Automatic wire bonder

An automatic wiring device and wire technology, applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of easy disconnection, inability to set the thermal expansion of electrode wire through tension, and inability to obtain the straightness of electrode wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

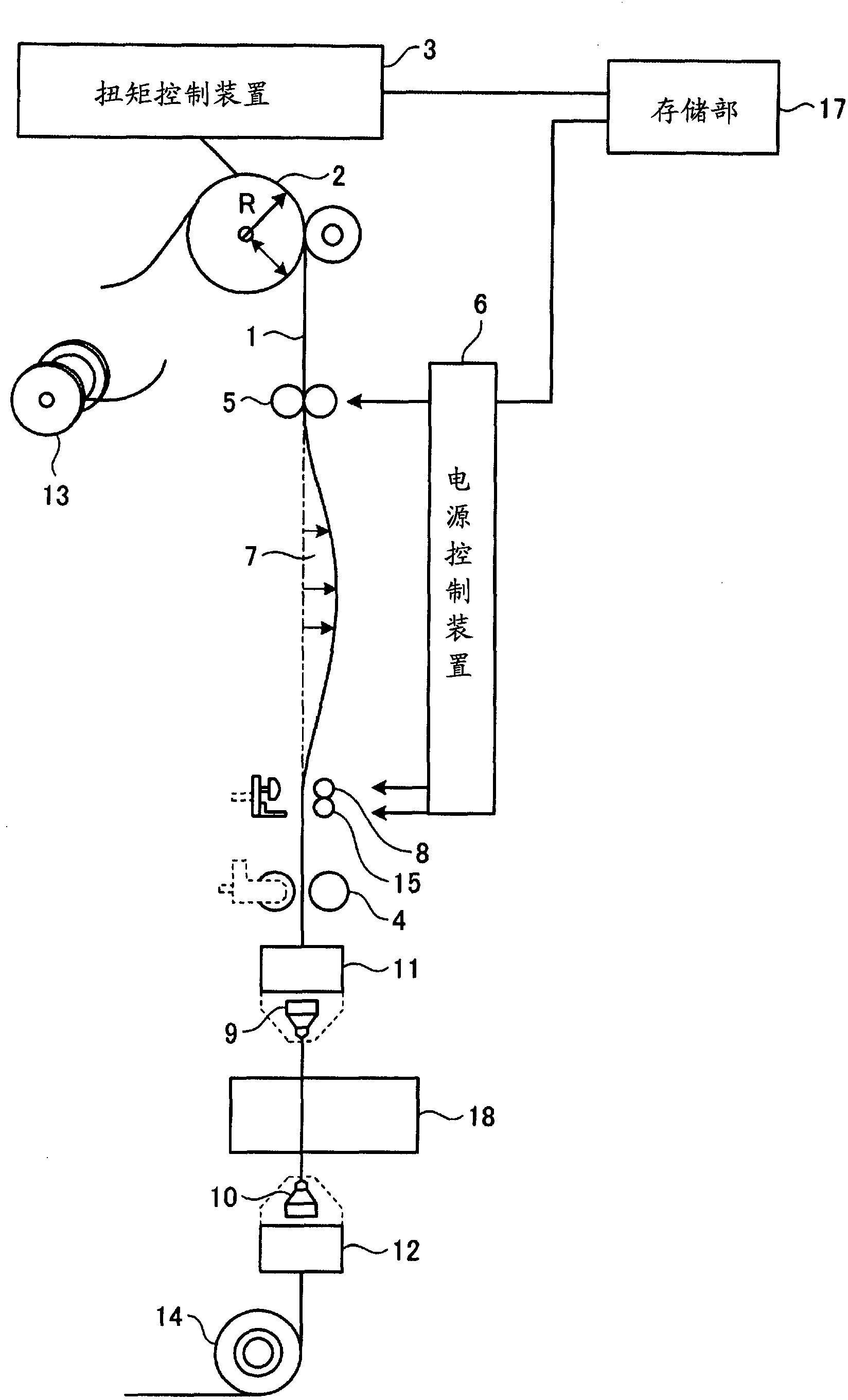

[0045] Next, Embodiment 1 of the present invention applied to the above-mentioned automatic wire splicing device will be described. That is, an automatic wire splicing device is described, which energizes the electrode wire 1 between the heating current electrode 5 and the GND electrode 15, and while applying tension to the electrode wire 1, the torque control device 3 controls the applied tension. The annealing treatment is performed in a state where the electrode wire 1 is hardly bent under tension.

