No-scrape chemical mechanical grinding technology

A chemical-mechanical and grinding technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve the problems of wafer surface scratches and increased wafer surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

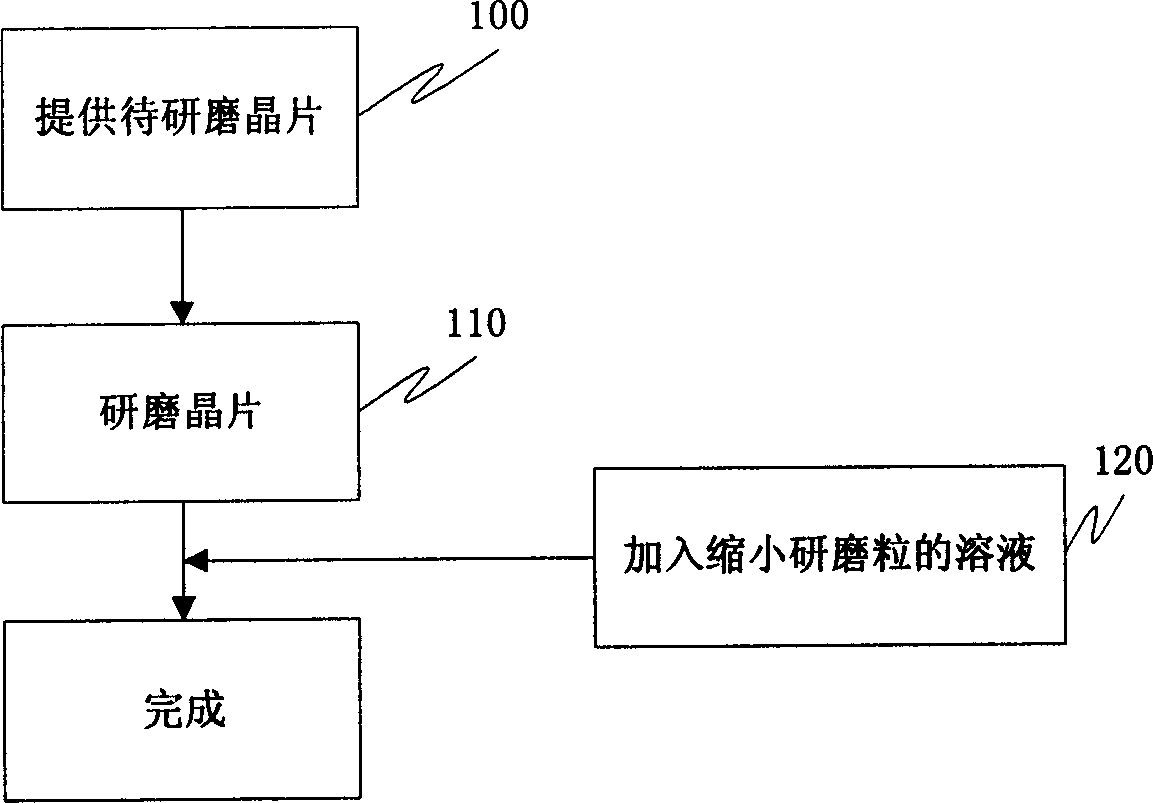

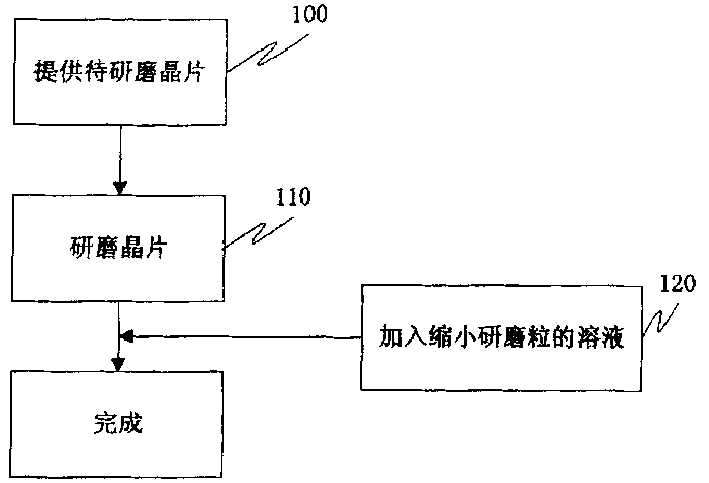

[0018] figure 1 It is a step diagram of a non-scratch chemical mechanical polishing (CMP) process according to a first embodiment of the present invention.

[0019] Please refer to figure 1 , in step 100, a wafer to be ground is provided. Then, in step 110, the wafer is ground, wherein the slurry used for grinding the wafer contains abrasive particles, such as silica particle abrasive particles.

