Patents

Literature

77results about How to "Reduce abnormal wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

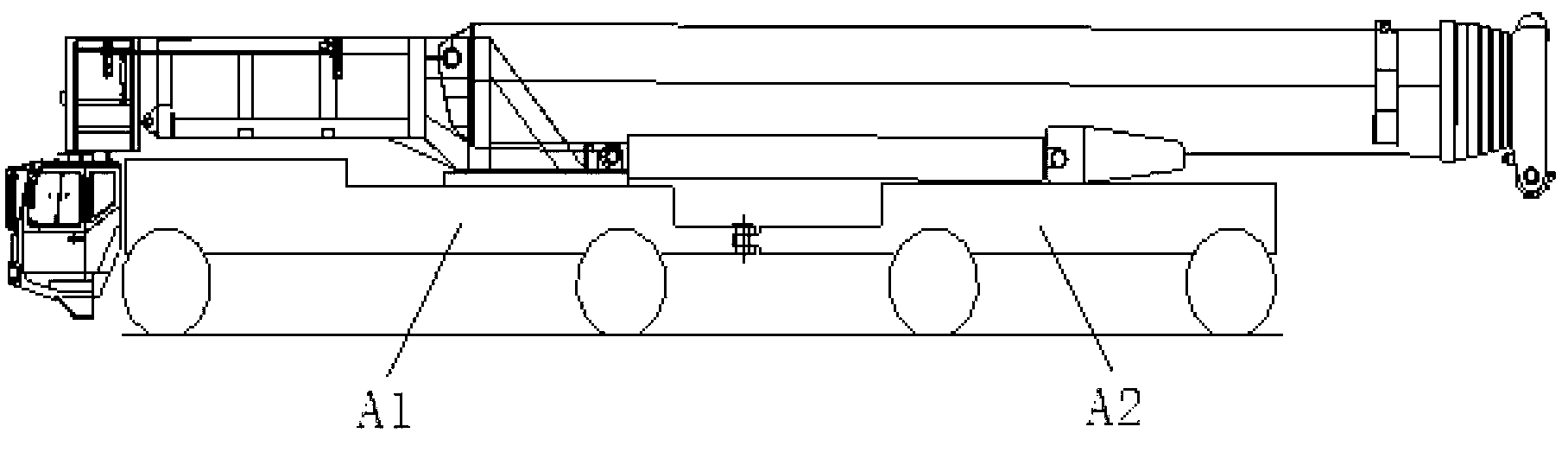

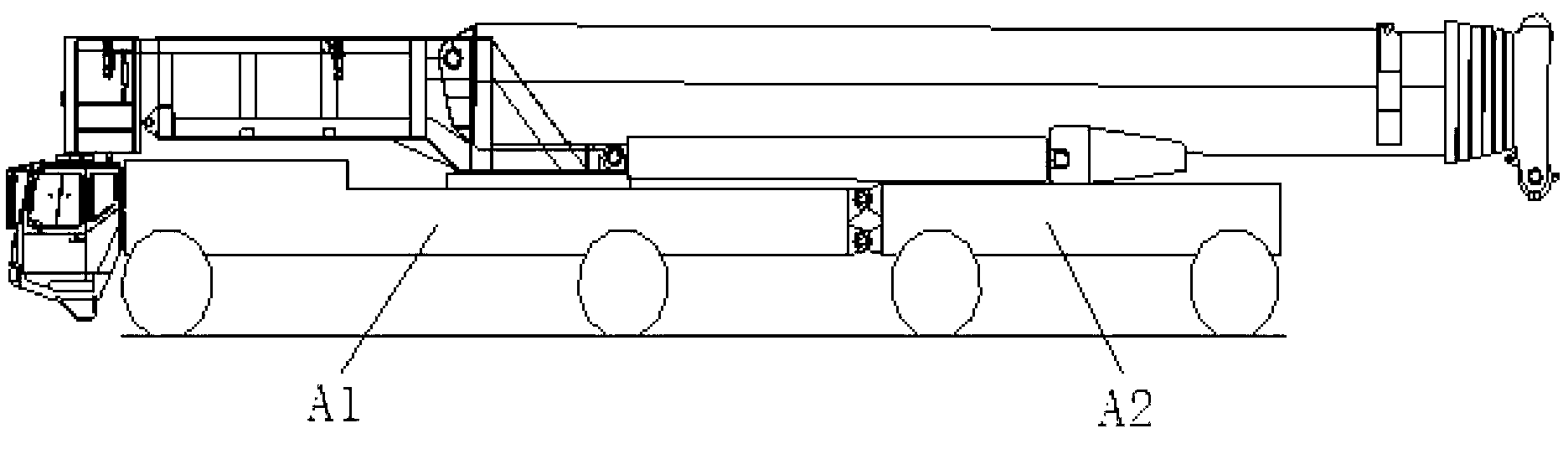

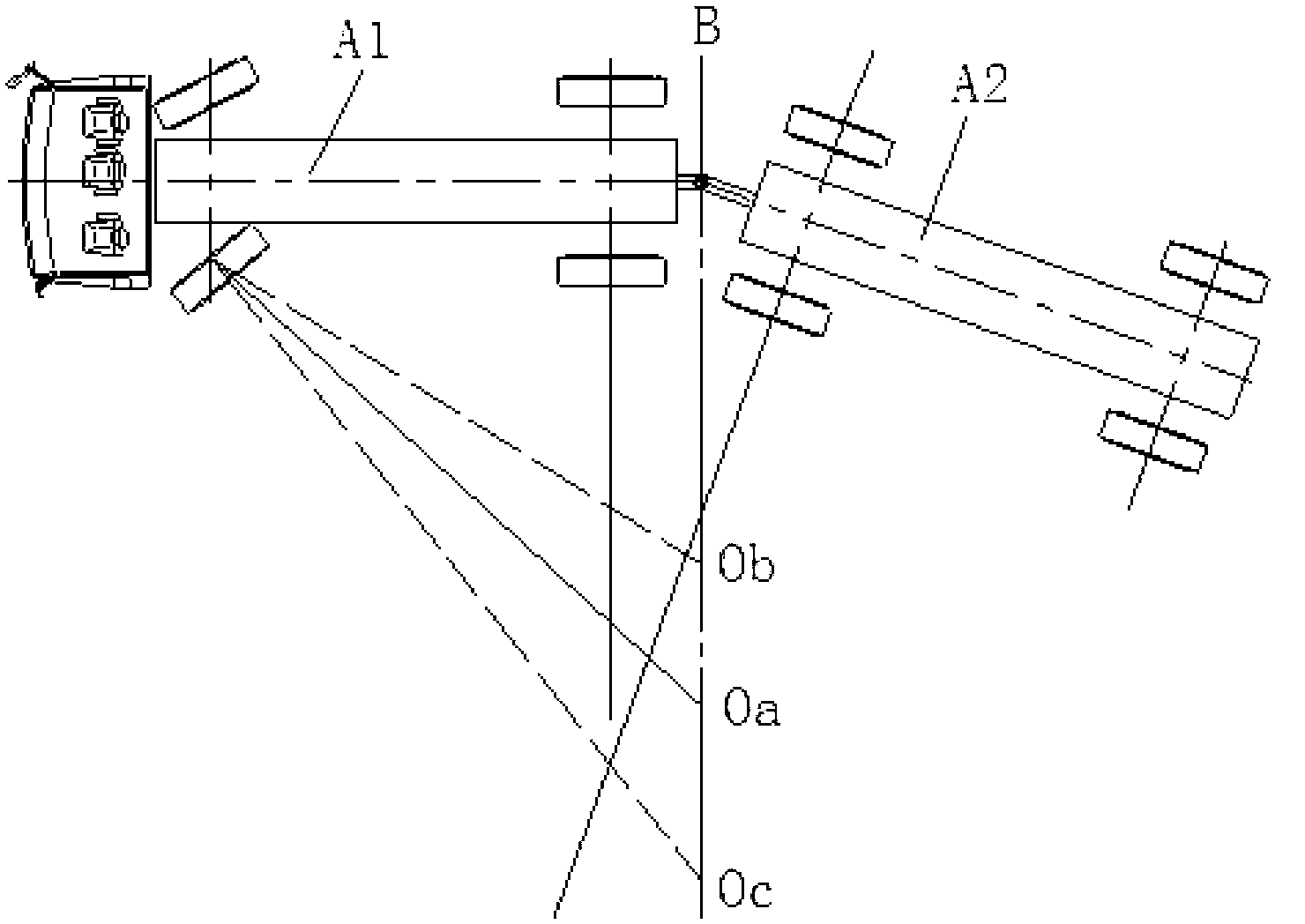

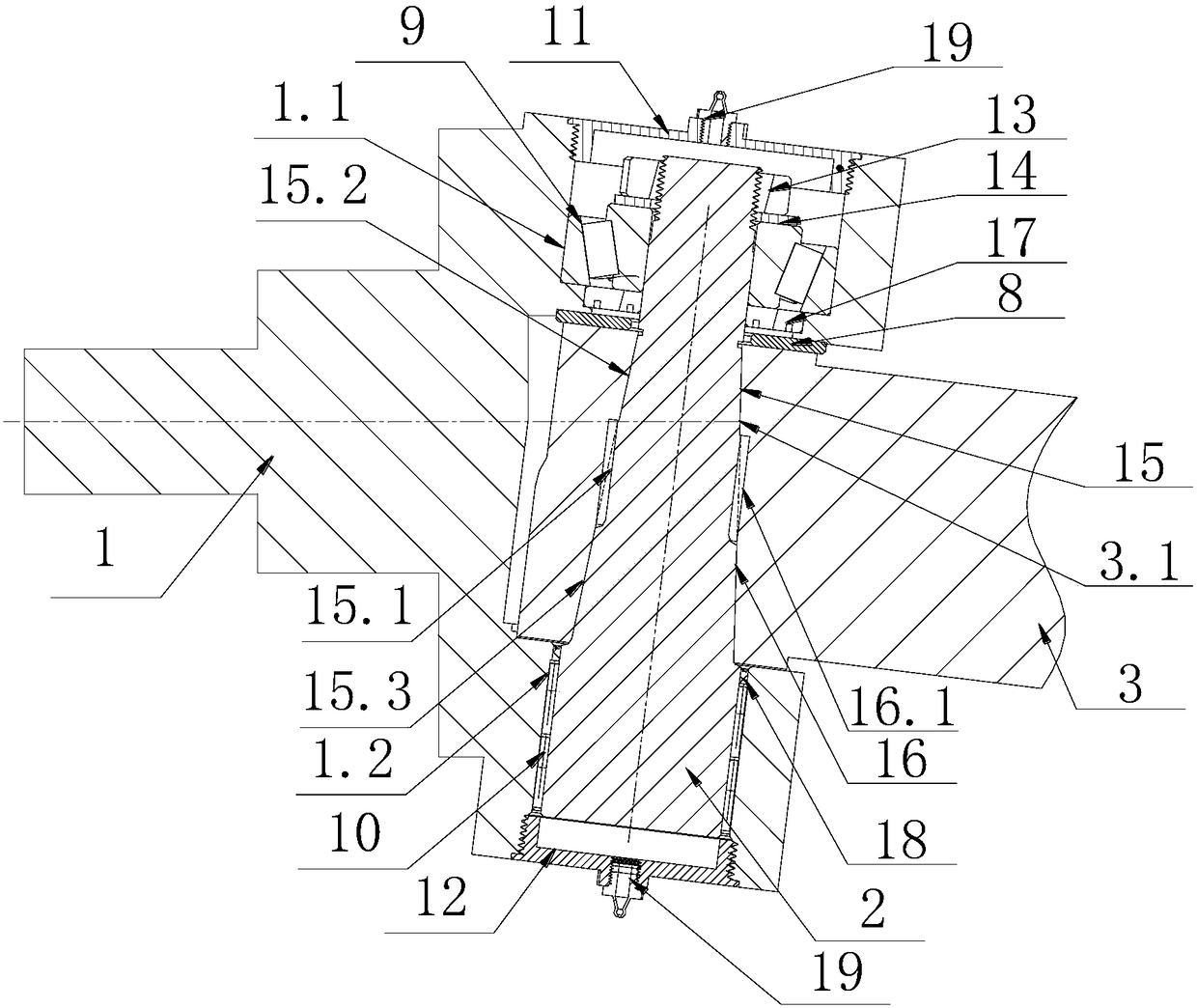

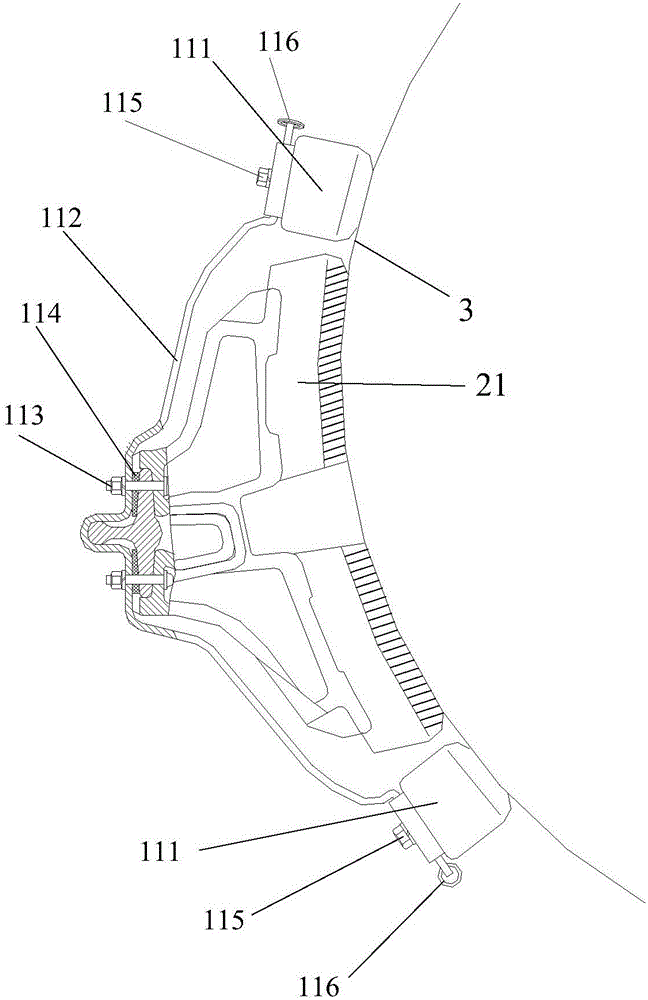

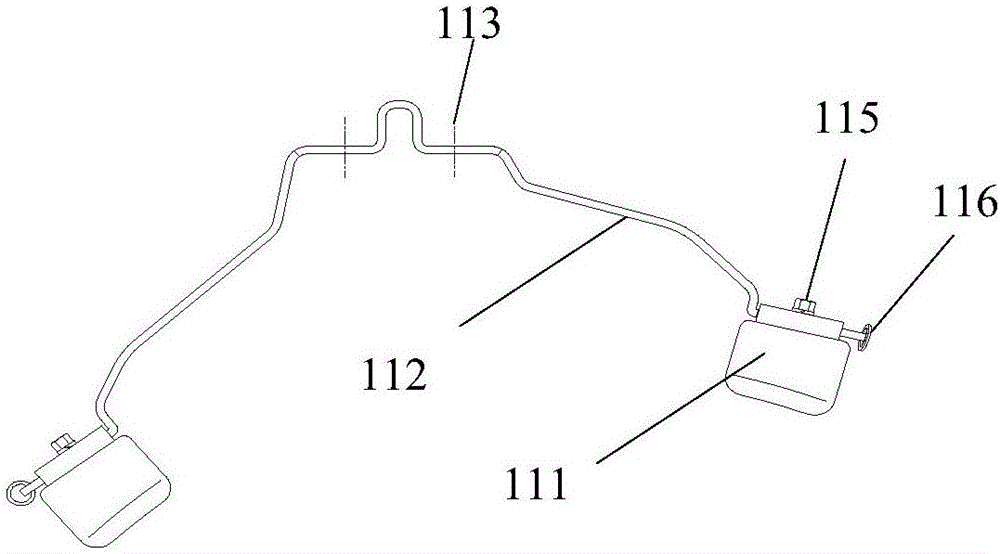

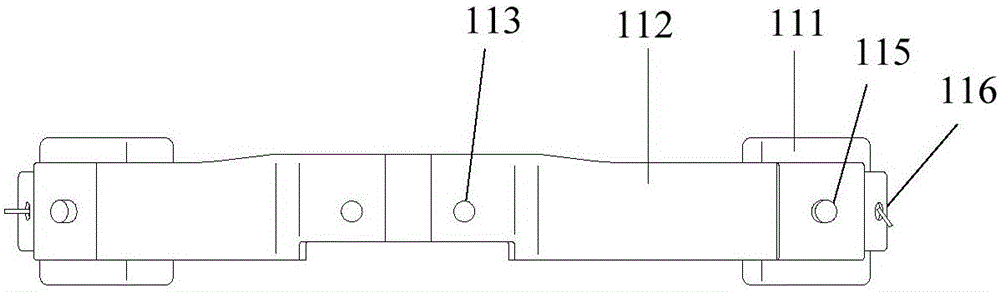

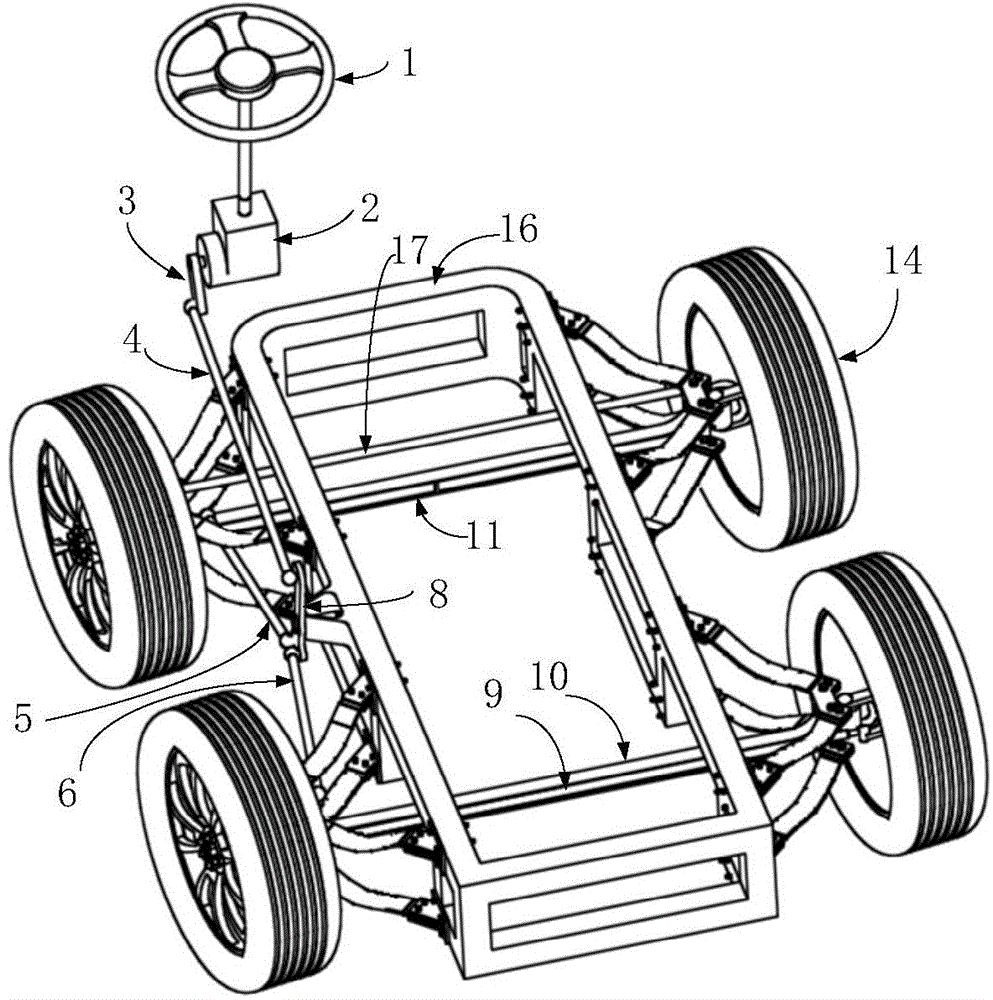

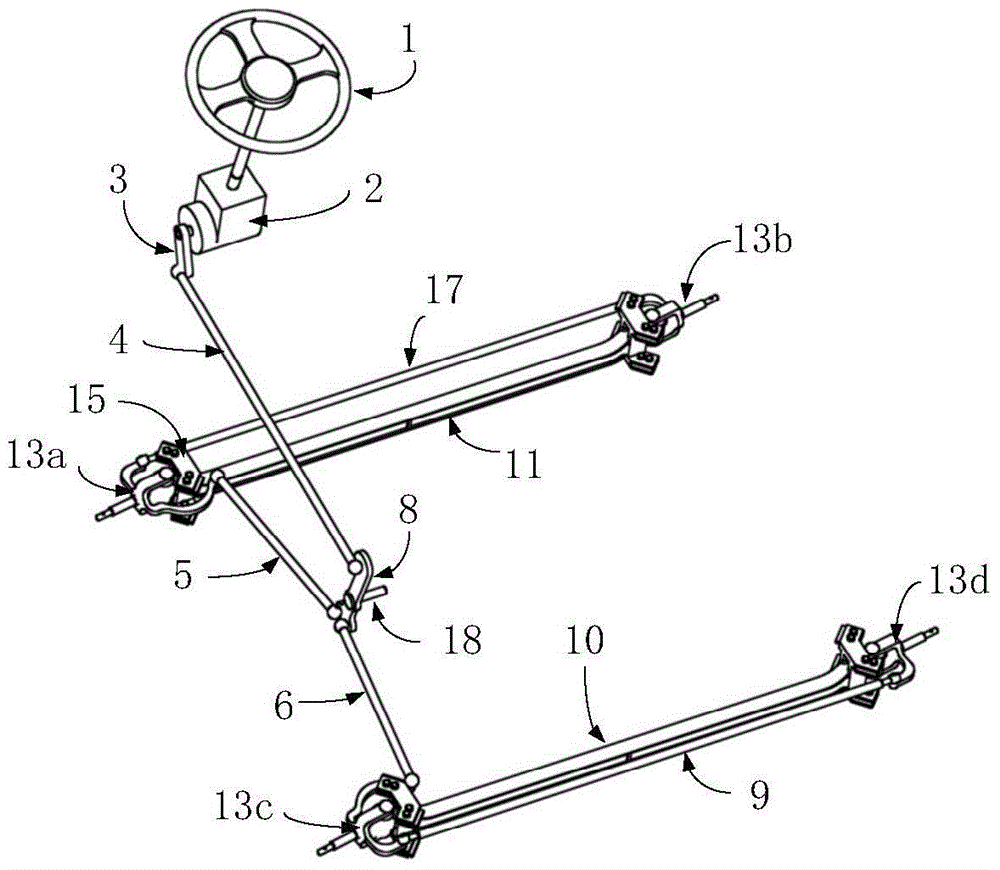

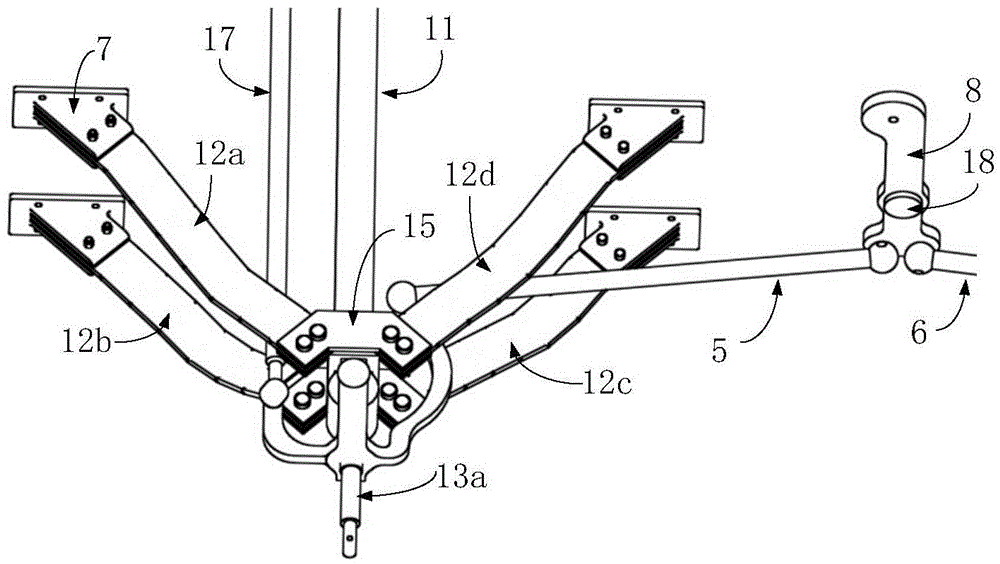

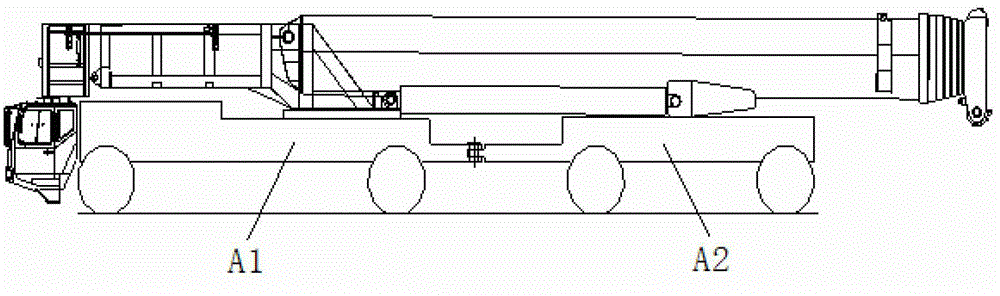

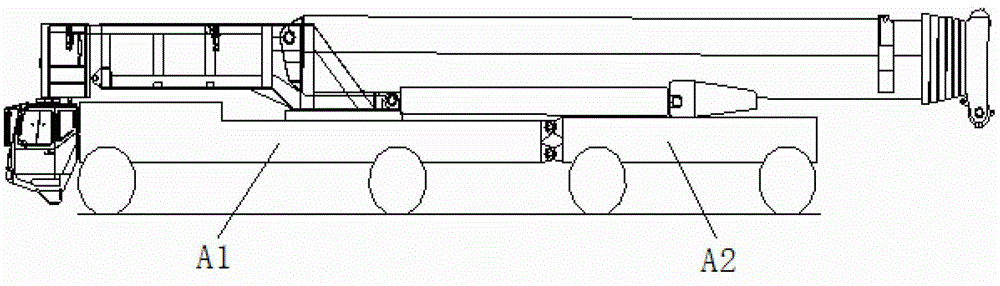

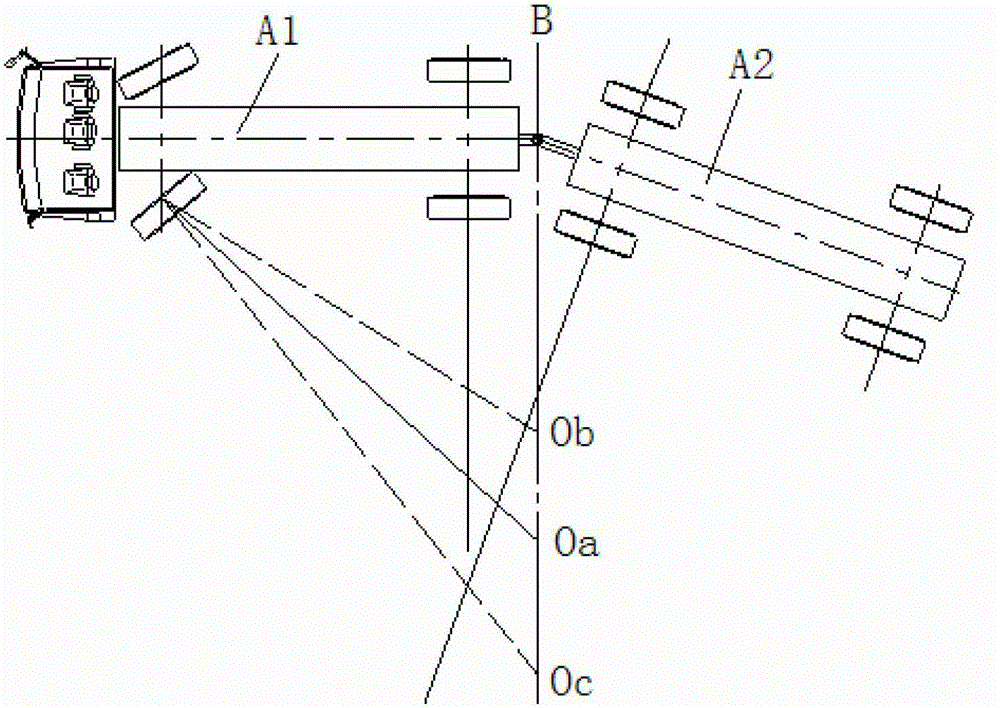

Trailer, steering control method for same, controller and steering system of trailer

ActiveCN103057586AImprove passabilityReduce abnormal wearSteering linkagesAutomatic steering controlVertical planeSteering wheel

A steering control method for a trailer includes firstly, controlling steering of front wheels of a tractor and acquiring deflection angles theta 1 of inner steering front wheels of front wheels of the tractor and an included angle alpha between a longitudinal central vertical plane of the tractor and a longitudinal central vertical plane of the trailer; and secondly, controlling steering of other pairs of steering wheels of the trailer, so that deflection angles of various other inner steering wheels on the tractor meet an inequality of arctan [(Li / L1)Xtan(theta 1)-3 degrees]< / =theta i< / ={arctan[(Li / L1)Xtan(theta 1)]+3 degrees, and deflection angles of various inner steering wheels on the trailer meet an inequality of [alpha-arctan(Z / P)-3 degrees]< / =theta j< / =[alpha-arctan(Z / P)+3 degrees]. The invention further provides a controller, the trailer and a steering system of the same. The steering control method, the controller, the trailer and the steering system have the advantages that the various wheels of the trailer can at least rotate around the same steering central area, abnormal abrasion to tires is obviously relieved, and the steering stability and the passing ability of the trailer are improved.

