Patents

Literature

148results about How to "Improve quality pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edge drop control method of cold-rolled non-oriented silicon steel

ActiveCN103464469ARealize closed-loop controlHigh control precisionRoll mill control devicesMetal rolling arrangementsEffect functionEngineering

The invention provides an edge drop control method of cold-rolled non-oriented silicon steel. The edge drop control method includes that a cold rolling five frame and all six roller rolling mill is utilized as an object; an objective function is that the horizontal thickness difference of the non-oriented silicon steel is minimum; the complete set of working roller forecast and feedback and working roller bending compensation control method for edge thinning control of the non-oriented silicon steel is established through introduction of an efficiency effected function array. According to the edge drop control method of the cold-rolled non-oriented silicon steel, the original control device is fully utilized; the maintenance is easy; the technology import capital investment is saved; meanwhile the influence on the flatness control accuracy can be effectively reduced and the horizontal thickness control accuracy of the non-oriented silicon steel can be improved to enable the horizontal thickness difference to decrease from 25 microns to 8 microns below and accordingly the laminated rate of the non-oriented silicon steel finished product and the qualified rate of the quality of the finished product are improved and a new solution is provided to adapt to the edge drop control presetting and feedback of industrial application.

Owner:ANGANG STEEL CO LTD

Control method of toothed wheel steel band structure

ActiveCN101381803AMeet needsControl or lighten banding levelsTemperature control deviceHeat treatment process controlBand shapeSteel bar

The invention relates to a method for controlling a strip tissue of pinion steel, which belongs to the technical field of the tissue of the pinion steel. The method adopts the following process flow for producing a continuous casting billet of the pinion steel: the pretreatment of molten iron, primary smelting in a converter, refining in a ladle refining furnace or refining in the ladle refining furnace and a vacuum degassing furnace, and continuous casting; the steel billet is heated and is subjected to continuous rolling through 20 short stress line high-rigidity closed-type red ring rolling machines; and different final rolling temperatures are respectively controlled to produce a hot-rolled round steel bar material in order that the level of a steel ferrite and pearlite strip tissue is less than or equal to 2.5. The method has the advantages that different specifications and different final rolling temperatures of the rolled steel are controlled by cooling and other means to realize the aim of enlightening the level of the strip tissue by the steel material with Phi of between 14 and 80 mm<2>. By effectively controlling the level of the strip tissue, the method can meet the requirement of a user on the high-quality pinion steel and improve the qualification rate of the quality of the high-quality pinion steel.

Owner:SHOUGANG CORPORATION

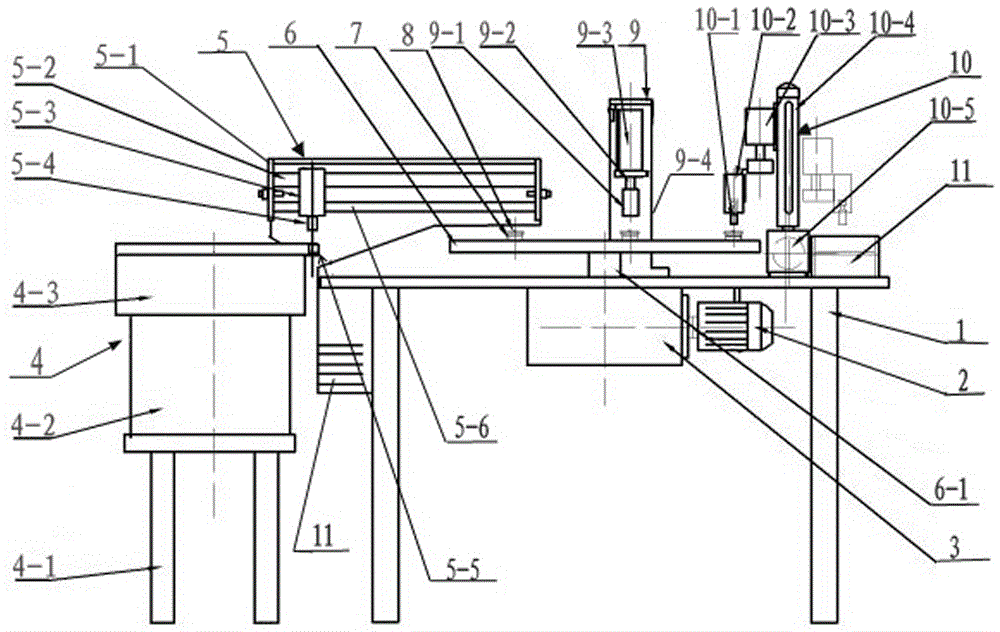

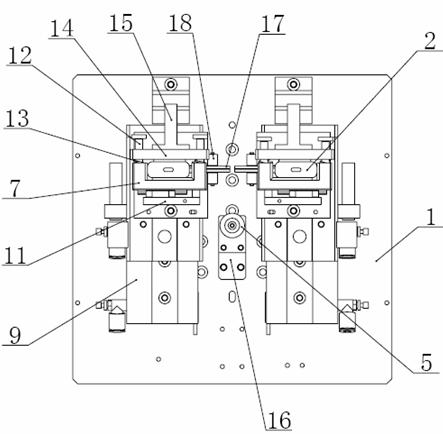

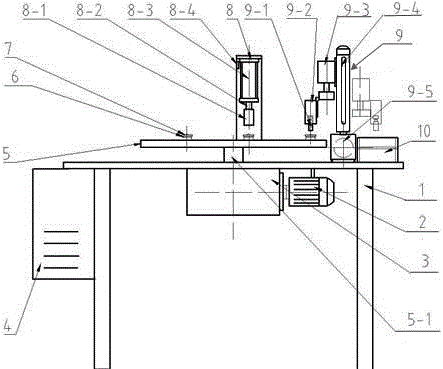

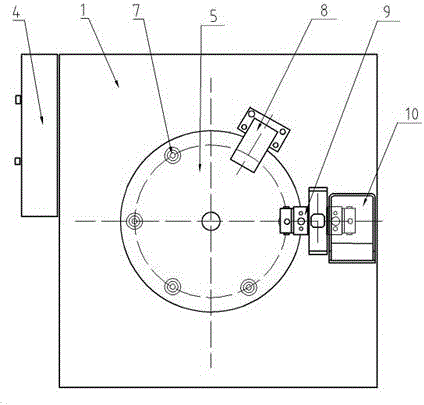

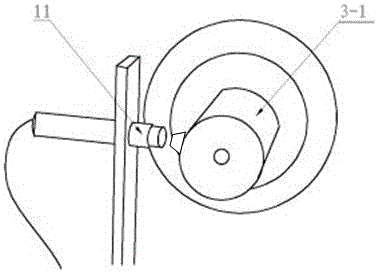

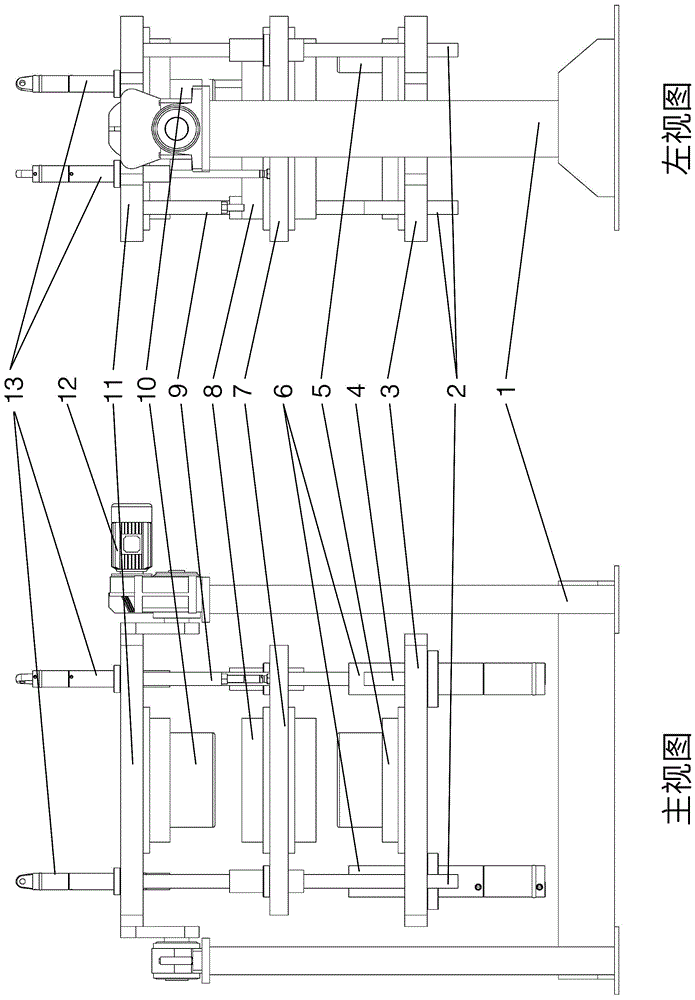

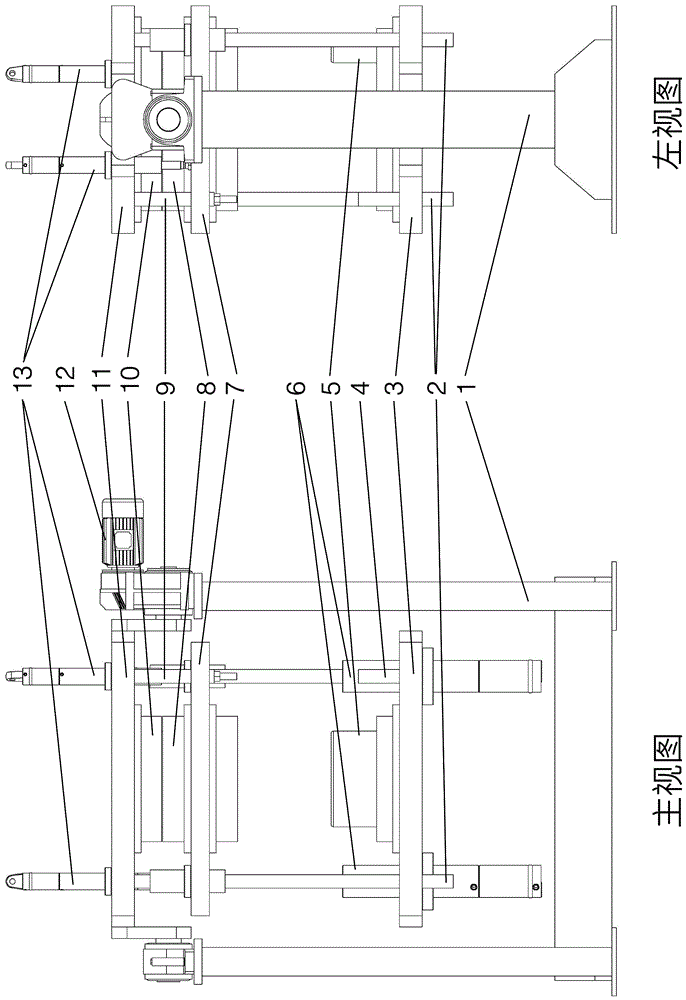

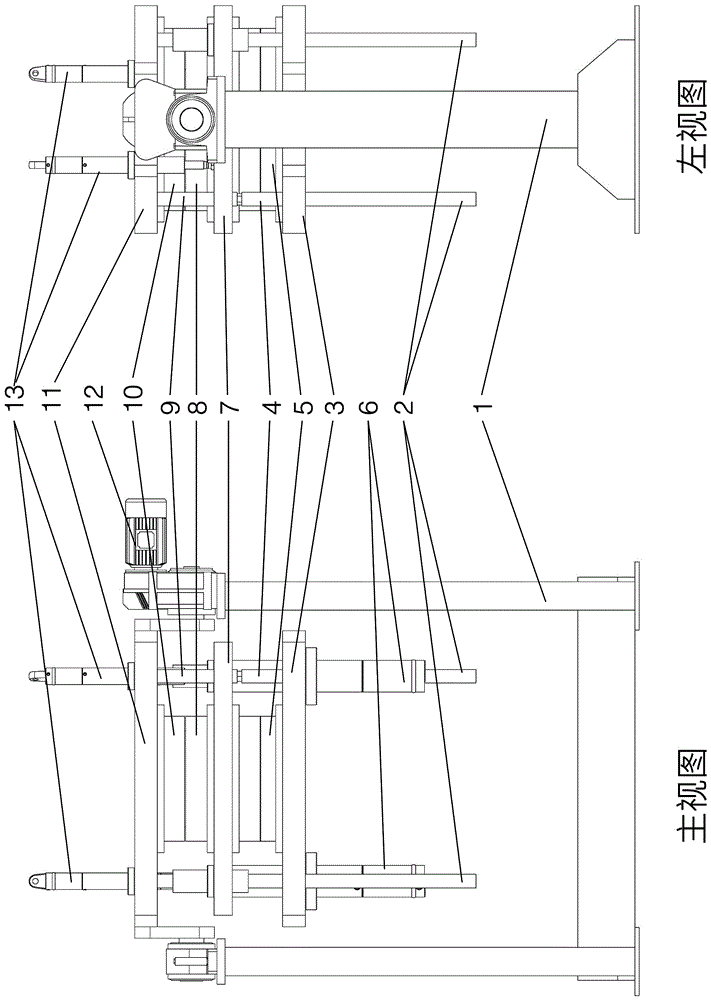

Automatic feeding and press fit machine of self-cleaning automobile shock absorber triple-linked part and control method thereof

The invention relates to an automatic feeding and press fit machine of a self-cleaning automobile shock absorber triple-linked part. The automatic feeding and press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a station rotary disc, a vibration feeding mechanism, a feeding mechanical hand, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with a variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the vibration feeding mechanism, the feeding mechanical hand, the pneumatic press fit mechanism and the collection box are arranged on one side of the workbench. The automatic feeding and press fit machine cooperates with an automatic control method to achieve automatic feeding and press fit of the self-cleaning shock absorber triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation time is shortened, the press fit accuracy is high, the action is reliable, the consistency is high, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

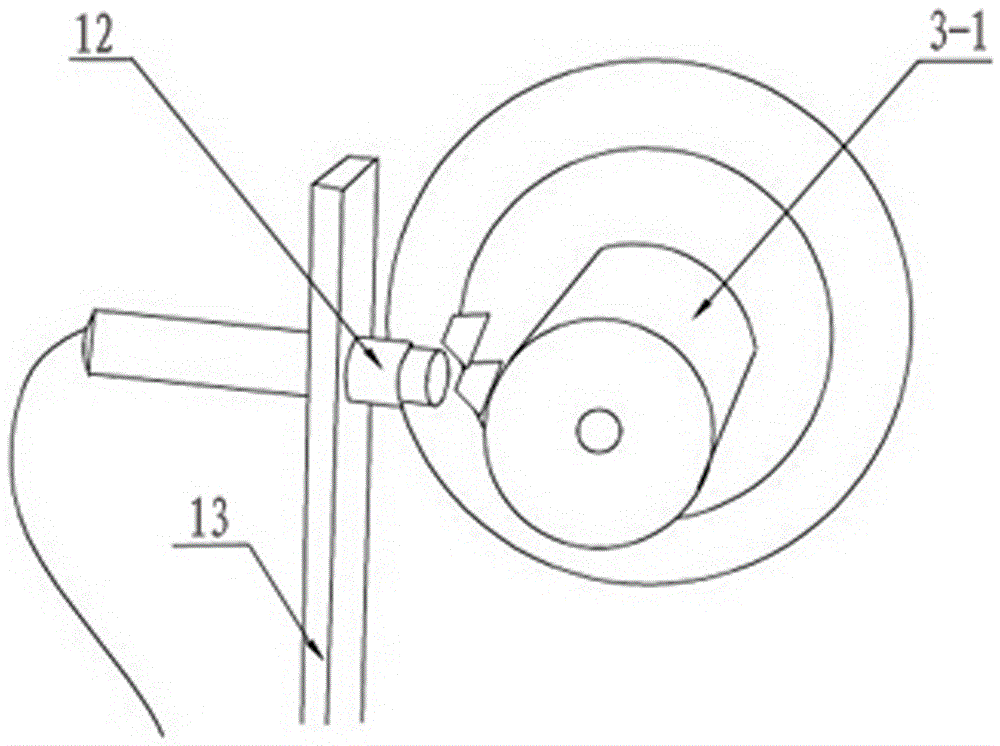

Novel slide plate brick for automatic slag-retaining slide gate of converter and preparation method of slide plate brick

The invention discloses a novel slide plate brick for an automatic slag-retaining slide gate of a converter and a preparation method of the slide plate brick. The slide plate brick is characterized by containing the following components in percentage by weight: 58%-68% of tabular corundum, 6%-8% of 98 magnesia, 8%-11% of electrically-fused spinel, 3%-5% of graphite, 4%-7% of a-aluminum oxide powder, 1%-2% of sintering agent, 2%-7% of aluminum-silicon alloy powder and 4%-5% of resin. The slide plate brick can be prepared from the components through the processes of mixing, shaping, drying, sintering, oil immersing, roasting, and machining. By virtue of adjustment on the formula of the slide gate brick and simplification on the production technology of the slide gate brick, the comprehensive performance of the slide gate brick is enhanced, the direct benefit of slag-free tapping with the slide plate brick is high, and beneficial conditions are provided for development of good-quality steel grades, so that the slide plate brick and the preparation method of the brick have a very wide application prospect and remarkable economic and social benefits.

