Patents

Literature

105results about "Second resist pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printed wiring board, method for producing printed wiring board and semiconductor device

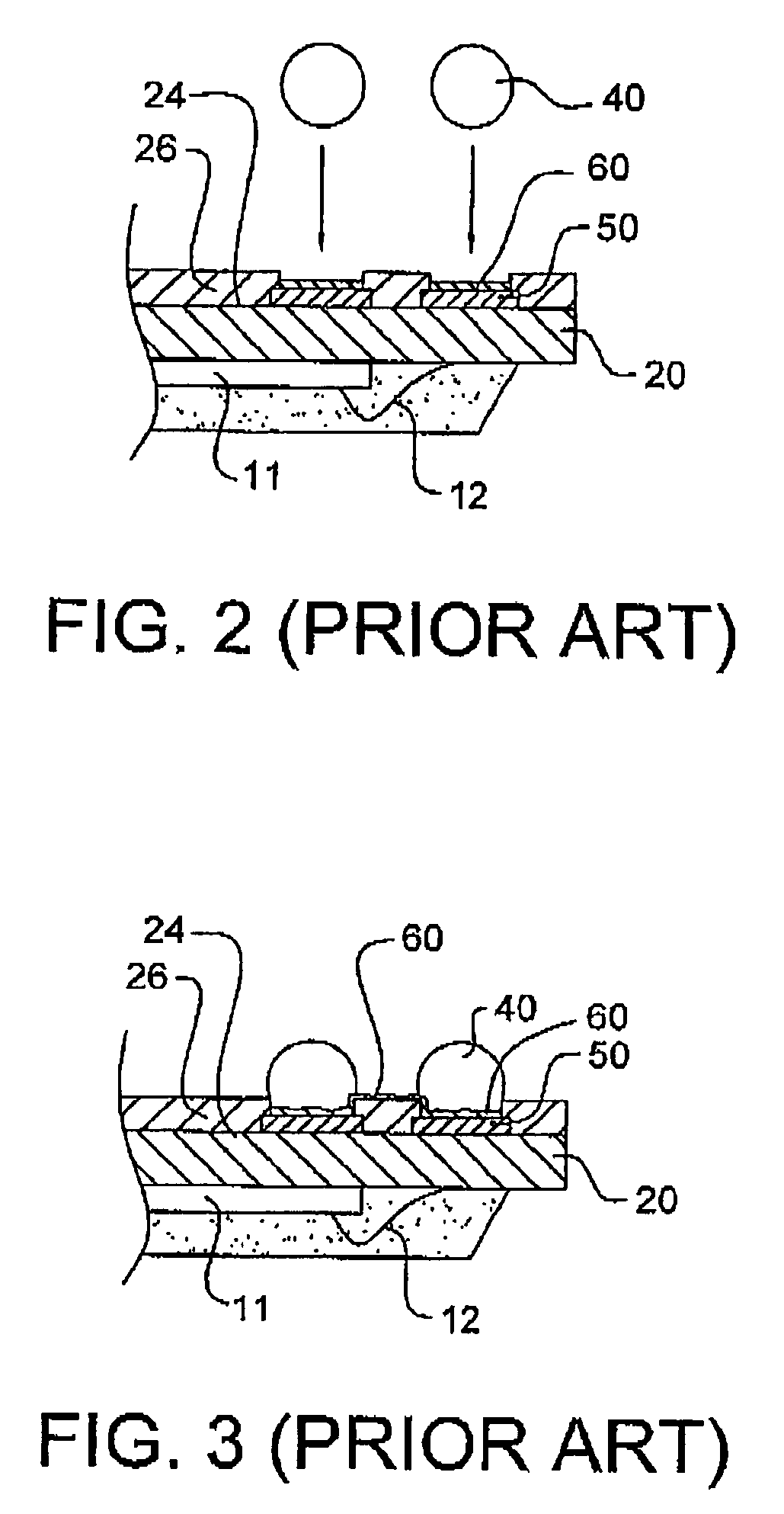

InactiveUS20160322293A1Efficient productionHigh hardnessSecond resist patternSemiconductor/solid-state device detailsResistElectrical conductor

The present invention provides a printed wiring board comprising: a conductor circuit on an insulating substrate, a white solder resist layer which is composed of a photosensitive resin composition on the insulating substrate having the conductor circuit, and a protective layer which is composed of a silicone resin composition on the white solder resist layer. The inventive printed wiring board shows superior thermo-discoloration resistivity and excellent patterning resolution.

Owner:SHIN ETSU CHEM IND CO LTD

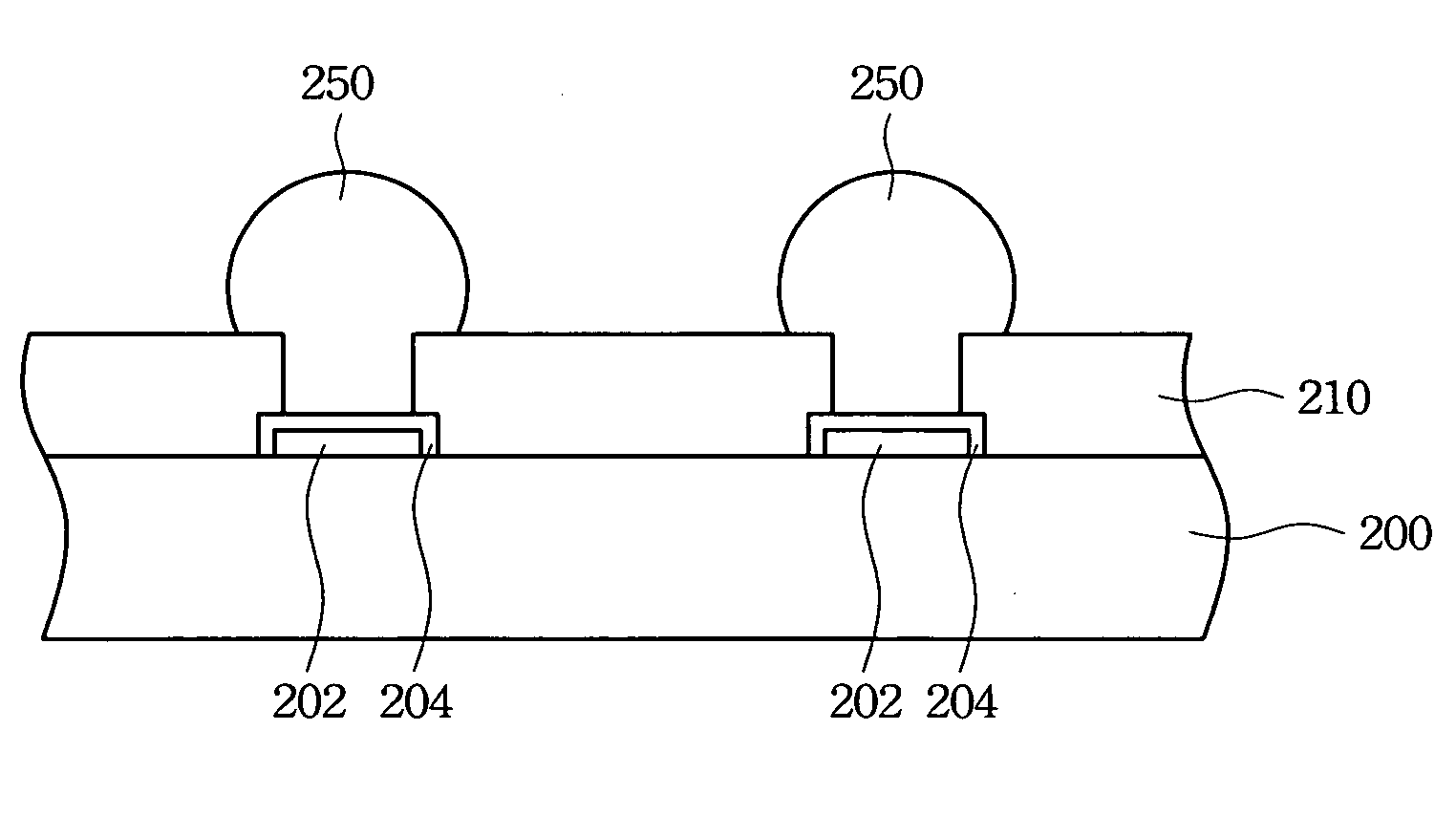

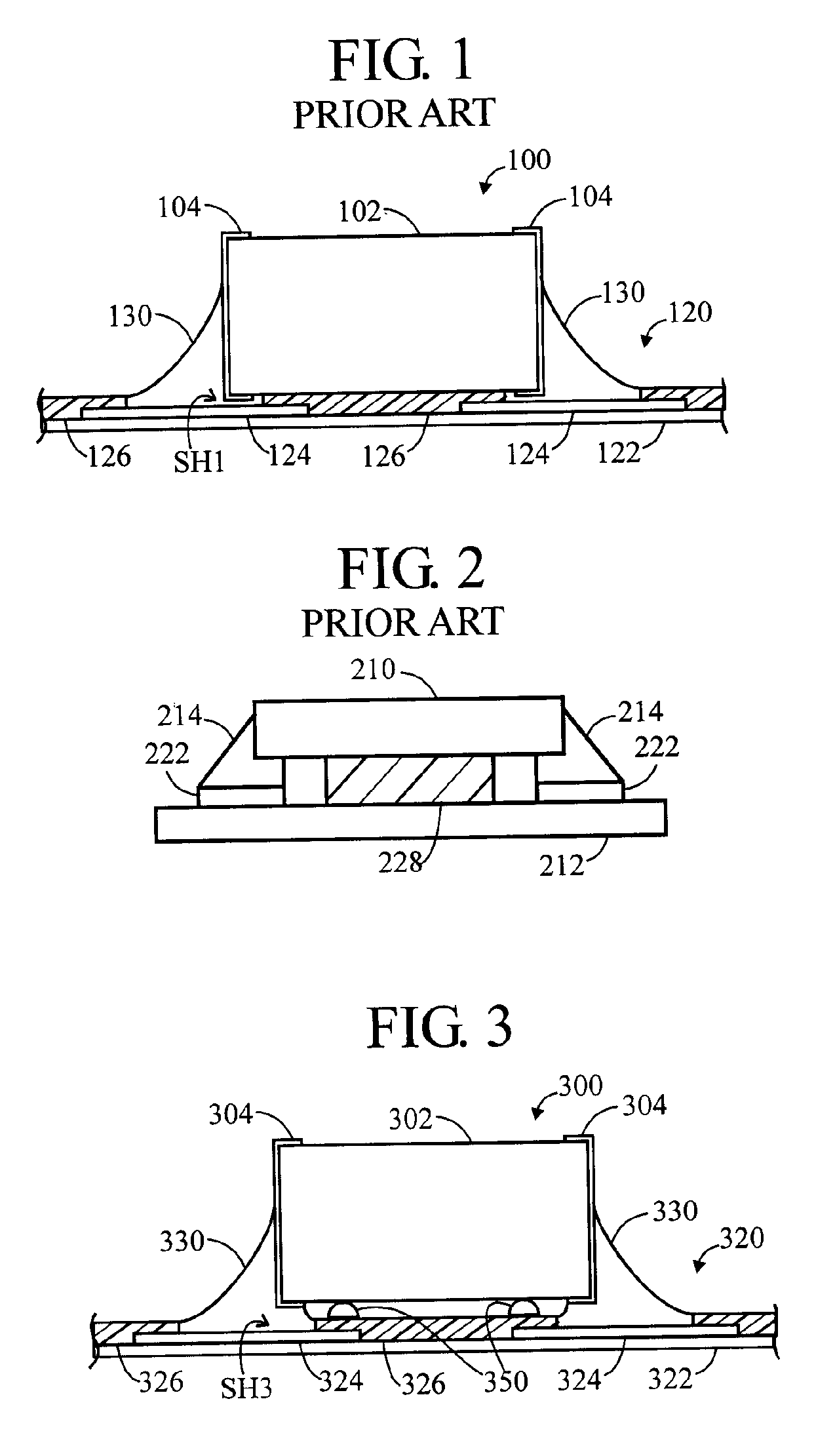

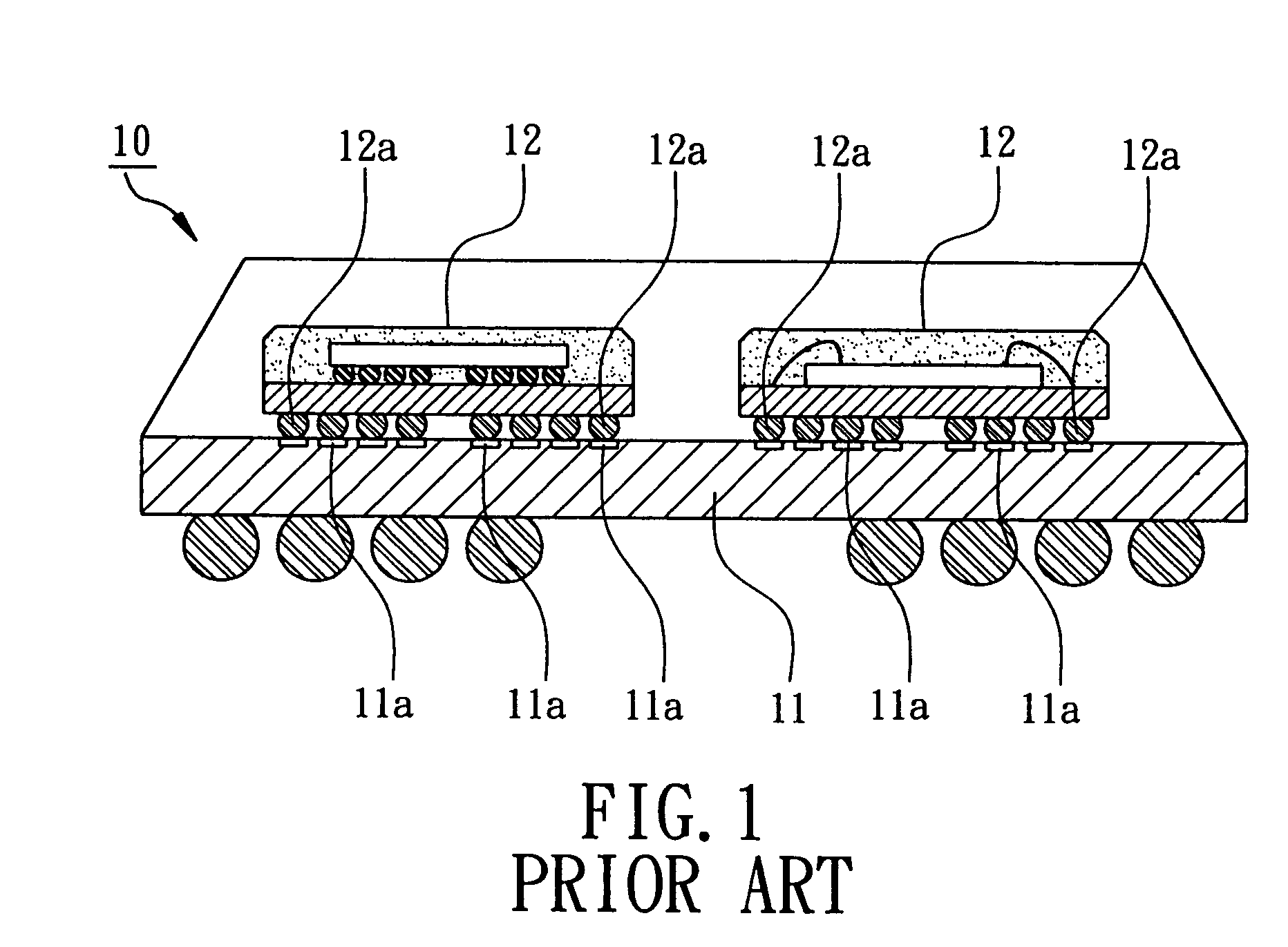

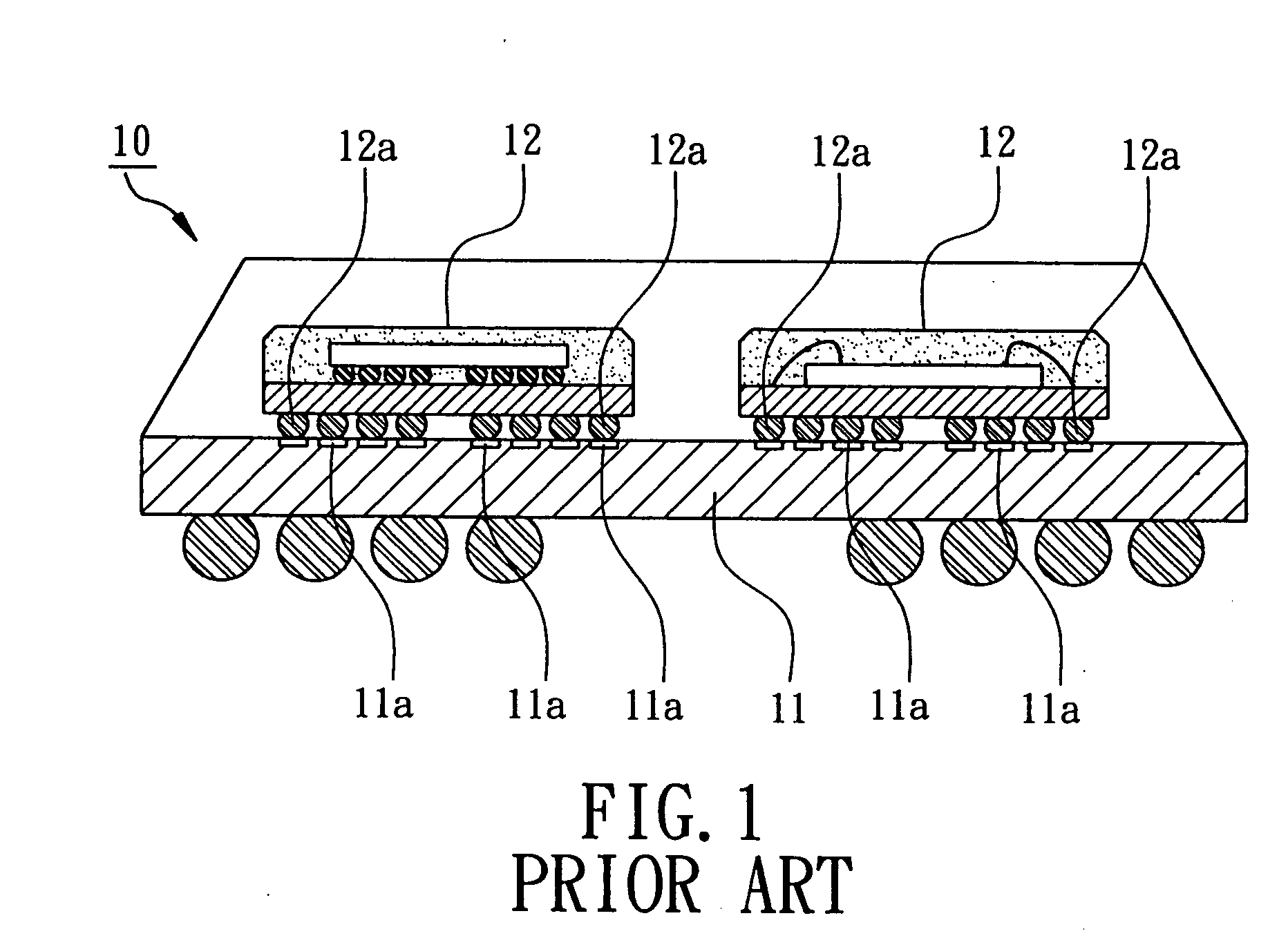

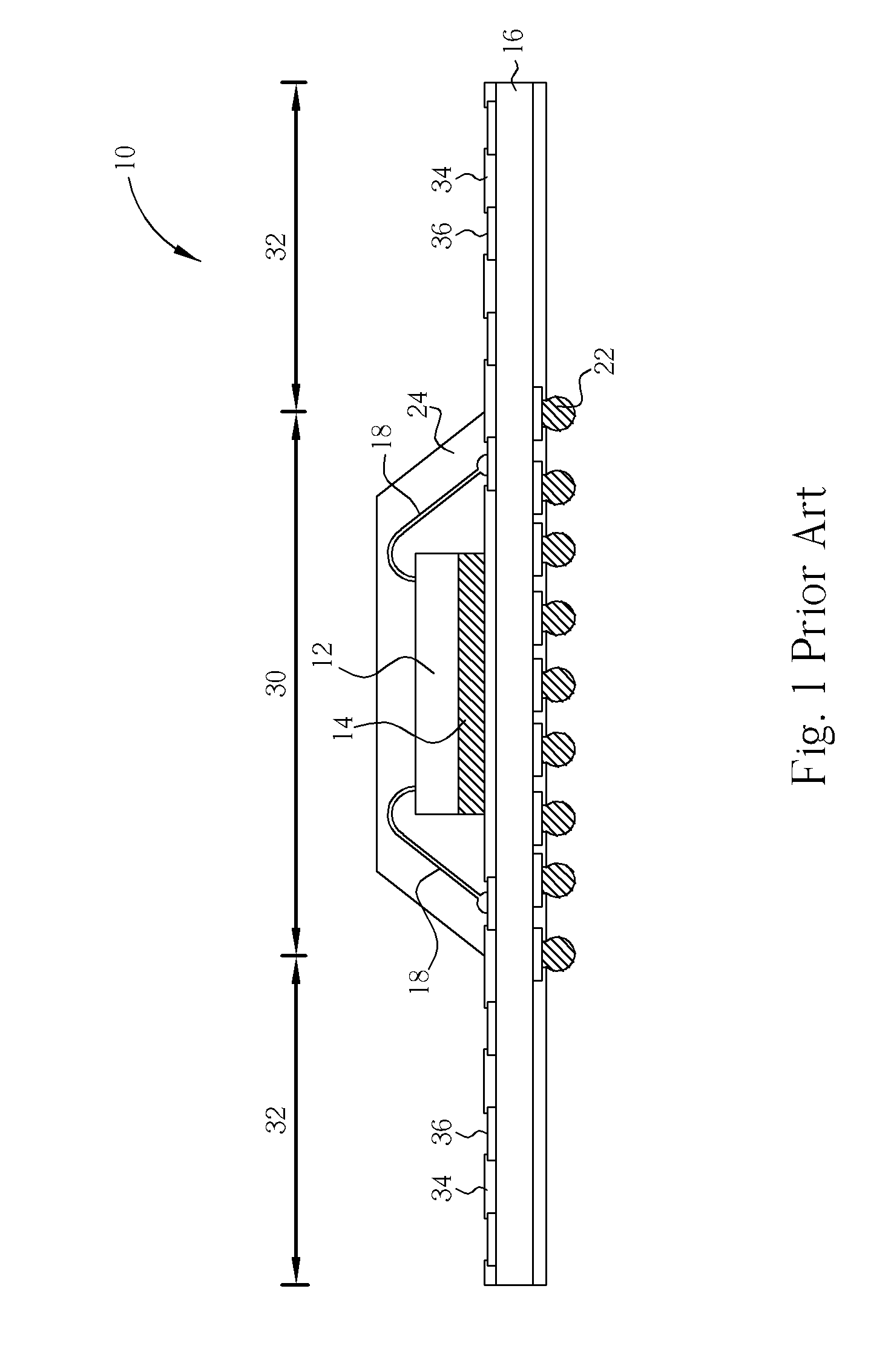

System-in-package structure

ActiveUS7417329B2Improve pollutionImproving yield and stabilitySecond resist patternSemiconductor/solid-state device detailsSolder maskEngineering

A system-in-package structure includes a carrier substrate having a molding area and a periphery area, at least a chip disposed in the molding area, an encapsulation covering the chip and the molding area, a plurality of solder pads disposed in the periphery area, and a solder mask disposed in the periphery area and partially exposing the surface of the solder pads. The solder mask includes at least a void therein.

Owner:ADVANCED SEMICON ENG INC

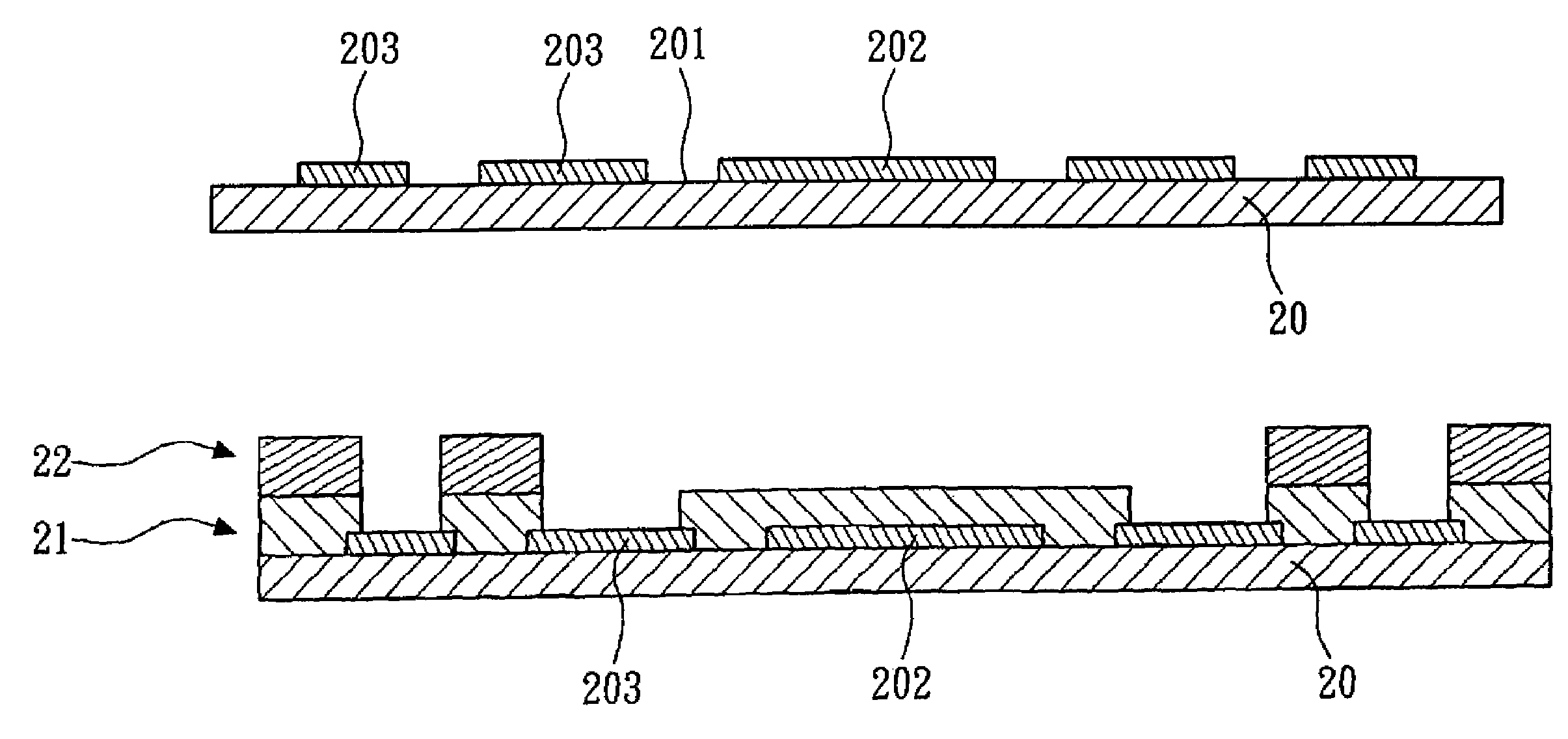

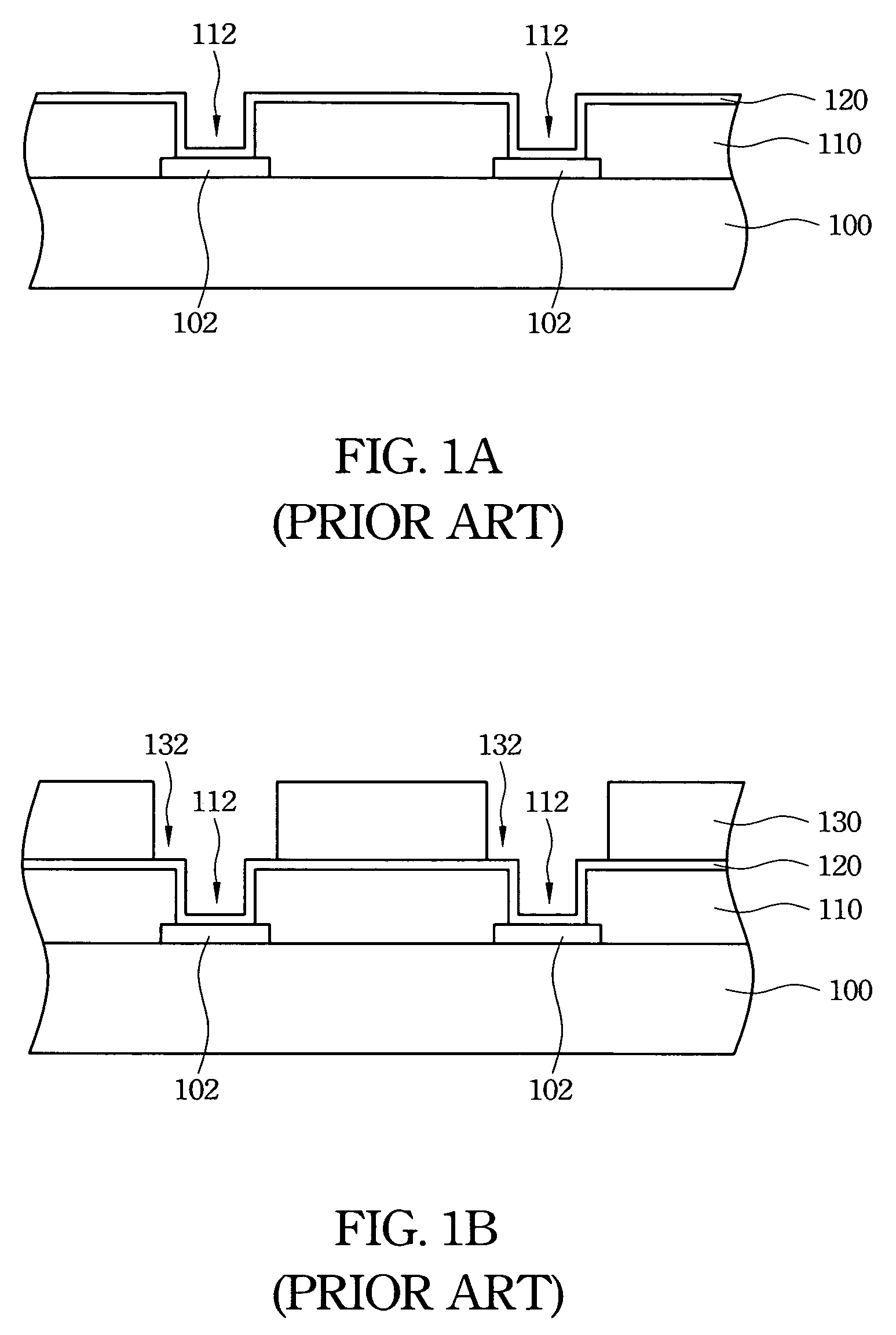

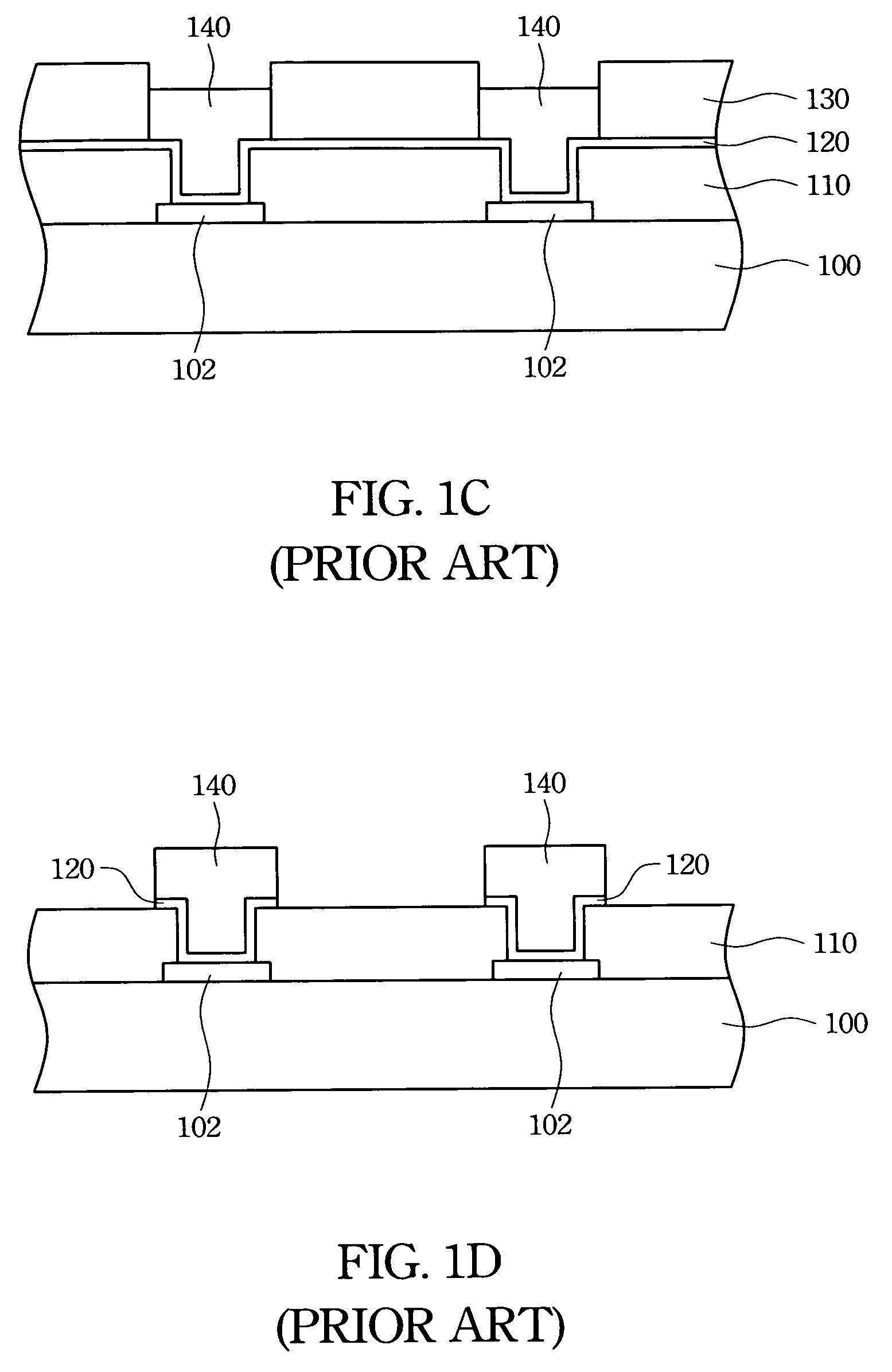

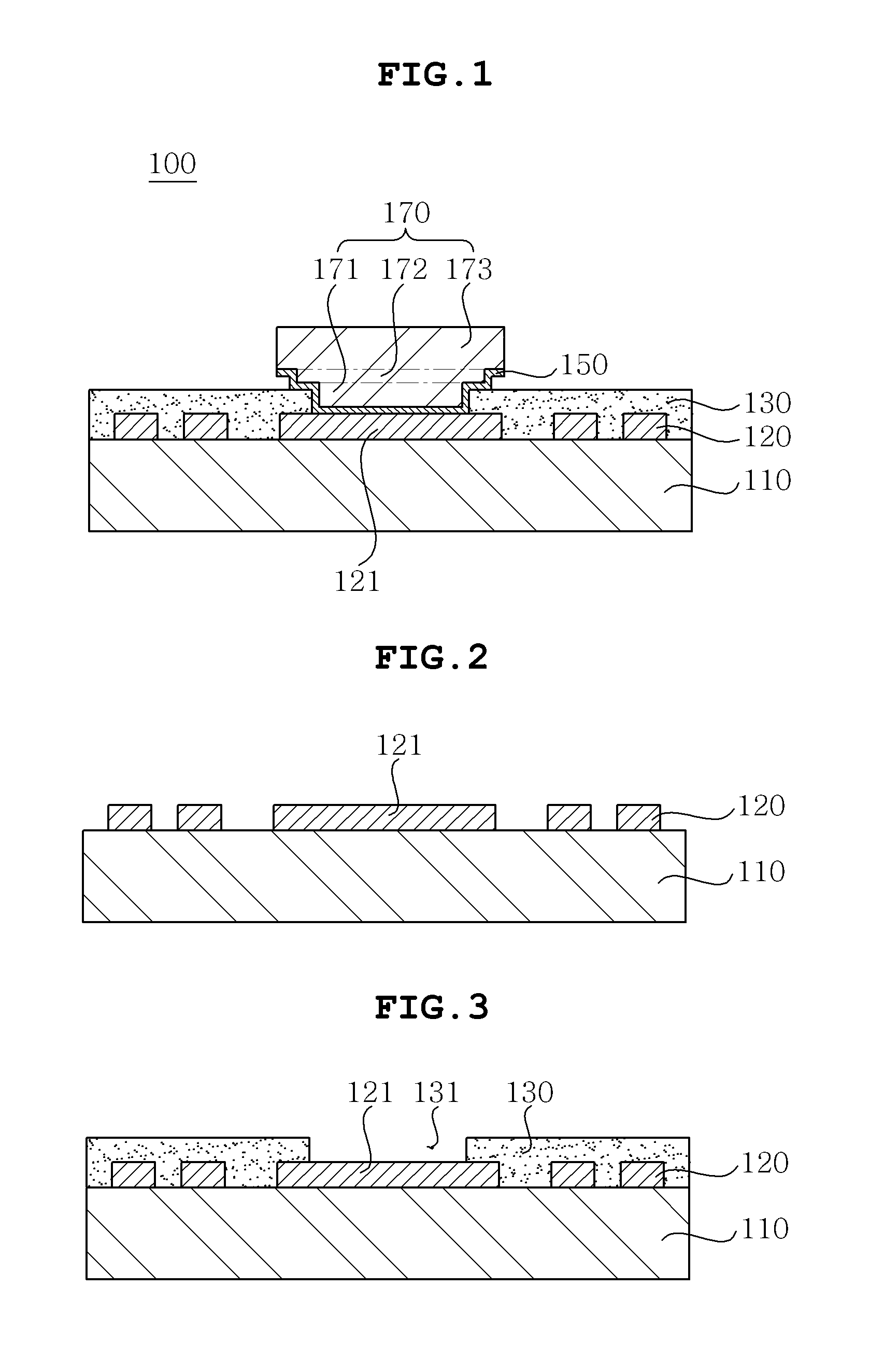

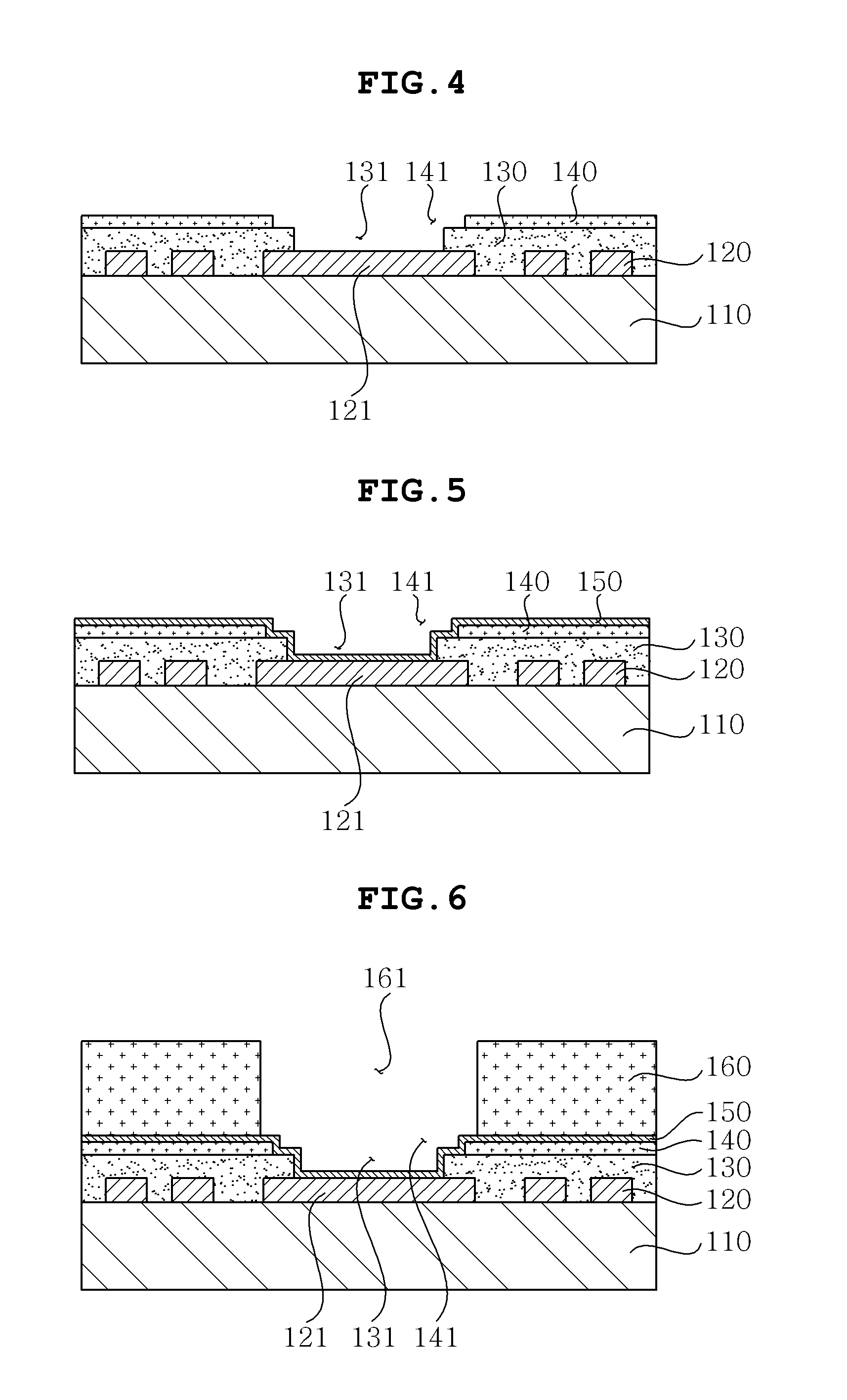

Substrate structure having a solder mask and a process for making the same

ActiveUS7473629B2Avoid crackingPrevent overflowSecond resist patternSolid-state devicesSolder maskMaterials science

A substrate structure having a solder mask and a process for making the same, including (a) providing a substrate having a top surface, the top surface having a die pad and a plurality of solder pads; (b) forming a first solder mask on the top surface, the first solder mask having a plurality of openings, each opening corresponding to each solder pad so as to expose at least part of the solder pad; and (c) forming a second solder mask on the first solder mask. The substrate structure can be used for packaging a thicker die so as to prevent the die crack and the overflow of molding compound will be avoided.

