Brake caliper assembly of normally open type wind driven generator main shaft system

A technology for wind turbines and brake calipers, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of high maintenance cost, complex structure, low brake pad and brake disc life, etc. Abnormal wear, increased service life, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

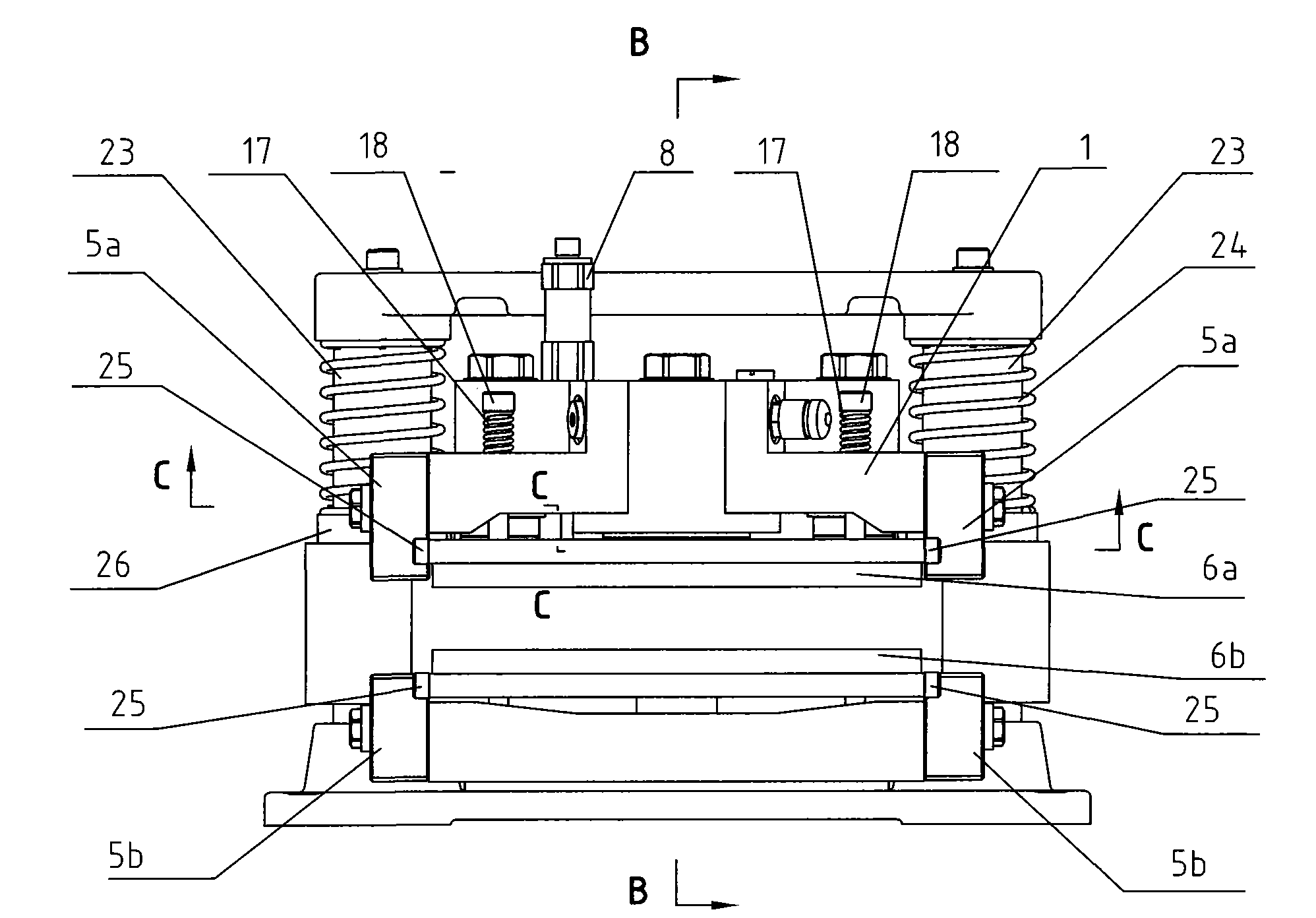

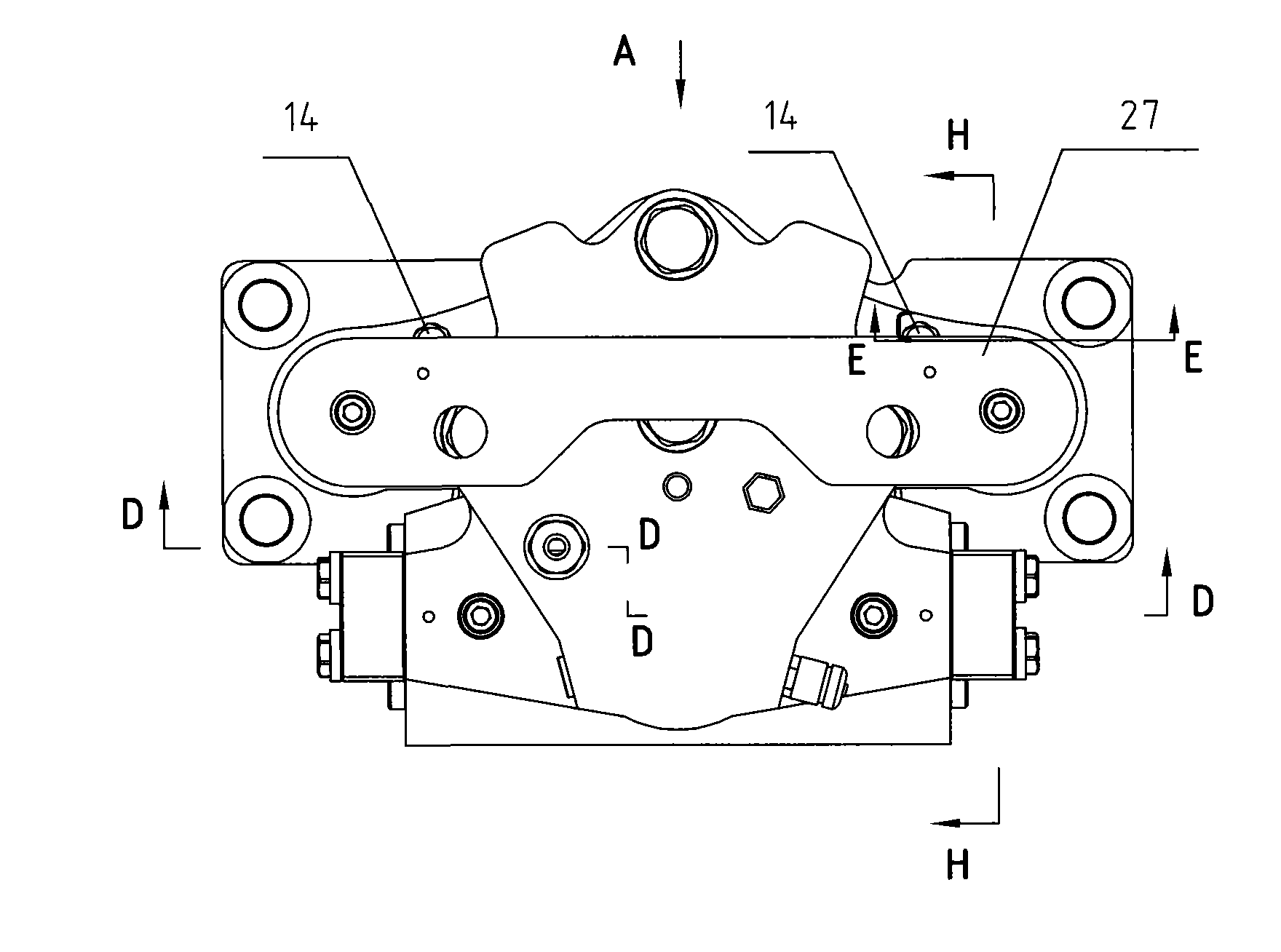

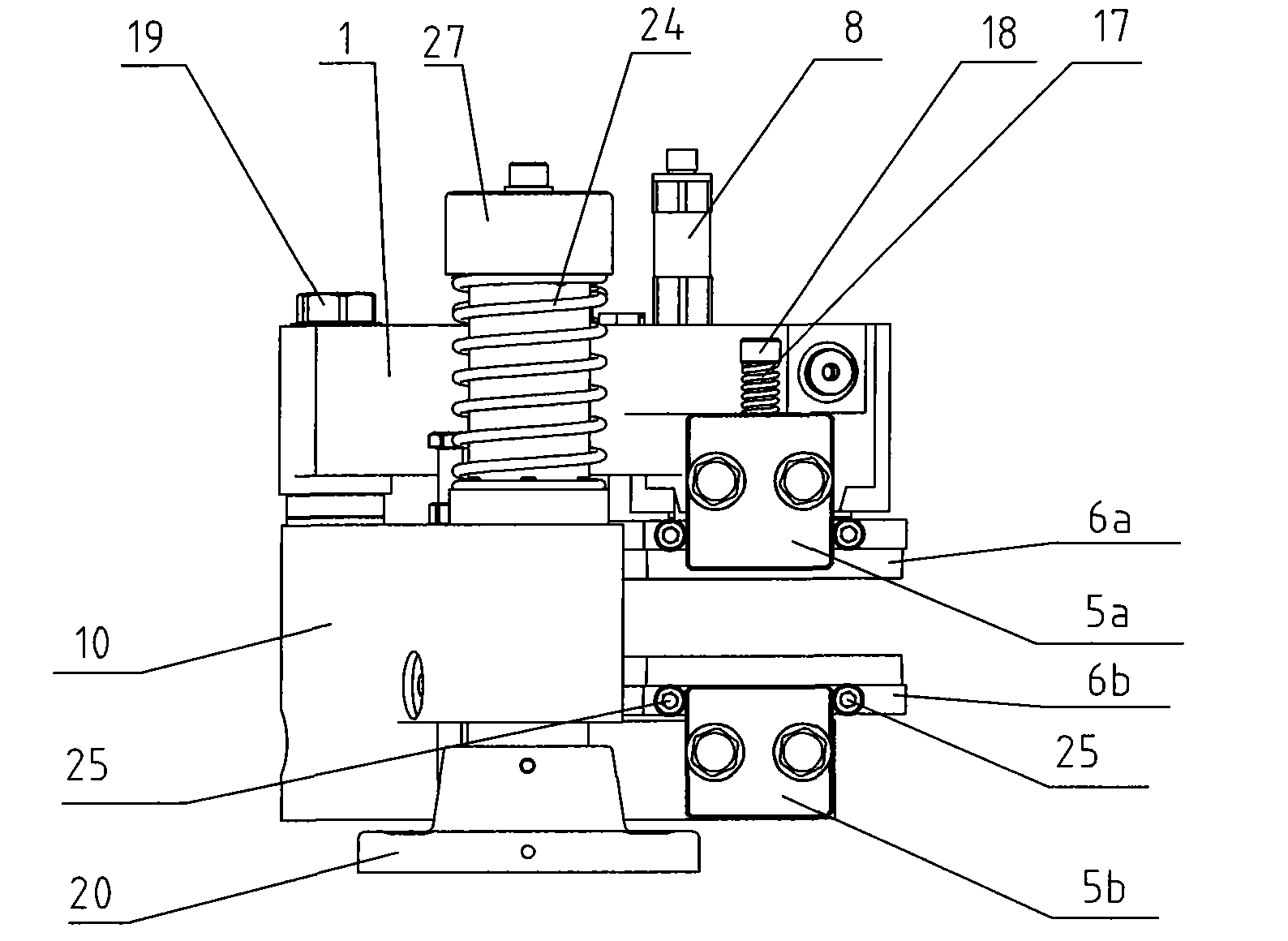

[0024] figure 1 It is a structural schematic diagram of the brake caliper assembly of the present invention; figure 2 for figure 1 top view of image 3 for figure 1 left view of Figure 4 for figure 1 Sectional view along B-B direction; Figure 5 for figure 2 View along direction A; Figure 6 for figure 1 Sectional view along C-C direction; Figure 7 for figure 2 Sectional view along D-D; Figure 8 for figure 2 Middle H-H sectional view; Figure 9 for figure 1 Top view of middle piece 1; Figure 10 for Figure 9 Middle F-F sectional view; Figure 11 for figure 2 Sectional view along E-E direction.

[0025] as the picture shows:

[0026] The brake caliper assembly of the normally open wind power generator main shaft system of the present invention includes a brake caliper body, the brake caliper body includes a first half 1 and a second half 10, the first half 1 and the second half The halves 10 are connected by screws 19 .

[0027] Wherein, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com