Patents

Literature

155results about How to "Reduced chance of scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

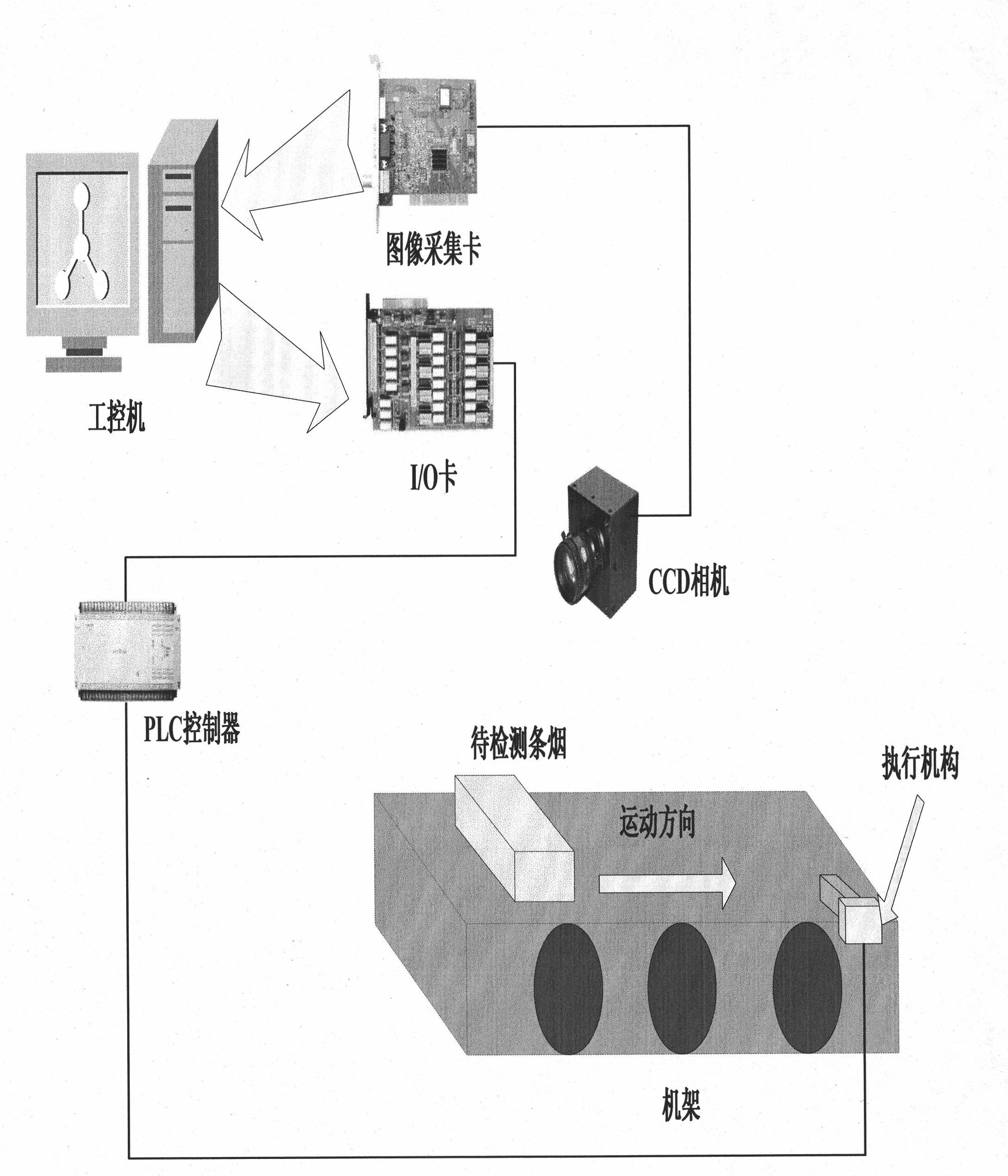

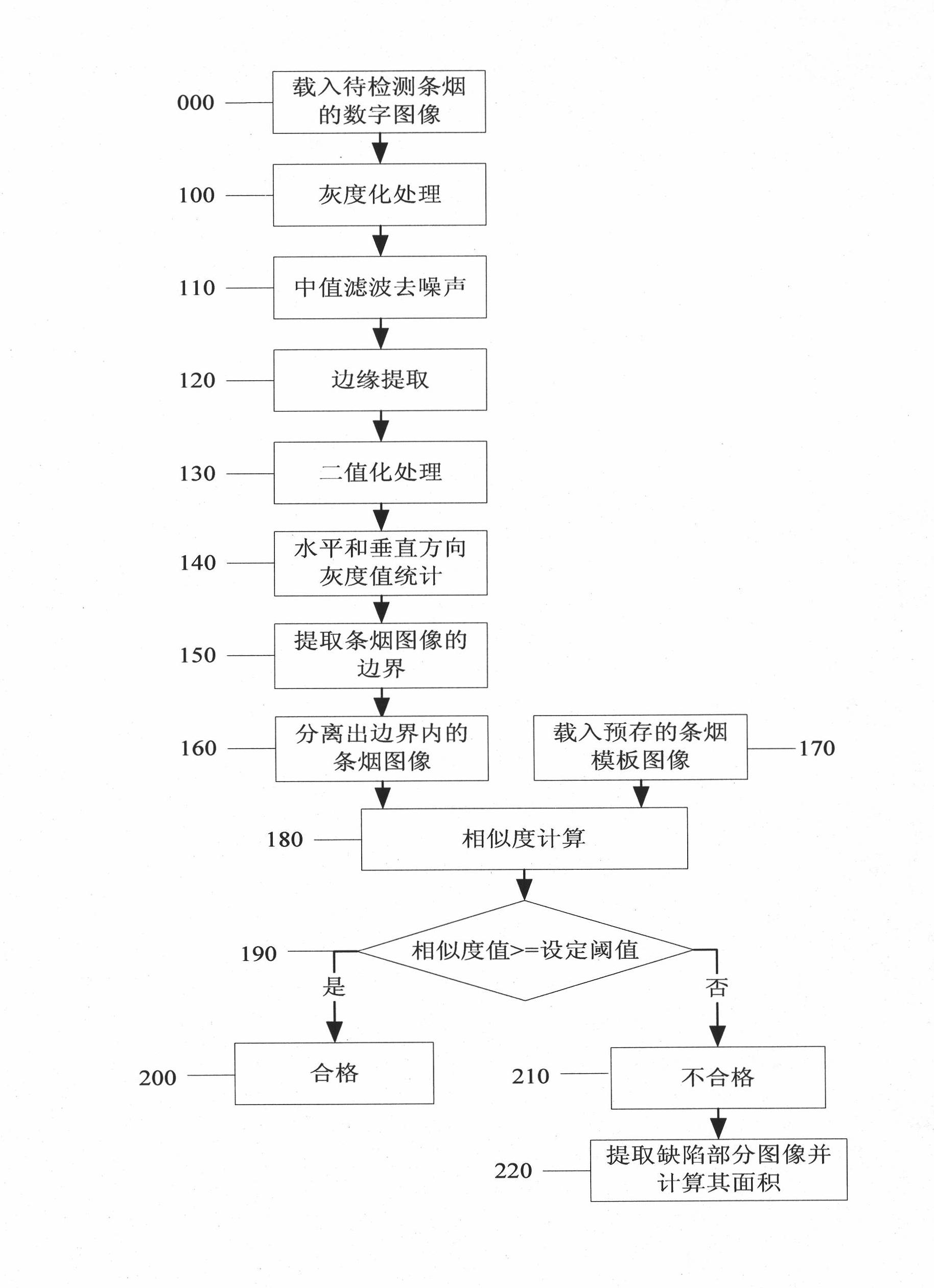

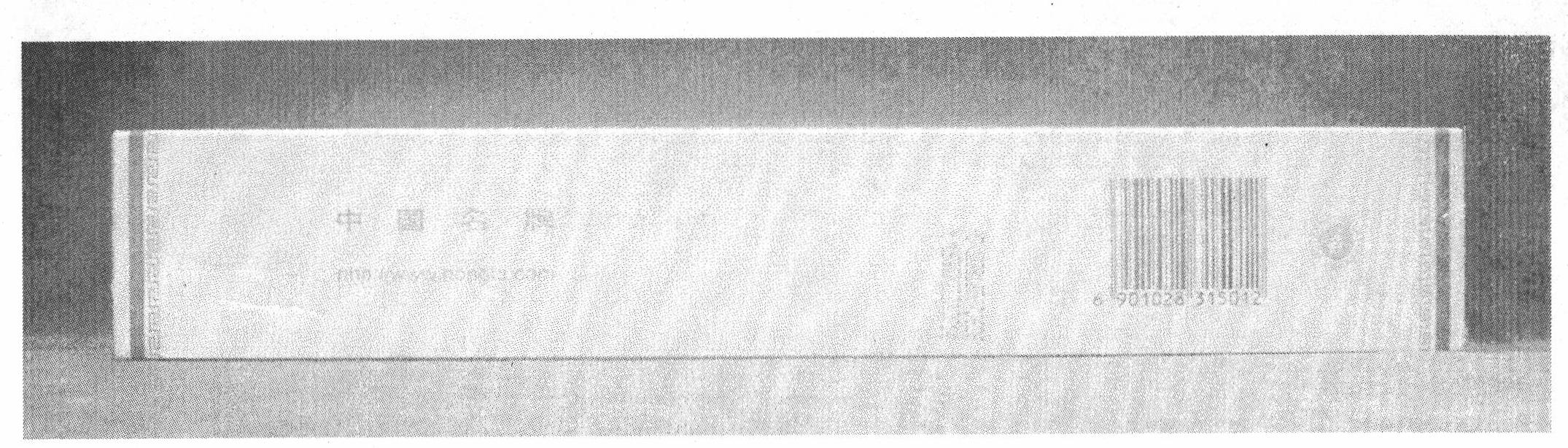

Visual detection method for transparent paper defect of outer package of strip cigarette

InactiveCN102020036AImproving the Efficiency of Defect Visual InspectionAchieve separationPackaging automatic controlCartonDigital image

The invention discloses a visual detection method for the transparent paper defect of the outer package of a strip cigarette, which aims to improve the efficiency of visual detection for the transparent paper defect of the outer package of the strip carton The method comprises the following steps: performing gray scale transformation on the shot digital image of the strip cigarette, filtering to remove noise and performing pretreatment on the image; performing edge detection on the pretreated image and extracting an edge image; performing binaryzation treatment on the edge image, performing gray value statistics in the horizontal and vertical directions by using a projection method, and extracting the boundary of the strip carton image to realize separation of the strip cigarette image; calculating similarity between the separated strip cigarette image and a template image, and setting a judgment threshold; and finally comparing the similarity value and the threshold to determine whether the strip cigarette image is qualified, extracting a pixel image of the defect part of the unqualified strip cigarette image by using a difference image method, and counting the pixel value which is taken as the pixel area of the defect part.

Owner:KUNMING UNIV OF SCI & TECH

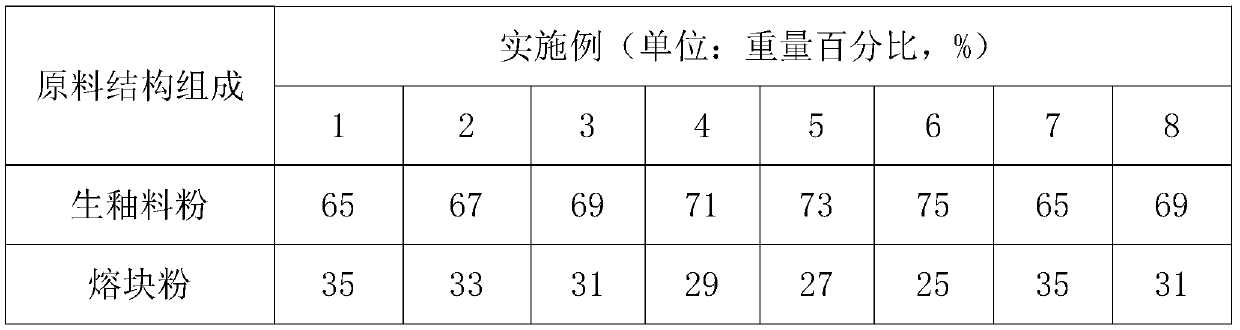

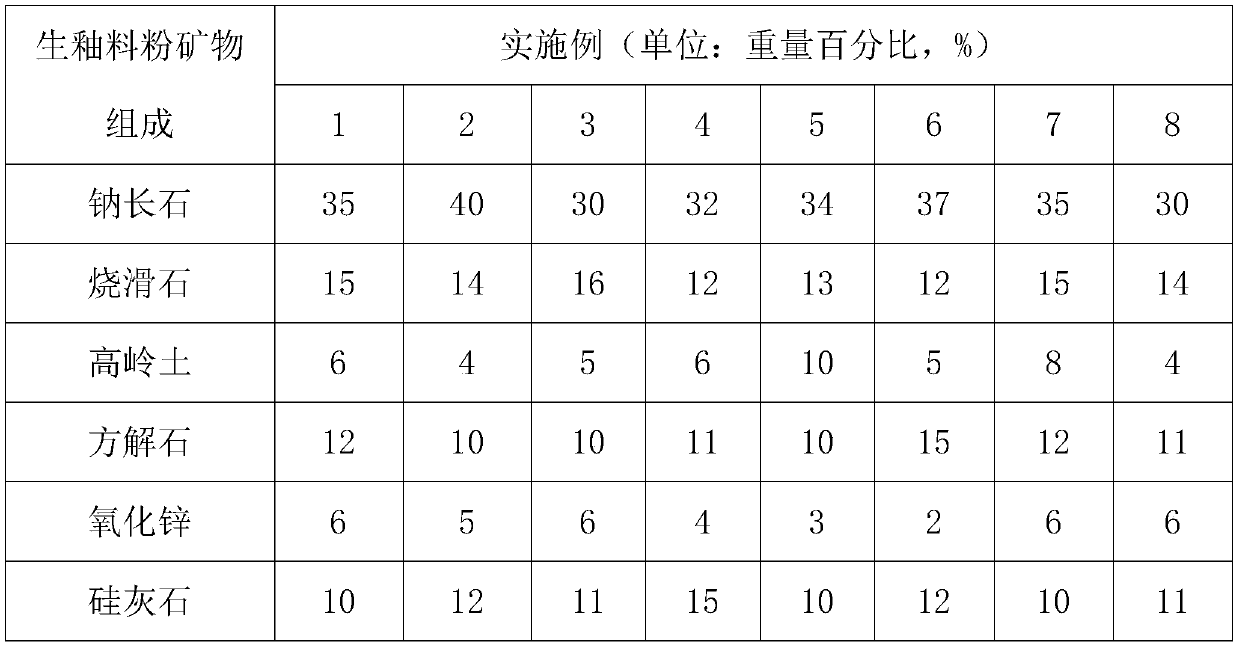

High-performance wear-resistant glaze and preparation method thereof

The invention relates to the technical field of building ceramics, particularly to a high-performance wear-resistant glaze and a preparation method thereof, wherein the high-performance wear-resistantglaze comprises, by weight, 65-75% of raw glaze powder and 25-35% of frit powder, the raw glaze powder comprises, by weight, 30-40% of albite, 12-16% of calcined talc, 4-10% of kaolin, 10-15% of calcite, 2-8% of zinc oxide, 10-15% of wollastonite, 10-20% of corundum and 2-8% of barium carbonate. A purpose of the invention is to provide a high-performance wear-resistant glaze and a preparation method thereof, wherein the flatness of the glazed brick prepared from the glaze meets the production process requirements while the contradiction between the transparency and the wear resistance of theglaze layer is solved, and the prepared glazed brick is greatly improved in wear resistance, high in flatness and good in color development.

Owner:FOSHAN DONGPENG CERAMIC +2

Cold forging method and metal housing processing method

ActiveCN102688966AReduce the chance of crackingReduced chance of scratchesAnodisationMetal-working apparatusMetallic materialsMetal

The invention provides a cold forging method and a metal housing processing method. The cold forging method comprises steps of performing anodic oxidation treatment to the metal material surface so as to obtain an anode oxide film; enabling the anode oxide film to adsorb a lubricant, forging and pressing the metal material absorbed with the lubricant, and removing the anode oxide film. The damage of a mold in the cold forging process is greatly reduced by the method, and the products prepared by the method are excellent in appearance without scratching.

Owner:BYD CO LTD

Corneal contact lens polishing solution and preparation method thereof

ActiveCN103805069AReduce surface scratch rateHigh glossPolishing compositions with abrasivesChemistryCorneal contact lens

The invention relates to a corneal contact lens polishing solution which comprises the following components in parts by weight: 10-30 parts of inorganic polishing powder, 0.5-5 parts of dispersing agent, 1-15 parts of thickening agent, 10-30 parts of moistening agent, 0.1-5 parts of surfactant and 100 parts of water. A preparation method of the corneal contact lens polishing solution comprises the following steps: (1) putting 100 parts by weight of hot water into a beaker, adding 10-30 parts by weight of inorganic polishing powder and 0.5-5 parts by weight of dispersing agent into the hot water, and stirring and dispersing till the water temperature is reduced to be the room temperature, so as to obtain suspension; (2) adding 1-15 parts by weight of thickening agent into the suspension, and stirring till the thickening agent is completely decomposed so as to obtain a mixture solution; (3) adding 10-30 parts by weight of moistening agent and 0.1-5 parts by weight of surfactant into the mixture solution of the step (2) at one time, and continuing stirring till a uniform mixture solution is obtained, that is, the high-performance polishing solution for hard contact lenses.