Owner:ADVANCED SEMICON ENG INC

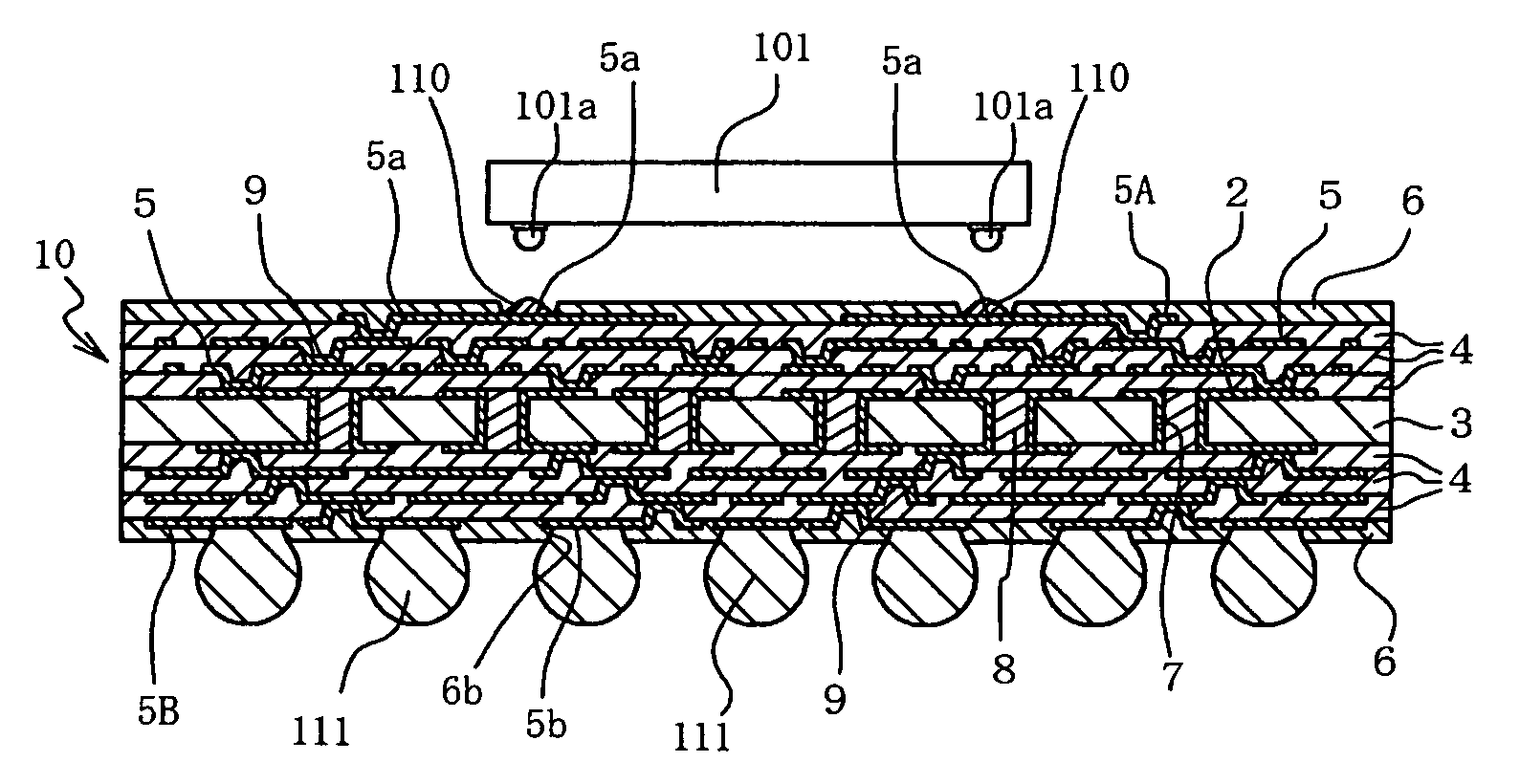

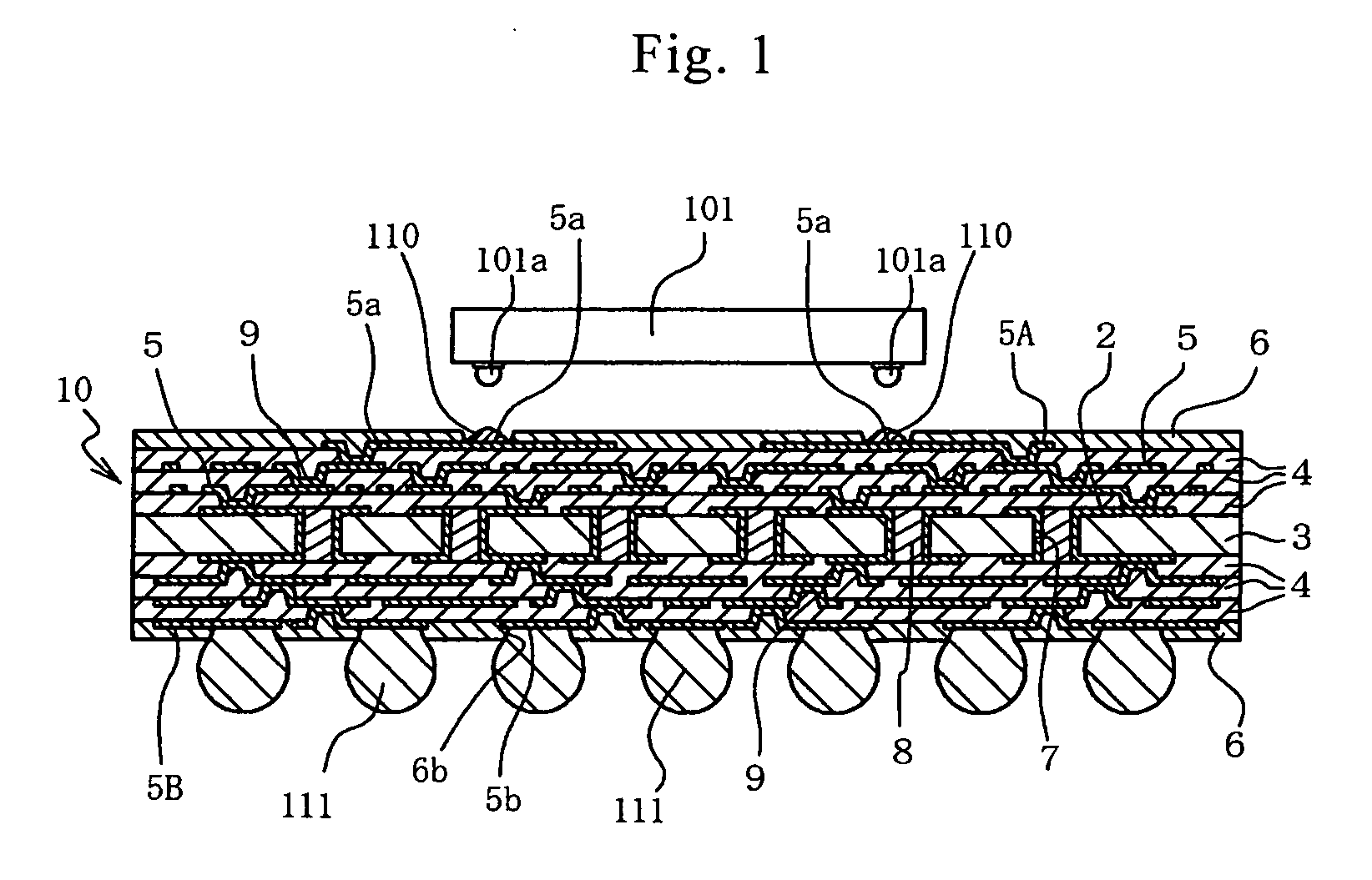

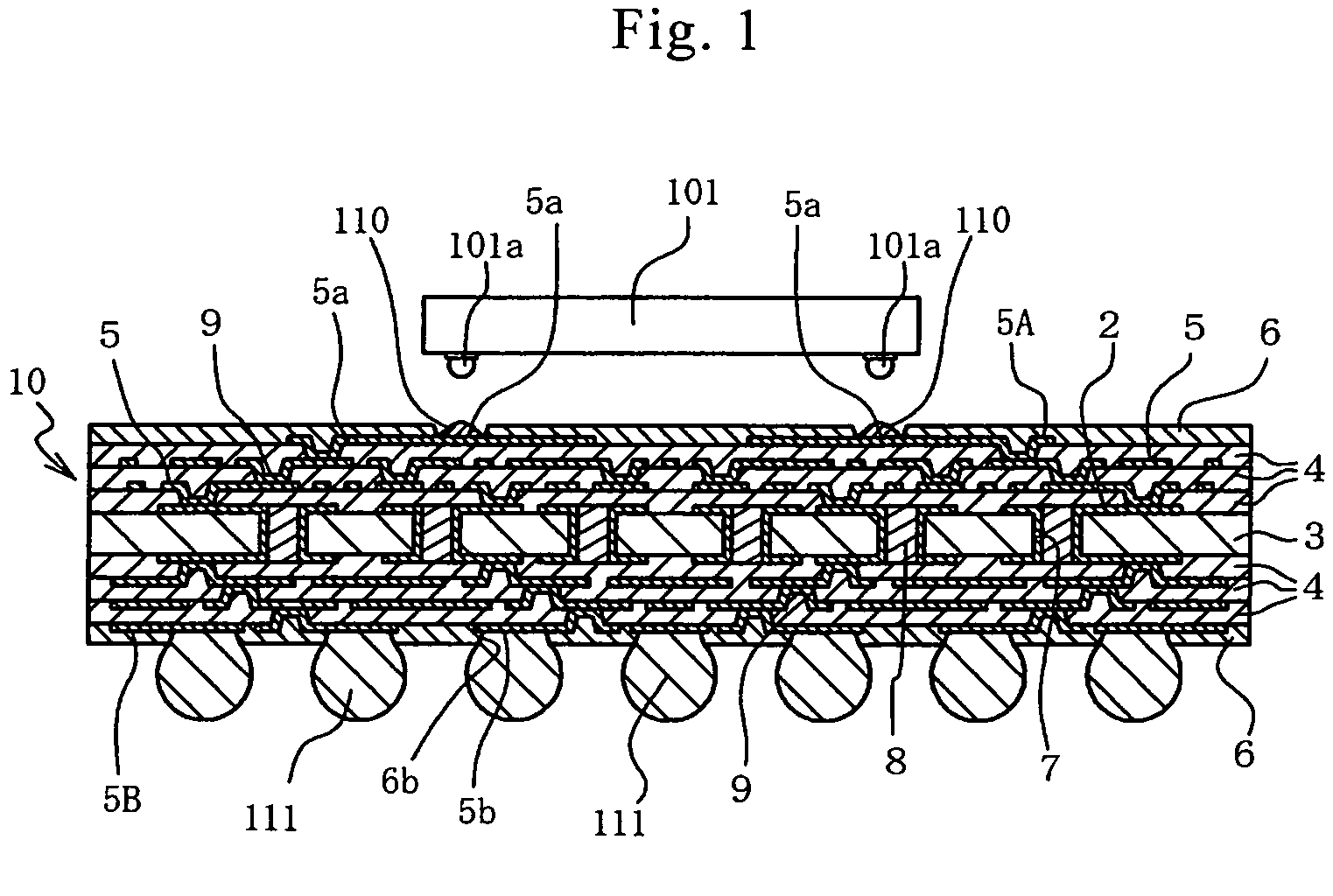

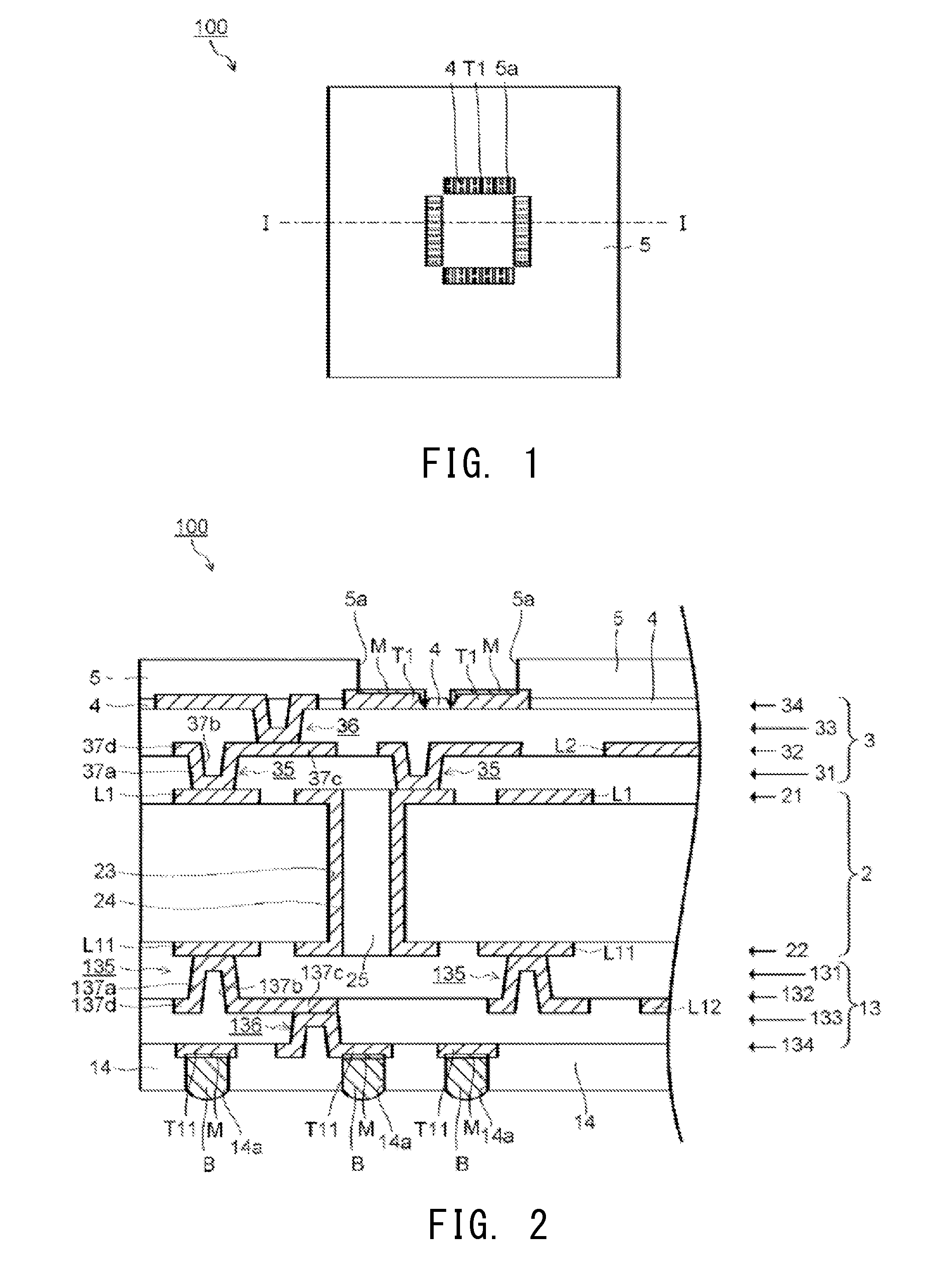

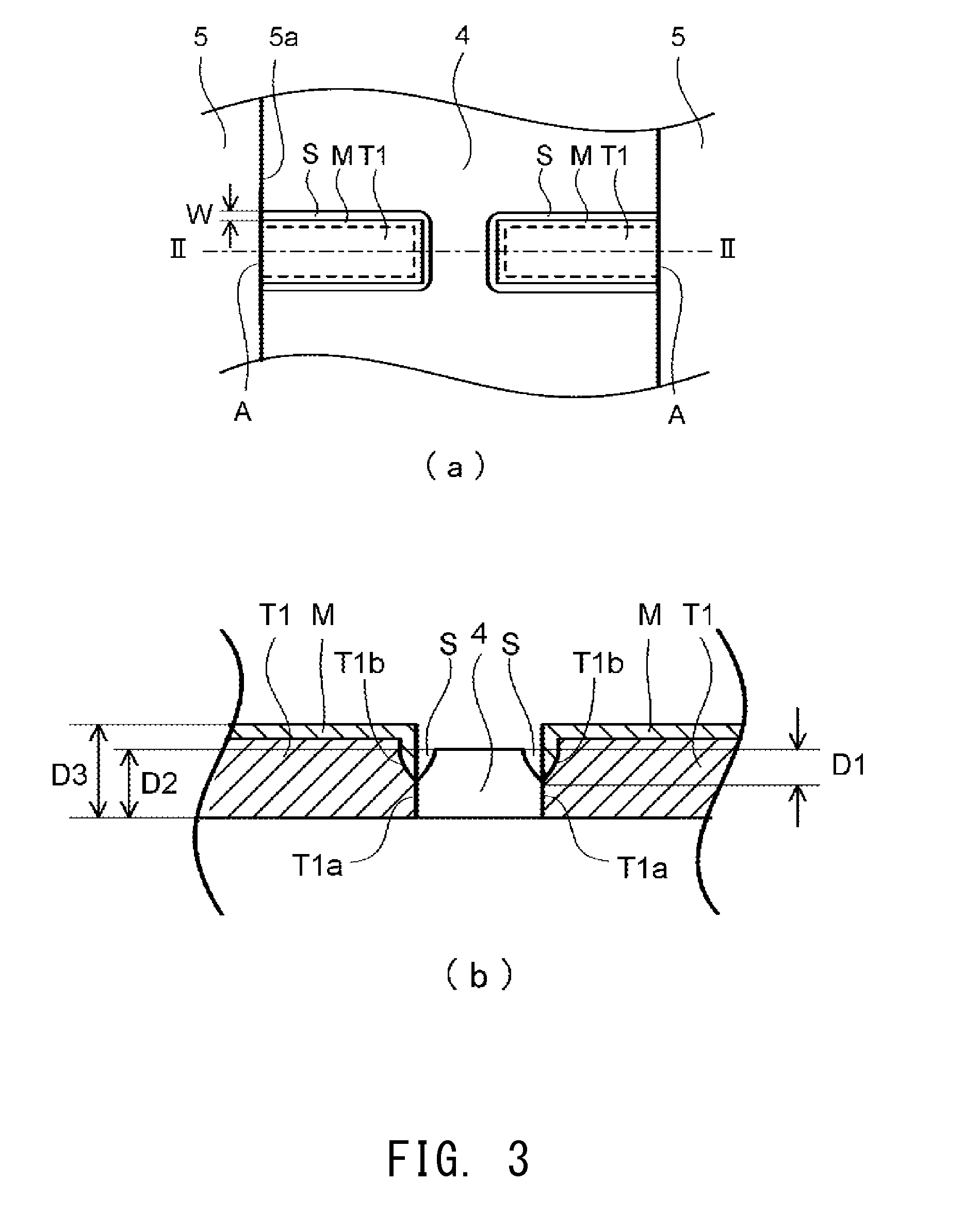

Multilayer Wiring Substrate, and Method of Manufacturing the Same

InactiveUS20110198114A1Improve welding strengthReliable formingLine/current collector detailsSecond resist patternInsulation layerEngineering

A plurality of openings are formed in a resin insulation layer on a top surface side of a wiring laminate portion, and a plurality of openings are formed in a resin insulation layer on a bottom surface side thereof. A plurality of connection terminals are disposed to correspond to the openings. Peripheral portions of terminal outer surfaces of the connection terminals are covered by the resin insulation layer on the top surface side, and peripheral portions of terminal outer surfaces of the connection terminals are covered by the resin insulation layer on the bottom surface side. Each of the second-main-surface-side connection terminals has a concave portion at the center of the terminal outer surface, and the deepest portion of the concave portion is located on the interior side in relation to the peripheral portion of the terminal outer surface.

Owner:NGK SPARK PLUG CO LTD

Process for fabricating circuitry on substrates having plated through-holes

Circuitry is formed on a substrate having at least one plated through-hole employing two different photoresist materials. A first photoresist is applied on a conductive layer located on a substrate and is developed to define a desired conductive circuit pattern. A second photoresist is laminated onto the structure and is developed so that the second photoresist material remains in the vicinity of the through-hole. The conductive layer is etched to provide the desired circuit pattern, and the remaining portions of the second and first photoresists are removed.

Owner:IBM CORP

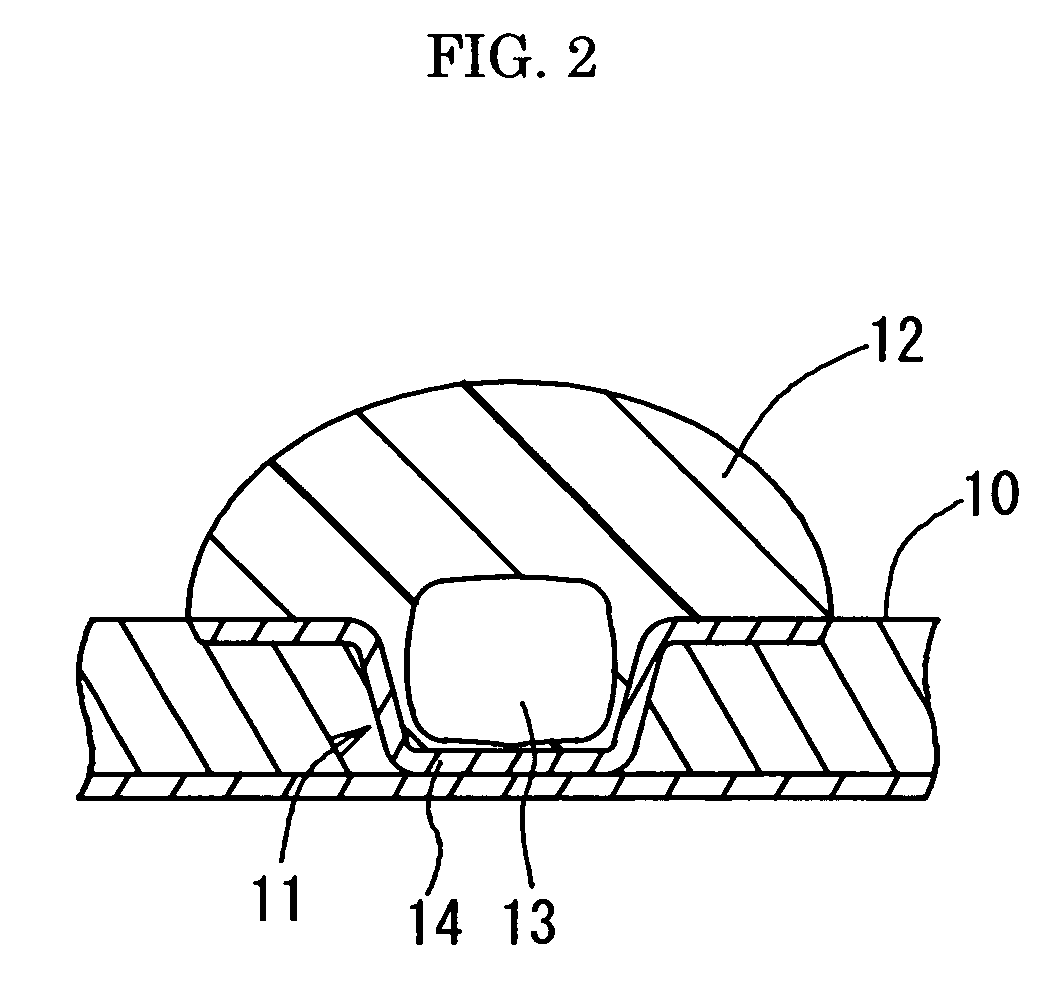

Solder deposition method and solder bump forming method

ActiveUS7452797B2Avoid it happening againAccurate storagePrinted circuit assemblingSecond resist patternMetallurgyFine pitch

The present invention provides a solder deposition method that includes the step of forming a dam around an electrode on a substrate, the step of applying a solder precipitating composition to the substrate, and the step of depositing solder on the surface of the electrode while heating the solder precipitating composition applied. This solder deposition method is suitable for forming large bumps at fine pitches. In particular, it is capable of depositing solder in a desired height precisely and easily, and yet preventing occurrence of voids.

Owner:HARIMA CHEM INC

Method for forming metal bumps

InactiveUS20070232051A1Poor in size can be solvedLow costSecond resist patternSolid-state devicesResistSolder mask

A method for forming metal bumps is disclosed, comprising: providing a substrate including a plurality of pads; forming a solder mask on the substrate, wherein the solder mask has first openings to expose the pads; forming a photoresist layer on the solder mask, wherein the photoresist layer has second openings to expose the pads; forming a conductive layer on the phototresist layer, wherein a sidewall of each second opening, a sidewall of each first opening and the pads are covered with the conductive layer; forming a metal layer on the conductive layer by electroplating to fill the first and second openings; performing a planarization step to remove the conductive layer and the metal layer on the photoresist layer so as to remain the conductive layer and the metal layer in the first and second openings; removing the photoresist layer and performing a reflow step to form metal bumps.

Owner:ADVANCED SEMICON ENG INC

Printed circuit board, method of producing the same, and electronic unit

InactiveUS20070187136A1Easy to makePrevent outflowSecond resist masksSecond resist patternAcute anglePrinted circuit board

A printed circuit board is disclosed that is able to prevent outflow of a potting resin out of a sealing region. The printed circuit board includes a conductive pattern formed on an insulating substrate, an electrode for connecting an electronic part to the conductive pattern, and a stripe-like resin-outflow-prevention dam arranged in a periphery of a resin-sealing region covering the electronic part. An outer side surface and an upper surface of the resin-outflow-prevention dam subtend an acute angle.

Owner:RICOH KK

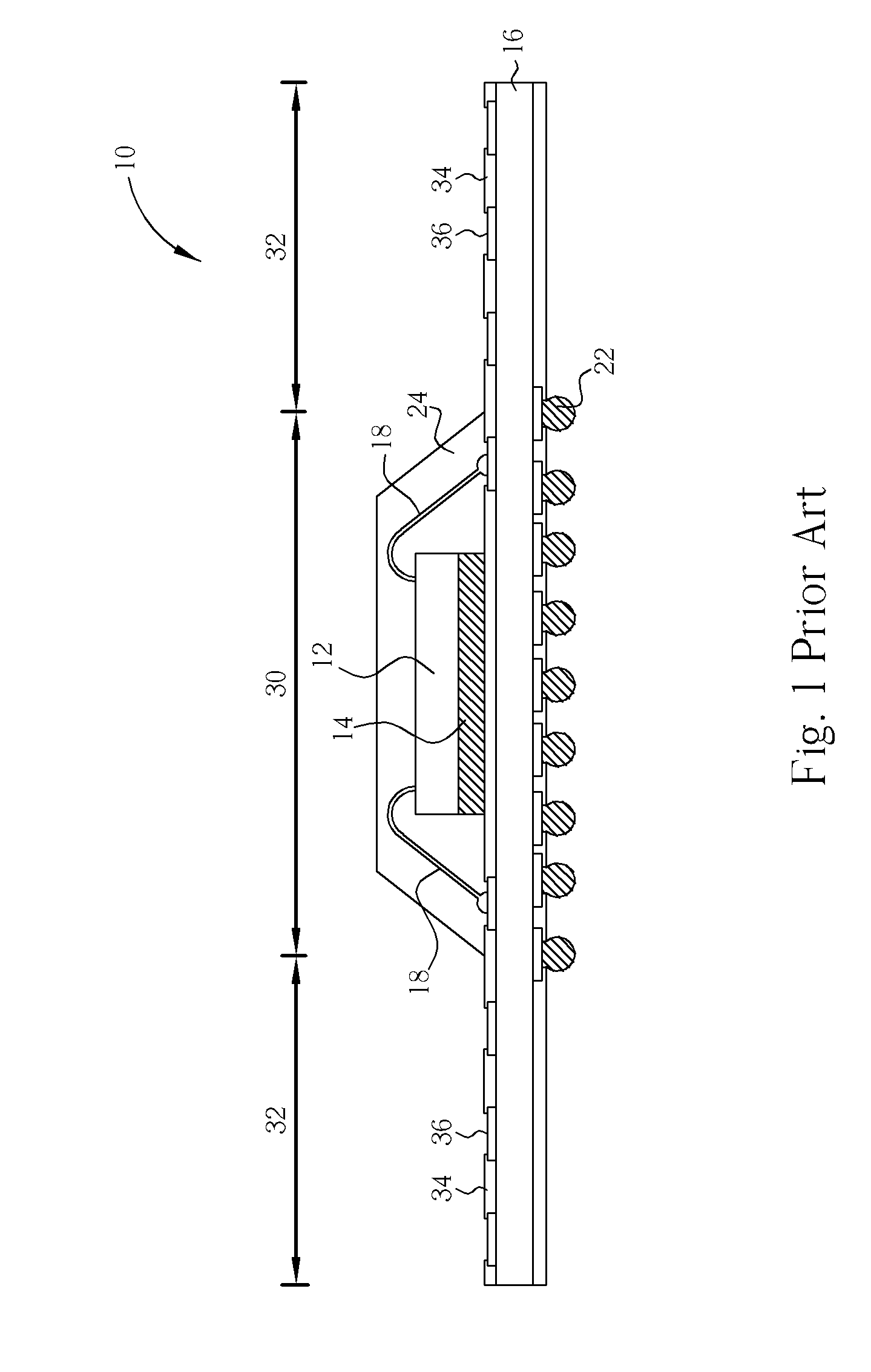

Standoff structures for surface mount components

InactiveUS20070007323A1Improve surface mount interconnect reliabilityIncrease the amount of solderSecond resist patternFinal product manufactureEpoxySurface mounting

Increasing standoff height for surface mount components mounted to a laminate by image screening at least one standoff structure in a footprint area on the laminate surface. The standoff structure may comprise a filled epoxy and curing agents and may be cured by thermal treatment or by exposure to actinic radiation. The use of legend ink as a standoff structure offers a method and a structure for improving component standoff height without additional processing operations or cost.

