Integrated efficient dyeing and finishing device for textile fabric

A high-efficiency technology for textile cloth, applied in the field of integrated high-efficiency dyeing and finishing devices for textile cloth, can solve the problems of slow dyeing speed, complicated process, and low work efficiency, so as to ensure fluidity and uniformity, improve drying rate, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

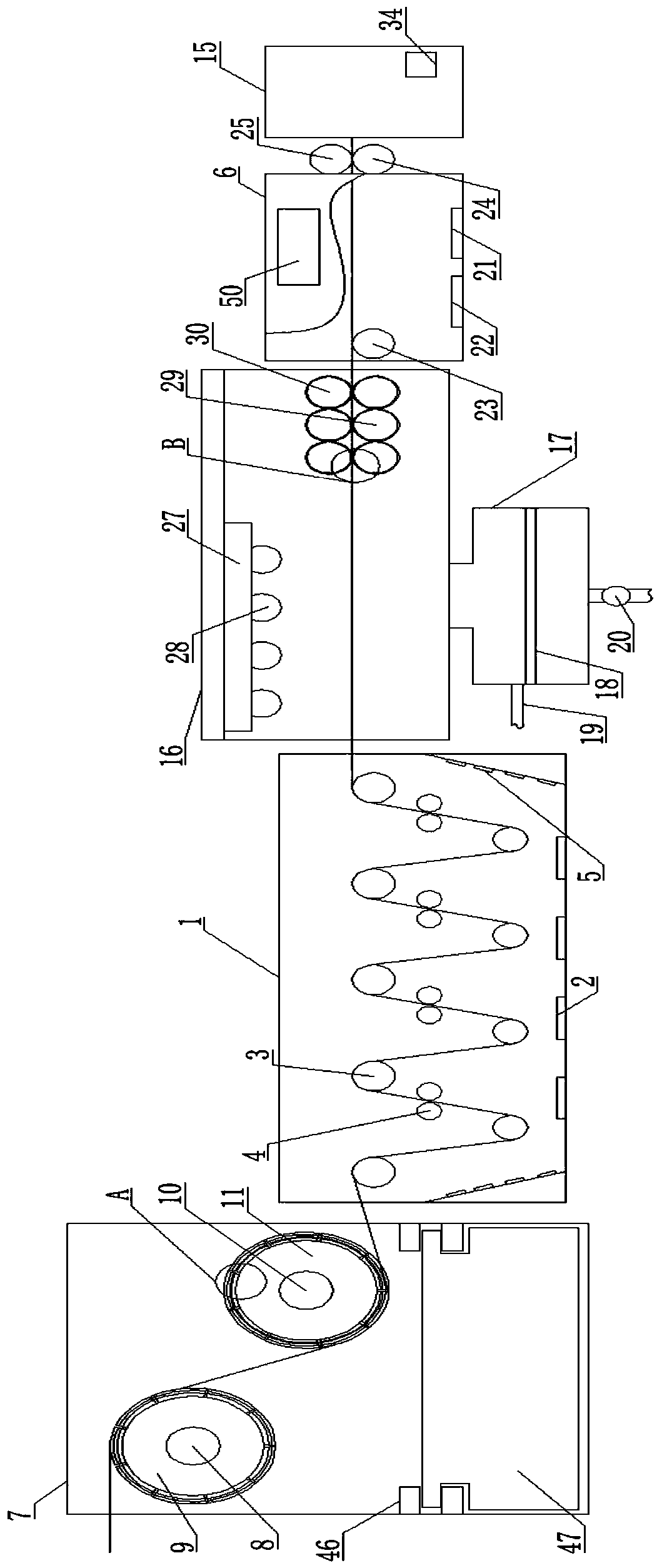

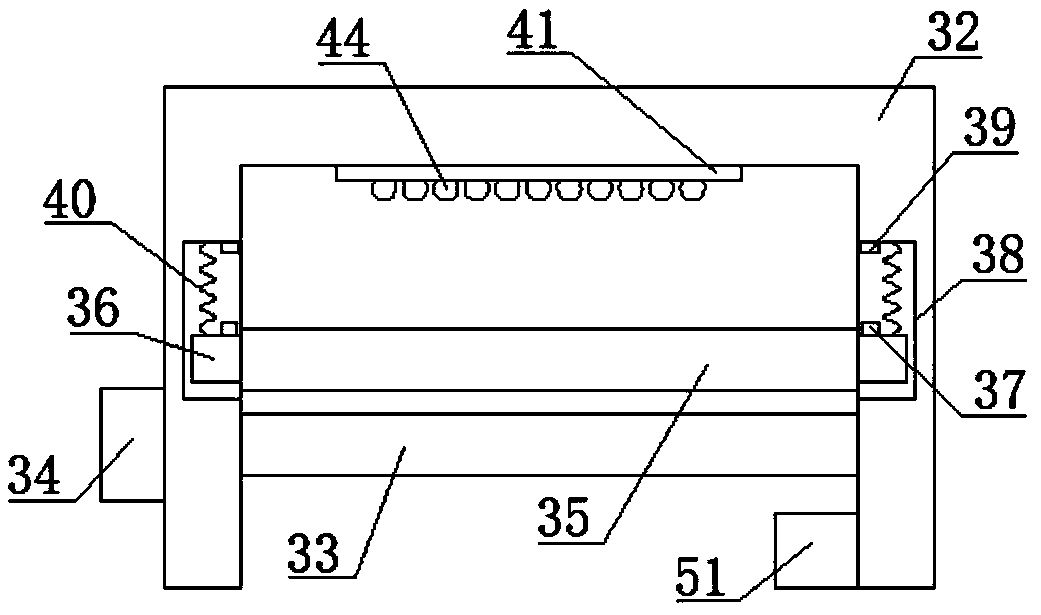

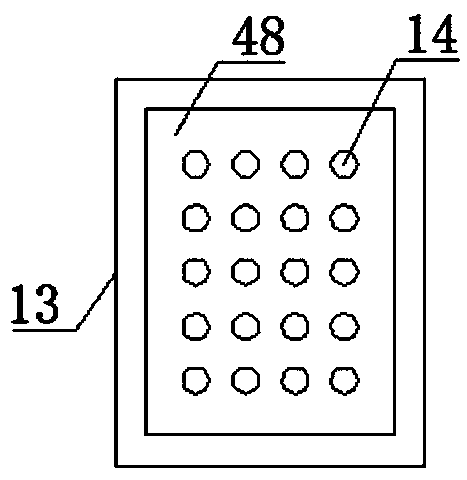

[0023] Example. An integrated high-efficiency dyeing and finishing device for textile cloth, which is composed of Figures 1 to 9 As shown, including the solid dyeing box 1, a plurality of vibration plates 2 connected in parallel are installed on the inner bottom surface of the solid dyeing box 1; rollers 3 are installed above each vibration plate 2, and every two adjacent rollers 3 Brush rollers 4 are installed between them; the inner wall of the fixing box 1 is provided with a plurality of parallel heating strips 5; one side of the fixing box 1 is provided with a drying box 6, and the other side is provided with a dust removal box 7. The inner wall of the dust removal box 7 is provided with a first installation roller 8, and the first installation roller 8 is sleeved with a first dust removal rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com