Electromagnet drive flexible glue adhering gripping device

A grabbing device and electromagnet technology, which is applied in the field of material grabbing devices, can solve problems such as poor safety performance and damage to objects, and achieve the effects of easy disassembly and replacement, rapid release, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

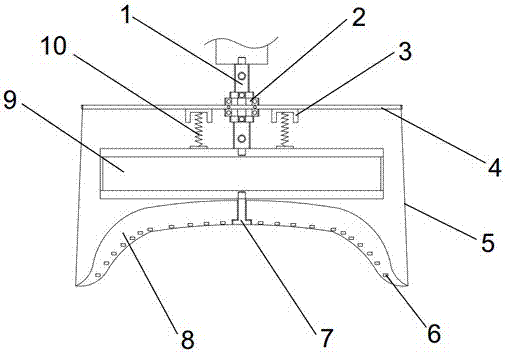

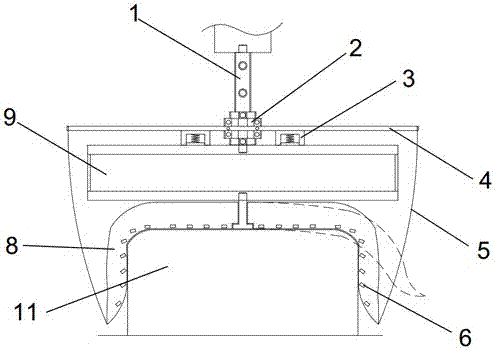

[0020] An electromagnet-driven flexible adhesive grabbing device, including a linear guide rail 1, a slider 2 is installed on the linear guide rail, an electromagnet 9 is fixed below the linear guide rail, a cross bar 4 is fixed on the slider, and a cross bar 4 is fixed on the cross bar A concave iron block 3 is provided at the spring fixing part of the spring, a spring 10 is fixed between the slider and the electromagnet, and a flexible colloid 8 is fixed by a screw 7 under the electromagnet. The flexible colloid is made of silica gel, and the S magnetic pole of the small permanent magnet block 6 Upward and N magnetic pole facing down, embedded in the lower edge of the flexible colloid, and the end of the flexible colloid is designed as an arc; .

[0021] The silicone material has good elasticity and suitable viscosity, which can not only withstand repeated deformation, but also maintain the viscosity for a long time, and can be used repeatedly.

[0022] In the non-working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com