Owner:IBM CORP

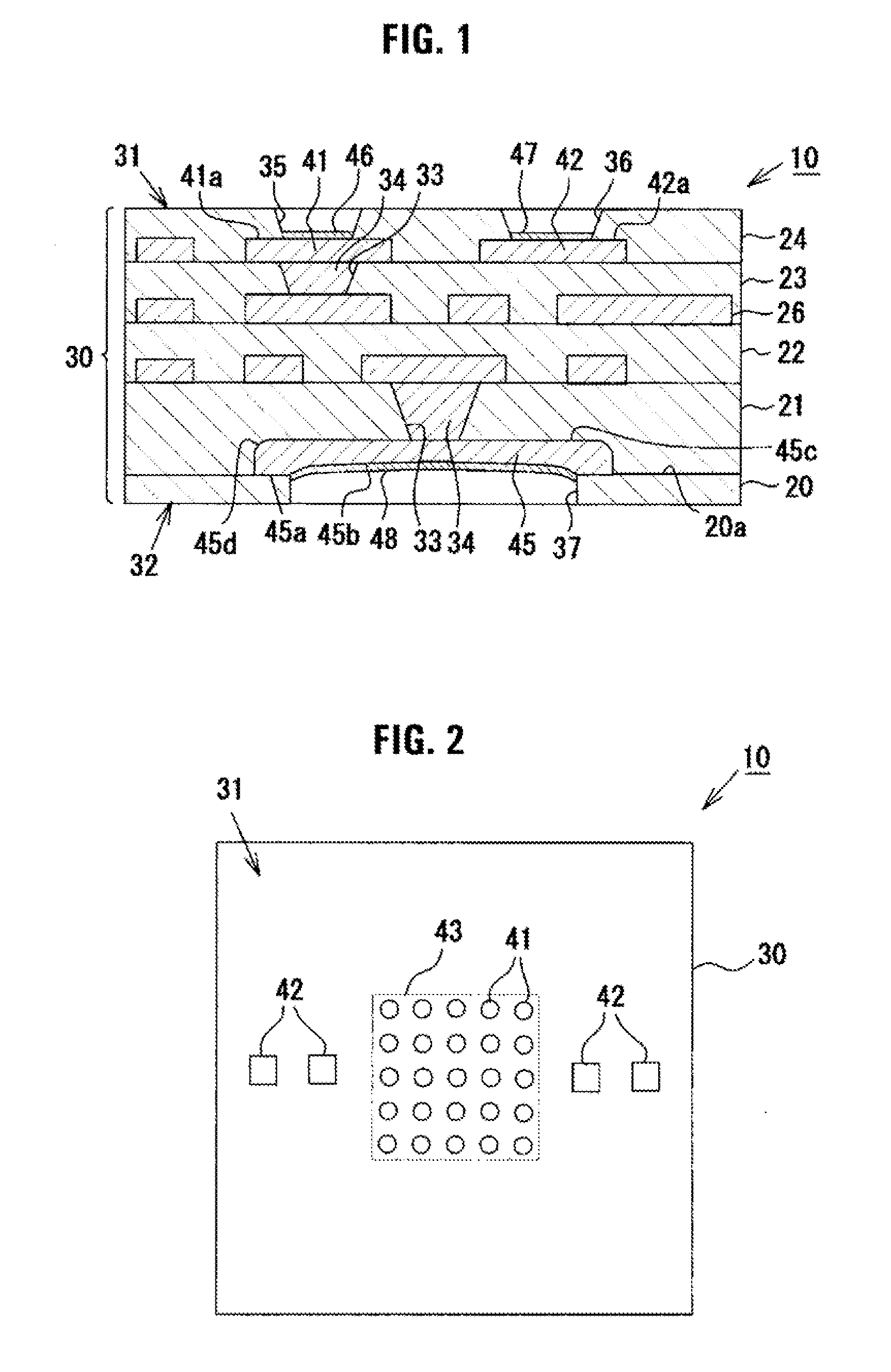

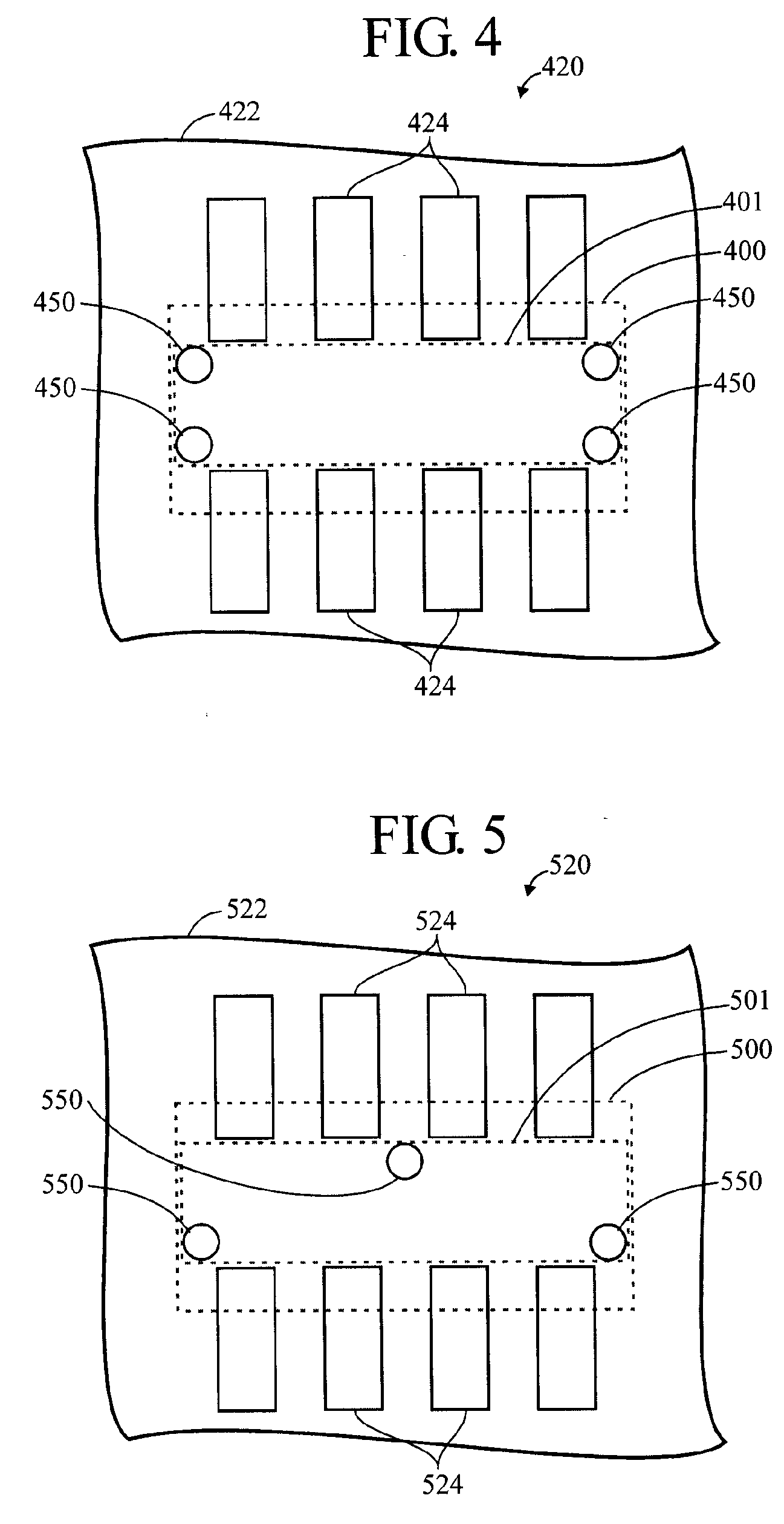

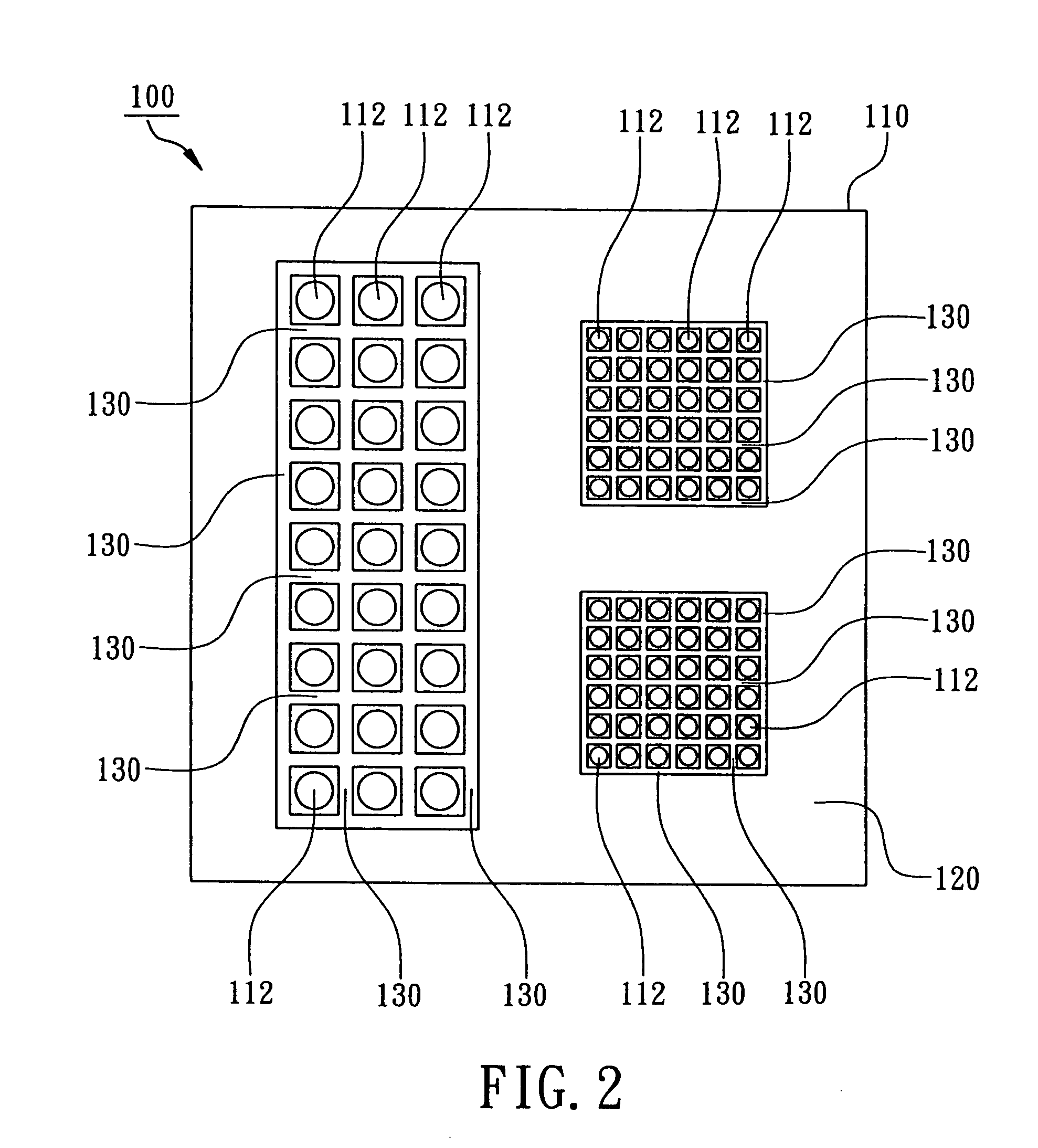

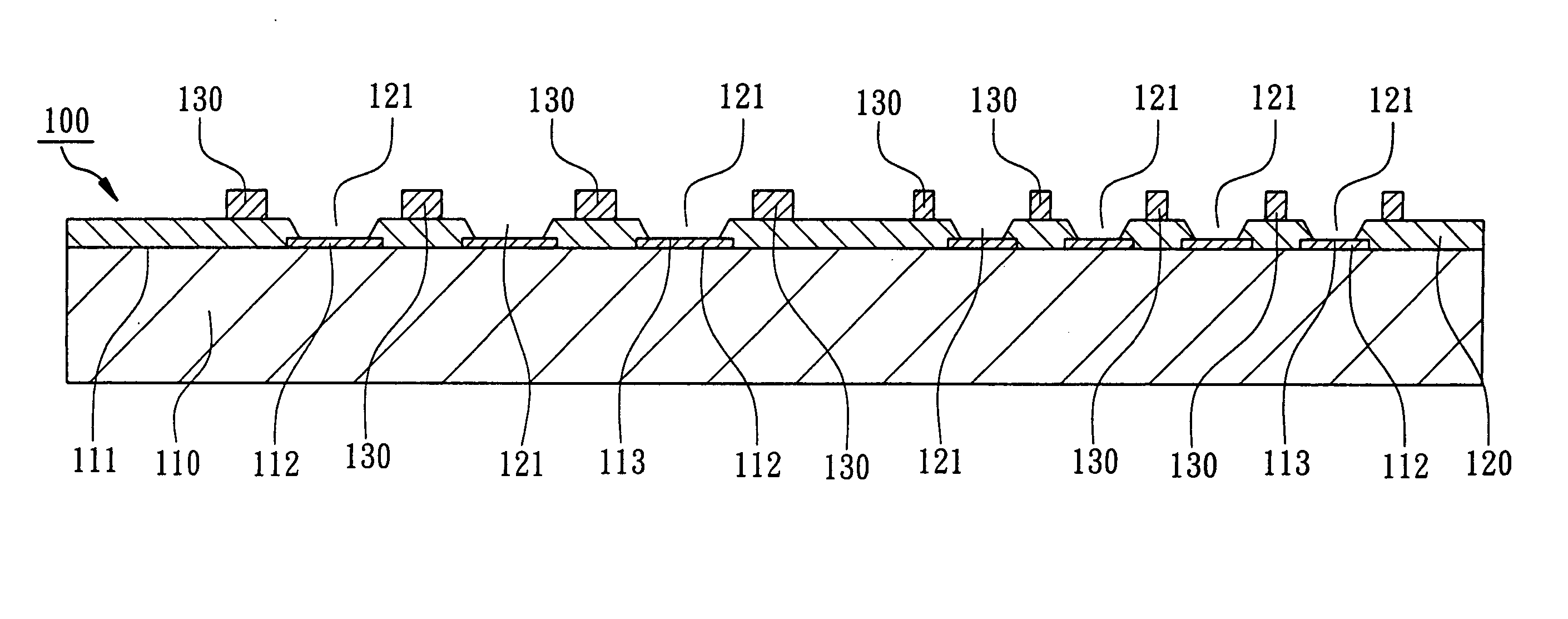

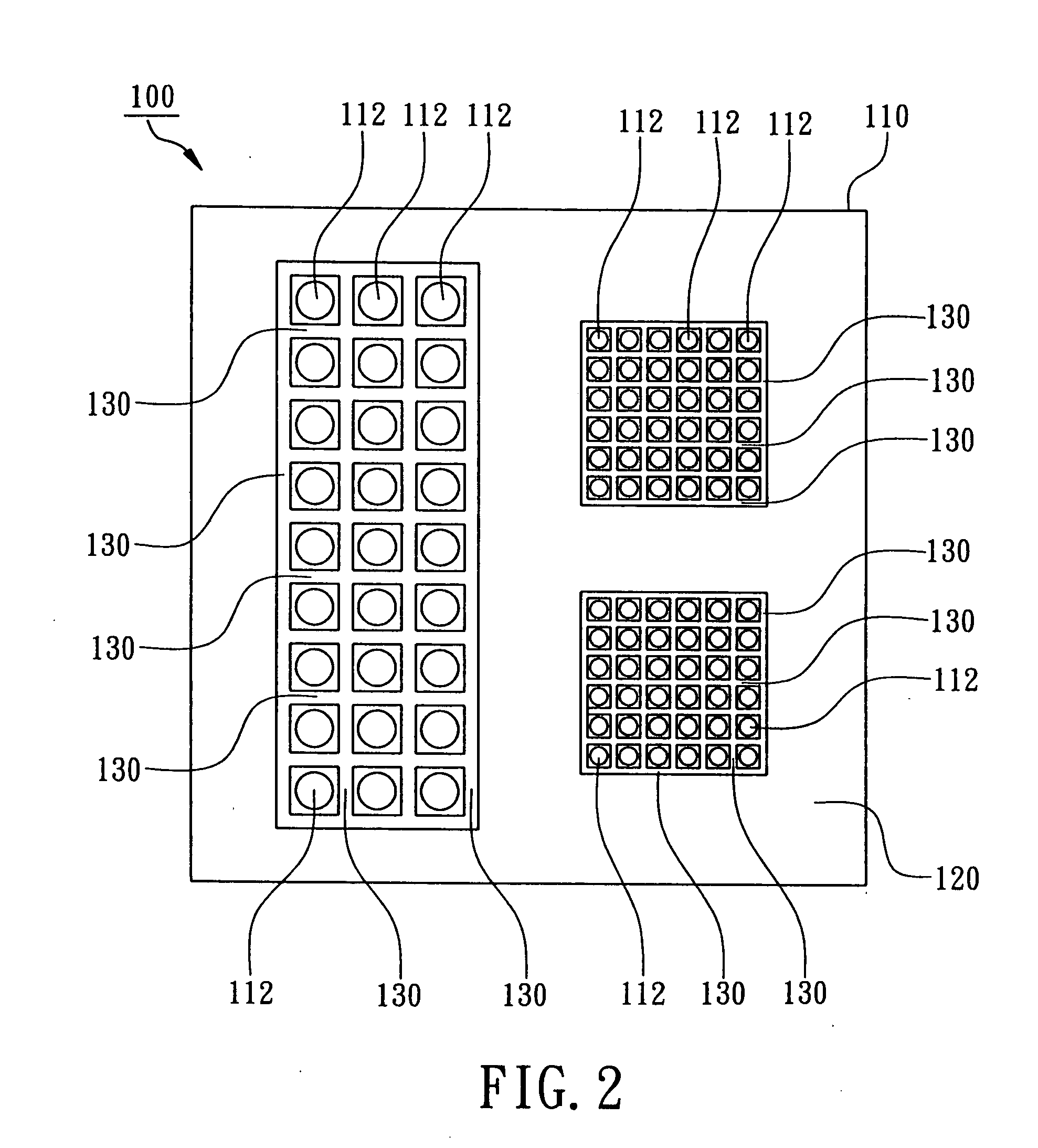

Mesh shaped dam mounted on a substrate

ActiveUS7180181B2Prevent bridgingPrinted circuit assemblingSecond resist patternSolder maskContact pad

A substrate is provided for carrying at least a semiconductor device. The substrate mainly includes a carrier body, a plurality of contact pads, a solder mask and a plurality of dams of a mesh. The contact pads are disposed on a surface of the carrier body and each has a bonding surface exposed out of the solder mask for connecting with the external terminals of the semiconductor device. The dams are disposed above the surface of the carrier body. The dams protrude from and located between the bonding surfaces of the contact pads to prevent solder paste, flux or the external terminals of the semiconductor device from bridging.

Owner:ADVANCED SEMICON ENG INC

Substrate with mesh

ActiveUS20050082680A1Prevent bridgingPrinted circuit assemblingSecond resist patternSolder maskContact pad

A substrate is provided for carrying at least a semiconductor device. The substrate mainly includes a carrier body, a plurality of contact pads, a solder mask and a plurality of dams of a mesh. The contact pads are disposed on a surface of the carrier body and each has a bonding surface exposed out of the solder mask for connecting with the external terminals of the semiconductor device. The dams are disposed above the surface of the carrier body. The dams protrude from and located between the bonding surfaces of the contact pads to prevent solder paste, flux or the external terminals of the semiconductor device from bridging.

Owner:ADVANCED SEMICON ENG INC

Printed circuit board and method for manufacturing the same

InactiveUS20130161085A1Mounting stability is improvedInhibition formationFinal product manufactureSemiconductor/solid-state device detailsResistSolder mask

Disclosed herein are a printed circuit board (PCB) and a method for manufacturing the same. The PCB includes a base substrate, a circuit layer formed on the base substrate and including a connection pad, a solder resist layer formed on an upper portion of the base substrate and having an opening exposing the connection pad, a metal post formed on upper portions of the connection pad and the solder resist layer and having a plurality of diameters, and a seed layer formed on the upper portion of the solder resist layer and inner walls of the opening along an interface of the metal post.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

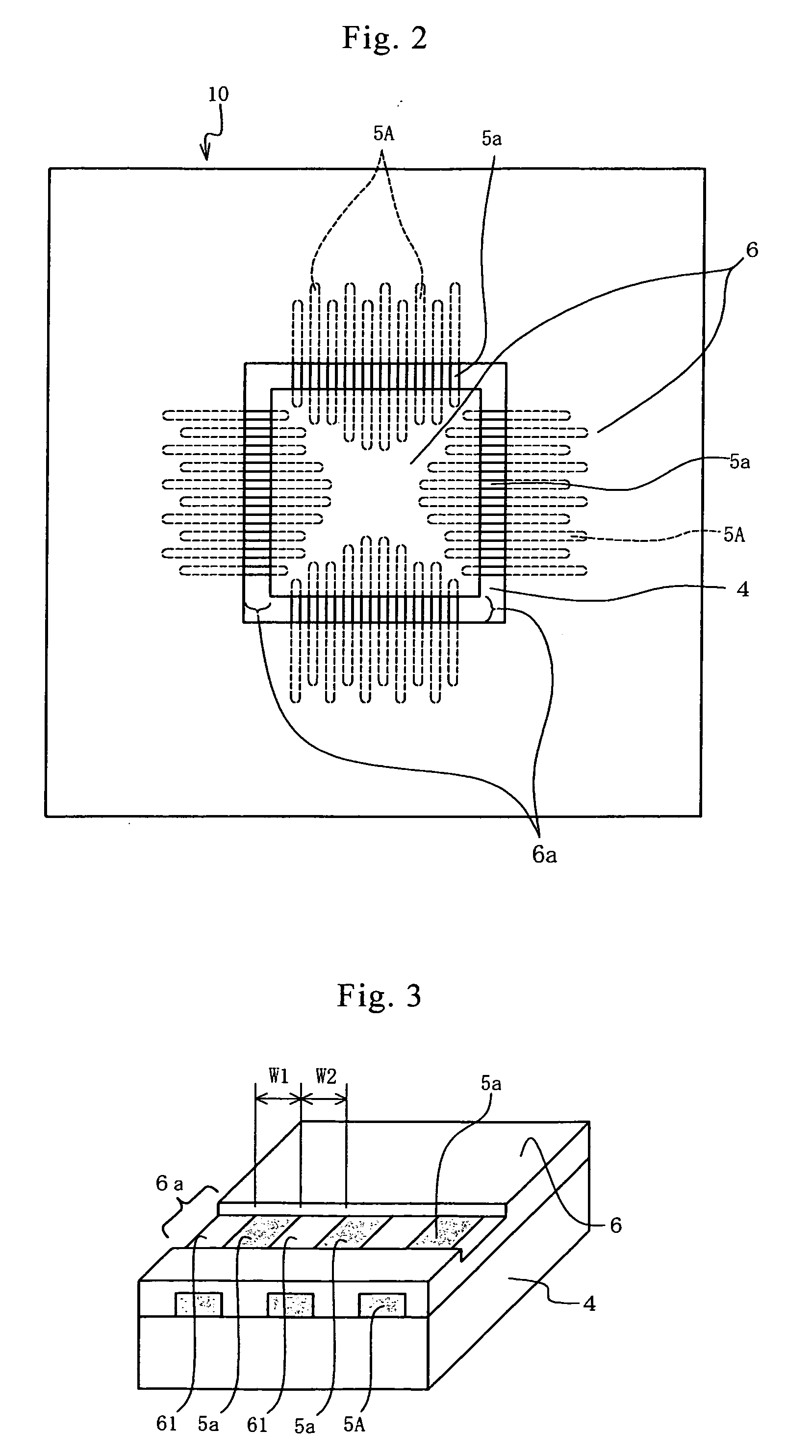

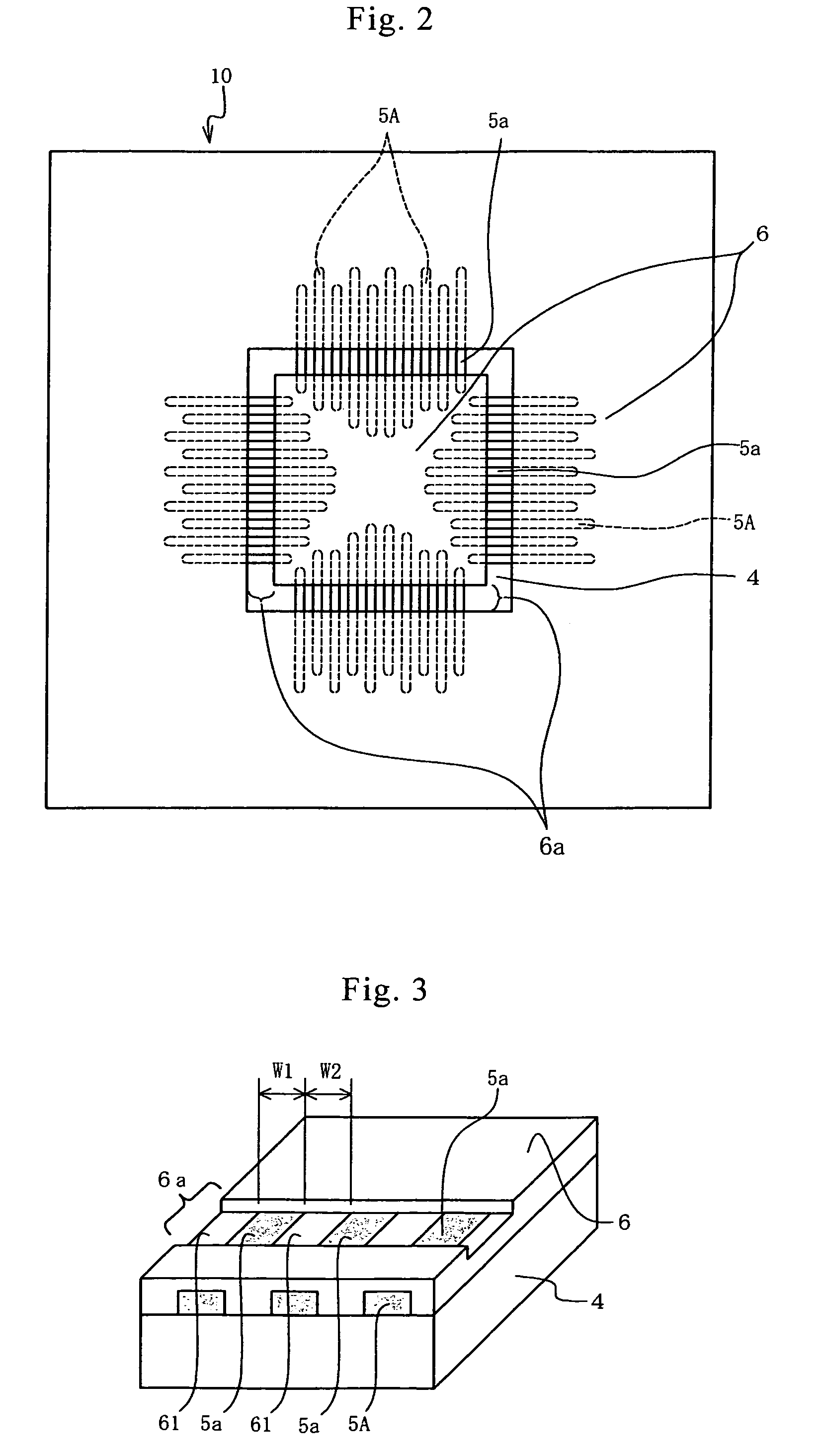

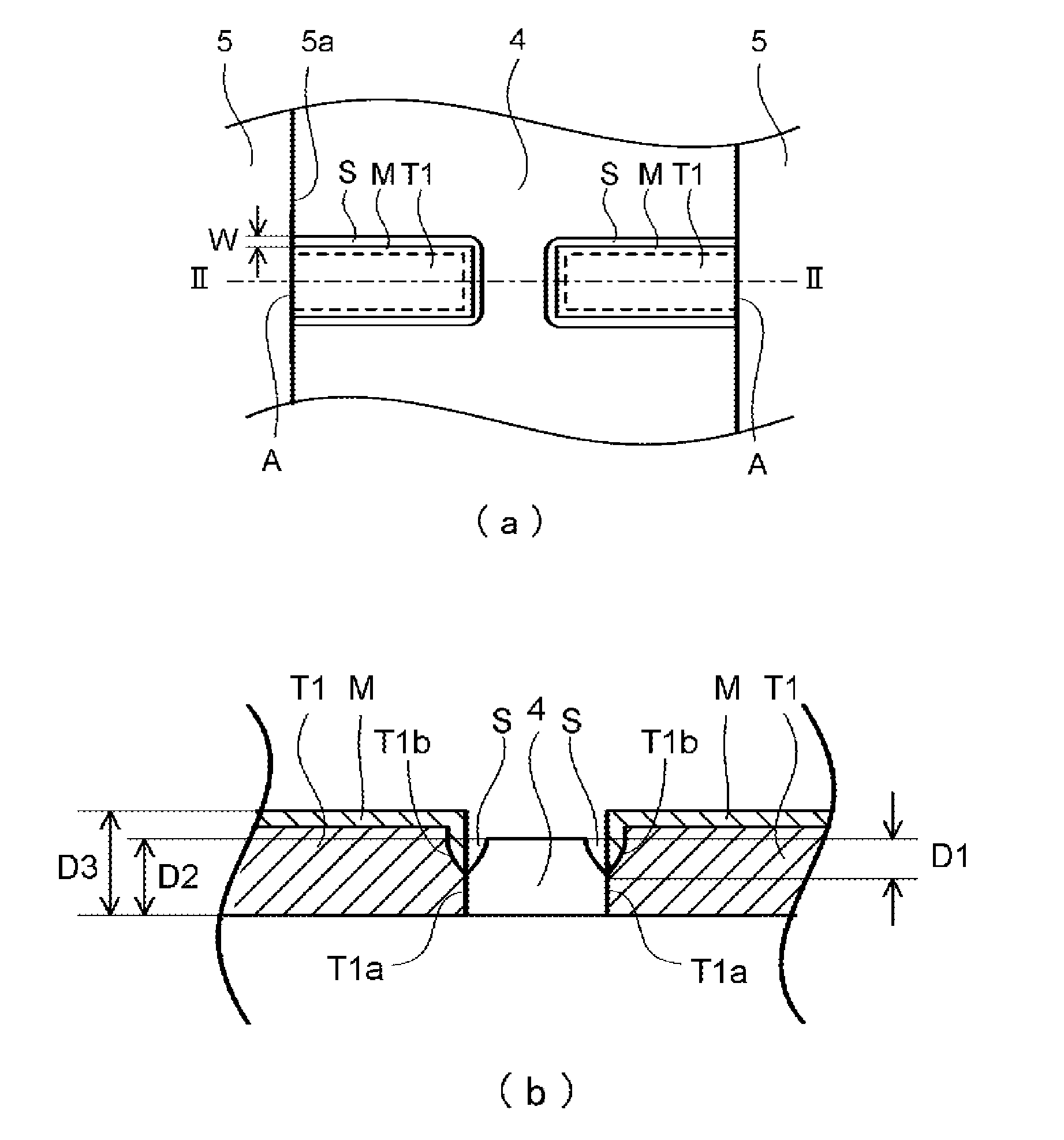

Wiring board and manufacturing method thereof

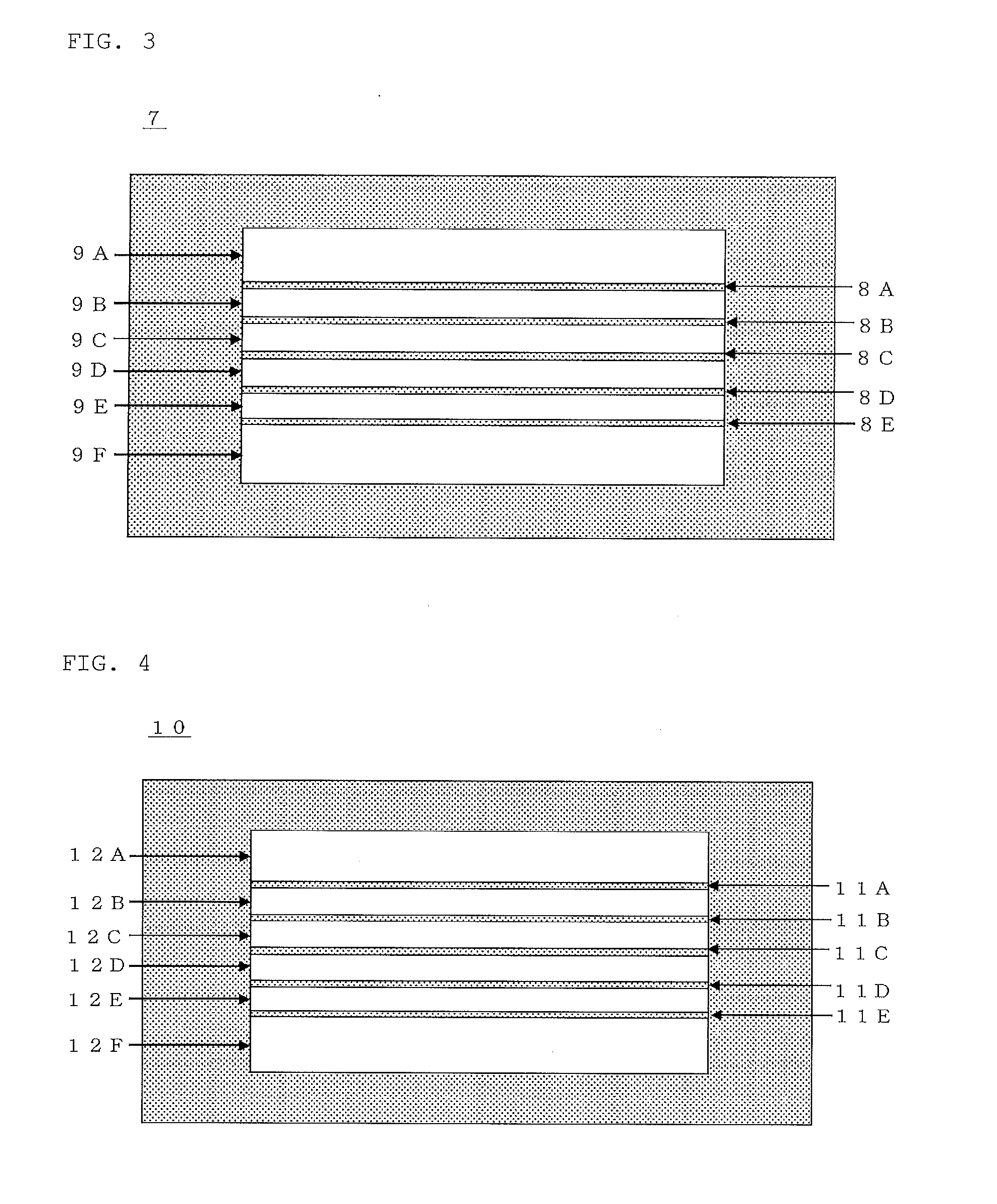

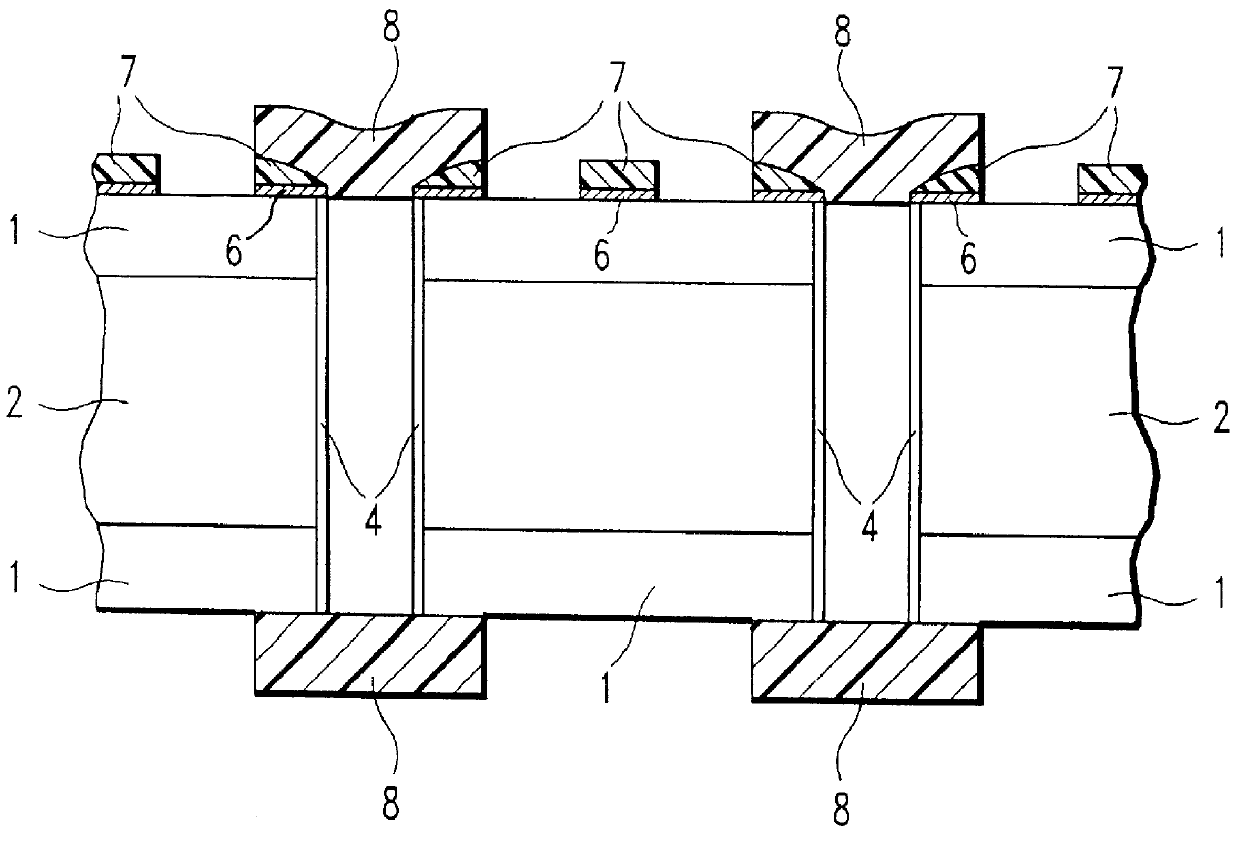

ActiveUS20080302563A1Excellent electric connection reliabilityForming accuratelySecond resist patternSemiconductor/solid-state device detailsResistElectrical conductor

In a wiring board, insulation layers and wiring conductors are alternately laminated, and a plurality of strip-shaped wiring conductors for connecting semiconductor elements are arranged side by side on the outermost insulation layer. Each of the wiring conductors partly has a connection pad to which the electrode terminals of the semiconductor elements are connected by flip-chip bonding. In the wiring board, a solder resist layer is deposited over the outermost insulation layer and the strip-shaped wiring conductors so as to have slit-shaped openings for exposing the upper surfaces of the connection pads. The solder resist layer fills up the space between the connection pads adjacent to each other and exposed within the slit-shaped openings.

Owner:KYOCERA CORP

Method for the production of an electronic component

InactiveUS6929975B2Avoid supportAvoid pollutionPrinted circuit assemblingSecond resist patternScreen printingEngineering

Electronic packages are produced as follows. Vias in a support body are closed with a highly viscous screen printing material following application of a first metallizing layer forming a base metallization on the support body and in the lead-throughs for the vias. A low viscosity passivating layer, which has been applied on the entire surface of the top and bottom sides of the support body, is selectively removed from certain areas of the top side. A second metailizing layer forming the final metallization of a low-melting point material is applied to the first metallization layer in the areas from which the passivating layer was removed. Electronic components of the circuit arrangement are applied on the top side of the support body and contacted by a soldering process.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

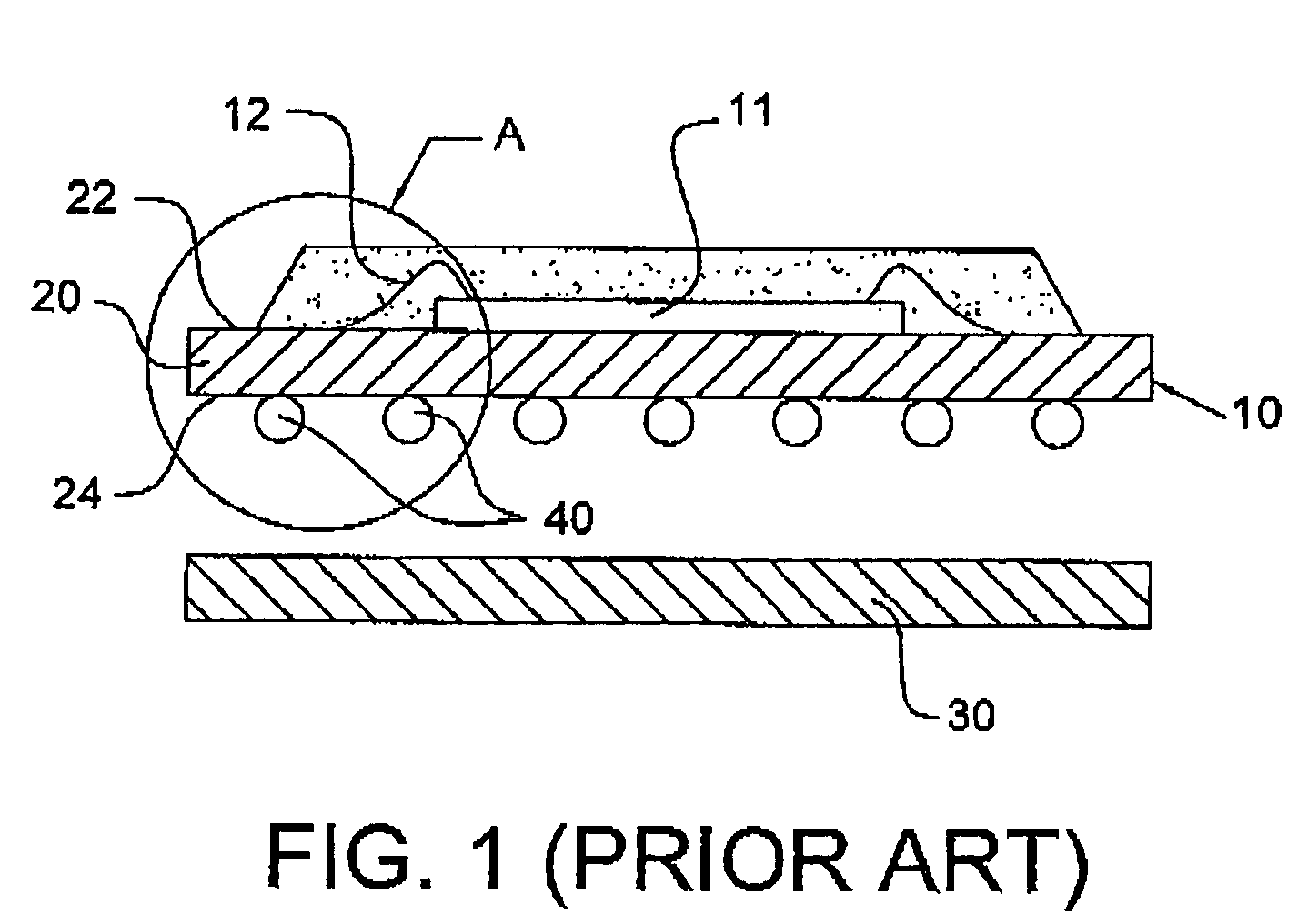

Ball grid array package and method thereof

InactiveUS7315085B2High positioning accuracyShift problemPrinted circuit assemblingSecond resist patternSolder maskSolder ball

