Method of cutting high-hardness material with multi-wire saw

A high-hardness, wire-saw technology, applied in the direction of metal sawing equipment, stone processing tools, stone processing equipment, etc., can solve problems such as not easy, to achieve the suppression of cutting wire breakage, good sharpness, reduce bending and warping The effect of music

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

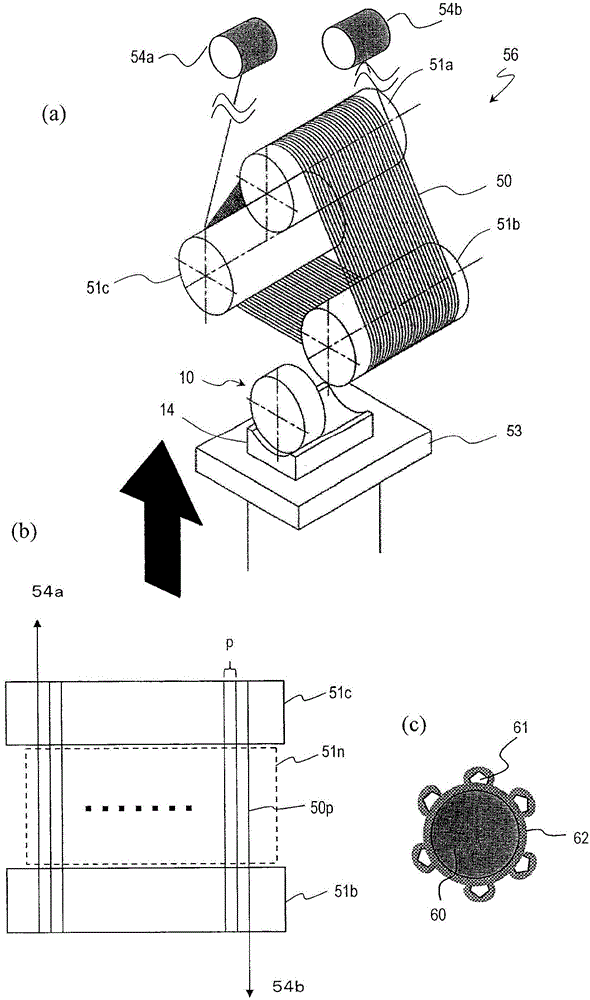

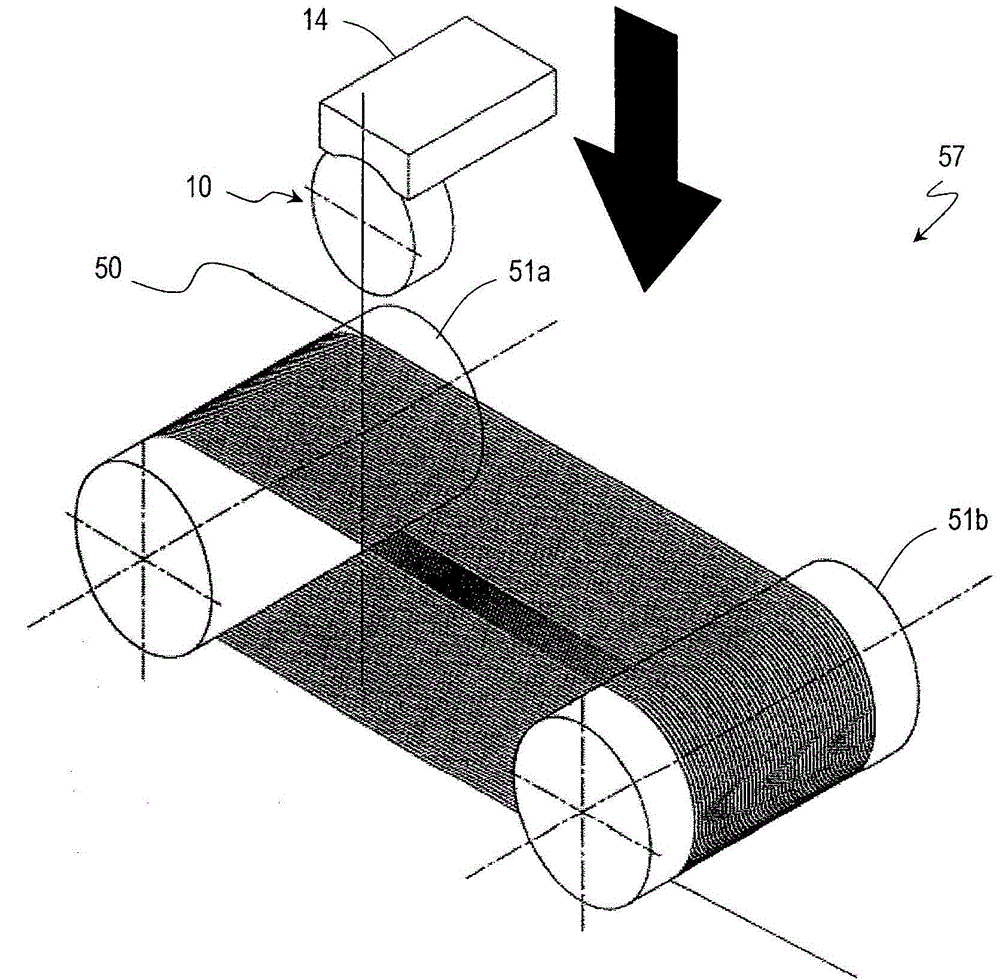

[0074] Hereinafter, an experimental example in which an ingot of a high-hardness material is cut by the cutting method of this embodiment and warpage of a wafer, etc. is studied will be described.

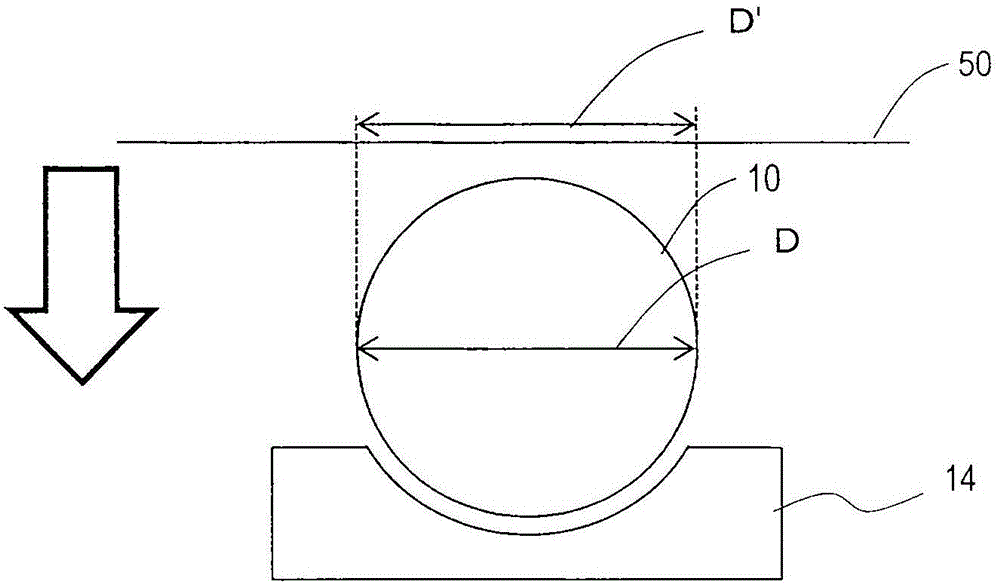

[0075] As an ingot of a high-hardness material, a columnar single-crystal sapphire ingot with a diameter of 150 mm (6 inches) was prepared by cutting out a wafer having the r-plane as a main surface. The ingot was severed using a multi-wire saw, fixed abrasive cutting wire, and cutting fluid as indicated below.

[0076] Multi-wire saw: Multi-wire saw MWS-34 by Takatori

[0077] Cutting wire: diamond electrodeposition cutting wire produced by Allied-material

[0078] (diameter of cutting line: 180μm, average diameter of abrasive grains: 35μm)

[0079] Cutting fluid: DKW-2 produced by Allied-material

[0080] The thickness of the sliced wafer, the maximum contact total length a of the ingot and the dicing wire, the continuous travel distance b, and the new wire discharge amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com