Patents

Literature

163results about How to "Effective disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

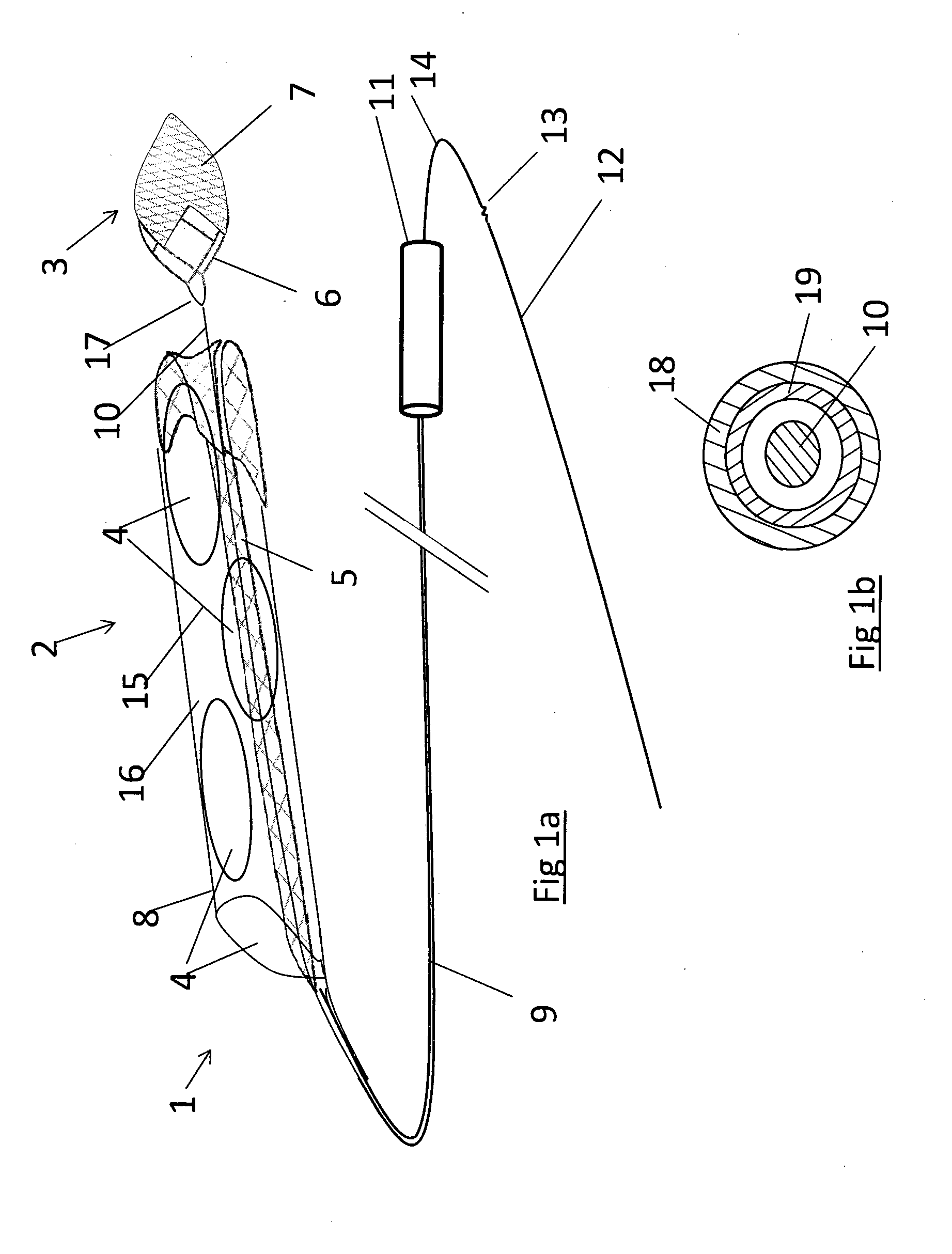

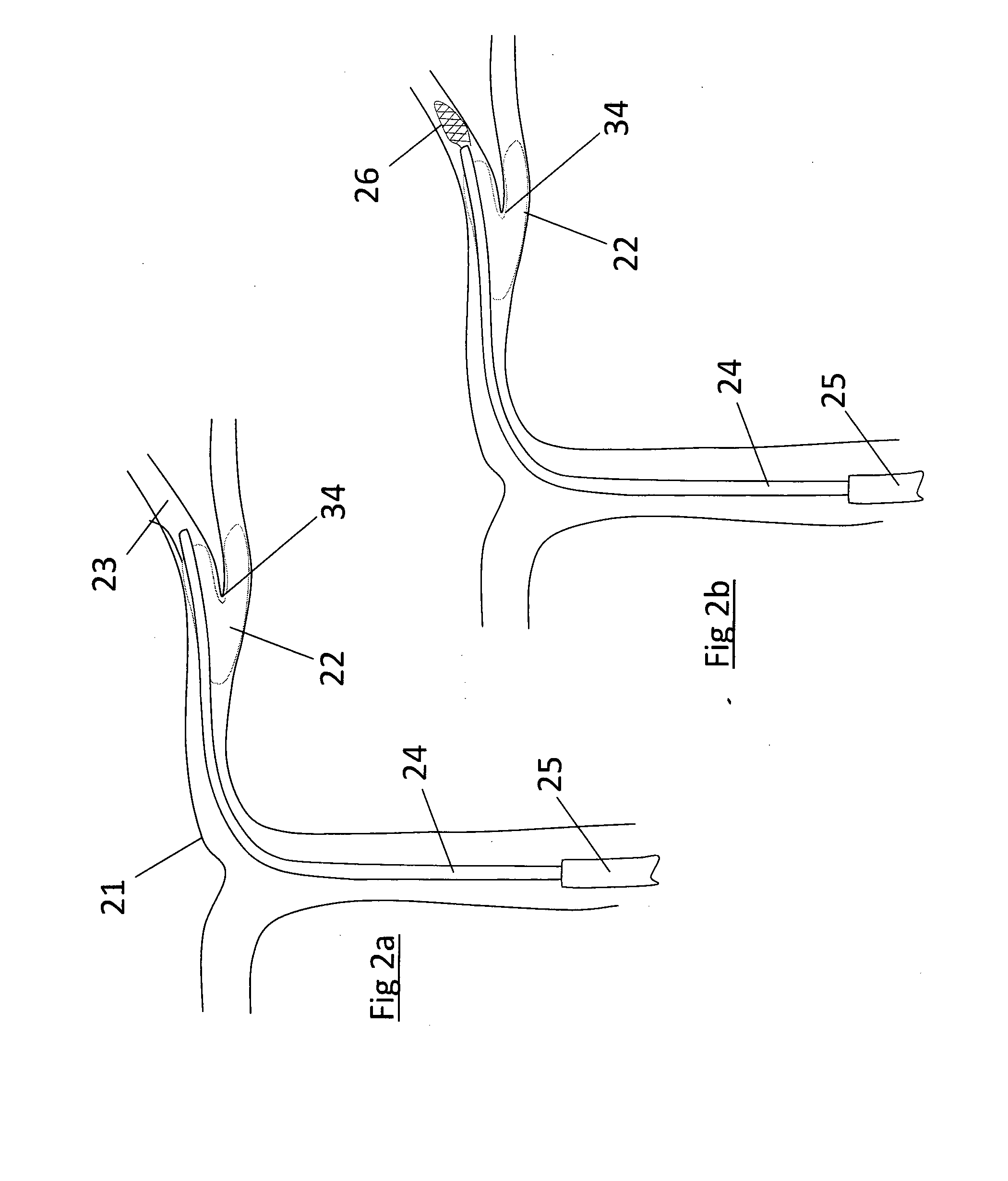

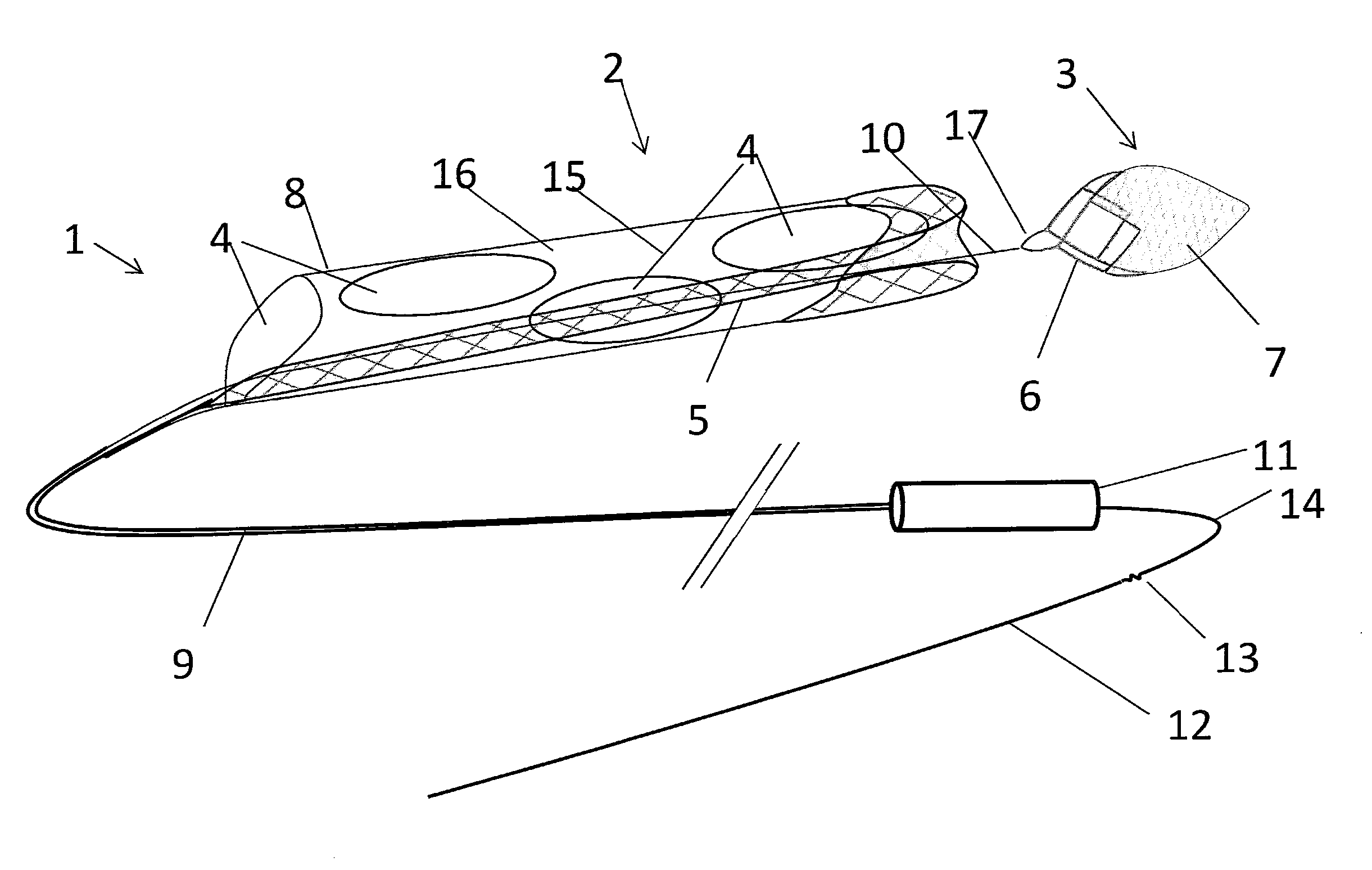

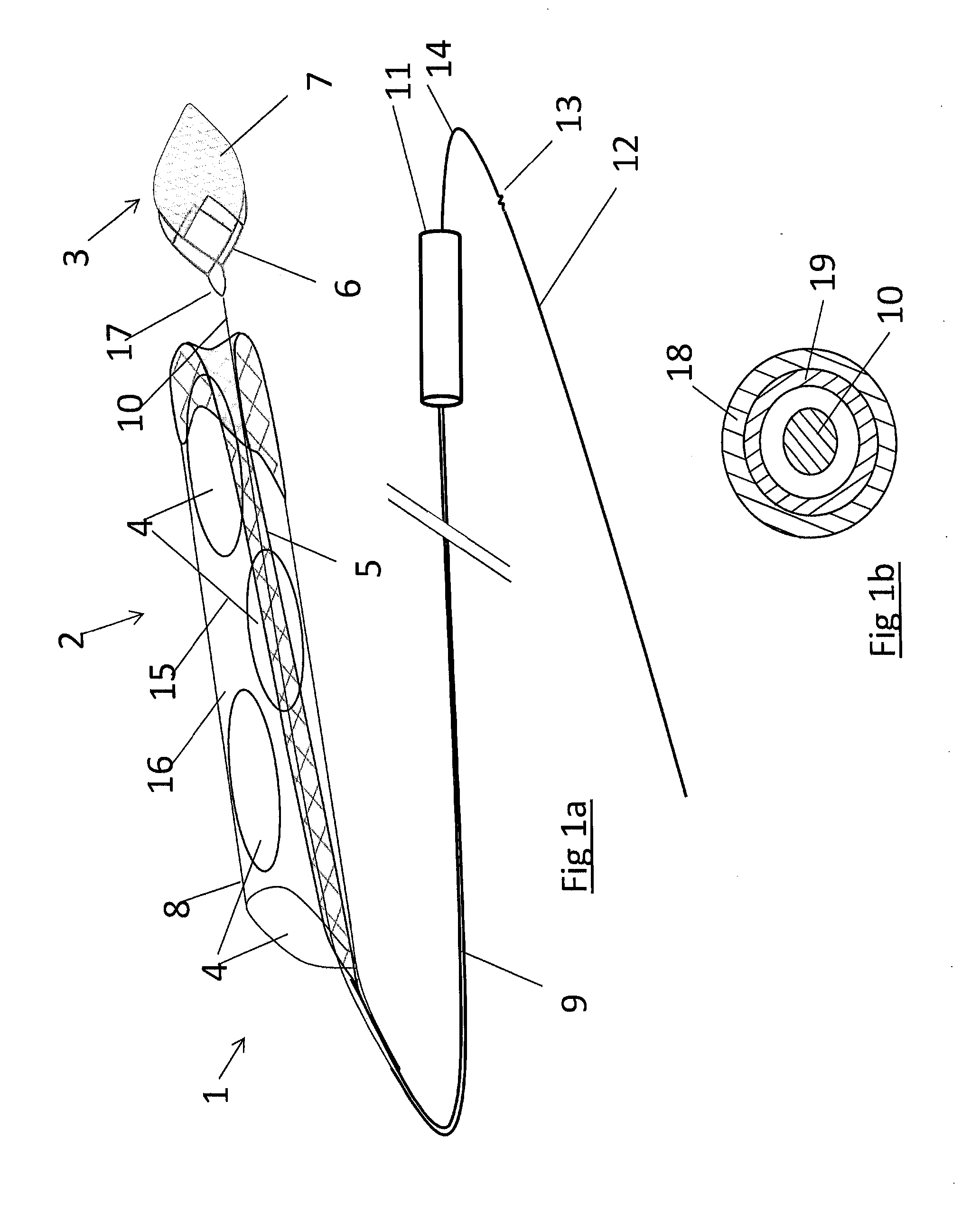

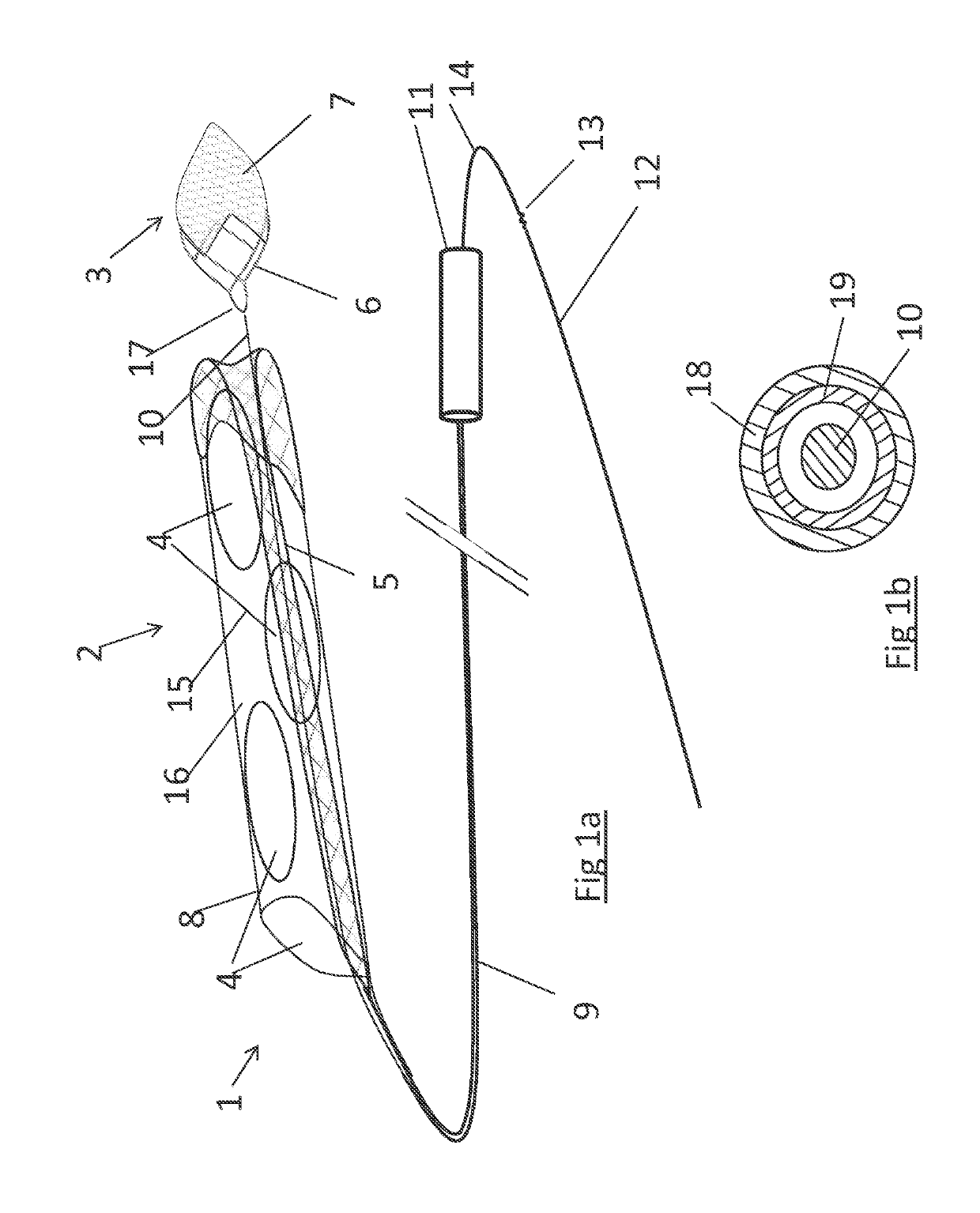

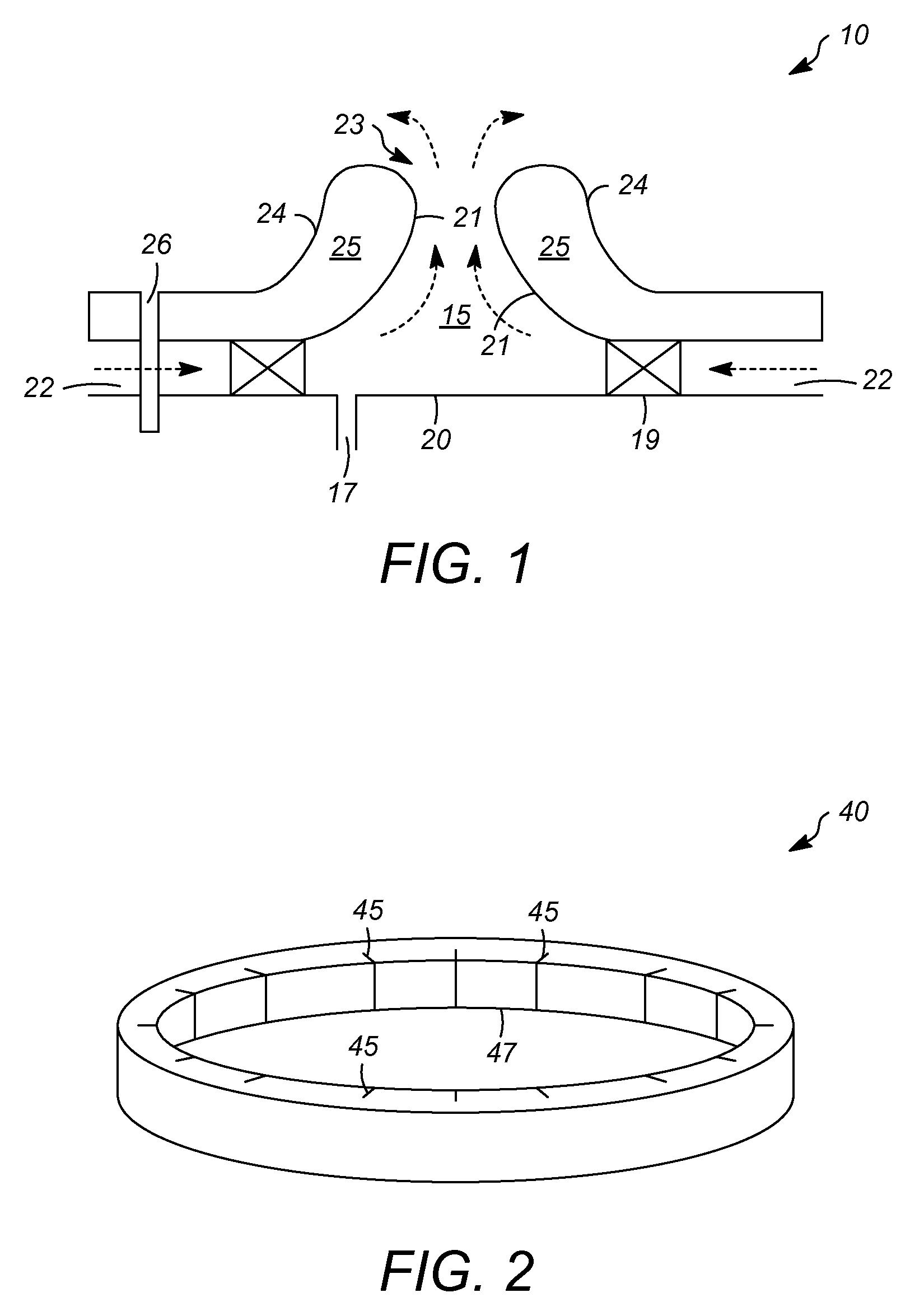

Clot retrieval device for removing occlusive clot from a blood vessel

ActiveUS20130345739A1Facilitate blood flowFacilitate flowDilatorsExcision instrumentsBlood vesselStent

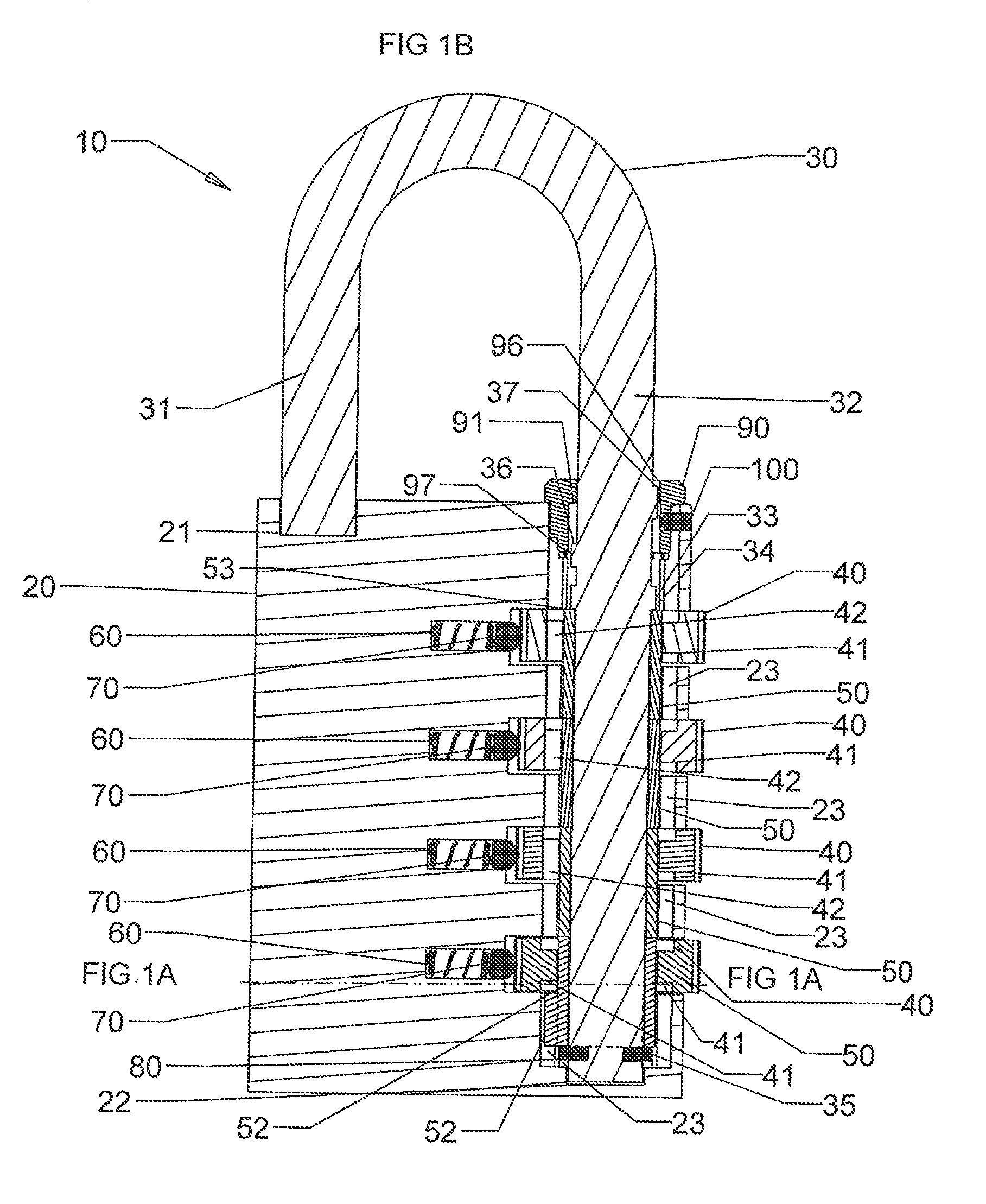

A clot retrieval device (9501) for removing occlusive clot from a blood vessel comprises an inner elongate body (9503) and an outer elongate body (9504) at least partially overlying the inner elongate body (9503). The device also comprises an elongate member or shaft (9502) having a proximal end which extends exterior of a patient so that a user can retrieve the stent-basket device and captured clot by retracting the shaft (9502). The outer elongate body (9504) and the inner elongate body (9503) are connected to the distal end of the shaft (9502) and are expandable relative to the shaft (9502) from a collapsed delivery configuration to an expanded deployed configuration. The outer elongate body (9504) is expandable relative to the inner elongate body (9503) to a radial extent which is greater than the radial extent of the inner body (9503) in the deployed configuration.

Owner:NEURAVI

Clot retrieval device for removing occlusive clot from a blood vessel

ActiveUS20140200608A1Reducing device contact forceEffective disengagementDilatorsExcision instrumentsBlood vesselBuilding construction

A clot retrieval device (9501) for removing occlusive clot from a blood vessel comprises an inner elongate body (9503) and an outer elongate body (9504) at least partially overlying the inner elongate body (9503). The device also comprises an elongate member or shaft (9502) having a proximal end which extends exterior of a patient so that a user can retrieve the stent-basket device and captured clot by retracting the shaft (9502). The outer elongate body (9504) and the inner elongate body (9503) are connected to the distal end of the shaft (9502) and are expandable relative to the shaft (9502) from a collapsed delivery configuration to an expanded deployed configuration. The outer elongate body (9504) is expandable relative to the inner elongate body (9503) to a radial extent which is greater than the radial extent of the inner body (9503) in the deployed configuration. The stent-basket construction of the device creates a reception space (9507) between the inner (9503) and outer (9504) to receive the target clot. The outer body (9504) is configured to allow as much as possible of the clot to migrate through it into the internal reception space (9507). Housing the clot in this reception space rather than pinning it to the wall of the vessel means that the clot is under less compression and can thus be retracted at a lower force. The inner elongate body (9503) and a distal capture net (9505) protect the distal vascular bed from embolisation.