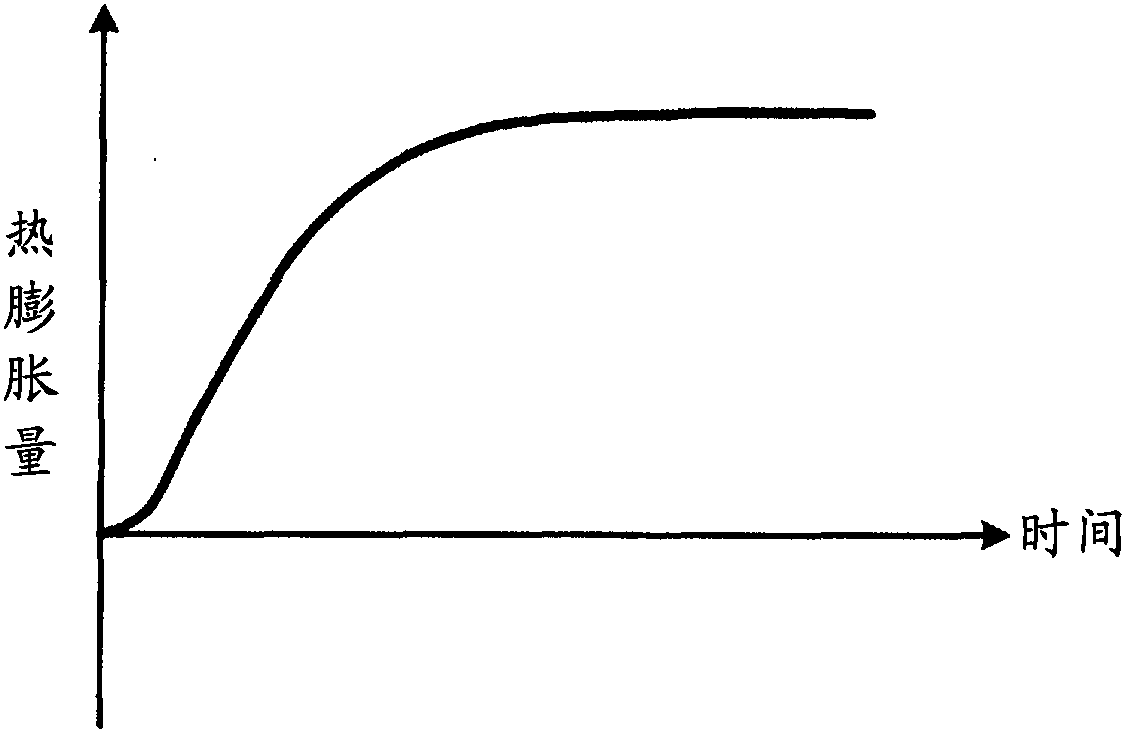

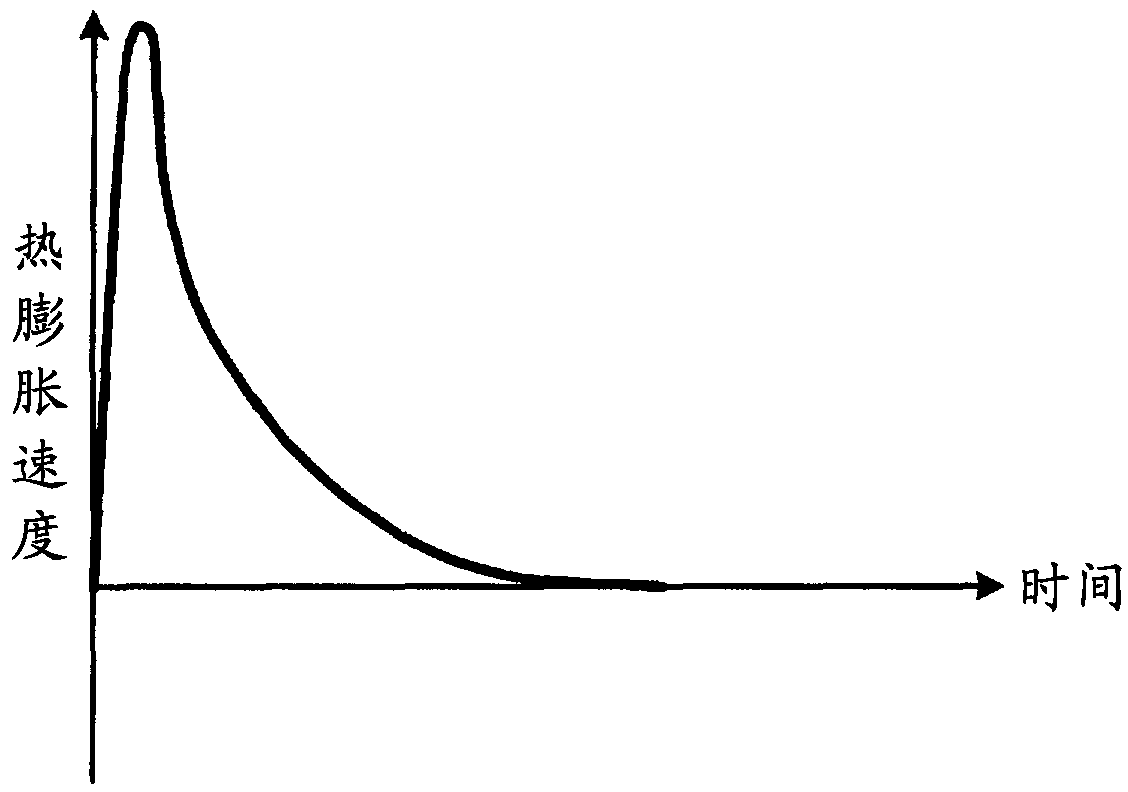

[0046] When current flows through the electrode wire 1 , the electrode wire 1 generates heat and its temperature rises due to the resistance of the electrode wire 1 , but heat transfer also occurs due to a temperature difference with the surroundings. When the electrode wire 1 is heated by passing current, the temperature of the electrode wire 1 rises sharply at first, and after a certain amount of time, the heat transfer also increases due to the temperature difference with th...

Embodiment approach 2

[0087] Figure 5 It is a figure which shows the flowchart for demonstrating the procedure of the process performed by the control apparatus of Embodiment 2. In Embodiment 1, it is determined from the initial torque command τ by the elapsed time since the current is applied to the electrode wire 1 . 1 The determination of the timing of the torque command from the torque control device 3 is reduced. On the other hand, in Embodiment 2, when the expansion amount of the electrode wire 1 reaches a predetermined amount of thermal expansion L 1 , the torque command is switched from the initial torque. In addition, the same reference numerals are assigned to the same configurations as those in the above-mentioned first embodiment, and detailed description thereof will be omitted.

[0088] When tension is continuously applied to the electrode wire 1 at the initial torque value, the tension setting roller 2 is rotated by the amount of thermal expansion of the wound electrode wire 1 . ...

Embodiment approach 3

[0095] Figure 6 It is a diagram showing a flowchart for explaining the procedure of processing executed by the control device according to the third embodiment. In Embodiment 1 and Embodiment 2, it is specified that the torque command from the torque control device 3 is changed from the initial torque value τ 1 Change to the final torque value τ 2 switching time t 2 , but otherwise, if in the elapsed time from the start of the switch (from t 1 The elapsed time from the start) reaches the set torque conversion time t 2 Before, the expansion of the electrode wire 1 reached the specified limit expansion L 2 , then transfer the torque command directly to τ 2 .

[0096] That is, by detecting the rotation amount of the tension setting roller 2 with an encoder of the tension setting roller 2 or the like, it is detected how much thermal expansion of the electrode wire 1 has occurred. When the elapsed time from the start of switching the torque command from the torque control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com