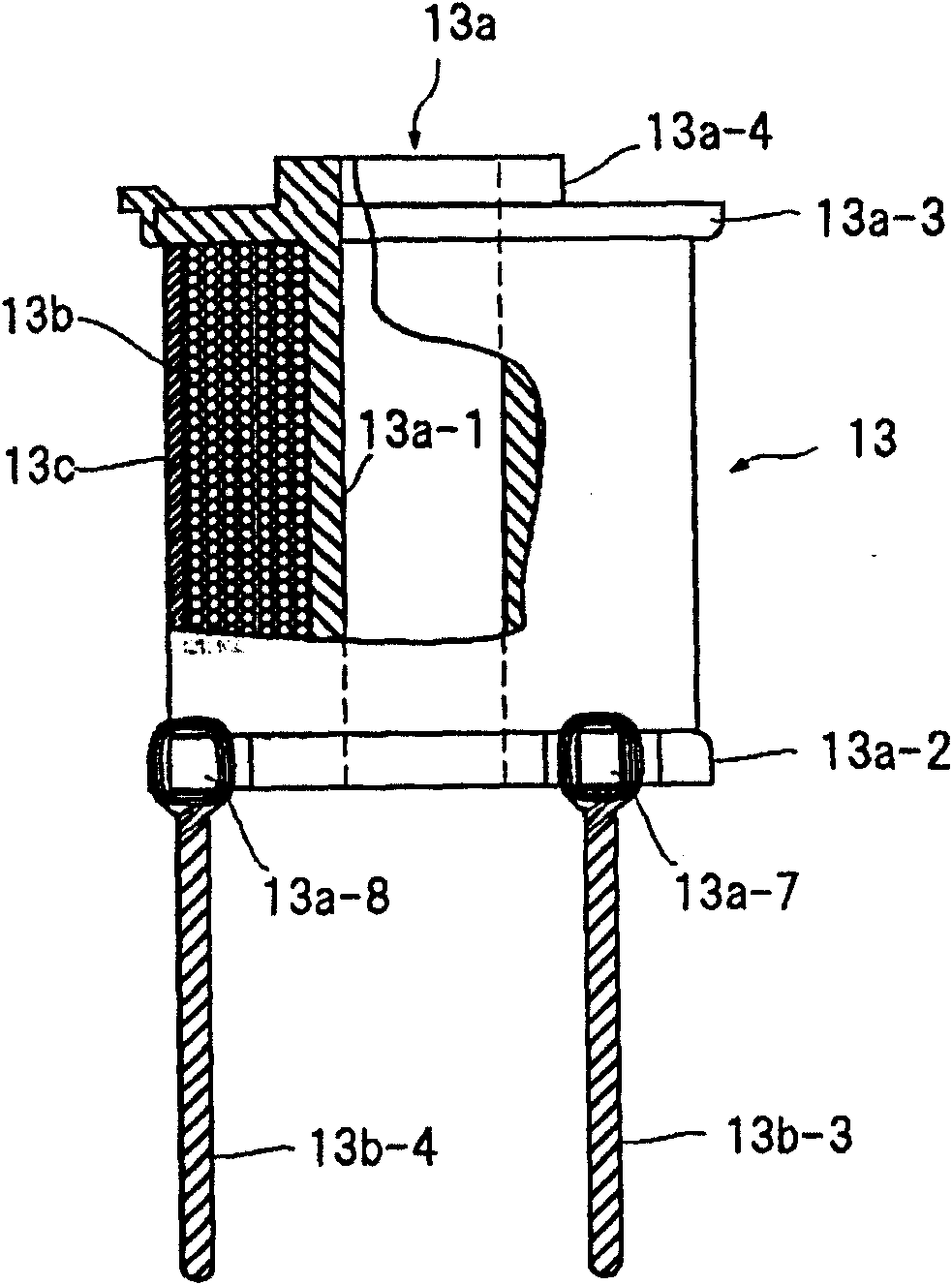

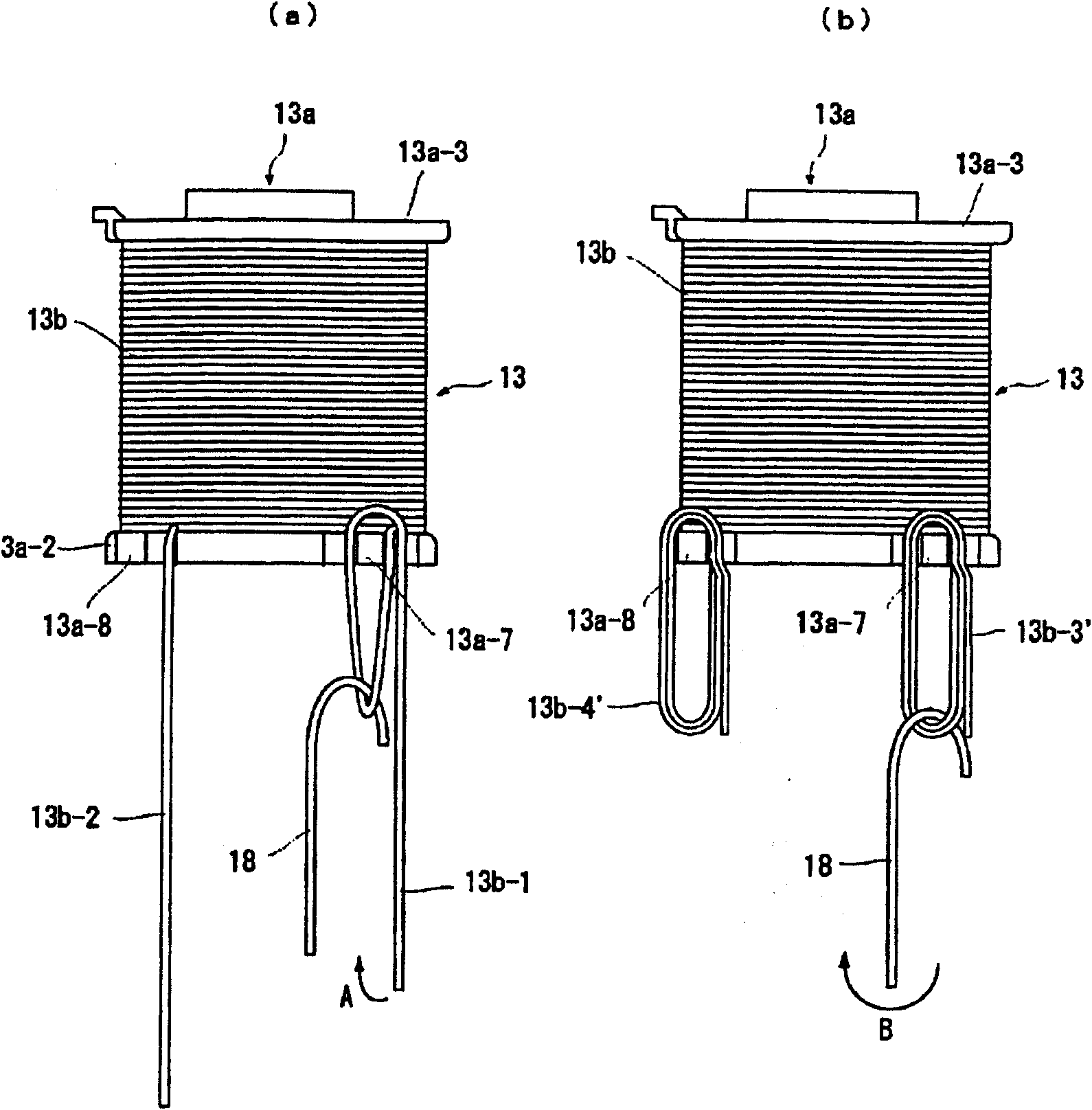

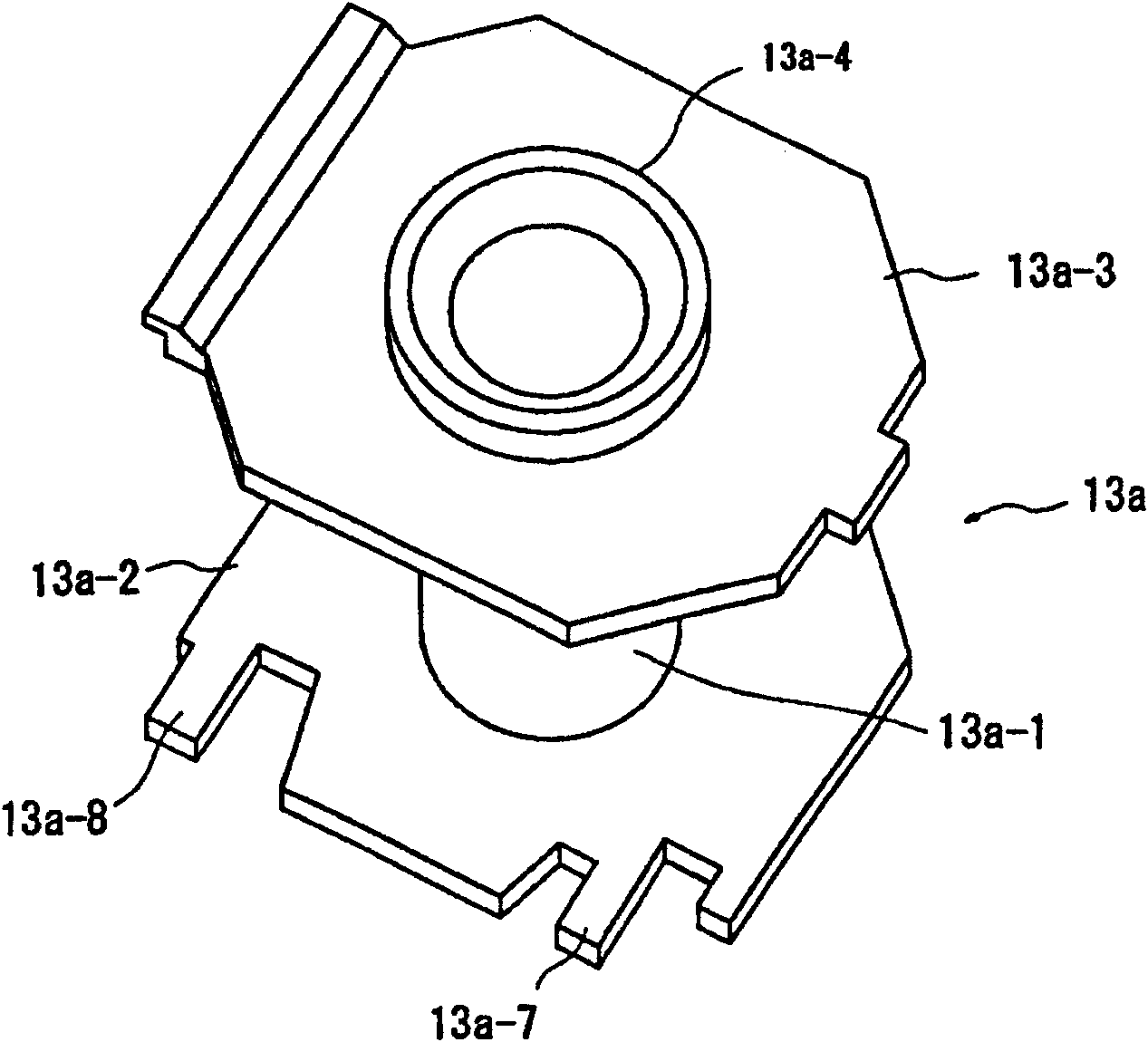

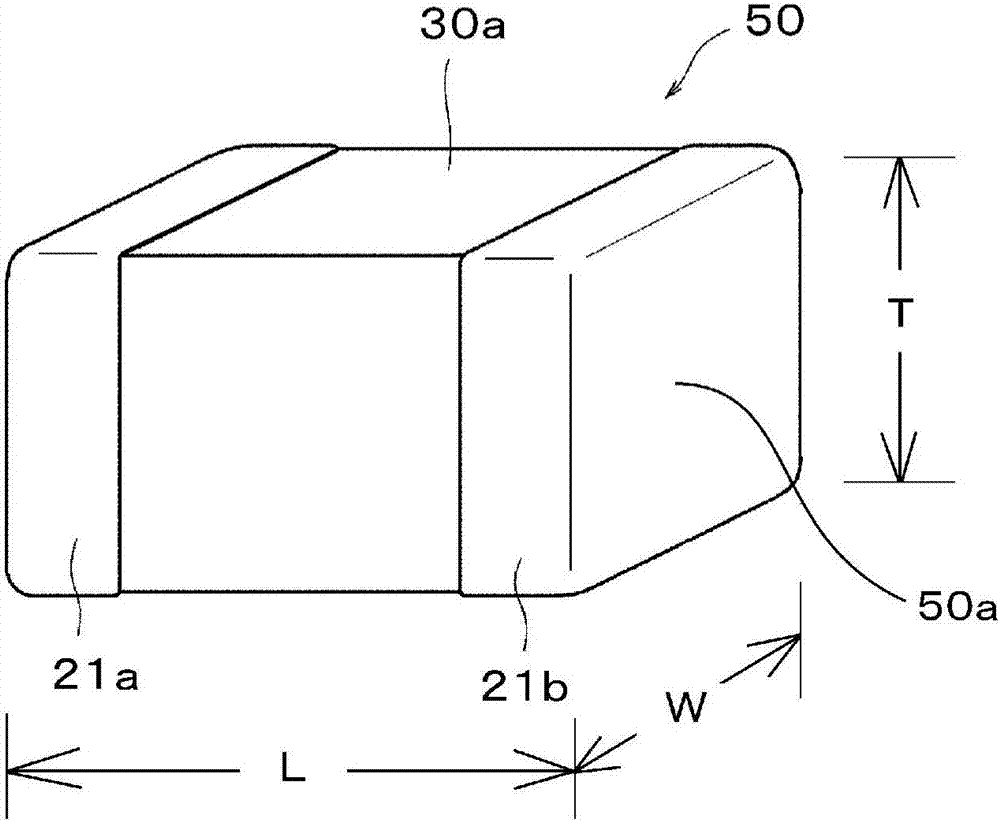

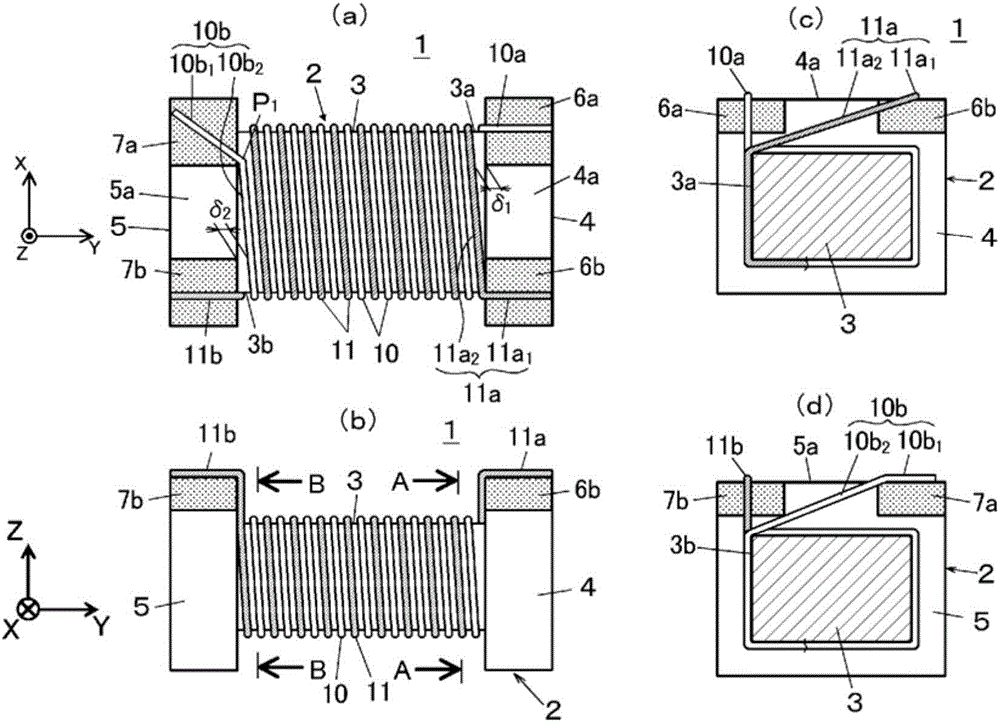

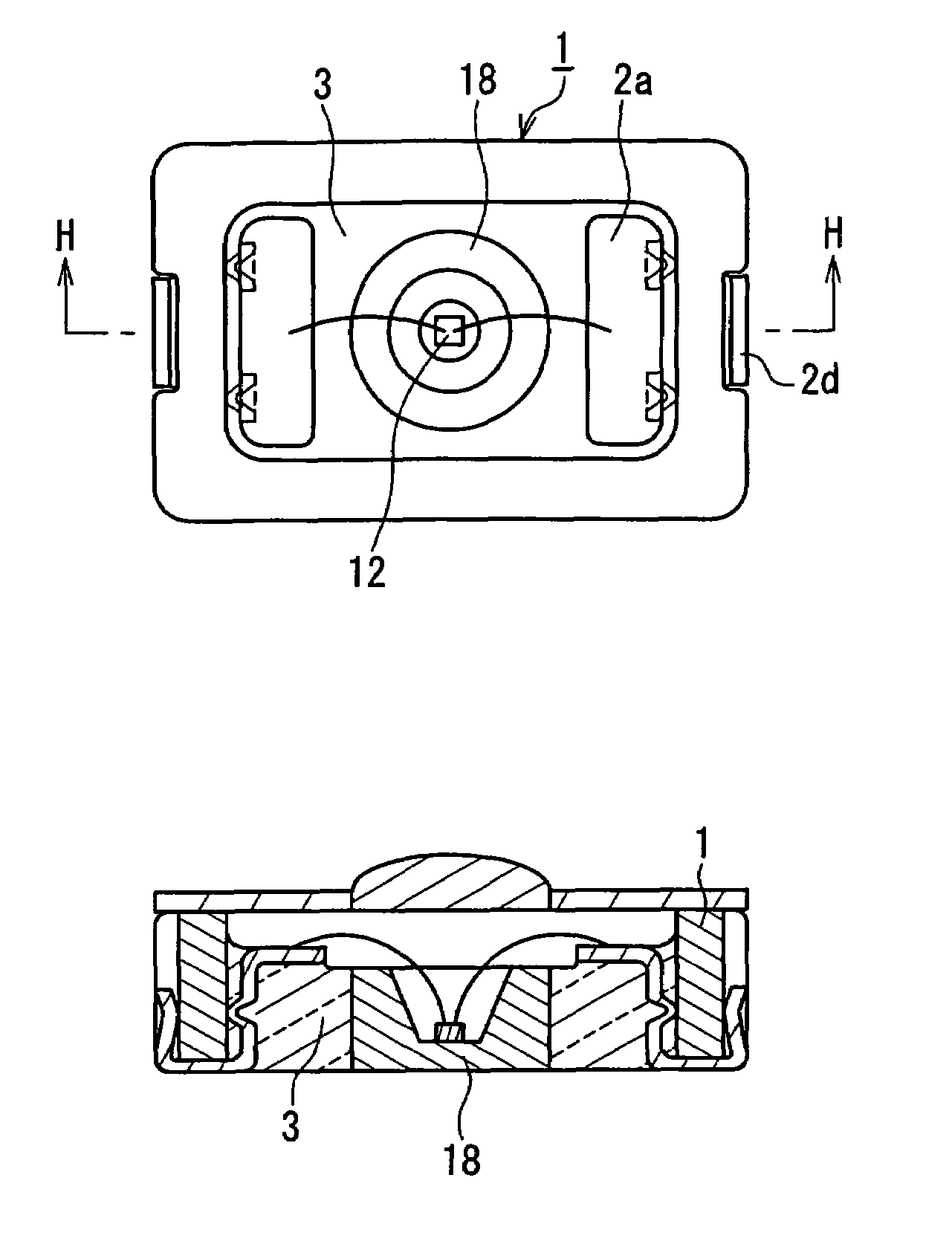

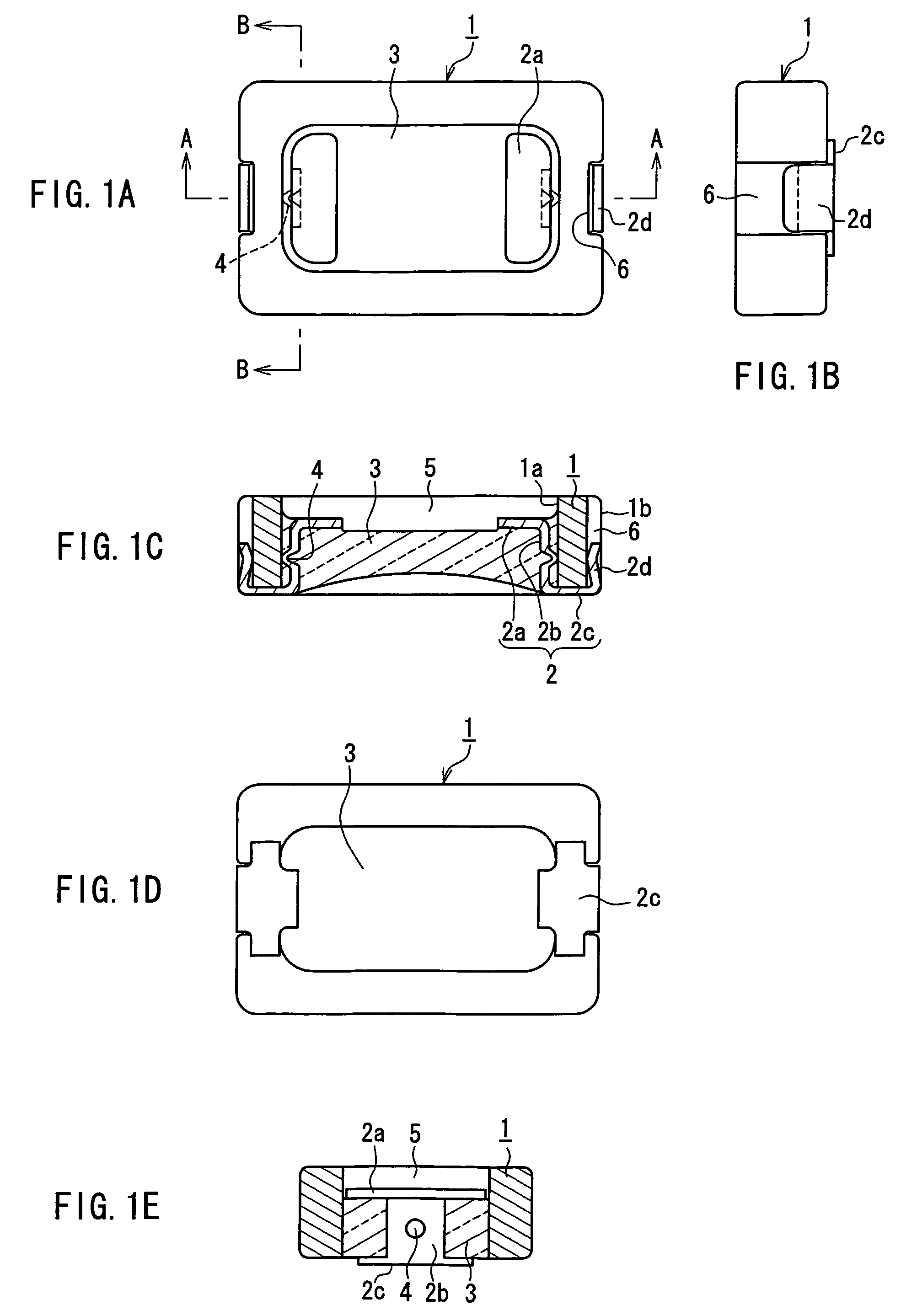

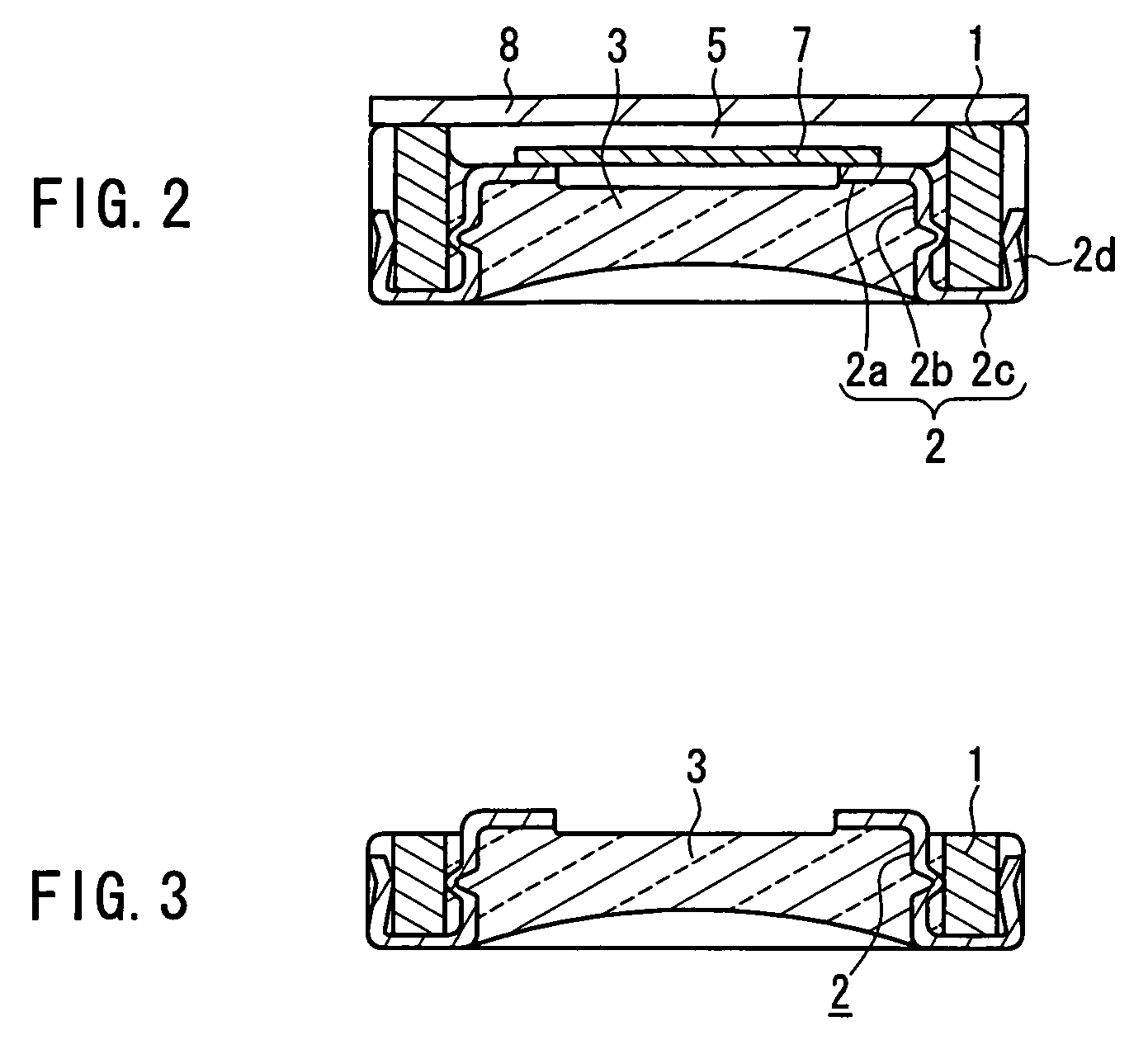

Core for wire-wound electronic component, wire-wound electronic component, and common mode choke coil

ActiveCN104347236AAvoid dangling stateSuppress disconnectionTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringElectronic component

A core for a wire-wound electronic component. The core has a winding base to be wound with a wire, and flanges located at both ends of the winding base in an extending direction of the winding base. The flanges protrude from the winding base in a first direction perpendicular to the extending direction. Each of the flanges has a plurality of protrusions on a first surface at a side of the flange in the first direction. An inclined surface is provided to extend from the first surface of each of the flanges to a second surface of the winding base at a side of the winding base in the first direction.