Owner:AUTEK CHINA

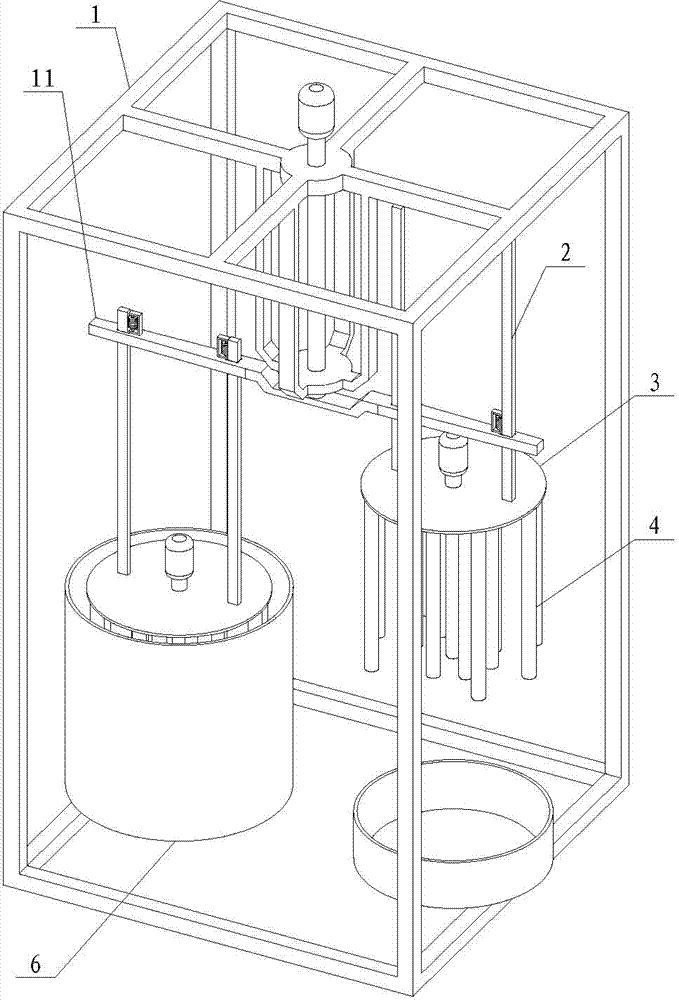

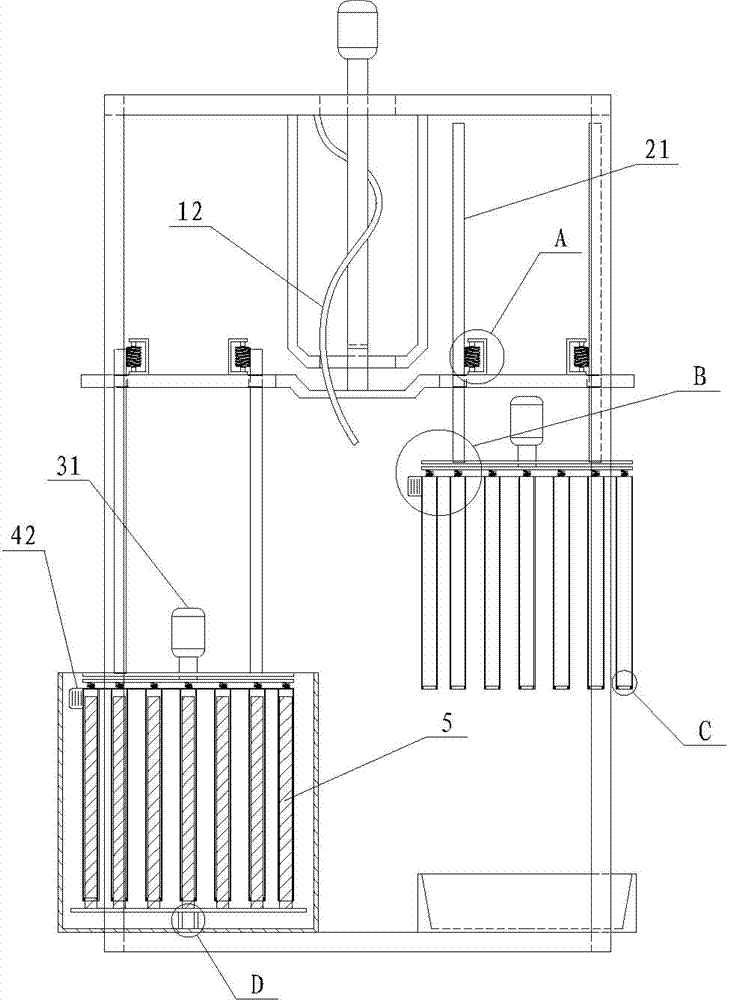

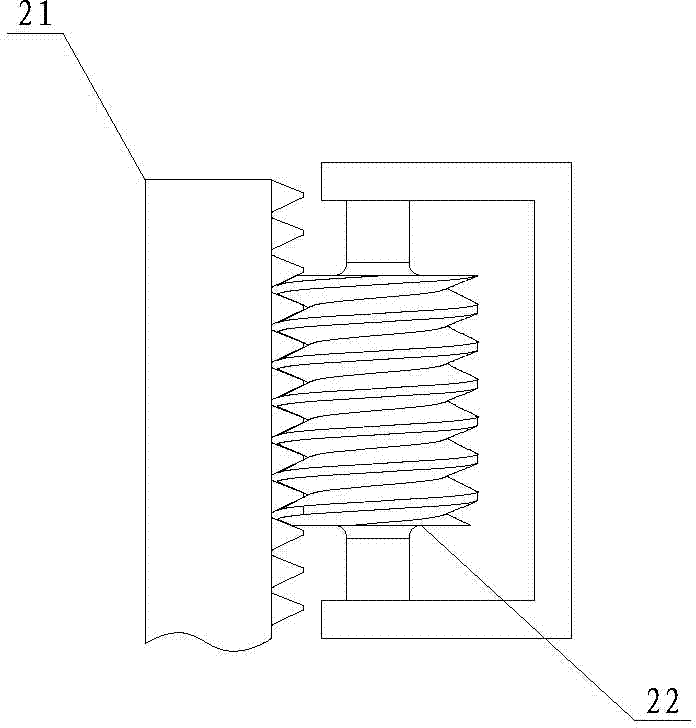

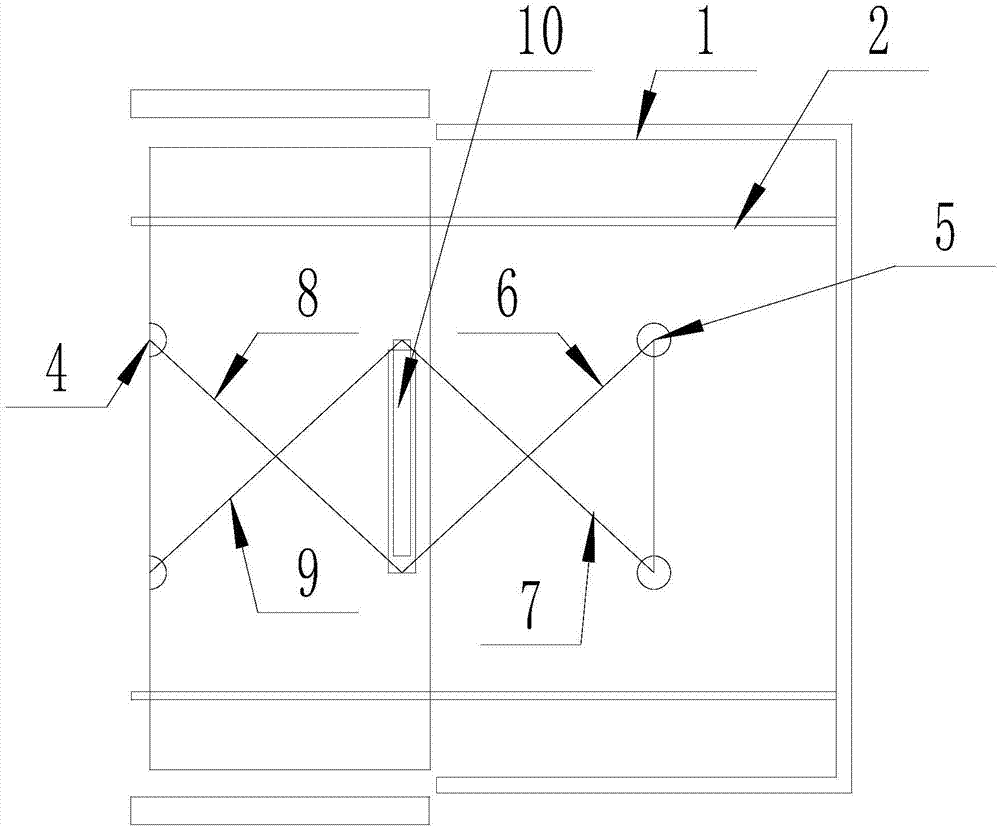

Method and equipment for eliminating iron scraps from raw materials

The invention discloses method and equipment for eliminating iron scraps from raw materials. The equipment comprises a rack, a charging bucket and a group of magnetic rods, and is characterized in that rotary arms are arranged on the rack and can horizontally rotate around the rack; a lifting mechanism is arranged on each of the rotary arms; rotary mechanisms are connected to the bottoms of the lifting mechanisms; a group of iron barrels are connected to the lower parts of each of the rotary mechanisms; a connection plate, a vibrator and an iron barrel connected with the connection plate are arranged in the group of iron barrels; the group of iron barrels is driven by the lifting mechanisms to sleeve iron barrels on the magnetic rods in the group of the magnetic rods; a motor, a rotary disc and a spring are arranged in each of the rotary mechanisms; each of the rotary disc is connected with each of the motors; a spring is fixed between each of the connection plates and each of the rotary discs; and vibrators are arranged on the connection plates. The method and the equipment have the beneficial effects that the iron barrels and the magnetic rods rotate in the charging bucket when irons are attracted, so that the contact probability of the iron barrels and slurries is increased, and the iron-attraction effect is improved; and when the iron barrels are subjected to iron removal, another group of iron barrels are quickly sleeved on the magnetic rods to perform the next round of iron attraction, so that the iron removal time is shortened, and the efficiency is improved.

Owner:ZIBO S & N MAGNET MFG

Method of preventing surface of strip steel from being scratched when strip steel passes through finishing mill without being rolled

ActiveCN103170507AImprove quality pass rateImprove "lubricated" conditionsRoll mill control devicesMetal rolling arrangementsStrip steel

The invention provides a method of preventing the surface of strip steel from being scratched when strip steel passes through finishing mill without being rolled. By means of the fact that a hydraulic AGC cylinder of the finishing mill is accelerated and a part of upper step mat base plates are omitted, a roll gap of the finishing mill when the strip steel passes through the finishing mill without being rolled is enlarged; the angle of a front loop and the angle of a rear loop are calibrated again, and the height of the strip steel supported by the loops is increased; and meanwhile, by means of control of input of oil and water, the temperatures of mill rolls are decreased, lubricating conditions between the strip steel and the mill rolls are improved, the problem that the surface of the strip steel is scratched by the mill rolls or protective boards when the strip steel passes through the finishing mill without being rolled is resolved thoroughly, the percent of pass of quality of the strip steel is improved greatly, the percent of pass of quality of the strip steel is improved 75% to 95%, and smooth proceeding of production is guaranteed.

Owner:ANGANG STEEL CO LTD

Damage-free processing method in mountain banana production

InactiveCN103190267AImprove product valueFix damagePlant protectionManual conveyance devicesCushioningBanana peel

The invention discloses a damage-free processing method in mountain banana production. The method includes conducting flower erasing, peduncle cushioning and bag sleeving in the banana fruiting management process, erasing gamophyllous perianth, stigma, male flower and free perianth of a banana flower from the growing base portion when the banana flower at the top end of banana fruitlet becomes grey, interlaying pearl wool or a kraft paper pad between banana fruit space when the banana fruitlet between an upper fruit space and a lower fruit space of the banana are contacted after the flower erasing step is finished and conducting bag sleeving on clusters when the peduncle cushioning is finished. When the banana is harvested, backpacks and harvesting cableways special for the mountain banana are adopted to transport the banana cluster to a package site, the banana cluster does not fall onto the ground, friction between the banana and other objects is avoided, and damage to the banana peel is reduced. Further, workers can operate conveniently under the mountain condition, and working efficiency is improved. The whole set of measures from production to harvesting all effectively solve the problems of banana damage, low product level and low benefit of the existing mountain banana production.

Owner:HEKOU YUNSHAN AGRI TECH +1

Numerical control machine tool with automatic scrap iron cleaning function

InactiveCN108436587AImprove practicalitySimple structureMaintainance and safety accessoriesNumerical controlSpray nozzle

The invention relates to a numerical control machine tool with an automatic scrap iron cleaning function. The machine comprises a main body and a base, and further comprises a cooling mechanism and acleaning mechanism, wherein the cleaning mechanism comprises a driving assembly, a power block, a supporting rod, a first spring, a lifting sleeve, a connecting rod, a scraping plate, a connecting shaft, two moving wheels and two guide assemblies; the cooling mechanism comprises a first guide rail, a first moving assembly, a second guide rail, a second moving assembly and a nozzle. The numerical control machine tool with the automatic scrap iron cleaning function can automatically clean the scrap iron in the base through the cleaning mechanism, so that the cleaning efficiency is improved, theprobability that operators are scratched by the scrap iron is reduced, and the practicability of the numerical control machine tool is improved; the position of the nozzle is adjusted which is realized through the cooling mechanism, so that the nozzle can be always positioned above a workpiece during operation of the numerical control machine tool, and therefore the cooling effect of nozzle on theworkpiece is improved, the practicability of the numerical control machine tool is further improved.

Owner:NANAN DATENG COMML SERVICE CO LTD

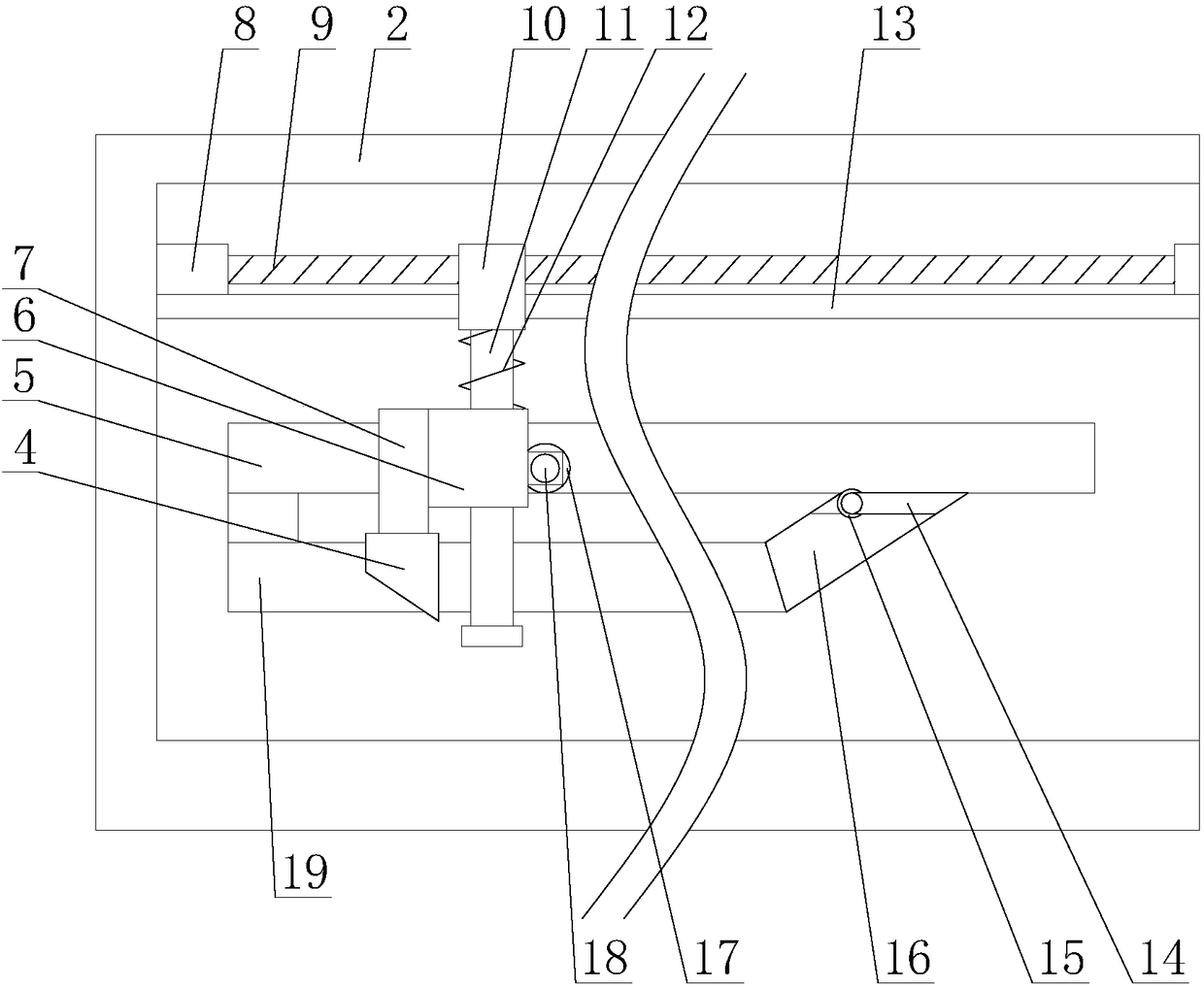

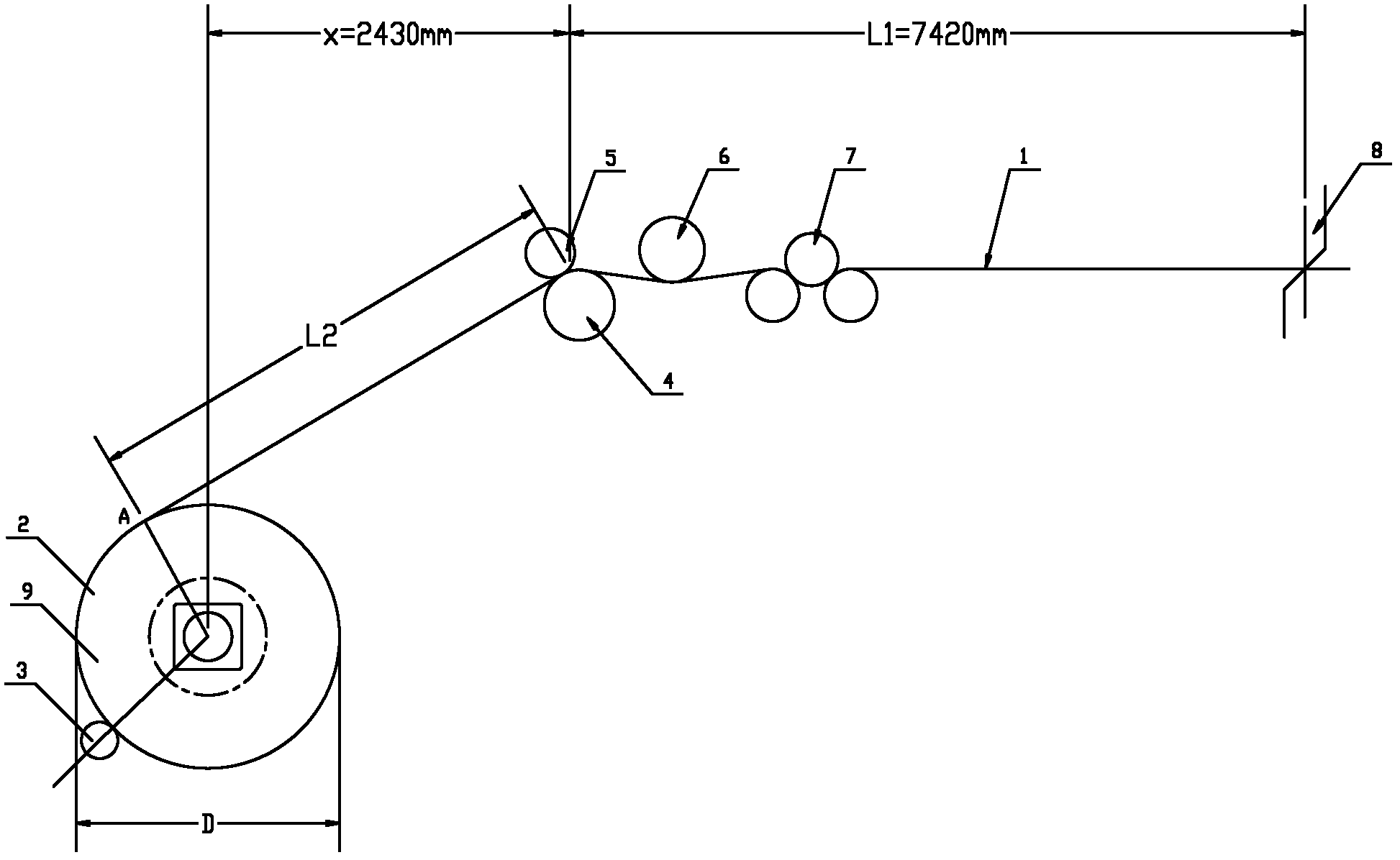

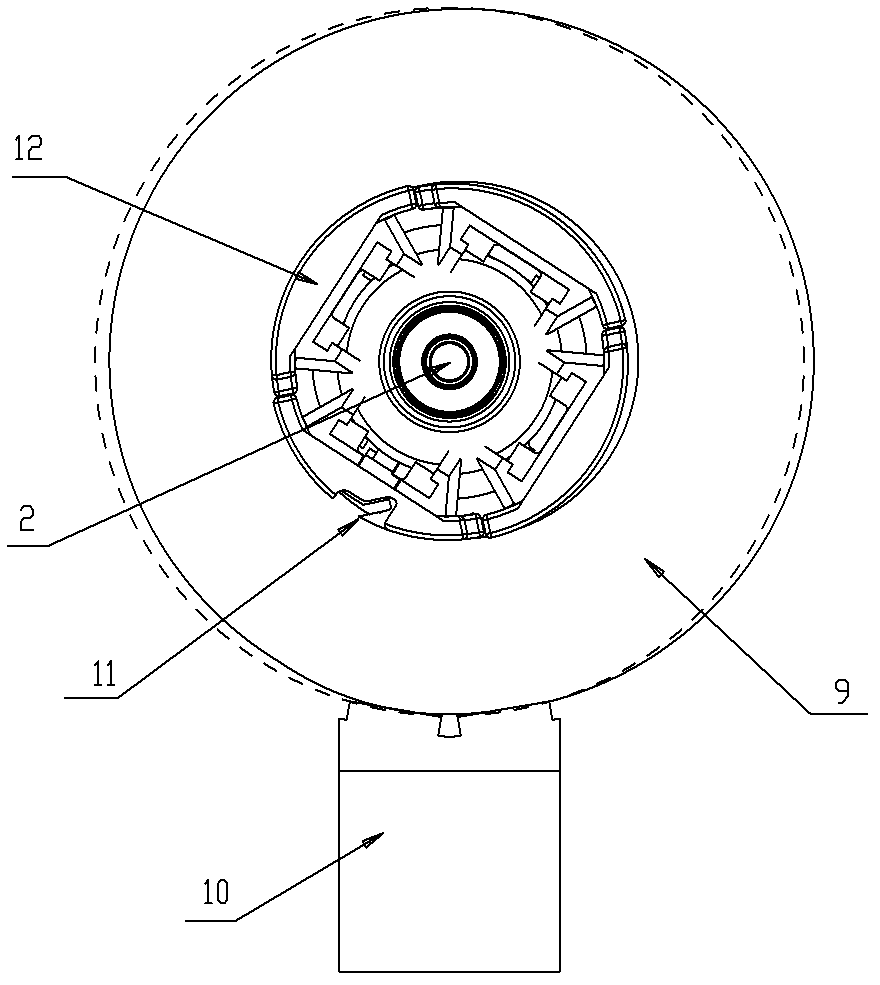

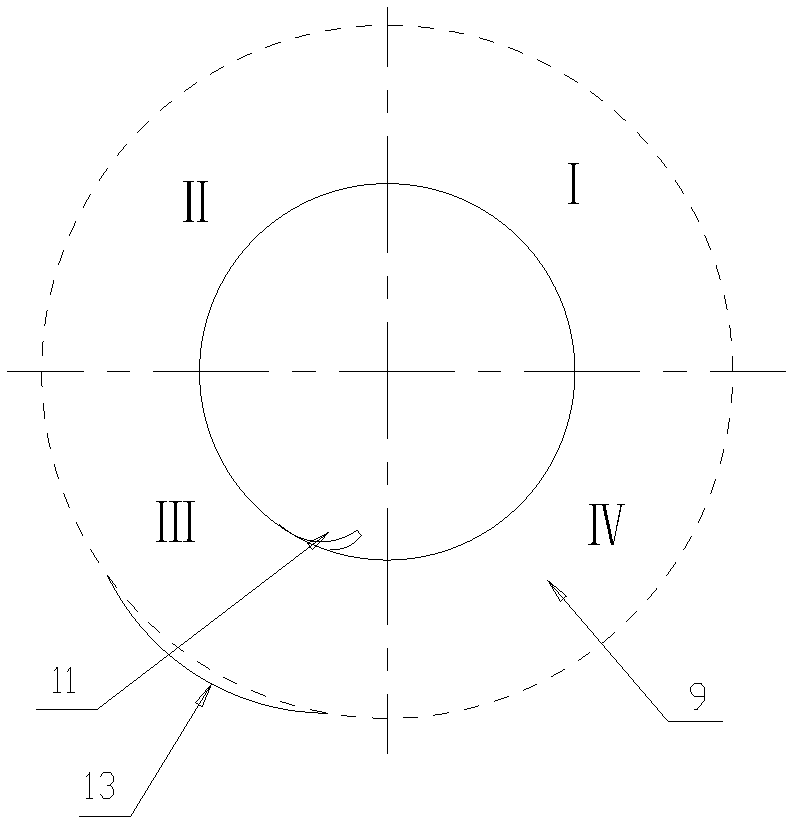

Method for positioning jaw opening of coiler mandrel

The invention relates to a method for positioning jaw opening of coiler mandrel, which is characterized in that: 1) when the length of the steel coil reaches requirement, after the detection device sends signal, the mandrel motor is stopped; 2) the cycle N of rotation of the jaw opening after cutting is calculated, wherein N=1 / 3+(L1+L2) / PiD, the position of the jaw opening when the plate coiling is terminated is calculated by combining the cycle N, and the jaw opening must be located on the horizontal line at center of the mandrel; 3) the mandrel motor is started, to start to establish tension and perform cutting operation; 4) the tape tail is stopped at the position of the cradle roll under the guide of a tape tail grating detection device, and the mandrel motor is stopped. Compared with the prior art, by the sectioning operation of a sectioning machine, and controlling the position of the jaw opening at cutting, the probability of the scratch of inner circle of the plate steel coil longer than 8 mm is greatly reduced, and the product yield is improved by 0.4-0.5% or above.