Owner:无锡市南方耐材有限公司

Method of ultra-low-carbon steel dephosphorization outside furnace

The invention provides a method of ultra-low-carbon steel dephosphorization outside a furnace. According to the invention, a converter tapping target temperature is reduced, and small-particle lime is added to a ladle according to a proportion that 2.3-3.1kg of the small-particle lime is added to every ton of steel; during an LF refining process, appropriate amounts of lime and refining slag are respectively added, increased-temperature slagging is carried out, and temperature compensation is controlled; when the temperature increasing process is finished, and the slag is completely melted, an argon stirring dephosphorization process is carried out. According to the invention, temperature controlling is carried out, appropriate amounts of lime and refining slag are respectively added to the ladle and the LF furnace, and dephosphorization is carried out with the argon stirring measure, such that thermo-dynamical and dynamical conditions of dephosphorization are improved, and the controlling level of phosphorus in ultra-low-carbon steel is improved. With the method, an average dephosphorization rate after tapping is above 35%, steel judgment accidents and economic loss caused by standard-exceeding phosphorus content are reduced, and qualification rate of ultra-low-carbon steel quality is improved.

Owner:ANGANG STEEL CO LTD

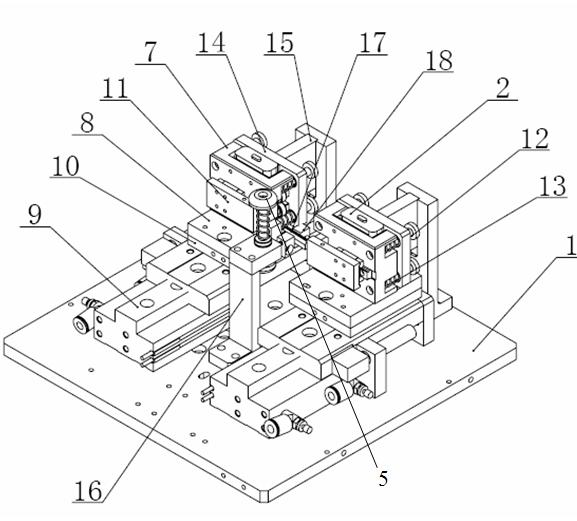

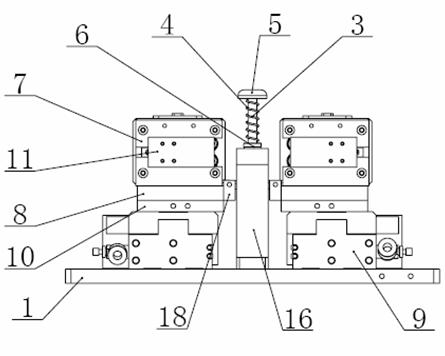

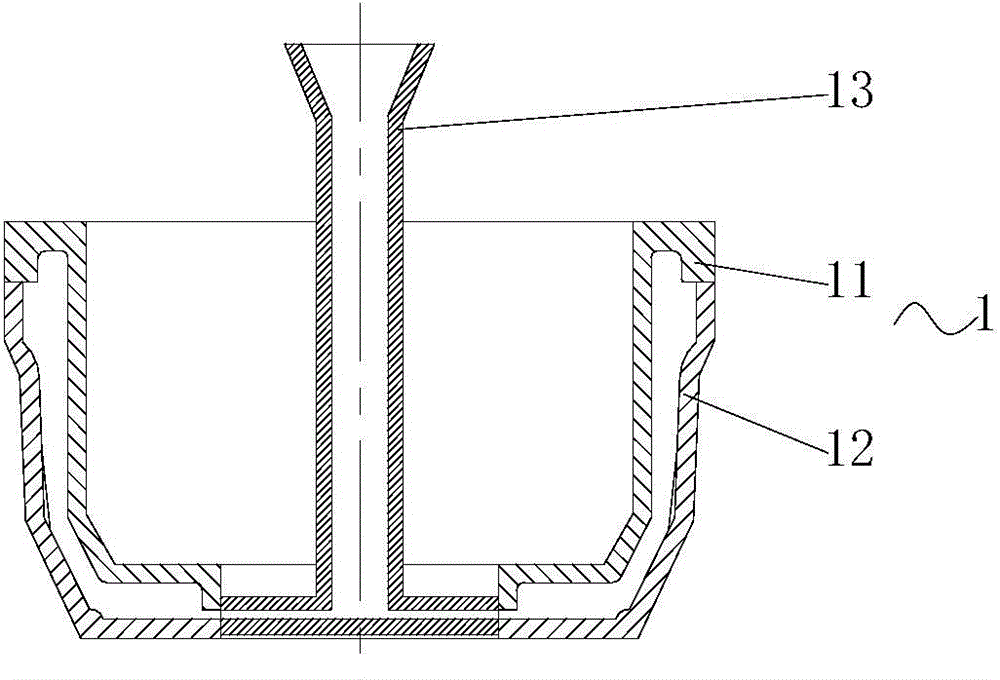

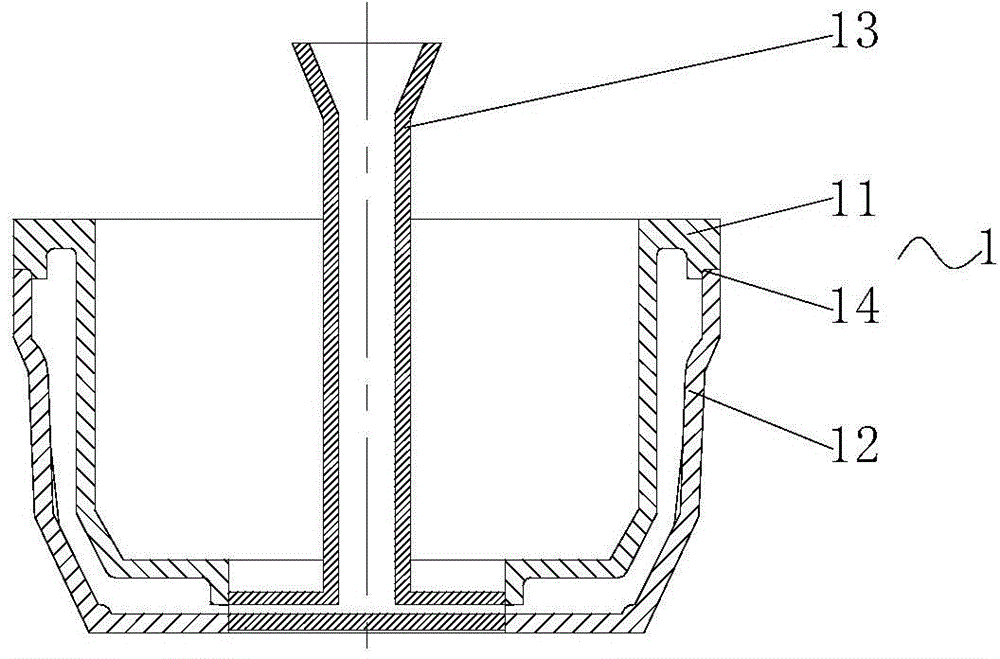

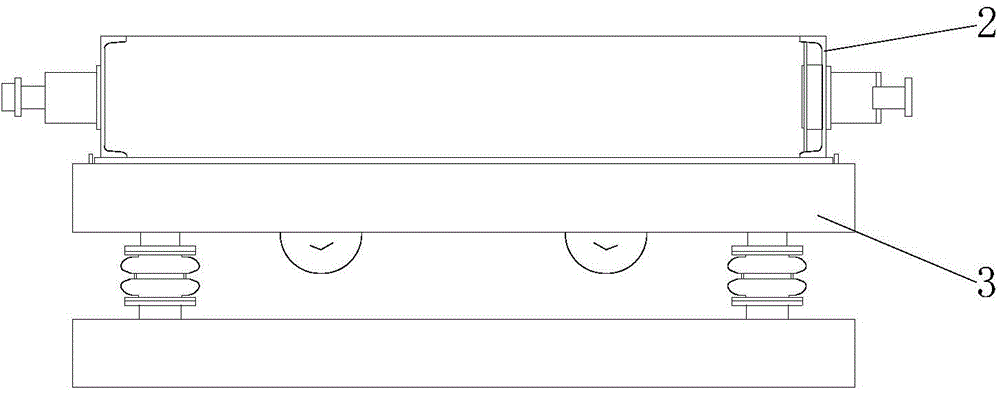

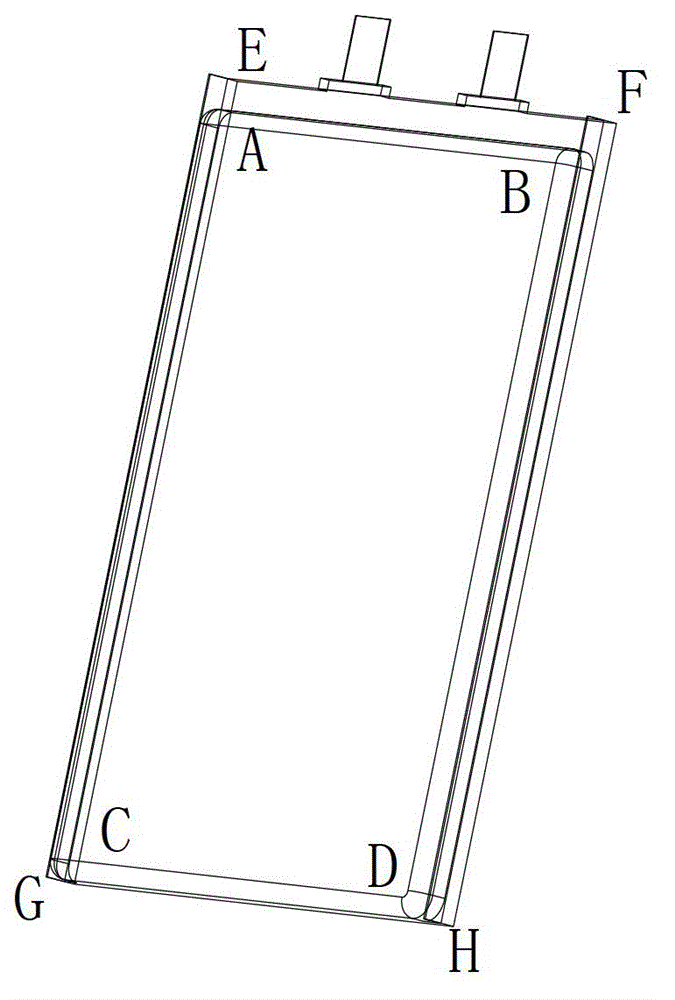

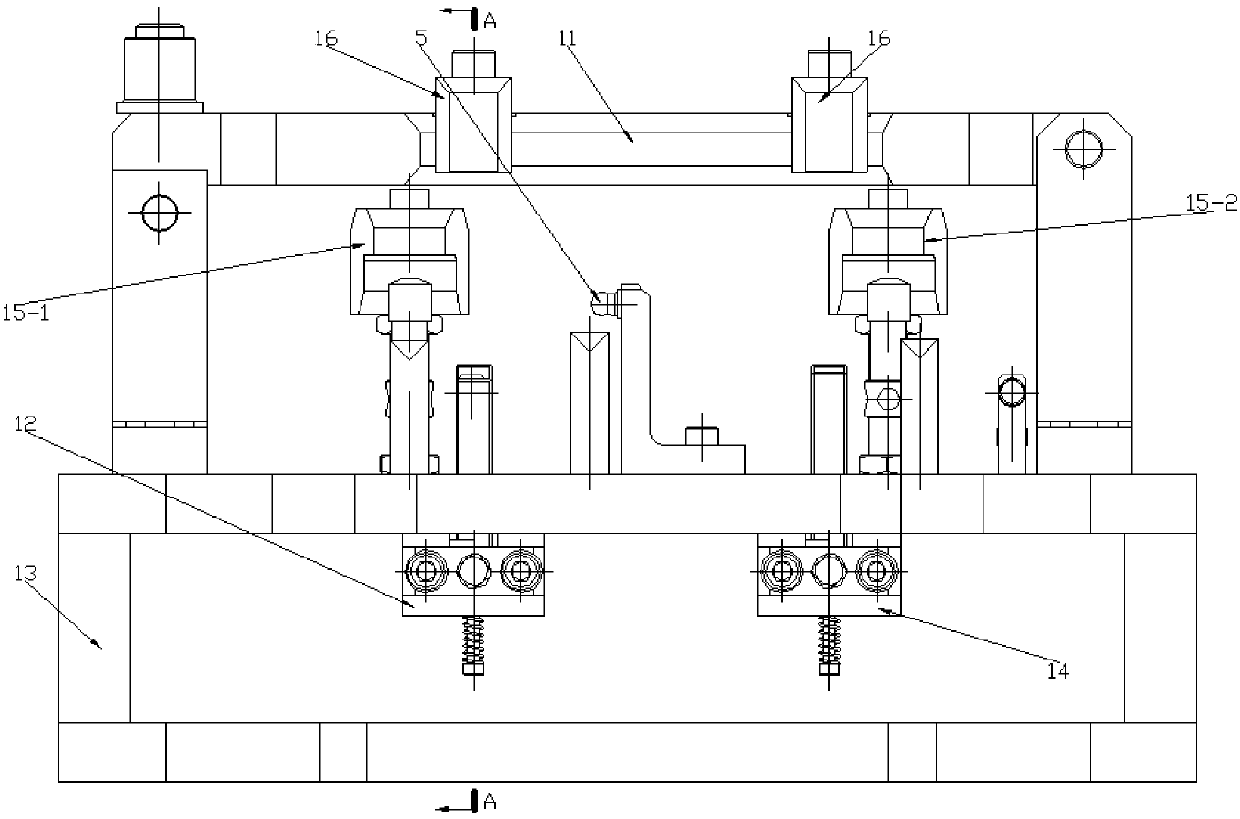

Laser welding fixture for power batteries

ActiveCN102000919AMaintain stabilityImprove quality pass rateWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryPower battery

The invention discloses a laser welding fixture for power batteries. The fixture comprises a bottom plate (1), wherein two limiting plates (15) used for welding are arranged at the rear end of the bottom plate (1) at an interval; a sliding table cylinder (9) is respectively arranged right ahead each limiting plate (15) used for welding; a battery fixture positioning plate (7) and a mobile limiting plate (14) are respectively arranged on the upper surface of each sliding table cylinder (9) in tandem; at least one battery fixture guide shaft (12) is respectively fixed to the left end and the right end of each battery fixture positioning plate (7); each mobile limiting plate (14) is connected with each battery fixture positioning plate (7) through the battery fixture guide shaft (12); and a groove is reserved in the middle of each battery fixture positioning plate (7). The laser welding fixture for the power batteries disclosed by the invention can maintain the stability of battery clamping, ensures the welding reliability of the power batteries in various welding fields, and improves the quality passing rate of the power batteries.

Owner:TIANJIN LISHEN BATTERY

Manufacturing method of brake drum

The invention discloses a manufacturing method of a brake drum. The manufacturing method mainly comprises the following steps: respectively manufacturing an upper mould shell model, a lower mould shell model and a sprue cup shell model on a core shooting machine, then assembling to form an integral film-coated sand shell model; placing a sand box on a ramming platform; putting dried sand into the sand box, and ramming to form a bottom sand layer; placing the assembled film-coated sand shell model into the sand box, putting the dried sand into the sand box, and ramming; coating a back film, vacuumizing; and pouring, releasing a negative pressure, opening the box, drawing and removing a casting head of a casting of the brake drum. The manufacturing method achieves the characteristic of combining advantages of two processes by combining a V-method casting process and a film-coated sand shell model casting process.

