Electromagnetic coil and method for processing coil terminal thereof

A technology of electromagnetic coils and terminals, applied in the direction of coils, coil manufacturing, circuits, etc., can solve the problems of difficulty in confirming twisting processing, increased manufacturing costs, and low reliability of wire strengthening operations, so as to improve reliability and suppress external force breaking. line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

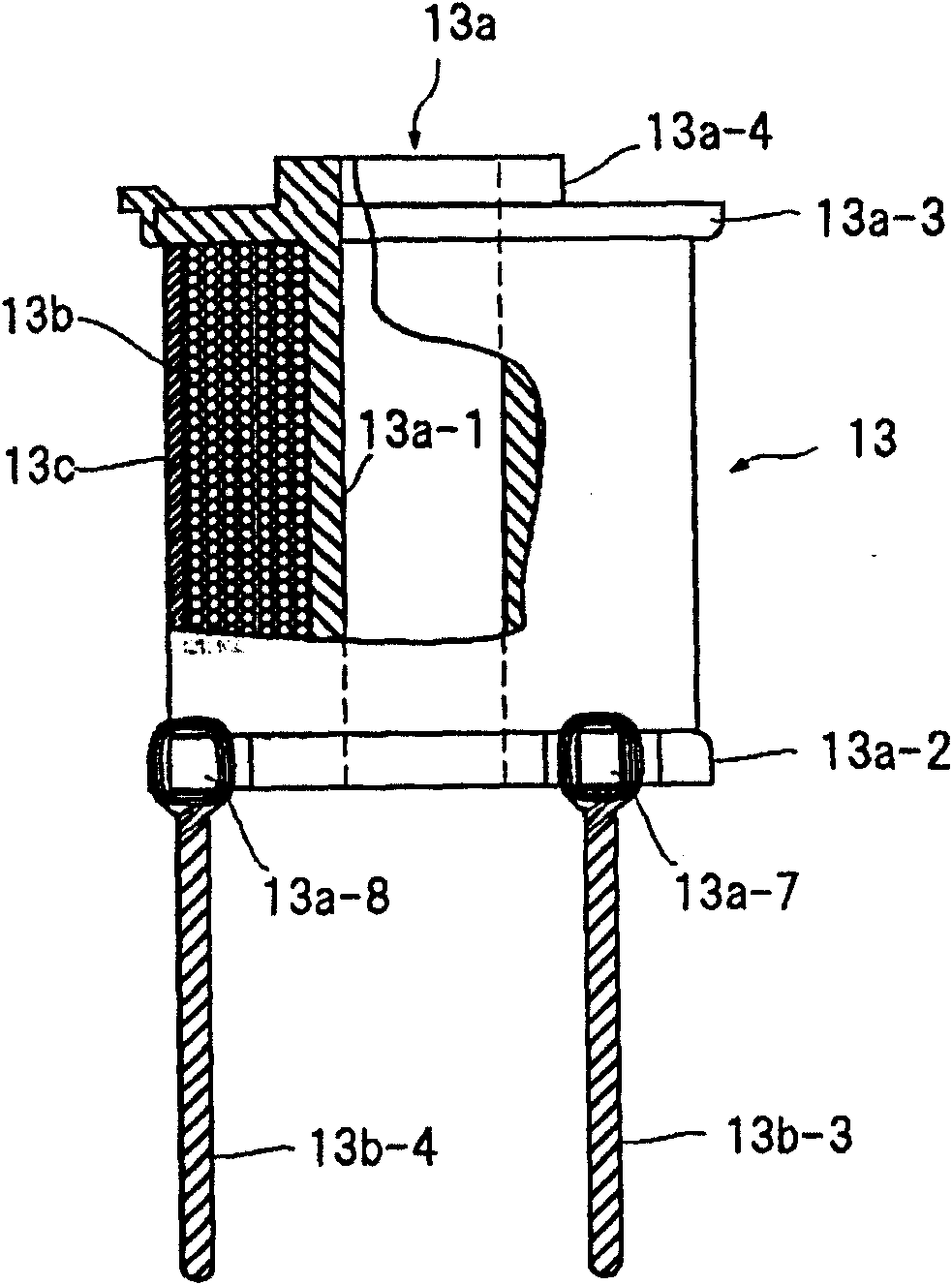

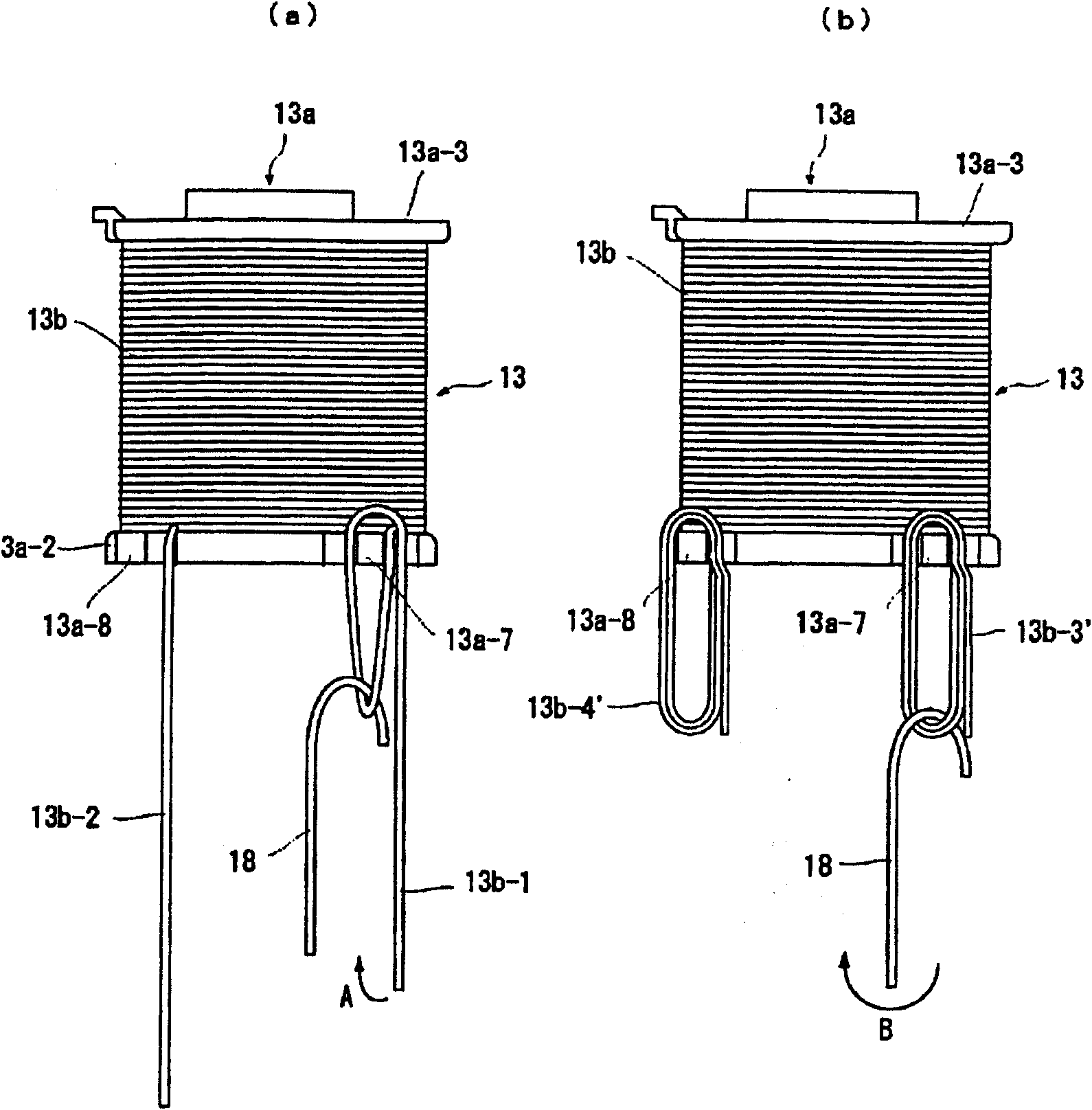