Owner:ADVANCED SEMICON ENG INC

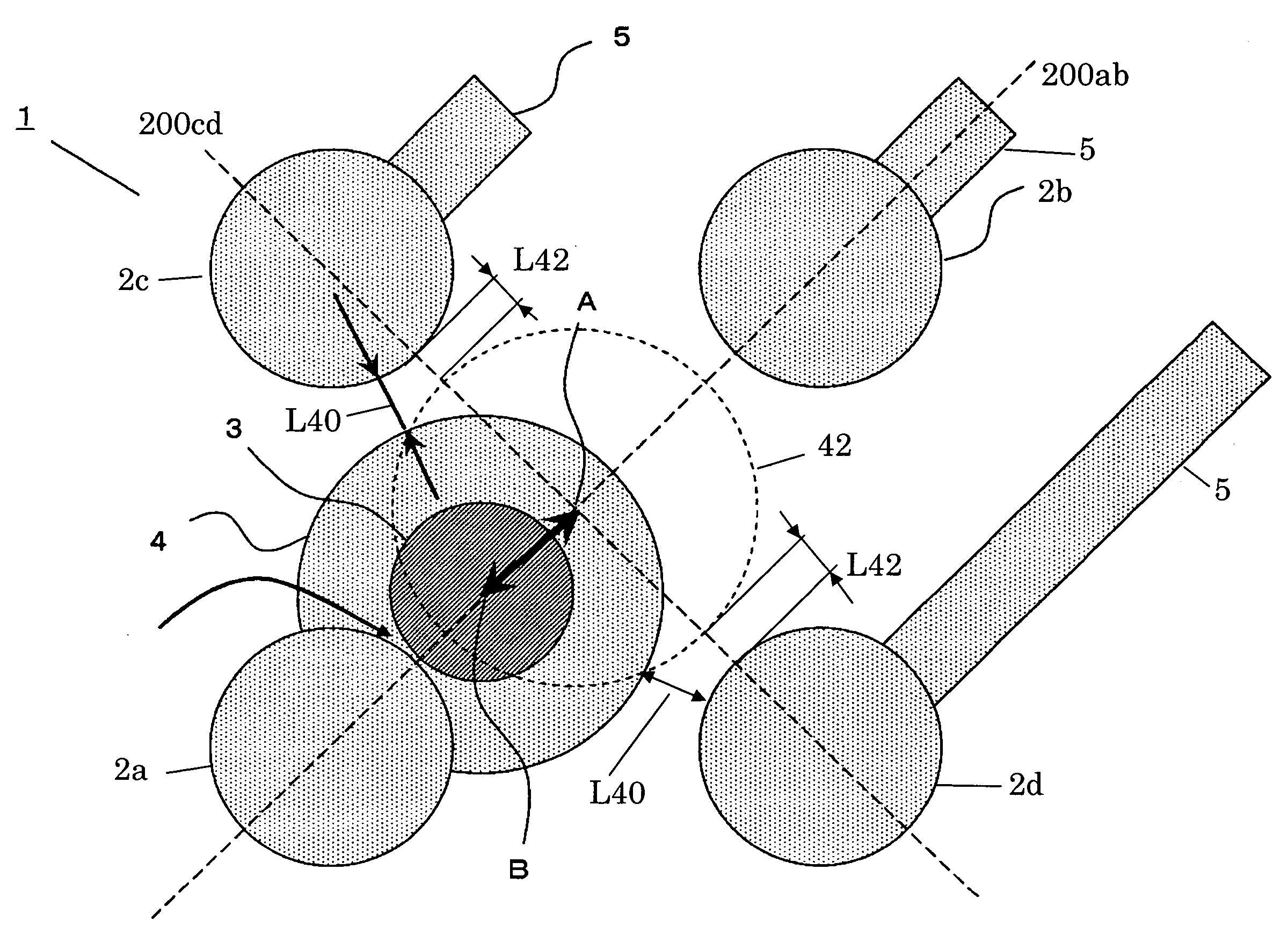

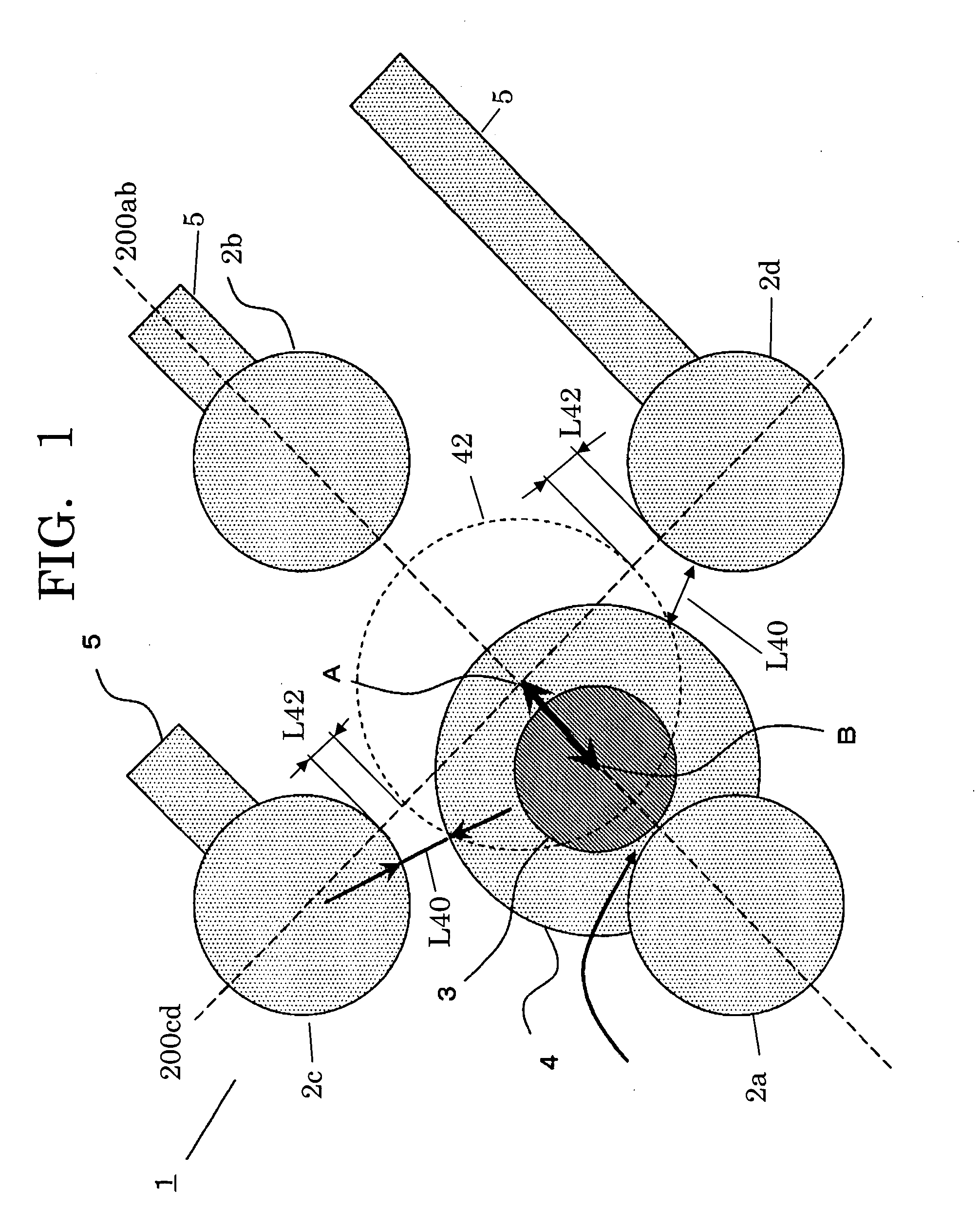

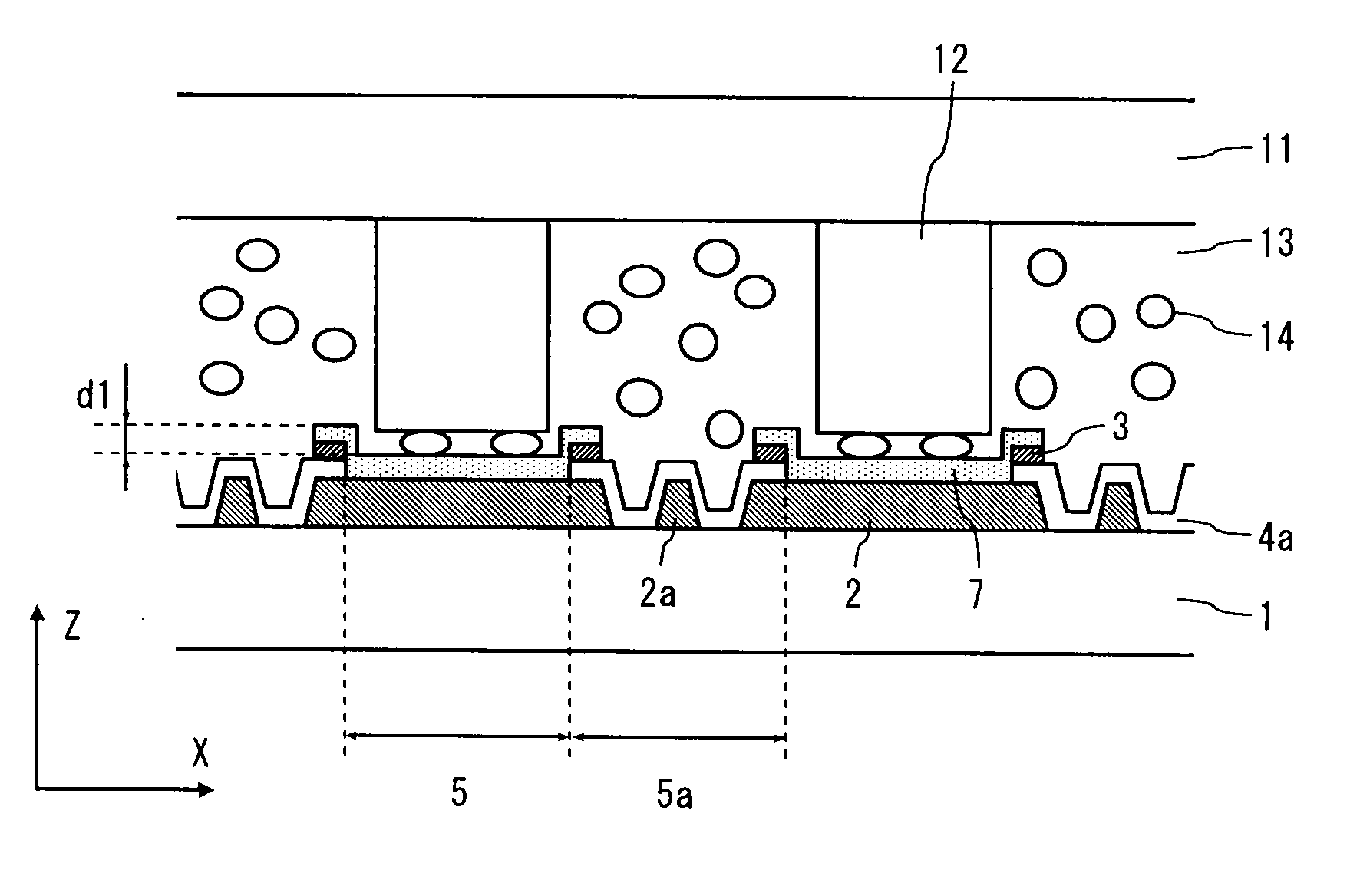

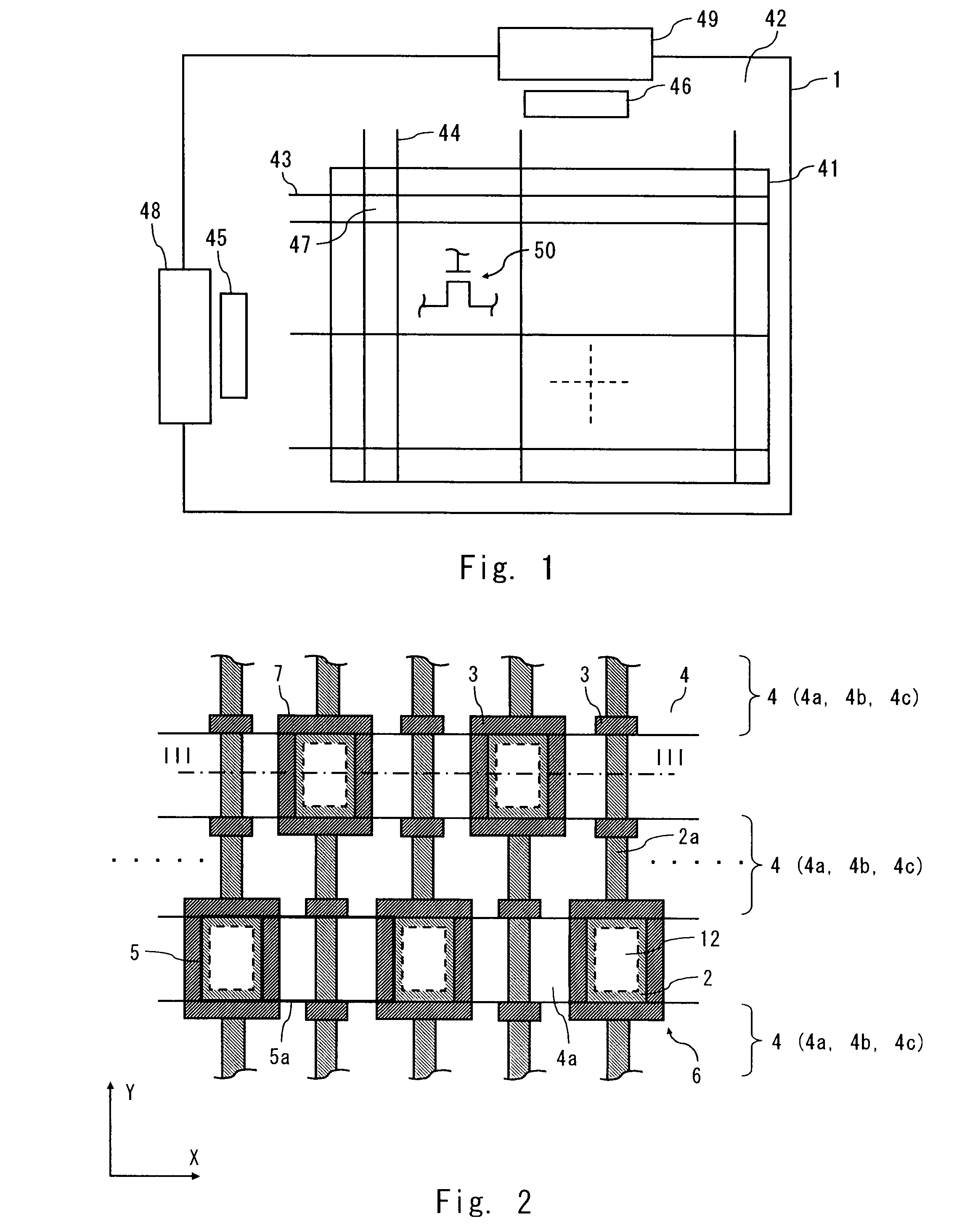

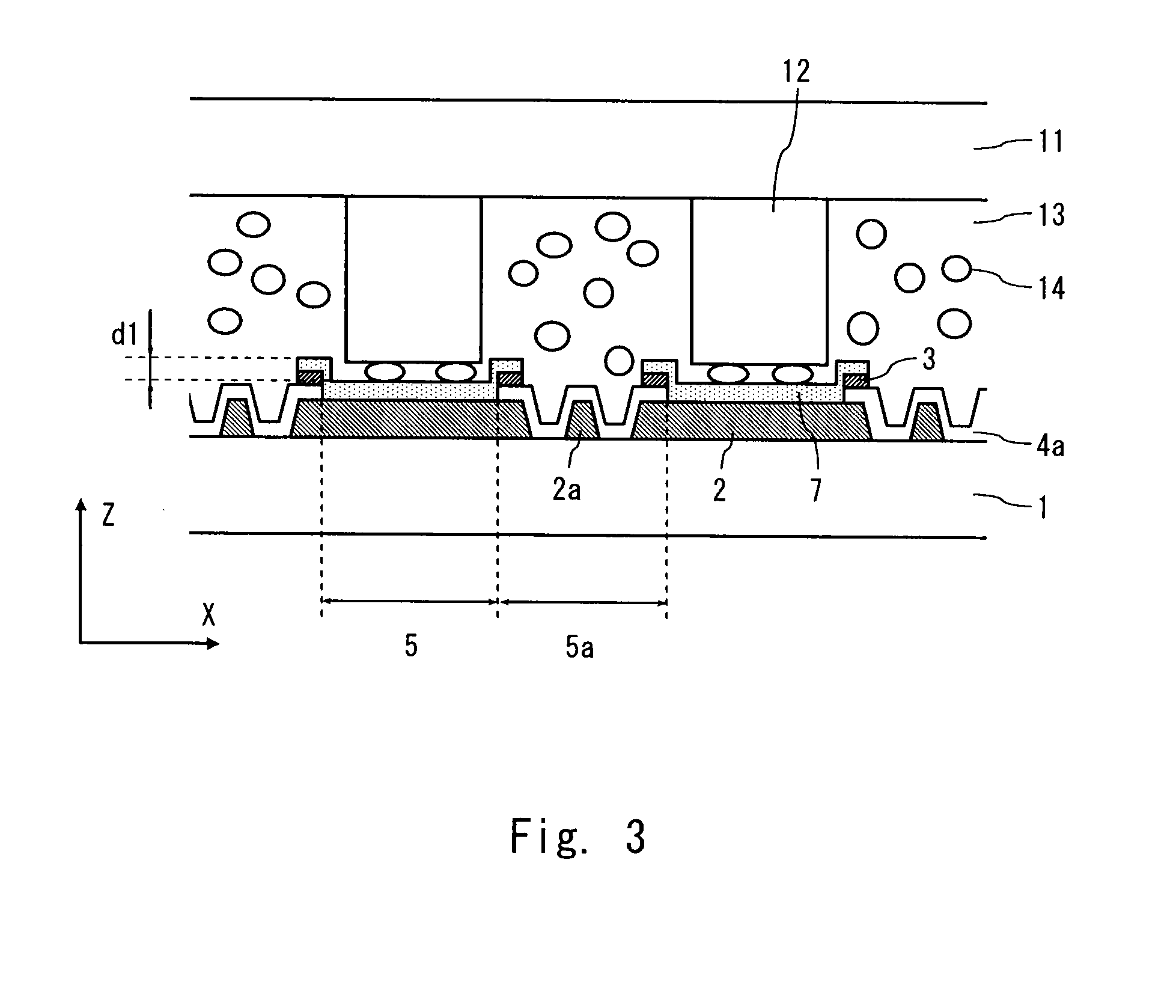

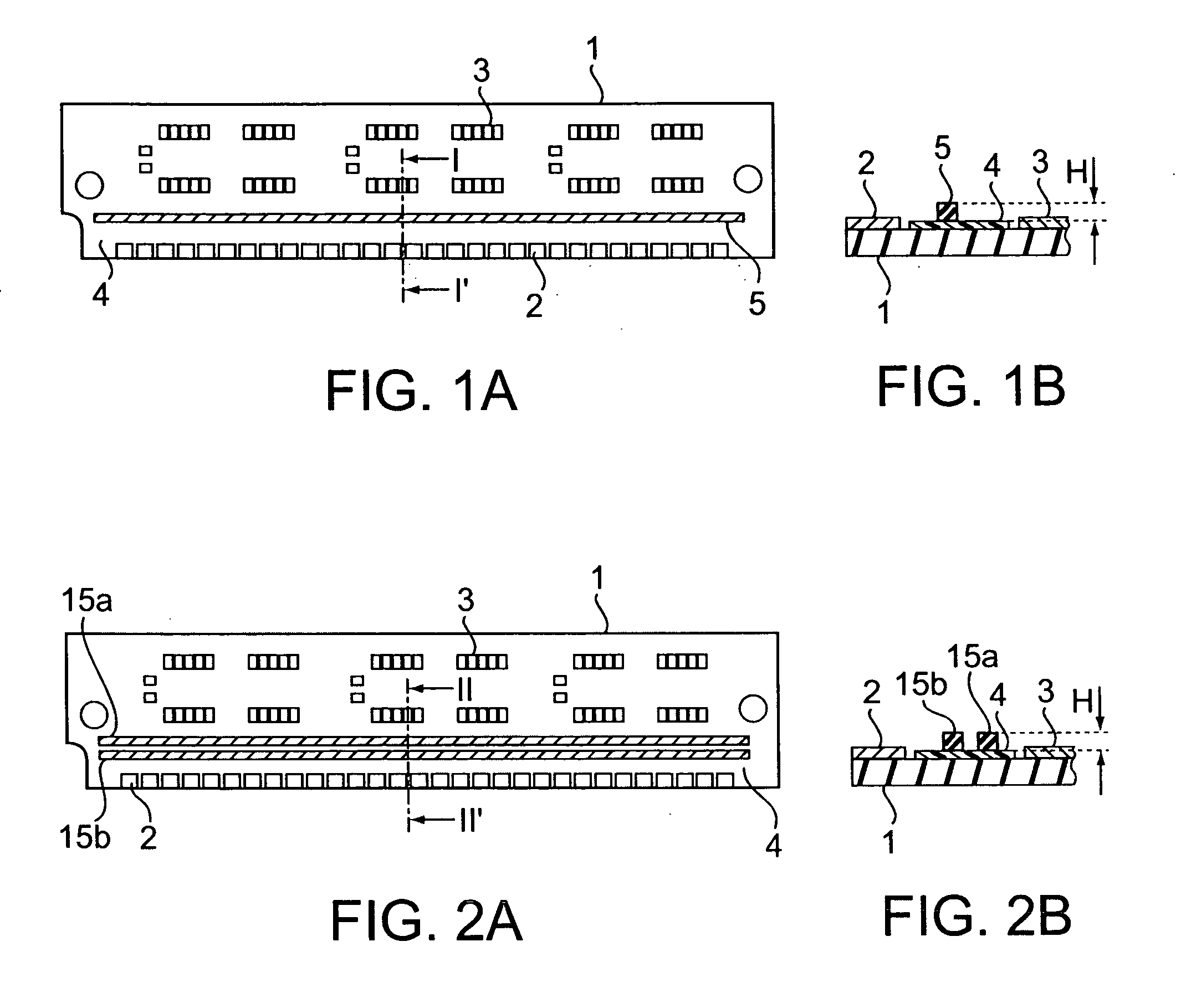

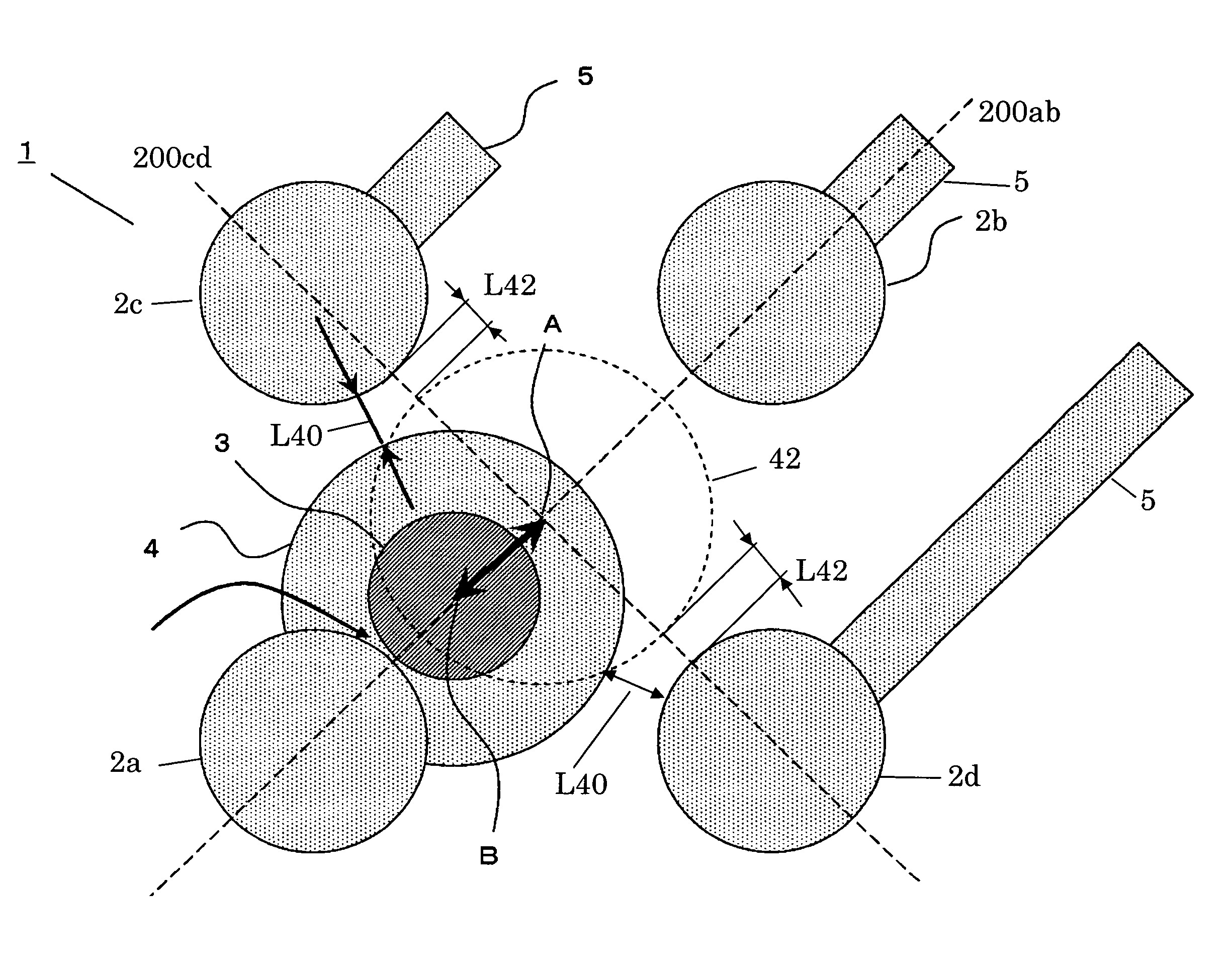

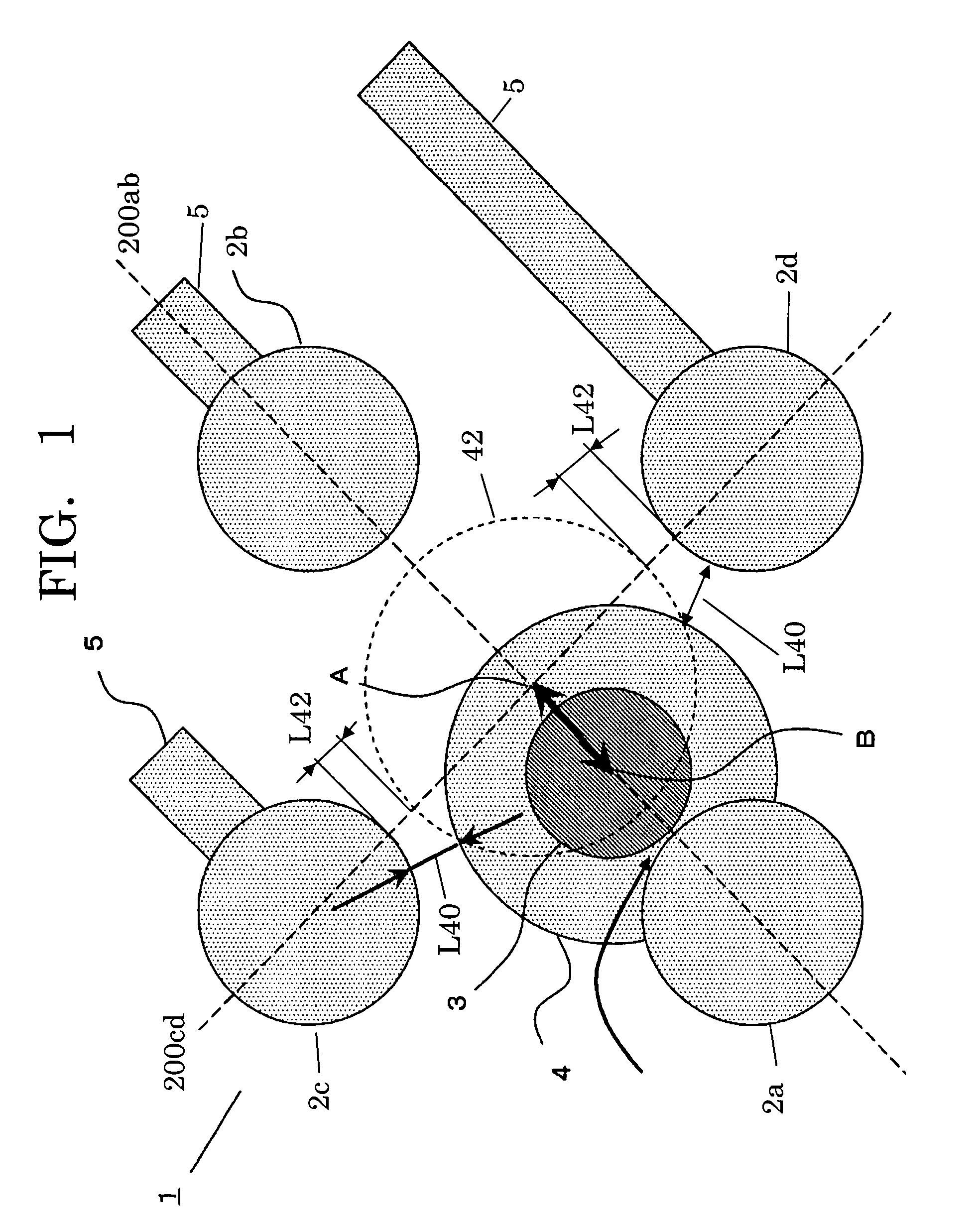

Printed Circuit Board and Its Designing Method, and Designing Method of Ic Package Terminal and Its Connecting Method

InactiveUS20080277152A1Low costPrinted circuit assemblingSecond resist patternSolder ballEngineering

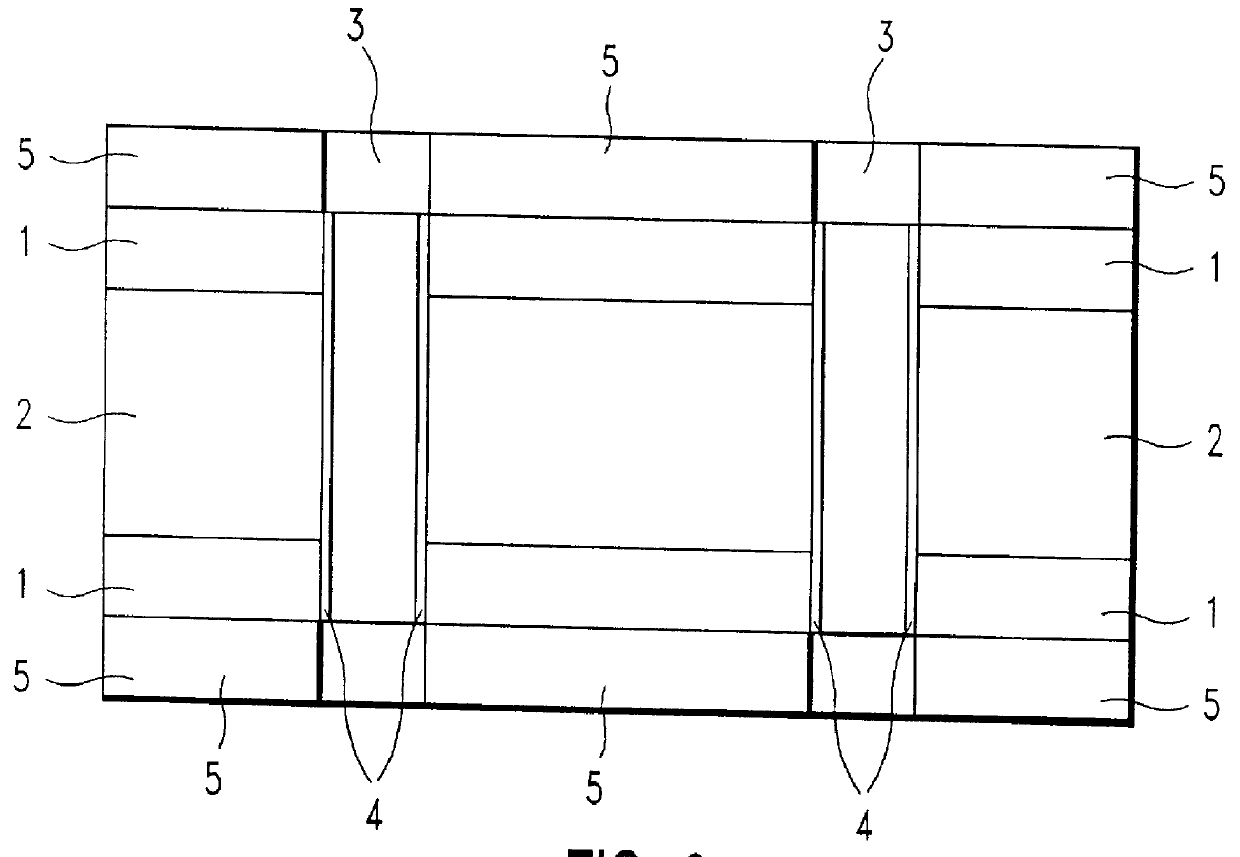

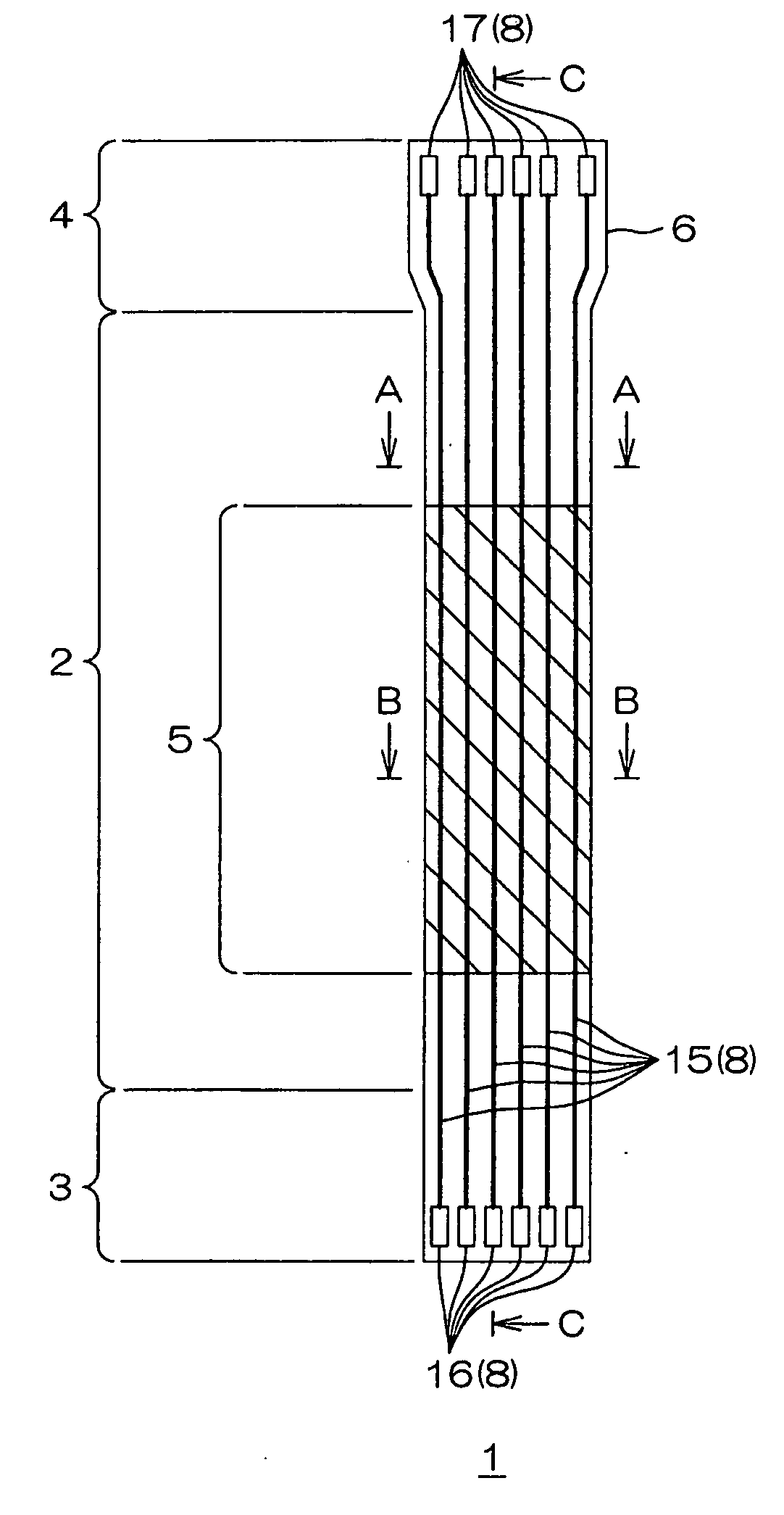

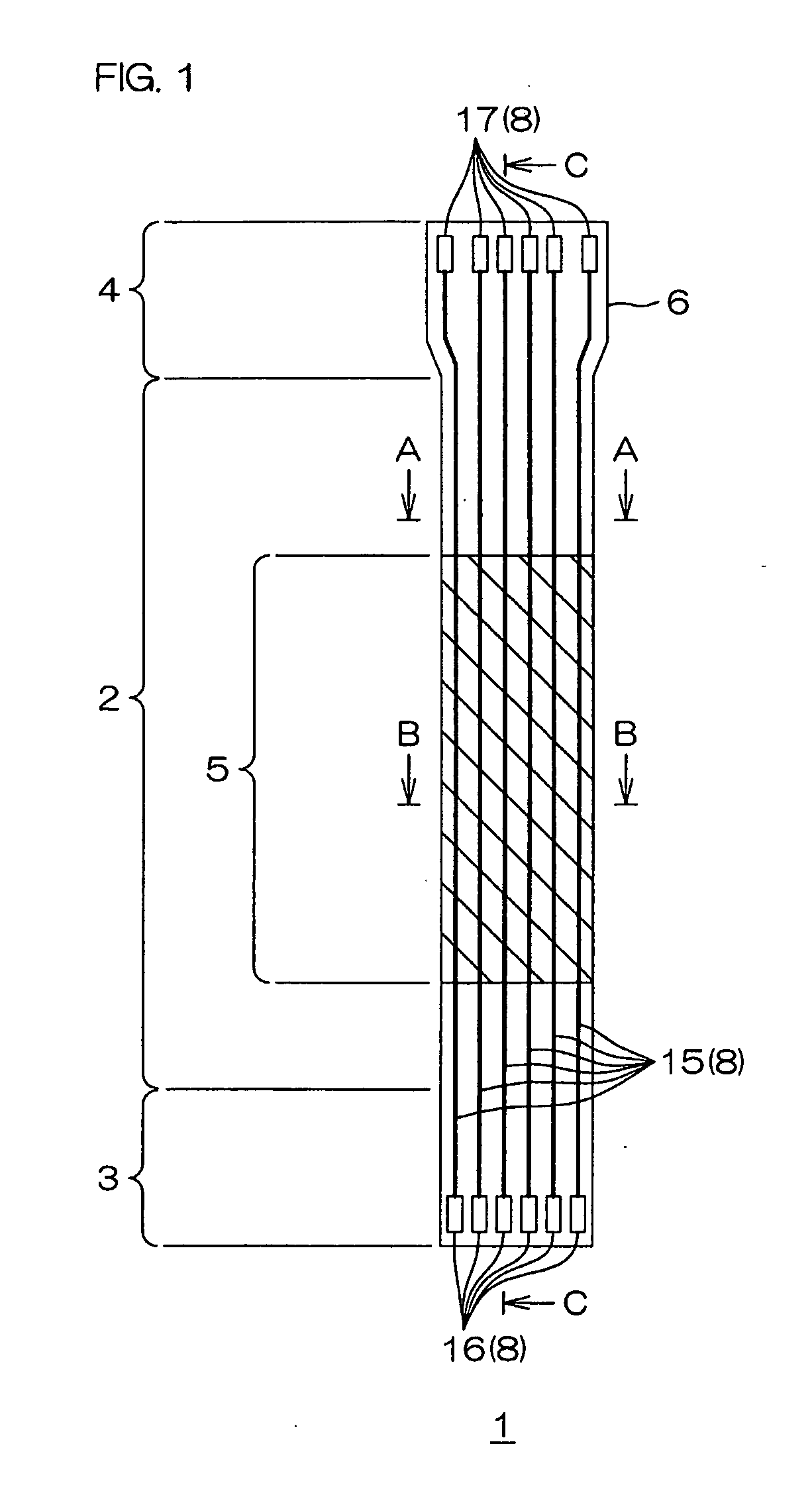

The invention provides a printed circuit board capable of mounting BGA or other IC package of narrow terminal interval by using through-holes of conventional size. On one principal surface of printed circuit board (1), soldering lands (2a), (2b), (2c), and (2d) for connecting solder balls are disposed in lattice. Central point (B) of through-hole (3) is set eccentric to the side of soldering land (2a) at the same potential as through-hole (3), remote from intersection (A) formed by diagonal line (200ab) linking soldering lands (2a) and (2b) and diagonal line (200cd) linking soldering lands (2c) and (2d).