Owner:ANGANG STEEL CO LTD

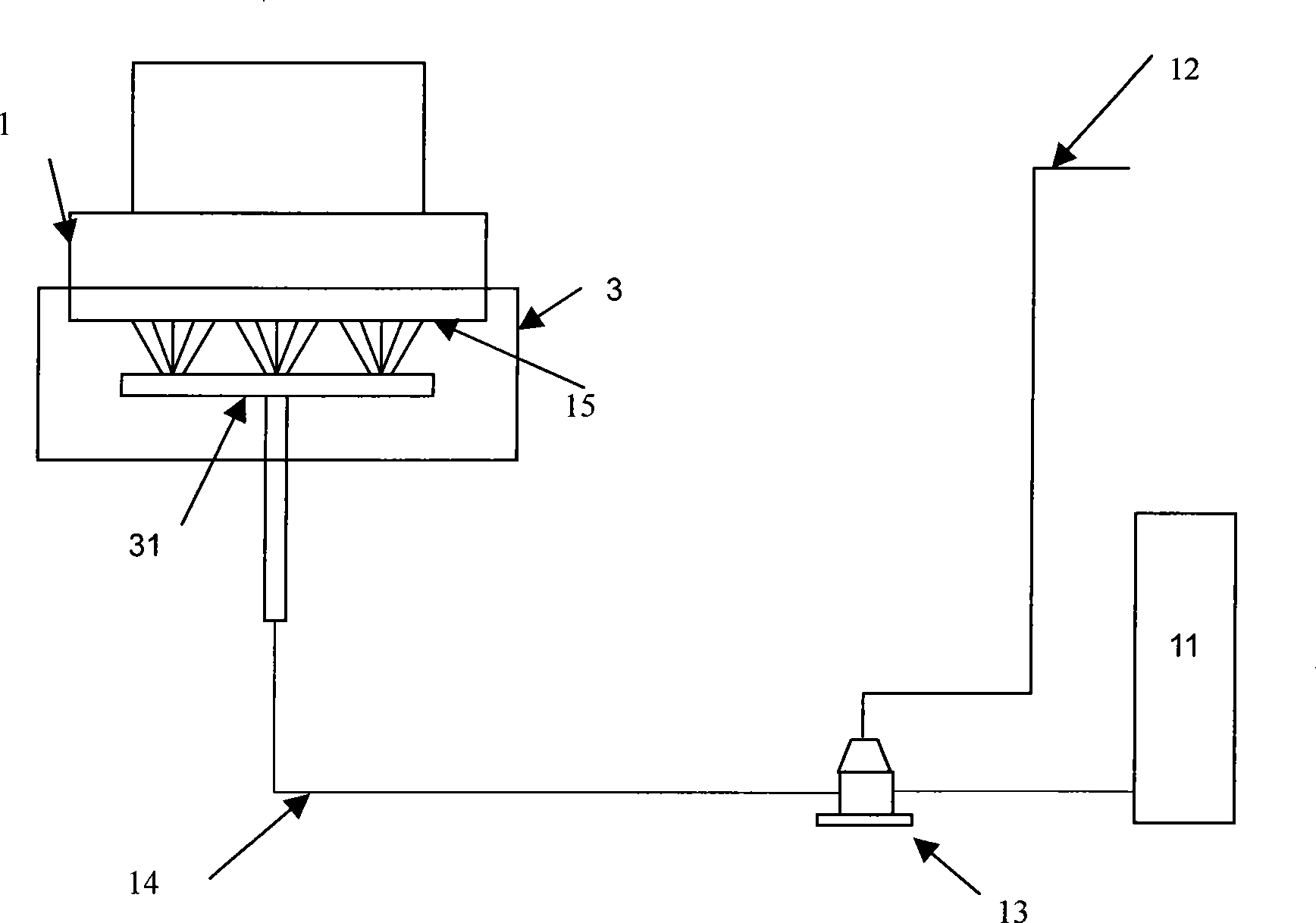

Cleaner for CMP equipment grinding head

InactiveCN101439494APrevent crystallizationReduce scratchesSemiconductor/solid-state device manufacturingLapping machinesComputer moduleEngineering

The invention discloses a device used for cleaning the grinding head of CMP equipment, comprising a water supply module, a grinding head cleaning control air passage, a pneumatic water valve 1, a bearing platform water supply pipe, and a grinding head assembly / disassembly device; wherein, the internal bottom of the grinding head assembly / disassembly device is a silicon plate bearing platform which is provided with pure water nozzles which are communicated with the bearing platform water supply pipe; the device also comprises a pneumatic water valve 2 and a peripheral cleaning water supply pipe; the grinding head cleaning control air passage controls the openness and closeness of the pneumatic water valve 1 and the pneumatic water valve 2 at the same time, thus communicating or preventing the pure water in the water supply module from entering the bearing platform water supply pipe and the peripheral cleaning water supply pipe; one end of the peripheral cleaning water supply pipe is a peripheral cleaning nozzle which is additionally arranged beside the grinding head assembly / disassembly device; furthermore, the outlet of the nozzle faces inwards; the gushed pure water can wash the grinding head peripheral area above the grinding head assembly / disassembly device. The device used for cleaning the grinding head of CMP equipment can reduce the frequency and time of maintenance operation of CMP equipment, and can reduce the possibility that the grains exceed the standard and the product is scraped.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

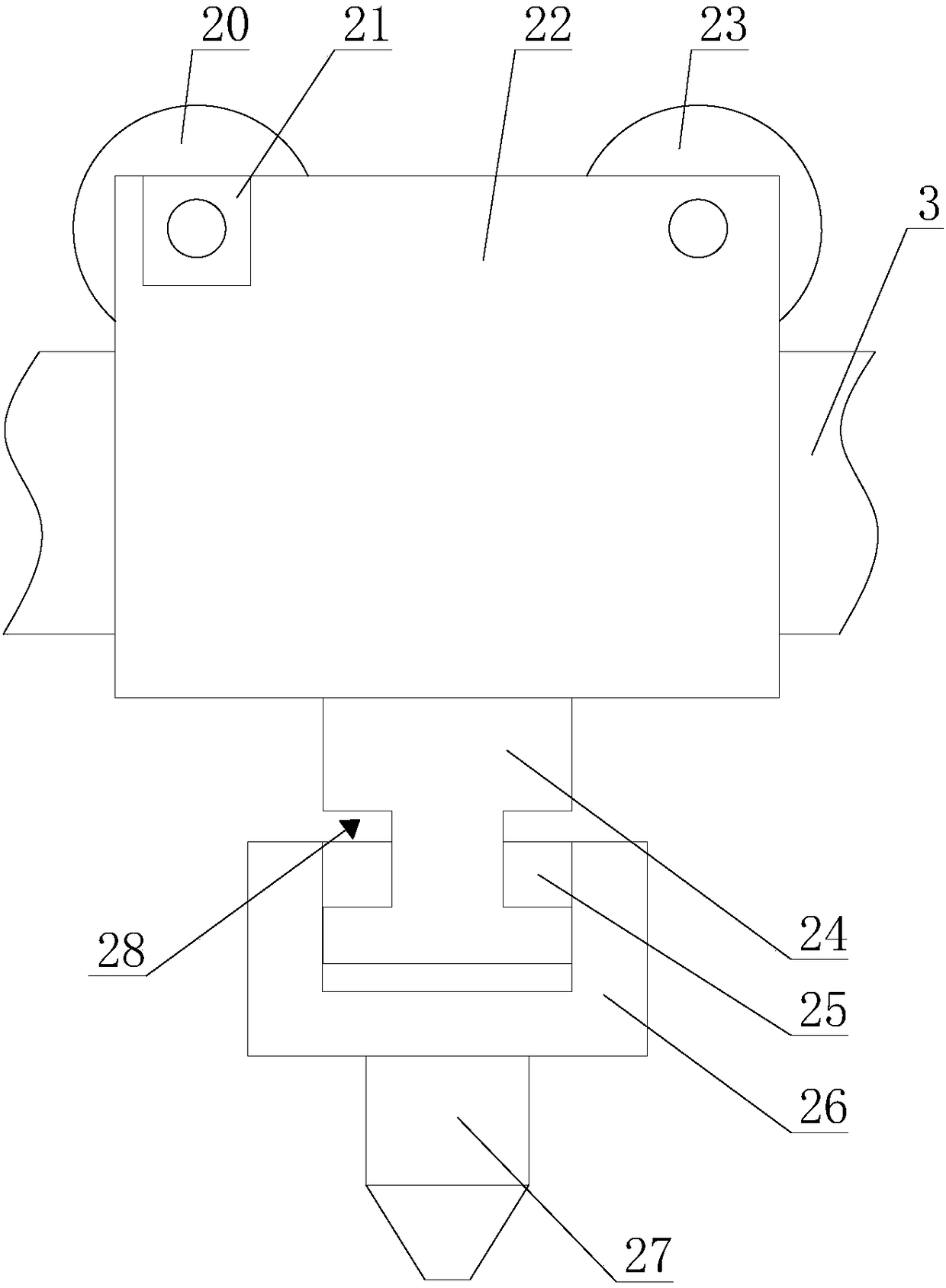

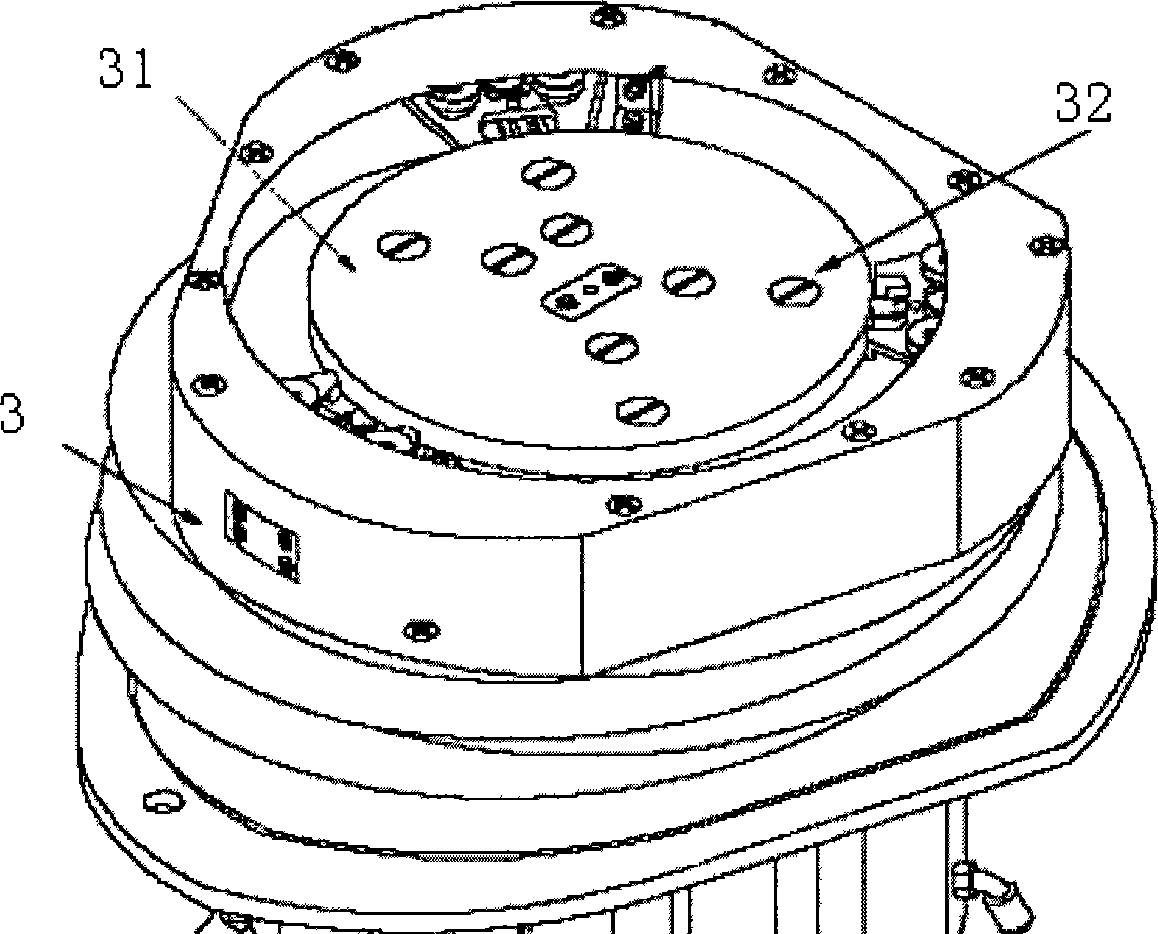

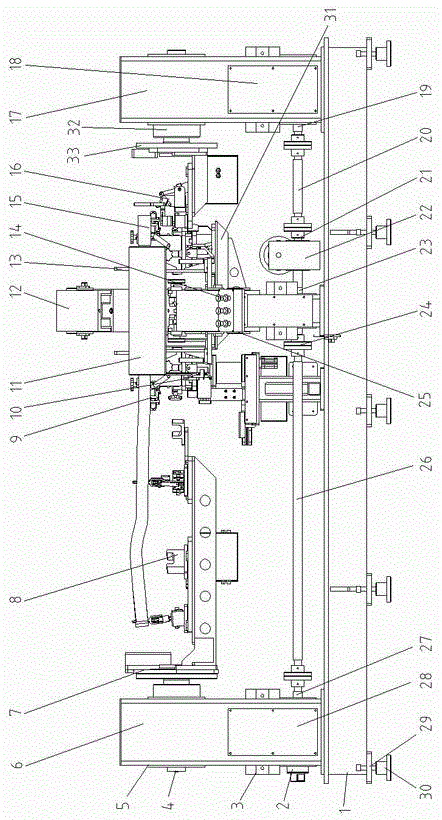

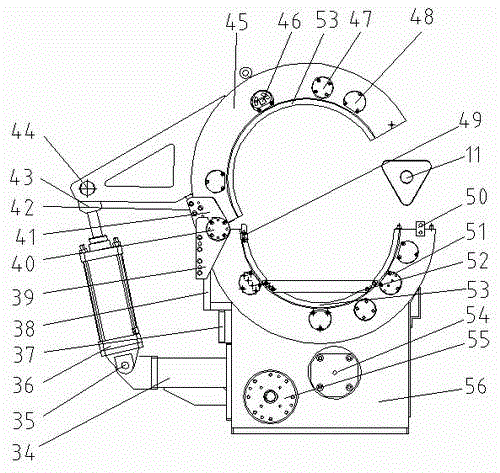

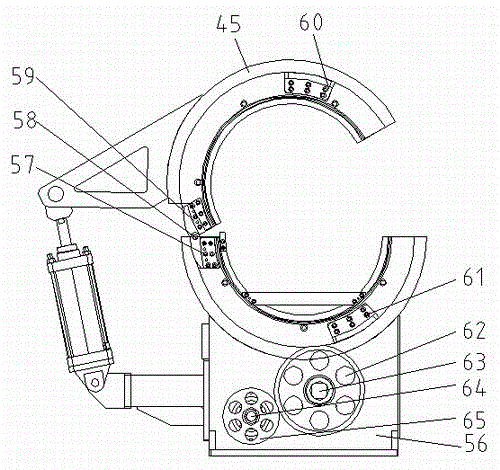

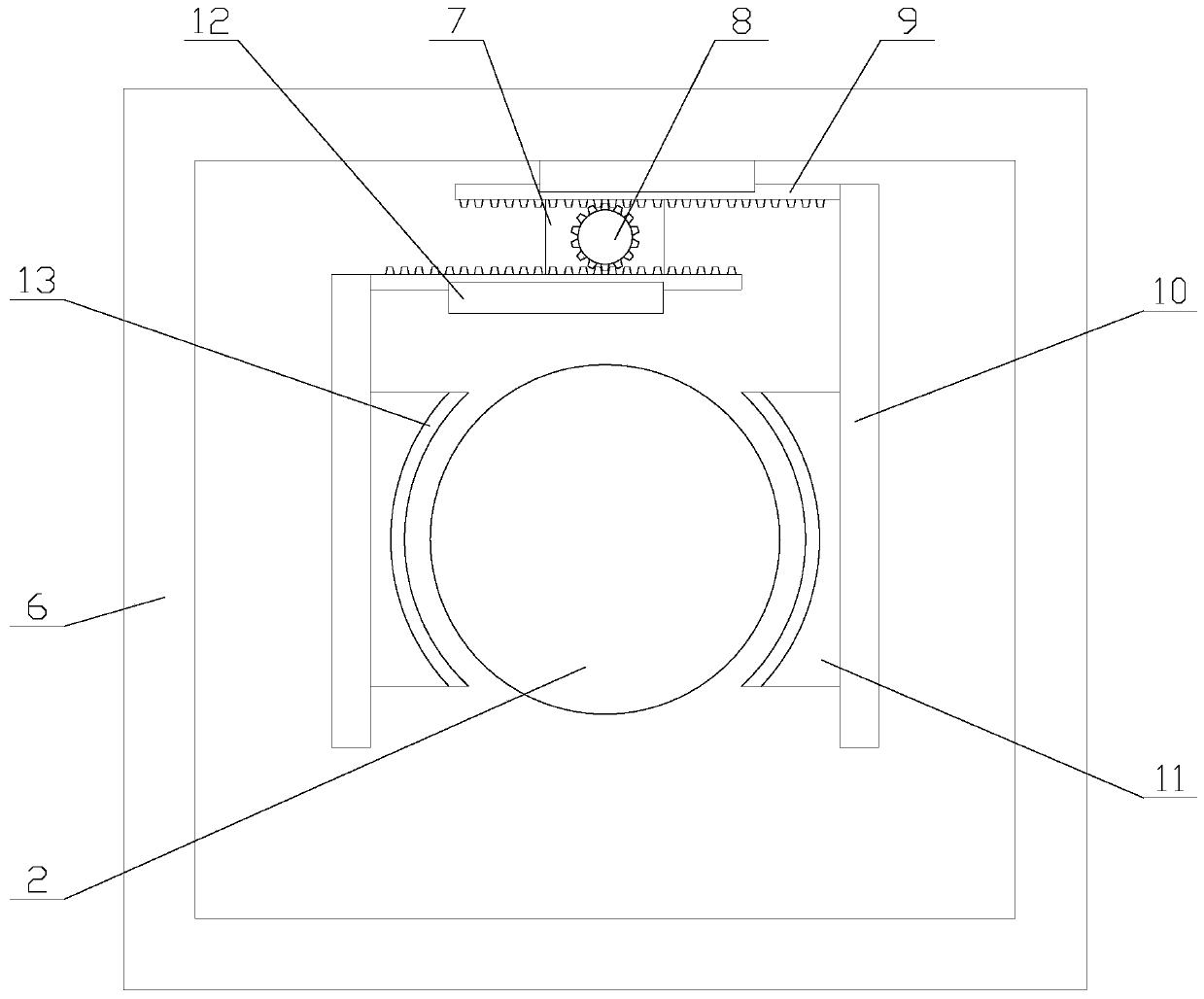

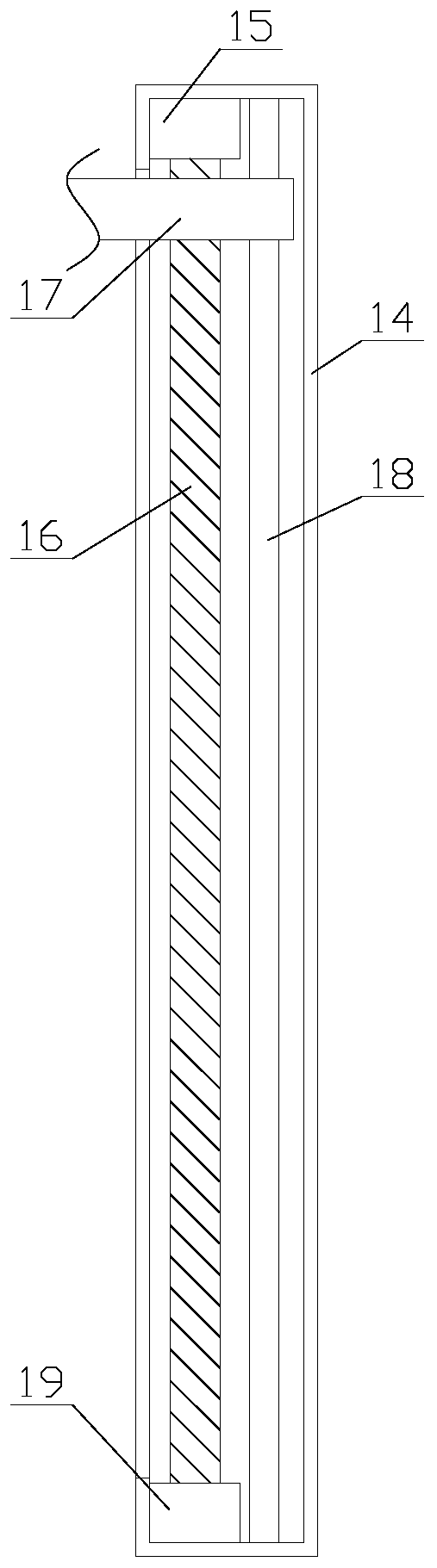

Special circumference weld opening/closing machine capable of tracking welding position automatically

ActiveCN104625501AReduced pickup processReduce the chance of scratchingWelding/cutting auxillary devicesAuxillary welding devicesCollision rateMachining

The invention belongs to the technical field of special machining devices, and provides a special circumference weld opening / closing machine capable of tracking the welding position automatically. A middle opening / closing box body with an upper box body and a lower box body is mainly adopted for the circumference weld opening / closing machine. An air cylinder supporting base fixed to the lower box body is connected with the lower end of an air cylinder through a pin shaft. An air cylinder connection block is directly connected with a piston rod of the air cylinder and connected with the upper box body through a connection pin shaft. The upper box body is connected with the lower box body through an opening / closing shaft. The upper box body is provided with an adjustment shaft, a blocking shaft and a side jacking shaft. The lower box body is provided with a correction block, a small opening stopping block and an opening / closing gear supported by a supporting wheel, and the two sides of the lower box body is provided with a blocking shaft and a side jacking shaft respectively. A small gear in the middle opening / closing box is meshed with the opening / closing gear through an intermediate gear. According to the circumference weld opening / closing machine, the middle opening / closing box body is designed to be of an opening / closing structure, the part taking process is reduced for operators, the operators can directly take out products from the front, meanwhile the scratching and collision rate of the products is lowered, and working efficiency and product quality are improved.

Owner:大连河野智能装备有限公司

Multimeter having probe storage and dedusting functions

InactiveCN109709367AImprove securityAffect display clarityMulti-tester circuitsElectric machineCLARITY

The invention relates to a multimeter having probe storage and dedusting functions. The multimeter includes a main body, two probes, two cables, a dustproof mechanism and two storage mechanisms; the storage mechanisms include fixing boxes; the fixing boxes are provided with steady assemblies; each steady assembly includes a first motor, a drive gear, two racks and two reinforcing units; the reinforcing units include connection plates and reinforcing plates; the dustproof mechanism includes a cover plate and two movable assemblies; and movable boxes are provided with second motors, rotating shafts and slide blocks. Through the storage mechanisms, the probes can be stored into the fixing boxes when equipment is in idle, so that damage probability can be reduced, and the security of the multimeter can be enhanced; and through the dustproof mechanism, dustproof work can be performed on a display screen, so that dust can be prevented from covering the display screen to affect the display clarity of the display screen.

