Patents

Literature

404results about How to "Reduce magnetic field strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

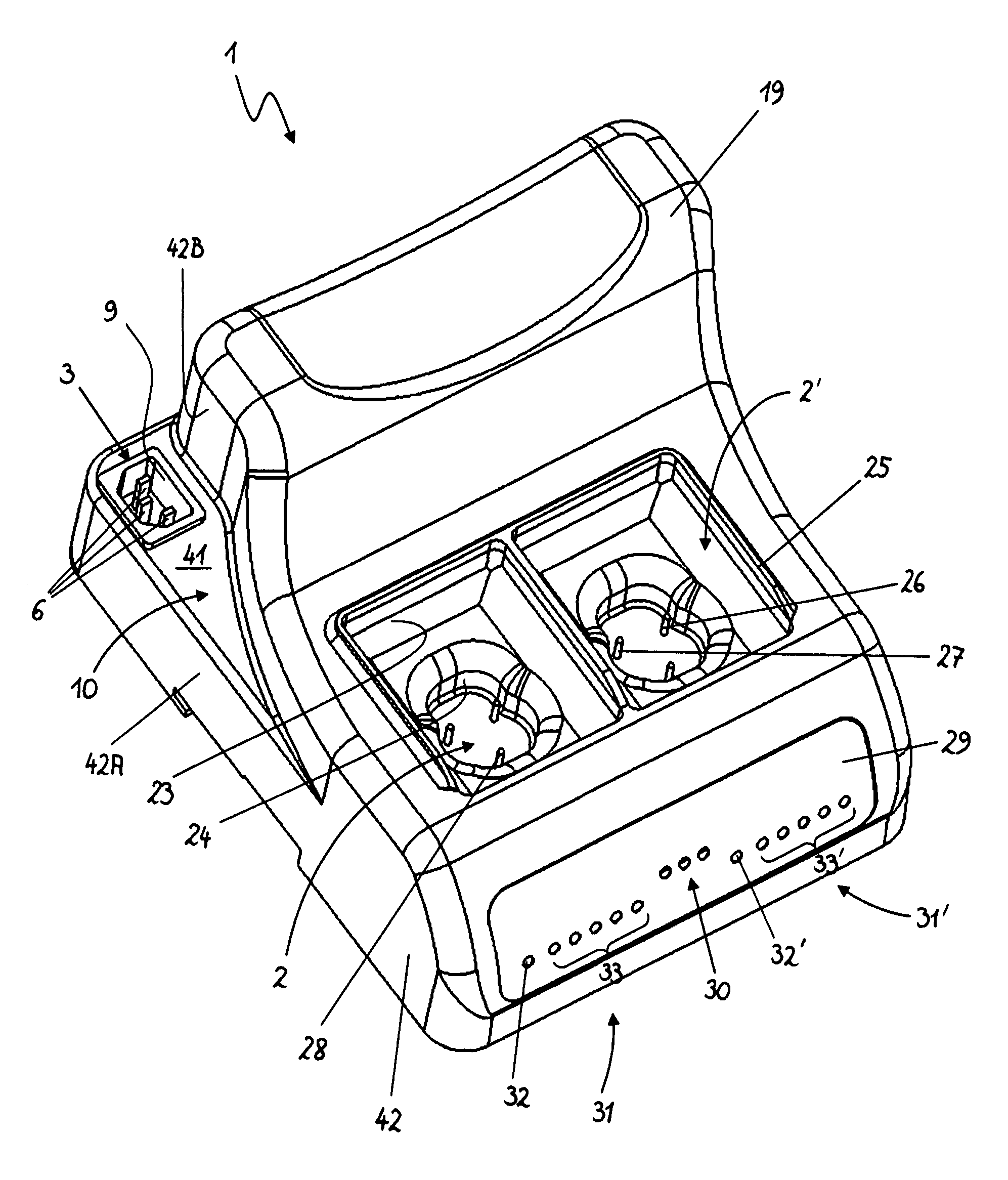

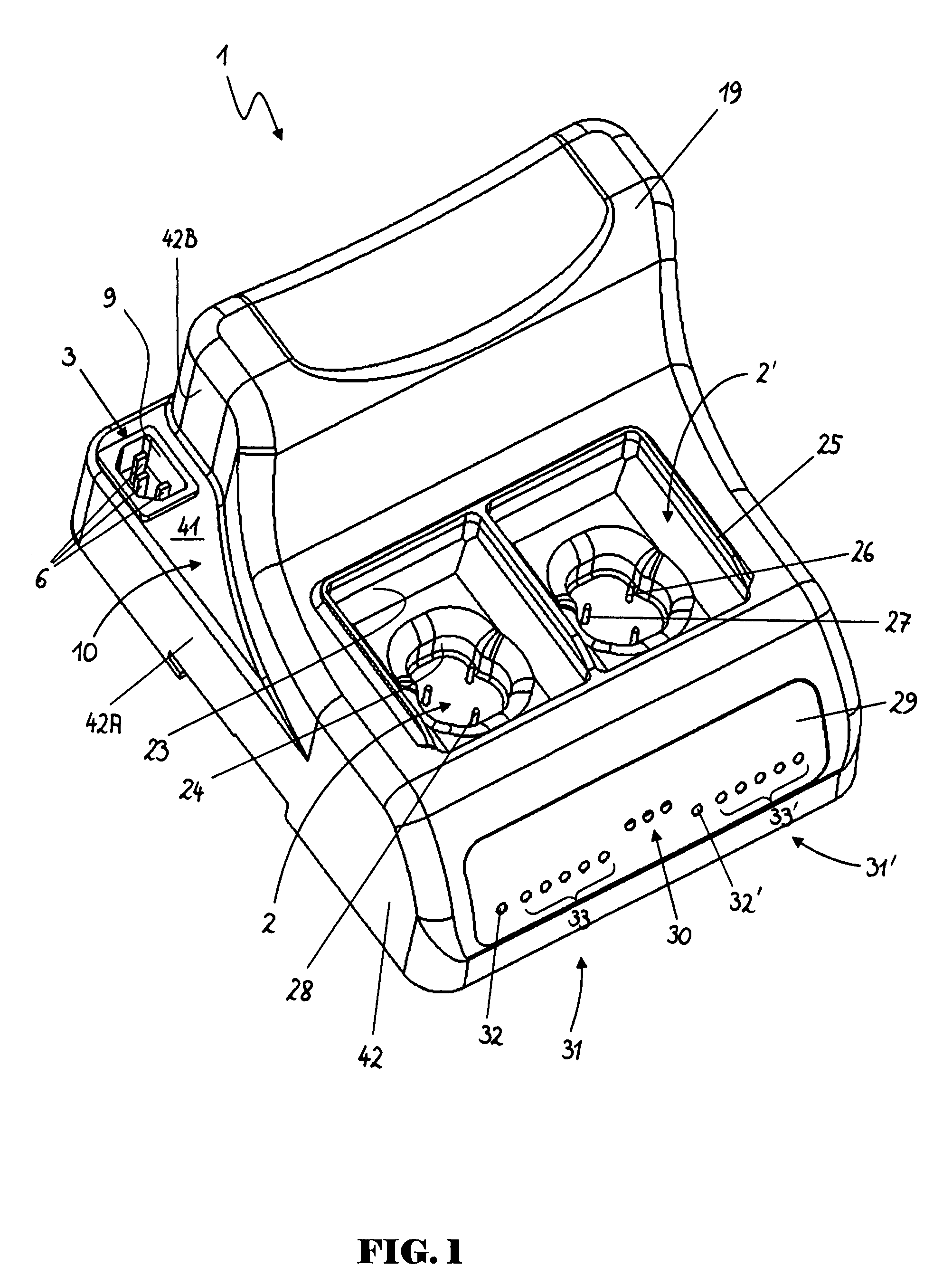

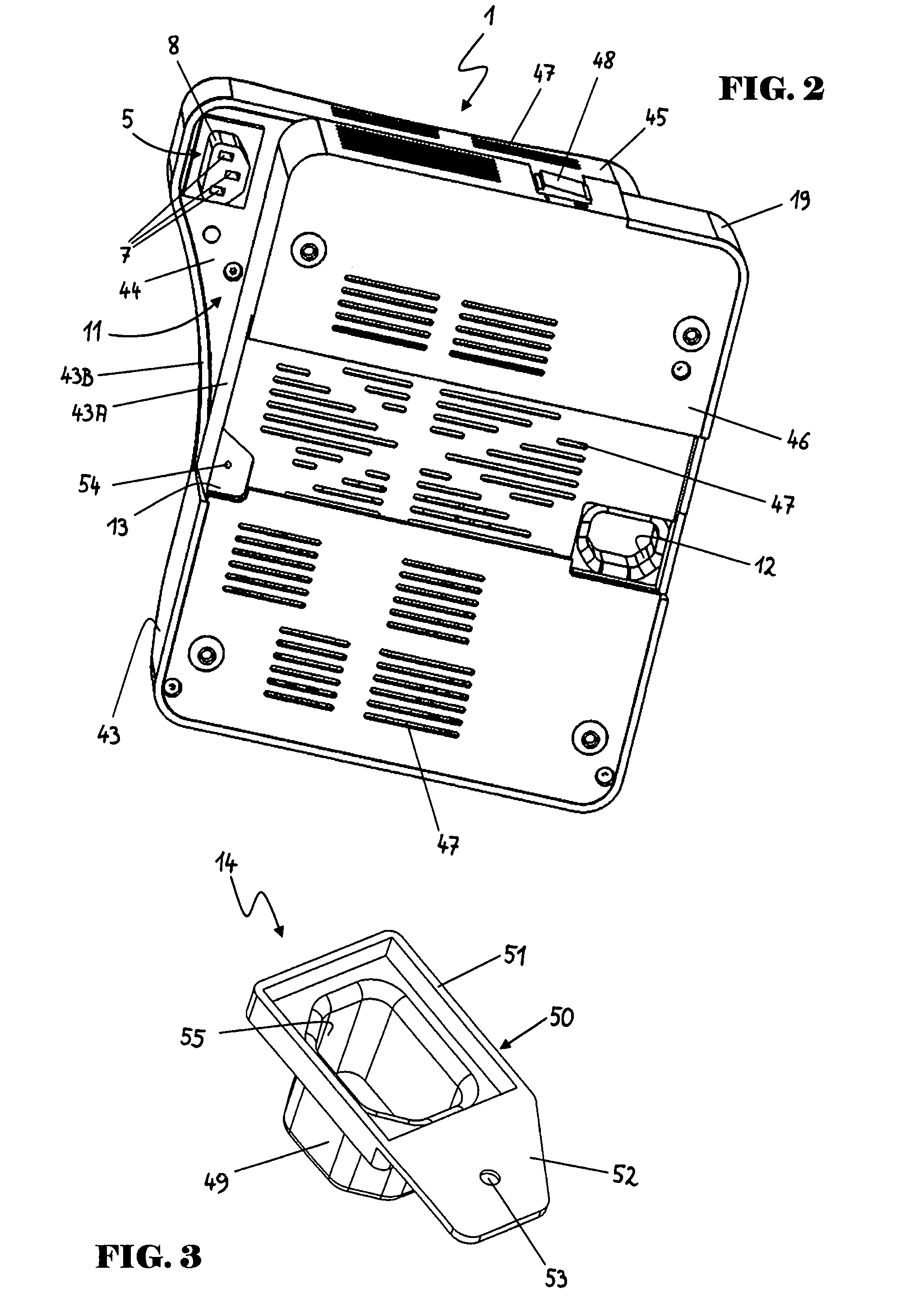

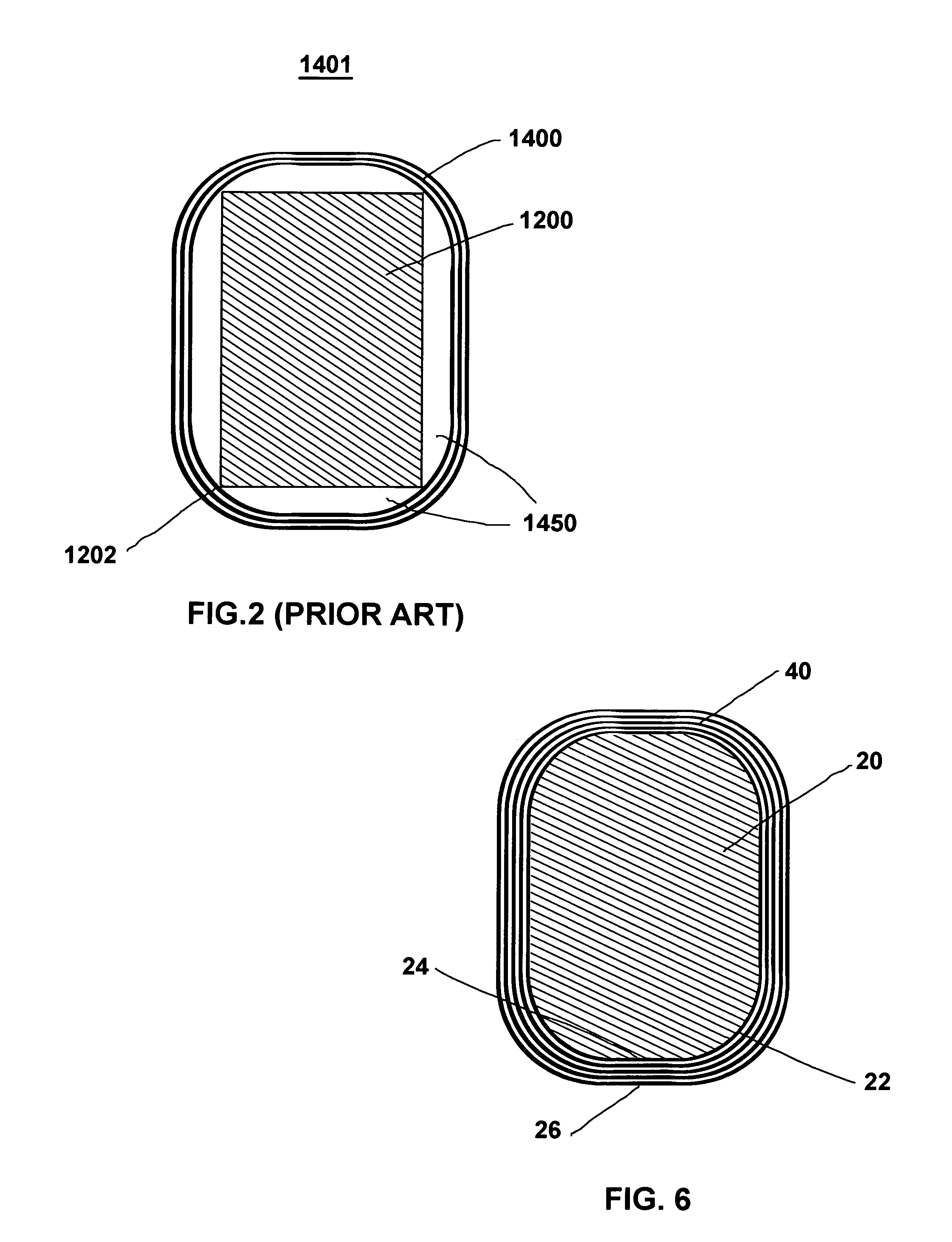

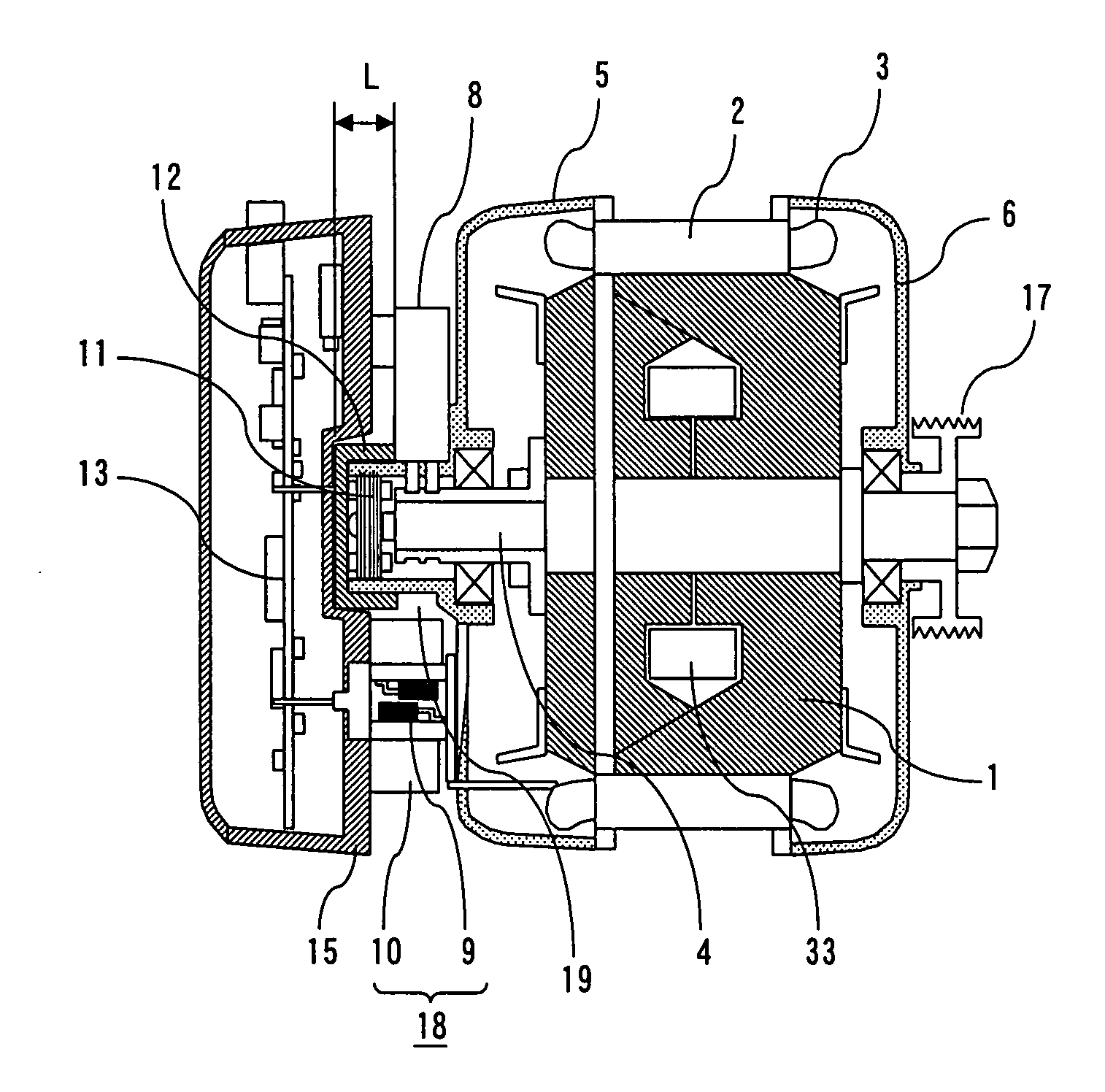

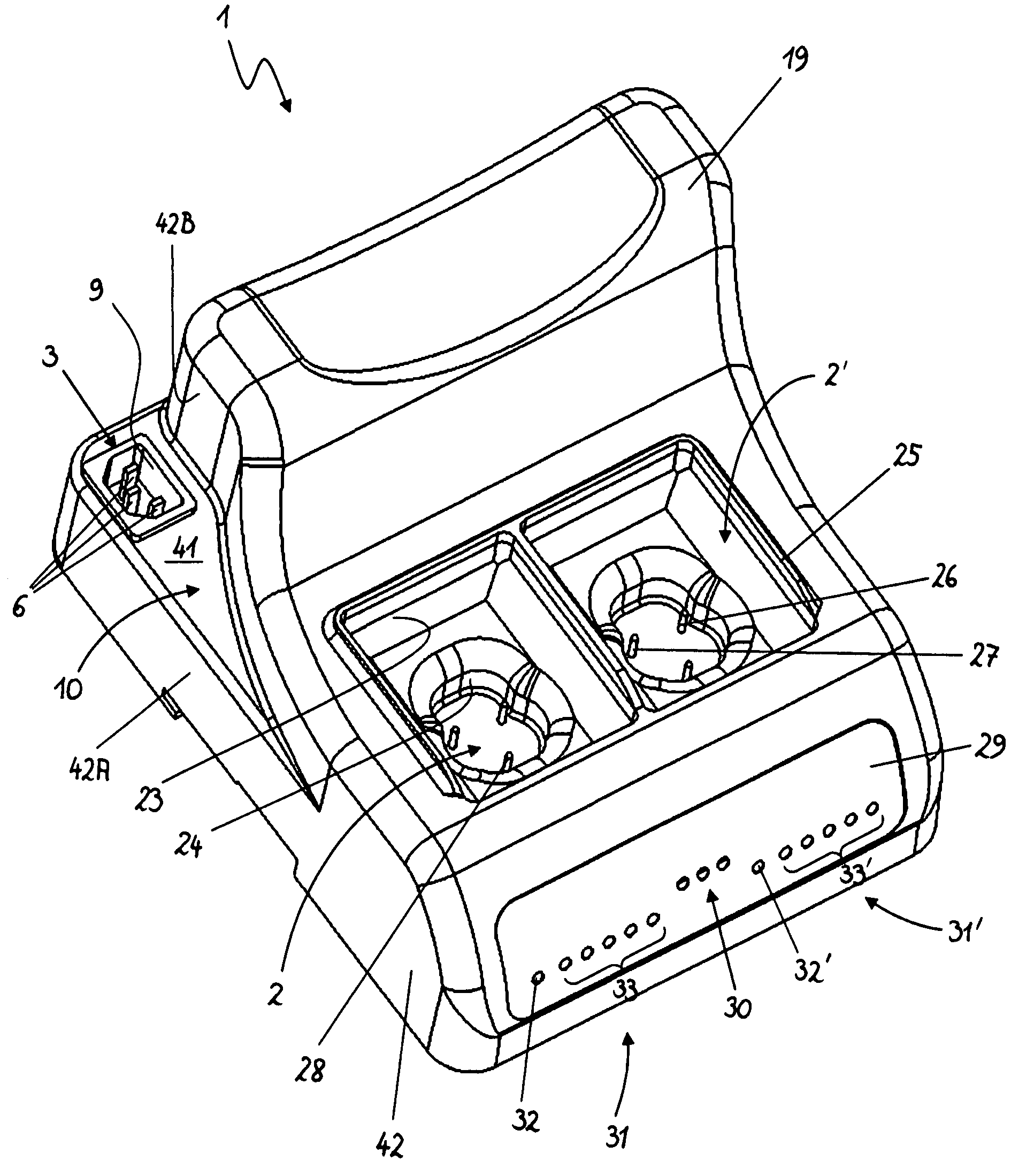

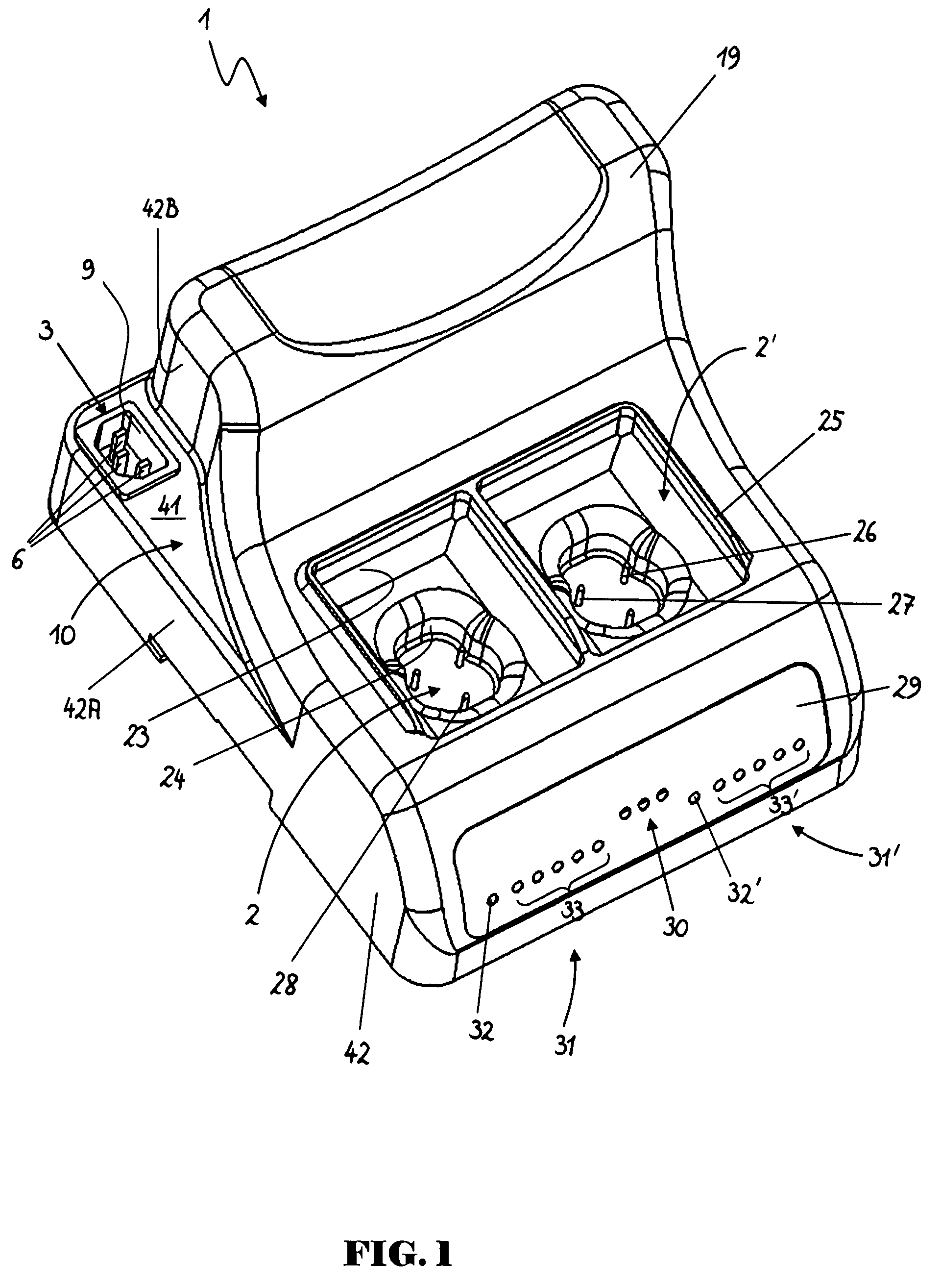

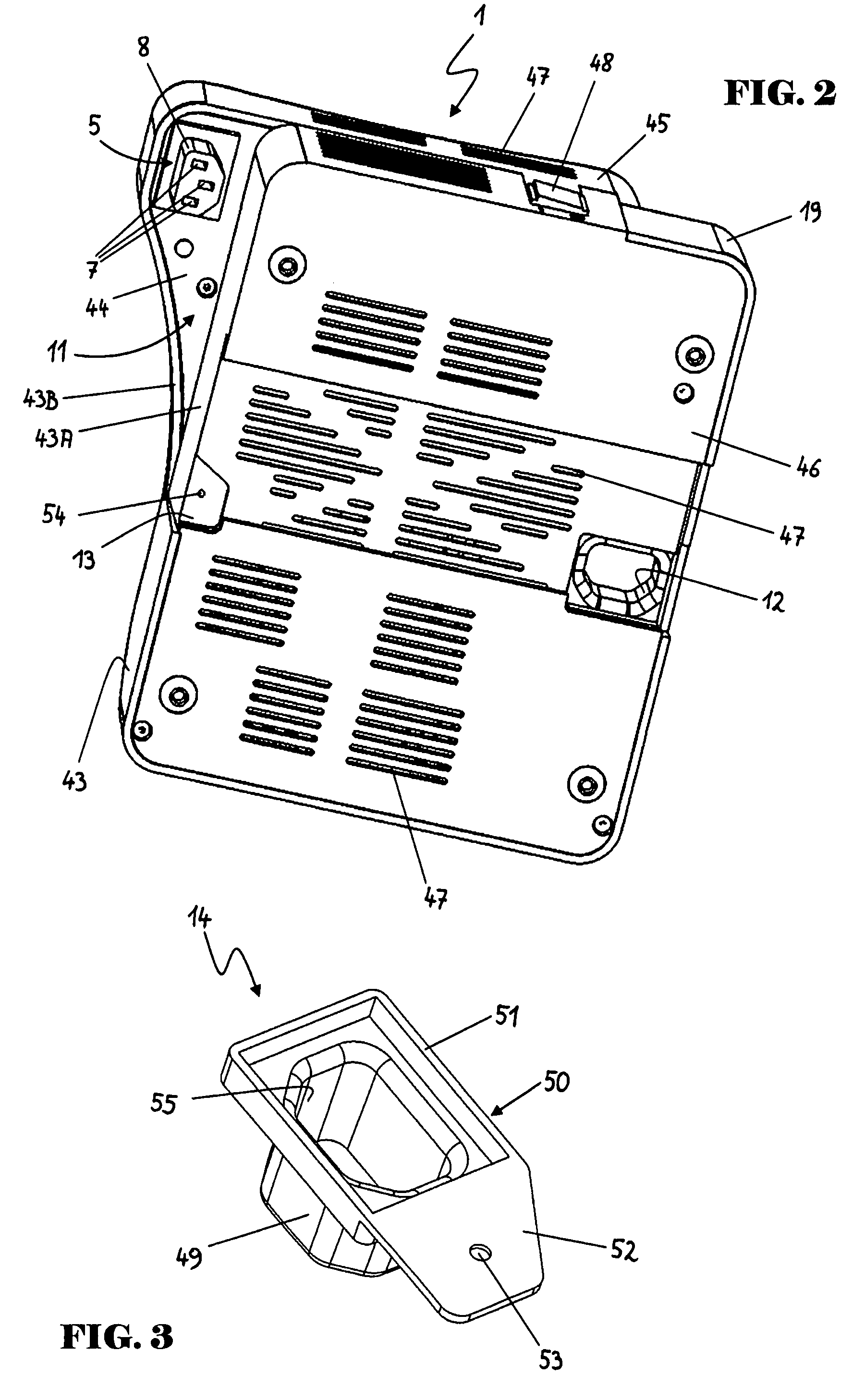

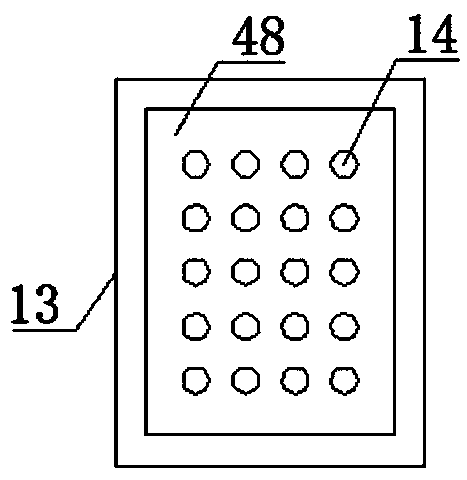

Device for charging batteries

ActiveUS20080079391A1Resistant to soilingImprove the immunityCells structural combinationSecondary cells charging/dischargingIdentification deviceEngineering

Chargers which can be connected to batteries with different charging requirements and which have an identification device for identification of the different batteries are disclosed. With these chargers, the different types of batteries are recognized by a magnetic identification device. In a first exemplary embodiment, the identification device comprises at least one magnetic sensor, which is arranged in or on the charger and detects at least one magnetic parameter of a magnetic element, which is mounted in or on the battery. In a second exemplary embodiment, the identification device has at least one magnetic element and at least one magnetic sensor for detection of at least one magnetic parameter of the at least one magnetic element. The battery comprises a shielding and / or amplifying device, which alter(s) the at least one magnetic parameter of the at least one magnetic element.

Owner:ARTHREX

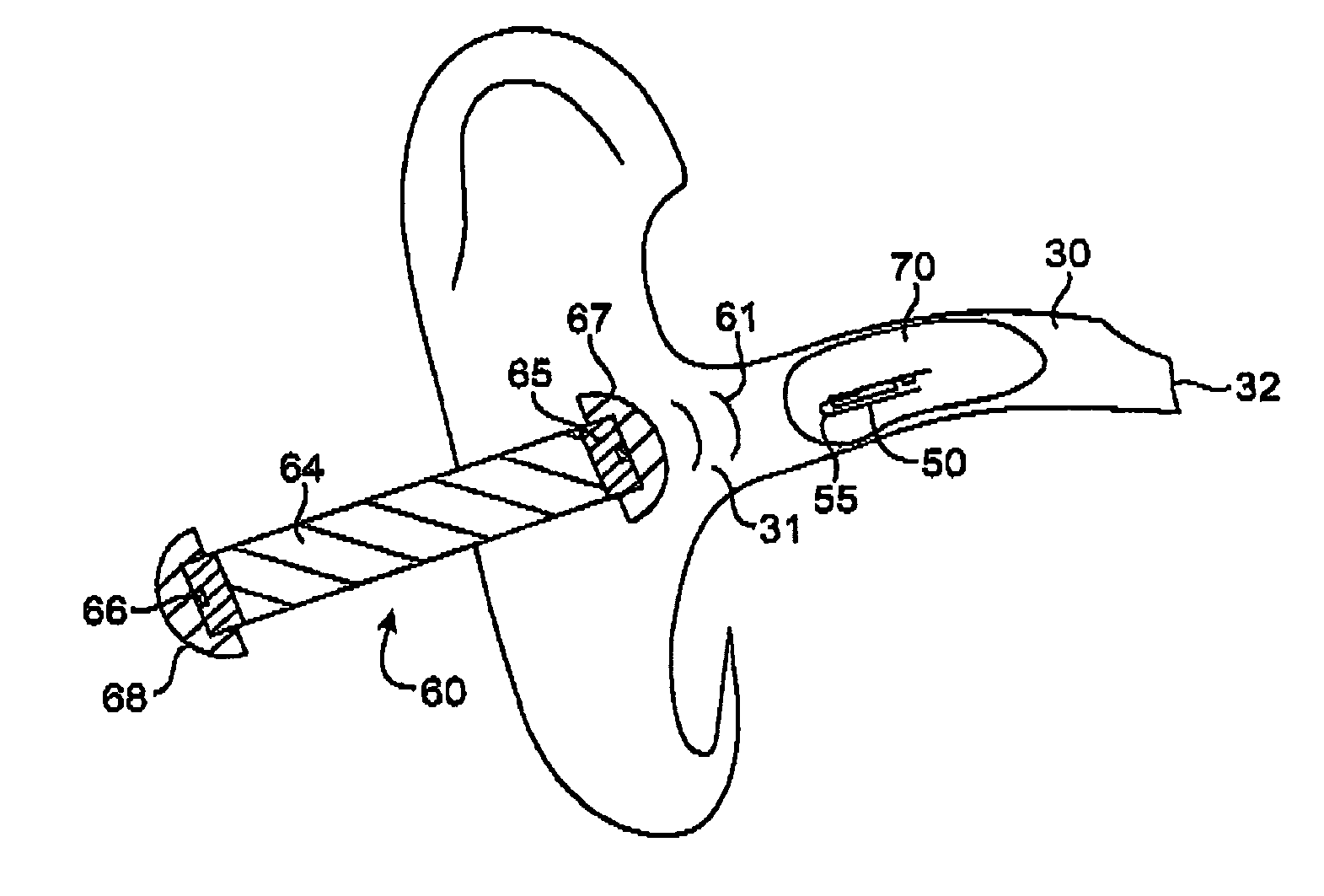

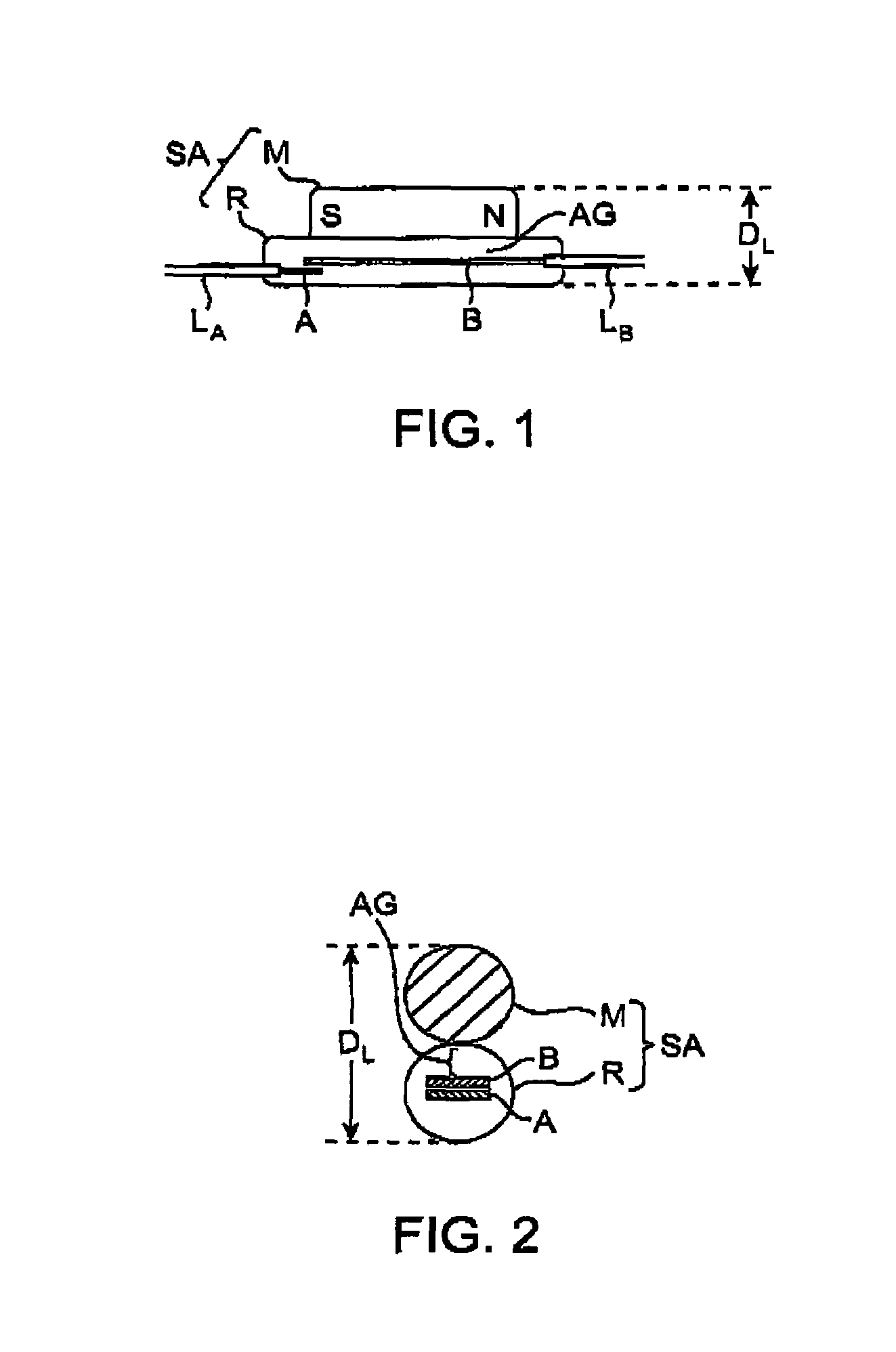

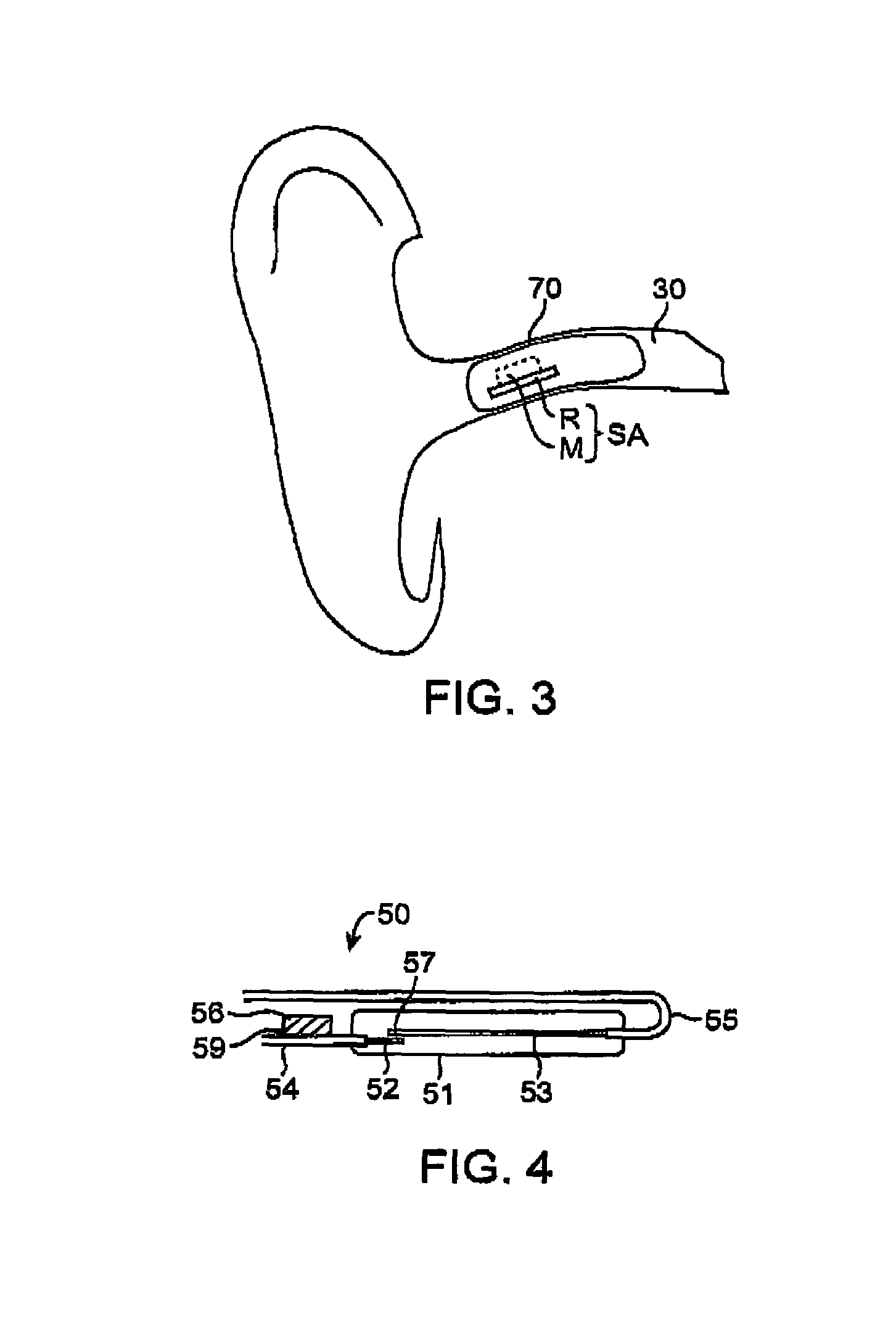

Remote magnetic activation of hearing devices

A magnetic switch assembly for hearing devices designed for remote activation by the user is highly miniaturized with a self-contained latching mechanism. The switch is activated and deactivated by the user via a hand-held magnet placed in proximity to the hearing device. The switch assembly includes a miniature reed switch and a miniature latching magnet affixed directly to one of the reeds or the associated lead wire. Direct attachment minimizes the air gap between the latching magnet and a reed thus enabling latching with only an extremely small magnet. The latching magnet produces a magnetic field of adequate strength to hold the reeds together in electrical contact after the air gap between the reeds is closed by the user's placement of the external hand-held magnet in proximity thereto. But the latching magnet's field is of inadequate strength for unaided closure of the air gap between the reeds. Consequently, once the reeds are closed the latching magnet prevents separation thereof until the reeds are exposed to an external magnetic field of opposite polarity and sufficient strength to overcome the field produced by the latching magnet.