Owner:ZOOMLION HEAVY IND CO LTD

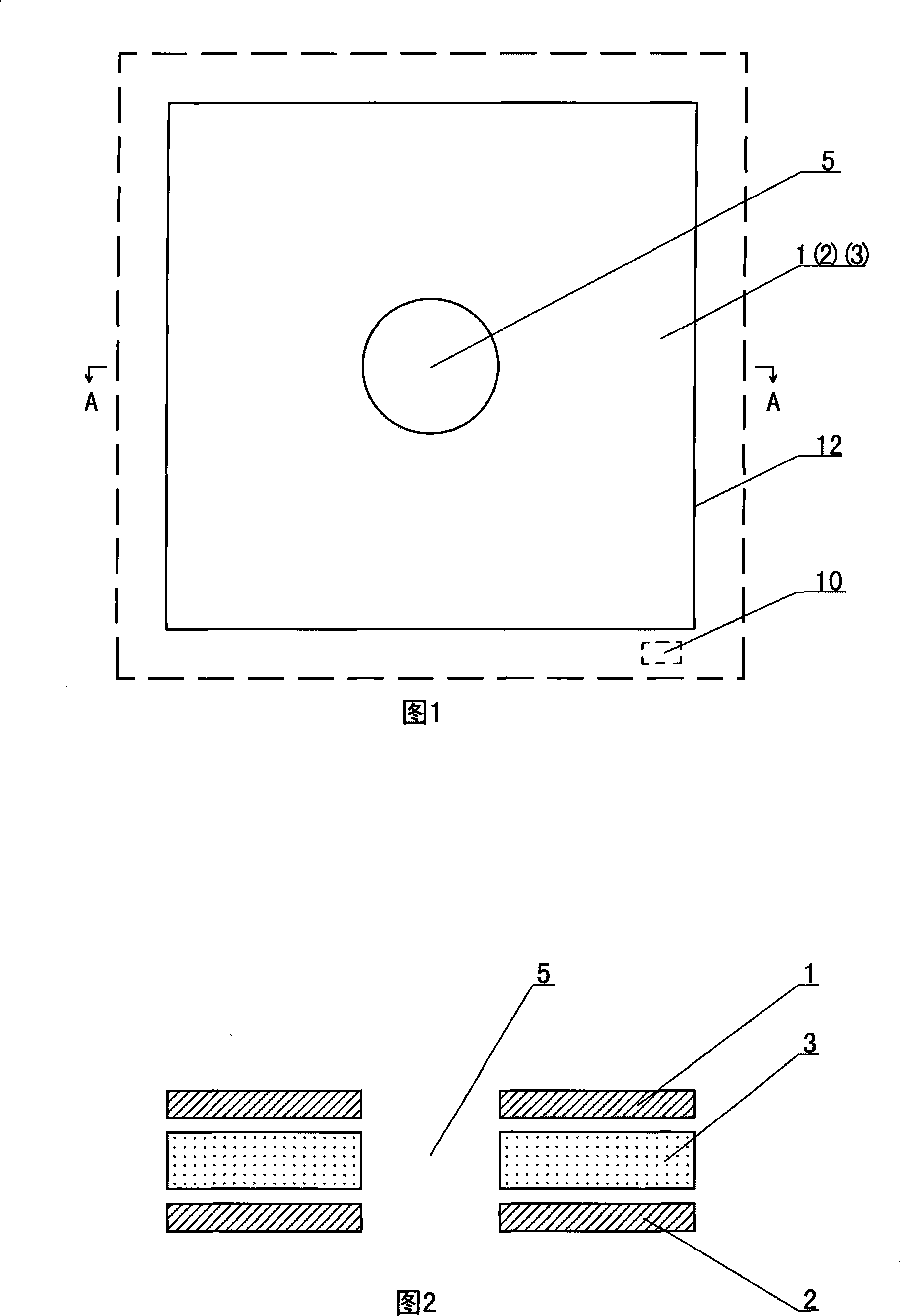

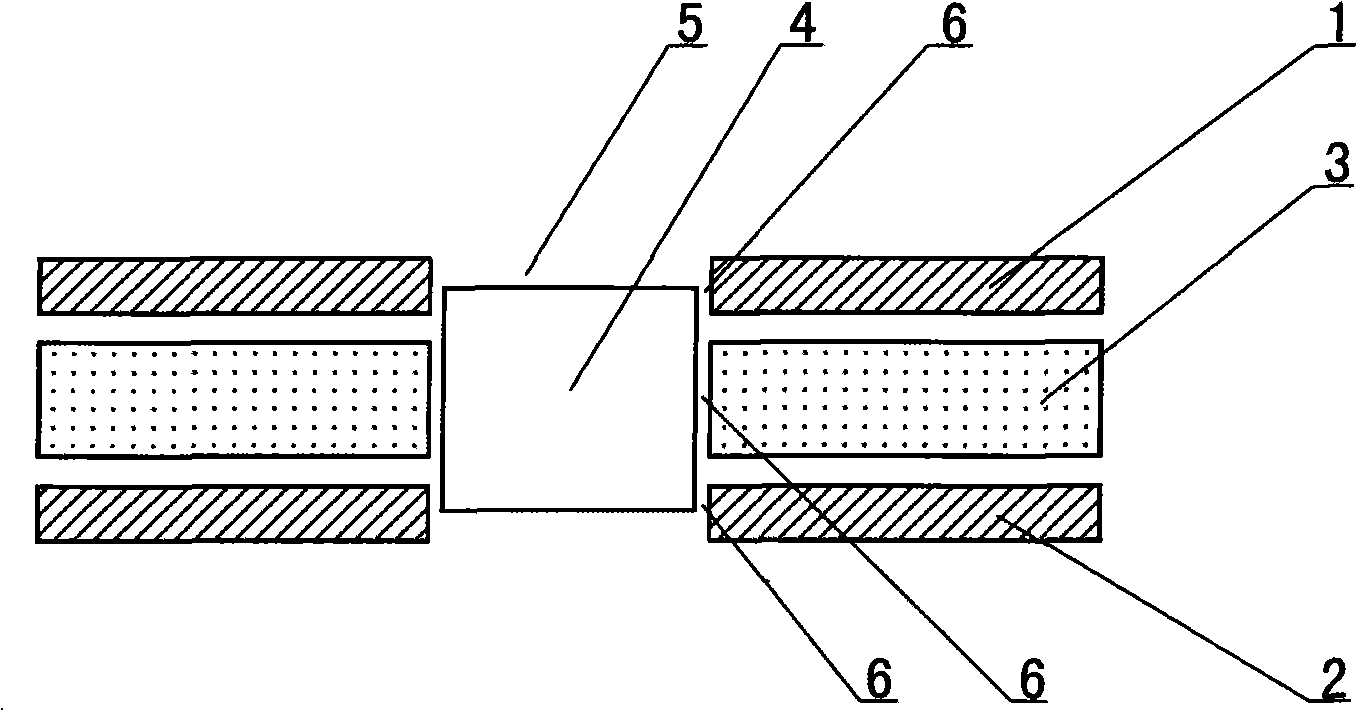

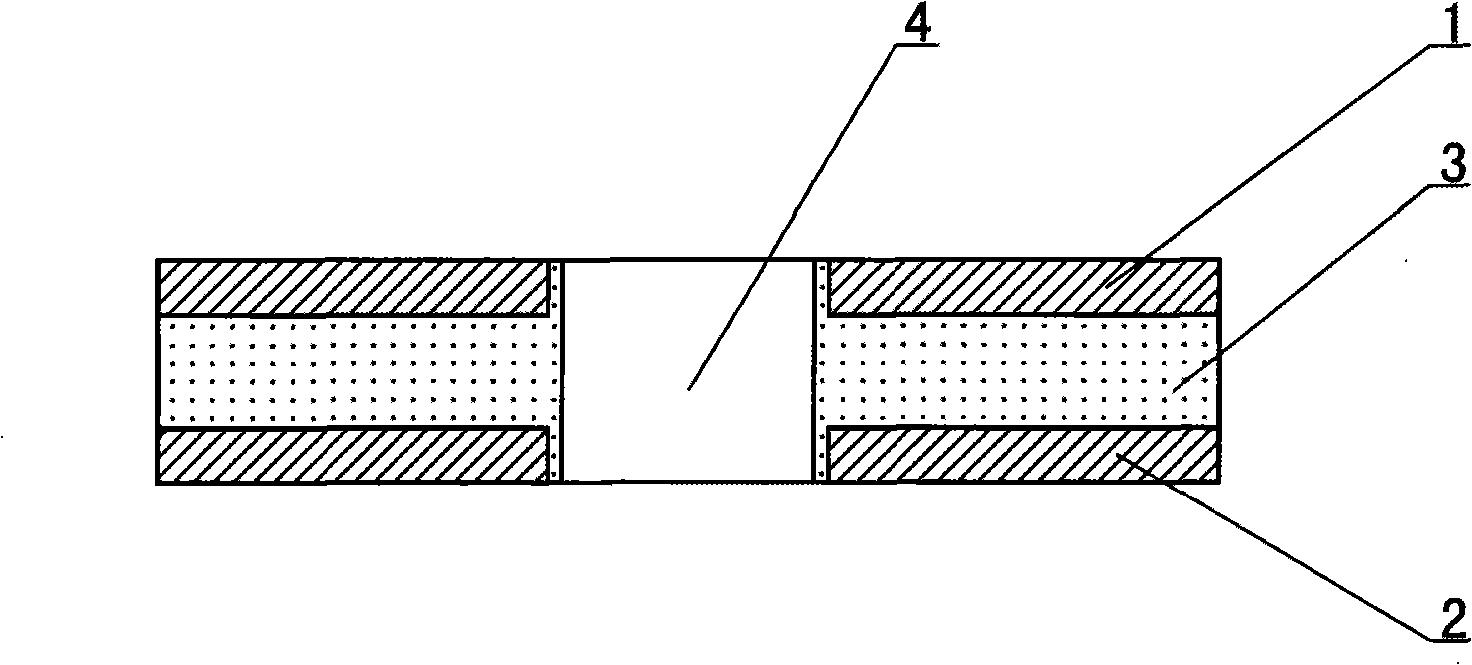

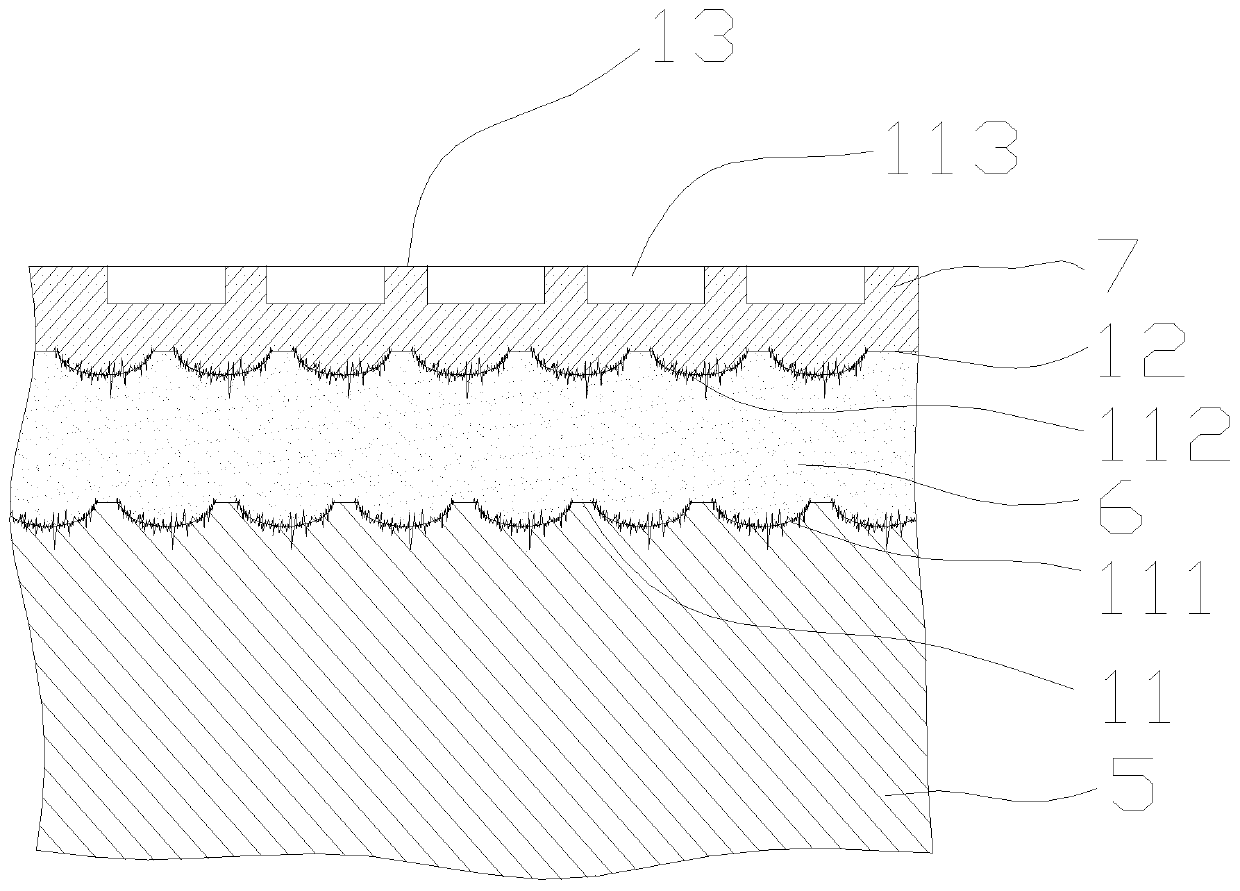

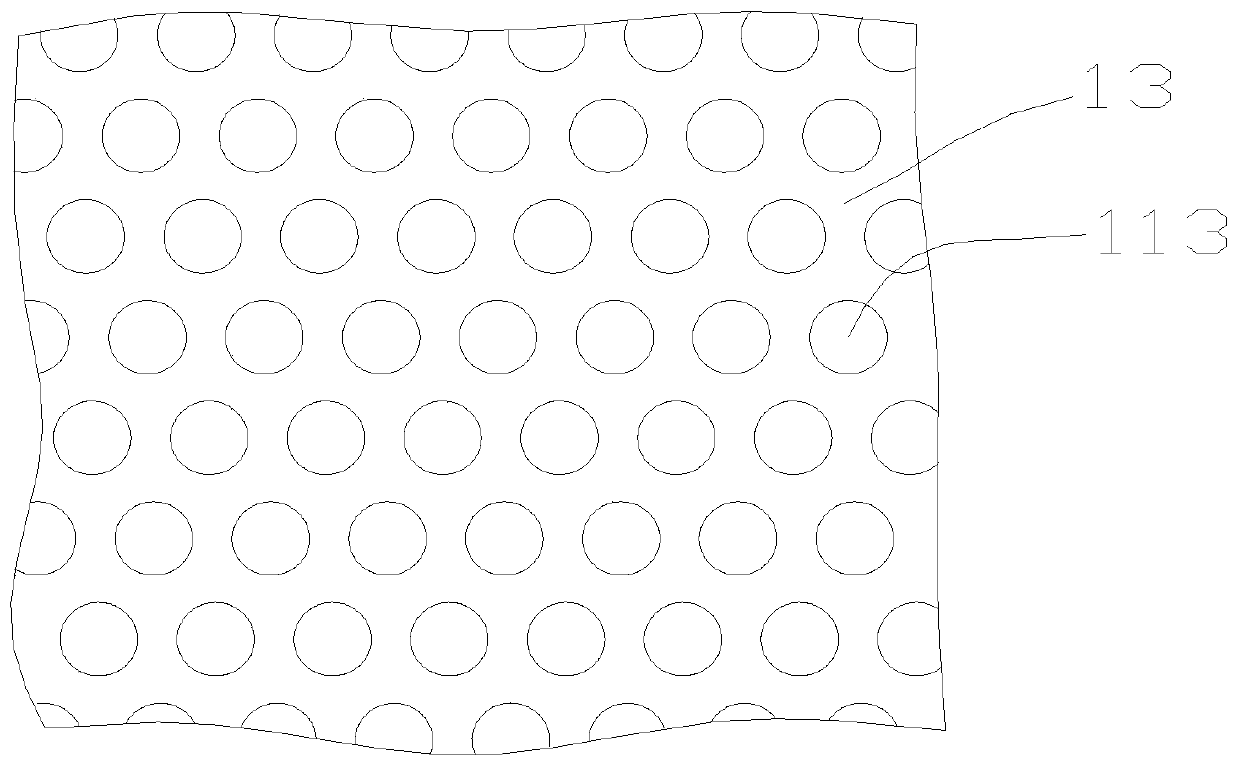

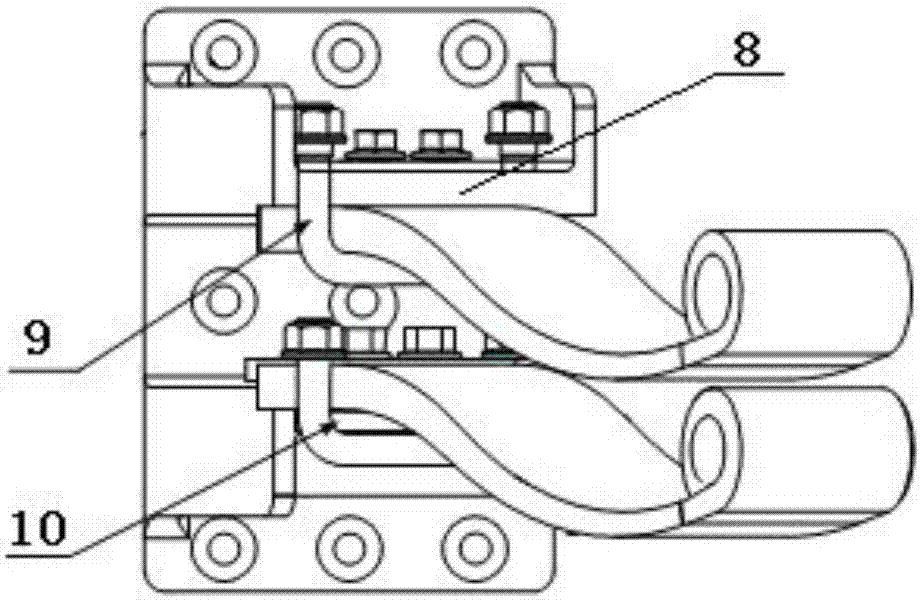

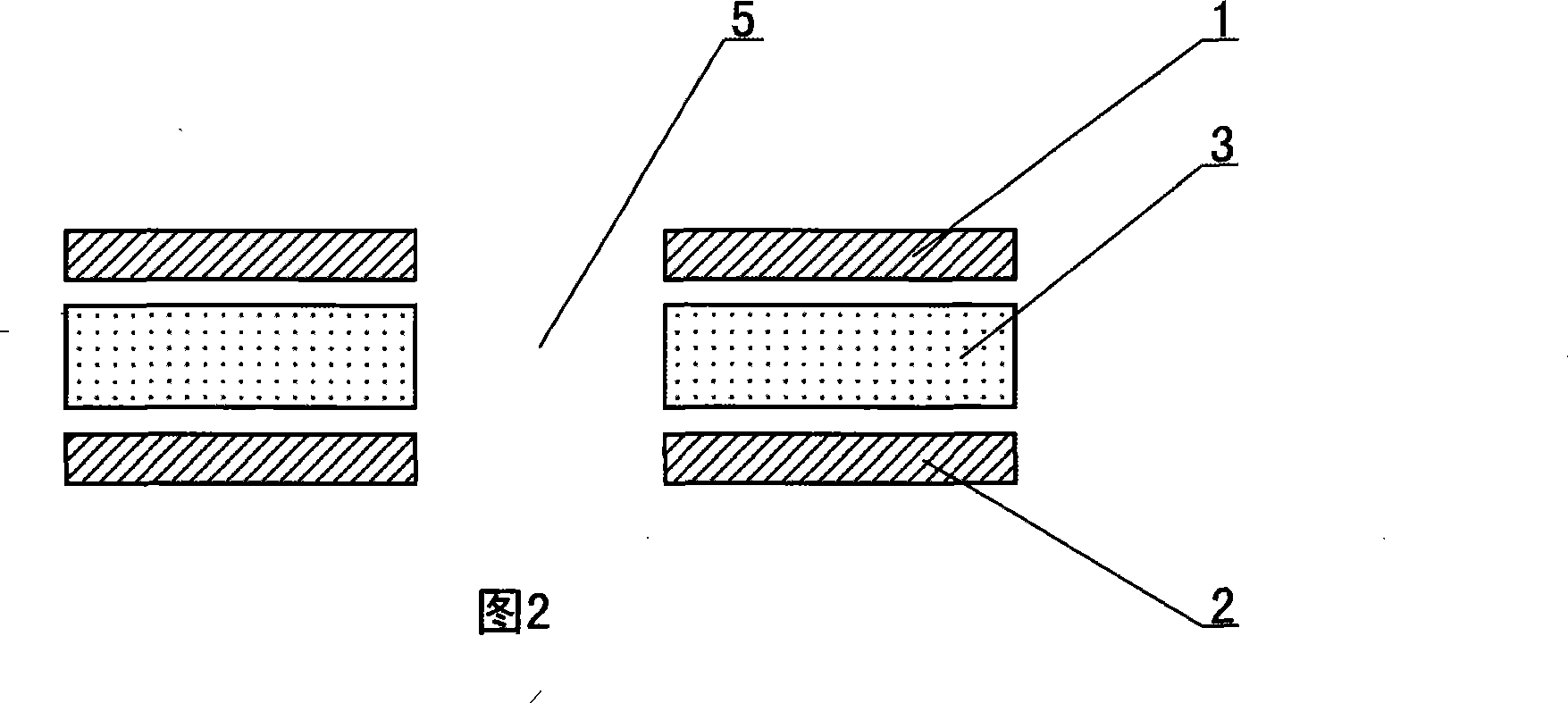

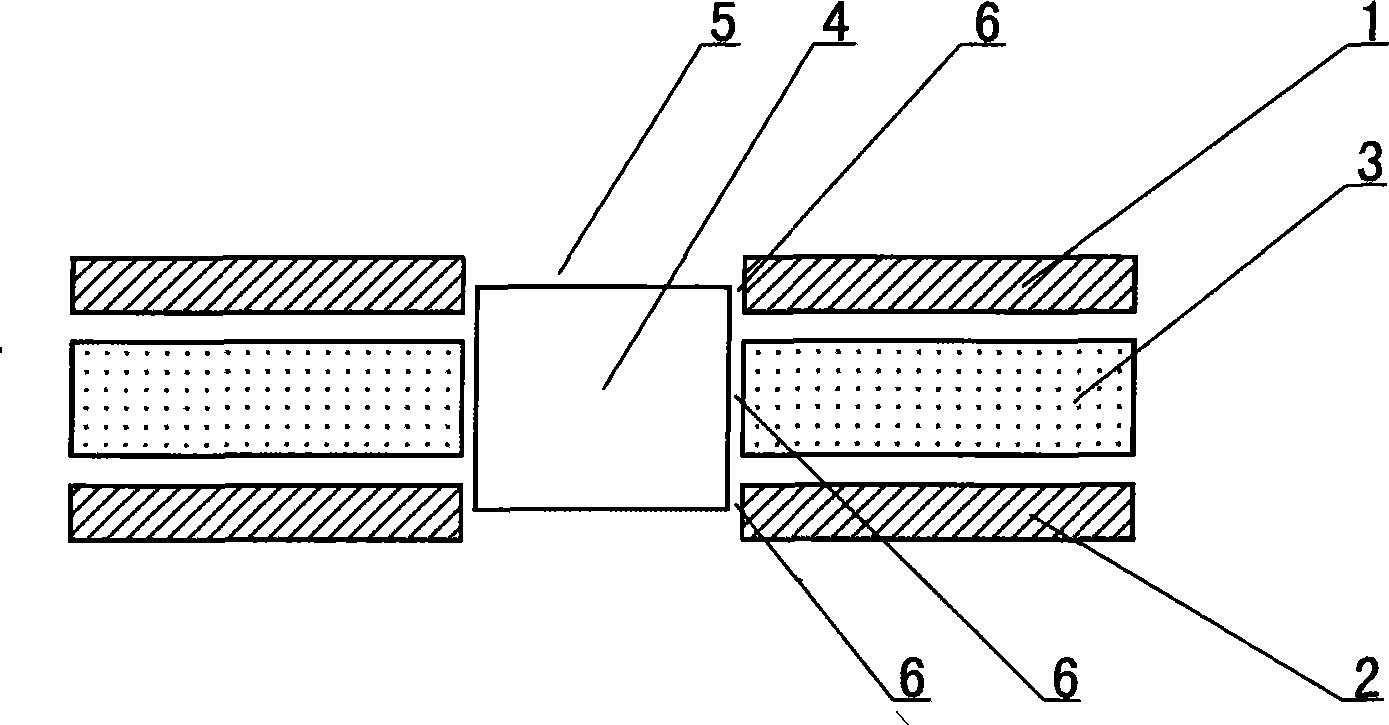

Manufacturing method for embedding heat radiating fin on printed circuit board

InactiveCN101257770AGood embedding effectSolve the problem of sagMultilayer circuit manufactureCooling/ventilation/heating modificationsHeat sinkPrinted circuit board

A making method for embedding fins on a printed circuit board includes following steps: 1) opening a tool hole on the position to be embedded with fins in a circuit board and a prepreg forming region, and drilling a pre-positioning hole outside of the forming region; 2) arranging the prepreg between two adjacent circuit board, pre-positioning the circuit boards and the prepreg through the pre-positioning