Owner:江西弘旺汽车制动器制造有限公司

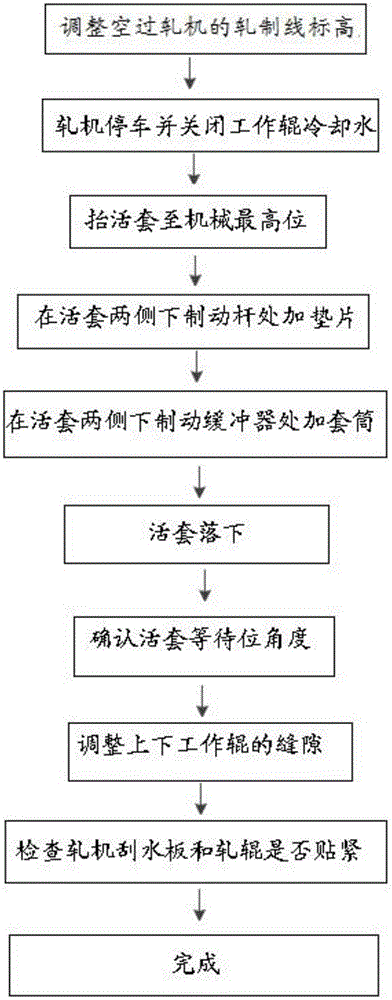

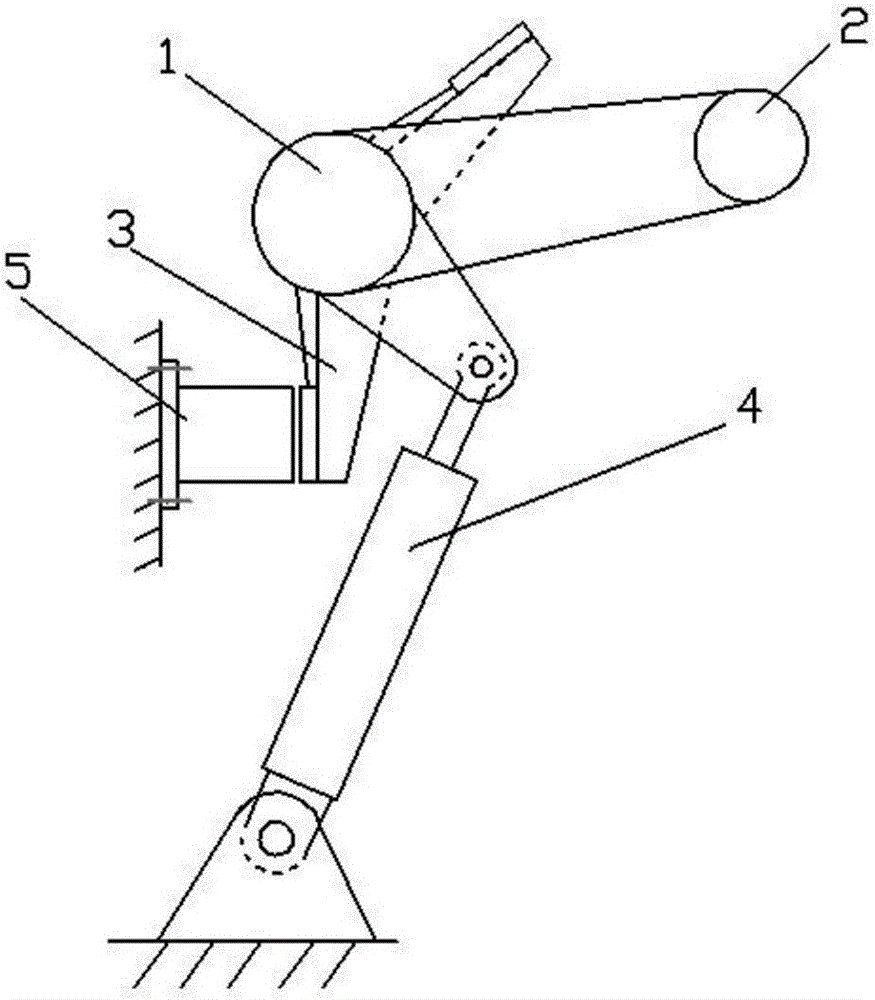

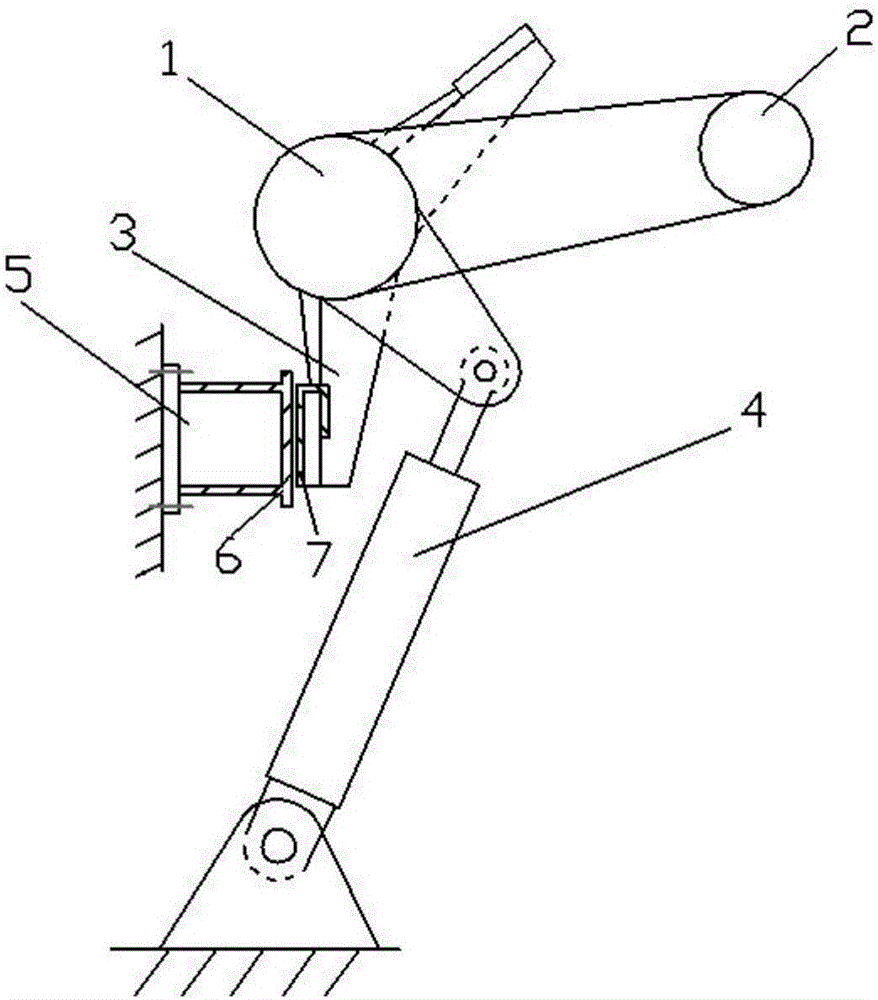

Method of preventing heavy gauge strip steel from being scratched among finishing mill racks

ActiveCN105728460AAvoid compressionSolve the scratchMetal rolling stand detailsFlexible work arrangmentsPosition angleStrip steel

The invention provides a method of preventing heavy gauge strip steel from being scratched among finishing mill racks. The method comprises the following steps of: adjusting the elevation of a rolling line of an idle rolling mill to right elevation; and adjusting the mechanical position of a downstream loop of the idle rolling mill, to be specific, lifting the loop to the mechanical highest position, arranging a gasket on a brake bar below the loop and a sleeve on a buffer below the loop, dropping down the loop, and identifying the waiting position angle of the loop. The method has the beneficial effects that the rolling line is in the right elevation, and strip steel is lifted; the waiting position angle of the loop is increased by adjusting the mechanical position of the downstream loop of the idle rolling mill, thereby preventing the lower surface of the strip steel from scratching a lower guide plate of a rolling mill outlet, completely solving the surface scratching problem of the strip steel, greatly increasing the percent of pass of strip steel quality and ensuring the smooth production.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

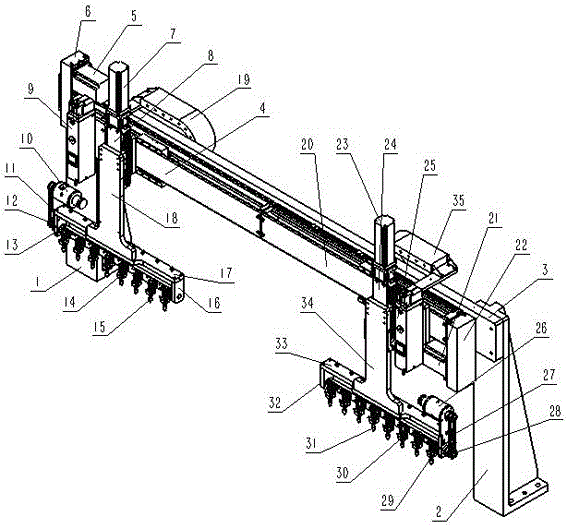

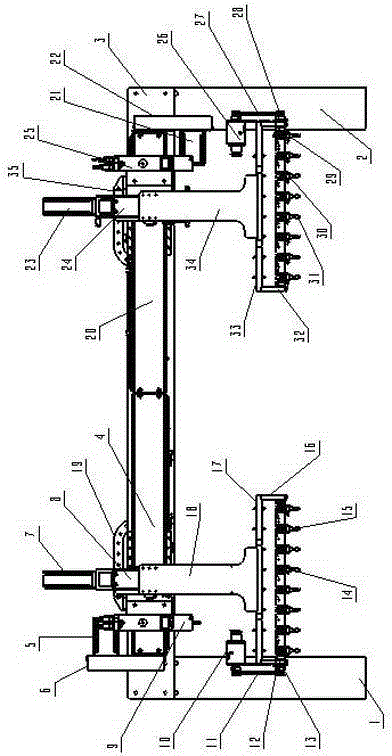

Winding product taking and discharging machine

The invention discloses a winding product taking and discharging machine, and relates to the technical field of inductance electronic equipment manufacturing. The winding product taking and discharging machine comprises a rack and at least one feeding device set arranged on a supporting beam of the rack. Each feeding device set comprises a transverse moving mechanism, a longitudinal moving mechanism, a rotating mechanism, a vacuum generator and suction cups, wherein the transverse moving mechanism is installed on the supporting beam, the longitudinal moving mechanism is vertically loaded on the transverse moving mechanism, the longitudinal moving mechanism is provided with a connecting support, and the rotating mechanism is installed on the connecting support. Each rotating mechanism comprises a rotating shaft with the multiple suction cups and a rotation air cylinder driving the rotating shaft to rotate, and the suction cups are connected with the vacuum generators. The winding product taking and discharging machine solves the problems that existing mini-type winding products are taken and discharged with low accuracy, and the production efficiency is low.

Owner:广西昭信平洲电子有限公司

Method for producing ultralow-sulfur steel under high vacuum

InactiveCN102787209AImprove slag capacityImprove quality pass rateManufacturing convertersAlkalinityMolten steel

The invention provides a method for producing an ultralow-sulfur steel under high vacuum, the sulfur content of steel discharged by a converter can be controlled below 0.010%; during the LF furnace refine treatment process, the sulfur content can be controlled at 0.005-0.007%, the slag alkalinity in the later stage can be controlled between 2.0-4.5, thereby a CaO-MgO-Al2O3-CaF slag system is formed, the total slag amount can be controlled at 8.5-10kg / ton steel, the argon flow during the whole process is 150-250N1 / min; and a VD furnace high vacuum treatment is carried out by using argon with a flow of 450-550N1 / min for mixing. Thereby the molten slag equivalent of slag can be enhanced, great flip of a molten steel surface can be avoided, the addition of the molten steel nitrogen absorption and impurities can be minimized, rapid operation during desulphurization process can be promoted, the sulfur content of the finished product can be controlled below 0.005%, and nitrogen content of the finished product can be controlled below 25ppm, and the qualified rate of ultralow-sulfur steel production can be increased.

Owner:ANGANG STEEL CO LTD

Heavy-rail steel sulfur content controlling method

ActiveCN102443670AAchieve desulfurizationControl desulfurizationManufacturing convertersSulfideSulfur content

The invention provides a heavy-rail steel sulfur content controlling method. According to the invention, sulfur weight during a converter tapping process is controlled, LF furnace and VD furnace slagging manners are improved, and casting parameters of a casting machine are adjusted. With the measures, desulphurization speed in the processes are effectively controlled, such that heavy-rail steel sulfur weight is stably controlled in a range of 0.08-0.20%. Compared to existing technologies, with the method provided by the invention, large-amplitude desulphurization of the LF furnace and the VD furnace can be realized, and desulphurization during the processes can be effectively controlled. With traditional technologies, included sulfide caused by large-amplitude desulphurization can hardly be sufficiently discharged. With the method provided by the invention, the problem is solved, such that a defect of over-standard heavy-rail steel sulfide is avoided. With the method, a sulfur weight of a tundish finished product is improved from 0.0052% to 0.0124%. The proportion of S>0.008% is improved from 42.6% to 99.1%, such that the quality qualification rate of heavy-rail steel is substantially improved.

Owner:ANGANG STEEL CO LTD

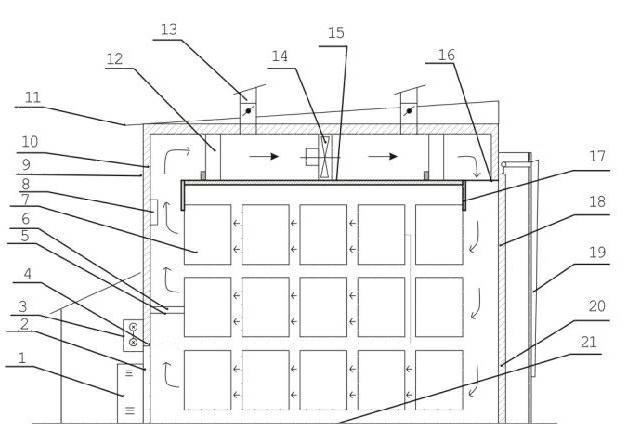

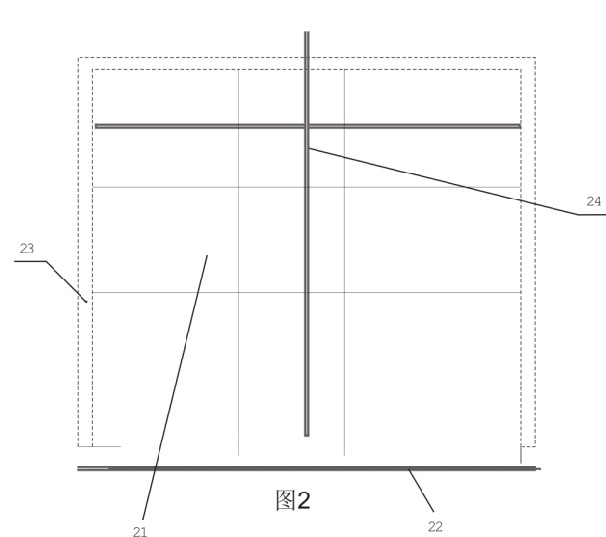

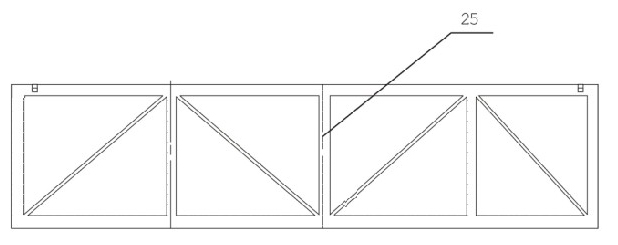

Novel automatically-controlled wood drying kiln

InactiveCN102654351AReduce manufacturing costReasonable kiln volumeDrying gas arrangementsDrying chambers/containersAutomatic controlEngineering

The invention discloses a novel automatically-controlled wood drying kiln, comprising a left wall body, a right wall body, a rear wall body, a front gate (18), a top floor wall body, and a foundation (21), wherein a ceiling support (16) is connected below the top floor wall body via radiating tube supports (25) and a fan support (26); the ceiling support (16) is connected with a ceiling baffle (15); the top floor wall body and the ceiling baffle (15) form an inner-kiln top floor circulation channel; a wood drying space is formed between a position below the ceiling baffle (15) and the foundation (21); the radiating tube supports (25) are respectively arranged in front of and at back the fan support (26); a dehumidification channel (13) communicated with the outside of the kiln from the inside of the kiln is arranged on the top floor wall body between the fan support (26) and the radiating tube supports (25) in front of and at back of the fan support (26); a radiating channel (12) is connected with the radiating tube supports (25); and an electric fan (14) is connected with the fan support (26). The novel automatically-controlled wood drying kiln disclosed by the invention saves the cost by about 50% compared with that of the conventional drying kiln; the qualified rate of products is high, and especially round and hard wood stick products, the radial cracking rate is less than 5%; and the economic efficiency is obviously increased.

