Photosensitive composition, photosensitive film, photosensitive laminate, permanent pattern forming method, and printed substrate

A kind of photosensitive composition, photosensitive layer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

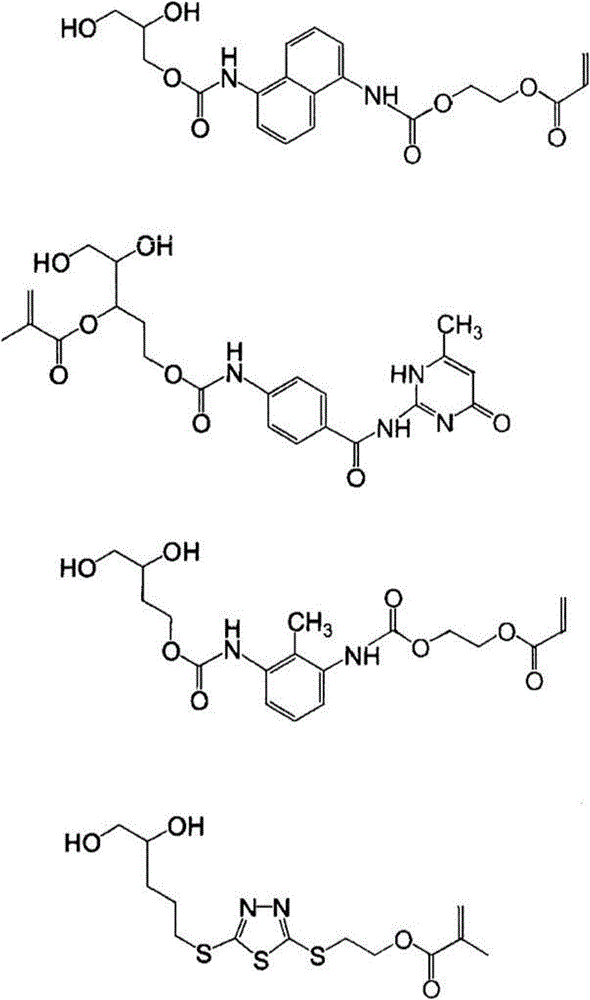

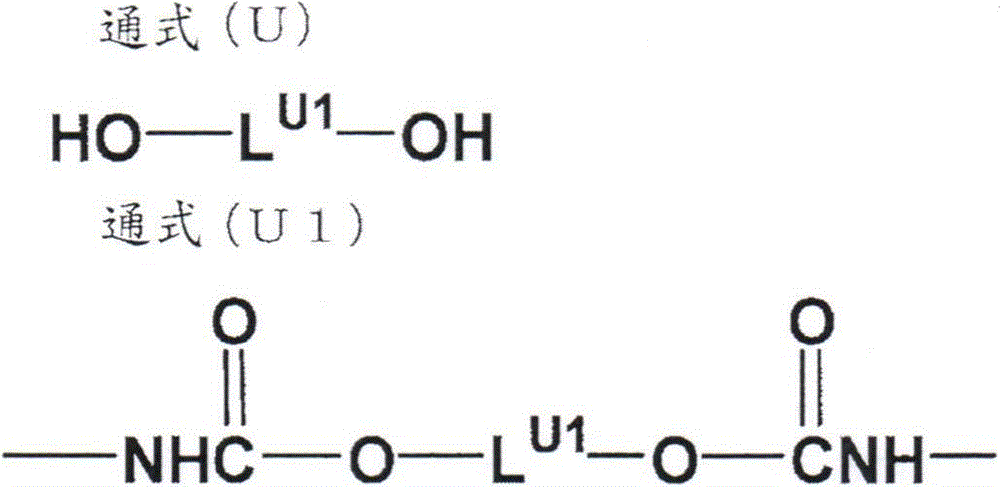

Method used

Image

Examples

example

[0259] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited by these examples at all. In addition, "parts" in the examples means "parts by weight".

[0260] In addition, the acid value and weight average molecular weight in a preparation example were measured by the following method.

[0261]

[0262] The acid value is measured according to JIS K0070. However, when the sample does not dissolve, dioxane, tetrahydrofuran, or the like is used as a solvent.

[0263]

[0264] The weight average molecular weight is measured using a high-speed GPC apparatus (HLC-802A manufactured by Toyo Soda Co., Ltd.). That is, a 0.5 wt% THF (tetrahydrofuran) solution was used as the sample solution, one TSKgel HZM-M (trade name) was used in the column, 200 μL of the sample was injected, and the THF solution was used to elute the solution at 25. Measured with a refractive index detector at °C. Next, the w...

example 1

[0317] -Manufacture of photosensitive film-

[0318] A photosensitive composition solution containing the following composition was applied on a polyethylene terephthalate film (manufactured by Toray Industries, Ltd., 16FB50) with a thickness of 16 μm as a support, and dried on the support. A photosensitive layer with a thickness of 38 μm was formed. On the photosensitive layer, a 20 μm-thick polypropylene film (manufactured by Oji Special Paper Co., Ltd., ALPHAN E-200) was laminated as a protective layer to produce a photosensitive film.

[0319] -Composition of photosensitive composition solution-

[0320] · Flame retardant dispersion liquid a-3 of Preparation Example 9 ...... 27.06 parts by weight

[0321] · Pigment dispersion liquid of Preparation Example 11 ...... 4.26 parts by weight

[0322] ·The acid-modified ethylenically unsaturated group-containing polyurethane resin U1 solution of Preparation Example 1 (adjusted to a solid concentration of 40%) ……………………………… 6.6...

example 2~ example 3、 comparative example 1~ comparative example 5

[0382] In Example 1, except having replaced the flame retardant dispersion liquid with the flame retardant dispersion liquid described in Table 3, it carried out similarly to Example 1, and obtained the photosensitive composition, the photosensitive film, etc.

[0383] The same evaluation as in Example 1 was performed. The results are shown in Table 3.

[0384] [table 3]

[0385]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com