Owner:INSOUND MEDICAL INC

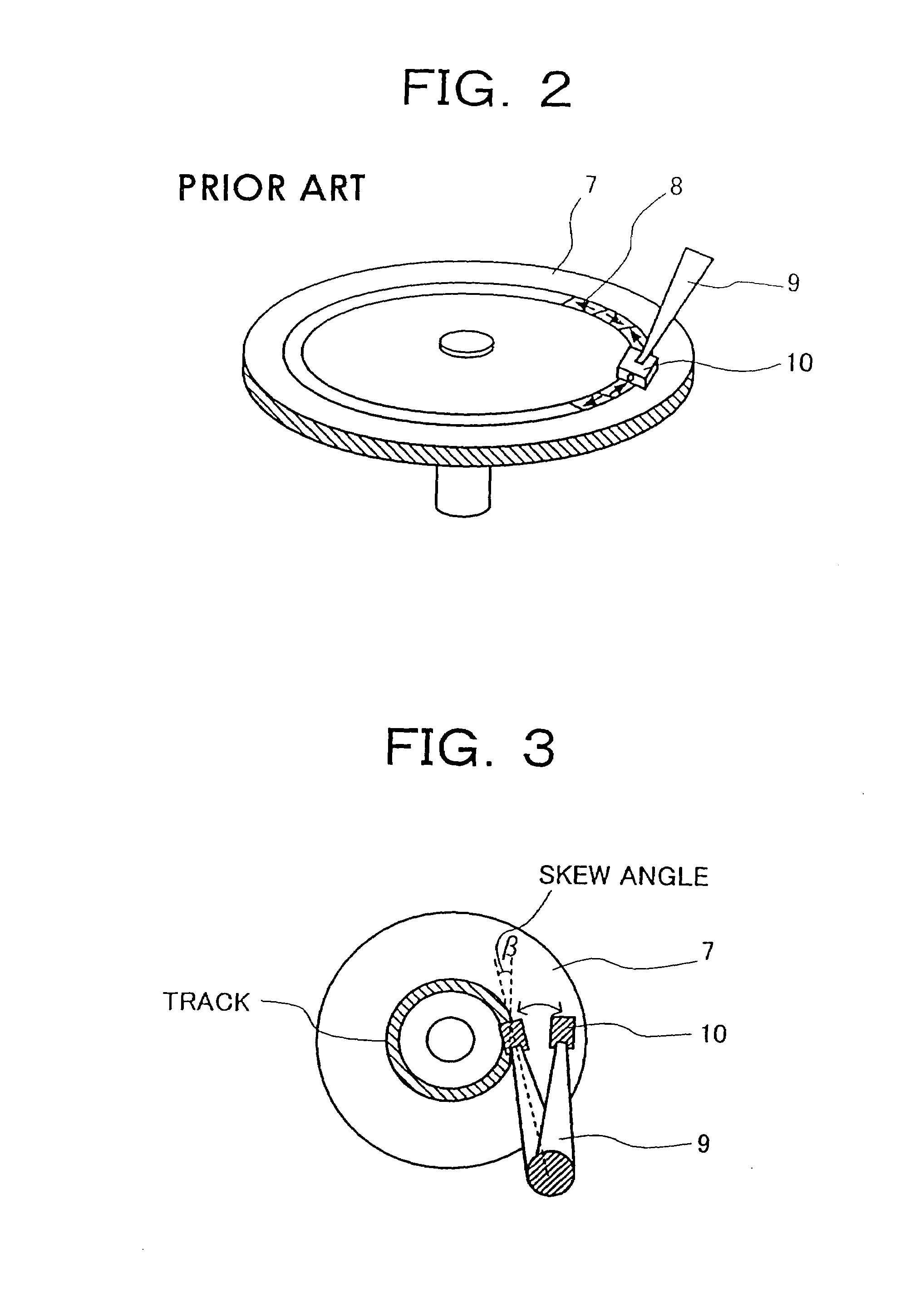

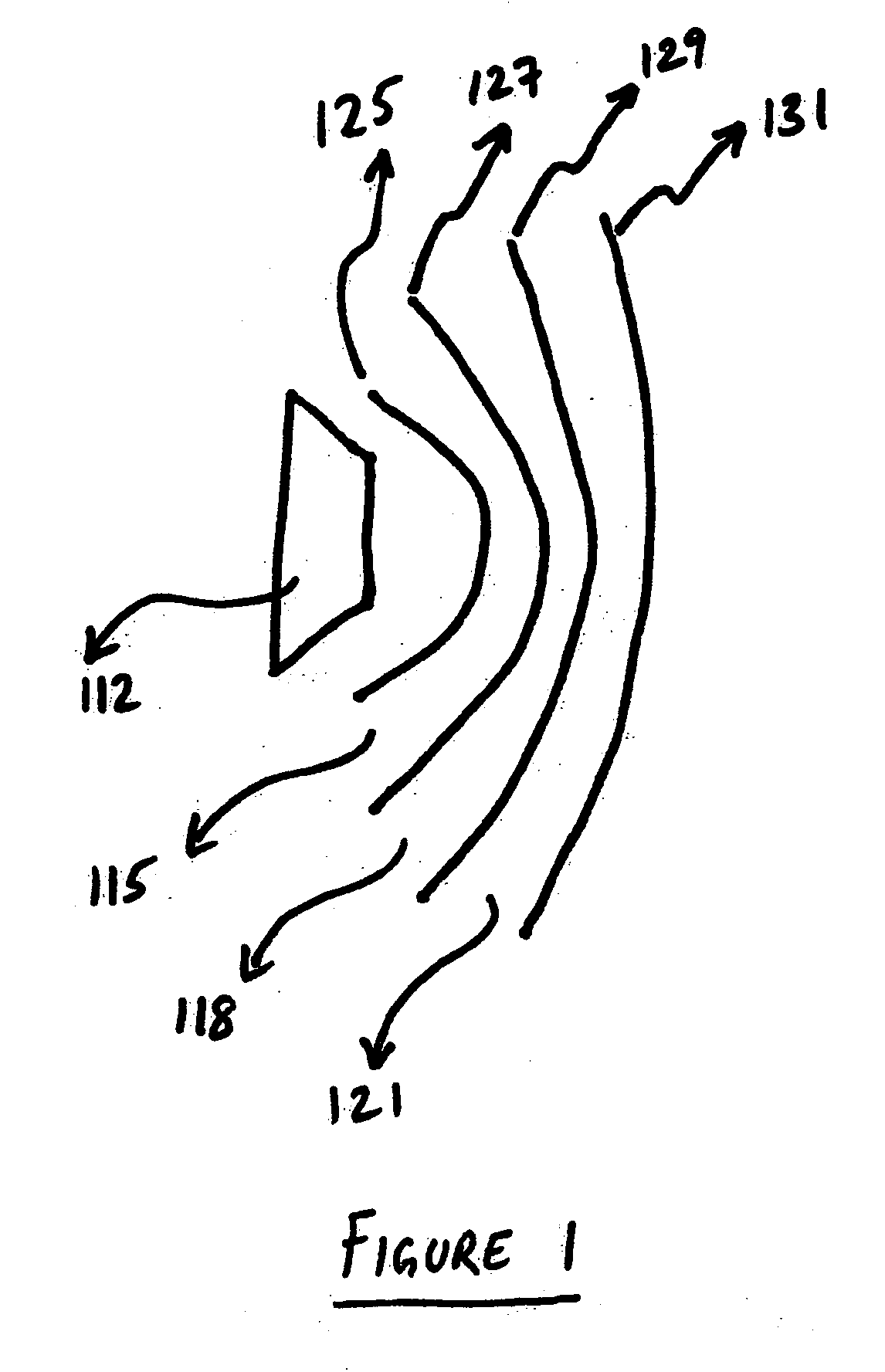

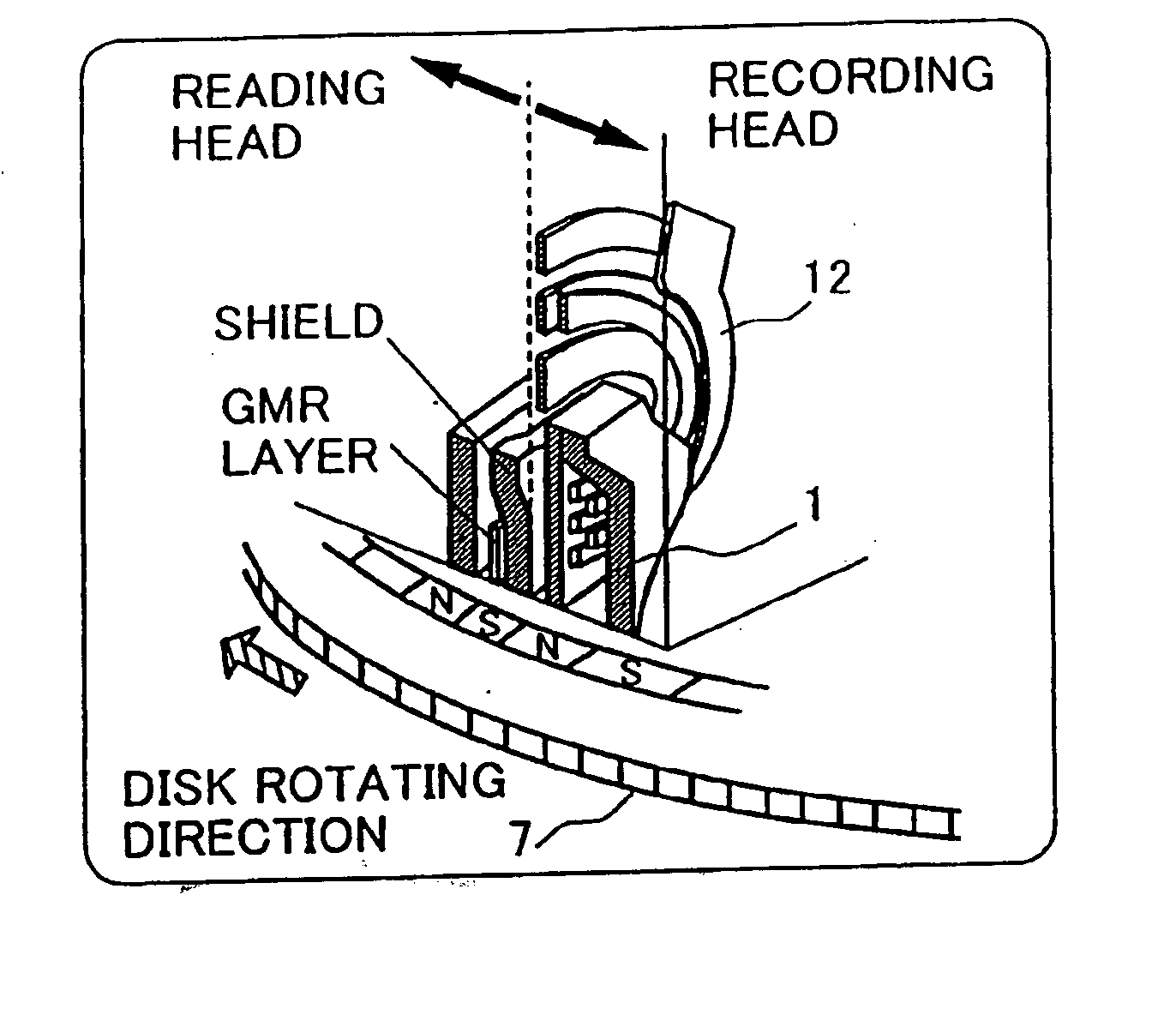

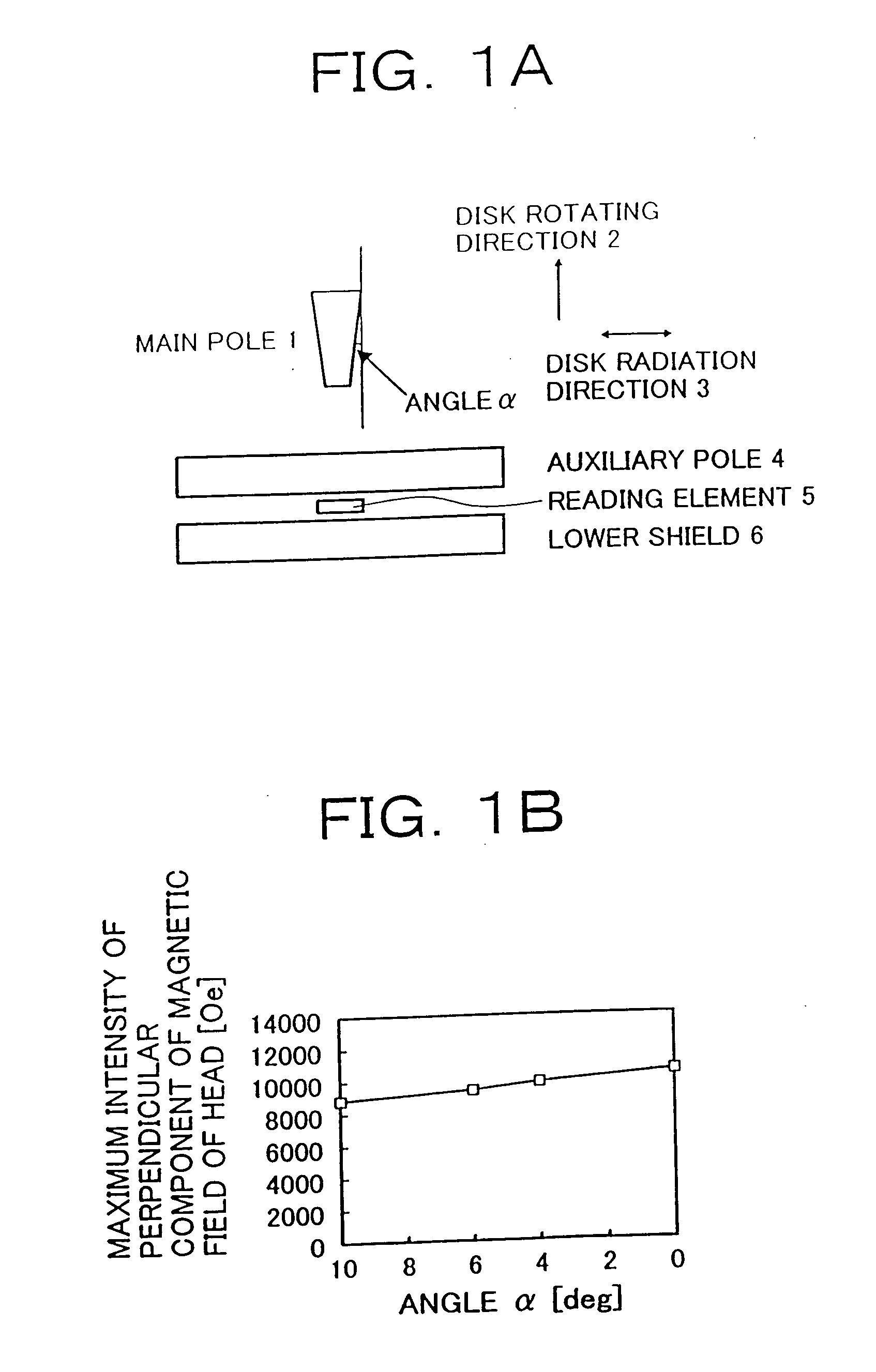

Single pole type recording head with tapered edges

InactiveUS7006326B2Reduce magnetic field strengthHigh area recording densityNanotechRecord information storageLeading edgeEngineering

A magnetic head for perpendicular recording without writing from the lateral sides of a mains pole and without erasing data on adjacent tracks. A magnetic disk storage apparatus using the magnetic head. The lateral side of the main pole of a magnetic head for perpendicular recording may have an inverted tapered shape obtained by forming a groove as a track portion to an inorganic insulating layer and then forming a magnetic layer and then flattening the upper surface. A leading edge, a trailing edge, or both lateral edges of the magnetic head may be tapered. The taper may be either smooth and linear or curved in profile.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

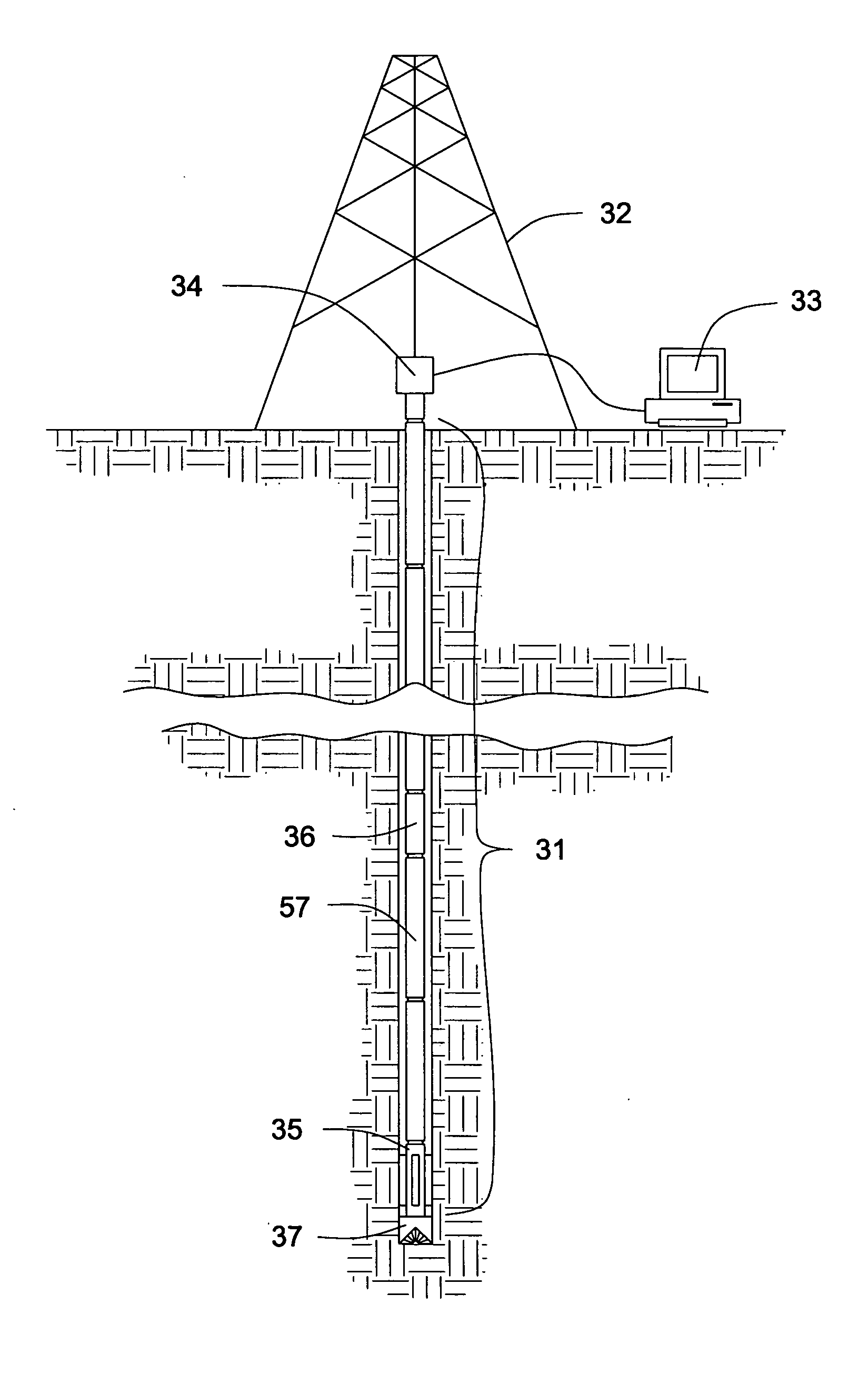

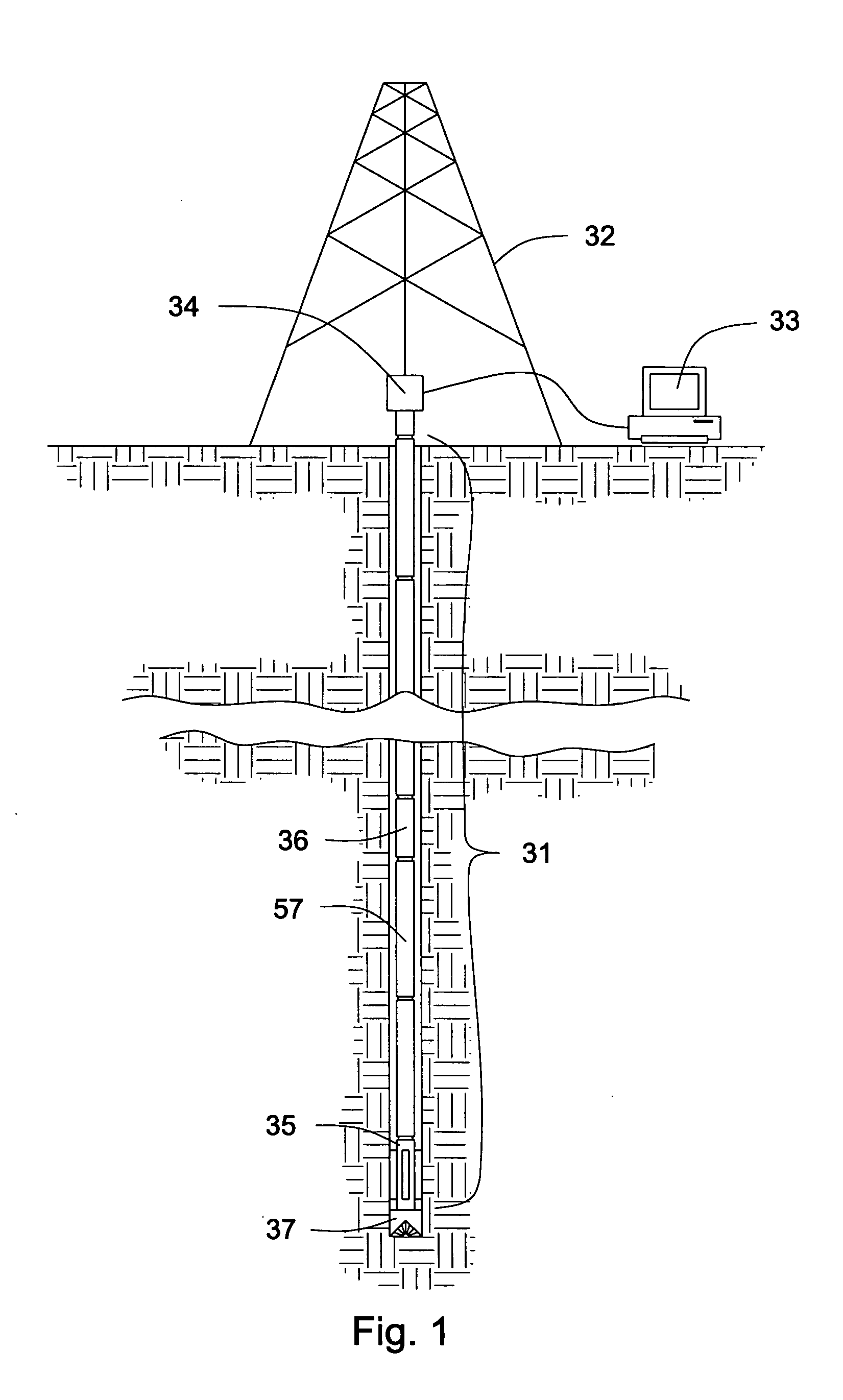

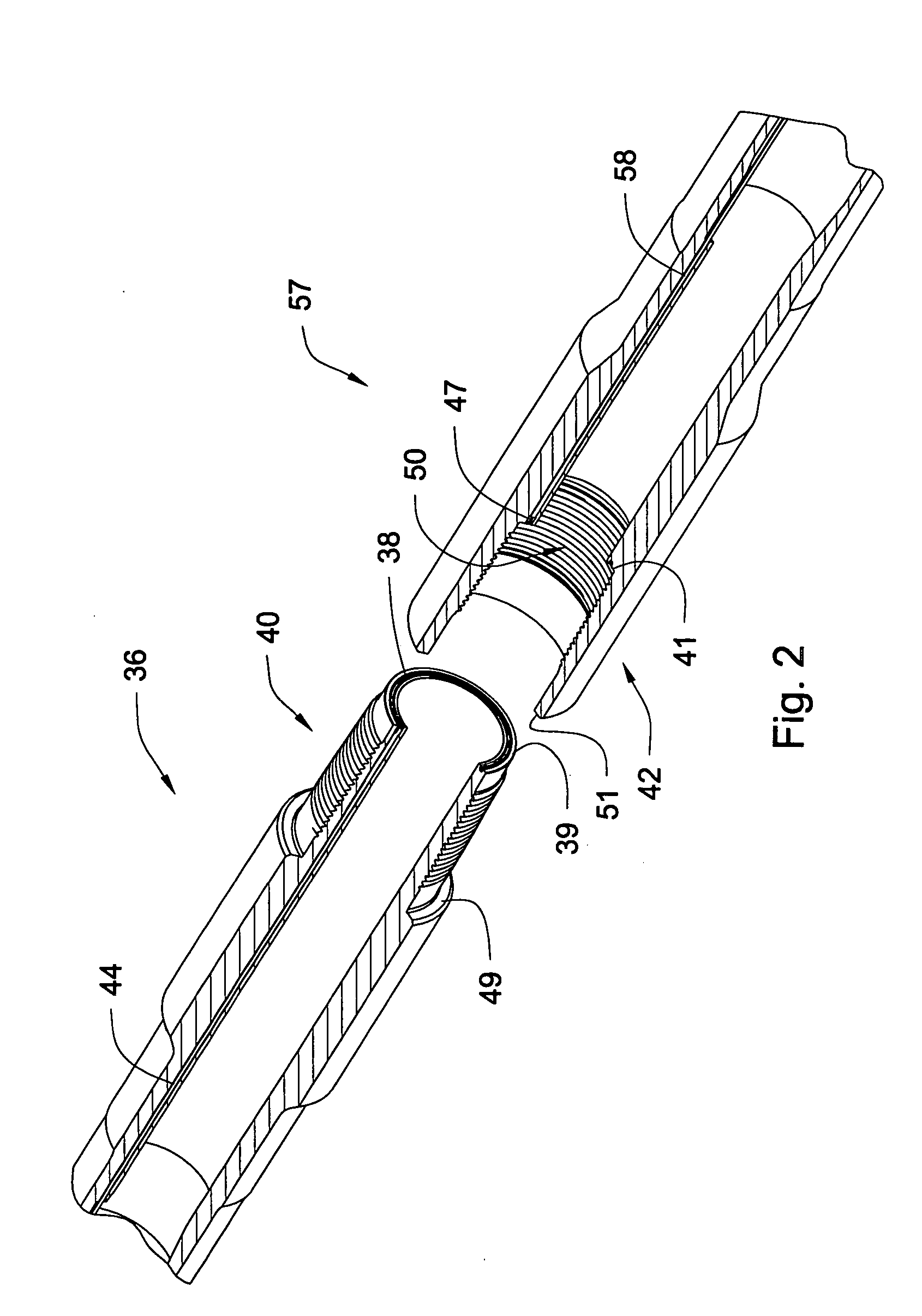

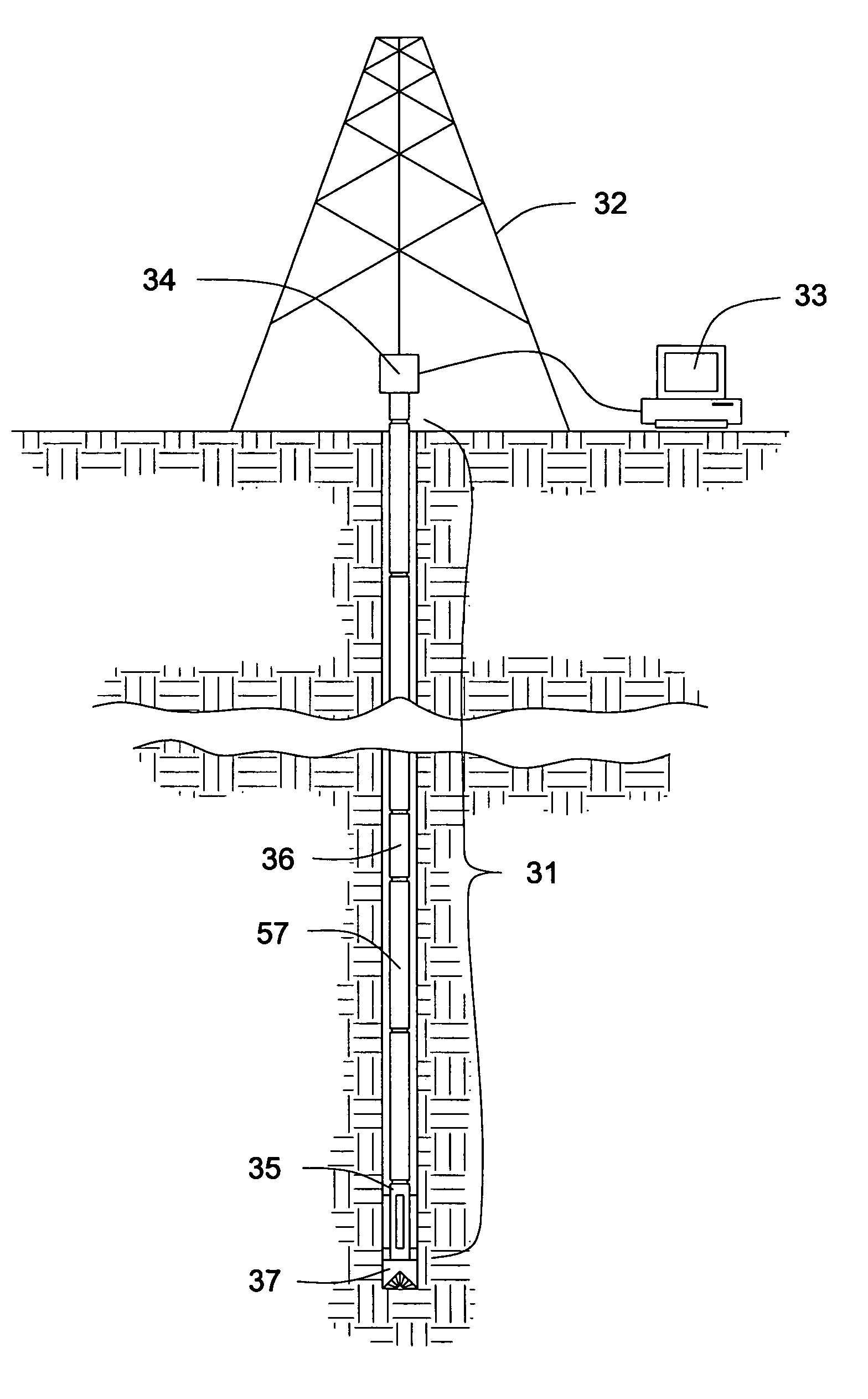

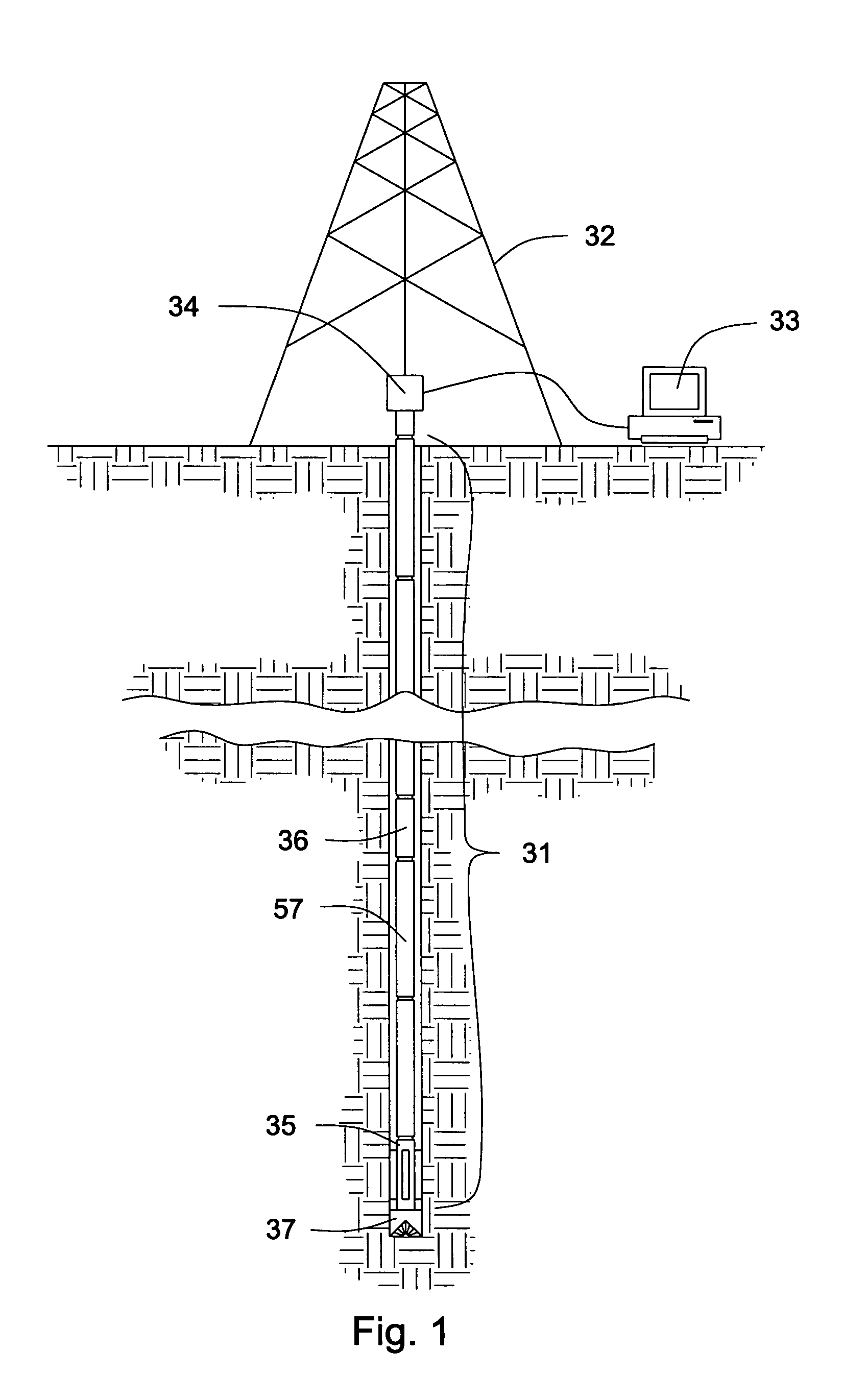

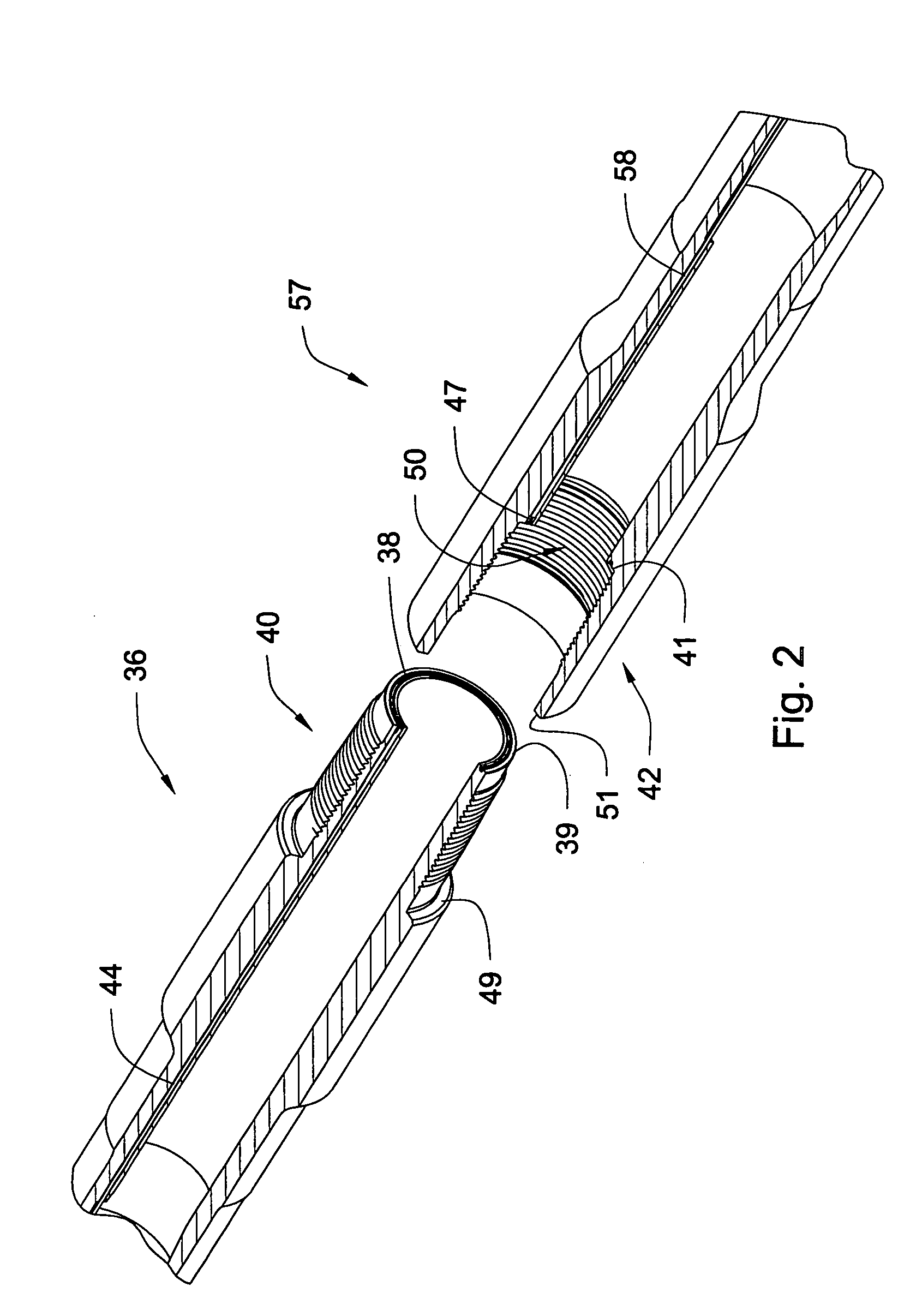

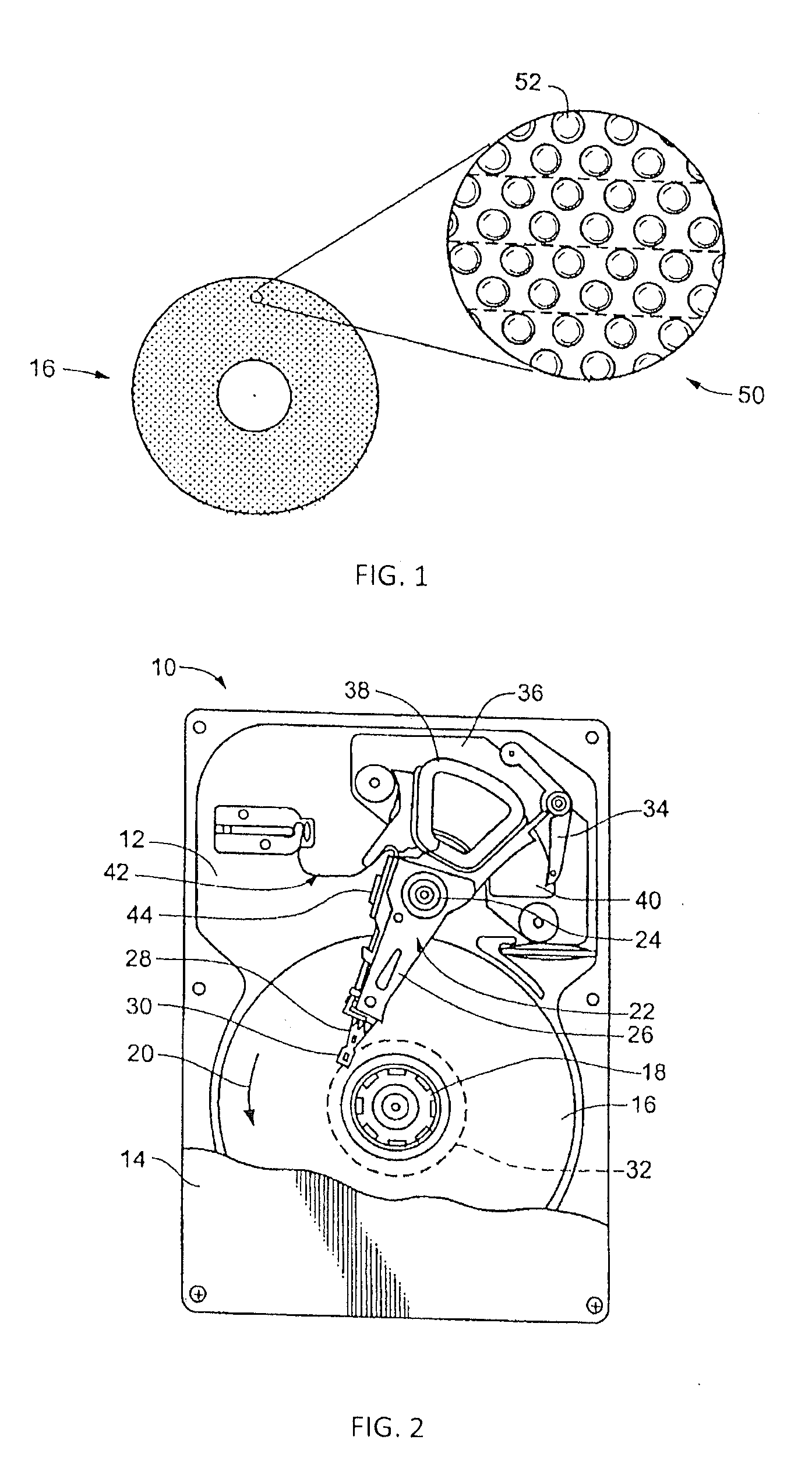

Element of an inductive coupler

ActiveUS20050285705A1Reduce magnetic field strengthNear-field transmissionDrilling rodsAlloyConductive materials

An element for an inductive coupler in a downhole component comprises magnetically conductive material, which is disposed in a recess in annular housing. The magnetically conductive material forms a generally circular trough. The circular trough comprises an outer generally U-shaped surface, an inner generally U-shaped surface, and two generally planar surfaces joining the inner and outer surfaces. The element further comprises pressure relief grooves in at least one of the surfaces of the circular trough. The pressure relief grooves may be scored lines. Preferably the pressure relief grooves are parallel to the magnetic field generated by the magnetically conductive material. The magnetically conductive material is selected from the group consisting of soft iron, ferrite, a nickel iron alloy, a silicon iron alloy, a cobalt iron alloy, and a mu-metal. Preferably, the annular housing is a metal ring.

