Machining liquid processing apparatus for electrospark wire processing apparatus

A processing device and electric spark wire technology, which is applied in the field of processing fluid processing devices, can solve problems such as temperature rise, reduction in processing accuracy, wire electrode disconnection, etc., so as to reduce the temperature change of the processing fluid, improve the processing accuracy, and suppress thermal deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

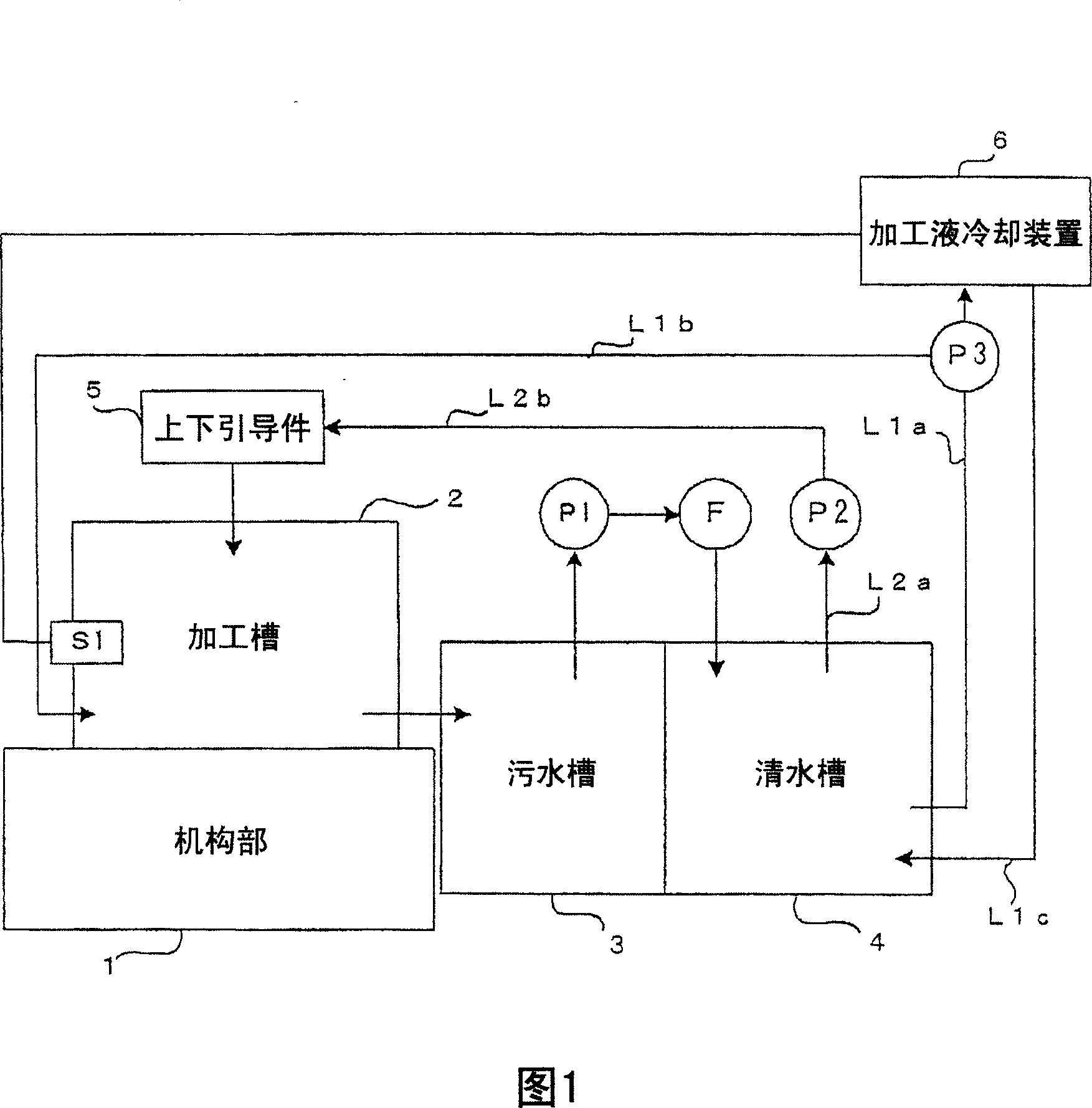

