Wire material for saw wire and method for producing same

A manufacturing method and wire technology, which are applied in manufacturing tools, semiconductor/solid-state device manufacturing, sawing machine devices, etc., can solve the problems of easy breakage of hacksaws and decreased yield, and achieve reduced cutting costs and high resistance to breakage. , the effect of suppressing disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

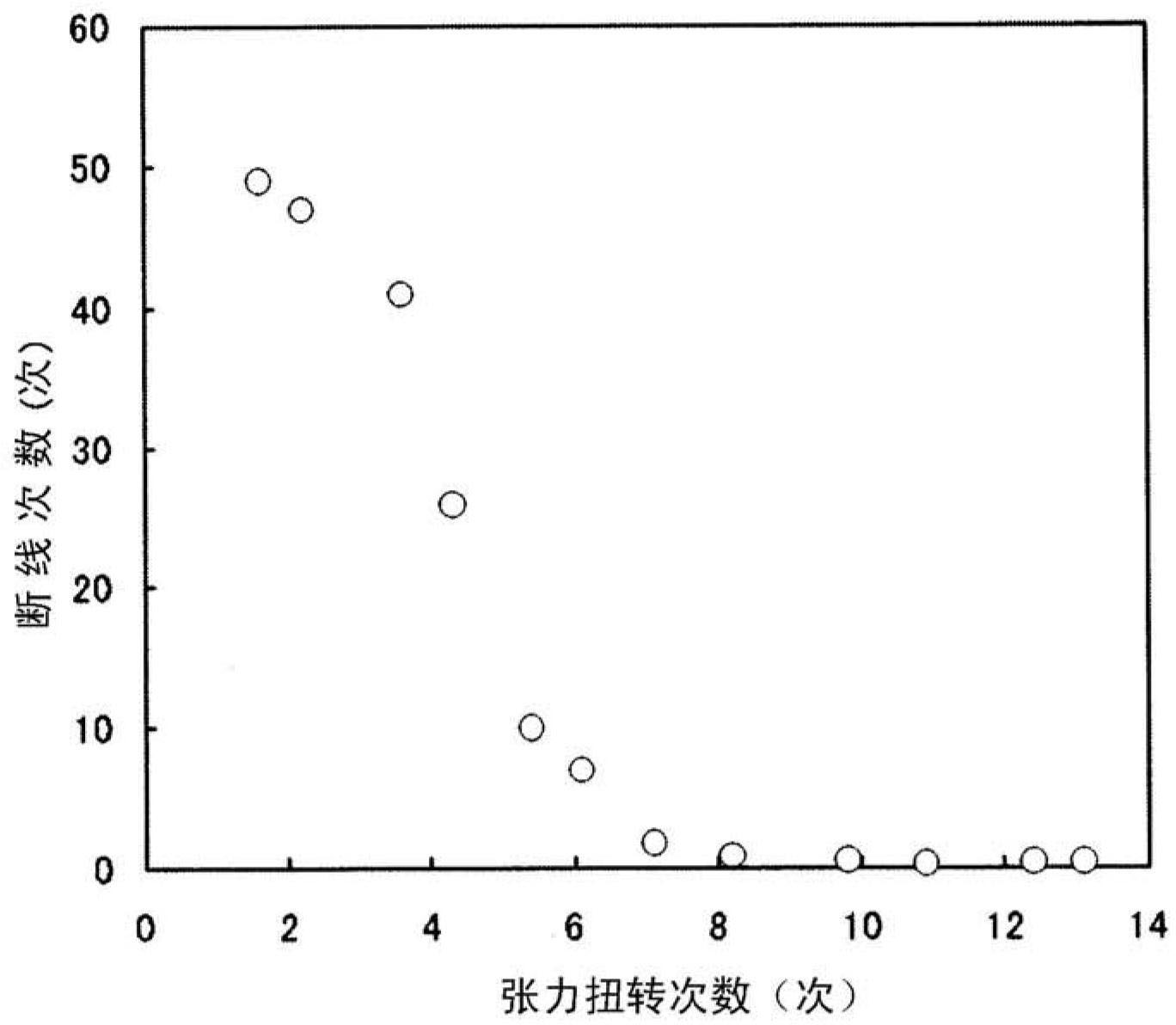

[0163] Next, experiments performed by the inventors of the present invention will be described. Conditions and the like in these experiments are examples adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to these examples.