Owner:INTELLISERV

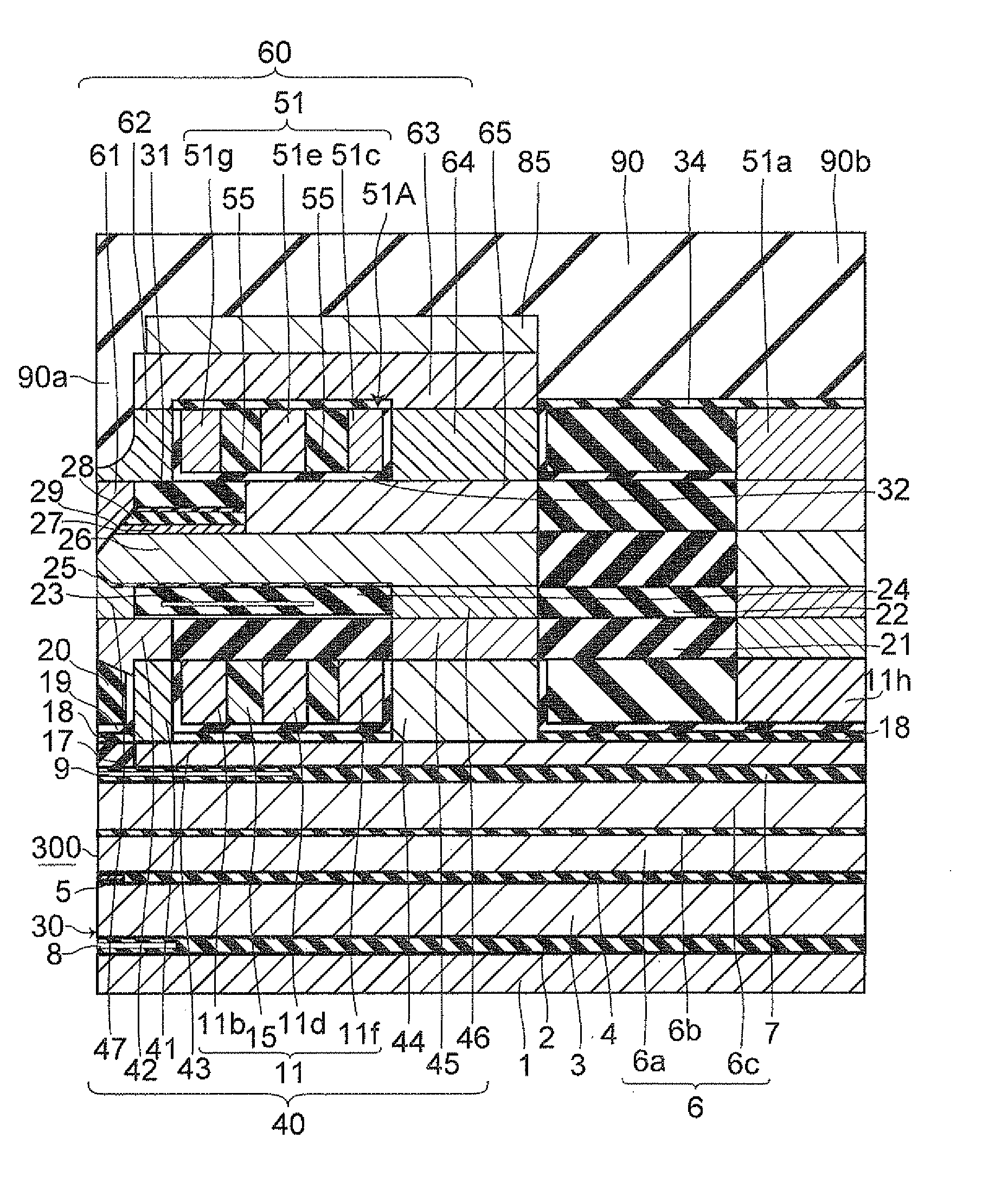

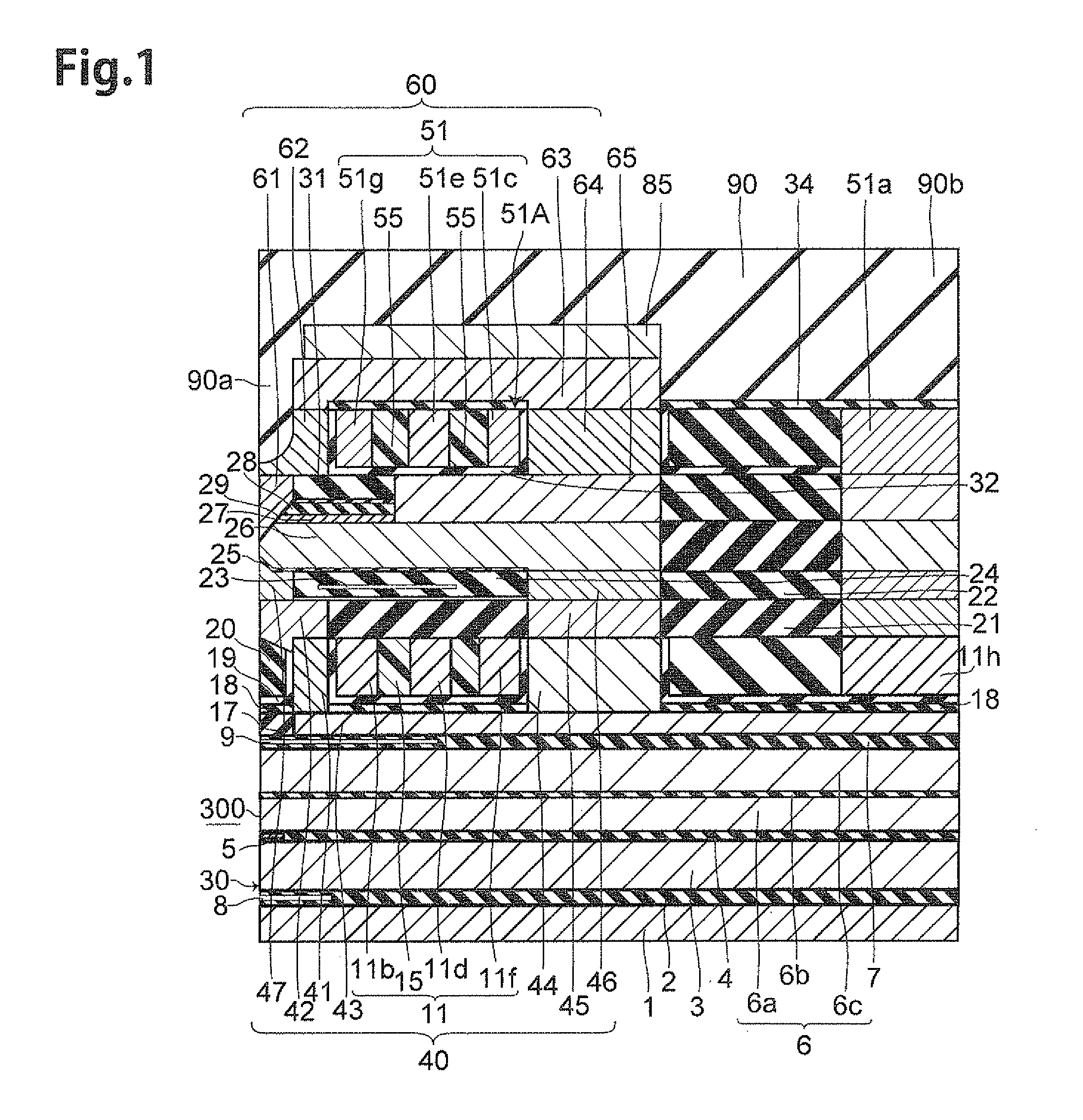

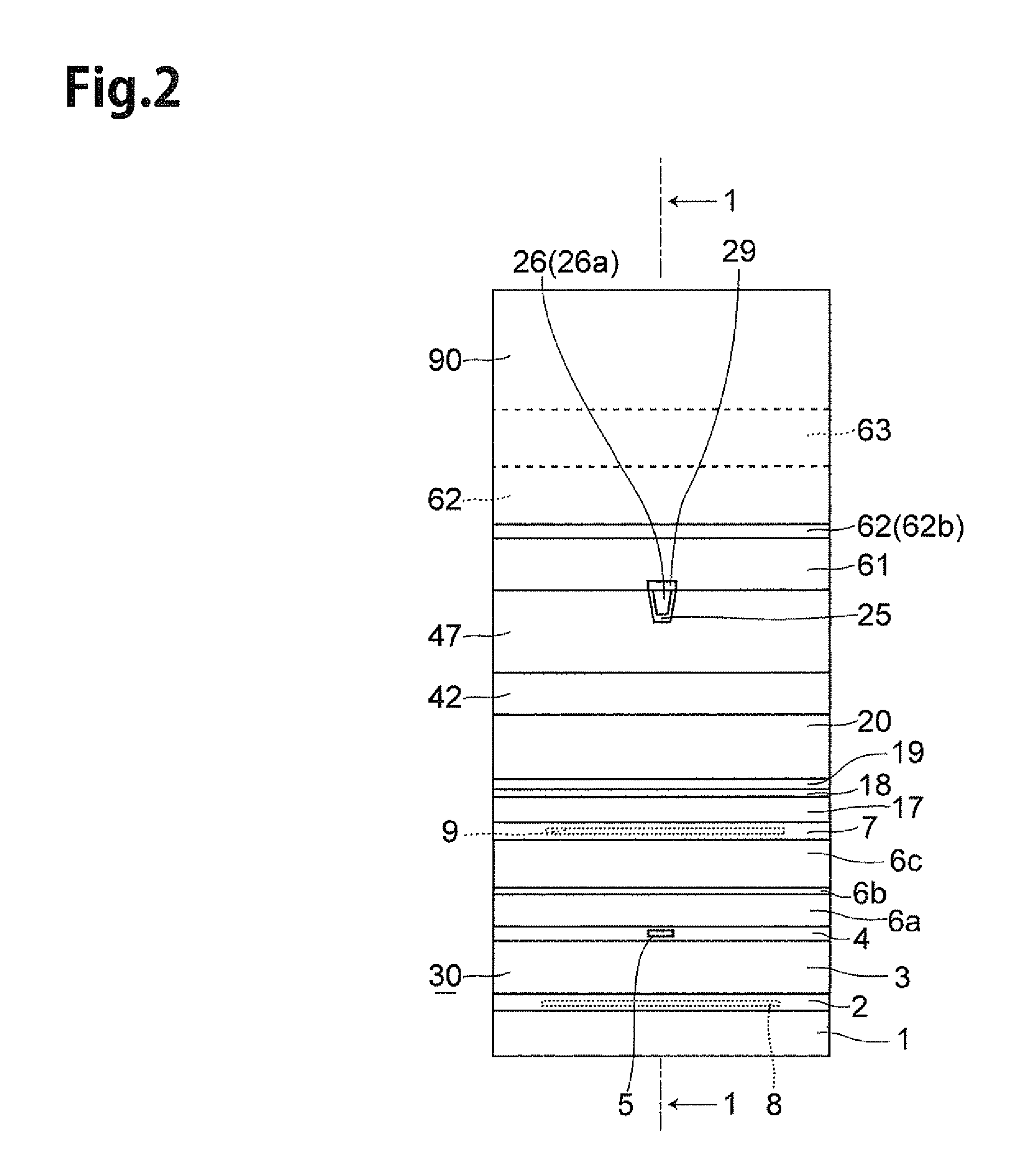

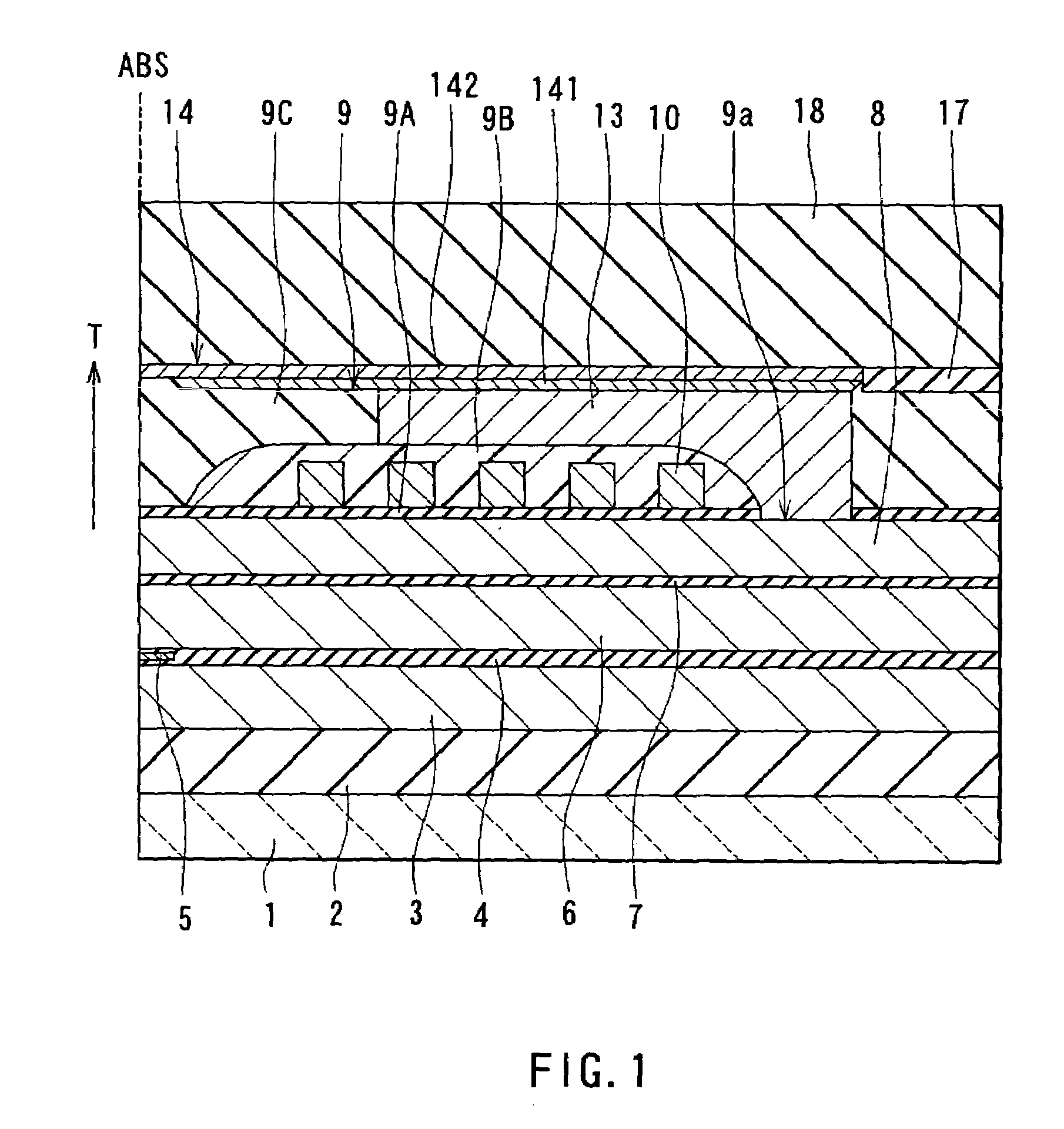

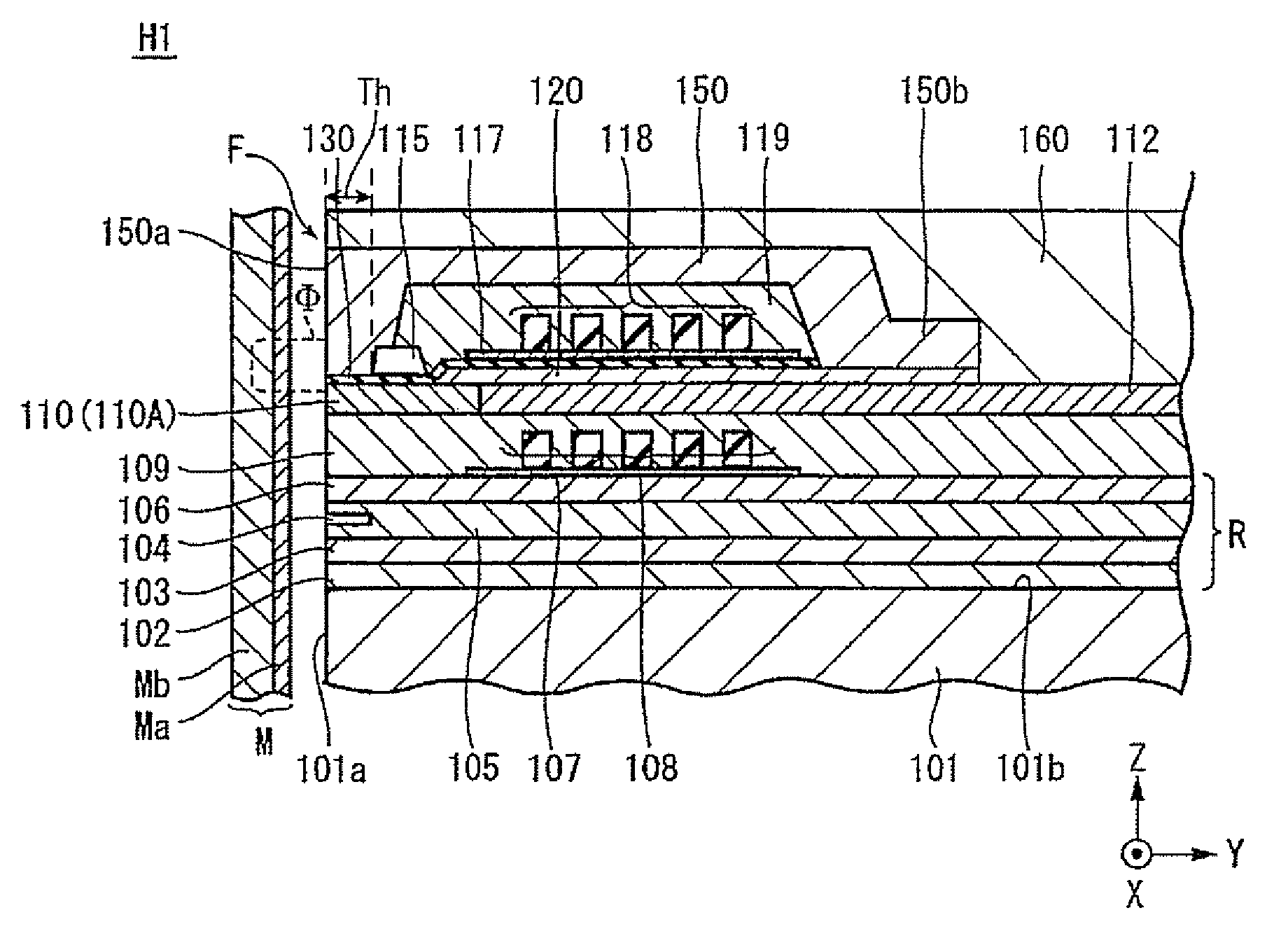

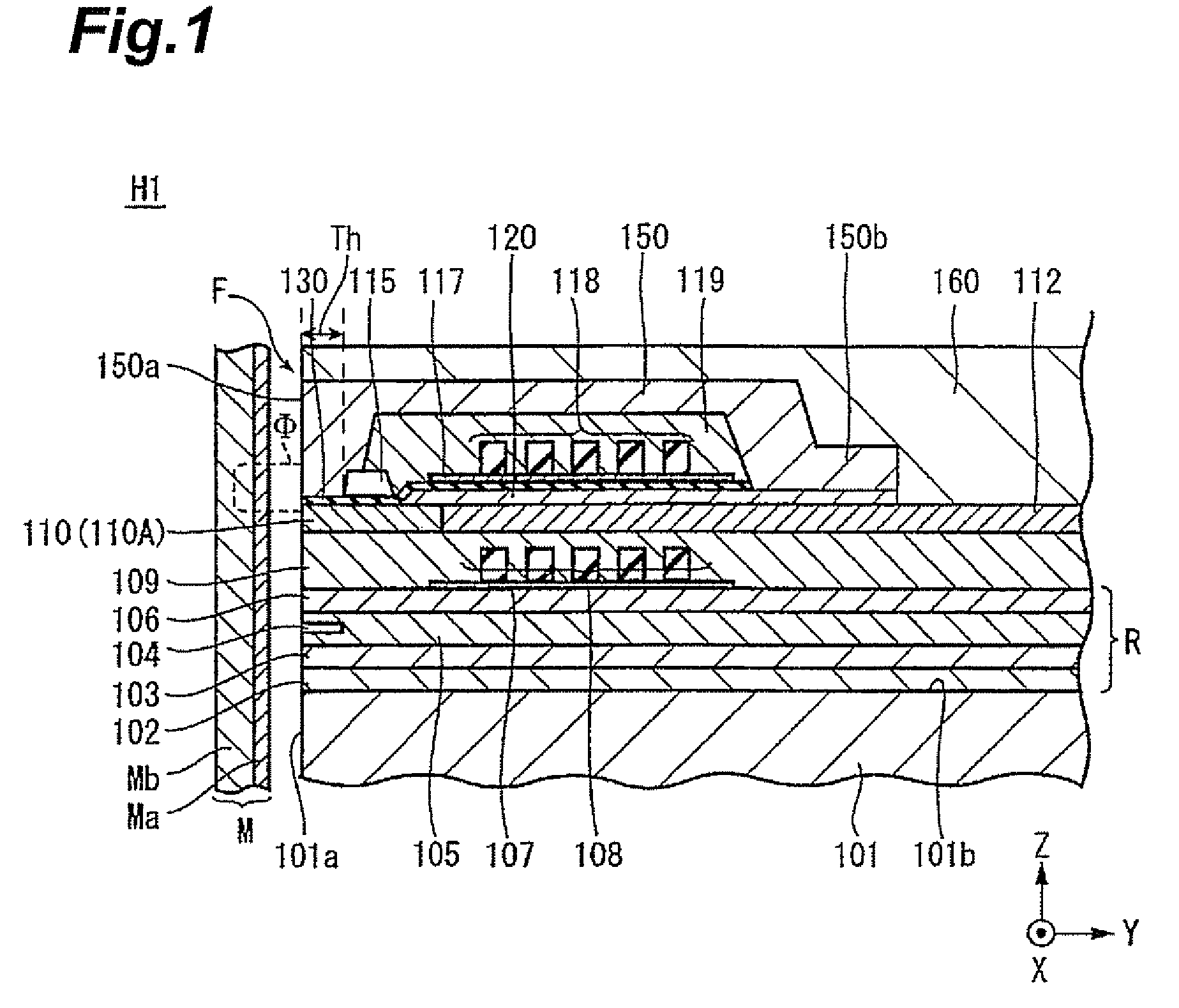

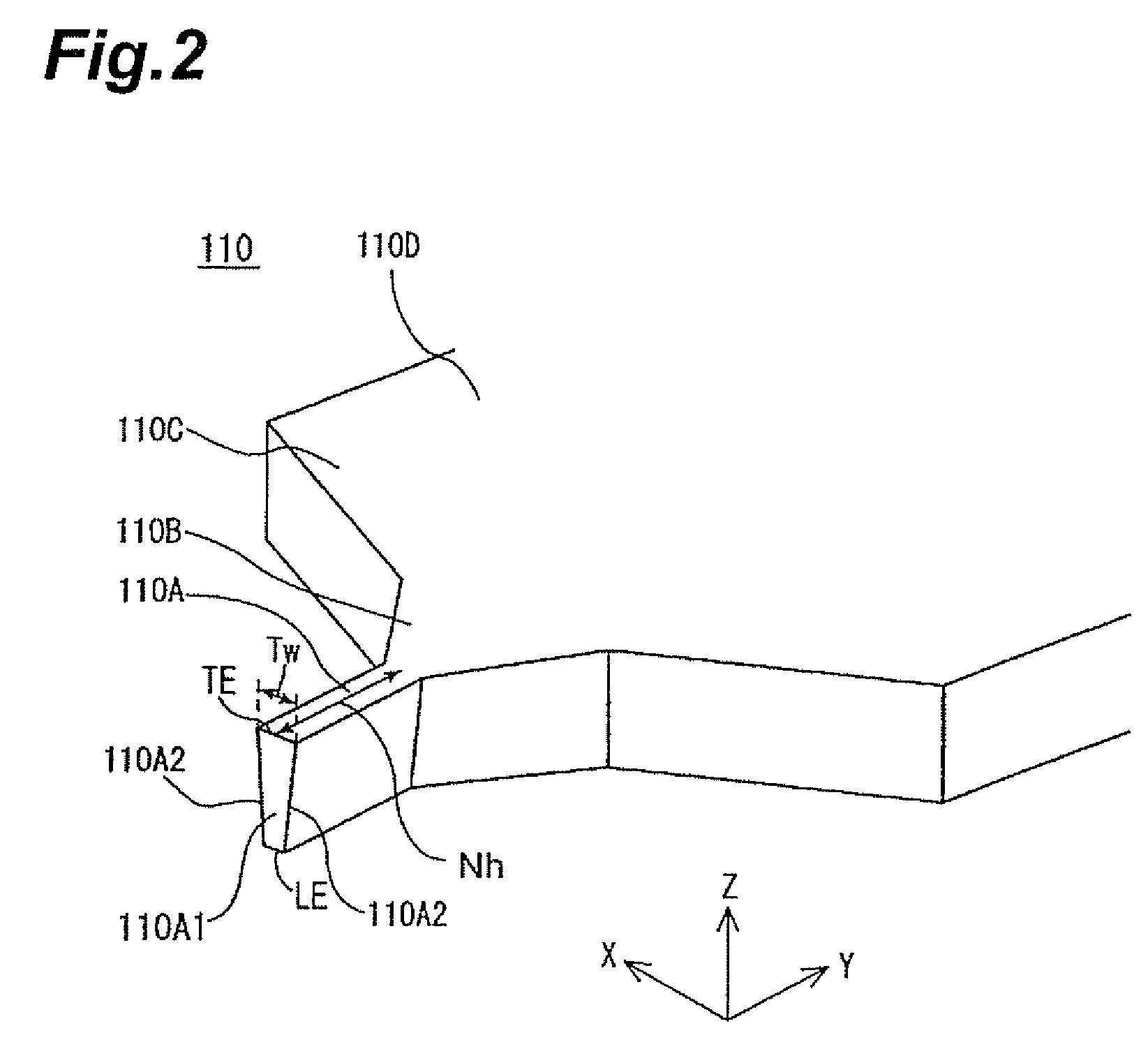

Thin-film magnetic head, method of manufacturing the same, head gimbal assembly, and hard disk drive

ActiveUS8310787B1Lower resistanceSuppress feverHeads using thin filmsRecord information storageHard disc driveMagnetic poles

A thin-film magnetic head is constructed such that a main magnetic pole layer, a write shield layer, a gap layer, and a thin-film coil are laminated on a substrate. The thin-film magnetic head has a shield magnetic layer. The shield magnetic layer is connected to the main magnetic pole layer. The shield magnetic layer has a lower front shield part. A front end angle representing an angle formed between a front end face of the lower front shield part and a lower end face is set at an obtuse angle. The front end face is disposed in the medium-opposing surface. The lower end face is disposed at a position closest to the substrate in the lower front shield part.

Owner:HEADWAY TECH INC +1

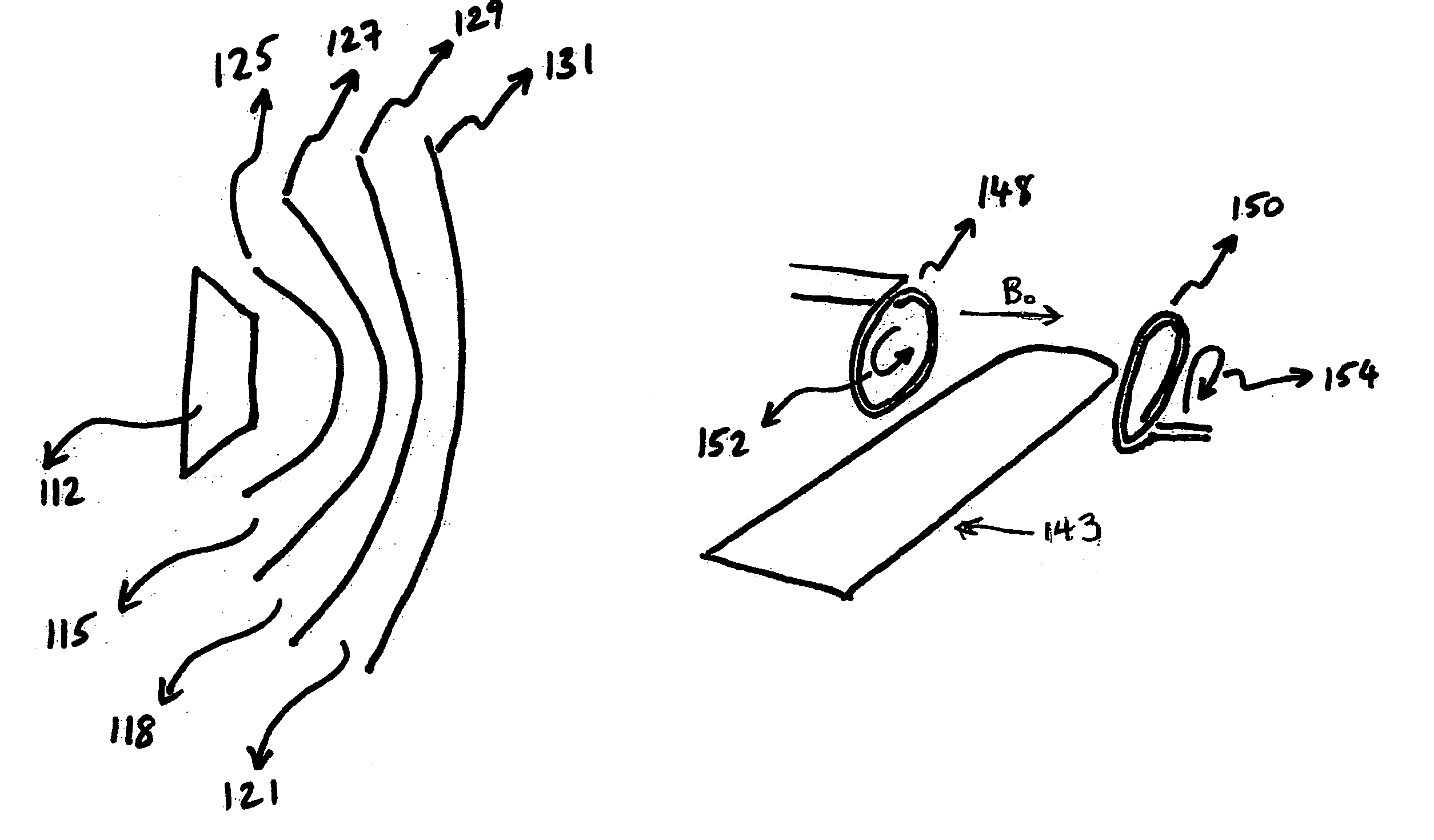

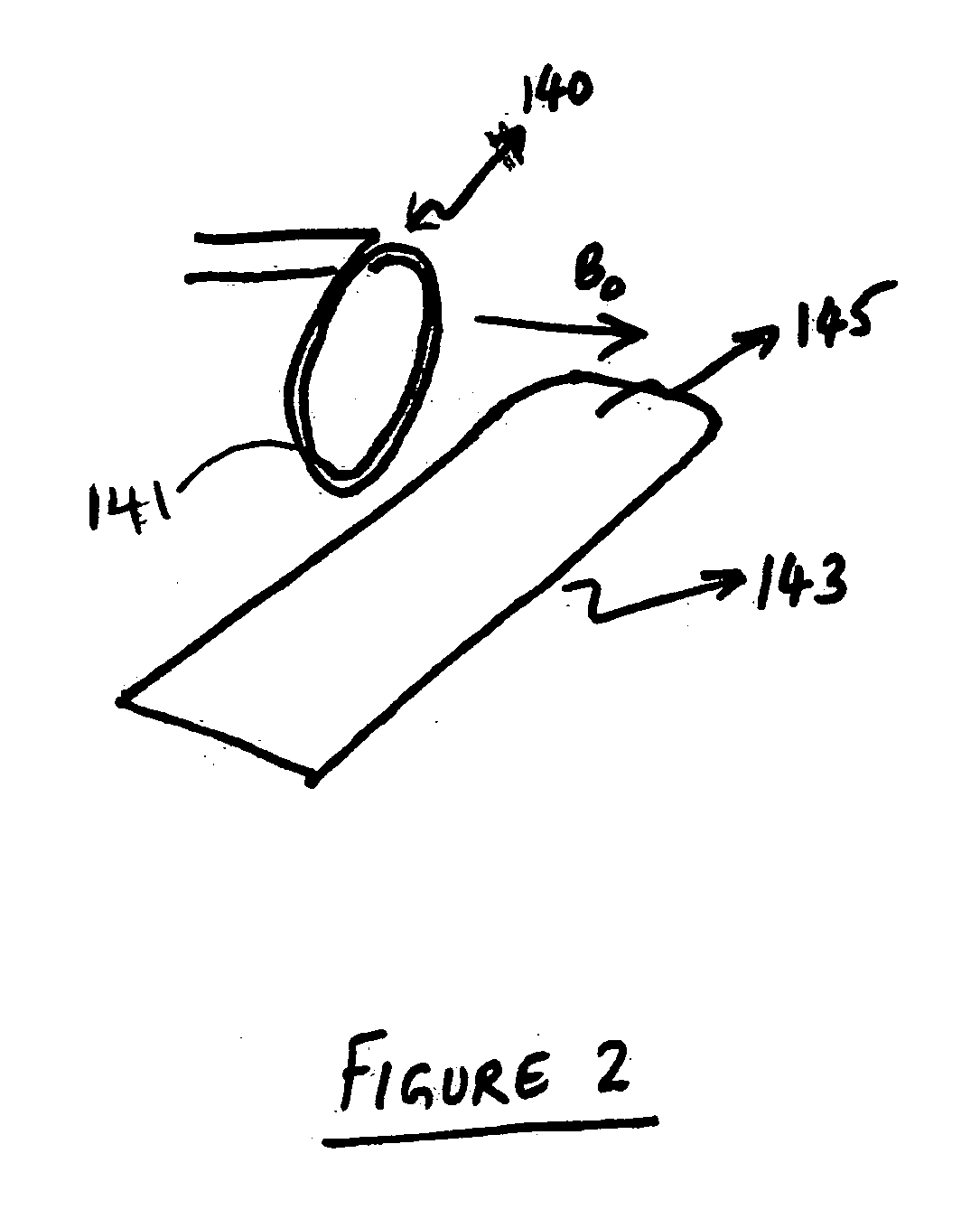

Method and apparatus for high-gain magnetic resonance imaging

InactiveUS20070085544A1Improve signal-to-noise ratioLower static magnetic field strengthNanomagnetismMagnetic measurementsElectrical resistance and conductanceElectrical conductor

A method and apparatus for Magnetic Resonance Imaging with specialized imaging coils possessing high Signal-to-Noise-Ratio (SNR). Imaging and / or Radio Frequency receiving coils include a ballistic electrical conductor such as carbon nanotubes, the ballistic electrical conductor having a resistance that does not increase significantly with length. Due to their enhanced SNR properties, system designs with smaller static magnetic field strength can be constructed for the same quality of imaging, leading to substantial reductions in system size and cost, as well as to enhanced imaging with existing MRI systems.