Owner:PANASONIC CORP

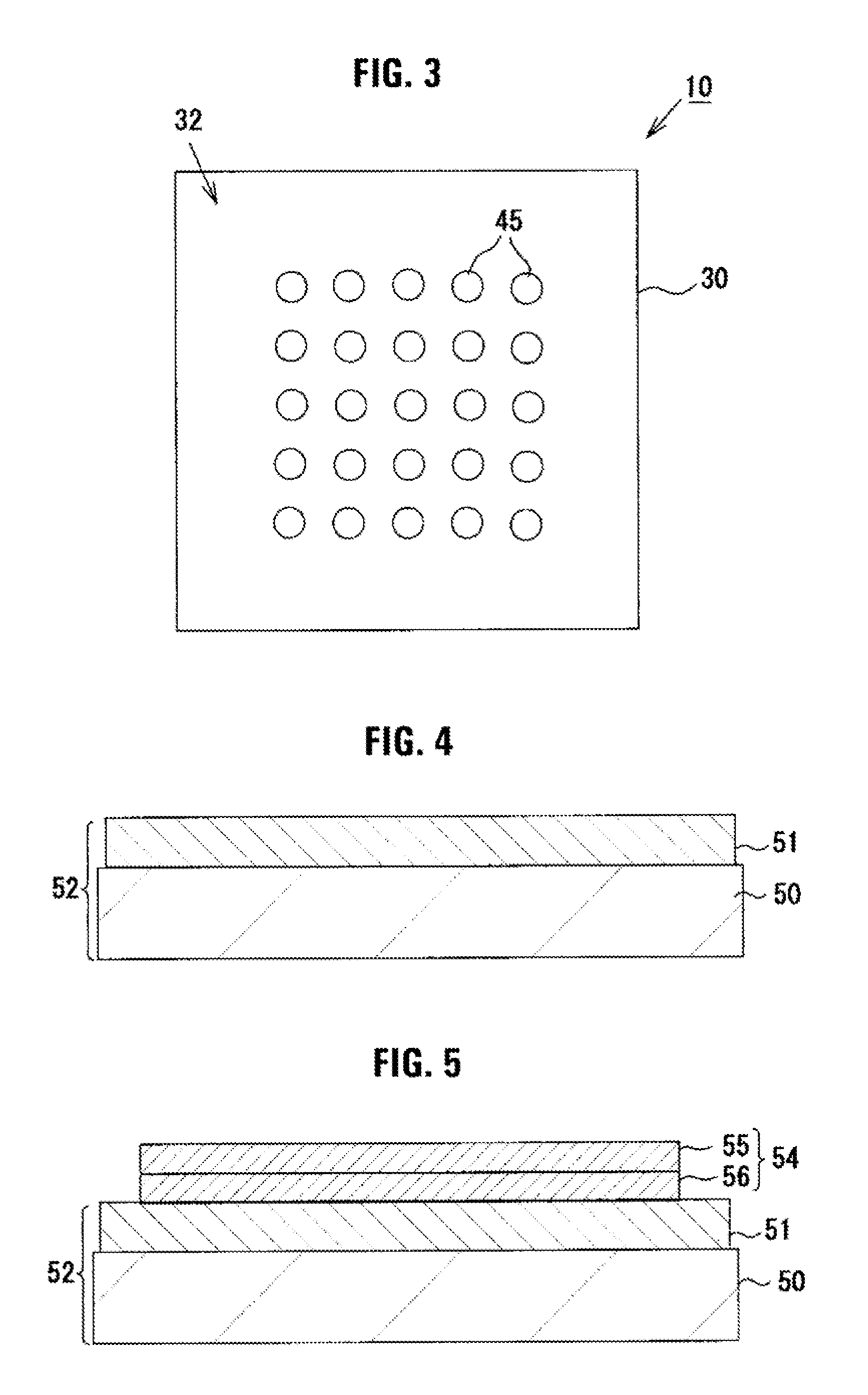

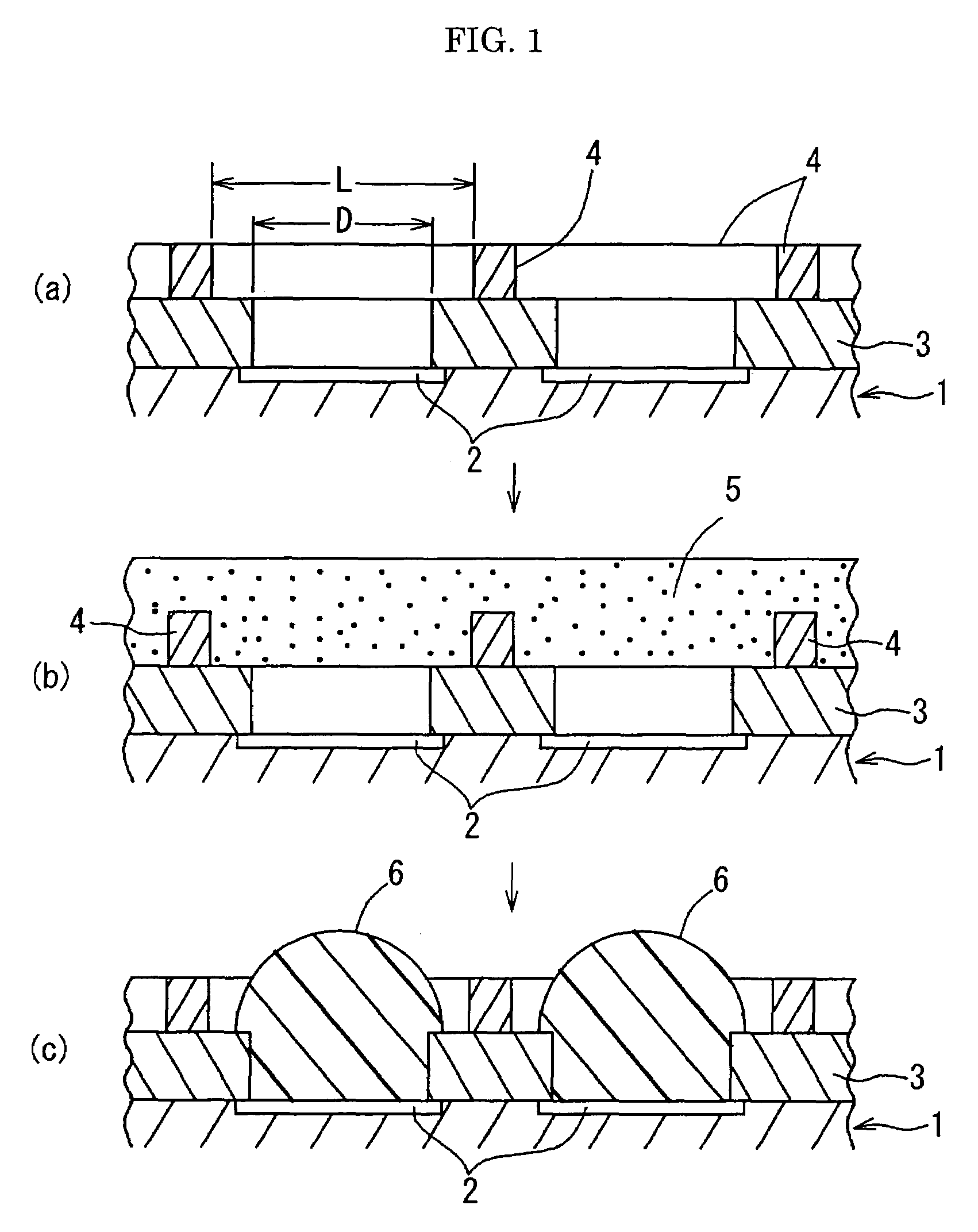

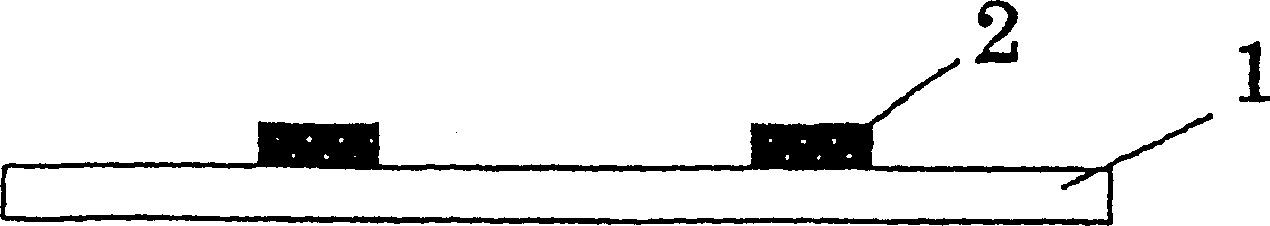

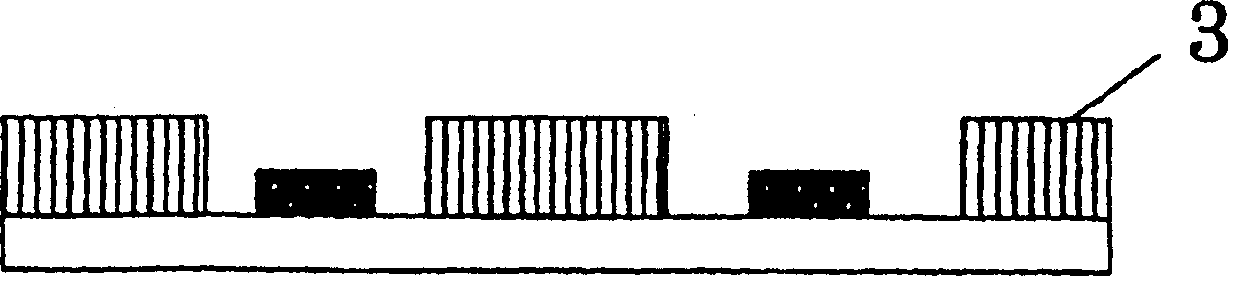

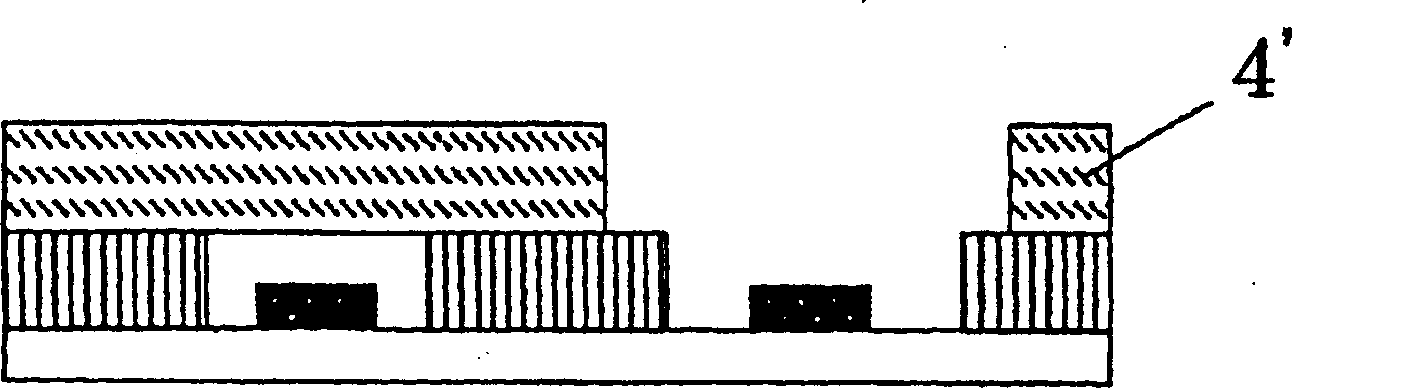

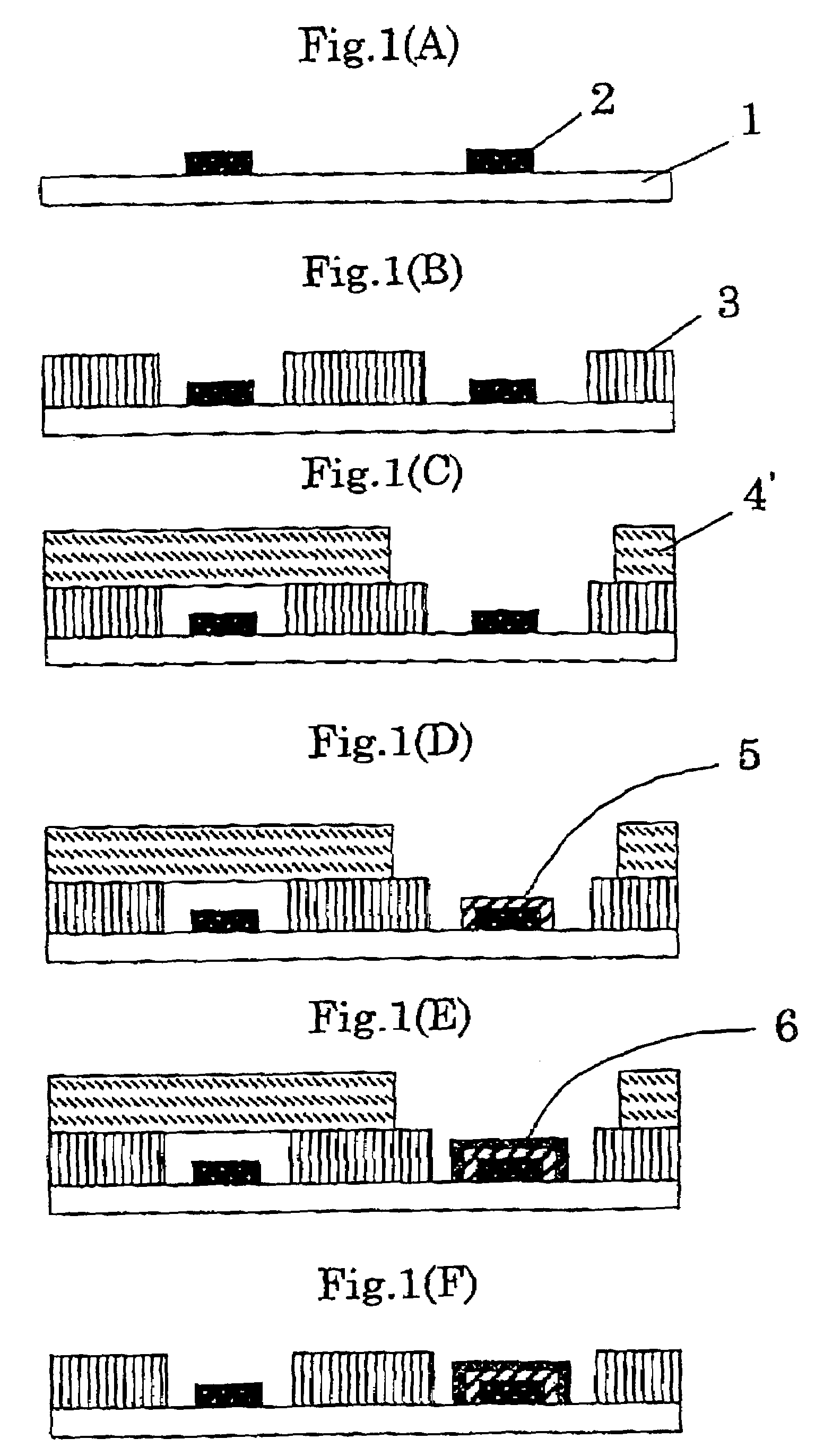

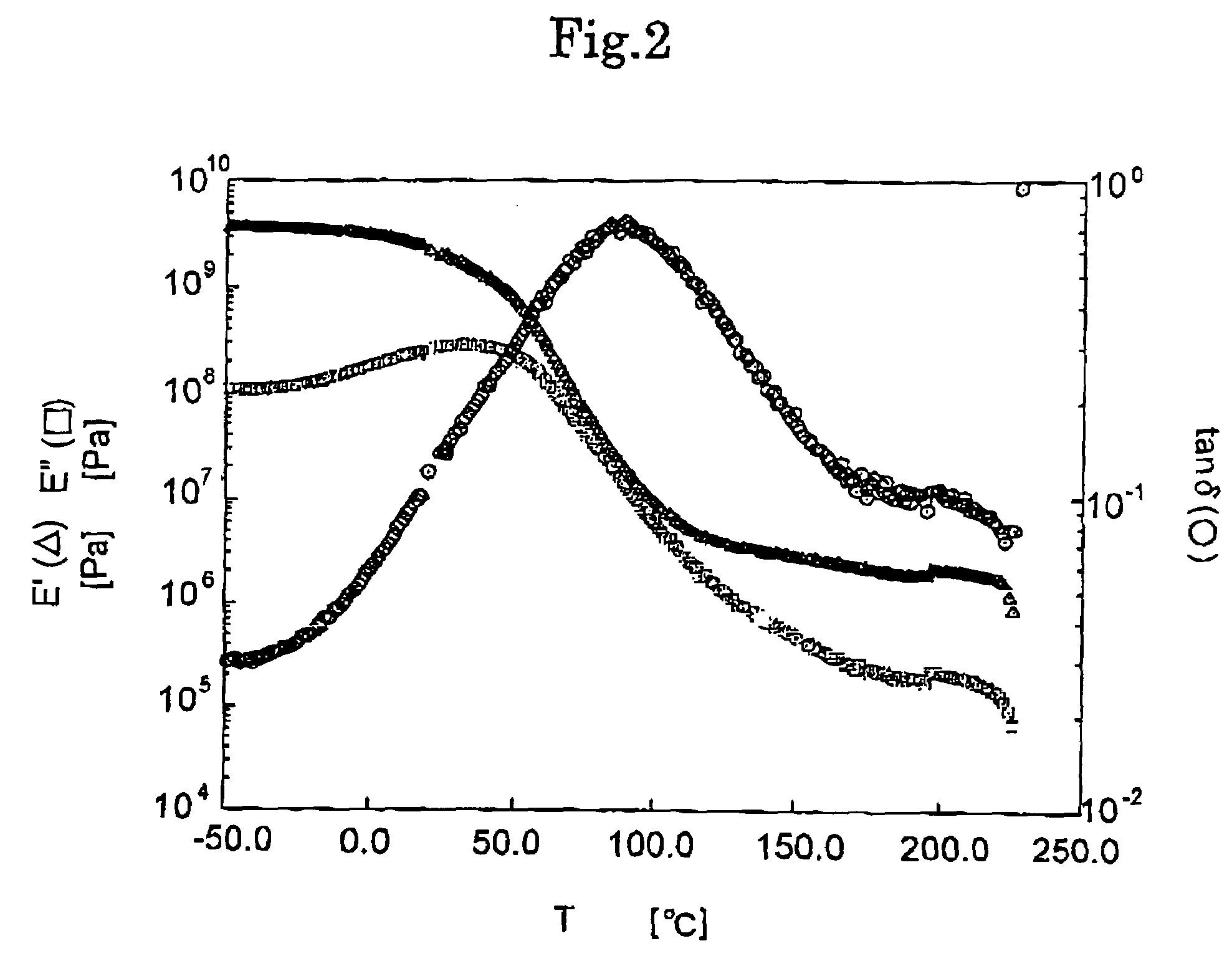

Method for mfg. printed wiring board and photosenstive resin compsn. to be used for it

InactiveCN1500232AExcellent plating resistanceExcellent peelabilitySecond resist patternStacked resist layersResistSolder mask

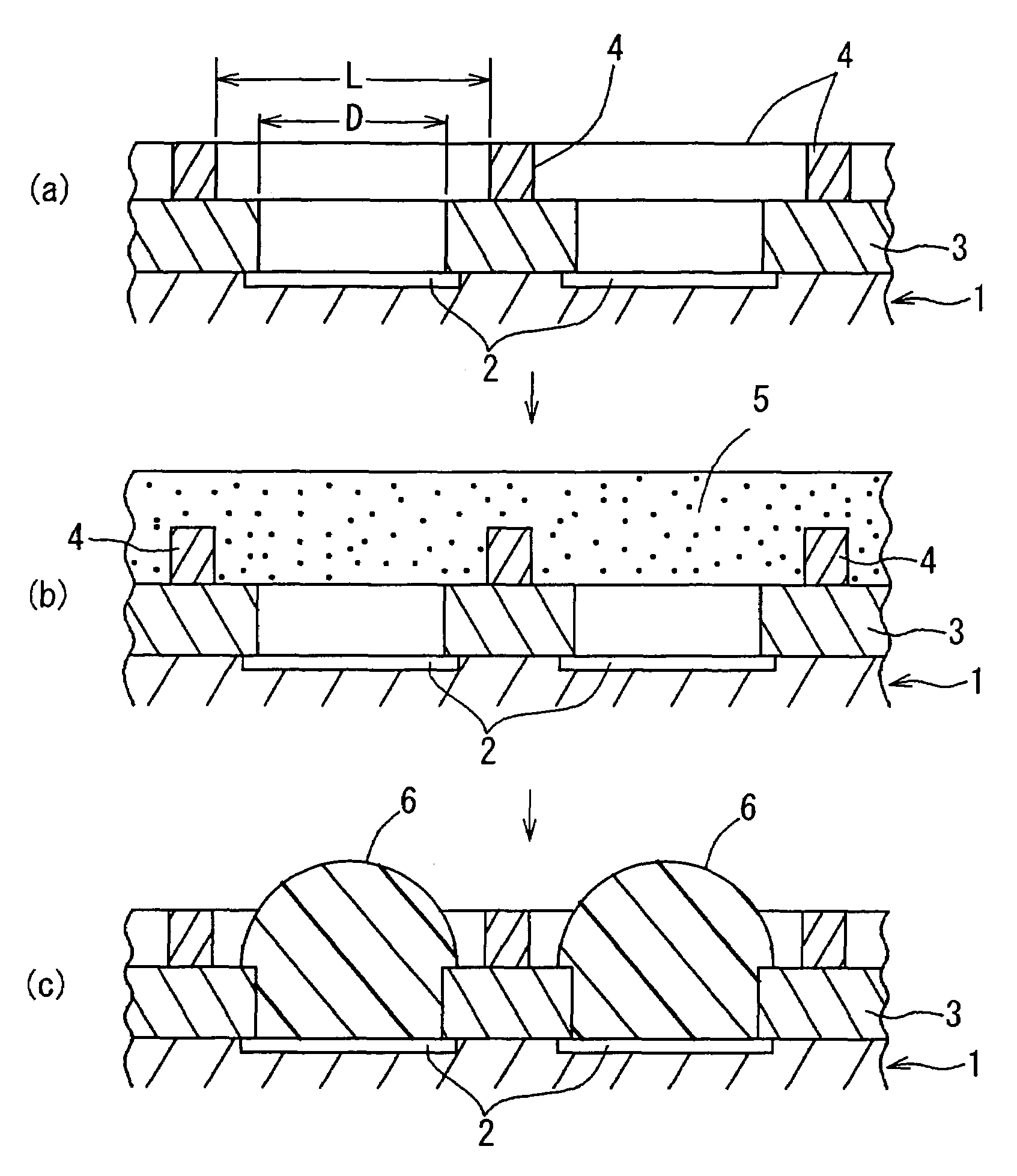

An object of the present invention is to provide a process for producing a printed wiring board, which is advantageous not only in that the reduction in size and increase in density of the wiring board are achieved and further the steps are simplified, but also in that the connection reliability of mount parts and the yield are improved, and a photosensitive resin composition used in the process. The present invention is directed to a process for producing a printed wiring board, comprising the steps of: (i) forming a solder resist on a wiring board having a circuit; (ii) laminating a preliminarily molded layer of a photosensitive resin composition on the solder resist; (iii) subjecting the layer of the photosensitive resin composition to exposure and development to form a resist pattern of the photosensitive resin composition; (iv) subjecting the entire surface of the resultant board to electroless plating, and (v) stripping the layer of the photosensitive resin composition, wherein the steps are conducted in this order, as well as a photosensitive resin composition and the layer thereof used in the process.

Owner:RESONAC CORPORATION

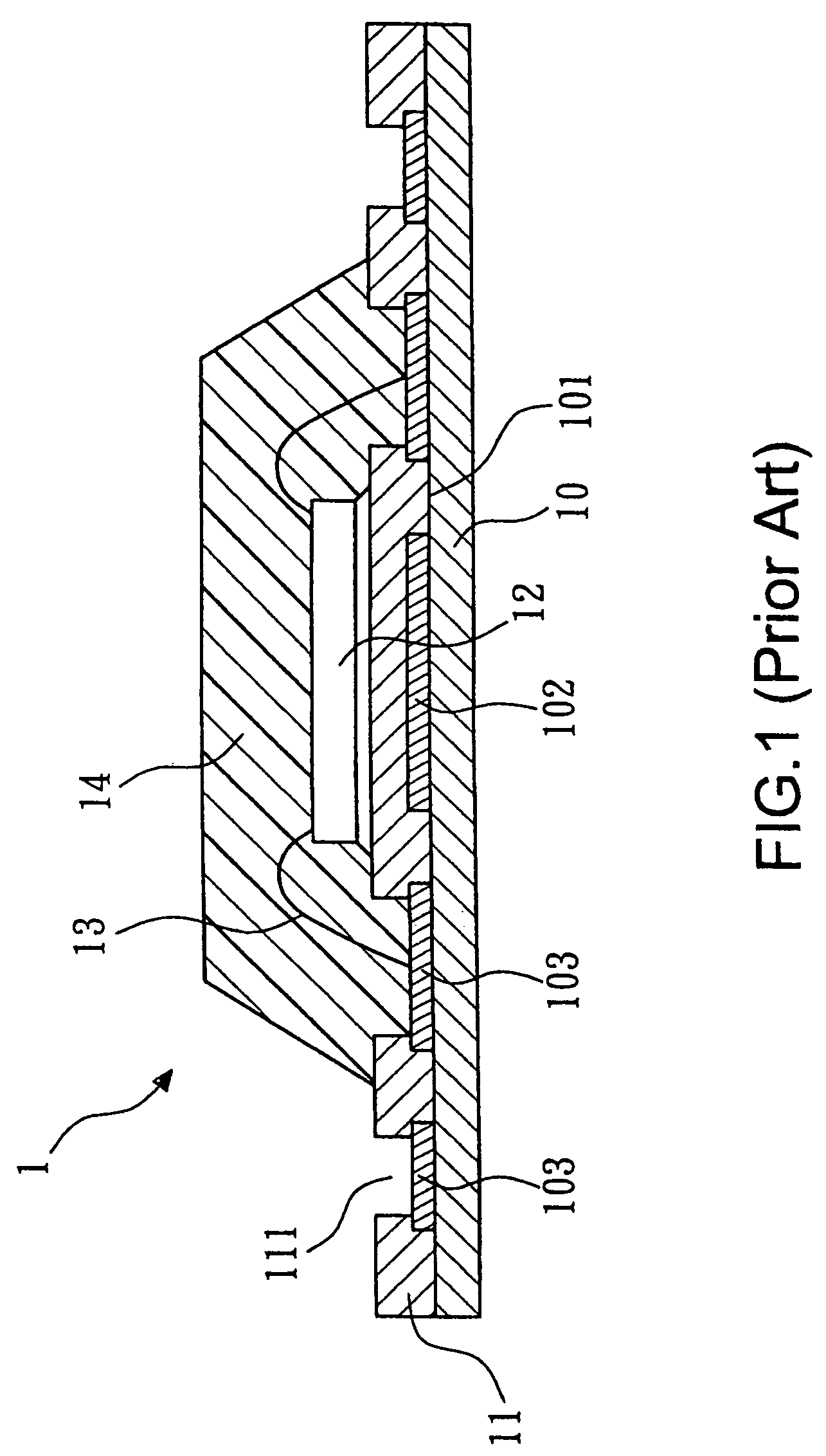

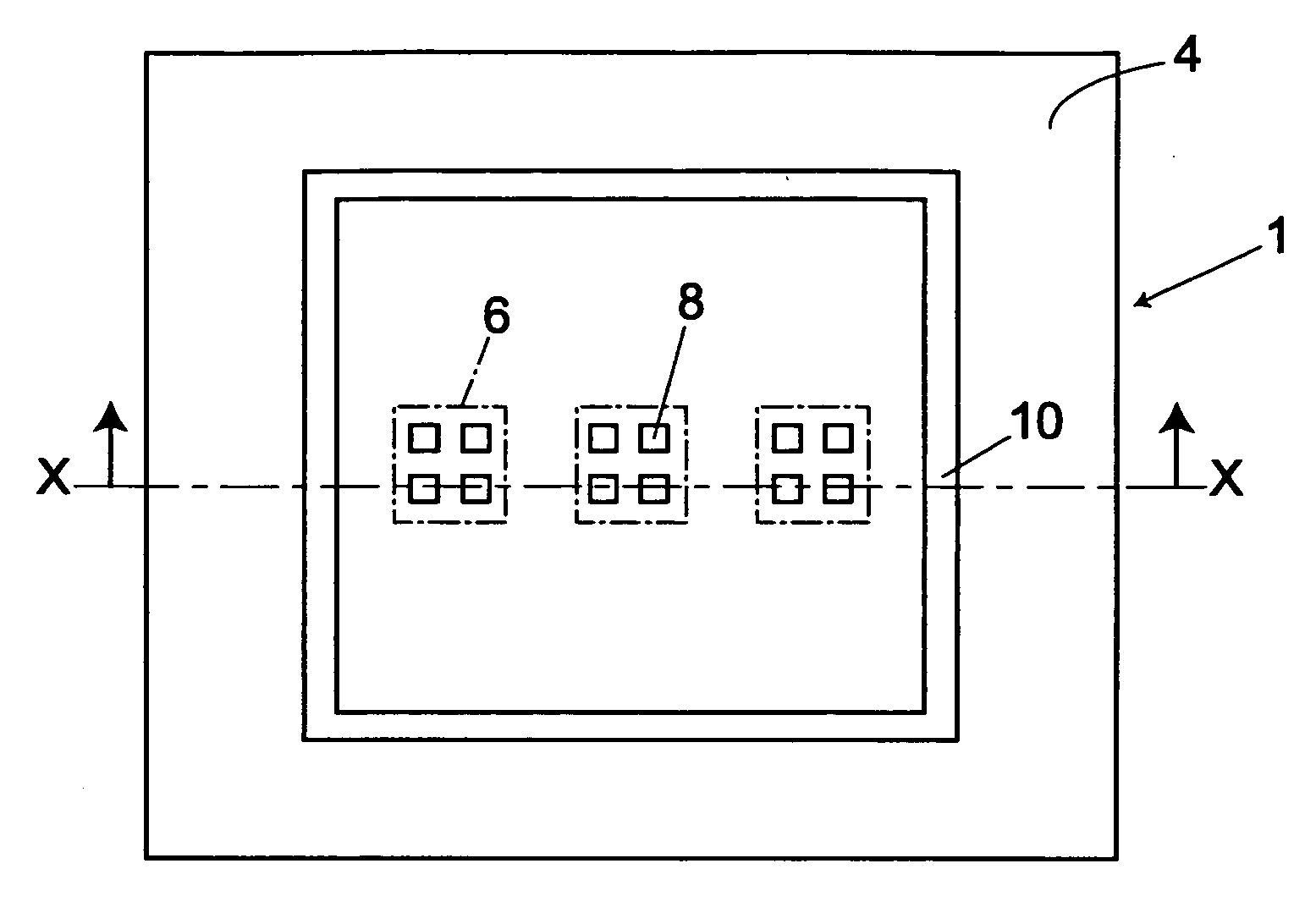

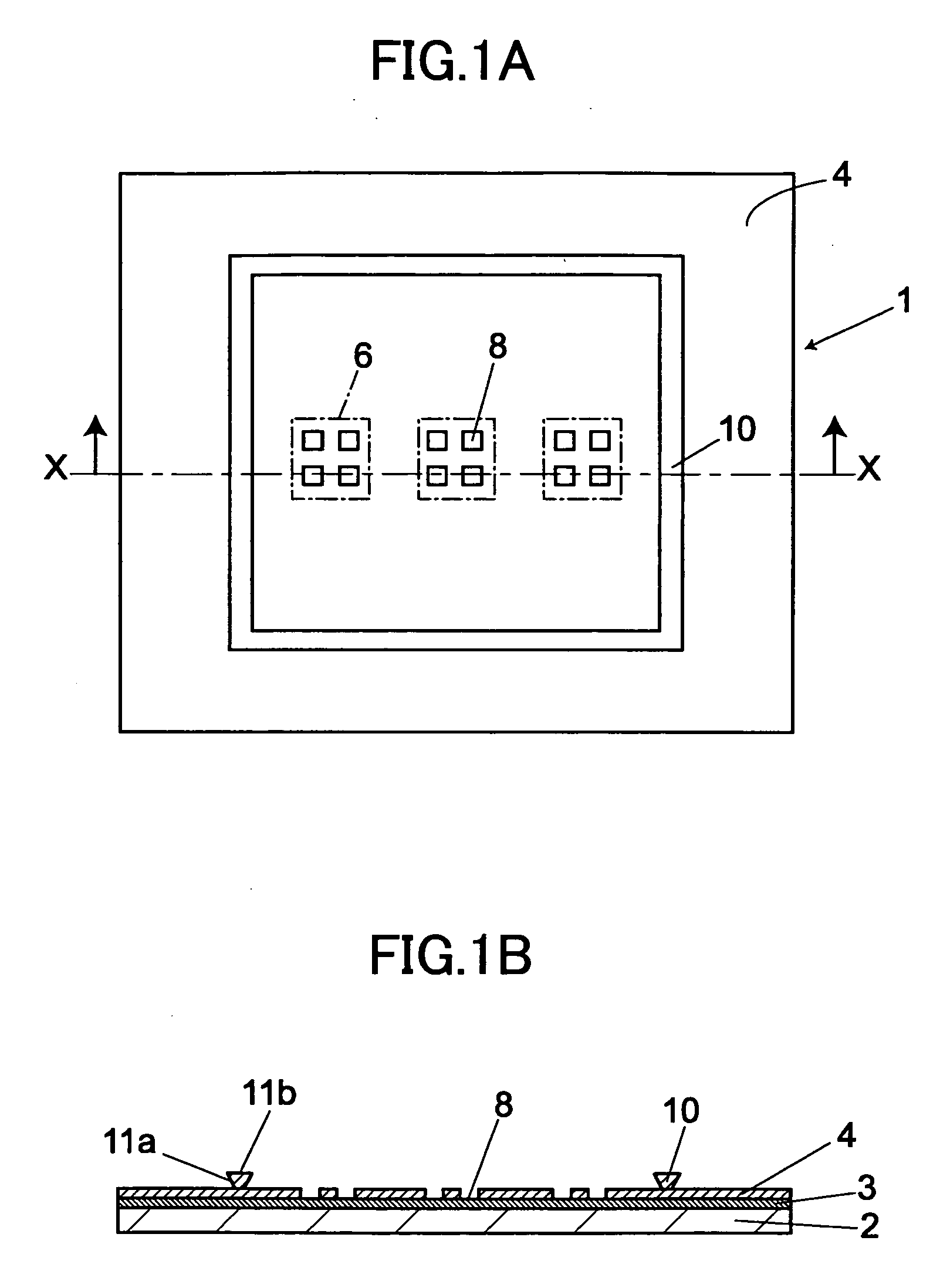

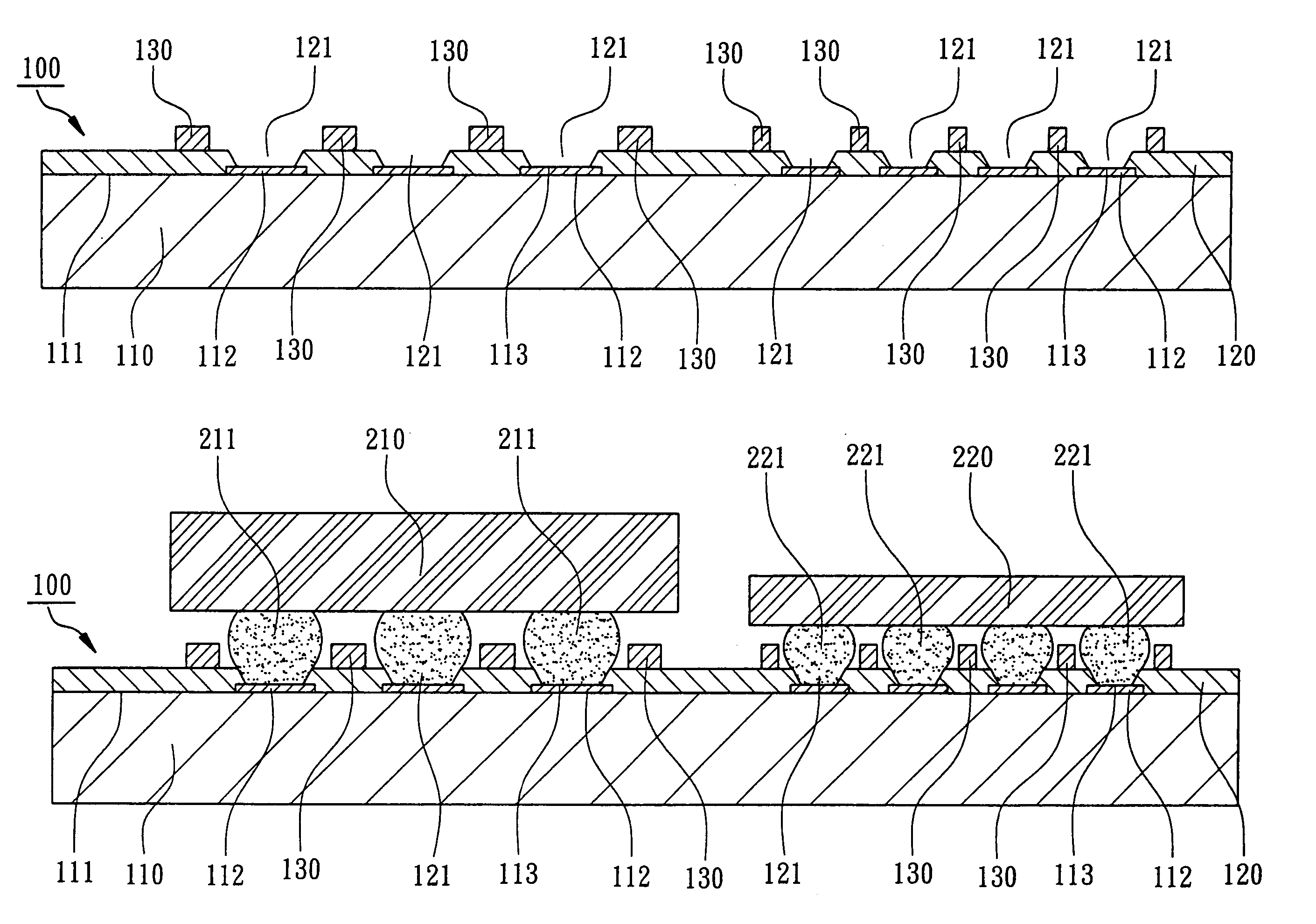

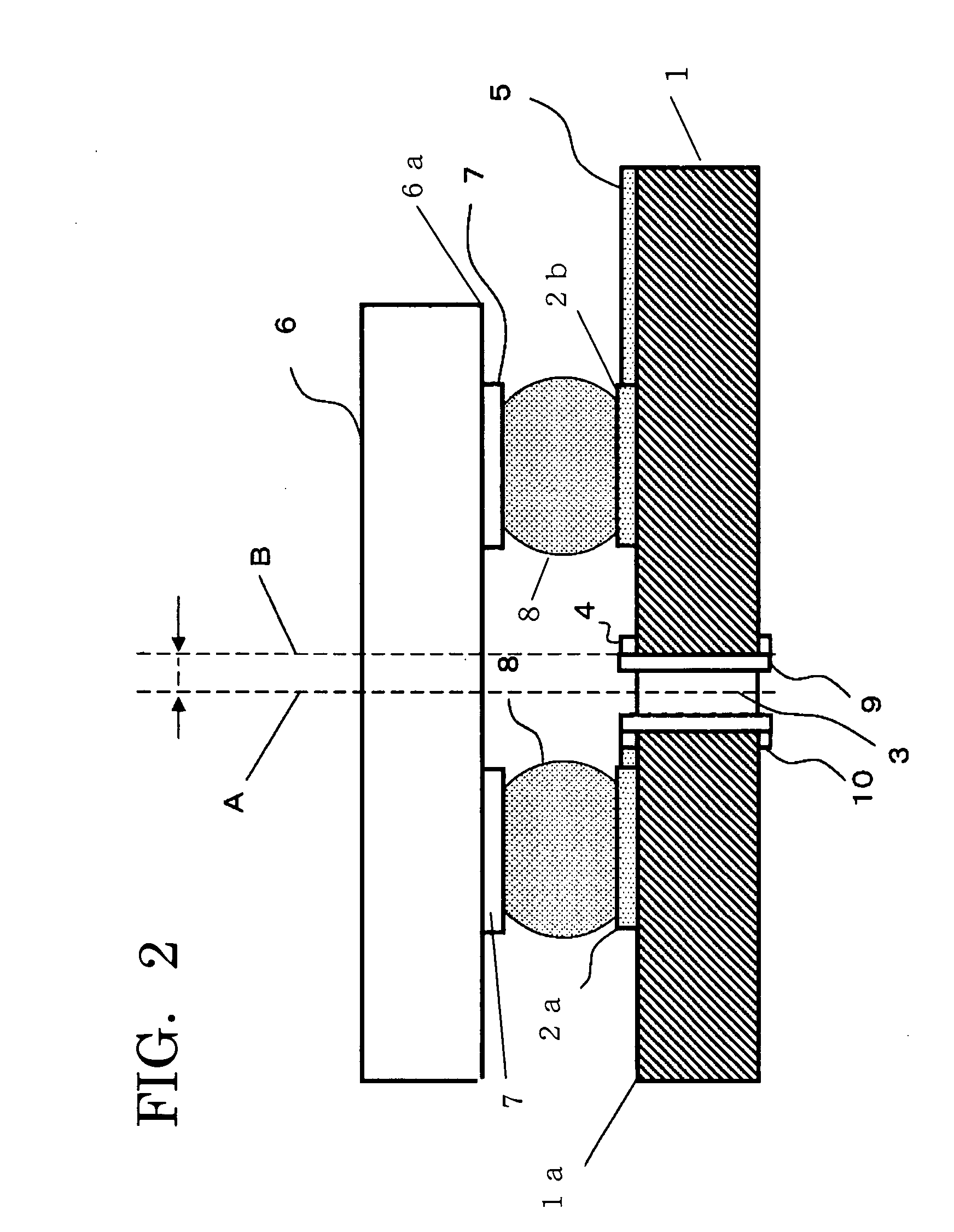

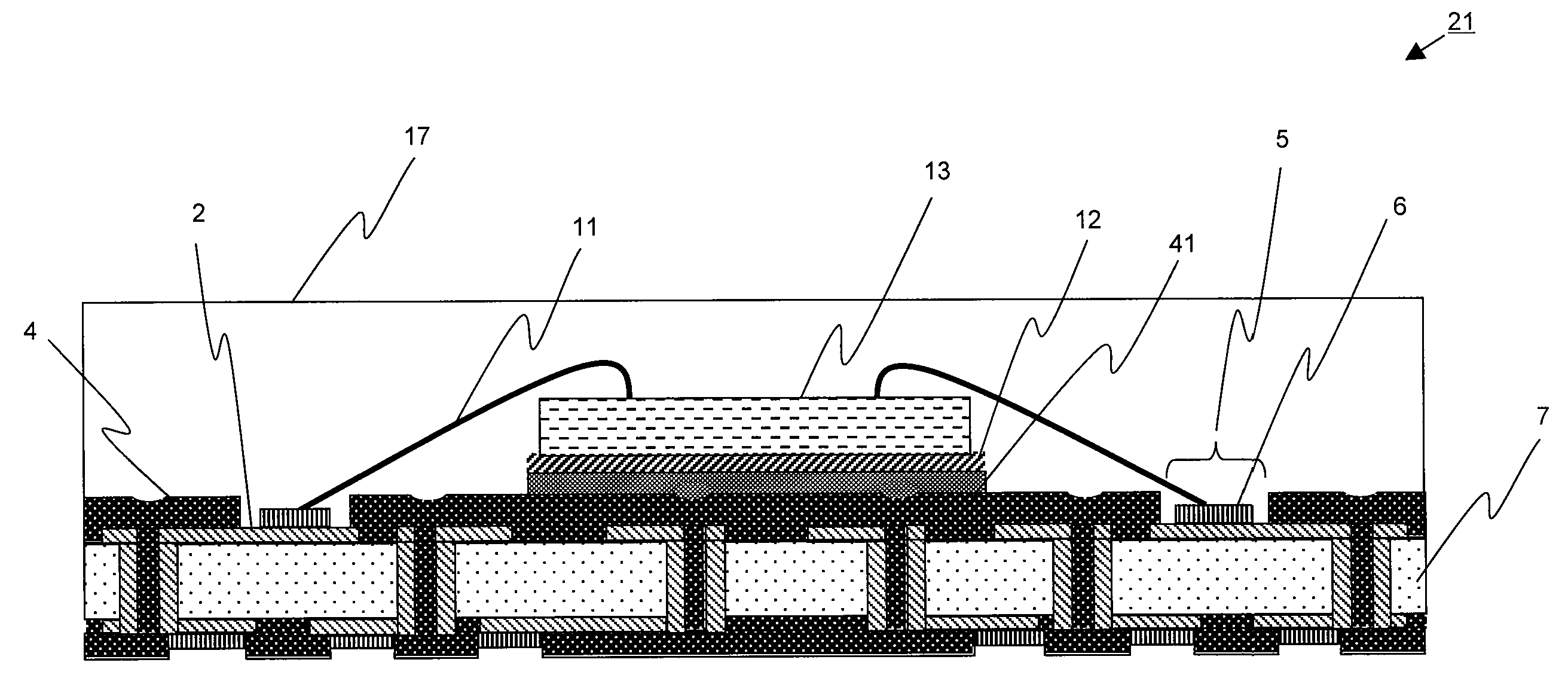

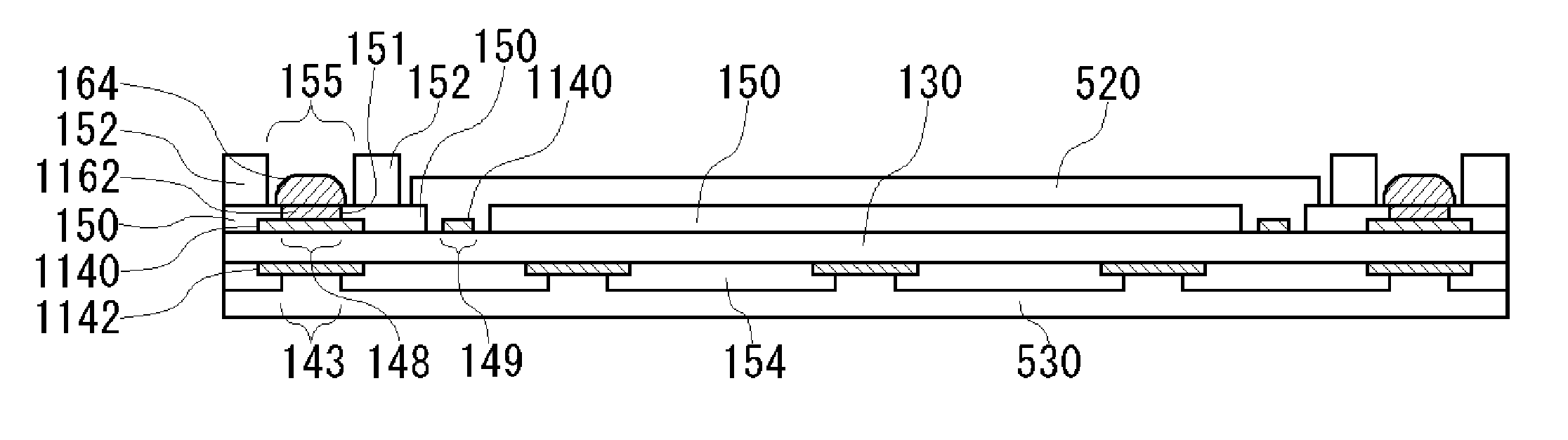

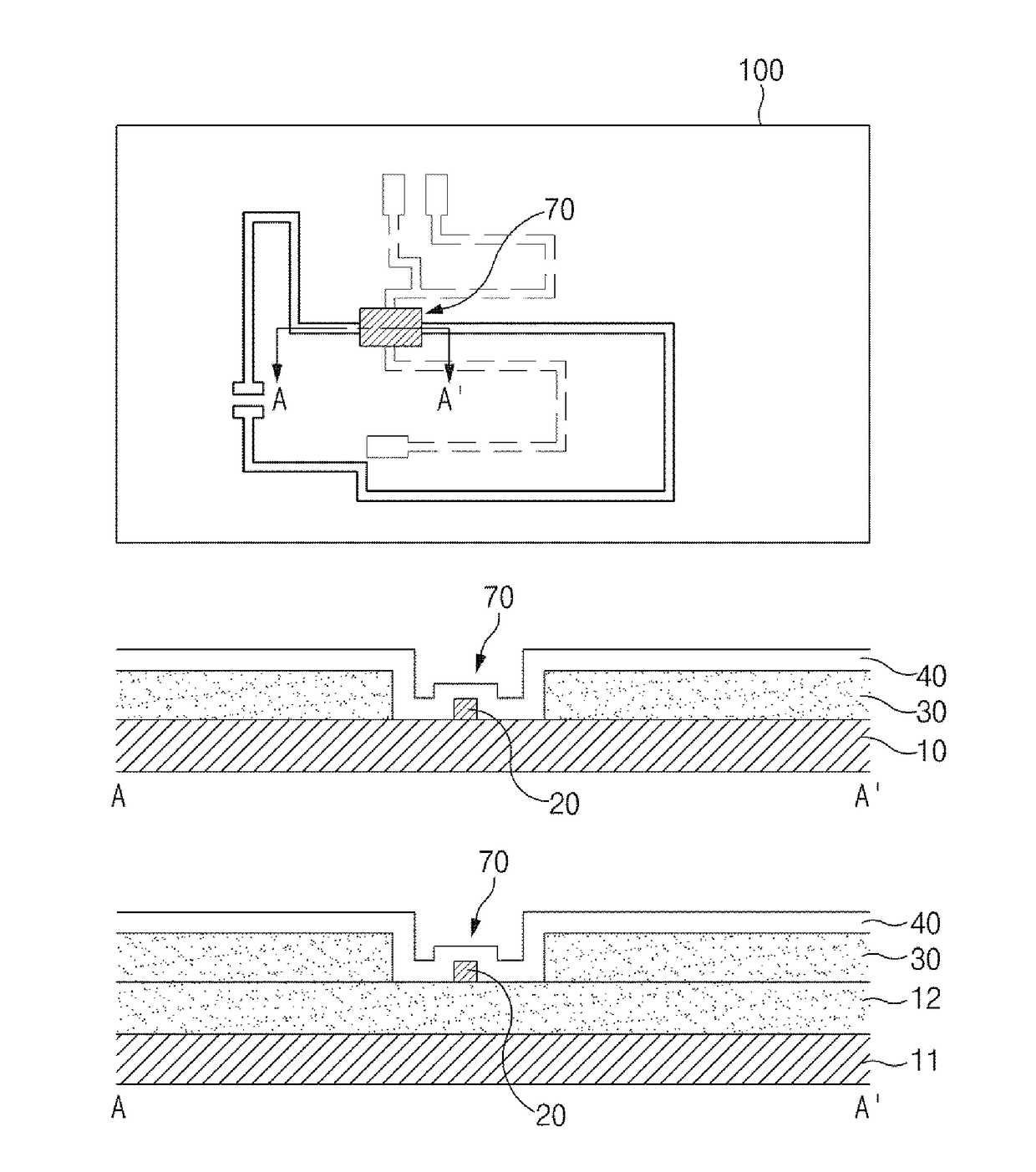

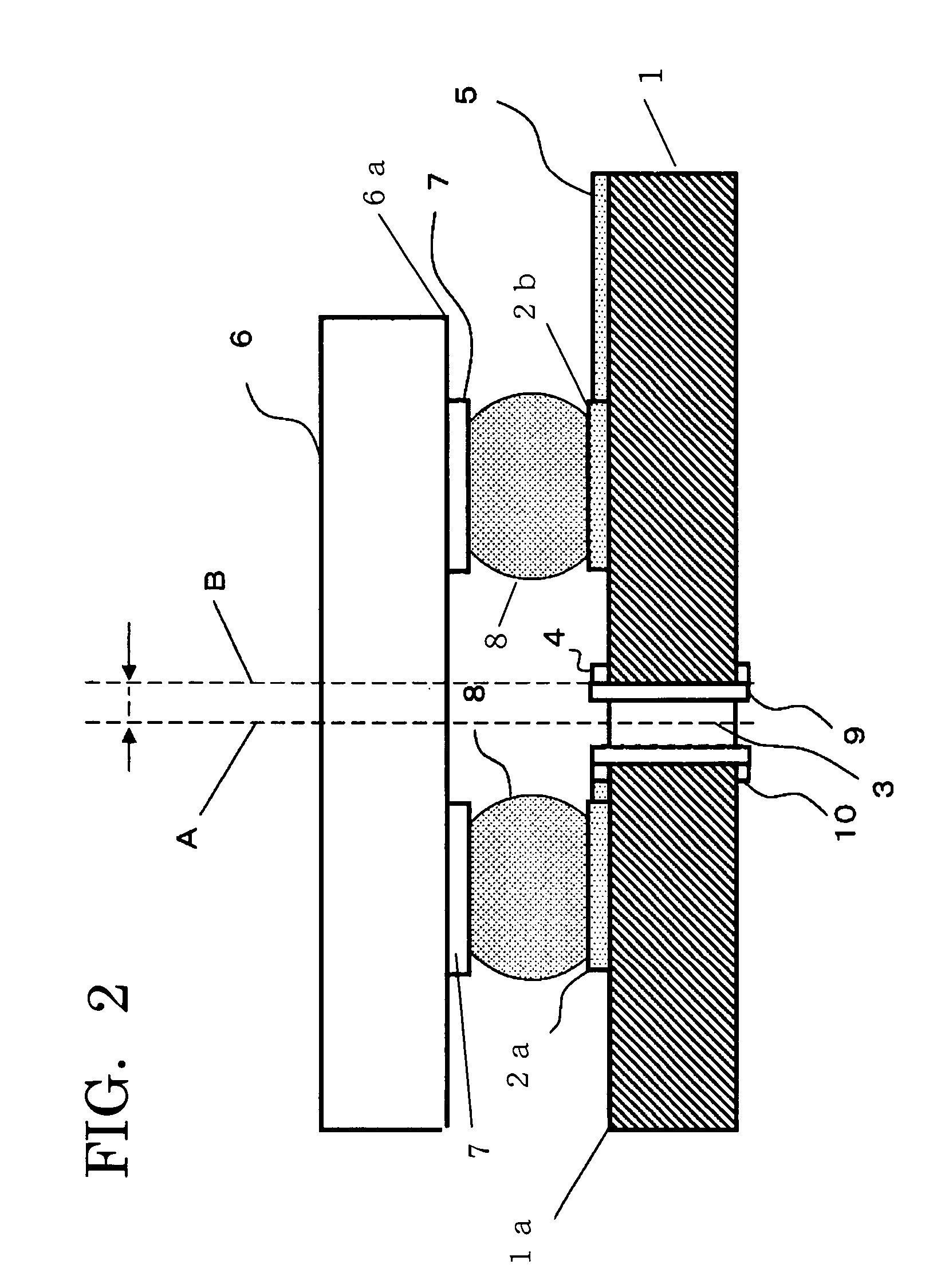

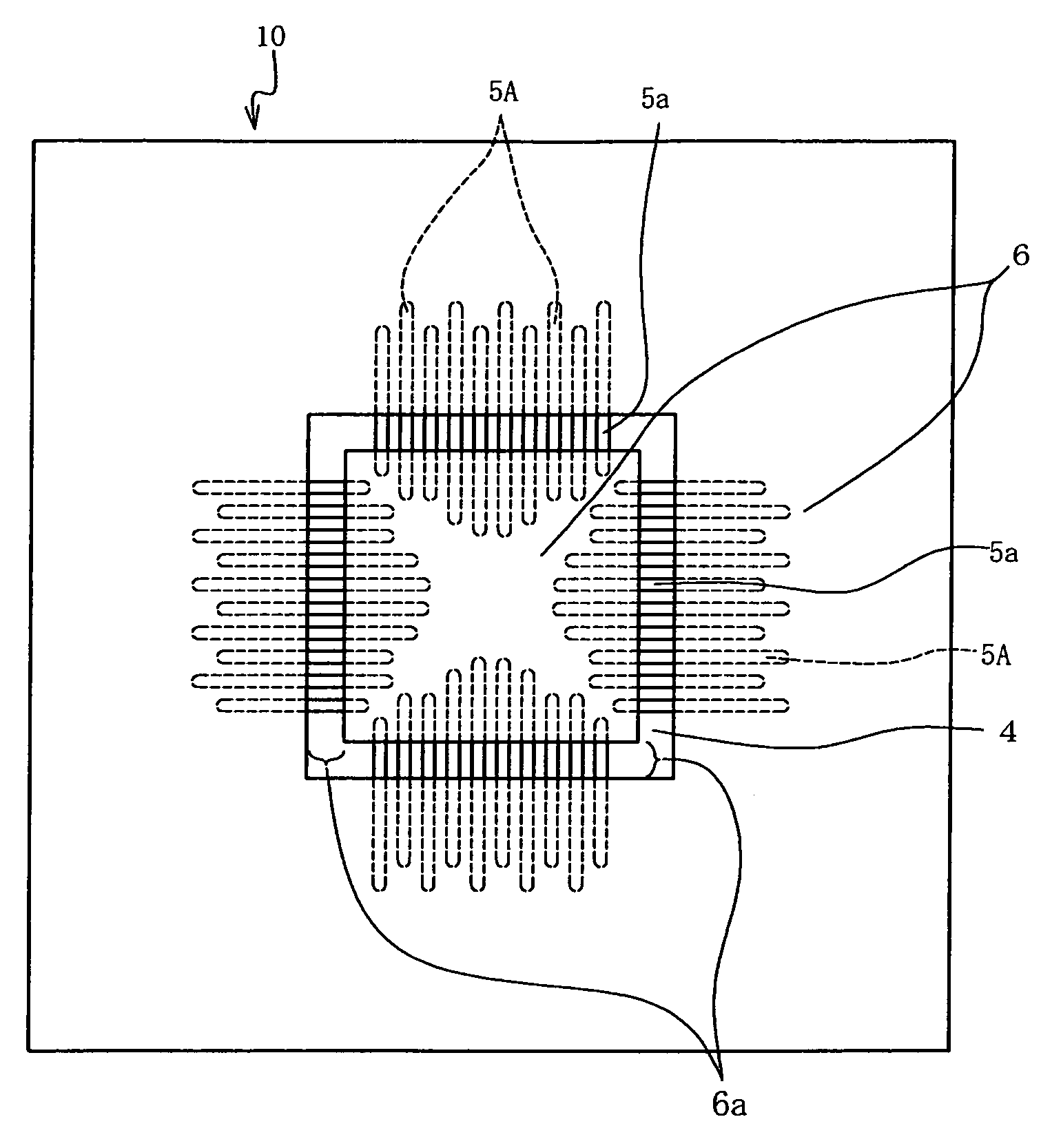

Wiring substrate for use in semiconductor apparatus, method for fabricating the same, and semiconductor apparatus using the same