Owner:刘晓慧

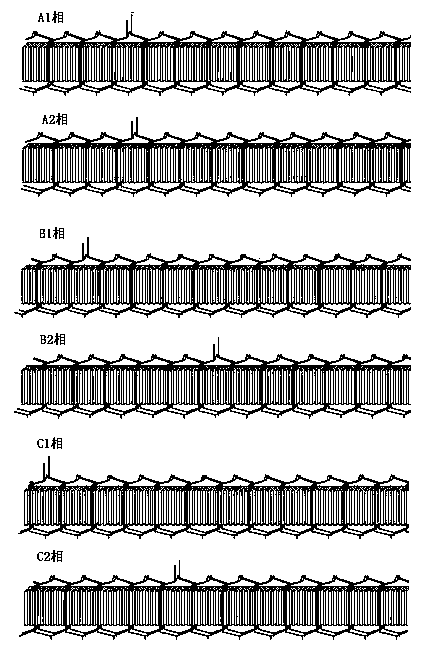

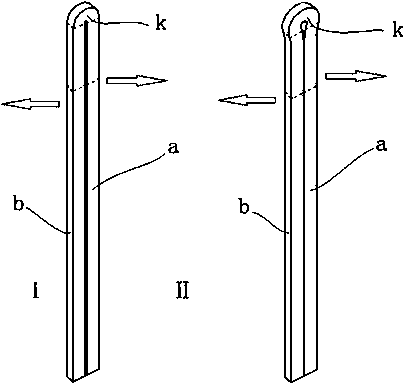

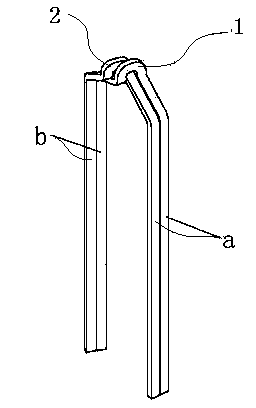

Stator assembly of automotive engine or driving motor

ActiveCN103795170AIncrease slot fill rateIncreased power volume densityManufacturing dynamo-electric machinesWindings conductor shape/form/constructionCross connectionCopper wire

The invention relates to a stator assembly of an automotive engine or a driving motor. The stator assembly comprises a stator iron core and multiple phases of windings, and is characterized in that each phase of winding is composed of multiple sets of rectangular copper wire base winding elements, a rectangular copper wire cross connection element and a rectangular copper wire outlet element, wherein the multiple sets of rectangular copper wire base winding elements are connected end to end and sequentially inserted into winding grooves of the stator iron core, and the rectangular copper wire cross connection element and the rectangular copper wire outlet element are connected between the first set of the rectangular copper wire base winding elements and the last set of the rectangular copper wire base winding elements in series. The middle portion of the base winding element body I of each rectangular copper wire base winding element and the middle portion of the base winding element body II of the rectangular copper wire base winding element are twisted together, and the straight sides of the two element bodies located on the same side are attached side by side. A certain span is formed between the straight side a of each element body on the front side and the straight side b of the corresponding element body on the rear side. The straight side a of each element body is inserted into the first layer position of the corresponding winding groove and the second layer position of the corresponding winding groove. The straight side b of each element is inserted into the third layer position of another corresponding winding groove and the fourth layer position of another corresponding winding groove. The defect that the sides of the elements are easily scratched through the bending method of a structure welding end of an existing rectangular copper wire stator assembly, and therefore defective products are formed after insulating enameled leather falls is overcome, power generation capacity and power generation efficiency of the engine are improved, and temperature rise and noise are reduced.

Owner:JINZHOU WONDER AUTO DIANZHUANGPIN

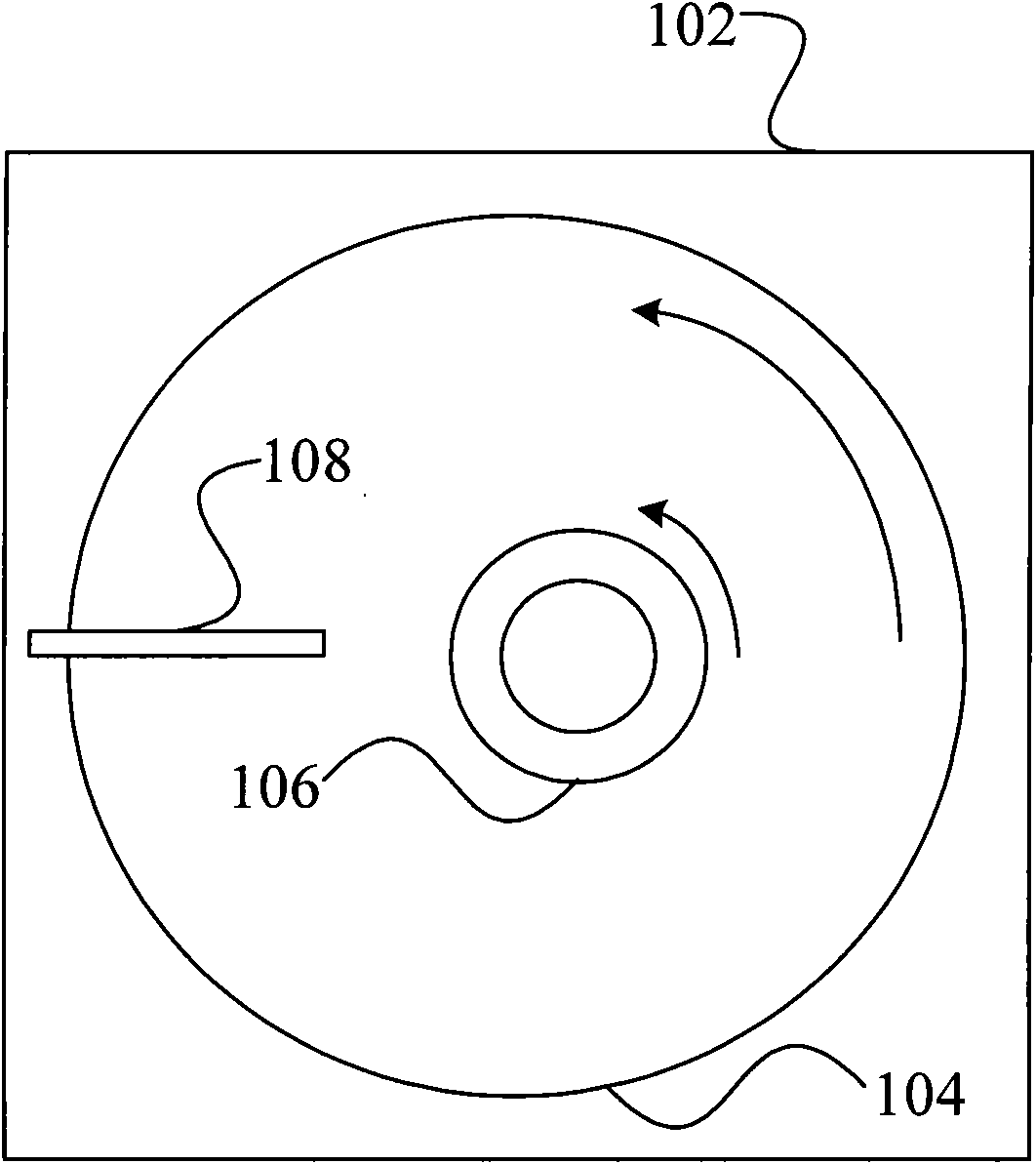

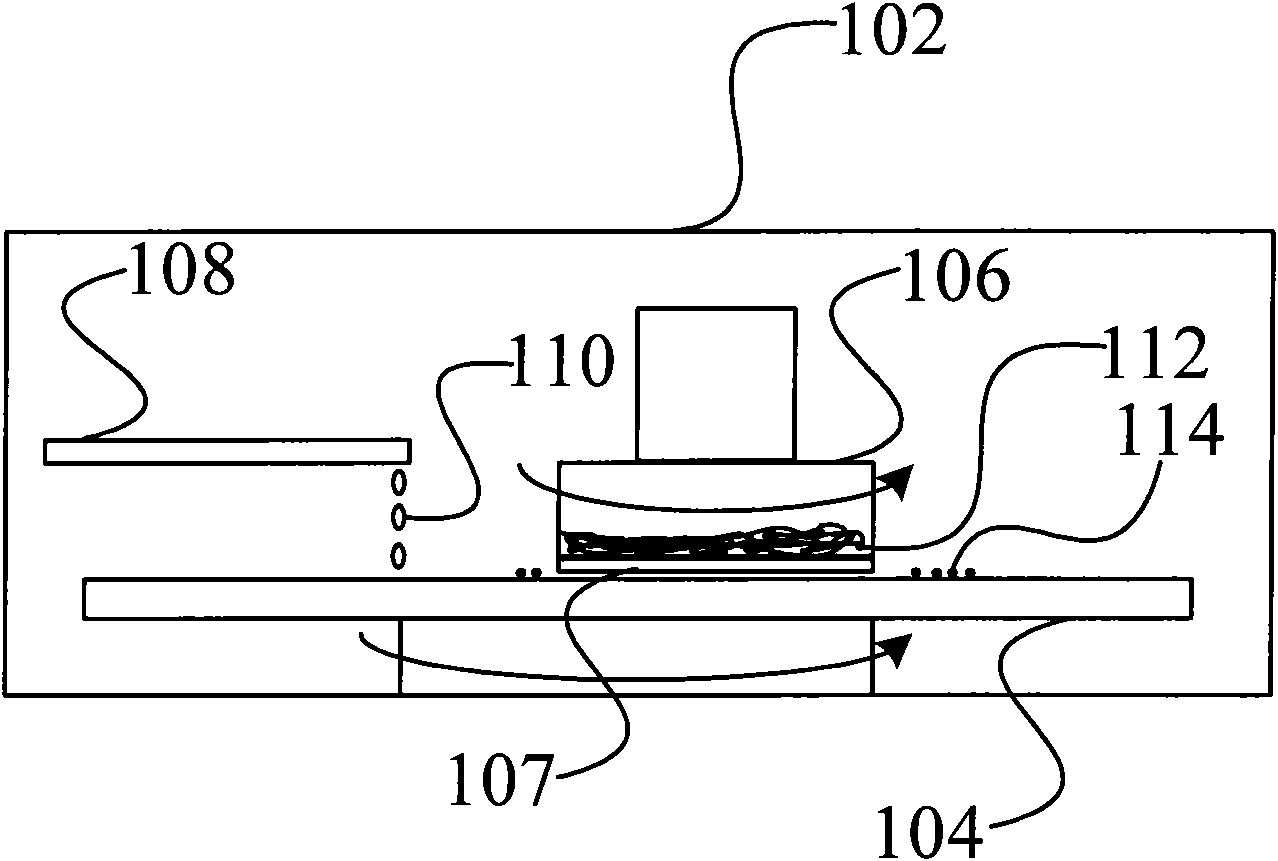

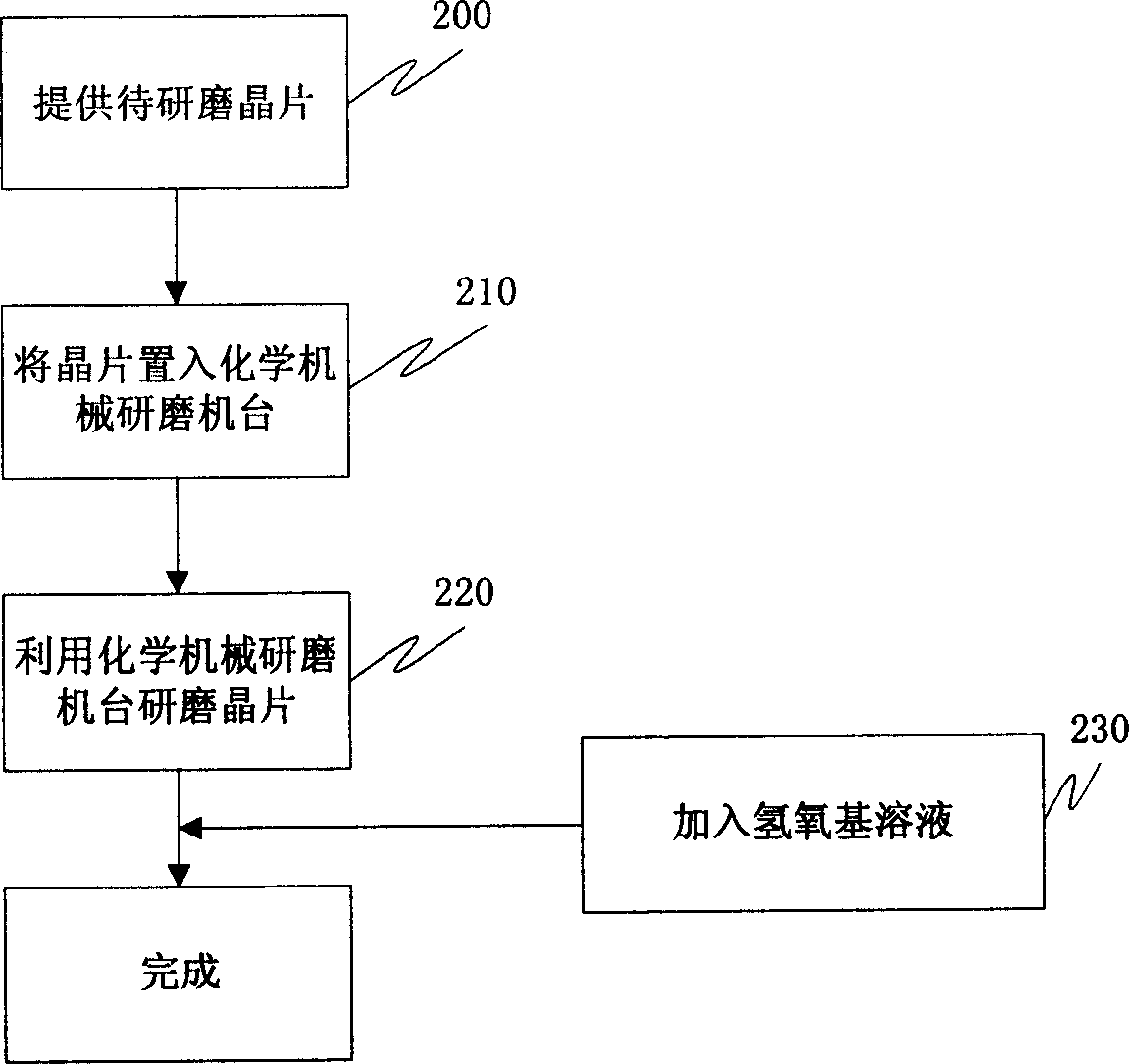

Chemical mechanical polishing system

InactiveCN102001035AReduce the chance of scratchesThe process is simplePolishing machinesSemiconductor/solid-state device manufacturingChemical-mechanical planarizationEngineering

The invention provides a chemical mechanical polishing system, which comprises an outer housing and a chemical mechanical polishing device positioned in the outer housing, and also comprises an ultrasonic sprayer for spraying towards the inside of the outer housing. Based on the existing chemical mechanical polishing system, the ultrasonic sprayer for the medical filed is additionally arranged, so that the ambient humidity inside the outer housing is large enough, and a grinding liquid is not easy to adhere to a grinding head and condense into crystallized particles, or even if the crystallized particles are adhered to the grinding head, the crystallized particles are easy to wash off with deionized water in an environment with large enough humidity, thereby avoiding that the crystallized particles fall on a grinding pad to scratch the surface of a wafer. The chemical mechanical polishing system has the advantages of greatly reducing the probability of scratching the surface of the wafer in the chemical mechanical polishing process, simplifying the process and improving the production efficiency.