hole; 3) arranging fins in the tool hole in a stitching pre-lamination process; 4) stitching the circuit boards and the prepreg to fill the gap between the tool hole and fins by flowing latex, the prepreg cures automatically during stitching, combining the fins and the circuit boards; 5) mechanical brushing and grinding board elements, cleaning residual prepreg material on surfaces of circuit boards. The invention avoids the inanition phenomenon, solves depression or protrusion of circuit board surfaces, reduces abnormal wear of grinding brush wheels in following process, thereby the embedding effect of fins is good.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

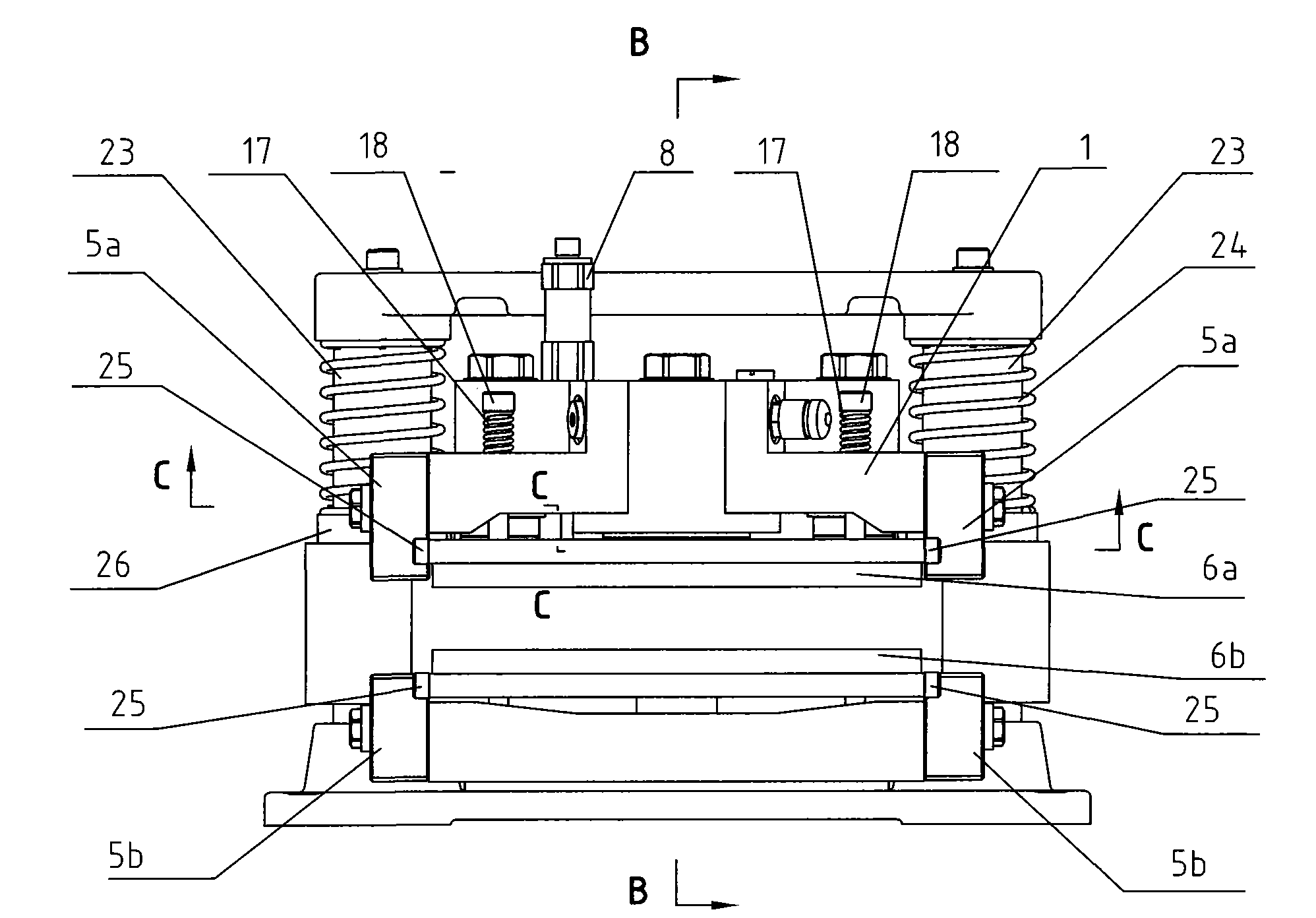

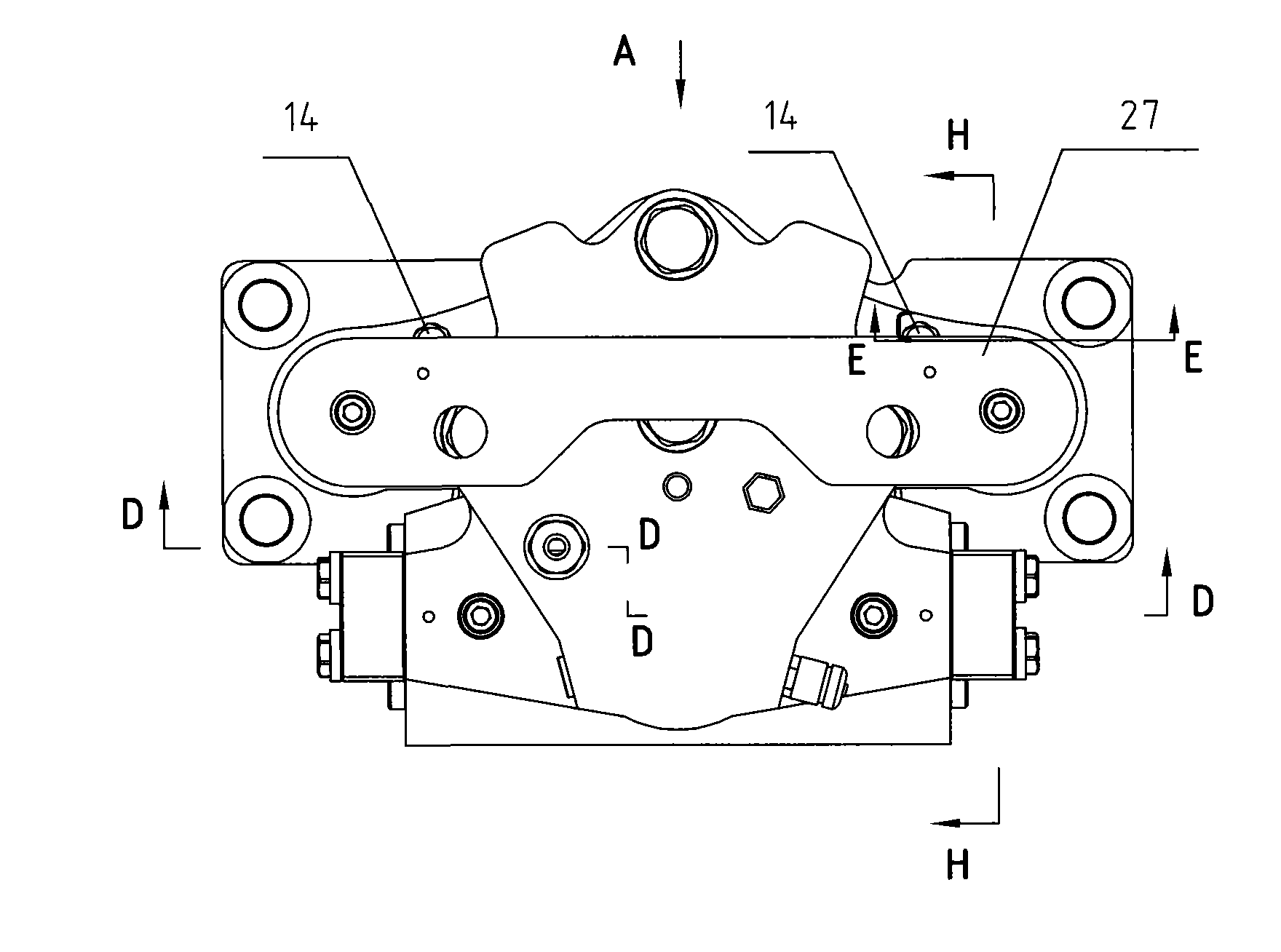

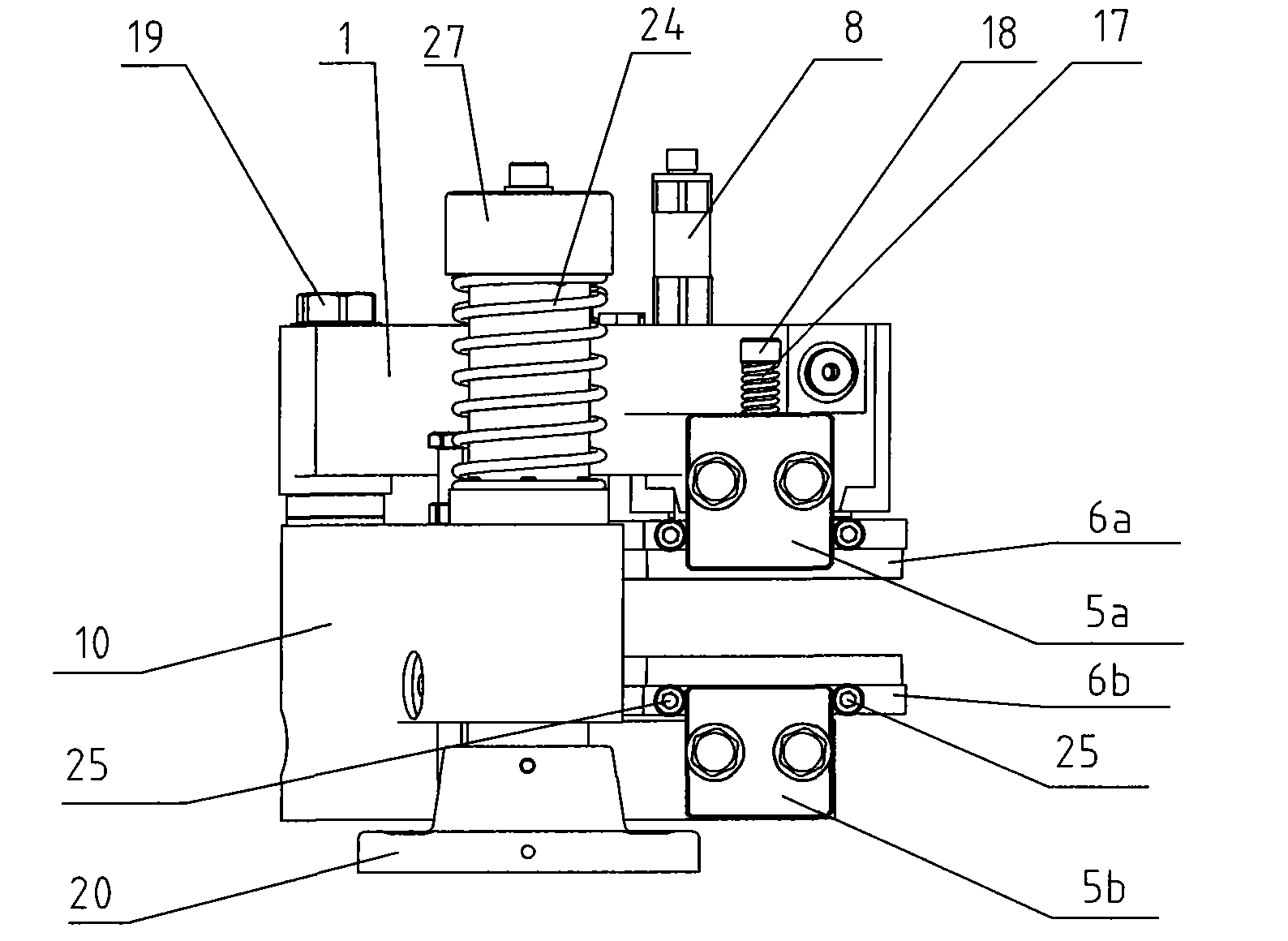

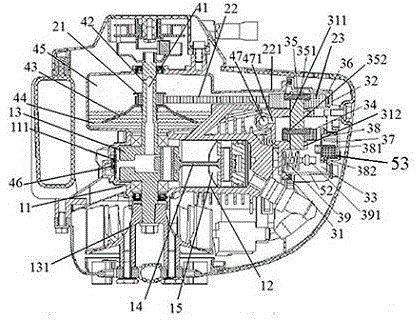

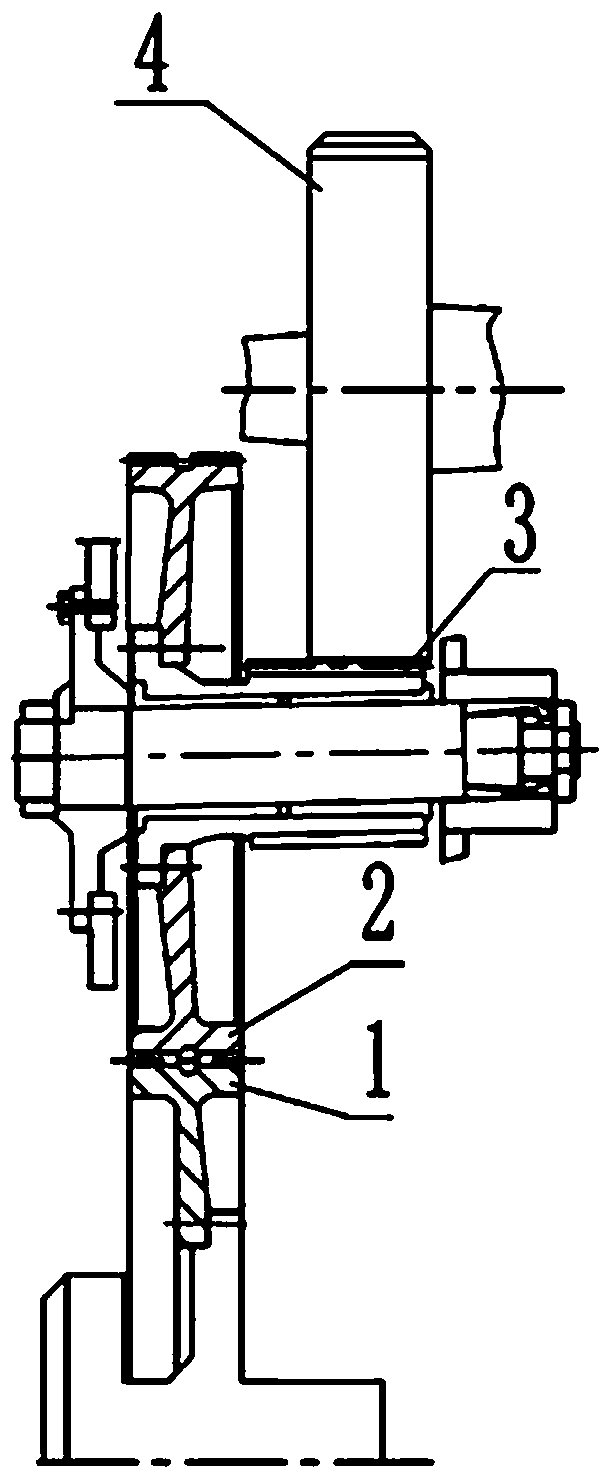

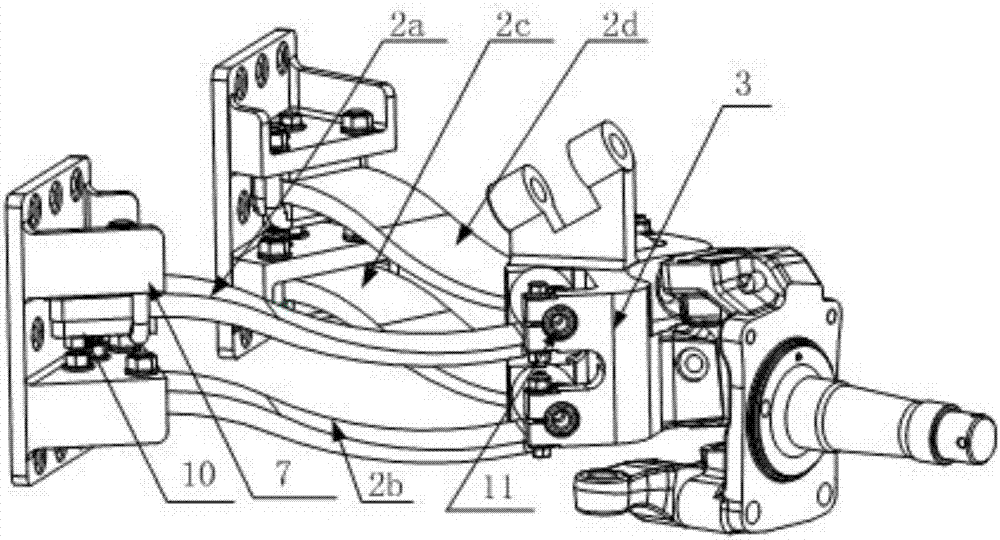

Brake caliper assembly of normally open type wind driven generator main shaft system