Owner:NEURAVI

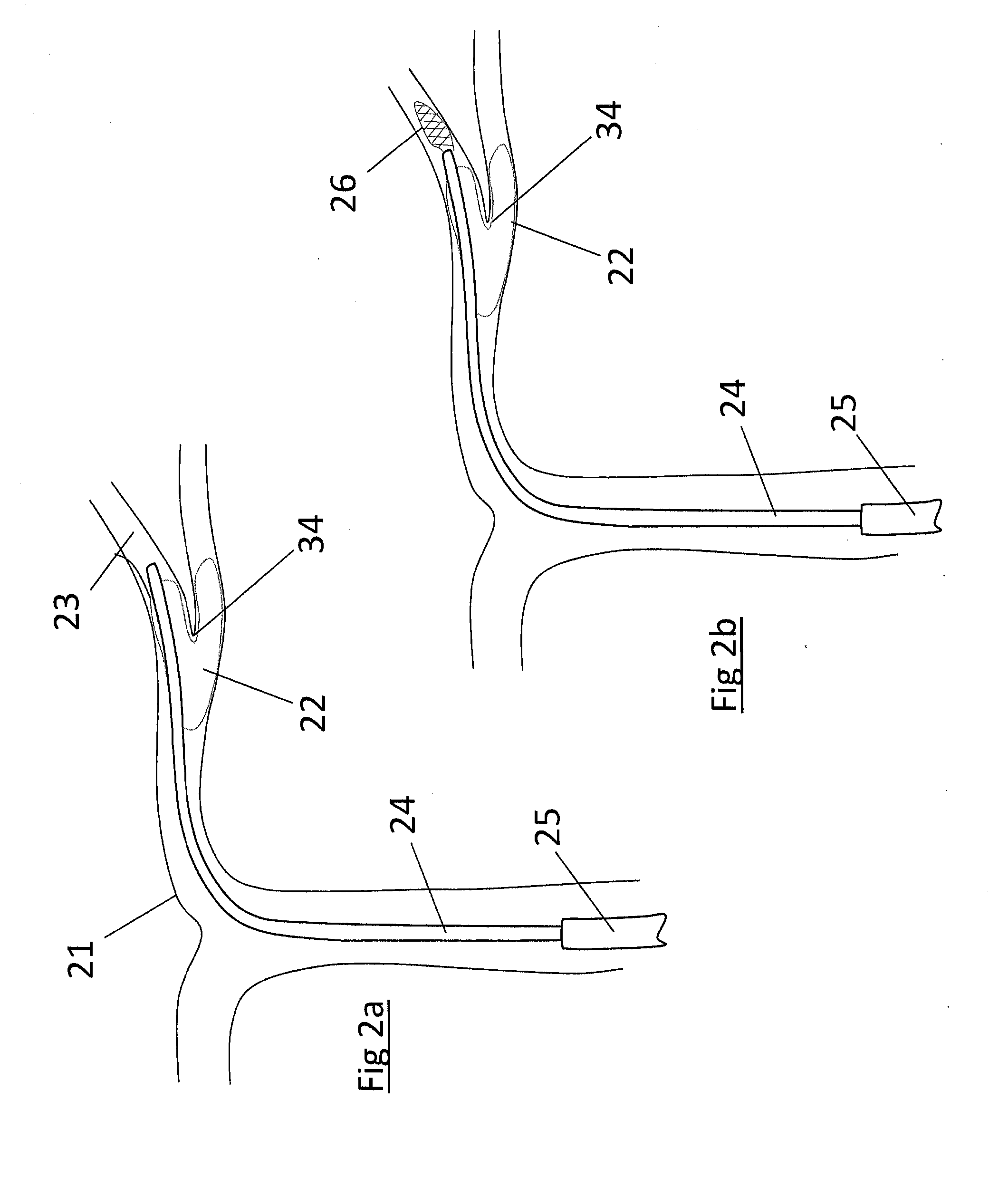

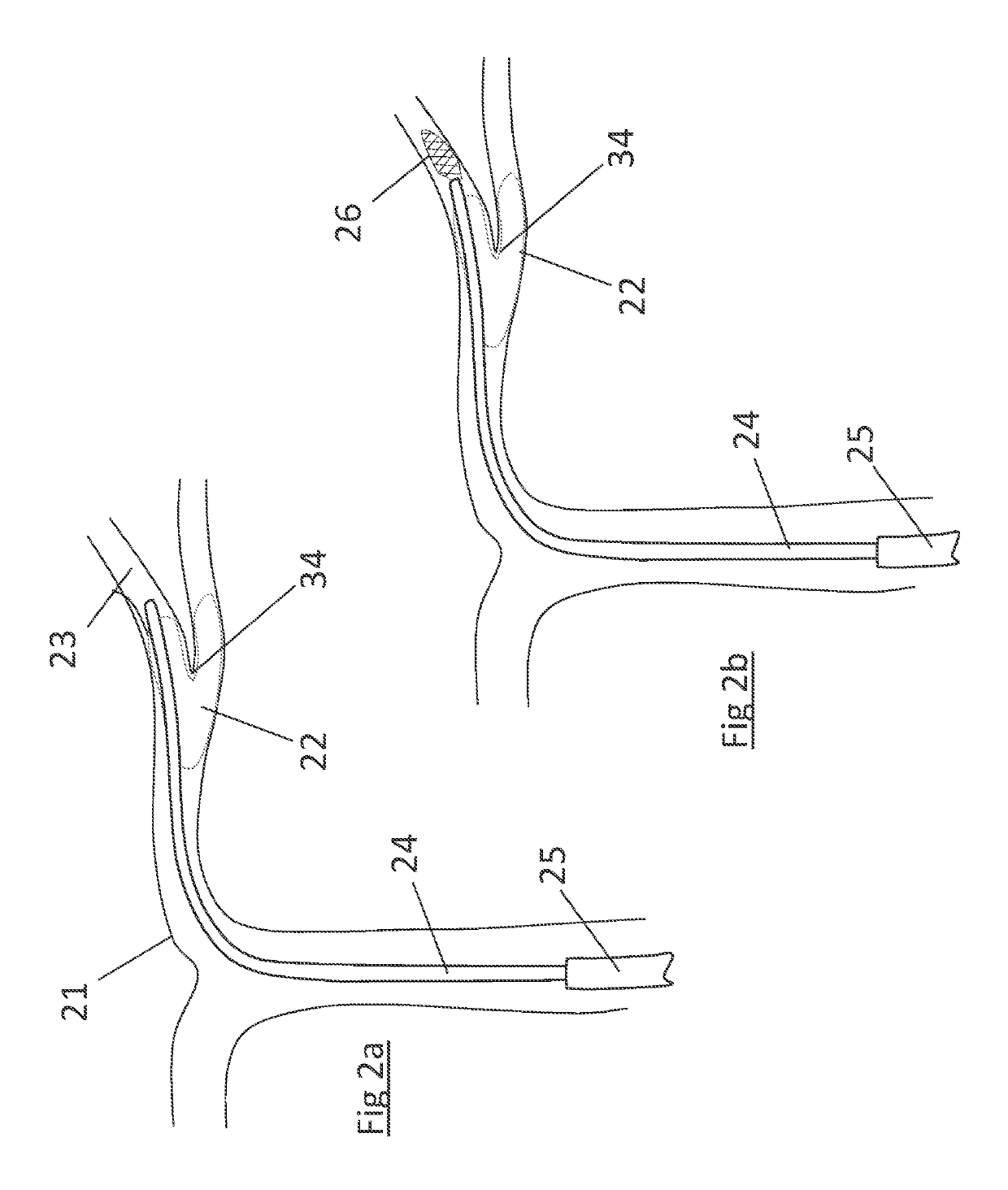

Clot retrieval device for removing clot from a blood vessel

ActiveUS20190239907A1Easy accessEasy to moveExcision instrumentsBlood vessel filtersSurgeryBlood vessel

Owner:NEURAVI

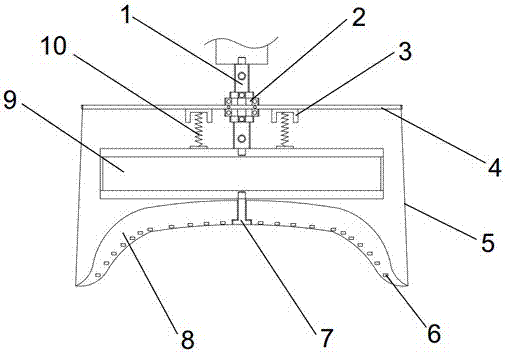

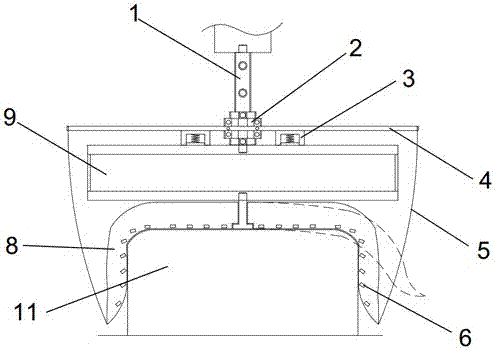

Cleat Spike Insole

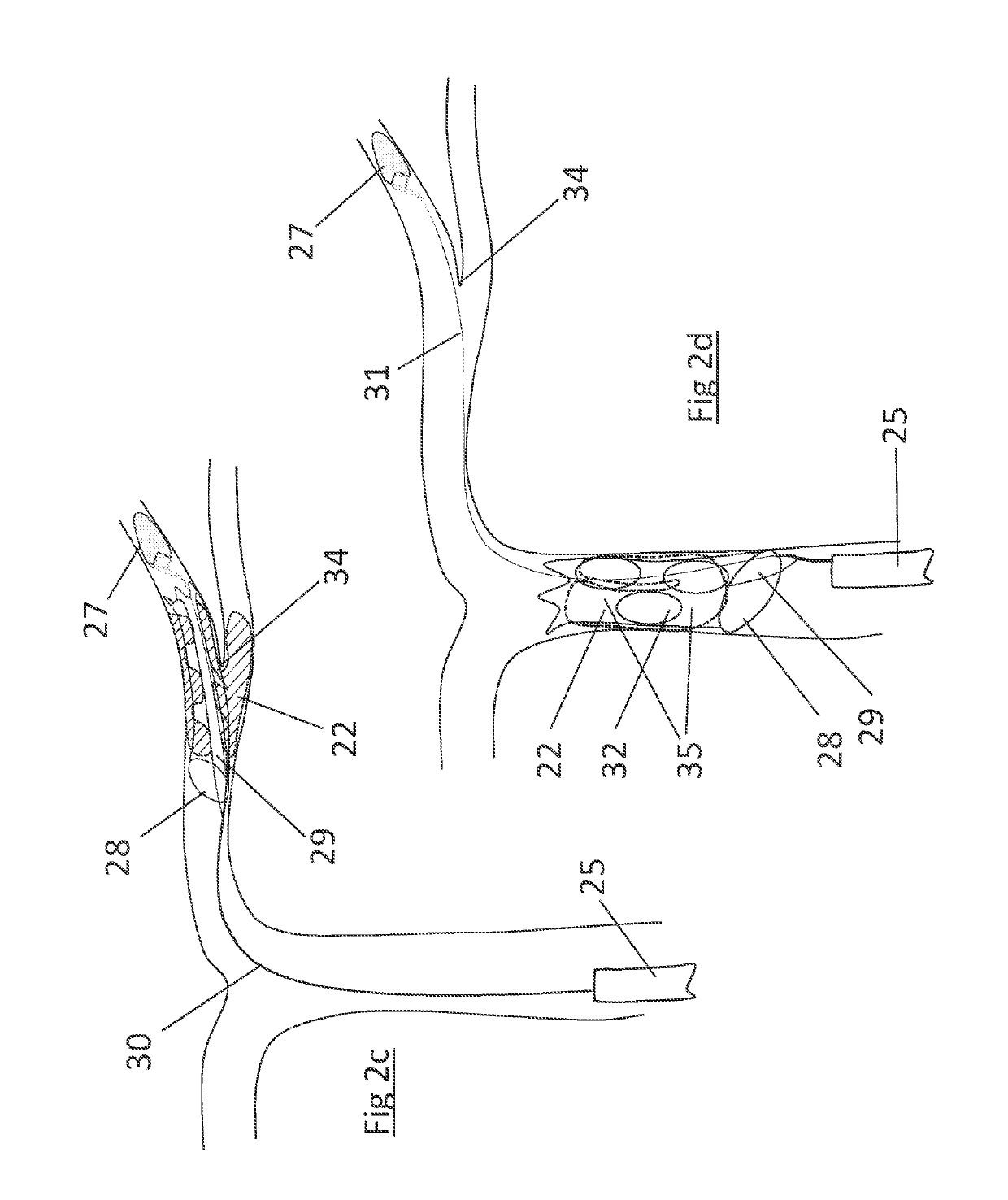

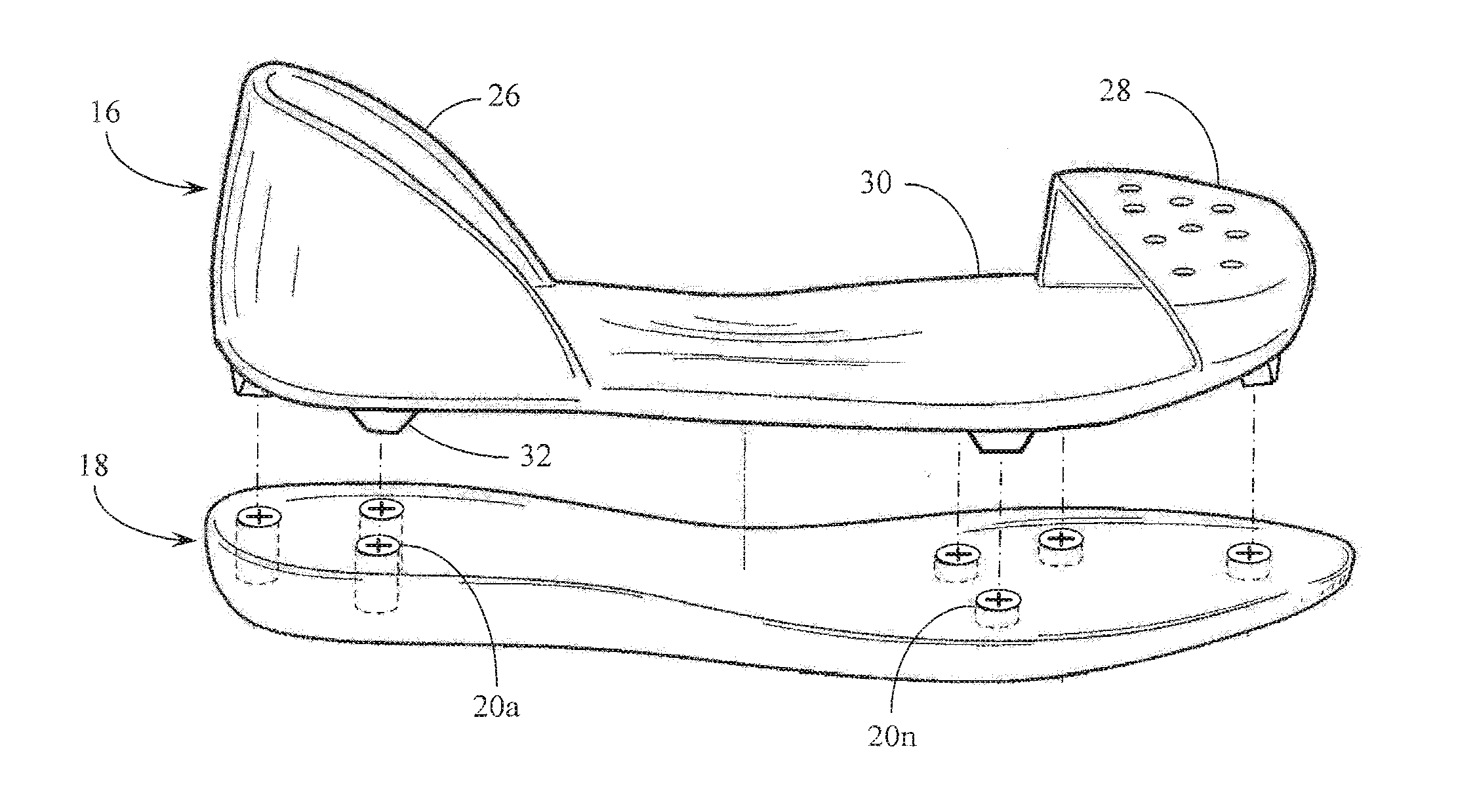

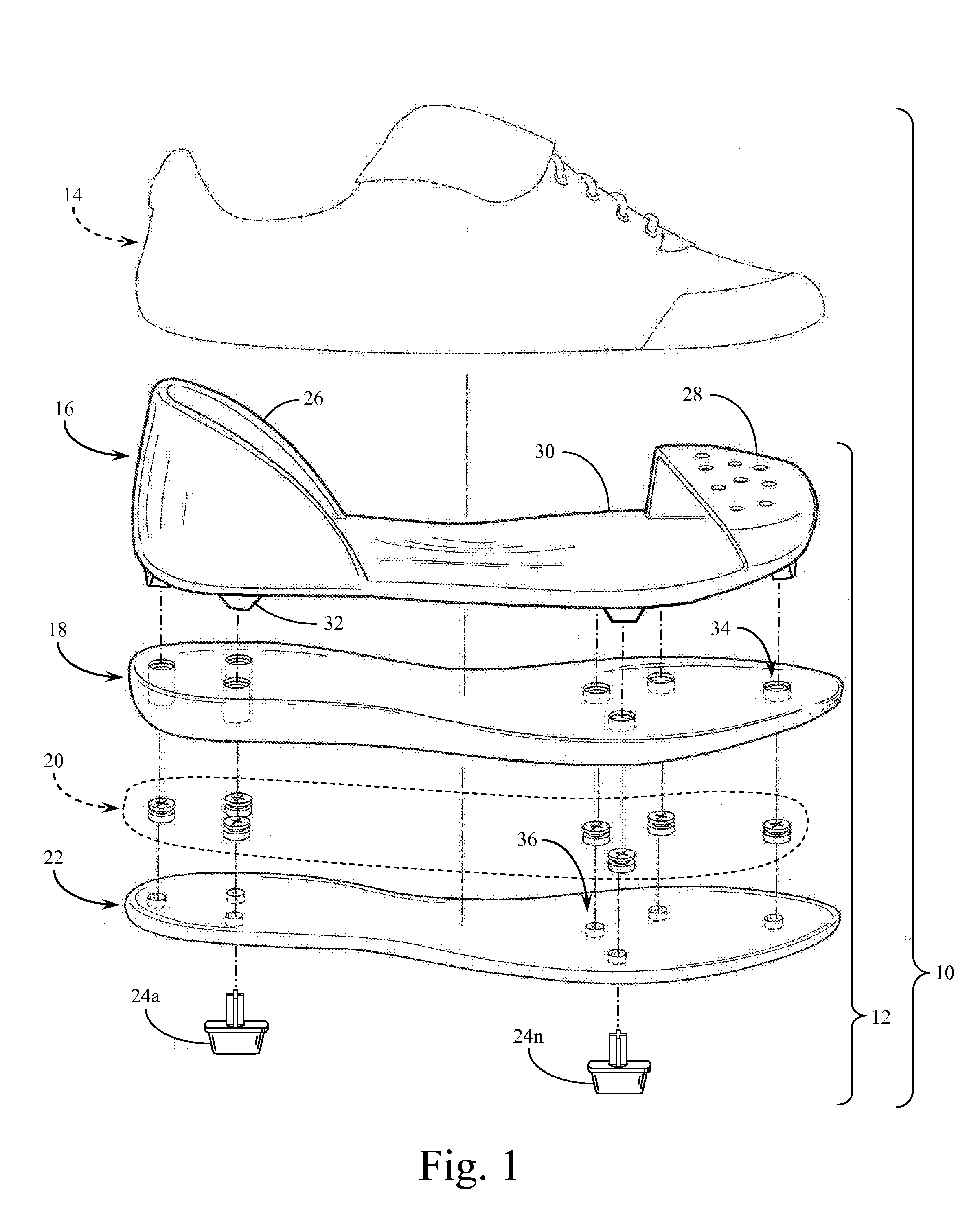

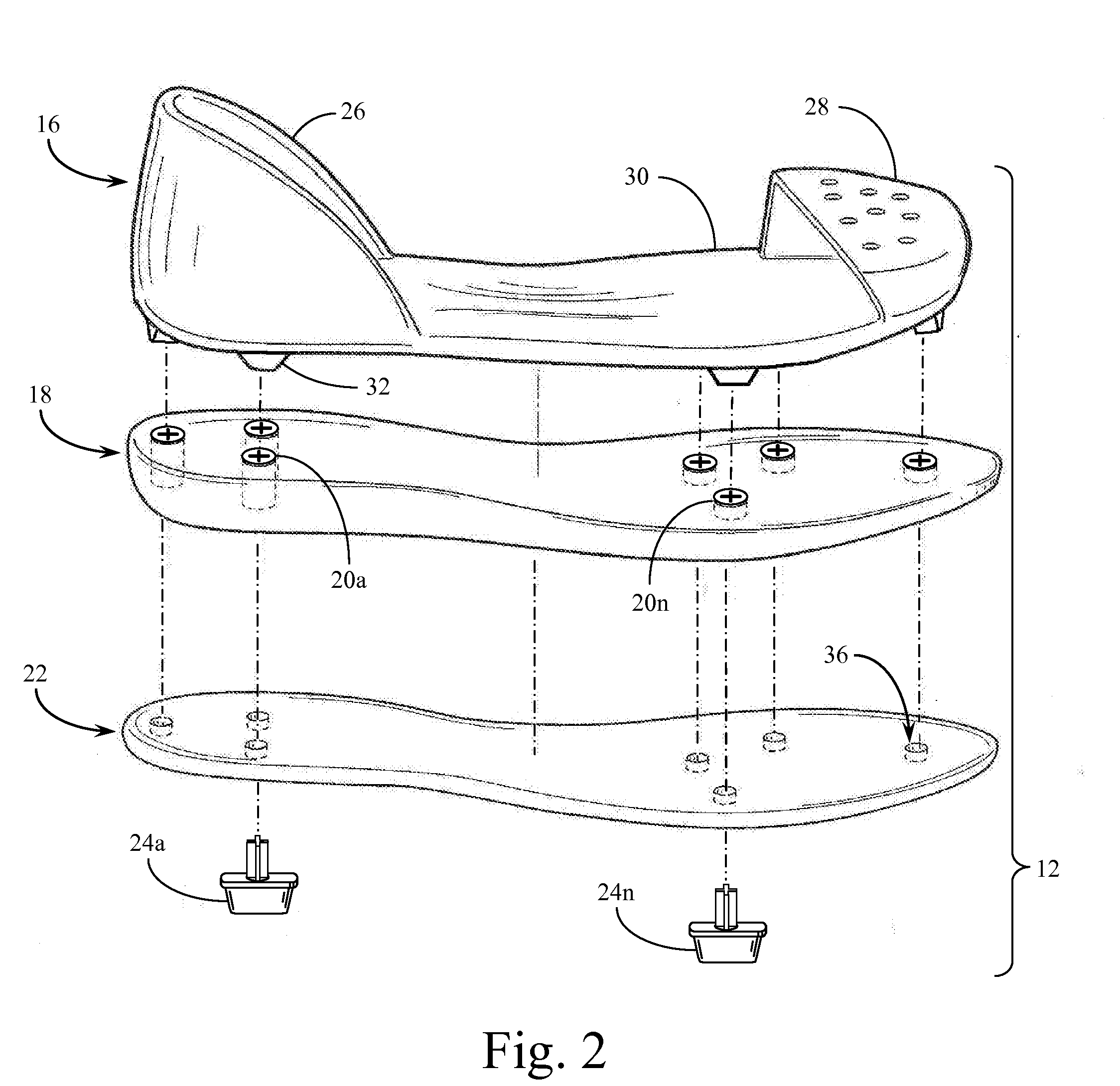

InactiveUS20110252664A1Reduce manufacturing costSimple manufacturing processSolesInsolesEngineeringMechanical engineering

A shoe foundation assembly for receiving and retaining a number of cleats or spikes into the bottom sole of the shoe such as might be utilized in various sporting events. The shoe foundation assembly includes a unitarily molded shoe cradle component with a toe guard at a first end, a heel guard at a second end, and arch medial. An outsole is bonded to the midsole component sized and shaped to be positioned on the underside base of the shoe cradle component. The detachable cradle incorporates hillock apertures for positioning a number of sealable inserts to receive the cleat / spikes. Bonded to the midsole is an outsole component having a plurality of slit apertures also positioned to receive the plurality of cleat / spikes. A number of different types of cleats or shoe spikes may be inserted into the apertures in the outsole and through the sealable inserts within the midsole. Each of the cleat / spikes incorporates a structure for the retention of the cleat / spike onto the shoe foundation.

