Method for mfg. printed wiring board and photosenstive resin compsn. to be used for it

A technology of photosensitive resin and printed circuit board, which is applied in the field of photosensitive resin composition, and can solve problems such as many processes, no effective solution has been established, and low reliability of solder ball welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

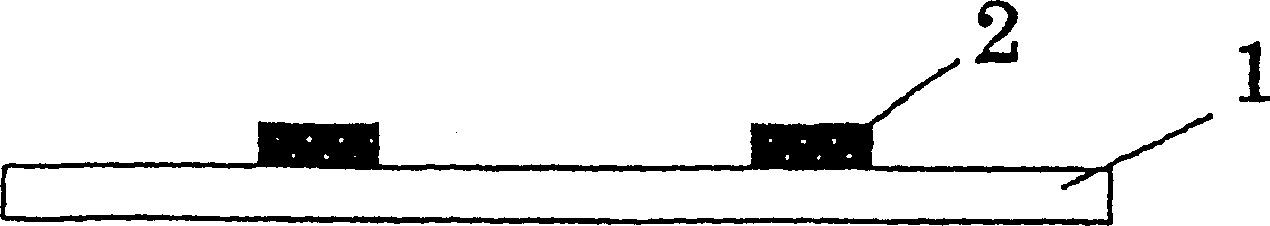

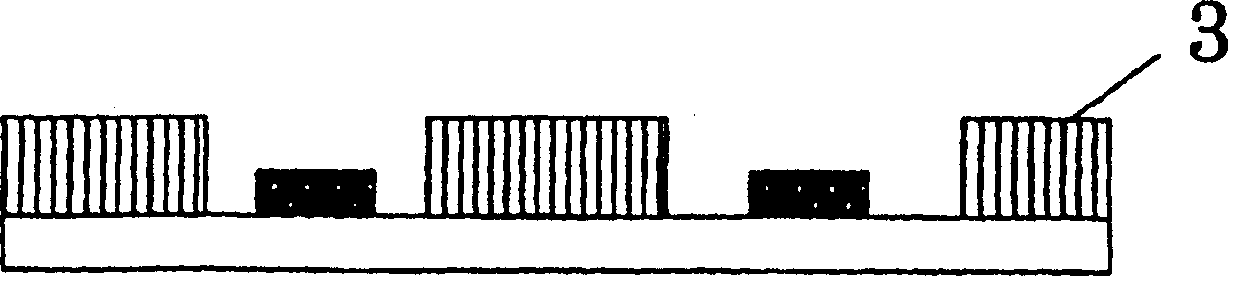

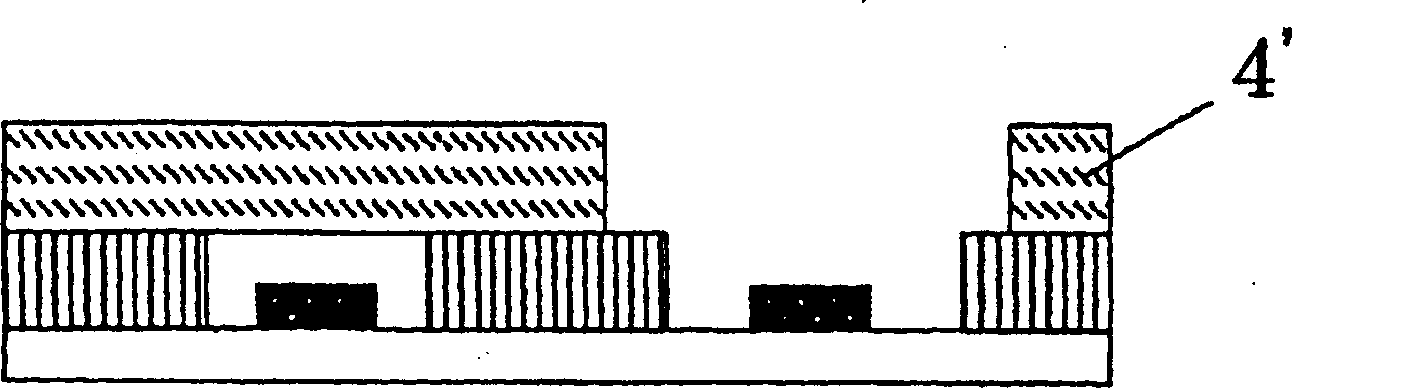

Method used

Image

Examples

Embodiment

[0085] Hereinafter, the present invention will be more specifically described by way of examples of the present invention and comparative examples thereof, but the present invention is not limited to these examples.

[0086] Synthesis of binder polymer

[0087] In the flask that is equipped with stirrer, reflux cooler, thermometer, dropping funnel and nitrogen inlet tube, add the ethylene glycol monomethyl ether of 700 grams to the mixed solution (hereinafter referred to as solution A) of 3: 2 for the weight ratio of toluene, while Blow in nitrogen gas and heat to 85°C while stirring. Add 110 grams of methacrylic acid, 225 grams of methyl methacrylate, 135 grams of ethyl acrylate, 30 grams of styrene, and 3 grams of azobisisobutyronitrile into the solution A at 85 °C for 4 hours. , and then kept stirring at 85°C for 2 hours. Then, 60 g of the solution A was taken, 0.3 g of azobisisobutyronitrile was dissolved therein, and the solution was dropped into the flask over 10 minut...

example 1

[0100] (a) With the material formulation shown in Table 1, the photosensitive resin composition solution of the present invention was obtained.

[0101] (b) On a polyethylene terephthalate film (hereinafter referred to as PET) of a size (380 mm in width x 20 microns in thickness), apply the solution of the photosensitive resin composition obtained in the previous process until it dries. The film thickness was 50 micrometers. Then, it was dried at 100° C. using a hot-air convection dryer, and a polyethylene film having a thickness of 35 μm was placed thereon, and coated with pressure with a roll to obtain the photosensitive element of the present invention.

example 2~12

[0103] A photosensitive member of the present invention was obtained as in Example 1 except that the composition formula shown in Table 1 was replaced.

[0104] In Table 1, the formulation of the photosensitive resin composition of Examples 1-12 is shown. In the table, the unit is parts by weight. Binder polymer is expressed by weight of non-volatile matter.

[0105] example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

Example 9

Example 10

Example 11

Example 12

binder polymer

60

60

60

60

60

60

60

60

60

60

60

60

bisphenol A polyethylene oxide

dimethacrylic acid

Esters (BPE-500)

-

-

-

-

-

20

-

-

-

20

-

-

bisphenol A polyethylene oxide

dimethacrylic acid

Esters (BPE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com