Printed wiring board and method for manufacturing same

A technology for printed circuit boards and wiring patterns, applied in printed circuit manufacturing, printed circuits, secondary processing of printed circuits, etc. properties, bleed-out suppression, and effects of improving plating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

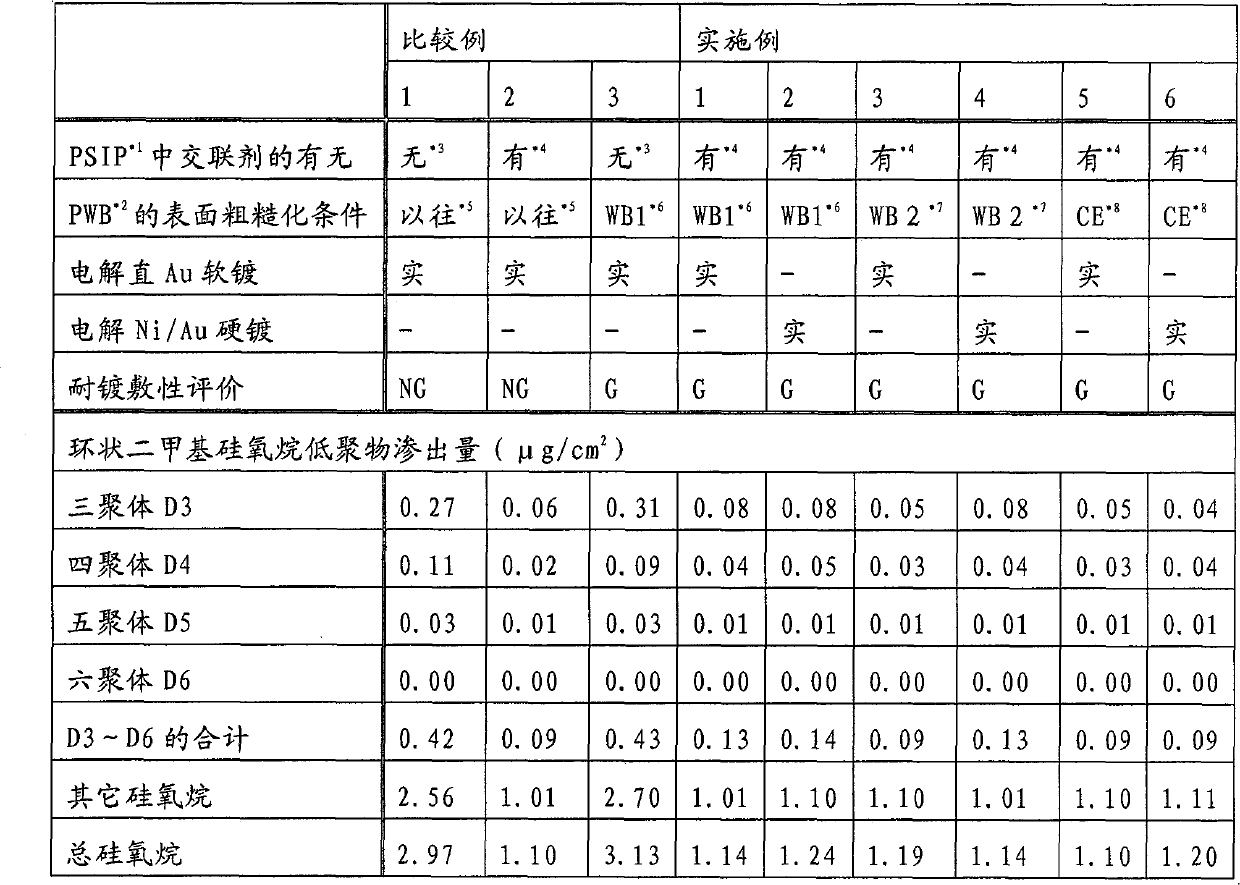

[0072] Hereinafter, the present invention will be specifically described by way of examples.

reference example 1

[0073] Reference Example 1 (Photosensitive Silicone Polyimide Resin Composition Containing a Crosslinking Agent)