Owner:MURATA MFG CO LTD

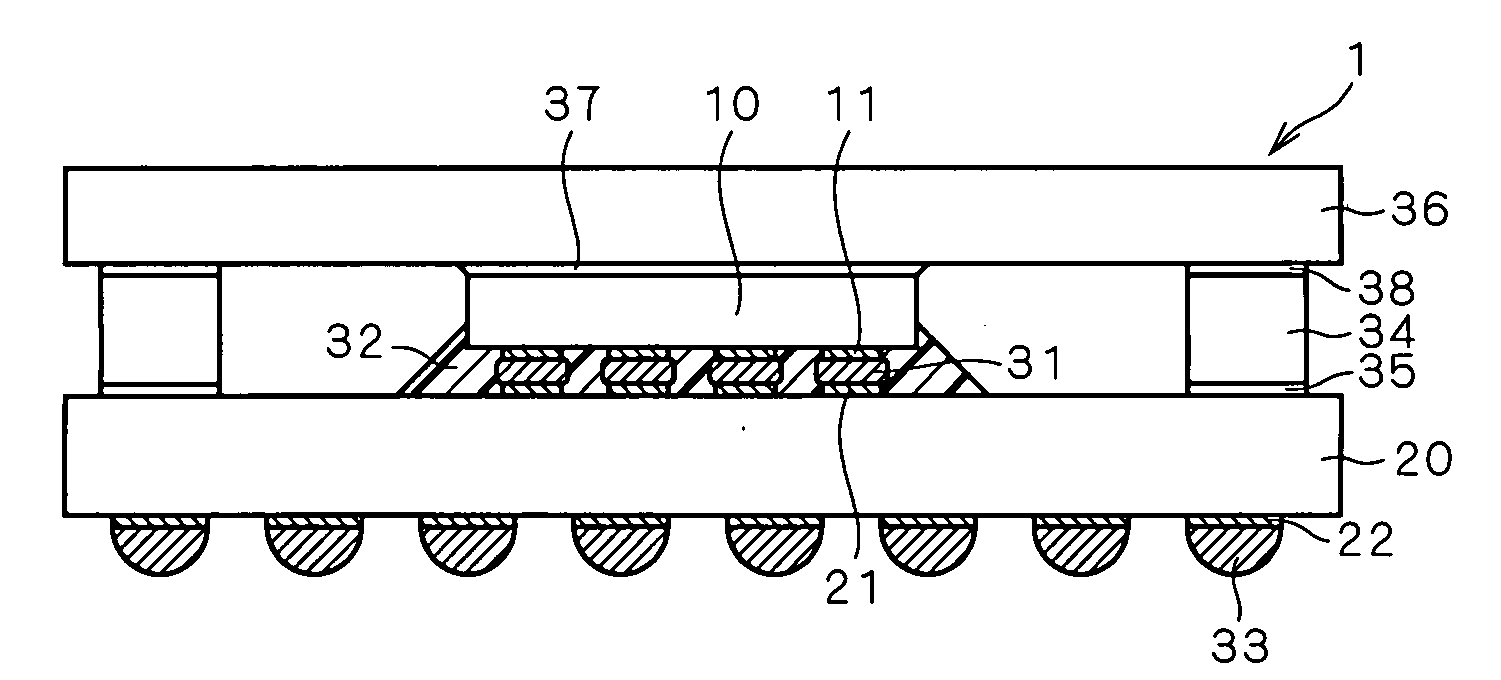

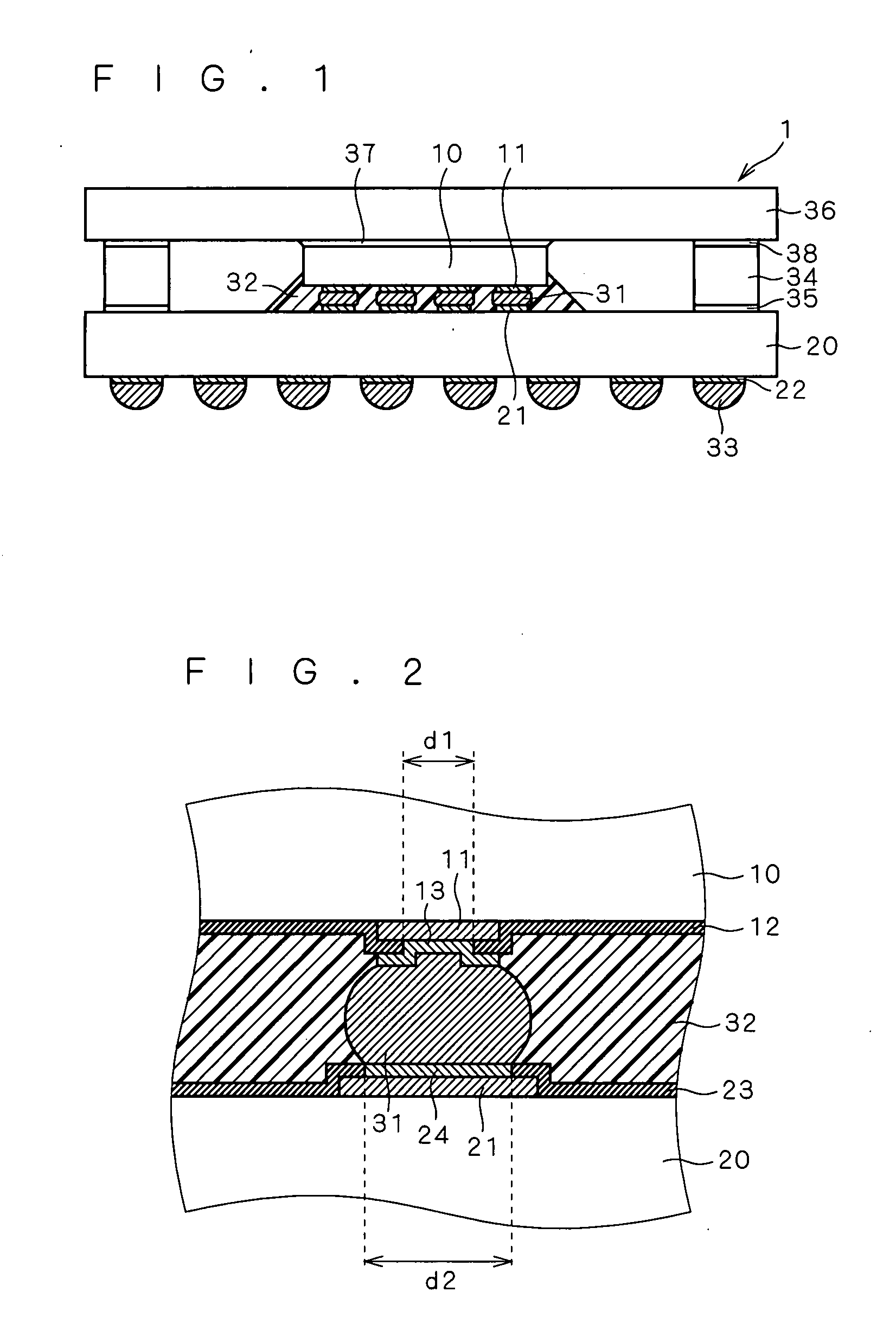

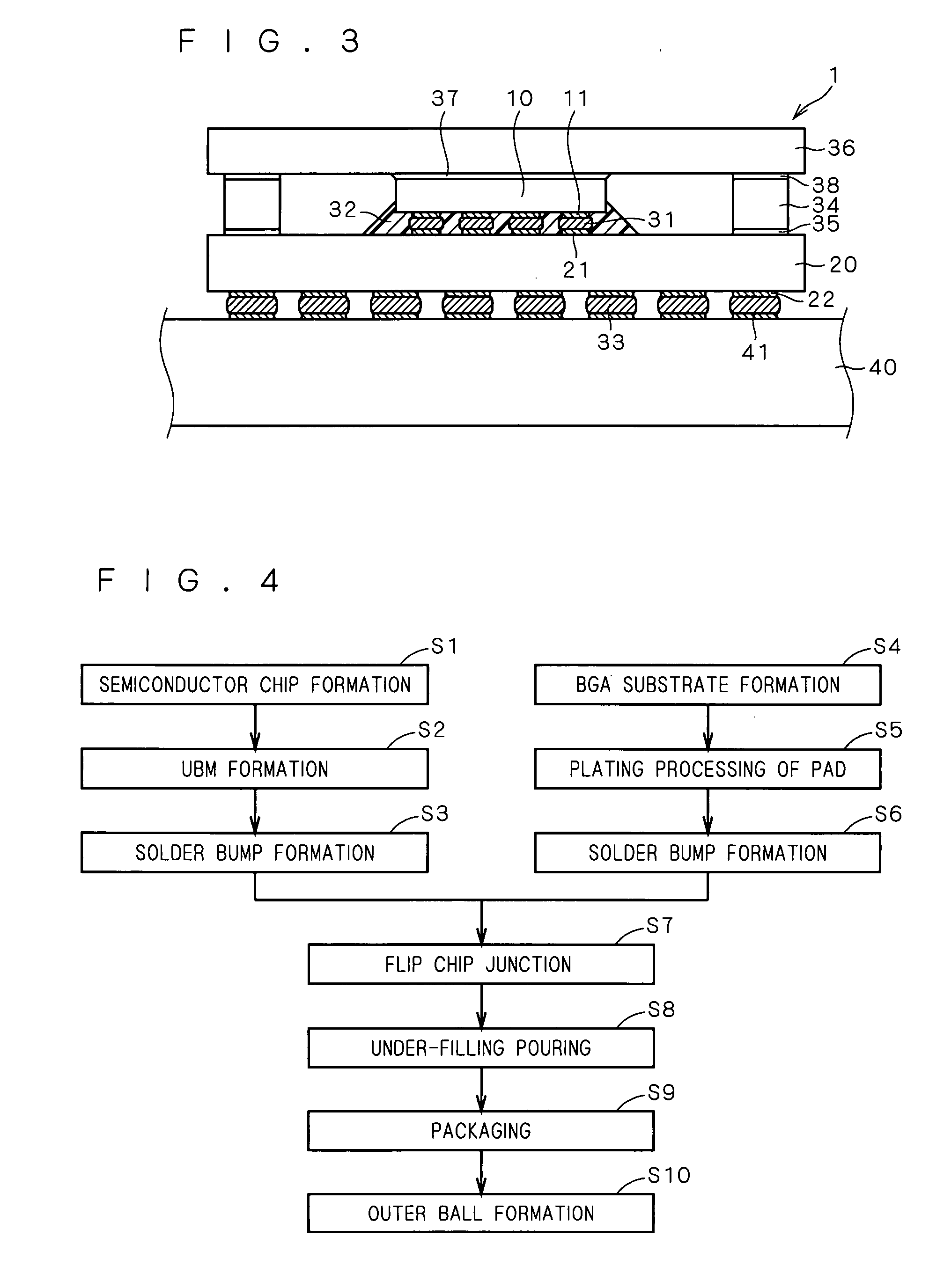

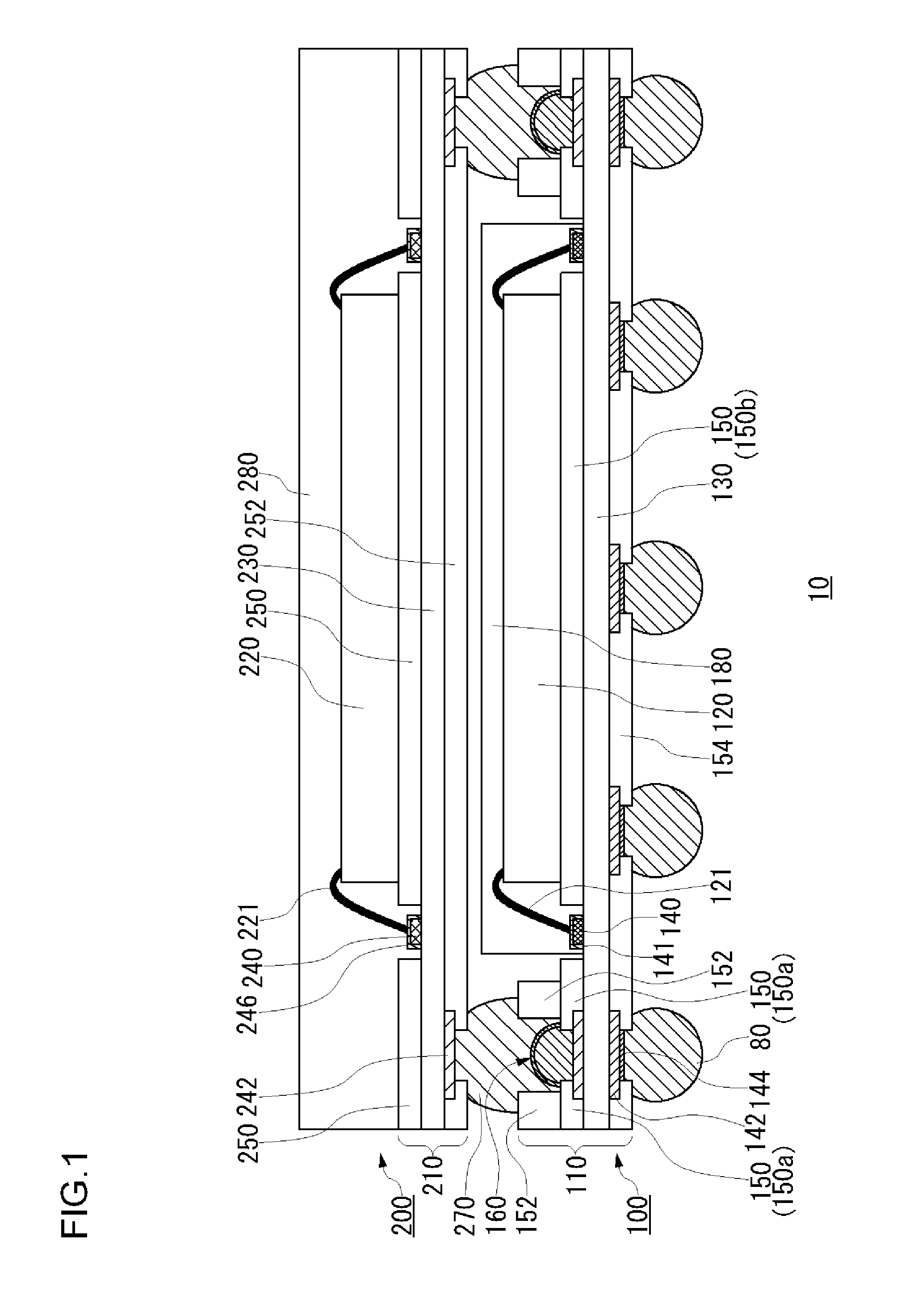

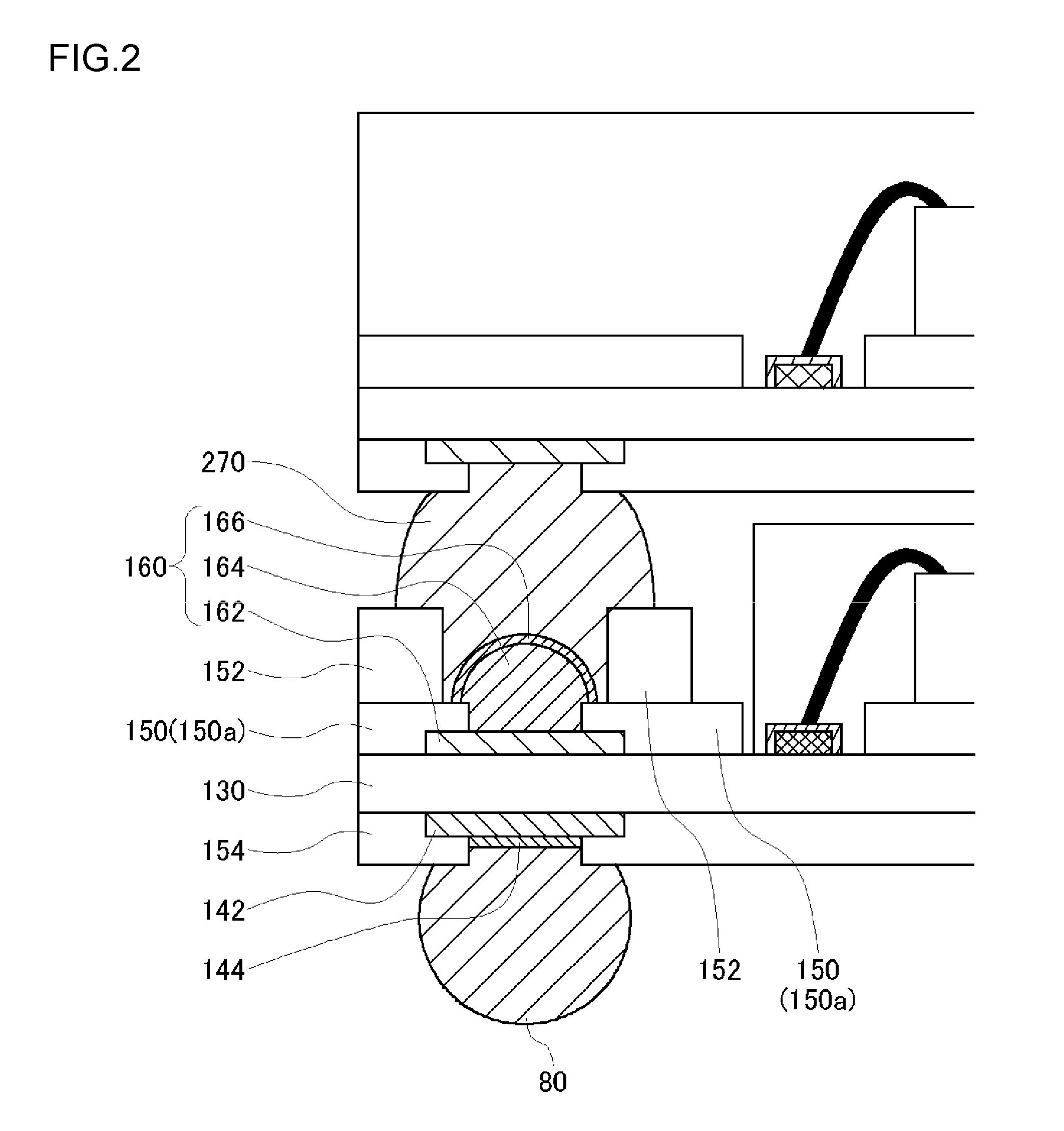

Semiconductor Device

InactiveUS20080128887A1Stress relief concentrationDisconnectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSolder ball

Regarding a semiconductor device, especially the present invention suppresses disconnection of the connection structure concerned in the semiconductor device which has the electric and mechanical connection structure using solder, and aims at improving connection reliability. And to achieve the above objects, the semiconductor device has the solder bump which electrically connects a semiconductor chip and a package substrate, the under-filling resin with which it filled up between the semiconductor chip and the package substrate, and a solder ball which electrically connects a package substrate with the outside, and the solder bump's elastic modulus is made lower than the elastic modulus of a solder ball.

Owner:RENESAS ELECTRONICS CORP

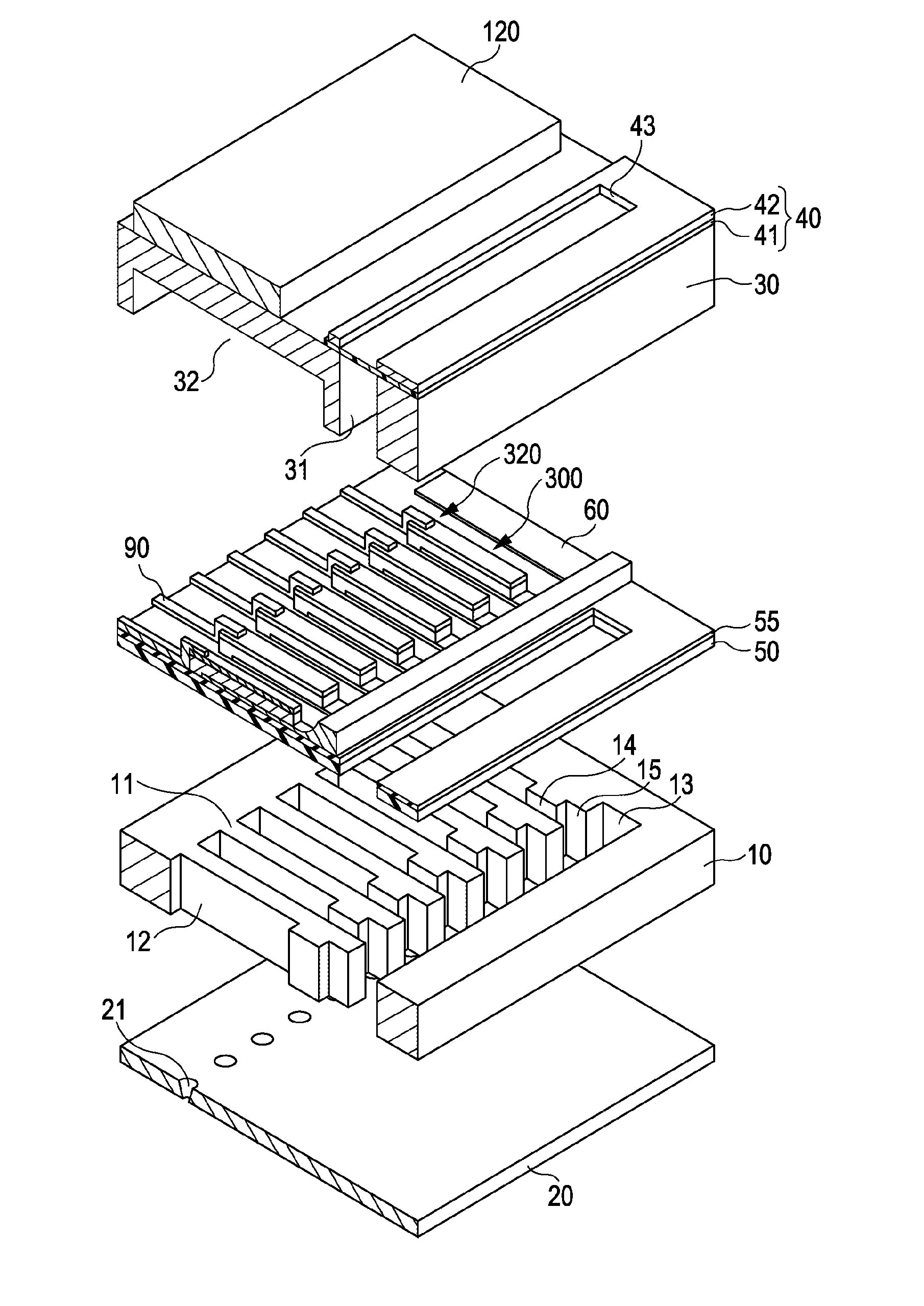

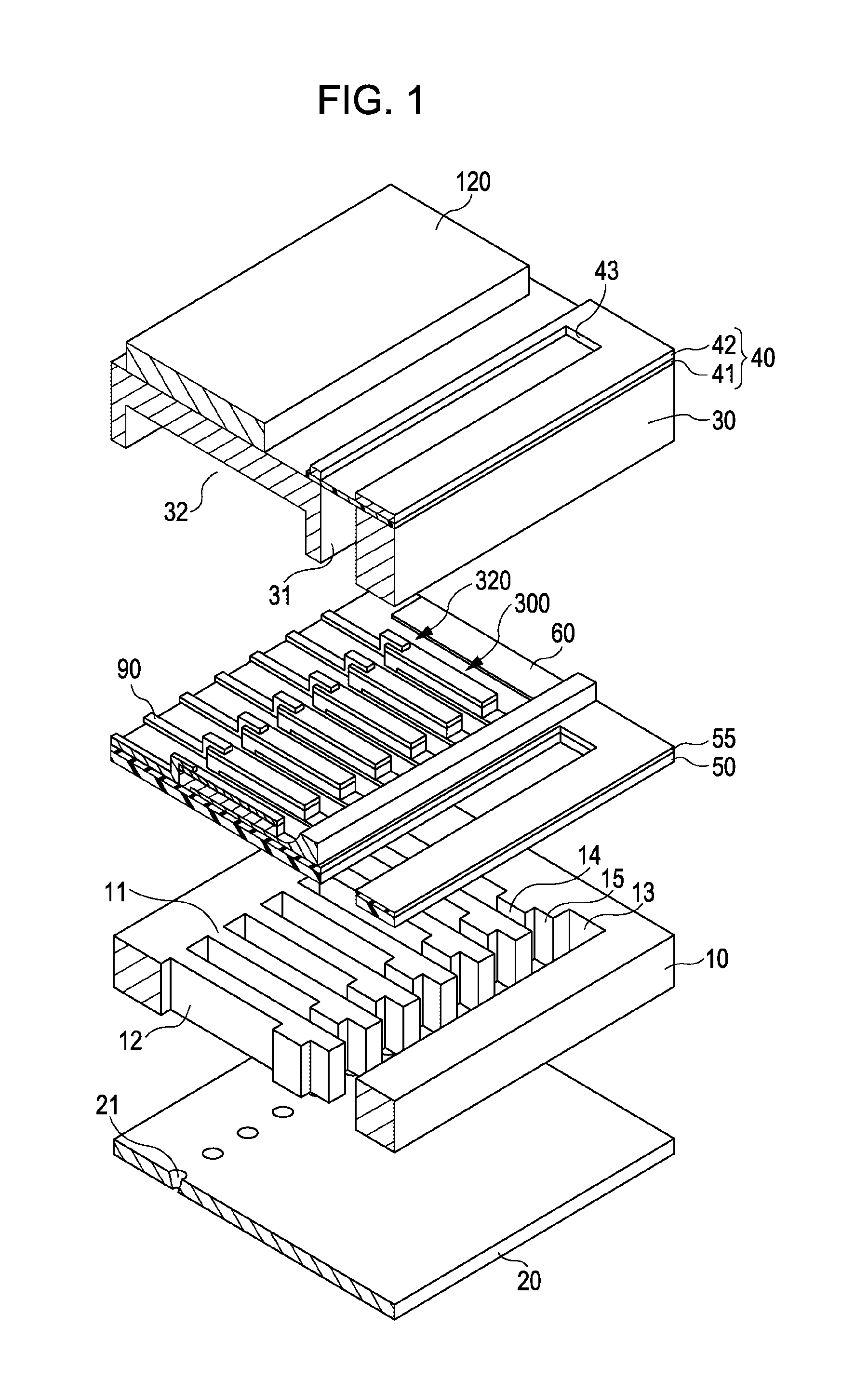

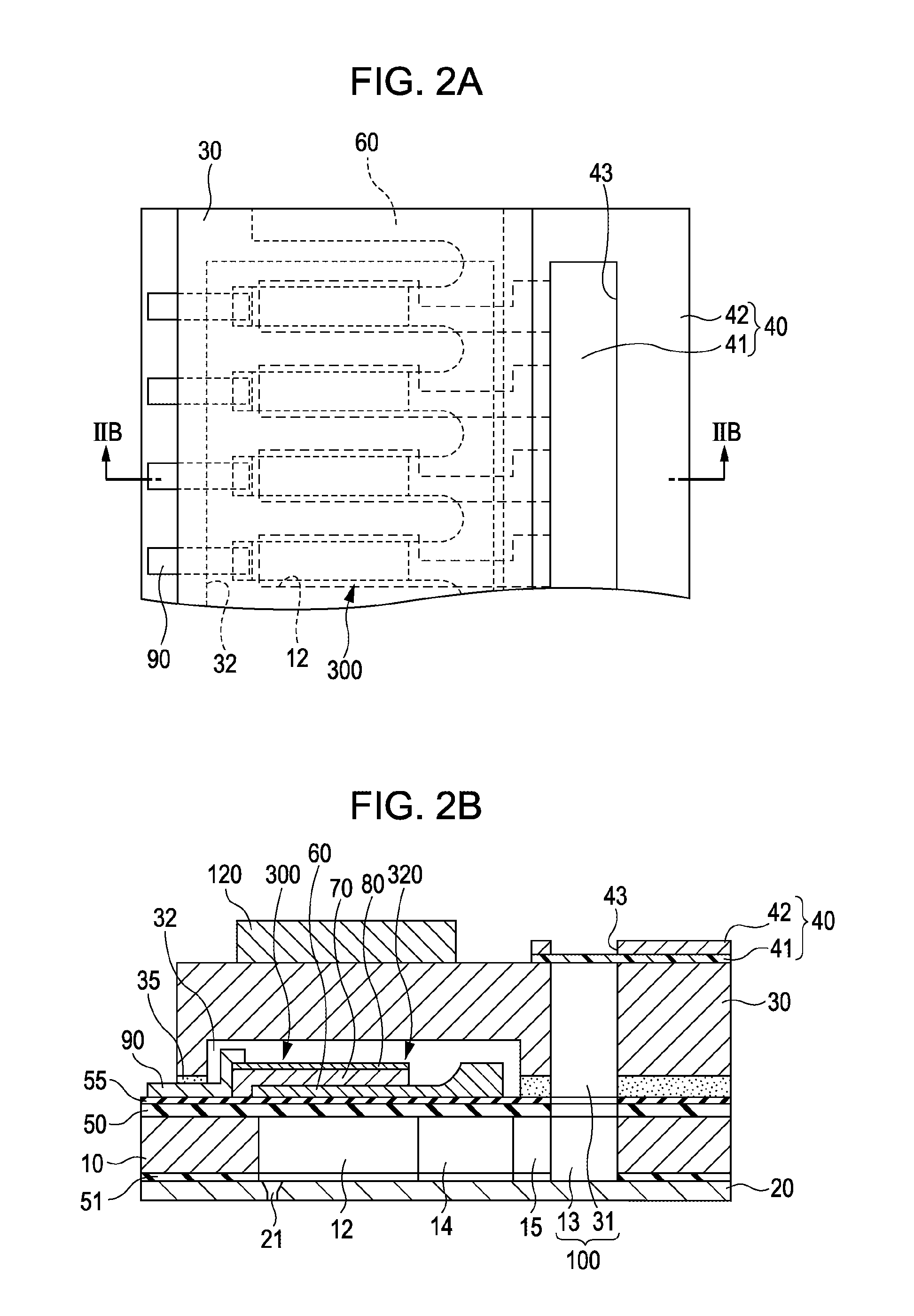

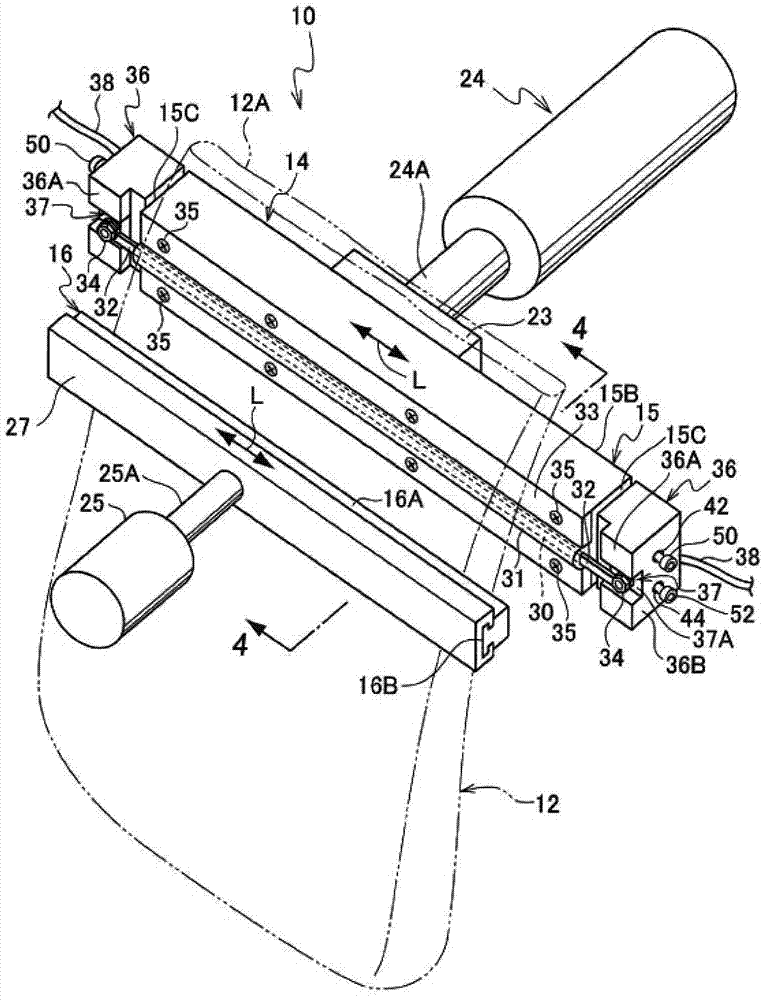

Liquid ejecting head and method of manufacturing liquid ejecting head

ActiveUS20160263887A1Avoid changeImprove reliabilityInking apparatusElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