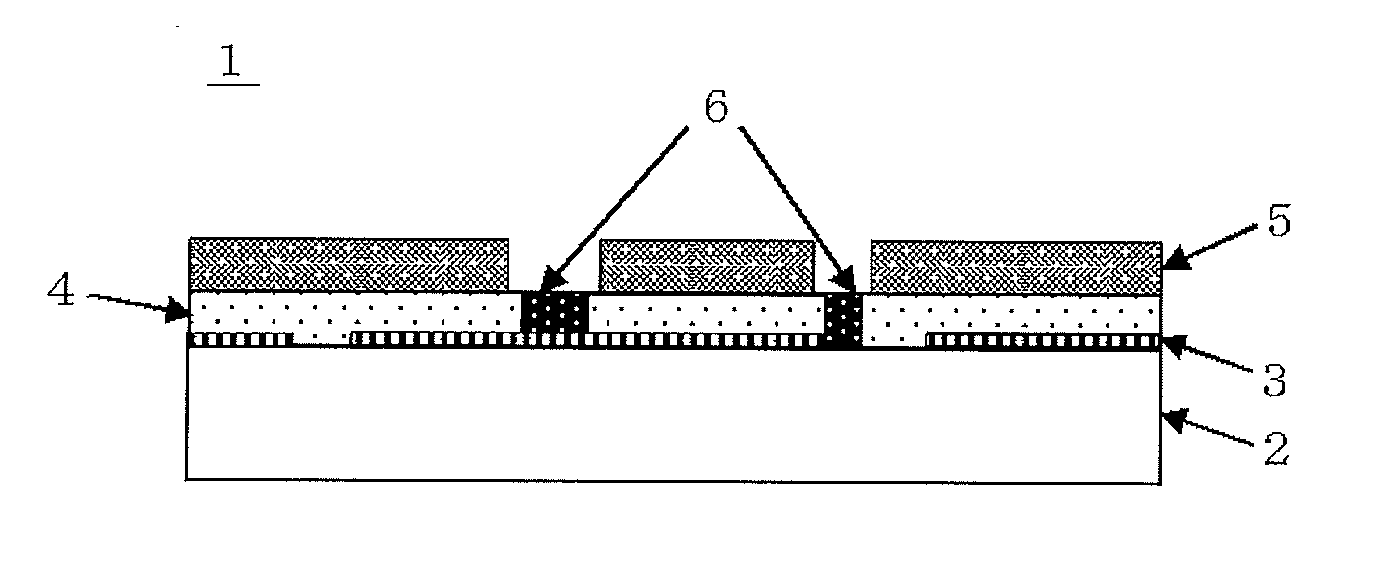

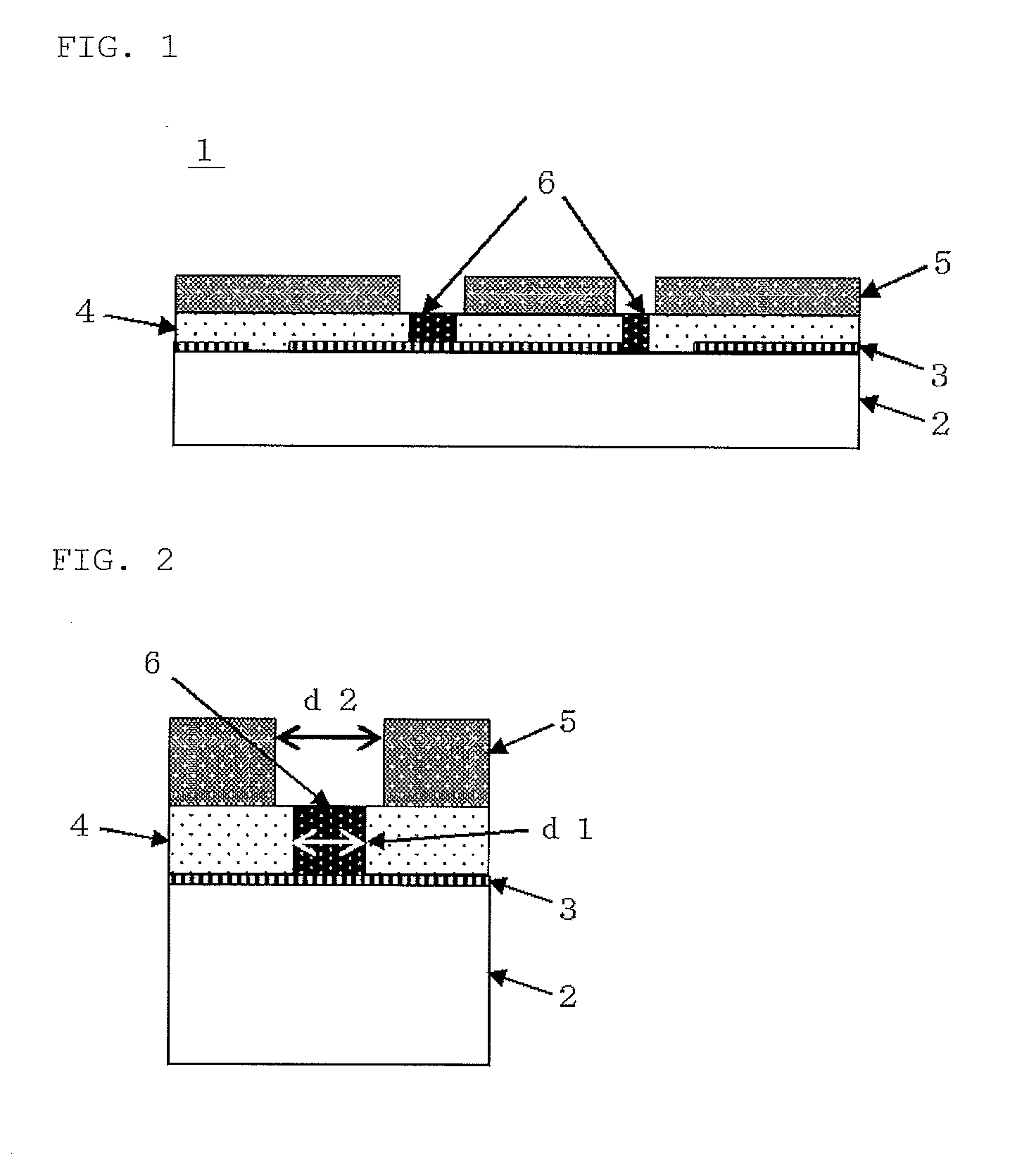

ActiveUS20090201657A1Reduce unevennessQuality improvementSecond resist patternSemiconductor/solid-state device detailsResistElectrical conductor

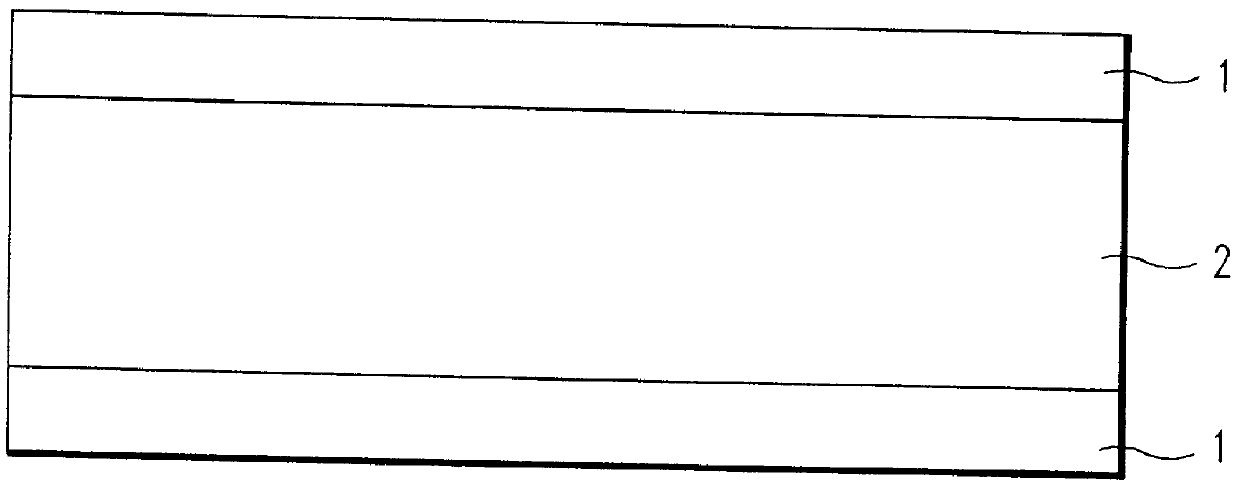

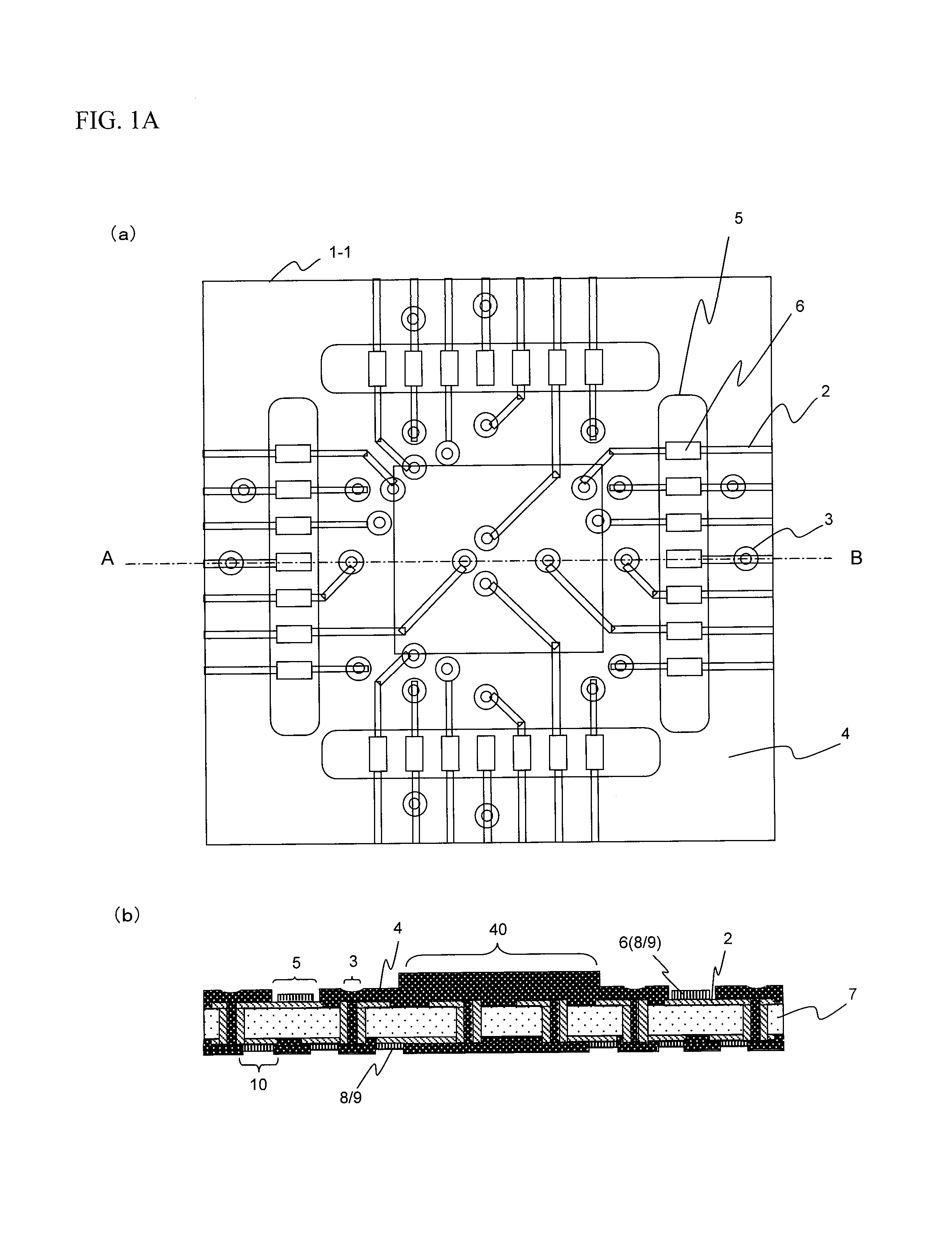

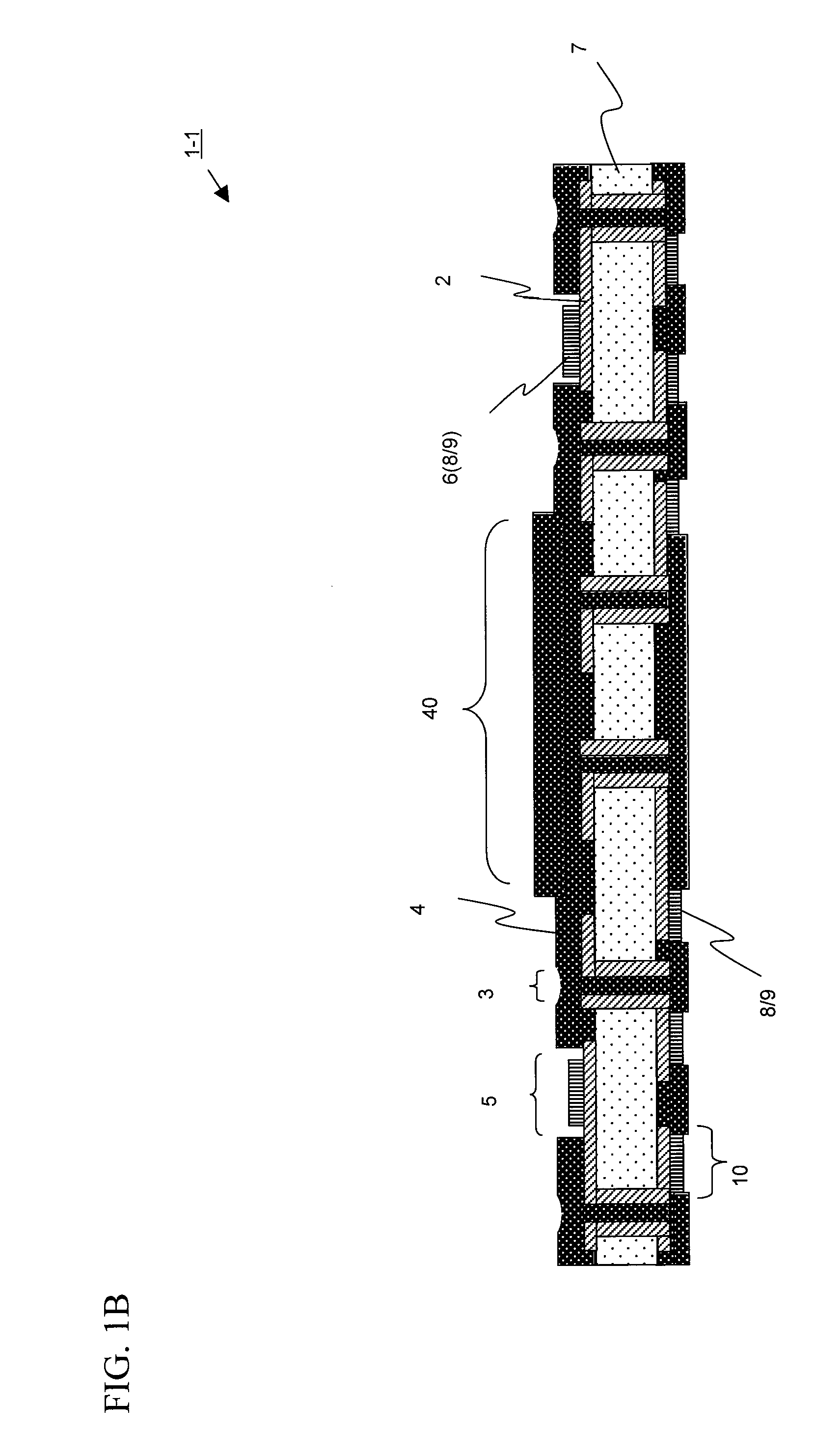

On a printed-wiring board 1-1, a conductor layer 2 is laminated to both the top surface and the bottom surface of a substrate core 7 so as to pattern the substrate core, and a solder resist 4 is laminated to the substrate core. The solder resist 4 laminated to the top surface of the printed-wiring board 1-1 forms a raised portion 40 in a semiconductor chip mounting area such that the thickness of the raised portion is greater than the thickness of the solder resist 4 laminated to areas other than the semiconductor chip mounting area, so that the surface of the semiconductor chip mounting area is flat.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