Owner:TURSIOP TECH

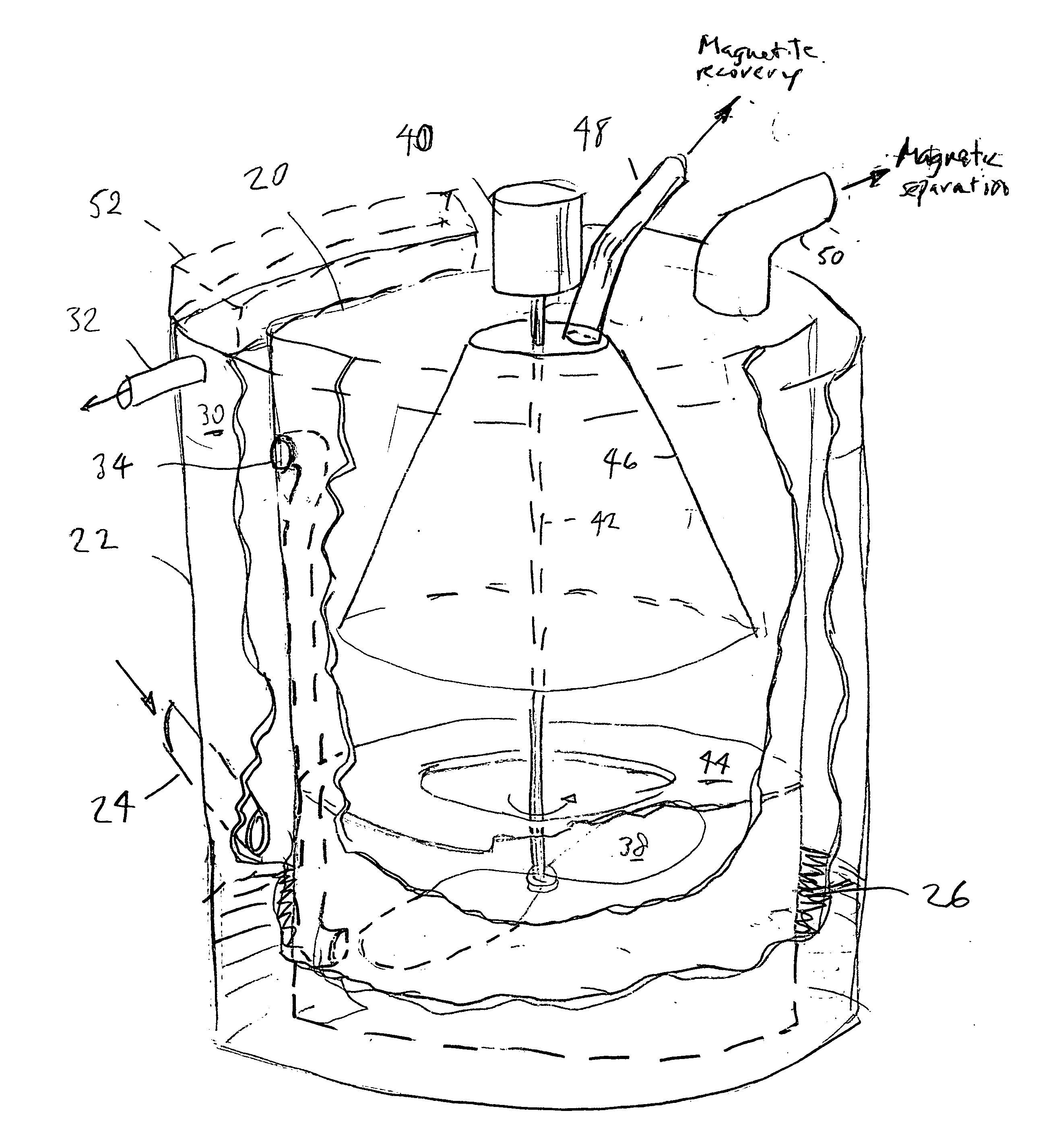

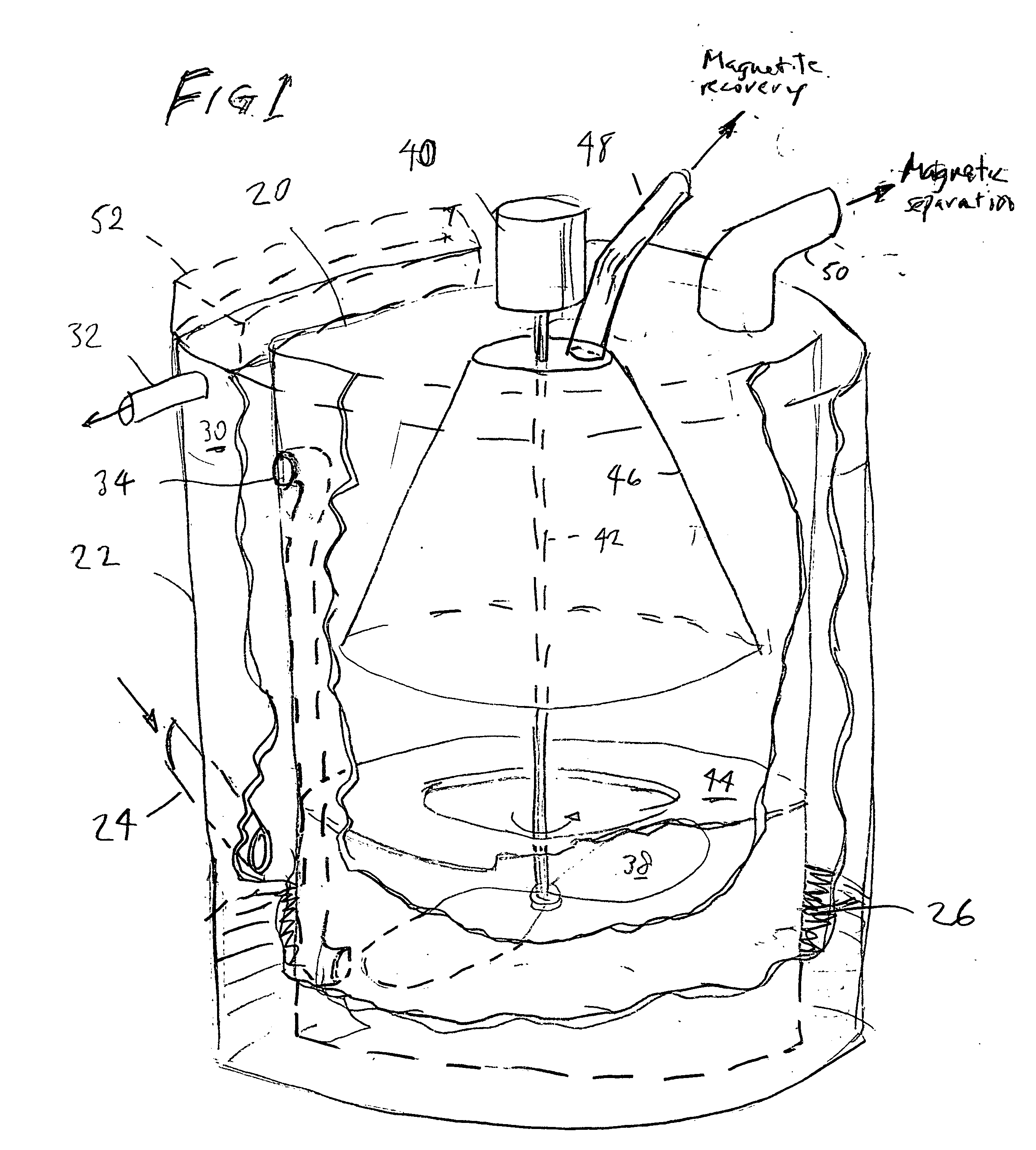

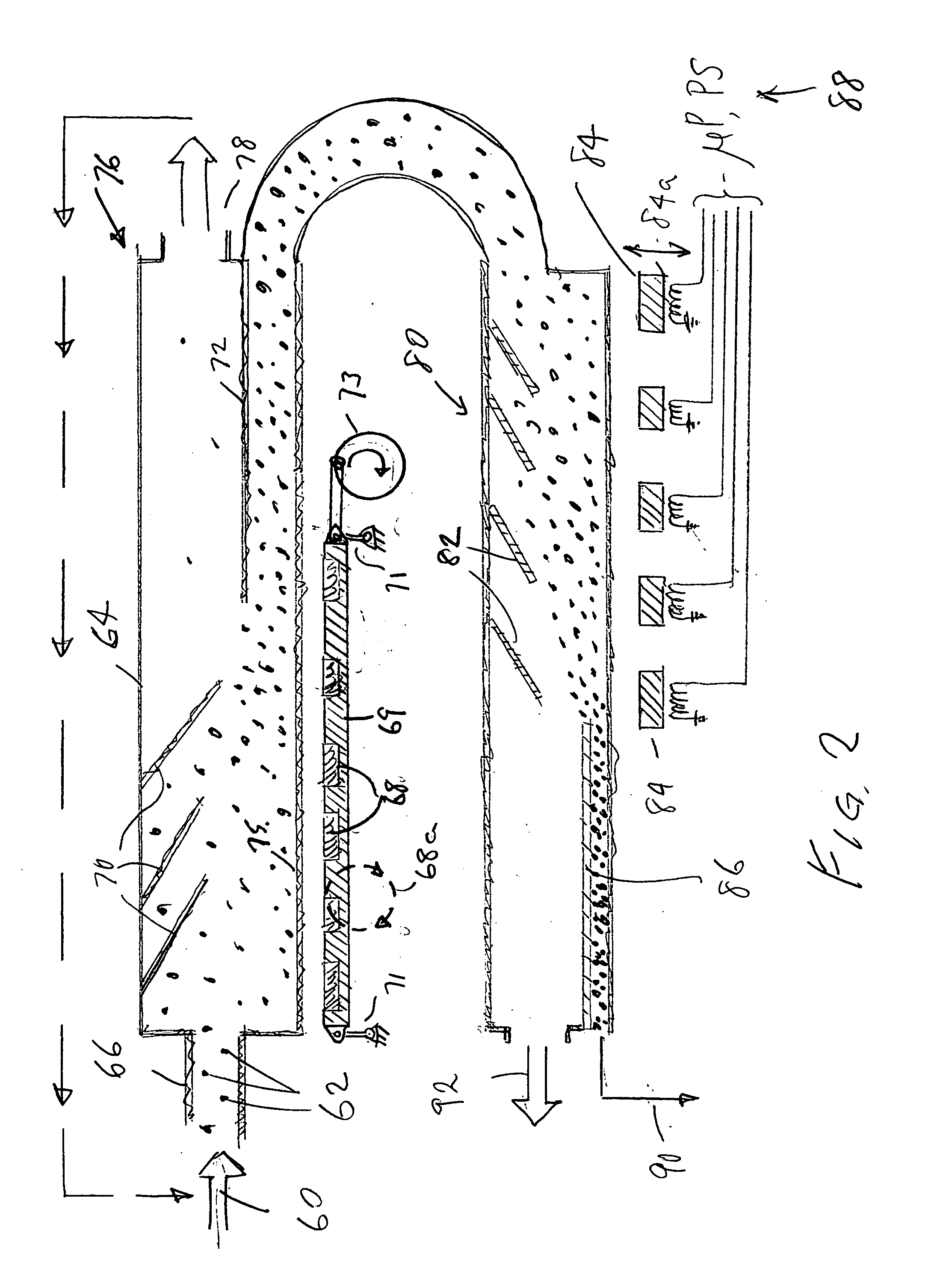

Water treatment using magnetic and other field separation technologies

InactiveUS20070039894A1Avoid scrappingInexpensive and mechanically simpleWater/sewage treatment by magnetic/electric fieldsSedimentation separationWater flowField separation

Apparatus and methods for removal of pollutants from a stream of water, by binding the pollutant particles to magnetic seeding particles using a flocculating polymer, and then removing the composite magnetic particles from the water stream in a simple and efficient apparatus. The invention is applicable to many common water treatment applications but is especially important for high flow applications requiring efficiency and simplicity. Magnetic fields concentrate the composite magnetic particles in a stratified layer that is then continually separated from the moving stream of water. In another preferred embodiment, vortex separation is combined with magnetic separation to enhance magnetic seed material cleaning and to reduce the solids load on the final magnetic collector.

Owner:CORT STEVEN L

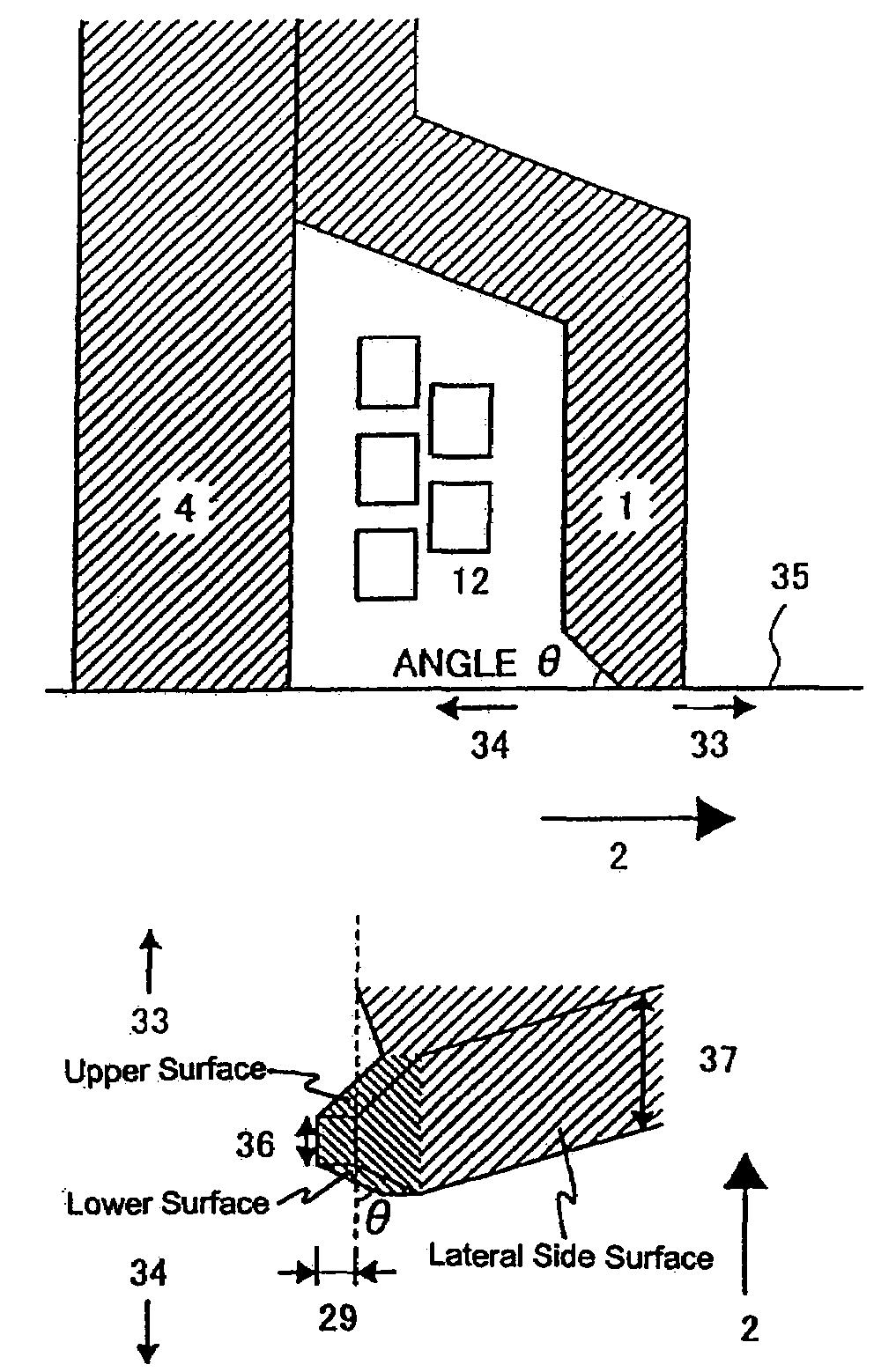

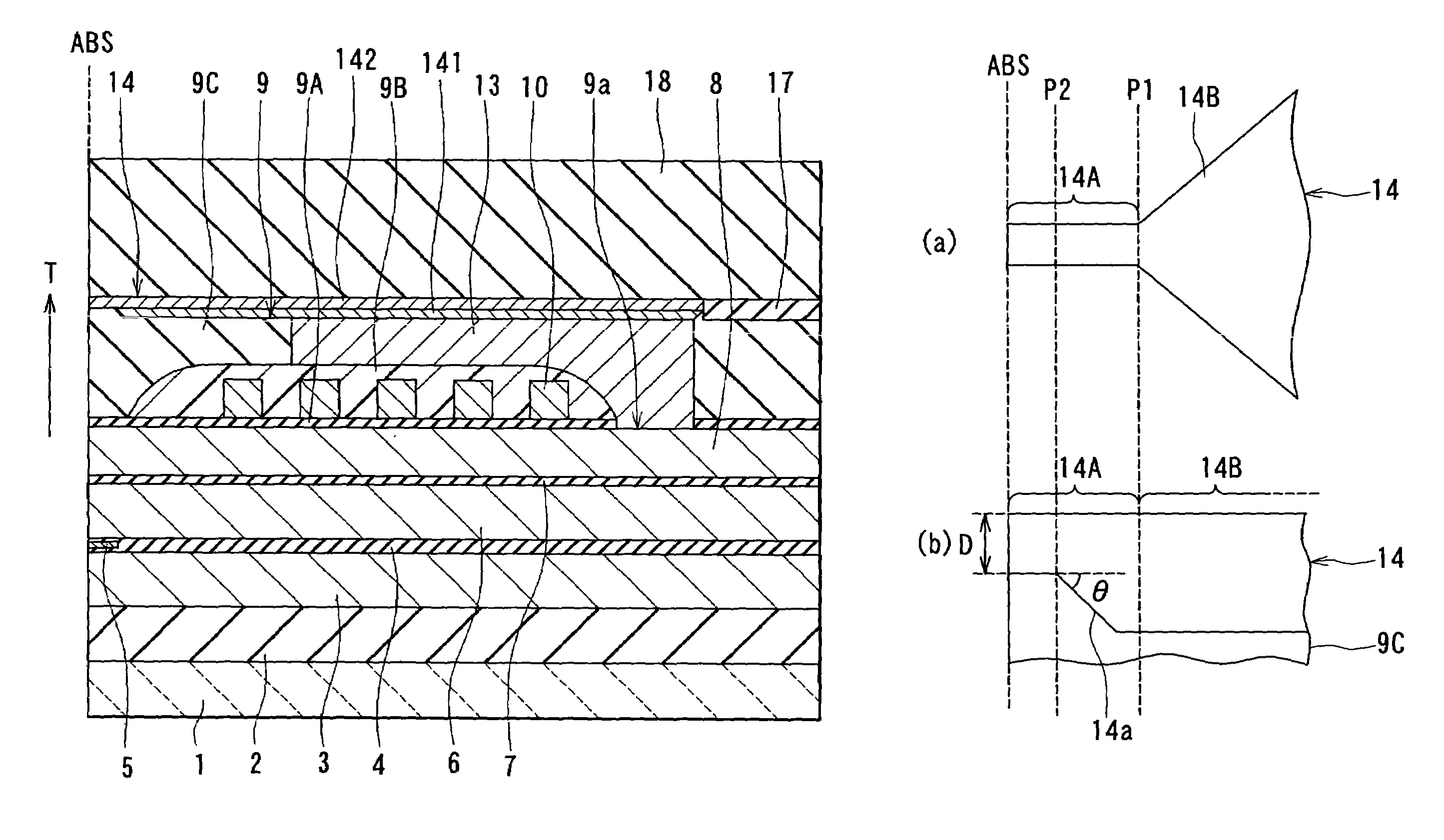

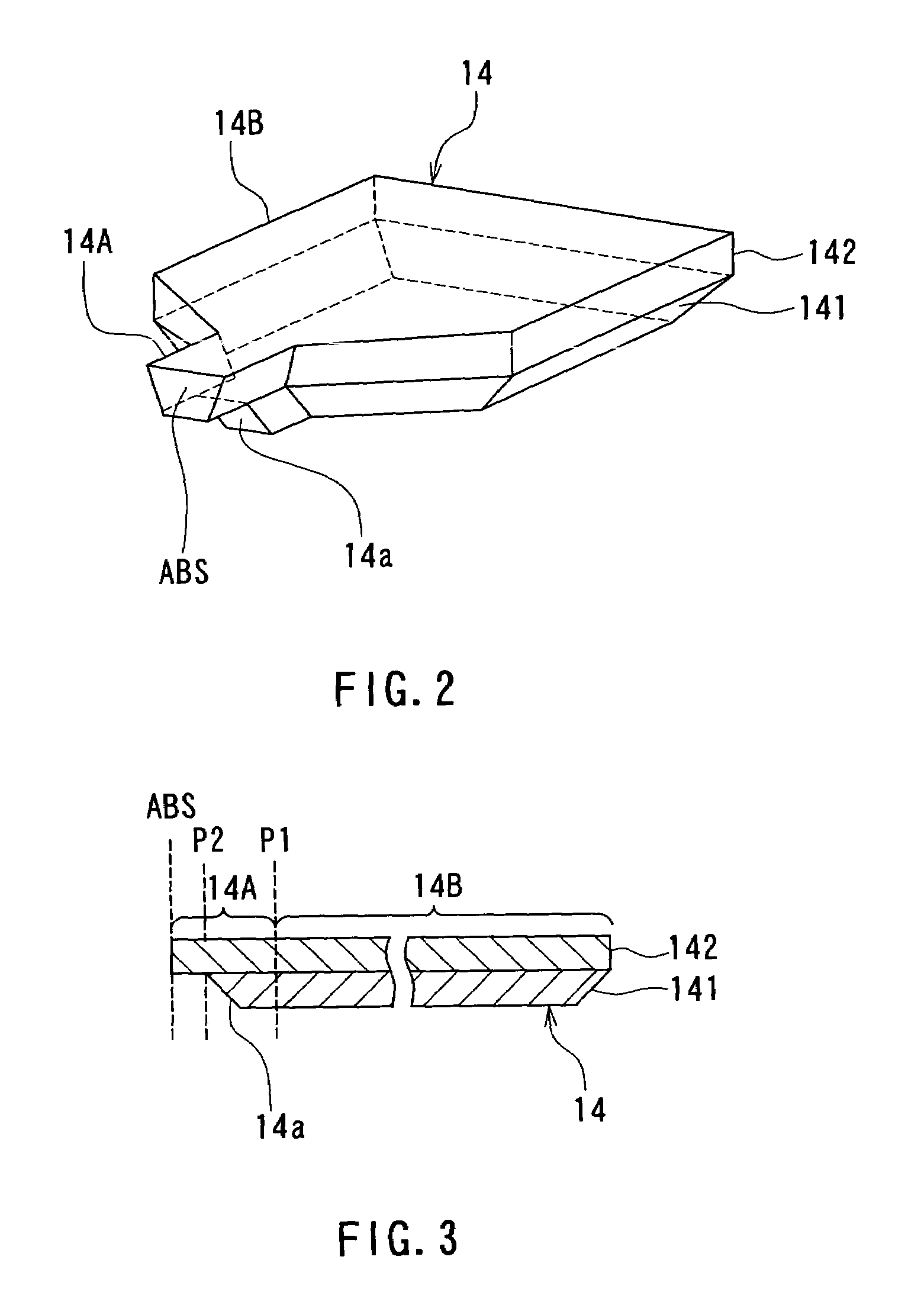

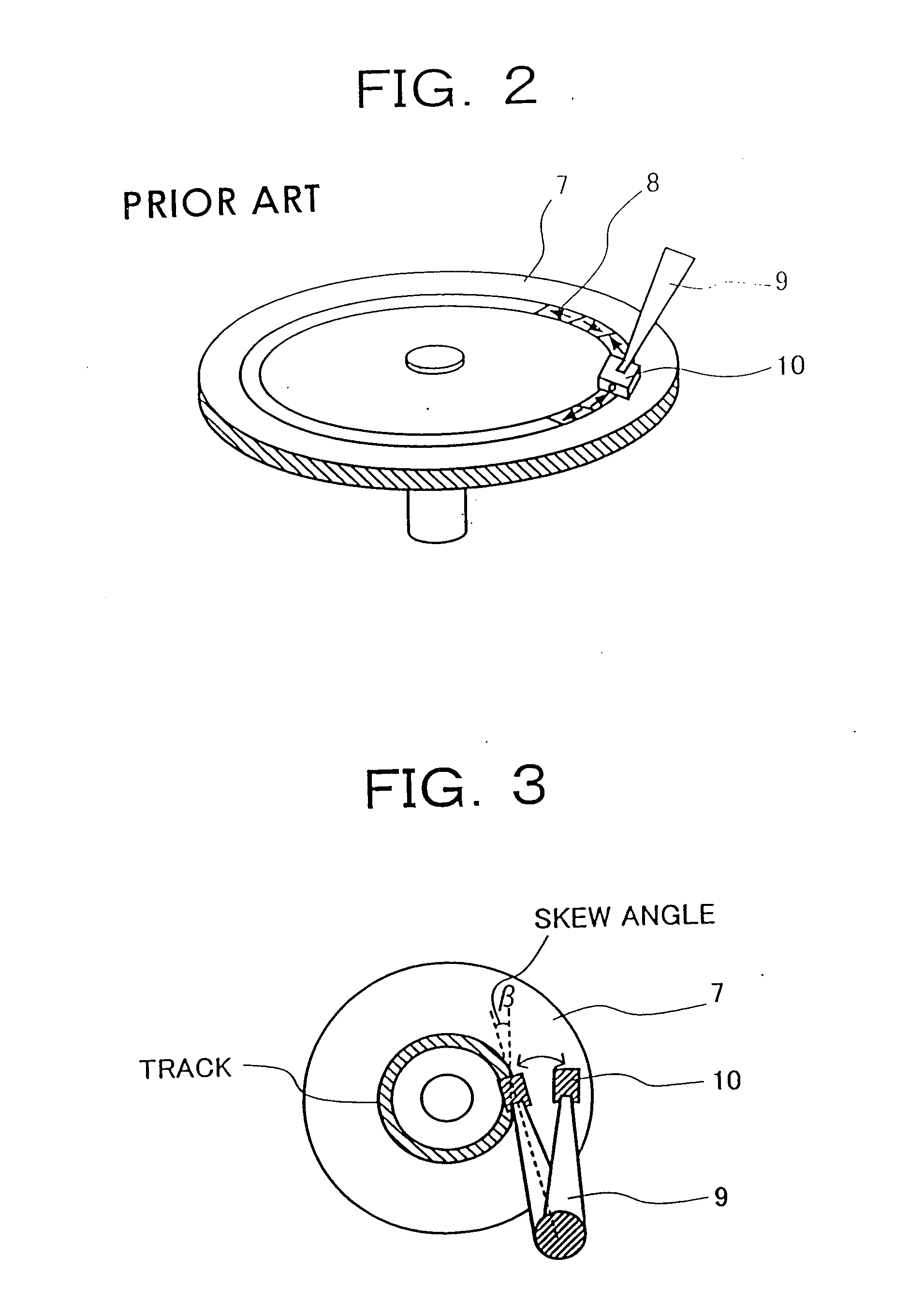

Magnetic head for vertical magnetic recording including main pole layer having varying width and thickness, head gimbal assembly, and hard disk drive

ActiveUS7245454B2Inhibition decreasedAvoid writingManufacture head surfaceHeads using thin filmsHard disc driveMagnetic flux

A write head of a magnetic head for vertical magnetic recording comprises: a coil; a main pole layer that allows the magnetic flux corresponding to the magnetic field generated by the coil to pass therethrough and generates a write magnetic field; an auxiliary pole layer; a gap layer provided between the main pole layer and the auxiliary pole layer; and a yoke layer for magnetically coupling the main pole layer to the auxiliary pole layer. The main pole layer has a flat top surface. In the main pole layer the position in which the thickness starts to increase is located between the medium facing surface and the position in which the width starts to increase.

Owner:TDK CORPARATION

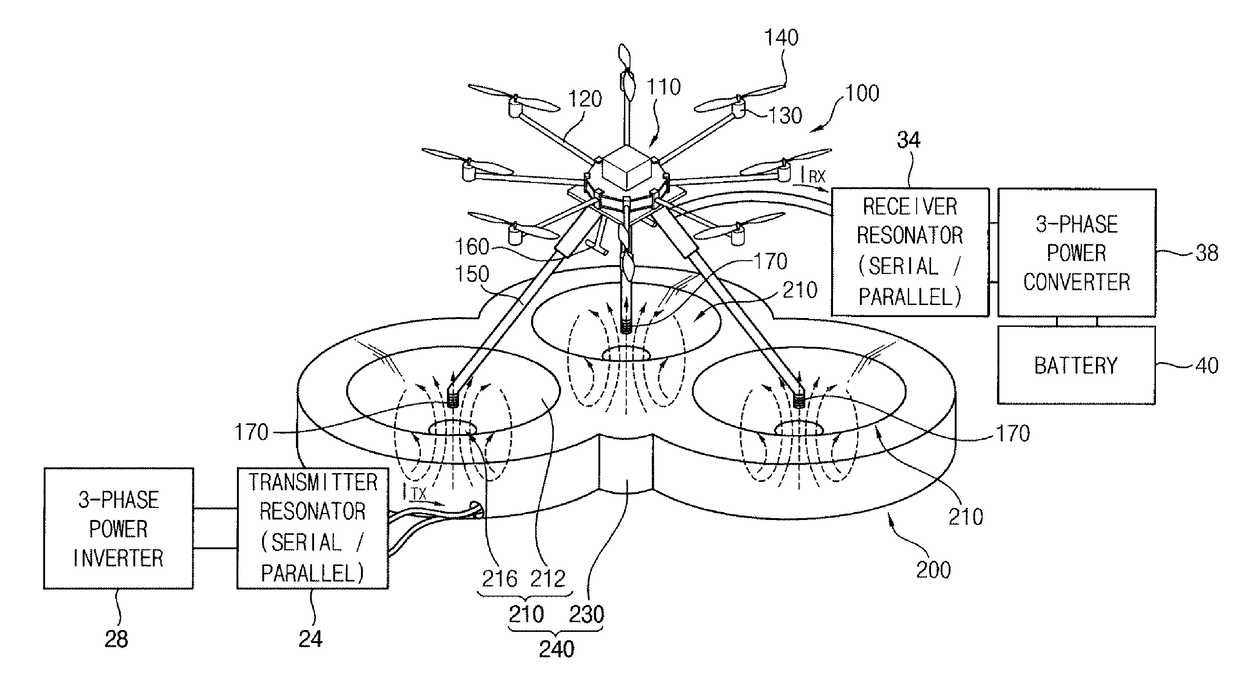

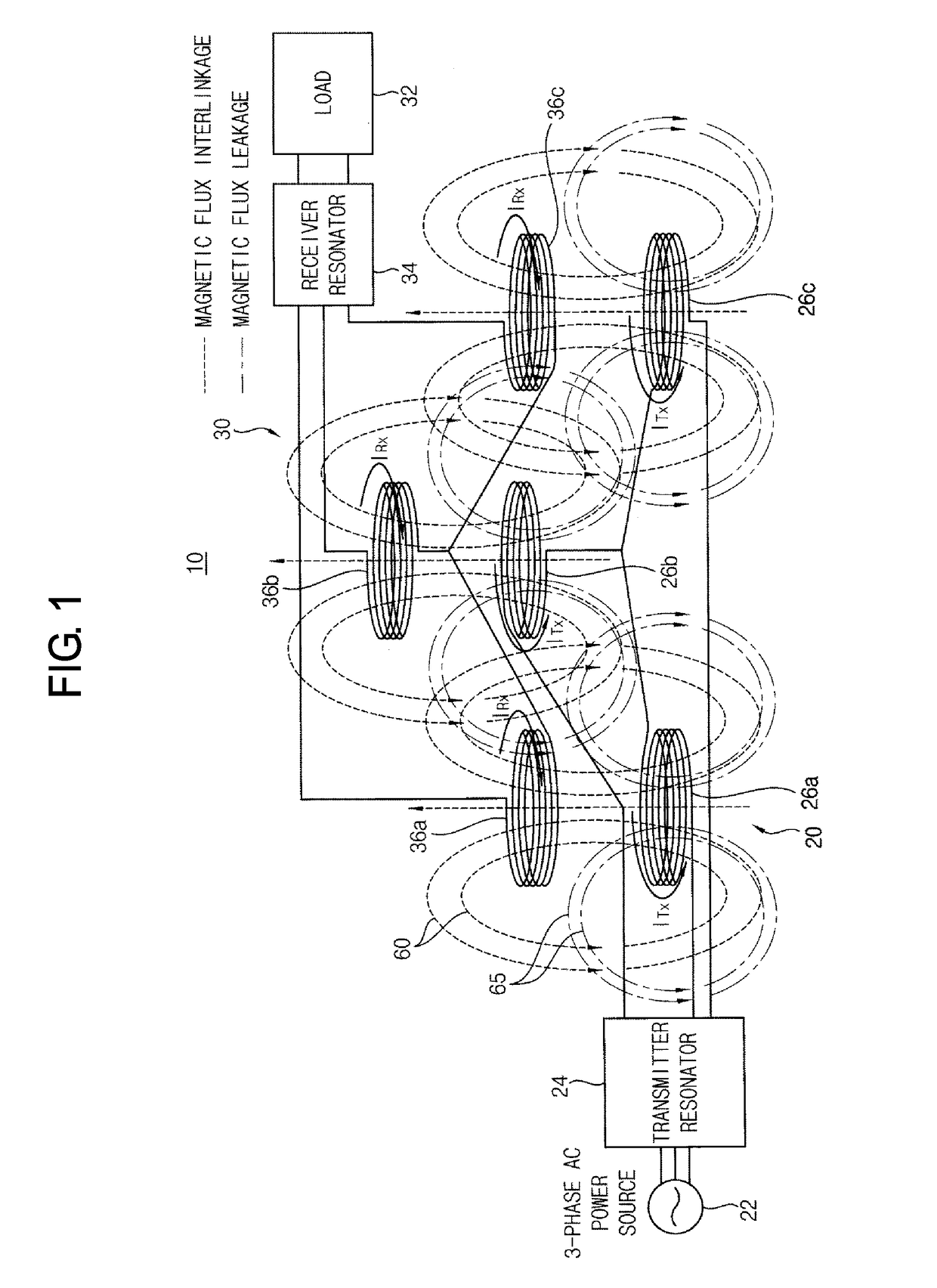

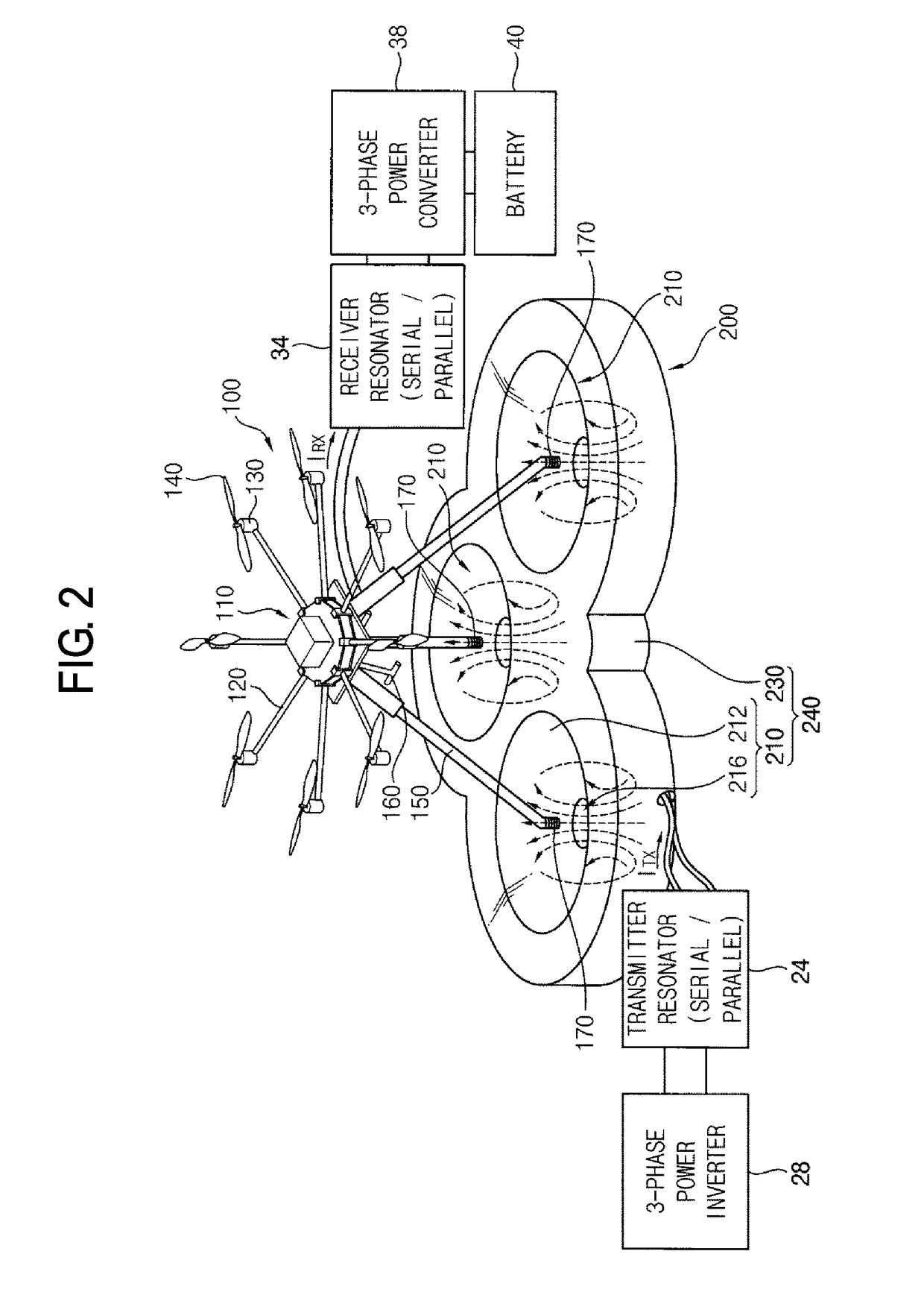

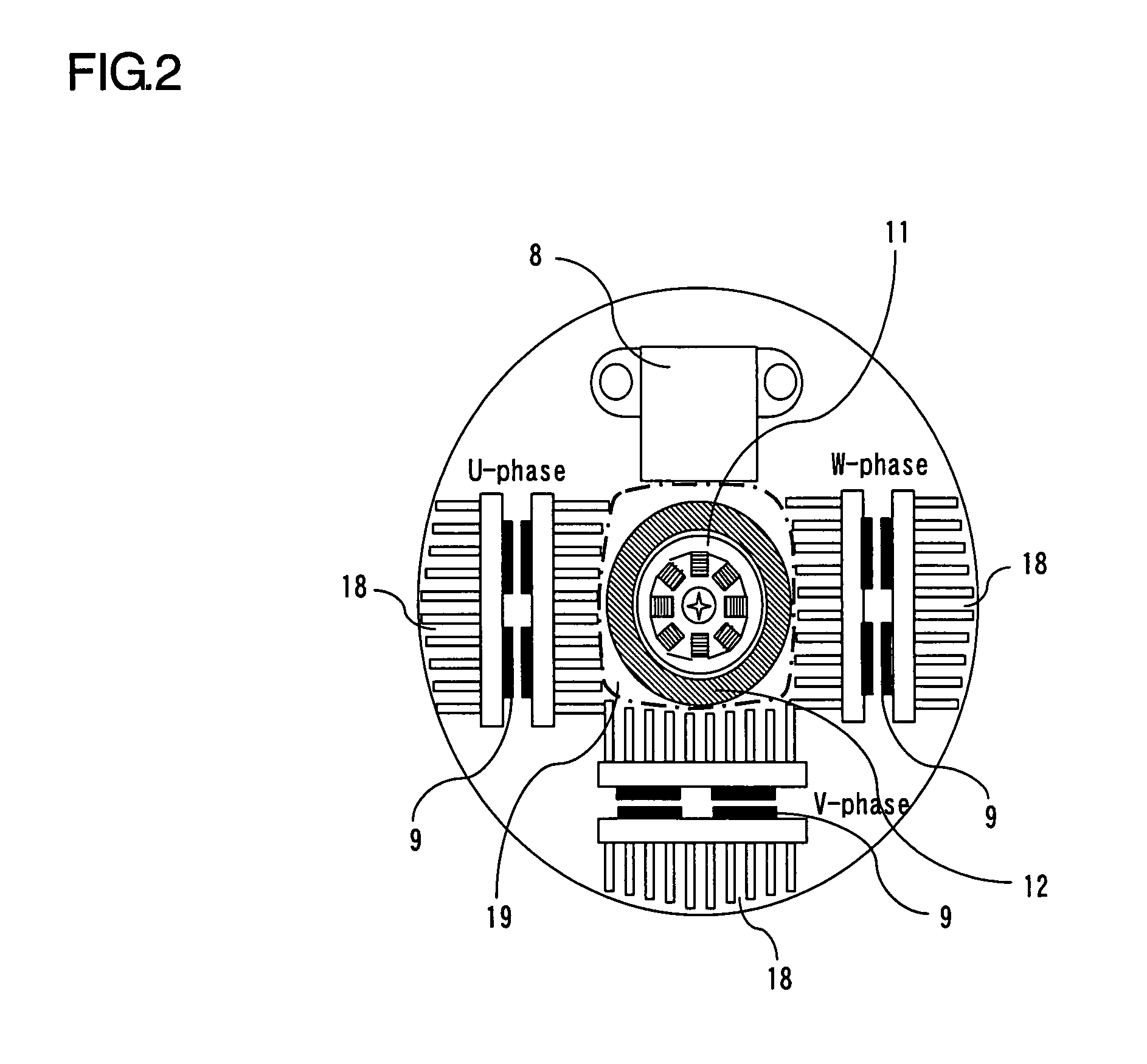

Three-Phase Wireless Power Transfer System And Three-Phase Wireless Chargeable Unmanned Aerial Vehicle System Based On The Same

ActiveUS20180056794A1Reduce magnetic field strengthReduce EMI noiseCharging stationsUnmanned aerial vehiclesElectric power transmissionDc current

Disclosed are a three-phase wireless power transfer (WPT) system and three-phase wireless rechargeable unmanned aerial vehicle (UAV) system based on the same. Three power receiving coils, including resonators, are installed at the ends of three landing leg of the UAV. A three-phase power converter installed in the UAV receives the three-phase AC induction current induced in three power receiving coils, including resonators, converting the three-phase AC induction current into a DC current to be charged in a battery. A three-phase power wireless charging apparatus wirelessly transfers three-phase power from three power transmitting coils to the three power receiving coils of the UAV when the three landing legs land on three coil seating units provided on a charging platform. A magnetic flux leakage shielding coil may be provided to prevent magnetic flux leakage from approaching the UAV. The power transfer efficiency is excellent, and electromagnetic interference can be also reduced.