Owner:SEMICON MFG INT (SHANGHAI) CORP

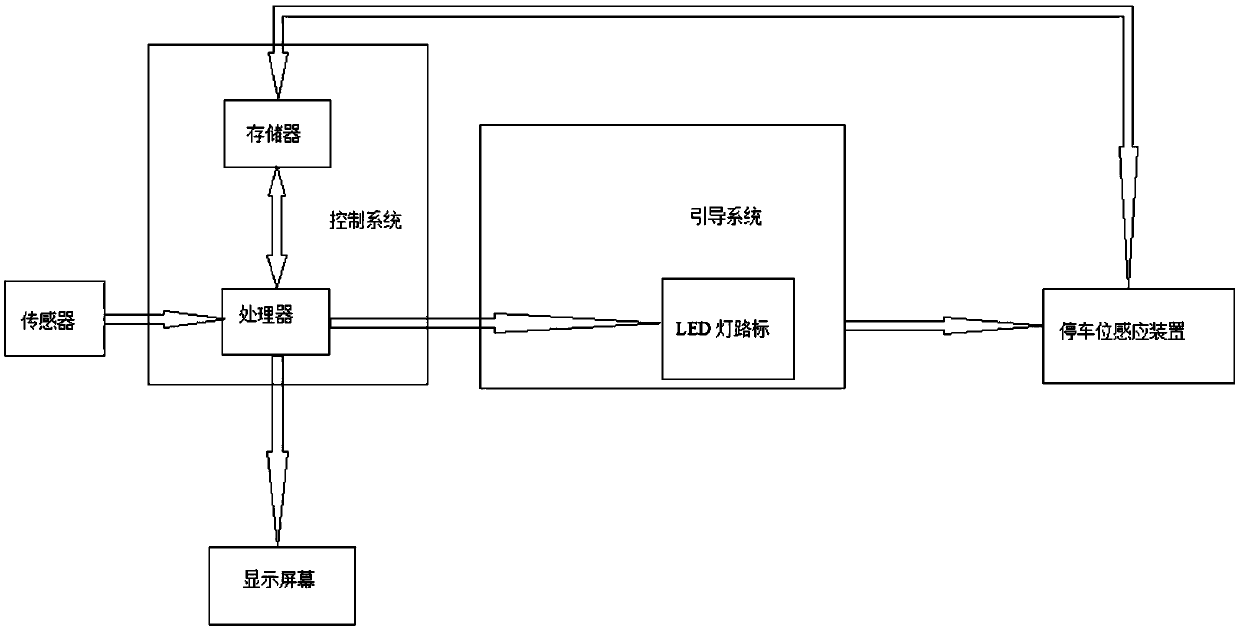

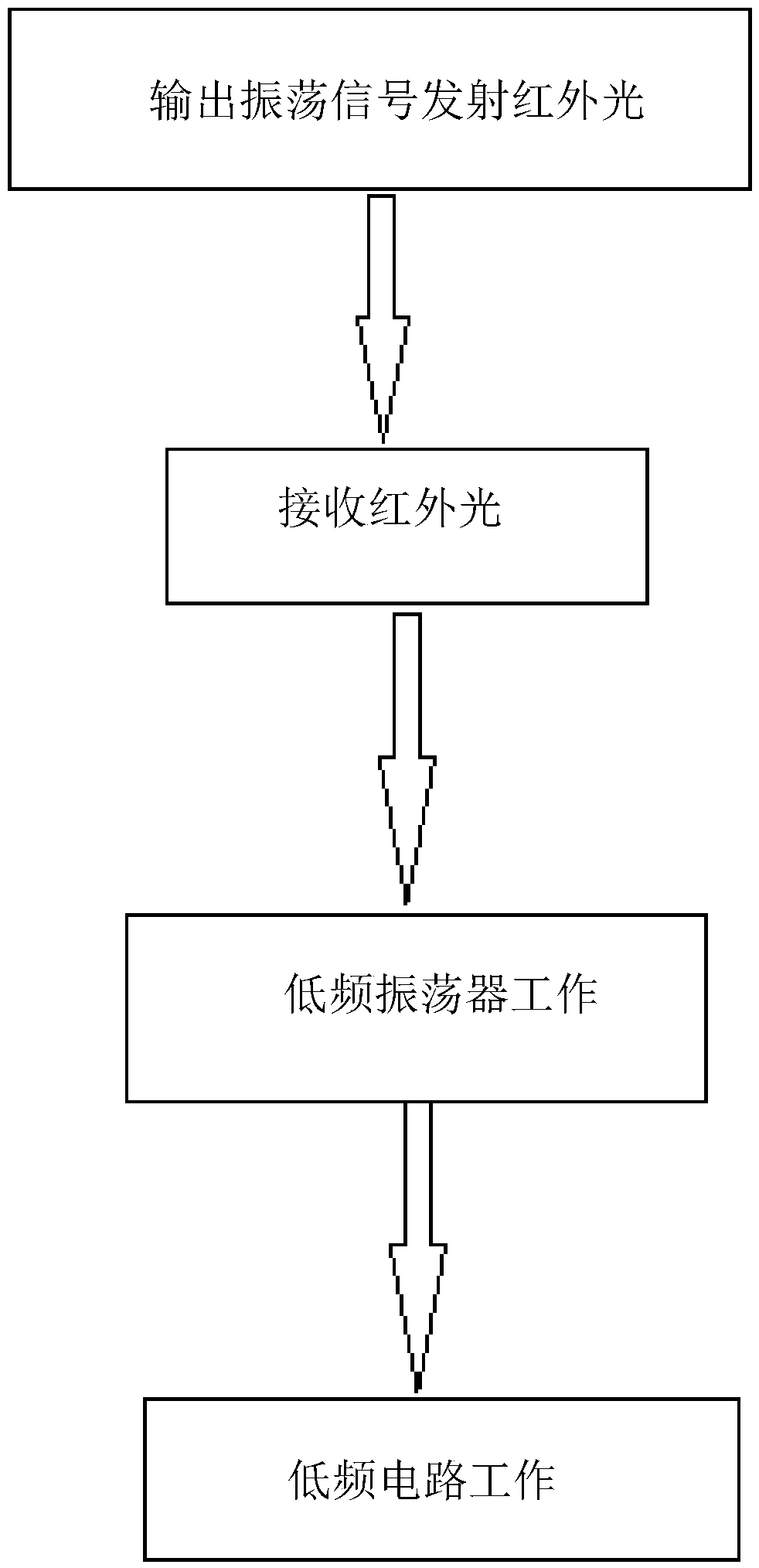

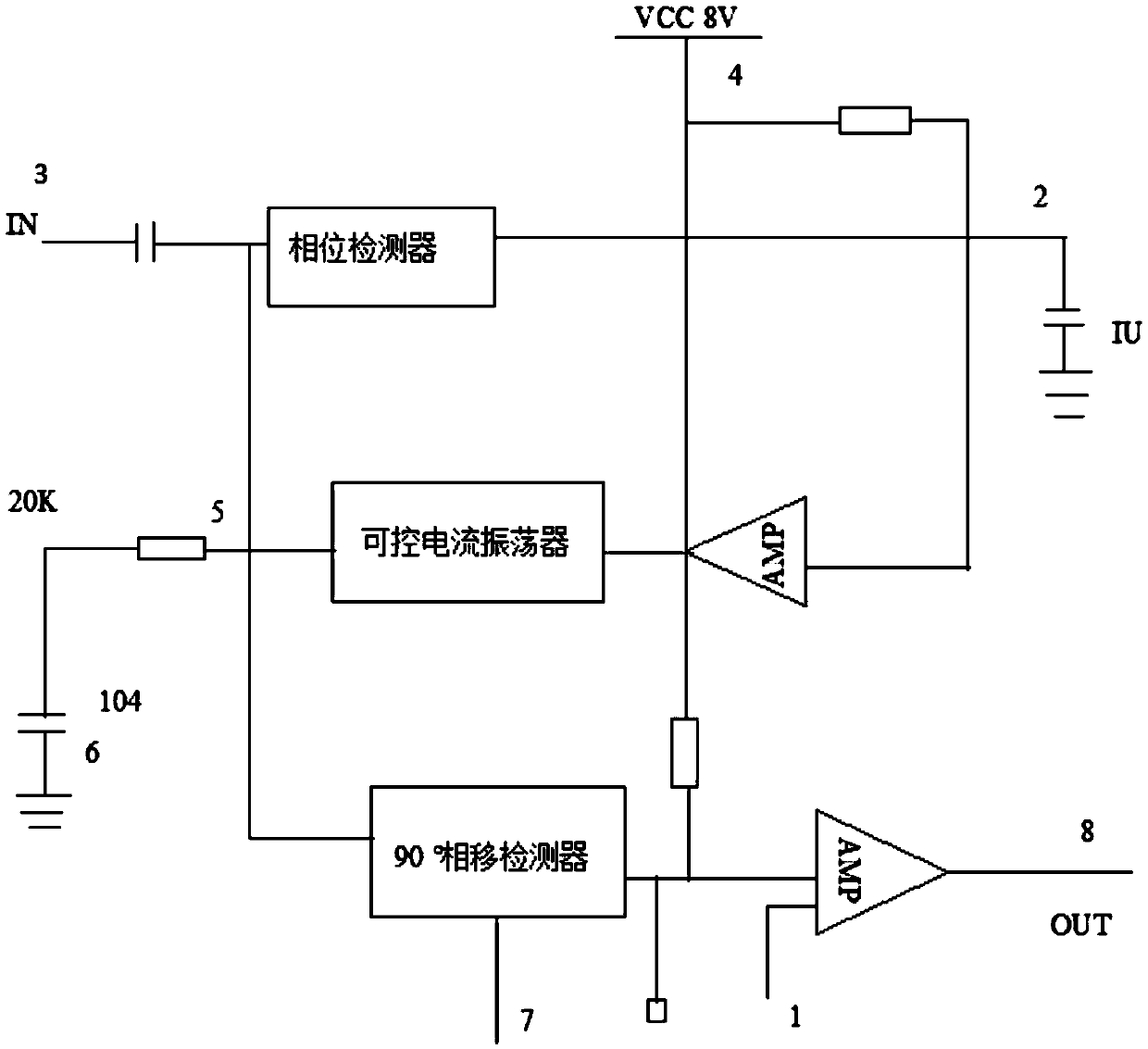

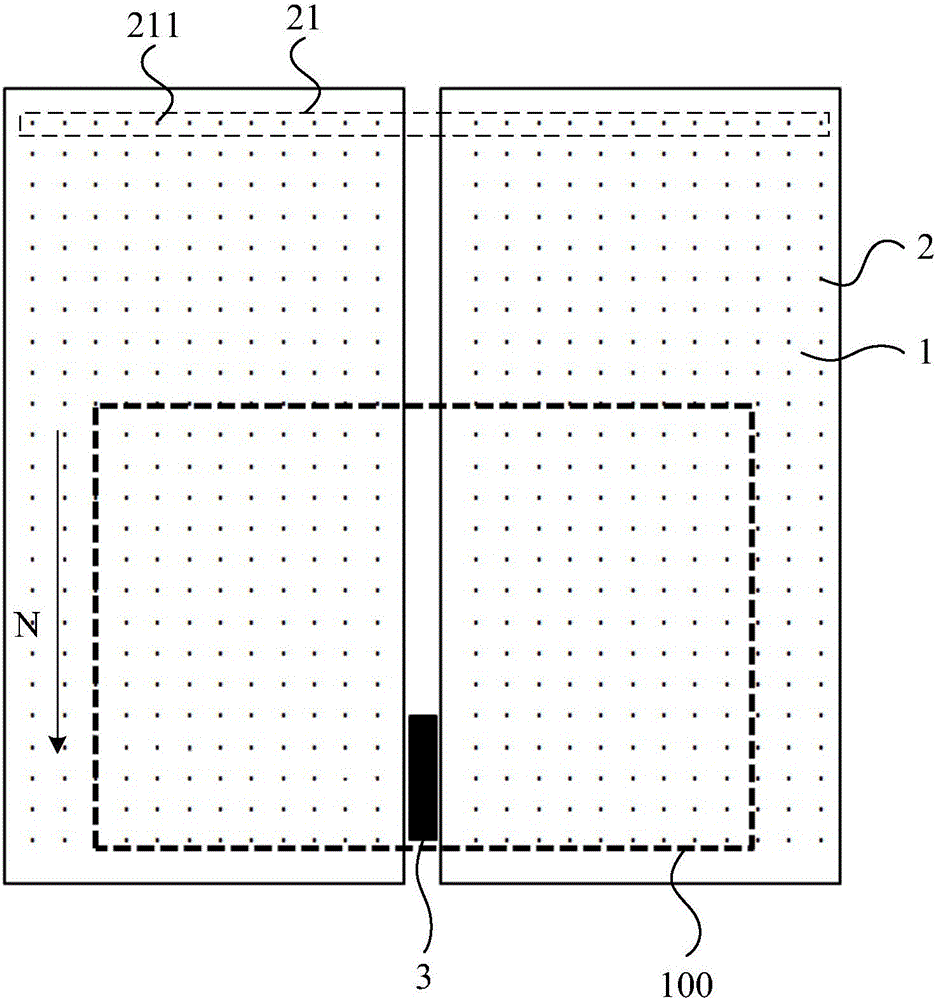

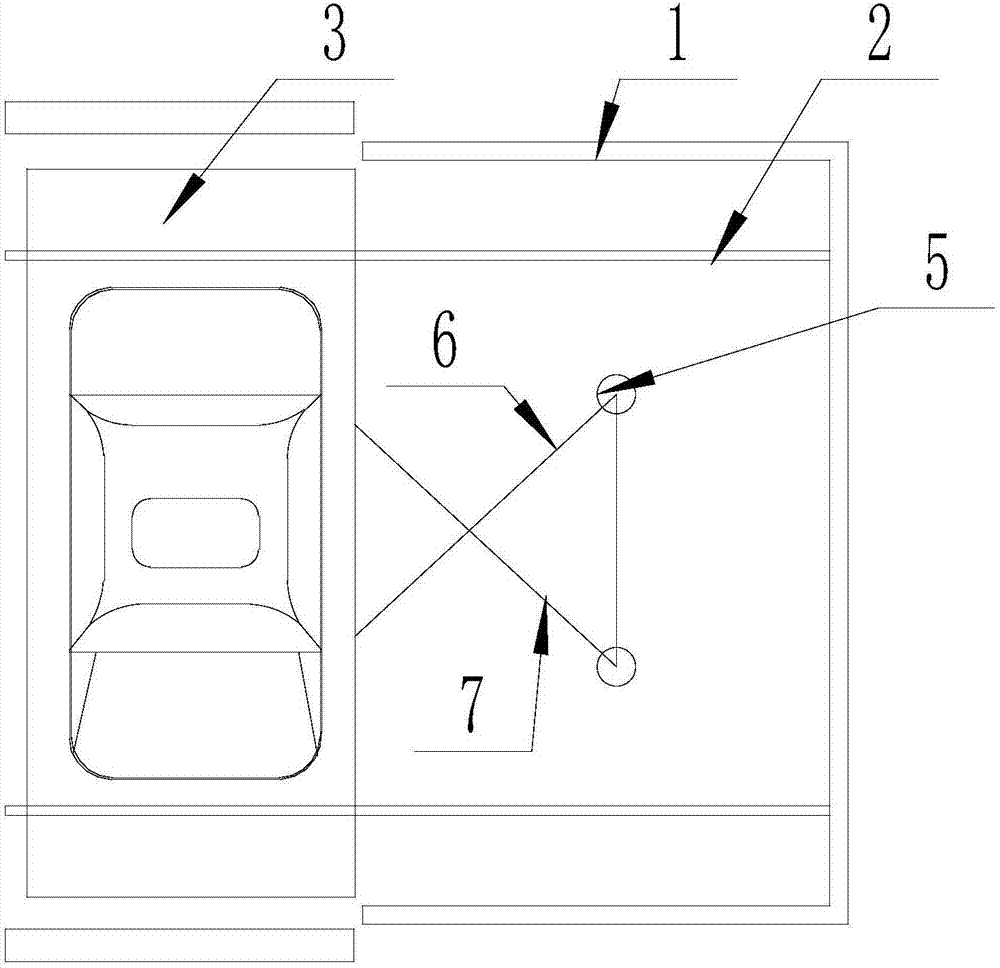

Intelligent guiding system for parking lot

InactiveCN105513363AReduced chance of scratchesShorten the timeDetection of traffic movementParking areaControl system

The invention relates to an intelligent guiding system for a parking lot. The intelligent guiding system comprises a sensor, a control system, a display screen, a guiding system and multiple parking space sensing devices; the sensor is installed at an entrance of the parking lot, the control system comprises a storage and a processor which are connected with each other, and the display screen is installed at the entrance of the parking lot; the guiding system comprises multiple LED lamp road signs which are installed on the road surface of the parking lot, and the LED lamp road signs point out the directions leading to the entrance of the parking lot or an exit of the parking lot or an elevator or a shopping mall; each parking space sensing device is installed on a parking space; the sensor, the display screen and the guiding system are electrically connected with the control system. The intelligent guiding system for the parking lot can automatically detect idle parking spaces nearest to the directions of the entrance of the parking lot or the exit of the parking lot or the elevator or the shopping mall and guide a vehicle to rapidly find a target parking space, the time of a vehicle owner is saved, and parking of the parking lot is orderly.

Owner:ZHENGZHOU TECHN COLLEGE

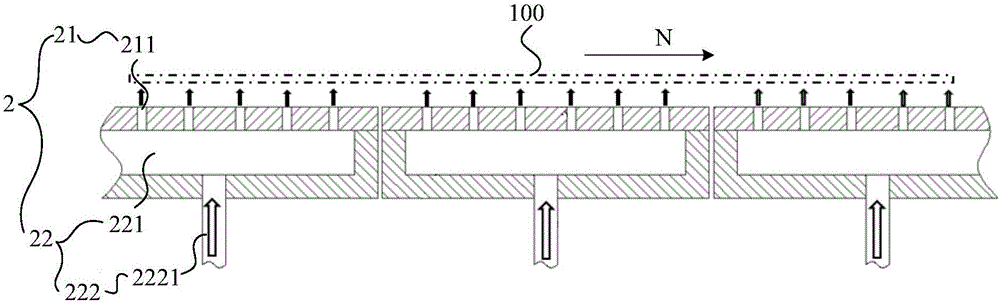

Base plate conveying device and control method thereof

InactiveCN106494889AReduces friction wear and scuffingImprove the smoothness of conveyingCharge manipulationConveyor partsMechanical engineeringBuoyancy

The invention discloses a base plate conveying device and a control method of the base plate conveying device, and relates to the technical field of base plate conveying equipment. The base plate conveying device aims at solving the problem that base plates are likely to be abraded or scratched or deformed when a roller type conveying machine is adopted for conveying the base plates in the prior art. The base plate conveying device comprises a conveying platform, a suspension assembly and a pulling device, wherein the suspension assembly is used for applying upward buoyancy force to base plates which the conveying platform bears so as to enable the base plates to be suspended above the conveying platform, and the pulling device is used for pulling the base plates to move in a suspended mode on the conveying platform along a preset path. The base plate conveying device is used for reducing the possibility that the base plates are abraded or scratched or deformed in the conveying process.

Owner:合肥欣奕华智能机器股份有限公司

Novel aluminum alloy material and production process thereof

The invention relates to the technical field of aluminum alloy production, in particular to a novel aluminum alloy material and a production process thereof. The novel aluminum alloy material comprises, by mass percentage, 0.05-0.22 wt% of nickel, 0.8-1.6 wt% of chromium, 0.024-0.032 wt% of manganese, 0.78-1.5 wt% of magnesium, 0.66-1.65 wt% of silicon, 0.45-1.2 wt% of iron, 3.5-5.8 wt% of copper, 4.8-6.5 wt% of zinc, and the balance aluminum and other inevitable impurities. The mechanical property and mechanics property of the novel aluminum alloy material are excellent, and the surface of an aluminum alloy profile can be effectively protected against scratches; and in addition, the process is simple and reasonable, and the production efficiency is high.

Owner:ANHUI HENGXING DECORATION ENG CO LTD

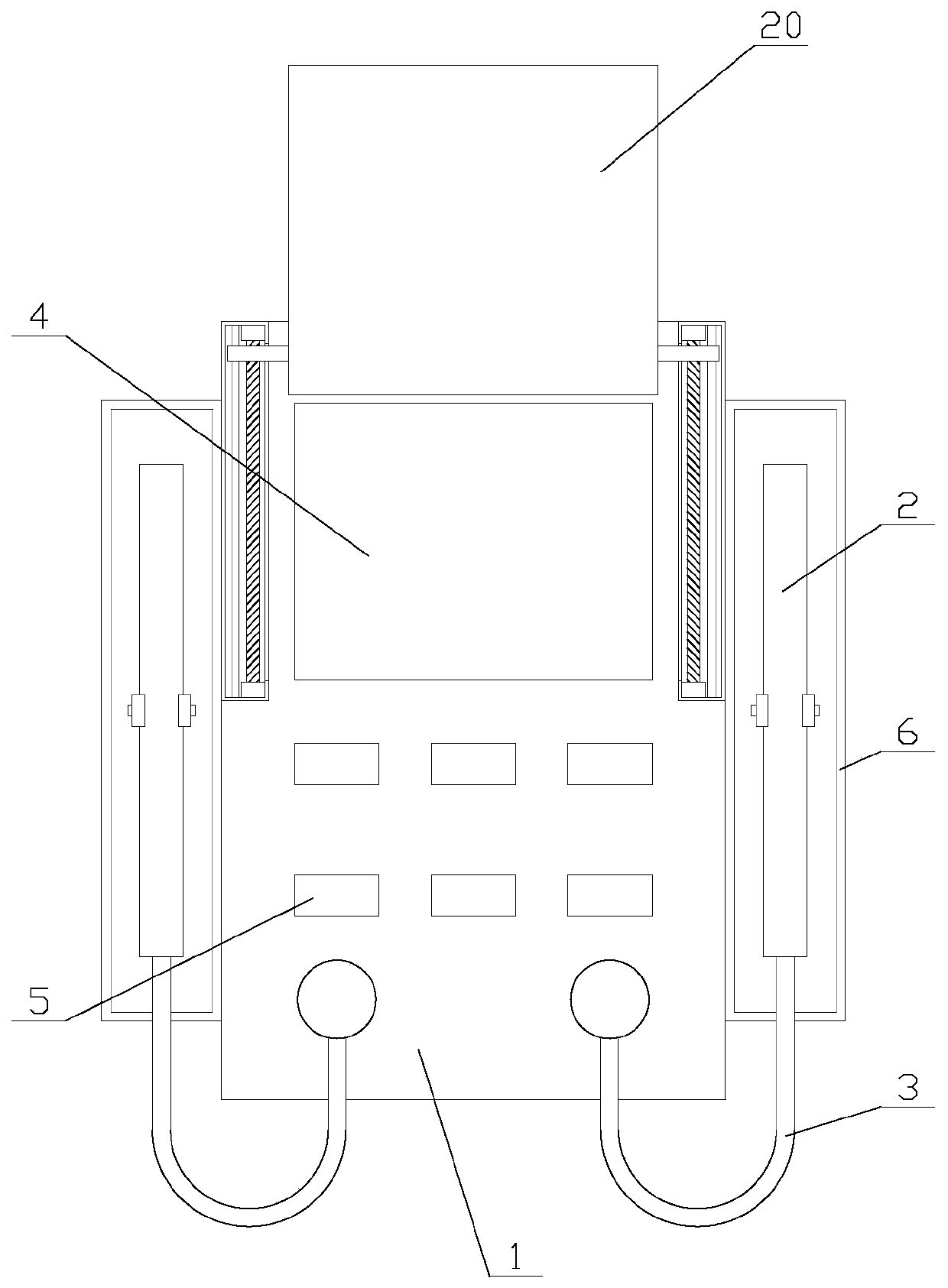

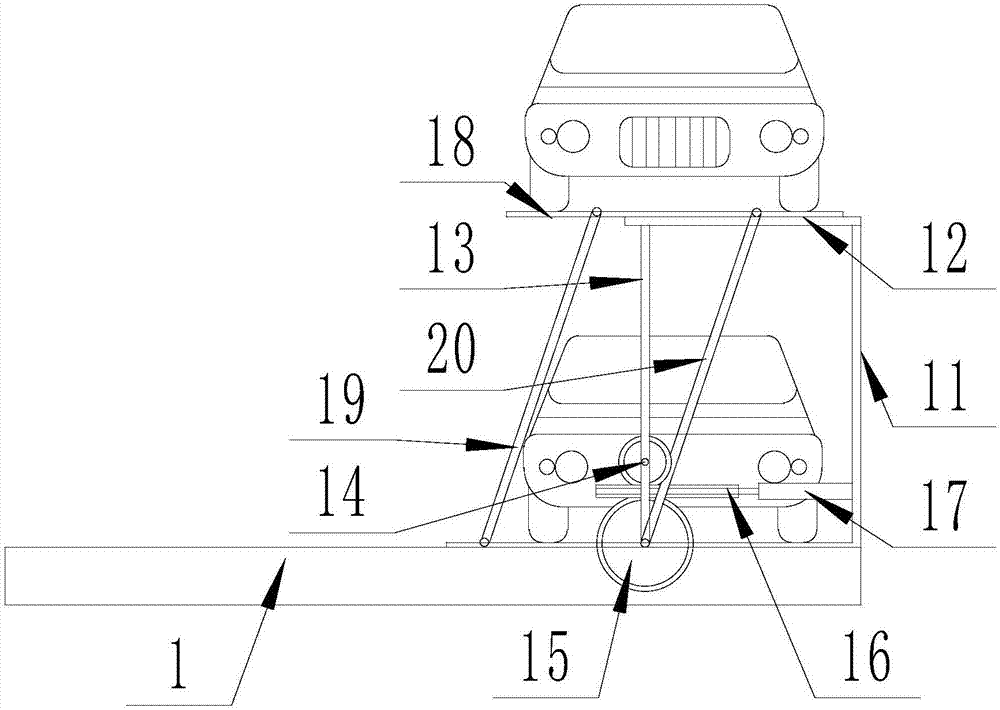

Full-hydraulic double-layer automatic parking device with car going up from side face

The invention discloses a full-hydraulic double-layer automatic parking device with a car going up from the side face. The full-hydraulic double-layer automatic parking device comprises a substrate. A parking device is arranged on the substrate, and the parking device comprises a bottom-layer parking device and a second-layer parking device. The bottom-layer parking device is jointly composed of a set of bottom-layer flat plate motional orbits, a bottom-layer motional orbit car, a set of orbit car fixed rotating shafts, a set of fixed rotating shafts, a first mother-son movable telescopic joint, a second mother-son movable telescopic joint and a supporting joint telescopic motion oil cylinder, wherein the set of bottom-layer flat plate motional orbits is arranged on the substrate, the bottom-layer motional orbit car is arranged on the bottom-layer flat plate motional orbits, the set of orbit car fixed rotating shafts is fixedly installed on one side of the lower surface of the bottom-layer motional orbit car, the set of fixed rotating shafts is arranged on one side of the substrate, the first mother-son movable telescopic joint and the second mother-son movable telescopic joint are installed on the fixed rotating shafts correspondingly, one end of the supporting joint telescopic motion oil cylinder is connected with the joint point of the first mother-son movable telescopic joint and a third mother-son movable telescopic joint, and the other end of the supporting joint telescopic motion oil cylinder is connected with the joint point of the second mother-son movable telescopic joint and a fourth mother-son movable telescopic joint. The full-hydraulic double-layer automatic parking device with the car going up from the side face has the beneficial effects that the structure is simple, and the practicability is high.

