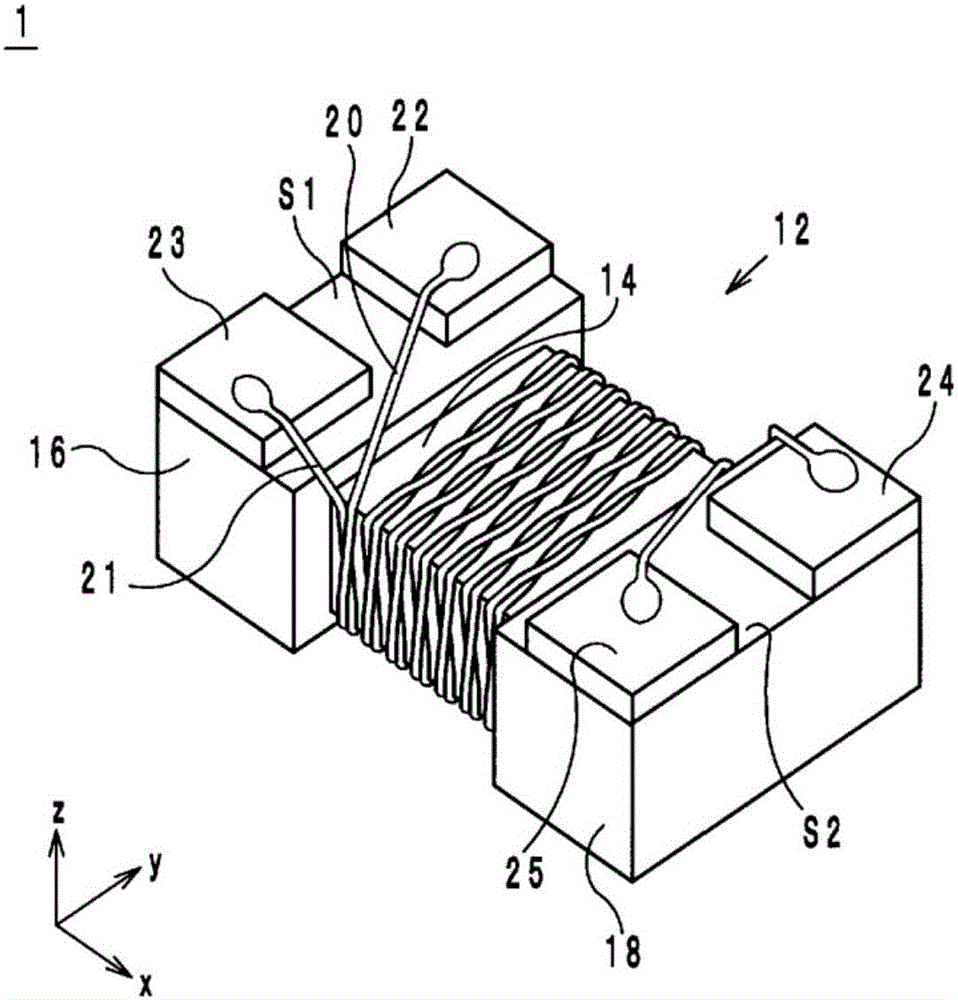

Method for manufacturing wound electronic component

A technology of electronic components and manufacturing methods, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problem that the pulling force cannot be properly transmitted to the wire, and achieve the effect of suppressing disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