Owner:KOREA ADVANCED INST OF SCI & TECH

Single pole type recording head with tapered edges

ActiveUS20060103978A1Improve controllabilityImprove accuracyNanotechRecord information storageLeading edgeMagnetic poles

A magnetic head for perpendicular recording without writing from the lateral sides of a main pole and without erasing data on adjacent tracks. A magnetic disk storage apparatus using the magnetic head. The lateral side of the main pole of a magnetic head for perpendicular recording may have an inverted tapered shape obtained by forming a groove as a track portion to an inorganic insulating layer and then forming a magnetic layer and then flattening the upper surface. A leading edge, a trailing edge, or both lateral edges of the magnetic head may be tapered. The taper may be either smooth and linear or curved in profile.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

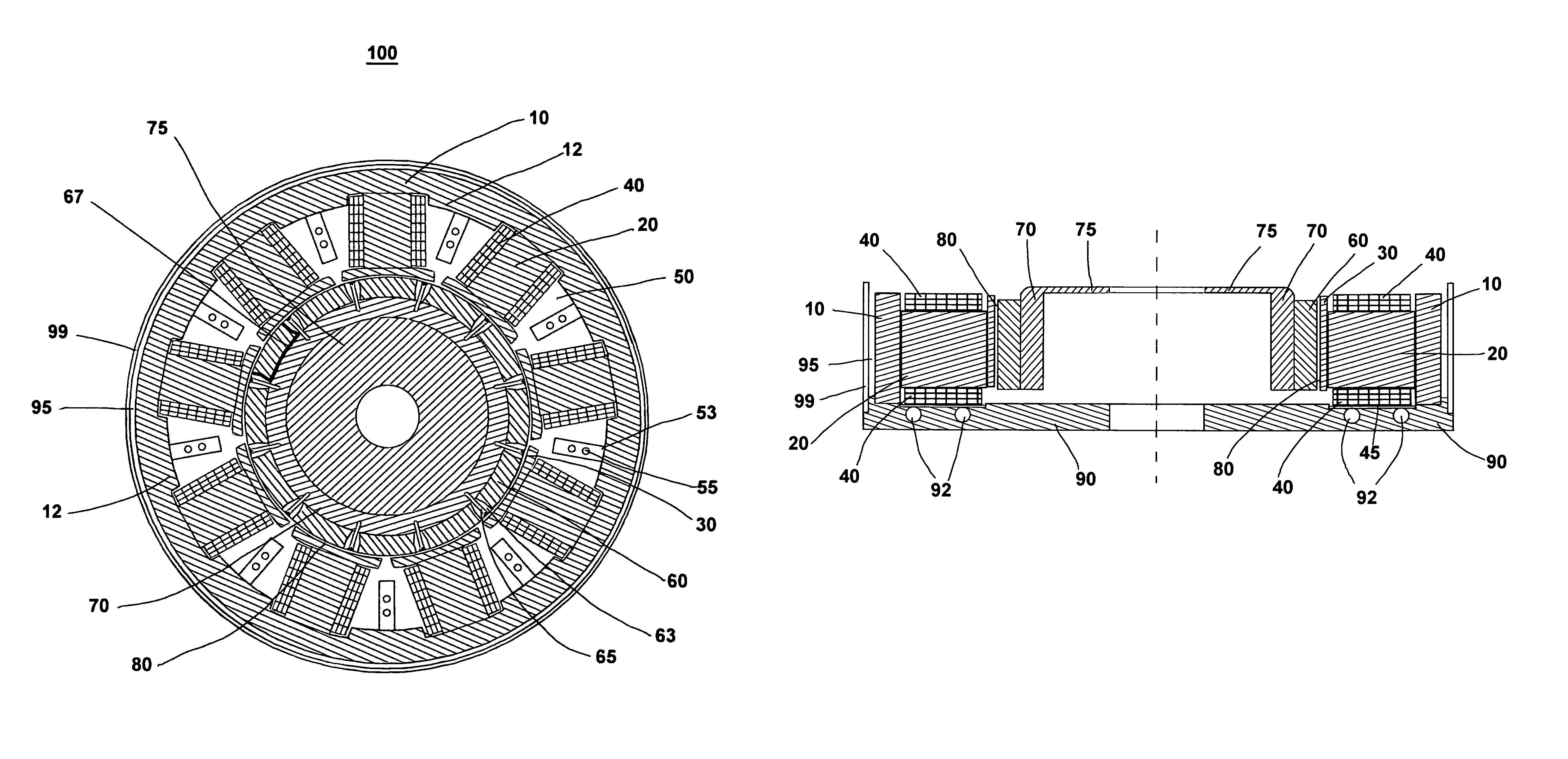

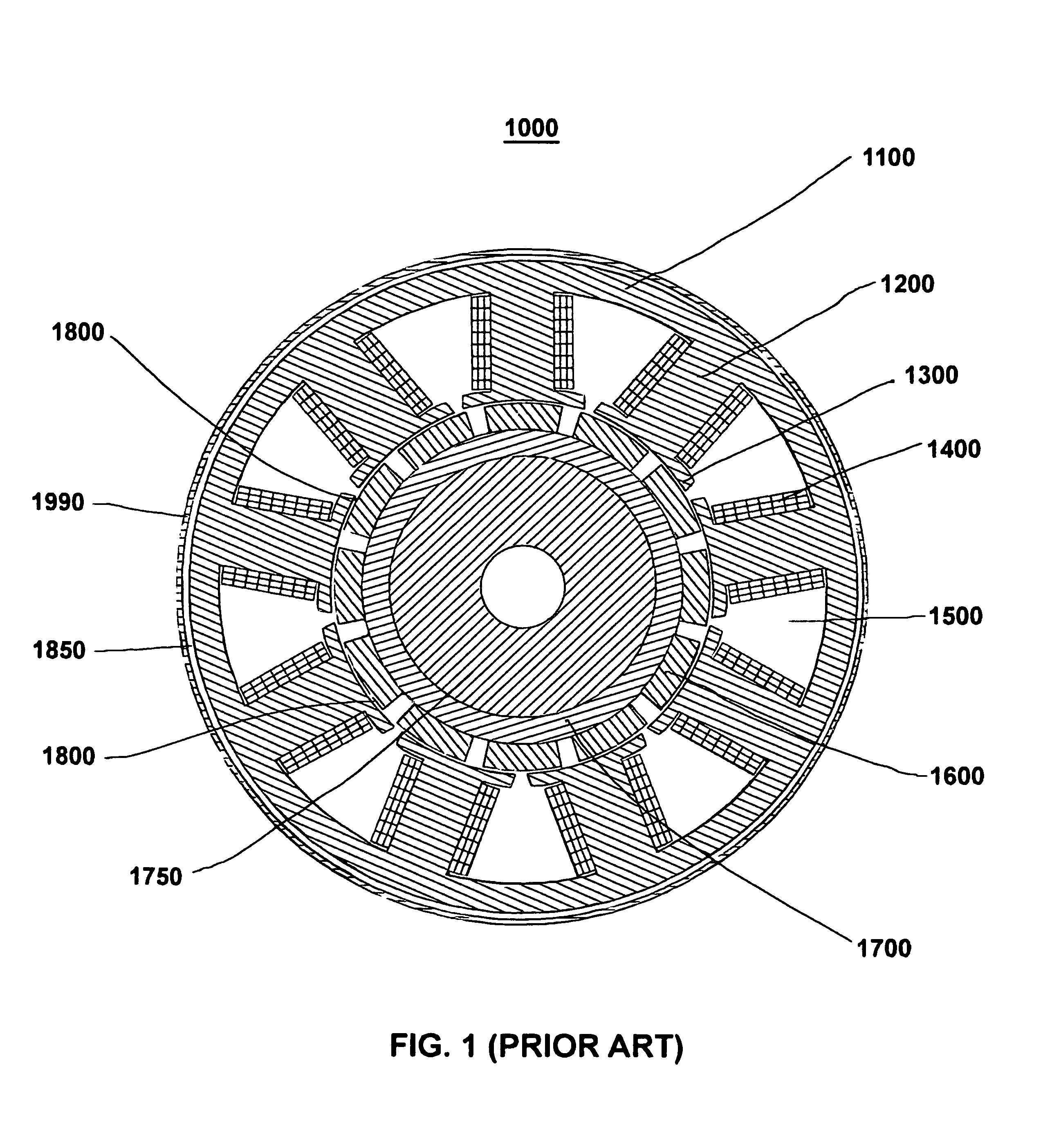

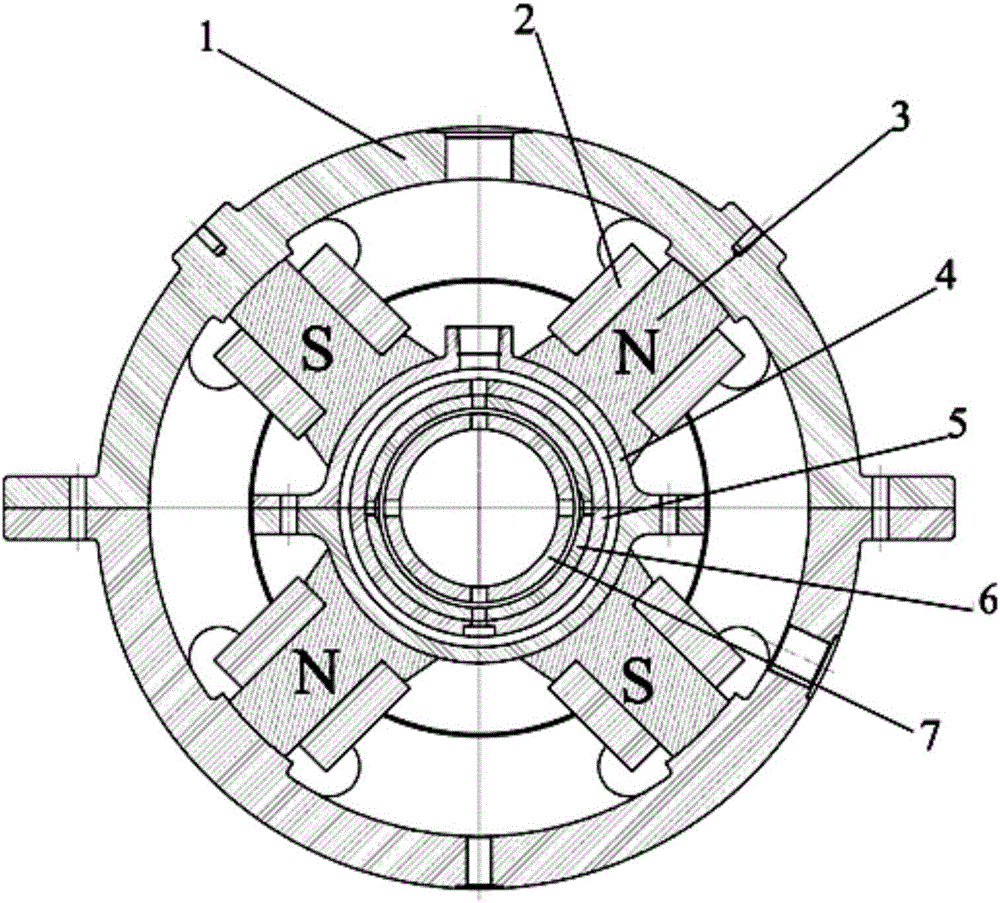

Radial flux permanent magnet AC motor/generator

InactiveUS8310126B1Heavy weightLow powerMagnetic circuit rotating partsMagnetic circuit stationary partsRing patternConductor Coil

A radial flux permanent magnet AC motor / generator employs a flat circular stator plate having a plurality of separately-formed electromagnets mounted in a ring pattern on a top surface thereof. A circular flux ring fabricated of powdered metal is mounted to the stator plate outside the ring of electromagnets. A plurality of permanent magnets are mounted in a ring pattern on the outer cylindrical surface of a steel rotor. The stator plate and rotor are axially and diametrically aligned such that the ring of permanent magnets rotates in close proximity to and inside the ring of electromagnets. The electromagnets utilize powder metal cores shaped to have rounded corners and flat sides that permit the use of heavier gauge windings and eliminate the air gaps that exist between the core and windings of prior art electromagnets.

Owner:PATENT LICENSORS

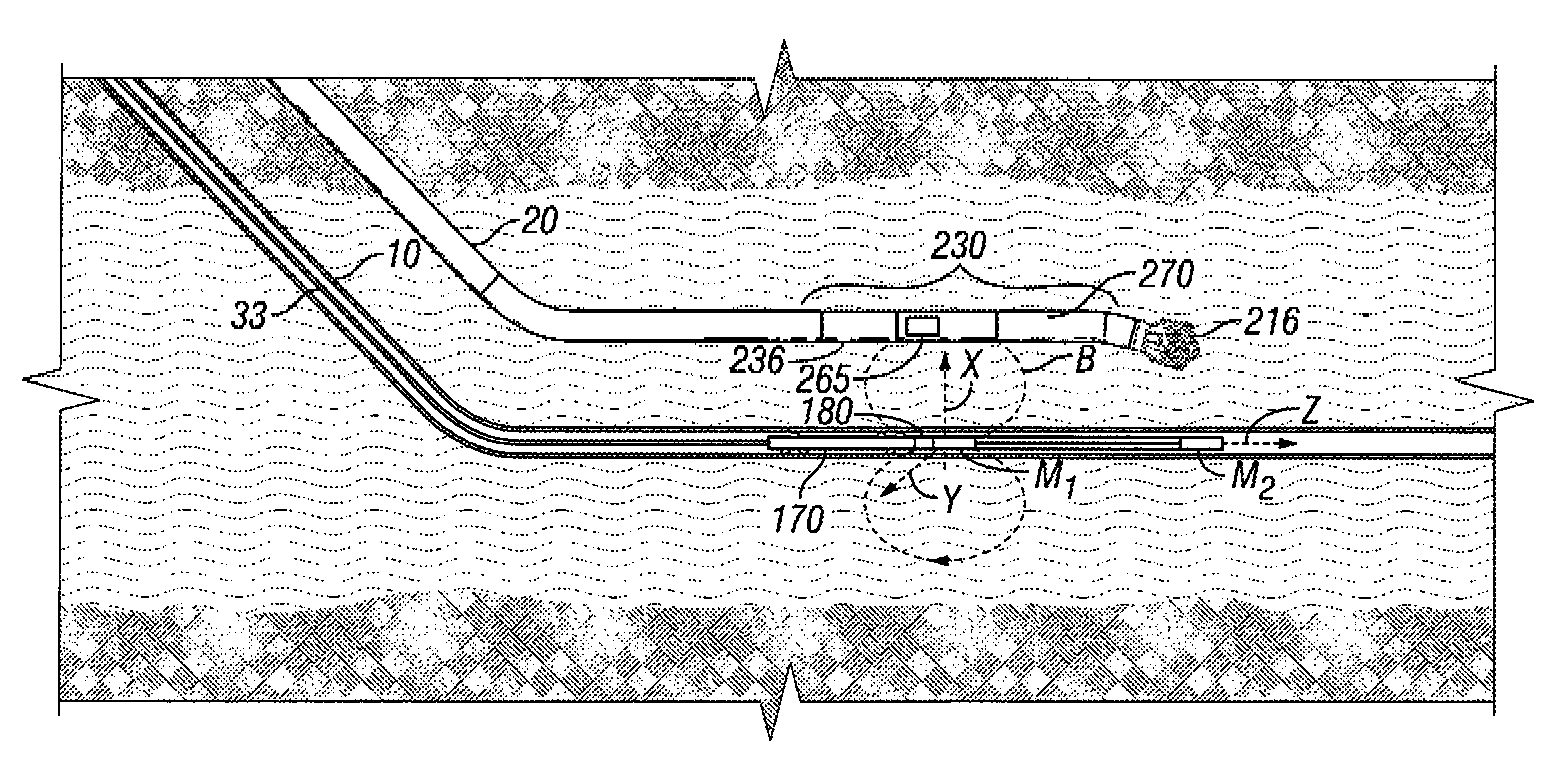

Element of an inductive coupler

ActiveUS7091810B2Reduce magnetic field strengthNear-field transmissionDrilling rodsAlloyConductive materials

An element for an inductive coupler in a downhole component comprises magnetically conductive material, which is disposed in a recess in annular housing. The magnetically conductive material forms a generally circular trough. The circular trough comprises an outer generally U-shaped surface, an inner generally U-shaped surface, and two generally planar surfaces joining the inner and outer surfaces. The element further comprises pressure relief grooves in at least one of the surfaces of the circular trough. The pressure relief grooves may be scored lines. Preferably the pressure relief grooves are parallel to the magnetic field generated by the magnetically conductive material. The magnetically conductive material is selected from the group consisting of soft iron, ferrite, a nickel iron alloy, a silicon iron alloy, a cobalt iron alloy, and a mu-metal. Preferably, the annular housing is a metal ring.

Owner:INTELLISERV LLC

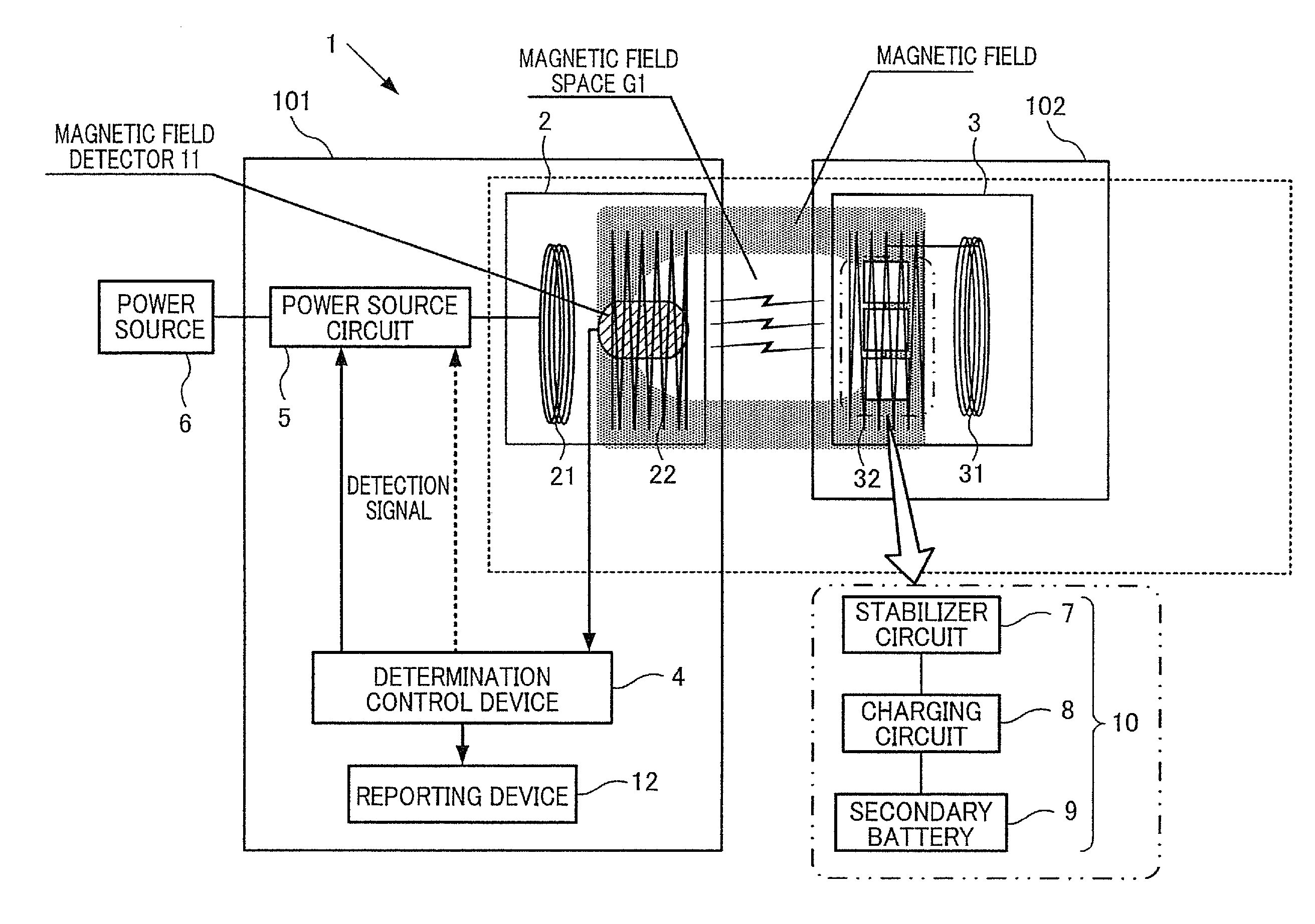

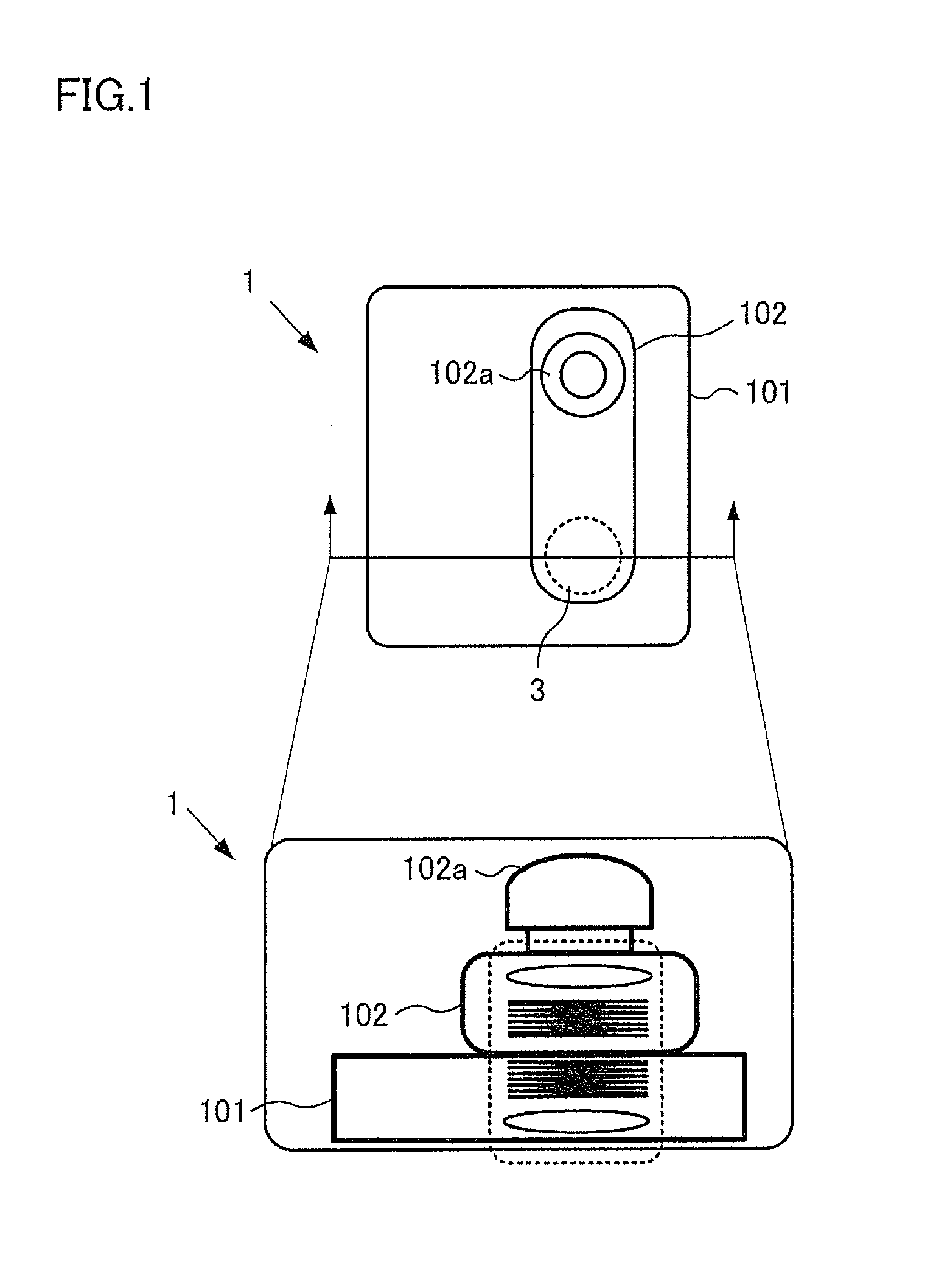

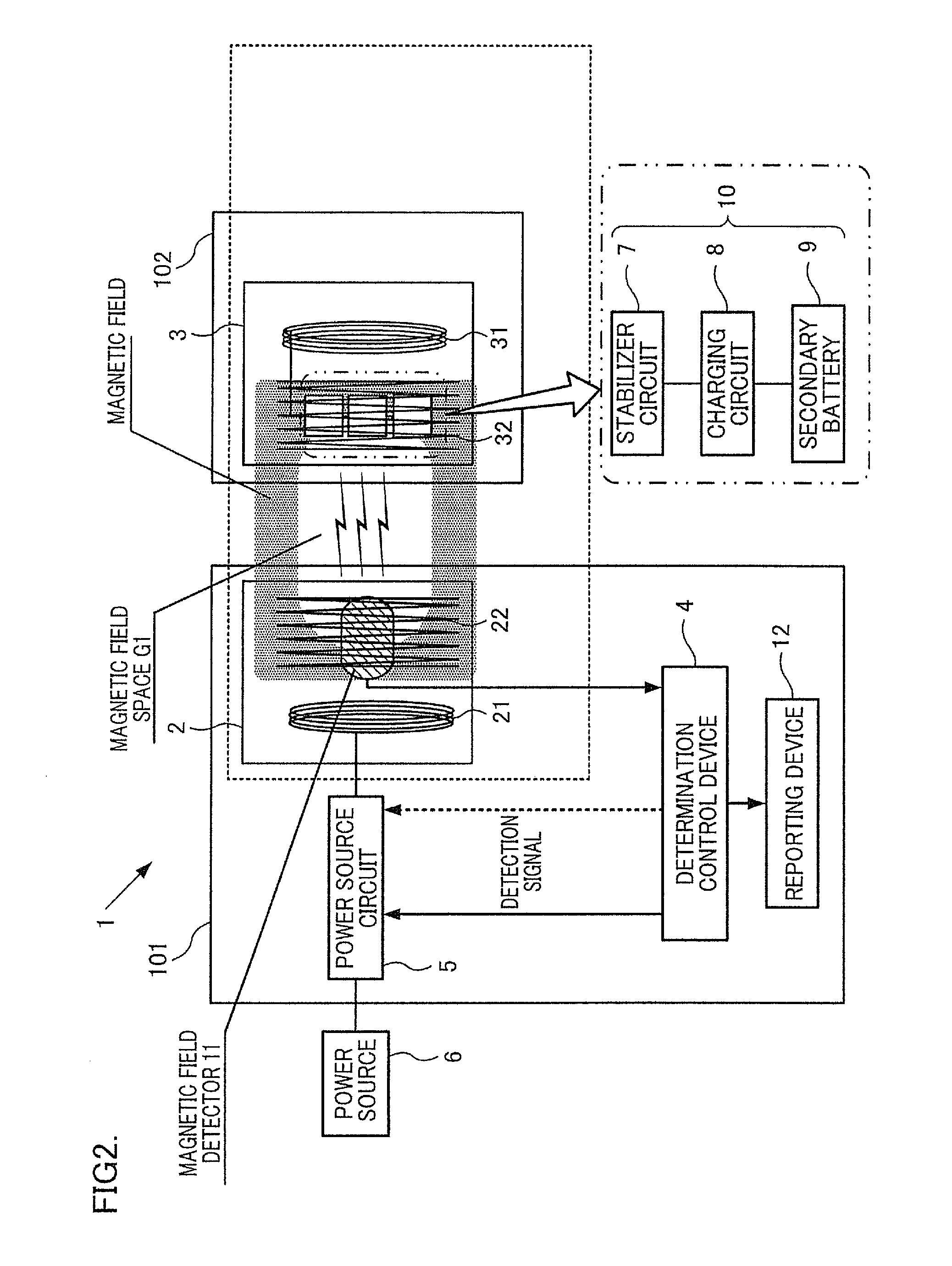

Wireless power transmission device

InactiveUS20160072306A1Reduce magnetic field strengthNear-field transmissionBatteries circuit arrangementsElectric forceResonance

There is provided a wireless power transmission apparatus including: a power-supplying module configured to supply power to a power-receiving module by means of a resonance phenomenon which is established between the power-supplying module and the power-receiving module so that a magnetic field space having a lower magnetic field strength than that of nearby portions is formed; a magnetic field detector which is disposed at a position where the magnetic field space is formed and which is configured to detect the magnetic field strength; and a determination control device configured to determine whether there is an anomaly in power supply to the power-receiving module based on a value of the magnetic field strength detected by the magnetic field detector.

Owner:NITTO DENKO CORP

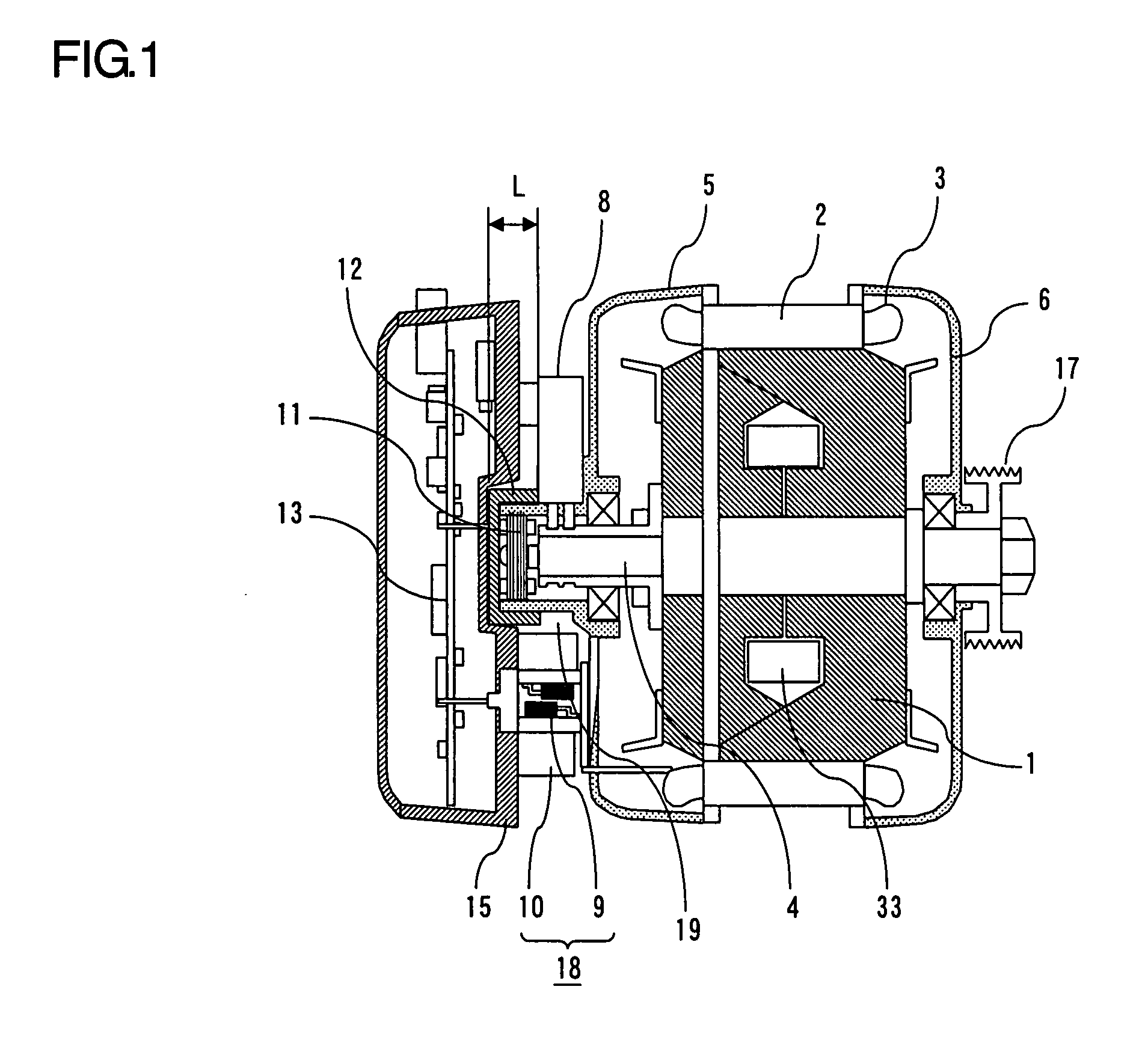

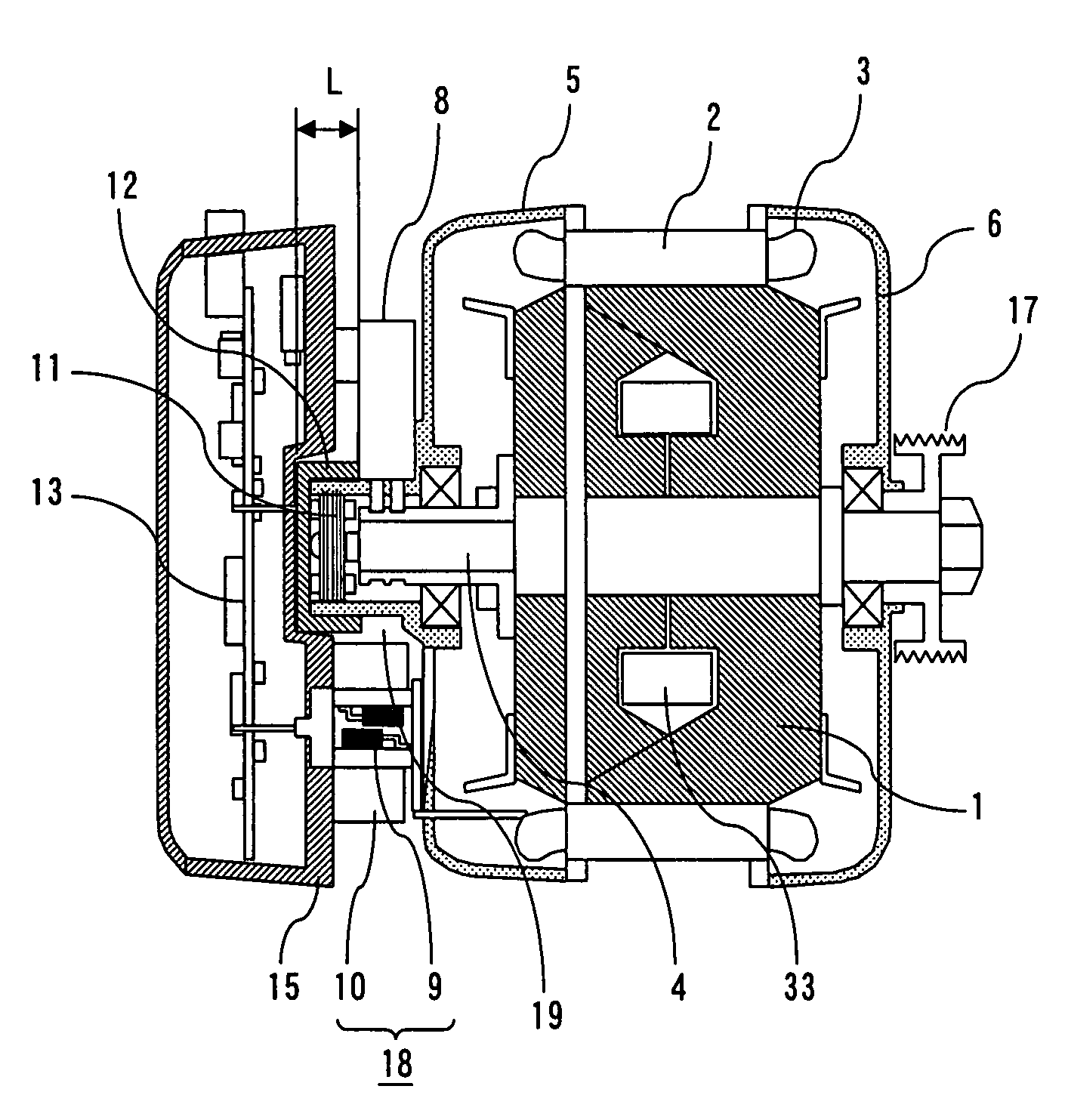

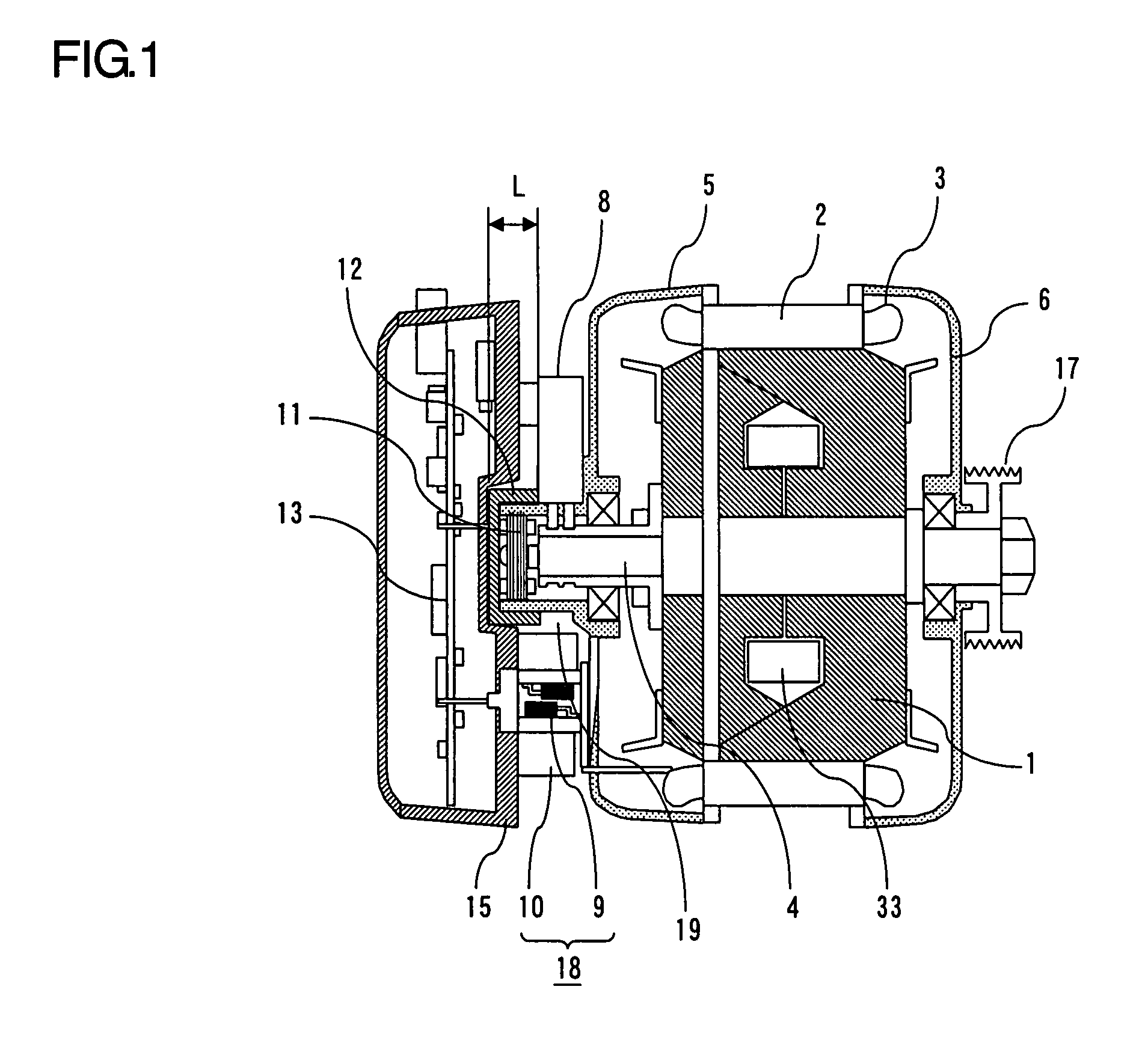

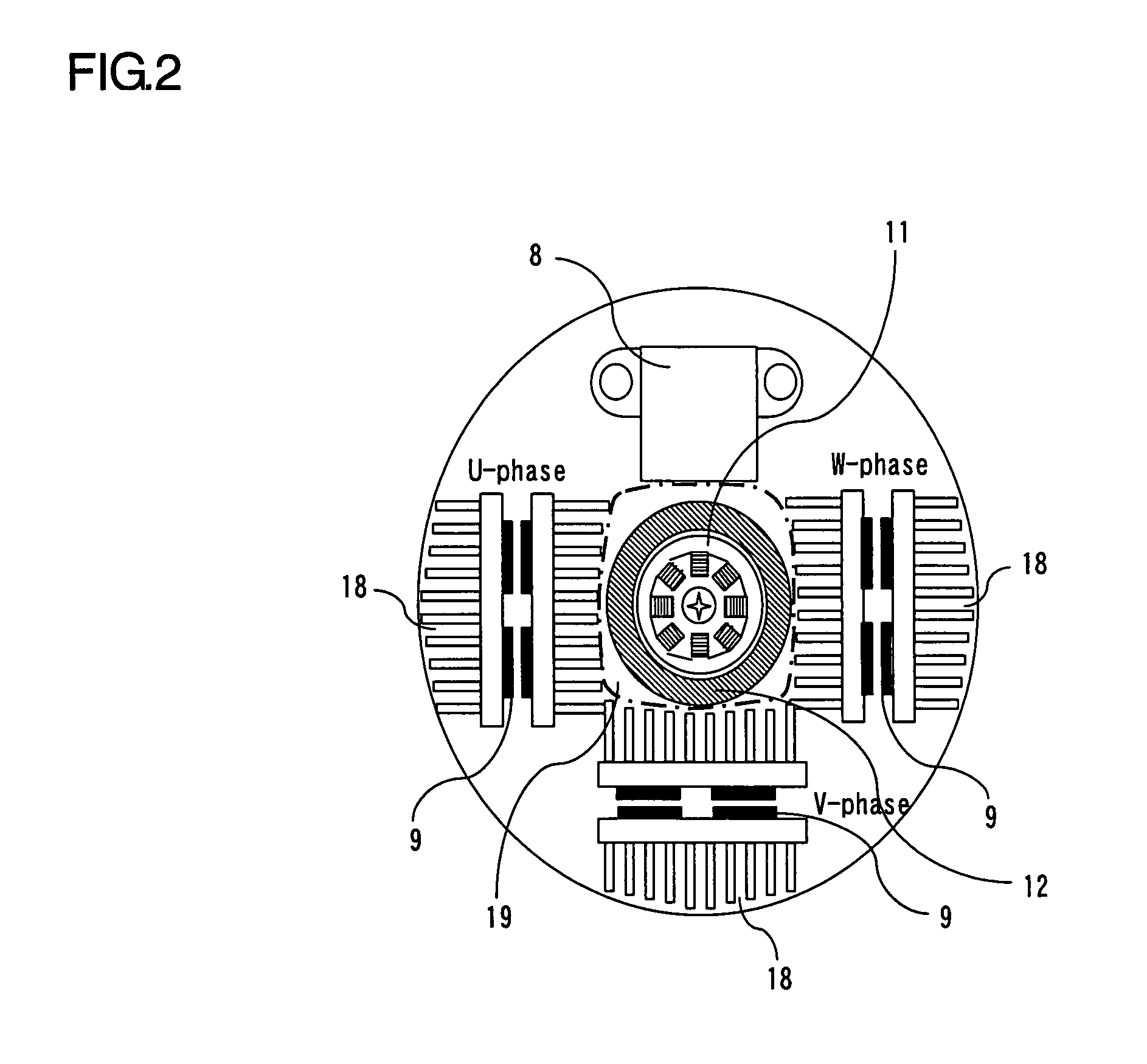

Electric rotating machine

ActiveUS20070216240A1Avoid failureReduce noiseSynchronous generatorsAssociation with control/drive circuitsElectric machineEngineering

An electric rotating machine comprises: a stator; a rotor that includes a rotary shaft, and rotates coaxially with the stator; a bracket supporting and fixing the stator, and supporting rotatably the rotary shaft; a rotational position detector disposed on the side opposite to the load of the rotary shaft to detect a rotational position of the rotor; and a power part including a switching element disposed on the outer circumferential side of the rotational position detector. A shield member is disposed at the rotational position detector to cover the circumference and shield a magnetic field generated by the switching element.