Owner:瑞安市兆达机车部件有限公司

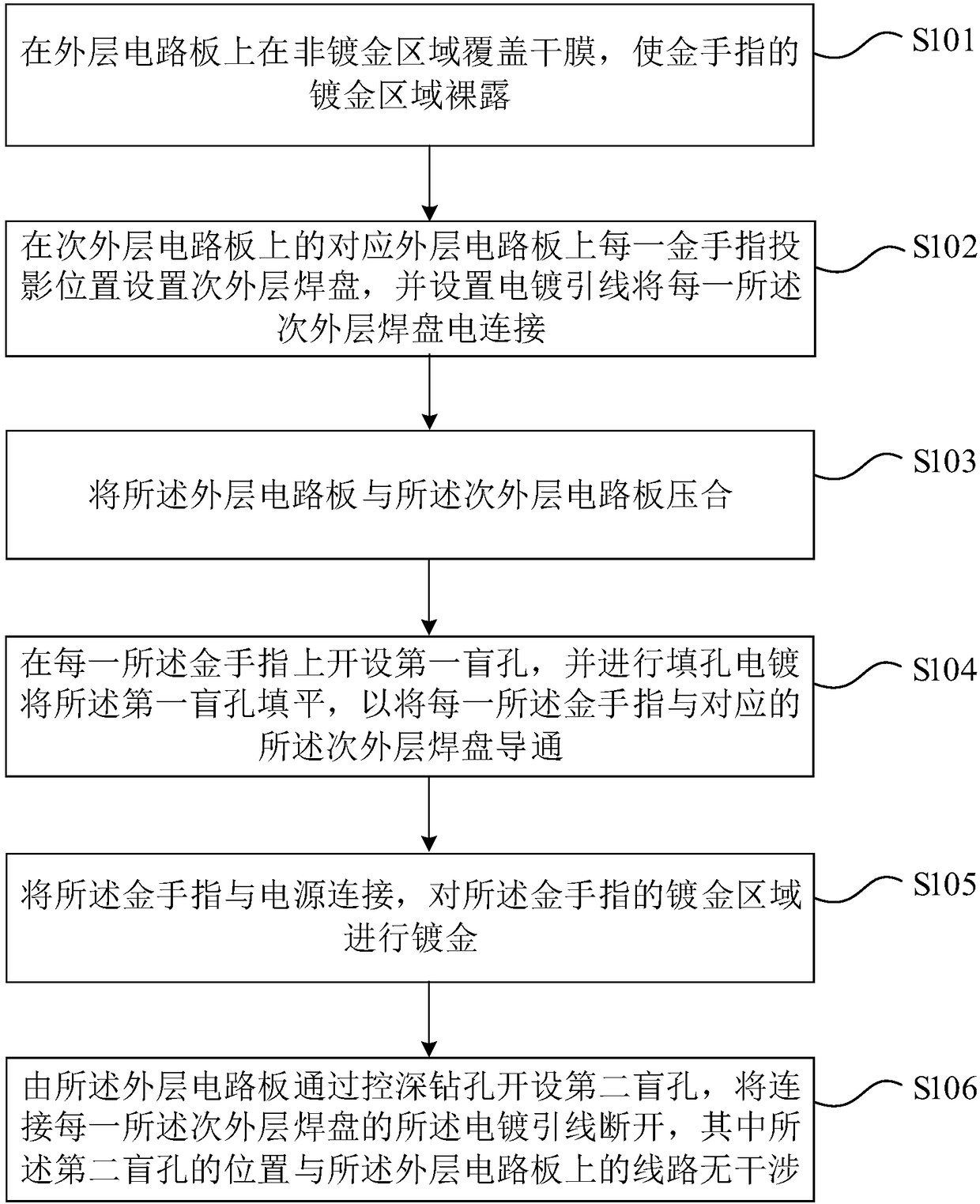

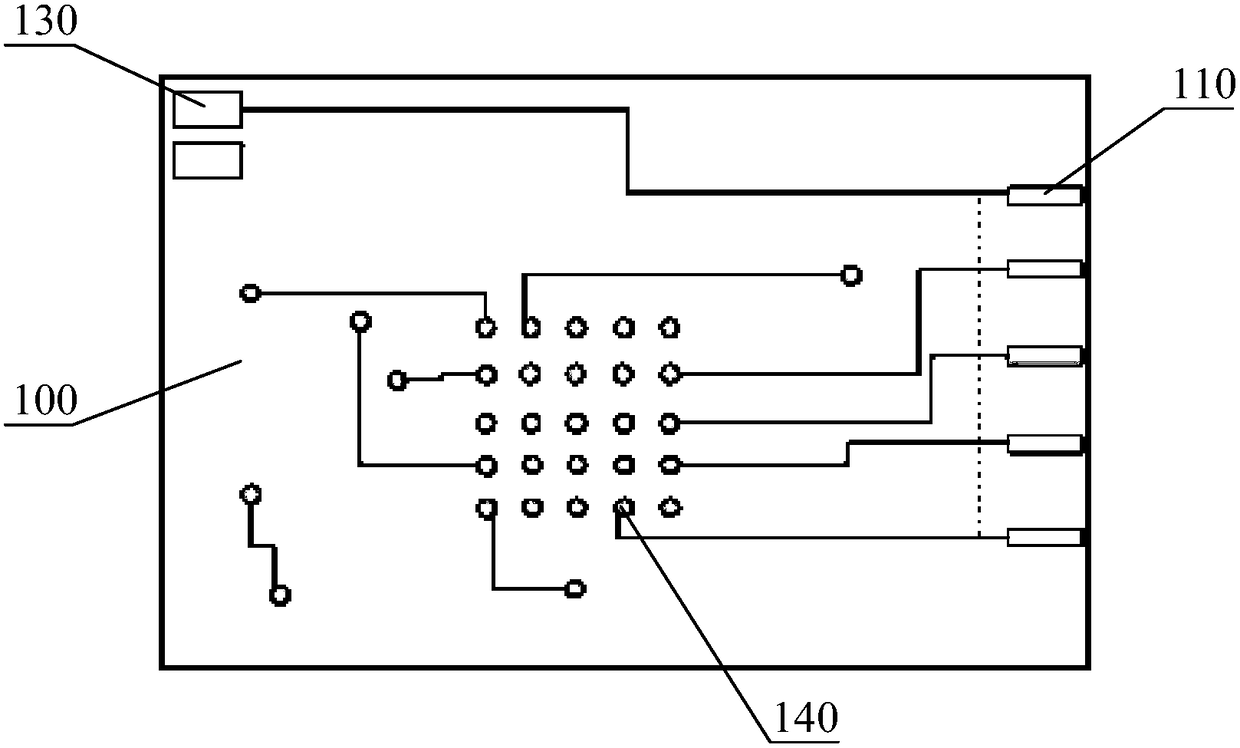

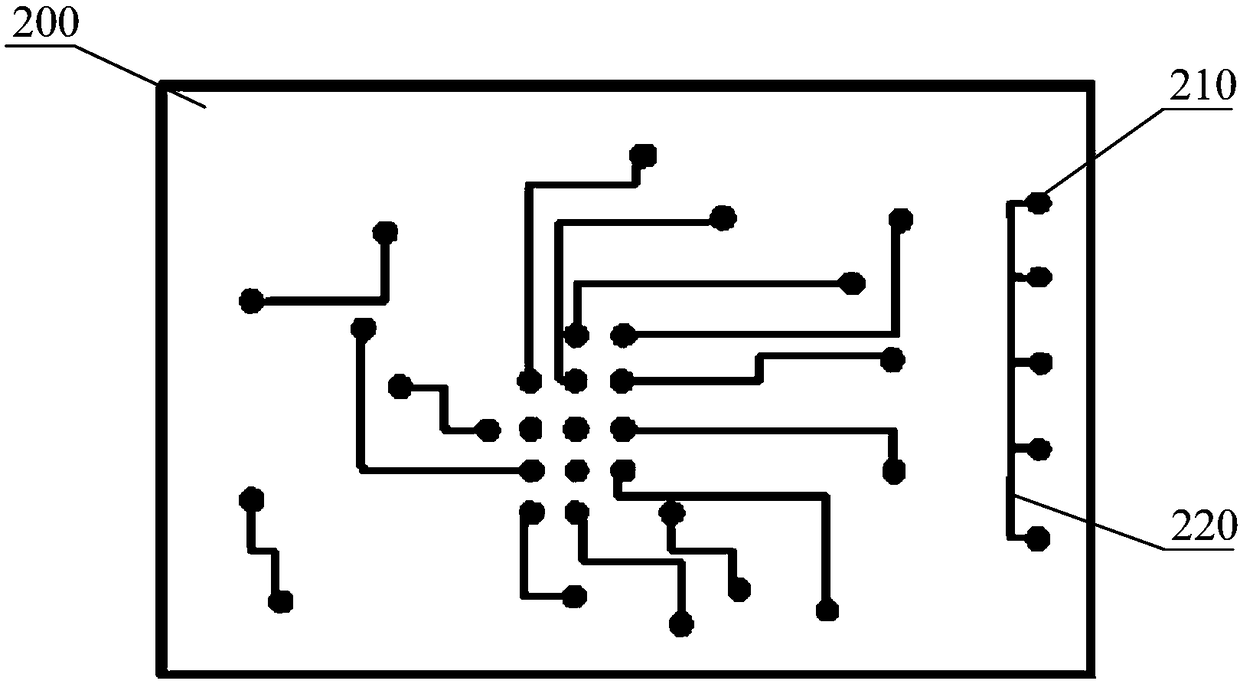

Gold plating method for gold fingers and gold finger circuit board

InactiveCN108882558AReduced chance of scratchesLow costElectrical connection printed elementsConductive pattern reinforcementEngineeringCopper

The invention provides a gold plating method for gold fingers and a gold finger circuit board. According to the gold plating method, a secondary outer pad is arranged corresponding to a projection position of each gold finger on an outer circuit board on a secondary outer circuit board; each secondary outer pad is electrically connected by adopting an electroplated lead; first blind holes are formed in each gold finger and are filled up through hole-filling electroplating, thereby conducting each gold finger and the corresponding secondary outer pad; the gold fingers are connected with a powersupply for carrying out gold plating; and the electroplated lead connected with each secondary outer pad is finally disconnected through depth-controlled drilling, so that each gold finger is broken,thereby achieving production of the gold fingers free of the electroplated lead on the surfaces. A gold-plated lead is arranged on the secondary outer circuit board and the electroplated lead is notdesigned on the surface of the outer circuit board, so that the scratch probability of the gold fingers in the production process is reduced, the quality of a product is improved, the material cost isreduced, gold permeating on a copper surface is avoided, the dependence on manual repair in the production process is reduced and the defect caused by the electroplated lead on the outer circuit board in the prior art is avoided.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

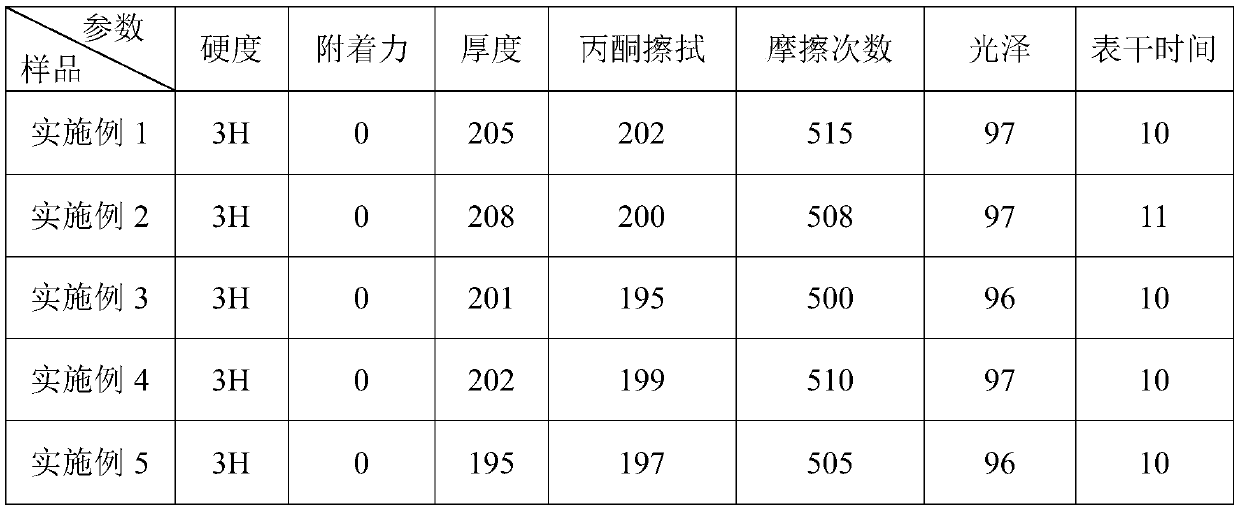

Waterborne gloss oil and preparation method and application thereof

The invention provides waterborne gloss oil and a preparation method and application thereof. The waterborne gloss oil is prepared from, by weight, 35-55 parts of a waterborne hydroxy-acrylic dispersing body, 5-12 parts of a waterborne acrylate hardening emulsion, 12-20 parts of a water dispersible isocyanate curing agent, 0.5-1.5 parts of anti-UV auxiliaries, 1-3.5 parts of anti-scratch hand feeling auxiliaries and 20-30 parts of water. The waterborne gloss oil has the high hardness and high wet film thickness, the surface can be rapidly dried, the hardness can reach the 3H level, the good anti-scratch performance is achieved, the abrasion, damage and scratch probability are greatly lowered, the friction resistance frequency under the load of 500 g can reach 500 or more, the good appearance and glossiness are achieved, the comprehensive performance is good, particularly when the gloss oil is applied to a carbon fiber bicycle, the good scratch resistance is shown, and the high application value and the good application prospect are achieved.

Owner:TEN TECH COMPOSITE TECH CORP

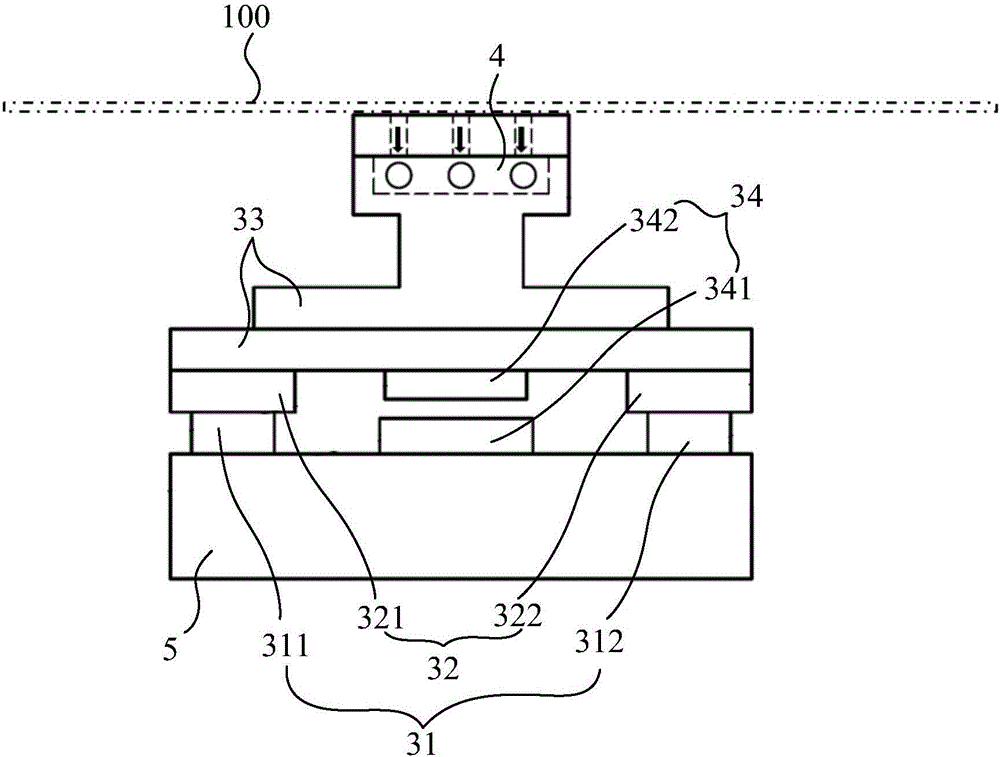

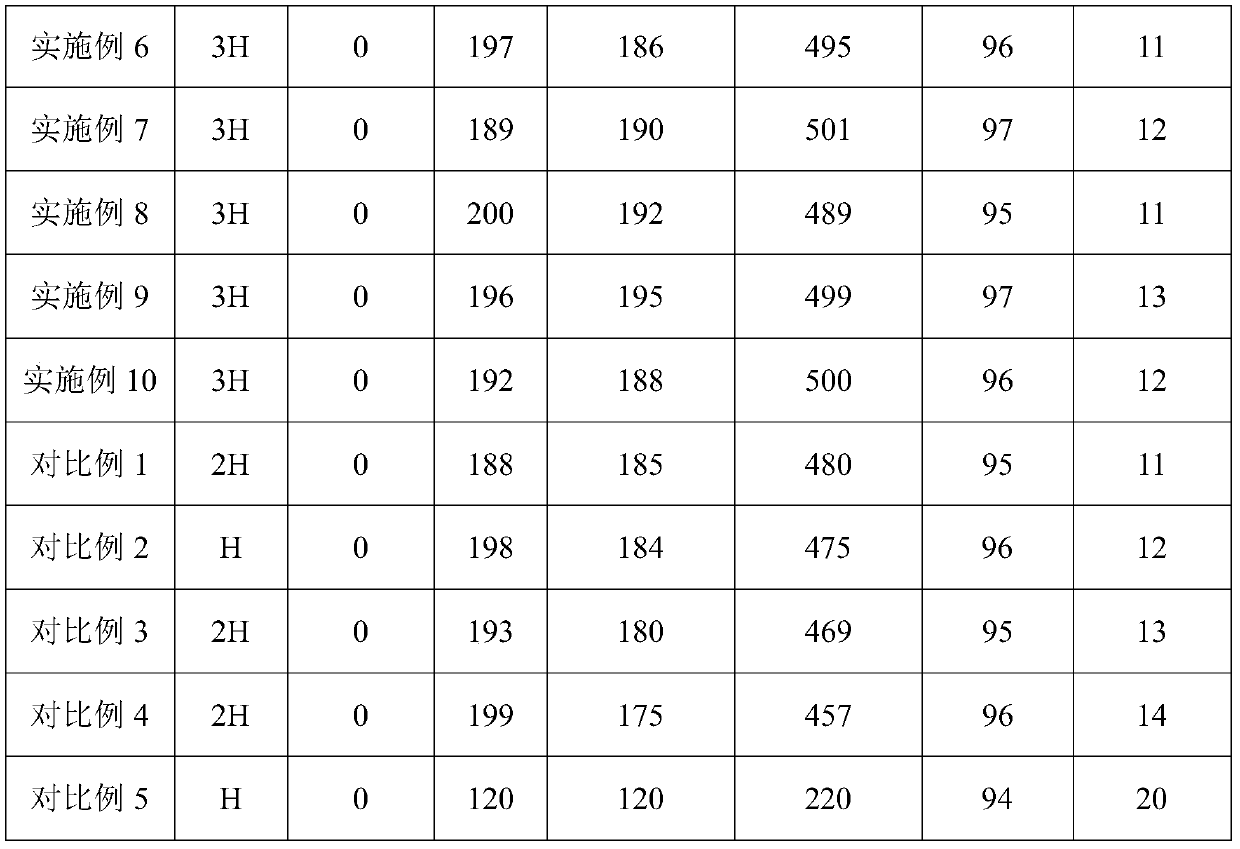

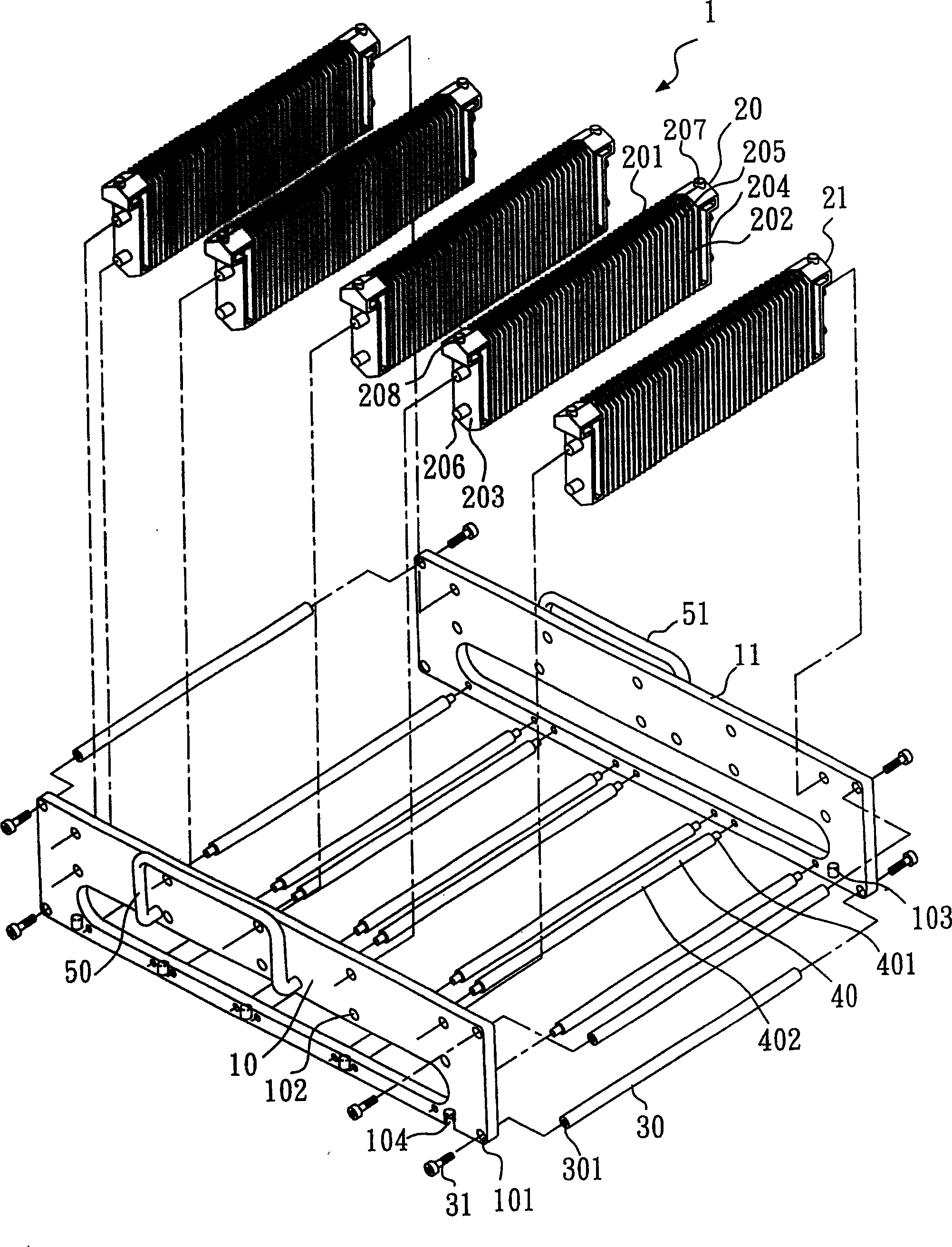

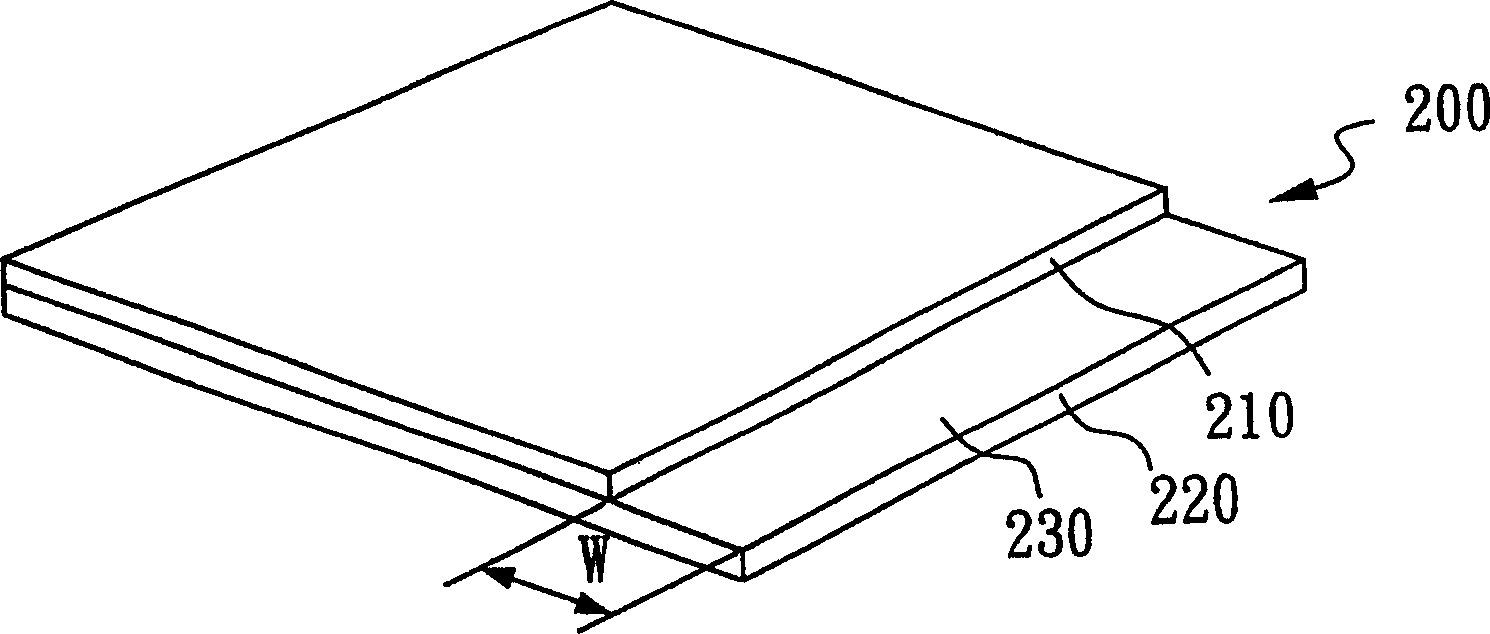

Substrate bearing apparatus

ActiveCN1567039AReduced chance of scratchesSimple structureNon-linear opticsEngineeringMechanical engineering