InactiveCN101660505AReduce abnormal wearExtended service lifeAxially engaging brakesMachines/enginesPistonWind driven

The invention discloses a brake caliper assembly of a normally open type wind driven generator main shaft system, comprising a first half part, a second half part and an inner brake block resetting mechanism which are correspondingly arranged, wherein, the inner brake block resetting mechanism comprises a return spring installation rod and an inner brake block return spring sheathed on the excircle of the return spring installation rod; the return spring installation rod and a piston are parallel and pass through the first part in the mode of reciprocating sliding lengthways; one end of the return spring installation rod is fixedly connected with the inner brake block lengthways; one end of the inner brake block return spring outwards supports the return spring installation rod, and the other end inwards supports the first half part; when the brake assembly enters a non-working state (the hydraulic cylinder releases pressure), the brake block can effectively and quickly separate from the brake disc by the brake block resetting mechanism, which reduces abnormal abrasion between the brake block and the brake disc so as to improve the service life of the brake block and the brake discand reduce maintenance cost.

Owner:CSG TRW CHASSIS SYST CO LTD

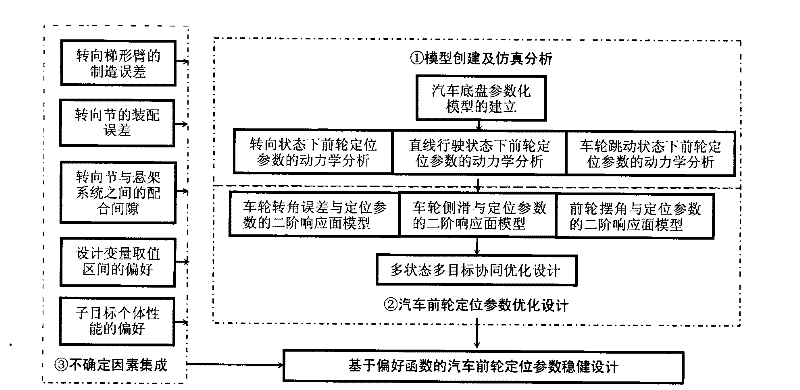

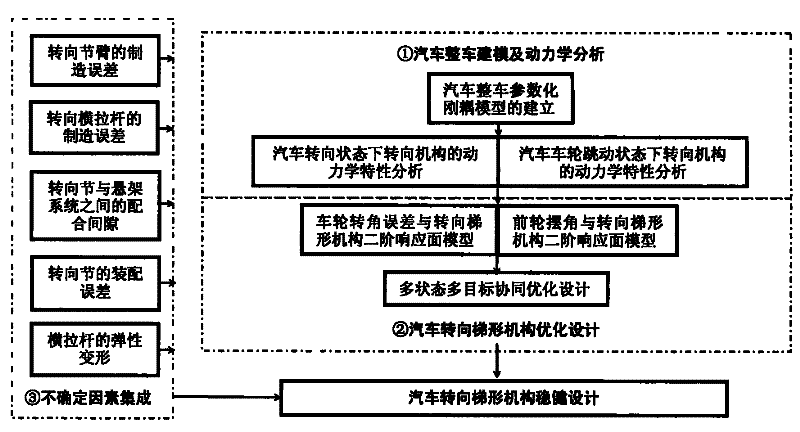

Robust design method for positional parameters of front vehicle wheels

InactiveCN102402636AImprove the design levelImprove handling stabilitySpecial data processing applicationsCamber angleNumerical range

The invention discloses a robust design method for positional parameters of front vehicle wheels. In the method, a robust design model for the positional parameters (a king pin inclination angle, a king pin caster angle, a front wheel camber angle, and a front wheel toe-in) of the front vehicle wheels is established by taking a multibody system dynamics theory as a basis, comprehensively considering the synergic relationship among a steering system, a drive system and a suspension system, analyzing the dynamics characteristics of the positional parameters of the front wheels under motor steering, straight running, wheel hopping and other various running states, integrating uncertain factors, such as the manufacturing errors of a steering trapezoidal arm, the assembling errors of a steering knuckle, a fit clearance between a steering mechanism and the suspension system, a designed variable numerical range, the preferences of all subgoal performances and the like, and taking the minimum angle turning error, the minimum sideslip during straight running and the minimum front wheel pivot angle during wheel hopping in a steering process as optimization goals. The robust design method disclosed by the invention has the advantage of improving the design level for the positional parameters of the front vehicle wheels in China, and can be widely applied to design of various types of vehicles.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

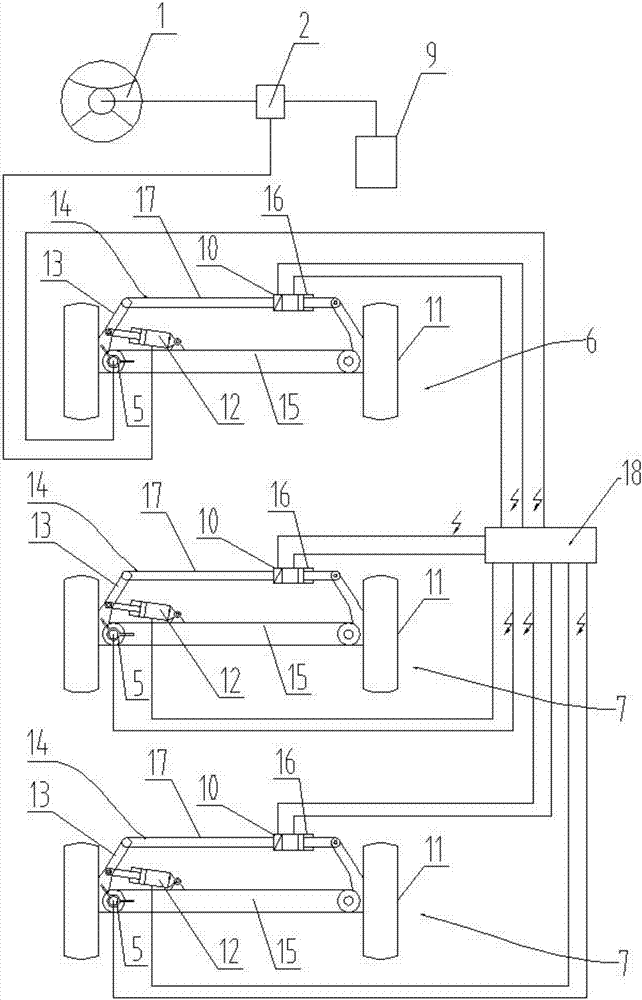

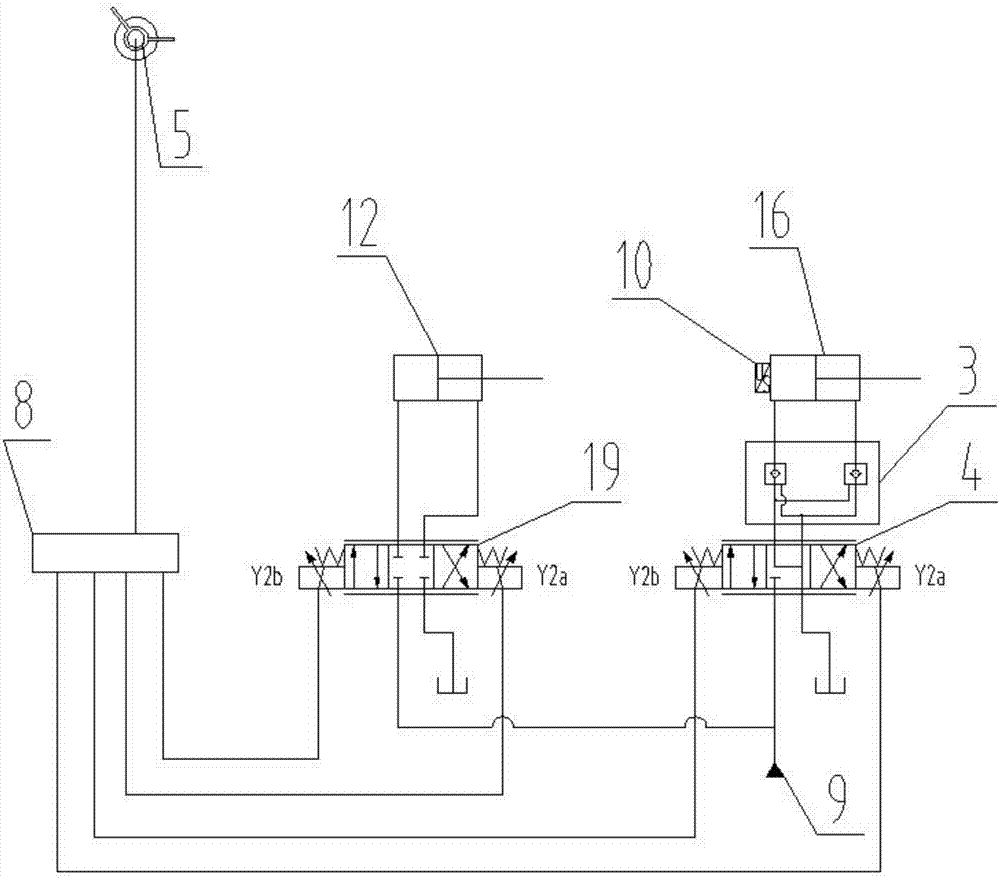

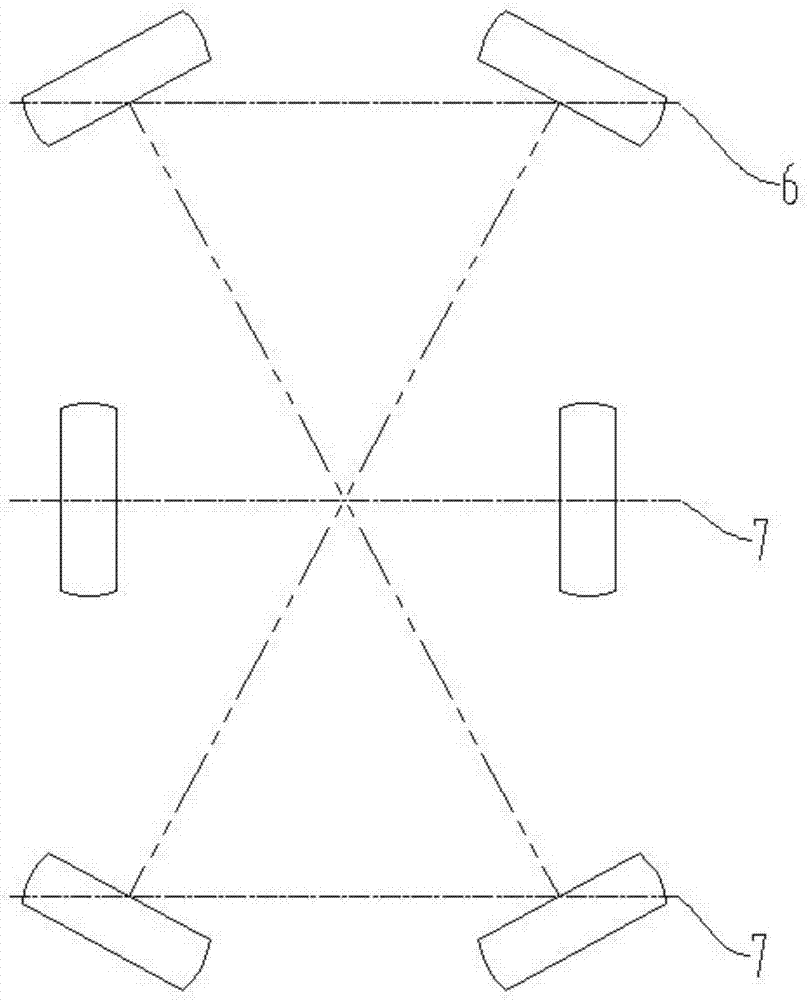

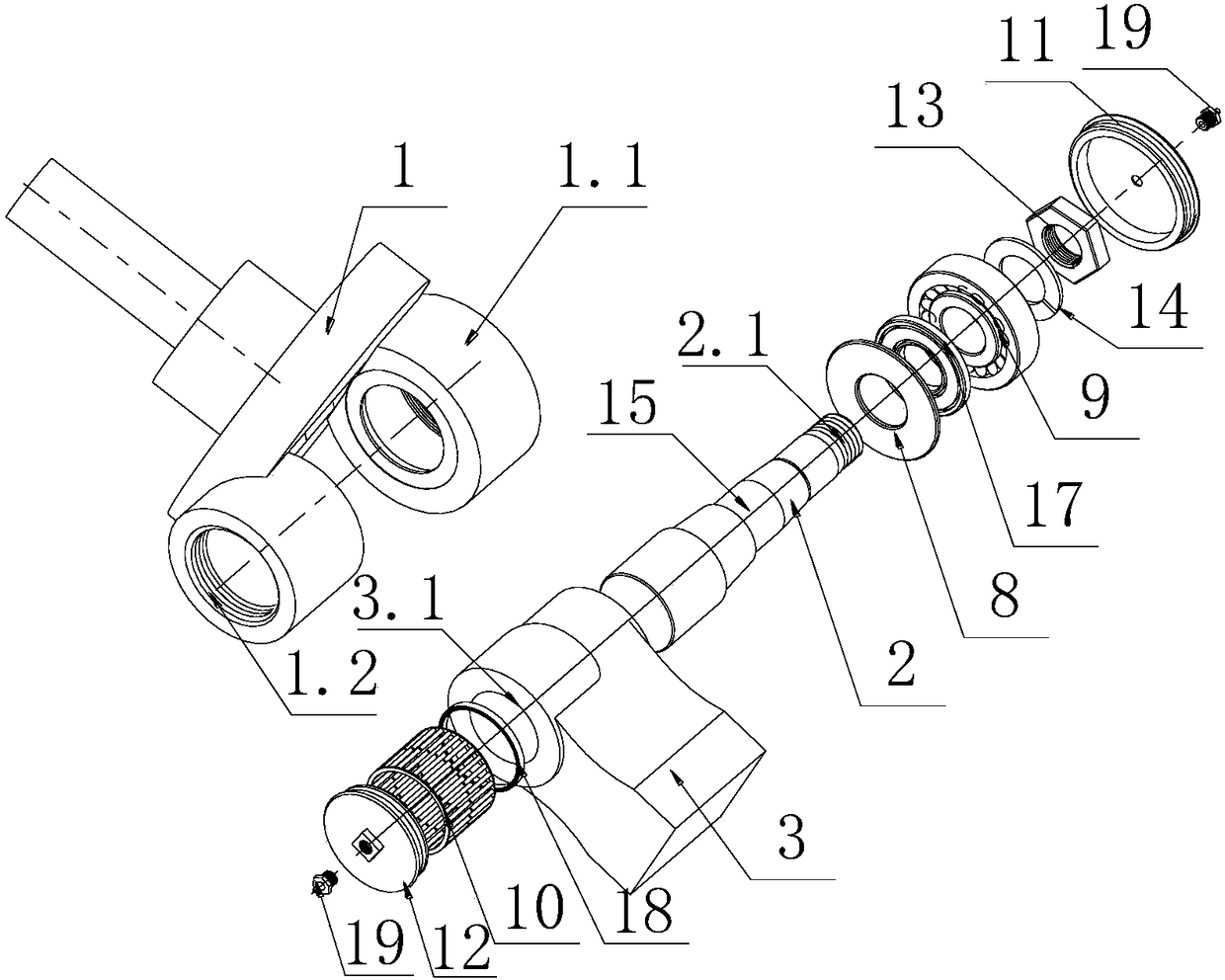

Electro-hydraulic steering control system for heavy-duty truck

ActiveCN107364489AMinimize steering angle errorReduces abnormal wear and fuel consumptionSteering linkagesFluid steeringTruckElectro hydraulic

An electro-hydraulic steering control system for a heavy-duty truck is provided. First and second trapezoidal steering systems are each mainly composed of an axle, two ladder-shaped arms symmetrically hinged to the outsides of the two ends of the axle, a draw bar hinged to the ends, away from the axle, of the two ladder-shaped arms, and at least one steering hydraulic cylinder, the outsides of the ends, close to the axle, of the two ladder-shaped arms are connected with two tires, the piston rod end of the steering hydraulic cylinder is hinged to the middle of one trapezoidal arm, the cylinder barrel base of the steering hydraulic cylinder is hinged to one side, close to the one trapezoidal arm, of the axle, and a corner sensor is also assembled at the hinge point of the axle and the one trapezoid arm. The draw bars of the first and second trapezoidal steering systems are each composed of a connecting rod and a draw bar hydraulic cylinder. Each draw bar hydraulic cylinder is internally provided with a displacement detection device. The corner sensors, the displacement detection devices and electromagnetic proportional valves are connected with a controller. The control system can effectively reduce or eliminate the steering angle error, and can effectively reduce the abnormal wear of the tires and fuel consumption.