Owner:JENNINGS JAMES EDWARD

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

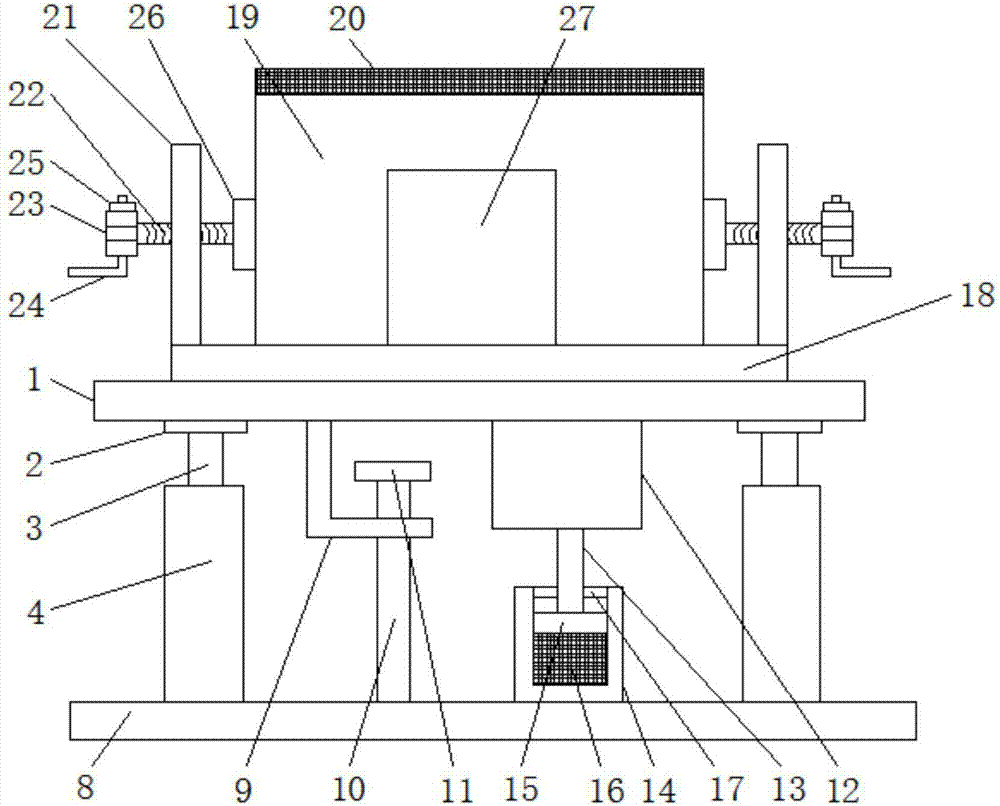

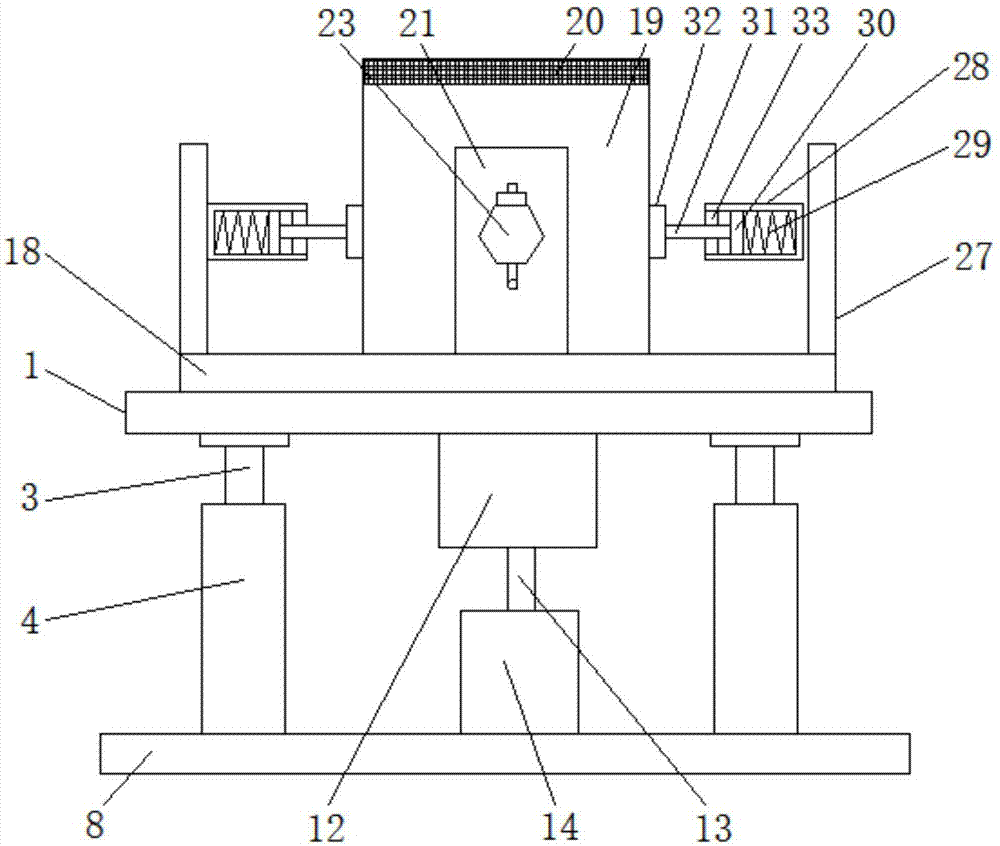

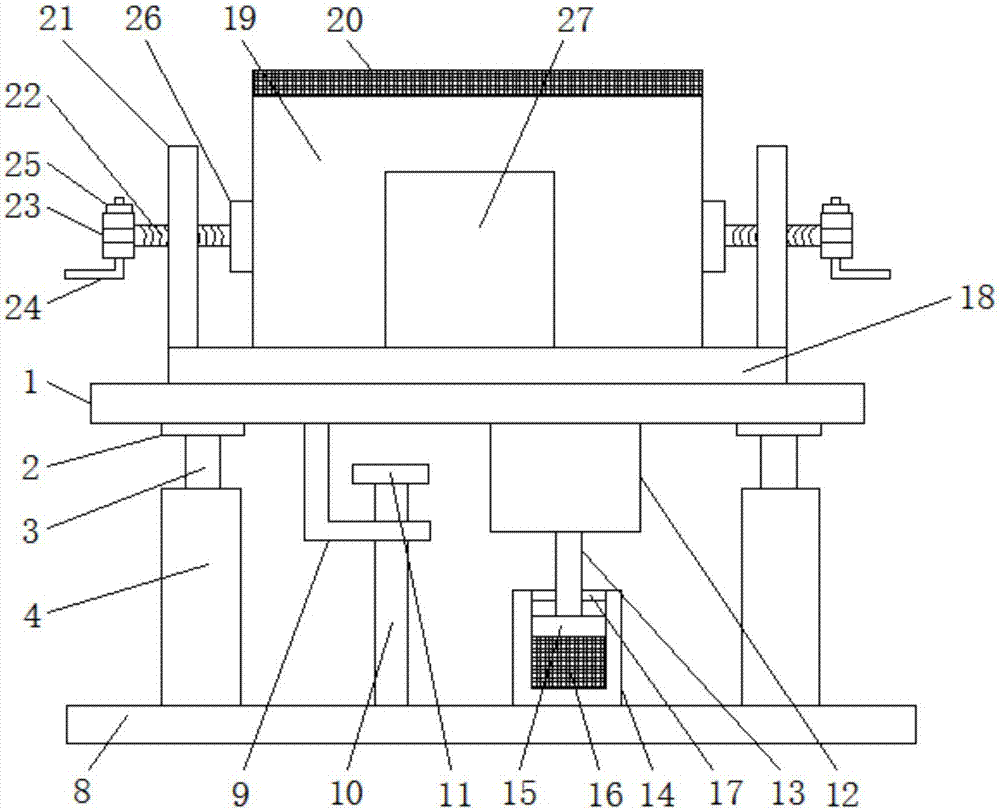

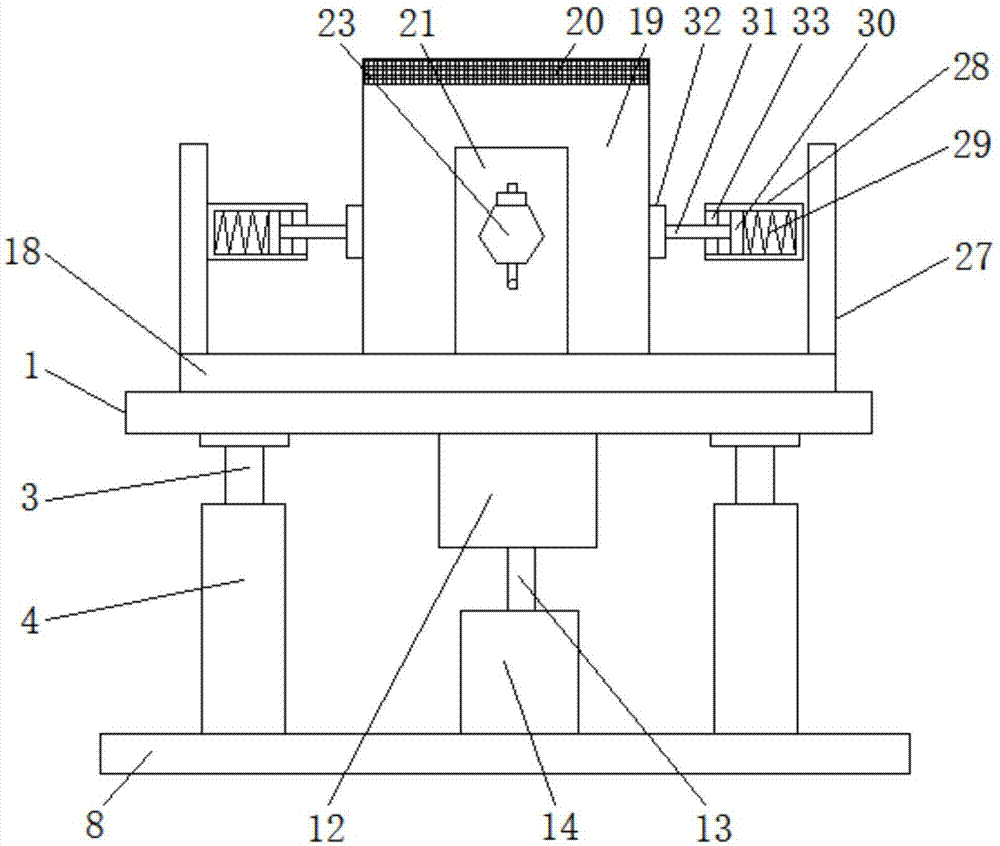

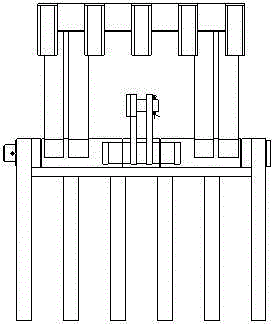

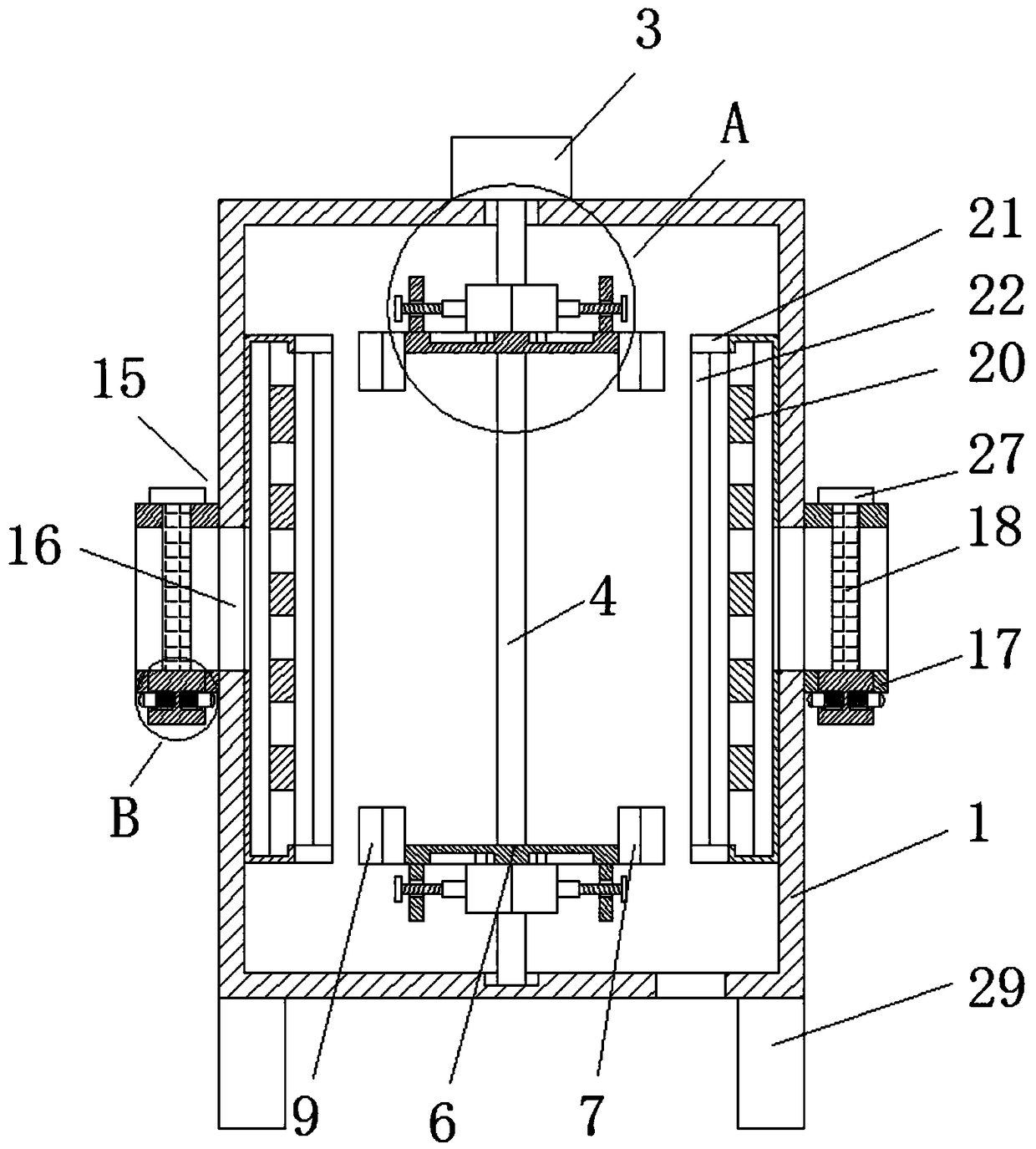

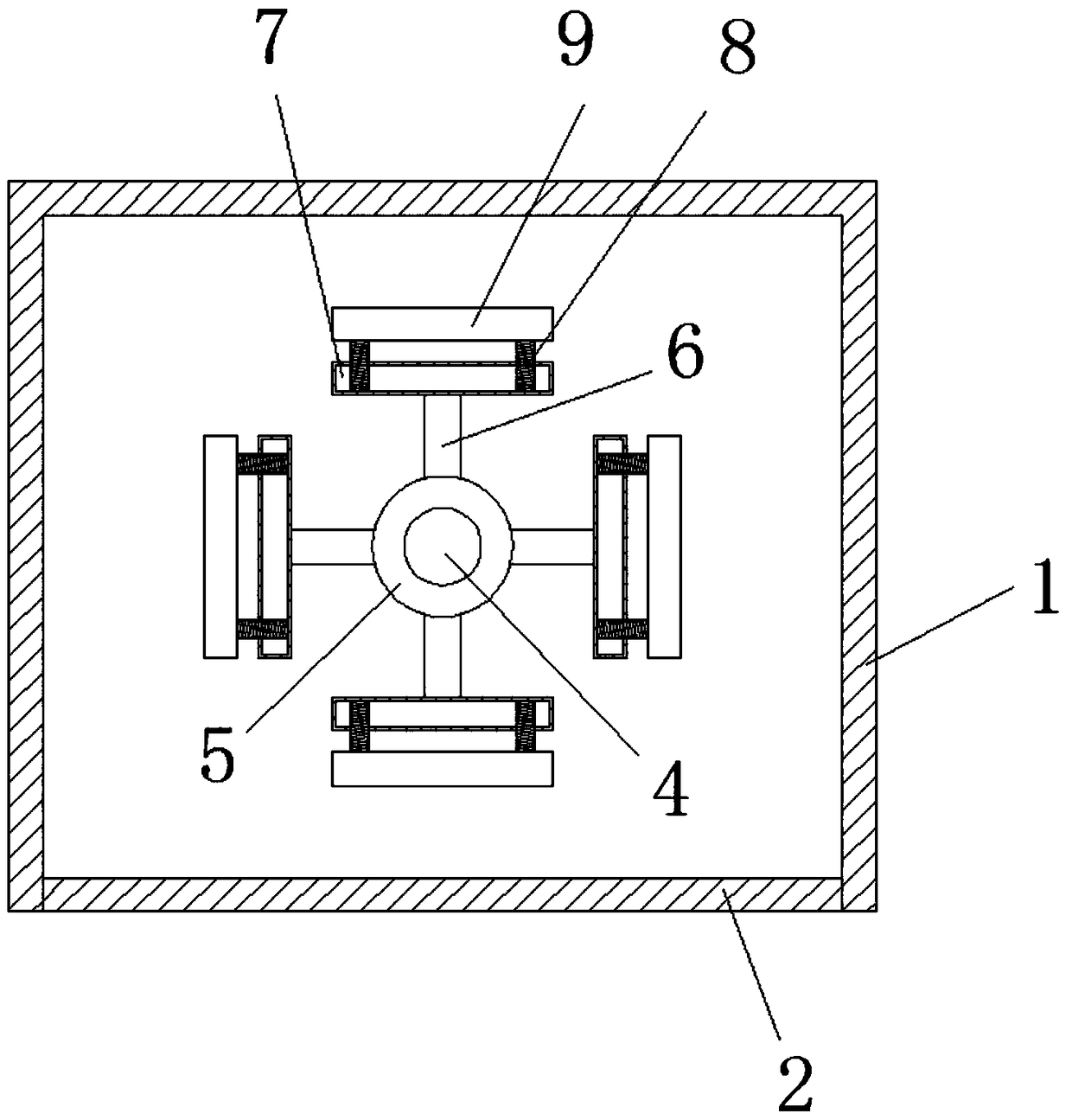

Collision-prevention electronic device control box

InactiveCN107493666ANot easy to damageAvoid damageNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringElectron

The invention provides an anti-collision electronic device control box, which relates to the field of electronic devices. The anti-collision electronic device control box includes a fixing plate, four corners of the bottom of the fixing plate are fixedly installed with connecting blocks, and the bottom of the connecting blocks is fixedly connected with the top of the first pressure rod. The bottom end penetrates the first shock absorber and extends to the inside of the first shock absorber and is fixedly connected with the top of the first pressing block. The anti-collision electronic device control box drives the second splint to clamp and fix the front and back of the box through the second shock absorber, and drives the first splint to clamp and fix the left and right sides of the box through the screw, so that the box is clamped and fixed. Reliably fixed, through the first shock absorber and the buffer shock absorption, the fixed plate drives the box body to move along the surface of the guide rod, so as to effectively buffer the box body and make it difficult for the box body to separate from the base. The electronic devices inside the protection box are not easily damaged, and the use cost is effectively reduced.

Owner:石国华

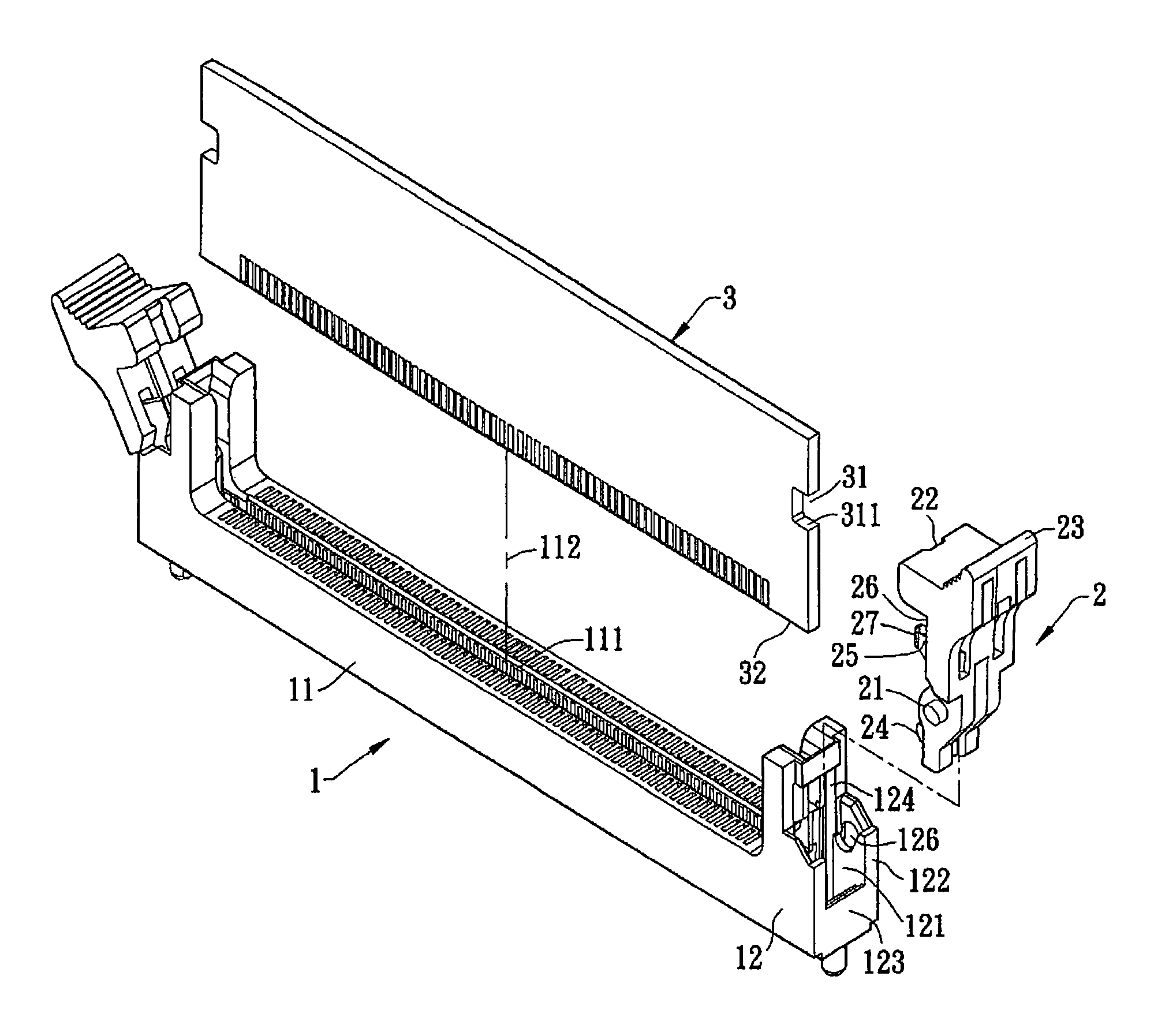

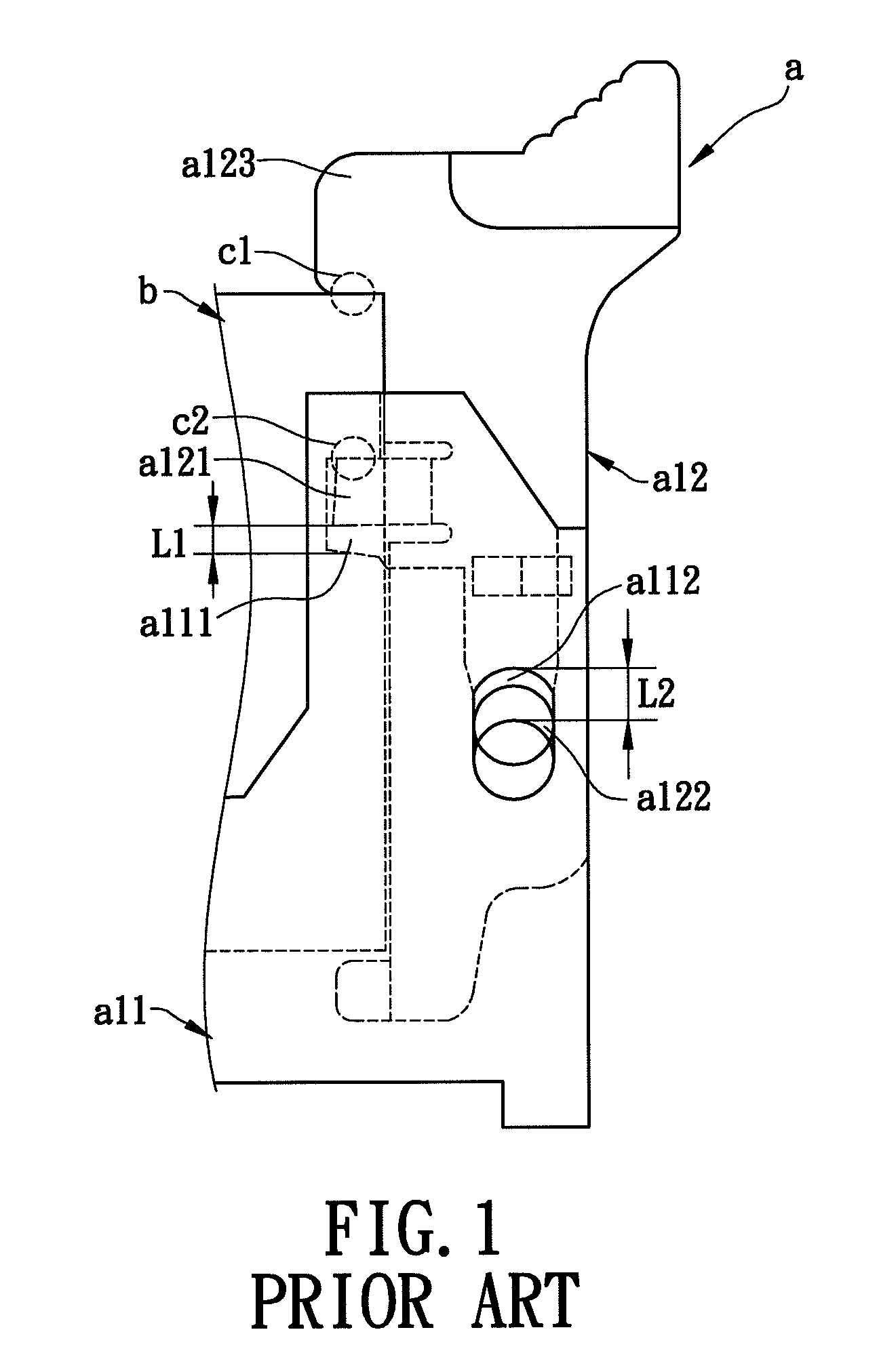

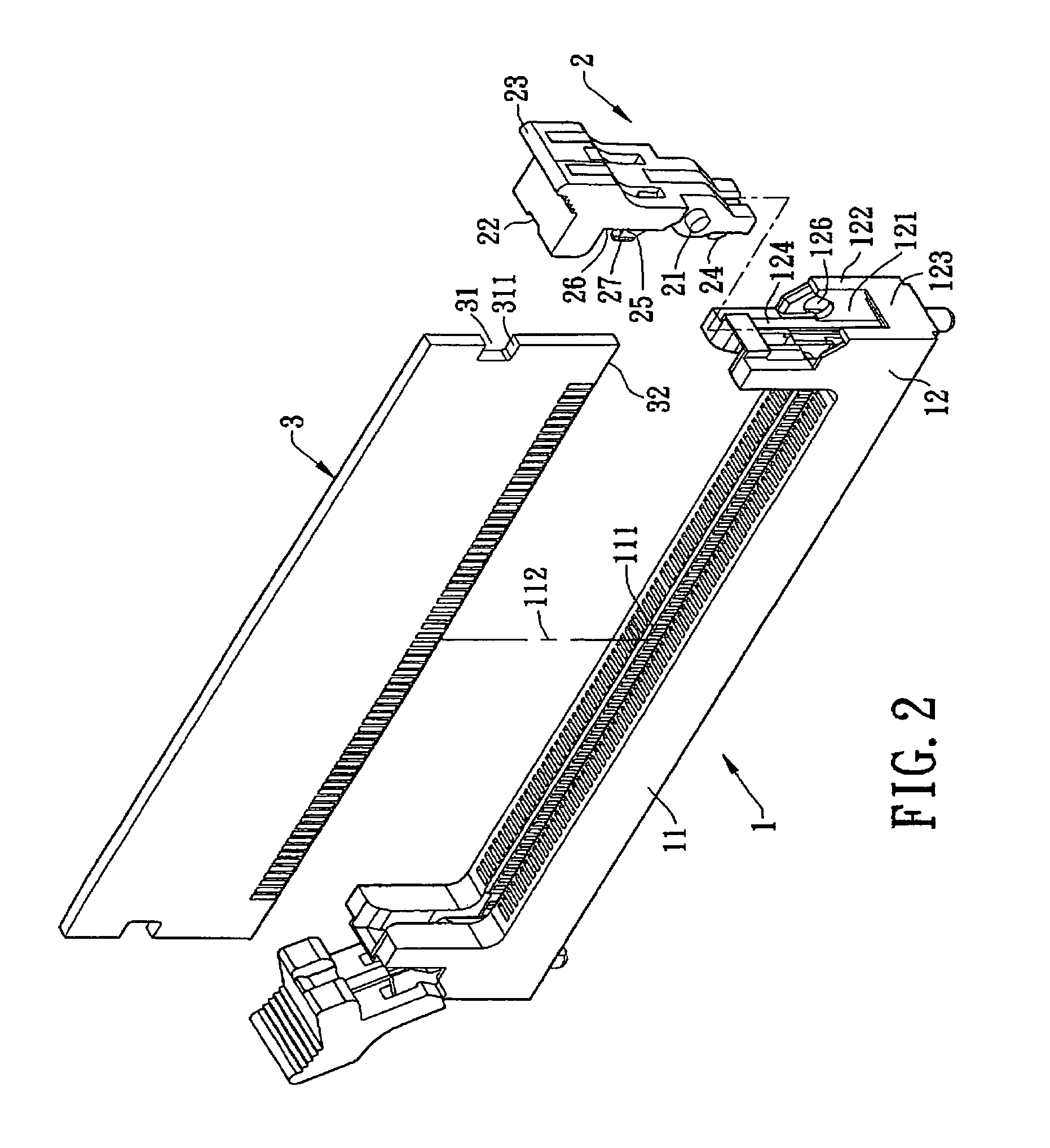

Card edge connector with a fastener with a detent portion with a snap-fitting surface

InactiveUS7938658B1Preventing disengagement of an electronic card more effectivelyEffective disengagementEngagement/disengagement of coupling partsDetentEngineering

The card edge connector includes: an electrical receptacle formed with an abutting surface; two fasteners pivoted to the electrical receptacle, wherein each of the fasteners is formed with a snap-fitting surface that makes contact with the fastened surface to form a fastening area, the fastening area has a contact point that is closest to a central perpendicular line of the electrical receptacle, and the contact point has a first distance from the central perpendicular line; and wherein each of the fasteners is provided with an abutting portion, and when the abutting portion abuts against the abutting surface correspondingly, an abutting area is formed which has an abutting point that is closest to the central perpendicular line of the electrical receptacle, and the abutting point has a second distance from the central perpendicular line that is less than the first distance.