Owner:JIANGXI TAISHENG INDAL

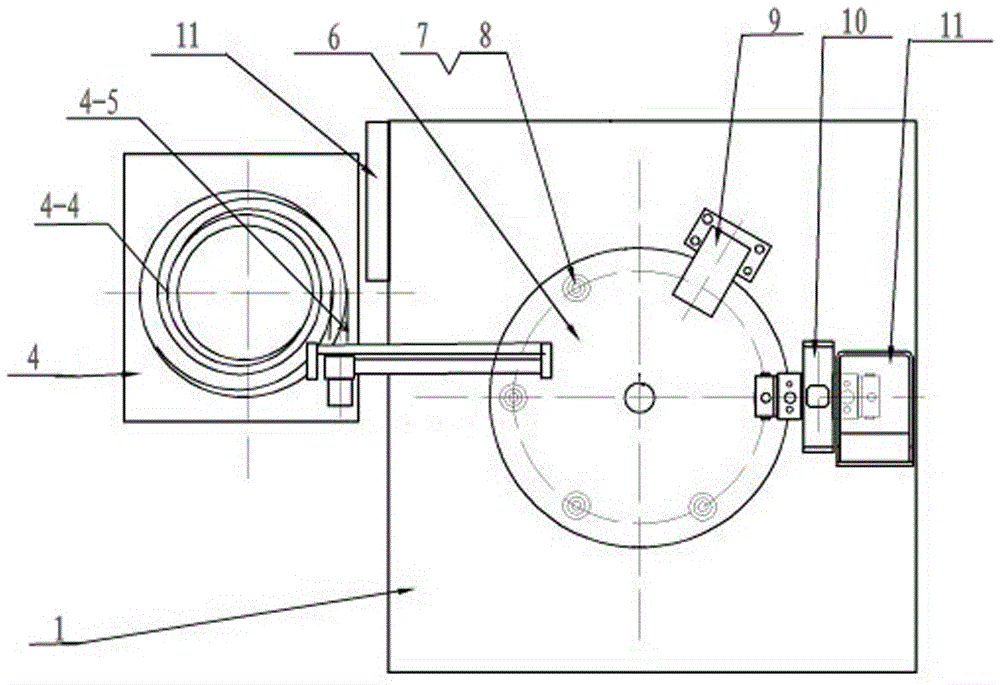

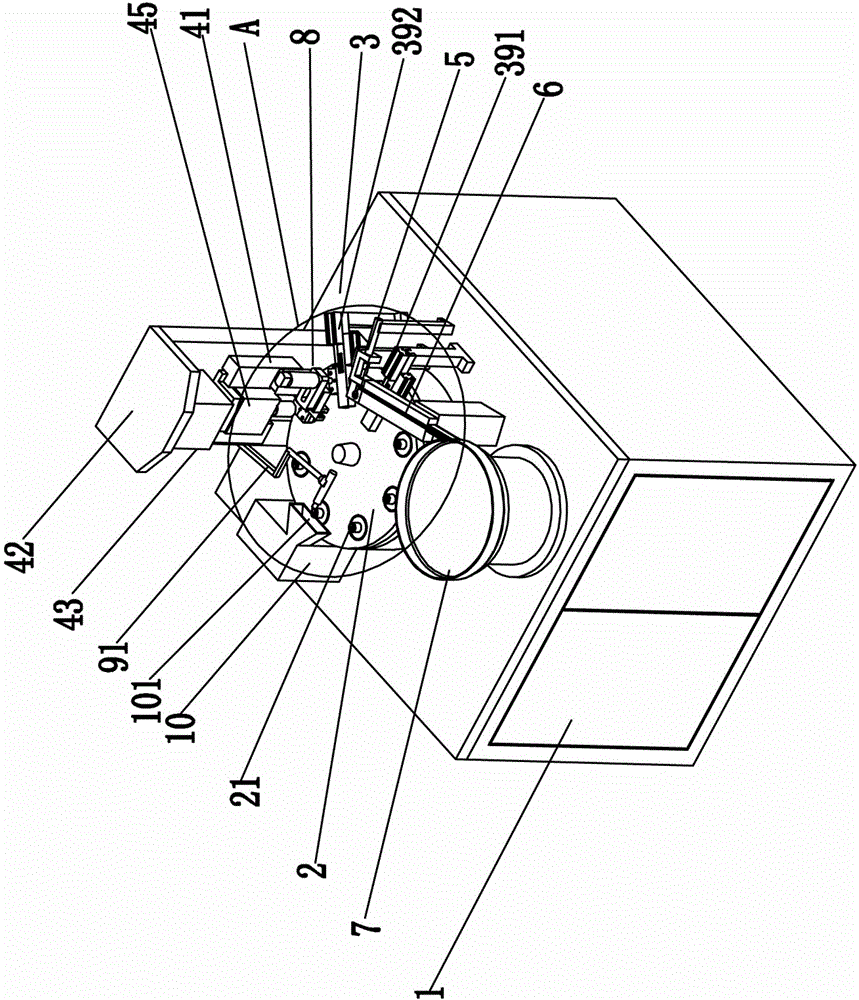

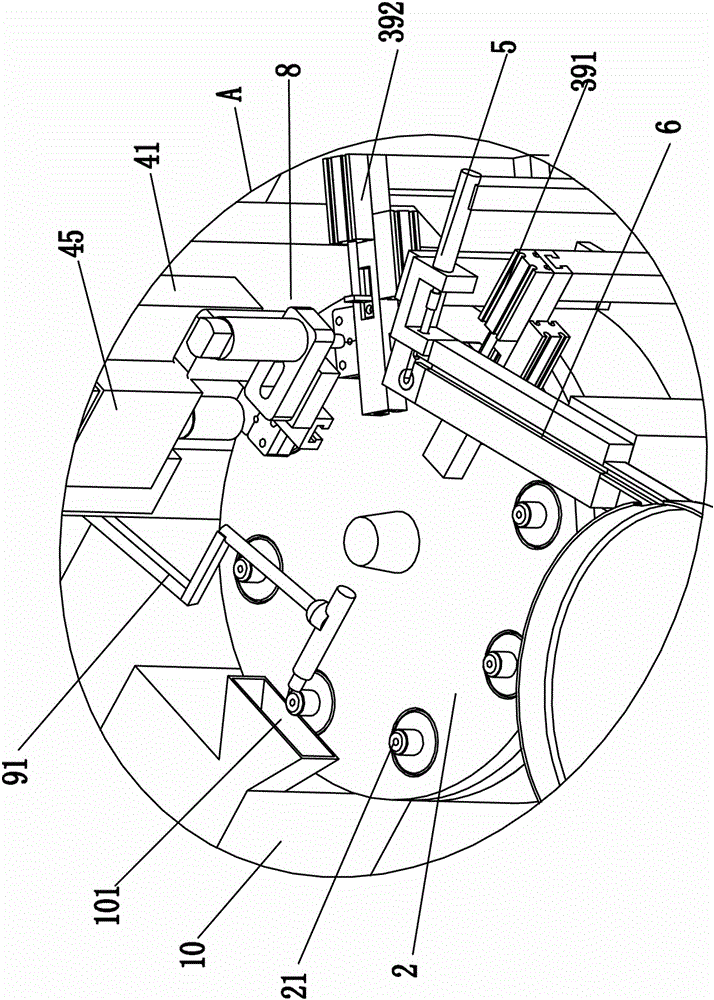

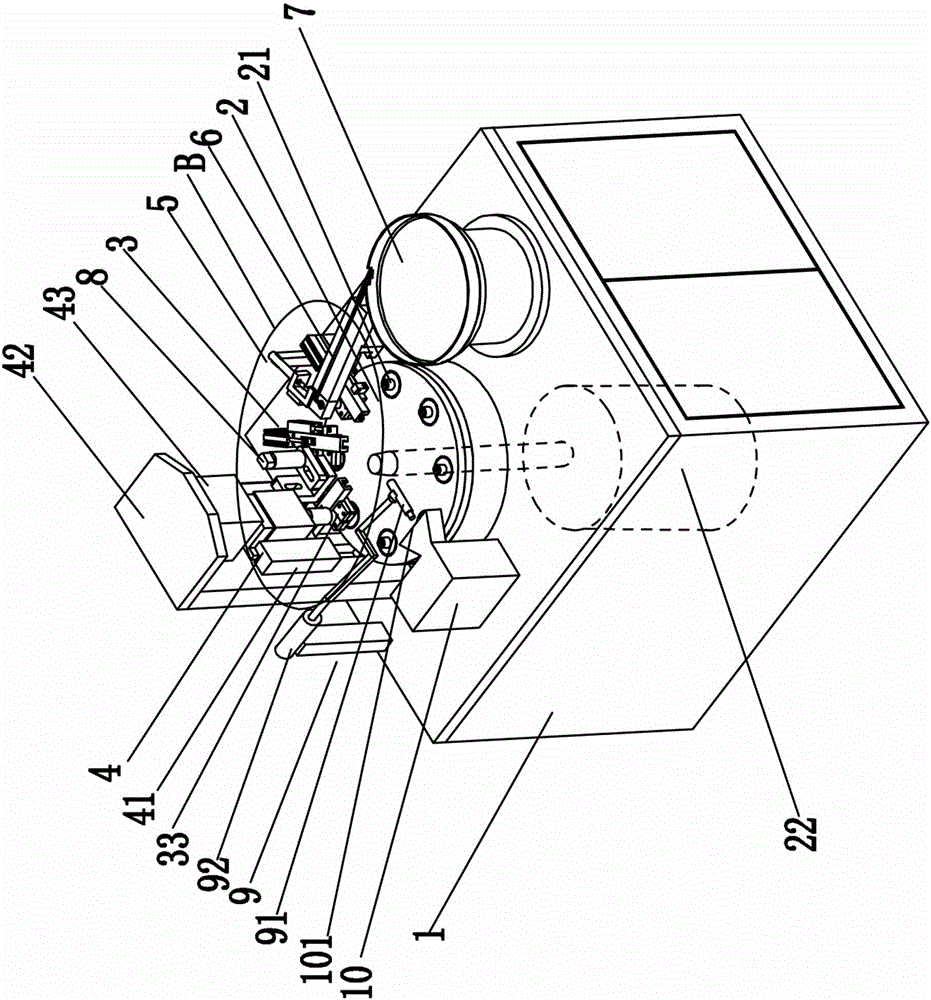

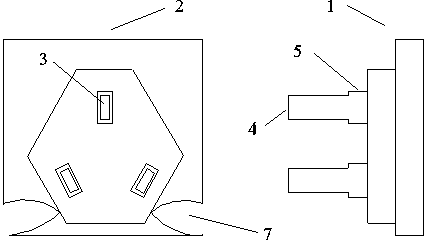

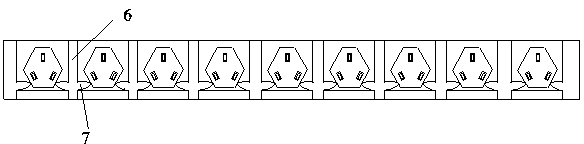

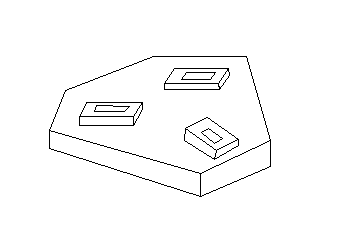

Automatic press fit machine of automobile shock absorber triple-linked part and automatic control method thereof

ActiveCN106112521ARealize continuous automatic pressingHigh speedAssembly machinesVehicle componentsAutomatic controlCoupling

The invention relates to an automatic press fit machine of an automobile shock absorber triple-linked part. The automatic press fit machine comprises a mechanical press fit part and an automatic control part, wherein the mechanical press fit part comprises a workbench, a splitter, a variable-frequency and variable-speed motor, a station rotary disc, a pneumatic press fit mechanism, a pneumatic mechanical hand and a collection box; the station rotary disc is fixedly mounted on the surface of the workbench; a plurality of press fit stations and pressing dies embedded on the stations are uniformly distributed on the station rotary disc; the splitter is arranged at the bottom of the surface of the workbench; an input shaft of the splitter is connected with the variable-frequency and variable-speed motor through a coupling; an output shaft of the splitter is connected with a rotating shaft of the station rotary disc; and the pneumatic press fit mechanism, the pneumatic mechanical hand and the collection box are fixedly mounted on the working surface, corresponding to the stations, on the station rotary disc. The automatic press fit machine cooperates with an automatic control method to achieve continuous automatic press fit of the triple-linked part, can improve press fit speed and accuracy, and has the advantages that the operation is easy and convenient, the operation time is shortened, the press fit accuracy is high, the action is reliable, the comprehensive cost is low, and the like.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

Automatic hollow bead forming machine

ActiveCN105105434AImprove work efficiencyImprove product qualification rateJewelleryPunchingMolding machine

The invention relates to an automatic hollow bead forming machine. According to the automatic hollow bead forming machine, a metal pipe blank is conveyed to a lower forming die of a turntable through a vibration feeding plate, a material guide slot and a material pushing mechanism, and is corrected by a correction mechanism; then the turntable rotates to convey the metal pipe blank on the lower forming die, so that the metal pipe blank is punched by an upper forming die mechanism to form thin-wall hollow beads; therefore, the automatic hollow bead forming machine realizes full automation of material screening, material conveying, material swinging and punching, and the specifications of the thin-wall spherical hollow beads punched by the automatic hollow bead forming machine are uniform; meanwhile, the potential safety hazard is eliminated; compared with the conventional hollow bead forming machine, the automatic hollow bead forming machine disclosed by the invention is high in automation degree, and the technical problems of large artificial operation error and low efficiency are solved; and the labor intensity of a worker and the production cost are effectively reduced, and the working efficiency and the product yield are improved, so that full automatic production of the thin-wall hollow beads is realized.

Owner:佛山市顺德区汇伦生产力促进服务中心有限公司 +1

Method for controlling center porosity defect of bearing steel

InactiveCN102784800ARealize continuous castingPrevent water clogging problemsRoll mill control devicesMetal rolling arrangementsPorosityCooking & baking

The invention provides a method for controlling a center porosity defect of bearing steel. Continuous casting adopts a weak cold system and low superheat and low drawing speed, a tundish adopts soft fire and automatic baking, electromagnetic stirring current intensity and frequency of a crystallizer are controlled, the heating charging temperature is smaller than 850 DEG C, the temperature of a soaking zone ranges from 1200 DEG C to 1220 DEG C, the heating total time is larger than or equal to 5 hours, high reduction rolling is adopted, the first two rolling reduction is controlled between 70mm and 80mm, and finished products are piled in a mode that multiple tanks are continuously piled in each steel tanks. By means of the method, continuous casting of the bearing steel can be achieved, slag blocking and control of oxygen content of tapping in the smelting process of a converter are not needed, special top slag modification treatment is avoided when refining is performed, the problem of water port blockage caused by impurities of the bearing steel can be effectively avoided, quality level of macrostructures of the bearing steel is greatly improved, inherent quality and using performance of bearing steel are improved, and the quality qualified rate of the bearing steel is increased.