[0164] (1st experiment)

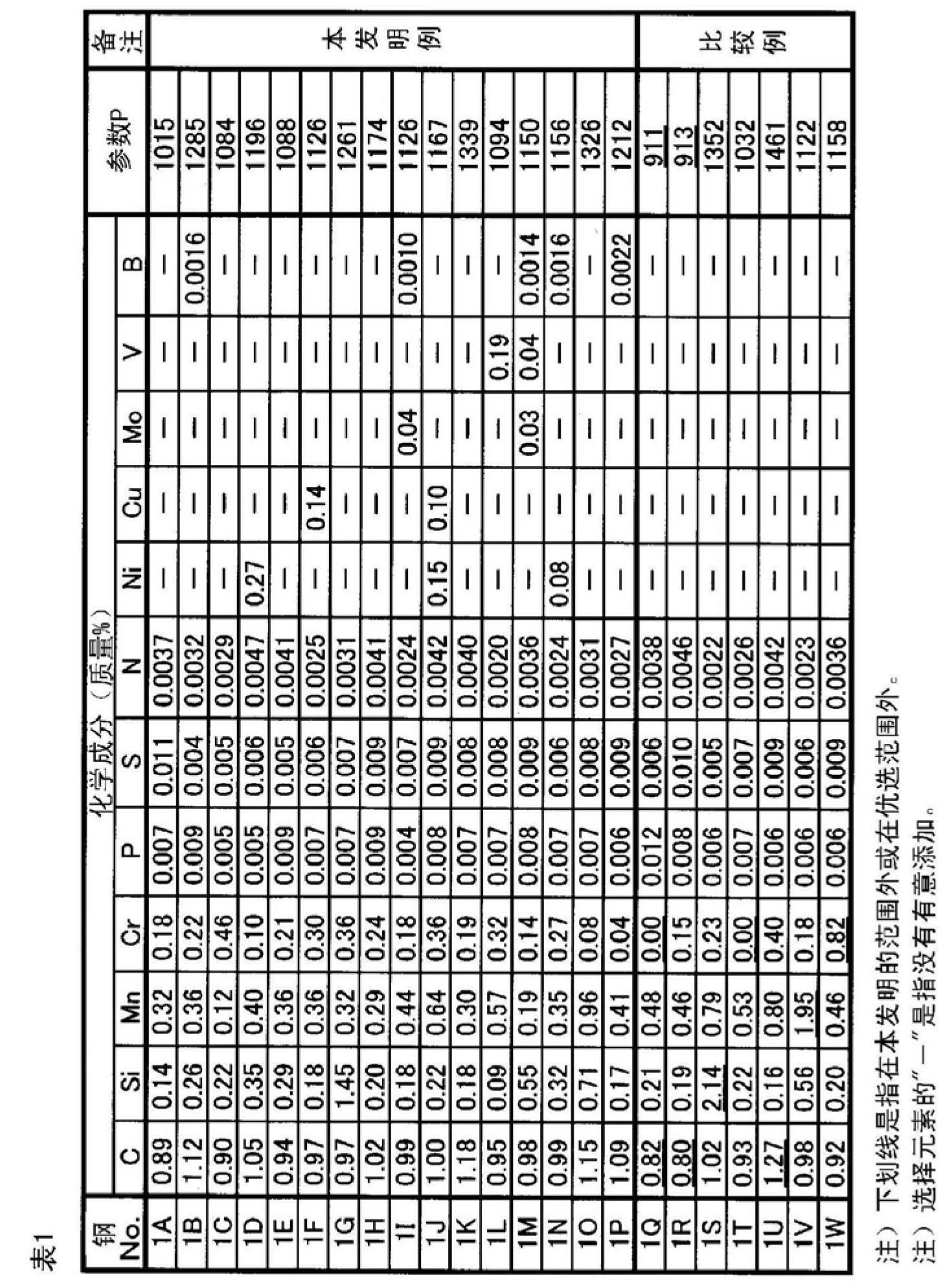

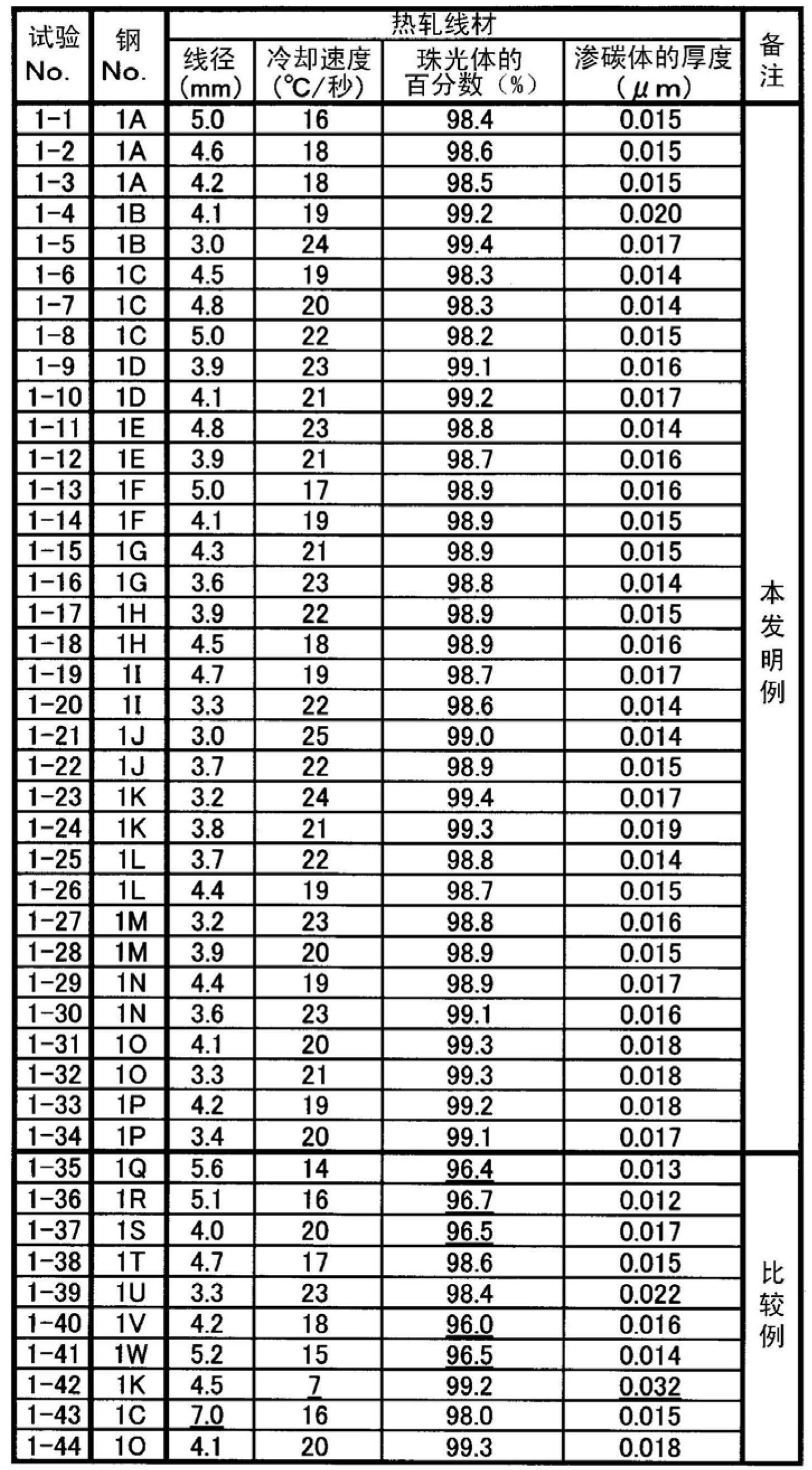

[0165] In the first experiment, first, steel billets (steel Nos. 1A to 1W) having the chemical compositions shown in Table 1 were hot-rolled, and then cooled at the cooling rates shown in Table 2 to obtain the slabs shown in Table 2. Wire diameter of hot-rolled wire rod (test No.1-1 to No.1-44). The finish rolling of the hot rolling is performed in the temperature range of 920°C to 950°C. The cooling rate is controlled by air supply. Then, the percentage of pearlite structure and the thickness of cementite in the hot-rolled wire rods were measured by the methods shown below. The results are shown in Table 2.

[0166] In the measurement of the percentage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com