Photosensitive conductive paste, method for producing multilayer electronic component using same, and multilayer electronic component

一种感光性、导电膏的技术,应用在分散在不导电无机材料中的导电材料、印刷电路制造、印刷电路零部件等方向,能够解决难以图案化、烧成收缩的程度大、光透射率降低等问题,达到防止脱层、抑制脱层、抑制收缩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Examples of the present invention are shown below, and the characteristic parts of the present invention will be described in more detail.

[0039] [1] Production of photosensitive conductive paste for electrode formation

[0040] In order to prepare the photosensitive conductive paste of this invention, (a) electroconductive powder, (b) photosensitive resin composition, and (c) glass frit demonstrated below are prepared.

[0041] (a) Conductive powder

[0042] As conductive powders, Ag powder (Ag powder I) having an average particle diameter of 4.0 μm and Ag powder (Ag powder II) having an average particle diameter of 2.0 μm were prepared.

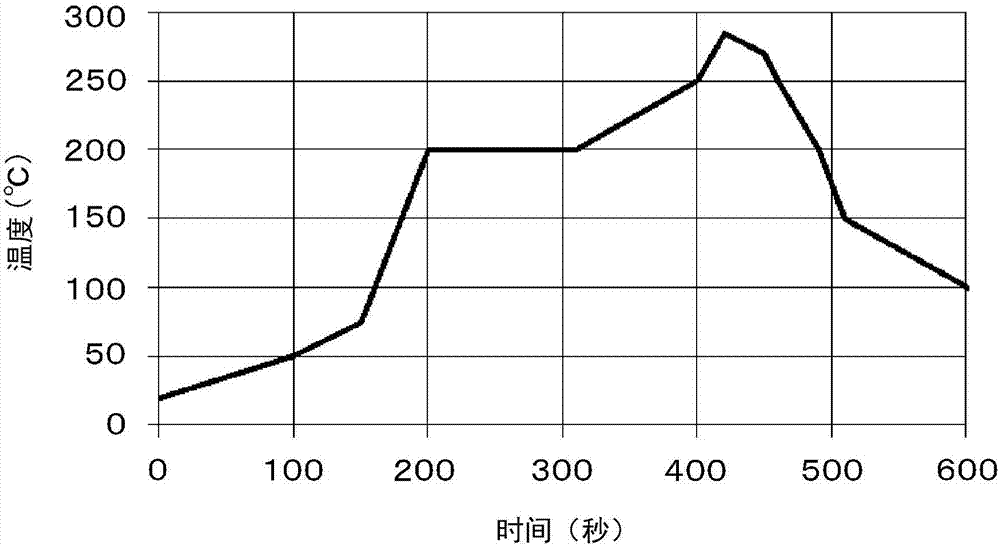

[0043]Then, the sintering start temperature of Ag powder I and Ag powder II was measured by the following method. 0.5 g of Ag powder was put into a mold, and it was pressurized at a pressure of 100 MPa by a press machine to produce a granular sample. This sample was set in a TMA (Thermomechanical Analyzer: Thermodynamic Analyzer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com