LCD device and method including a plastic substrate with metal layer containing copper surrounded by barrier metal film embedded in a groove within the plastic substrate

InactiveUS7564531B2Lower resistanceSuppress disconnectionSolid-state devicesNon-linear opticsHigh densityLiquid-crystal display

Owner:VISTA PEAK VENTURES LLC

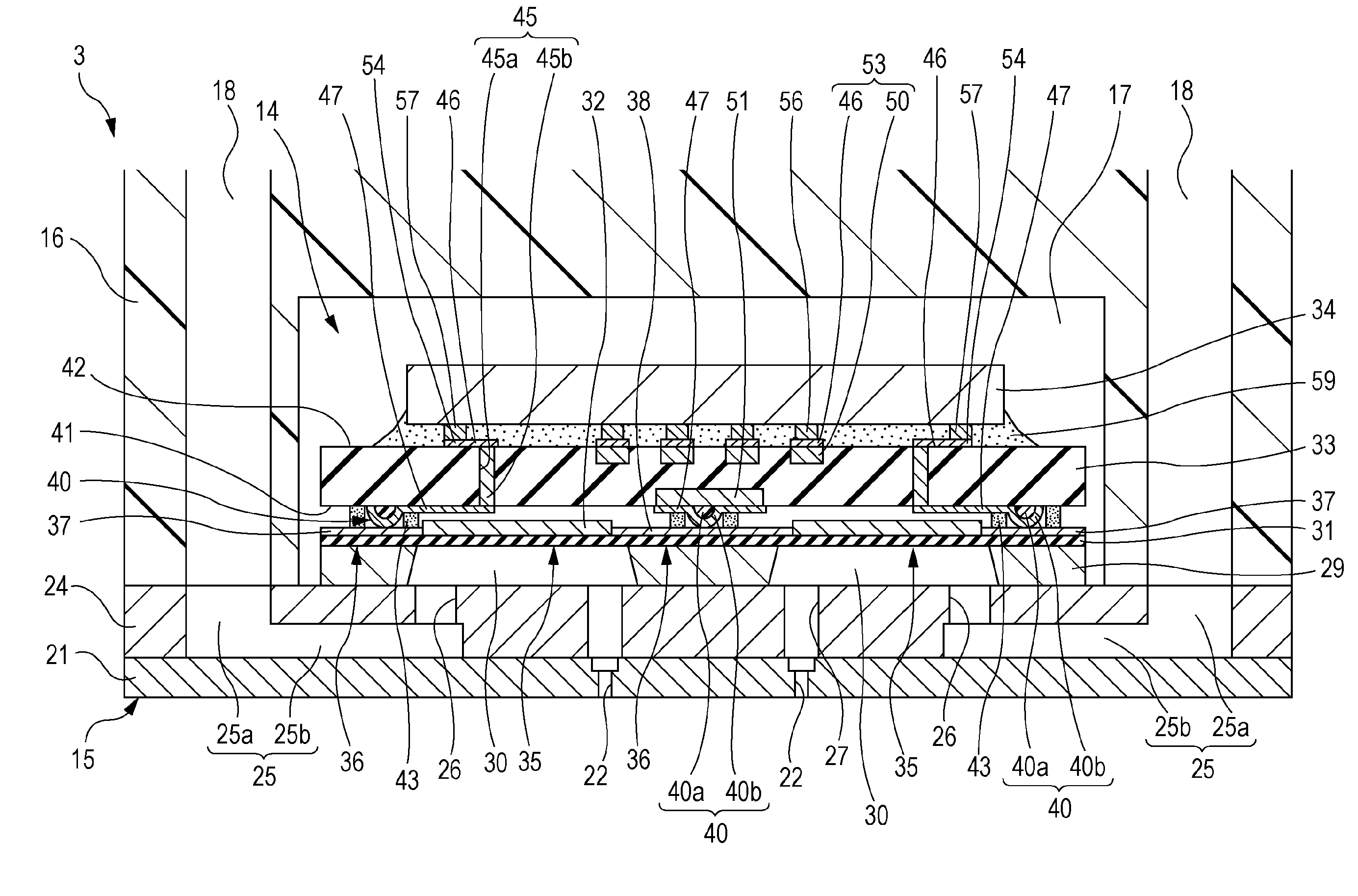

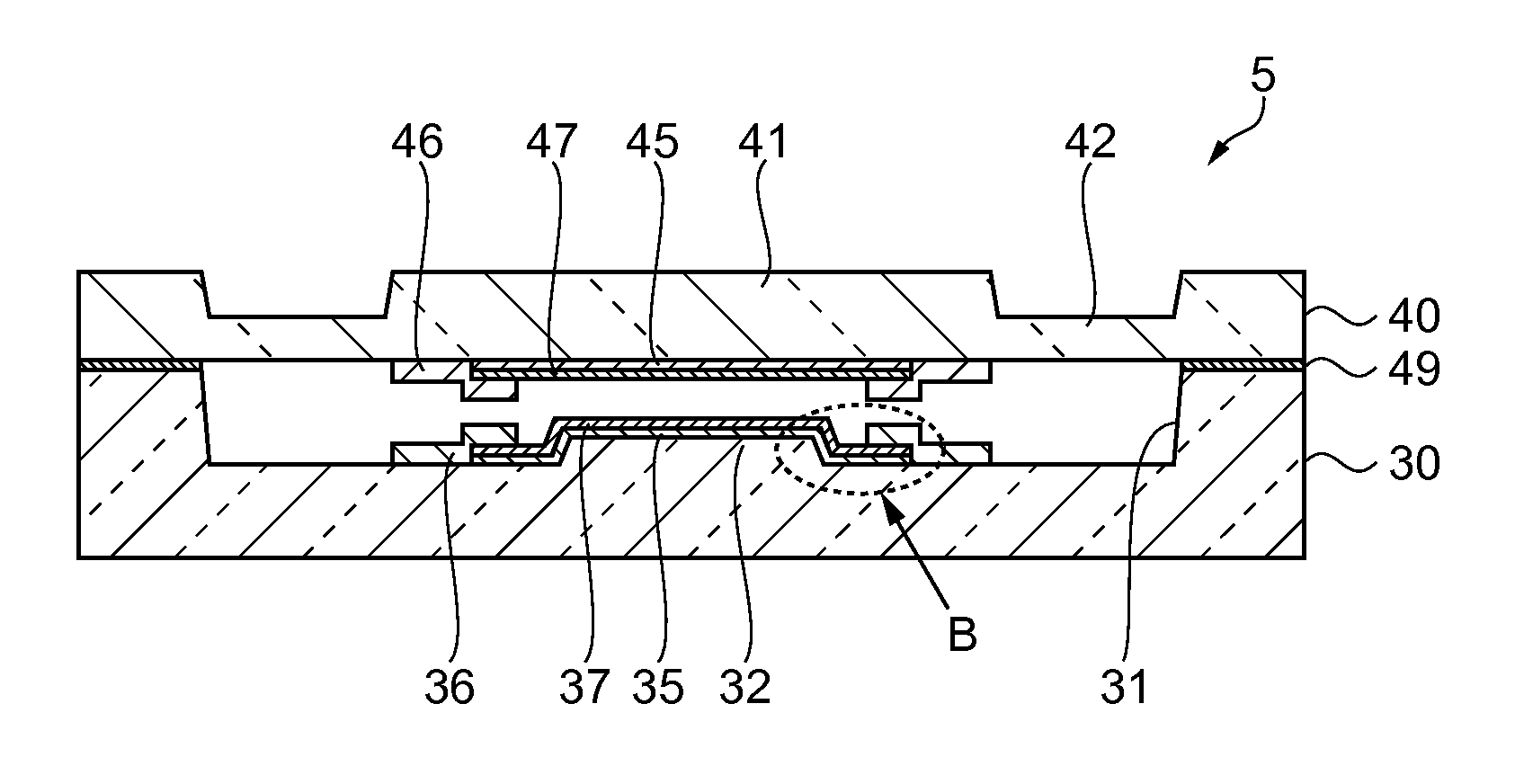

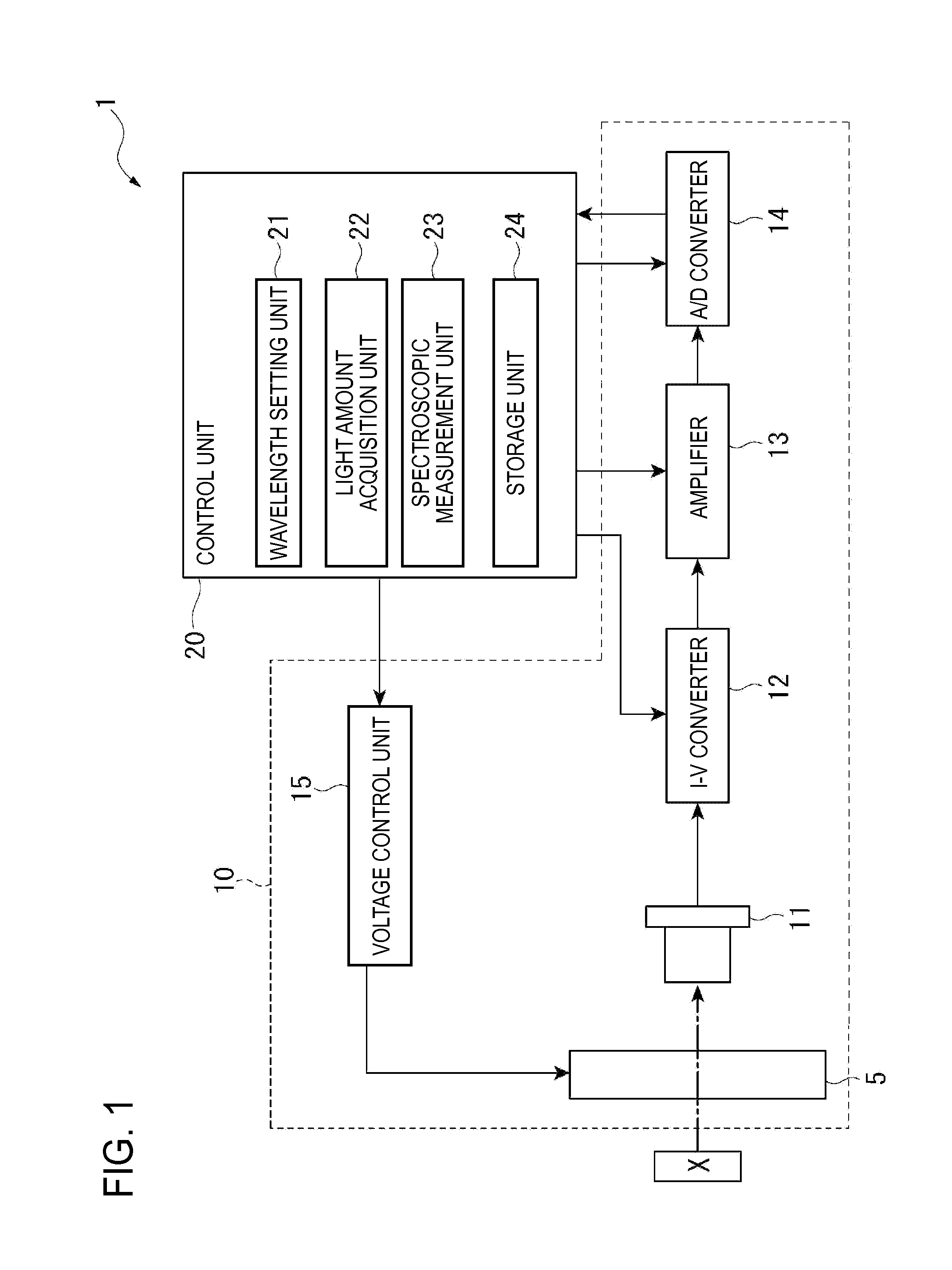

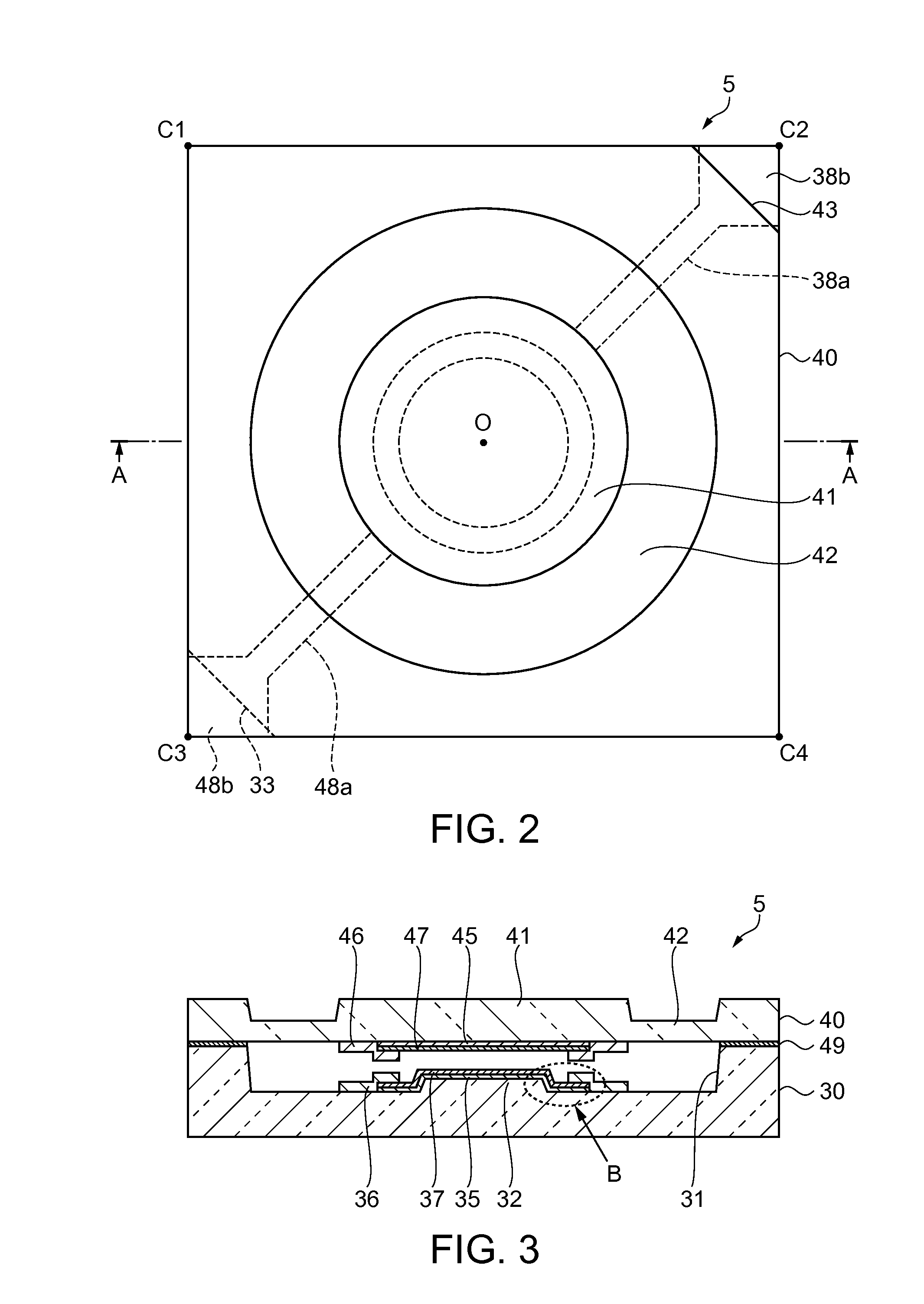

Wavelength variable interference filter, optical filter device, optical module, and electronic apparatus

InactiveUS20140240836A1Improve connection reliabilityImprove reliabilityOptical elementsOptical ModuleEngineering

The thickness of a first drive electrode is greater than the sum of the thickness of a first reflective film and the thickness of a first conductive film, the first drive electrode extends from the surface of a fixed substrate to the surface of the outer edge portion of the first conductive film and is in contact with the first conductive film, the thickness of a second drive electrode is greater than the sum of the thickness of a second reflective film and the thickness of a second conductive film, and the second drive electrode extends from the surface of a movable substrate to the surface of the outer edge portion of the second conductive film and is in contact with the second conductive film.

Owner:SEIKO EPSON CORP

Electromagnetic coil and method for processing coil terminal thereof

ActiveCN101923935AImprove reliabilitySuppress disconnectionCoils manufactureCoilsEngineeringConductor Coil

The invention aims to provide an electromagnetic coil device and a method for processing a winding terminal thereof. Even a coil winding made of thin wires can be also provided with a reinforced winding terminal part with high reliability. In addition, a coil winding made of wires with even a, more or less, large diameter can also easily achieve the operation strengthening. The solution method is that the periphery of a flange of a coil frame for winding a coil winding is provided with clamping sheets for clamping and stopping a coil winding terminal and for wires which, of a winding starting terminal part and a winding stopping terminal part of the coil winding winded on the coil frame, extends towards the outer side of the flange, base end sides thereof are clamped on the clamping sheets and are folded back for many times to form a folding-back wire bundle which has a specific length and is twirled for appropriate times for twisting to become a leading-out terminal sheaved and fixed on the clamping sheets of the flange of the coil frame.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

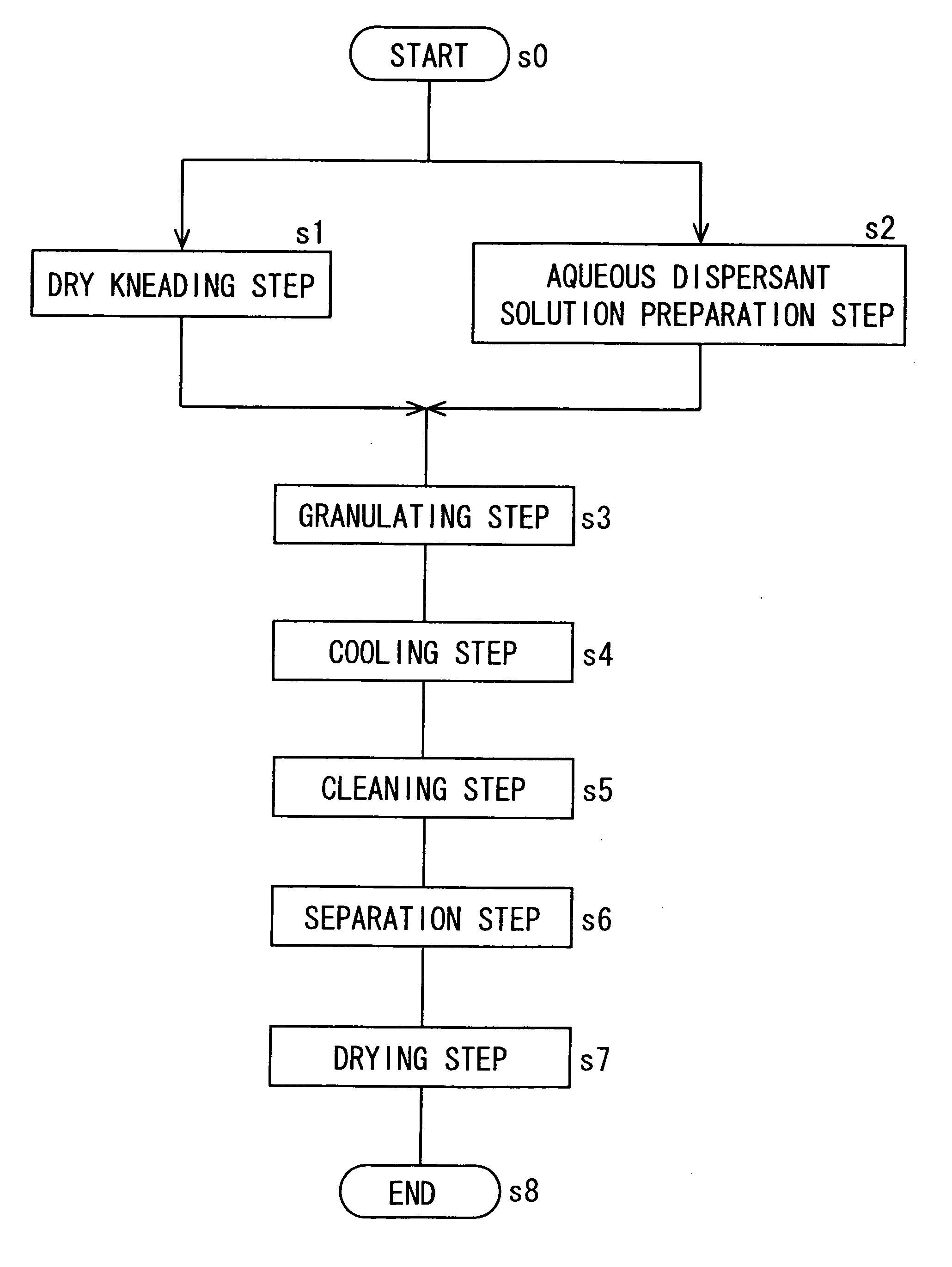

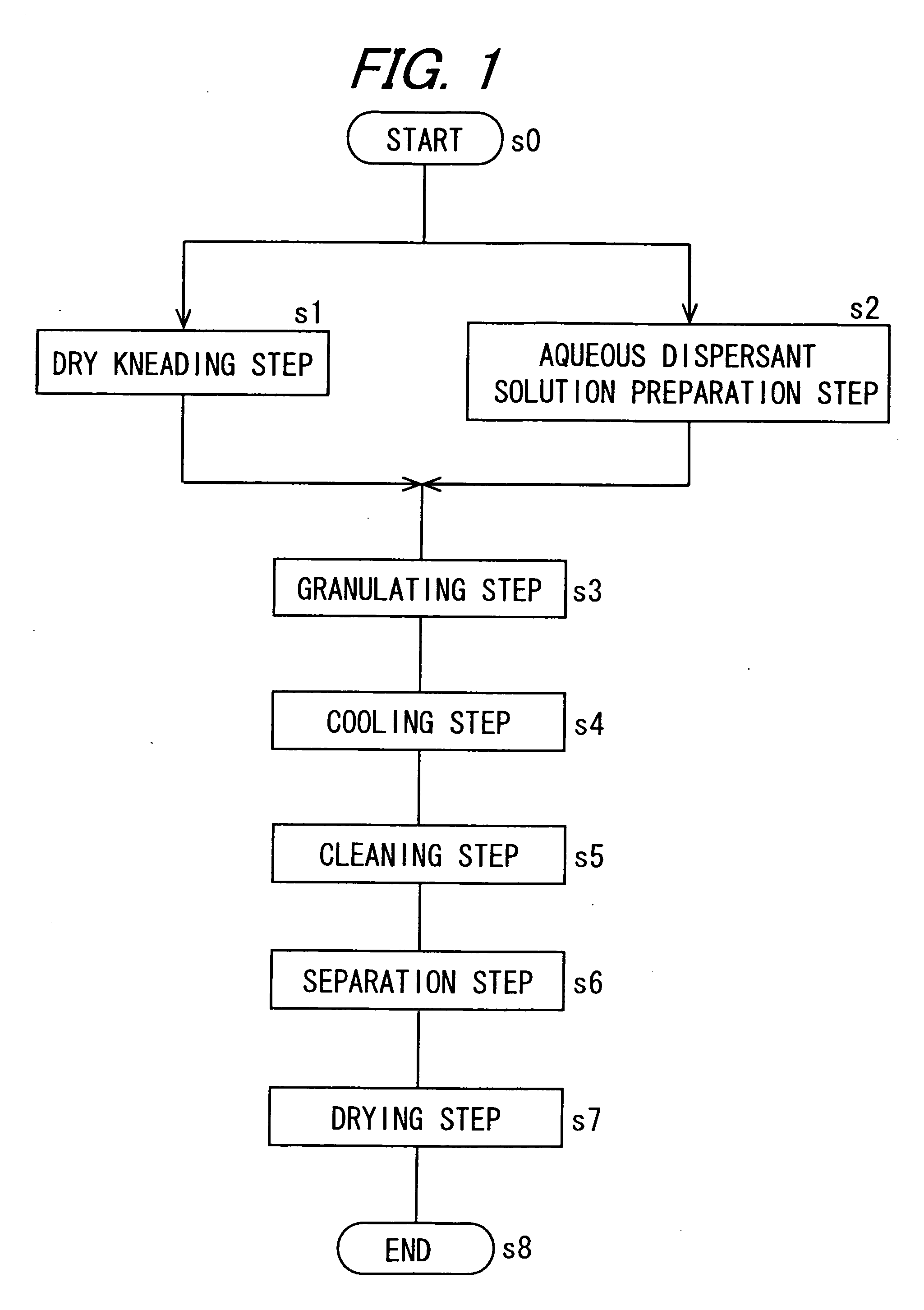

Toner and manufacturing method thereof

InactiveUS20070065746A1Inhibition decreasedReduce componentsDevelopersOrganic chemistryTetrahydrofuran

A toner of excellent anti-hot offsetting property, with no variety of the charging performance and suitable as a toner for the development of electrostatic images, and a manufacturing method thereof are provided. At first, a crosslinked resin at least containing a tetrahydrofuran insoluble component and a colorant are dry-kneaded. Next, the obtained kneaded resin product is mixed with an aqueous dispersant solution prepared in advance and they are heated, to form colorant-containing resin particles in a liquid mixture of the kneaded resin product and the aqueous dispersant solution. Then, the liquid mixture is cooled and the colorant-containing resin particles are separated from the liquid mixture.