Owner:AU OPTRONICS CORP

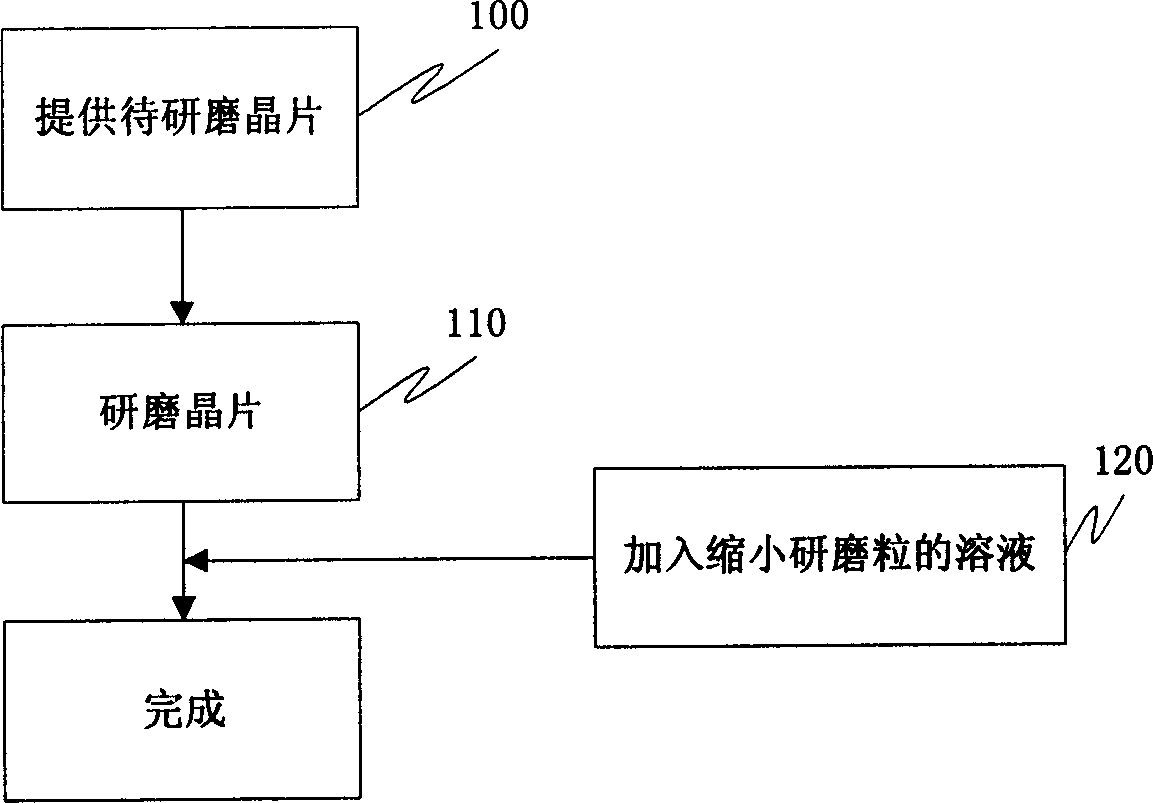

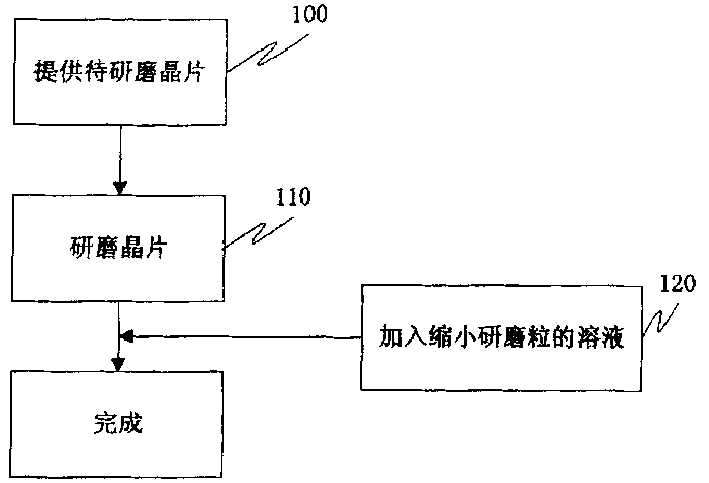

No-scrape chemical mechanical grinding technology

InactiveCN1479351ASmall sizeChange pHSemiconductor/solid-state device manufacturingSilicon dioxideGrind

The invented technique uses abrasive containing the grind grain of silicon dioxide to grind a layer to be ground on substrate. A solution capable of reducing size of grind grain is added to the grinding procedure when the procedure is close to end in order to prevent surfaces of wafers from scoring.

Owner:MACRONIX INT CO LTD

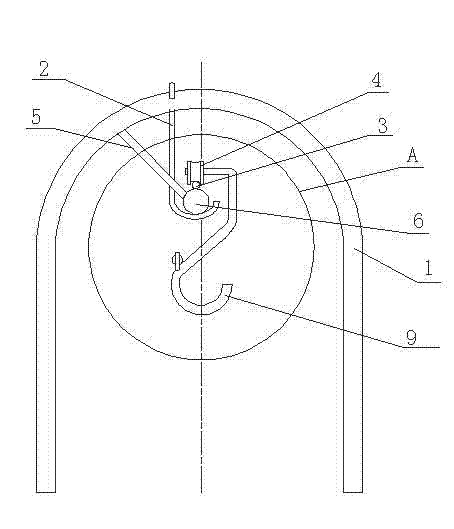

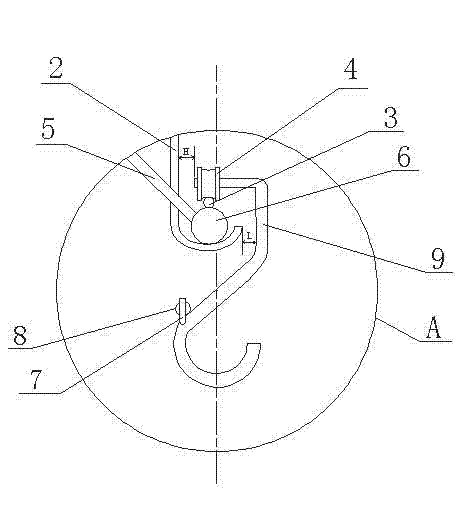

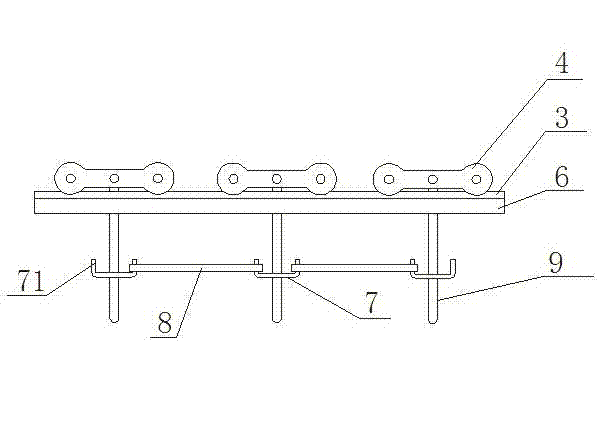

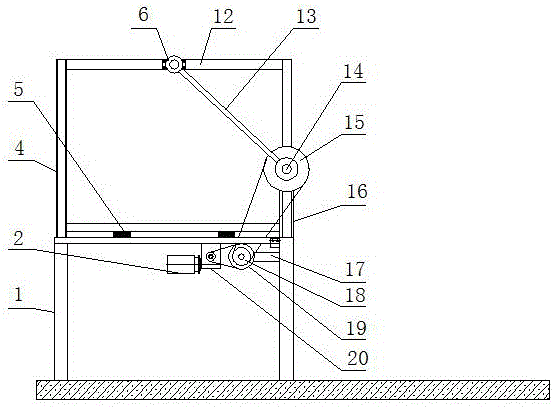

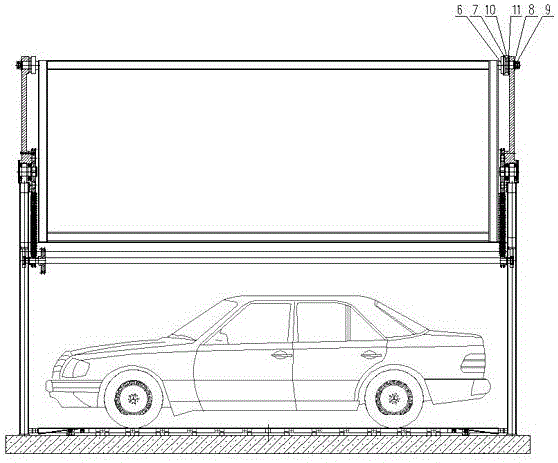

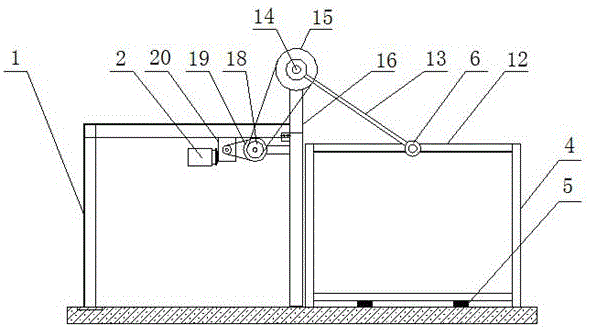

Arc hanging type vertical garage

The invention discloses an arc hanging type vertical garage. The arc hanging type vertical garage comprises a lower-layer garage body, an upper-layer garage body, an arc lifting device, a driving device, a safety protection system and a walking wheel type vehicle carrying platform. The arc lifting device is installed above the lower-layer garage body. The driving device and the safety protection system are installed at the upper end of the lower-layer garage body. The driving device and the arc lifting device are connected and drive the arc lifting device to conduct arc lifting and falling operation of the upper-layer garage body, and in addition, the swinging condition generated in the movement process of the upper-layer garage body can be controlled. The safety protection system and the driving device are connected so as to prevent out-of-control falling of the upper-layer garage body. The lower end of the lower-layer garage body is provided with the walking wheel type vehicle carrying platform which is used for accurately controlling entering and exiting of vehicles, and a plurality of damping devices are arranged at the lower end of the upper-layer garage body. The arc hanging type vertical garage is reasonable in structural design, entering and exiting of the upper-layer garage body are not affected by the lower-layer garage body, convenience and rapidness are achieved, operation is stable, the probability of rubbing of vehicles is lowered, reversing and turning are not needed, time is saved, efficiency is improved, and the service life is prolonged.

Owner:HANGZHOU XINGHE TRANSMISSION MACHINERY RES INST CO LTD

Film trimming and collecting device matched with coating machine

InactiveCN102825621AIncrease productivitySave time for slitting and trimmingMetal working apparatusEngineeringConductor Coil

The invention relates to a film trimming and collecting device matched with a coating machine. The film trimming and collecting device can be used for completing the trimming and collecting finished films while the coating machine produces and ensures that the finished film which is directly discharged from the coating machine can be trimmed, so the production efficiency is greatly increased, and the subsequent slitting process is dispensed. After the operation, not only the time for slitting and trimming can be saved, but also the winding and unwinding process is dispensed, the possibility that the finished film is scratched during the winding and unwinding process can be reduced once, and the percent of pass of the finished product is effectively improved.

Owner:苏州旭泽新材料科技有限公司

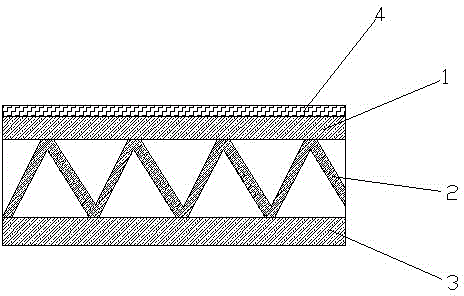

High-intensity waterproof type corrugated paper board

InactiveCN104452481AReasonable structural designImprove water resistanceSpecial paperPaper/cardboardCardboardSurface layer

The invention discloses a high-intensity waterproof type corrugated paper board. The high-intensity waterproof type corrugated paper board comprises a surface layer, a middle layer and an inner layer which are bonded by an adhesive, wherein the surface layer and the inner layer are paper board layers; the middle layer is a corrugated paper layer; a water-repellent coating layer is additionally arranged on the upper surface of the surface layer, and comprises the main components including water-borne acrylic resin, short glass fibers, relevant additives and a solvent. The invention discloses the high-intensity waterproof type corrugated paper board which is reasonable in structure design; the additionally arranged water-repellent coating layer on the surface layer endows the corrugated paper board with good waterproof performance and surface intensity, the scratching probability of the surface of the corrugated paper board can be effectively reduced, and the good use performance of the corrugated paper board can be guaranteed.