Owner:MITSUBISHI ELECTRIC CORP

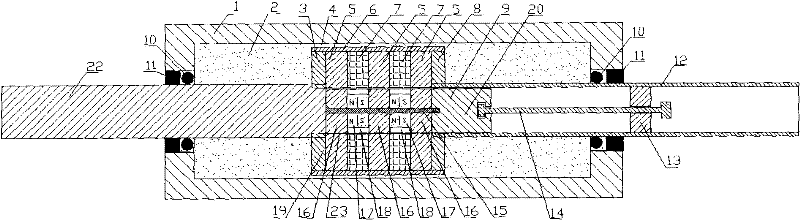

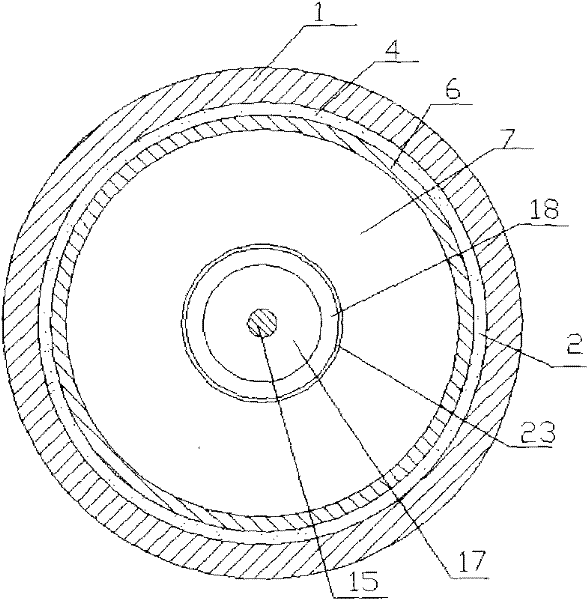

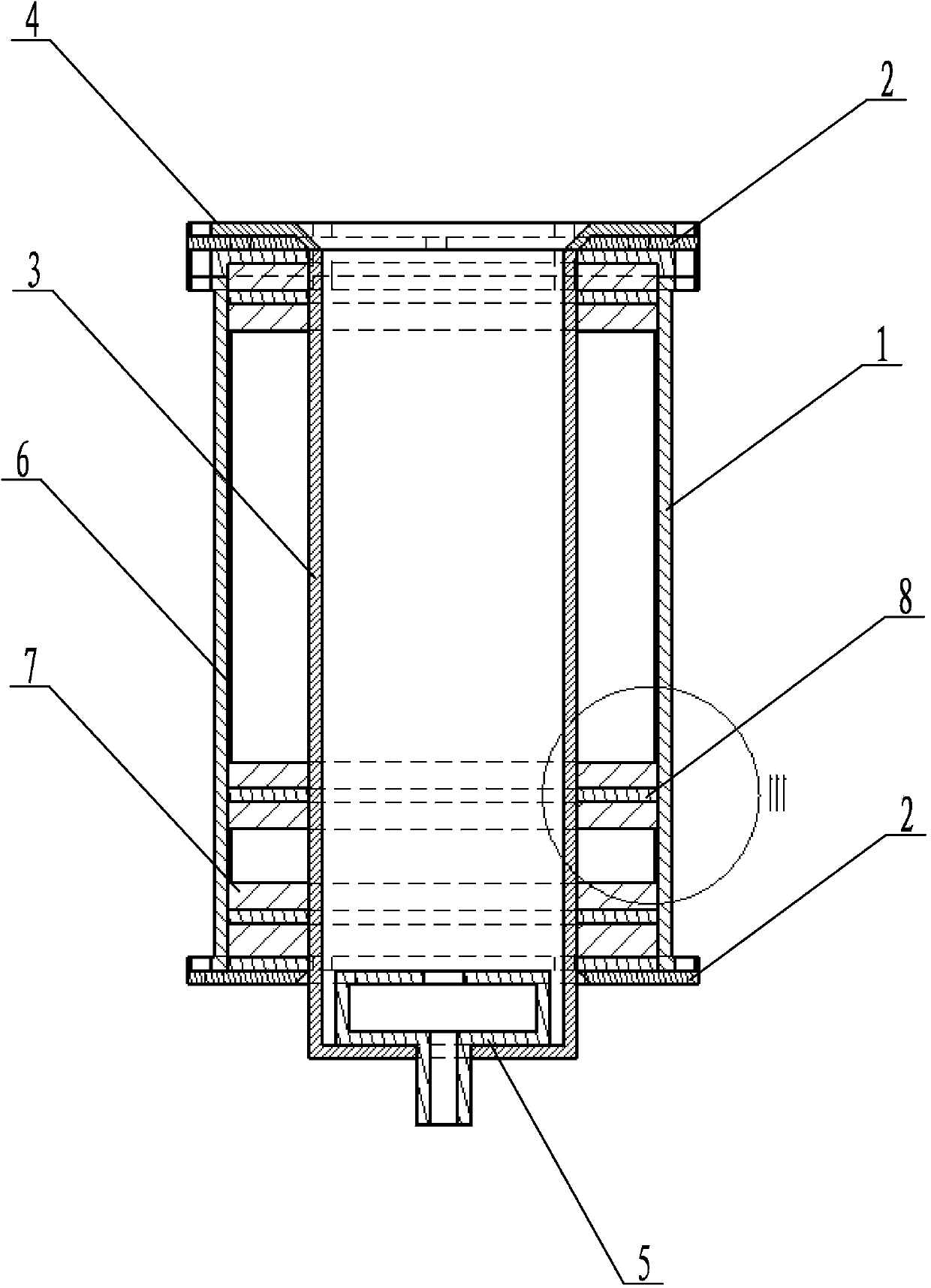

Damping force adjustable permanent magnet type magnetic current variable damper

InactiveCN101749358AEasy to useWide range of applicationsNon-rotating vibration suppressionMagnetEngineering

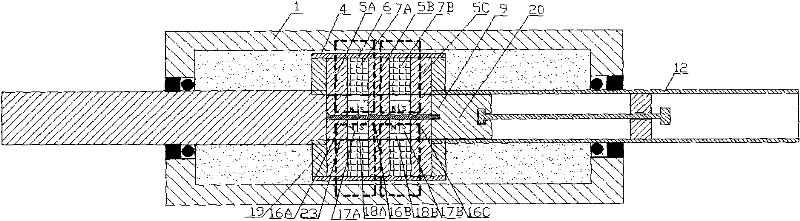

The invention discloses a damping force adjustable permanent magnet type magnetic current variable damper. The damper comprises a working cylinder, a piston, two piston rods, a built-in magnetic field generator and a position adjusting mechanism for the built-in magnetic field generator. The piston and one piston rod are both provided with a central through hole having a same diameter; the built-in magnetic field generator and the position adjusting mechanism for the built-in magnetic field generator are arranged in the piston and the piston rod which are provided with the central through hole; after a round high magnetic permeability metallic material is lapped with a round non-magnetic permeability metallic material which has a thickness as same as the high magnetic permeability metallic material, the piston is spliced, riveted or embedded into a non-magnetic permeability metallic tube so as to integrate together; and after a round high magnetic permeability metallic material is lapped with a round permanent magnet material which has a thickness as same as the high magnetic permeability metallic material, the built-in magnetic field generator is spliced, riveted or embedded into the non-magnetic permeability metallic tube so as to integrate together. The distance from the built-in magnetic field generator to a piston bottom hole can regulate the output damping force of the damping force adjustable permanent magnet type magnetic current variable damper.

Owner:CHONGQING MATERIALS RES INST

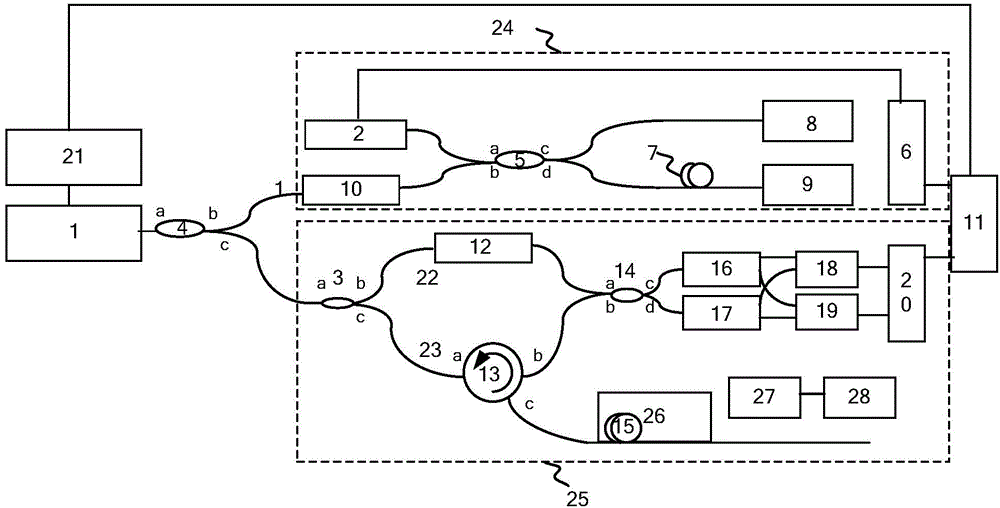

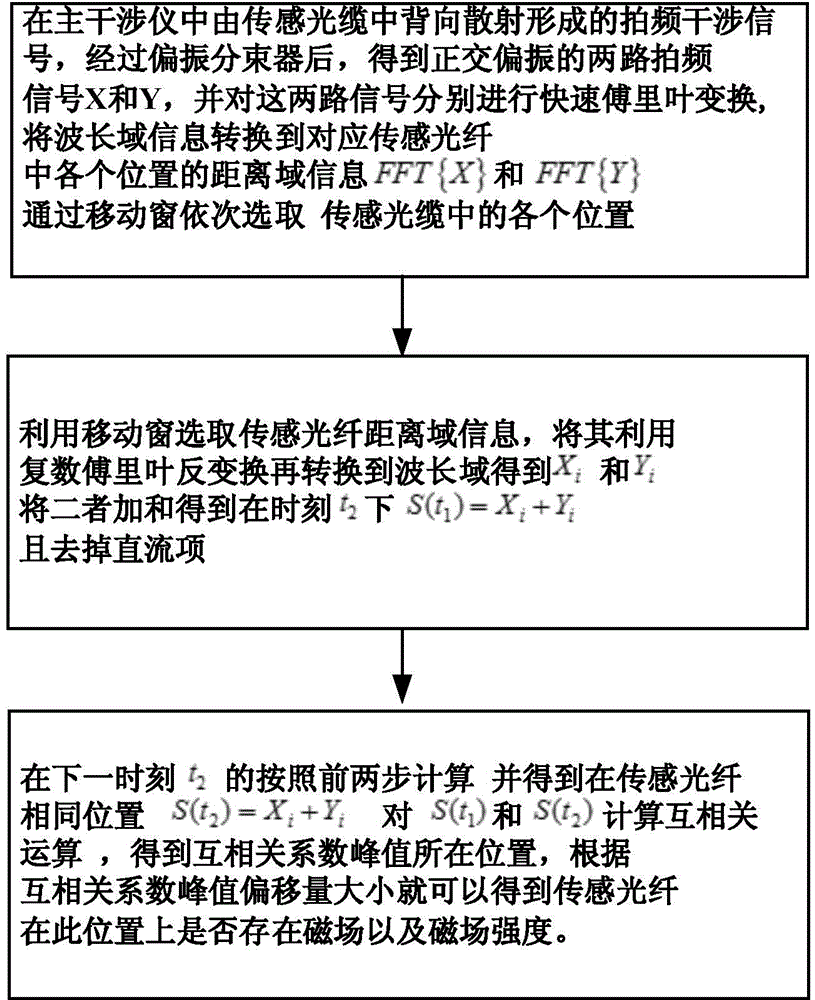

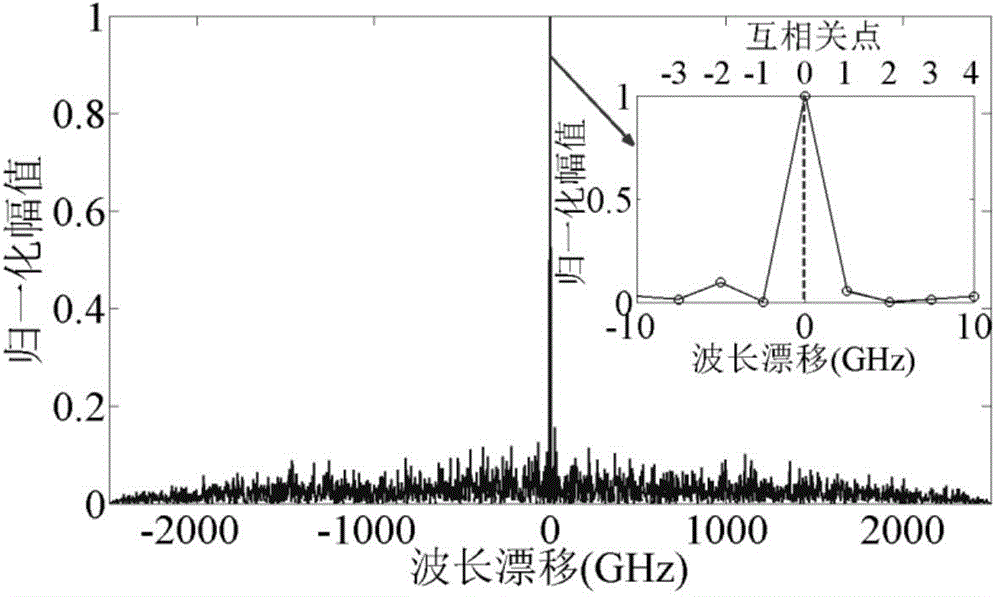

Distributed optical frequency domain reflection magnetic field sensing device based on magnetostriction and demodulation method

ActiveCN104155619AIncrease test distanceImprove spatial resolutionMagnetic field measurement using magneto-optic devicesFiberRayleigh scattering

The invention discloses a distributed optical frequency domain reflection magnetic field sensing device based on magnetostriction and a demodulation method, relating to the technical field of distributed optical fiber sensing instruments. The device comprises a main interferometer which obtains a sensing signal and an auxiliary interferometer which provides a clock trigger signal for a collection device, and a detected sensing fiber is packaged on a magnetostriction material. The method comprises the steps of obtaining different beat frequency signals at main interference through a light source of linear tuning, and converting wavelength domain information to distance domain information of each position in a corresponding sensing fiber by using rapid Fourier transform. The signal on the sensing fiber is selected through a mobile window, and then the conversion to a wavelength domain is carried out through plural rapid Fourier inverse transform, namely the Rayleigh scattering spectra. According to the distributed optical frequency domain reflection magnetic field sensing device and the demodulation method, the testing distance is raised, the spatial resolution and high, the accurate positioning of a multiple-point magnetic field can be carried out at the same time, the magnetic field strength can be measured at 5.3mT to the minimum, the testing distance can reach more than 300meters, and the magnetic field positioning accuracy can reach 14centimeters.

Owner:TIANJIN UNIV

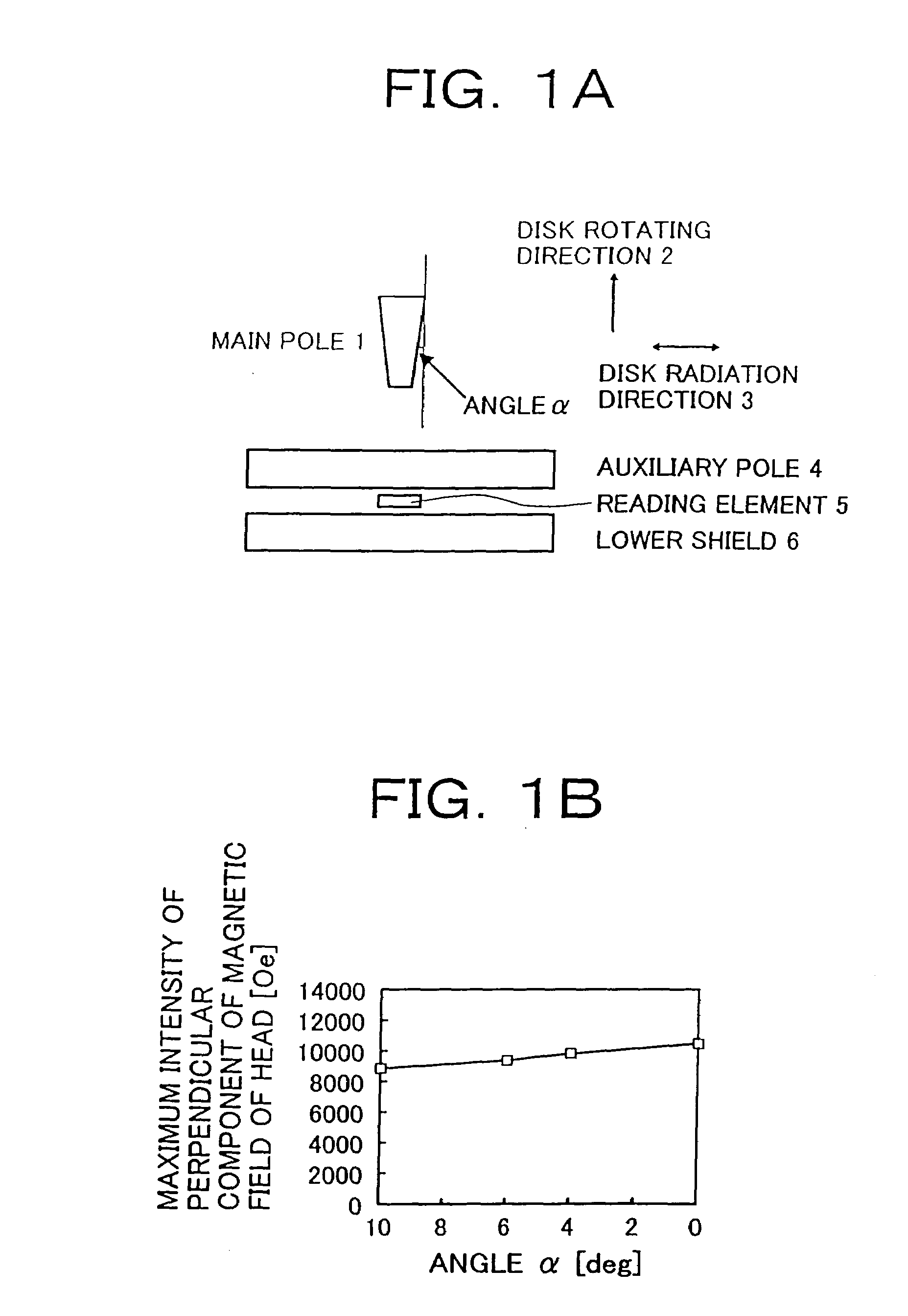

Perpendicular magnetic recording head

ActiveUS20080278862A1Suppress side fringingReduce magnetic field strengthManufacture head surfaceRecord information storageMagnetic polesEngineering

To provide a perpendicular magnetic recording head which can suppress side fringing while keeping the recording magnetic field intensity from decreasing.In a perpendicular magnetic recording head comprising a main magnetic pole layer and a return yoke layer which are laminated with a magnetic gap layer interposed therebetween on a medium-opposing surface, and a pair of side shield layers positioned on both sides in the track width direction of the main magnetic pole layer while interposing a nonmagnetic material layer therebetween, the magnetic gap layer is constituted by a first gap layer formed in a partial area in the track width direction bridging the main magnetic pole layer and the pair of side shield layers, and a second gap layer thinner than the first gap layer and interposed between the return yoke layer and the pair of side shield layers in a remaining area where the first gap layer is absent.

Owner:TDK CORPARATION

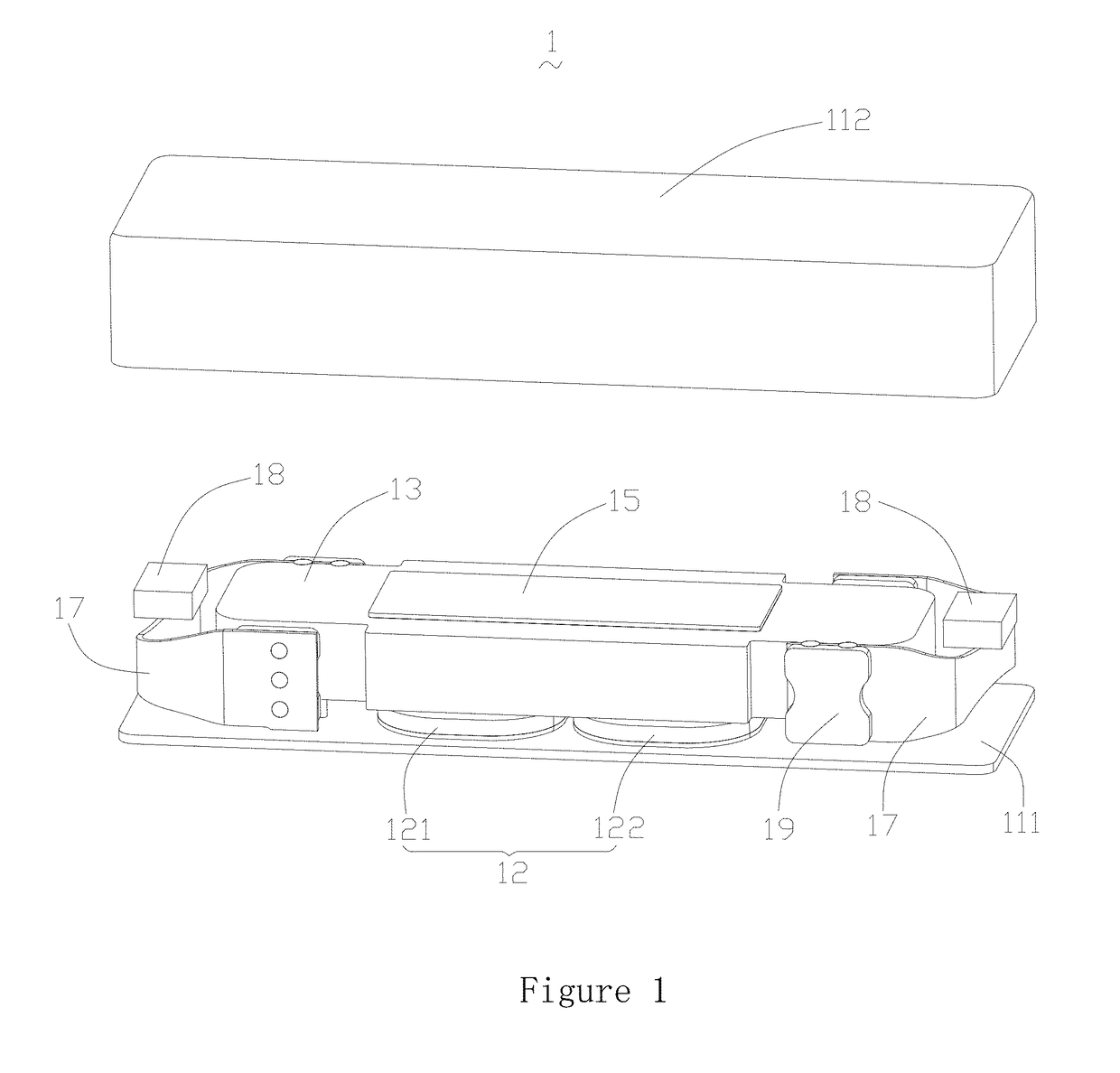

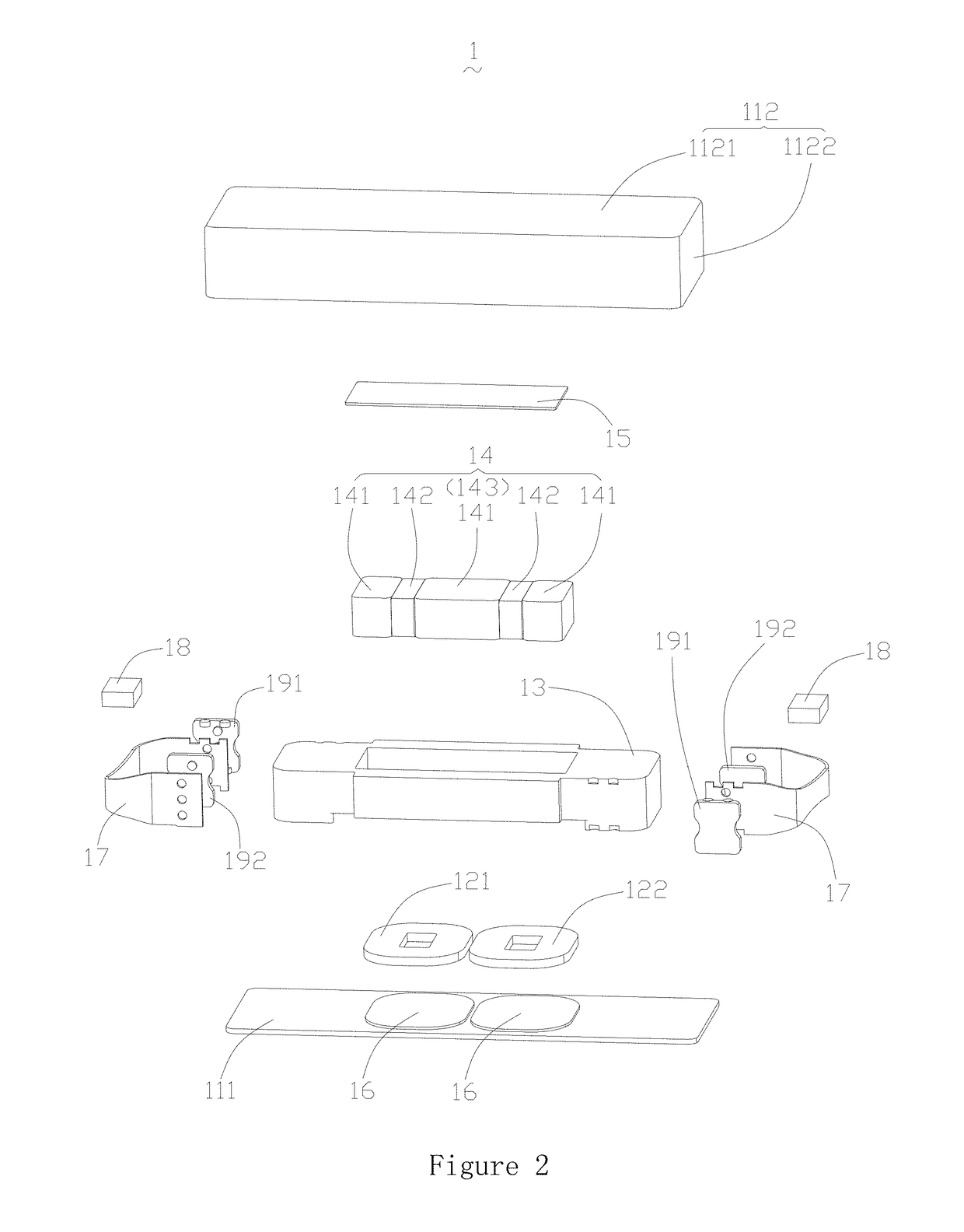

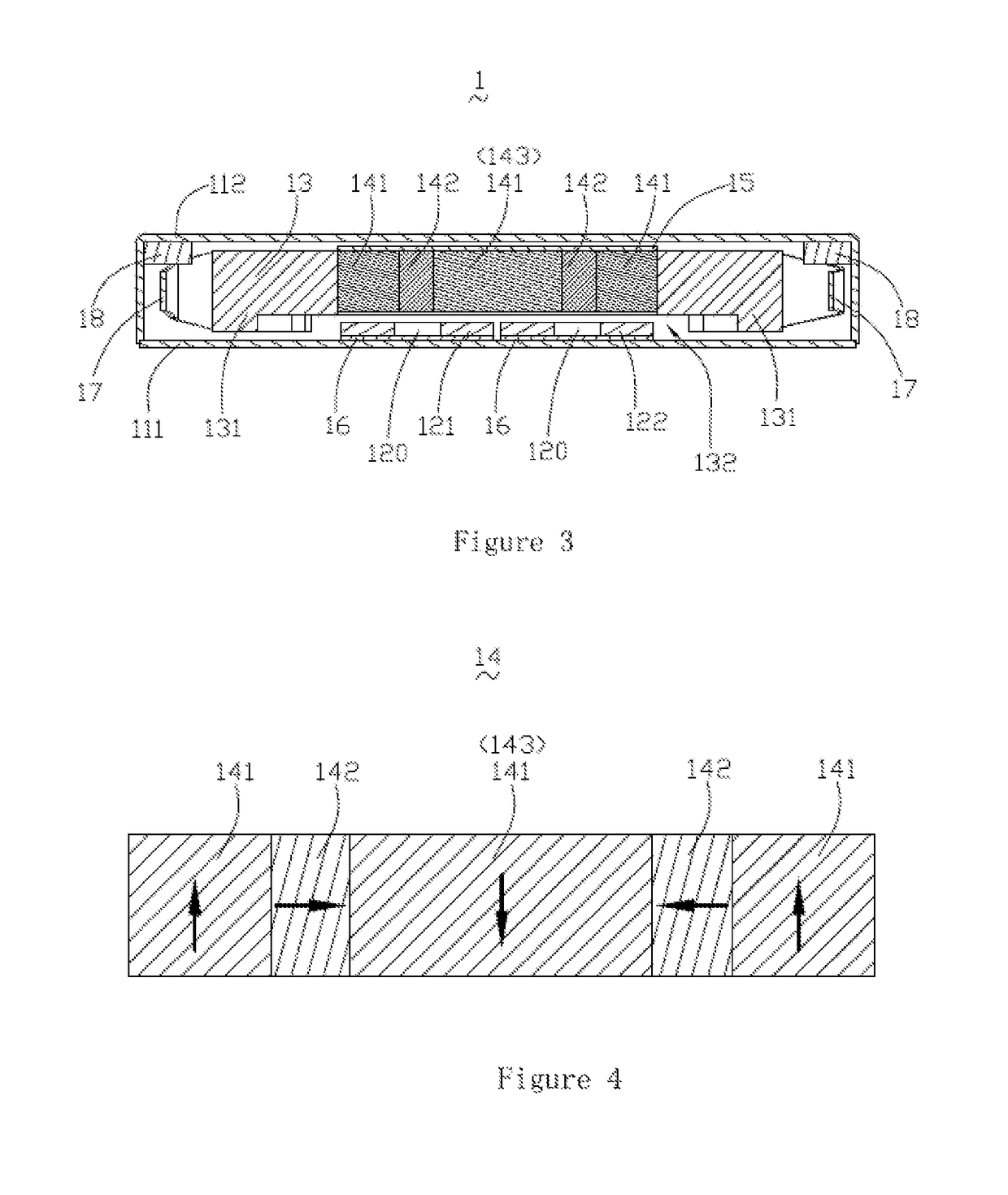

Linear vibrator

ActiveUS10063128B2Increase profitIncrease the magnetic field strengthDynamo-electric machinesMagnetizationVoice coil

The present disclosure relates to a linear vibrator including a bottom plate, a voice coil fixed on the bottom plate, a mass block which has a receiving space and located above the voice coil, a magnet array in the receiving space, the magnet array including odd number of longitudinally magnetized first magnets and even number of transversely magnetized second magnets, the first magnets and the second magnets being arranged alternately in a row, and the adjacent first magnets in opposite magnetization direction and the adjacent second magnets in opposite magnetization direction.

Owner:AAC TECH PTE LTD

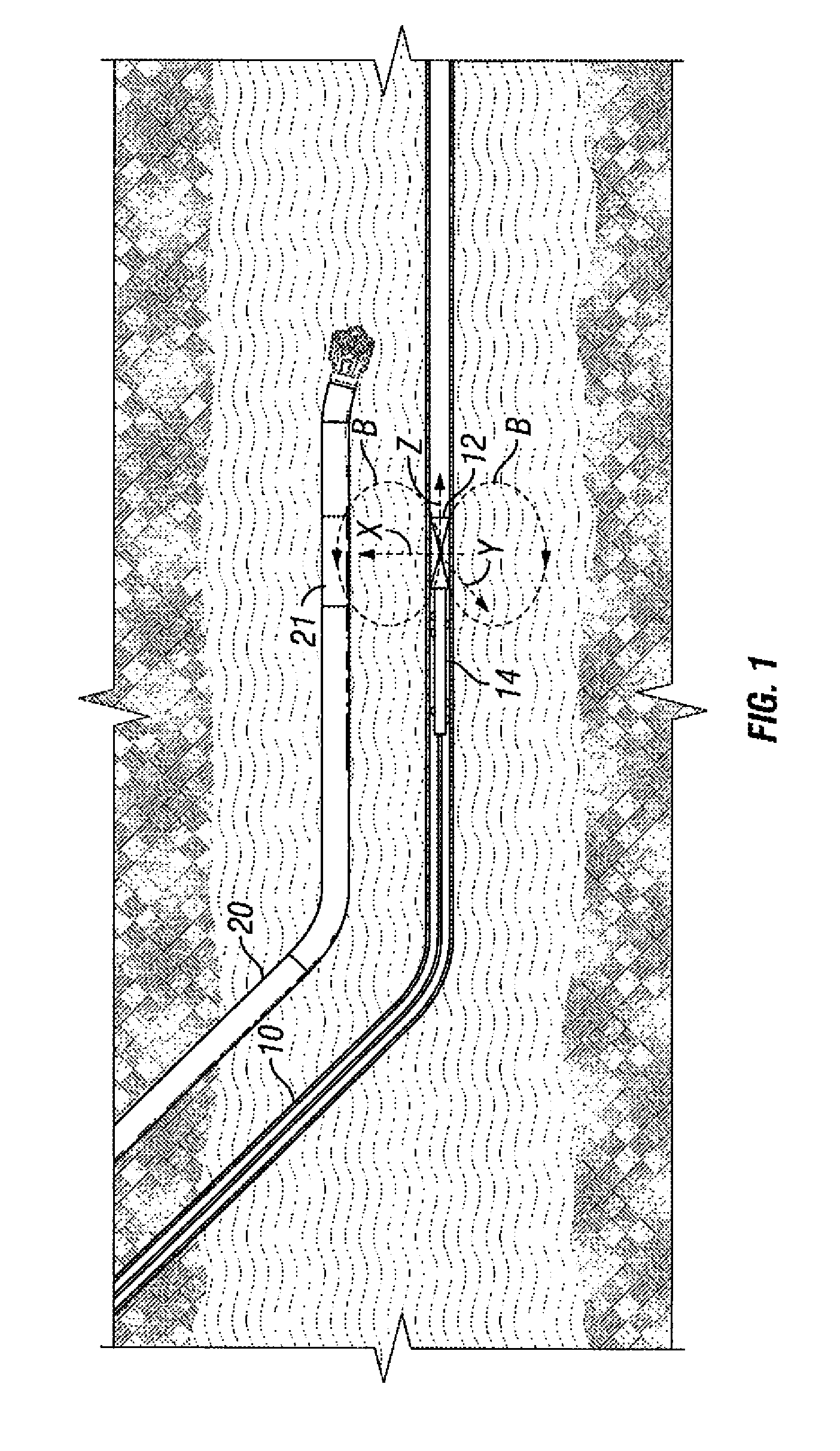

Magnetic ranging and controlled earth borehole drilling

InactiveUS8063641B2High and variable magnetic permeabilityReduce magnetic field strengthSurveyConstructionsMagnetic tension forceAtomic physics

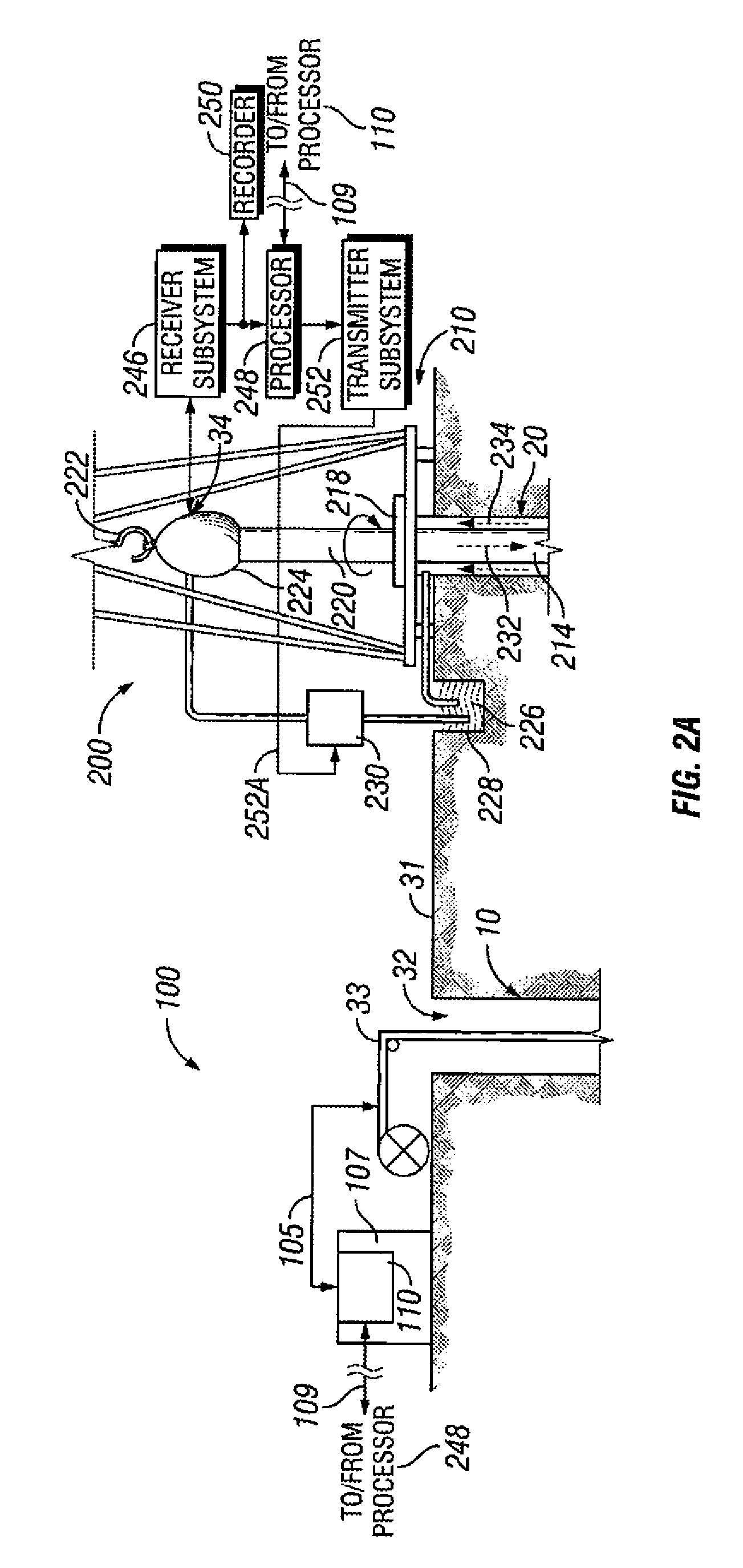

A method for determining the distance and / or direction of a second earth borehole with respect to a first earth borehole, includes the following steps: providing, in the first borehole, first and second spaced apart magnetic field sources; providing, in the second borehole, a magnetic field sensor subsystem for sensing directional magnetic field components; activating the first and second magnetic field sources, and producing respective first and second outputs of the magnetic field sensor subsystem, the first output being responsive to the magnetic field produced by the first magnetic field source, and the second output being responsive to the magnetic field produced by the second magnetic field source; and determining distance and / or direction of the second earth borehole with respect to the first earth borehole as a function of the first output and the second output.