Owner:SHARP KK

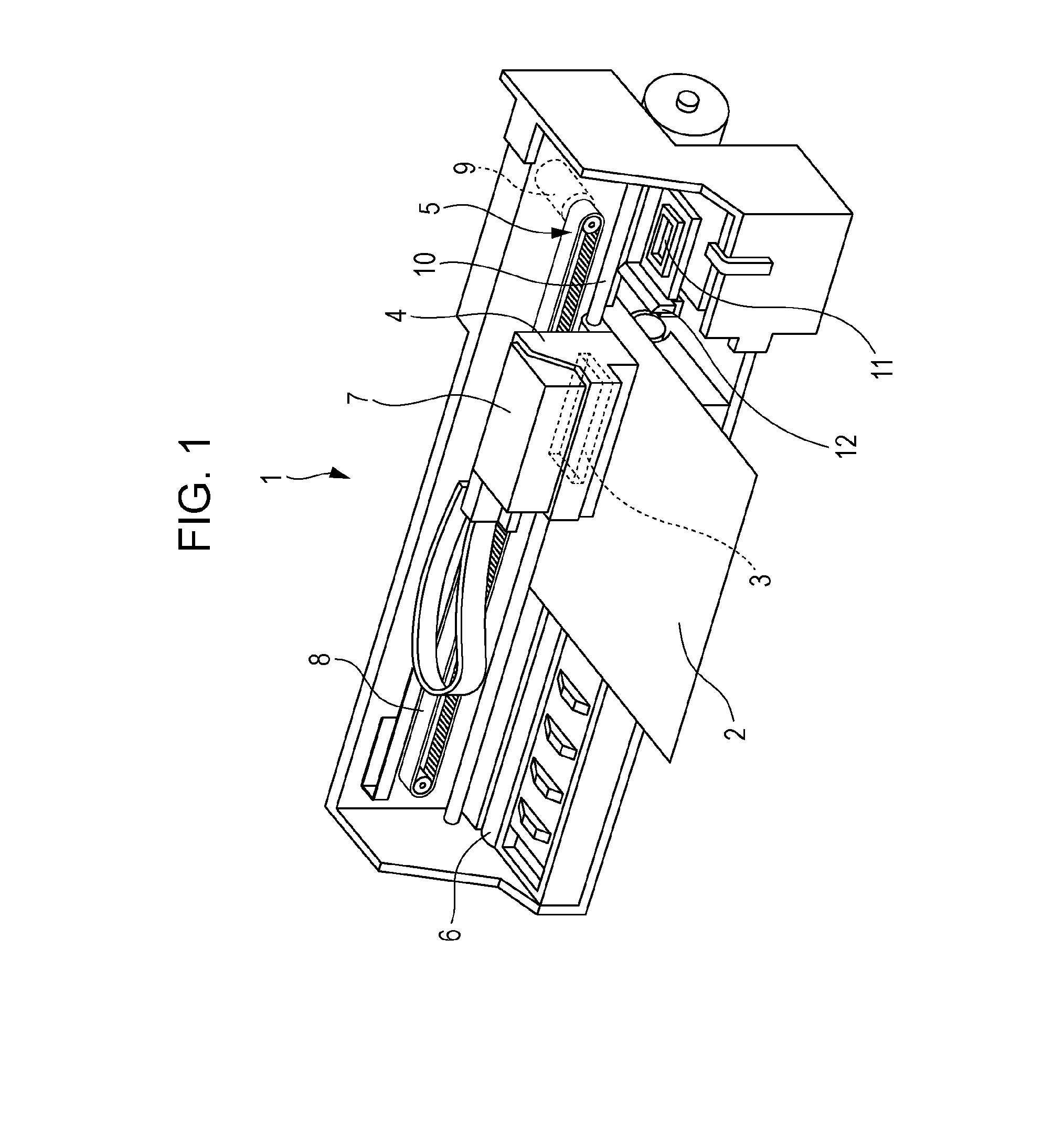

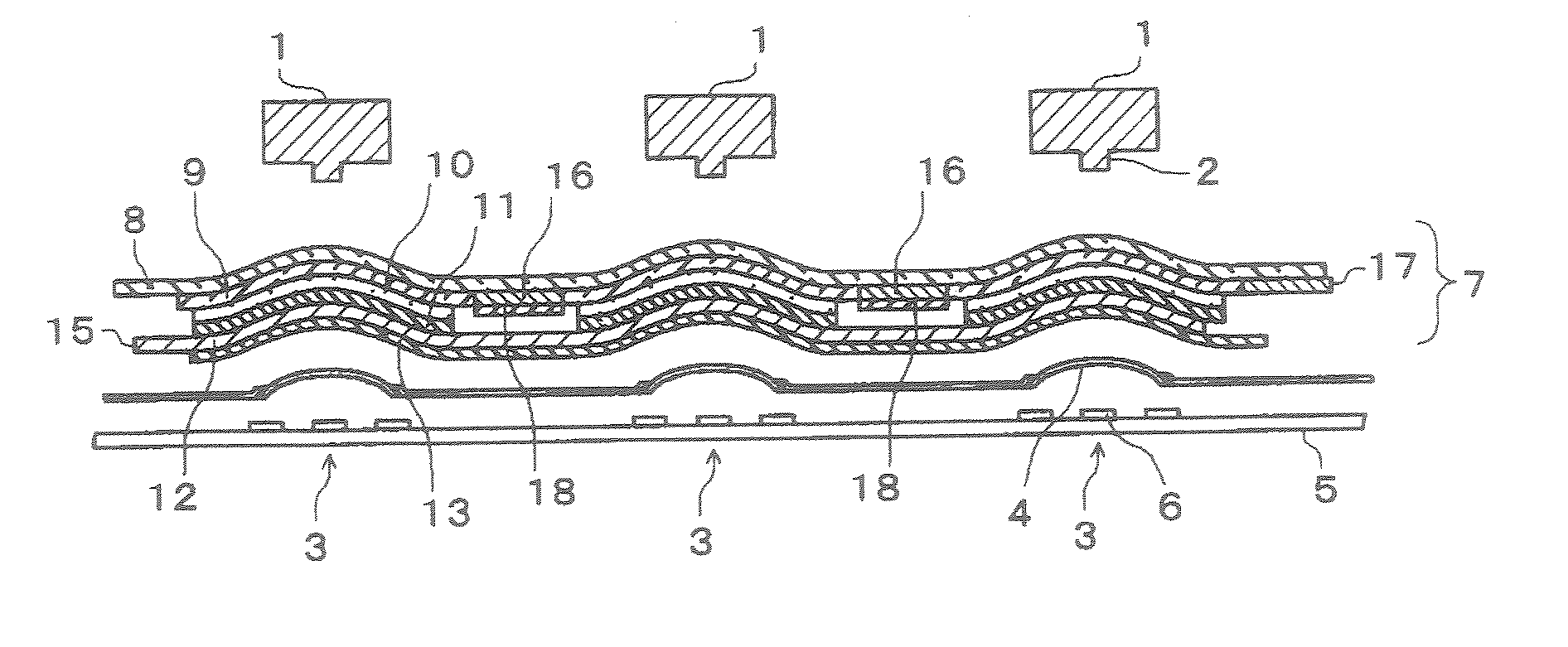

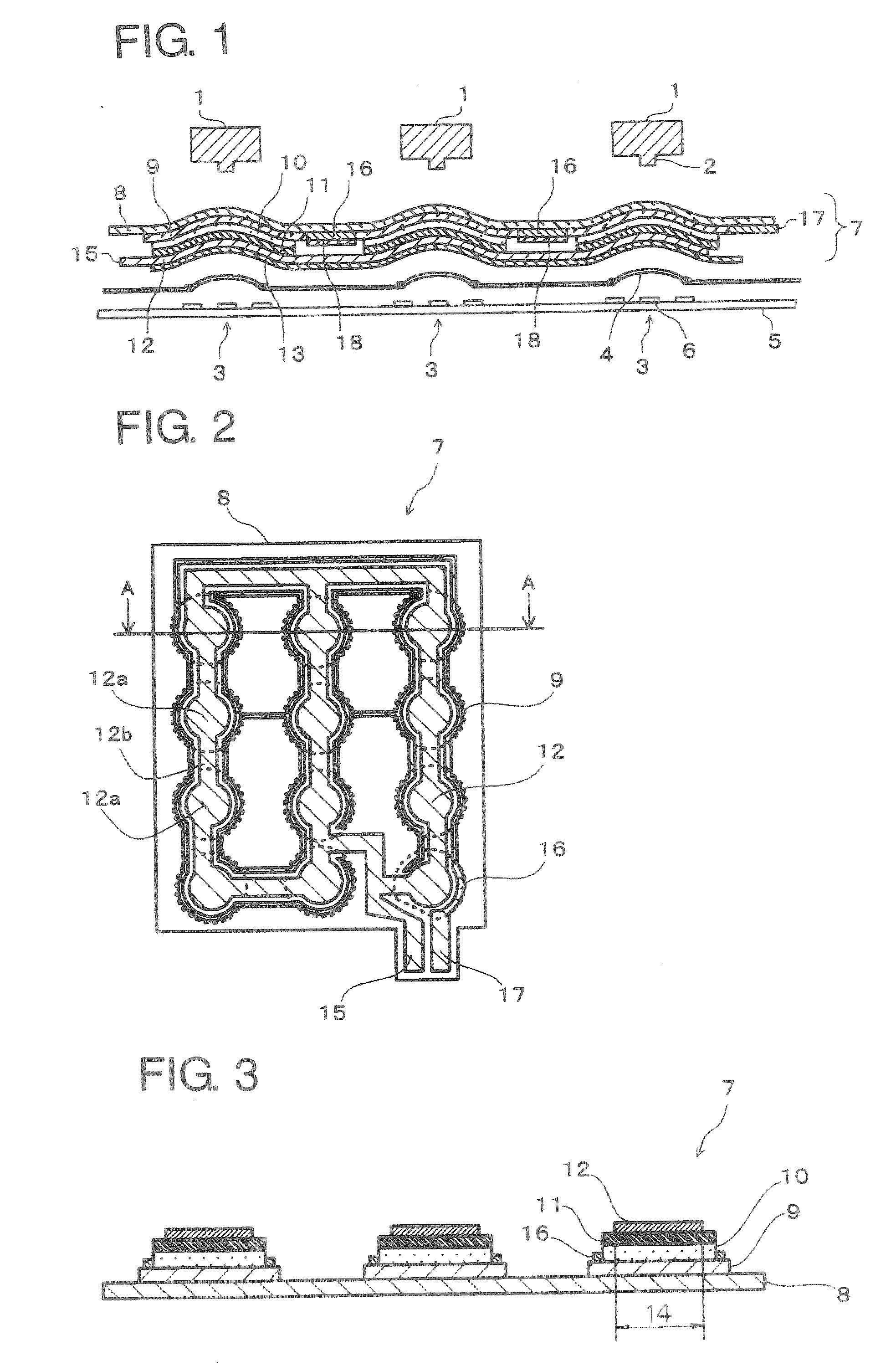

Switch lighting el sheet and lighting switch and electronic apparatus using it

InactiveUS20070177370A1Suppress breakage of wireSuppress disconnectionLegendsElectroluminescent light sourcesKey switchEngineering

A switch illuminating EL sheet (7) has a structure such that a transparent protection film (8), a transparent electrode layer (9), a light emitting layer (10), a dielectric layer (11) and a back electrode layer (12) are layered in order from a light emitting face side. The transparent protection film (8) has a thickness of 10 μm to 60 μm. Further, the transparent electrode layer (9) is constituted of a conductive polymer. Such an EL sheet (7) can suppress wire breakage or failure to light due to keystroke stress or the like without impairing reliability and clicking feeling of a key switch. The EL sheet (7) is arranged, for example, between a key top (1) and a switch mechanism portion (2) as a light source for illuminating the key top portion (1).

Owner:TOSHIBA MATERIALS CO LTD +1

Photosensitive conductive paste, method for producing multilayer electronic component using same, and multilayer electronic component

ActiveCN107003605ASuppress disconnectionImprove reliabilityPhotodevelopable thick filmNon-conductive material with dispersed conductive materialConductive pasteFrit

Provided is a photosensitive conductive paste which is capable of suppressing / preventing the occurrence of delamination between a conductor layer and an insulating layer even in cases where this photosensitive conductive paste is used for the formation of the conductor layer if a multilayer electronic component having a conductor layer and an internal conductor layer is produced by an integral firing process, and which enables fine patterning. This photosensitive conductive paste contains (a) a conductive powder in an amount of from 70.3% by mass to 85.6% by mass (inclusive) of the total mass of the paste, (b) a photosensitive resin composition containing an alkali-soluble polymer, a photosensitive monomer, a photopolymerization initiator and a solvent, and (c) a glass frit, and this photosensitive conductive paste is configured so as to satisfy such requirements that the mass ratio of the glass frit to the conductive paste, namely (glass frit / conductive paste) is from 0.020 to 0.054 (inclusive) and the softening point of the glass frit is not lower than the sintering initiation temperature of the conductive powder. As the glass frit, one having a softening point of 560 DEG C or more is used.

Owner:MURATA MFG CO LTD

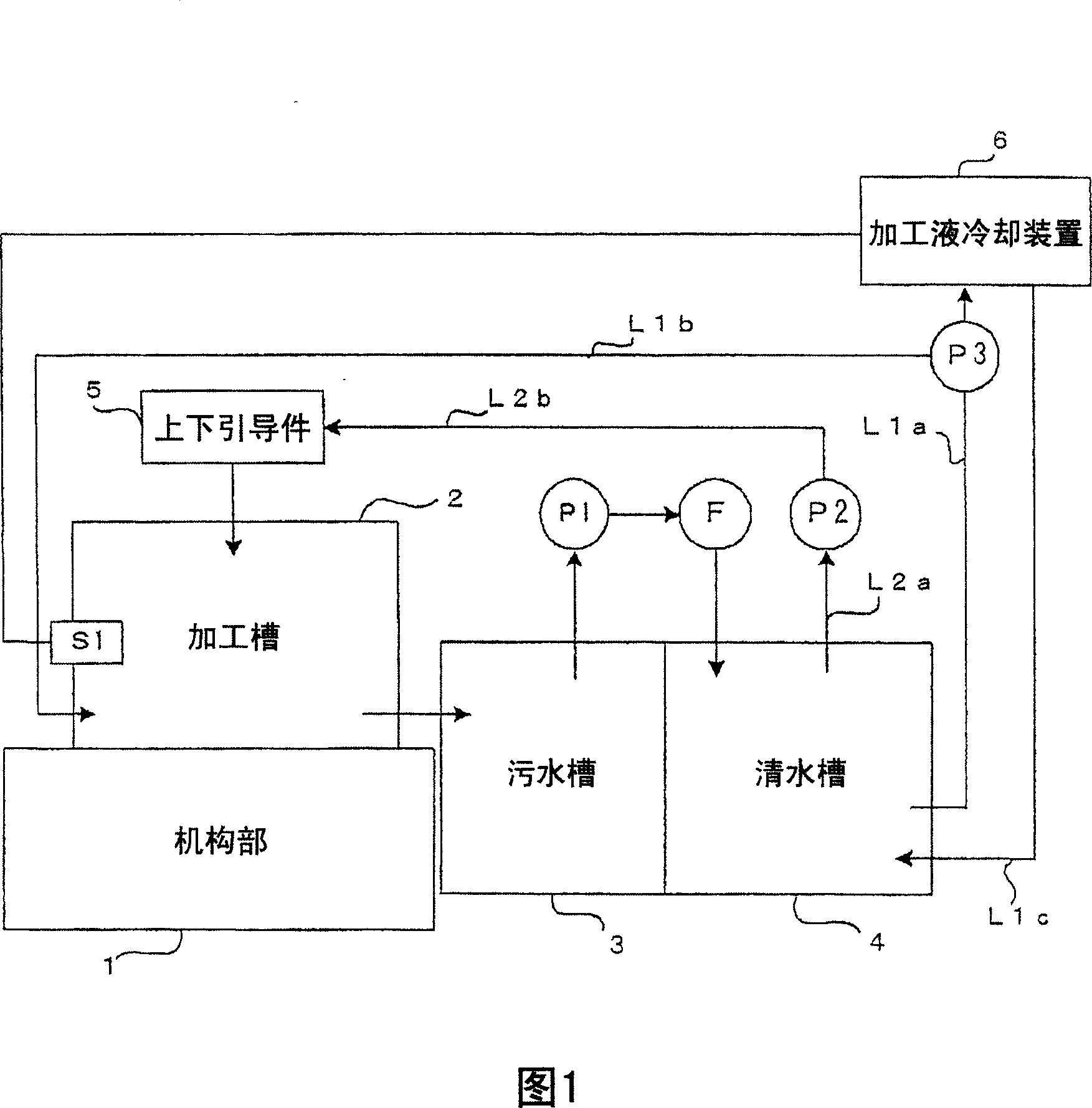

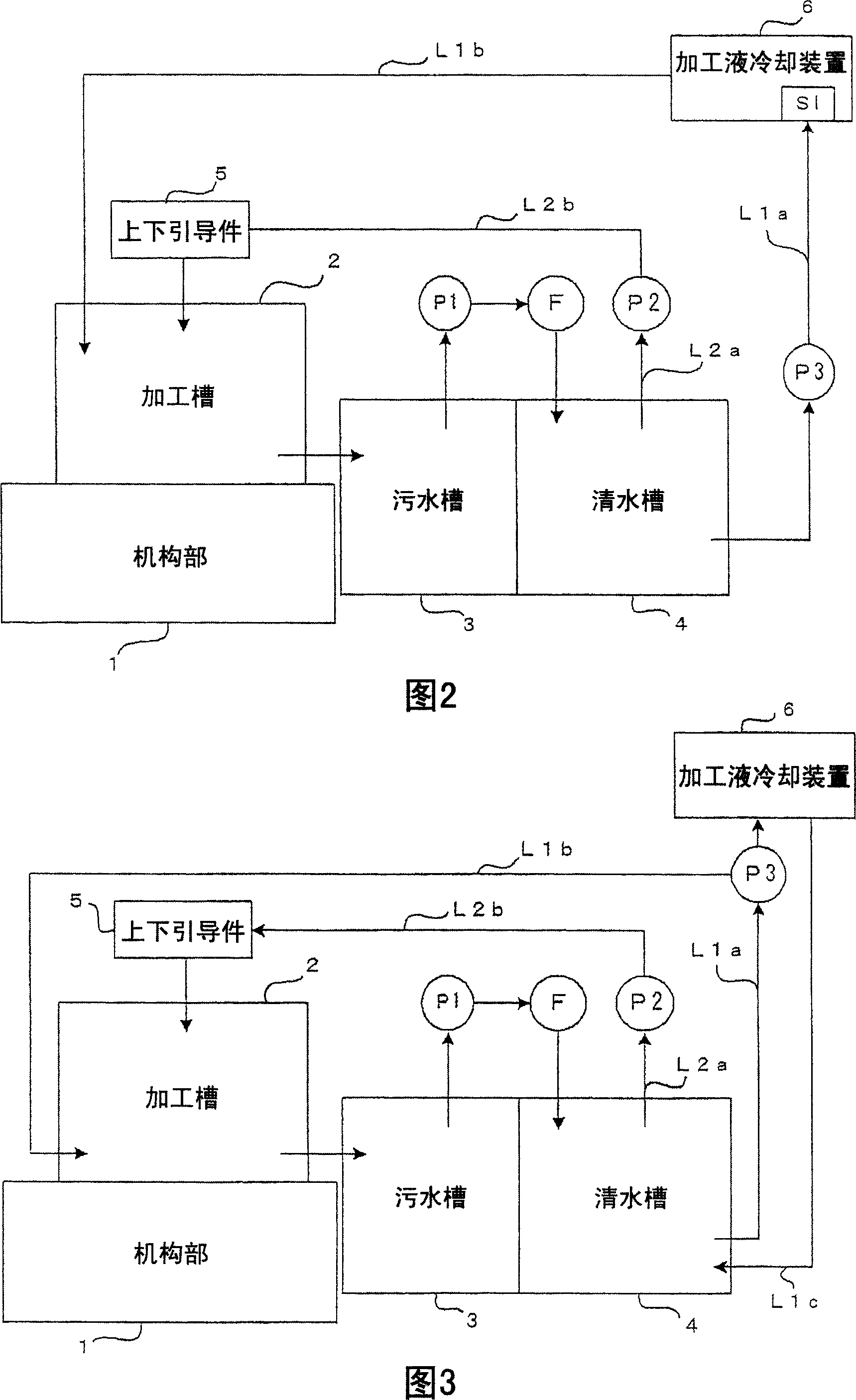

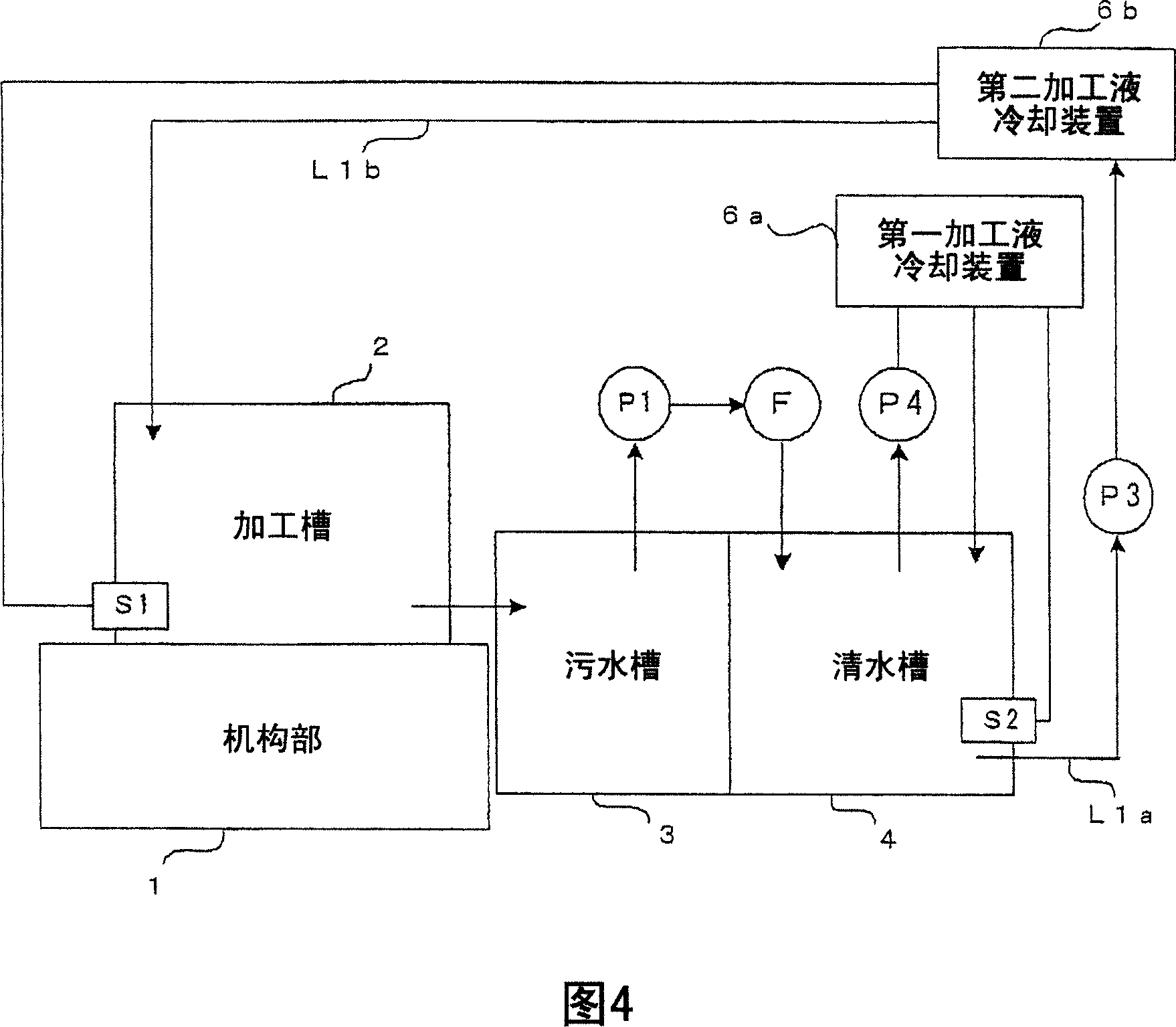

Machining liquid processing apparatus for electrospark wire processing apparatus

InactiveCN101011764ASmall temperature changePrevent thermal deformationLiquid temperatureMechanical engineering

Owner:FANUC LTD

Device mounting board and semiconductor module

InactiveUS20110100696A1Improve connection reliabilityFirmly connectedElectrically conductive connectionsSecond resist patternSolder ballComputer module

A semiconductor device is of a PoP structure such that first electrode portions provided on a first device mounting board constituting a first semiconductor module and second electrode portions provided in a second semiconductor module are joined together by solder balls. A first insulating layer having an opening is provided on one main surface of an insulating resin layer which is a substrate, and an electrode portion, whose top portion protrudes above the top surface of the first insulating layer, is formed in the opening. A second insulating layer is provided on top of the first insulating layer in the periphery of the top portion of the first electrode portion; the second insulting layer is located slightly apart from the top portion of the first electrode portion. The first electrode portion is shaped such that the top portion is formed by a curved surface or formed by a curved surface and a plane surface smoothly connected to the curved surface.