Owner:SHANXI NINGZHI TECH

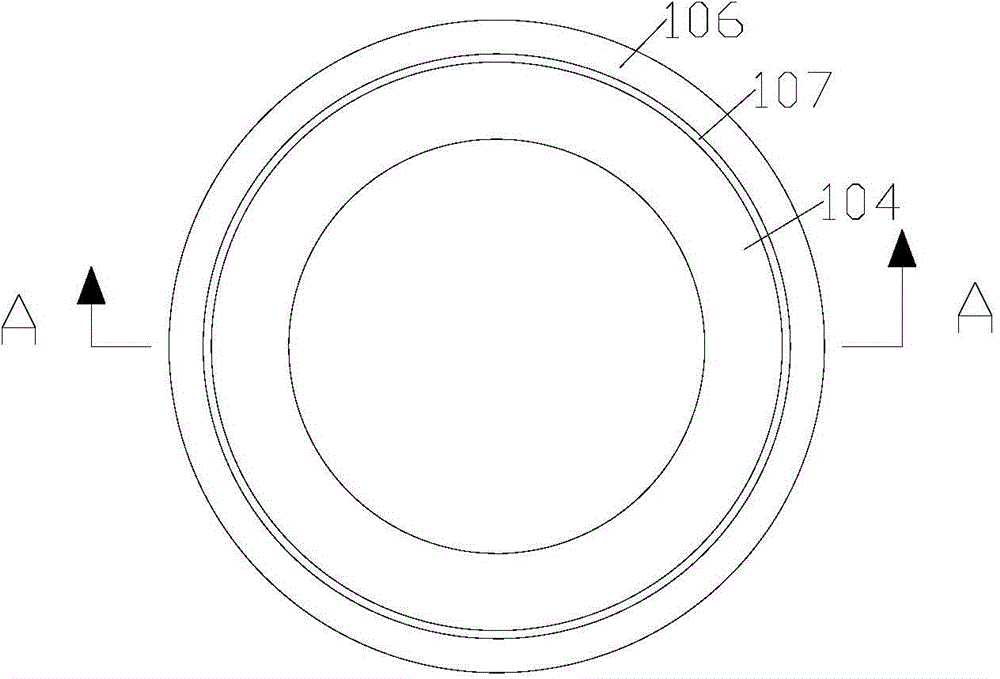

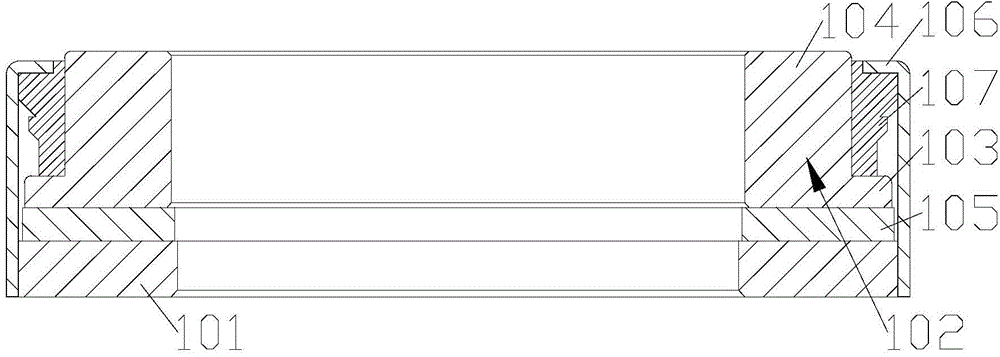

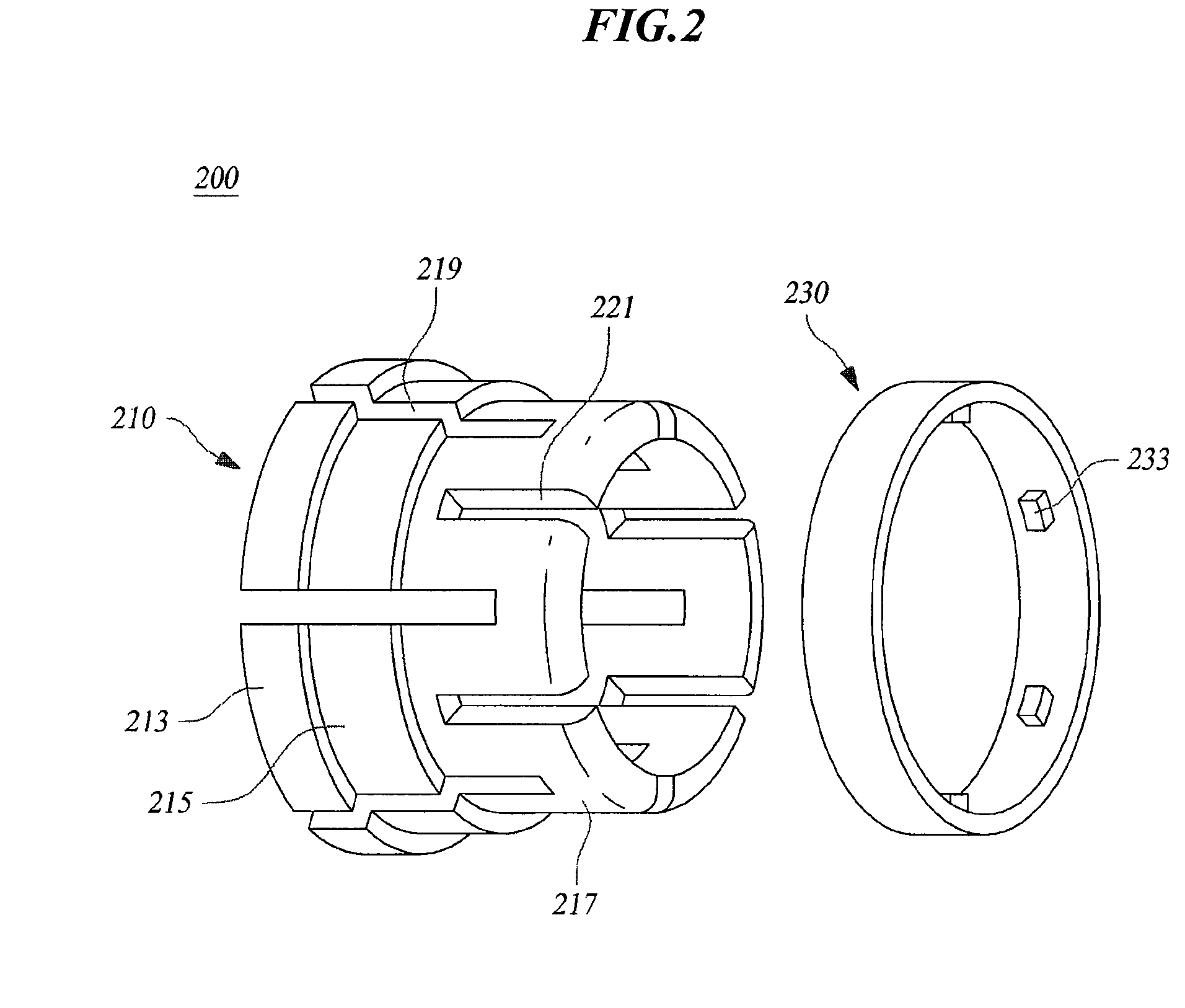

Damper bearing

The invention provides a damper bearing, belonging to the field of bearing. The damper bearing comprises a fixed loop, a movable loop, a damping loop, a shell and a sealing ring, wherein the movable loop comprises a first movable loop and a second movable loop which are connected with each other, the first movable loop is closer to the fixed loop relative to the second movable loop, the outer diameter of the first movable loop is greater than the outer diameter of the second movable loop; the damping loop is arranged between the first movable loop and the fixed loop; the fixed loop, the movable loops and the damping loop are arranged in the shell, and the shell is fixed with the fixed loop, the inner diameter of one end of the shell, far away from the fixed loop, is smaller than the outer diameter of the first movable loop, and the second movable loop penetrates through the shell; the sealing ring is arranged in a region formed by surrounding of the shell, the first movable loop and the second movable loop. The damper bearing with the structure can alleviate the abnormal abrasion between the damping loop and the first movable loop caused by impurities so that the service life of the damper bearing is long, and the performance is stable.

Owner:CHONGQING CHUANGHONG ELECTROMECHANICAL

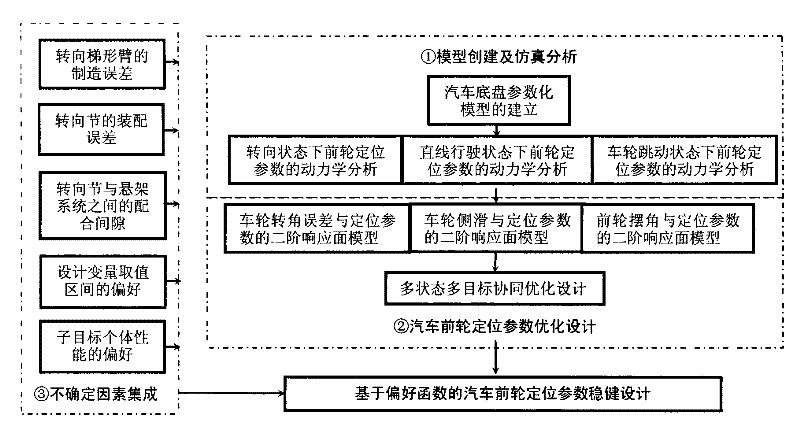

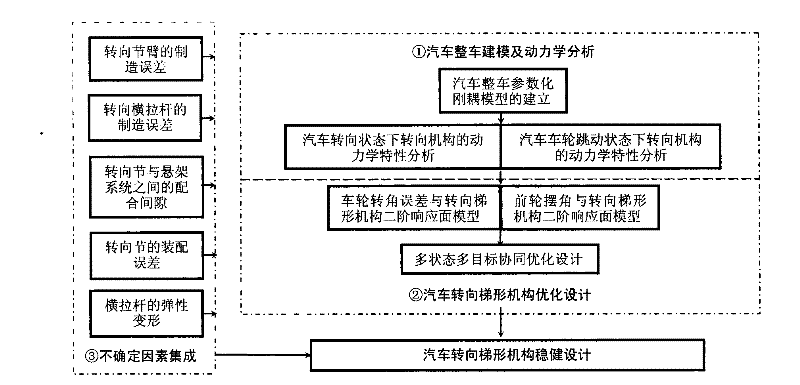

Steady design method for vehicle steering trapezoid mechanism

InactiveCN102393861AImprove handling stabilityReduce abnormal wearSpecial data processing applicationsSteering angleMultibody system

The invention relates to a steady design method for a vehicle steering trapezoid mechanism. The method comprises the following steps of: based on multi-body system dynamics theory, applying methods, such as a virtual model machine technology, multi-body dynamics, elasticity mechanics, steady design and the like, comprehensively considering a synergic relationship between a steering system and a suspension system, analyzing dynamics characteristics of the steering trapezoid mechanism under operating conditions, such as vehicle steering, vehicle wheel jumping and the like, and integrating uncertain factors impacting on a steering angle and a steering mechanism stress, such as a manufacturing error of a steering tie rod, a manufacturing error of a steering knuckle arm, an assembling error of a steering node, fit clearance between the steering mechanism and the suspension system, elastic deformation of the tie rod, and the like. An optimizing aim that corner error during the steering process is minimum, and a swing angle for a front wheel during vehicle jumping is minimum can be achieved, and a steady design model for the vehicle steering trapezoid mechanism is built. The steady design method has the advantages that: a design level of vehicle front wheel parameters can be improved, and the method can be widely applied to vehicle design with various types.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

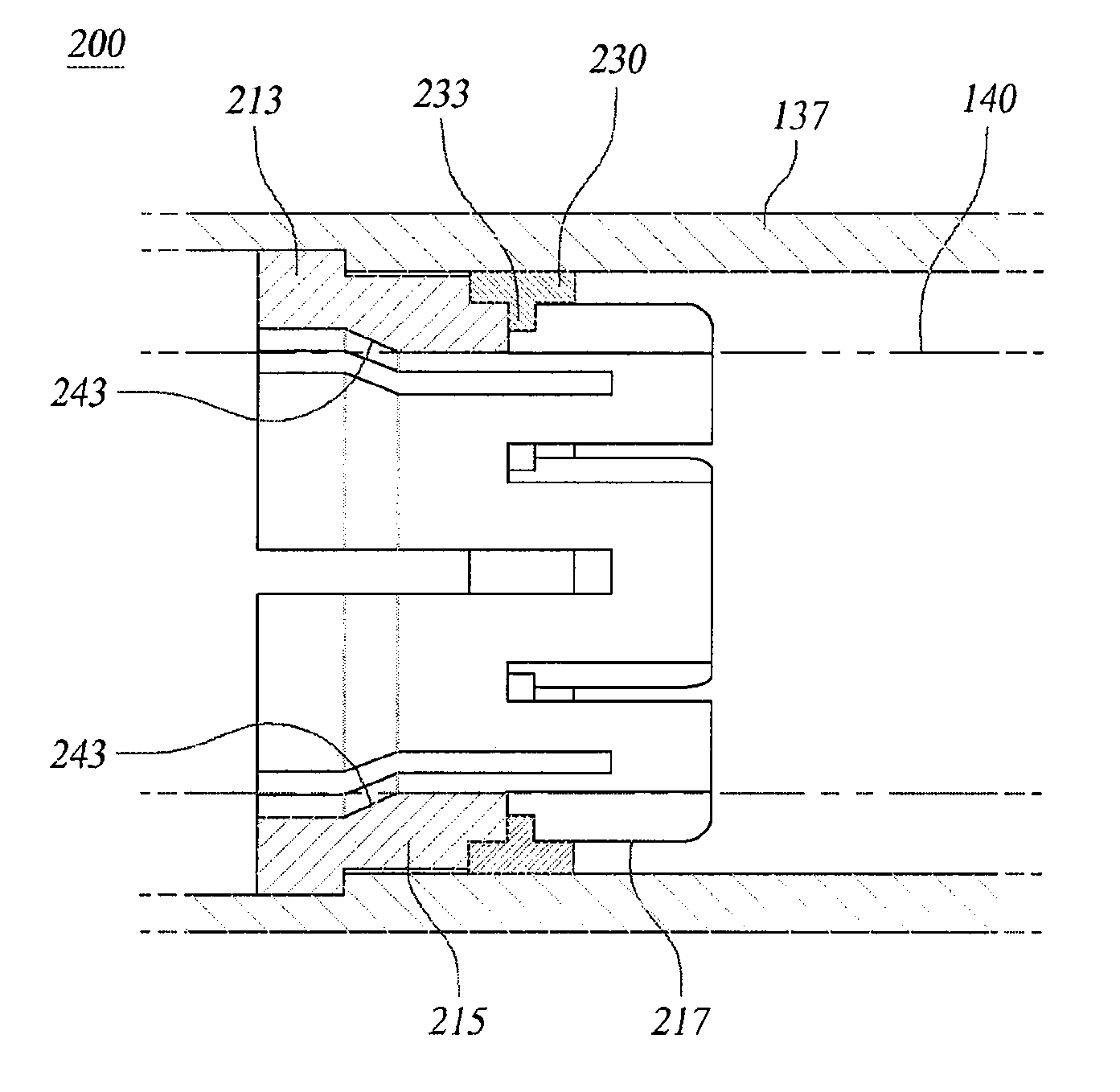

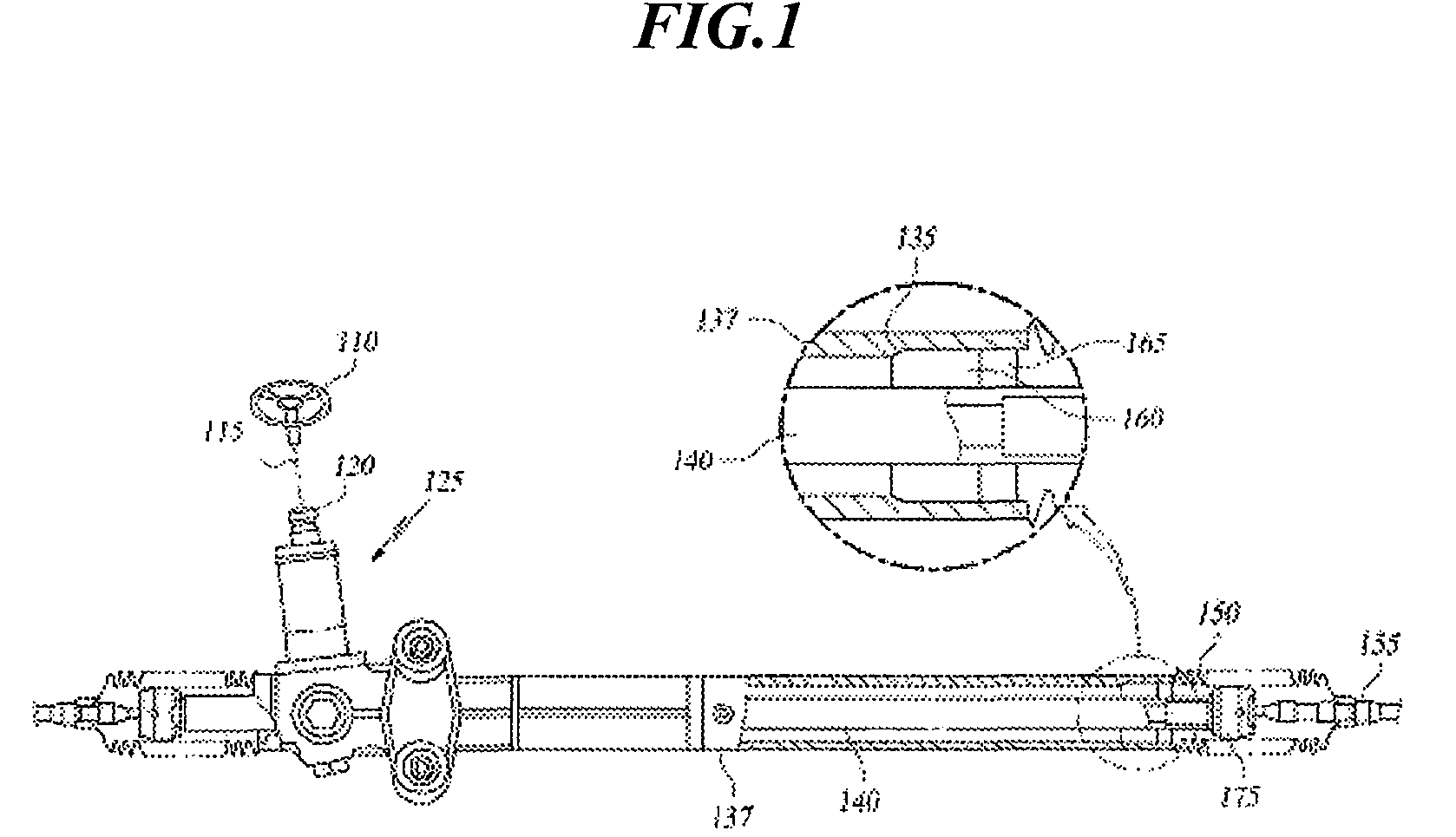

Rack bush and rack pinion type steering apparatus having rack bush for vehicle

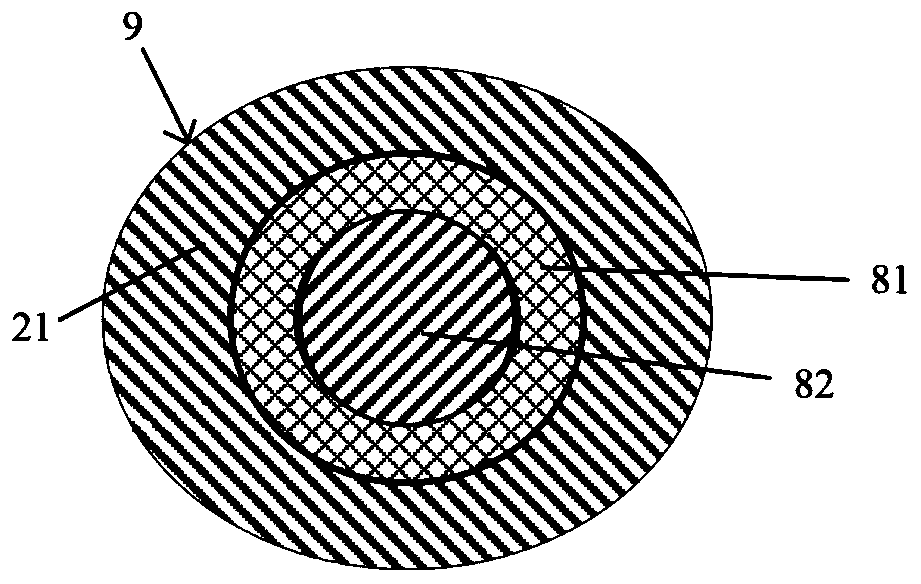

Disclosed is a rack bush and a rack pinion type steering apparatus having the rack bush for a vehicle, which can smoothly support a load in an axial direction and a vertical direction of a rack bar so that it is possible to reduce abnormal abrasion of the rack bush, reduce a rattle noise caused by external force transferred through the rack bar during movement of the rack bar, and prevent damage to the rack bar and a pinion through distribution of the load due to an external impact on the shaft.

Owner:HL MANDO CORP

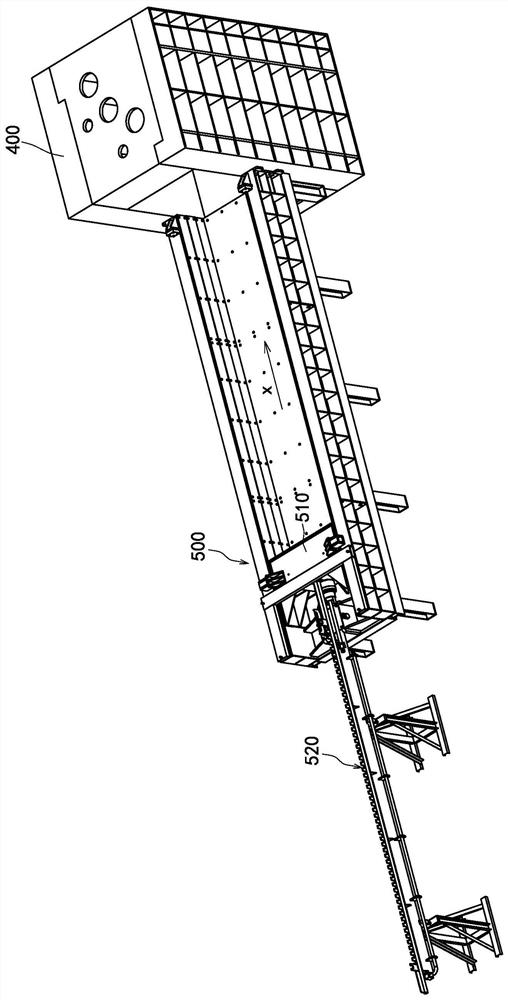

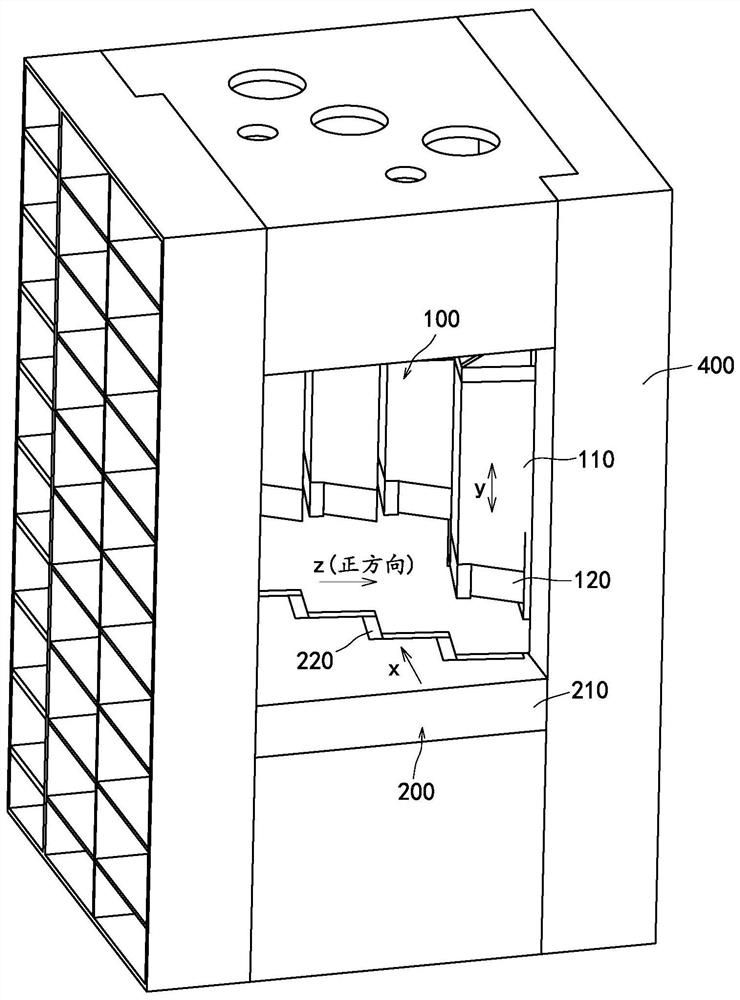

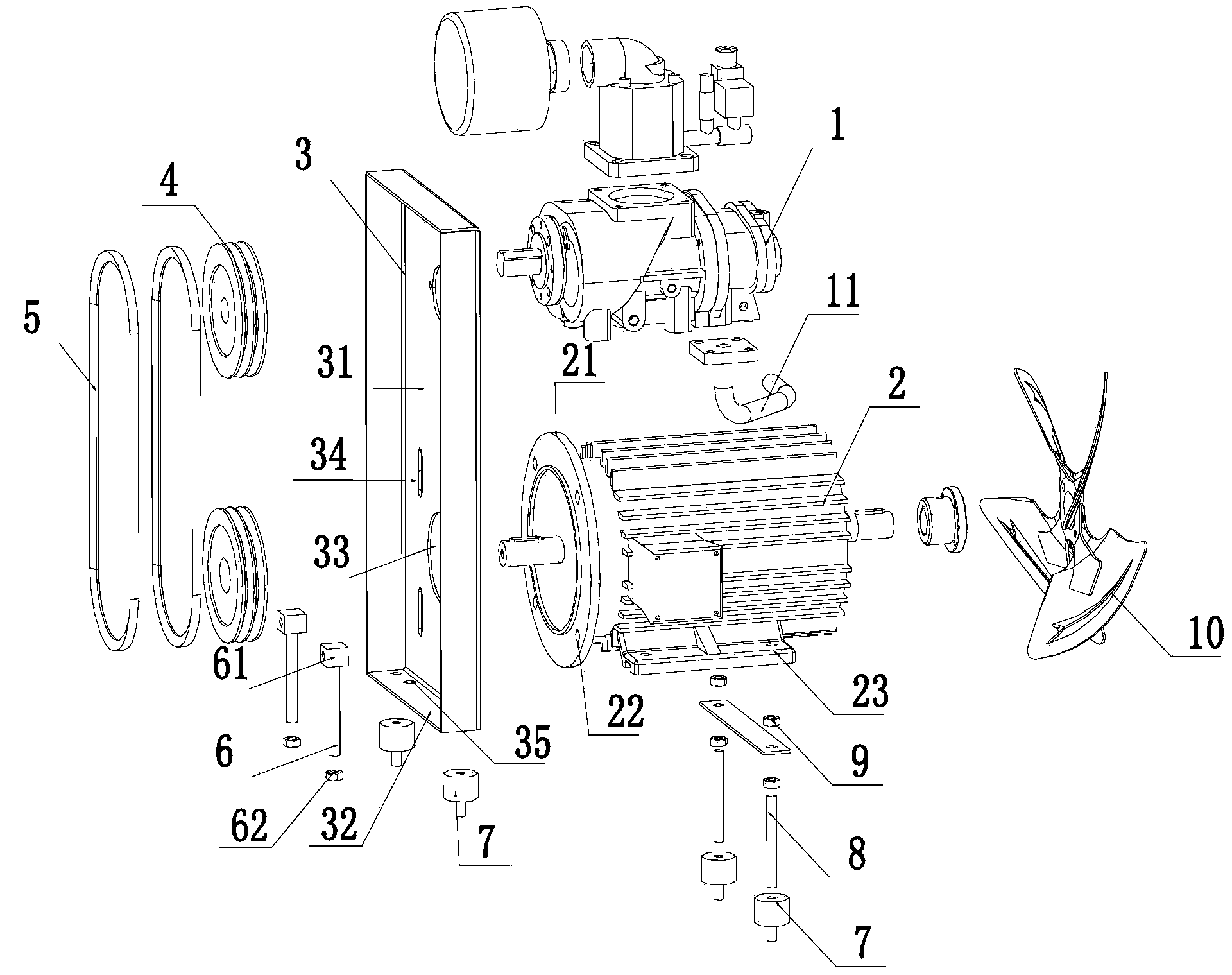

Shearing assembly and shearing machine

ActiveCN112893957AImprove shear efficiencyReduce abnormal wearShearing machinesEngineeringMechanical engineering

The invention provides a shearing assembly and a shearing machine, and relates to the technical field of shearing machines. The shearing assembly comprises a movable cutter assembly, a fixed cutter assembly and a power source; the movable cutter assembly comprises a movable cutter holder and a movable cutter installed on the movable cutter holder; the movable cutter is provided with a shearing cutting edge consisting of a transverse cutting edge and a longitudinal cutting edge; and the orthographic projection of the shearing cutting edge in the y-axis direction is in a step shape. The y-axis direction is the moving direction of the movable cutter assembly; the longitudinal cutting edge is provided with a front end close to the feeding side and a rear end close to the discharging side; and in the z-axis direction, the front end and the rear end are the same in position or the rear end is located in the positive direction of the front end. The z-axis direction is perpendicular to the x-axis direction and the y-axis direction; the x-axis direction is a feeding direction; in the z-axis direction, the direction from the fixed cutter to the movable cutter is set to be the positive direction; and according to the shearing assembly, on the basis that the step-shaped shearing cutting edge is adopted, the material can be sheared into a plurality of blocks at a time, and higher production efficiency is achieved.