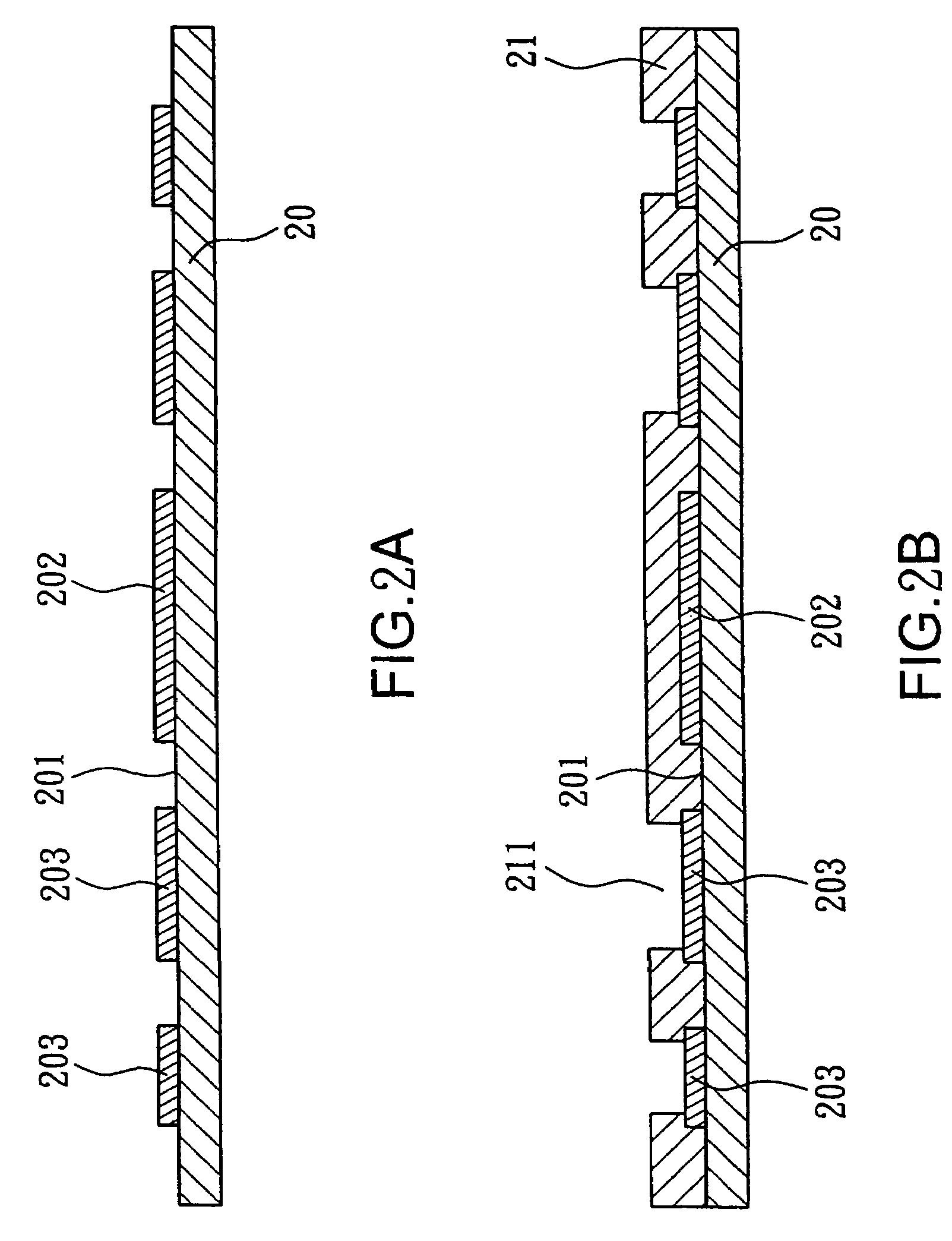

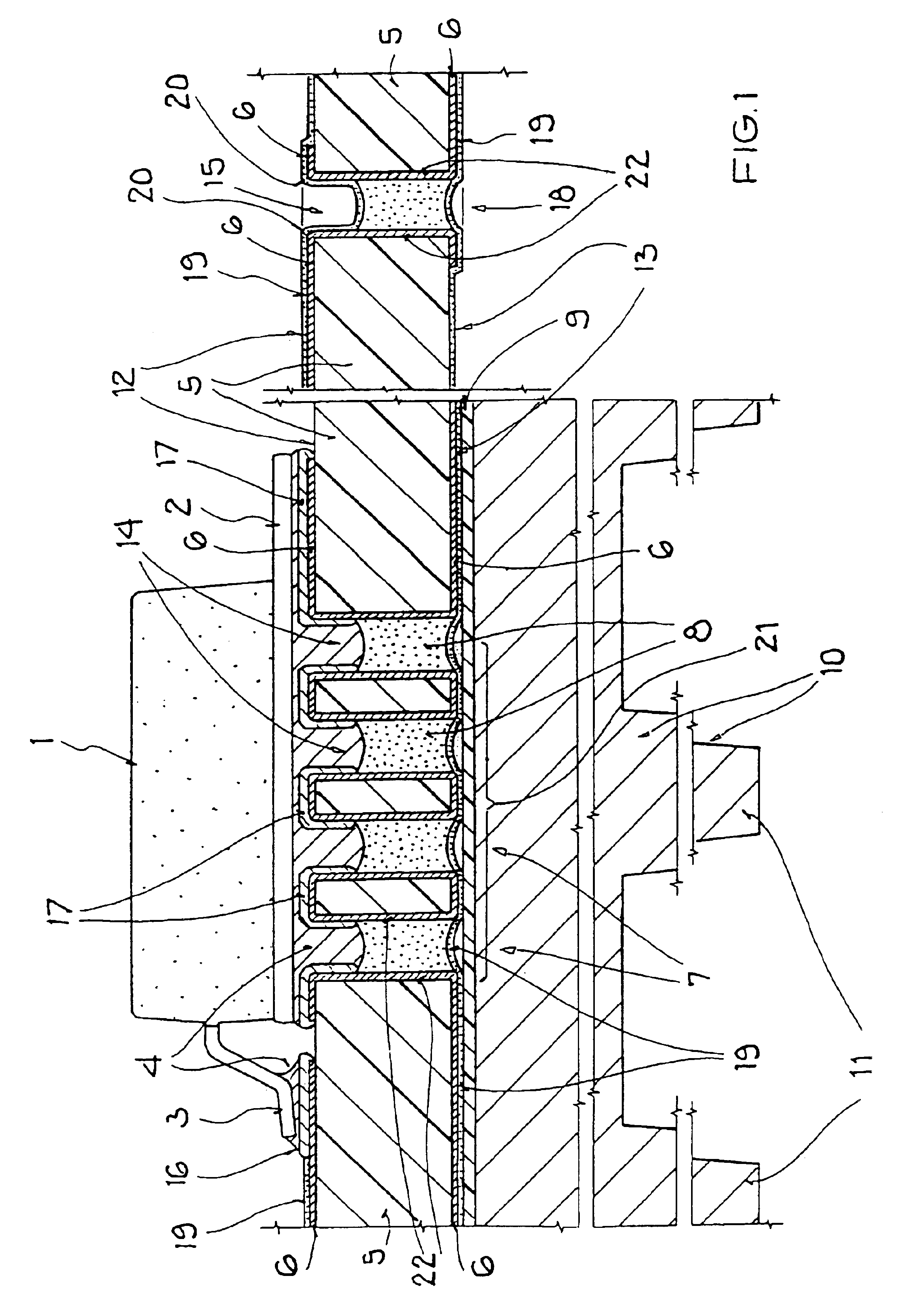

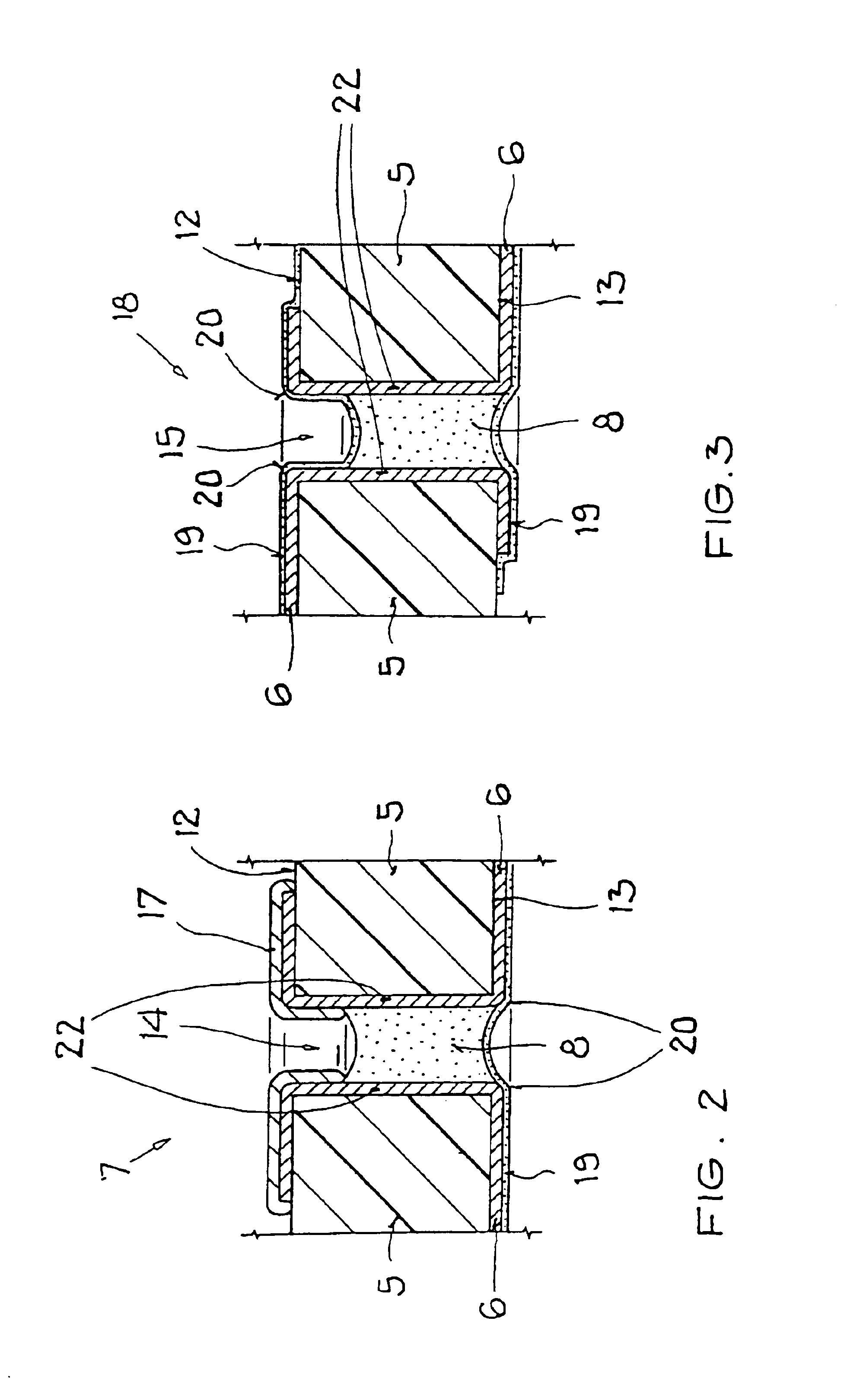

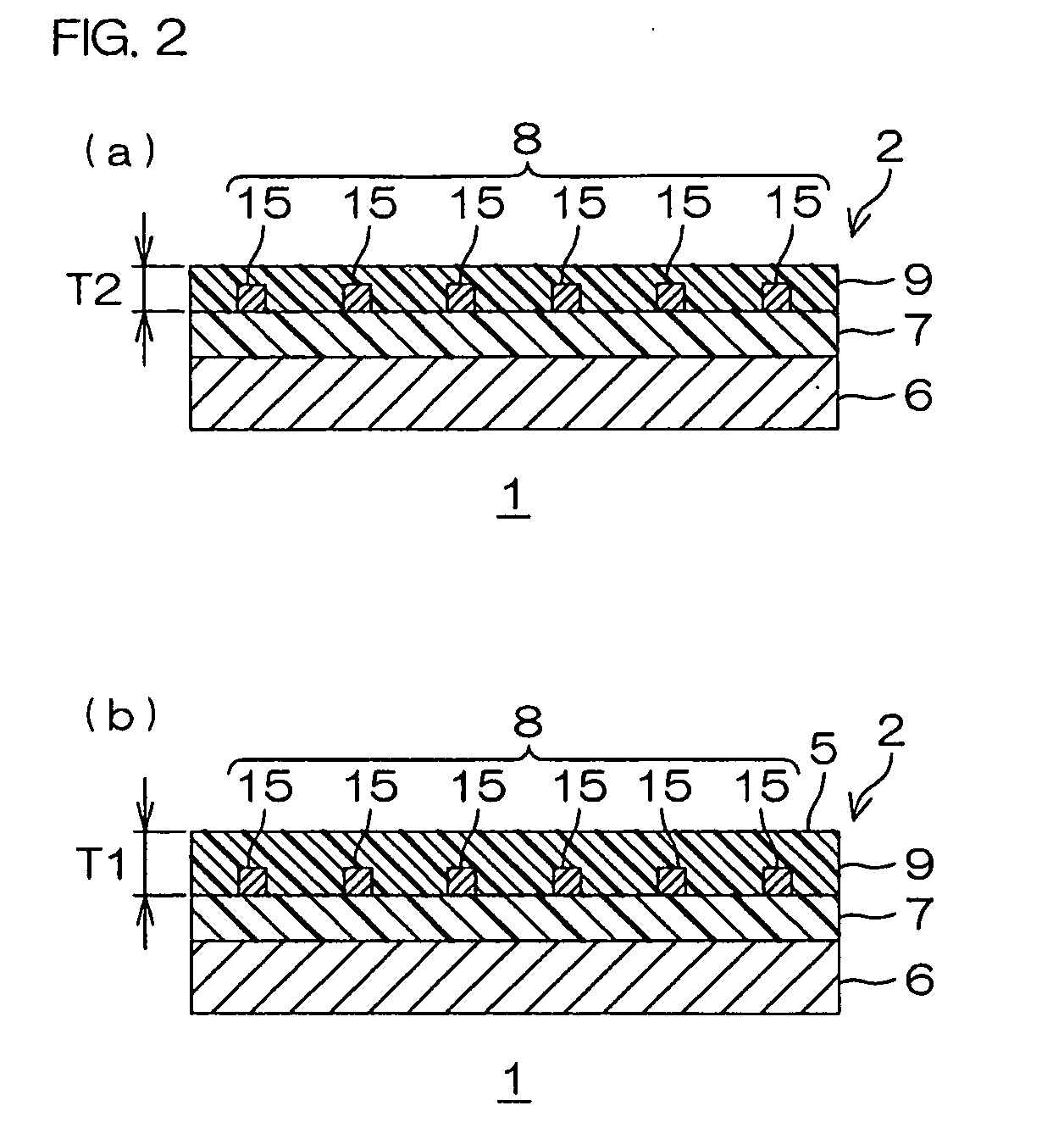

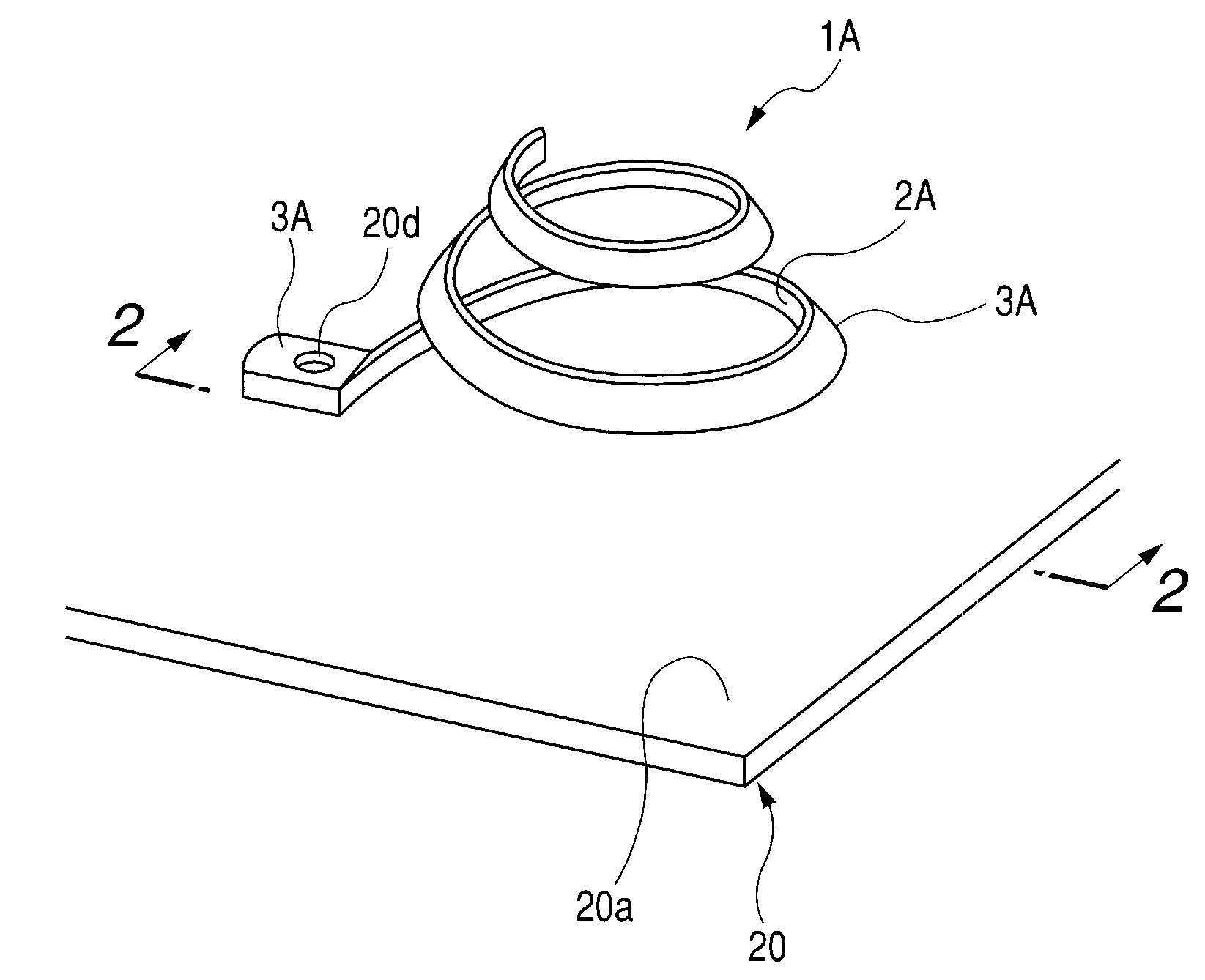

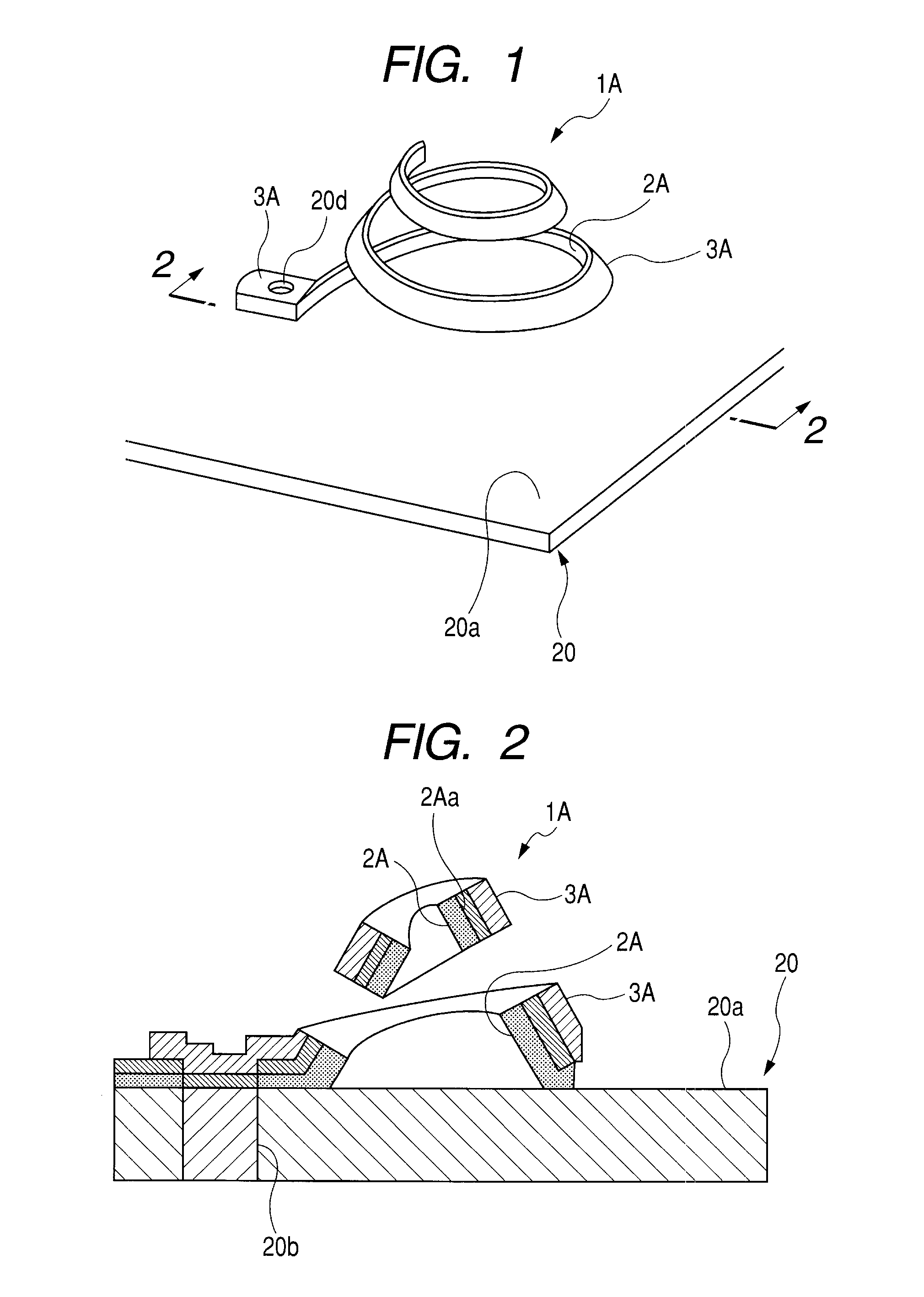

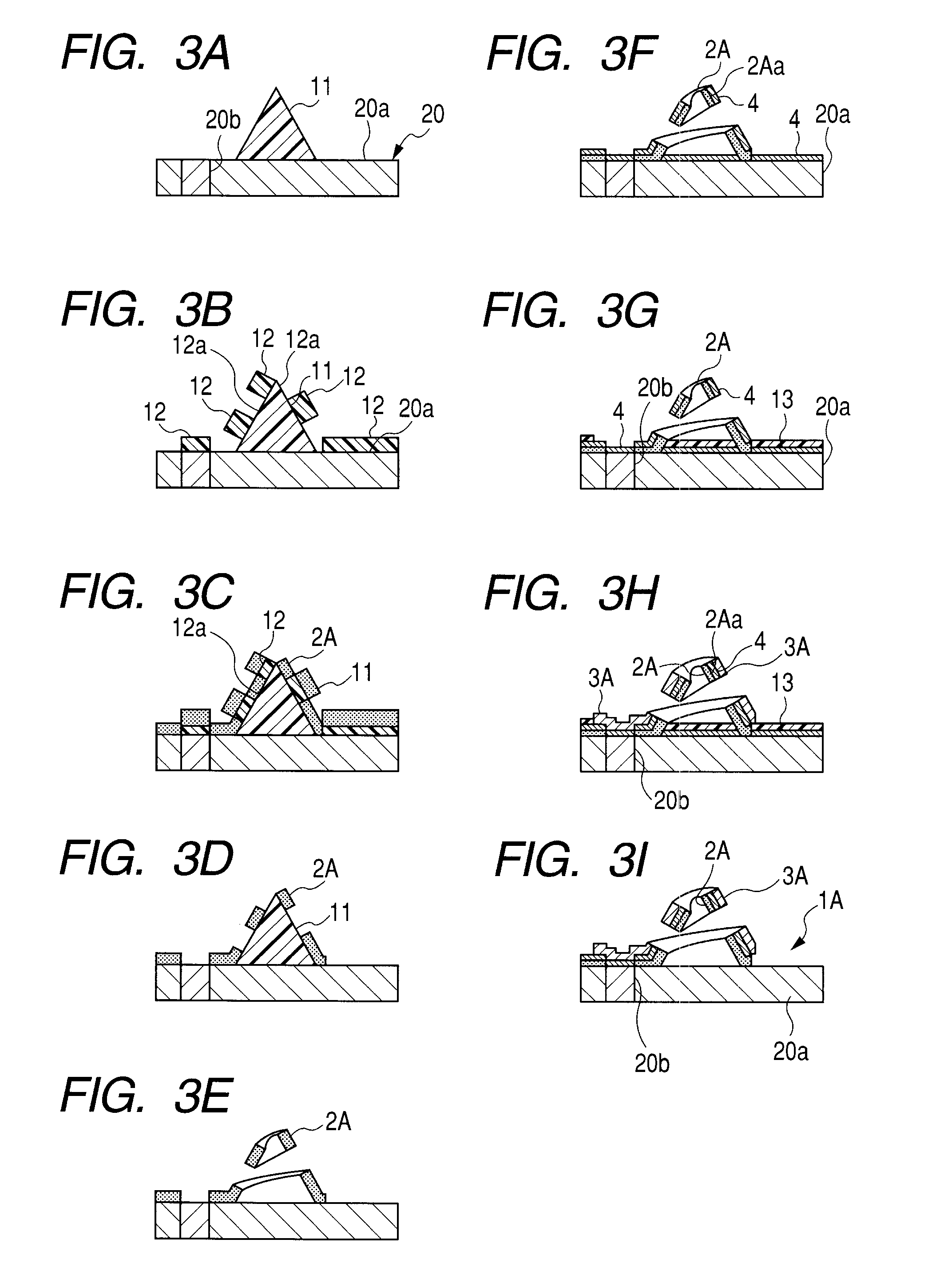

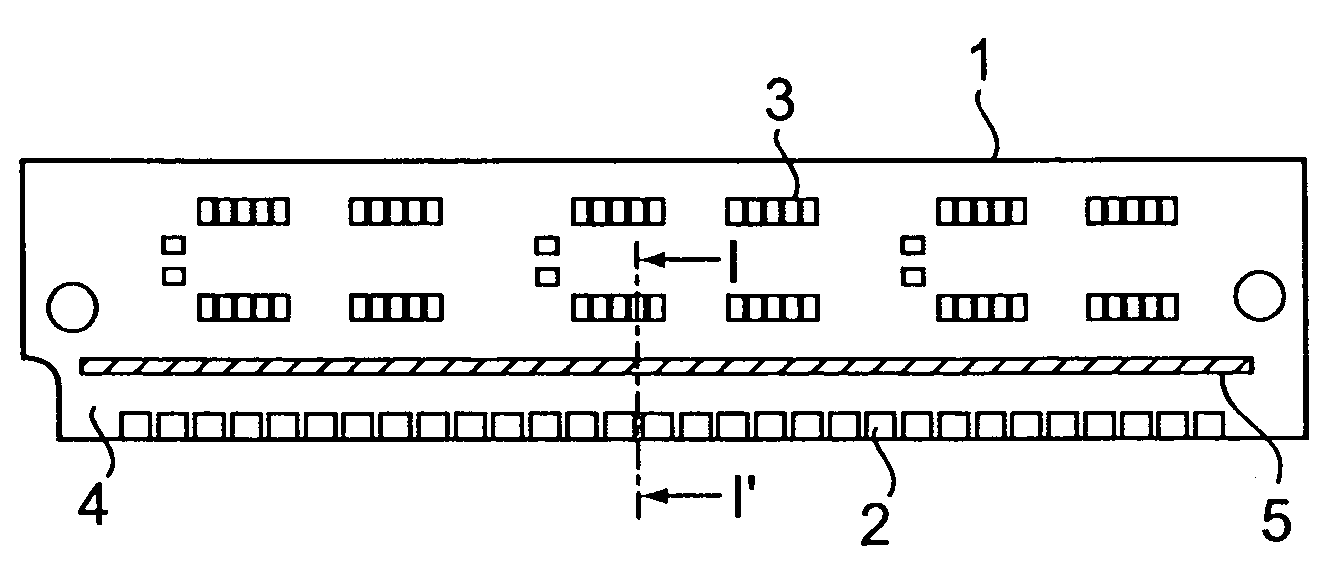

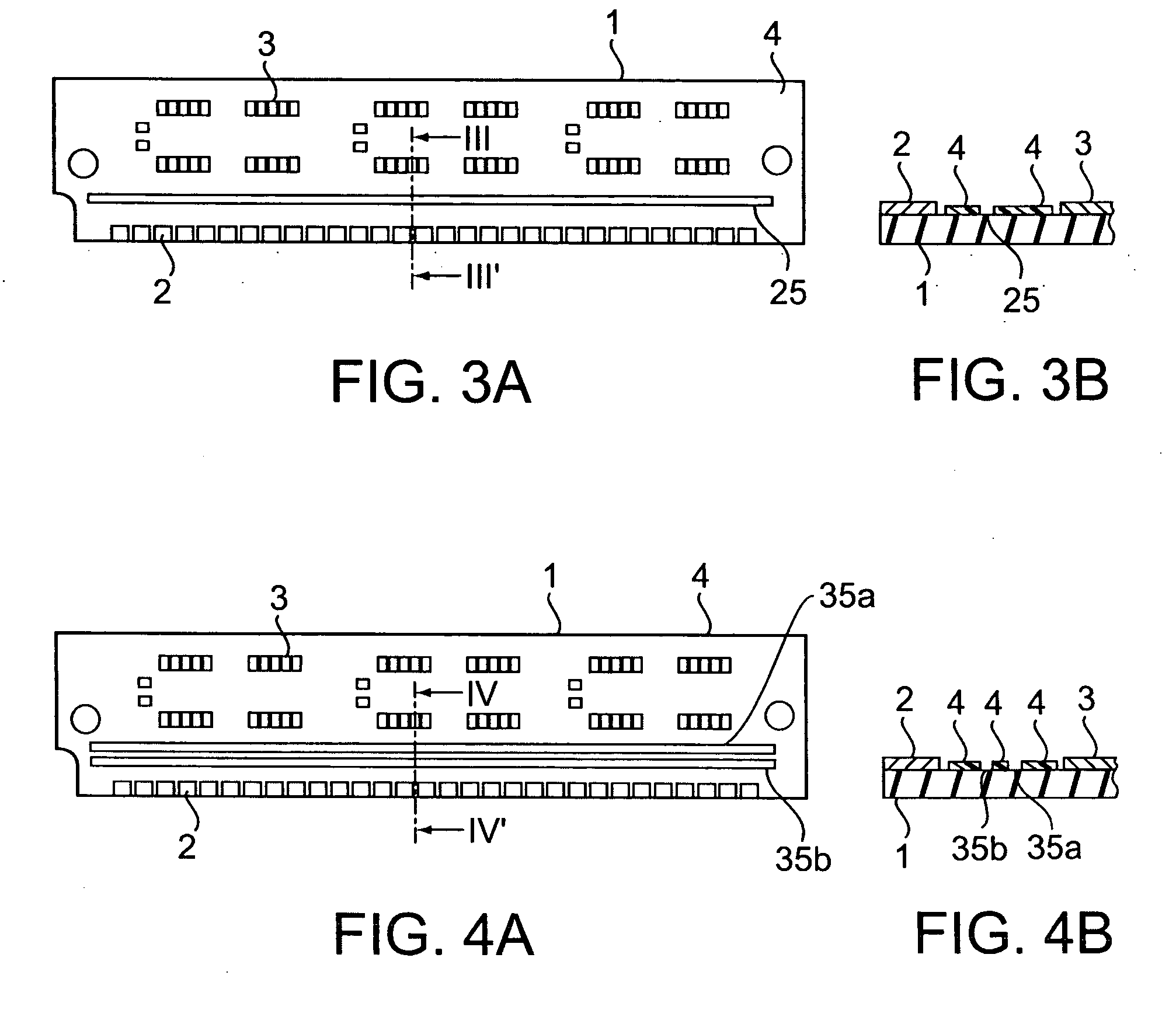

Suspension board with circuit and production method thereof

InactiveUS20100224391A1Avoid damageLarge thicknessSecond resist patternPrinted circuit aspectsElectrical conductorMetal

A suspension board with circuit includes a metal supporting board, an insulating base layer formed on the metal supporting board, a conductive pattern formed on the insulating base layer, an insulating cover layer formed on the insulating base layer so as to cover the conductive pattern, and an insertion portion to be inserted into an E-block. A thickness of the insulating cover layer in the insertion portion is larger than a thickness of the insulating cover layer in a portion other than the insertion portion.

Owner:NITTO DENKO CORP

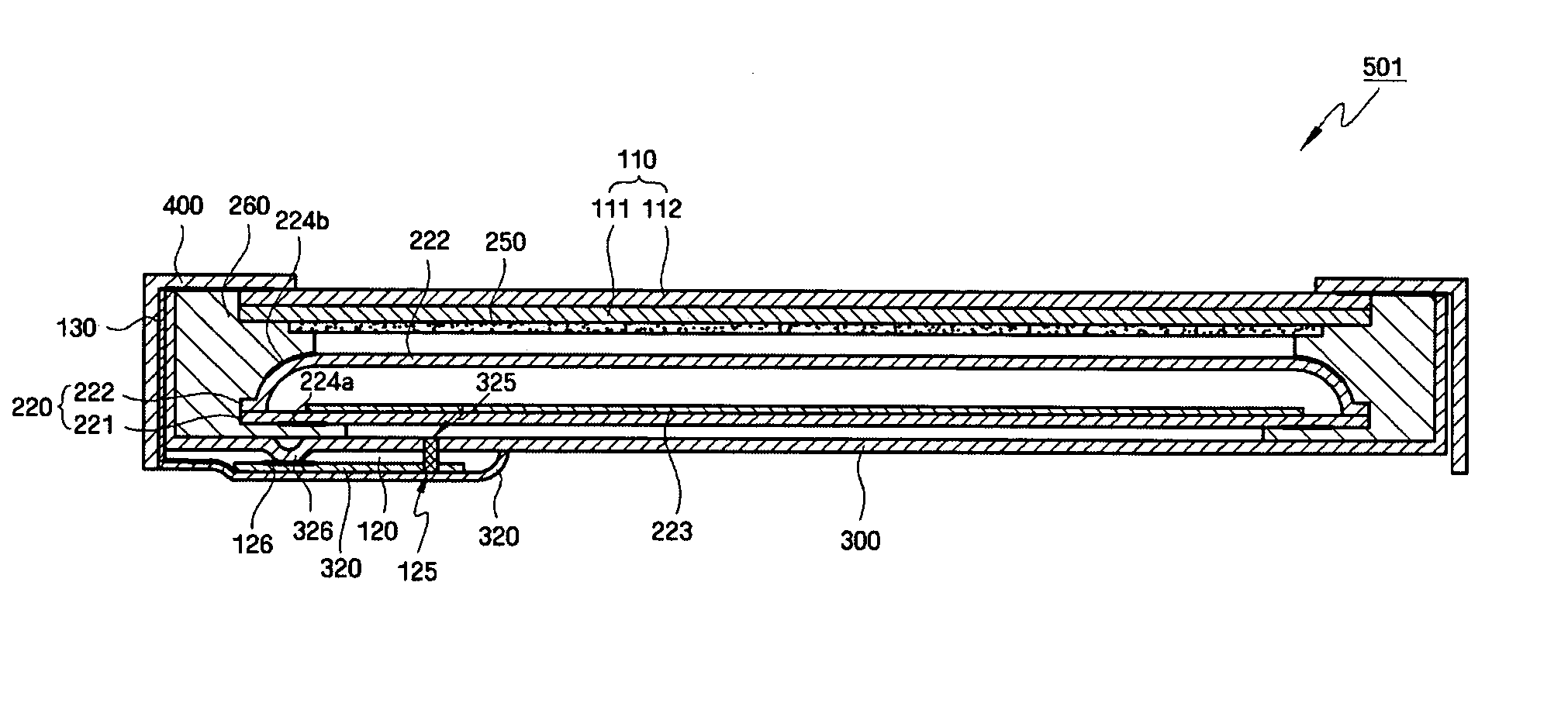

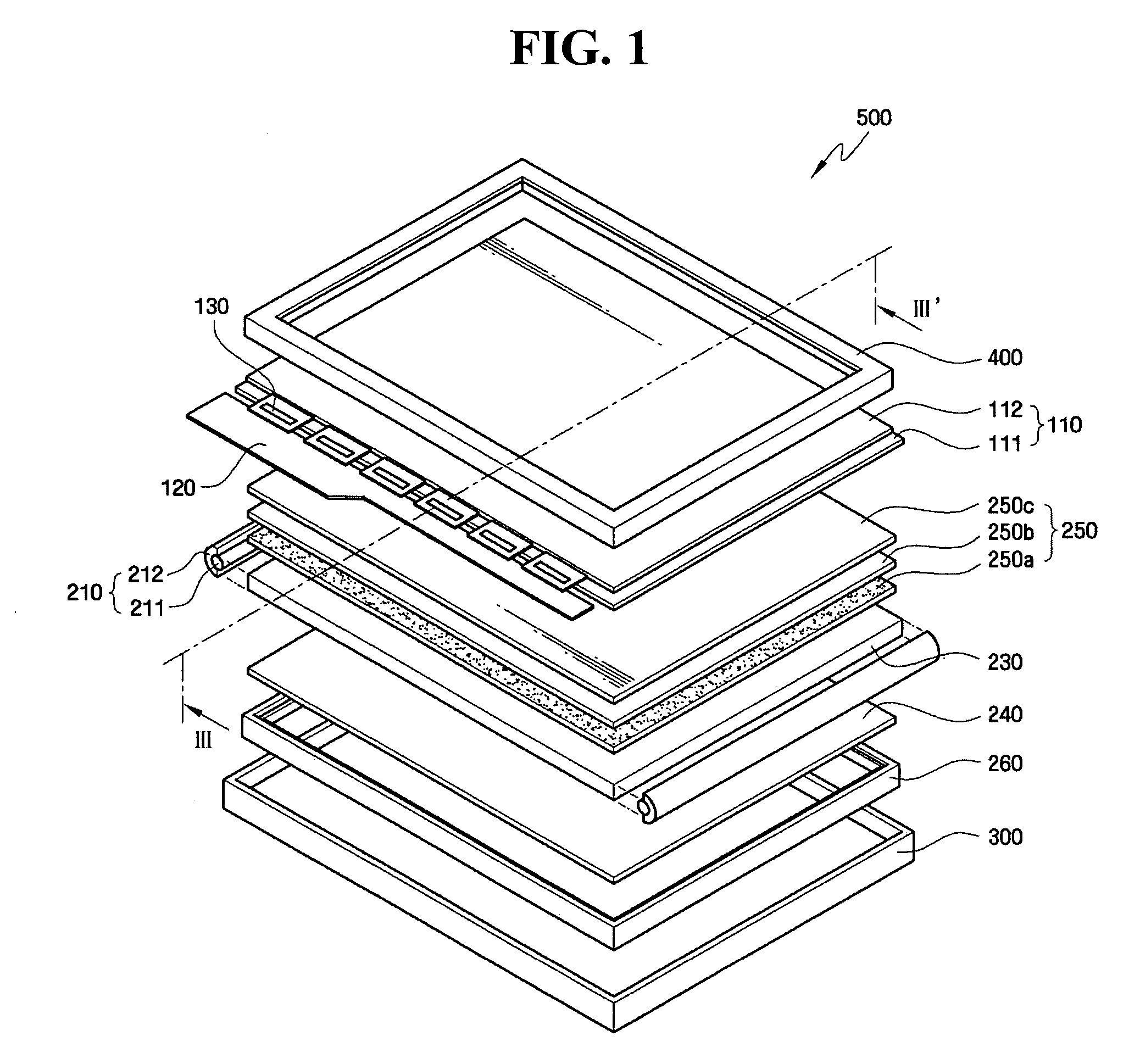

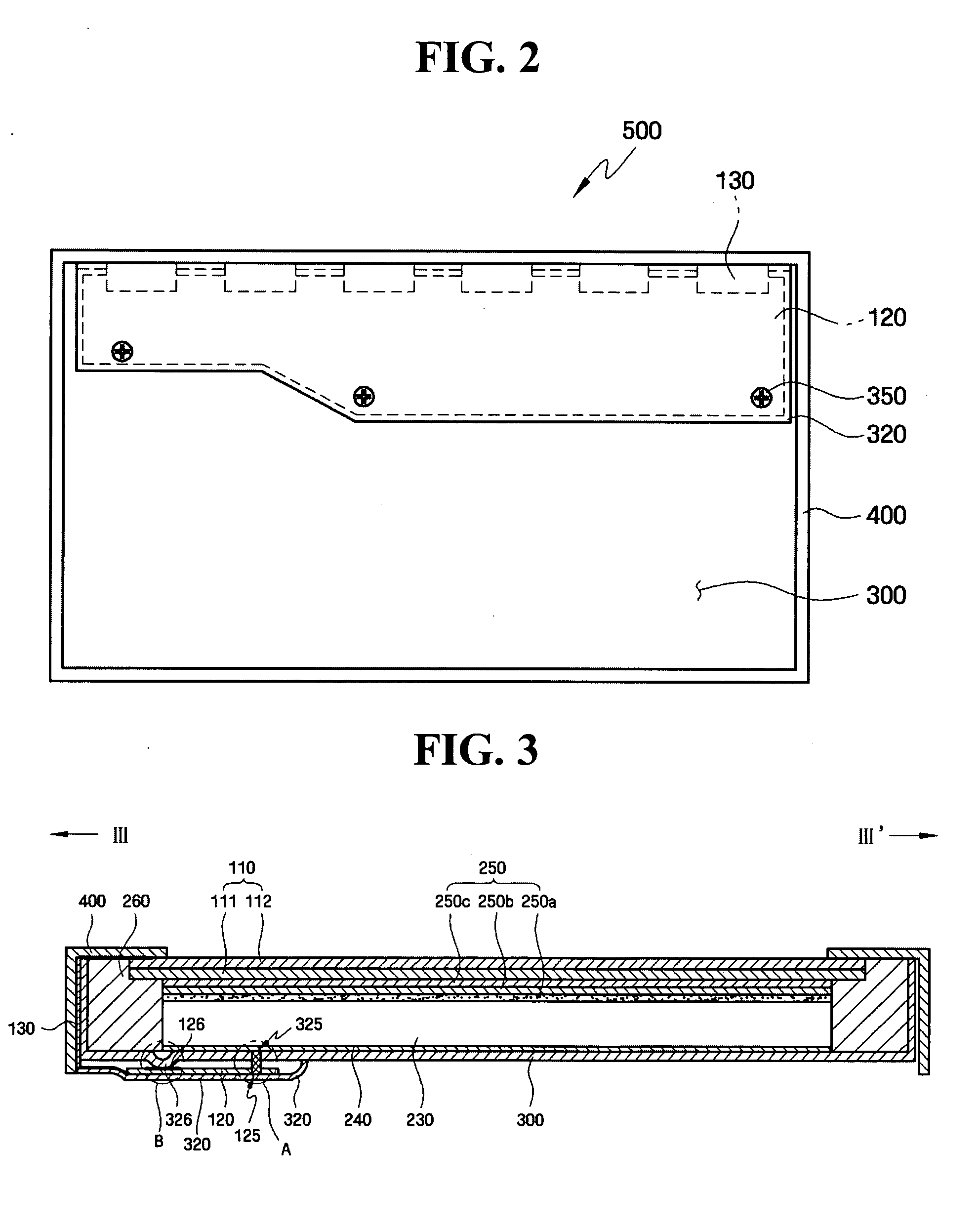

Printed circuit board and liquid crystal display having the same

ActiveUS20070035689A1Damage suppressionSecond resist patternPrinted circuit aspectsLiquid-crystal displayEngineering

A printed circuit board (PCB) and a liquid crystal display (LCD) including the same are provided. The PCB includes a metal pattern formed on an insulating substrate, an insulating layer covering the metal pattern, and at least one insulating layer protecting pattern formed on the insulating layer. The LCD includes a liquid crystal panel, a backlight assembly providing light to the liquid crystal panel, a bottom chassis having at least one support protruding from a surface thereof and receiving the liquid crystal panel and the backlight assembly, and a printed circuit board (PCB) including a metal pattern formed on an insulating substrate, an insulating layer covering the metal pattern, and at least one insulating layer protecting pattern formed on the insulating layer, wherein the printed circuit board is connected to the surface of the bottom chassis.