Owner:SANYO ELECTRIC CO LTD

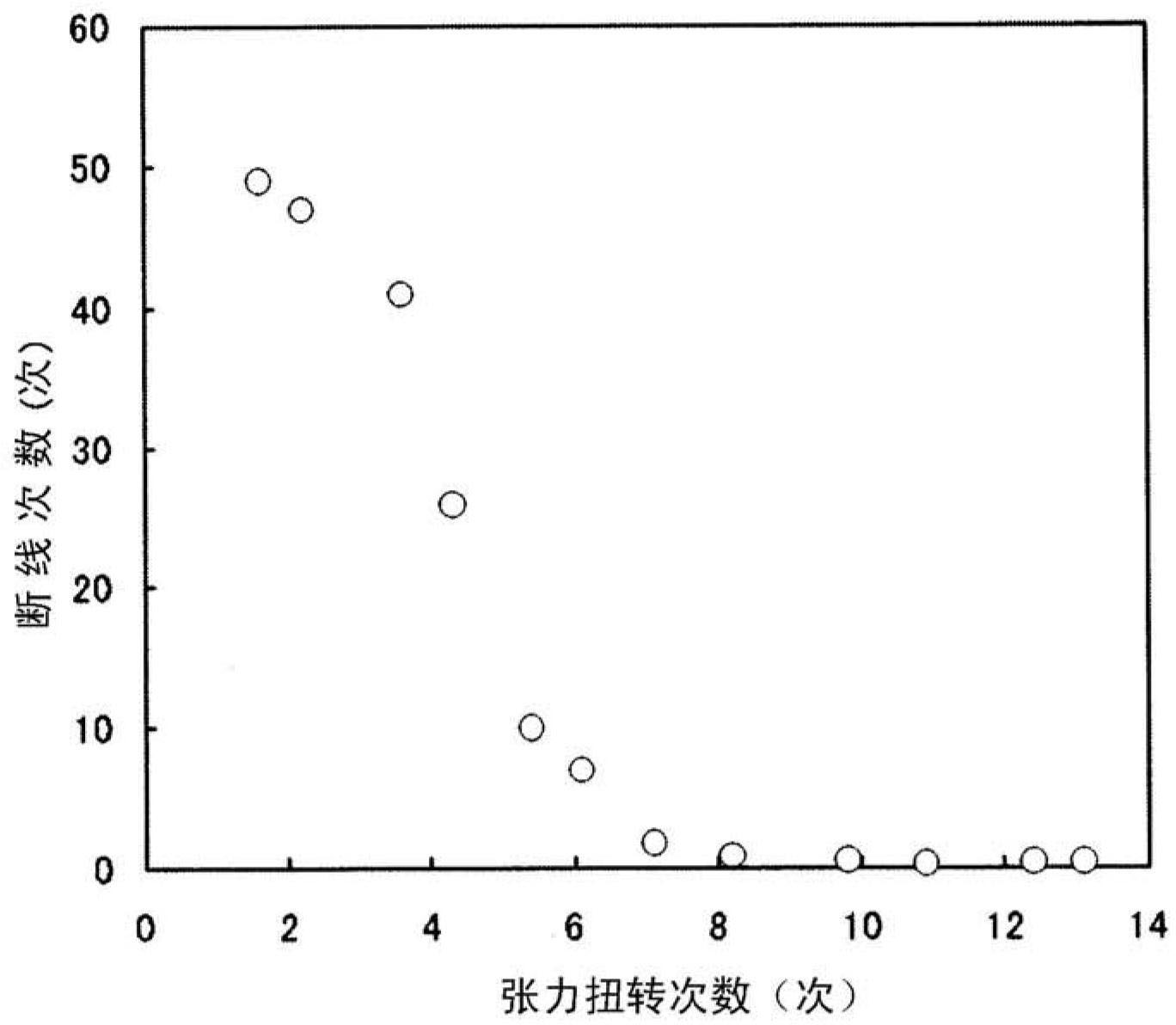

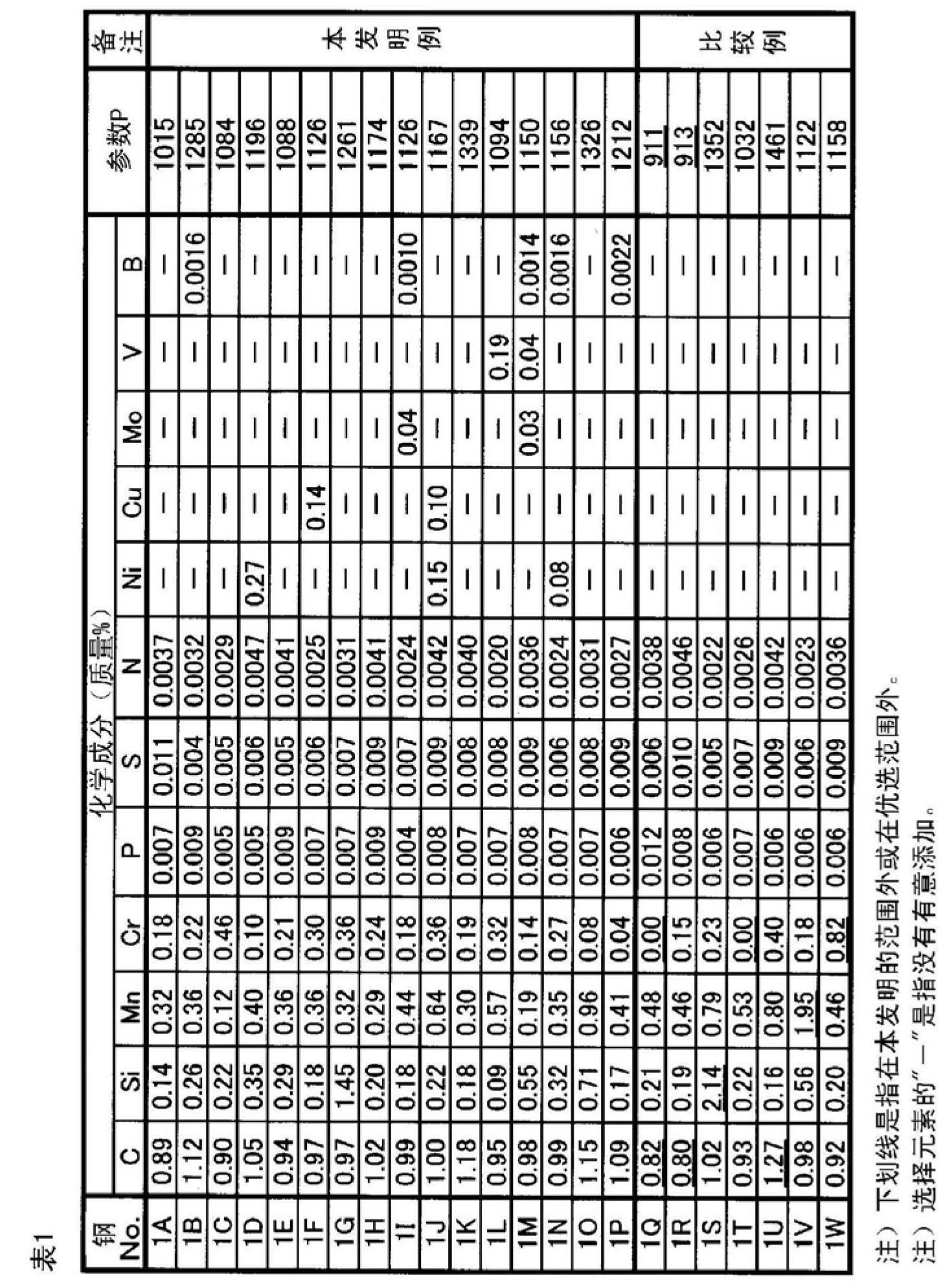

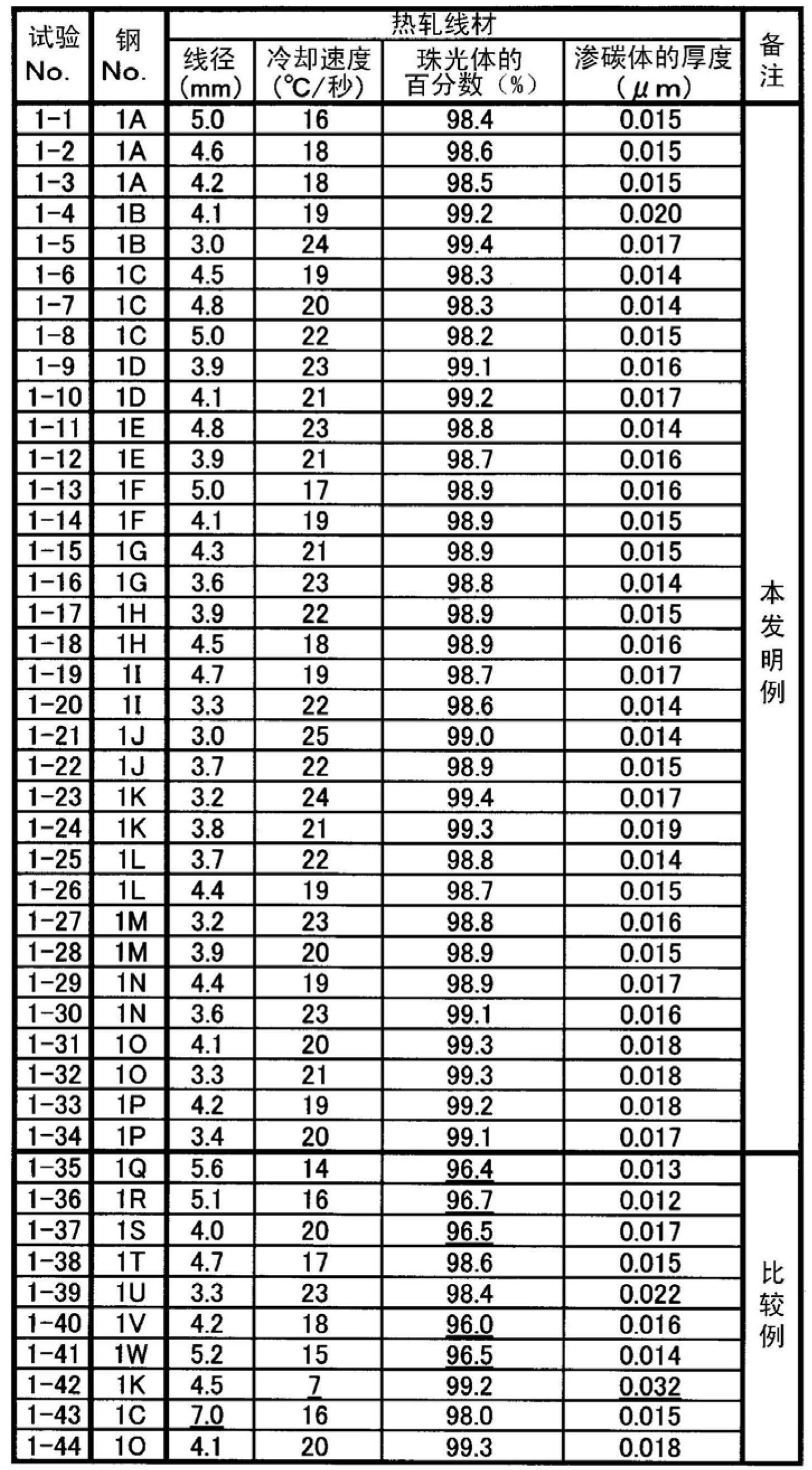

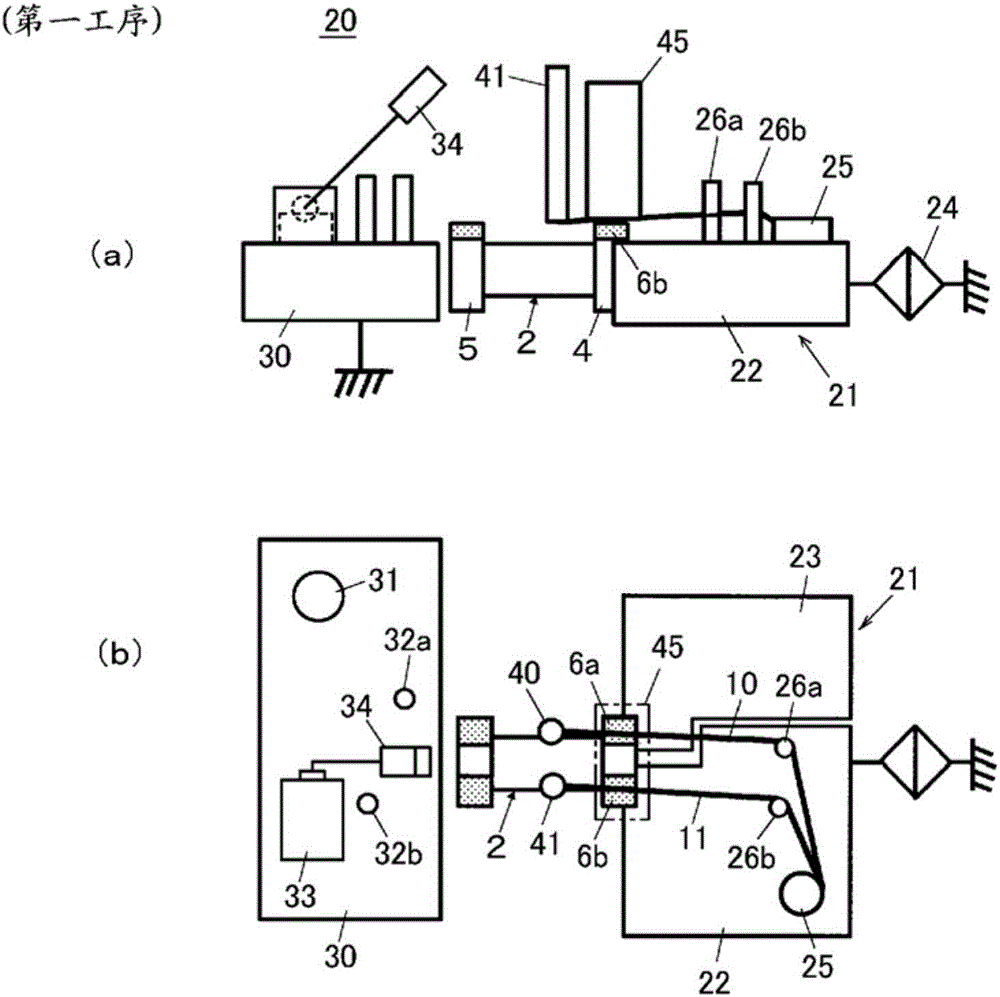

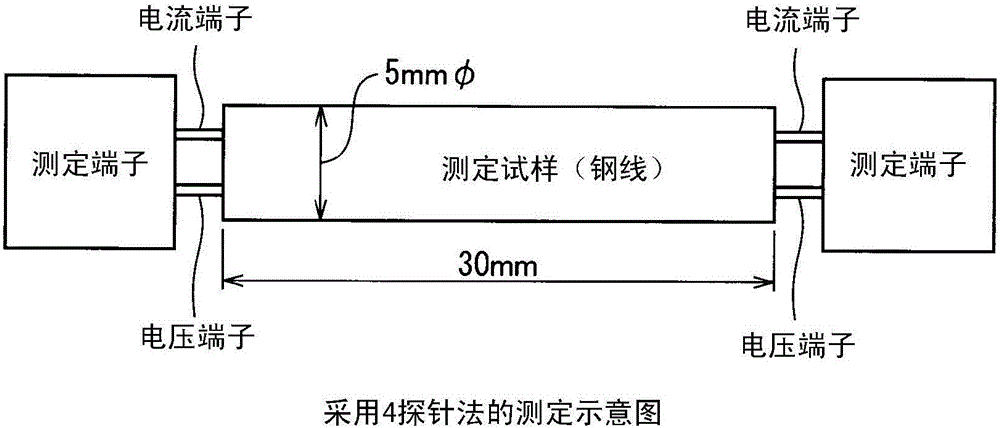

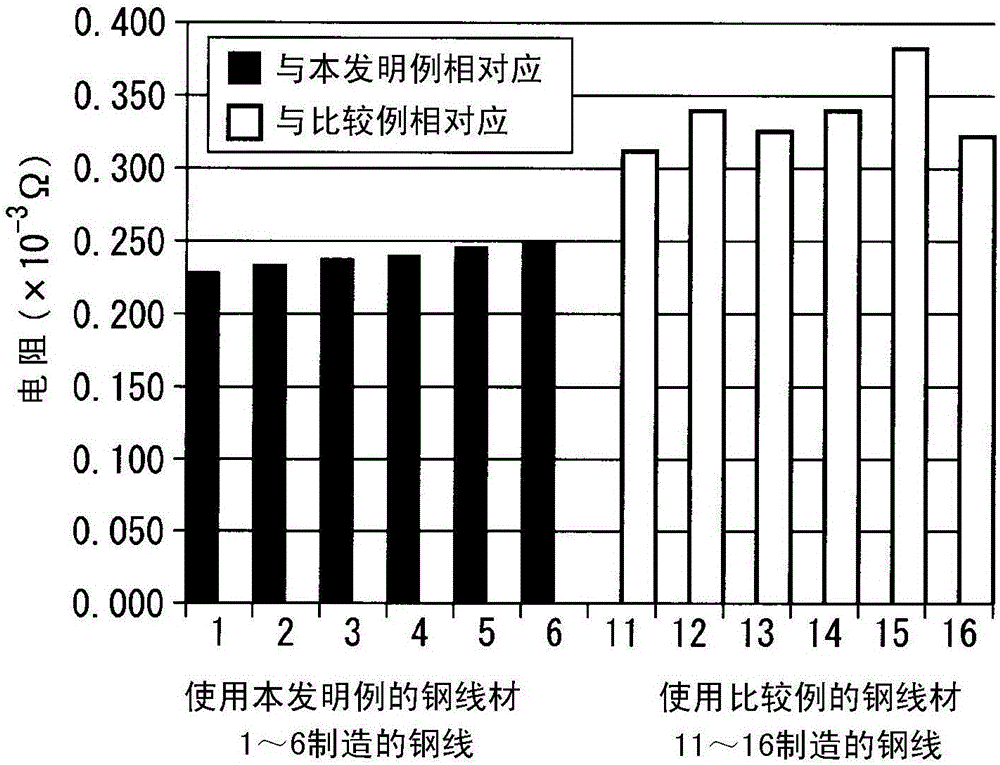

Wire material for saw wire and method for producing same

ActiveCN102597291AHigh strengthHigh breaking resistanceMetal sawing devicesAbrasion apparatusTorsion testMetallurgy

Disclosed is a wire material for a saw wire and a method for producing the same, wherein parameter P expressed by formula (1) for the C, Si, Mn, and Cr content is 1000 or higher. The metallographic structure includes an areal proportion of 98% or greater of drawn pearlite, and the diameter is 0.05 - 0.18 mm. The tensile strength is 4000 MPa. The grip spacing is 100 mm, and the number of twists in torsion tests with a load tension of tensile strength wire material cross-sectional area 0.5 is 5 or greater. P = 1098 [C] + 98 [Si] - 20 [Mn] + 167 [Cr]... (formula 1) (In formula (1), [C], [Si], [Mn], and [Cr] are the content (in mass%) of C, Si, Mn, and Cr, respectively.)

Owner:NIPPON STEEL CORP

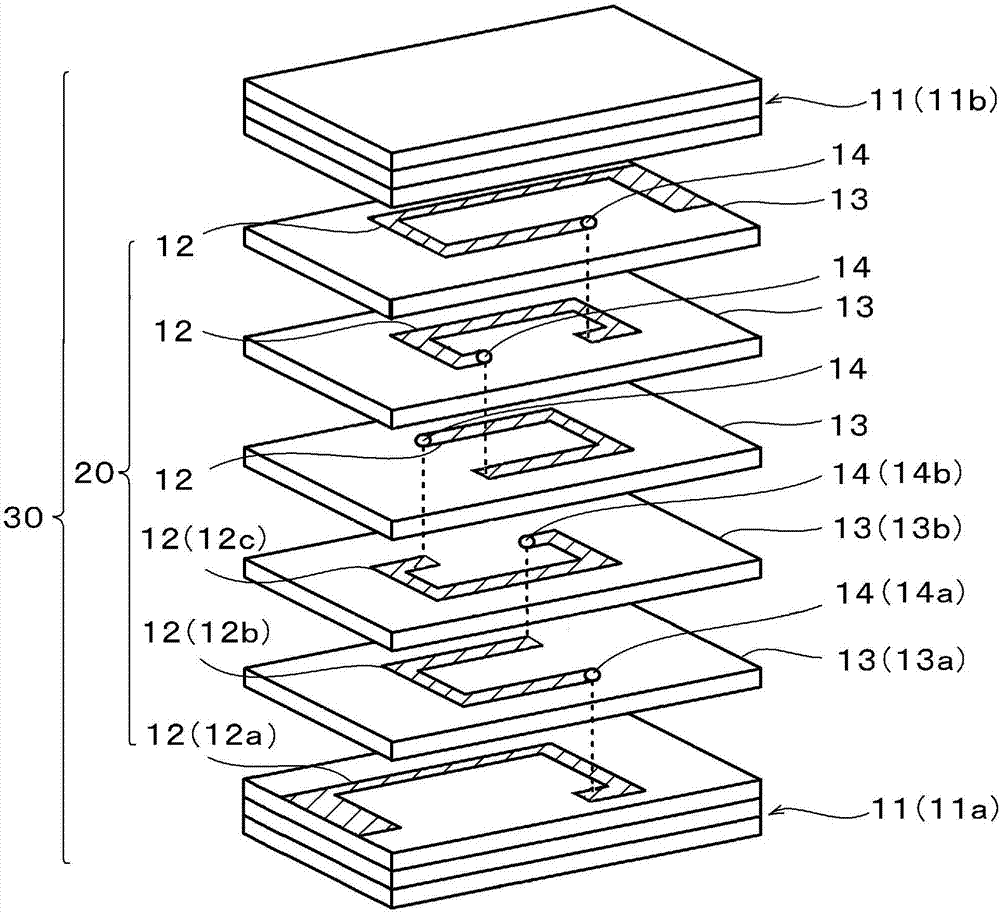

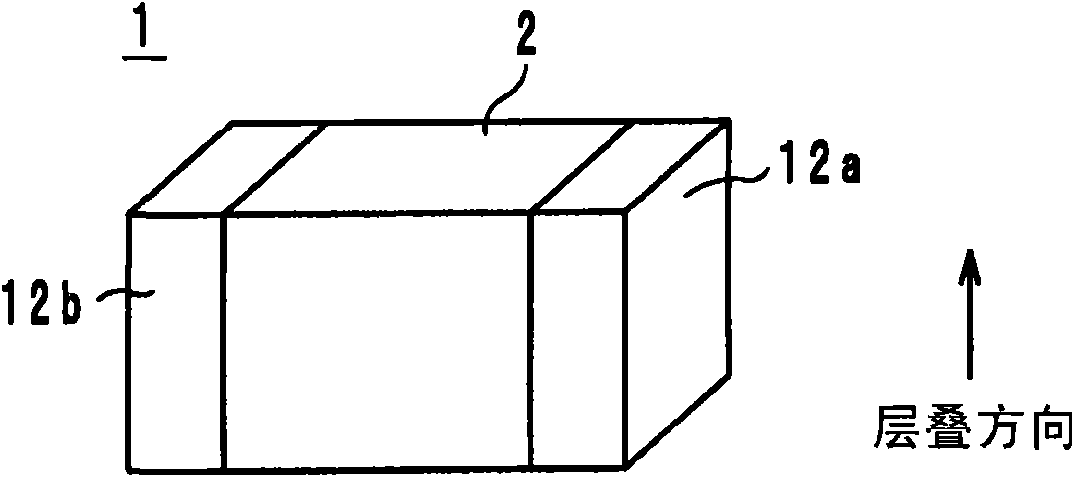

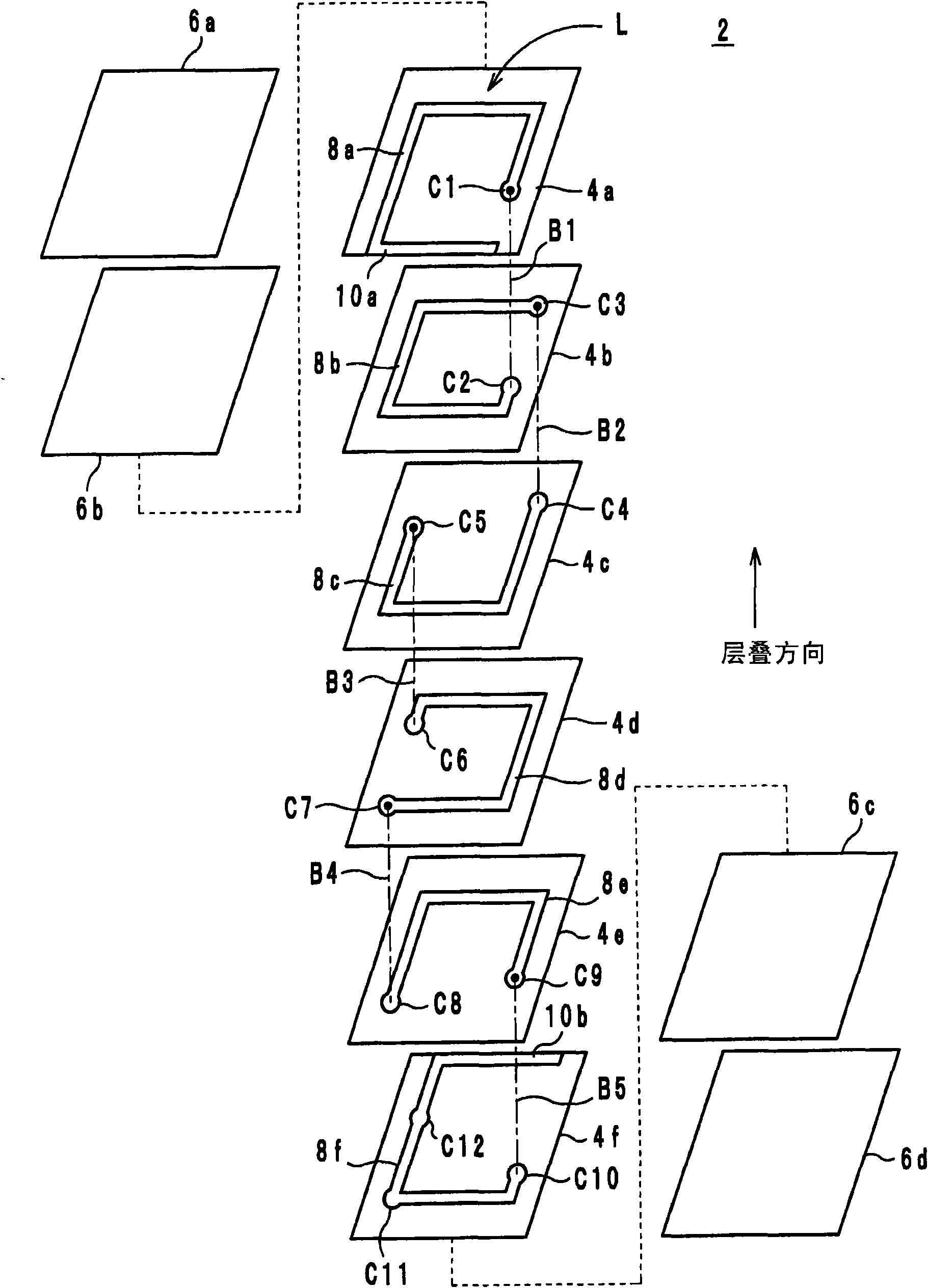

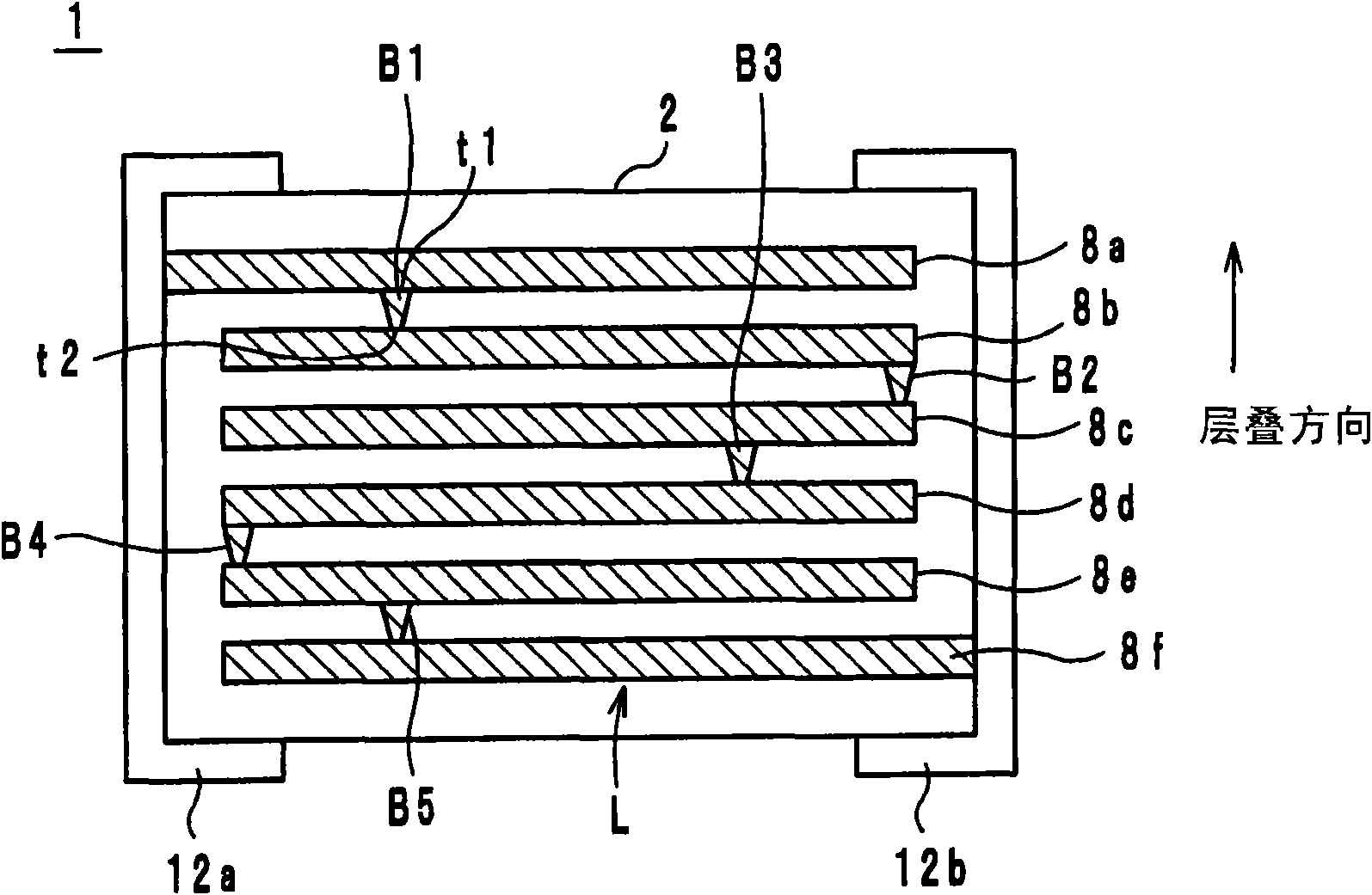

Stacking type electronic component and manufacturing method thereof

ActiveCN101572161AAvoid feverSuppress disconnectionTransformers/inductances coils/windings/connectionsFixed signal inductancesElectrical conductorElectronic component

The present invention provides a stacking type electronic component capable of preventing disconnection between a through-hole conductor and a coil electrode, and a method for manufacturing the same. A coil is composed of a plurality of coil electrodes (8). A stacking body (2) is formed by stacking a plurality of magnetic body layers (4) and a plurality of coil electrodes (8). A contact part (C) is connected to the a plurality of coil electrodes (8) and has a shape that one end area is larger than the other end area. An external electrode is formed on the surface of a stacking body and is connected with the coil. A coil electrode (8a) is longer than a coil electrode (8f). the coil electrode (8a) is connected with the end part of a contact part (B1).

Owner:MURATA MFG CO LTD

Liquid ejecting head and liquid ejecting apparatus

A common electrode includes a plurality of individual sections arranged so as to correspond to pressure chambers that are divided by a plurality of slits, and a base section that joins one end of the individual sections. The individual sections on a base section side gradually widen in plain view. The common electrode has thin film sections at the individual sections and a thick film section at the base section, and the film thickness gradually increases from the thin film sections towards the thick film section in a region between the thin film sections and the thick film section.

Owner:SEIKO EPSON CORP

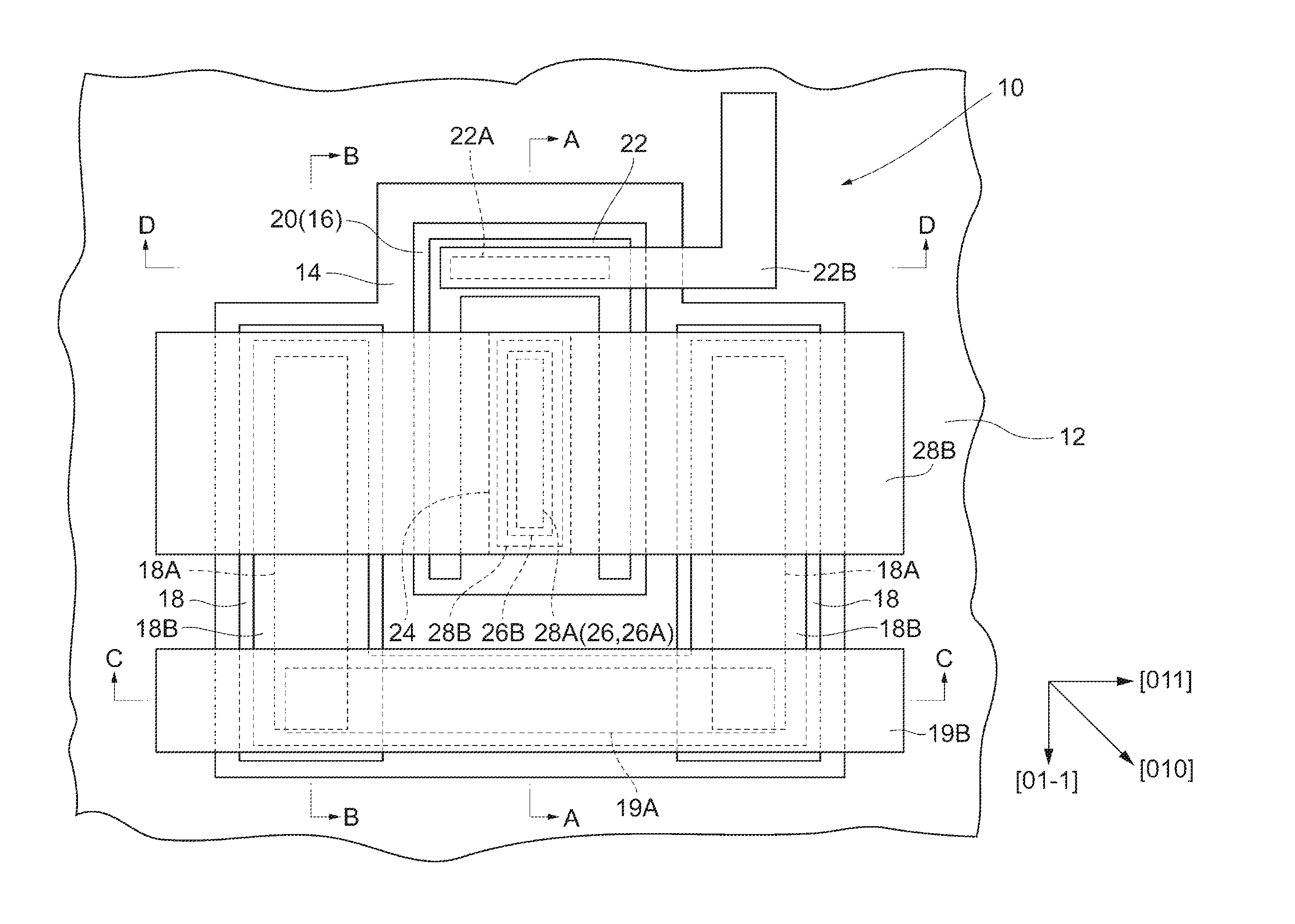

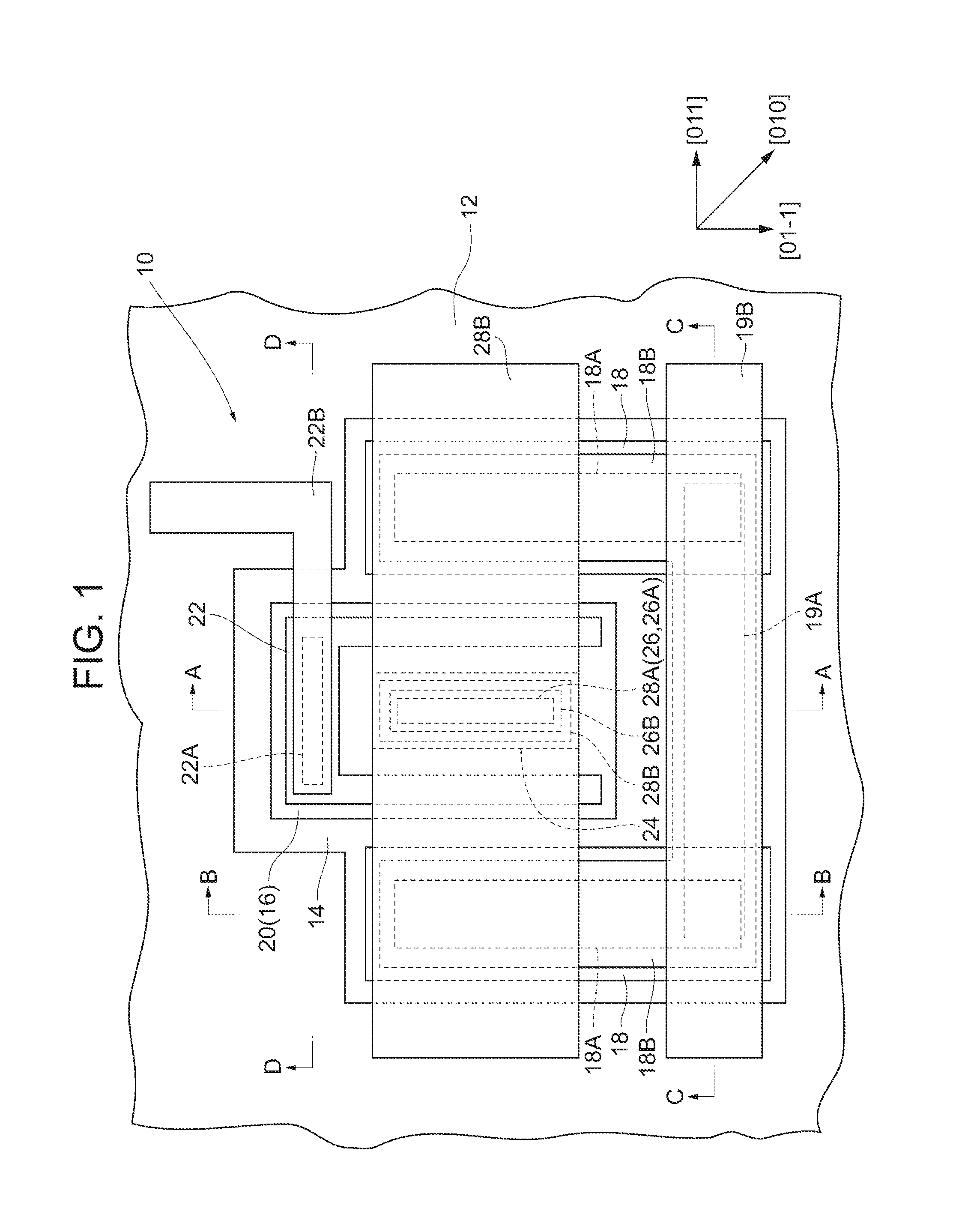

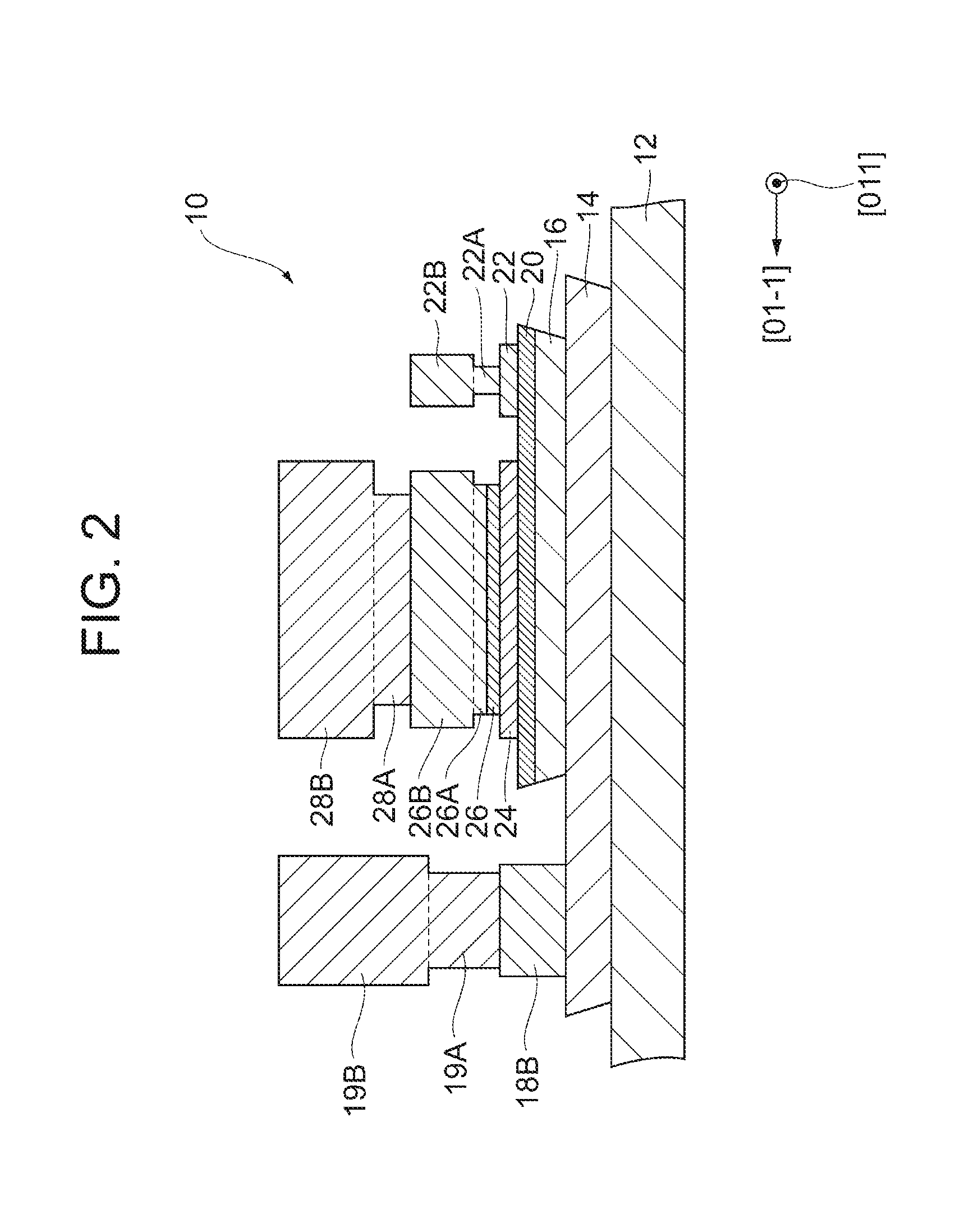

Bipolar transistor, semiconductor device, and bipolar transistor manufacturing method

InactiveUS20150035121A1Suppress disconnectionTransistorSemiconductor/solid-state device detailsDevice materialCrystal orientation

Disconnection of a base line is suppressed even when a short-side direction of a collector layer is parallel to crystal orientation [011]. A bipolar transistor includes: a collector layer that has a long-side direction and a short-side direction in a plan view, in which the short-side direction is parallel to crystal orientation [011], a cross-section perpendicular to the short-side direction has an inverted mesa shape, and a cross-section perpendicular to the long-side direction has a forward mesa shape; a base layer that is formed on the collector layer; a base electrode that is formed on the base layer; and a base line that is connected to the base electrode and that is drawn out from an end in the short-side direction of the collector layer to the outside of the collector layer in a plan view.