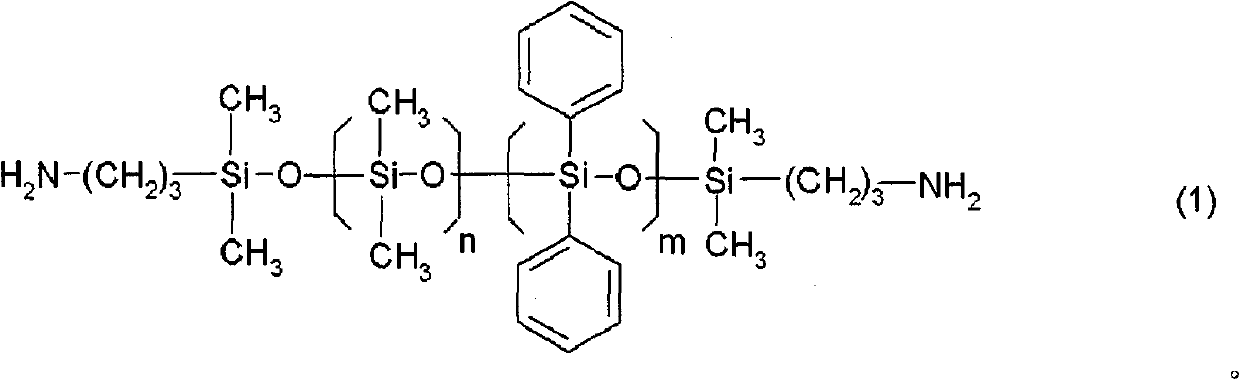

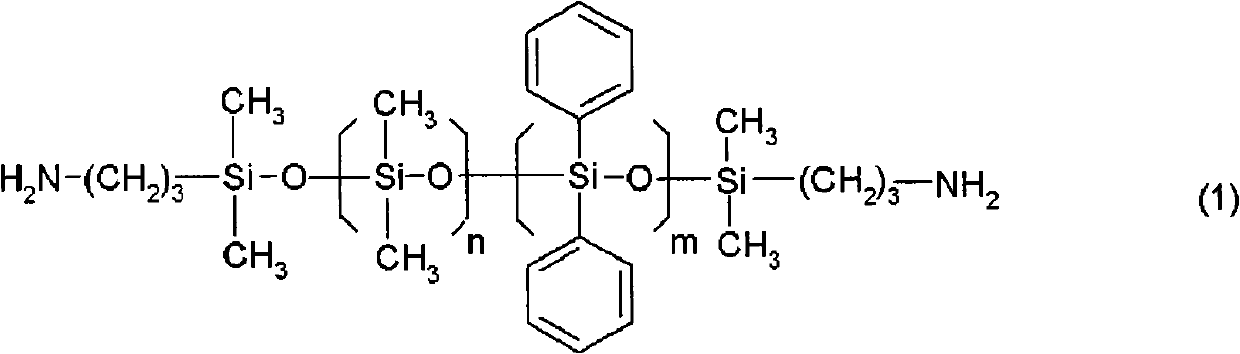

[0074] (1) Manufacture of siloxane polyimide resin

[0075] In the reaction vessel of the polyimide resin synthesis device equipped with Dean-Stark (Dean-Stark), drop 862.65g (0.639mol) of diaminosiloxane (diaminodiphenyl / dimethyl Siloxane (amine equivalent: 675 g / mol, trade name: X-22-9409, manufactured by Shin-Etsu Chemical Co., Ltd.), 363.6 g (1.01 mol) of 3,3',4,4'-diphenylsulfone tetracarboxylate Acid dianhydride (リカシツドDSDA, manufactured by Nippon Physical and Chemical Co., Ltd., purity 99.6%), the triglyme of 547g and the toluene of 200g, the mixture was fully stirred for 2 hours. Then, the temperature was raised to 185° C., and kept at this temperature For 2 hours, the reaction solution was stirred under reflux while recovering water with a Dean-Stark.

[0076] The obtained reaction mixture was applied to a silicon wafer from which the oxide film had been...

reference example 2

[0080] Reference Example 2 (Photosensitive silicone polyimide resin composition without crosslinking agent)

[0081] Except liquid epoxy resin (jER807, Japan Epoxy Resin Co.), benzo Except for oxazine (BF-BXZ, Konishi Chemical Co., Ltd.) and resole phenolic resin (BRL-274, Showa Polymer Co., Ltd.), a siloxane polyimide resin was obtained in the same manner as in Reference Example 1, and a photosensitive silicone resin was obtained. Alkane polyimide resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com