Owner:SCHLUMBERGER TECH CORP

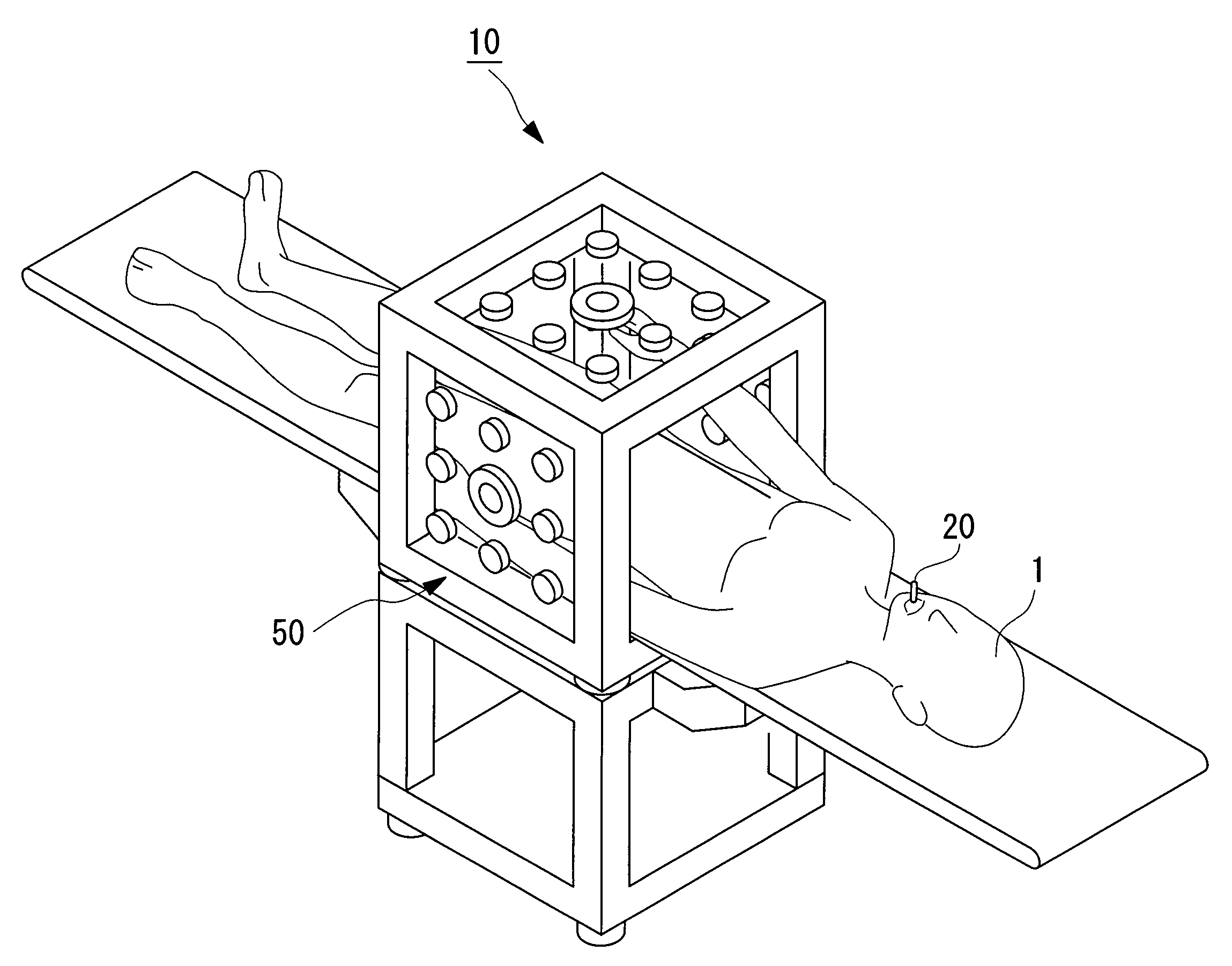

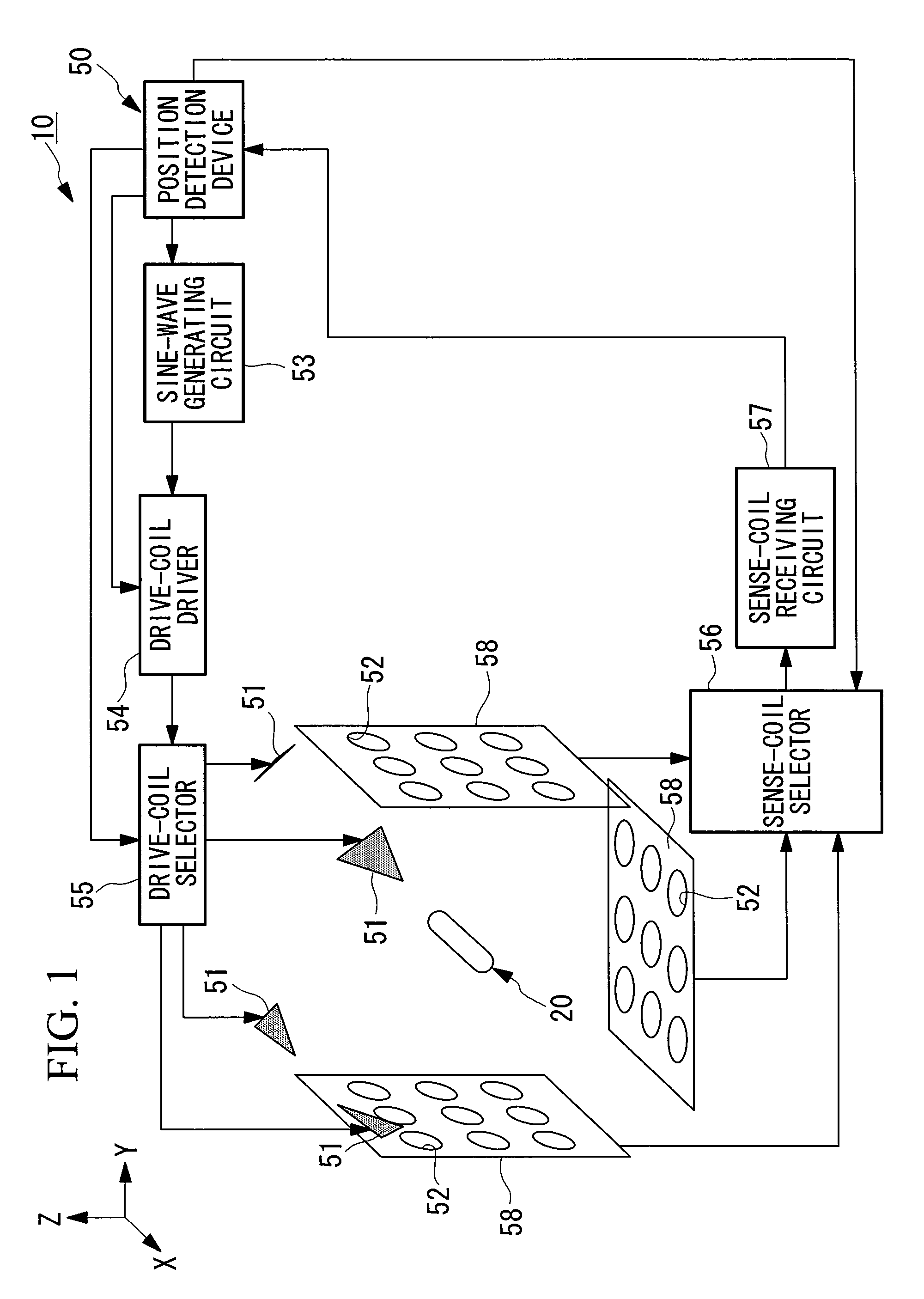

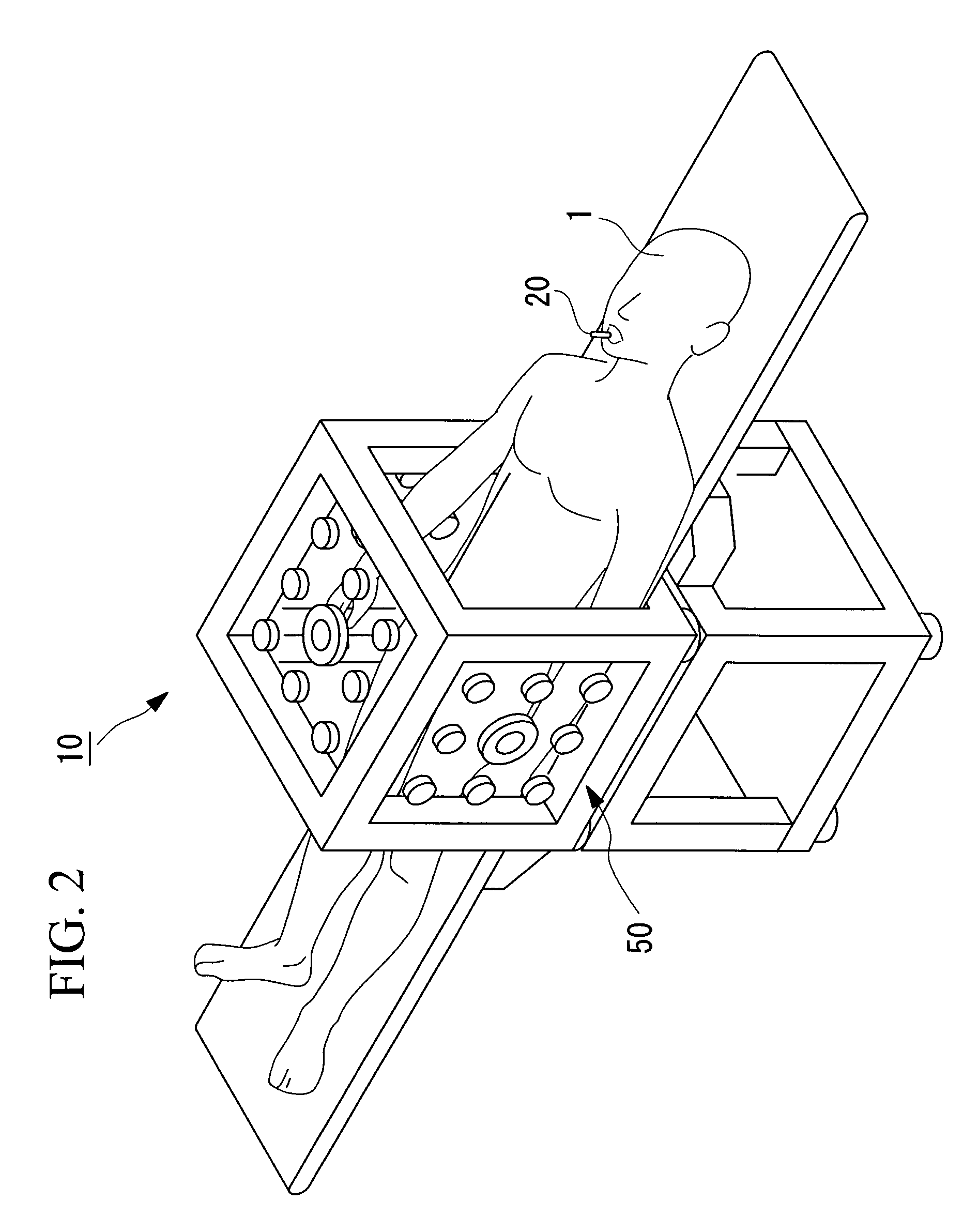

Position detection system

InactiveUS20090295386A1Reduce workloadReduce the amount requiredEndoscopesUsing electrical meansLocation detectionMagnetic inductance

A position detection system that does not require calibration measurement to be performed in advance and reduces the work required for detecting a position and so on is provided. The provided position detection system includes a device having a magnetic inductance coil; a drive coil that has a position-calculating frequency near a resonant frequency of the magnetic inductance coil and generates an alternating magnetic field which acts on the magnetic inductance coil; a plurality of magnetic-field sensors that is disposed outside the operating range of the device and detects an induced magnetic field generated by the magnetic inductance coil; amplitude-component detection section for detecting amplitude components whose phase is substantially orthogonal to the alternating magnetic field from the outputs of the magnetic sensors acquired by the plurality of magnetic sensors; and position analyzing section for calculating at least one of a position and an orientation of the device on the basis of the amplitude components.

Owner:OLYMPUS CORP

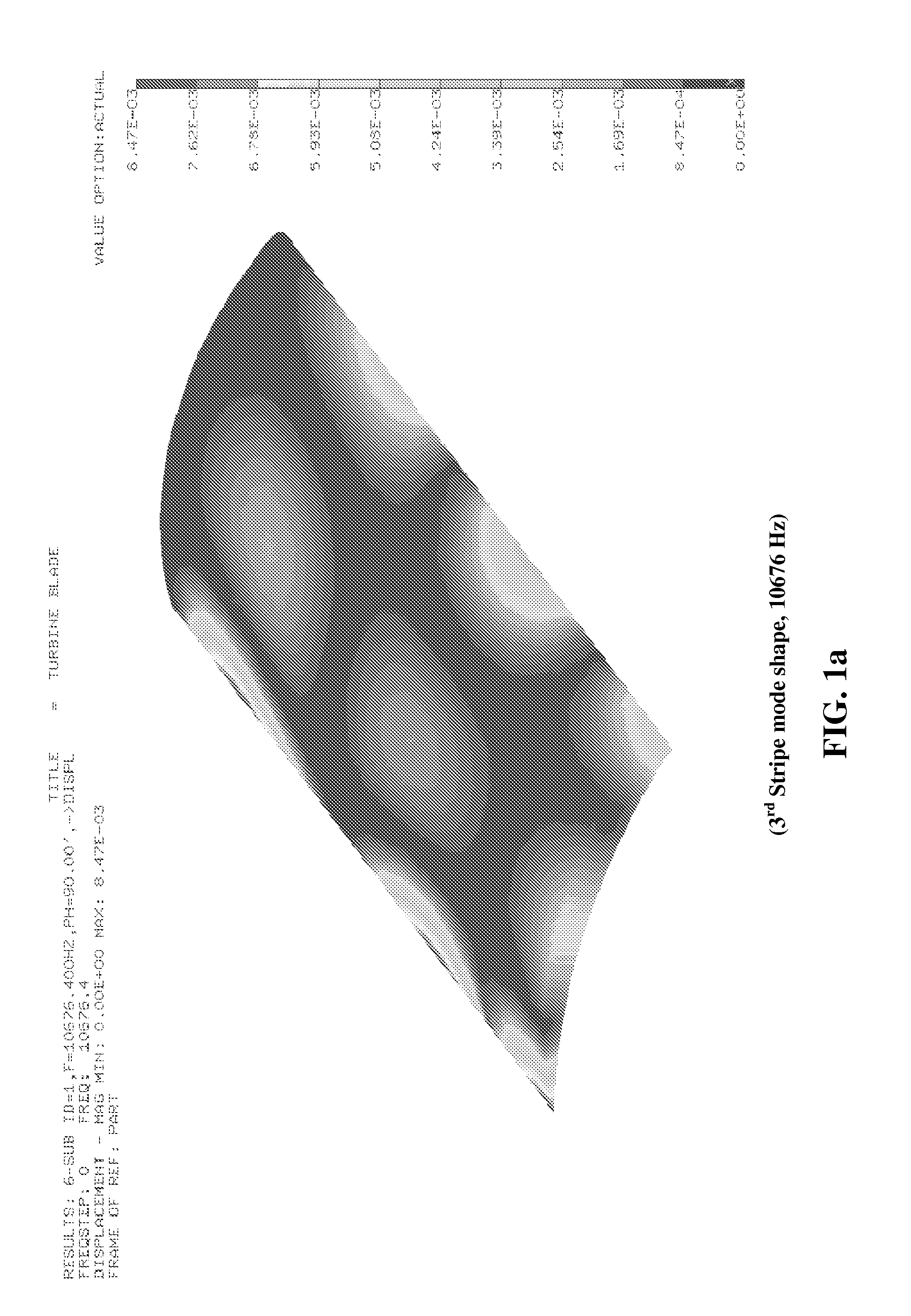

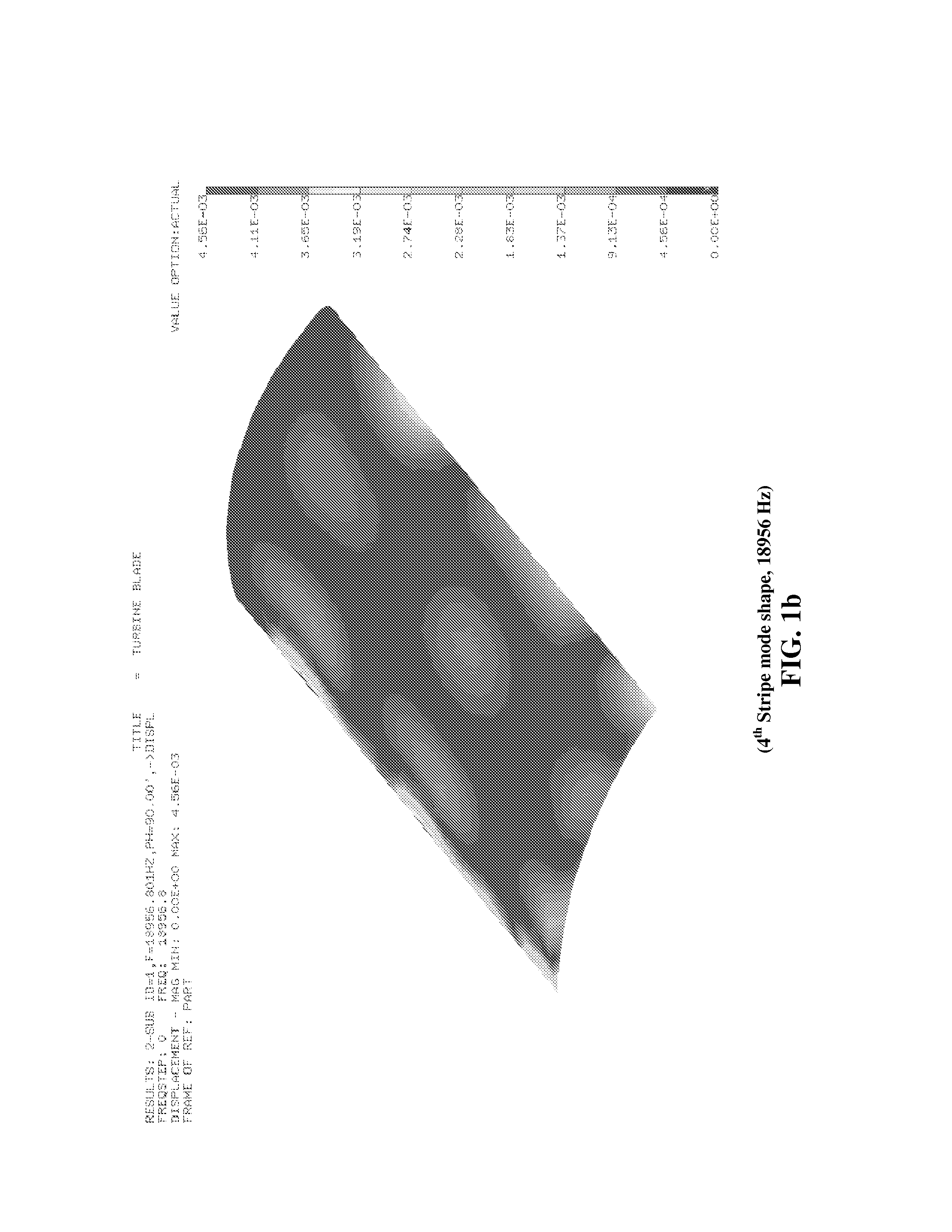

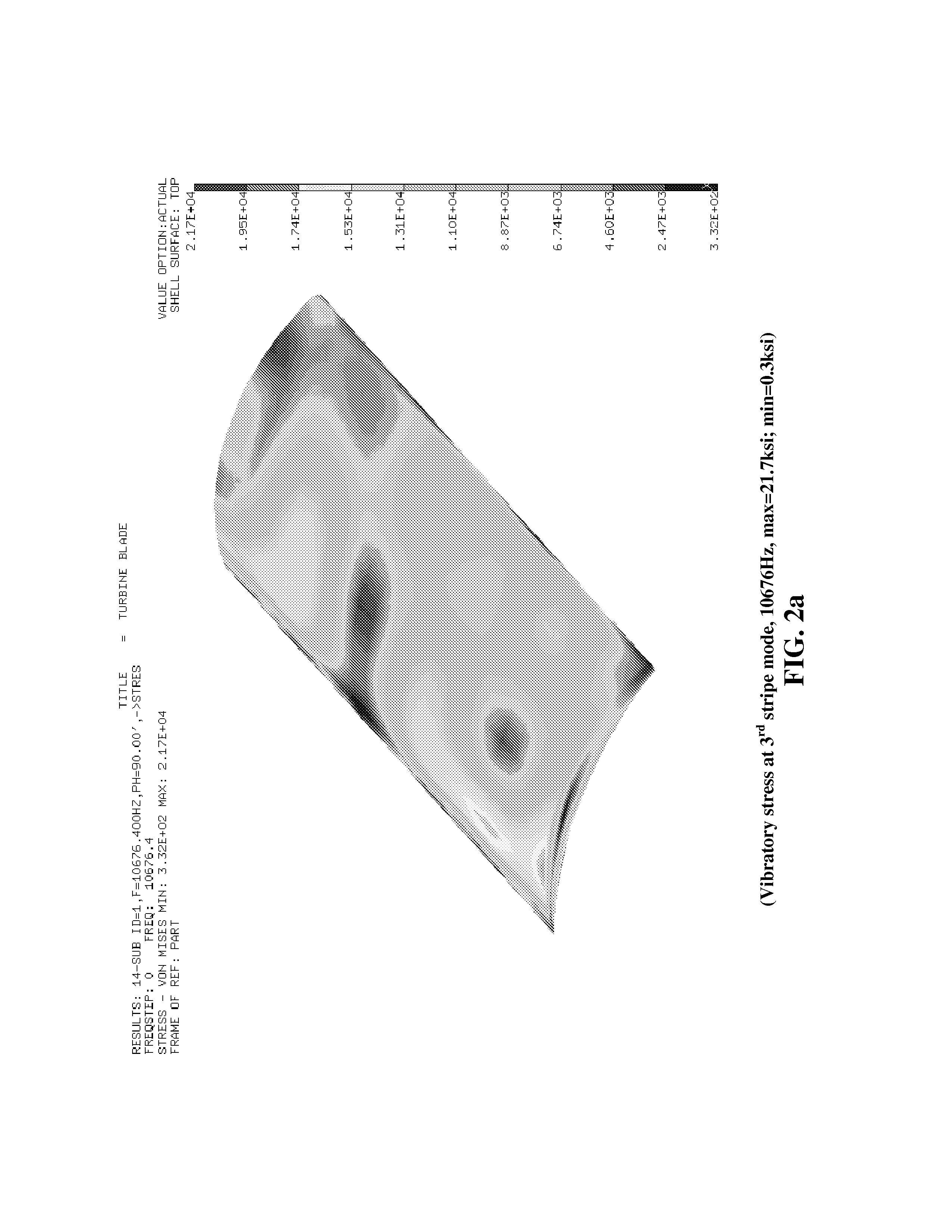

Free layer blade damper by magneto-mechanical materials

InactiveUS20080124480A1Maximum damping capabilityLarge resistanceLiquid surface applicatorsMolten spray coatingThermal sprayingGas phase

A coating for an article is provided to enhance vibration damping and fatigue strength, without diluting resistance to erosion, wear, and corrosion for metallic components such as blades, blisks, shafts and bearings of a gas turbine engine operating in a hostile environment. The invention includes a metallic substrate and a thin layer of magneto-mechanical material bonded to the surface of the substrate by a coating process. The coating material is made of the Fe—Cr—Al or Fe—Cr—Mo based magneto-mechanical materials and deposited to the surface of the substrate via a thermal spraying process in vacuum or in air. In order to achieve maximum damping capability and resistance to erosion, wear, and corrosion, several optimal compositions of the coating material in conjunction with new application methods have been developed. The coating is often very thin and smooth in order not to dilute aerodynamic efficiency and fatigue strength. The thin layer of magneto-mechanical material can also be applied and bonded to the substrate by a variety of methods, for example using a self-adhesive foil, made by Fe—Cr—Al or Fe—Cr—Mo alloys, on the surface of the substrate and via thermal spraying or physical vapor deposition processes.

Owner:SHEN MO HOW HERMAN

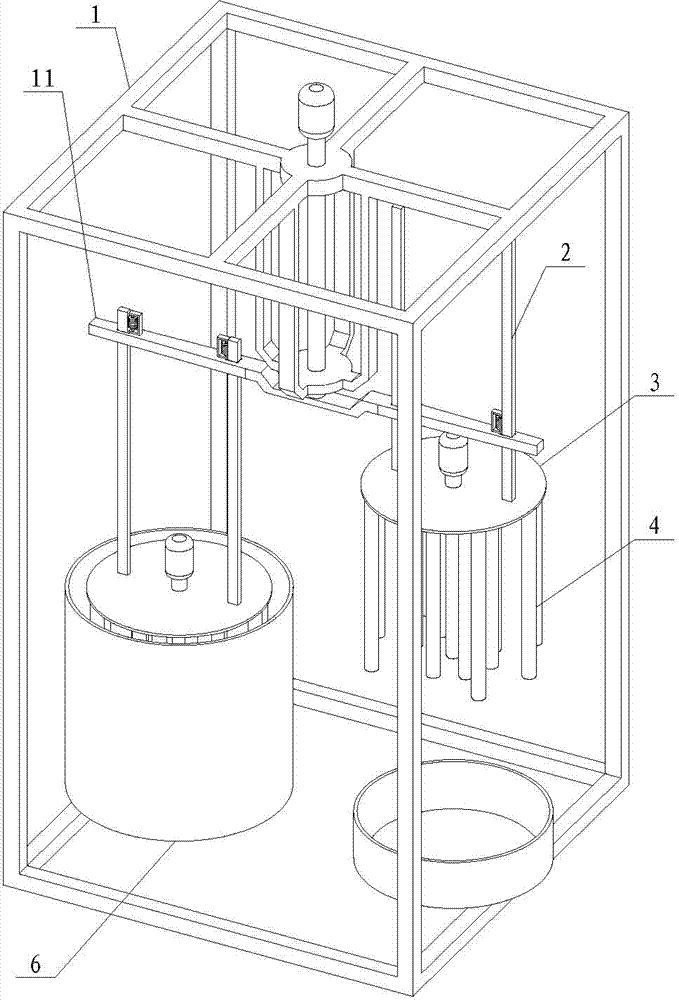

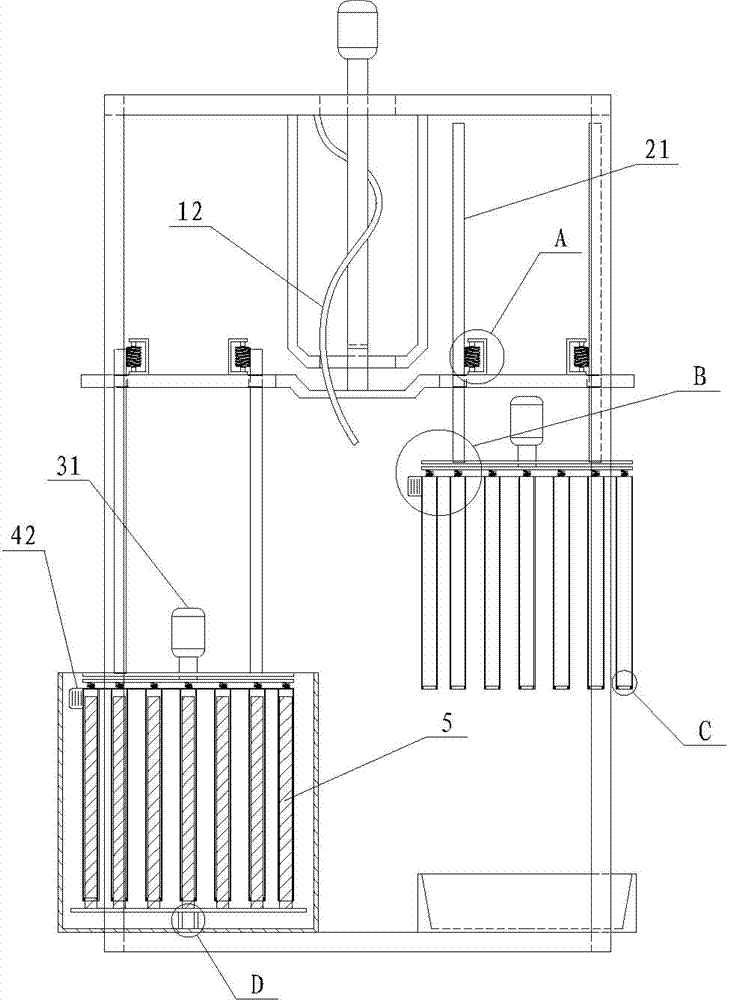

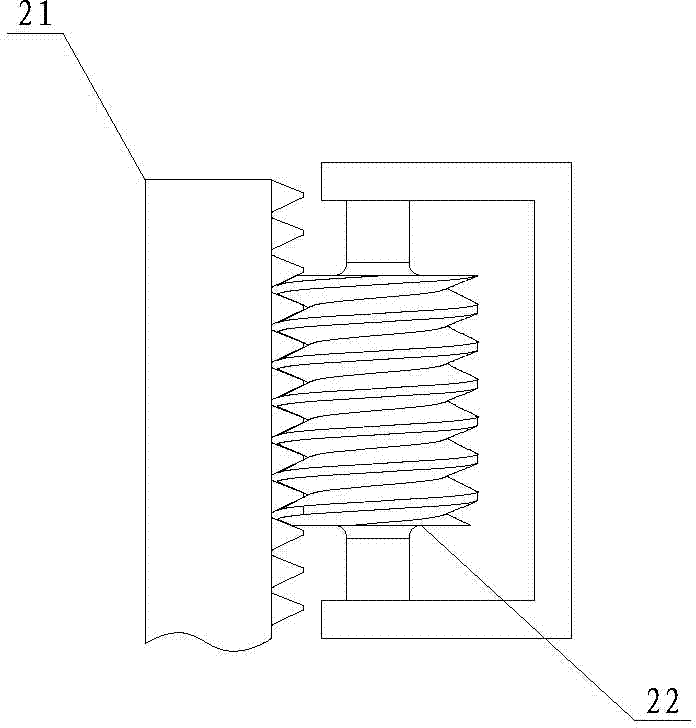

Method and equipment for eliminating iron scraps from raw materials

The invention discloses method and equipment for eliminating iron scraps from raw materials. The equipment comprises a rack, a charging bucket and a group of magnetic rods, and is characterized in that rotary arms are arranged on the rack and can horizontally rotate around the rack; a lifting mechanism is arranged on each of the rotary arms; rotary mechanisms are connected to the bottoms of the lifting mechanisms; a group of iron barrels are connected to the lower parts of each of the rotary mechanisms; a connection plate, a vibrator and an iron barrel connected with the connection plate are arranged in the group of iron barrels; the group of iron barrels is driven by the lifting mechanisms to sleeve iron barrels on the magnetic rods in the group of the magnetic rods; a motor, a rotary disc and a spring are arranged in each of the rotary mechanisms; each of the rotary disc is connected with each of the motors; a spring is fixed between each of the connection plates and each of the rotary discs; and vibrators are arranged on the connection plates. The method and the equipment have the beneficial effects that the iron barrels and the magnetic rods rotate in the charging bucket when irons are attracted, so that the contact probability of the iron barrels and slurries is increased, and the iron-attraction effect is improved; and when the iron barrels are subjected to iron removal, another group of iron barrels are quickly sleeved on the magnetic rods to perform the next round of iron attraction, so that the iron removal time is shortened, and the efficiency is improved.

Owner:ZIBO S & N MAGNET MFG

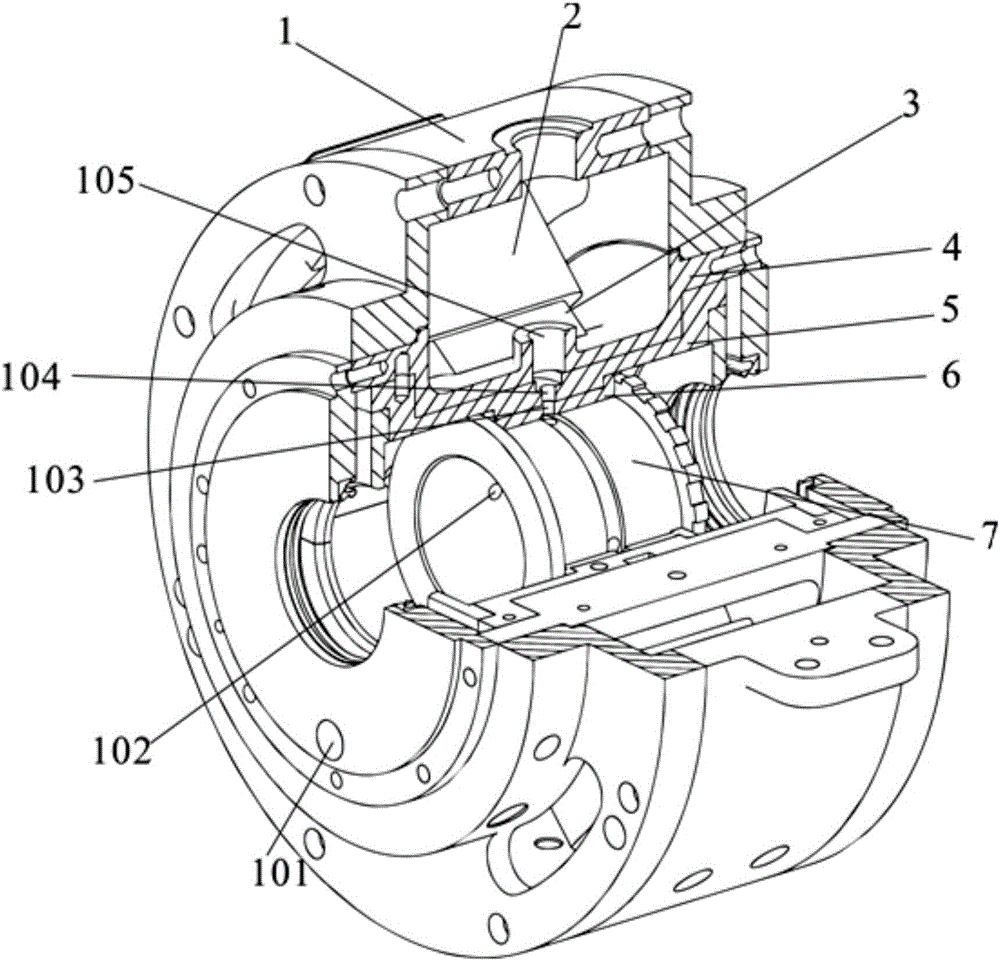

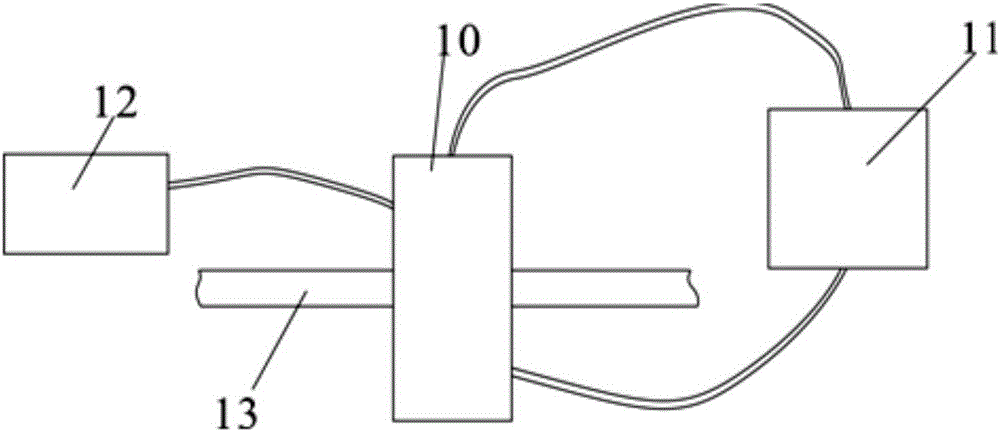

Intelligent controllable bearing and method for controlling rotor vibration

ActiveCN105840657AImprove bearing capacityGood damping propertiesSpringsNon-rotating vibration suppressionSemi activeVibration control

The invention provides an intelligent controllable bearing and a method for controlling rotor vibration. The bearing comprises an excitation system, a bearing block, a bearing shell, a bearing bush and a floating ring. Magnetorheological fluid is adopted as a lubricating agent. After the magnetorheological fluid is supplied, the shaft neck and the inner surface of the floating ring form a lubricating oil film, namely, an inner oil film, and the outer surface of the floating ring and the bearing bush form a lubricating oil film, namely, an outer oil film. The property of the magnetorheological fluid is changed by the magnetic field generated by the excitation system, the property of the lubricating oil films is further changed, and intelligent behaviors of the bearing are achieved. The floating ring rotates at the speed lower than that of a rotary shaft. By means of the external magnetic field, stiffness and damping characteristics of the bearing are changed, so that vibration control of a rotor is achieved. The method is suitable for rotor occasions sensitive to vibration, and semi-active control over a rotor system can be easily achieved.