Owner:MURATA MFG CO LTD

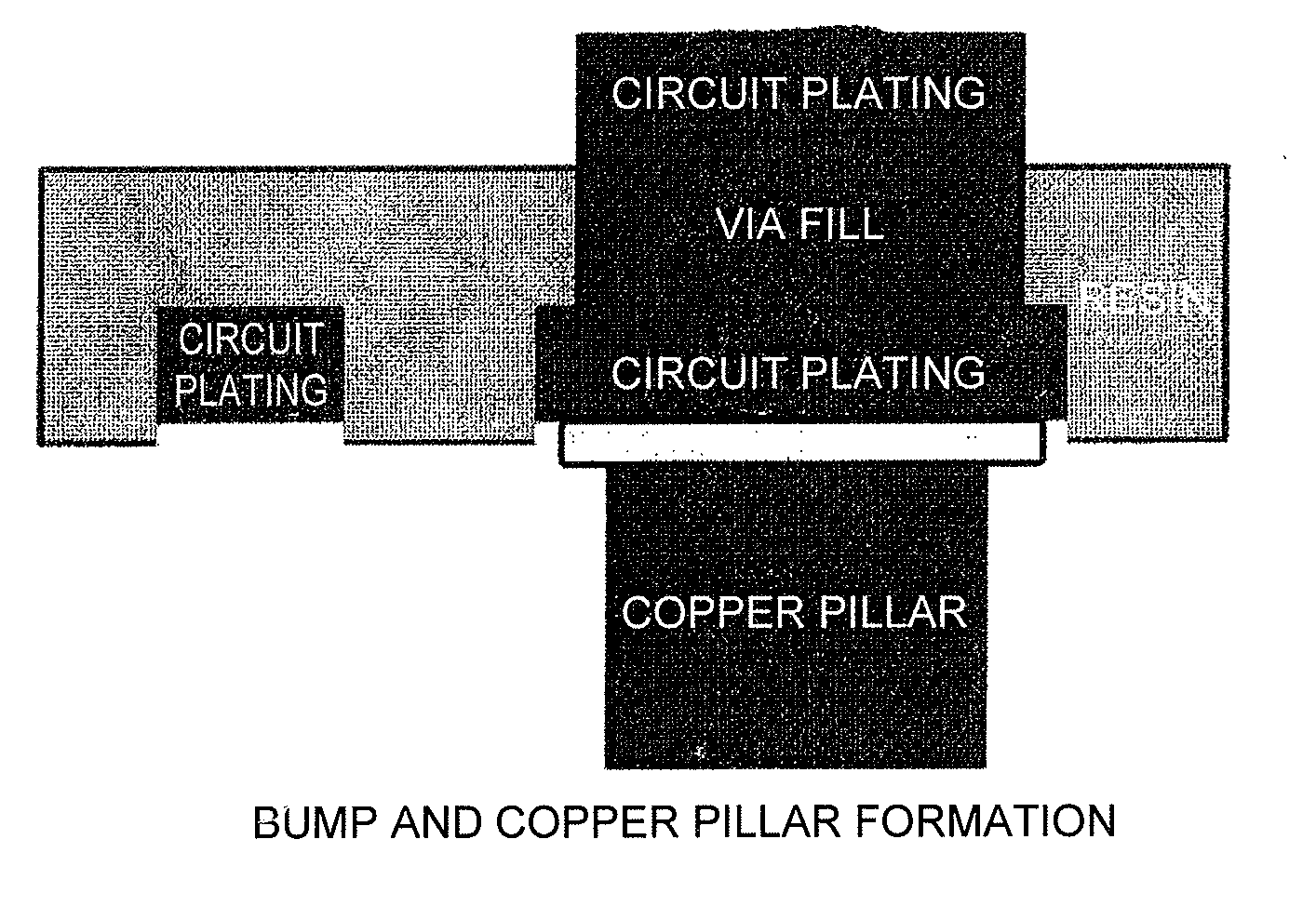

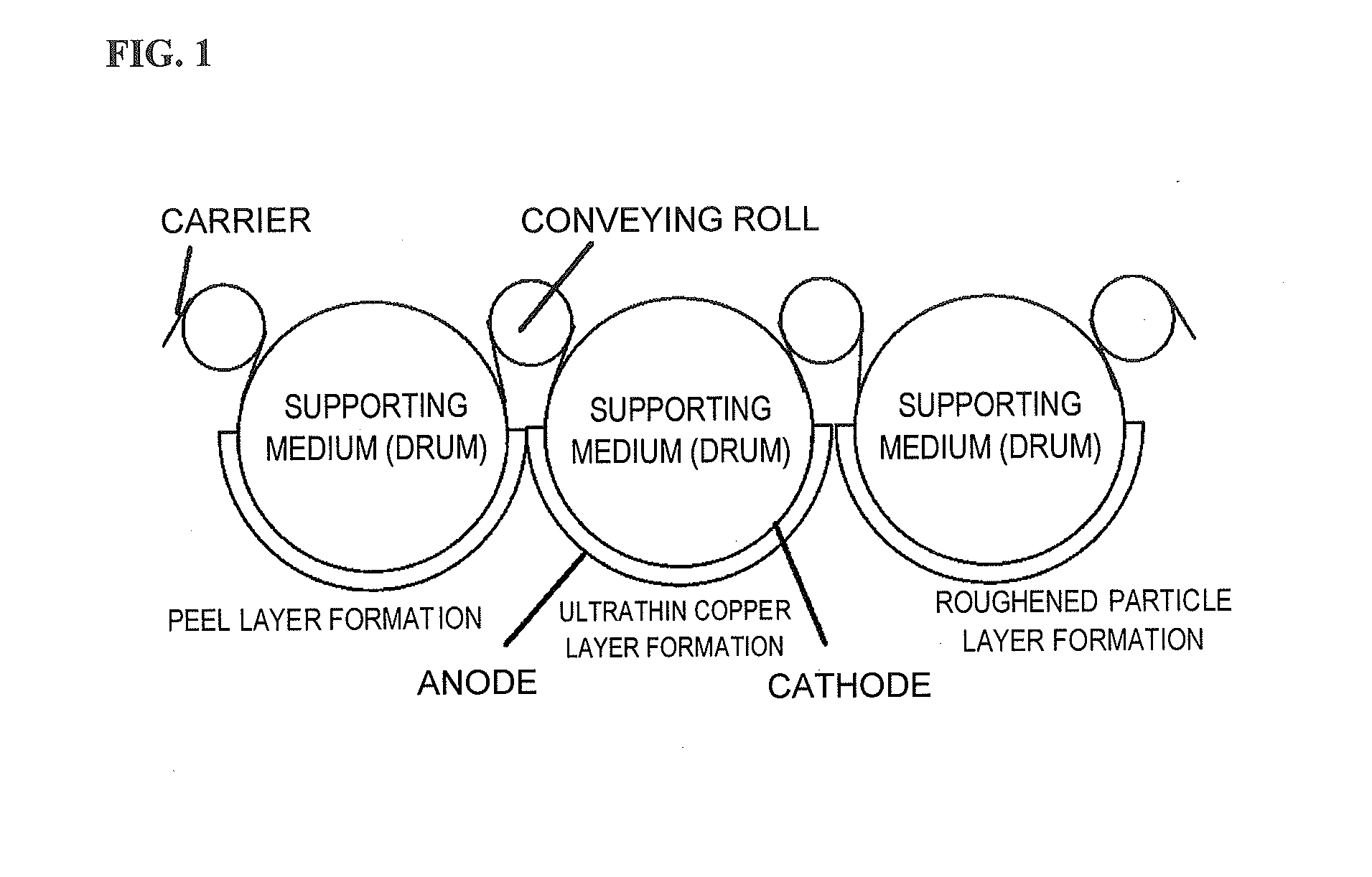

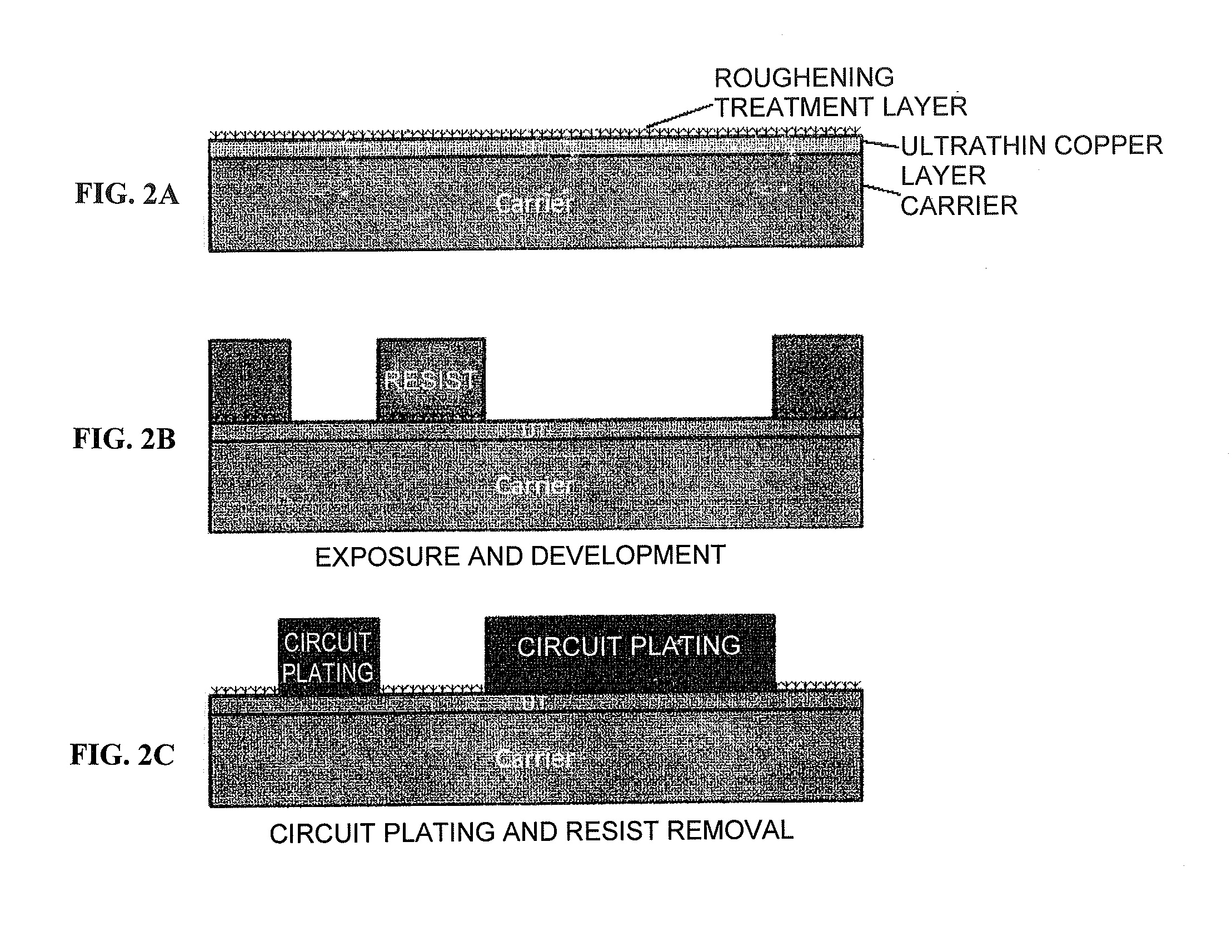

Copper foil provided with carrier, laminate, printed wiring board, electronic device, and method for fabricating printed wiring board

ActiveUS20160212846A1Suppress disconnectionFine circuitDecorative surface effectsRecord information storageCopper foilInter layer

Provided is a copper foil provided with a carrier which enables to form an extremely fine circuit and to suppress the disconnection of a circuit well. A copper foil provided with a carrier having, in order, an intermediate layer and an ultrathin copper layer on one side or both sides of the carrier, wherein the ultrathin copper layer is an electrolytic copper layer; and the thickness of the ultrathin copper layer measured by using a gravimetric method is 1.5 μm or less and the number of pinholes in the ultrathin copper layer is 0 pinholes / m2 or more and 5 pinholes / m2 or less.

Owner:JX NIPPON MINING& METALS CORP

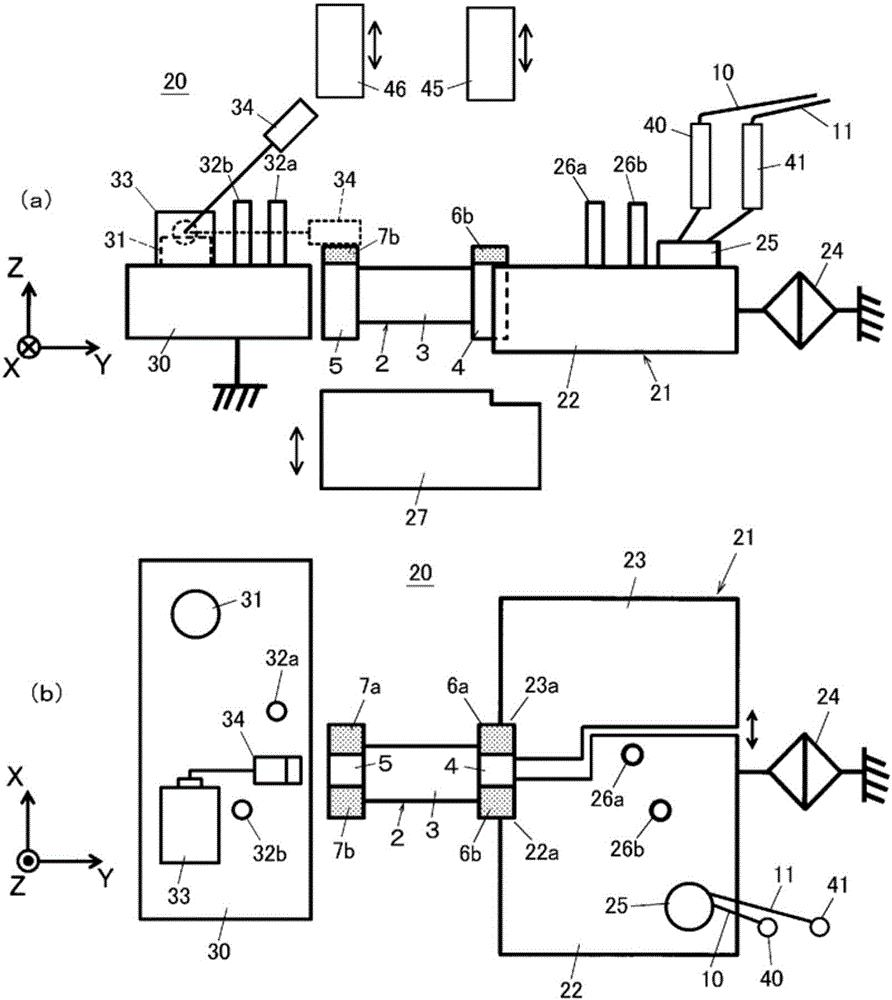

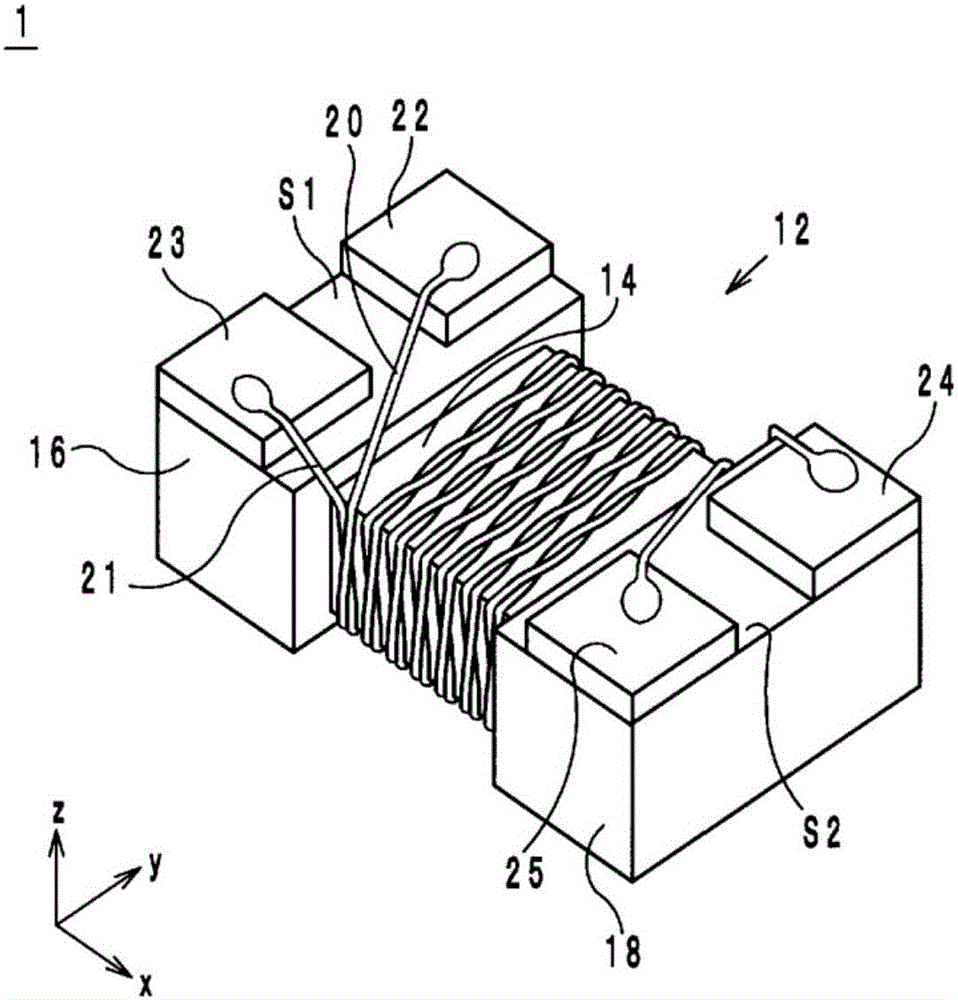

Multiple-wire winding method, multiple-wire winding device, and wound coil component

ActiveCN106463257AAvoid injuryGuaranteed distanceBroad-band transformersCoils manufactureEngineeringConductor Coil

To provide a multiple-wire winding method, a multiple-wire winding device, and a wound coil component that make it possible to reduce both damage done to wires and the risk of short-circuits between said wires and electrodes at different potentials. In this winding method, starting sections of a plurality of wires are first guided from the outside of a flange on one end to the inside thereof and then laid out on top of and affixed to electrodes on said flange. The wires are guided laterally with respect to the axis of a core and are wound around a winding-core section together. Next, a wire-bending implement is made to contact a flat surface of a flange on the other end between a plurality of electrodes, ending sections of the wires are guided from the inside of said flange to the outside thereof, and the ending section of at least one wire is hooked between the wire-bending implement and the flange on the other end and bent with said wire(s) under tension. The ending sections of the plurality of wires are then affixed to the corresponding electrodes on the flange on the other end. By bending the wire ending section(s) laterally, the risk of short-circuits with electrodes at different potentials is reduced.

Owner:MURATA MFG CO LTD

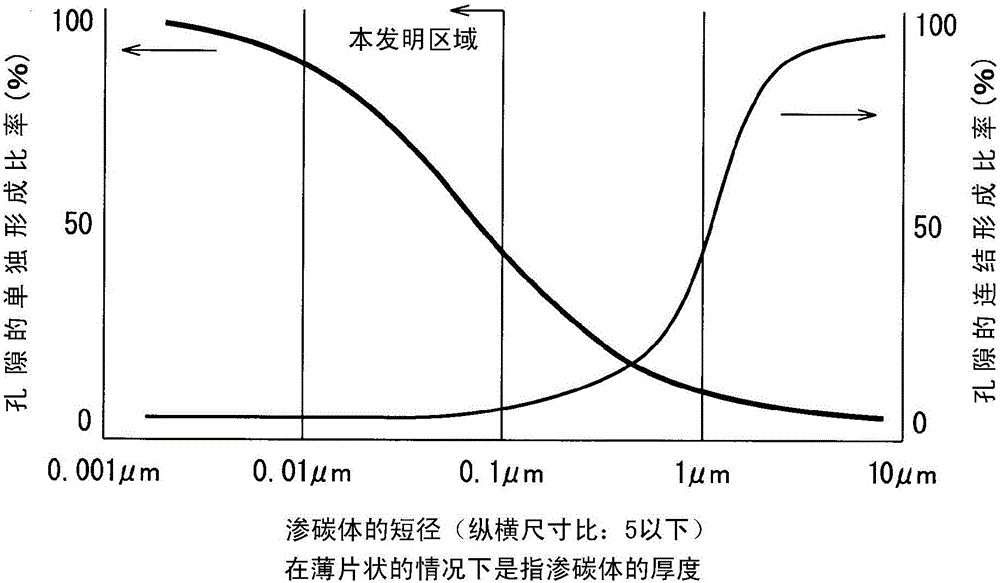

Favorably workable steel wire and method for producing same

ActiveCN105899705AEasy to processSuppress disconnectionFurnace typesHeat treatment bathsMetallurgyMinor axis

The present invention provides a steel wire provided with stable workability performance. This steel wire is wire having a steel component containing, in mass%, C in the amount of 0.20-0.60%, Si in the amount of 0.15-0.30%, Mn in the amount of 0.25-0.60%, P in the amount of <=0.020%, and S in the amount of <=0.010%, with the remainder constituting Fe and inevitable impurities, the steel wire being characterized by having cementite as an internal structure, and in that 80% or more, in a unit number ratio, of the cementite in a cross-section perpendicular to the lengthwise direction of the wire has a minor axis of 0.1Mum or less, and an aspect ratio of the major axis to the minor axis of 2.0 or less.