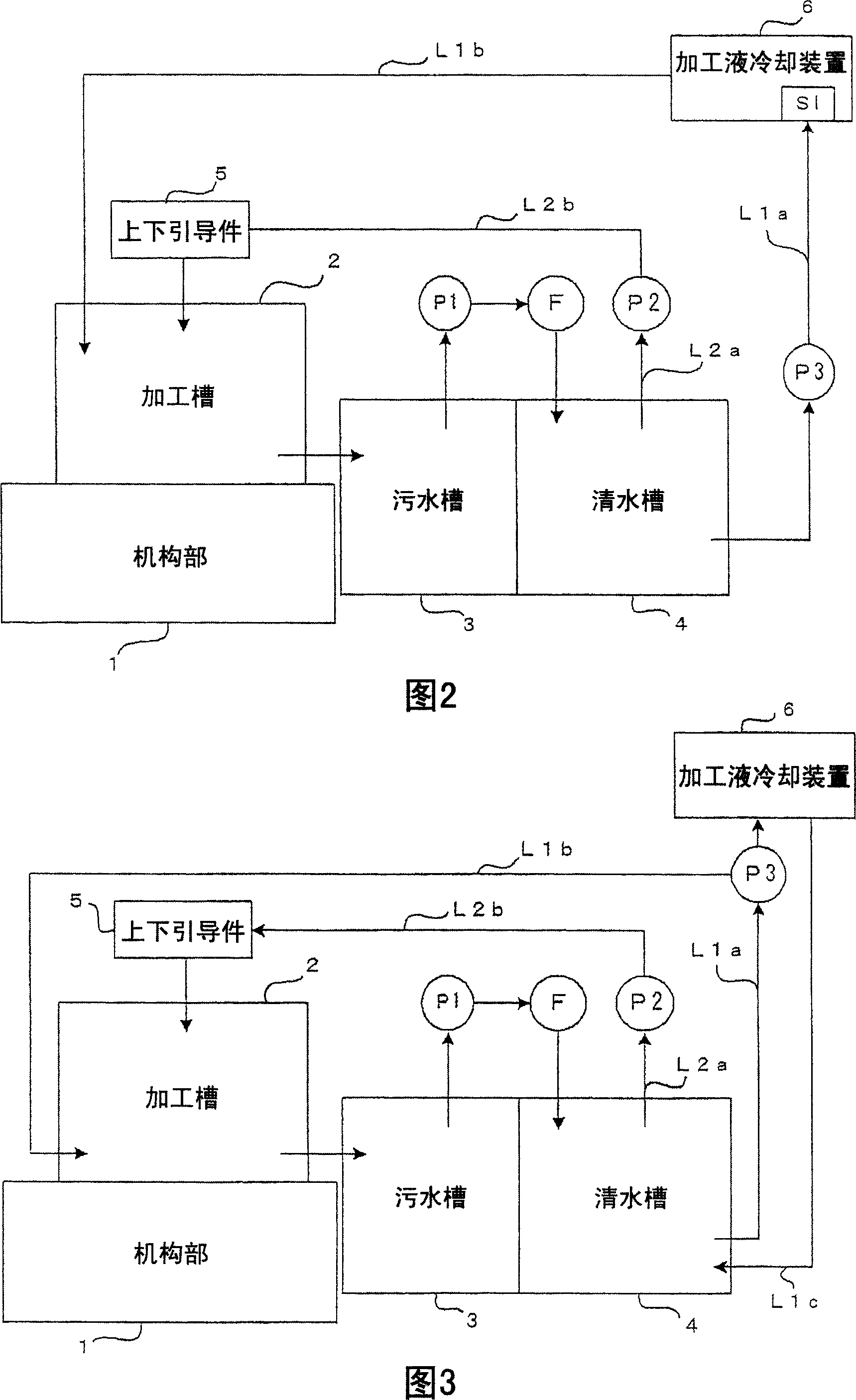

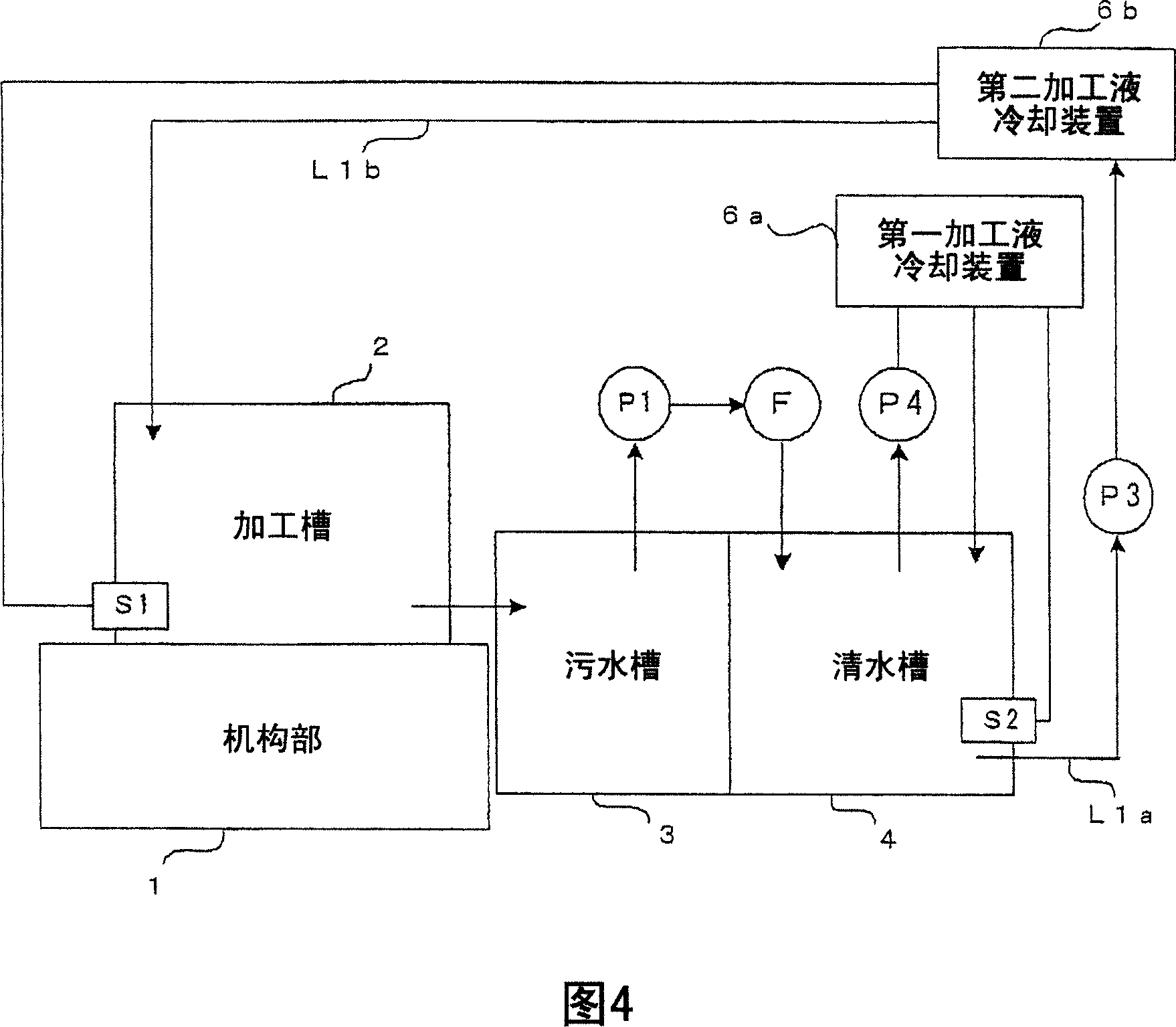

[0025] FIG. 1 is a schematic block diagram of a machining fluid processing device according to an embodiment of the present invention. On the other hand, the same elements as those of the conventional working fluid processing apparatus are denoted by the same reference numerals.

[0026] Similar to the conventional machining liquid processing apparatus, a machining tank 2 is provided in the mechanism part 1 of the wire electric discharge machining apparatus, and an electric discharge machining part is provided in the machining tank 2 . That is, the workpiece (processed object) is installed on the mechanism part 1 and mounted on the table, a voltage is applied between the workpiece and a wire electrode not shown to generate a discharge, and the wire electrode is relatively moved with respect to the workpiece, thereby EDM the workpiece.

[0027] In addition, the machining fluid is supplied to and stored in the machining tank 2 . The machining fluid in the machining tank 2 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com