Owner:长沙中金智能装备有限公司

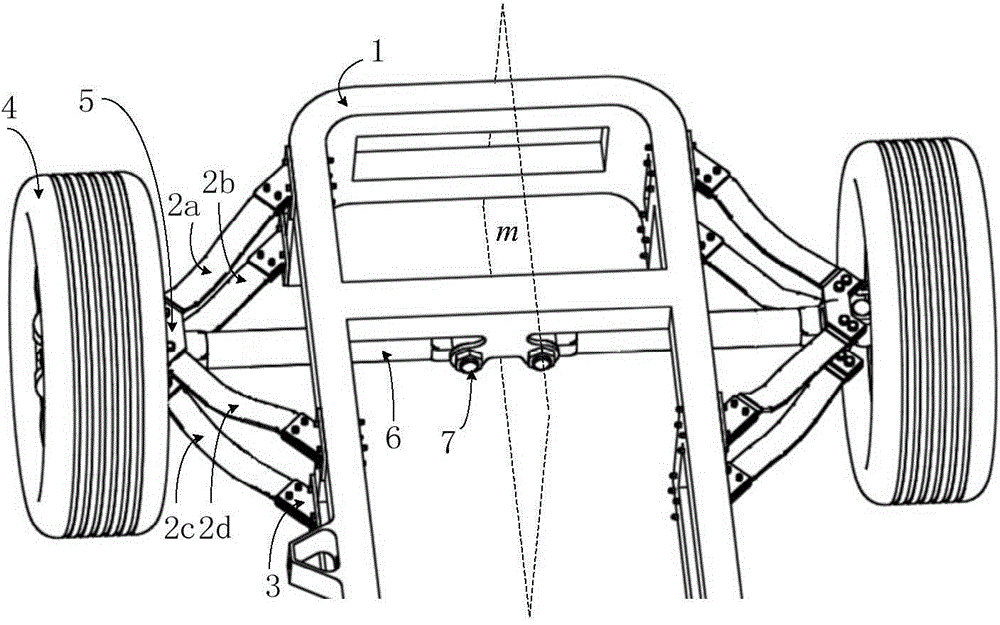

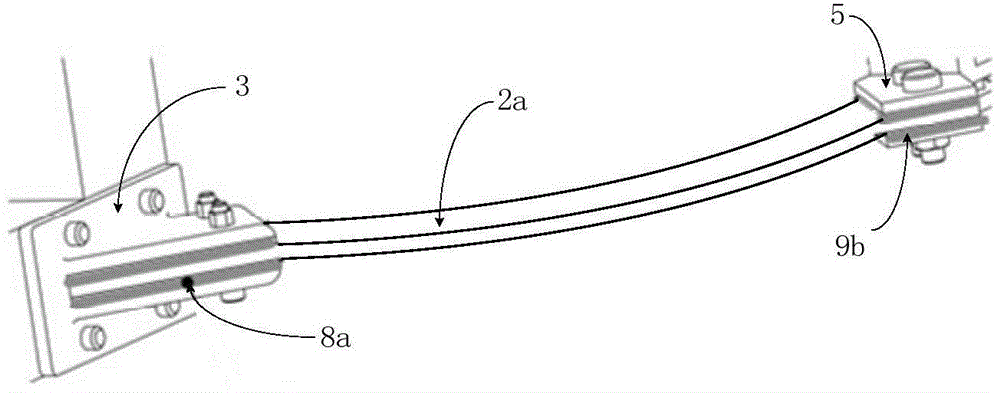

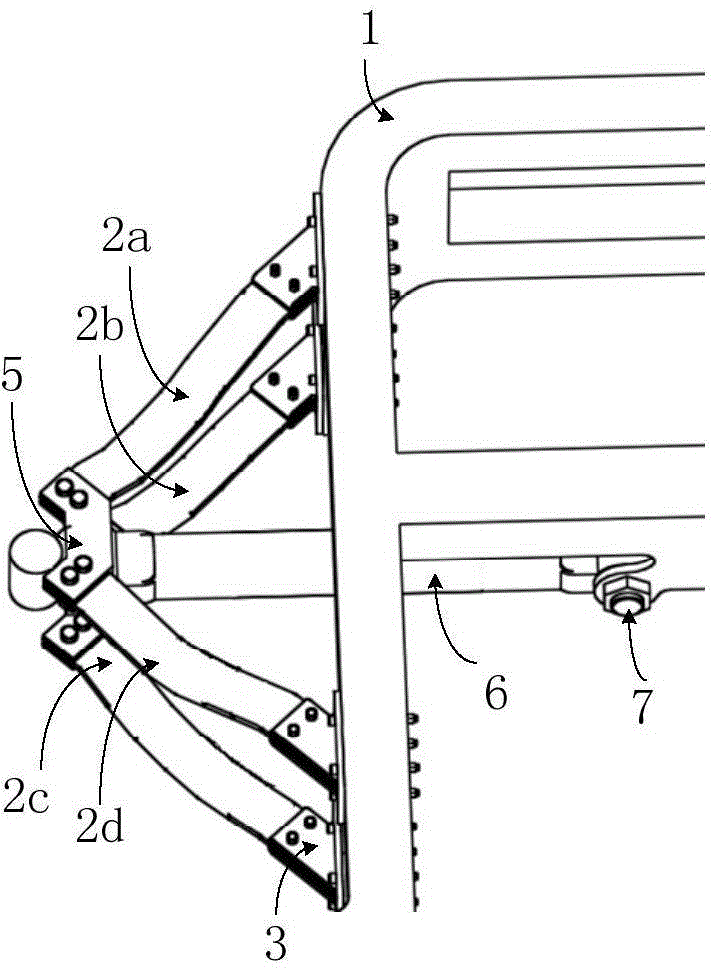

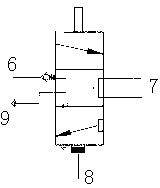

Semi-independent suspension with inclined leaf springs

ActiveCN104890464AGuaranteed carrying capacityGuaranteed reliabilityLeaf springsLow speedVehicle frame

The invention provides a semi-independent suspension with inclined leaf springs and belongs to the field of automobile engineering. The suspension comprises a frame, a half axle, and two semi-independent suspension devices on the two sides of the frame; the suspension device on each side comprises four inclined leaf springs; the first and fourth inclined leaf springs are symmetrical about the half axle, while the second and third inclined leaf springs are symmetrical about the half axle; the line of intersection of longitudinal symmetrical central planes determined by the first and fourth inclined leaf springs is parallel to or collinear to the line of intersection of longitudinal symmetrical central planes determined by the second and third inclined leaf springs. According to the semi-independent suspension, the wheels on the left and right two sides are directly connected without a hard shaft, and therefore, the semi-independent suspension is better than a traditional non-independent leaf spring suspension in manipulation stability and driving smoothness. Meanwhile, four leaf springs connected in parallel are capable of effectively bearing and alleviating impact to achieve better bearing capability and reliability; in addition, the distance between the bearing centers on the two sides and the steering range of the wheels are increased, and therefore, the whole vehicle is enabled to be better in low-speed flexibility.

Owner:TSINGHUA UNIV

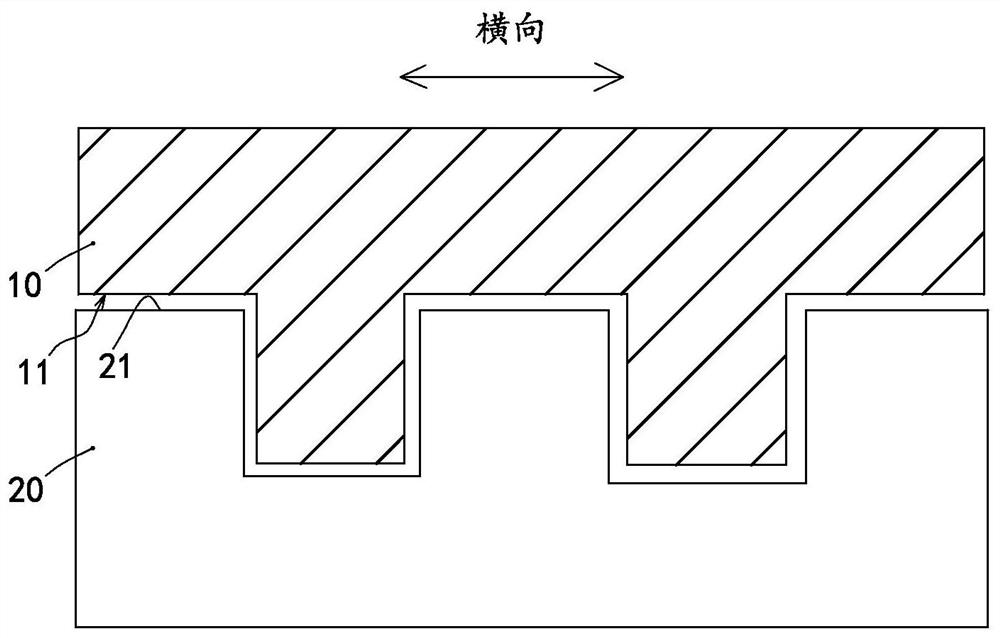

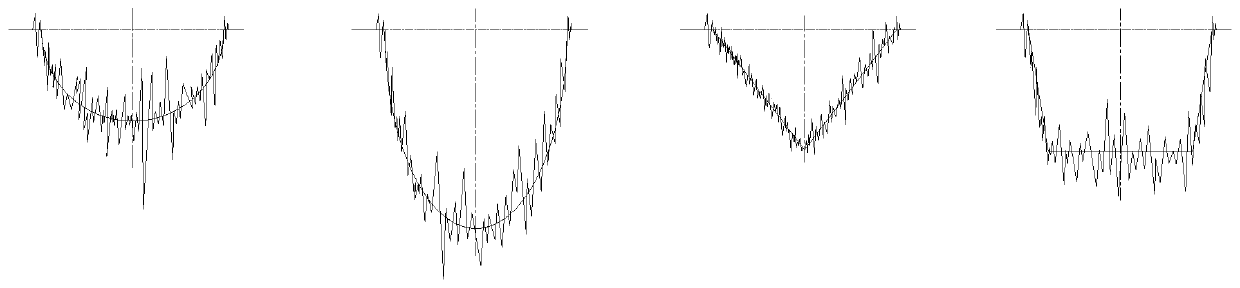

Friction structure, friction part and compressor

InactiveCN110374881AImprove bindingStable lubricationRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringBinding force

The invention provides a friction structure, a friction part and a compressor. The friction structure comprises a base and multiple coatings combined on the base in sequence. A first contact face between the base and the adjacent coating, a second contact face between the two adjacent coatings and the outer surface of the coating on the outermost layer are arranged to be of surface texture structures. The base, the coating and the two adjacent coatings combined with the outer surface are arranged to be of the surface texture structures, the binding force is high, lubrication is stable, and abnormal wear is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

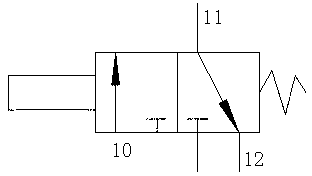

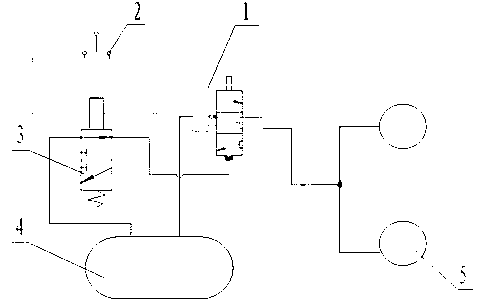

Three shaft bus servo bridge lifting control system

InactiveCN103158481AAchieve inflatableReduce abnormal wearResilient suspensionsControl systemControl theory

The invention relates to the field of bus servo bridges, in particular to a three shaft bus servo bridge lifting control system. The three shaft bus servo bridge lifting control system at least comprises a gas storage cylinder and a gas bag. The Three shaft bus servo bridge lifting control system is characterized in that an output terminal of the gas storage cylinder is connected with the gas bag through a lifting height adjusting valve, and the other output terminal of the gas storage cylinder is connected with the lifting height adjusting valve through a two-position three-way lifting height adjusting valve controlled by a rocker switch and is connected with the gas bag through the lifting height adjusting valve. Due to the fact that a driver controls the rocker switch, air filling and air exhausting of the gas bag are achieved, the effect of lifting the servo bridge gas bag is achieved, the center of the servo bridge is lowered during loading a car and unloading the car, loading is reduced, and abnormal wear to tires is reduced.