Owner:ANGANG STEEL CO LTD

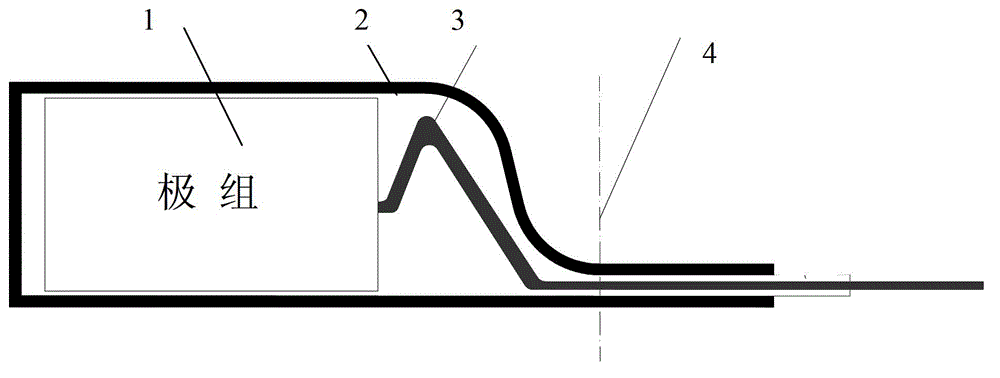

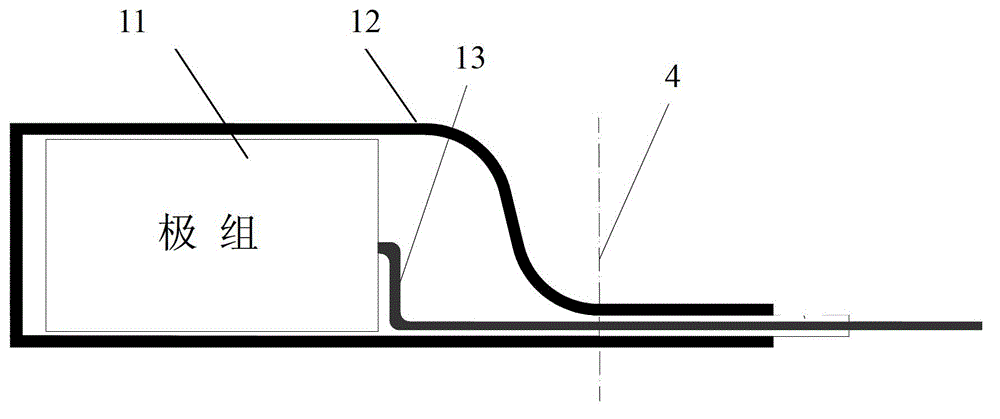

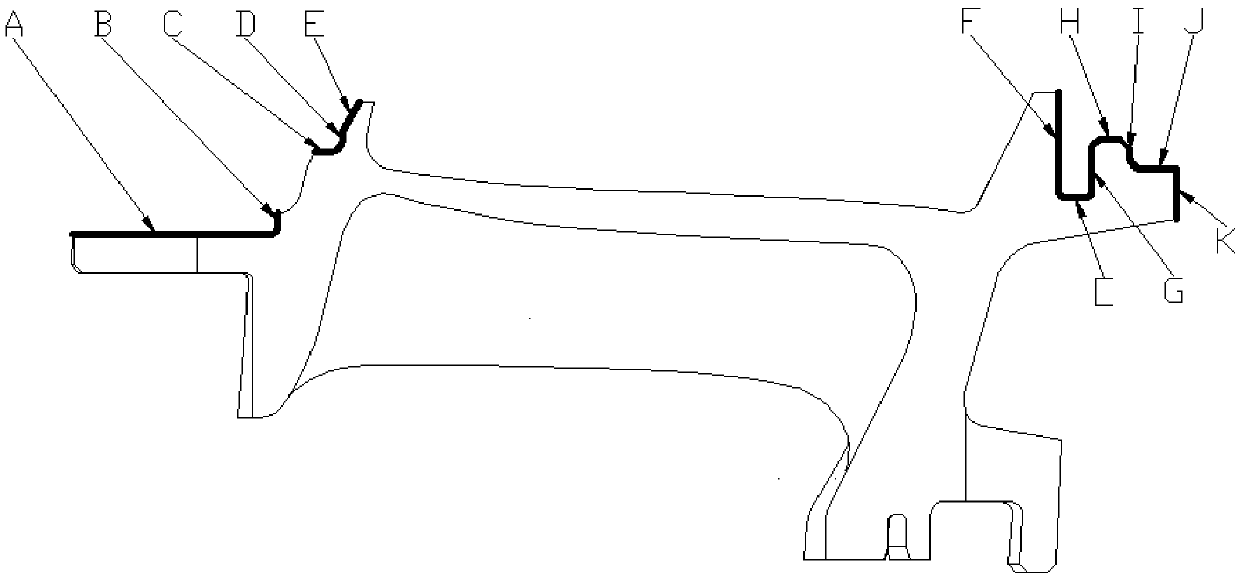

Polymer lithium ion battery

InactiveCN102983304AImprove reliabilityGuaranteed internal resistanceSecondary cellsCell component detailsElectricityElectrical battery

The invention discloses a polymer lithium ion battery which comprises a pole group, a battery case and a pole lug, wherein the pole group is packaged in the battery case, the inner end of the pole lug is fixedly connected with an electrode of the pole group, the outer end of the pole lug extends to the outside of the battery case, and a part of the pole lug located in the battery case is bent. According to the polymer lithium ion battery disclosed by the invention, because the part of the pole lug located in the battery case is bent, a situation that the pole lug is broken under the action of a force in the drop test process of the battery can be avoided by using the buffer action of the bent part, so that the reliability of the battery is effectively improved; meanwhile, the technique can ensure that the electrical properties such as internal resistance and the like of the battery meet the requirements, thereby improving the applicability of the battery in electronic products; and then the quality qualified ratio of the battery is improved, so that the improvement of market application prospects of products of battery manufacturers is facilitated, and the polymer lithium ion battery has great production practice significance.

Owner:TIANJIN LISHEN BATTERY

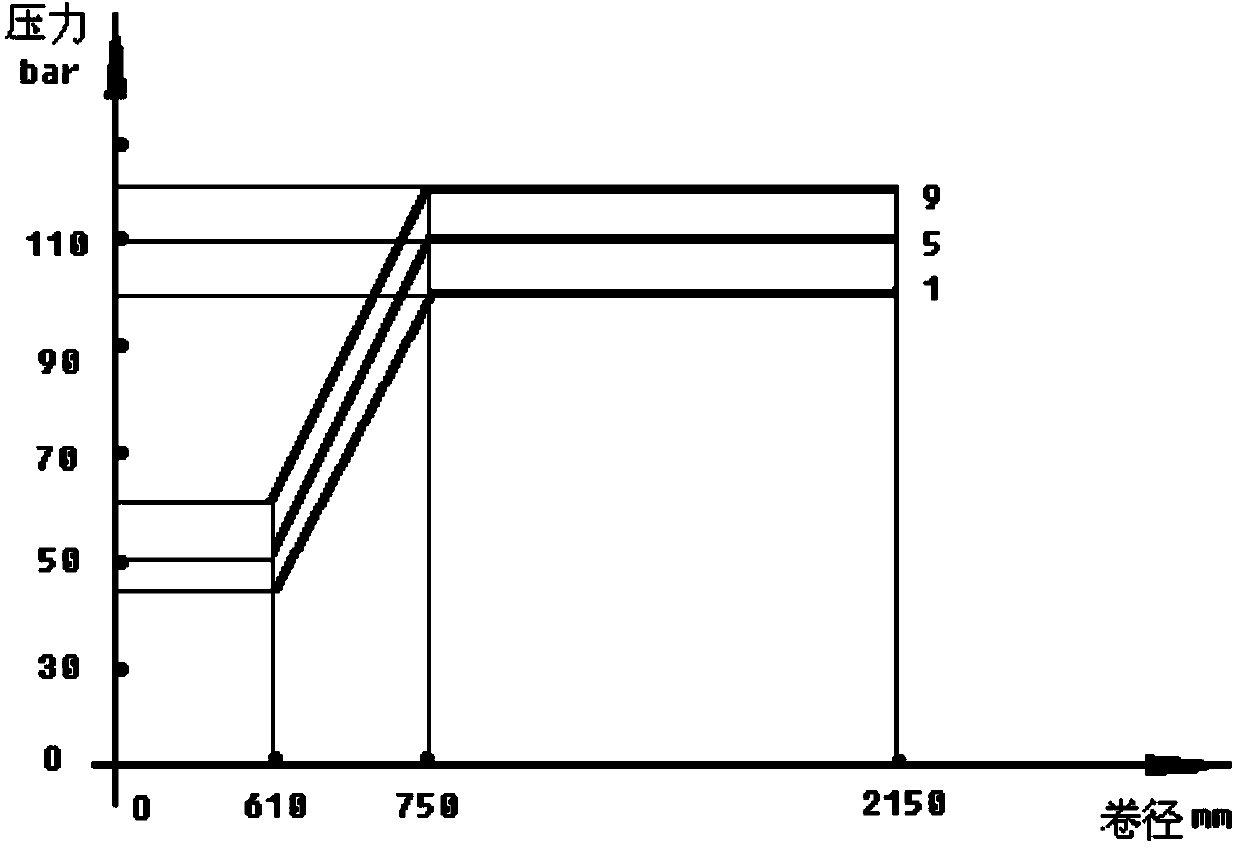

Method for dynamic adjustment of radial expansion force of uncoiler

ActiveCN103472862AReduces scratch defectsGuaranteed uptimeMechanical pressure/force controlClosed loopStrip steel

The invention provides a method for dynamic adjustment of radial expansion force of an uncoiler. According to the method for dynamic adjustment of the radial expansion force of the uncoiler, a data curve of the radial expansion force, the coiling diameter and the unit tension is formed according to traditional strip steel coiling diameter parameters and traditional unit tension parameters, and a PLC control program is compiled; pressure adjustment is carried out by a primary computer with a pressure adjustment critical point which is formed when the rolling diameter is decreased to 750mm; a proportional decompression valve is arranged in a decompression circuit of a coiling block expanding and contracting hydraulic system of the uncoiler, remote pressure control is carried out on the proportional decompression valve by means of expansion force parameters of the primary computer and the control program in a PLC unit, and closed-loop adjustment and real-time control are achieved by the proportional decompression valve and a pressure sensor. According to the method for dynamic adjustment of the radial expansion force of the uncoiler, the expansion force is controlled by means of the proportional decompression valve, the radial expansion force can change dynamically along with the change of the outer diameter of a steel coil, a system can operate stably, pressure adjustment can fully meet design requirements, scratches on the surface of strip steel can be effectively reduced, and the quality and percent of pass of products are improved.