Owner:常熟市常隆包装有限公司

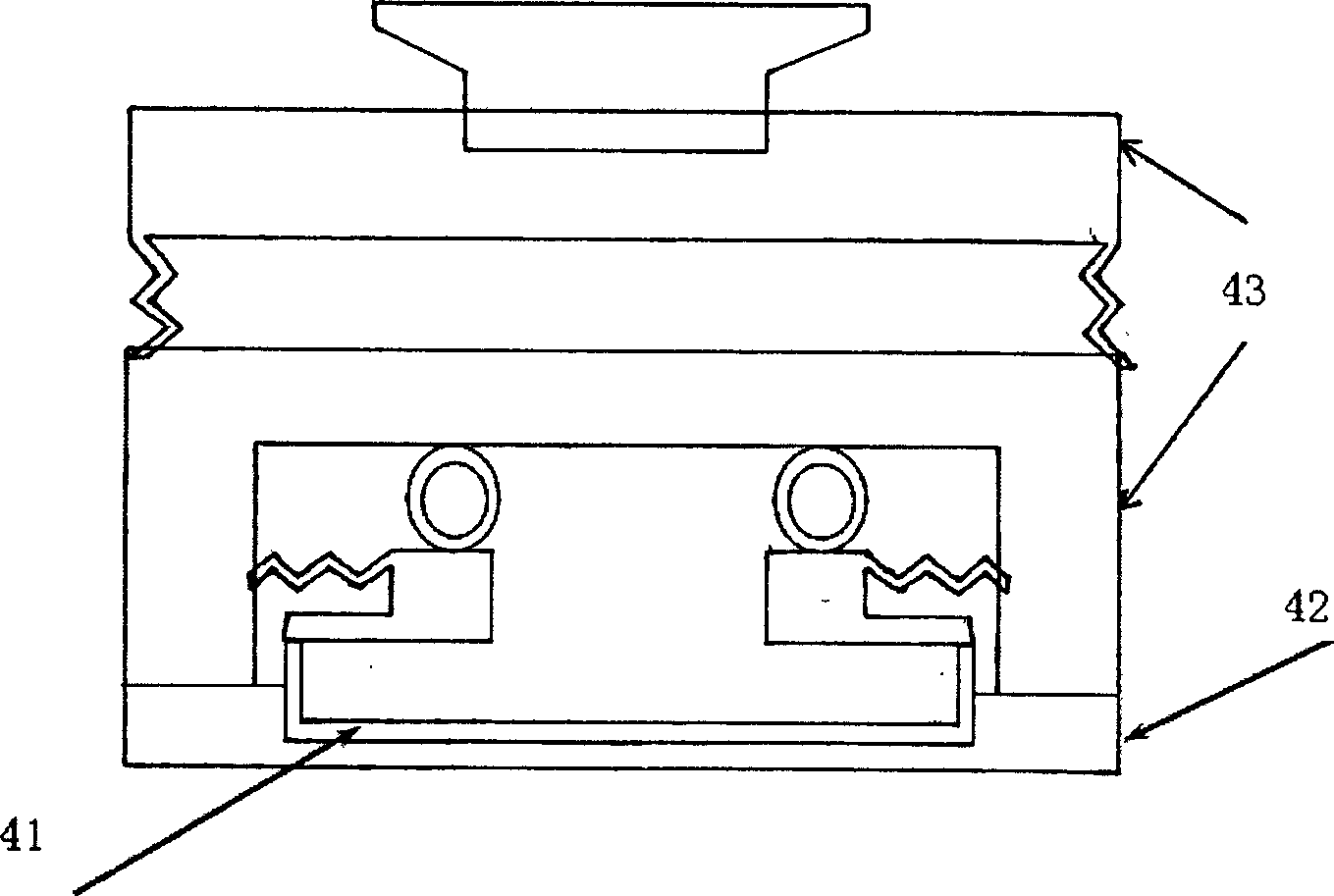

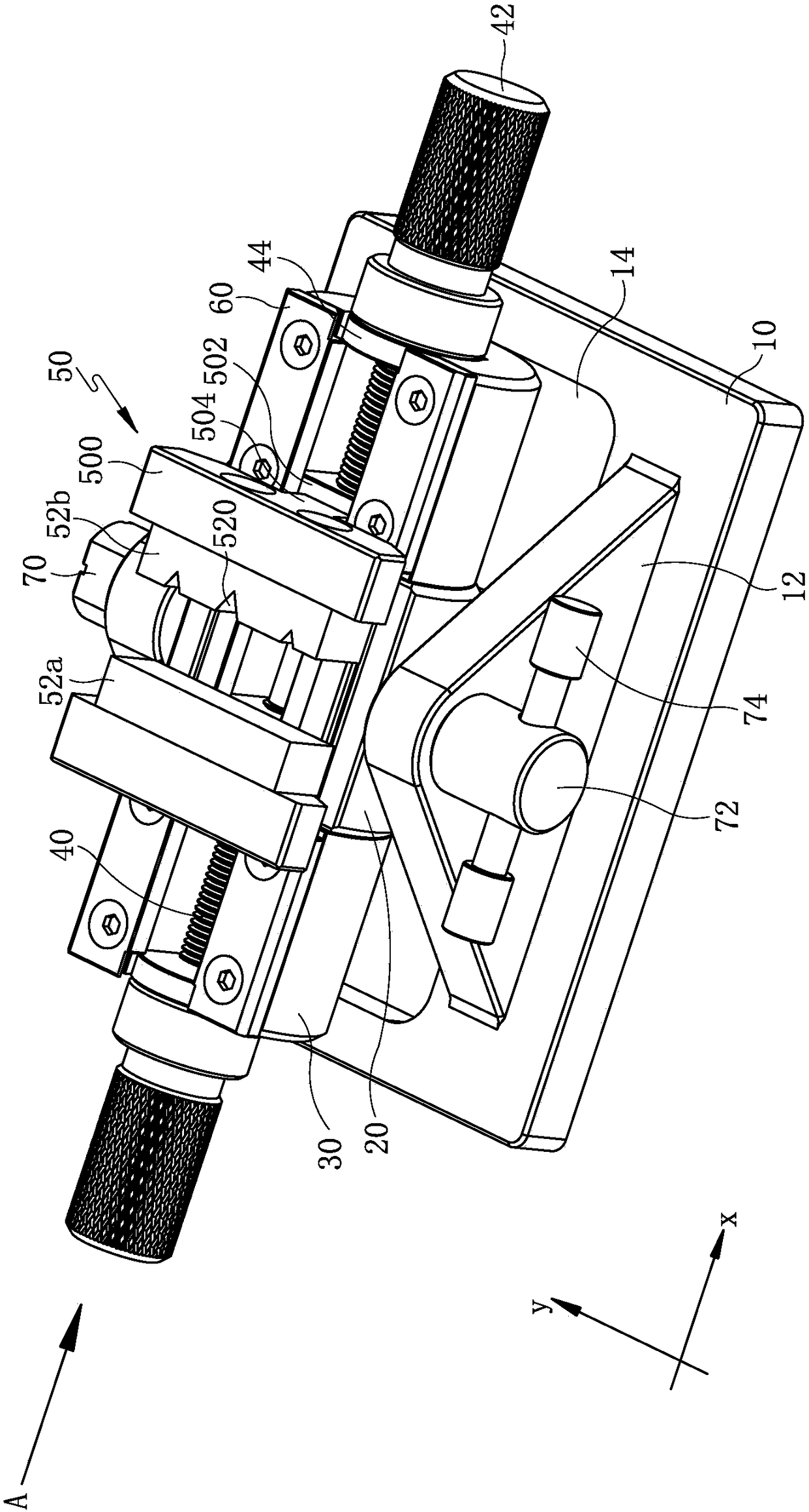

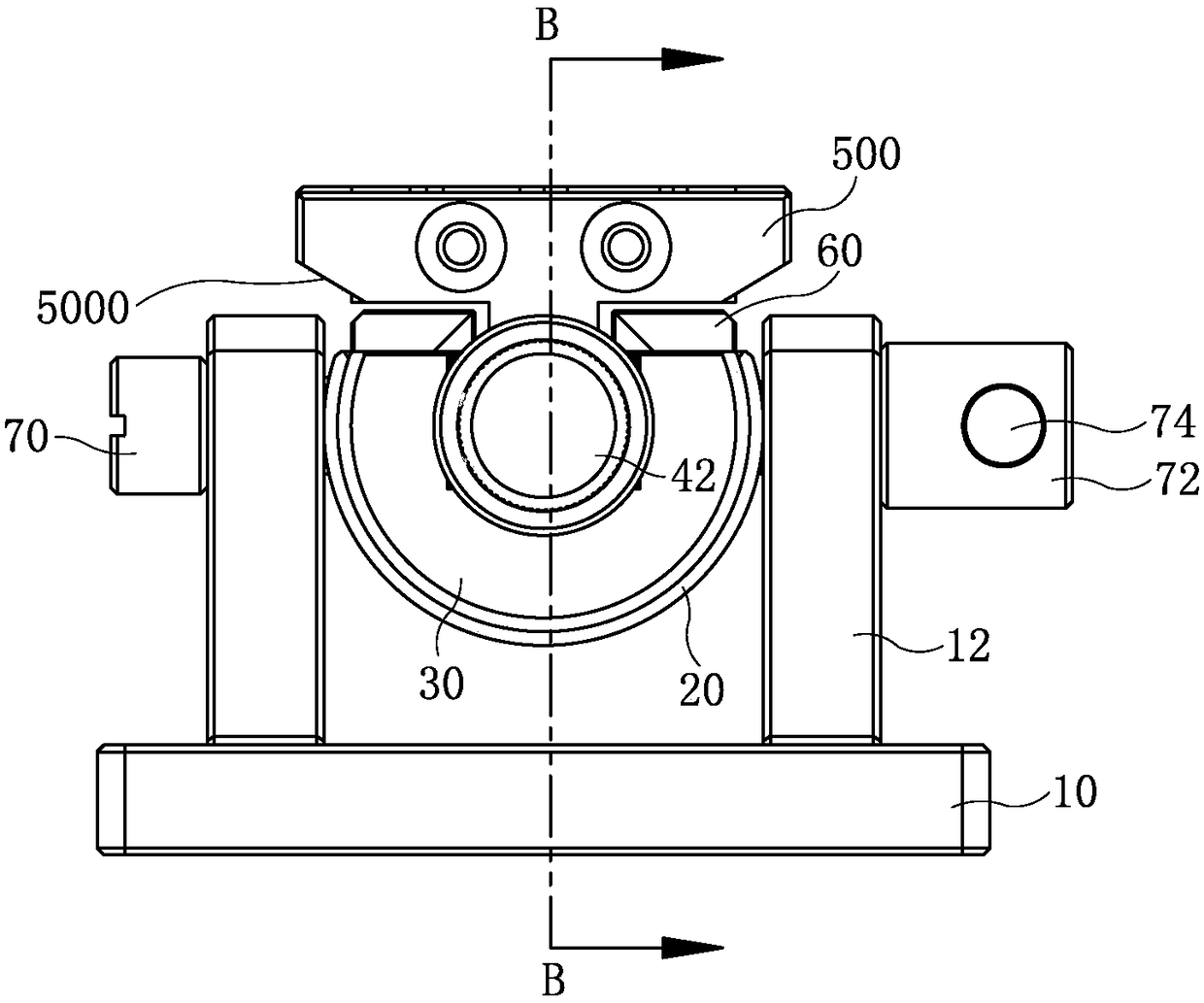

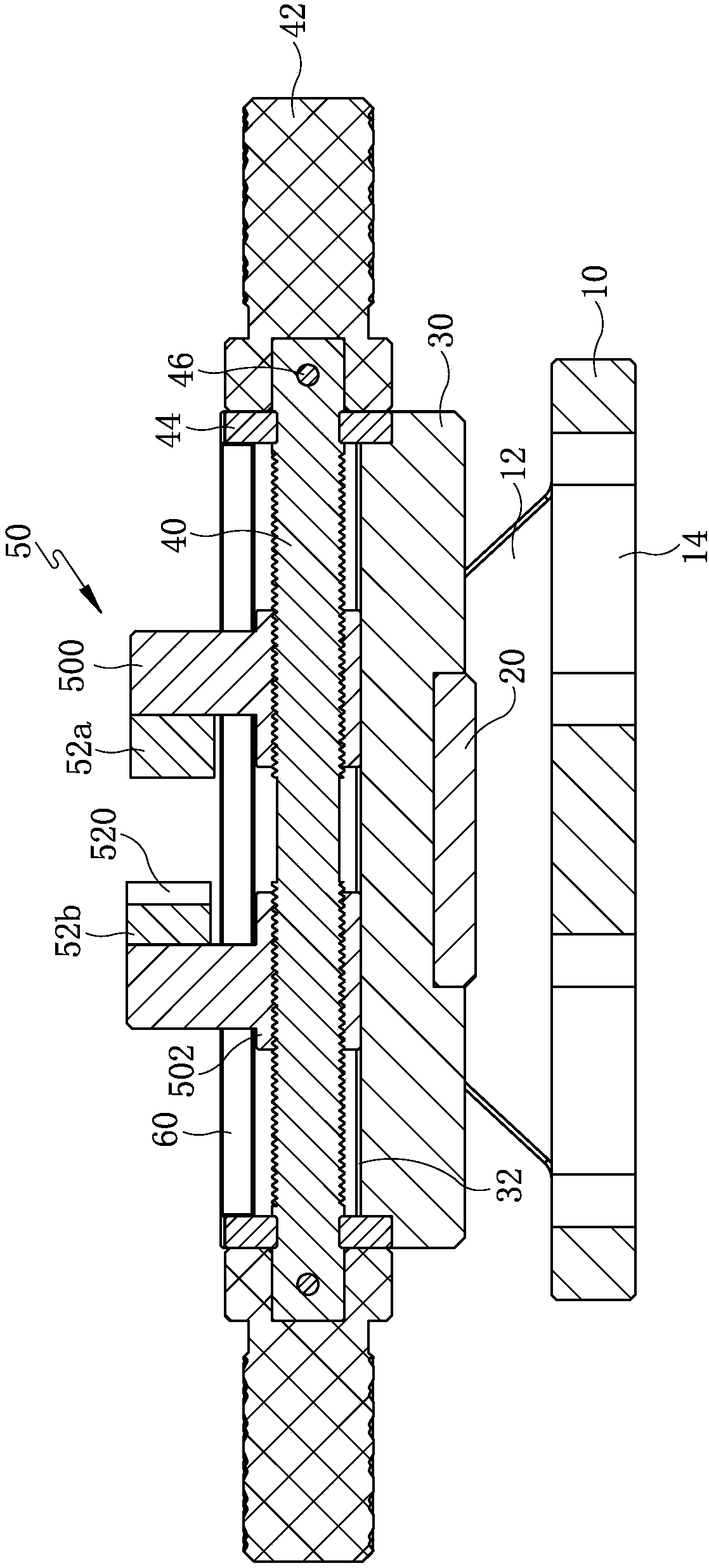

Workpiece clamping mechanism

PendingCN108127591AShorten the timeImprove processing efficiencyWork holdersAssistive device/technologyEngineering

The invention discloses a workpiece clamping mechanism, and relates to the technical field of workpiece production auxiliary equipment. The workpiece clamping mechanism comprises a base, a bracket capable of rotating around the y axis is installed on the base, and an arc sliding groove adopting the x axis direction as the axial direction is formed in the bracket; a rotating cylinder capable of rotating around the x axis is rotationally installed inside the arc sliding groove, the axial direction of the rotating cylinder is the x axis direction, two clamping blocks are installed on the rotatingcylinder, and at least one of the two clamping blocks can axially reciprocate and slide along the rotating cylinder. The workpiece clamping mechanism solves the technical problems that in the prior art, when workpieces need to be machined and detected in multiple directions, repeated clamping is needed, and the clamping efficiency is low, multi-directional machining or detecting of workpieces canbe achieved only through one-time clamping, the machining and detecting efficiency of the workpieces is improved, meanwhile, the probability that the workpieces are scratched is lowered, the productyield is increased, and the production cost of an enterprise is lowered.

Owner:GEER TECH CO LTD

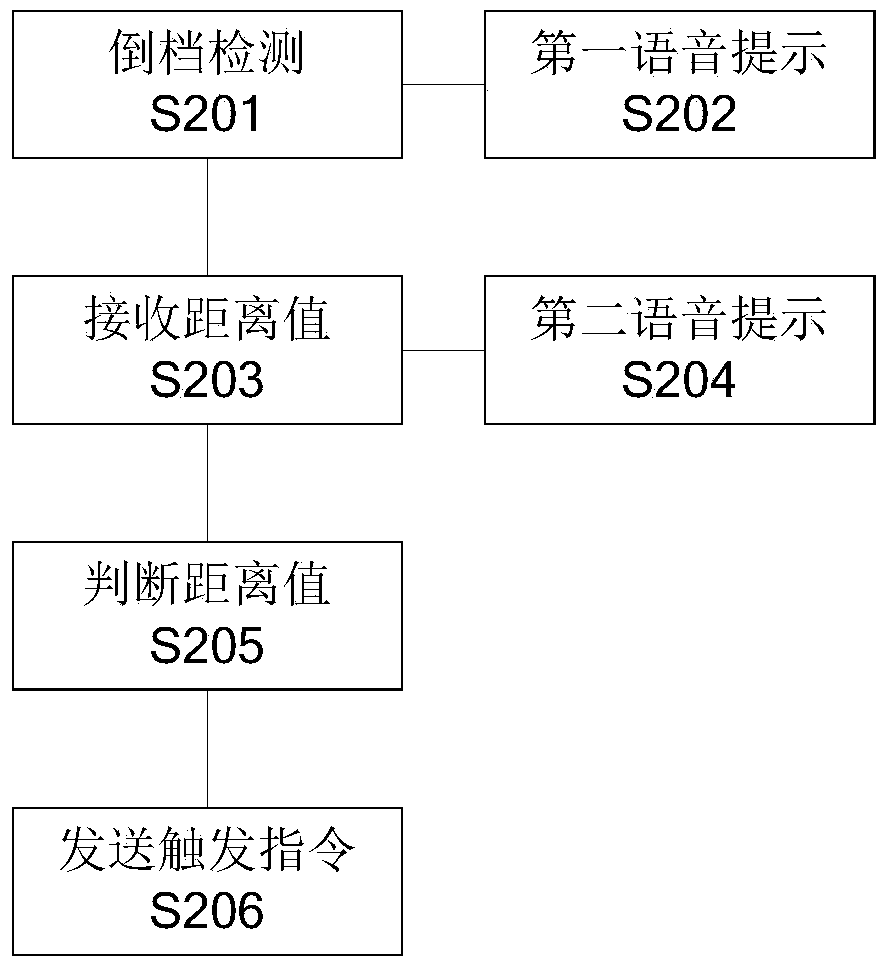

Reverse parking auxiliary method, reverse parking auxiliary device and reverse parking auxiliary system

InactiveCN104325968AKnow the status in real timeEnsure safetyAutomatic initiationsRadarAuxiliary system

The invention provides a reverse parking auxiliary method, a reverse parking auxiliary device and a reverse parking auxiliary system, belonging to the field of vehicle equipment. The reverse parking auxiliary system comprises a radar, a reverse parking auxiliary control device, a brake device and a voice prompt device; when an automobile is detected to enter the reverse gear, the actual distance between the tail of the automobile and the barrier which is closest to the back of the tail of the automobile can be automatically detected; when the value of the actual distance is detected to be less than or equal to the preset value of the safe distance, the automobile is controlled to brake directly by the brake device, so that the scratch probability can be greatly reduced in the reverse parking process; furthermore, the method, the device and the system are simple to operate and convenient to use. In the reverse parking process, the related voice prompt is played synchronously, so that the auxiliary effect is improved.

Owner:SICHUAN SHENG LI XING ELECTRONICS TECH +1

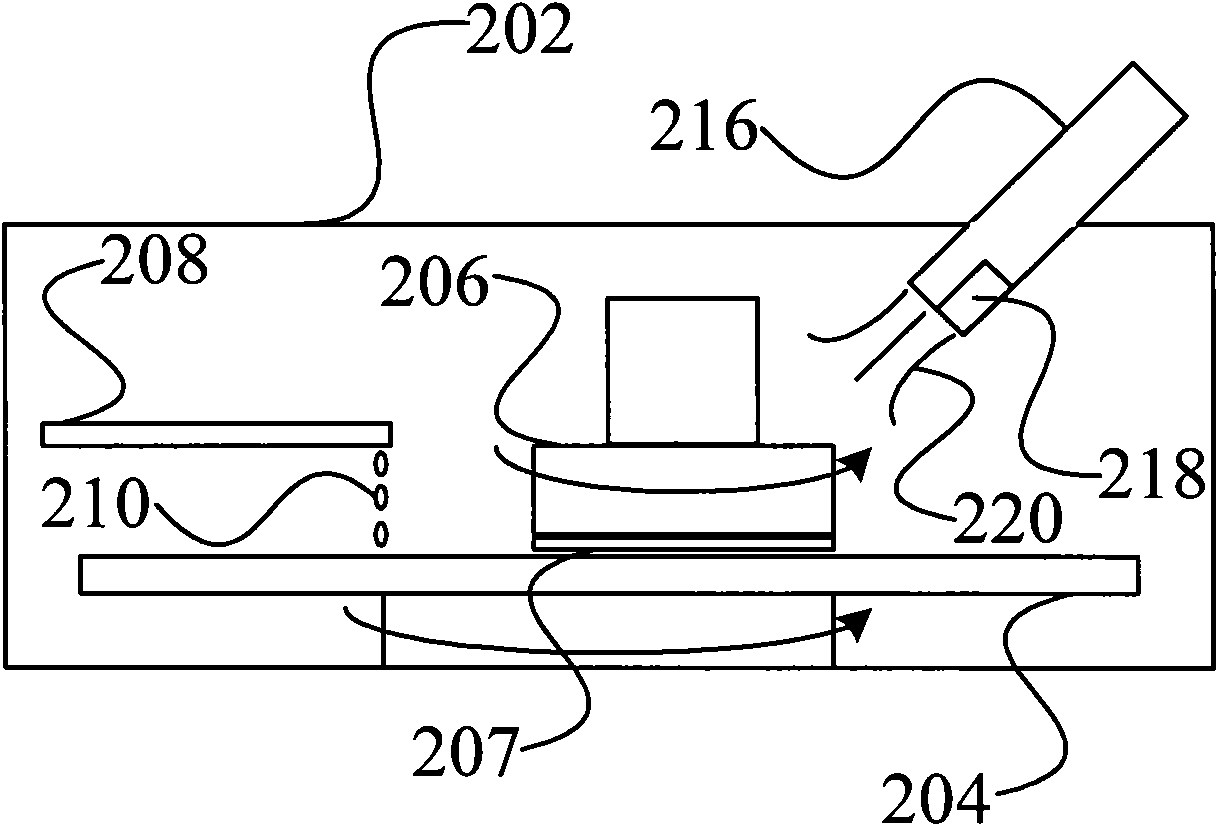

Washing device used for chemical mechanical polishing equipment

InactiveCN103878668AReduced chance of scratchesImprove yieldPolishing machinesCleaning using liquidsWater pipeLiquid crystal

The invention discloses a washing device used for chemical mechanical polishing equipment. The washing device is characterized by including a shell and multiple nozzles arranged at intervals and in a row, the nozzles include straight nozzles used for spraying water to wafers and bent straight nozzles used for spraying water to the inner wall of the top cover of the chemical mechanical polishing equipment, the nozzles are connected with an outside water incoming pipe through a water pipe, the straight nozzles are vertically arranged on the shell, each bent nozzle is bent to be an obtuse angle, water outlets of the bent nozzles are different in direction, and the washing device is arranged at a position adjacent to each polishing platform of the chemical mechanical polishing equipment. By the washing device, the wafers can be washed while the inner wall of the top cover of the chemical mechanical polishing equipment is washed to enable the inner wall to constantly maintain humid, so that grinding liquid sprayed on the inner wall of the top cover in the process of polishing cannot be dried and crystallize, probability that grinding liquid crystals drop down and scratch the wafers in the process of polishing is lowered, and finished product rate of polishing production is increased. The washing device is simple in structure, convenient to use and low in cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

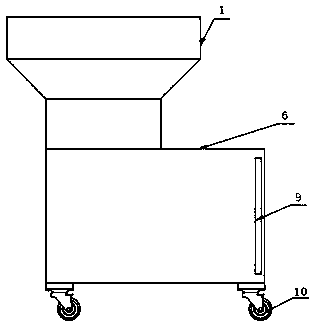

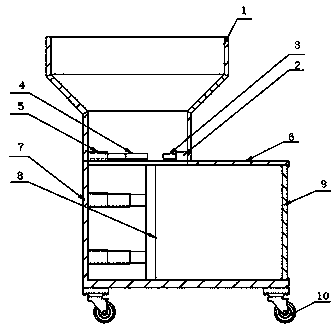

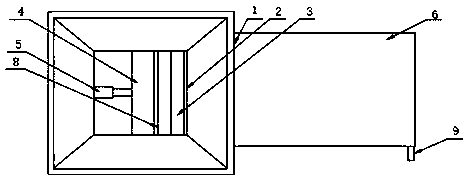

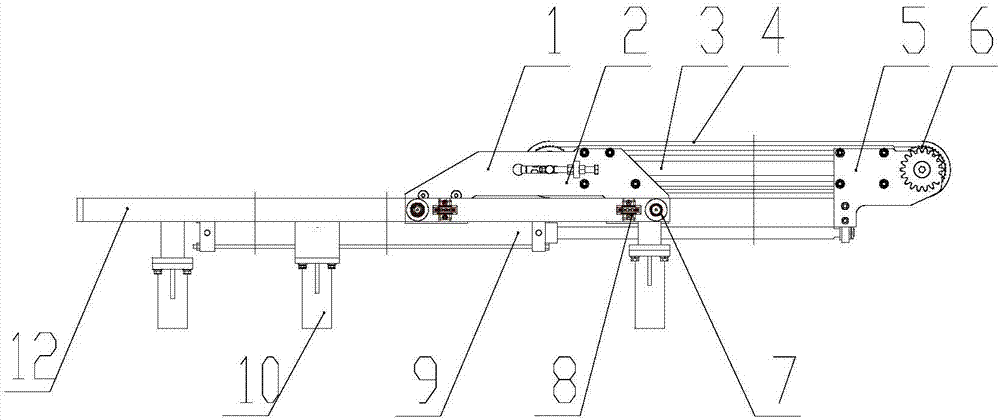

Metal waste processing device

InactiveCN110815919AReduced chance of scratchesGuarantee personal safetyGrain treatmentsPressesWaste processingProcess engineering

The invention discloses a metal waste processing device, and particularly relates to the technical field of metal waste processing. The metal waste processing device comprises a feeding funnel; a fixed plate is fixedly arranged on one side wall inside the feeding funnel; a first sawtooth knife is fixedly arranged on one side of the fixed plate; a second sawtooth knife is arranged on one side of the first sawtooth knife; a first bamboo joint type electric push rod is arranged on one side of the second sawtooth knife; an extrusion box is fixedly arranged at the bottom of the feeding funnel; a second bamboo joint type electric push rod is arranged in the extrusion box; the second bamboo joint type electric push rod is arranged at the bottom of the first bamboo joint type electric push rod; and an extrusion plate is arranged on one side of the second bamboo joint type electric push rod. According to the metal waste processing device, the feeding funnel is moved below a working machine, sothat metal waste directly enters into the extrusion box through the feeding funnel and is extruded into blocks by the extrusion plate, the whole extrusion process does not need manual operation, the operation is simple, the working efficiency is high, and the safety of construction personnel is effectively guaranteed.

Owner:徐州给力磁业有限公司

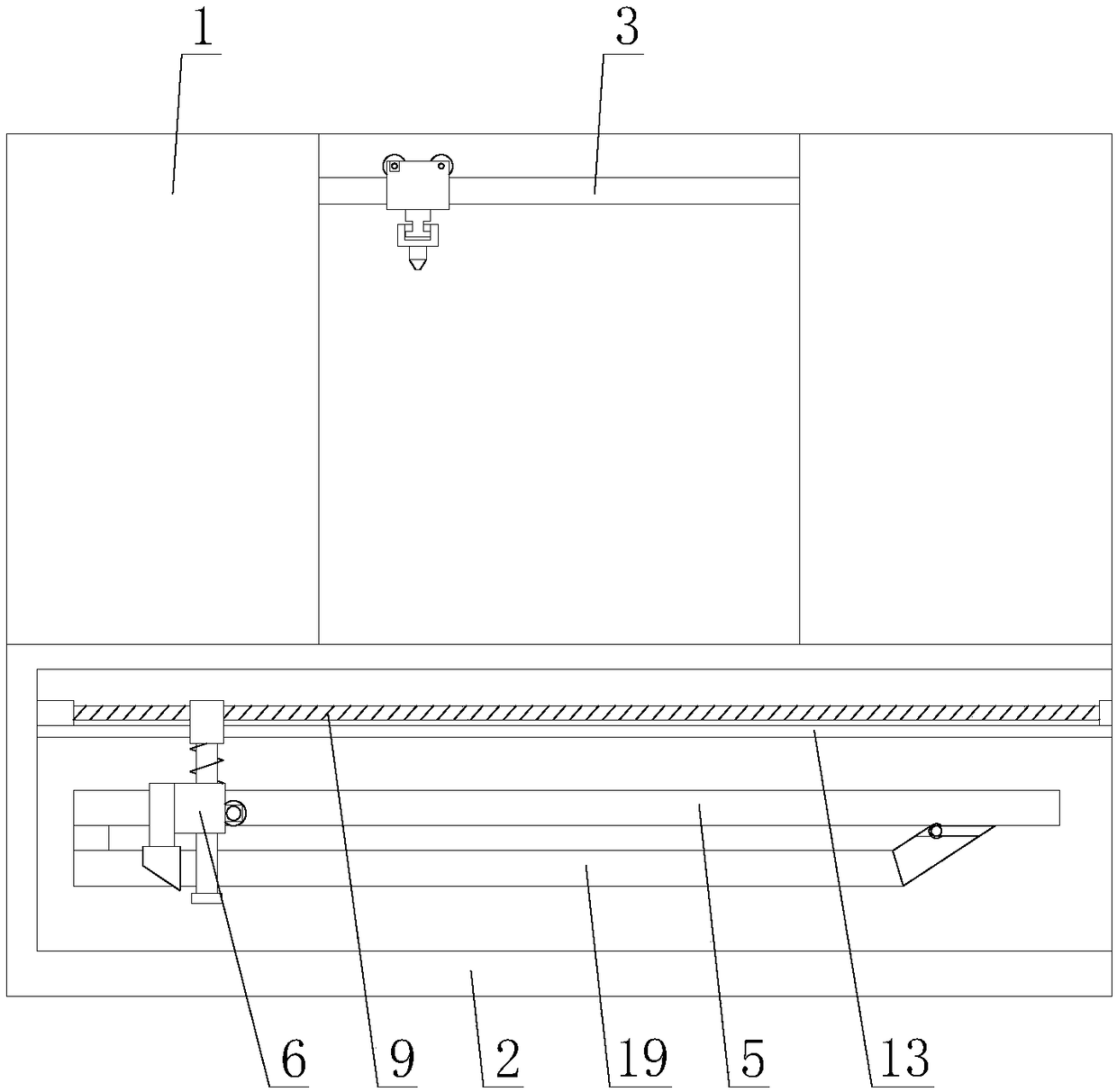

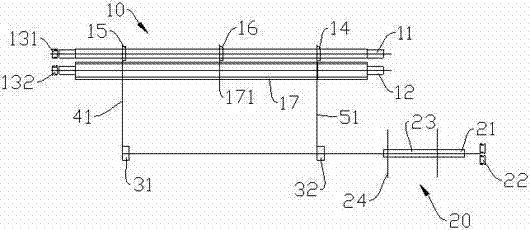

Aluminum profile on-line straightening telescopic intermediate feeder

The invention belongs to the technical field of aluminum profile extrusion forming aftertreatment and relates to an aluminum profile on-line straightening telescopic intermediate feeder. A driving wheel supporting mechanism and a driven wheel tensioning mechanism are mounted on the upper portion of a machine frame. The driving wheel supporting mechanism is provided with a driving belt wheel. The driven wheel tensioning mechanism is provided with a driven synchronous belt wheel. An aluminum beam is mounted between the driving belt wheel and the driven synchronous belt wheel. A synchronous belt is arranged outside the driving belt wheel and the driven synchronous belt wheel in a sleeving mode. A center hinge shaft air cylinder connected with the aluminum beam is mounted on the lower portion of the machine frame. A plurality of sliding wheels are mounted at the joint of the center hinge shaft air cylinder and the aluminum beam. Guiding wheels corresponding to the sliding wheels are mounted on the upper end face of the machine frame. Supporting mechanisms are fixedly mounted on the lower portion of the machine frame. The problem that an air cylinder of a synchronous belt transmission gas bridge is large in occupied space and inconvenient to mount when being put on one side of an aluminum beam is solved.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com