Owner:SHAANXI EUROSTAR AUTOMOBILE

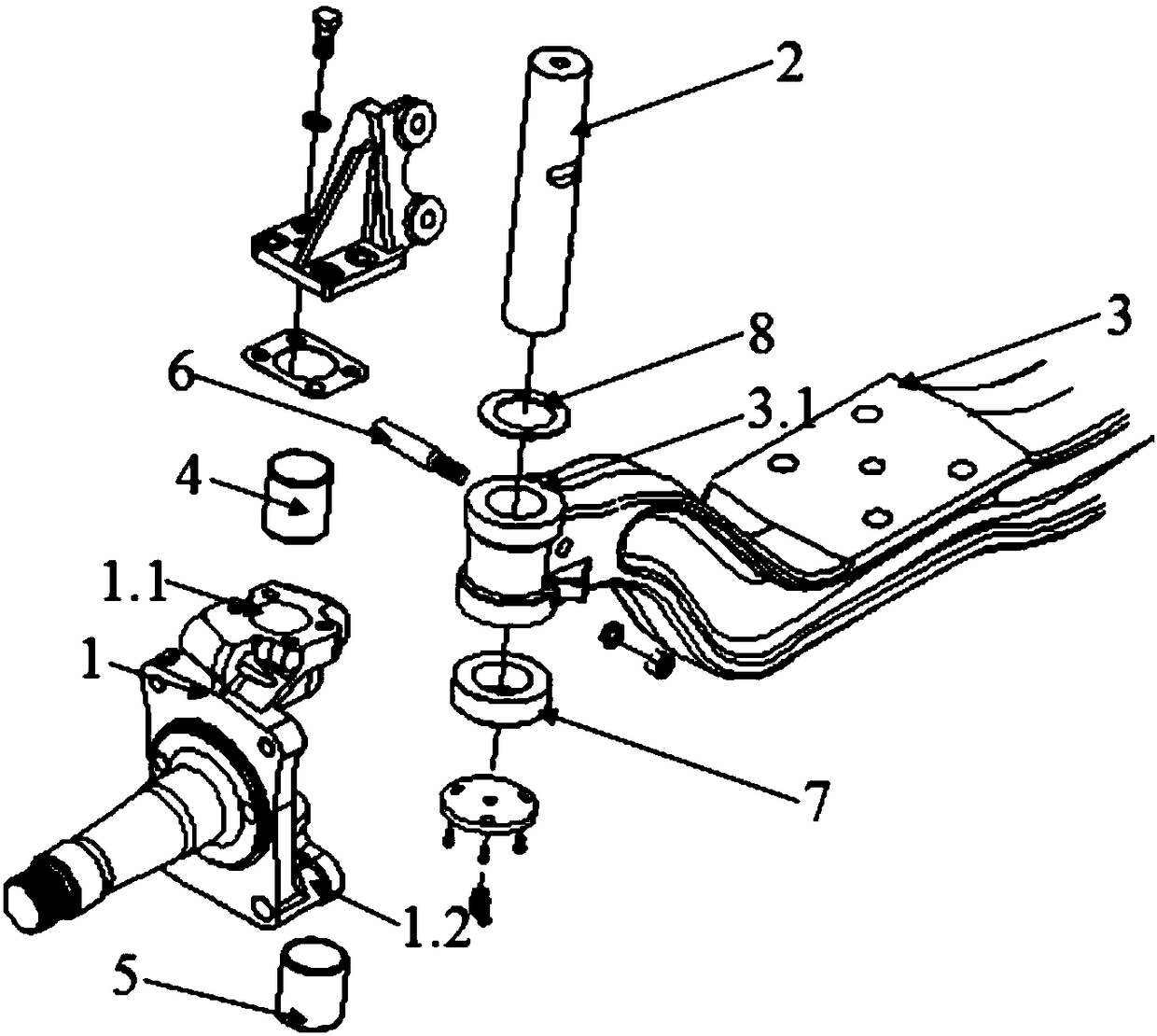

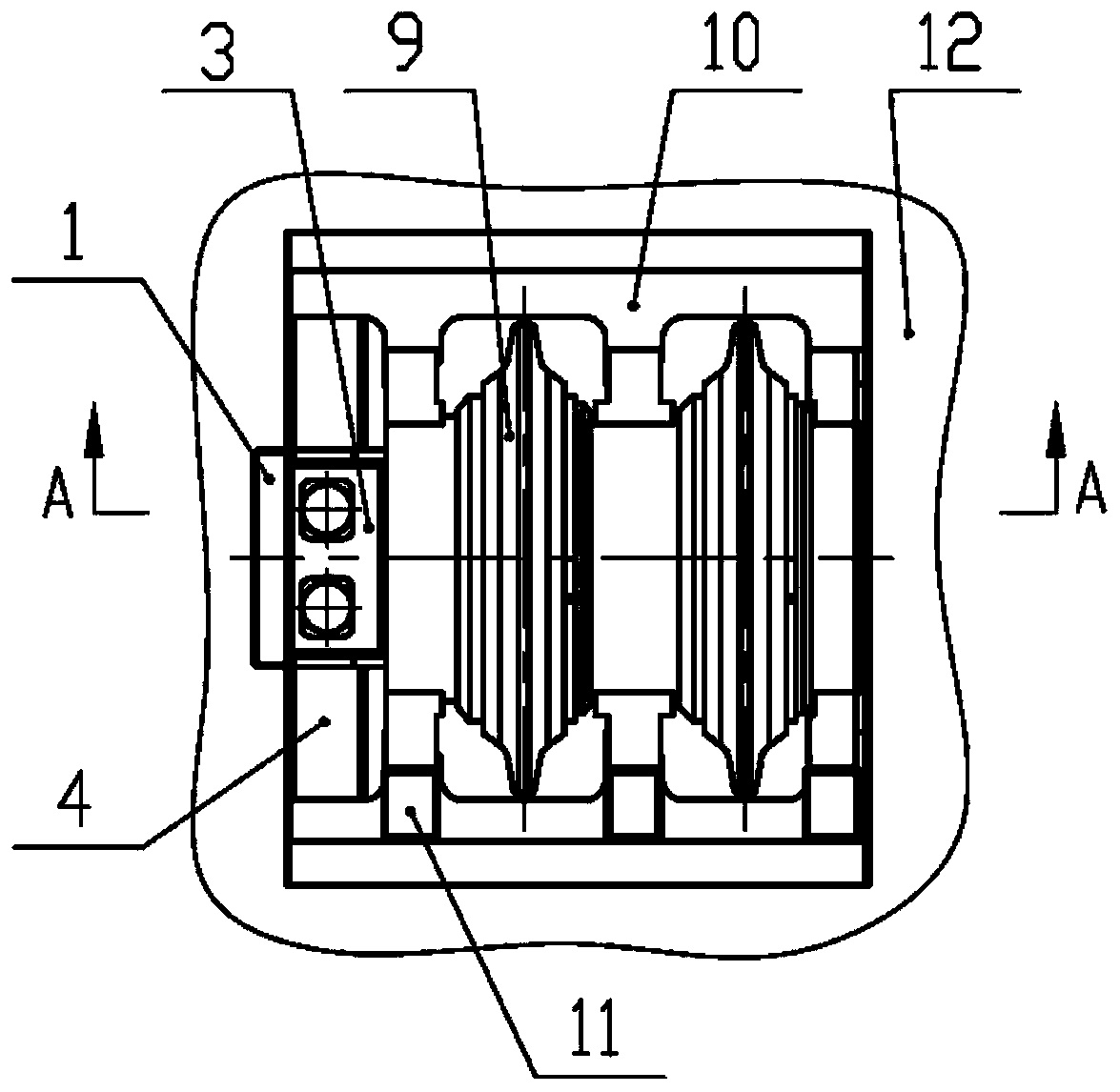

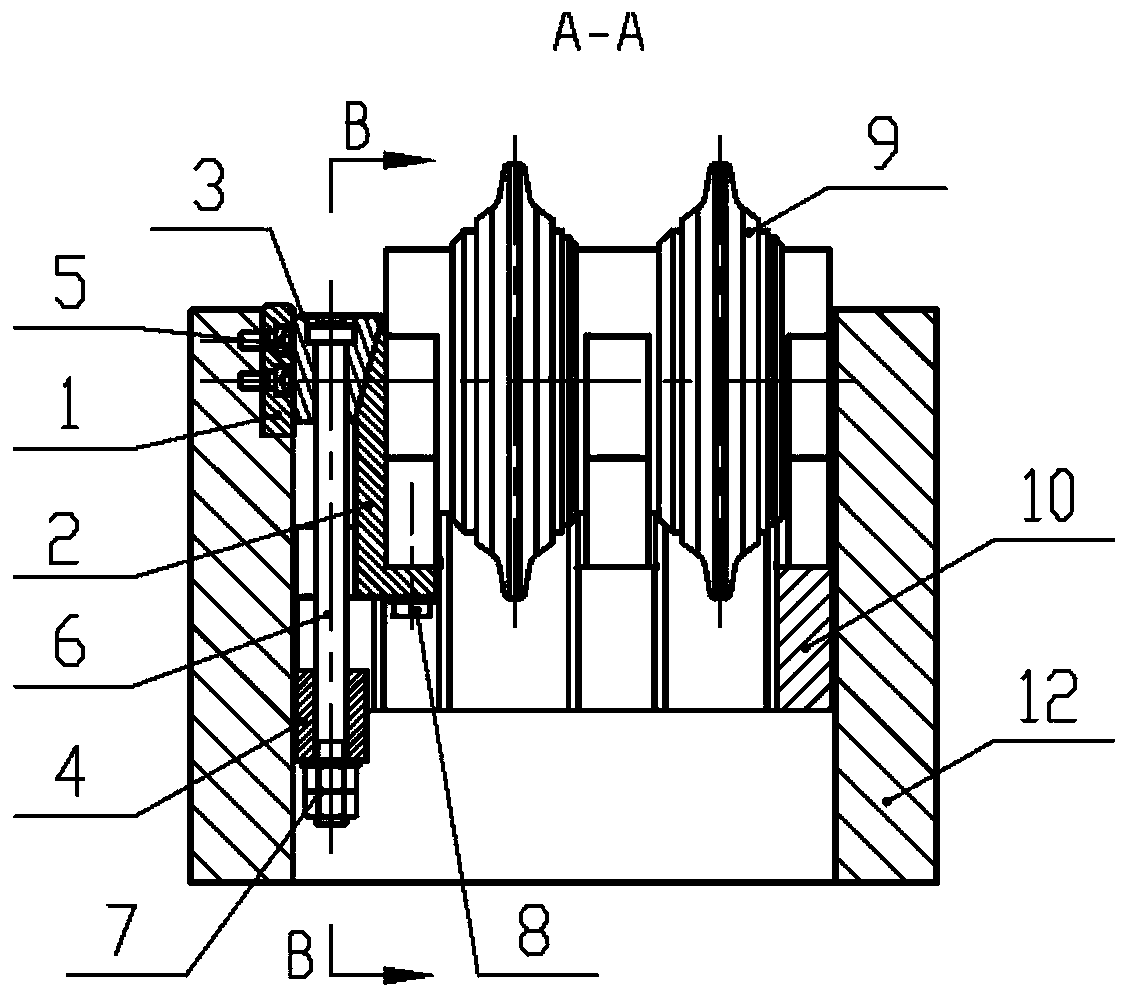

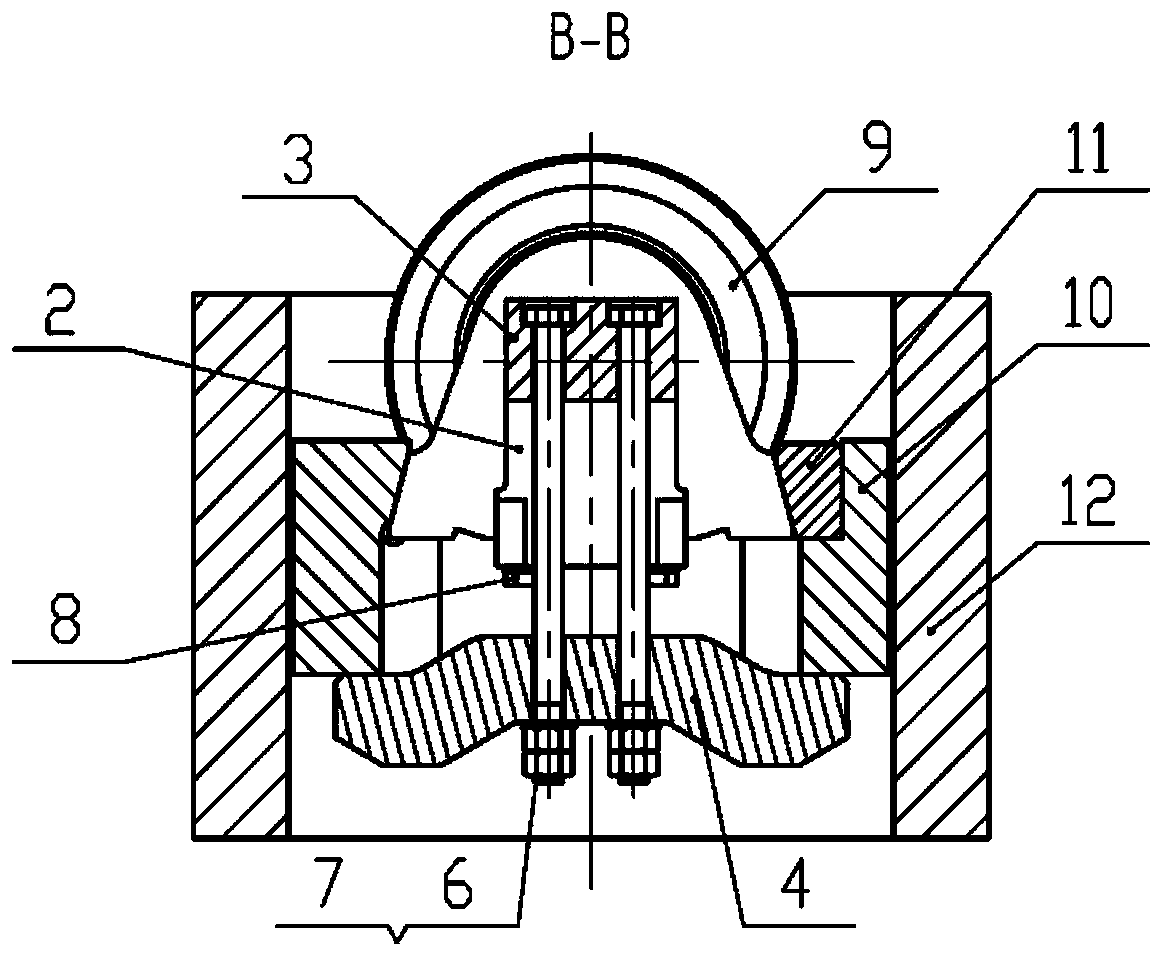

Automobile front axle steering knuckle and front axle connecting mechanism

PendingCN108482482AImprove bearing capacityNot easy to looseSteering linkagesCouplings for rigid shaftsInterference fitNeedle roller bearing

The invention discloses an automobile front axle steering knuckle and front axle connecting mechanism. The mechanism comprises a steering knuckle and a front axle which are connected through a masterpin, and is characterized in that an upper cylindrical bore and lower cylindrical bore of the steering knuckle are respectively in interference fit with a tapered roller bearing and a roller pin bearing, the tapered roller bearing and the roller pin bearing are in transition fit, the upper cylindrical bore is internally provided with a first limiting device cooperating with the tapered roller bearing and axially limiting the master pin, a master pin bore of the front axle is internally provided with a second limiting device matched with the surface of the master pin, and the second limiting device limits the master pin axially and radially through the axial acting force of the first limiting device on the master pin. The automobile front axle steering knuckle and front axle connecting mechanism has the advantages that the tapered roller bearing not only can bear the axial force, but also can bear the radial force, the bearing capacity is large, and the looseness is not easy; the masterpin and the lower end of the steering knuckle are connected through the roller pin bearing, and the steering is light and convenient.

Owner:HUBEI TRI RING AXLE

Four-stroke engine of vertical shaft OHC structure

InactiveCN104989522AReduce consumptionEasy dischargeValve drivesNon-pressurised lubricationExhaust valveTiming belt

The invention discloses a four-stroke engine of a vertical shaft OHC structure. The four-stroke engine of the vertical shaft OHC structure comprises an engine body and a timing transmission mechanism arranged above the engine body. The engine body mainly comprises a crankcase, a cylinder body and a cylinder head. The timing transmission mechanism is mainly composed of a driving belt wheel, a timing belt and a driven belt wheel which are located above the oil face of lubrication oil, and further mainly comprises a gas distribution mechanism, a lubrication mechanism and an oil-gas separation and lubrication oil recycling mechanism. The gas distribution mechanism is mainly composed of a cam, a cam rocker, a cam transmission shaft and an inlet and exhaust valve. The lubrication mechanism mainly comprises a lubrication oil mist generation mechanism and a lubrication channel. The oil-gas separation and lubrication oil recycling mechanism mainly comprises a cylinder head cavity, a partition board and a returned oil sucker. The novel vertical shaft OHC structure is adopted and the oil mist lubrication mode is adopted; the structural design is reasonable and compact; the cost is low; the consumption of the lubrication oil can be effectively reduced; engine emission is optimized; the operation reliability of the engine is improved.

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

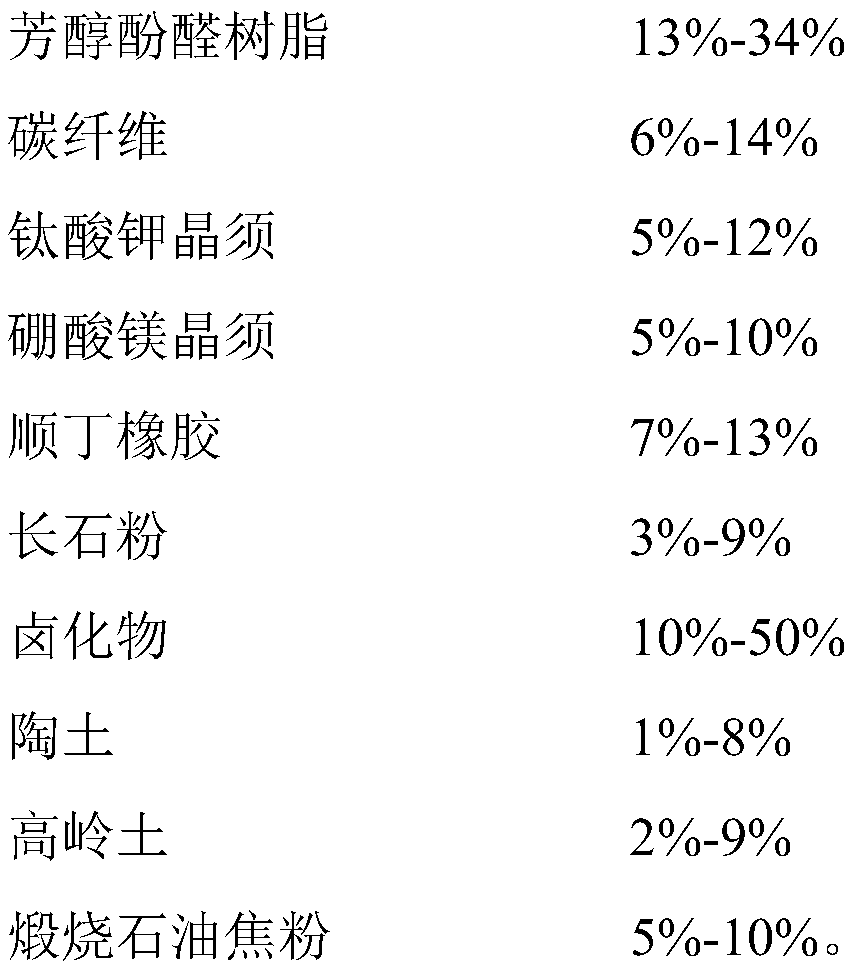

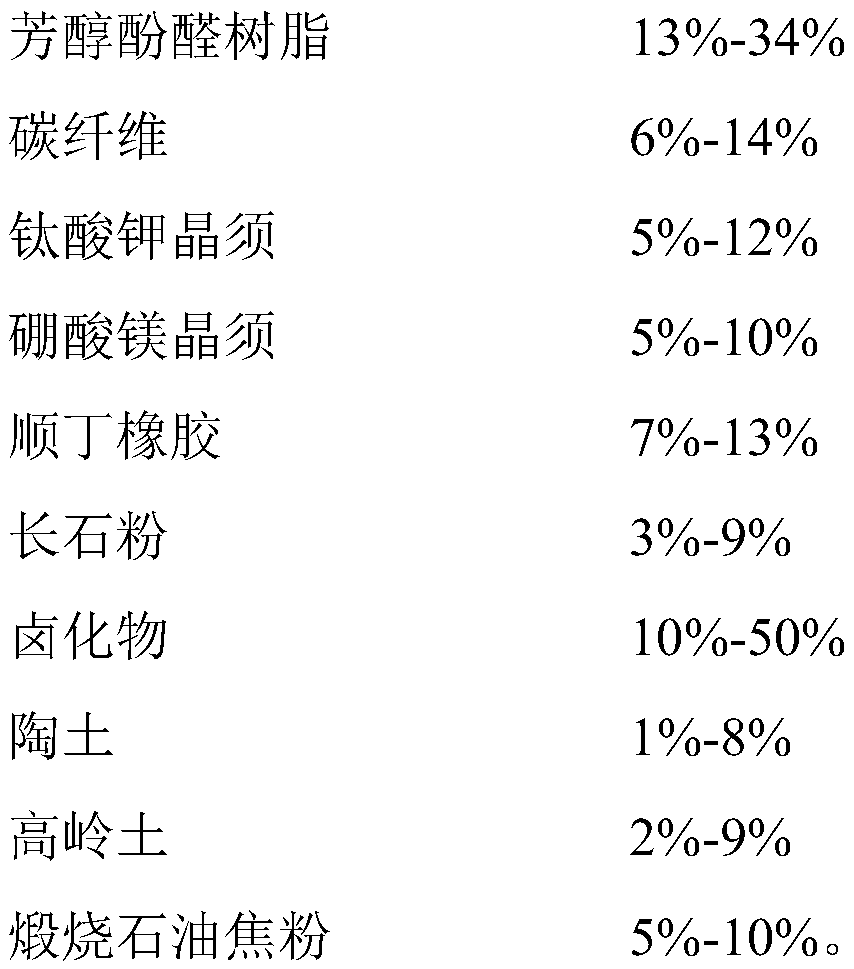

Halide-containing brake material and preparation method and application thereof

ActiveCN110778629AImprove thermal conductivityNo crackOther chemical processesDomestic articlesCarbon fibersKaolin clay

The invention relates to a halide-containing brake material and a preparation method and application thereof, and belongs to the technical field of brake materials. The preparation method comprises the following steps: adding aromatic alcohol phenolic resin, butadiene rubber, feldspar powder, argil, kaolin, calcined petroleum coke powder and halide into a mixer according to a proportion, mixing and stirring for 20-25min, then adding carbon fibers, potassium titanate whiskers and magnesium borate whiskers according to a proportion, and mixing and stirring for 12-18min until the mixture is uniform to obtain the halide-containing brake material; and placing a steel backing and the brake material into a mold for compression molding, placing the mold into an oven for heating and curing after demolding, and finally machining to obtain an automobile brake pad or a rail transit vehicle brake pad. The friction material of the automobile brake pad and the rail transit vehicle brake pad is particularly suitable for a brake disc with a dual material being aluminum alloy, the porosity of a microporous material is large, the hardness is low, and damage to the brake disc is reduced. The microporous material and the aluminum alloy brake disc are high in heat dissipation speed, the working temperature of a friction pair can be reduced, and the friction pair can bear larger load.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

Herringbone gear assembly positioning method and device, assembling method and high-power diesel engine

The invention belongs to the technical field of diesel engine manufacturing, and discloses a herringbone gear assembly positioning method and device, an assembling method and a high-power diesel engine. The herringbone gear assembly positioning method includes the steps that datum tooth scale lines of a right-rotation gear tooth ring and datum tooth scale lines of a left-rotation gear tooth ring are aligned for visual inspection coarse tuning; and datum teeth of the left-rotation gear tooth ring are used as a datum for fixation with fixed positioning teeth of a positioning device, automatic alignment is conducted through movement of movable positioning teeth to obtain the correct positions of datum teeth of the right-rotation gear tooth ring based on the positional accuracy between the movable positioning teeth and the fixed positioning teeth of the positioning device as well as the body dimensional accuracy of the two positioning teeth, and positional assembling between the datum teeth of the right-rotation gear tooth ring and the datum teeth of the left-rotation gear tooth ring is carried out. According to the herringbone gear assembly positioning method and device, the assembling method and the high-power diesel engine, by using the intermediate-speed high-power diesel engine combined-type herringbone gear assembly, assembly accuracy is improved, assembly technology stability is ensured, the economic cost of herringbone tooth gears is reduced, and operational reliability of diesel engine gears is guaranteed; and the application field is broad and the popularization valueis good.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Brake shoe protector and railway vehicle brake system

ActiveCN106515785AReduce abnormal wearExtended service lifeVehicle cleaningRailway auxillary equipmentBrake shoeTread

The invention provides a brake shoe protector and a railway vehicle brake system. The brake shoe protector provided by the invention comprises two grinding bodies and a mounting plate which is fixedly arranged on the back face of a brake shoe. The two ends of the mounting plate extend out of the upper and lower ends of the brake shoe and fix the two grinding bodies to the upper and lower ends of the mounting plate. The inner surface of each grinding body makes contact with a wheel tread. According to the brake shoe protector and the railway vehicle brake system, fragments and foreign bodies on the wheel tread are removed through the grinding bodies of the brake shoe protector, micro protrusions are prevented from generating on the wheel tread, abnormal abrasion to the brake shoe is relieved, the service life of the brake shoe is prolonged, and the maintenance cost of a railway vehicle is lowered.

Owner:CRRC SHENYANG CO LTD

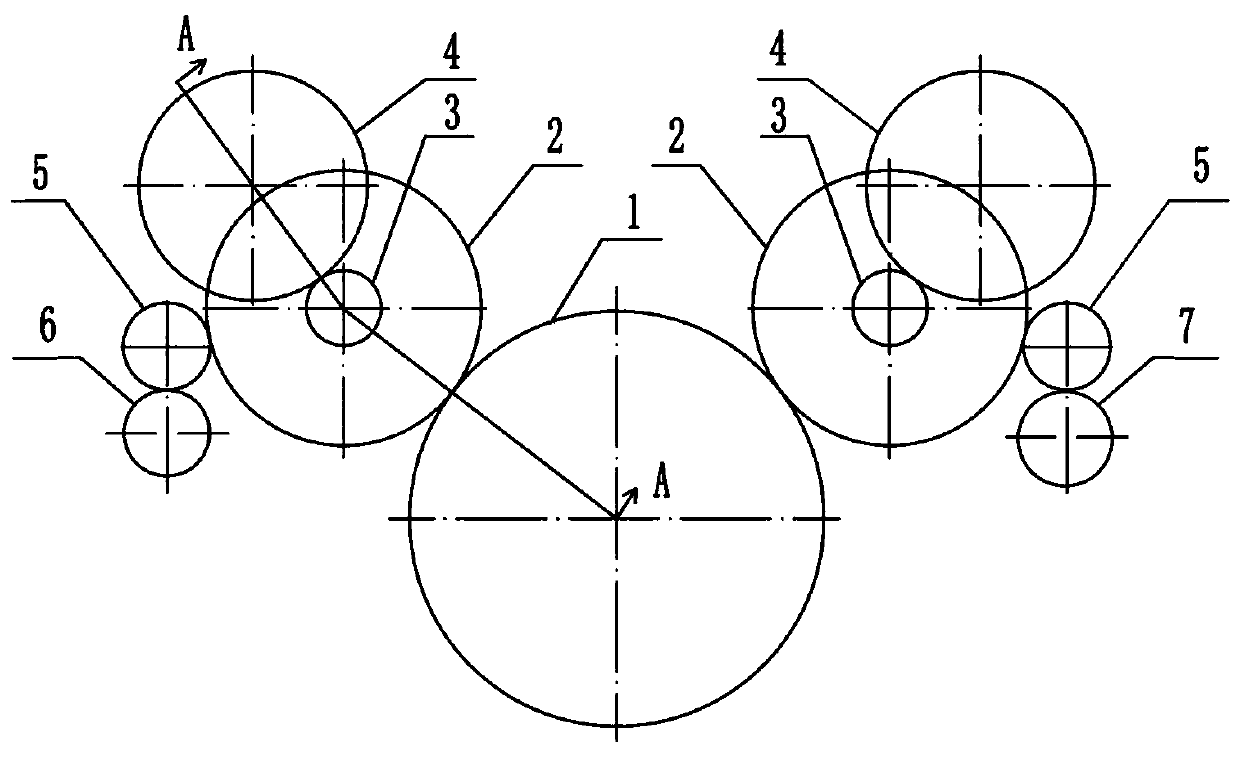

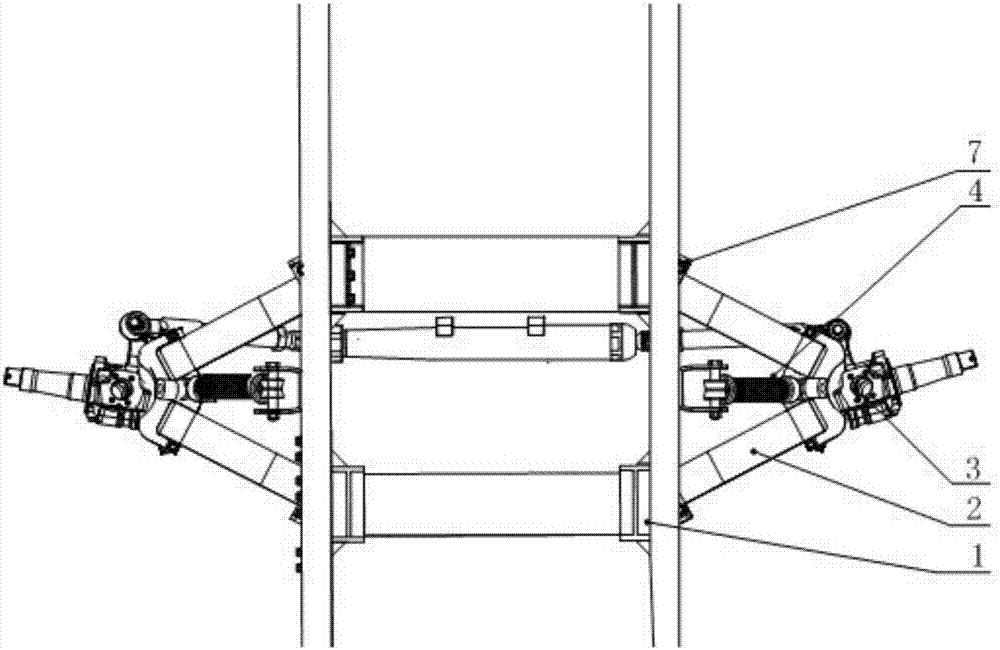

Automotive double-front-axle structure adopting non-independent oblique leaf spring suspensions

ActiveCN104875567AImprove roll resistanceIncrease stiffnessSteering linkagesResilient suspensionsLow speedVehicle frame

An automotive double-front-axle structure adopting non-independent oblique leaf spring suspensions comprises a frame, a first front axle, a second front axle and a steering system, wherein each of the two front axles comprises two oblique leaf spring suspensions, an integral axle and a trapezoid steering mechanism; each oblique leaf spring suspension comprises four oblique leaf springs, the first oblique leaf spring and the fourth oblique leaf spring are symmetrical about the axle, and the second oblique leaf spring and the third oblique leaf spring are symmetrical about the axle, and an intersecting line of longitudinal symmetric center surfaces determined by the first oblique leaf spring and the fourth oblique leaf spring is parallel to or collinear with an intersecting line of longitudinal symmetric center surfaces determined by the second oblique leaf spring and the third oblique leaf spring. Compared with a conventional double-front-axle structure adopting non-independent longitudinal leaf spring suspensions, the automobile double-front-axle structure has high bearing capability, the positional parameter variable quantity of wheels can be reduced, the bearing center distance of the leaf springs is increased, and the abnormal wear of the tires is reduced; the wheel steering range is increased, and a whole automobile has better low-speed flexibility.