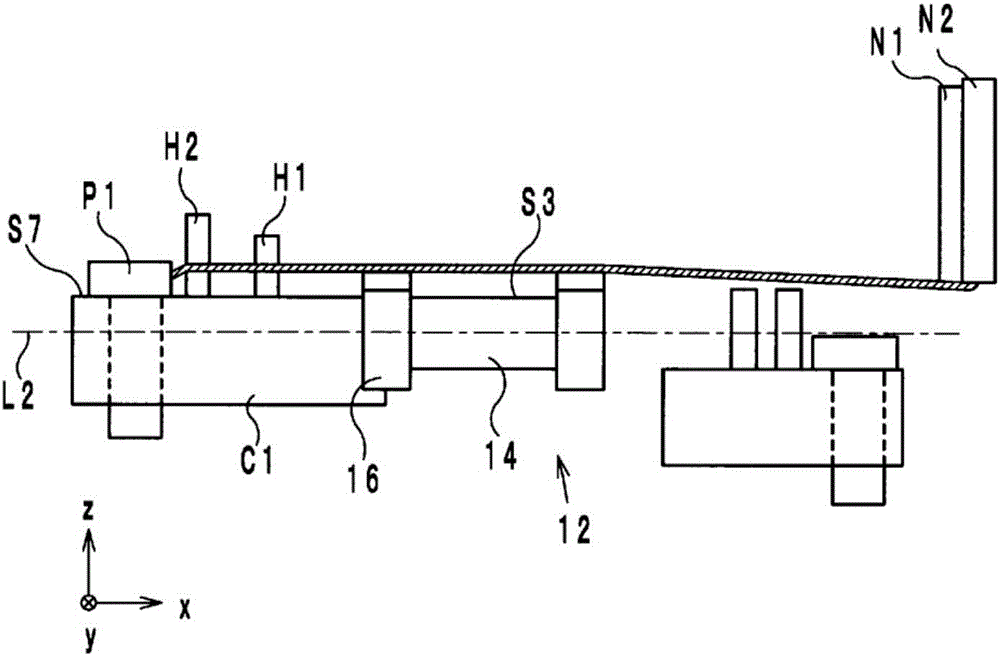

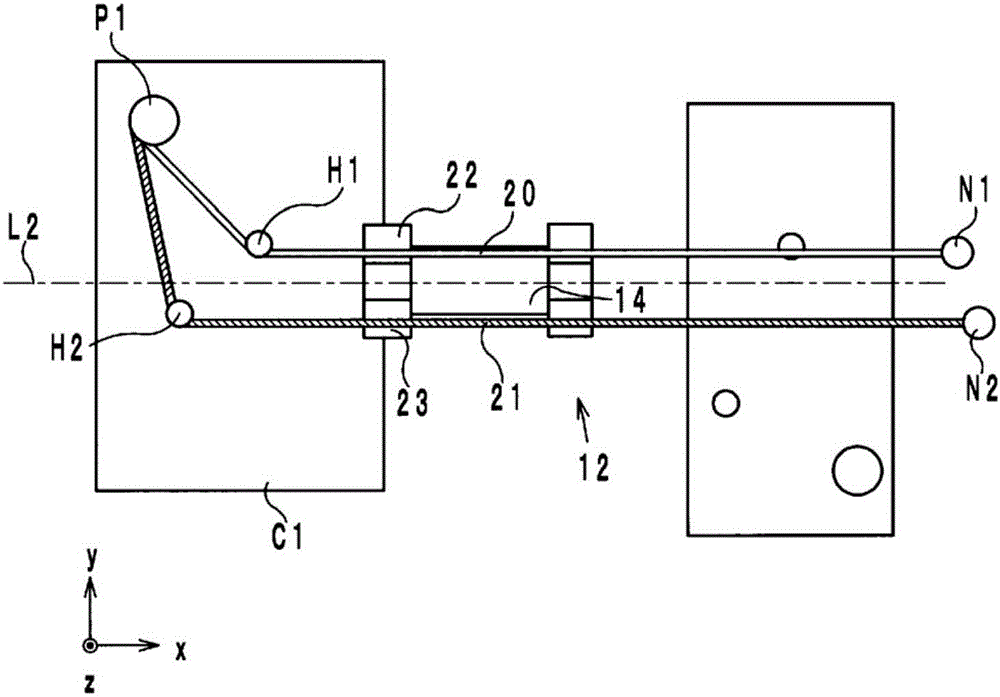

[0071] (Refer to the third embodiment Figure 12 ~ Figure 17 )

[0072] The manufacturing method of the coil-type electronic component of the third embodiment differs from the method of manufacturing the coil-type electronic component of the first embodiment in the method of fixing the coils 20 and 21 to the flange portion 16. The following is a specific description.

[0073] In the manufacturing method of the coil type electronic component of the third embodiment, after the coils 20 and 21 are caught on the hook pins H1 and H2 of the chuck C1, the chuck C1 is rotated by about 90°. As a result, the coil 20, 21 is Picture 12 as well as Figure 13 It is caught at the angle E1 formed by the surface S1 of the flange portion 16 and the surface S4 on the positive side of the x-axis direction of the flange portion 16 as shown.

[0074] Next, like Figure 14 as well as Figure 15 As shown, in the state where the windings 20 and 21 are caught at the angle E2 formed by the surface S5 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com