Multiple-wire winding method, multiple-wire winding device, and wound coil component

A winding method and winding device technology, applied in coil manufacturing, electrical components, fixed transformers or mutual inductance, etc., can solve problems such as wire injury and wire disconnection, and achieve the effects of preventing injury, not easy to loosen, and reducing the risk of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example -

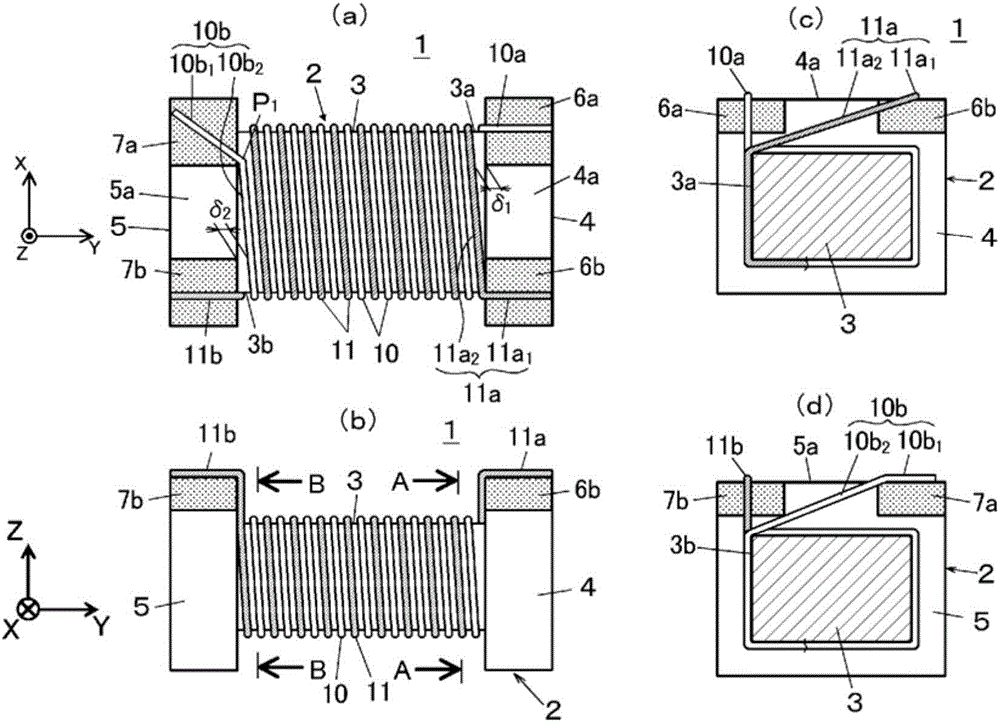

[0049] figure 1 It is an example of the coil component 1 manufactured by the winding method concerning this invention, and the example of a 2-wire common mode choke coil is shown here. The present coil component 1 includes a core body 2 made of a magnetic material. The core body 2 has a winding core portion 3 at its central portion, and a pair of flange portions 4, 5 at both ends in the axial direction. The winding core portion 3 has a rectangular parallelepiped shape having an upper and lower surface and two side surfaces, and two electric wires 10 and 11 are wound in parallel on the peripheral surface of the winding core portion 3 . Among them, in figure 1 Here, the axial direction of the core body 2 is defined as the Y axis, the horizontal direction perpendicular to the Y axis is defined as the X axis, and the vertical direction is defined as the Z axis.

[0050] On the mounting surface side of the flange parts 4, 5 (in figure 1 (indicated as the upper side, but it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com