Owner:ANGANG STEEL CO LTD

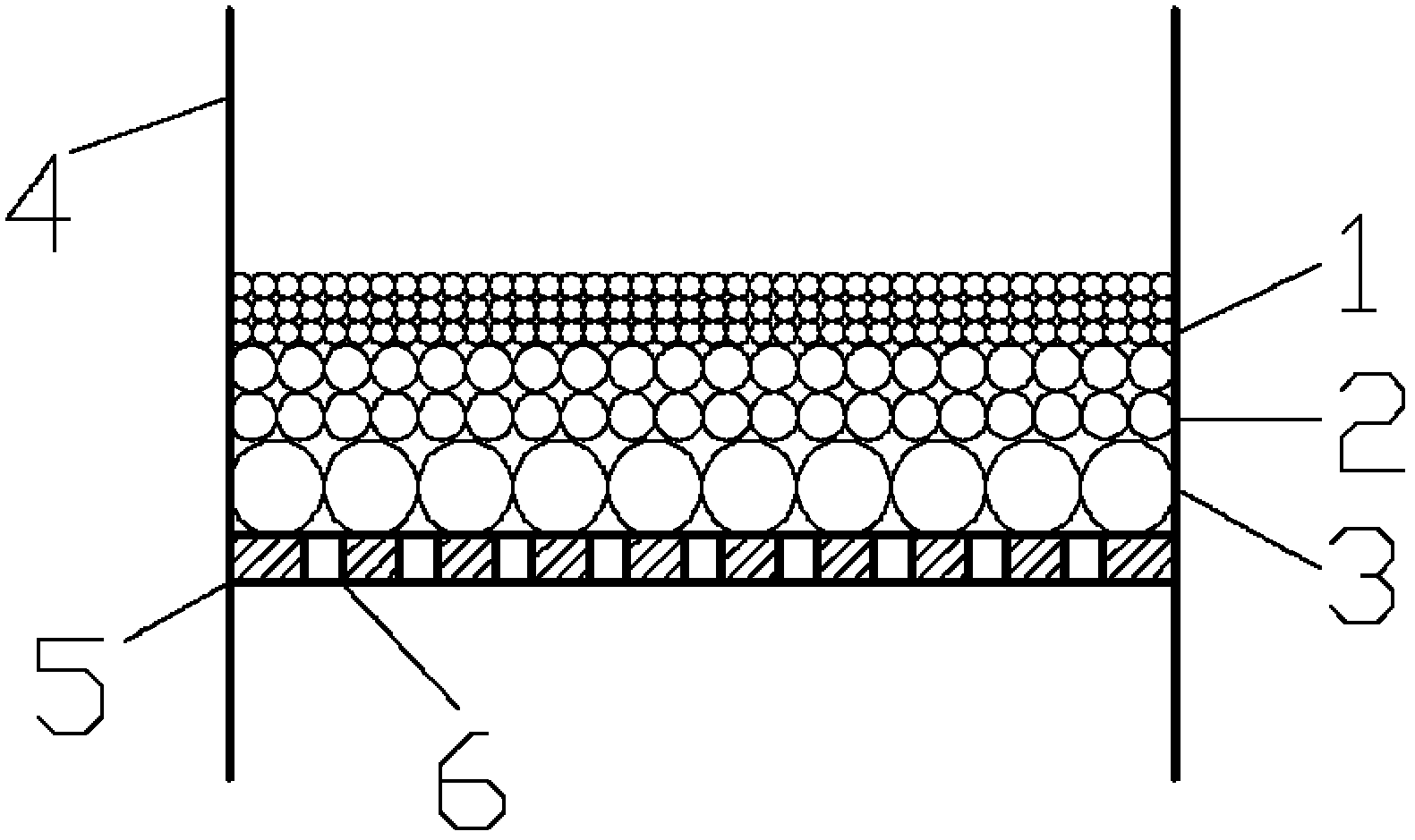

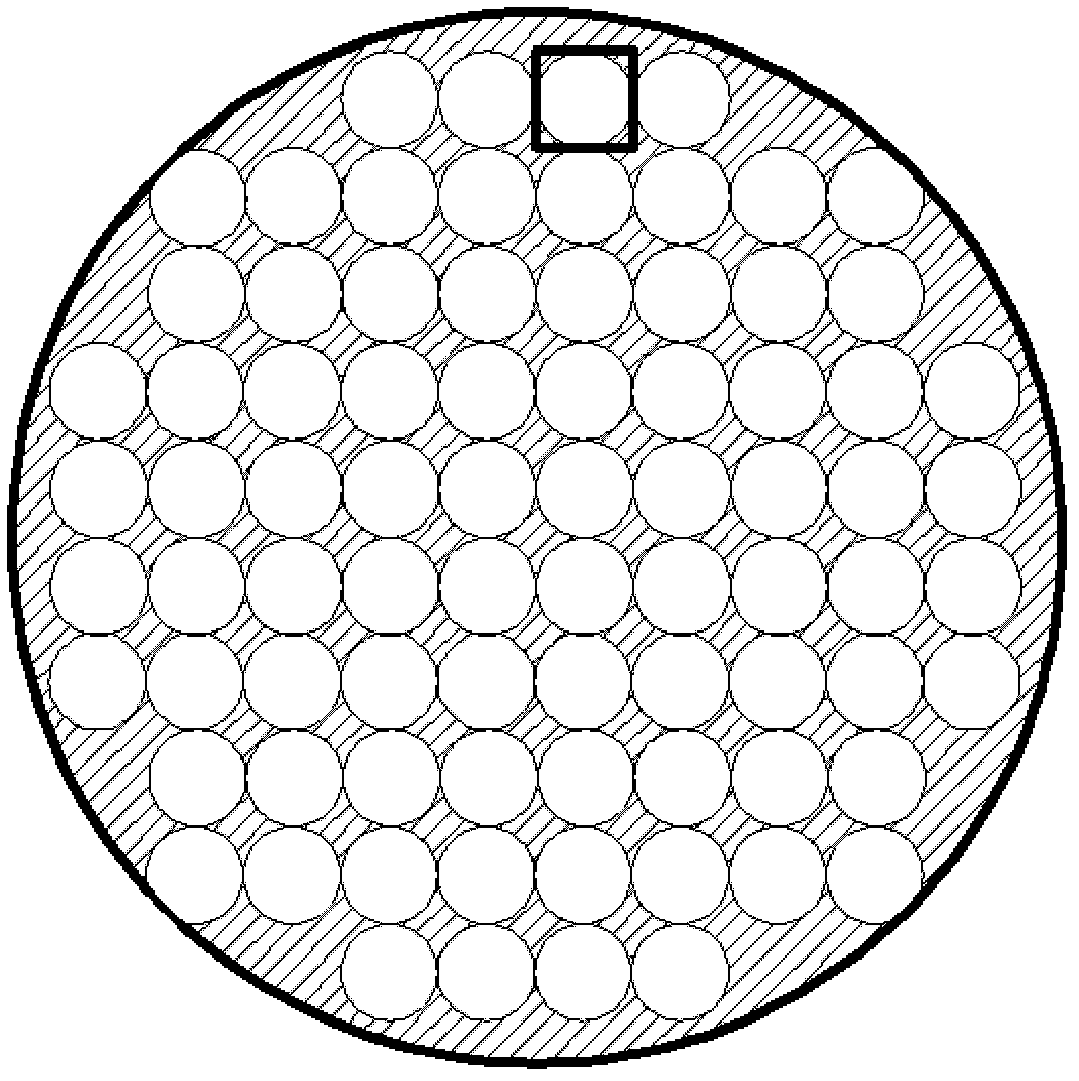

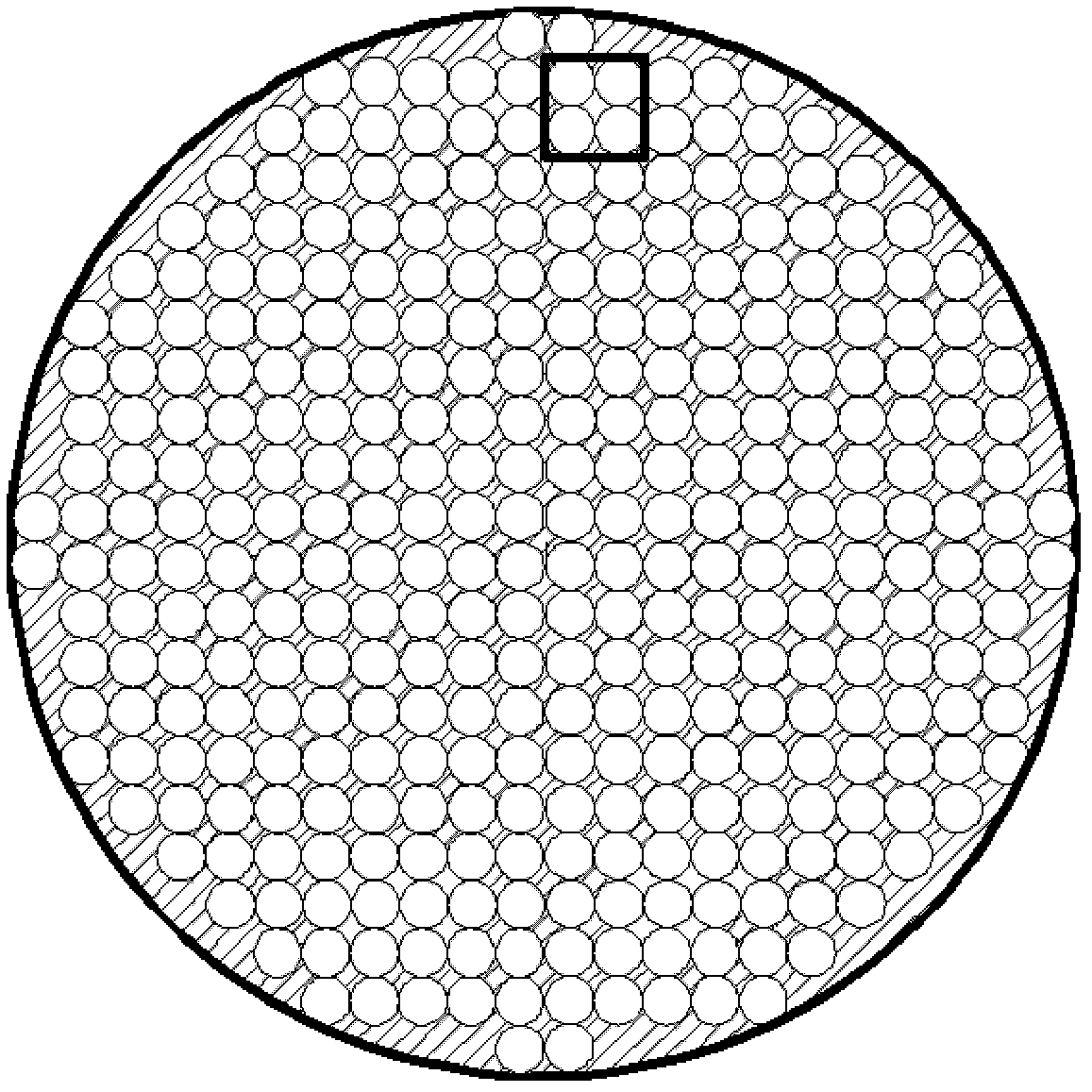

Magnetball distributing plate for fluidized bed

InactiveCN102631872ASimple and fast operationSolve uneven distributionChemical/physical processesFluidized bedEngineering

The invention provides a magnetball distributing plate for a fluidized bed, belonging to the technical field of a fluidized bed reactor. The device comprises a distributing plate which is formed by the means that magnetballs are regularly arranged on a support frame at the bottom of a reactor bed, the magnetballs are regularly and tightly arranged and are fully distributed on the support frame at the bottom of the reactor bed, and the magnetballs are distributed into monolayer or multilayer. The magnetic mutual attraction force between every two magnetballs is not less than 10N. Gas or liquid can be evenly and stably distributed after passing through the device, the magnetball distributing plate can be widely used in the technical fields such as gas-solid reaction, liquid-solid reaction, catalytic reaction and the like, and the problem that the gas can not be evenly distributed after passing through the distributing plate can be overcome. The regular magnetballs are taken as the distributing plate, so that the gas can be completely and evenly distributed after passing through the distributing plate, and the reaction time that the gas passes through a fluidized bed can be effectively controlled, therefore, the reaction efficiency can be improved, and the yield of the product can be improved.

Owner:BEIJING UNIV OF TECH

Vertical high-pressure grouting forming machine demolding process

ActiveCN106239712AEffective disengagementImprove quality pass rateDischarging arrangementMolding machineEngineering

The invention discloses a vertical high-pressure grouting forming machine demolding process. The vertical high-pressure grouting forming machine demolding process comprises the following steps that a bottom diemold is subject to diemold splitting, a middle diemold is subject to diemold splitting, a layer board is arranged to be in place, and demolding is carried out. In the demolding step, a PLC controls an outer-diemold pressurization hole of an upper diemold to be connected with an air compressor, an outer-diemold water and gas discharging hole of the upper diemold is closed at the same time, the air compressor blows compression air to the upper diemold through the outer-diemold pressurization hole of the upper diemold, and a water film is formed between the inner surface of the upper diemold and a blank; and the blank falls to the layer board due to the gravity of the layer board, the pressure of the compression air keeps to range from 0.01 Mpa to 0.2 Mpa, and the time lasts for 5 seconds to 15 seconds. By means of the above process, the process can adapt to grouting production of at least three diemolds distributed vertically, defects of the blank can be prevented from generating in the demoling process, the quality passing percentquality yield of the blank is improved, the demolding time can be further shortened, and the production efficiency is improved.

Owner:JOMOO KITCHEN & BATHROOM

Oxidation resistant protection method for ears of pole plate of accumulator

InactiveCN1917257AEliminate cleaning processImprove quality pass rateElectrode manufacturing processesElectrode carriers/collectorsGratingMicrocrystalline wax

A procedure for producing pole plate includes steps: first, preparing metal sheet grating; manufacturing raw pole plates from sheet gratings; being installed into accumulator, raw pole plates are as chemical energy source to be activated; painting a layer of protective agent on plate ear of sheet grating after sheet grating being heated to 15-100 within 24 hours after sheet grating being produced; temperature of the protective agent is controlled at 180-80 deg.C. Boiling point of the protective agent is higher than temperature in each step of producing raw pole plates, and is lower than temperature when flow weld or burnt together are carried out between plate ear and bus bar. The said protective agent is prepared by using vacuum residue of microcrystalline wax as raw material through following steps: propane deasphalting, furfural refining, acetone-benzene dewaxing and deoiling, additional treatment of clay. Features are: high production rate, and preventing lead pollution.

Owner:湖北雄韬电源科技有限公司

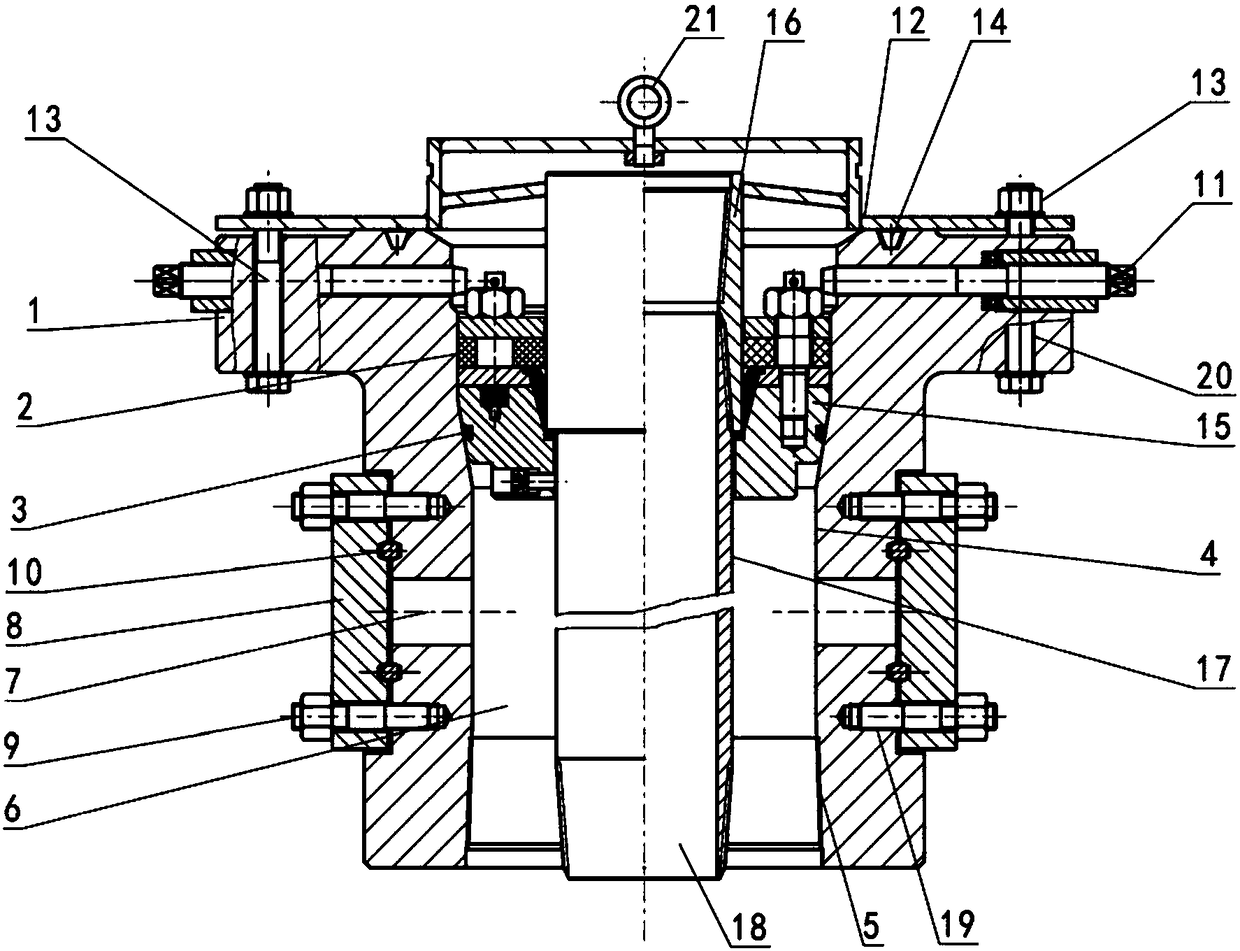

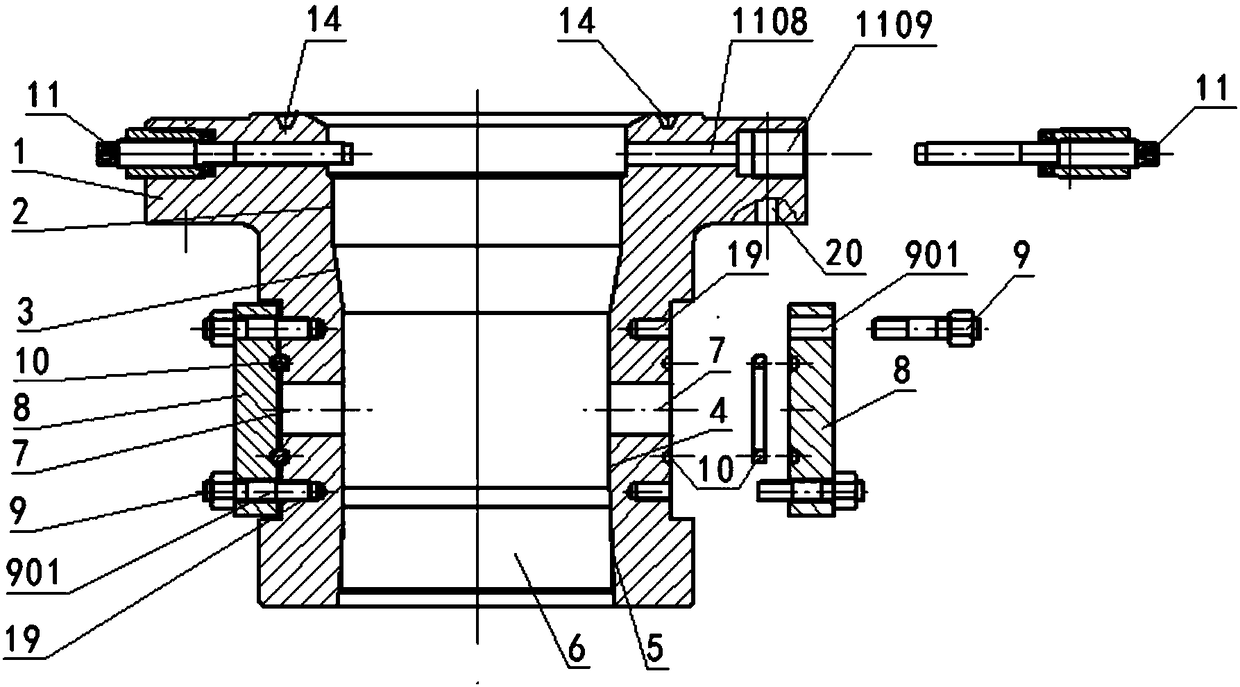

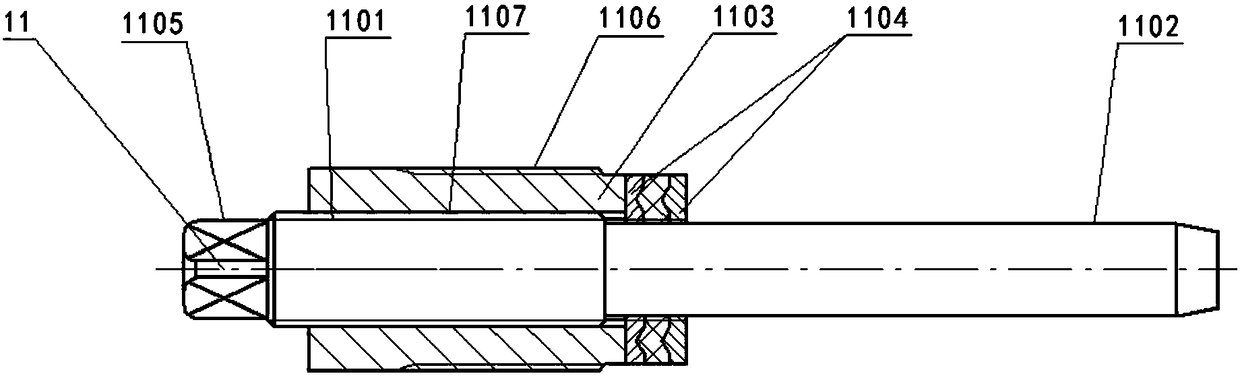

Well completion transformation casing head

ActiveCN108386154AReduce cutting phenomenonRelaxed operating environmentSealing/packingCouplingEngineering

The invention relates to a well completion transformation casing head. An overall structure of the casing head integrates the advantages of a mandrel casing head and a slip casing head. More transformation connecting, sealing and mounting structures and the like for a complicated completion wellhead are formed based on a coupling casing head structure; multiple connecting and mounting plans are predesigned according to possible wellhead complexity on site; for example, a casing coupling hanger in a coupling casing head is transformed into a casing body hanger with higher generality; for another example, the advantage of a BT sealing technology is integrated into a special transformation wellhead sealing flange; a composite sealing structure such as a special sealing element is derived; andfor another example, the transformation wellhead sealing flange and the special transformation wellhead sealing flange are applicable to common standard transformation structures such as a standard flange, non-standard double flanges, a non-standard welding flange and a non-standard threaded flange in a completion process.