Owner:SAMSUNG DISPLAY CO LTD

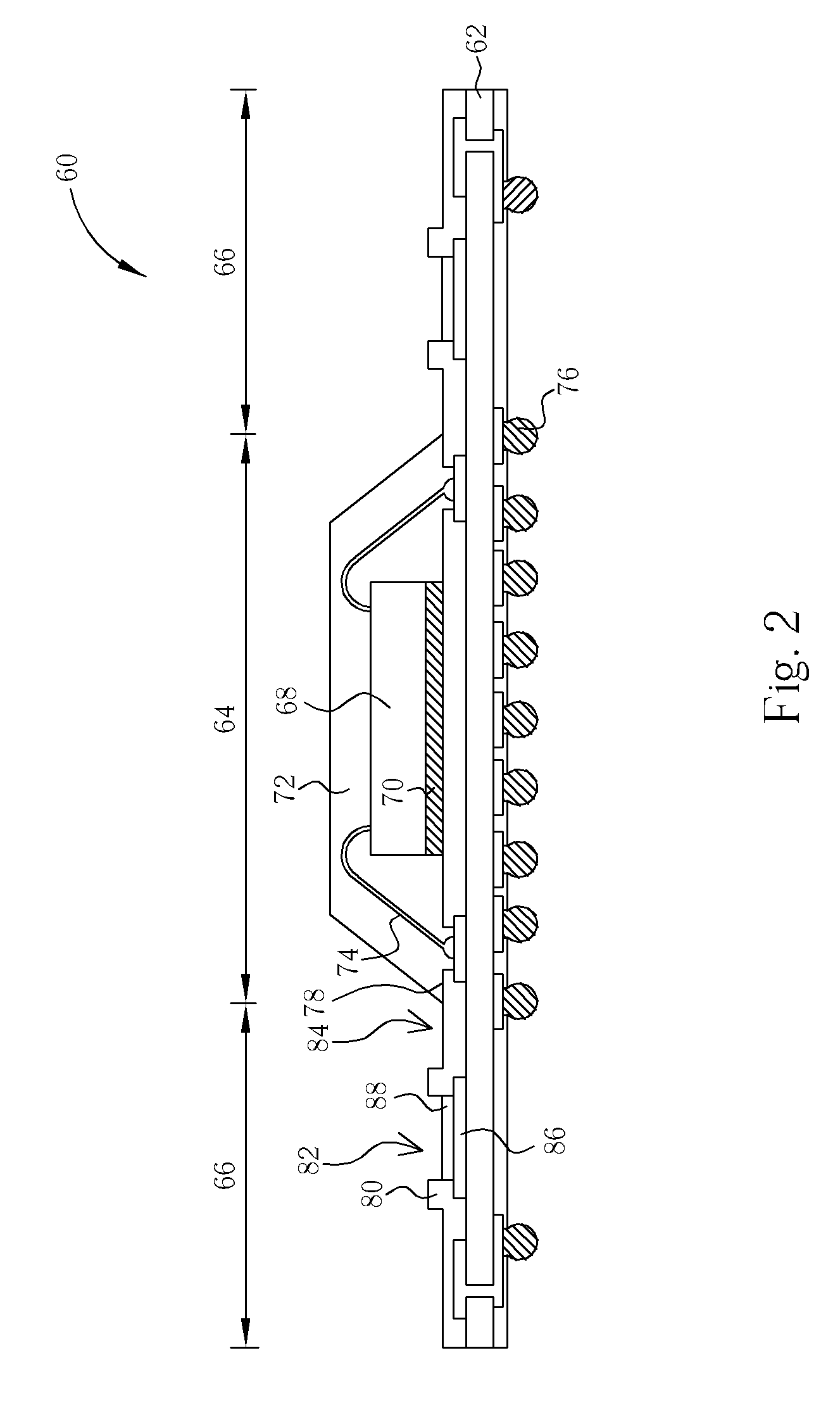

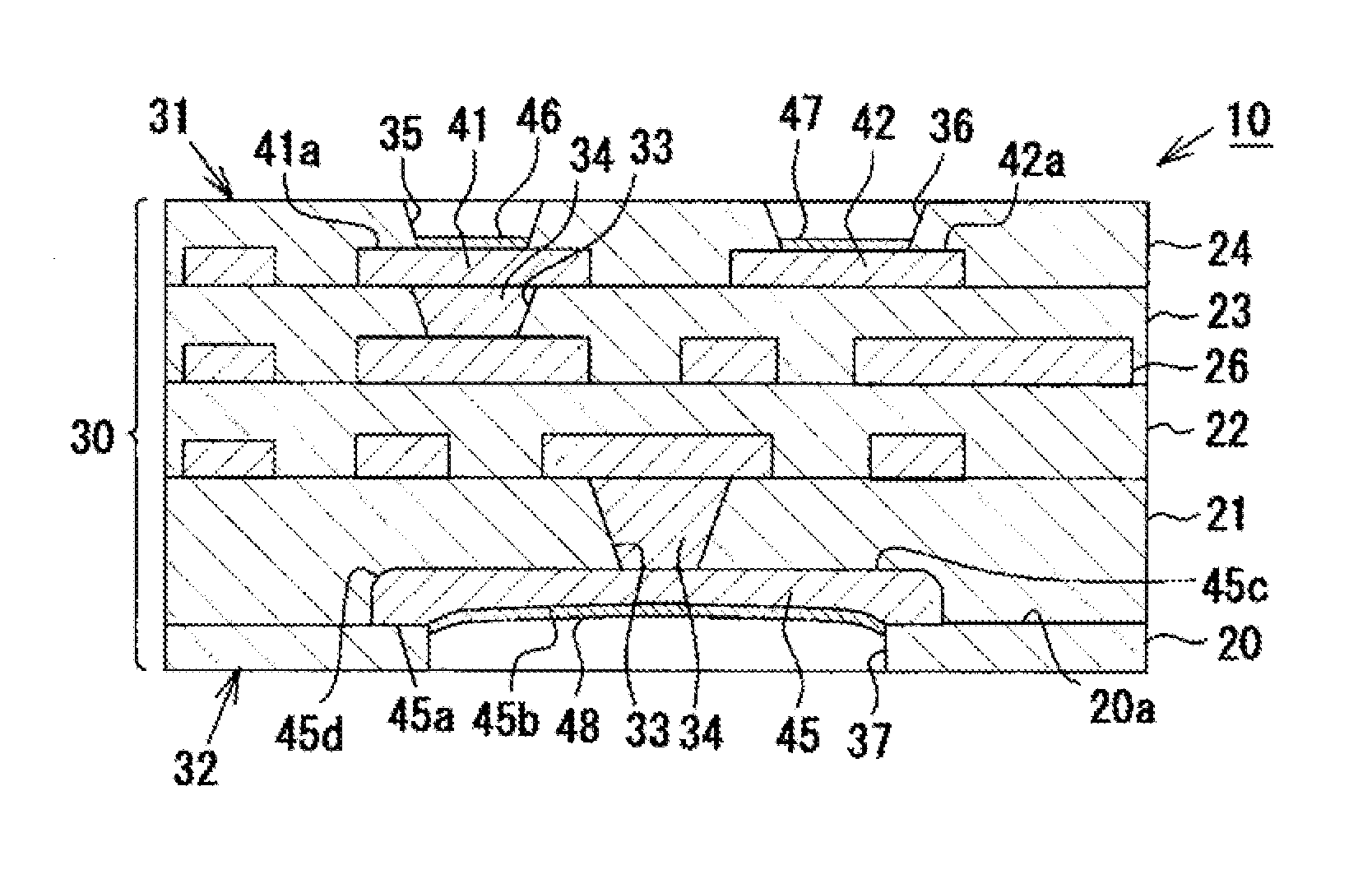

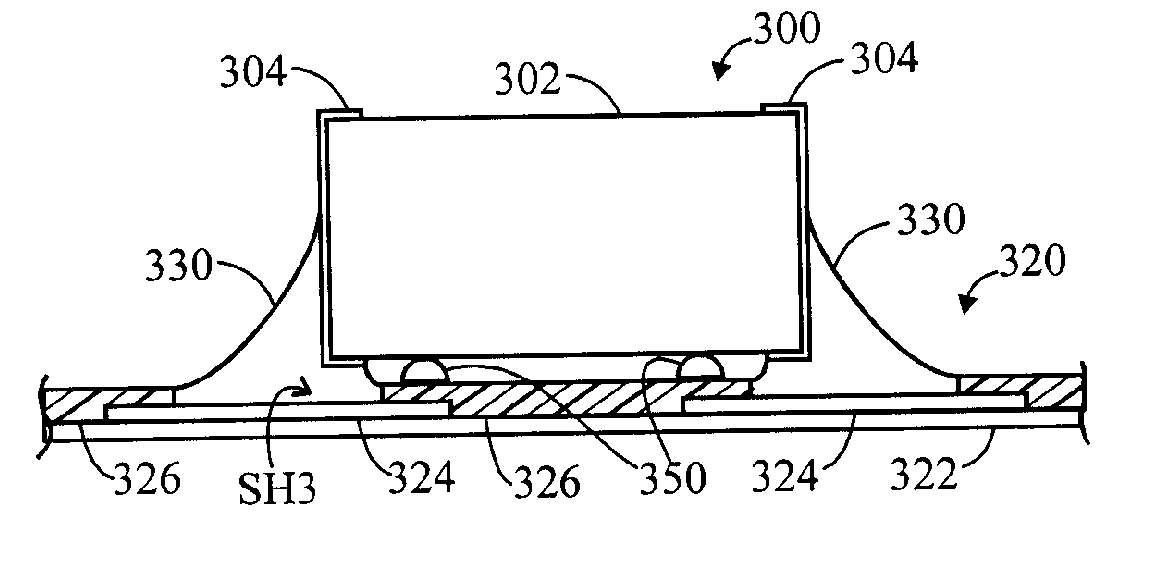

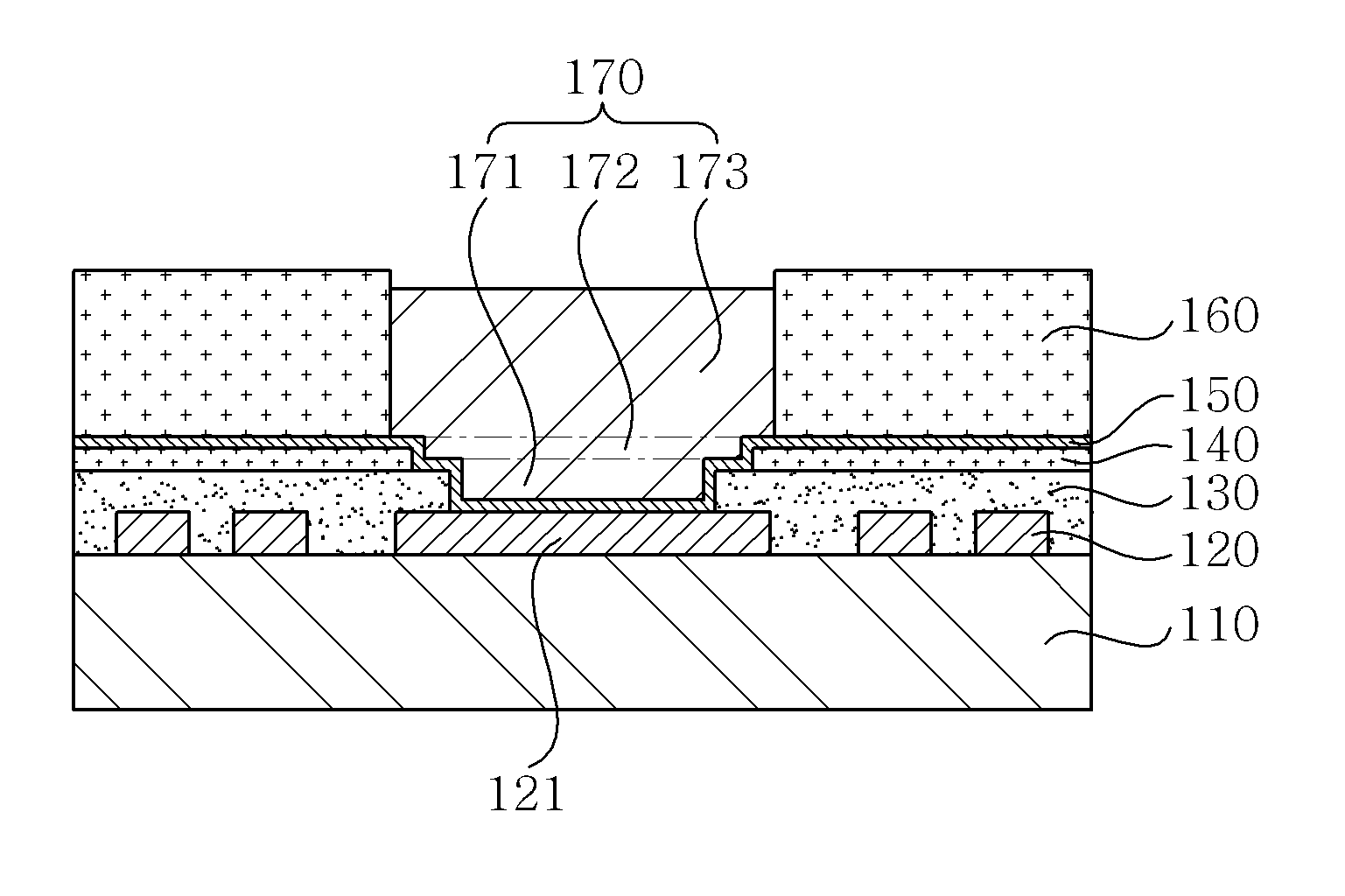

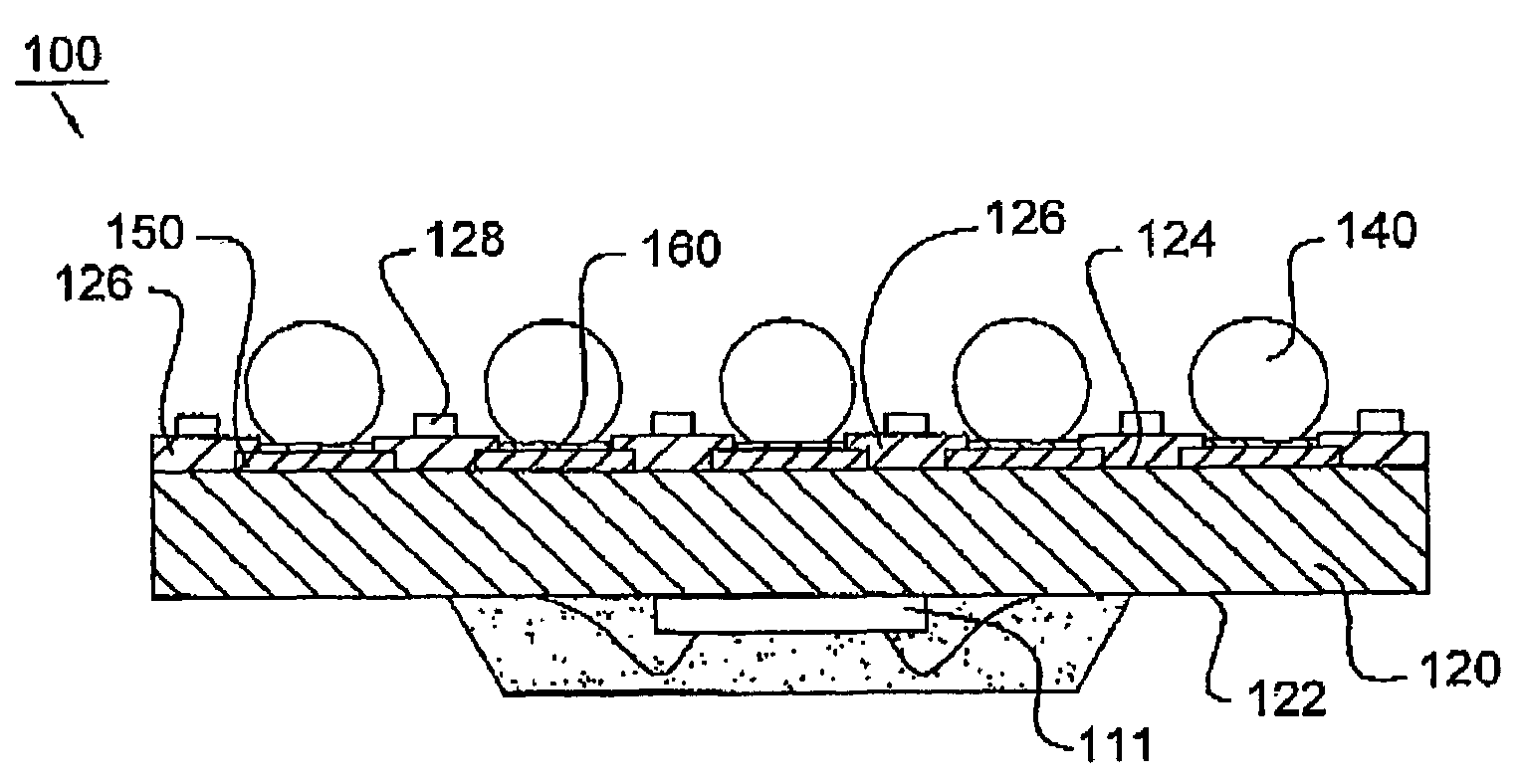

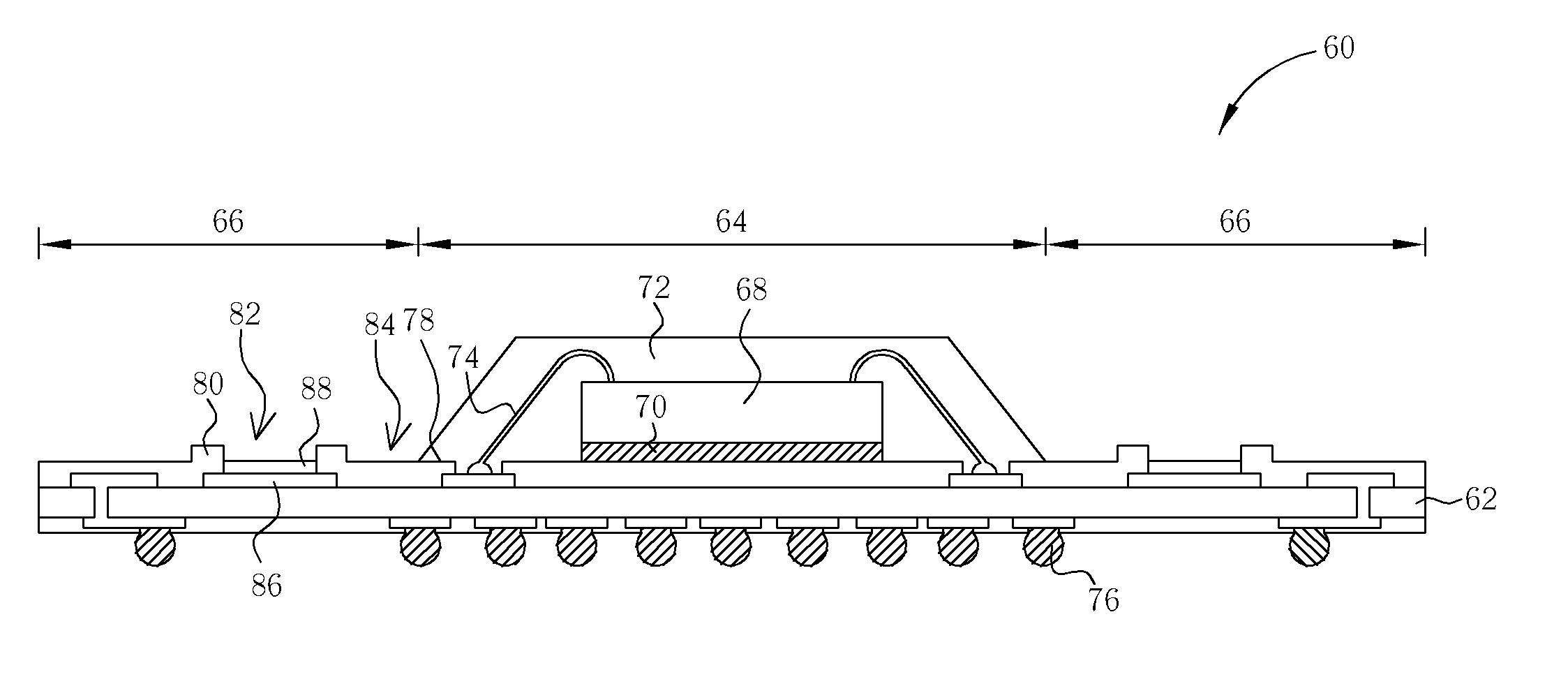

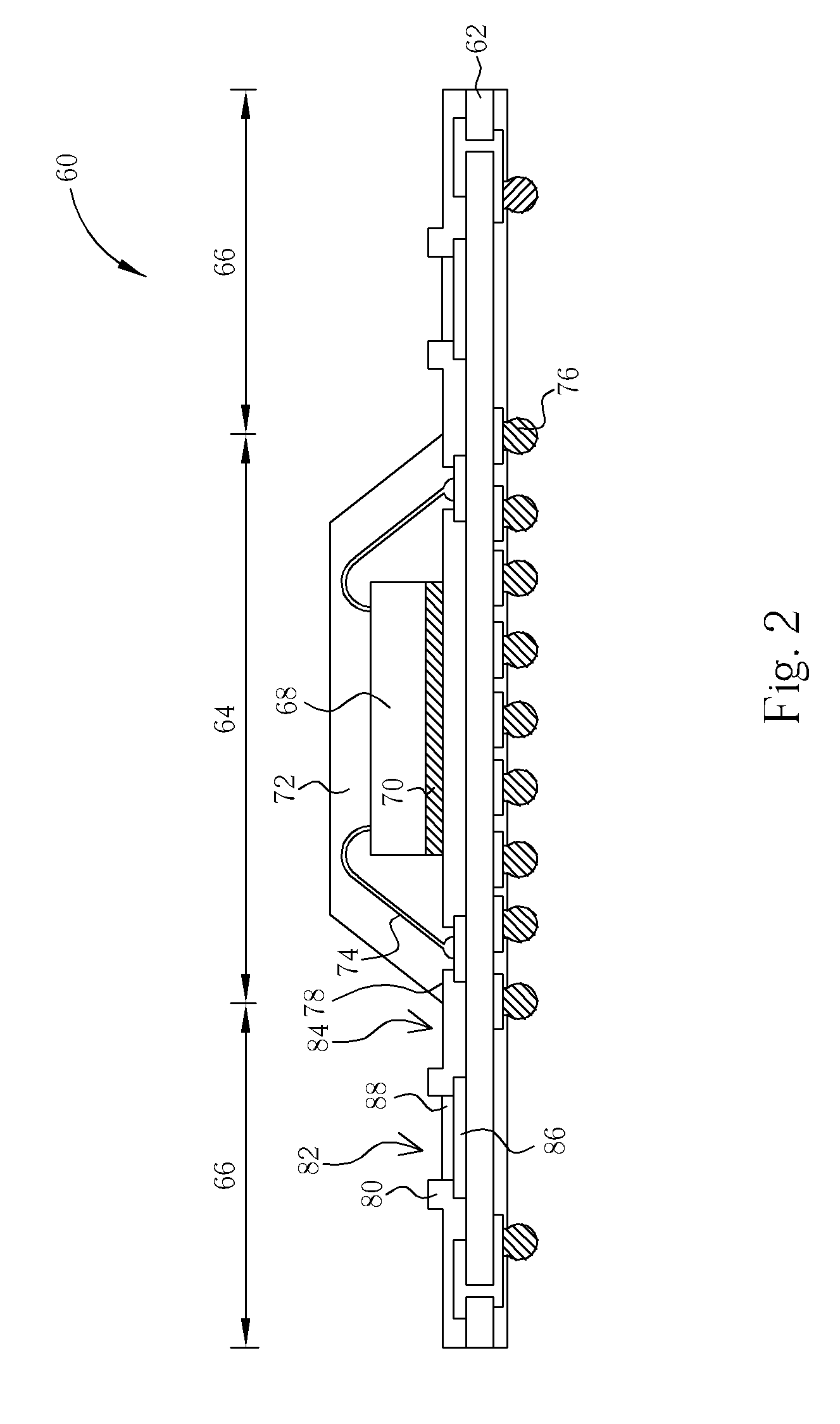

System-in-package structure

ActiveUS20070132093A1High yieldImprove stabilitySecond resist patternSemiconductor/solid-state device detailsSolder maskEngineering

A system-in-package structure includes a carrier substrate having a molding area and a periphery area, at least a chip disposed in the molding area, an encapsulation covering the chip and the molding area, a plurality of solder pads disposed in the periphery area, and a solder mask disposed in the periphery area and partially exposing the surface of the solder pads. The solder mask includes at least a void therein.

Owner:ADVANCED SEMICON ENG INC

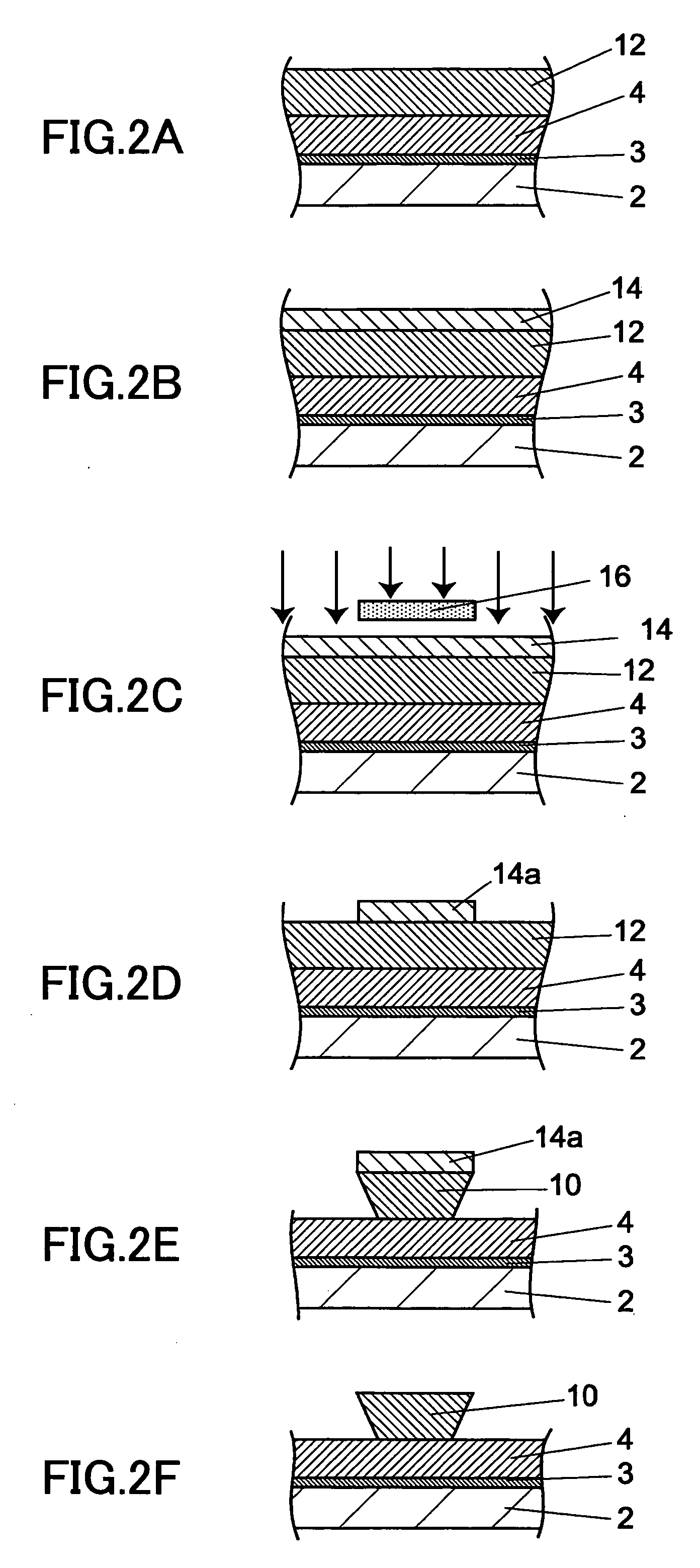

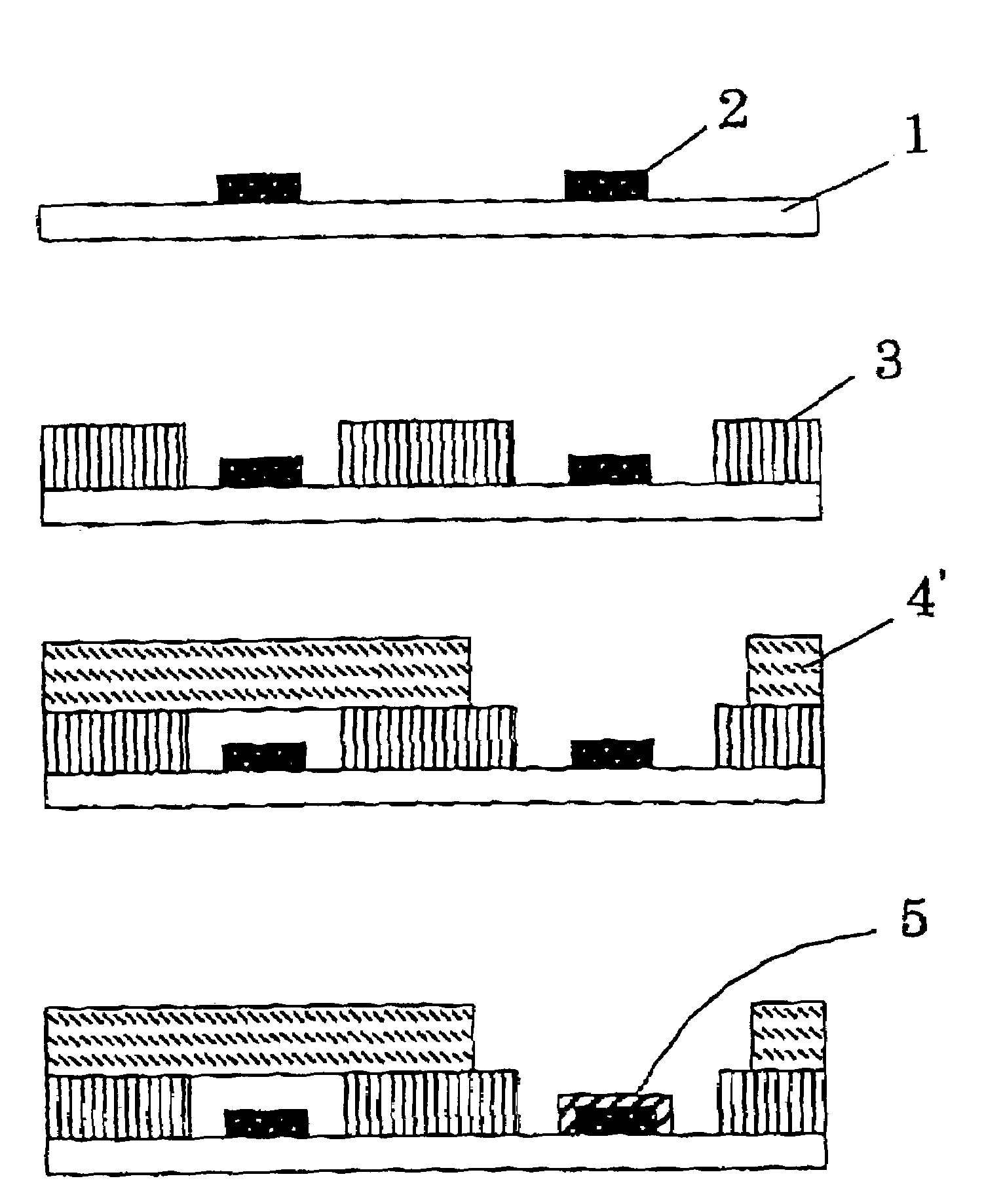

Process for producing printed wiring board and photosensitive resin composition used in the same

InactiveUS7338751B2Improve routing densitySimple stepsPhotosensitive materialsSecond resist patternResistEngineering

An object of the present invention is to provide a process for producing a printed wiring board, which is advantageous not only in that the reduction in size and increase in density of the wiring board are achieved and further the steps are simplified, but also in that the connection reliability of mount parts and the yield are improved, and a photosensitive resin composition used in the process. The present invention is directed to a process for producing a printed wiring board, comprising the steps of: (i) forming a solder resist on a wiring board having a circuit; (ii) laminating a preliminarily molded layer of a photosensitive resin composition on the solder resist; (iii) subjecting the layer of the photosensitive resin composition to exposure and development to form a resist pattern of the photosensitive resin composition; (iv) subjecting the entire surface of the resultant board to electroless plating, and (v) stripping the layer of the photosensitive resin composition, wherein the steps are conducted in this order, as well as a photosensitive resin composition and the layer thereof used in the process.

Owner:HITACHI CHEM CO LTD

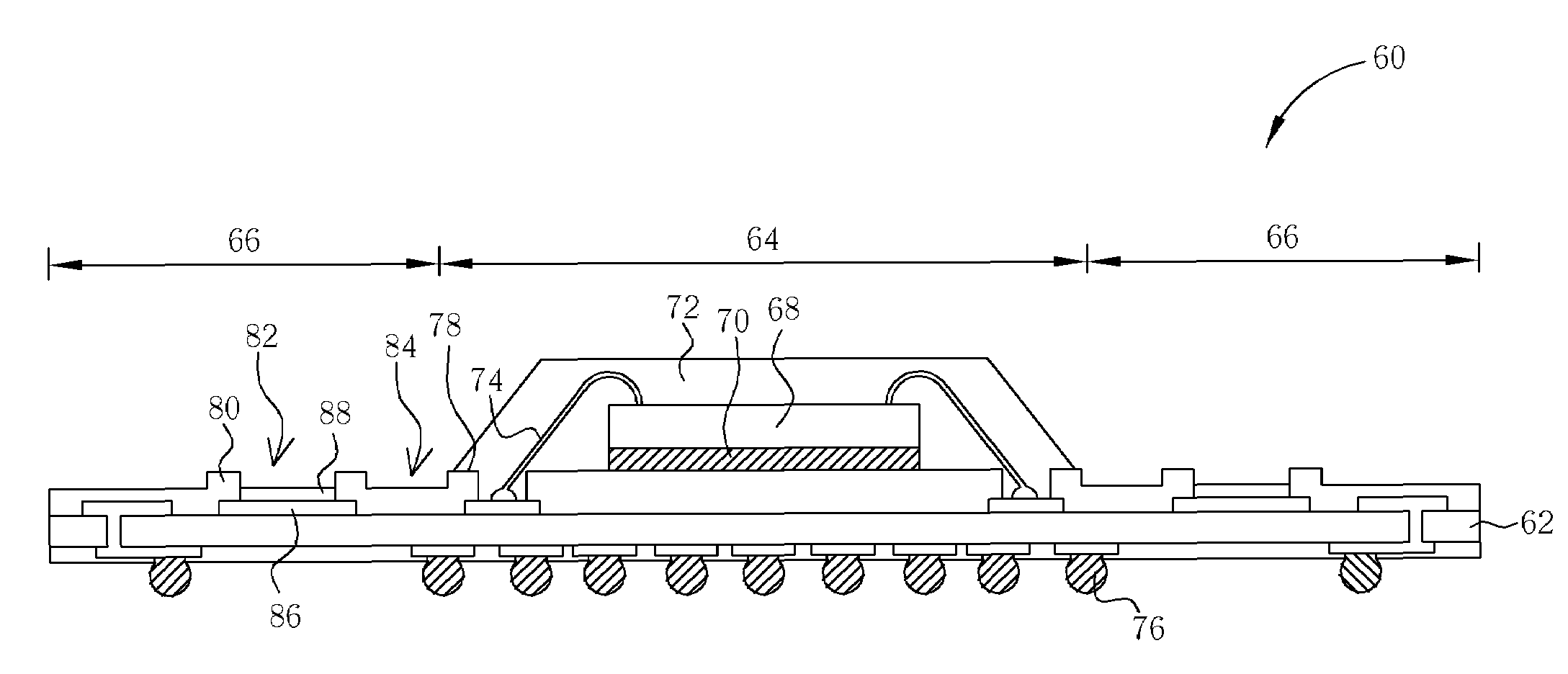

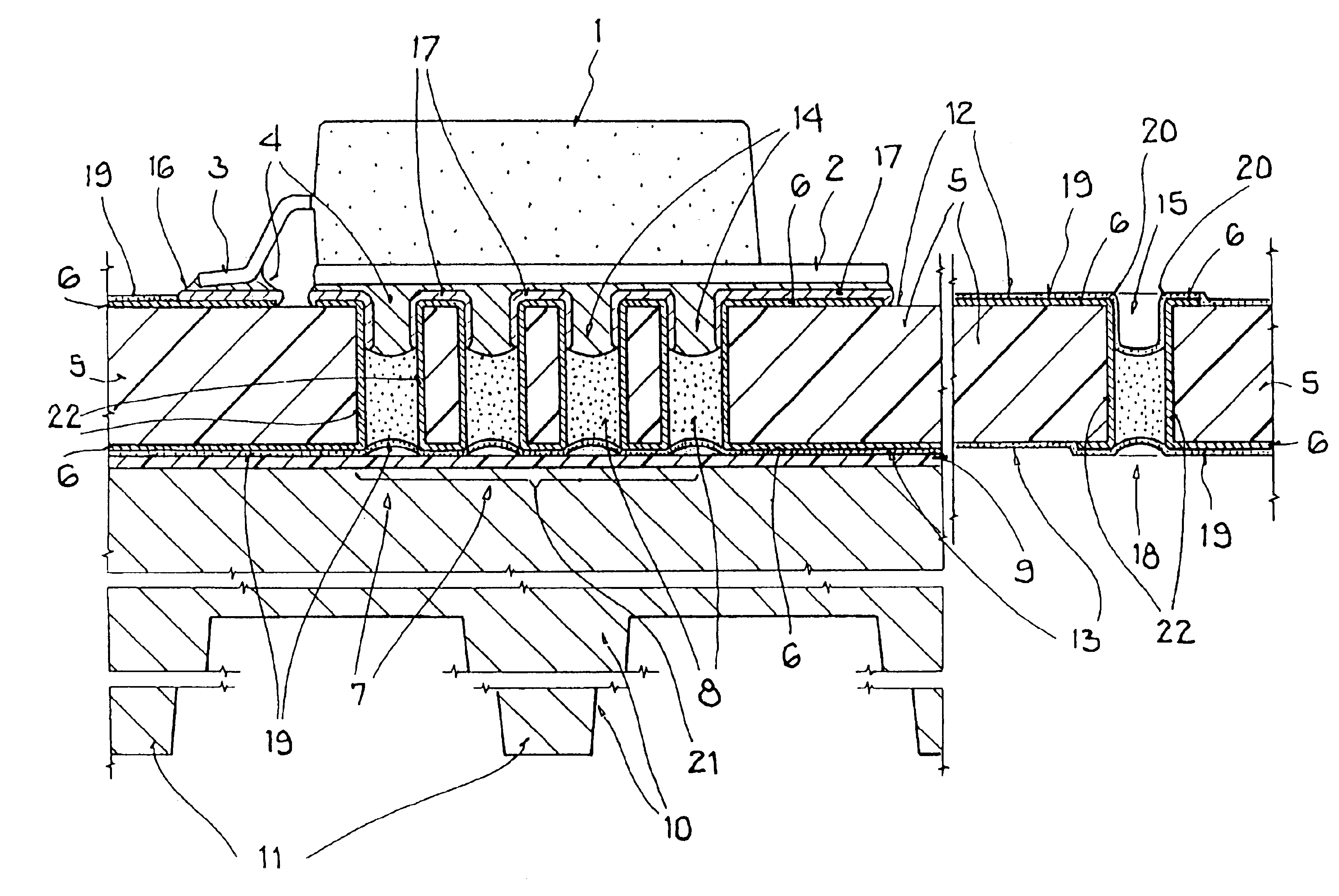

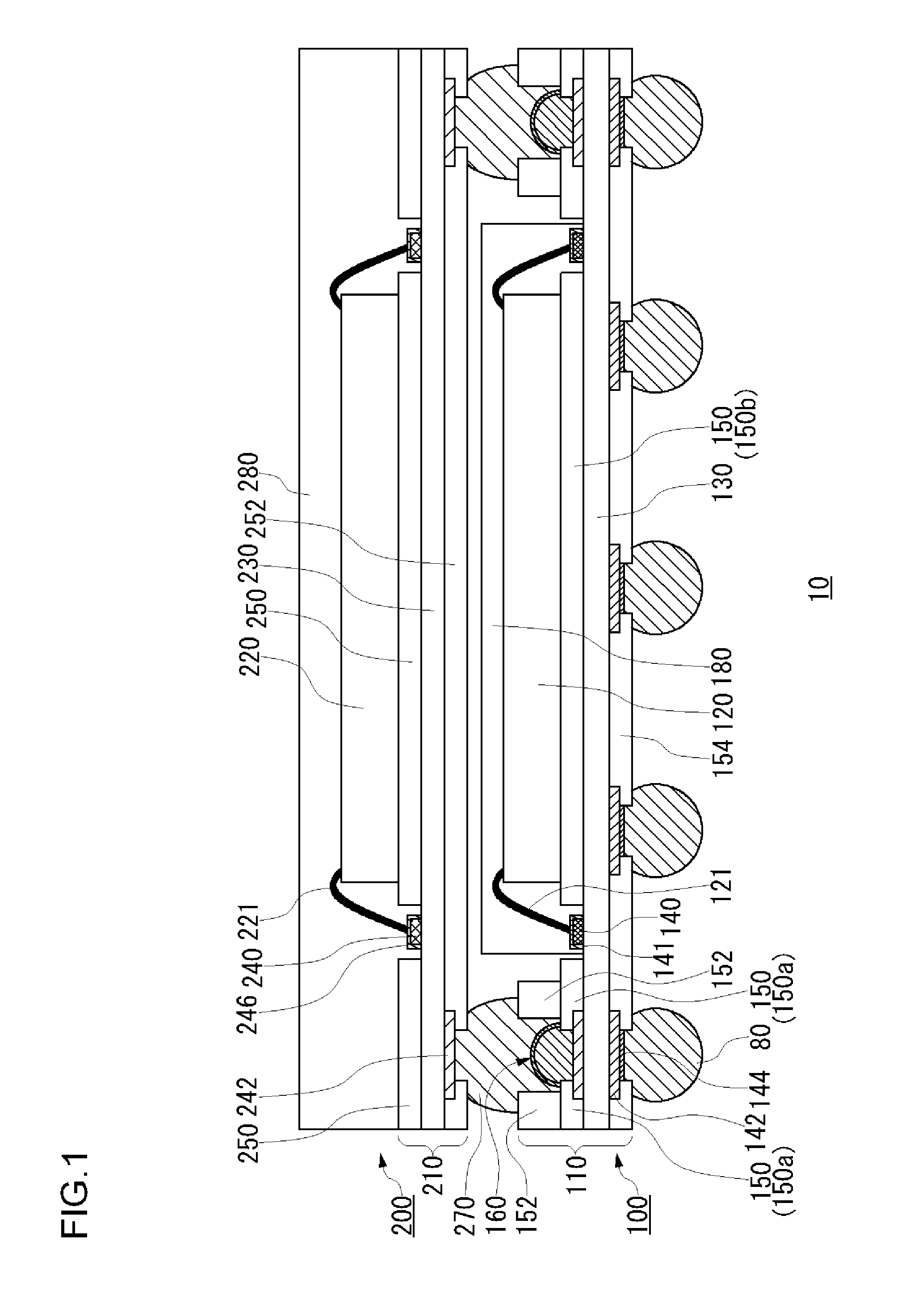

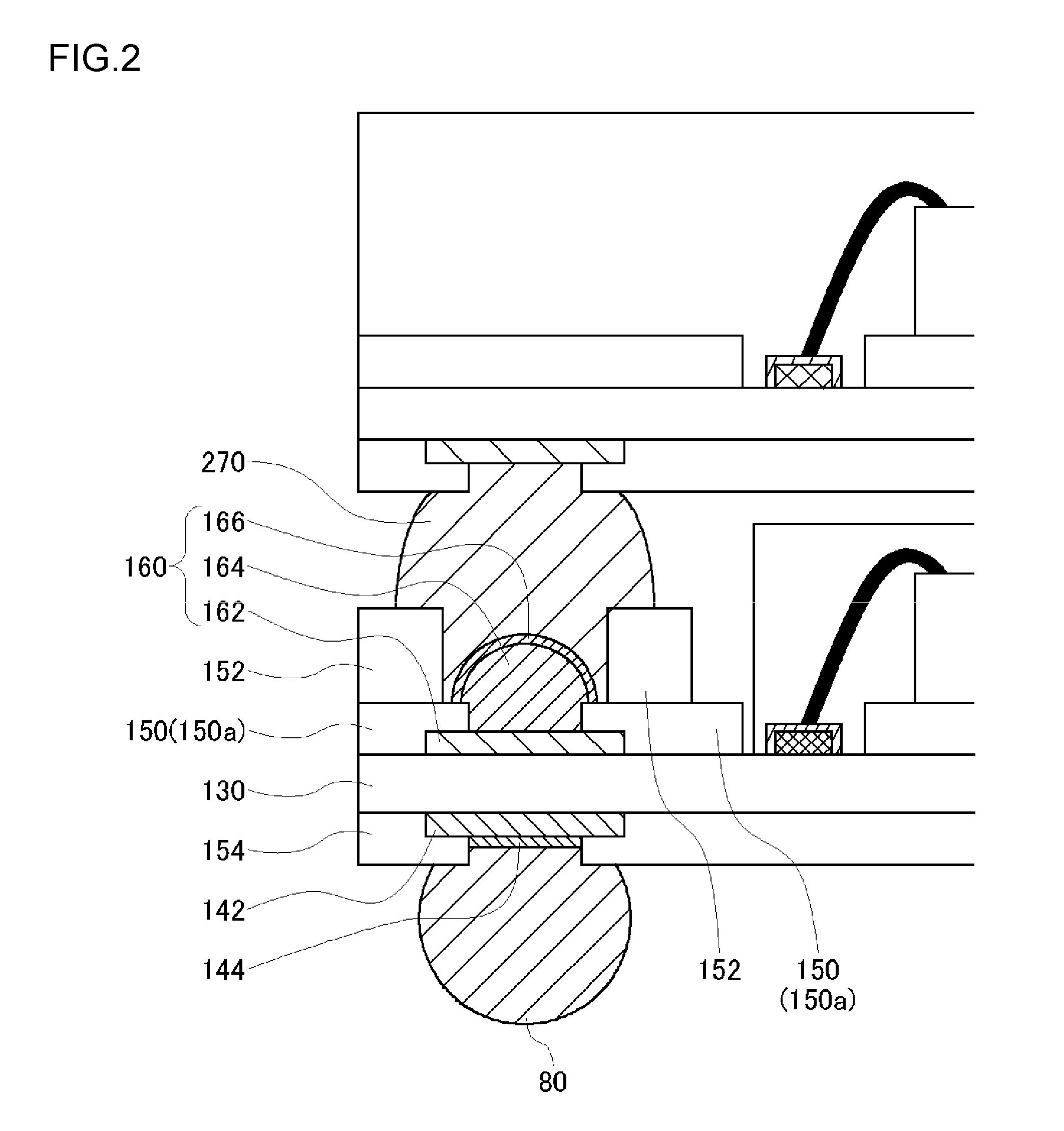

Device mounting board and semiconductor module

InactiveUS20110100696A1Improve connection reliabilityFirmly connectedElectrically conductive connectionsSecond resist patternSolder ballComputer module

A semiconductor device is of a PoP structure such that first electrode portions provided on a first device mounting board constituting a first semiconductor module and second electrode portions provided in a second semiconductor module are joined together by solder balls. A first insulating layer having an opening is provided on one main surface of an insulating resin layer which is a substrate, and an electrode portion, whose top portion protrudes above the top surface of the first insulating layer, is formed in the opening. A second insulating layer is provided on top of the first insulating layer in the periphery of the top portion of the first electrode portion; the second insulting layer is located slightly apart from the top portion of the first electrode portion. The first electrode portion is shaped such that the top portion is formed by a curved surface or formed by a curved surface and a plane surface smoothly connected to the curved surface.

Owner:SANYO ELECTRIC CO LTD

Wiring substrate and method of manufacturing same, and display device

InactiveUS20090026462A1Increase tolerance rangeSecond resist patternPrinted circuit aspectsDisplay deviceEngineering

Owner:MITSUBISHI ELECTRIC CORP

Contact made of ceramic and its manufacturing method

InactiveUS20080293263A1Avoid YieldCoupling device connectionsContact member manufacturingProbe cardRoom temperature

A contact of the invention includes a spring portion and a conductive portion. The spring portion is formed on the surface of a wiring substrate of a probe card, using ceramic. The conductive portion is formed thinly so as to cover at least the surface of the spring portion that faces the bump. Thus, as one of the features of a manufacturing method of the contact, the spring portion is formed at room temperature by an aerosol deposition method.

Owner:ALPS ALPINE CO LTD

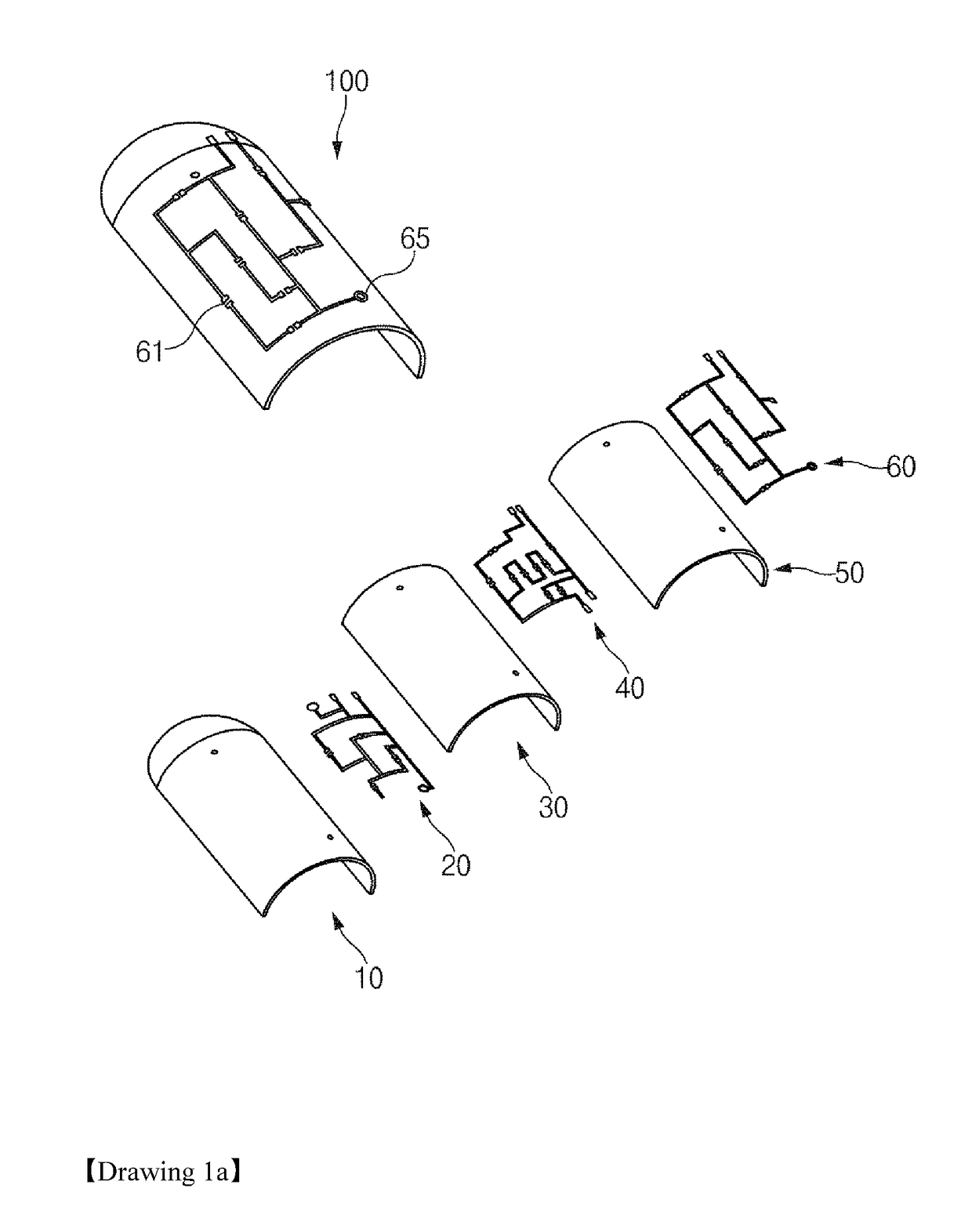

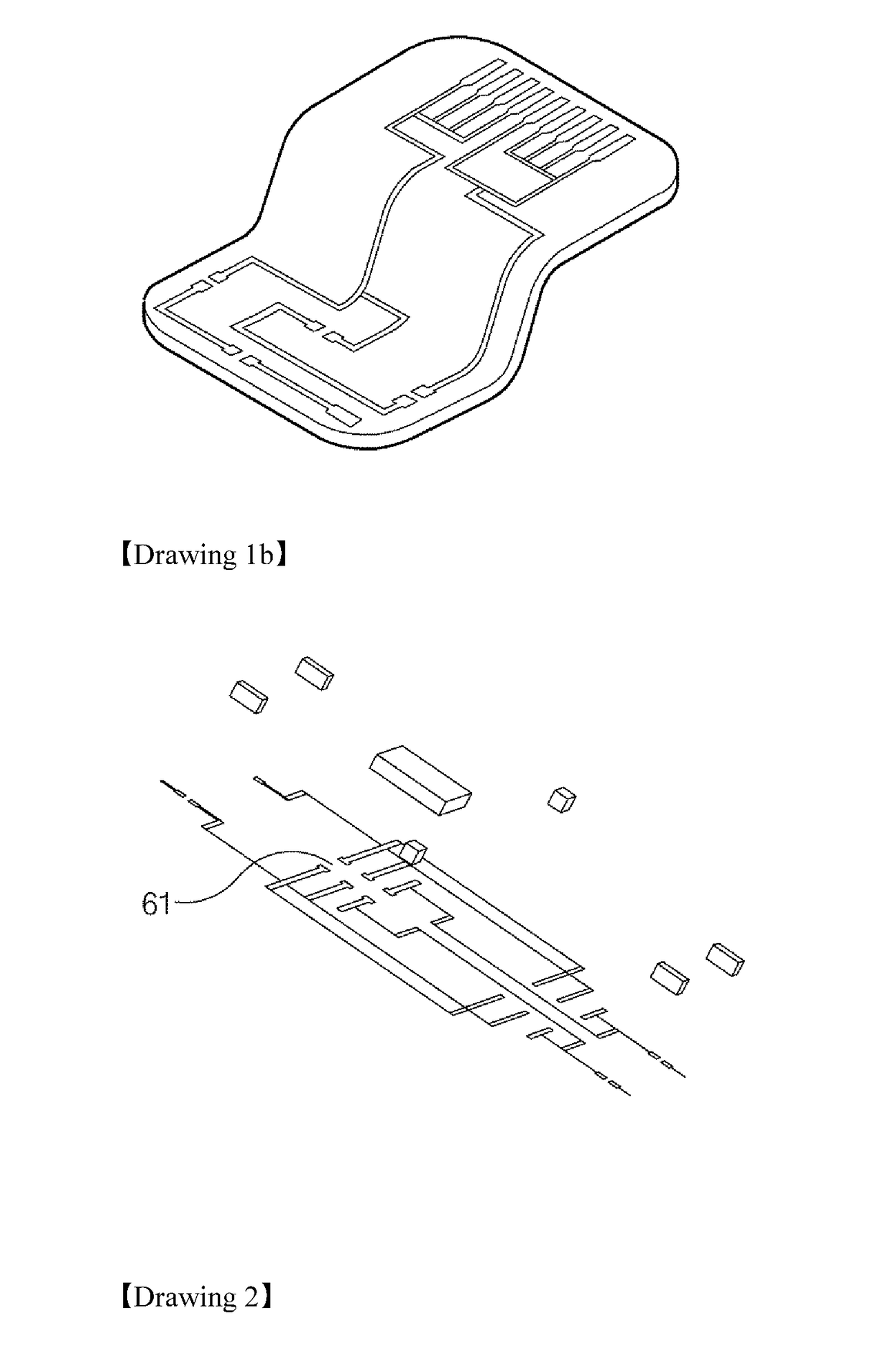

Method for manufacturing a circuit having a lamination layer using laser direct structuring process

ActiveUS20170094801A1Delay manufacturing processEfficient use ofResist coatingSecond resist patternEngineeringInjection moulding

The present disclosure relates to the method of manufacturing circuit having lamination layer using LDS (Laser Direct Structuring) to ease the application on surface structure for applied product of various electronic circuit and particularly, in which can form circuit structure of single-layer to multiple-layer on the surface of injection-molded substrate in the shape of plane or curved surface, metal product, glasses, ceramic, rubber or other material.

Owner:KYOCERA AVX COMPONENTS (SAN DIEGO) INC

Module circuit board for semiconductor device having barriers to isolate I/O terminals from solder

A module circuit board for a semiconductor device by a solder reflow process includes a plurality of pads on which the semiconductor device to be mounted, a plurality of terminals formed on a side edge of the board, a resist film covering an area between said pads and said terminal on the board, and a barrier formed between said pads and said terminals.

Owner:LAPIS SEMICON CO LTD

Printed circuit board and its designing method, and designing method of IC package terminal and its connecting method

InactiveUS8097815B2Low costPrinted circuit assemblingSecond resist patternSolder ballPrinted circuit board

The invention provides a printed circuit board capable of mounting BGA or other IC package of narrow terminal interval by using through-holes of conventional size. On one principal surface of printed circuit board (1), soldering lands (2a), (2b), (2c), and (2d) for connecting solder balls are disposed in lattice. Central point (B) of through-hole (3) is set eccentric to the side of soldering land (2a) at the same potential as through-hole (3), remote from intersection (A) formed by diagonal line (200ab) linking soldering lands (2a) and (2b) and diagonal line (200cd) linking soldering lands (2c) and (2d).

Owner:PANASONIC CORP

Wiring board and manufacturing method thereof

ActiveUS8304663B2Excellent electric connection reliabilityForming accuratelySecond resist patternPrinted electric component incorporationResistElectrical conductor

Owner:KYOCERA CORP

Wiring board

ActiveUS20150027750A1Reduce spacingPrevent short-circuitingPrinted circuit assemblingSecond resist patternInsulation layerElectrical conductor

To provide a wiring substrate which can prevent short circuit between connection terminals, and which realizes reduction of the pitch between the connection terminals. The wiring substrate of the present invention includes a layered structure including one or more insulation layers and one or more conductor layers, and the wiring substrate is characterized in that a plurality of connection terminals are formed on the layered structure so as to be separated from one another; a filling member is filled between the connection terminals; and each of the connection terminals has a side surface composed of a contact surface which is in contact with the filling member, and a spaced surface which is not in contact with the filling member and which is located above the contact surface and below the top surface of the filling member.

Owner:NGK SPARK PLUG CO LTD

Popular searches

Semiconductor/solid-state device manufacturing Electrical connection printed elements Circuit susbtrate materials Semiconductor devices Multilayer circuit manufacture Metallic pattern materials Liquid/solution decomposition chemical coating Solid/suspension decomposition chemical coating Special surfaces Surface layering apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com