Photosensitive siloxane polyimide resin composition

A technology of siloxane polyimide resin and siloxane diamine is applied in the field of inhibiting the exudation of cyclic dimethylsiloxane oligomers from the protective layer of printed wiring boards, and can solve the problem that the dimethicone cannot be sufficiently removed. Methylsiloxane oligomer and other problems, to achieve the effect of suppressing bleeding and good plating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

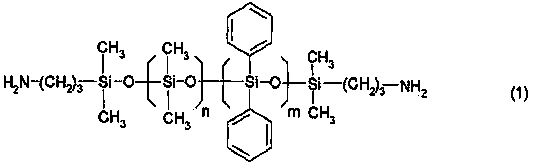

[0055] (1) Preparation of siloxane polyimide resin

[0056] Drop into the diaminosiloxane (diaminodiphenyl / dimethylsiloxane) of 862.65g (0.639mol) in the reaction vessel of the polyimide resin synthetic device that has Dean-Stark trap (Amino equivalent: 675 g / mol), trade name: X-22-9409, manufactured by Shin-Etsu Chemical Co., Ltd.), 363.6 g (1.01 mol) of 3,3'4,4'-diphenylsulfone tetracarboxylic dianhydride (Rikasid DSDA, manufactured by Nippon Chemical Co., Ltd., purity 99.6%), 547 g of triglyme, and 200 g of toluene, and the mixture was fully stirred for 2 hours. Then, the temperature was raised to 185° C., and the temperature was maintained for 2 hours. While recovering water with a Dean-Stark trap, the reaction solution was refluxed and stirred.

[0057] The obtained reaction mixture was coated on a silicon wafer from which the oxide film was removed, dried at 100° C. for 10 minutes, and the terminal functional group was identified by the FT-IR transmission method. at 17...

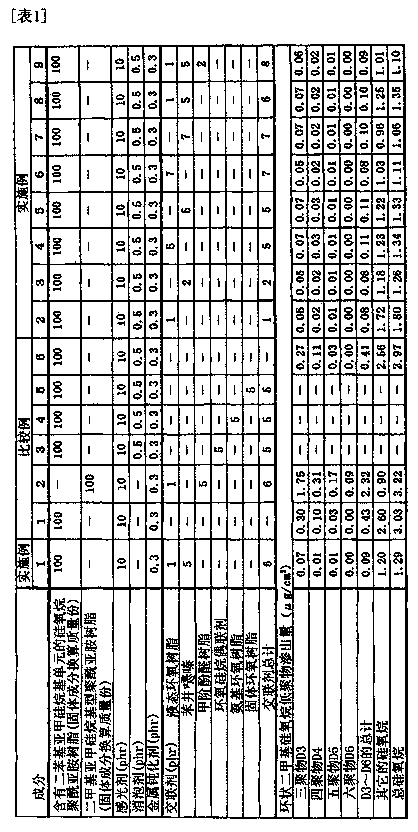

Embodiment 2~9 and comparative example 6

[0078] In order to study the influence of the addition amount of a crosslinking agent, Examples 2-9 and Comparative Example 6 (example which did not use a crosslinking agent) were performed.

[0079] (1) Preparation of siloxane polyimide resin

[0080] A siloxane polyimide resin was prepared in the same manner as in Example 1.

[0081] (2) Preparation of photosensitive siloxane polyimide resin composition

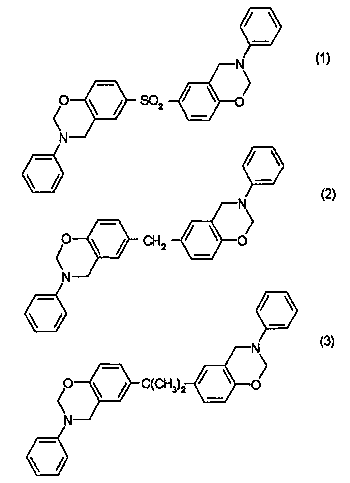

[0082] In the varnish of silicone polyimide resin, add photosensitive agent (4NT-300, Toyo Gosei Kogyo Co., Ltd.) 10phr, defoamer (FA-600, Shin-Etsu Chemical Co., Ltd.) 0.5phr, metal deactivator (Rust preventive agent) (CDA-10, ADEKA Co., Ltd.) 0.3phr, liquid epoxy resin (jER807, Japan Epoch Resin Co., Ltd.), bisphenol F type benzo Oxyzine (BF-BXZ, manufactured by Konishi Chemical Industry Co., Ltd.) and / or a resole phenolic resin (BRL-274, manufactured by Showa High Molecular Co., Ltd.) were uniformly mixed at room temperature to obtain a photosensitive silicone polyimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com