Owner:LOTES

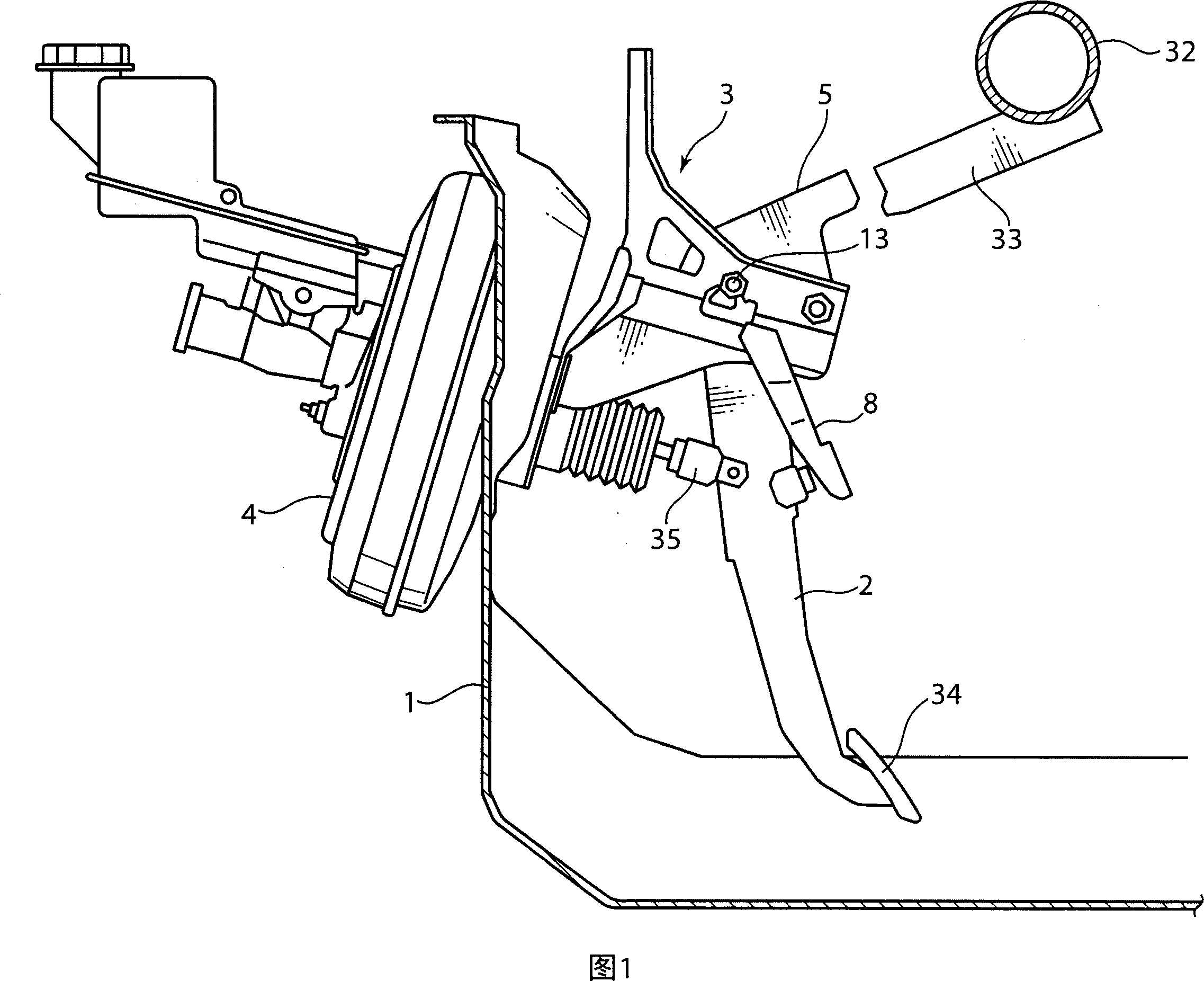

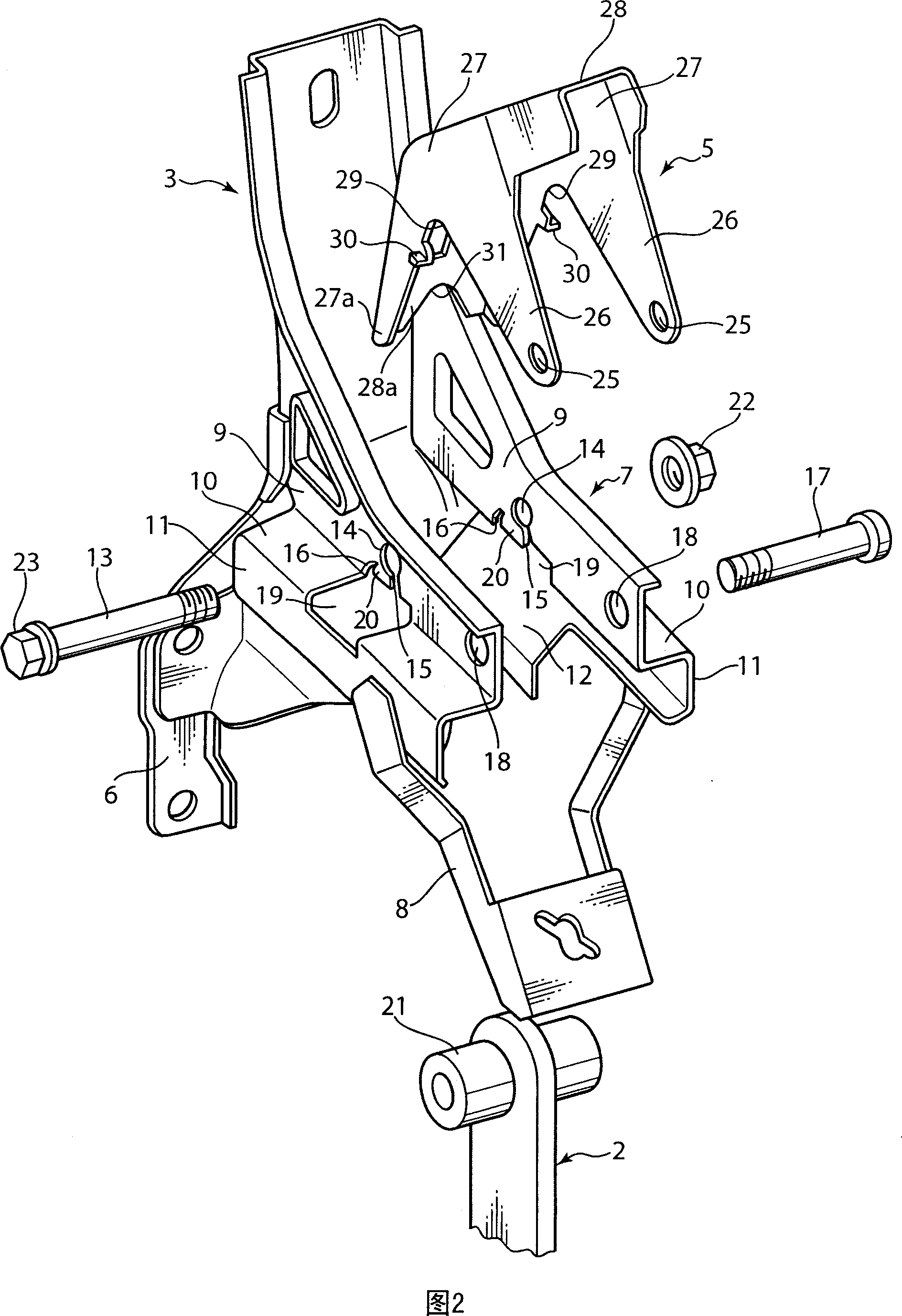

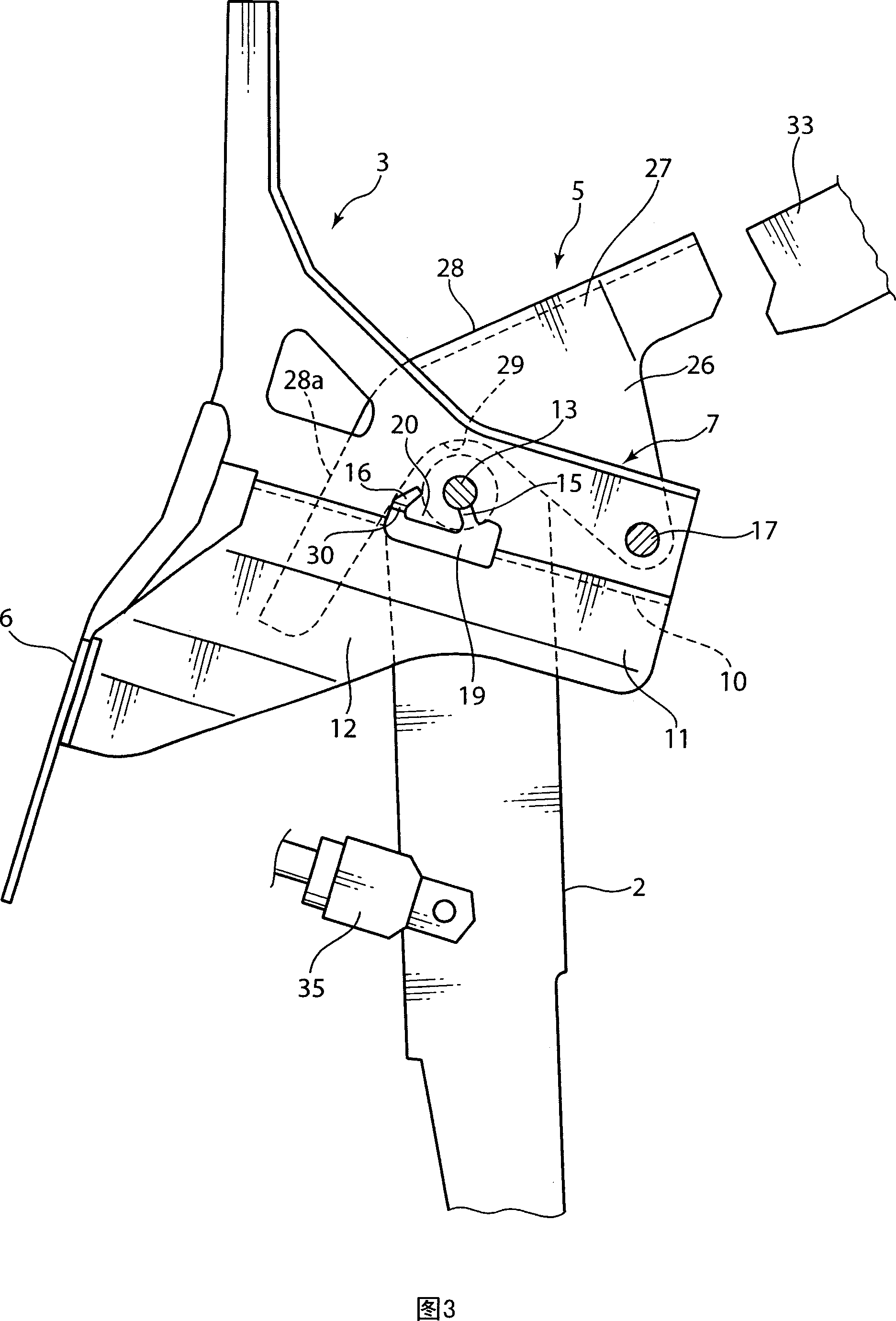

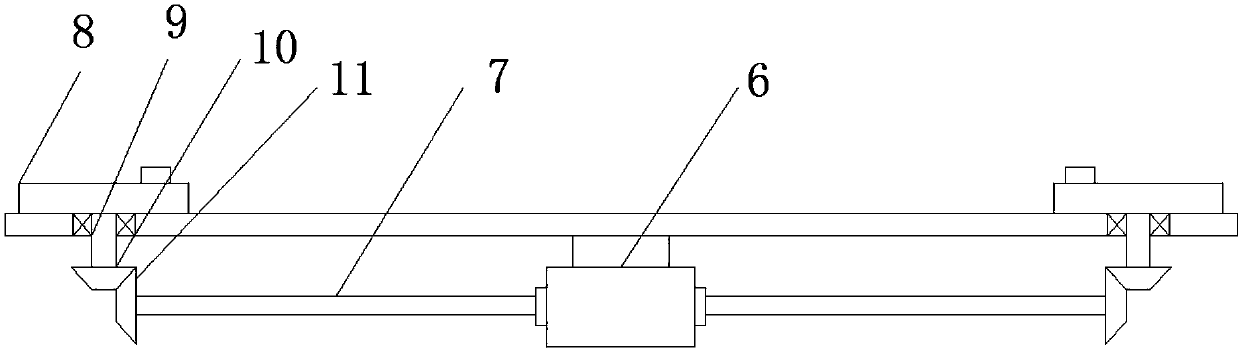

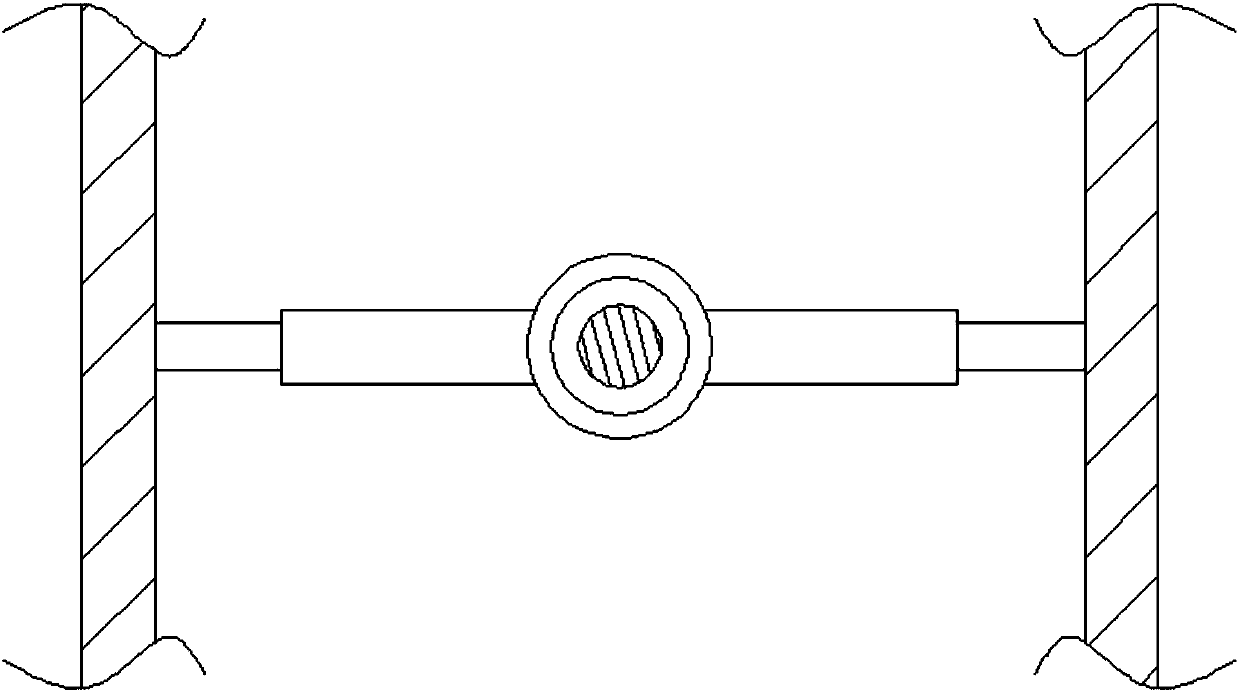

Support structure for control pedal

InactiveCN1966300APrevent overloadingSimple structureControlling membersPedestrian/occupant safety arrangementDriver/operatorNormal state

Disclosed is a control pedal support structure, which comprises a pedal bracket 3 fixed to a dash panel to extend in a rearward direction of a vehicle body, and a pedal body 2 swingably supported relative to the pedal bracket 3 through a pedal pivot shaft (first pivot shaft) 13 mounted to the pedal bracket 3 to extend in a lateral direction of the vehicle body. In the support structure, the pedal bracket 3 includes a mount hole zone 14 for mounting thereon the pedal pivot shaft 13, and a support zone 20 located below the mount hole zone 13 and adapted to support the pedal pivot shaft 13 from therebelow. The support structure includes dropping means adapted, during a vehicle collision, to deform the support zone 20 so as to allow the pedal pivot shaft 13 to be dropped below the mount hole zone 14. The present invention is capable of maintaining a desirable operational feeling of a pedal body in a normal state, and effectively preventing a rearward movement of a foot pad during a vehicle collision in a simplified mechanism to reduce a load to be imposed on driver's foot.

Owner:MAZDA MOTOR CORP +1

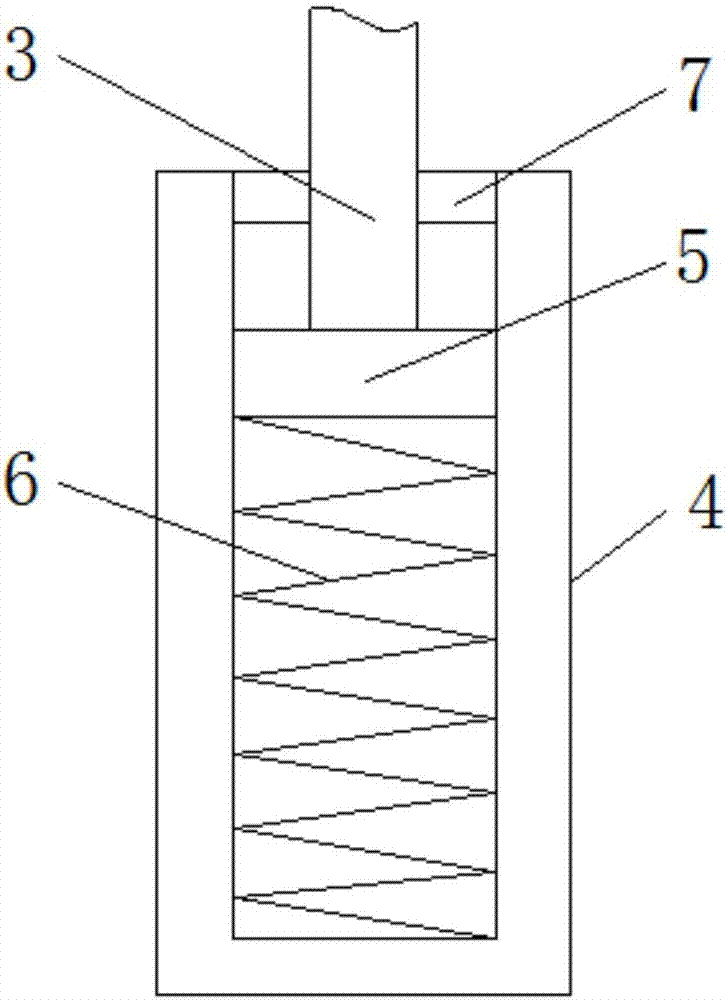

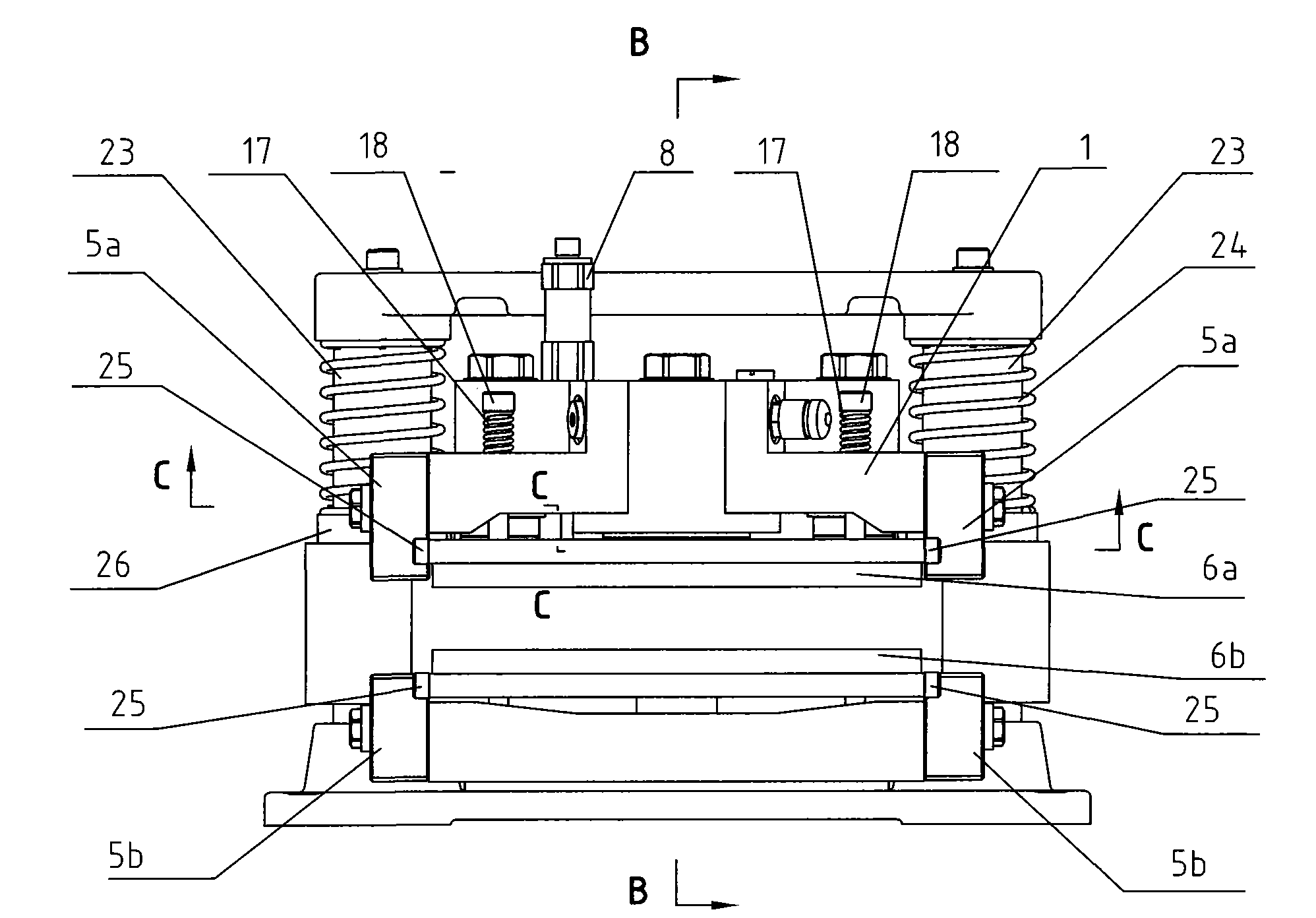

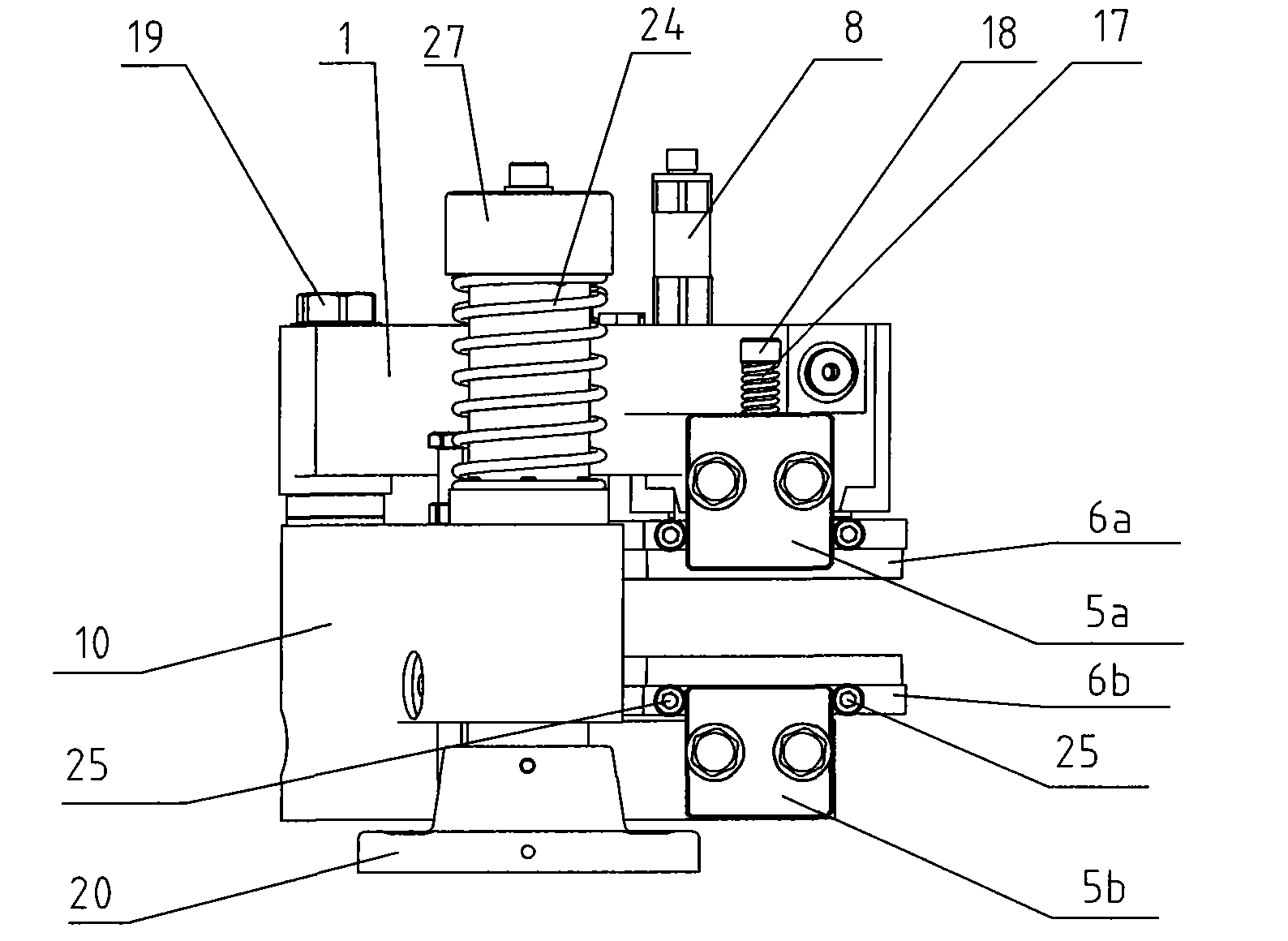

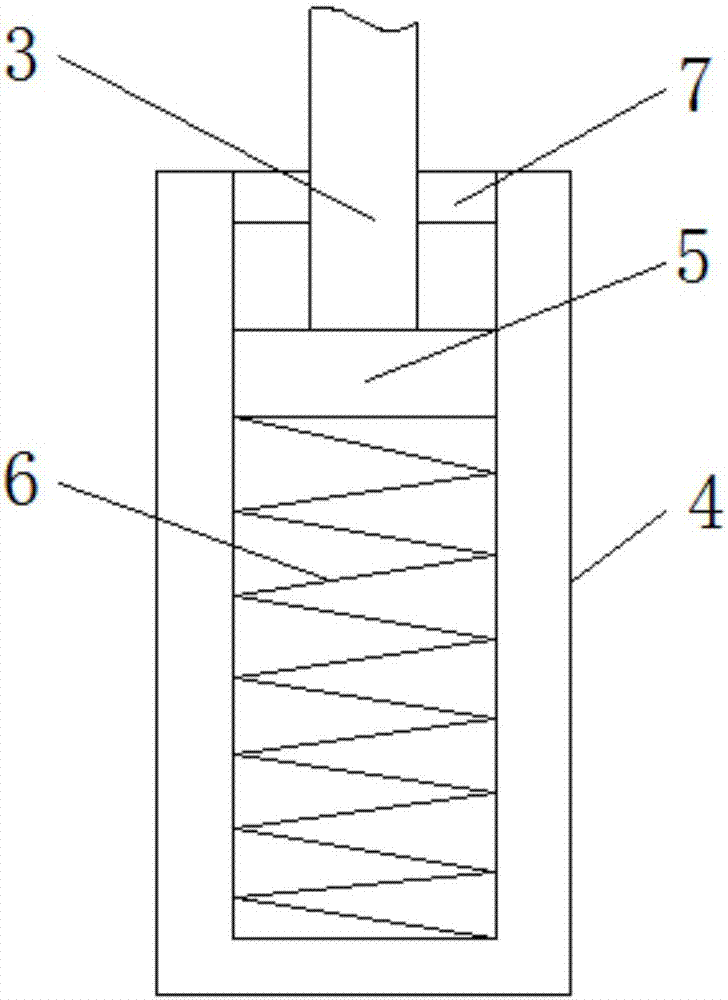

Brake caliper assembly of normally open type wind driven generator main shaft system

InactiveCN101660505AReduce abnormal wearExtended service lifeAxially engaging brakesMachines/enginesPistonWind driven

The invention discloses a brake caliper assembly of a normally open type wind driven generator main shaft system, comprising a first half part, a second half part and an inner brake block resetting mechanism which are correspondingly arranged, wherein, the inner brake block resetting mechanism comprises a return spring installation rod and an inner brake block return spring sheathed on the excircle of the return spring installation rod; the return spring installation rod and a piston are parallel and pass through the first part in the mode of reciprocating sliding lengthways; one end of the return spring installation rod is fixedly connected with the inner brake block lengthways; one end of the inner brake block return spring outwards supports the return spring installation rod, and the other end inwards supports the first half part; when the brake assembly enters a non-working state (the hydraulic cylinder releases pressure), the brake block can effectively and quickly separate from the brake disc by the brake block resetting mechanism, which reduces abnormal abrasion between the brake block and the brake disc so as to improve the service life of the brake block and the brake discand reduce maintenance cost.

Owner:CSG TRW CHASSIS SYST CO LTD

Control method of collision-prevention electronic device

InactiveCN107454780AAvoid damageEasy to fixNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringCollision prevention

The invention provides an anti-collision electronic device control method, which relates to the field of electronic devices. The anti-collision electronic device control box includes a fixed plate, the four corners of the bottom of the fixed plate are fixedly equipped with connection blocks, the bottom of the connection block is fixedly connected with the top of the first pressure rod, and the top of the first pressure rod The bottom end passes through the first shock absorber and extends to the inside of the first shock absorber to be fixedly connected with the top of the first pressure block. The anti-collision electronic device control box drives the second splint to clamp and fix the front and back of the box body through the second shock absorber, and drives the first splint to clamp and fix the left and right sides of the box body through the screw rod, so that the box body Reliably fixed, through the buffering and shock absorption of the first shock absorber and the buffer, the fixed plate drives the box body to move along the surface of the guide rod, thereby effectively cushioning the box body and making it difficult for the box body to detach from the base, thereby The electronic devices inside the protective box are not easily damaged, which effectively reduces the cost of use.

Owner:石国华

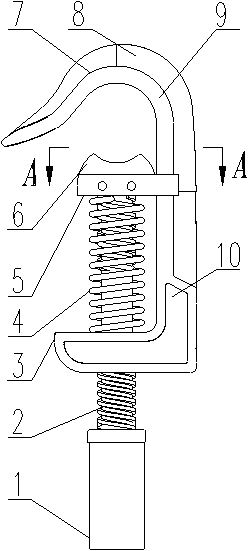

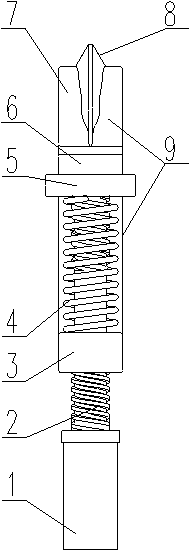

Anti-off quick-loading hook type short-circuit grounding wire clamp

PendingCN110137716AEffective clampingWhen clamping, it is effective to twist the double-ended threaded rod to disengage the second threaded rodElectric connection basesApparatus for overhead lines/cablesEngineeringScrew thread

The invention belongs to the technical field of electric safety tools and particularly relates to an anti-off quick-loading hook type short-circuit grounding wire clamp. The anti-off quick-loading hook type short-circuit grounding wire clamp comprises a base, a double-head threaded rod is connected to a middle portion of a bottom surface of the base, the double-head threaded rod includes a first threaded rod, a polished rod and a second threaded rod, the first threaded rod and the second threaded rod are threadingly connected to the base, and the polished rod is slidingly connected to the base. A bottom end surface of the double-head threaded rod is fixedly connected to a connecting rod, a top end of the double-head threaded rod is rotatingly connected to a slider, and a top surface of theslider is fixedly connected to a pressing block. A compression spring is set between the slider and the base, and the compression spring sleeves the outside of the double-head threaded rod. The top of the base is fixedly connected with a tongue-shaped hook, the middle portion of a right end of the slider is provided with a guiding groove, and the slider is slidingly connected to a vertical portion of the tongue-shaped hook through a guiding groove. The overall structure of the wire clamp is reasonable, the operations of hanging and removing a grounding wire are simple, the wire can be effectively clamped, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:JIAOZUO POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