Owner:SHANGHAI JIAO TONG UNIV

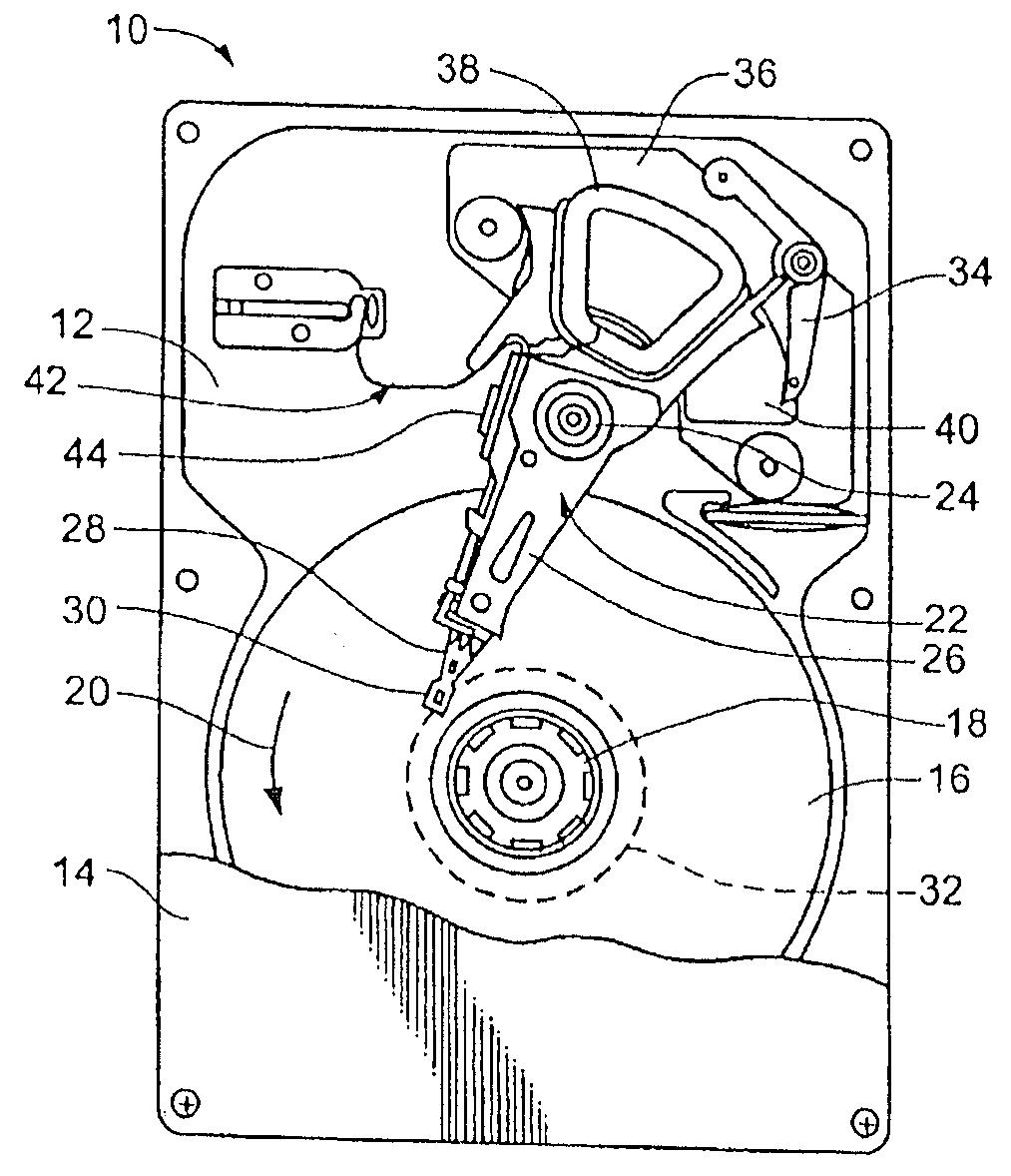

Patterned media bits with cladding shell

InactiveUS20100033872A1Good magnetic stabilitySimple structureDecorative surface effectsPatterned record carriersMagnetic dotsNon magnetic

A bit patterned media (BPM) includes many magnetic dots arranged in tracks on a substrate. The magnetic dots each have a hard magnetic core, a soft magnetic cladding surrounding the core and a thin non-magnetic layer that separates the hard magnetic core from the soft magnetic ring. The soft magnetic cladding stabilizes the magnetization at the edges of the hard magnetic core to improve the signal to noise ratio of the magnetic dots. The soft magnetic rings also narrow the magnetic field of the dots which reduces the space requirements and allows more dots to be placed on the substrate.

Owner:SEAGATE TECH LLC

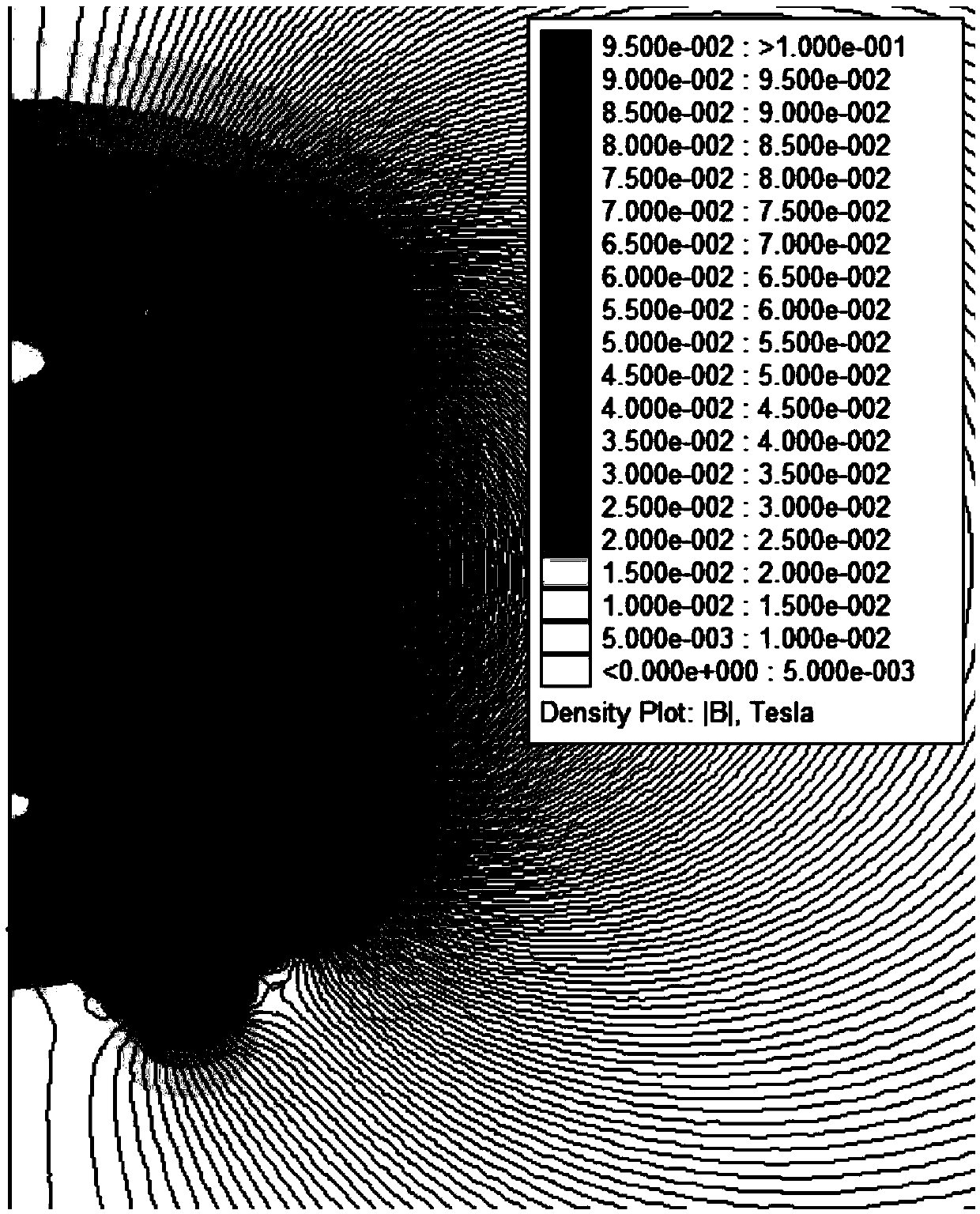

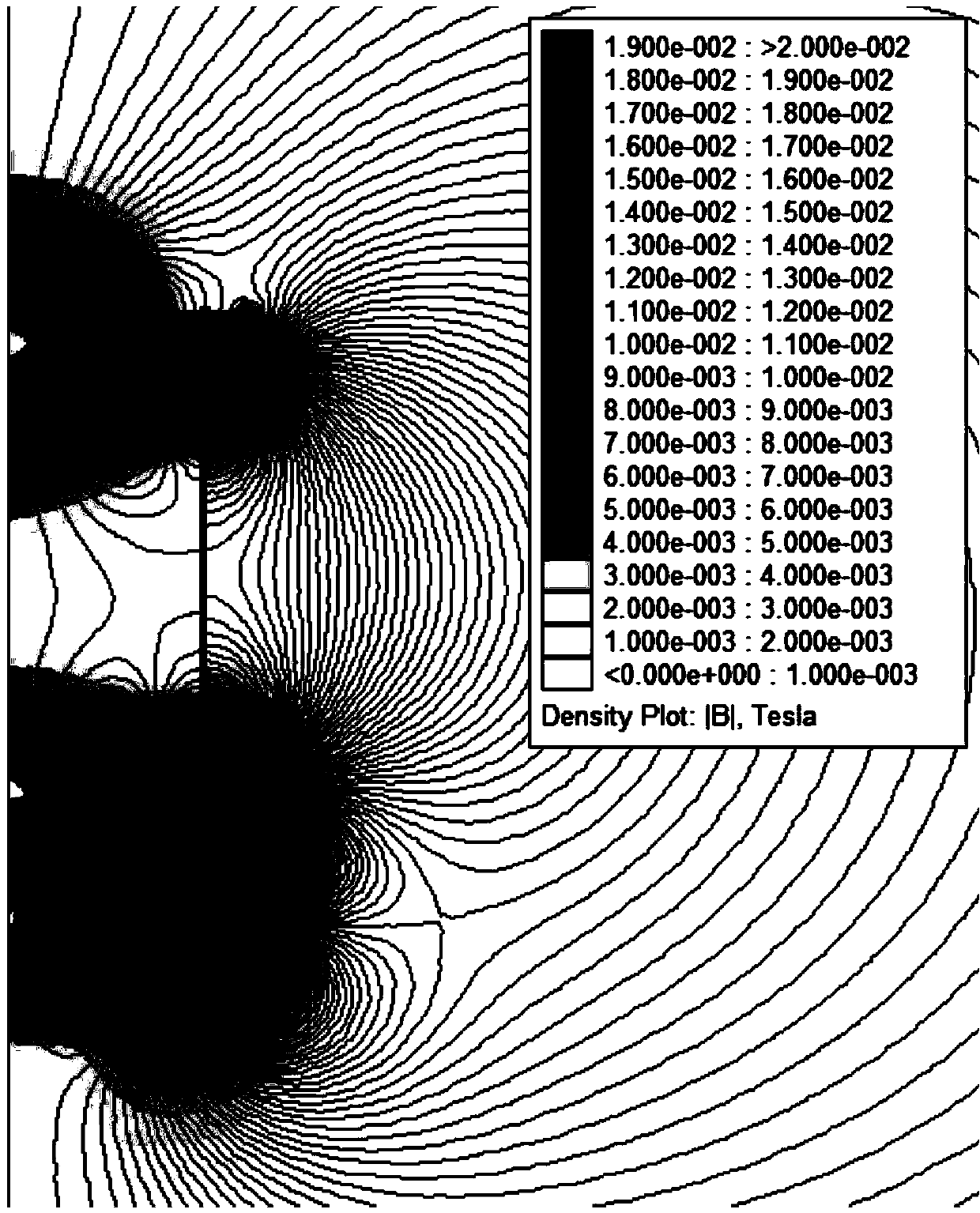

Current homogenizing magnetic field structure of multistage cusped magnetic field plasma thruster

ActiveCN104202895AReduce magnetic field strengthThe magnetic mirror effect worksPlasma techniqueIonizationPhysics

The invention relates to a current homogenizing magnetic field structure of a multistage cusped magnetic field plasma thruster, and aims to solve the problems that the magnetic field intensity of a discharge channel wall of an existing multistage cusped magnetic field plasma thruster is too high, a magnetic induction line emitted by the tip of a magnetic mirror is too close to the axis of a discharge channel, consequently, electron distribution is non-uniform, ionization rate is low, and a magnetic interface has a large angle. Two fixing end plates are mounted on the upper surface and the lower surface of a shell respectively, a ceramic sleeve is vertically mounted in the shell, an anode and a ventilator are mounted at the bottom end of the inner wall of the ceramic sleeve and extend out of the bottom end of the ceramic sleeve, two magnetic rings are arranged on the upper end face and the lower end face between the inner side wall of the shell and the outer side wall of the ceramic sleeve respectively, one magnetic ring is arranged in a permanent magnet ring to form a component, a plurality of components are horizontally mounted in an inner cavity between the ceramic sleeve and the shell, and a plurality of magnetic field guide rings are arranged on the inner side wall of the shell. The current homogenizing magnetic field structure is used for the field of aerospace.

Owner:HARBIN INST OF TECH

Device for charging batteries

ActiveUS7847515B2Resistant to soilingImprove the immunityCells structural combinationSecondary cells charging/dischargingEngineeringBattery charger

In a second preferred variant of the second exemplary embodiment, the magnetic sensor detects the presence of a magnetic field of the magnetic element as long as no battery is connected to the charger. The battery comprises a shielding device which deflects or shields the magnetic field from the magnetic sensor, so that after connecting the battery to the charger, the magnetic sensor detects that no magnetic field is present and emits an identification signal. This variant is advantageous, in particular in stepped contact devices, whereby one of the two elements is a sensor or magnet at the bottom of the step and the other of the two elements is arranged on the leg at an angle thereto. This makes it possible to achieve a particularly good shielding effect. In this variant, several magnetic elements and magnetic sensors may also be provided.

Owner:ARTHREX

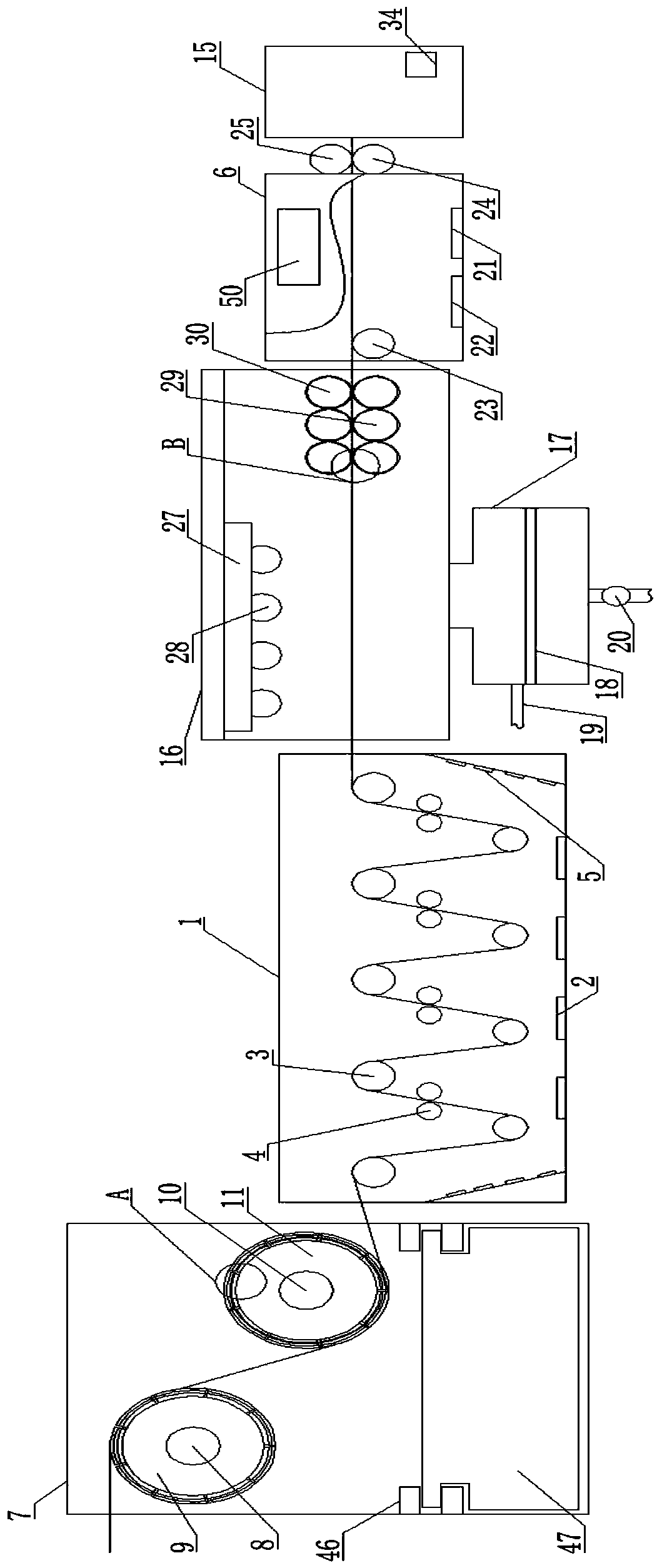

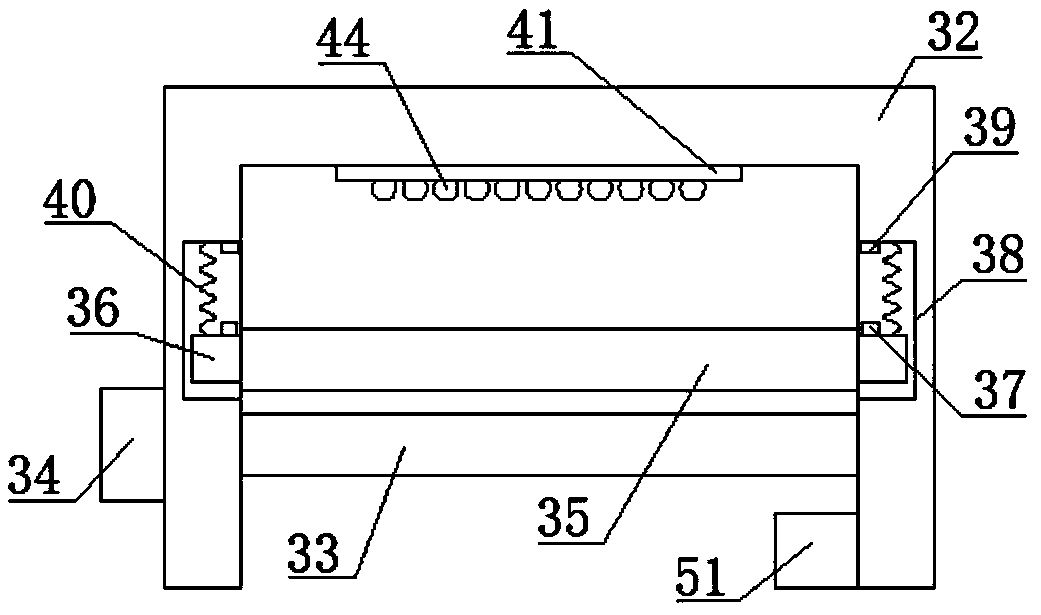

Integrated efficient dyeing and finishing device for textile fabric

InactiveCN109355838AGuaranteed liquidityGuaranteed uniformityMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsEnvironmental resistanceBristle

The invention discloses an integrated efficient dyeing and finishing device for textile fabric. The device comprises a fixation dyeing box, and multiple vibration plates, rolling shafts, brushing rollers and heating strips are installed in the fixation dyeing box; a drying box is arranged at one side of the fixation dyeing box, and a dust removal box is arranged at the outer side of the fixation dyeing box; a first dust removal roller and a second removal roller are arranged in the dust removal box; multiple arc static plates are both installed on the outer surface of the first dust removal roller and the outer surface of the second dust removal roller, and an arc brushing plate is arranged between each arc static plate and the second dust removal roller or between each arc static plate and the first dust removal roller; multiple evenly-distributed carding bristles are arranged on each arc brushing plate; a rolling device is connected to one side of the drying box, and a rinsing box isconnected to the outer side of the drying box; a dye filter box is connected to the lower portion of the rinsing box, and a filter screen, a return pipe and a water pump are arranged on the dye filter box. The integrated efficient dyeing and finishing device for the textile fabric has the advantages that the dyeing quality and working efficiency can be improved, dyeing is even, the utilization rate of dye is high, the environment is protected, the drying speed is high, sterilization is achieved, the cloth rolling effect is good, and the device is convenient to clean.

Owner:湖州市菱湖石淙兴吴绸厂

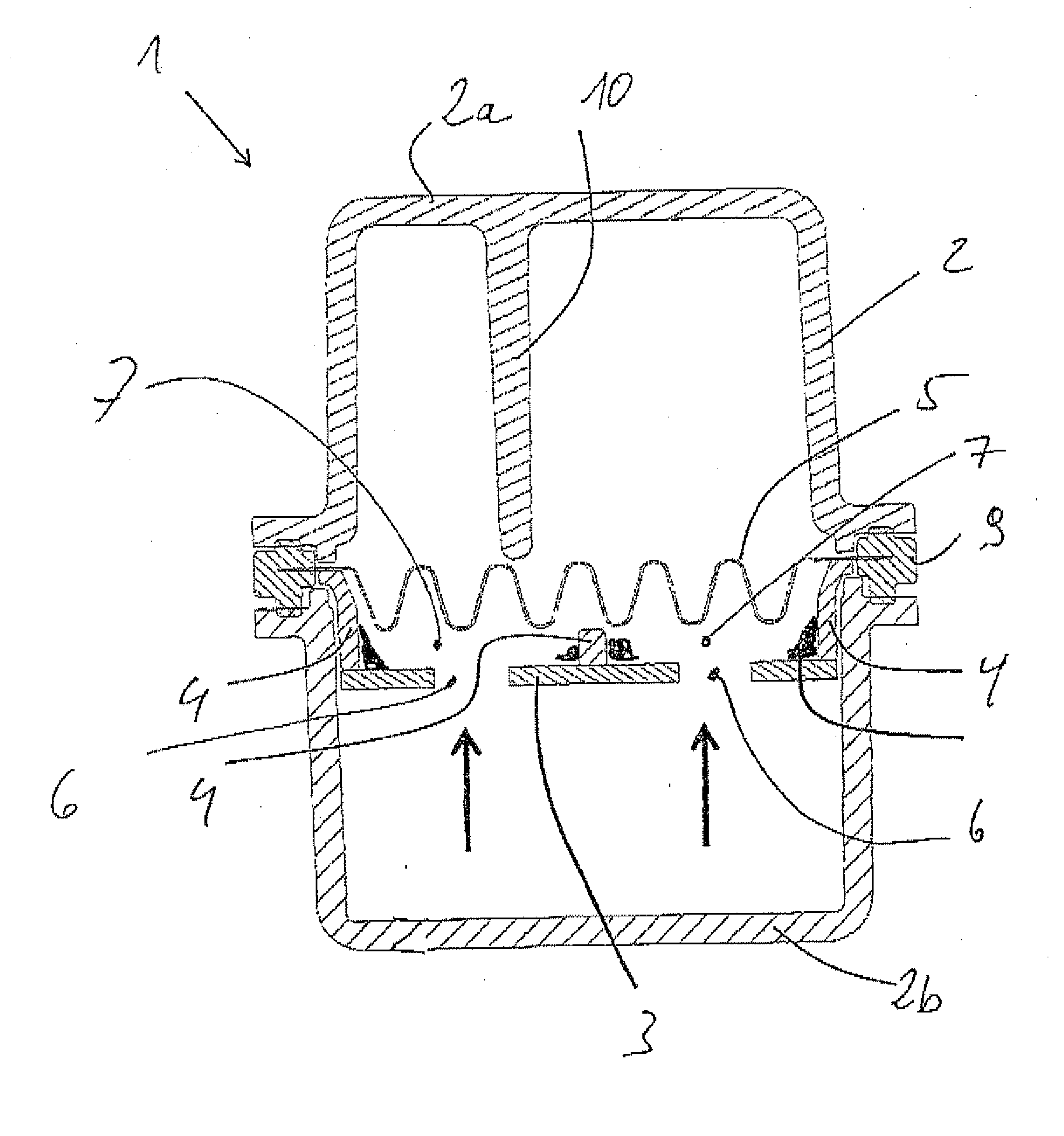

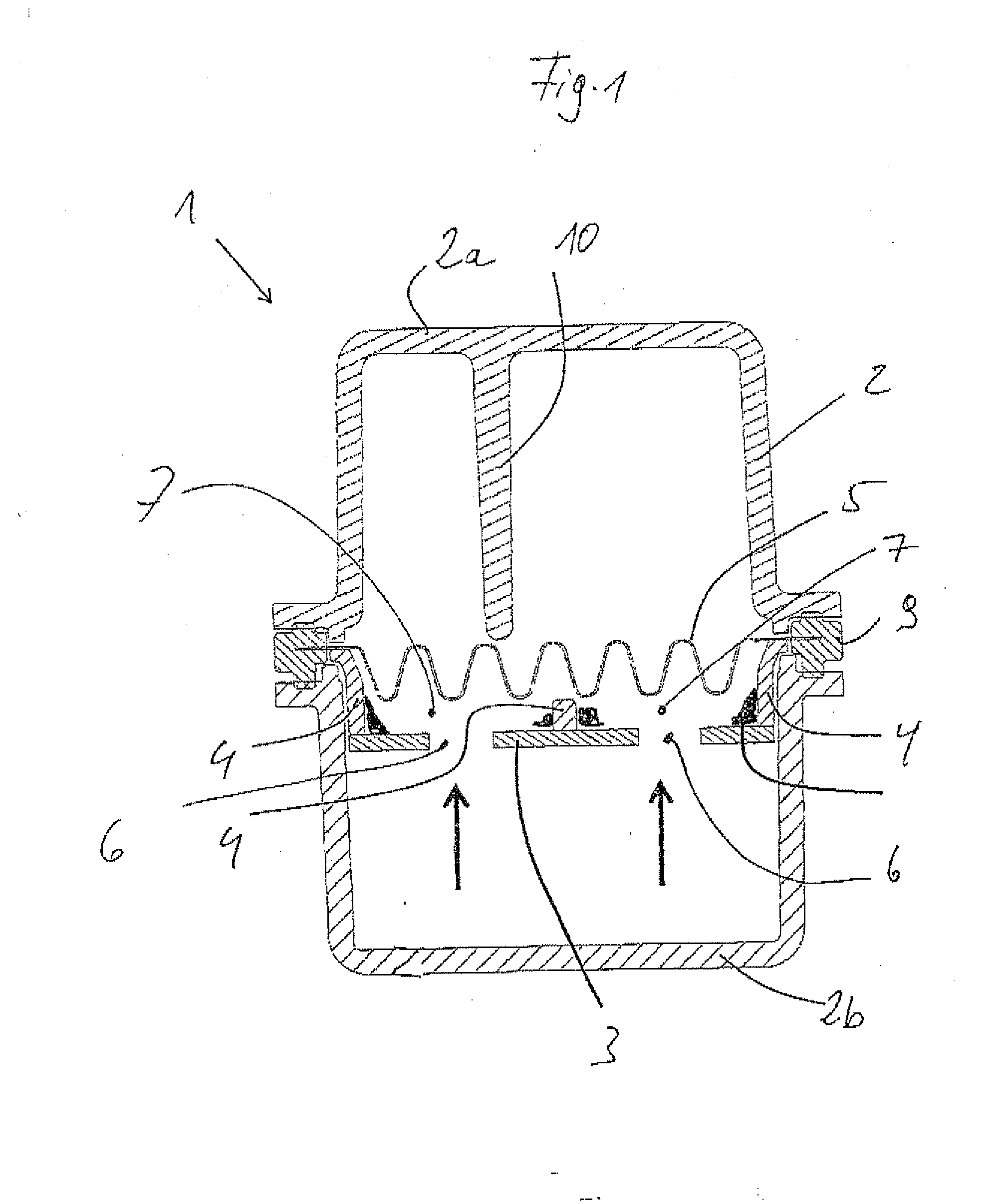

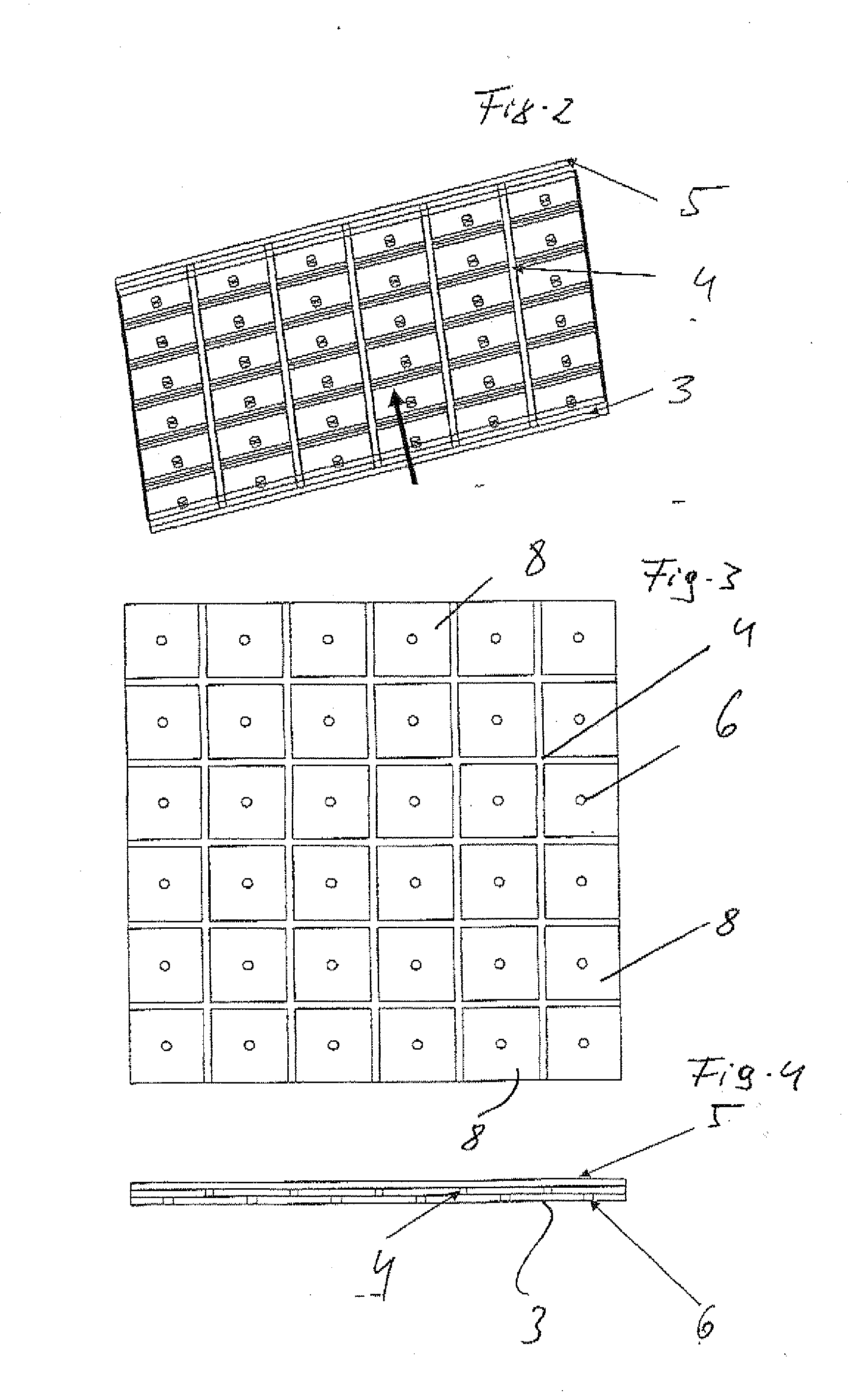

Filter arrangement

InactiveUS20130118964A1Save installation spaceEffectively and permanently keepMachines/enginesMembrane filtersMagnetEngineering

A filter arrangement for the filtration of oil or an ATF fluid, in particular a transmission oil filter, has at least a first and a second filtration layer which are arranged spaced apart by at least one spacer in a filter housing to form at least one intermediate chamber. At least one magnet or a magnet arrangement for keeping iron particles out of the oil flow are provided between the first and the second filtration layers.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

Electric rotating machine

ActiveUS7479718B2Reduce noiseAvoid failureSynchronous generatorsAssociation with control/drive circuitsEngineeringMechanical engineering

An electric rotating machine comprises: a stator; a rotor that includes a rotary shaft, and rotates coaxially with the stator; a bracket supporting and fixing the stator, and supporting rotatably the rotary shaft; a rotational position detector disposed on the side opposite to the load of the rotary shaft to detect a rotational position of the rotor; and a power part including a switching element disposed on the outer circumferential side of the rotational position detector. A shield member is disposed at the rotational position detector to cover the circumference and shield a magnetic field generated by the switching element.

Owner:MITSUBISHI ELECTRIC CORP

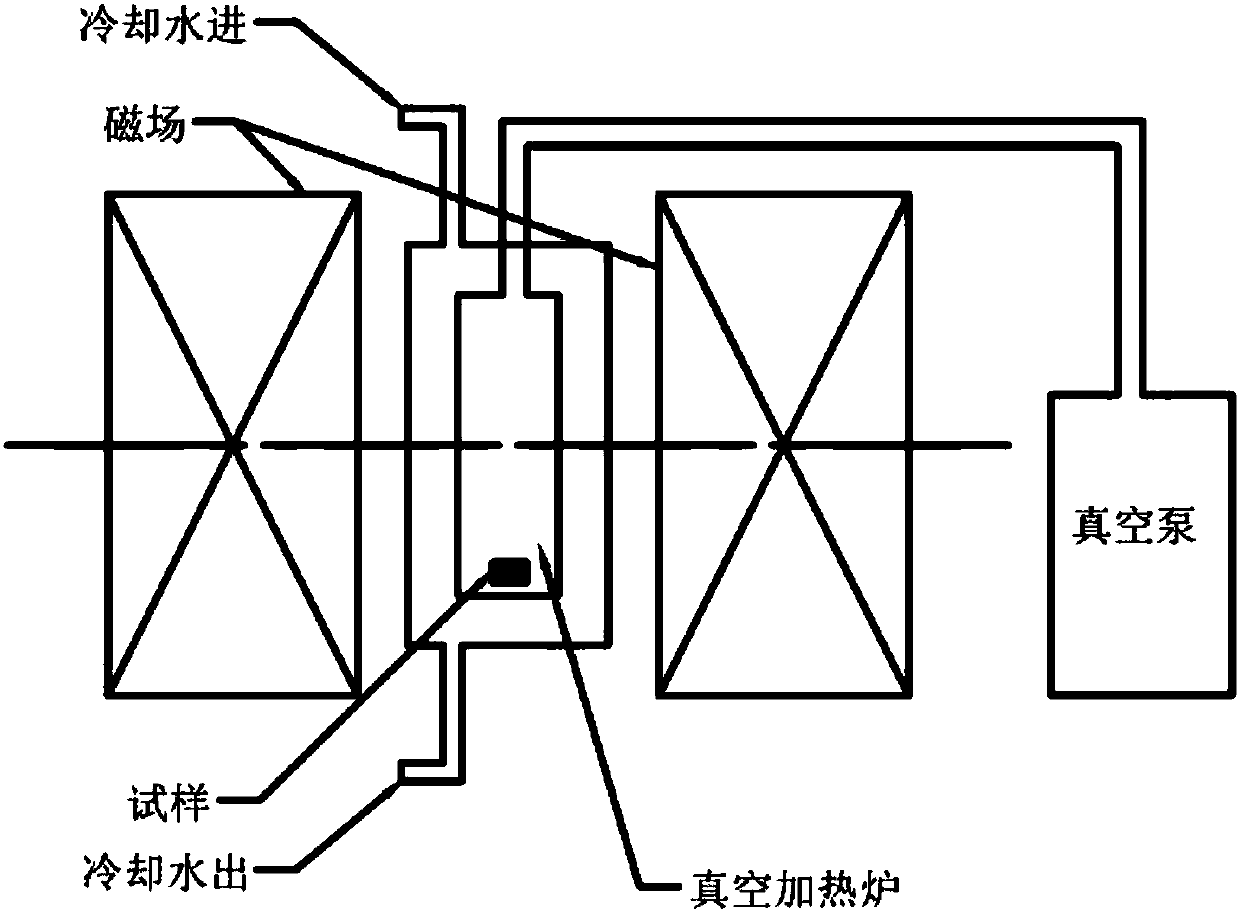

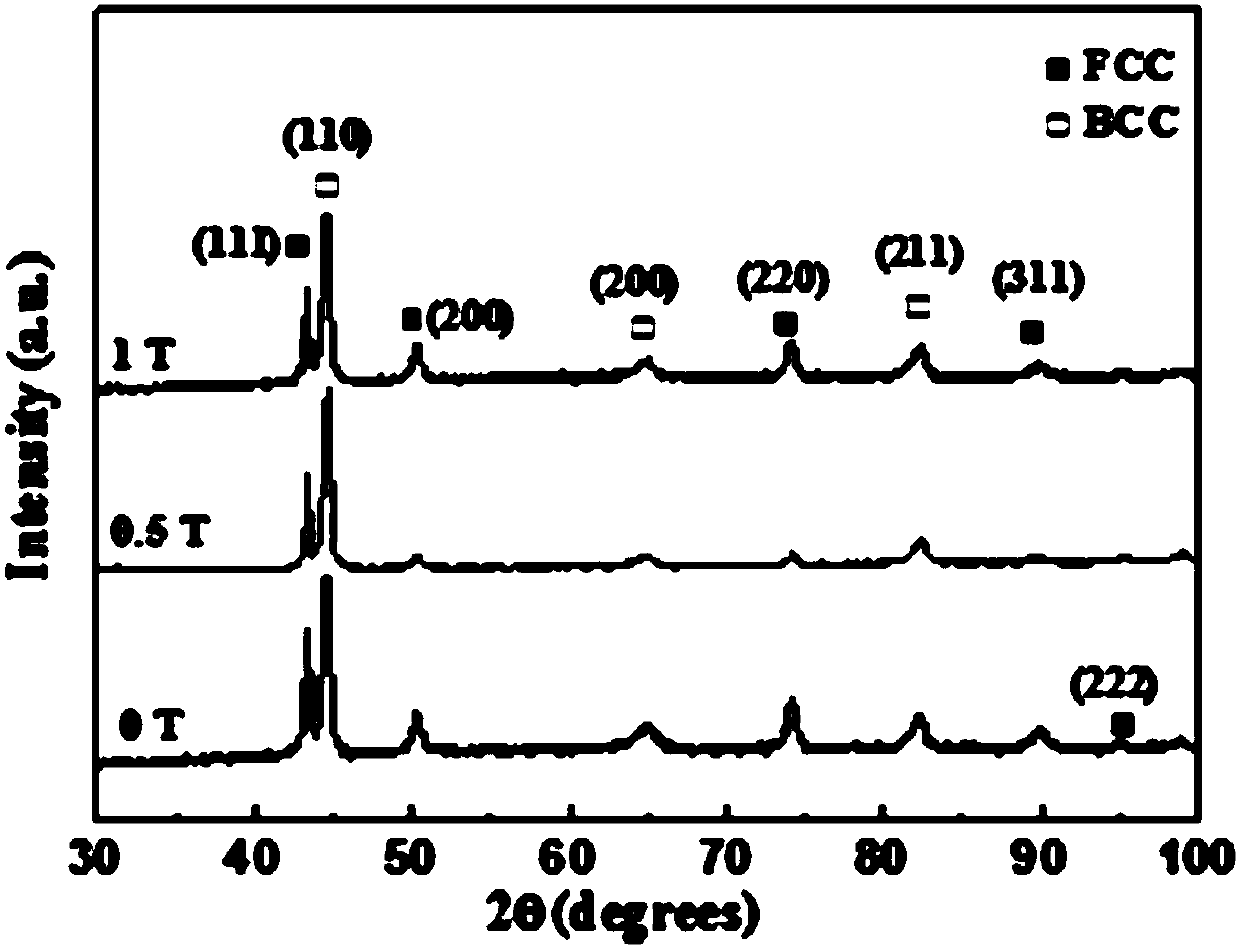

Method for improving magnetic property of high-entropy alloy by heat treatment through constant magnetic field

ActiveCN107858579AImprove magnetismSignificant changes in organizational structureHigh entropy alloysUltimate tensile strength

The invention discloses a method for improving magnetic property of high-entropy alloy by heat treatment through a constant magnetic field. By heat treatment through the magnetic field, the content ofa BCC phase in a FeCoNi(CuAl)0.8 high-entropy alloy microstructure is increased, and the magnetic property is improved. The purpose of improving the magnetic property of the alloy can be achieved without changing ingredients of the alloy. The high-entropy alloy is subjected to heat treatment through the magnetic field, the tissue structure is changed obviously, and the magnetic property is improved remarkably; and the heat treatment temperature is low relatively, and the magnetic property of the alloy can be greatly improved under the condition that magnetic field strength is small.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com