Owner:CNPC BOHAI DRILLING ENG +1

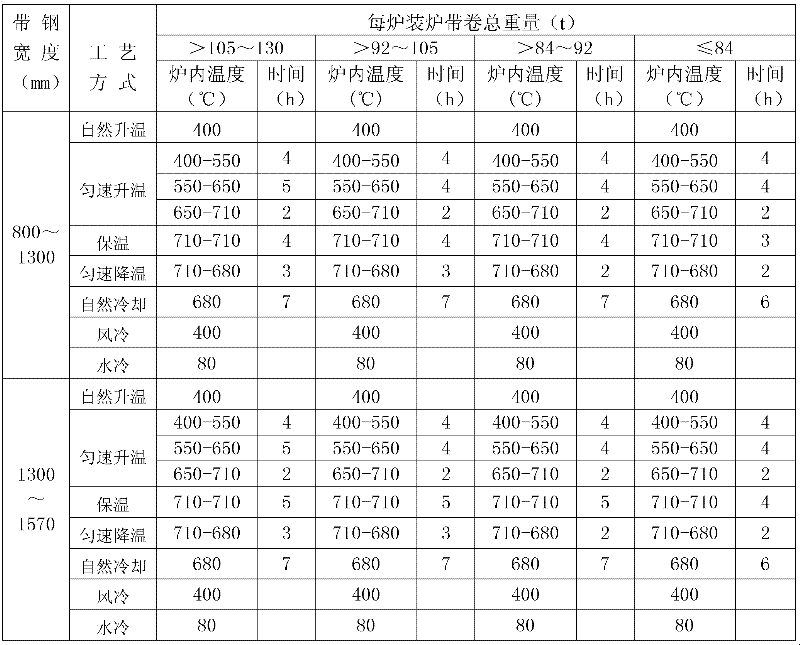

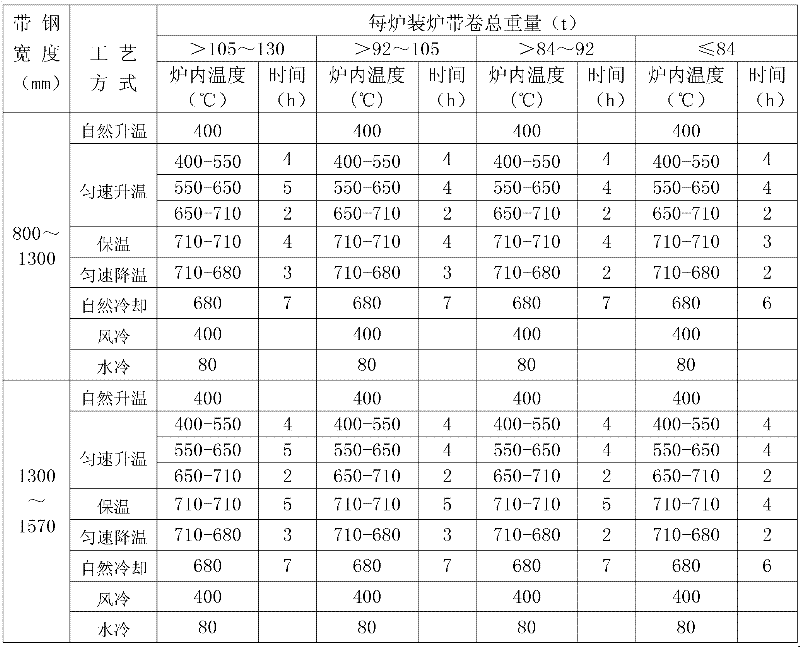

Method for eliminating low carbon steel cover annealing yield point elongation

InactiveCN102534186AReduce lossesHigh yieldHeat treatment process controlProcess efficiency improvementProcess systemsStrip steel

The invention provides a method for eliminating low carbon steel cover annealing yield point elongation. In the method, rational cover annealing process system and leveling elongation are specified and adopted, namely the wider the strip steel width, the larger the overall weight of strip coil filled in a furnace each time and the longer the annealing time; and the thicker the strip steel thickness, the higher the leveling elongation of the strip steel. Thus, the formation of the yield point elongation of steel is effectively controlled; the yield point elongation phenomenon occurring in low carbon steel cover annealing is eliminated; the quality qualification rate of the low carbon steel cold-rolled strip steel after cover annealing is increased from 90.04 percent to 97.95 percent; the amount of repeatedly leveled strip steel is greatly reduced; and the cost can be saved by 80 Yuan per ton. Meanwhile, the strip steel loss in a repeated leveling process is reduced; the yield of the strip steel is increased; the problem of slippage of the strip steel produced in a machining process of a user is avoided; and the service performance of the strip steel is guaranteed.

Owner:ANGANG STEEL CO LTD

Plug skeleton mould

InactiveCN103692616AImprove quality pass rateExtended service lifeCoatingsEngineeringMechanical engineering

Owner:WUHU SHUNCHENG ELECTRONICS

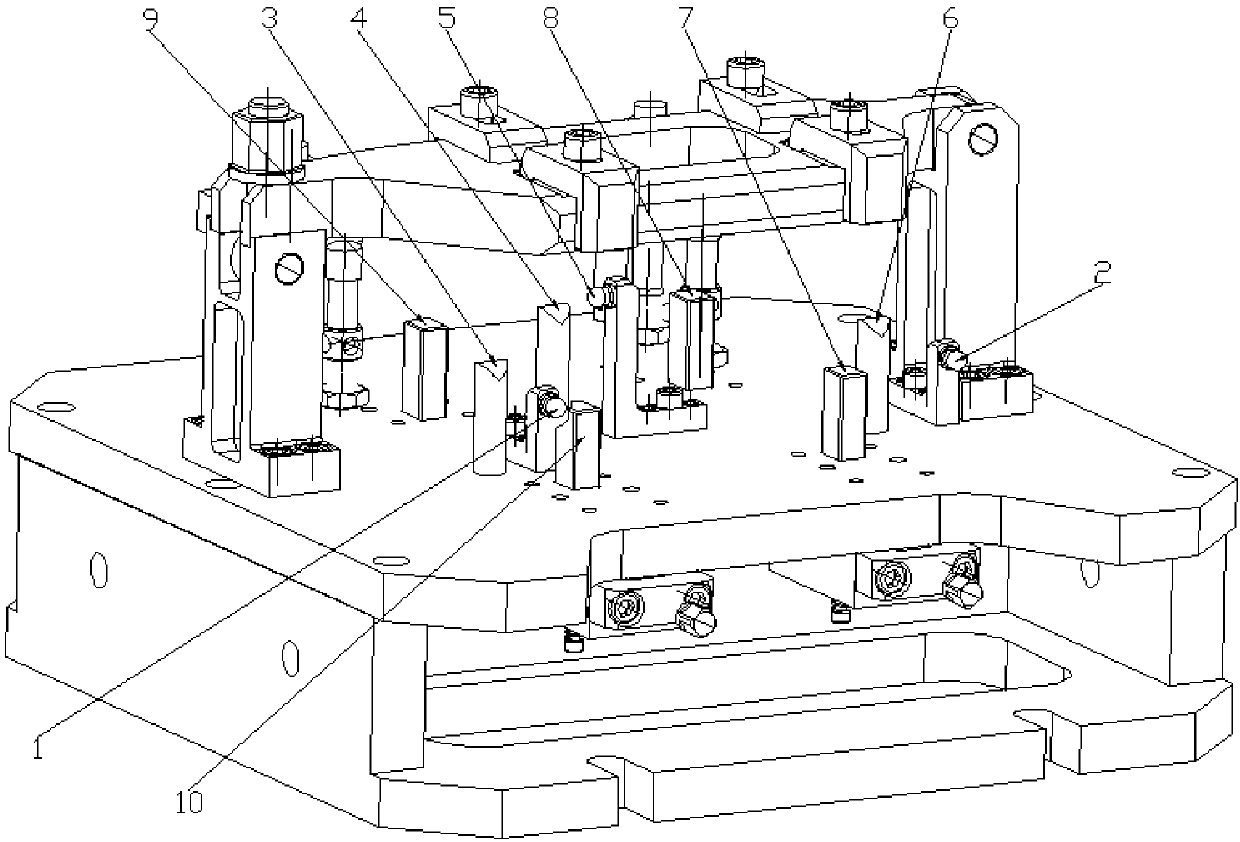

Tool for machining multiple guider blades of large gas turbine

ActiveCN107813162AQuick positioning installationEven by forceMilling equipment detailsPositioning apparatusMachine partsGas turbines

The invention discloses a tool for machining multiple guider blades of a large gas turbine. The tool comprises a tool base, and a positioning support mechanism and a pressing mechanism arranged on thetool base; the positioning support mechanism comprises a fixed positioning support mechanism and an auxiliary positioning support mechanism; and the pressing mechanism comprises a blade body pressingmechanism and a small end flange plate auxiliary pressing mechanism. Through cooperation between each support mechanism and the pressing mechanism, the quick installation and positioning of multiplexguider blade parts of the large gas turbine can be realized; the positioning stability of the machined parts is improved; the bruise of the parts is effectively prevented; and the machining quality of the parts is guaranteed.

Owner:AECC AERO SCI & TECH CO LTD

A kind of dephosphorization method in if steel ladle

The invention provides a dephosphorization method in the IF ladle. After the molten steel reaches the ladle refining furnace, that is, the LF refining position, a certain amount of lime is added to the ladle in 2 to 3 batches; After that, carry out argon blowing operation with large argon gas flow rate in the ladle. The present invention utilizes the principles of thermodynamics and kinetics respectively to realize the dephosphorization treatment of IF steel in molten steel tank during LF refining process, and the implementation effect is remarkable, which can improve the control level of phosphorus in IF steel and reduce the phosphorus content in molten steel by 50%. The above ensures that the phosphorus content reaches the standard, reduces the probability of steel modification caused by excessive phosphorus content in molten steel, improves the quality pass rate of steel, and avoids economic losses caused by steel modification.

Owner:ANGANG STEEL CO LTD

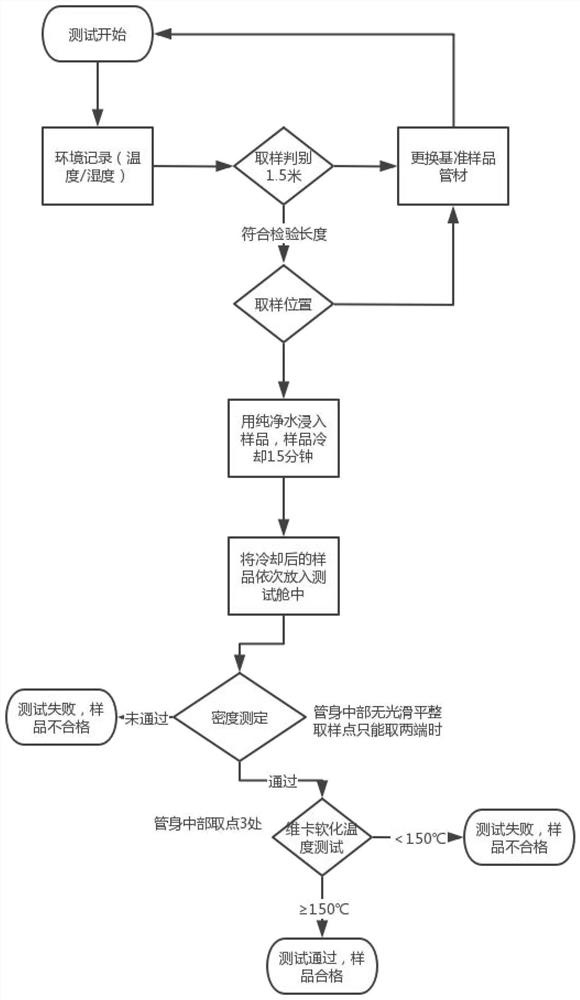

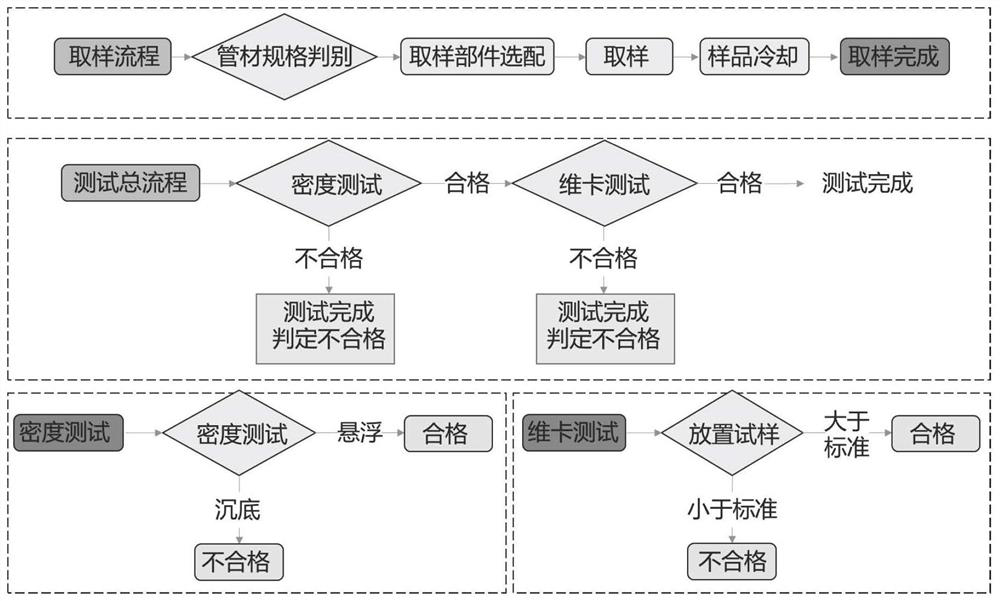

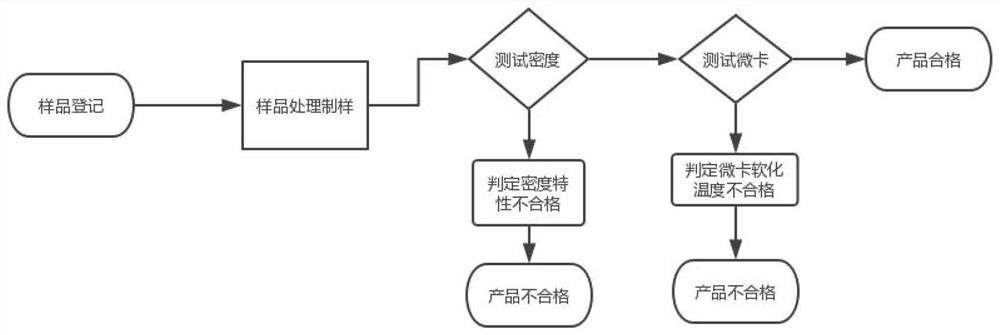

Inspection and test method for modified polypropylene plastic cable protection pipe

ActiveCN112540027AAvoid unqualified factorsImprove quality pass rateInvestigating phase/state changeSpecific gravity measurementStructural engineeringPolypropylene

The invention discloses an inspection and test method for a modified polypropylene plastic cable protection pipe. The inspection and test method comprises the following steps: 1) preparing inspectionpretreatment; 2) sampling the reasonable position of a modified polypropylene cable protection pipe; 3) testing an inspection reagent; 4) carrying out Vicat softening performance test; 5) judging an inspection result: judging that a test part is qualified when an upper limit solution of detection reagent samples is suspended and a lower limit solution of the samples is settled, otherwise, judgingthat the test part is unqualified; if the Vicat softening test temperature is more than 150 DEG C, judging that the sample is qualified, otherwise, judging that the sample is unqualified; and judgingthat the whole section of the inspection pipe is unqualified if unqualified samples appear. By means of the field density testing method, the mass density characteristics of related samples of the cable protection pipe can be accurately tested and evaluated, pre-detection is achieved, and the quality safety rate and the parameter qualification rate of products are increased.