Owner:NIPPON STEEL CORP

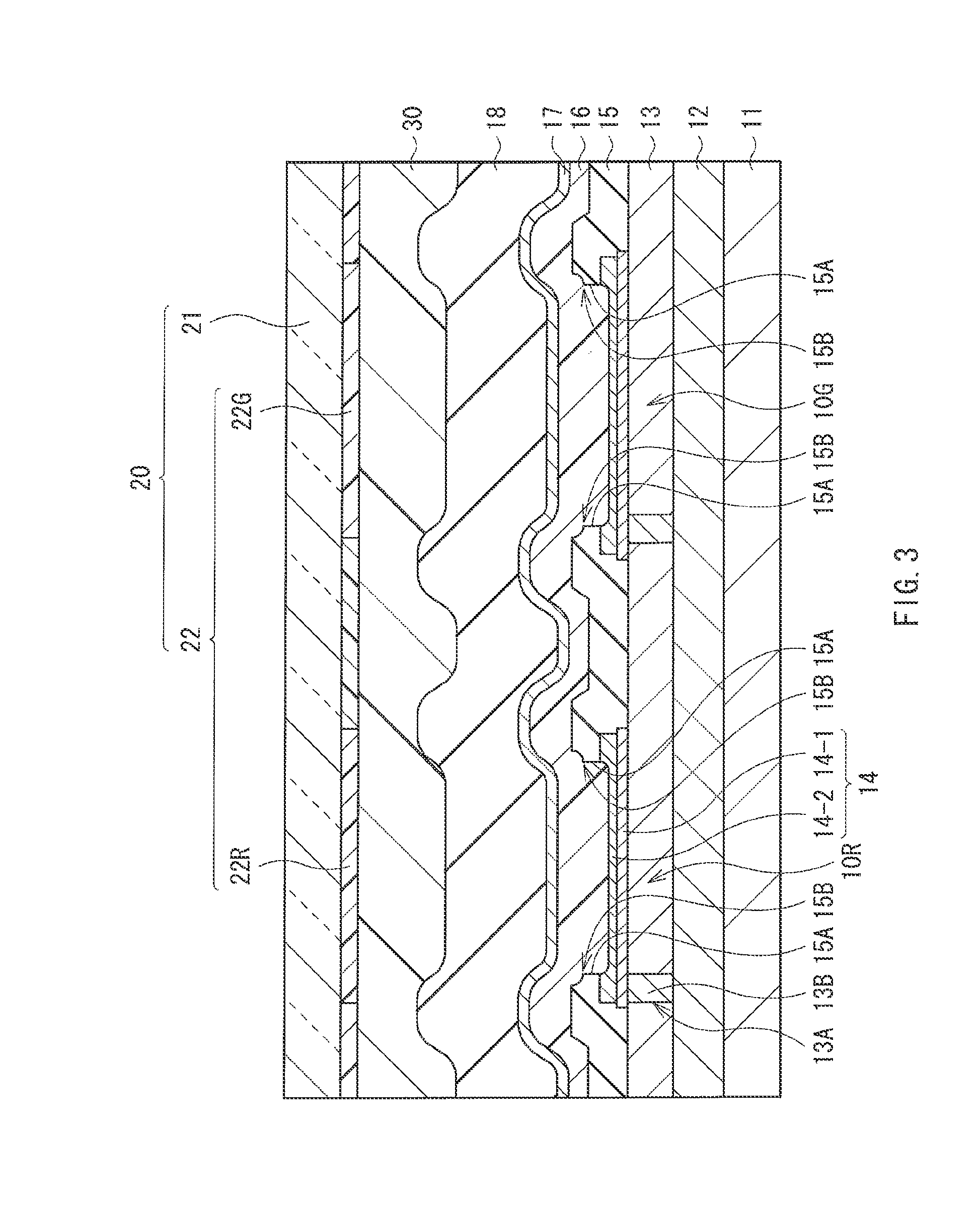

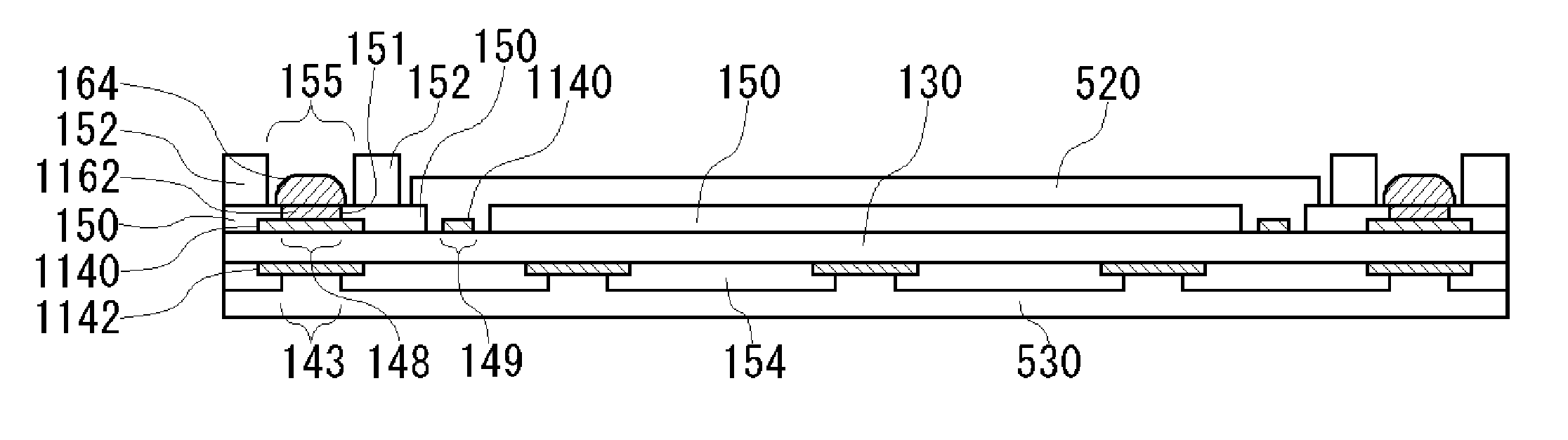

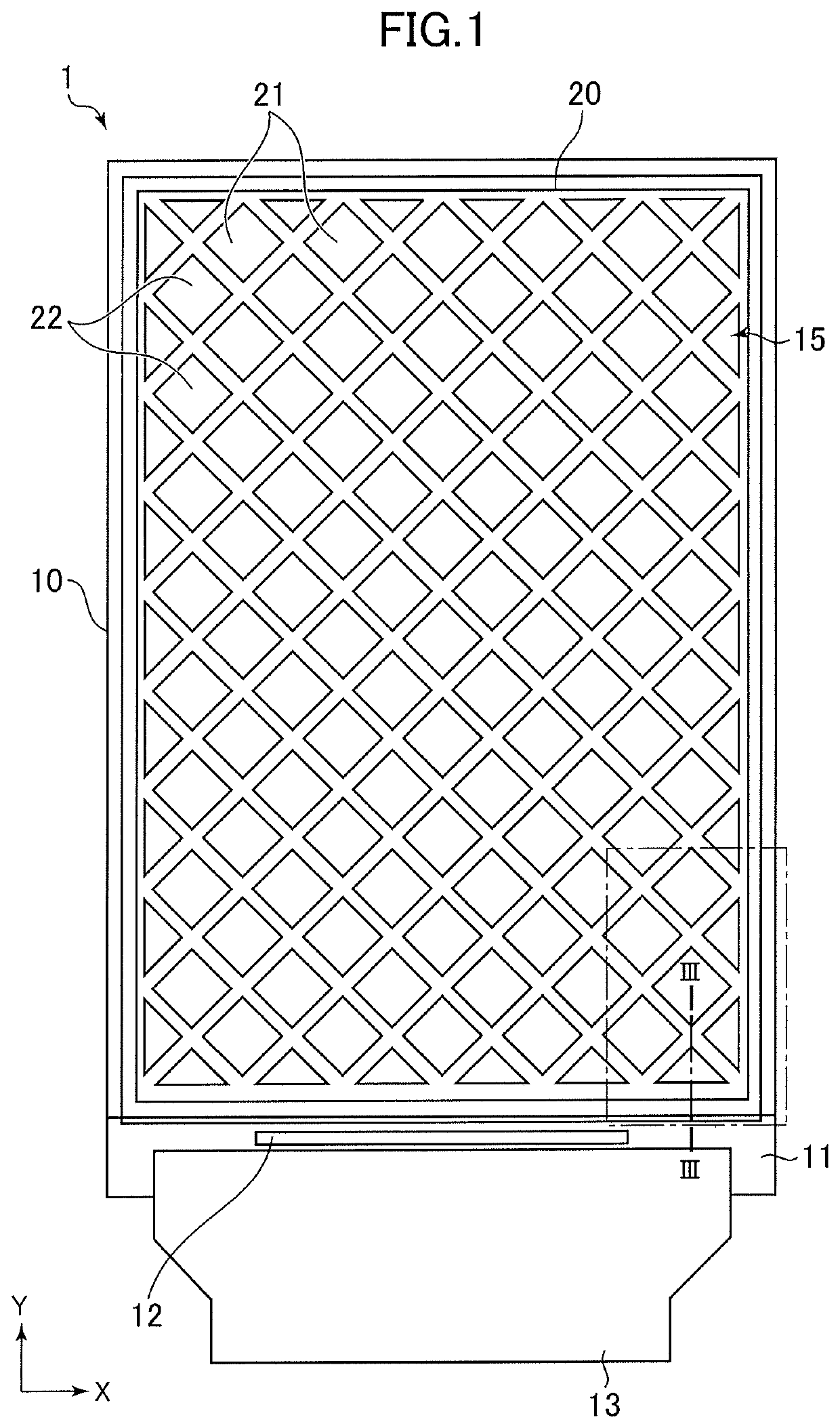

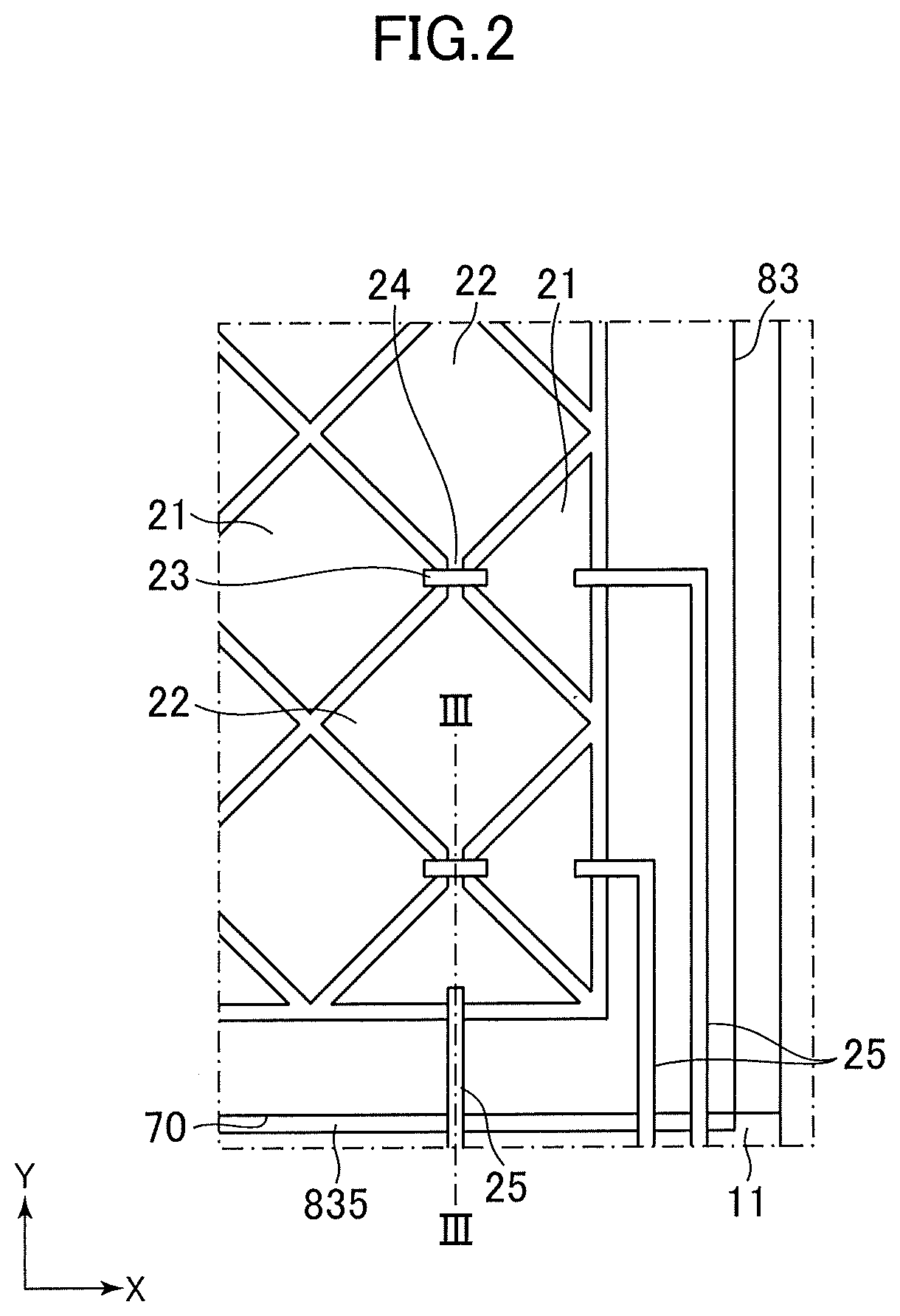

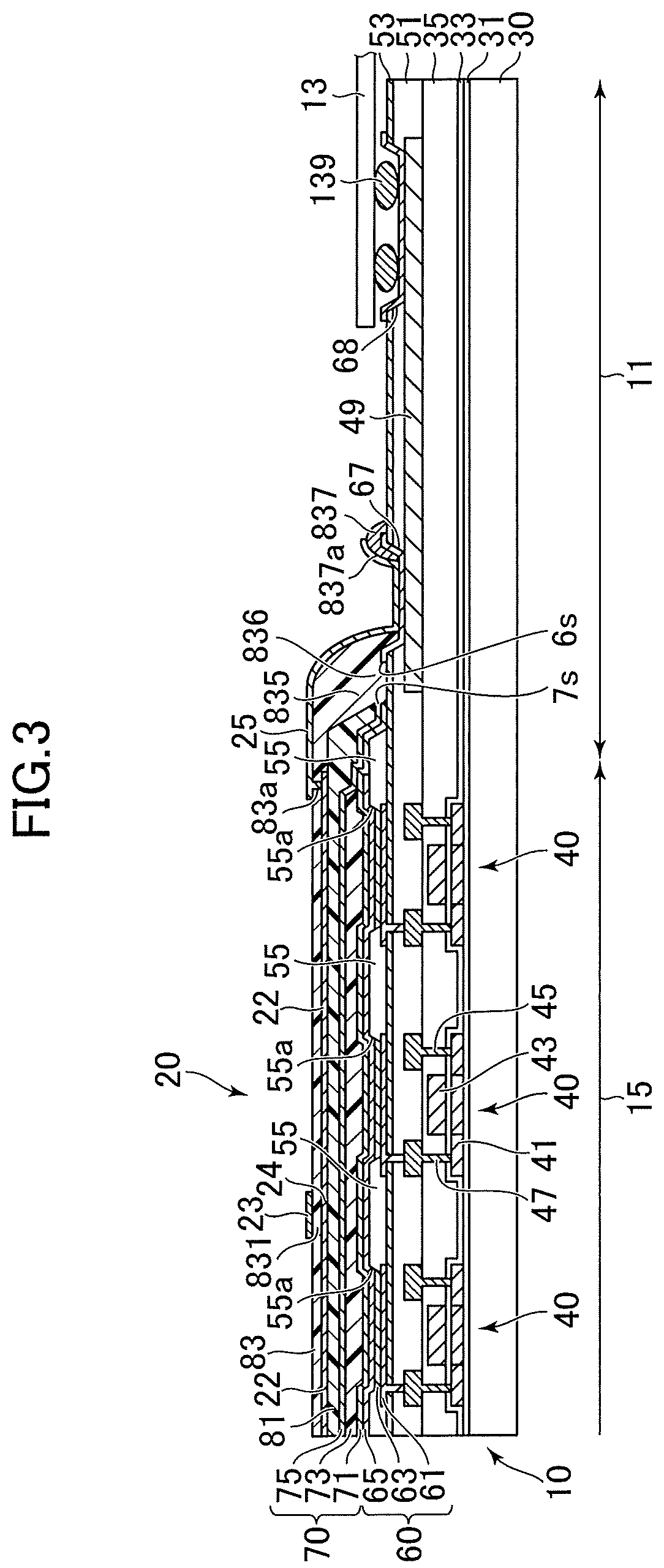

Display device with touch sensor

ActiveUS20200019281A1Suppress disconnectionElectroluminescent light sourcesSolid-state devicesPhysicsComposite material

A display device according to an embodiment of the invention includes: a base insulating film; a sealing film which covers the base insulating film; a plurality of first electrodes which are two-dimensionally arranged on the sealing film, the first electrodes adjacent in a first direction being connected via a first connection line; a plurality of second electrodes which are two-dimensionally arranged, the second electrodes adjacent in the second direction being connected via a second connection line intersecting the first connection line in plan view; an interlayer insulating film which is interposed between the first connection line and the second connection line and which fills a step formed by an outer edge of the sealing film and the base insulating film; and a lead-out wiring which is connected to the first electrode or the second electrode and which passes over a portion of the interlayer insulating film which fills the step.

Owner:JAPAN DISPLAY INC

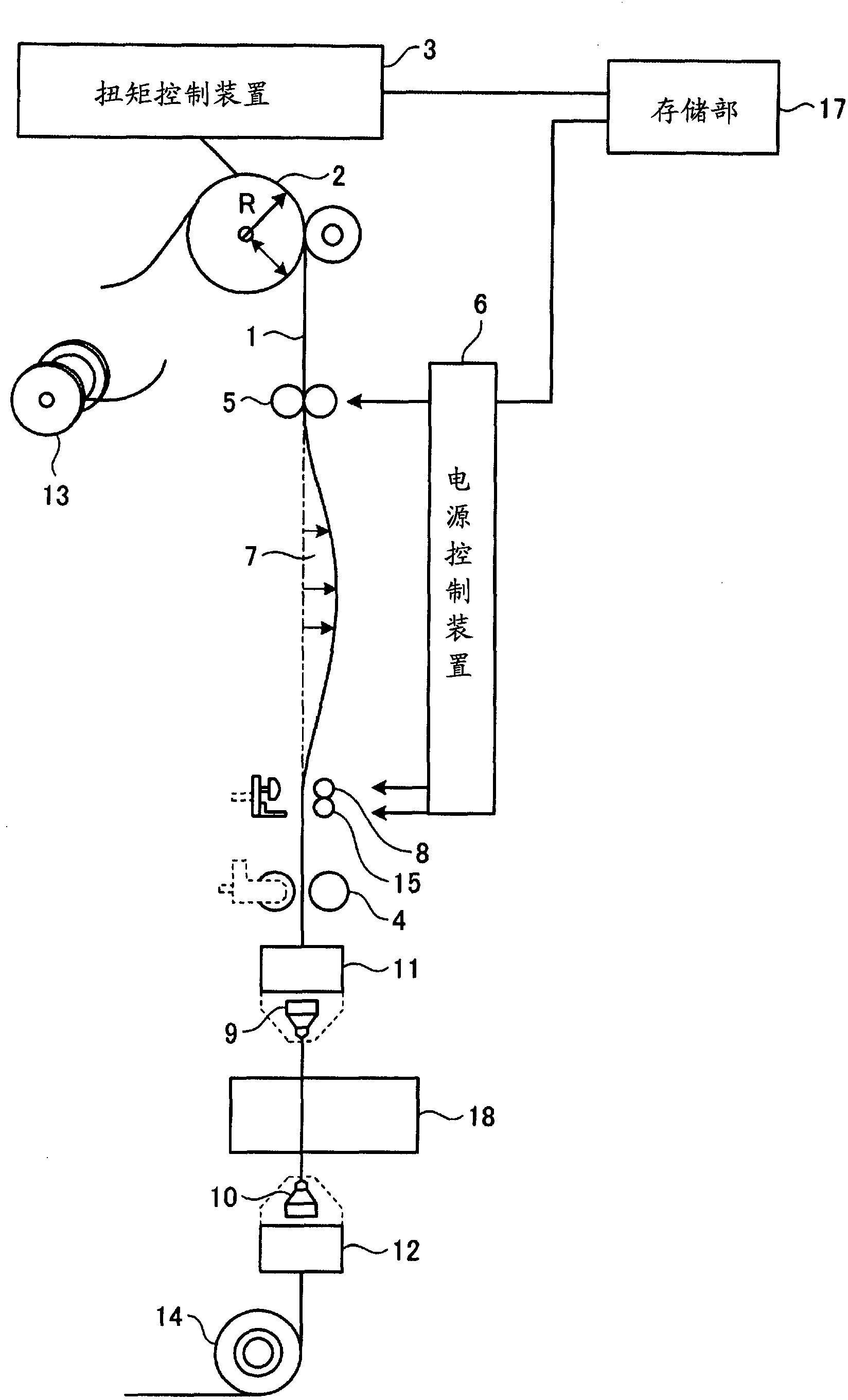

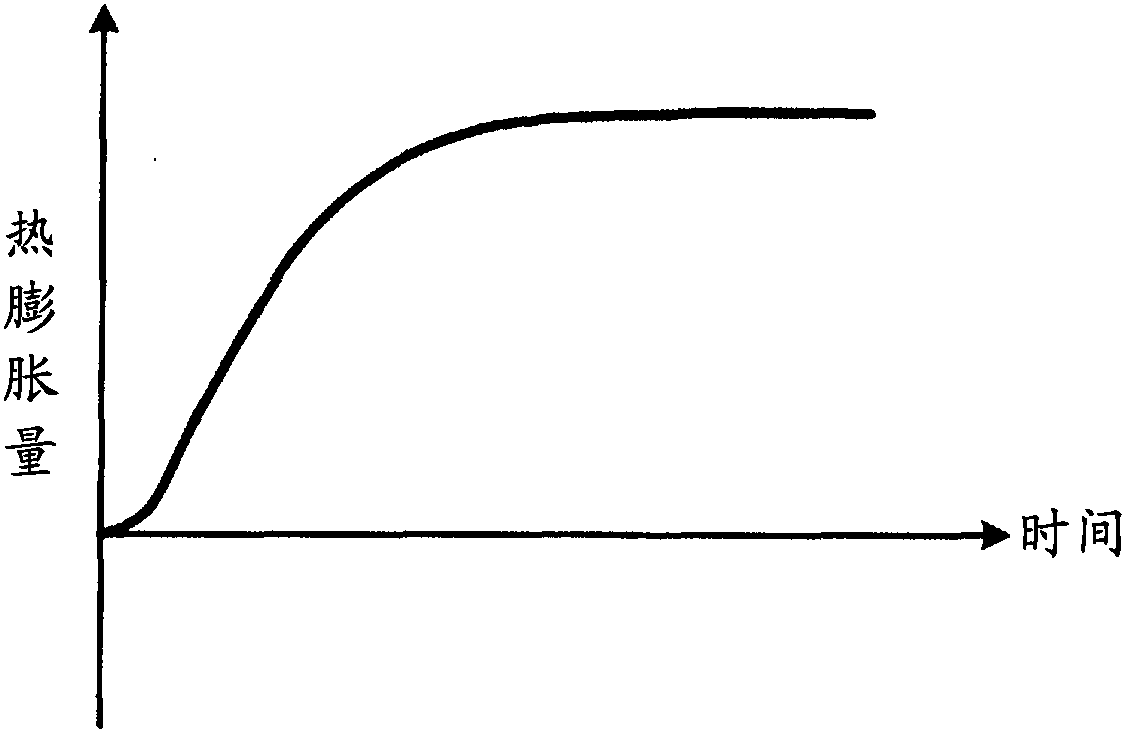

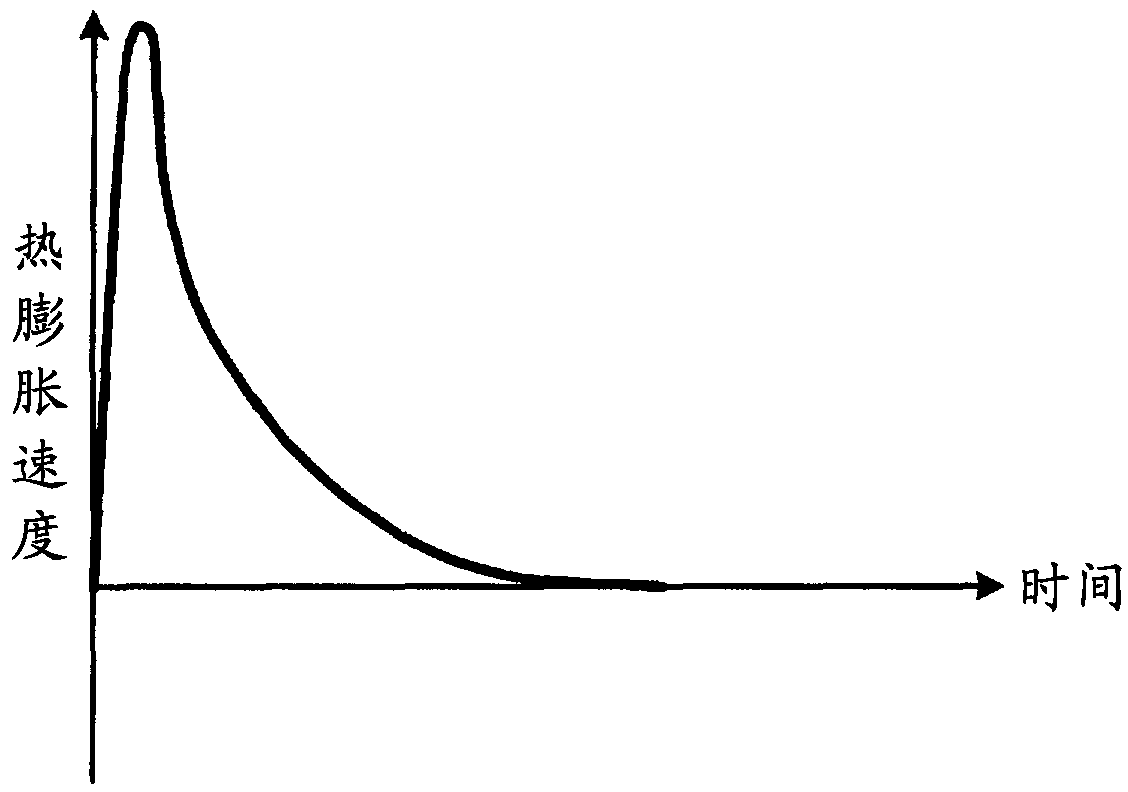

Heat-sealing device

InactiveCN103043261AReduce tensile stressSuppress disconnectionWrapper twisting/gatheringElectrical and Electronics engineeringWire breakage

The invention provides a heat-sealing device, wherein wire breakage caused by heat expansion of a heater is prevented. Shafts (50, 52) arranged on the pedestral plate (15) of the sealing component (14) at the side of the heater are inserted in the through holes (42, 44) of the terminal platform (36) of the terminal (32) fixedly provided with a strip-shaped heater (30). The terminal platform (36) can move along the shafts. When the strip-shaped heater (30) is expanded caused by heating, the terminal platform (36) moves along the shafts (50, 52) towards the strip-shaped heater (30), compared to the structure that a heater is contracted caused by the force of a spring, the load on the strip-shaped heater (30) when the strip-shaped heater (30) is contracted is minimized, wire breakage caused by heat expansion of the strip-shaped heater (30) is prevented.