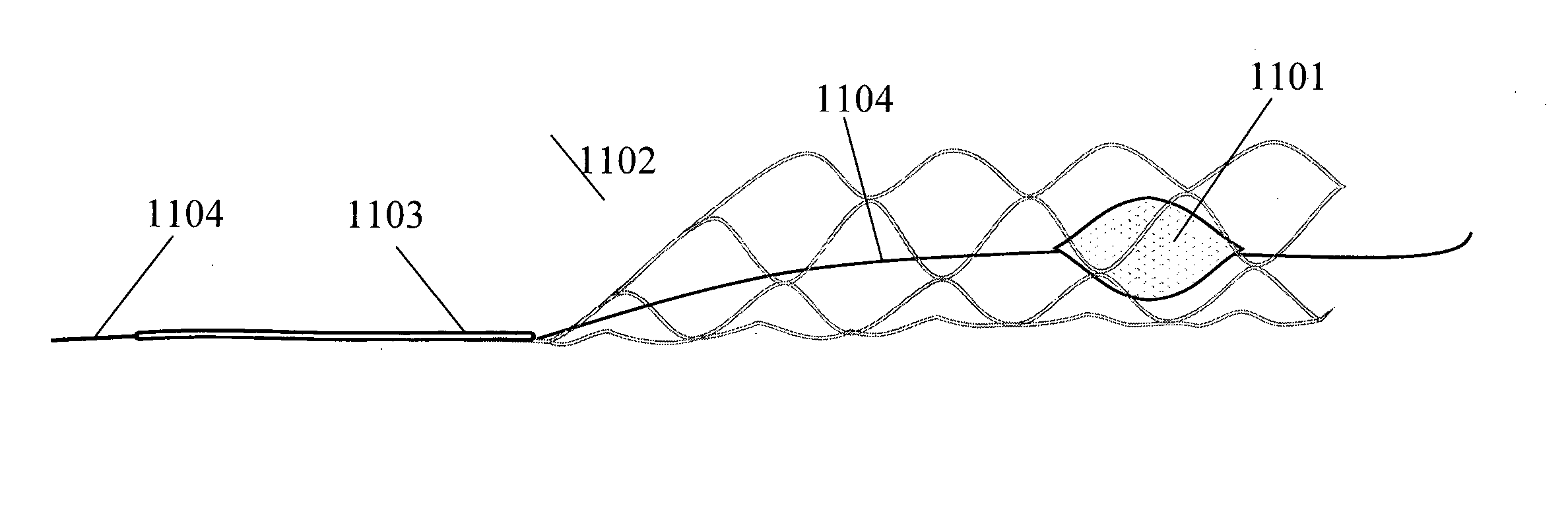

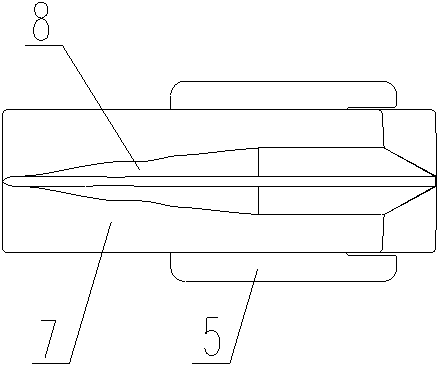

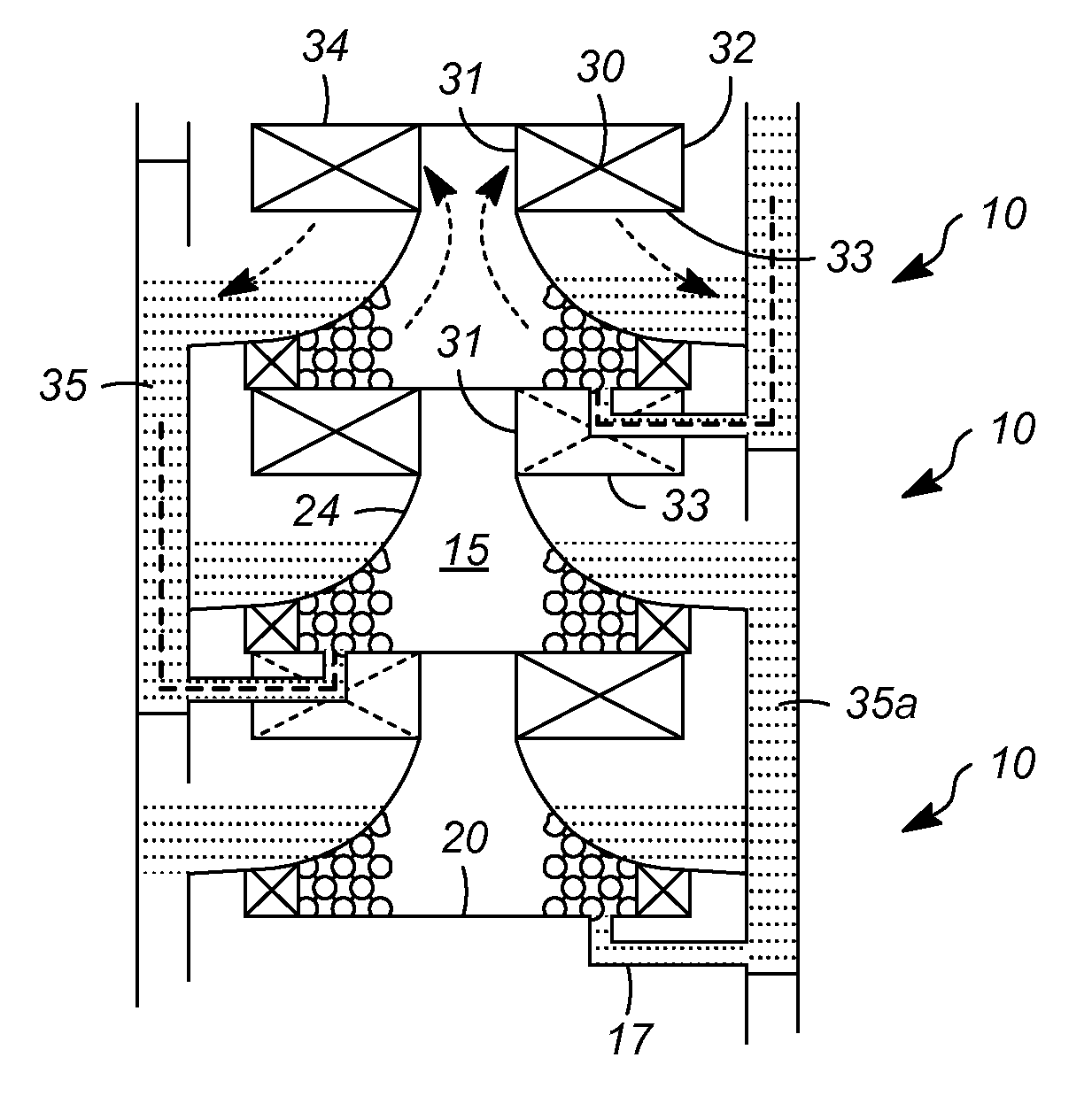

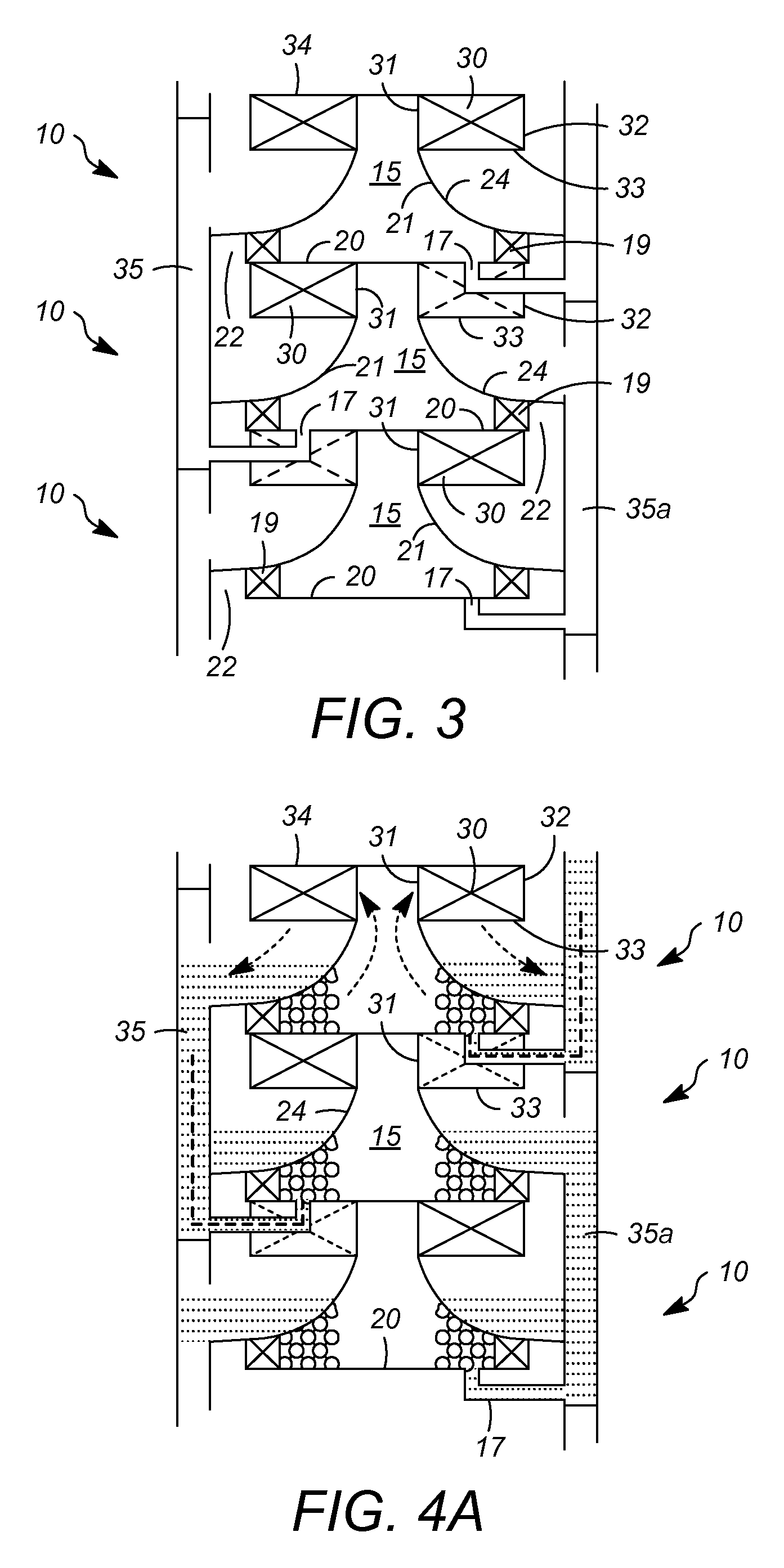

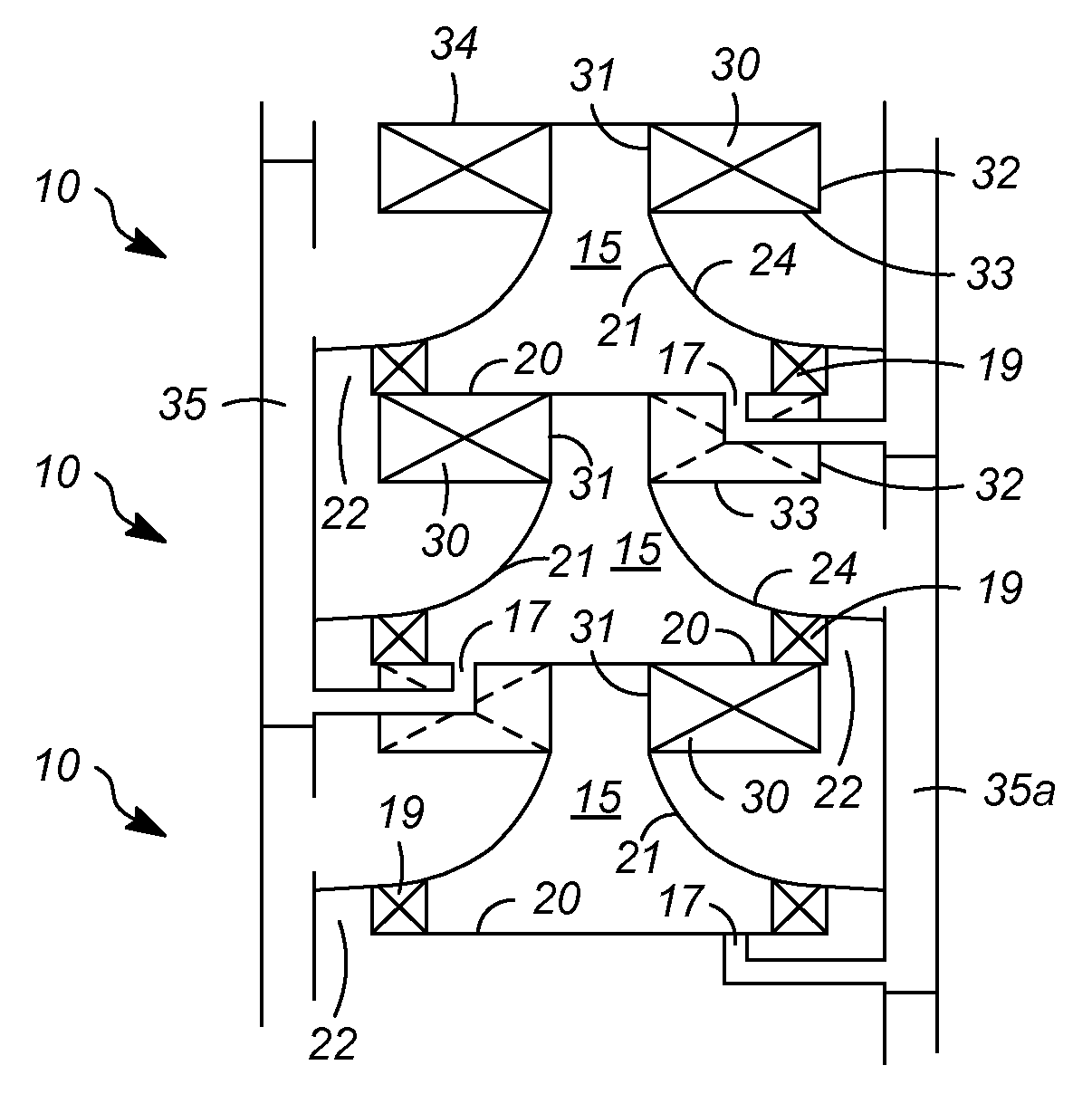

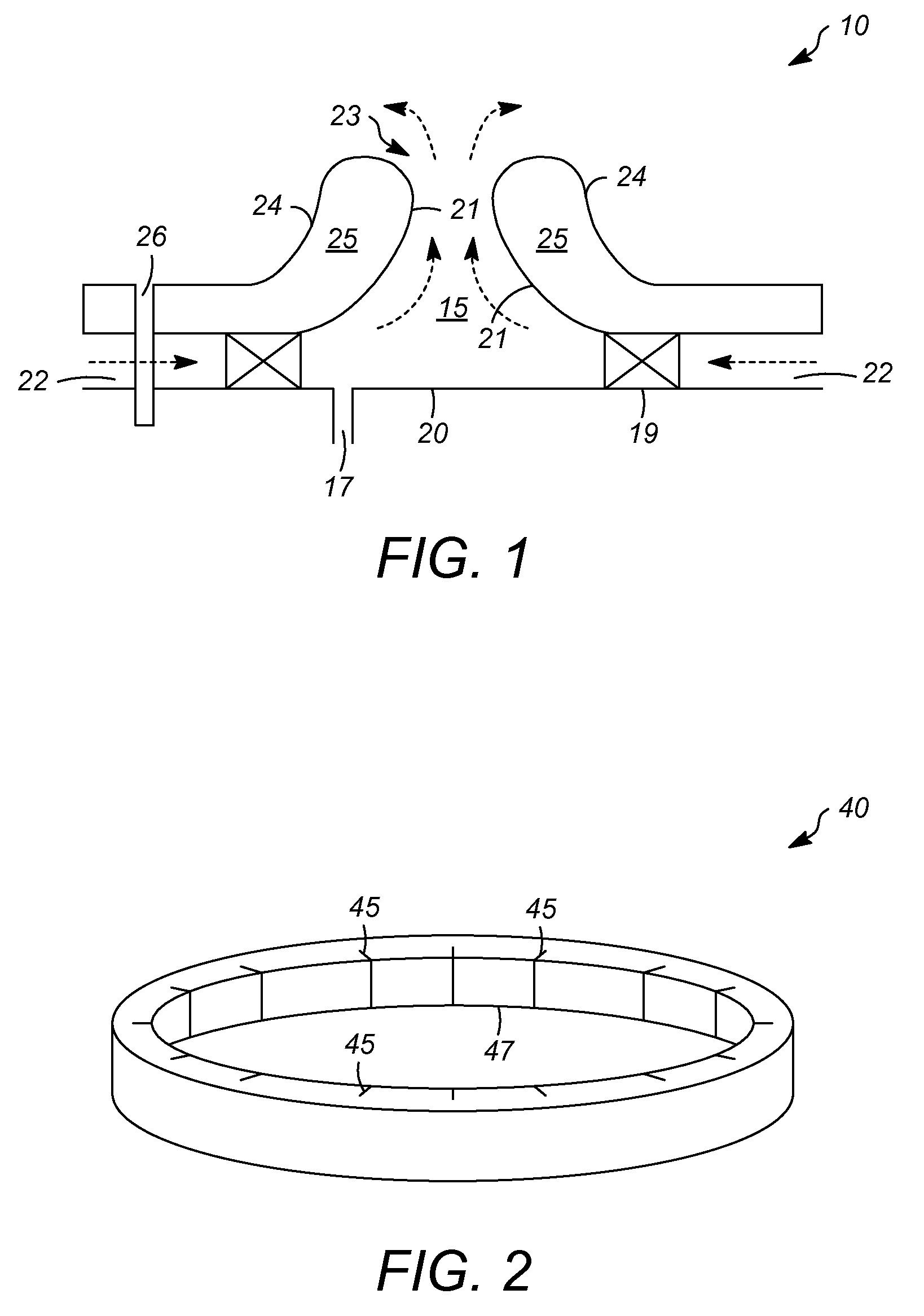

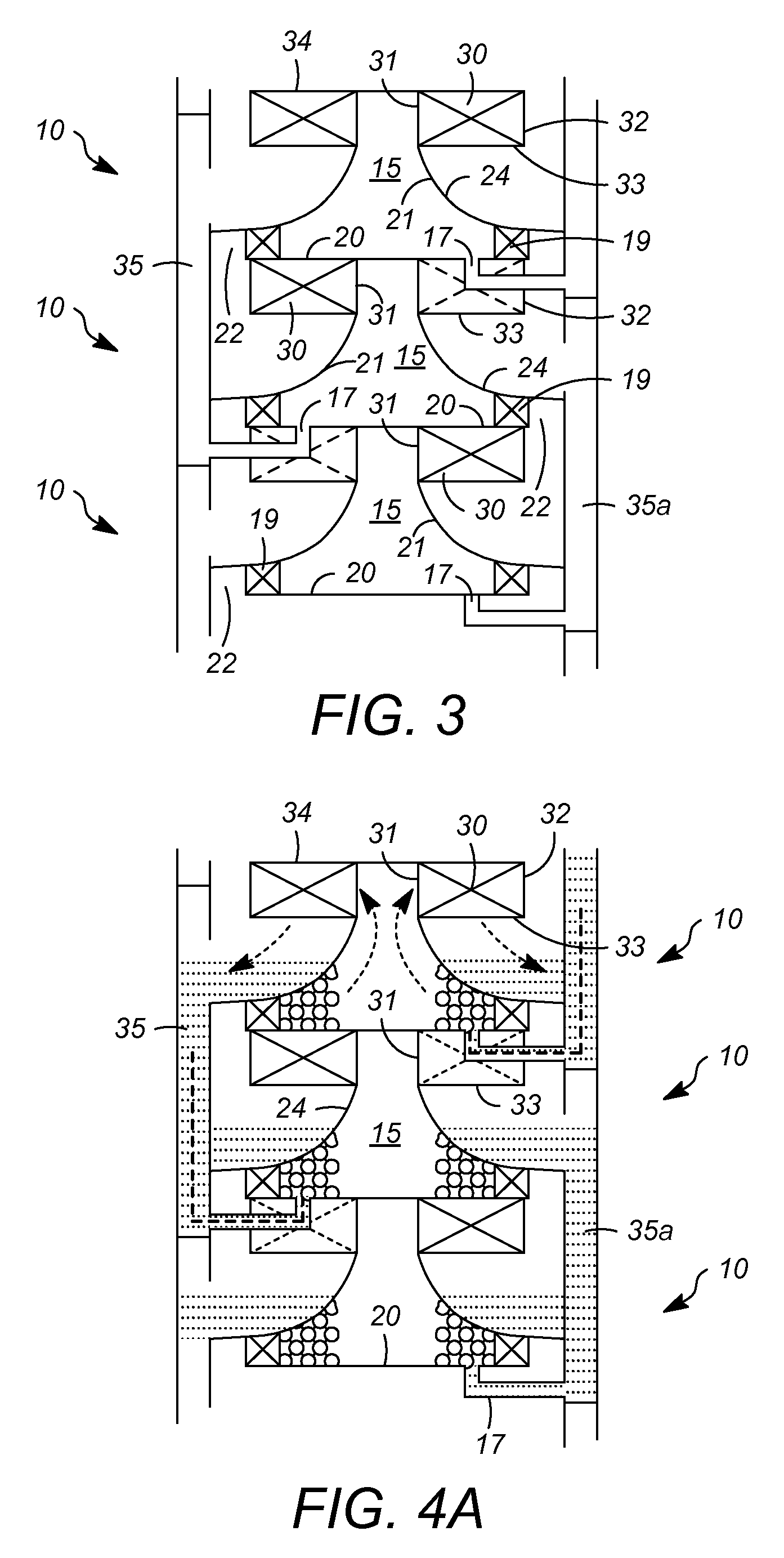

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS20100258427A1Narrow downReduction in stage efficiencyCombination devicesTransportation and packagingVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS8047509B2Reduce entrainmentLower overall pressure dropCombination devicesUsing liquid separation agentVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

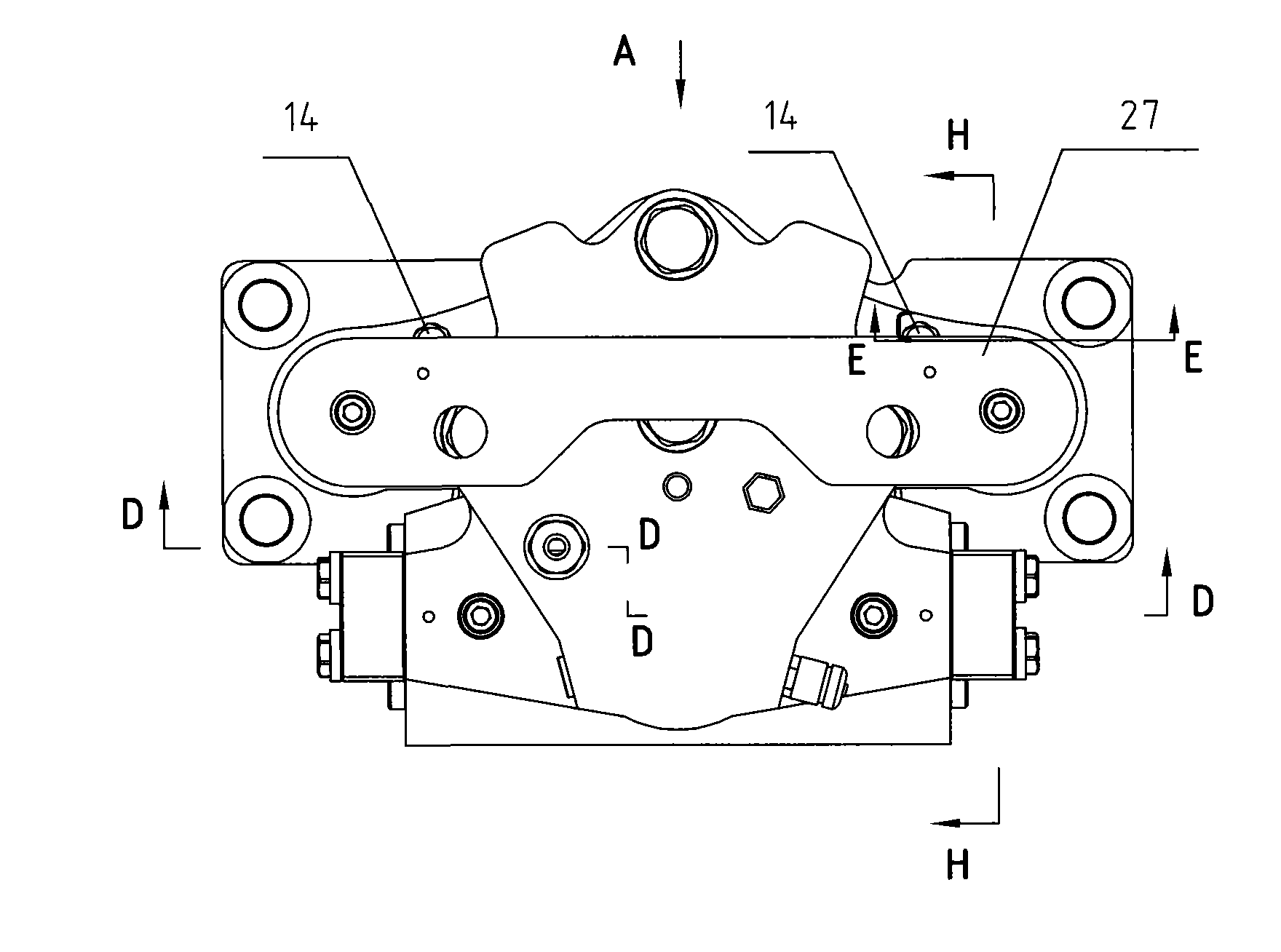

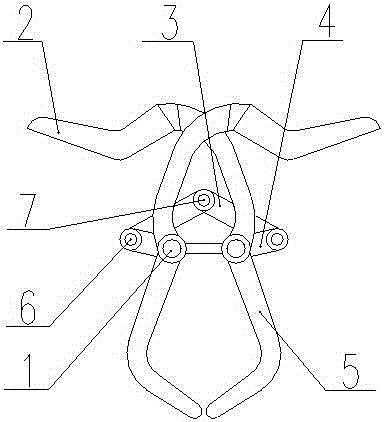

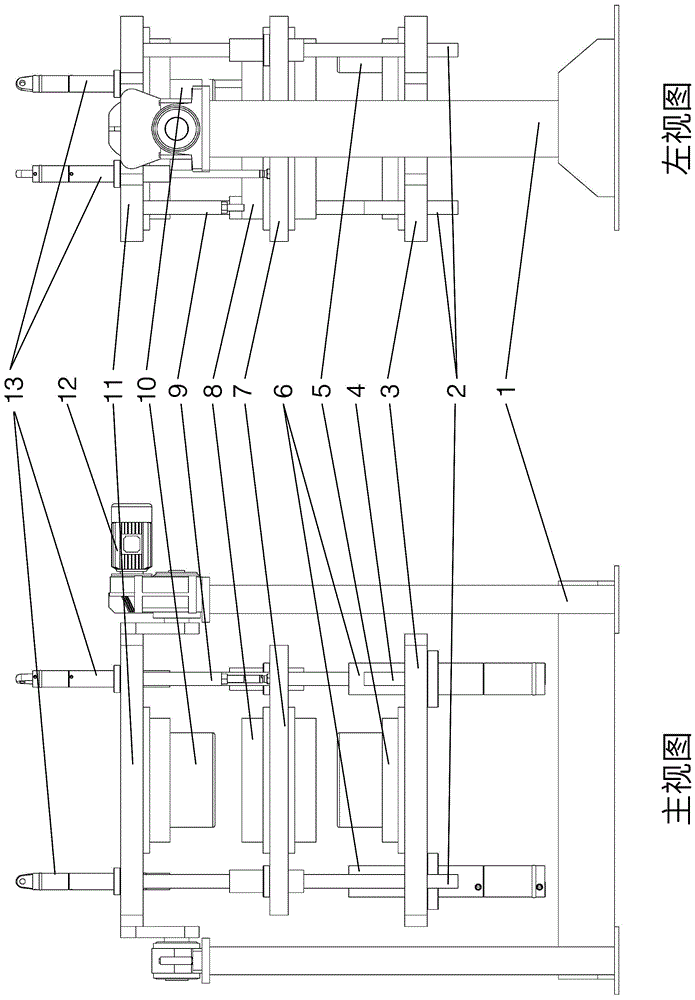

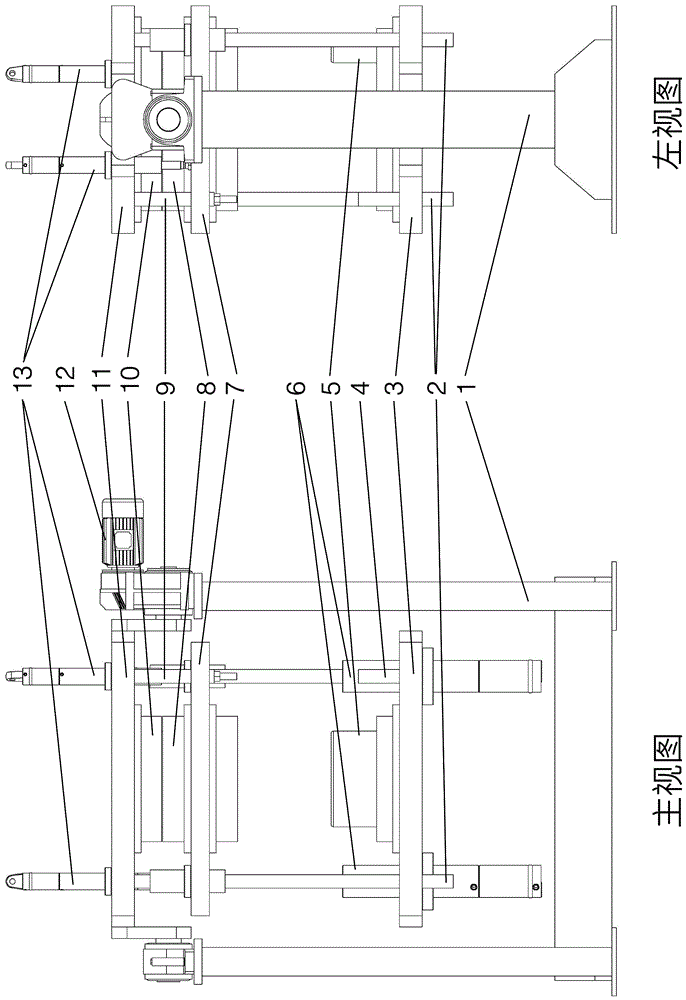

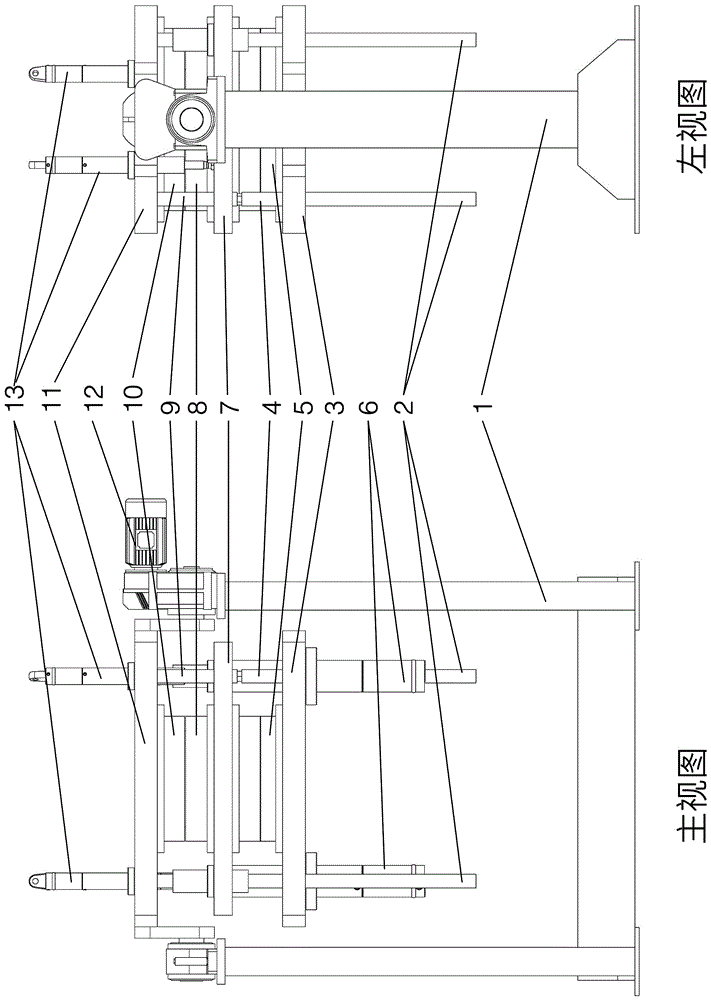

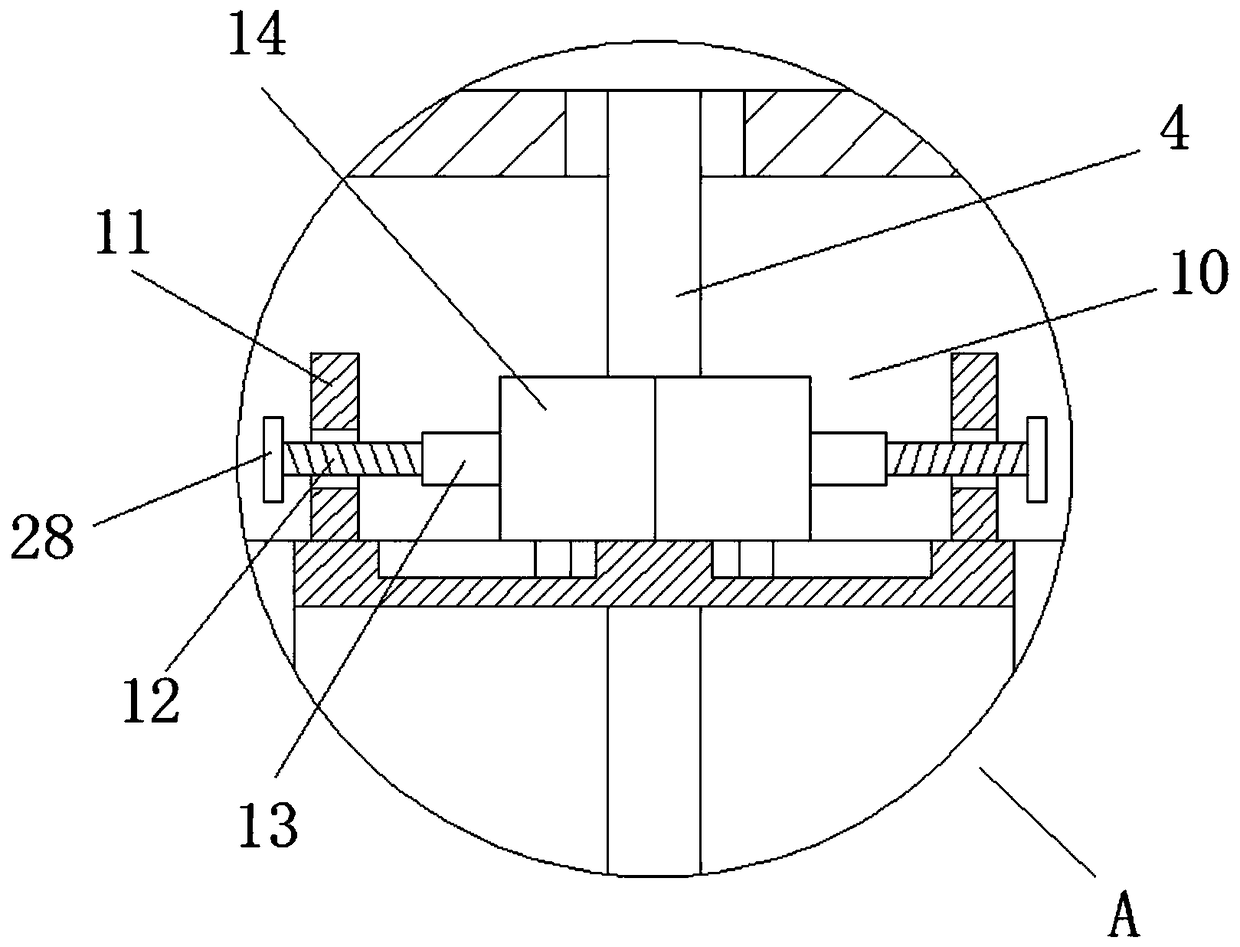

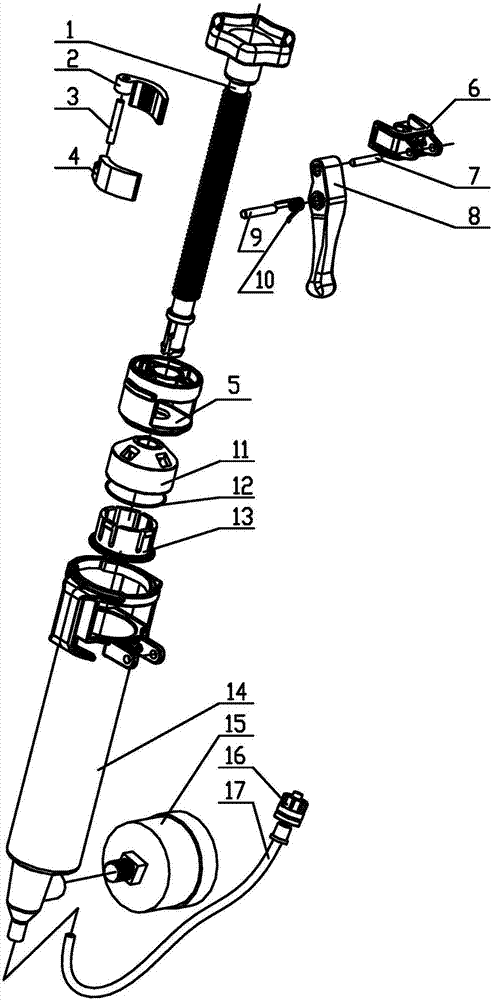

Dross dredger gripper

InactiveCN105202928AExcellent adhesionEffective disengagementCharge manipulationDrossElectrical and Electronics engineering

The invention discloses a dross dredger gripper which comprises main shafts (1), upper gripper bodies (2), upper connection sleeves (3), lower connection sleeves (4), lower gripper bodies (5), first pin shafts (6) and a second pin shaft (7). The pair of lower gripper bodies (5) are hinged to the two main shafts (1) respectively, and the pair of upper gripper bodies (2) are further hinged to the two main shafts respectively; the two main shafts (1) are hinged to one ends of the two lower connection sleeves (4) respectively, and the other ends of the two lower connection sleeves (4) are hinged to the two first pin shafts (6) respectively; the two first pin shafts (6) are further hinged to one ends of the two upper connection sleeves (3), and the other ends of the two upper connection sleeves (3) are hinged to the second pin shaft (7). According to the dross dredger gripper, the material of the gripper is reformed, the gripper is cast through high-temperature-resisting materials, the upper gripper bodies serving as dross separation devices are added, the dross can be more effectively separated from the gripper, and the dross in a furnace can be fished out in a dead-corner-free mode.

