Regeneration method for waste mercuric chloride contact agent

A technology of mercuric chloride and mercury catalyst, which is applied in chemical instruments and methods, catalyst regeneration/reactivation, chemical/physical processes, etc., can solve the problems of long reaction time, complicated treatment process, and large reagent consumption, and achieve effective Conducive to regeneration, process cleaning and environmental protection, large environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

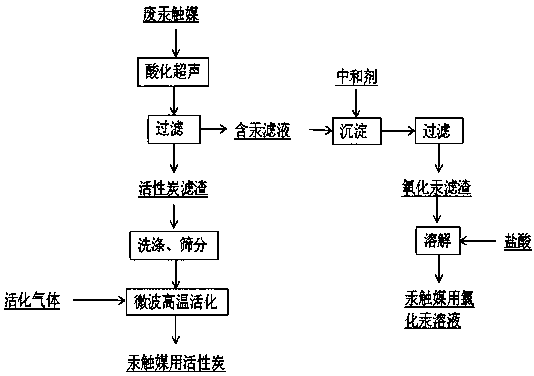

Method used

Image

Examples

Embodiment 1

[0025] A kind of regeneration method of waste mercuric chloride catalyst, specifically comprises the following steps:

[0026] (1) Add reagent A to the spent mercuric chloride catalyst at a mass ratio of 1:2 of spent mercuric chloride catalyst and hydrochloric acid and mix well to obtain mixture B.

[0027] (2) Under the action of ultrasound (frequency 1000Hz, power 100W), the mixture B obtained in step (1) was subjected to leaching reaction for 5 minutes; the temperature was 30°C, and the filtrate and filter residue were obtained.

[0028] (3) Control the temperature of the mercury-containing filtrate in (2) to 40°C, adjust the pH value to 4 with sodium hydroxide, and react for 30 minutes to completely convert the mercury ions in the solution into mercury oxide precipitates; after filtration, mercury oxide is obtained , Dissolved with hydrochloric acid to obtain mercuric chloride solution for mercury catalyst.

[0029] (4) Under the condition of passing water vapor (the flow...

Embodiment 2

[0033] A kind of regeneration method of waste mercuric chloride catalyst, specifically comprises the following steps:

[0034] (1) Add reagent A to the spent mercuric chloride catalyst at a mass ratio of 1:4 of spent mercuric chloride catalyst to sodium thiosulfate and mix well to obtain mixture B.

[0035] (2) Under the action of ultrasound (frequency 2500Hz, power 200W), the mixture B obtained in step (1) was subjected to leaching reaction for 15 minutes; the temperature was 50°C, and the filtrate and filter residue were obtained.

[0036] (3) Control the temperature of the mercury-containing filtrate in (2) to 60°C, use sodium carbonate to adjust the pH value to 6, and react for 60 minutes to completely convert the mercury ions in the solution into mercuric oxide precipitates; after filtration, mercuric oxide is obtained, Dissolve with hydrochloric acid to obtain mercury chloride solution for mercury catalyst.

[0037] (4) Under the condition of passing water vapor (the fl...

Embodiment 3

[0041] A kind of regeneration method of waste mercuric chloride catalyst, specifically comprises the following steps:

[0042] (1) Add reagent A to the spent mercuric chloride catalyst at a mass ratio of 1:6 of spent mercuric chloride catalyst to hydrogen peroxide and mix evenly to obtain mixture B.

[0043] (2) Under the action of ultrasound (frequency 100Hz, power 10W), the mixture B obtained in step (1) was subjected to leaching reaction for 25min; the temperature was 80°C, and the filtrate and filter residue were obtained.

[0044] (3) Control the temperature of the mercury-containing filtrate in (2) to 80°C, adjust the pH value to 9 with sodium hydroxide, and react for 100 minutes to completely convert the mercury ions in the solution into mercuric oxide precipitates; after filtration, mercuric oxide is obtained , Dissolved with hydrochloric acid to obtain mercuric chloride solution for mercury catalyst.

[0045](4) Under the condition of feeding carbon dioxide gas (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com