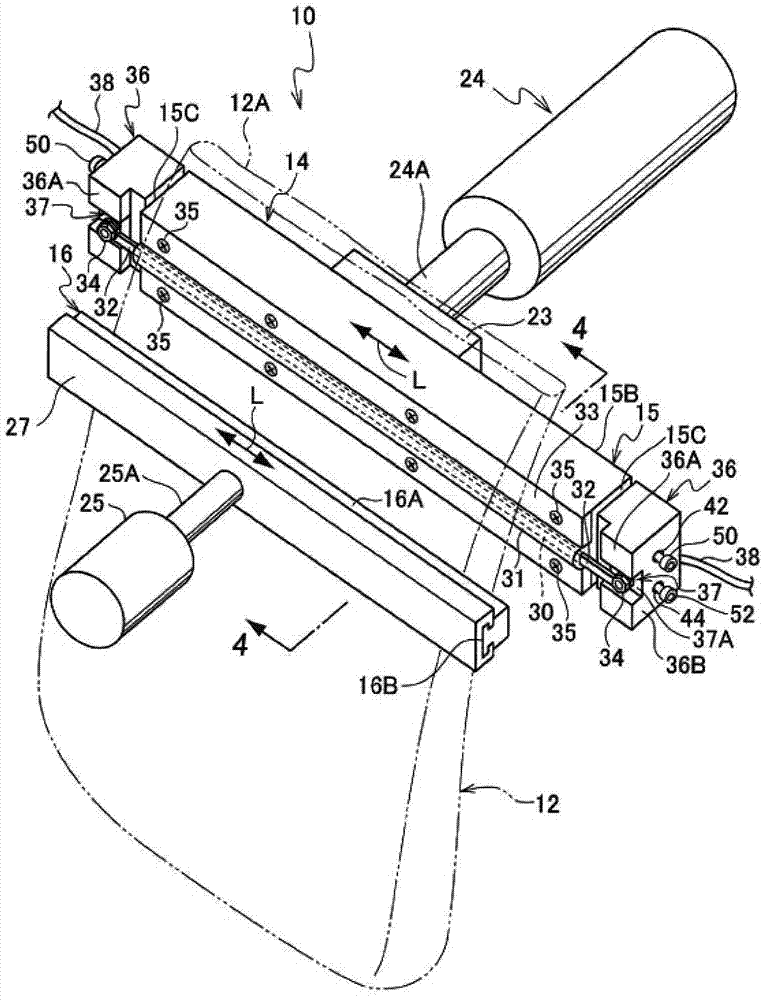

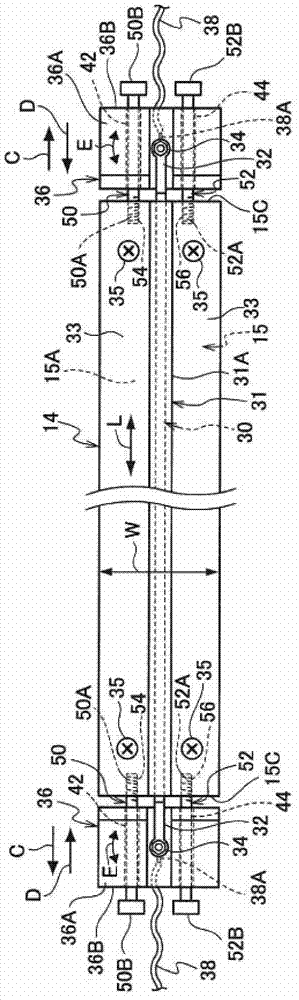

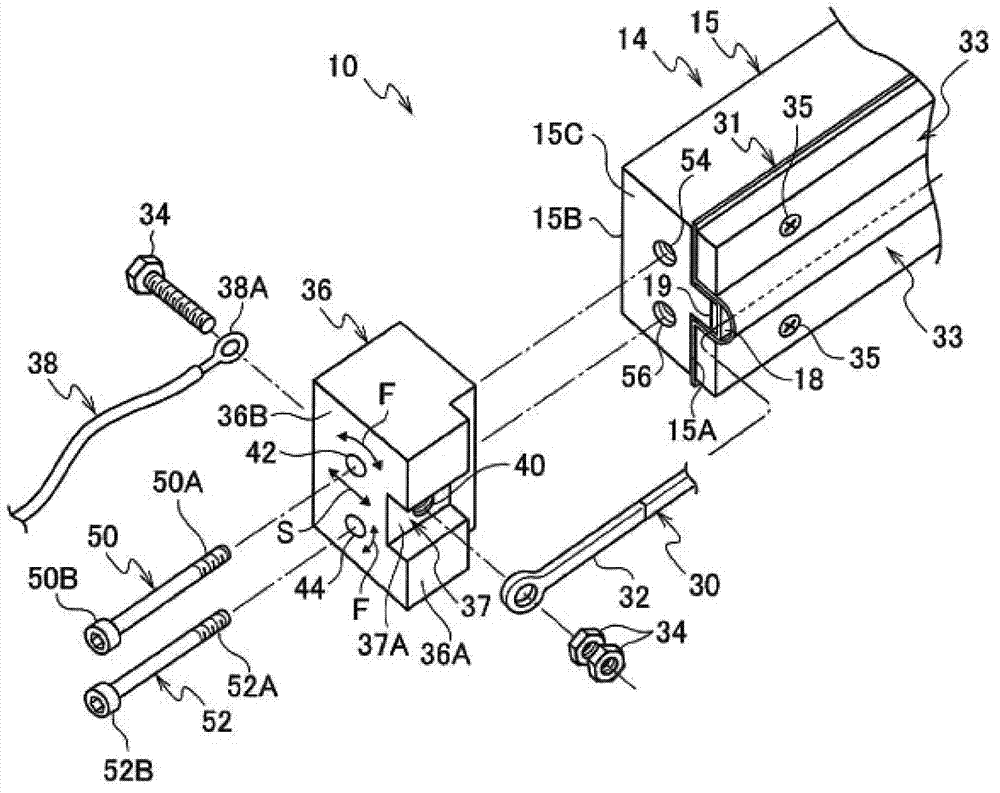

Heat-sealing device

A technology of heat sealing device and heater, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as wire breakage and heater fatigue, and achieve the effect of suppressing wire breakage and reducing tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064]As mentioned above, although this invention was demonstrated in detail based on specific embodiment, this invention is not limited to the said embodiment, It is clear to those skilled in the art that other various embodiment can be implemented within the scope of this invention. For example, in the above-described embodiment, the piston cylinders 24 and 25 are used as the seal member moving mechanism, but instead of the piston cylinder, other seal member moving mechanisms such as a motor and a solenoid may be used.

[0065] In addition, in the above-described embodiment, the heater-side seal member 14 and the press-side seal member 16 are configured to be able to move in both the pinching direction and the pinching opposite direction by the piston cylinders 24 and 25 as the seal member moving mechanism. Instead of this configuration, a seal member moving mechanism may be used so that only either of the heater-side seal member 14 and the press-side seal member 16 can be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com