Owner:NIFCO INC

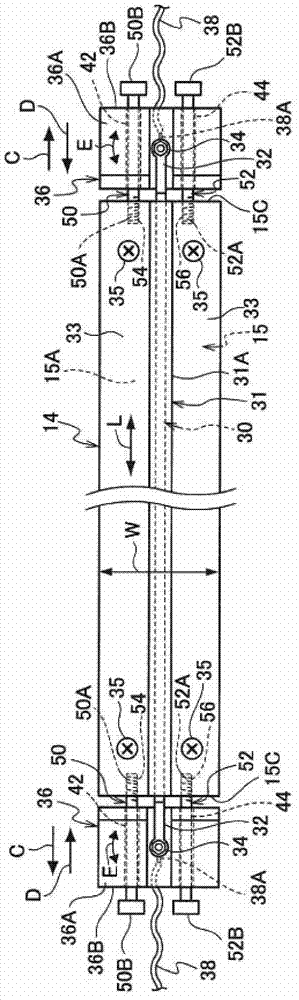

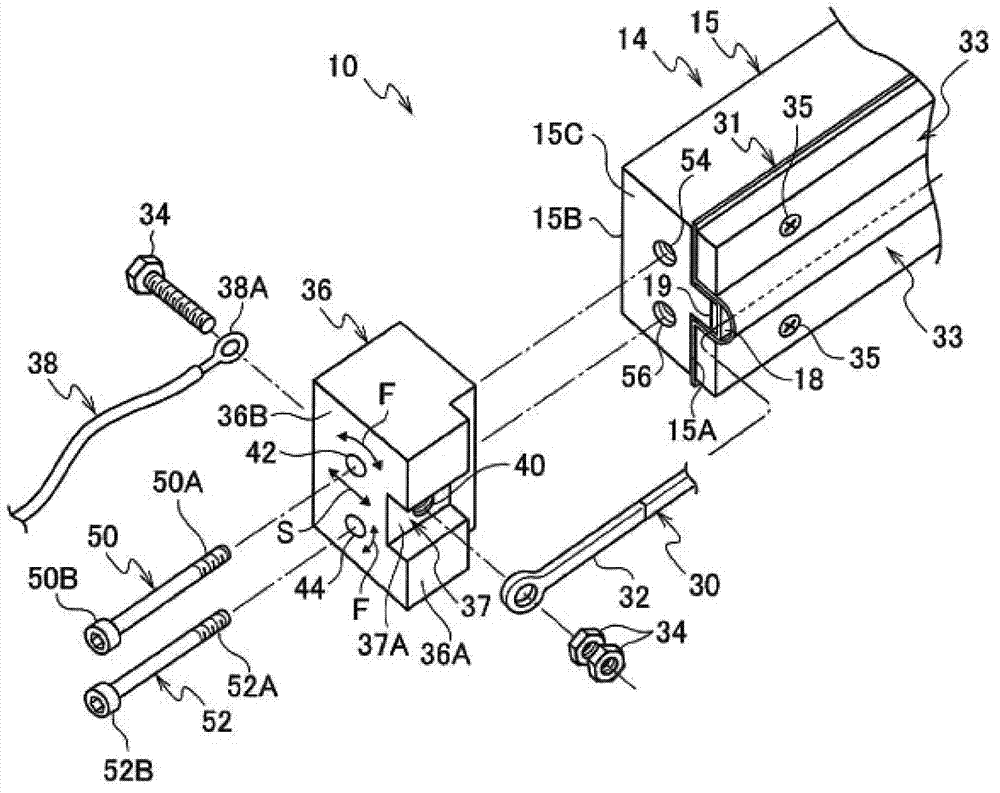

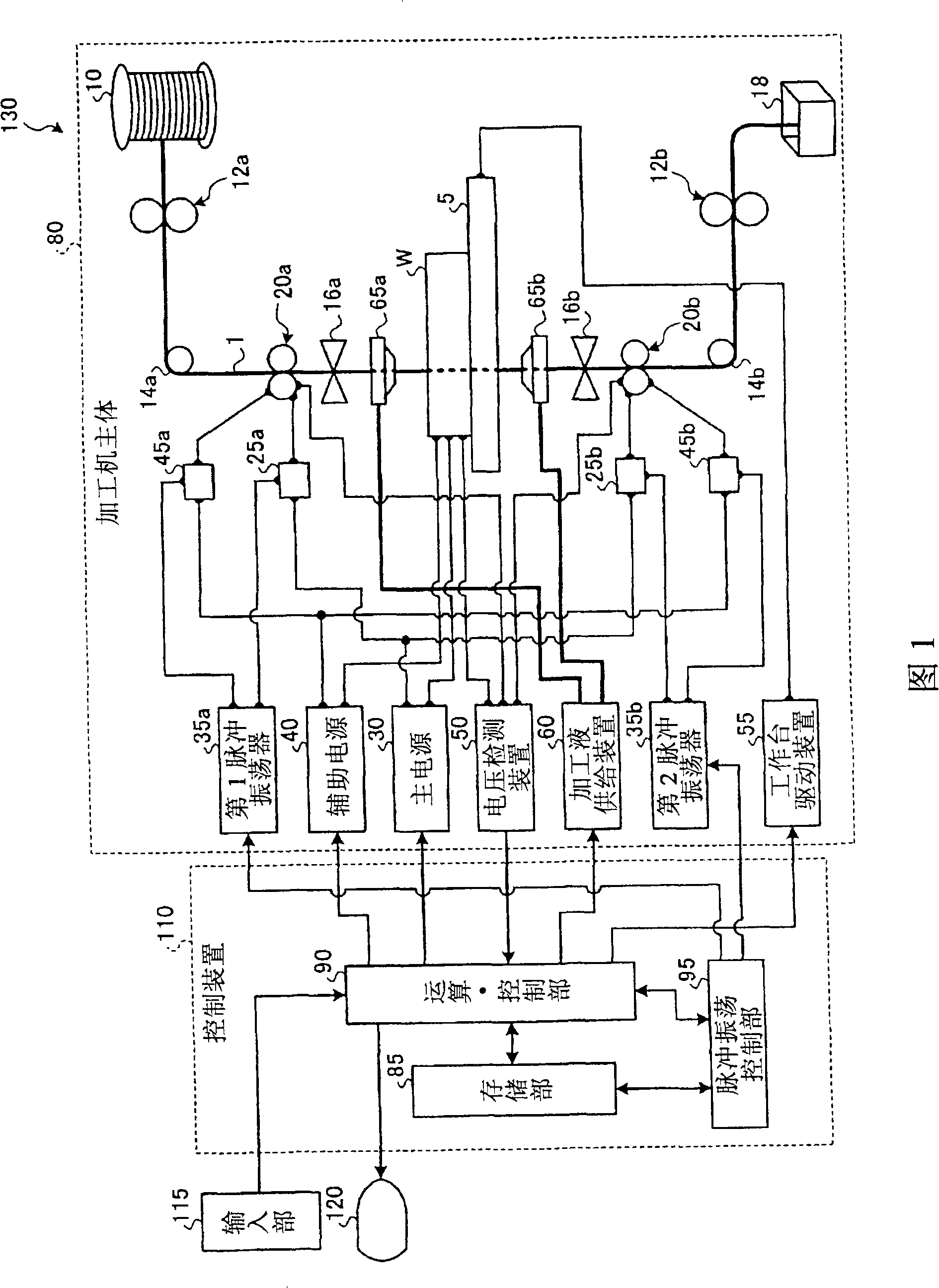

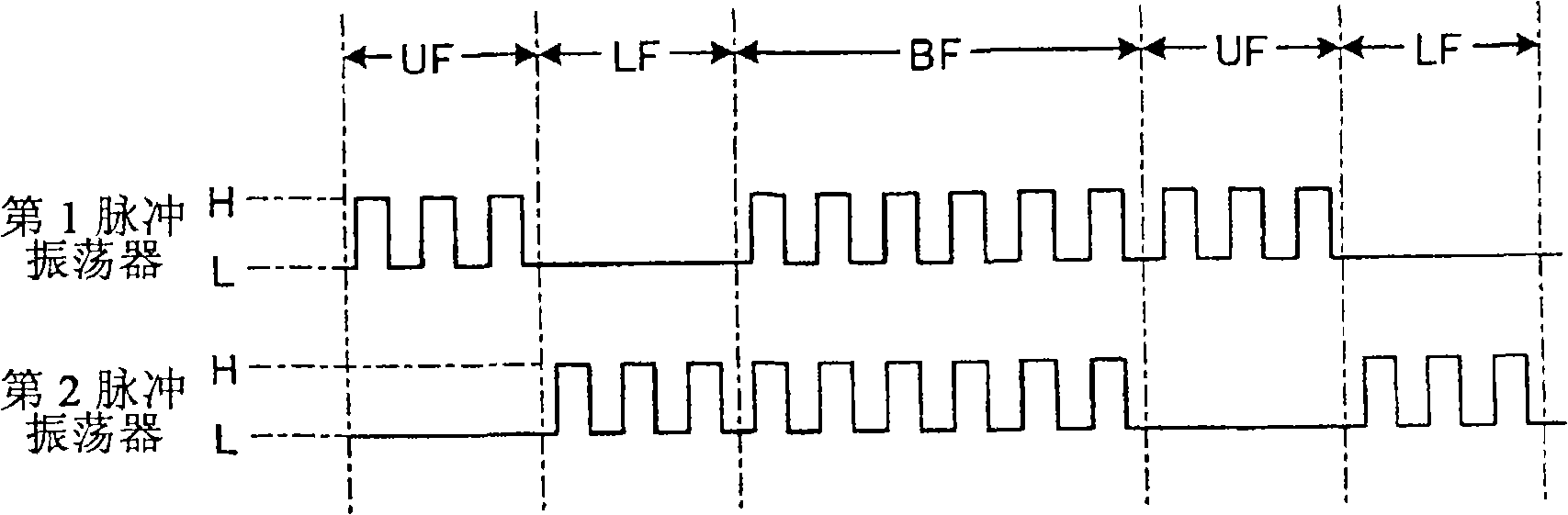

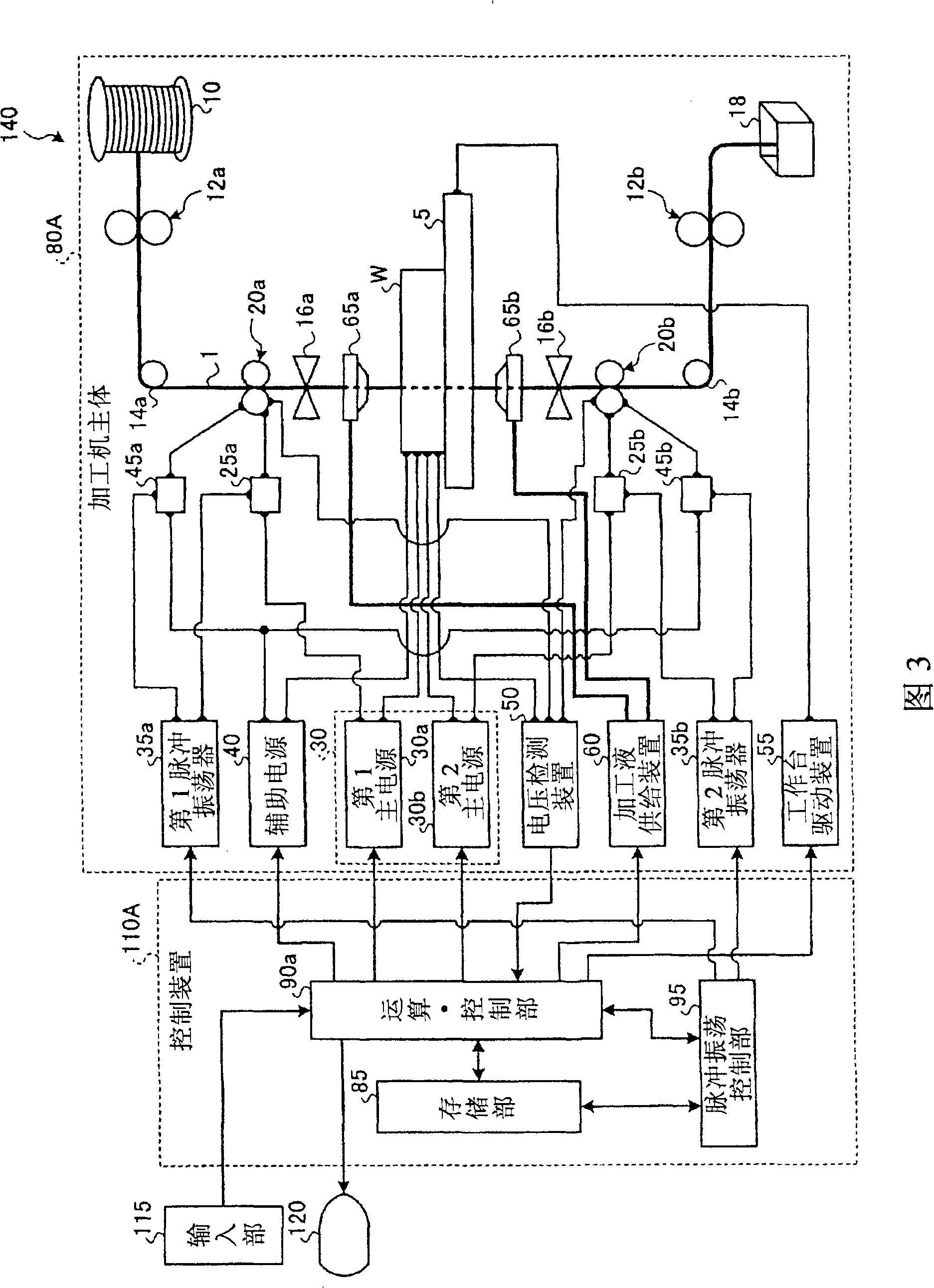

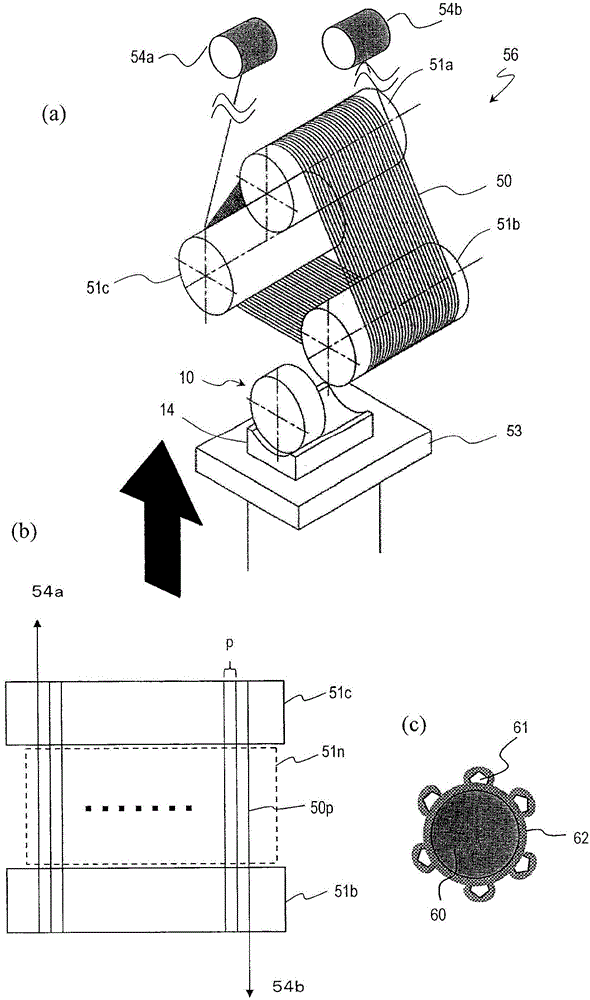

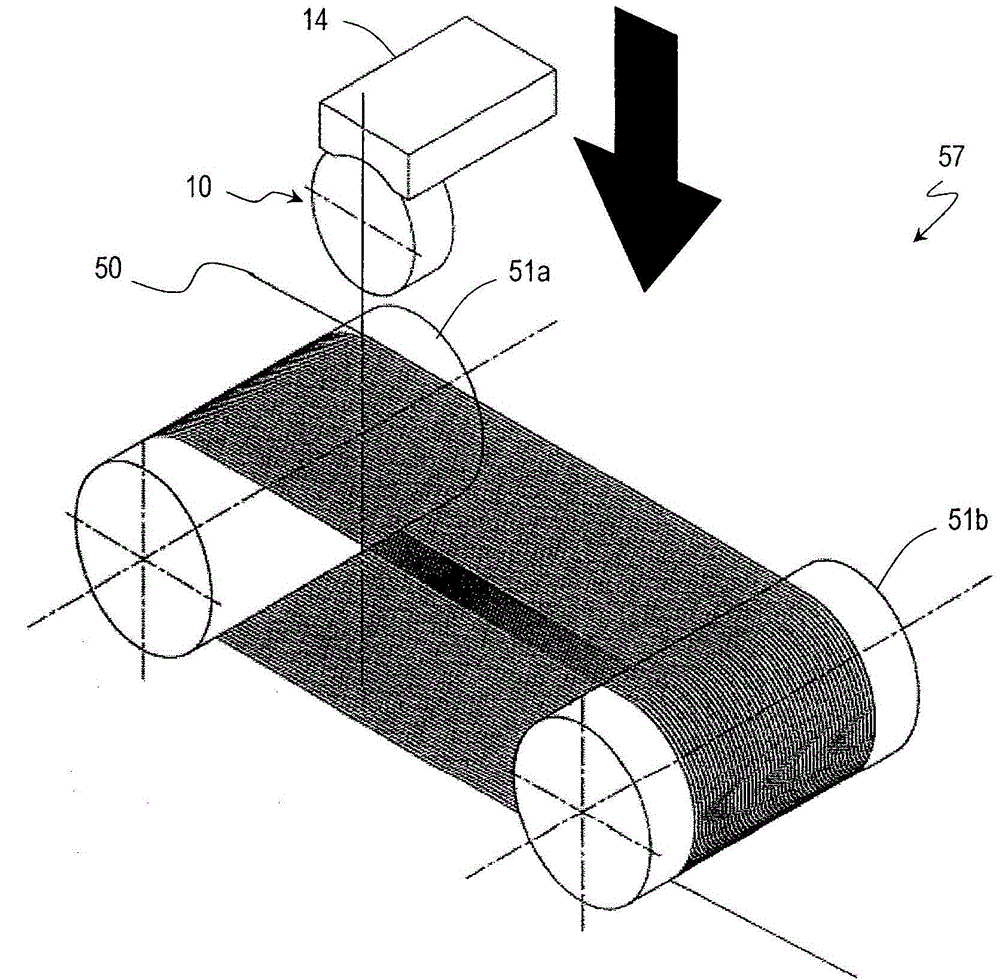

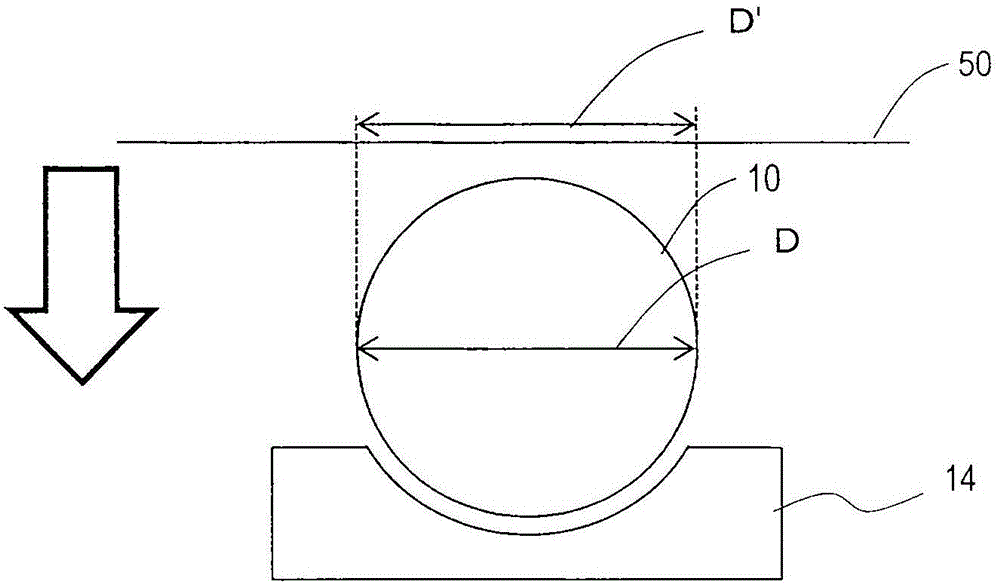

Discharging processor for line electrode

A wire discharge processing machine performs a feeding control in such a manner that there are mixed, during a discharge processing, an upper side feeding state in which a high frequency pulse voltage is applied to a wire electrode only from an upper feeding part disposed above a processed subject, a lower side feeding state in which a high frequency pulse voltage is applied to the wire electrodeonly from a lower feeding part disposed beneath the processed subject and a two-side feeding state in which the high frequency pulse voltages are synchronously applied to the wire electrode from boththe upper and lower feeding parts, thereby suppressing the short-circuiting between the wire electrode and the processed subject and also suppressing the wire brakes, thereby facilitating the improvement of productivity.

Owner:MITSUBISHI ELECTRIC CORP

Method of cutting high-hardness material with multi-wire saw

ActiveCN104786376AReduce workloadImprove sharpnessMetal sawing toolsFine working devicesReciprocating motionIngot

In a method of cutting a high-hardness material with a multi-wire saw, an ingot of the high-hardness material is sliced into a plurality of wafers by cutting the ingot at multiple points simultaneously with the multi-wire saw. The method comprises repeating a run cycle of reciprocating motion of a wire of the multi-wire saw so that the relationships (1) c1≧20, given C1=b / a and (2) 0.35≰c2≰1.55, given c2=d / a are satisfied, where a is a maximum total contact length defined as a sum of the lengths of the ingot as projected onto multiple cut points when projecting the ingot onto the wire in a direction in which the ingot is going to be cut, b is a continuous travel distance of the wire, and d is a length of the wire newly fed in each said run cycle.

Owner:HITACHI METALS LTD

Surface-mount base for electronic element

InactiveUS7351918B2Easy to manufactureImprove accuracyPrinted circuit assemblingImpedence networksSurface mountingEngineering

A surface-mount base for an electronic element includes: an insulative supporting member having a through hole; a plurality of lead terminals each having an element connecting terminal, a lead portion and a mounting terminal, the lead terminals being mounted to the supporting member with the lead portions passing through the through hole so that the element connecting terminals face a top face side of the supporting member and the mounting terminals face a bottom face side of the supporting member; and a sealing glass that is charged in the through hole of the supporting member for sealing the lead terminals in the through hole. The supporting member is composed of a supporting frame having an outer wall that defines the through hole, and at least one of the lead portion and the mounting terminal of each lead terminal has a shape and a dimension that cause a pressure against at least one of an inner face and an outer face of the outer wall, whereby the lead terminals are held on the supporting frame. The lead terminal is positioned on the supporting member while suppressing a disconnection or a rattle.

Owner:PANASONIC CORP

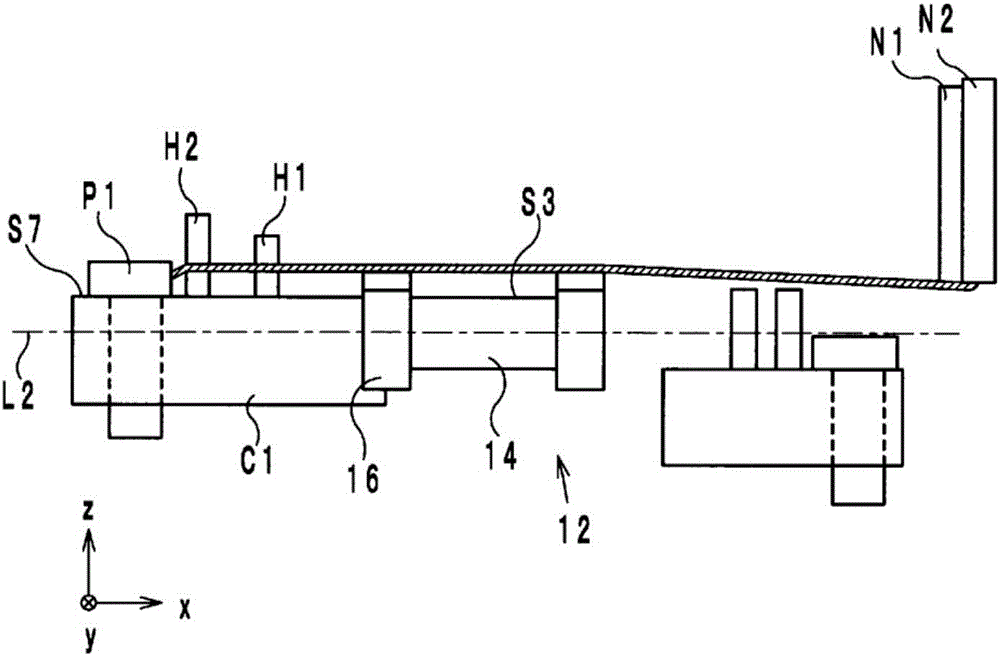

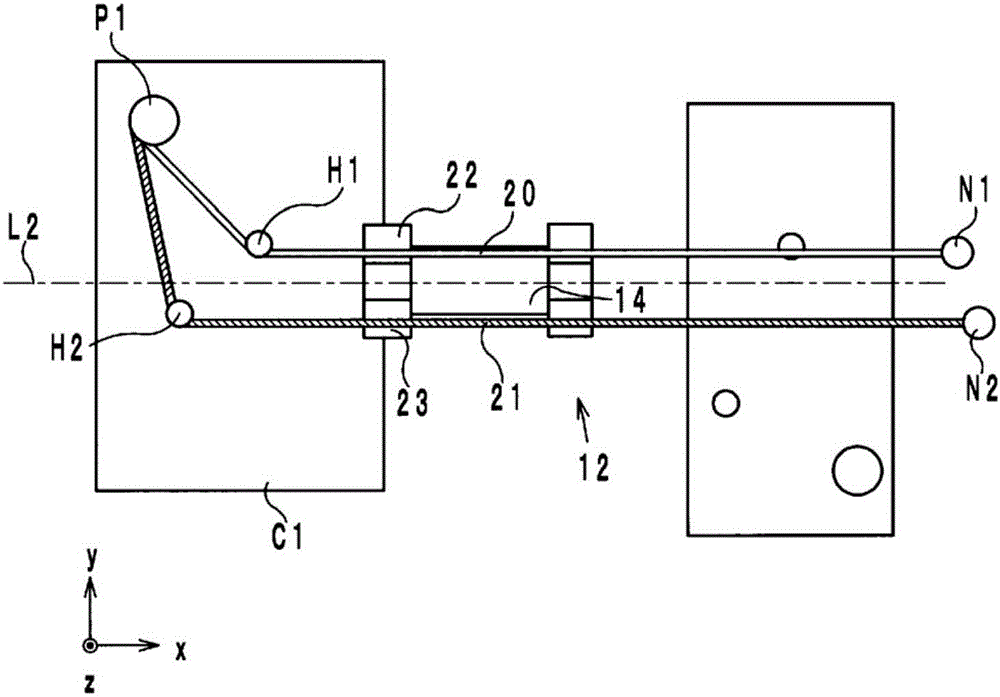

Method for manufacturing wound electronic component

ActiveCN106415754ASuppress disconnectionFilament handlingCoils manufactureEngineeringElectronic component

The purpose of this invention is to provide a method that is used to manufacture a wound electronic component using twisted wires and makes it possible, when twisting a plurality of winding wires together, to minimize breakage thereof. This method for manufacturing a wound electronic component (1) includes a preparation step in which a chuck (C1) is used to grip a core (12) that has a winding-core section (14) and flanges (16 and 18), a first step in which part of each of a number of winding wires (20, 21) supplied from respective nozzles (N1, N2) is affixed to one of the flanges (16), and a second step in which the chuck (C1) is rotated so as to twist the winding wires (20, 21).

Owner:MURATA MFG CO LTD

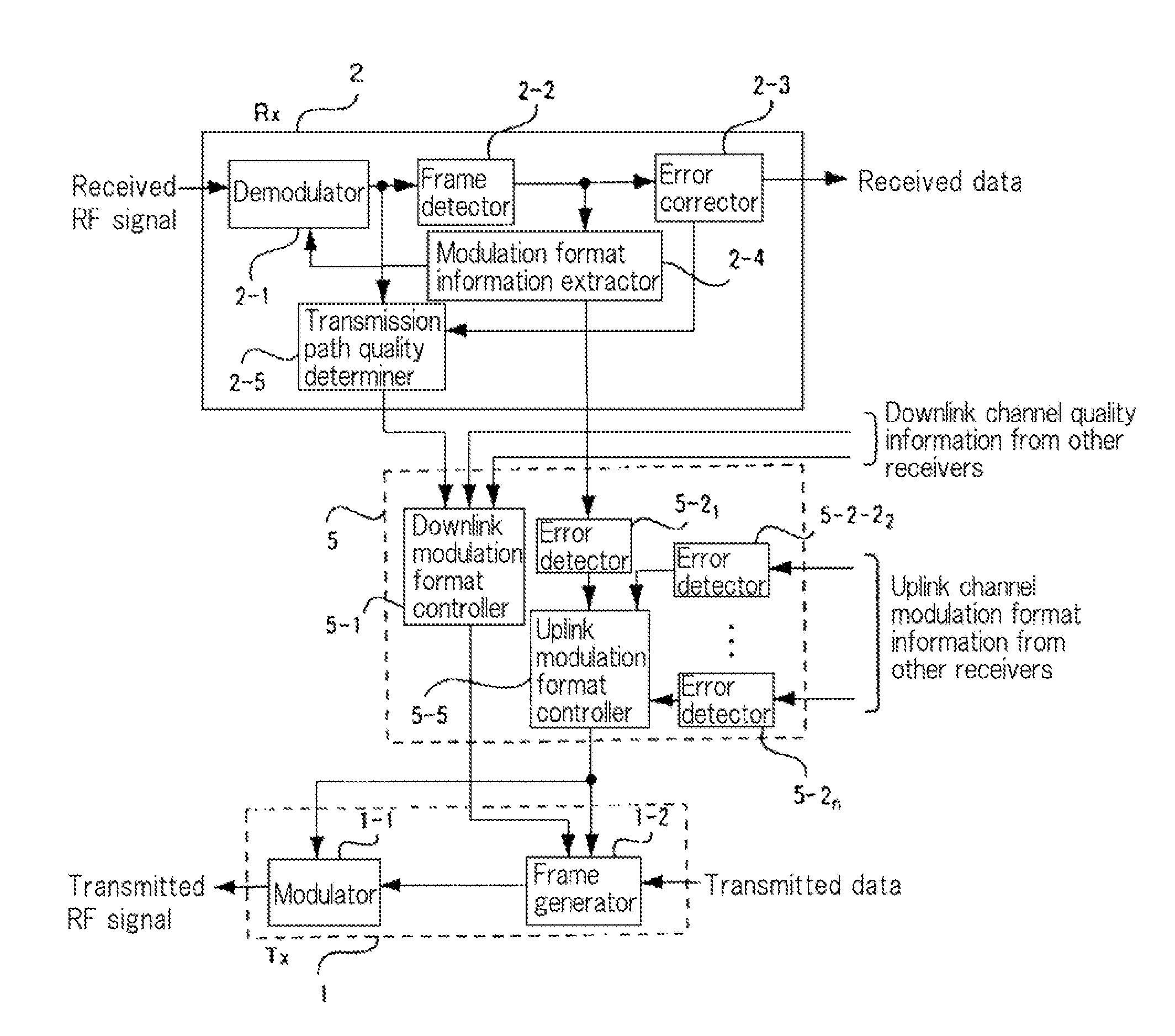

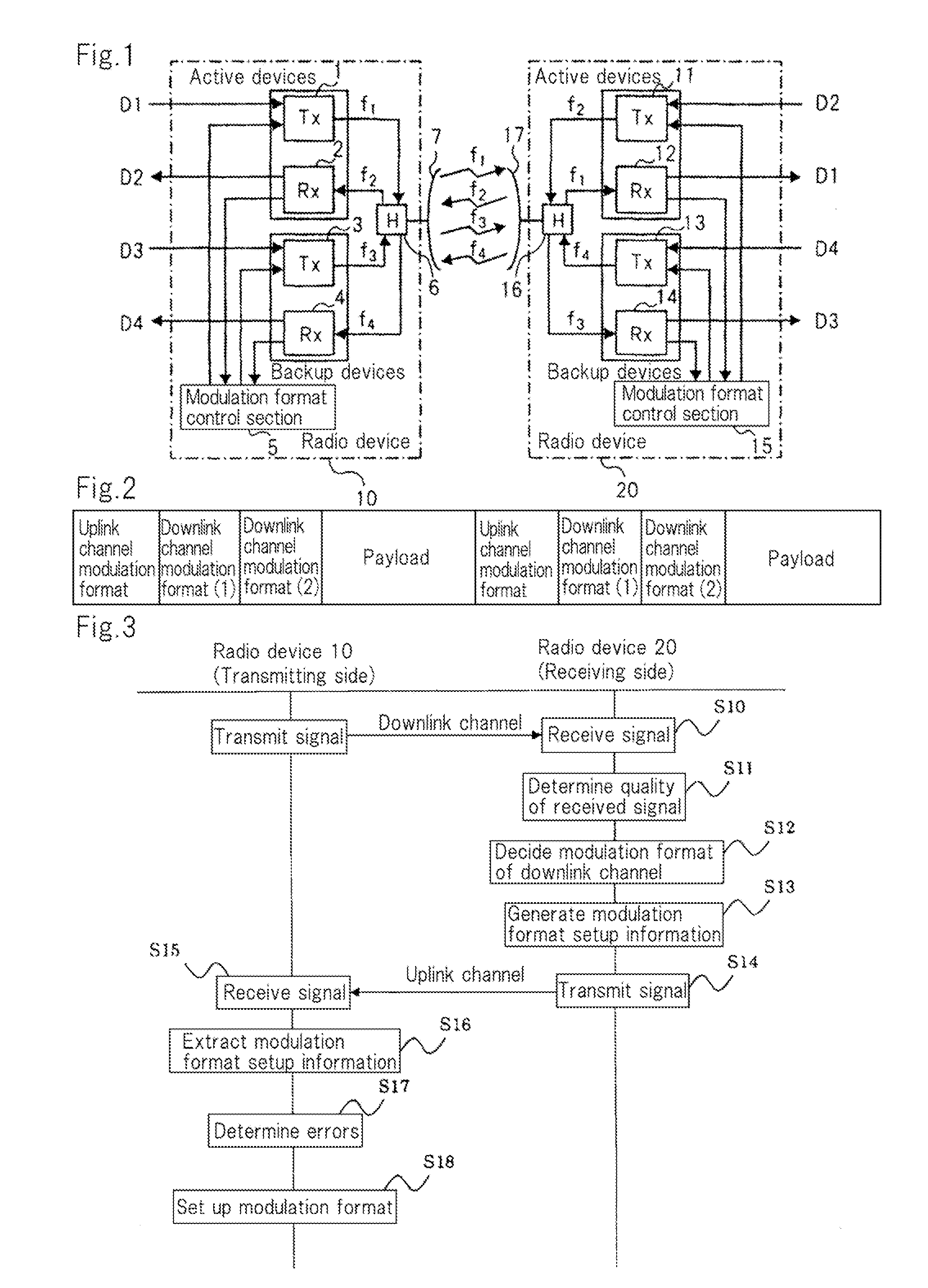

Adaptive modulation method, radio communication system, and radio device

InactiveUS20110286539A1Improve efficiencySuppress communication disconnectionEnergy efficient ICTModulation with suppressed carrierRadio equipmentCommunications system

Owner:NEC CORP

Automatic wire bonder

ActiveCN103347636ASuppress disconnectionImprove linearityElectrical-based machining electrodesPower flowEngineering

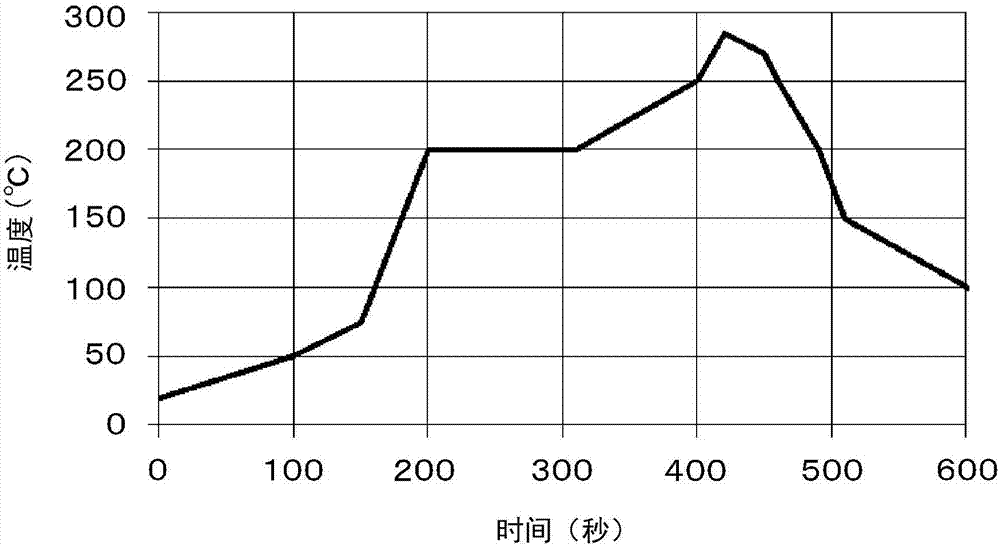

An automatic wire connecting device includes a heating electrode that heats an electrode wire by applying a current to the electrode wire, a tension applying unit that applies a tension to the electrode wire to which the current is applied by the heating electrode, a tension control unit that controls the tension applied by the tension applying unit, and a power supply control unit that applies a heating current smaller than a preset annealing current to the electrode wire until a first set time elapses since the current starts to be applied and increases the current applied to the electrode wire to reach the annealing current during a second set time after the first set time elapses since the current starts to be applied.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com