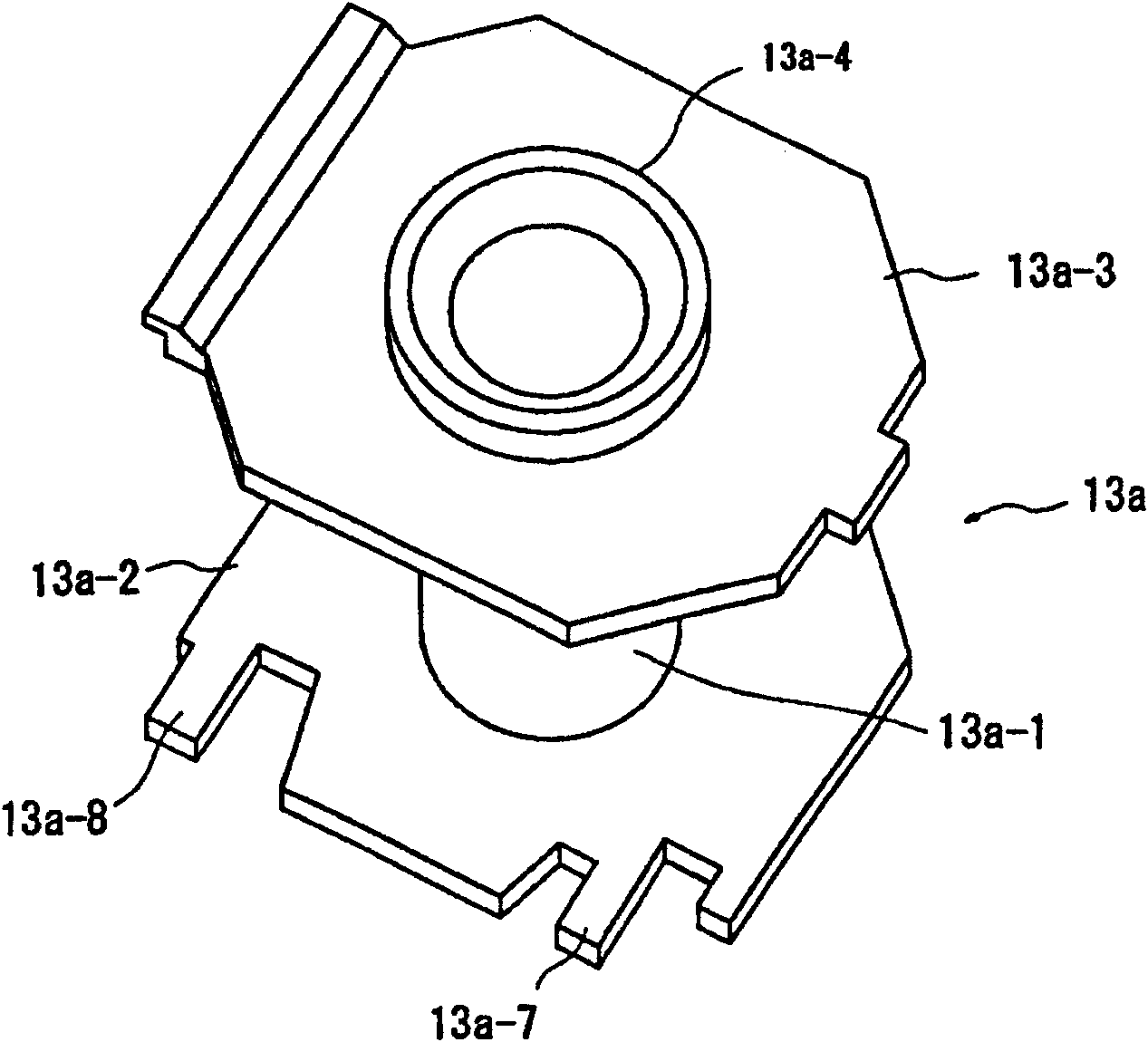

[0039] Figure 1 to Figure 3 represent the present invention. figure 1 is a partially cutaway configuration diagram showing an electromagnetic coil device according to an embodiment of the present invention, figure 2 It is a figure which shows the coil winding terminal processing process for strengthening the coil winding terminal of the embodiment of the present invention, image 3 It is a perspective view showing the skeleton structure of the coil used in the present invention.

[0040] exist Figure 1 to Figure 3In , the parts that are the same as those of the conventional device are denoted by the same symbols. In the above figure, the electromagnetic coil device 13 includes a coil skeleton 13a formed by an insulating resin mold, and a coil winding 13b formed by winding a winding wire on the coil skeleton with a desired number of turns. The outer circumference of the coil winding 13b is covered for protection. The winding start end portion 13b-1 and the winding end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com