Owner:JIANGSU ELECTRIC POWER CO +1

Production method for realizing continuous casting with low superheat degree

InactiveCN111715858AAutomatic adjustment of feeding speedSolve the problem of large changes in pouring superheatMetallurgyEquiaxed crystals

The invention belongs to the technical field of steelmaking and continuous casting, and specifically relates to a production method for realizing continuous casting with a low superheat degree. Moltensteel is cleanly smelted and cast in a tundish and a continuous casting machine, the temperature is reduced by adding a cold steel wire in the tundish, so that the superheat degree of the molten steel is stably controlled between 5 DEG C and 15 DEG C, the low magnification class C qualification rate of a continuous casting blank obtained reaches 80% or above, the equiaxed crystal area is expandedto 30-60%, and the columnar crystal area is reduced to 70% or below. The problem of large change in the pouring superheat degree between a furnace and a furnace caused by the unstable production rhythm of molten steel in the traditional process, the fluctuation of a pouring temperature and other factors is solved, stable low superheat degree pouring is achieved, and the stability of continuous casting pulling rate is ensured; and the production method for realizing continuous casting with the low superheat degree has obvious effects on improving the low-magnification quality of the continuouscasting blank, reducing the central segregation of the continuous casting blank in the thickness direction, and expanding the equiaxed crystal ratio of the continuous casting blank, especially for the low-magnification structure improvement of the extra-thick continuous casting blank of 300mm or above.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Tailstock device for machine tool

InactiveCN104999097ANo changeImprove stabilityTailstocks/centresWork clamping meansMachining processMachine tool

The invention discloses a tailstock device for a machine tool. The tailstock device comprises a base assembly and a clamping assembly, wherein the clamping assembly comprises a first clamping block, a second clamping block and a locking assembly; the right side of the first clamping block is a first arc; the left side of the second clamping block is a second arc; the diameter of the second arc equals to that of the first arc; the locking assembly comprises a first locking assembly and a second locking assembly, the first locking assembly is used for locking the sliding position of the first clamping block relative to the base, and the second locking assembly is used for locking the sliding position of the second clamping block relative to the base. The fixing of a workpiece belongs to surface contact of which the fixing firmness and stability are higher than those of point contact fixing. Meanwhile, in the machining process of the machine tool, the variation of the workpiece position cannot be caused by the accidental contact of the workpiece, and the quality qualified rate of products is effectively improved.

Owner:德清县南洋机械配件厂

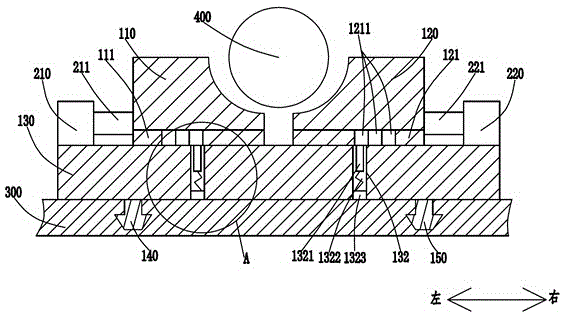

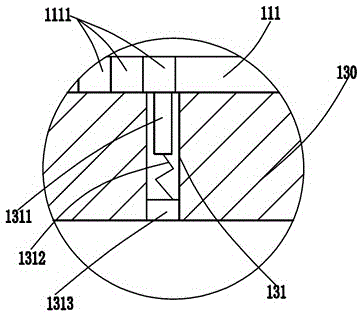

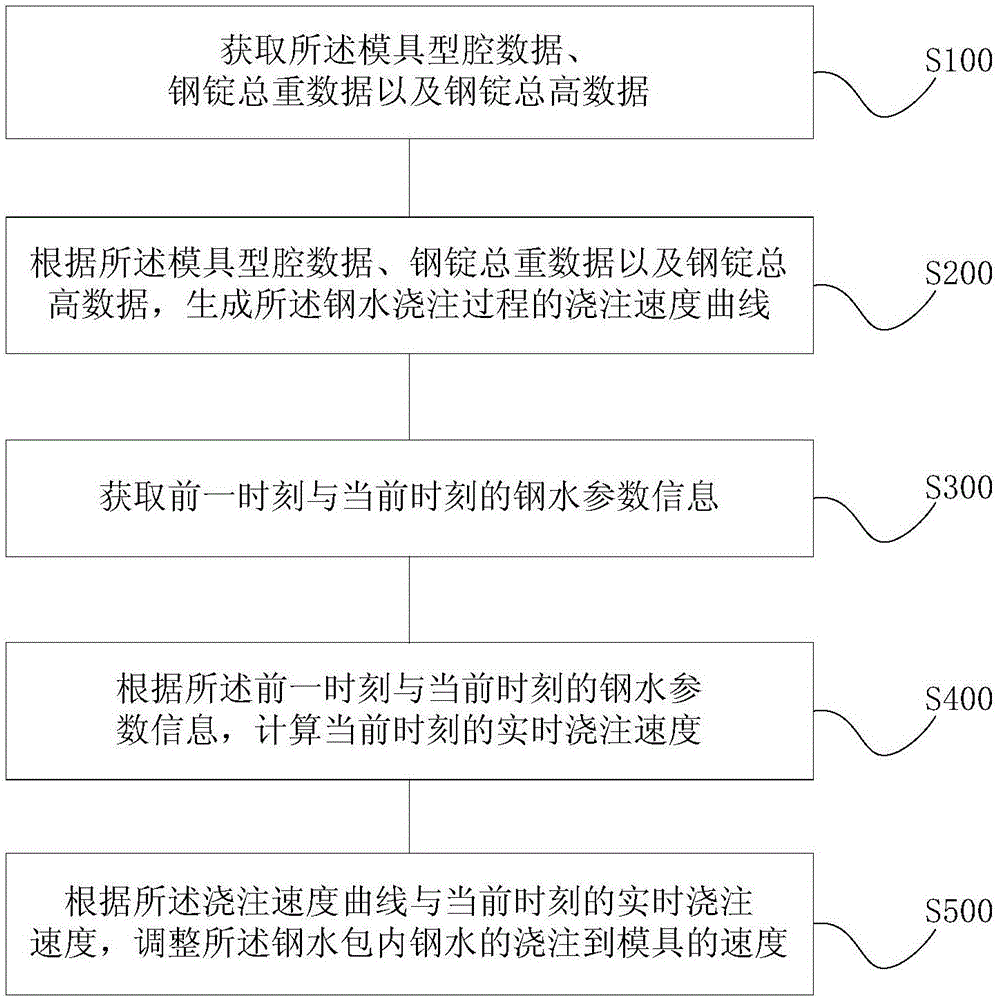

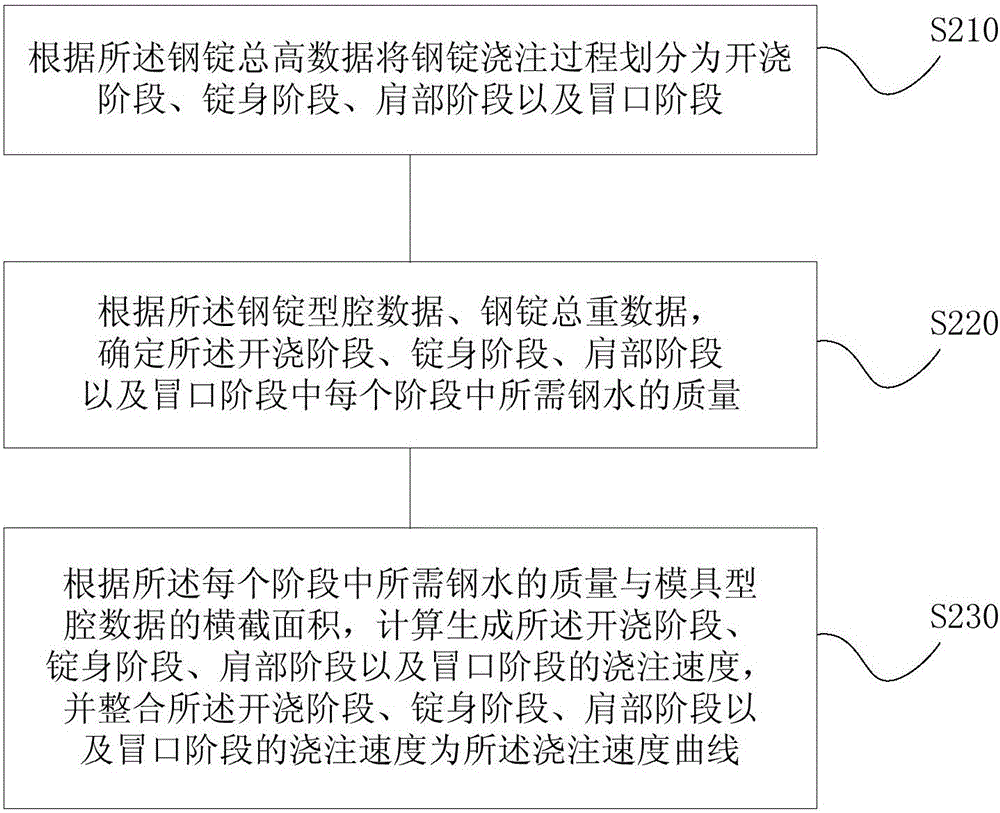

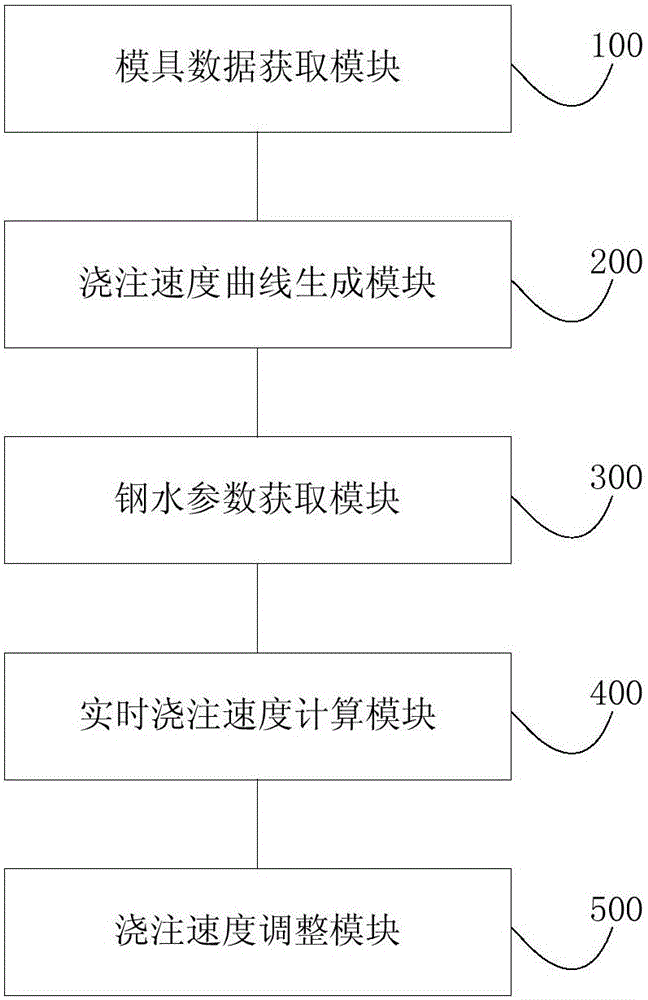

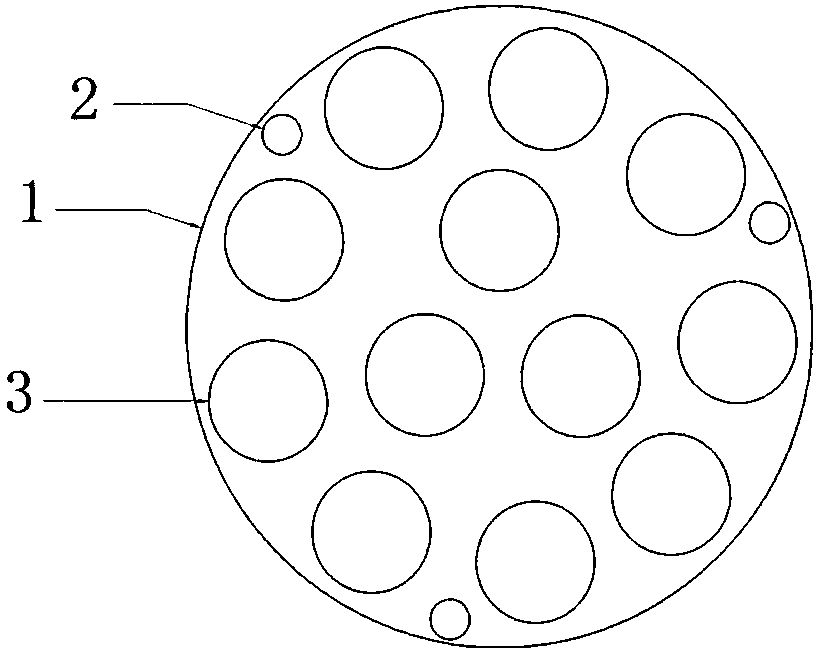

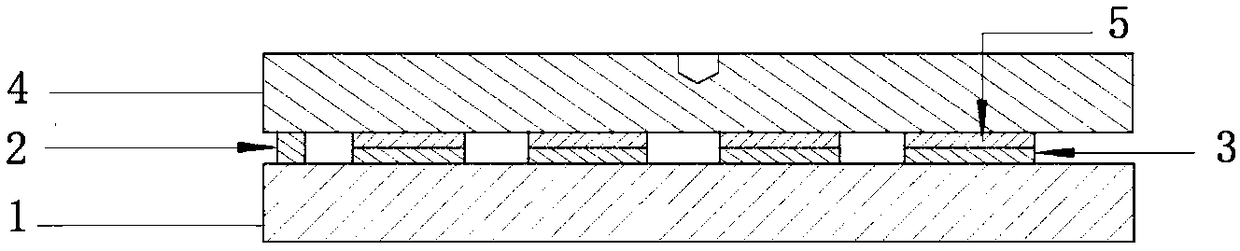

Control method and device of molten steel pouring

ActiveCN106694863AGuaranteed stabilityGuaranteed accuracyMolten metal pouring equipmentsMetallurgyInstability

The invention relates to a control method and device of molten steel pouring. The method comprises: acquiring data of a mold cavity, total weight data of a steel ingot and total height data of the steel ingot; acquiring a pouring speed curve of a molten steel pouring process according to the data of the mold cavity, the total weight data of the steel ingot and the total height data of the steel ingot; acquiring molten steel parameter information at the former moment and molten steel parameter information at the current moment; calculating the real-time pouring speed at the current moment according to the molten steel parameter information at the former moment and molten steel parameter information at the current moment; and regulating the speed for pouring the molten steel in a steel ladle onto a mold according to the pouring speed curve and the real-time pouring speed at the current moment. By using the control method and device of molten steel pouring, disclosed by the invention, the problems of randomness and instability of production carried out completely by virtue of experience of pouring workers in the steel ingot pouring process are solved, the repeatability and stability of production operation can be realized, the stability and accuracy of molten steel rise in the steel ingot pouring process can be guaranteed, and a guarantee is provided for the precise regulation in the molten steel pouring process.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Method for disc loading of optical thin sheet devices

InactiveCN108068007AOvercoming surface unevennessOmit blank thicknessLapping machinesEngineeringHeat stress

The invention provides a method for disc loading of optical thin sheet devices. A ground glass slab with small flatness errors is used as a standard used before disc loading of the optical thin sheetdevices, the upper surfaces of the multiple fixed optical thin sheet devices are located on one plane, the problem that the surfaces of the optical thin sheet devices are uneven is solved, the follow-up grinding time is shortened, and the follow-up grinding difficulty is reduced. In addition, as the upper surfaces of the multiple fixed optical thin sheet devices are on one plane, the workblank thickness, increased by the uneven upper surfaces of the multiple fixed optical thin sheet devices, of the optical thin sheet devices is saved, and raw material cost is saved. Meanwhile, low-melting-point hot melt adhesive is used in the method, the heat stress of the optical thin sheet devices and the contractility of a bonding material are reduced, deformation of the optical thin sheet devices after machining and unloading is reduced, and the machining quality and the product yield are improved.

Owner:XUZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com