Owner:青州市圣洁环保设备科技有限公司

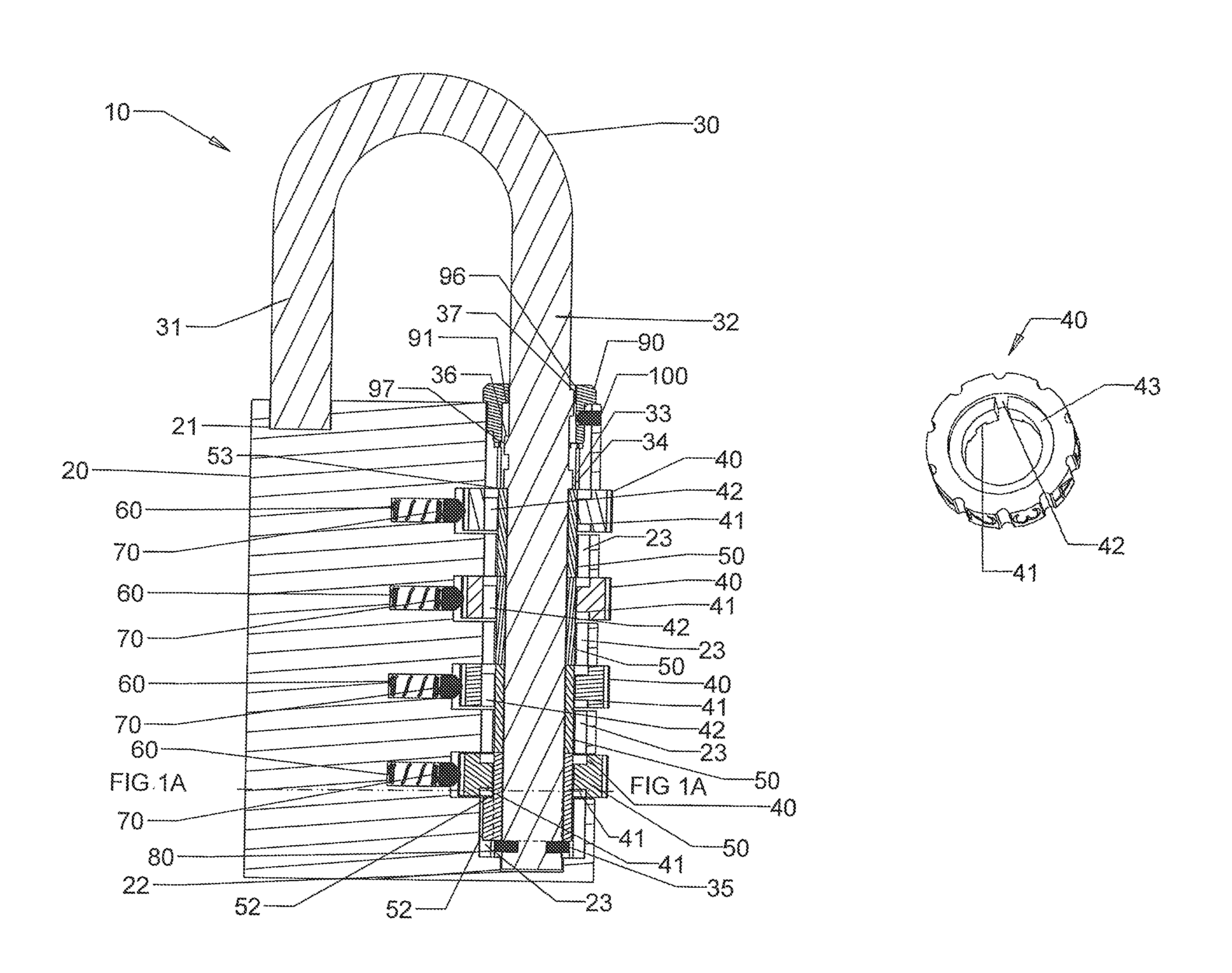

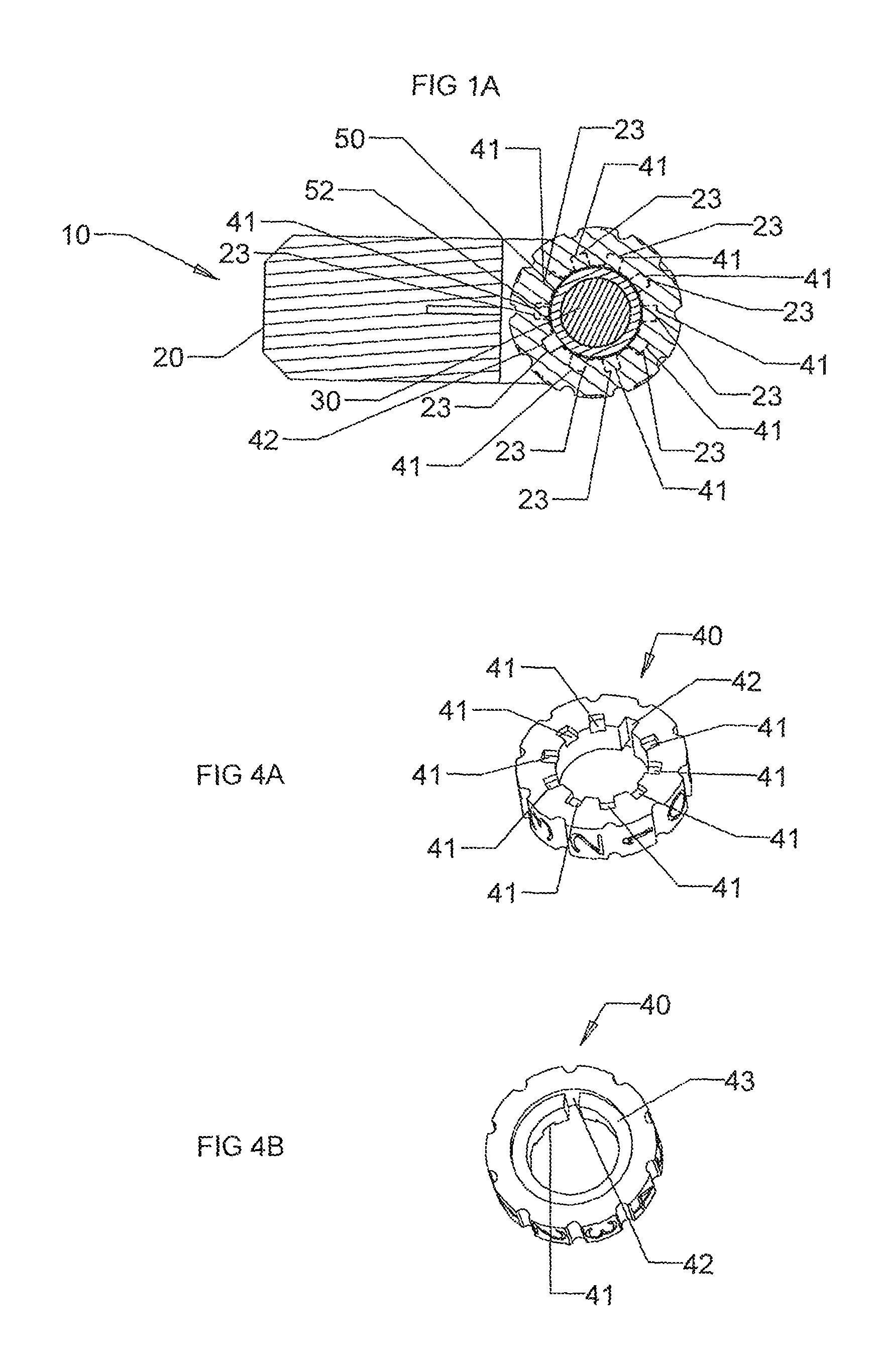

Combination padlock with anti-pick and anti-peek mechanism

A combination lock having a plurality of dials and clutches arranged to control a lock shackle is disclosed. Each of the dials is mounted on a different clutch to form a dial-clutch pair. The clutch has a protrusion and the dial has an open slot dimensioned to receive a protrusion and a plurality of faulty notches. The protrusion is so located that when the lock is in the lock mode, the protrusion in each of the dial-clutch pairs is disengaged from the open slot, allowing the dial to rotate relative to the clutch. Since the clutches do not turn along with the dials and the faulty notches look similar to the open slot, it would be difficult for an intruder to pick the lock by peeking the protrusion of the clutches while rotating the dials.

Owner:SUN LOCK COMPANY LIMITED -THE-

Portable escape equipment storage box and community intelligent fire-fighting early-warning integrated device

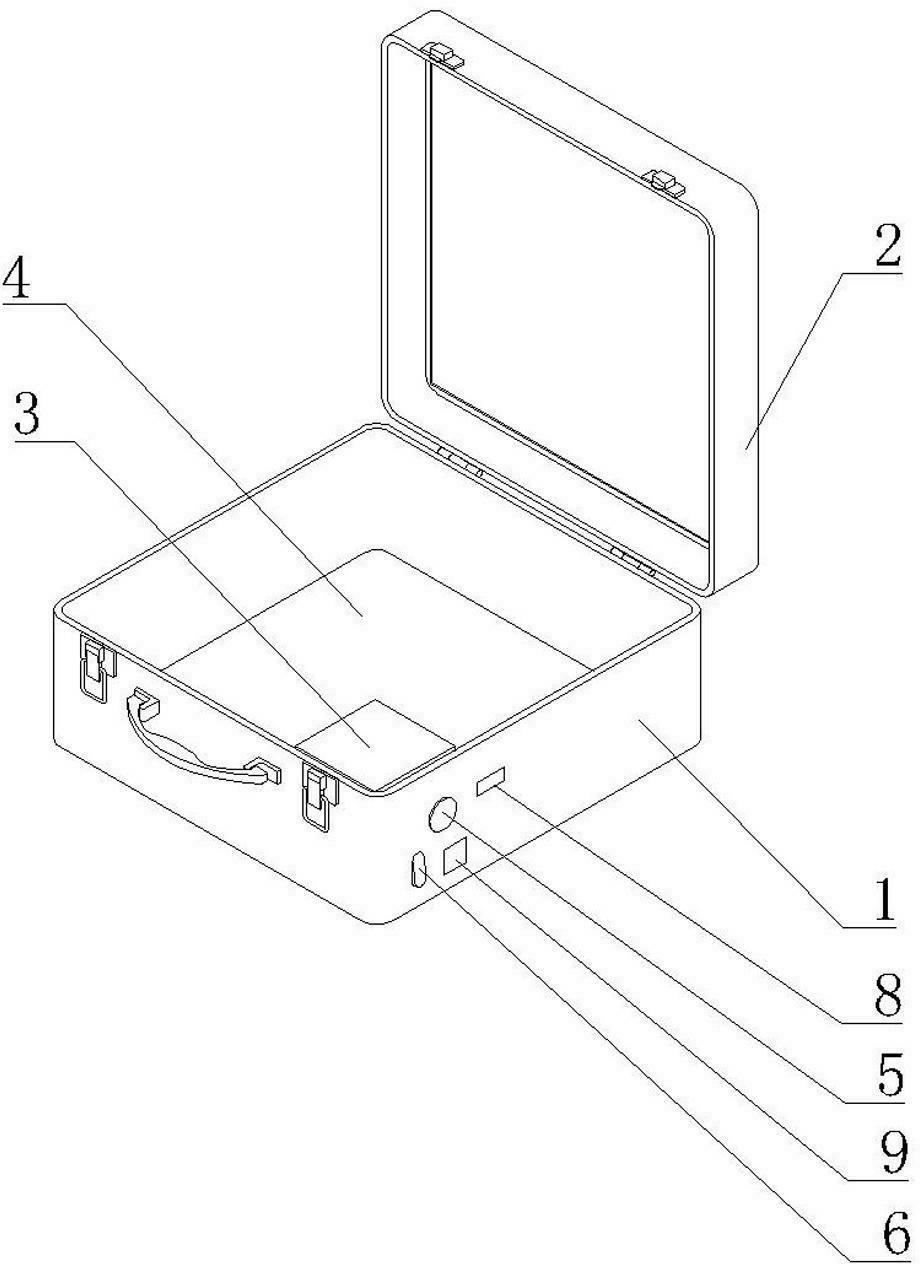

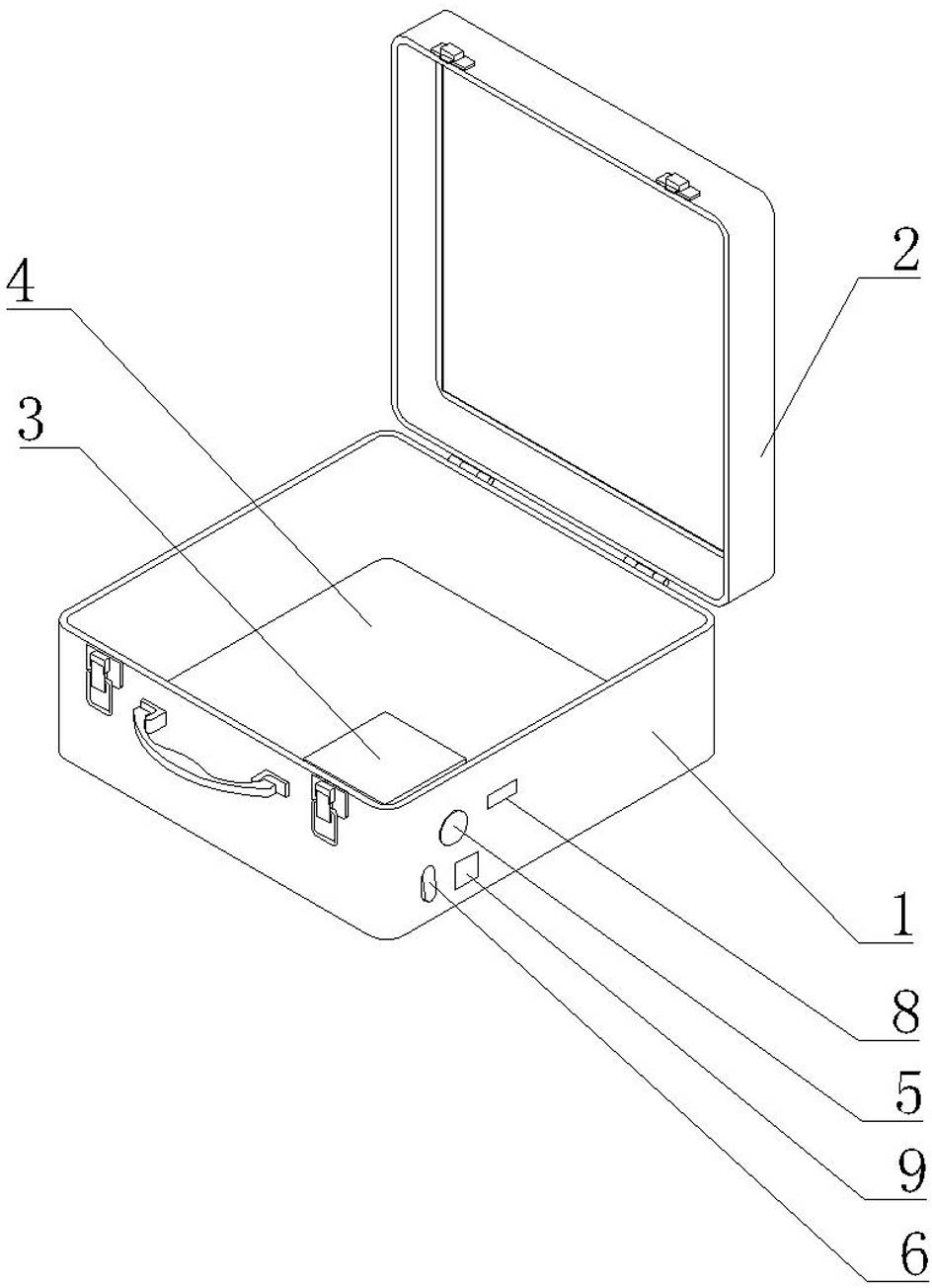

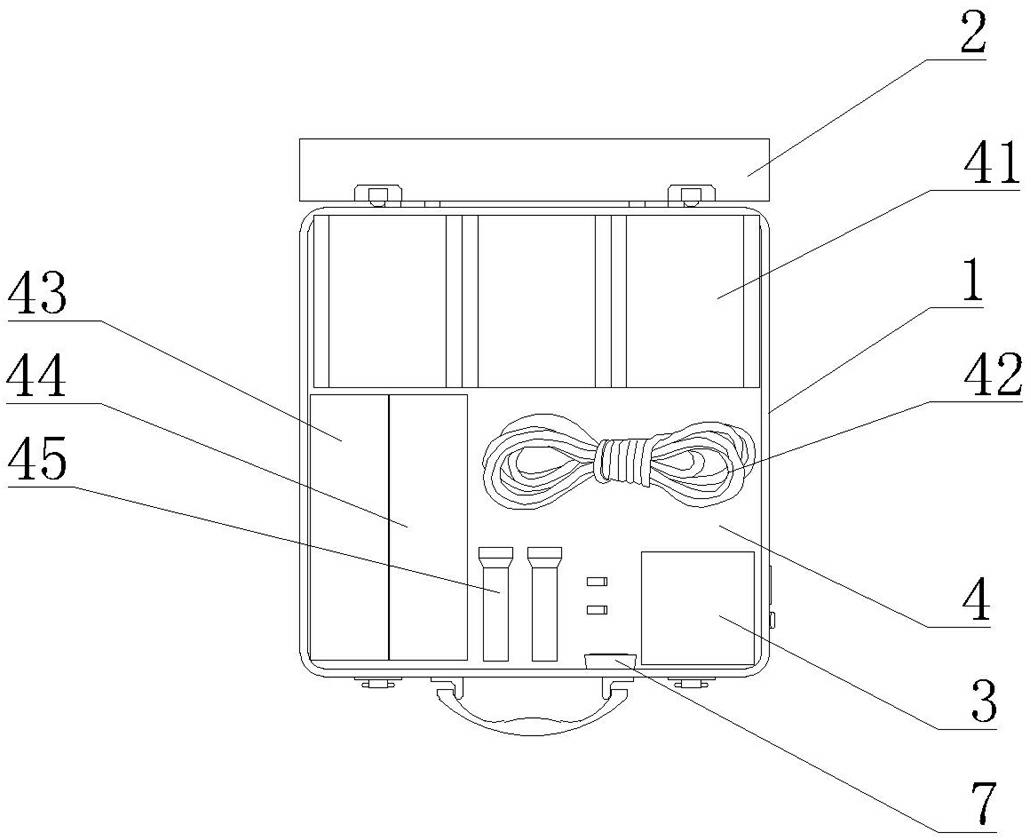

InactiveCN102521943AReduce volumeImprove reliabilityRespiratory device storageFire alarm smoke/gas actuationTransformerComputer module

The invention relates to a portable escape equipment storage box and a community intelligent fire-fighting early-warning integrated device. A control switch, a transformer and a storage battery are arranged on a box body. A signal receiving device, a signal output interface and a control module are arranged on the box body. Smoke alarms with a signal transmitting function are arranged on the box body corresponding to the signal receiving device. The signal output interface is in communication connection with a central control center. According to the invention, on one hand, when abnormal conditions such as a fire and the like burst, people in the field can be immediately warned and reminded; and on the other hand, the networked alarm with the central control center can be realized, and when a signal is immediately sent to the central control center, the central control center can timely know the fire alarm condition, immediately know the room or field in which the problem occurs and take necessary measures.

Owner:ZHEJIANG YUAN FIRE FIGHTING EQUIP

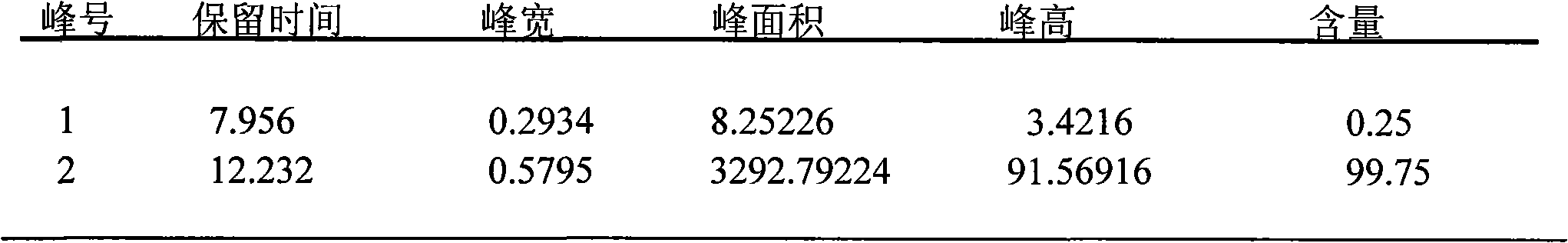

High purity scutellarin salt bulk drug and preparation method thereof

ActiveCN101683332ALow costPromote environmental protectionOrganic active ingredientsOrganic chemistryChemistryScutellarin

The invention relates to a new bulk drug in pharmaceuticals industry, and preparation process thereof. The bulk drug of the invention wherein has a weight percentage of more than 98% scutellarin salt.The preparation method is composed of following steps: first, using breviscapinun saled in market as raw materials, adding 5 to 10 times of water by weight, being heated to 60 to 80 DEG, adding 10 to20 weight percentage of aqueous slkali until the pH value is 5 to 8; second, centrifugating the solution obtained in the step one and discarding the deposition, then the obtained solution going through macroporous resin column, washing and removing, discarding the deep brown part of the first eluant, and then collecting the yellow eluant part; third, the collected eluant is disposed in vacuum concentrator, concentrating until concentration of the scutellarin salt solution is 100 to 200 mg / ml; fourth, adding organic solvent to the concentrated solution obtained in the step three and stirring,depositing, standing and filtering; fifth, washing by using the same organic solvent of the step four for 3 to 6 times, drain, and drying at a temperature of 60 to 80 DEG, then the bulk drug is obtained.

Owner:KUNMING LONGJIN PHARMA

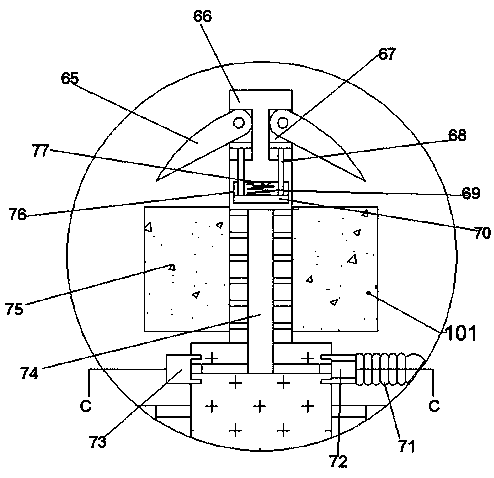

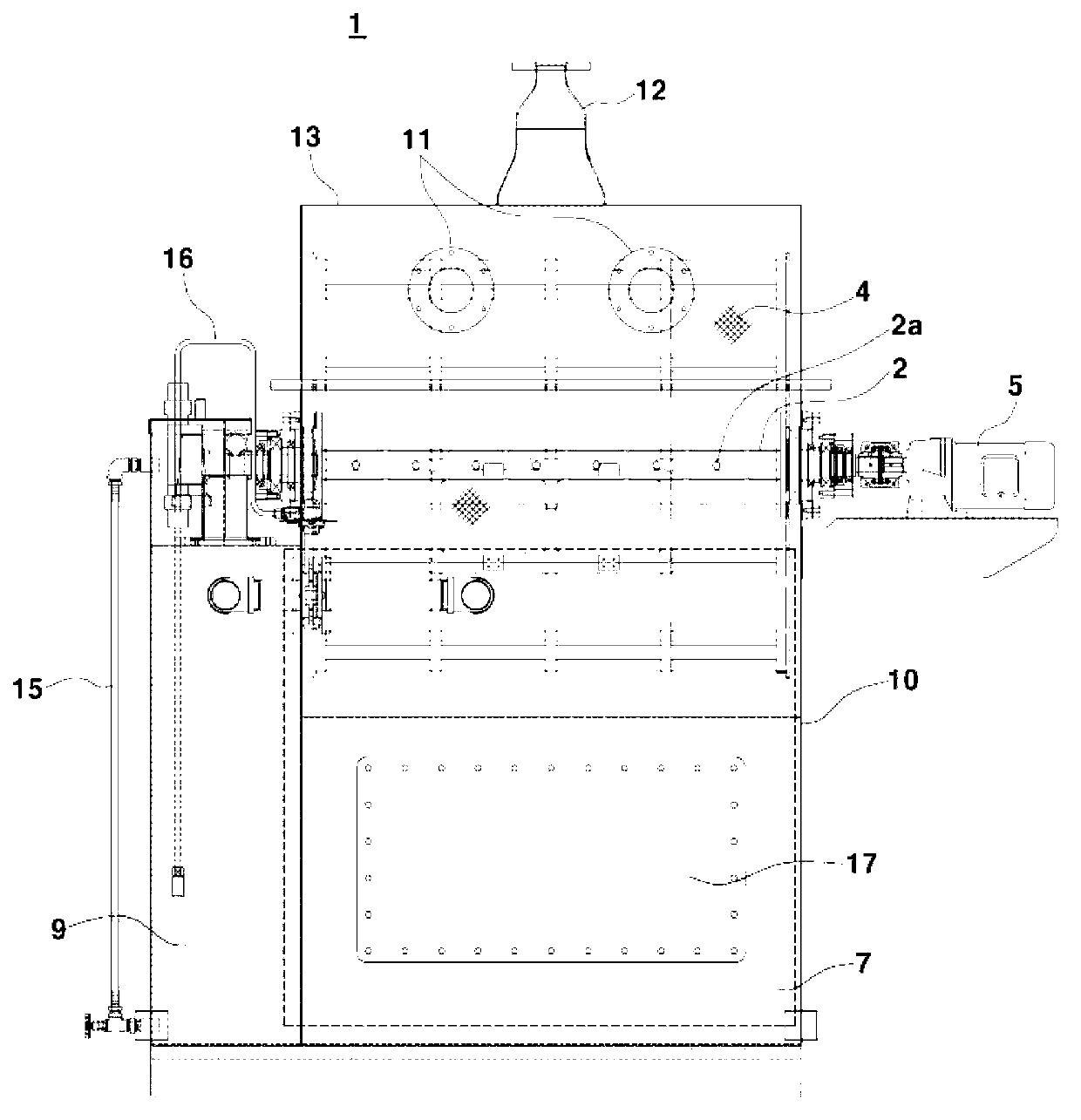

Vertical high-pressure grouting forming machine demolding process

ActiveCN106239712AEffective disengagementImprove quality pass rateDischarging arrangementMolding machineEngineering

The invention discloses a vertical high-pressure grouting forming machine demolding process. The vertical high-pressure grouting forming machine demolding process comprises the following steps that a bottom diemold is subject to diemold splitting, a middle diemold is subject to diemold splitting, a layer board is arranged to be in place, and demolding is carried out. In the demolding step, a PLC controls an outer-diemold pressurization hole of an upper diemold to be connected with an air compressor, an outer-diemold water and gas discharging hole of the upper diemold is closed at the same time, the air compressor blows compression air to the upper diemold through the outer-diemold pressurization hole of the upper diemold, and a water film is formed between the inner surface of the upper diemold and a blank; and the blank falls to the layer board due to the gravity of the layer board, the pressure of the compression air keeps to range from 0.01 Mpa to 0.2 Mpa, and the time lasts for 5 seconds to 15 seconds. By means of the above process, the process can adapt to grouting production of at least three diemolds distributed vertically, defects of the blank can be prevented from generating in the demoling process, the quality passing percentquality yield of the blank is improved, the demolding time can be further shortened, and the production efficiency is improved.