[0020] Then, in step 120, a solution that can reduce the abrasive grain is added to reduce the size of the abrasive grain, thereby reducing the probability of the wafer surface being scratched, wherein the solution that can reduce the abrasive grain is, for example, potassium hydroxide (KOH) solution; for example For example, when the concentration of potassium hydroxide solution added is about 1M, the pH value of the abrasive will gradually change from 10 to about 12, and the particle size of the abrasive particles will also be reduced from 130 nanometers. Moreover, in order to o...

no. 2 example

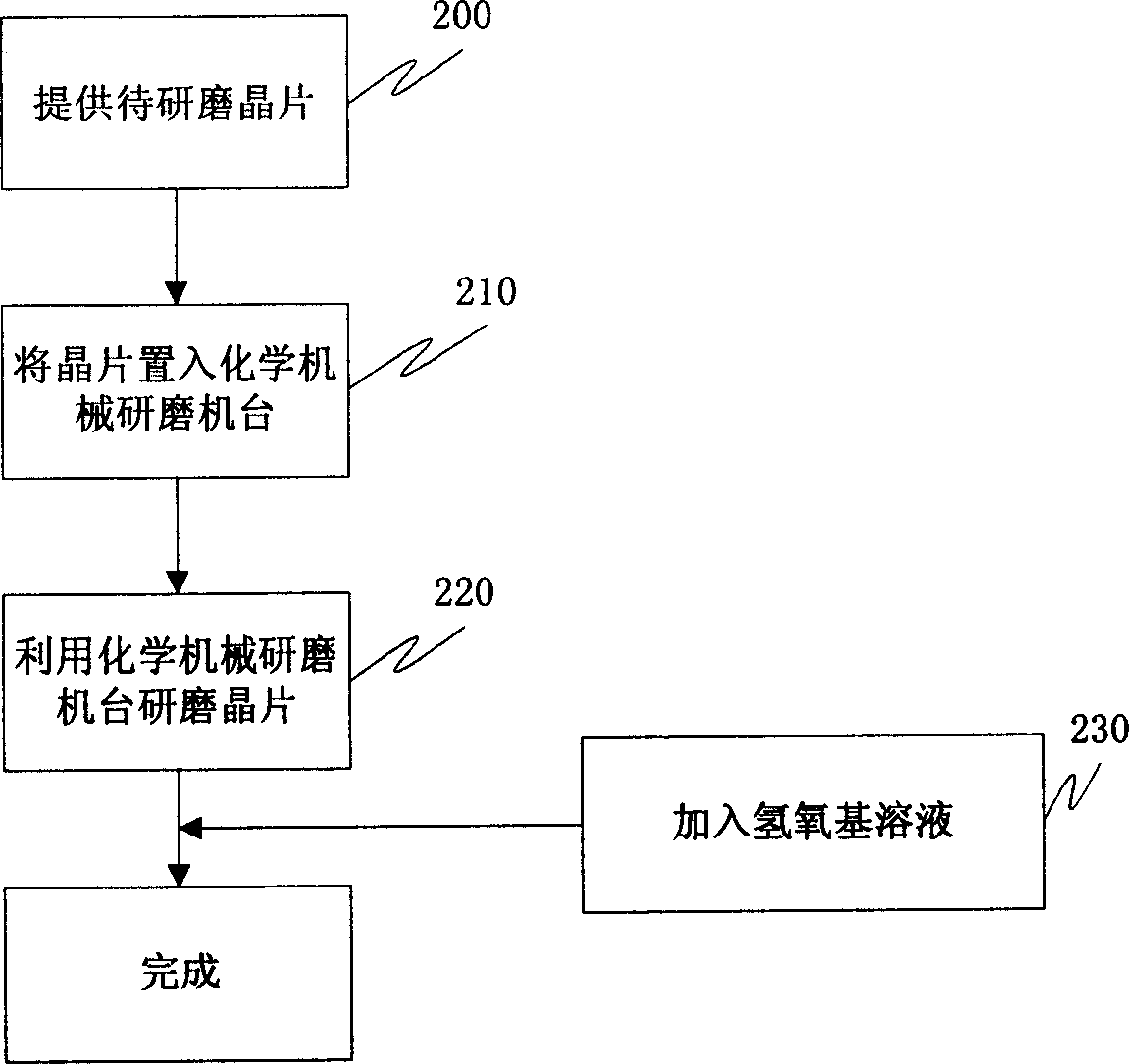

[0024] figure 2 It is a step diagram of a non-scratch chemical mechanical polishing process according to a second embodiment of the present invention, mainly using a chemical mechanical polishing machine for polishing.

[0025] Please refer to figure 2 , in step 200, a wafer to be ground is provided. Then, in step 210, the wafer is placed into a chemical mechanical polishing machine station to prepare for polishing. Subsequently, in step 220, the wafer is ground by using a chemical mechanical polishing machine, wherein the abrasive used for grinding the wafer contains silicon dioxide abrasive grains. Then, in step 230, a hydroxide solution is added, wherein the hydroxide solution is, for example, potassium hydroxide (KOH) solution; for example, when the concentration of the potassium hydroxide solution added is about 1M, the pH of the abrasive Will gradually change to greater than 10, while the size of the abrasive particles will also be reduced. Moreover, in order to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com