Owner:JOMOO KITCHEN & BATHROOM

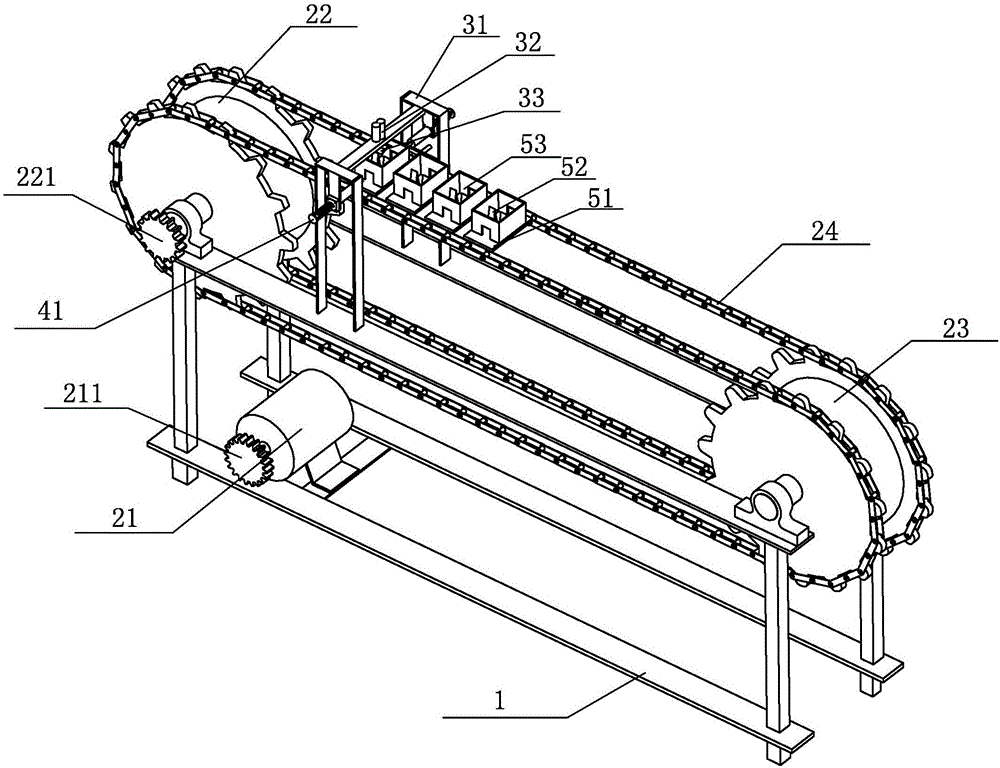

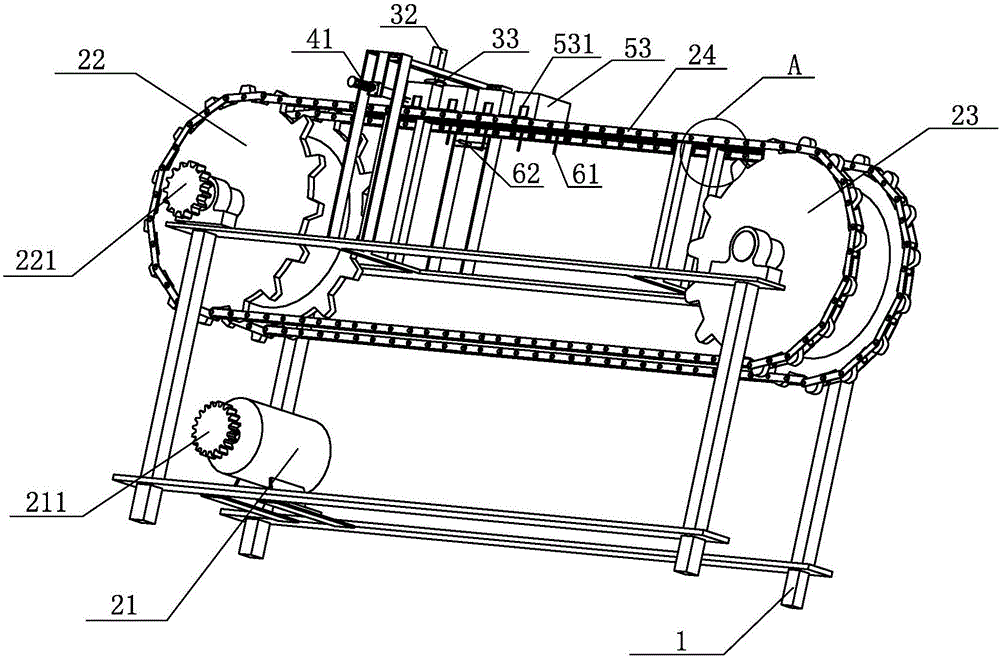

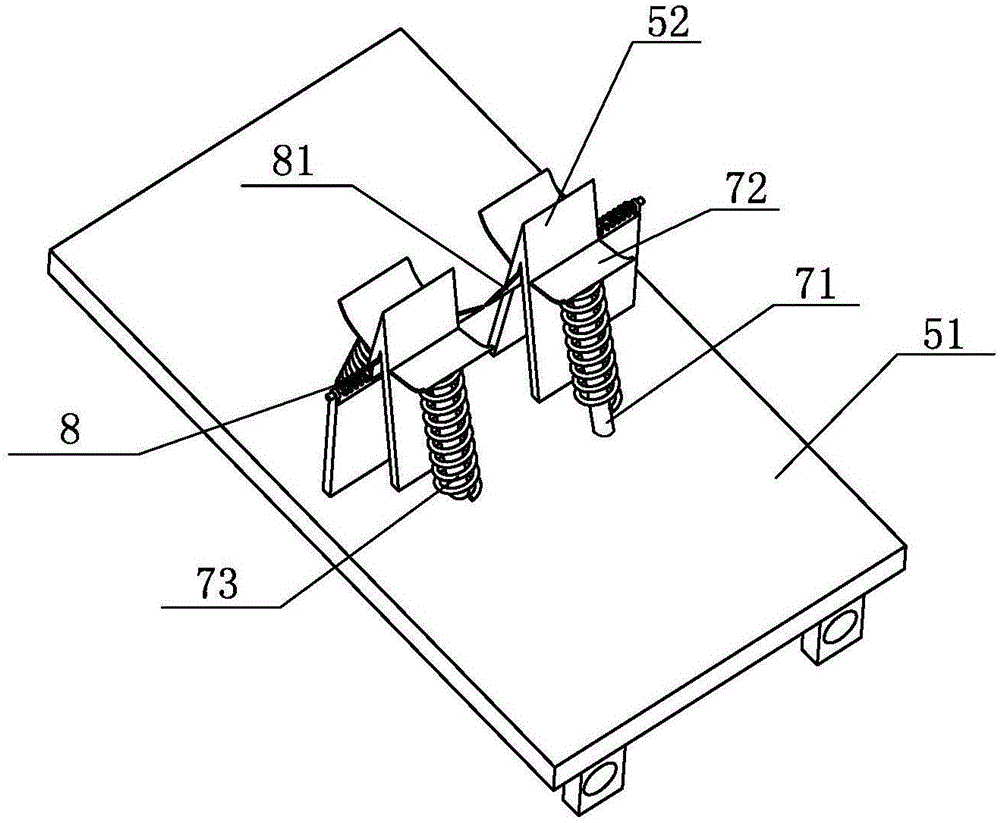

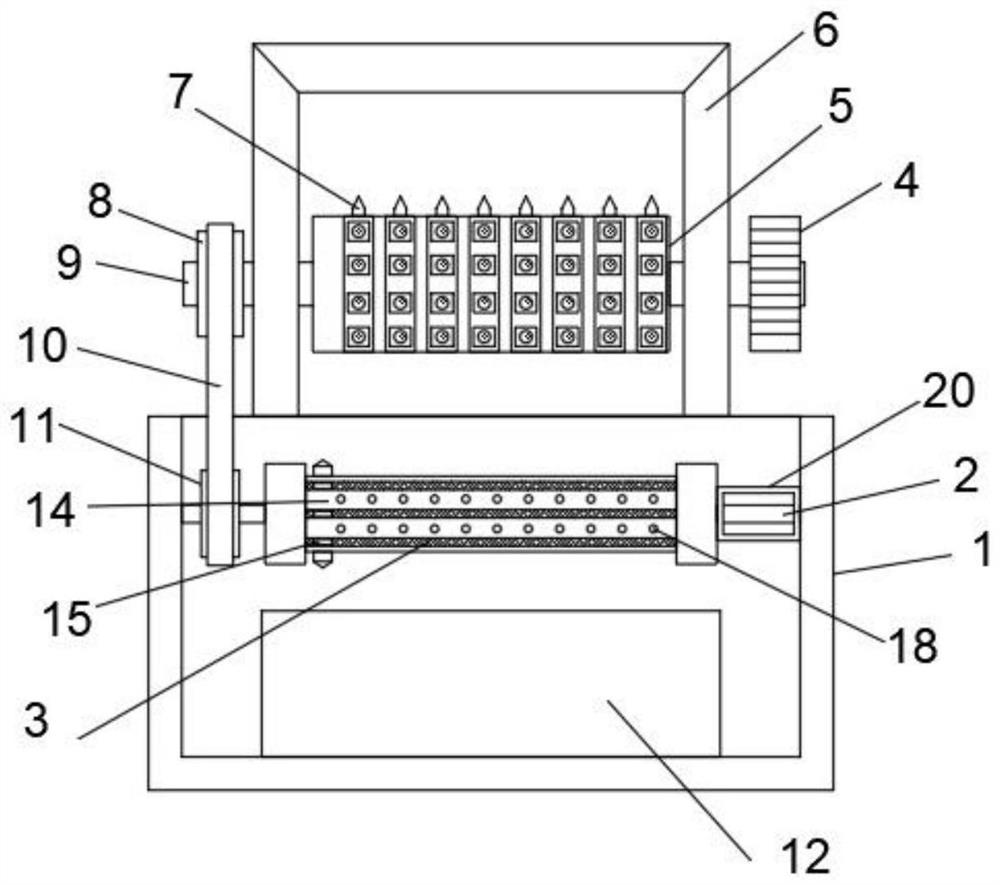

Freestone type peach pitting device

The invention discloses a freestone type peach pitting device. The freestone type peach pitting device comprises a device support, a transmission mechanism, a valve opening mechanism and a control circuit board, wherein the transmission mechanism comprises a driving motor, a driving chain wheel and a driven chain well, wherein the driving chain wheel and the driven chain wheel are correspondingly arranged on the upper portion of the device support and provided with two transmission chains in a sleeved mode; the driving motor is arranged under the device support and connected with the driving chain wheel in a chain transmission mode; the valve opening mechanism comprises a pressing device, a stone valve separating mechanism, a detecting and positioning unit and at least one group of initial positioning unit. By means of the initial positioning unit, the pressing device and the stone valve separating mechanism, the freestone type peach pitting device can easily achieve separation of peach stones and pulp, thereby effectively solving the problems of manual pitting manners such as injury to hands and high labor intensity.

Owner:SHANDONG JIAOTONG UNIV

Ore surface layer impurity removing device for mining industry

InactiveCN107790418AImprove collision and movementImprove cleaning effectCleaning using toolsCleaning using liquidsEngineeringSurface layer

The invention discloses an ore surface layer impurity removing device for the mining industry. The ore surface layer impurity removing device comprises a rack, a base, a cleaning box and an impurity removing box. The cleaning box is located in the middle of the rack, a transmission frame is installed on the rear side of the rack, and a first motor is arranged on the rear side of the transmission frame; transmission shafts are installed at the left end and the right end of the first motor, and transmission gears are installed on the transmission shafts on the left side and the right side of thefirst motor; rotating discs are installed at the front ends of the left side and the right side of the transmission frame, and rotating shafts are installed at the rear ends of the rotating discs onthe left side and the right side; and the rear end of each rotating shaft is provided with a driven gear, and the driven gears mesh with the transmission gears. Through the design, the cleaning box can move up and down, and collision and movement between ores can be improved, so that soil on the surfaces of the ores are effectively separated; and meanwhile, the soil is vibrated into the impurity removing box.

Owner:HENAN GAOSHENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Inner dirt removing device of solar water heating pipe

ActiveCN110542222AImprove practicalityEffective disengagementSolar heating energySolar heat collectors safetyEngineeringCleansing Agents

The invention discloses an inner dirt removing device of a solar water heating pipe. A machine body is included, and is internally provided with an engaging space with an upward opening; the left sidewall of the engaging space is provided with a gear cavity; a cleaning device used for cleaning the solar water heating pipe is arranged in the engaging space; firstly, clean water is added into a water tank on the upper side through a water adding port in the upper side, and a cleaning agent is added into a water tank on the lower side; the device can be used for automatically cleaning the solarvacuum water heating pipe; the device can be used for fixing the vacuum water heating pipe; meanwhile, through a rotating brush head and a scraper blade, water scale and impurities in the vacuum waterheating pipe are wiped away and scraped away; and meanwhile the brush head and the scraper blade can be freely lifted according to the length of the water heating pipe, the practicability of the device is improved, and when the brush head and the scraper blade rise, the cleaning agent is used for performing cleaning.

Owner:山东龙普太阳能股份有限公司

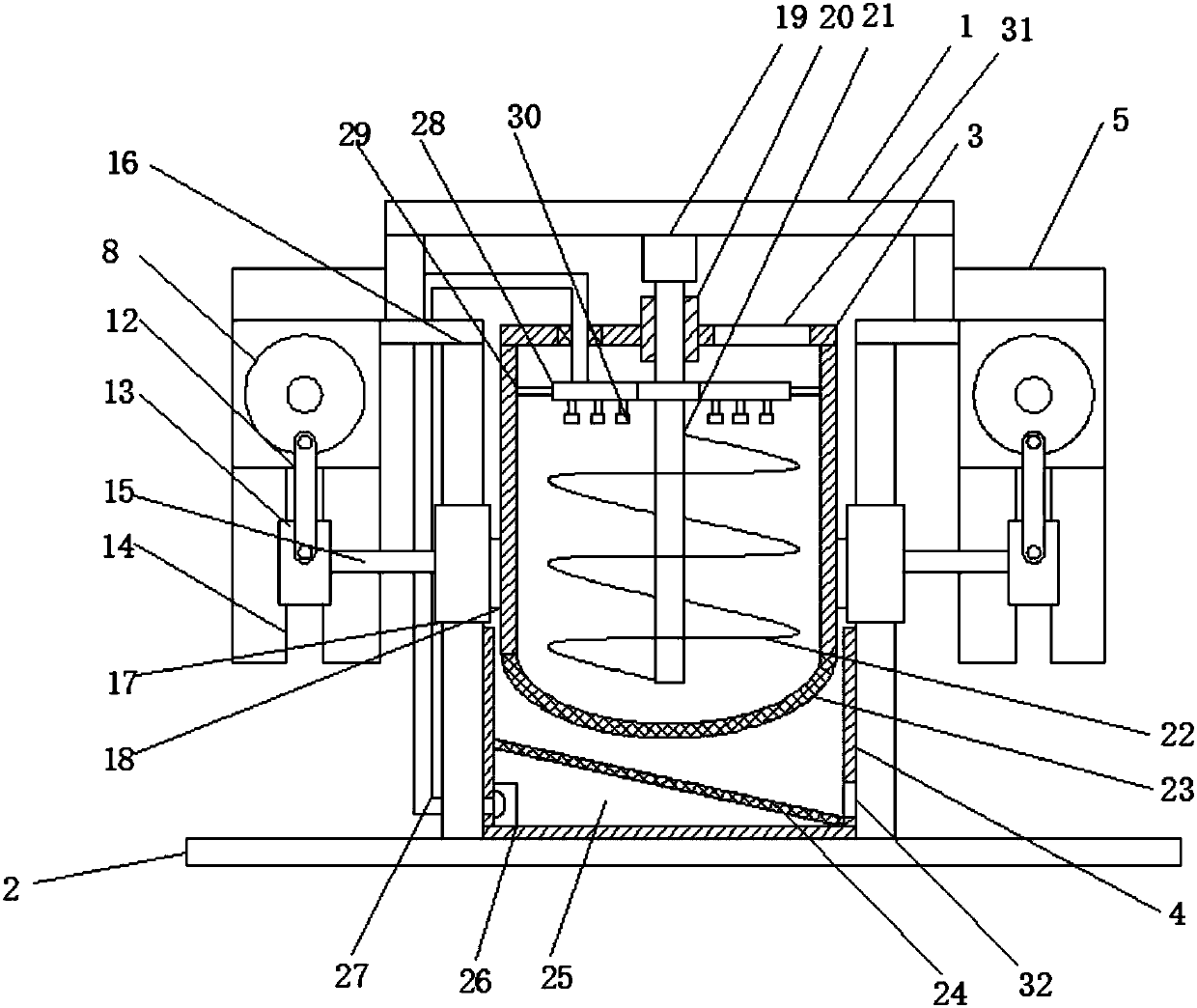

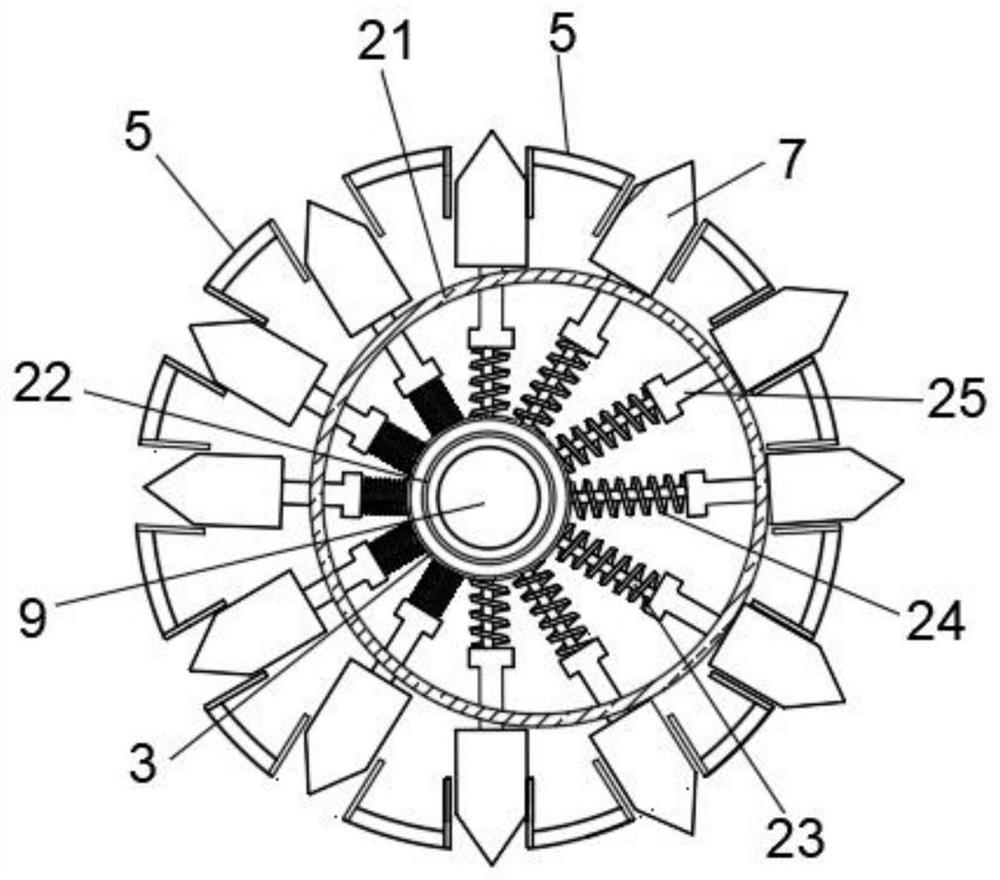

Secret-related electronic information carrier destroying equipment

The invention discloses secret-related electronic information carrier destroying equipment which comprises a box body, wherein a feeding hole is fixedly connected to the box body, two drive shafts aresymmetrically arranged in the feeding hole, the two ends of each drive shaft are rotationally connected to the inner side wall of the feeding hole, and the two drive shafts are sleeved with sleeve shafts; a plurality of rotating rings are arranged on the sleeve shafts in an equidistant annular array mode, a plurality of slide rods are arranged on the rotating rings in an equidistant annular arraymode, supporting columns are slidably connected to the ends, away from the sleeve shafts, of the slide rods, springs are fixedly connected between the supporting columns and the sleeve shafts, and crushing teeth are fixedly connected to the ends, away from the slide rods, of the supporting columns; a plurality of eccentric shafts are arranged between the crushing teeth and the sleeve shafts, theeccentric shafts are fixedly connected to the sleeve shafts, the two drive shafts and crushing rollers rotate, and the retractable crushing teeth are arrayed on each crushing roller at equal intervals, so that an information carrier is extruded and cut.

Owner:江苏益鑫通精密电子有限公司

Sassafras tsumu seed dormancy breaking and germination accelerating method suitable for Shandong region

InactiveCN103477754AImprove stabilityReduced number of reaction pointsGerminating apparatusSeed dormancyPrawn

The invention discloses a Sassafras tsumu seed dormancy breaking and germination accelerating method suitable for the Shandong region, and belongs to the tree planting field. The method is characterized in that the method comprises the steps of seed soaking treatment, oscillation pressure reduction treatment and germination accelerating treatment; and a seed soaking liquid is prepared by adding 0.6g of NaCl, 0.98g of KCl, 0.17g of CaCl2.2H2O, 0.11g of MgCl2.6H2O, 15mg of polyoxyethylene polyoxypropylene ether, 40mg of gamma-aminobutyric acid and 0.2g of astaxanthin to 1000ml of distilled water to prepare a solution. Compared with the prior art, the method has the advantages of acceleration of the Sassafras tsumu seed germination, improvement of the cold resistance of seedlings, and enhancement of the adaptation of Sassafras tsumu seeds to poor surroundings, so a high germination percentage and a high seedling survival rate can be obtained.

Owner:韩庆军

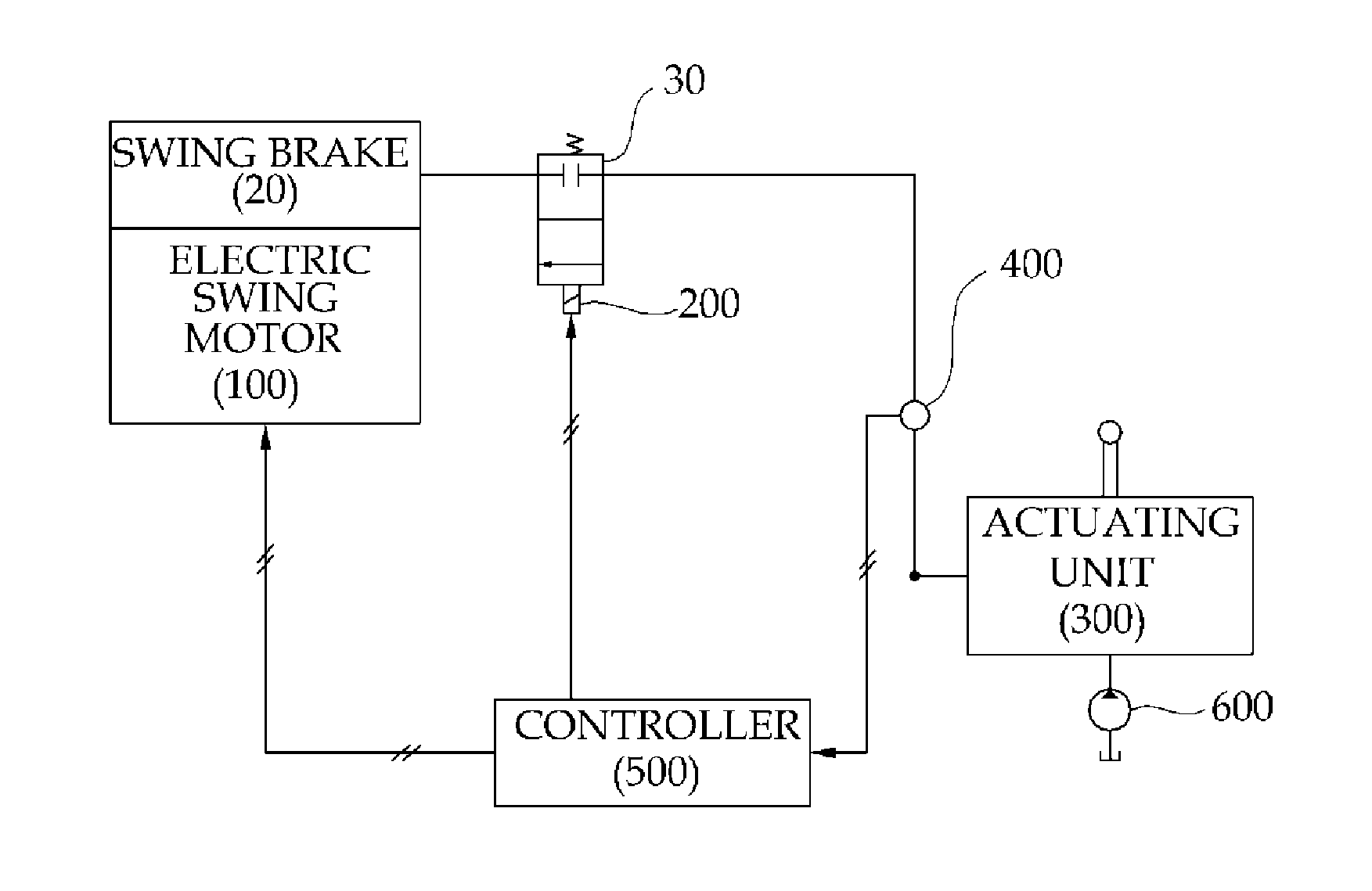

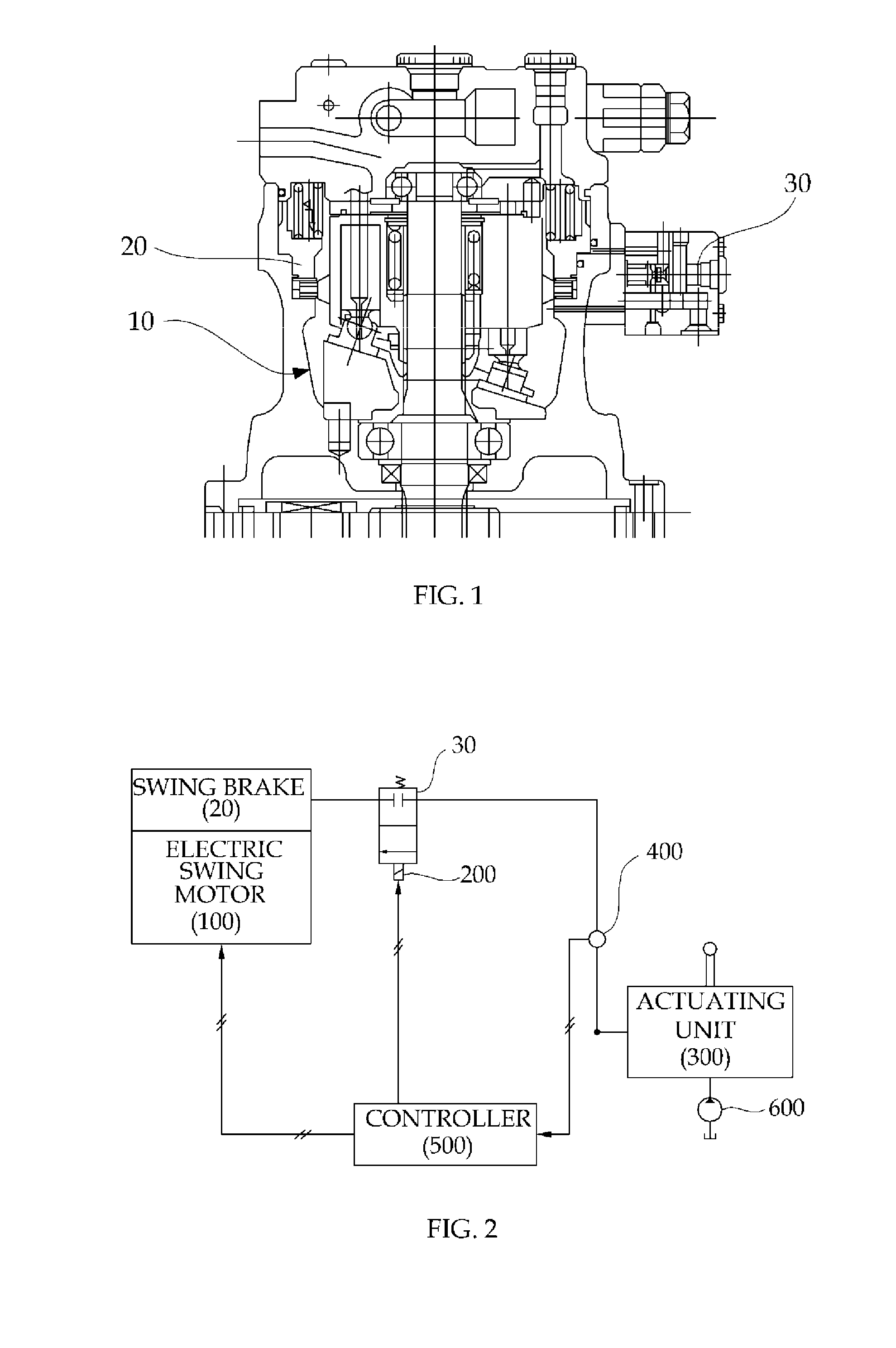

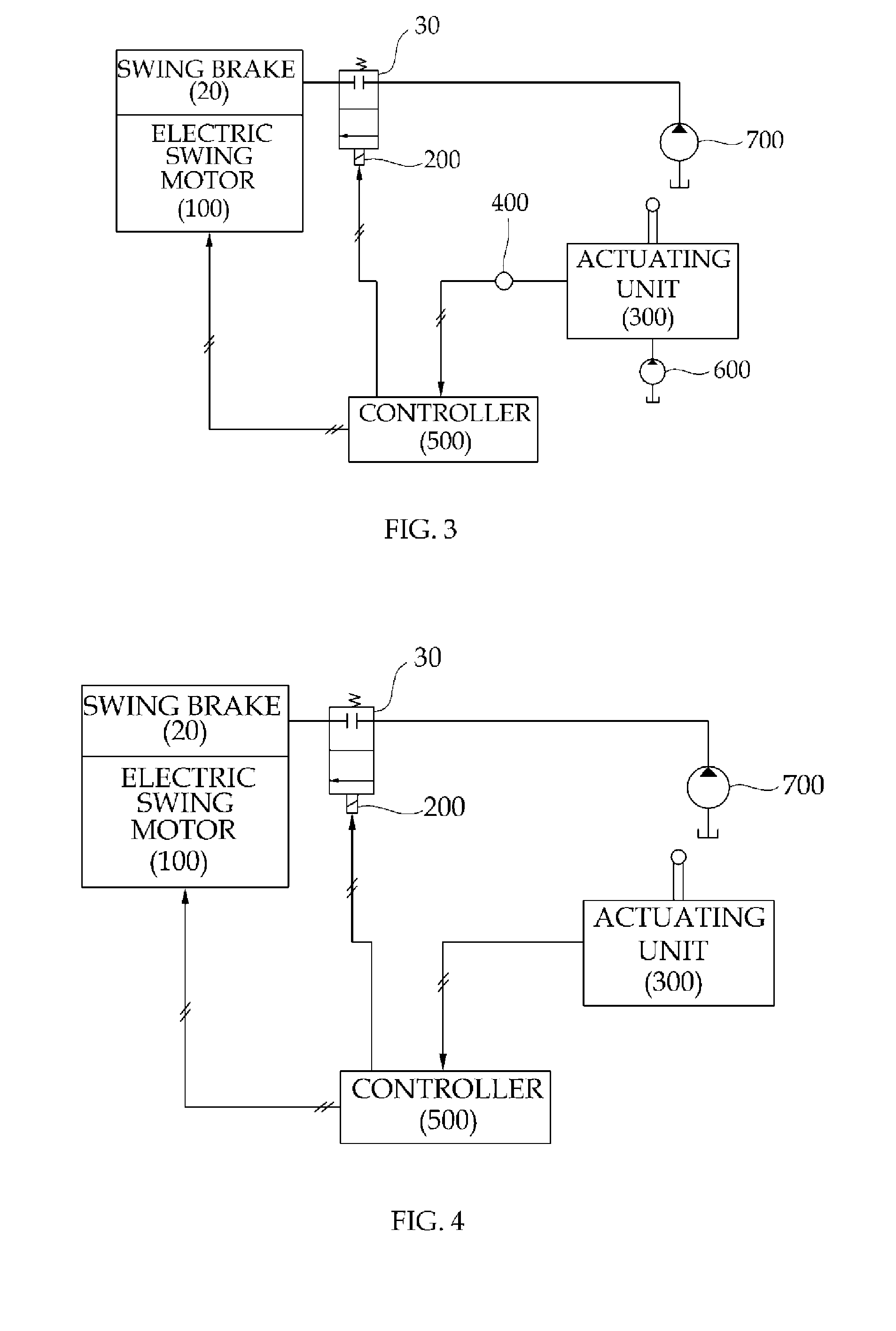

Swing brake control apparatus for construction machinery

ActiveUS20130008155A1Avoid damageAvoid accidentsFluid couplingsServometer circuitsSolenoid valveControl theory

The present disclosure relates to an apparatus for controlling a swing brake for construction machinery, comprising: a lower travel body; an upper swinging body supported at the lower travel body such that the upper swing body is capable of being swung; a swing motor for driving the upper swing body; a swing brake for braking the swing motor; a swing brake valve which operates to control the braking and releasing operations of the swing brake; a solenoid valve mounted on the swing brake valve to control the operation of the swing brake valve; an operation sensor which applies a first reference signal and a second reference signal in accordance with the motion of a swing operation control unit for controlling the operation of the upper swinging body, wherein said second reference signal is generated when an amount of displacement of the swing operation control unit is larger than the first reference signal; and a control unit, which operates the swing brake valve to release the swing brake when the first reference signal is inputted from the operation sensor, and which operates the swing motor when the second reference signal is inputted.

Owner:DOOSAN INFRACORE CO LTD

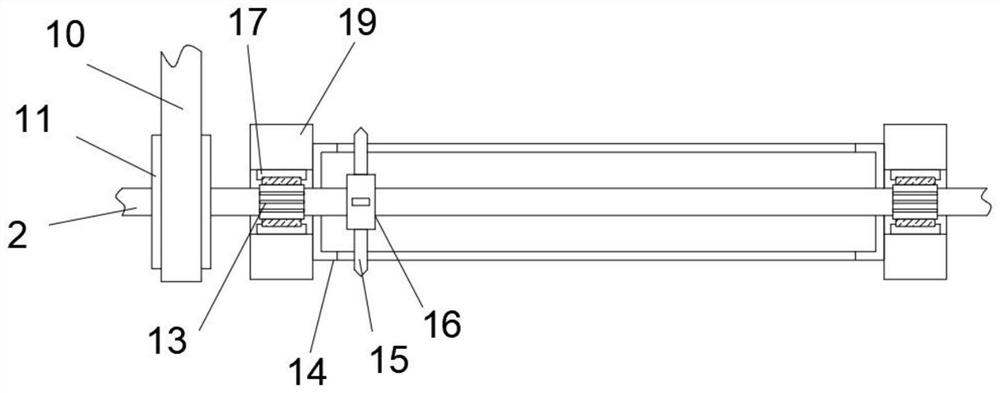

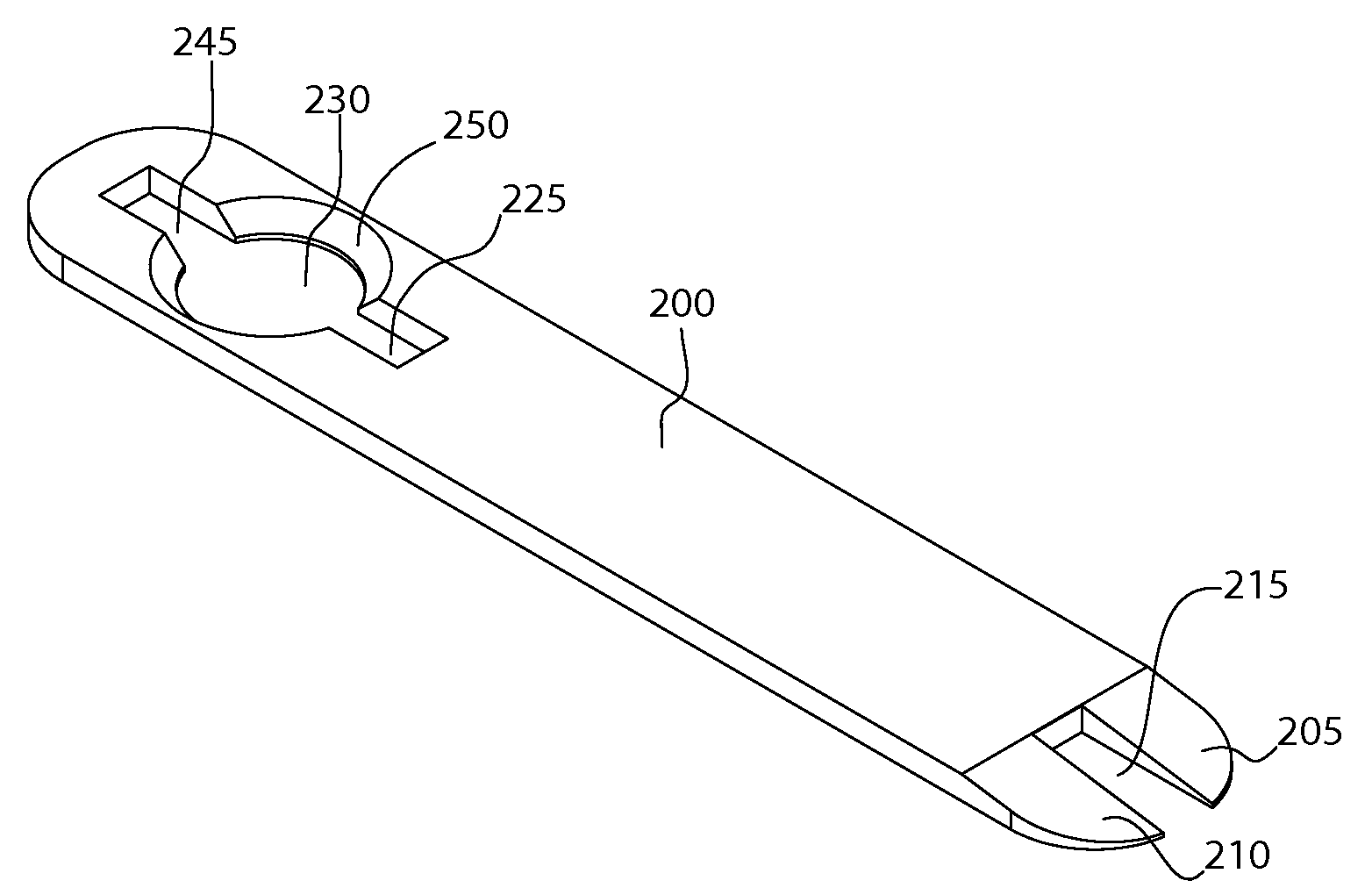

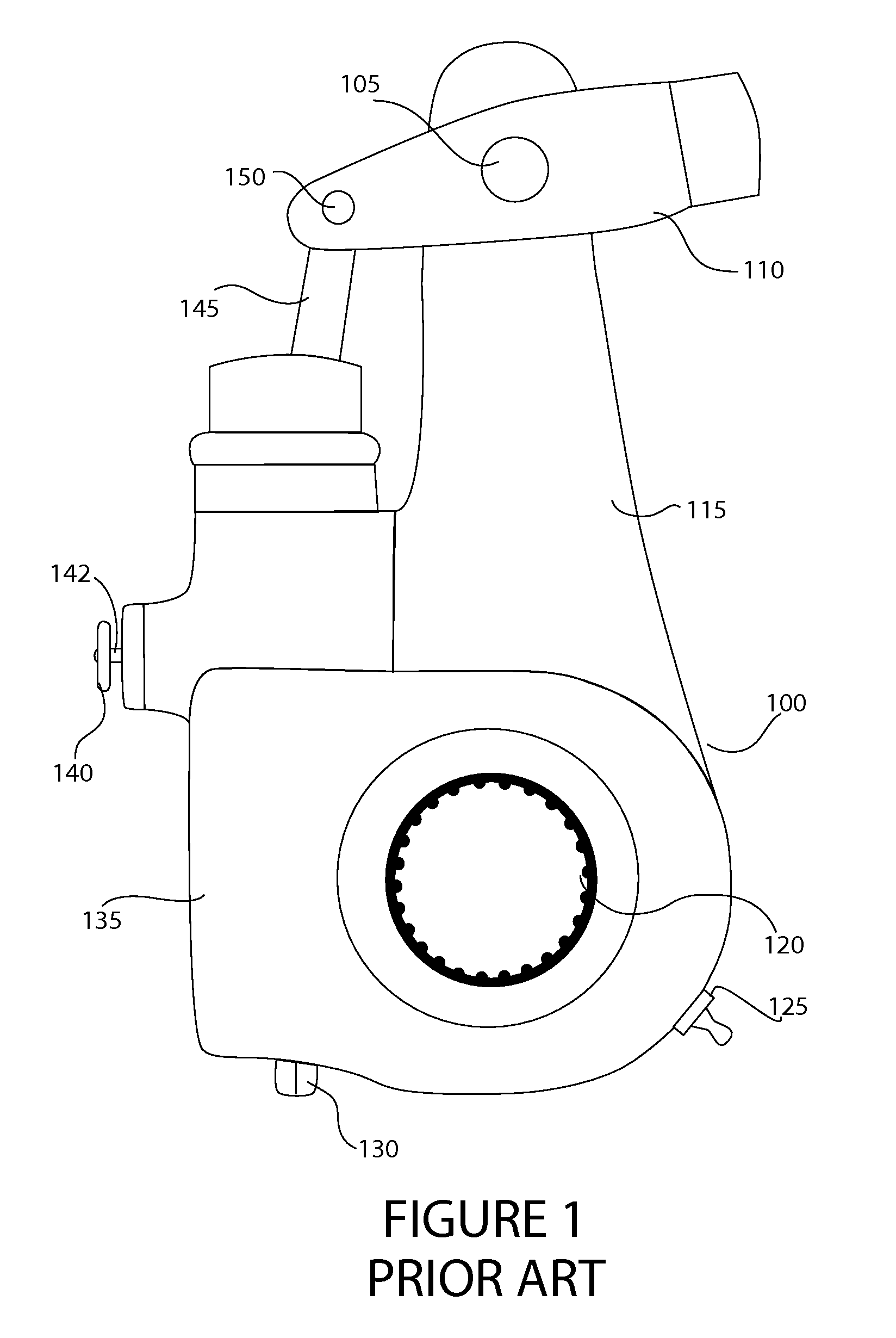

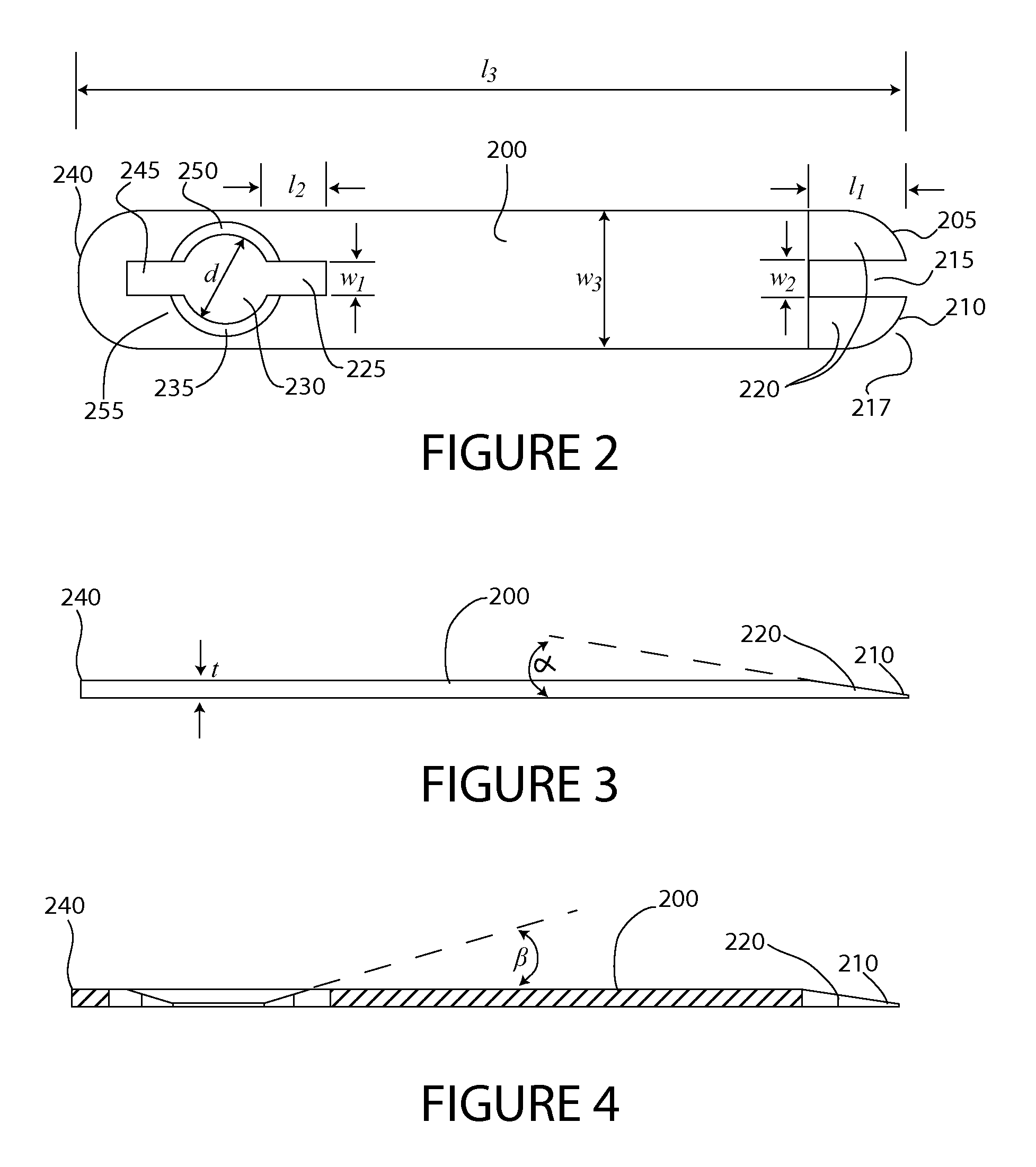

Automatic slack adjuster tool

A pawl disengagement tool intended for use with a slack adjuster has an elongated handle with a first end and an opposite second end, and a longitudinal axis extending from the first end to the second end. A slotted aperture formed at the first end includes a hole with a diameter that is greater than the first diameter of the pawl cap. A first slot extends from the hole and has a width that is greater than the second diameter of the pawl shaft of the pawl assembly of the slack adjuster. A portion of the tool defining the hole includes a chamfered periphery. The chamfered periphery defines an inclined plane leading to the first slot. The inclined plane has a thickness that increases up to a thickness equal to a disengagement thickness. The disengagement thickness is effective to cause disengagement of the pawl assembly. The second end of the tool includes a forked end that includes a pair of parallel spaced apart wedge-shaped prongs. In use, the forked end or slotted aperture is manipulated (e.g., slid) to a position between the pawl cap and the body of the slack adjuster. Then the slot of the pawl disengagement means is advanced between the pawl cap and the body of the slack adjuster, until the shaft reaches the end of the slot and the tool can be advanced no further. Upon completing this step, the pawl has been disengaged and the adjustment head may be freely rotated.

Owner:THOMPSON BARRY

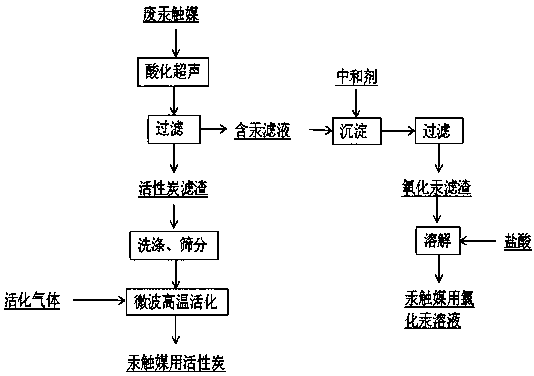

Regeneration method for waste mercuric chloride contact agent

InactiveCN109046403AEffective disengagementPromote regenerationCatalyst regeneration/reactivationActivated carbonMicrowave

The invention discloses a regeneration method for a waste mercuric chloride contact agent and belongs to a recycling technique of the waste mercuric chloride contact agent. The regeneration method comprises the following steps: firstly, performing wet-process leaching on the waste mercuric chloride contact agent, performing leaching reaction under an ultrasonic effect, and filtering, thereby acquiring a mercury-containing filtrate; controlling temperature, adding a neutralizer for regulating pH value, completely converting mercury ions in the solution into mercuric oxide sediments, and keepingtoxic phosphor and sulfur in the mercury contact agent still in the solution; dissolving mercuric oxide with hydrochloric acid, thereby acquiring a mercuric chloride solution used for preparing the mercury contact agent; performing microwave high-temperature activating on filter residue (waste contact agent for mercury removal) under the condition of activating gas, thereby acquiring a regenerated activated carbon for waste mercury contact agent; soaking the activated carbon for waste mercury contact agent in a mercuric chloride solution for waste mercury contact agent, thereby acquiring a new mercuric chloride contact agent. According to the invention, efficient recycling of mercuric chloride and regeneration of activated carbon can be simultaneously realized in the manner of combining ultrasonic acidizing leaching with microwave high-temperature activating treatment.

Owner:KUNMING UNIV OF SCI & TECH

Water removal device for cotton cloth processing

InactiveCN108759364AProblems Affecting Subsequent ProcessingEffective disengagementDrying machines with non-progressive movementsHeating arrangementCotton clothEngineering

The invention discloses a water removal device for cotton cloth processing. The water removal device comprises a box. An opening is formed in one side of the box, and the opening position is rotationally connected with a door panel. A rubber pad is arranged on the surface of the door panel. The top of the box is fixedly connected with a rotation motor. The output end of the rotation motor penetrates the top of the box through a first rolling bearing and is fixedly connected with a rotation rod. The bottom of the rotation rod is rotationally connected with the inner wall of the bottom of the box through a second rolling bearing. The outer wall of the rotation rod is sleeved with two sleeves in a sliding manner. Four symmetrically-distributed first supporting rods are fixedly connected to the outer walls of the sleeves. The ends, away from the sleeves, of the first supporting rods are fixedly connected with first clamping plates. First cavities are formed in the first clamping plates. Two first springs are arranged in each first cavity. By means of the water removal device for cotton cloth processing, water in the cotton cloth can be effectively separated, and cotton cloth differentin size can be conveniently clamped; and meanwhile, the cotton cloth can be conveniently dried, and a filter net can be conveniently replaced.

Owner:徐州锦翔纺织有限公司

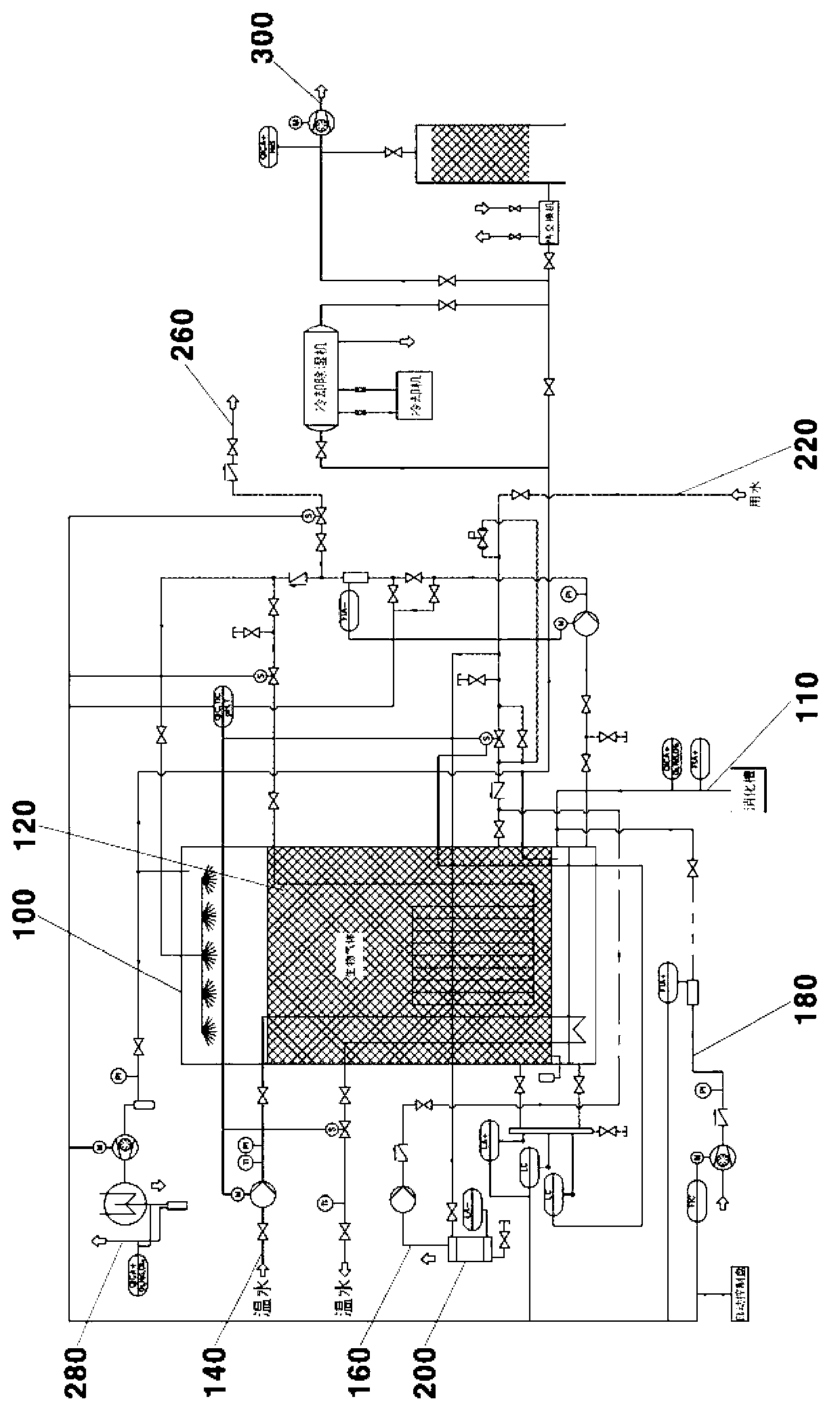

Bio-gas hydrogen sulfide removal device by using ion exchange fiber Pall ring for bio-gas purification

InactiveCN103127818AEffective disengagementImprove cleanlinessGas treatmentDispersed particle separationFiberIon exchange

The present invention relates to a bio-gas hydrogen sulfide removal device which can continuously remove hydrogen sulfide in bio-gas. The bio-gas hydrogen sulfide removal device adopts ion exchange fiber Pall ring for bio-gas purification. The Pall ring is filled in a net drum cylinder. The Pall ring is provided with ion-exchange fiber. When the drum rotates, the Pall ring precipitates in a regeneration liquid for ion exchange. Through the internal friction shock of the Pall ring, under the condition of without an external additional device, the regenerated chloride is removed efficiently, so that the hydrogen sulfide scavenging capacity is maintained at the maximum, and the use amount of the regeneration liquid is reduced. In addition, hydrogen sulfide from bio-gas is removed, so that the damage of hydrogen sulfide in the process of using bio-gas is minimized. Corrosion for power equipments and boilers can be prevented by using bio-gas as a fuel.

Owner:DH M

Electromagnet drive flexible glue adhering gripping device

InactiveCN106927251ASimple designEasy to disassemble and replaceConveyor partsEngineeringMechanical engineering

An electromagnet drive flexible glue adhering gripping device comprises a linear guide rail. A sliding block is mounted on the linear guide rail. An electromagnet is fixed to the lower portion of the linear guide rail. A transverse rod is fixed to the sliding block. An iron block is fixed to the transverse rod. A spring is fixed between the sliding block and the electromagnet. A flexible glue body is fixed under the electromagnet. The two ends of the flexible glue body are connected with the two ends of the transverse rod through stay cords. The sliding block can move on the linear guide rail, when the electromagnet is not electrified, the transverse rod is separated from the electromagnet through elastic force of the spring, the stay cords at the two ends of the transverse rod pull the flexible glue body open. When the electromagnet is electrified, the transverse rod is pulled down, a permanent magnet block embedded in the flexible glue body and the electromagnet reprehend each other, and thus materials are gripped. The wrapping force of the flexible glue body to the materials is increased by embedding the permanent magnet block, so that the materials are gripped more reliably.

Owner:ZHEJIANG UNIV OF TECH

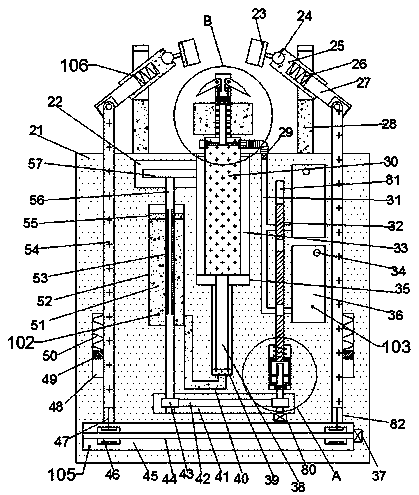

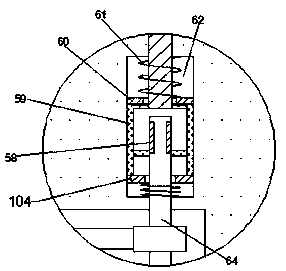

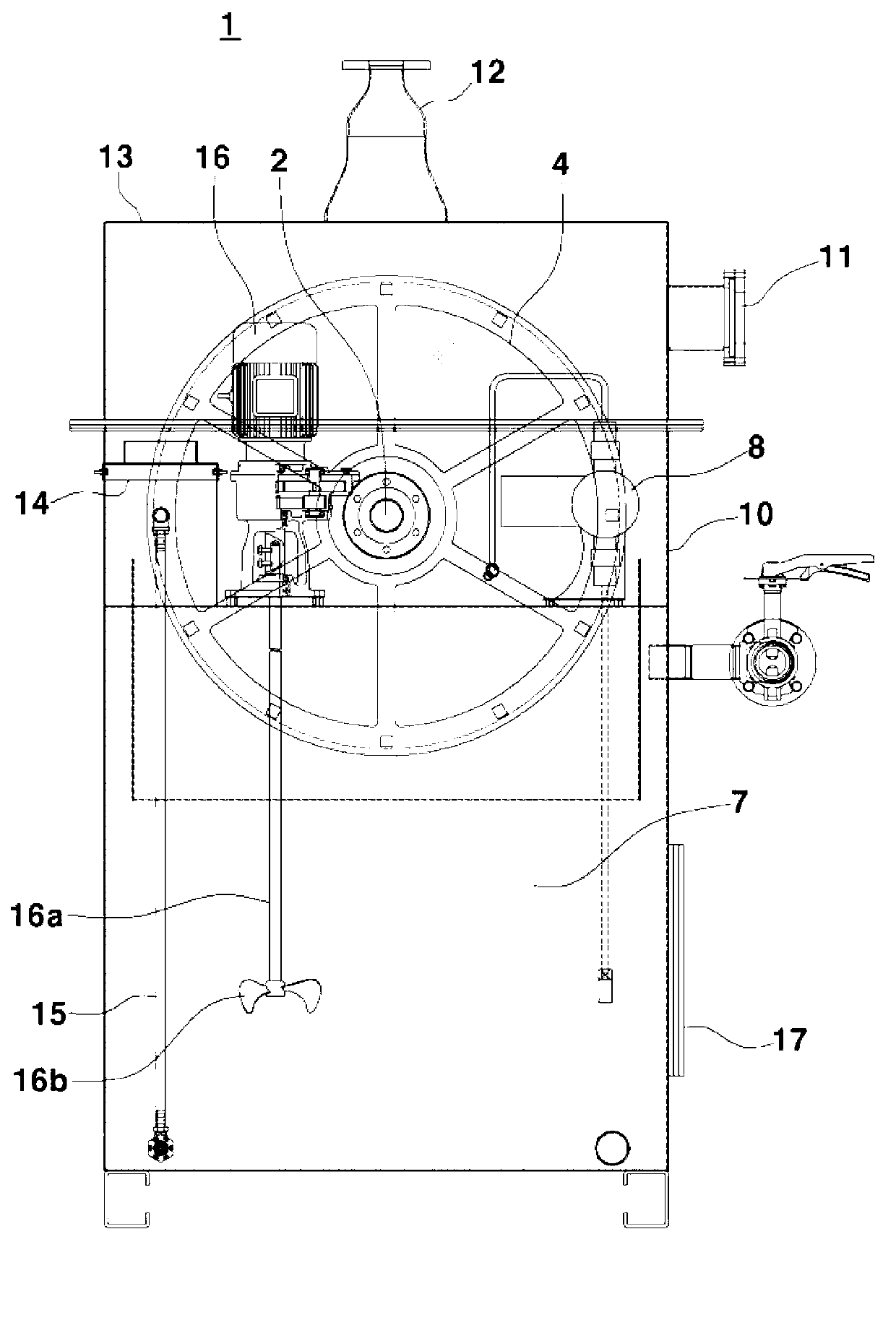

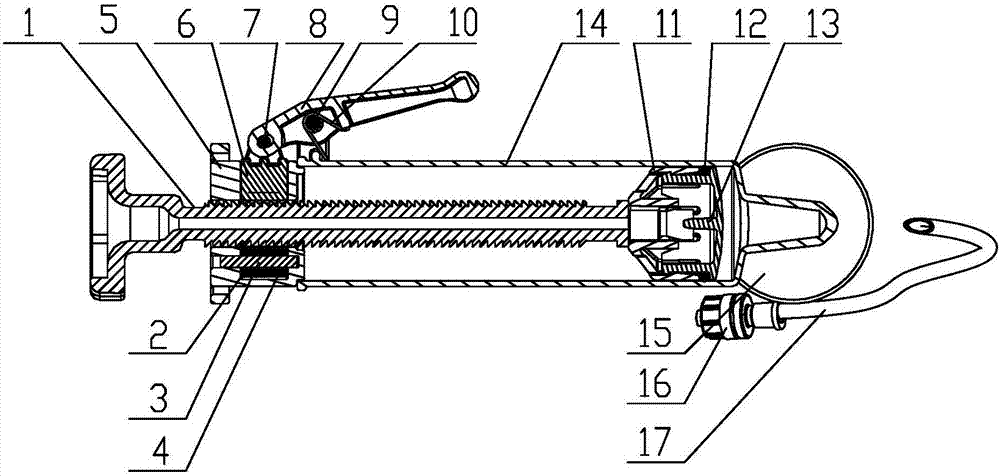

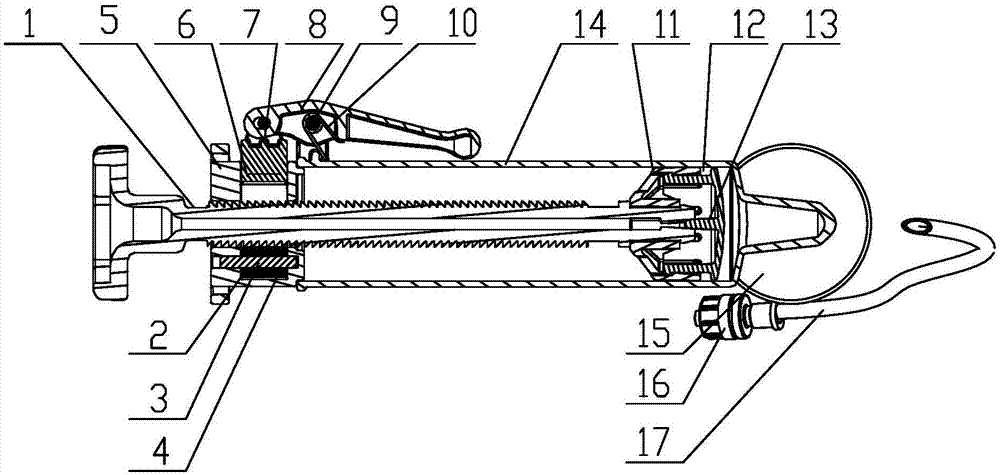

Medical pressure charging control device

Owner:MICRO TECH (NANJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com