Owner:TSINGHUA UNIV

Trailer, steering control method for same, controller and steering system of trailer

ActiveCN103057586BImprove passabilityReduce abnormal wearSteering linkagesAutomatic steering controlVertical planeSteering wheel

Owner:ZOOMLION HEAVY IND CO LTD

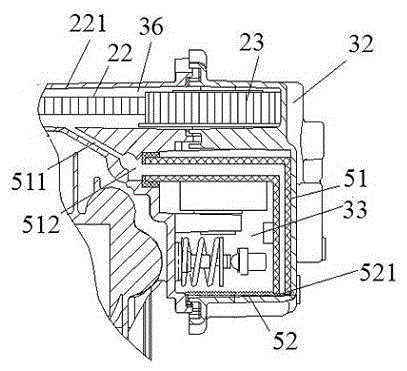

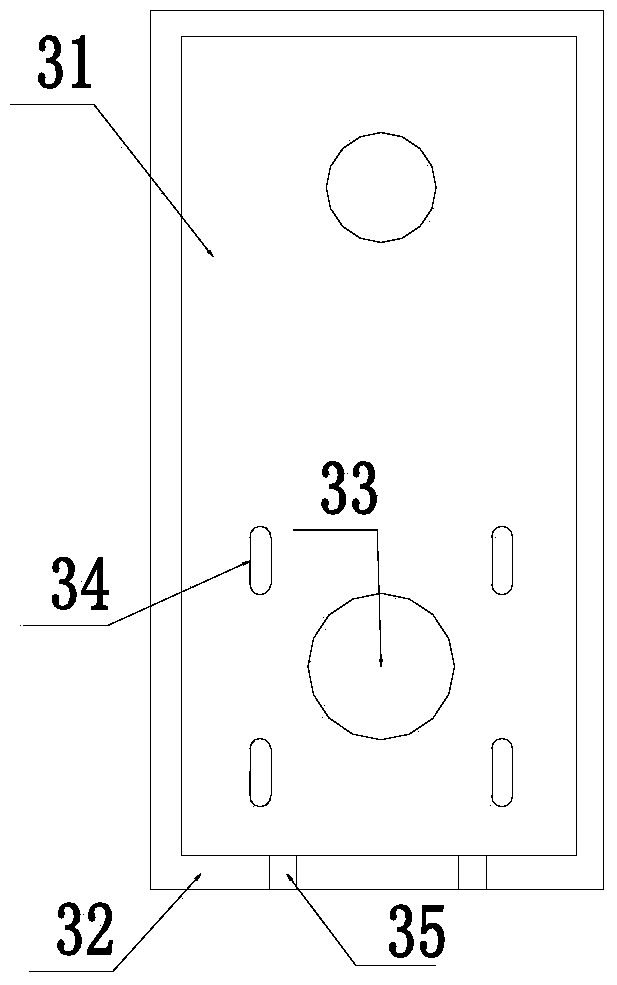

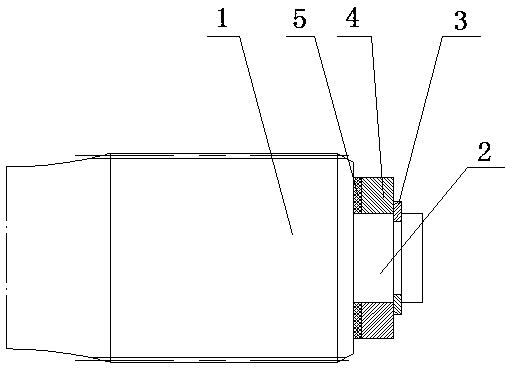

Screw-type air compressor

InactiveCN103591026ANo deviation in installation positionImprove assembly accuracyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringAir compressor

The invention relates to a screw-type air compressor. The screw-type air compressor comprises a machine frame, a base, a screw-type air compressor main unit and a motor, wherein the machine frame is a plate-type supporting frame; the plate-type supporting frame comprises a fixing plate and a frame border; the screw-type air compressor main unit is fixedly arranged above the fixing plate; a main body of the screw-type air compressor main unit is arranged on the right side of the fixing plate; a belt pulley of the screw-type air compressor main unit is arranged on the left side of the fixing plate; the motor is arranged below the fixing plate; an installing hole is formed in the fixing plate; a main shaft of the motor penetrates through the installing hole and is connected with the belt pulley; elongated adjusting holes are formed in the upper parts and the lower parts of the two sides of the installing hole respectively; a fixing disc is arranged on the left side section of the motor; the fixing disc is provided with fixing holes at positions corresponding to the four elongated adjusting holes. The screw-type air compressor is high in assembling precision and convenient to adjust; during parallel downward movement, the installing accuracy of a belt drive is not affected, thus reducing the abnormal wear of a belt and ensuring the driving torque.

Owner:钟仁志

Half shaft for drive axle

The invention discloses a half shaft for a drive axle. The half shaft comprises a half shaft body, wherein a boss is arranged at the spline end of the half shaft body; and a magnet is arranged on the boss. According to the half shaft disclosed by the invention, the boss assembled with the magnet is added in case of ensuring the invariable torque transfer function of the half shaft, and the magnet adsorbs wear iron chippings in a differential mechanism; and the iron chippings can be eliminated only by regularly extracting the half shaft, thus reducing the abnormal wear of components in the inter-wheel differential mechanism, reducing the faults of the differential mechanism, and improving the performance of an axle assembly.

Owner:ANHUI ANKAI FUTIAN SHUGUANG AXLE CO LTD

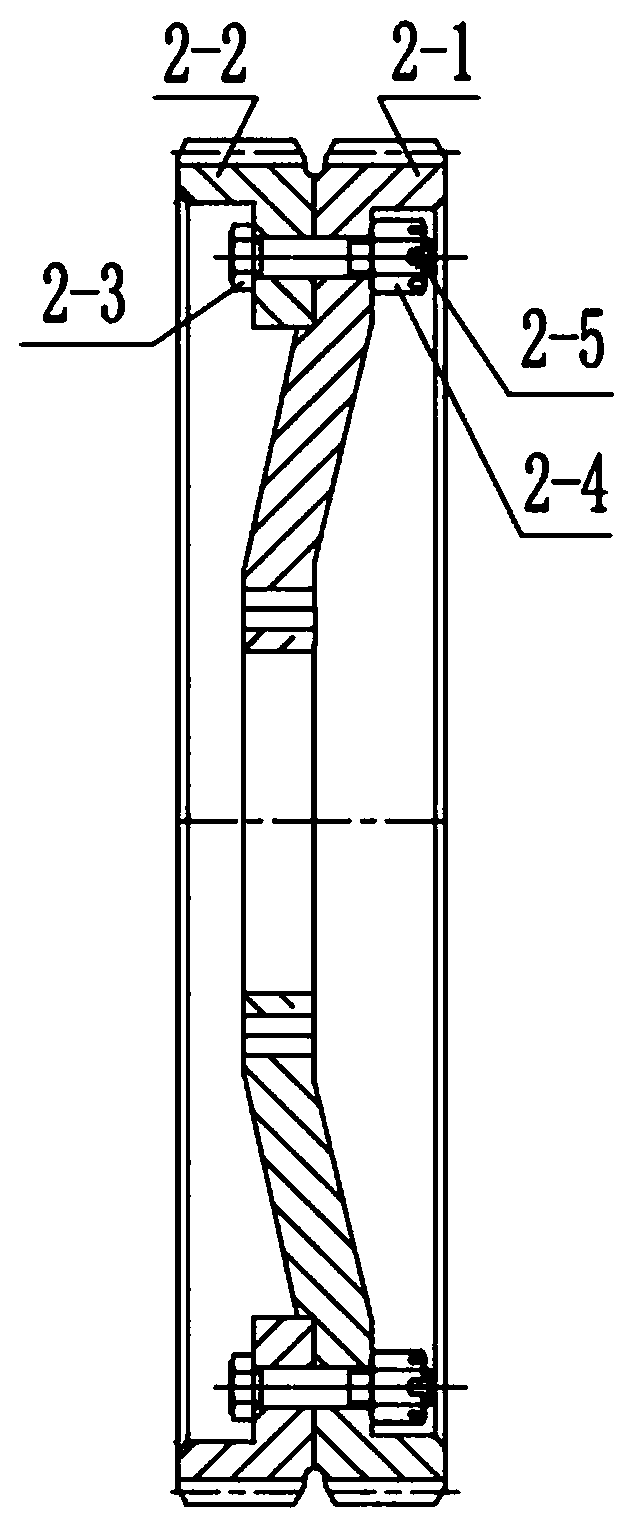

Heading machine and center hobbing cutter axial locking device thereof

The invention discloses a center hobbing cutter axial locking device. The center hobbing cutter axial locking device comprises a first pressing block and also comprises a second pressing block, wherein the first pressing block is used for being fixedly connected with a center hobbing cutter; and the second pressing block is used for extruding the first pressing block to tightly press the center hobbing cutter along the axial direction of the center hobbing cutter as well as tightly press the center hobbing cutter on a center knife holder for mounting the center hobbing cutter. The invention discloses a heading machine comprising the center hobbing cutter axial locking device. The center hobbing cutter axial locking device tightly presses the center hobbing cutter along the axial directionso as to improve the mounting stability and reliability of the center hobbing cutter, reduce abnormal abrasion and damage to the center hobbing cutter and prolong the service life of the center hobbing cutter.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Non-independent suspension frame

ActiveCN107225927AReduce the amount of variationRaise the steering angleResilient suspensionsVehicle springsSteering angleVehicle frame

The invention discloses a non-independent suspension frame comprising two obliquely-arranged plate spring assemblies which are symmetrically arranged on the two sides of a vehicle frame. Each obliquely-arranged plate spring assembly comprises four obliquely-arranged plate springs, wherein the two obliquely-arranged plate springs are located on the tops of the other two obliquely-arranged plate springs; one ends of the obliquely-arranged plate springs are connected with the vehicle frame; the other ends of the obliquely-arranged plate springs are connected with wheel hub connecting members; every two corresponding obliquely-arranged plate springs located on the tops and the vehicle frame form a triangular structure in an enclosed mode; and the other two corresponding obliquely-arranged plate springs located at the bottoms and the vehicle frame form a triangular structure in an enclosed mode. The non-independent suspension frame further comprises spring shock absorbers, and the two ends of the spring shock absorbers are connected with the vehicle frame and the wheel hub connecting members correspondingly and located on the upper portions of the obliquely-arranged plate spring assemblies. According to the non-independent suspension frame, application of the obliquely-arranged plate springs and the spring shock absorbers is combined, the carrying capacity and the lateral-tilting resistance capacity of a vehicle can be improved, wheel positioning parameters are improved, the steering angle is increased, the bearing center distance is increased, tire internally-tilting is avoided, and abnormal friction of tires is reduced.

Owner:TSINGHUA UNIV

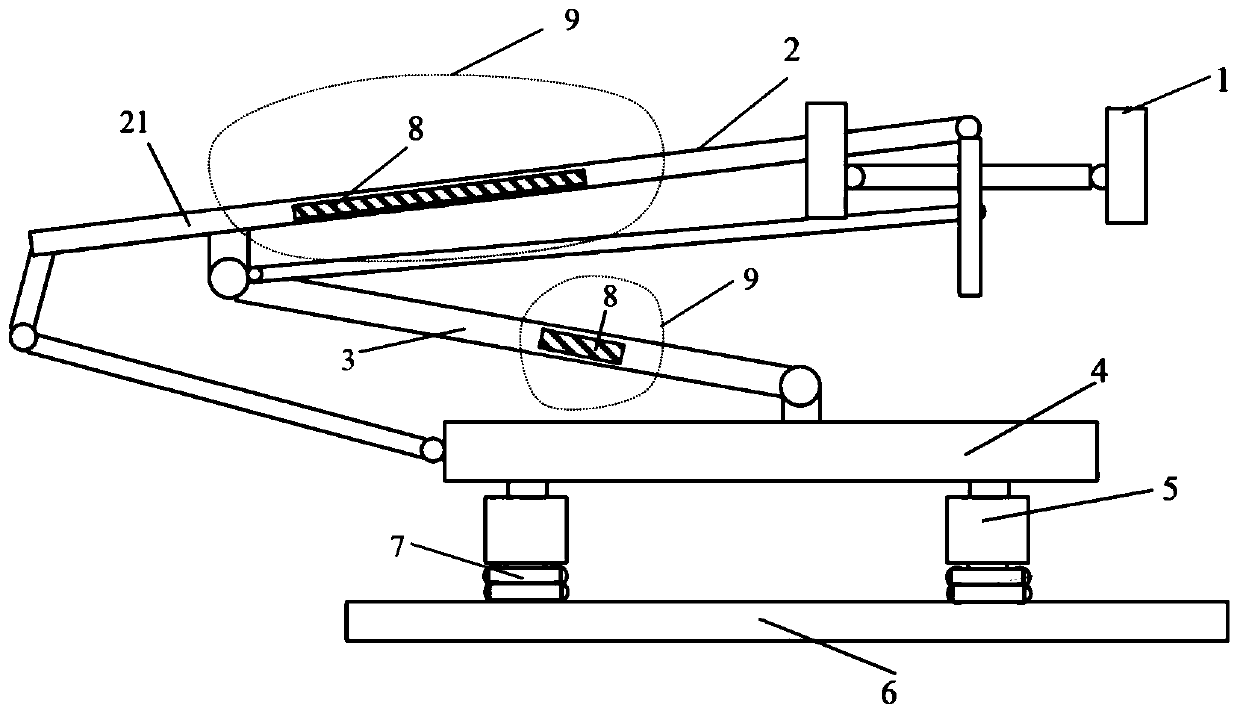

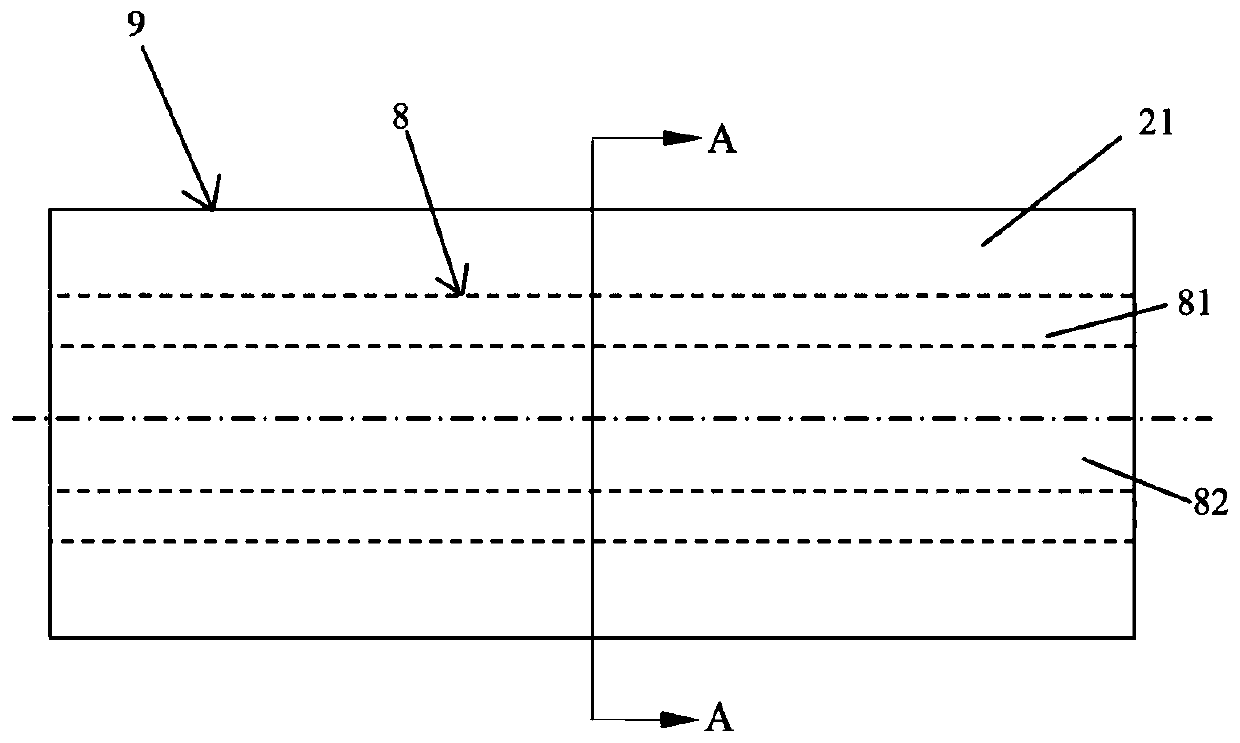

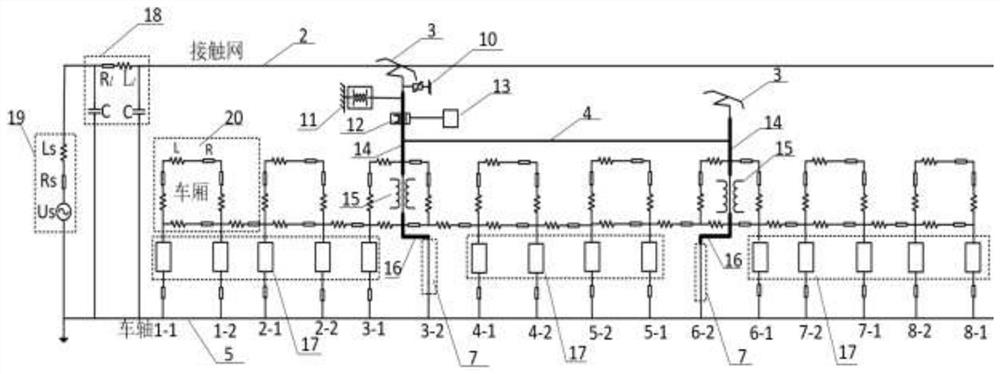

Damping pantograph for rail transit trains

PendingCN110329080AReduce abnormal wearImprove service life and safety factorPower current collectorsPantographElectricity

The invention relates to a damping pantograph for rail transit trains. The damping pantograph comprises a carbon sliding plate, an upper frame, a lower arm rod, a pantograph base frame, an insulatingpart and a roof mounting base which are sequentially connected. The damping pantograph for rail transit trains is characterized in that: the damping pantograph further comprises a resonance power damping unit and a vibration isolation unit, the upper frame comprises an upper beam and a cross beam, the resonance power damping unit is installed on the upper beam, the cross beam or the lower arm rod,the vibration isolation unit is arranged between the insulating part and the roof mounting base. Compared with the prior art, the carbon sliding plate and a contact net point do not jump greatly, sothat abnormal abrasion of the pantograph is avoided, and the carbon sliding plate and the contact net point have economic and safe significance on daily operation of rail transit.

Owner:SHANGHAI UNIV OF ENG SCI

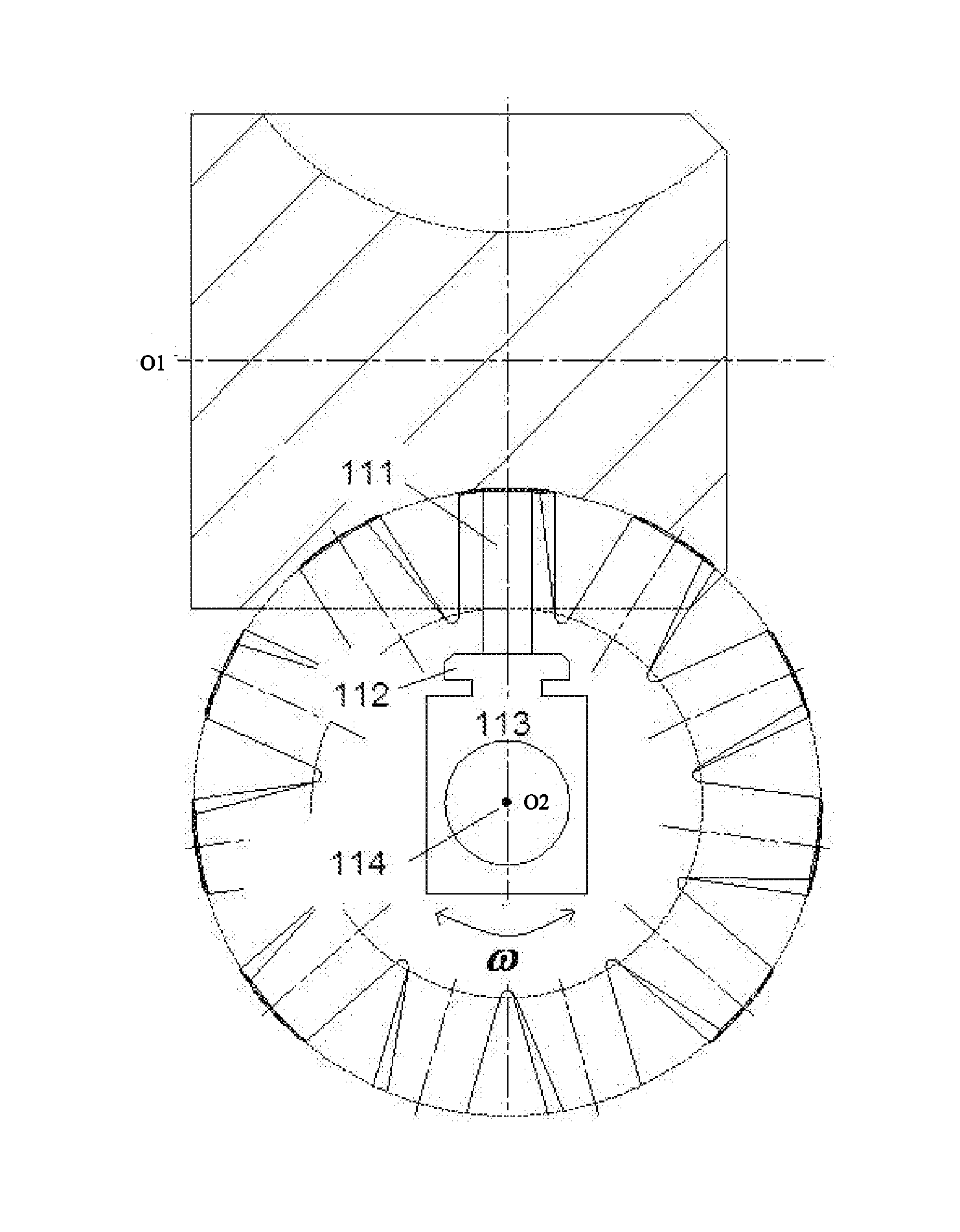

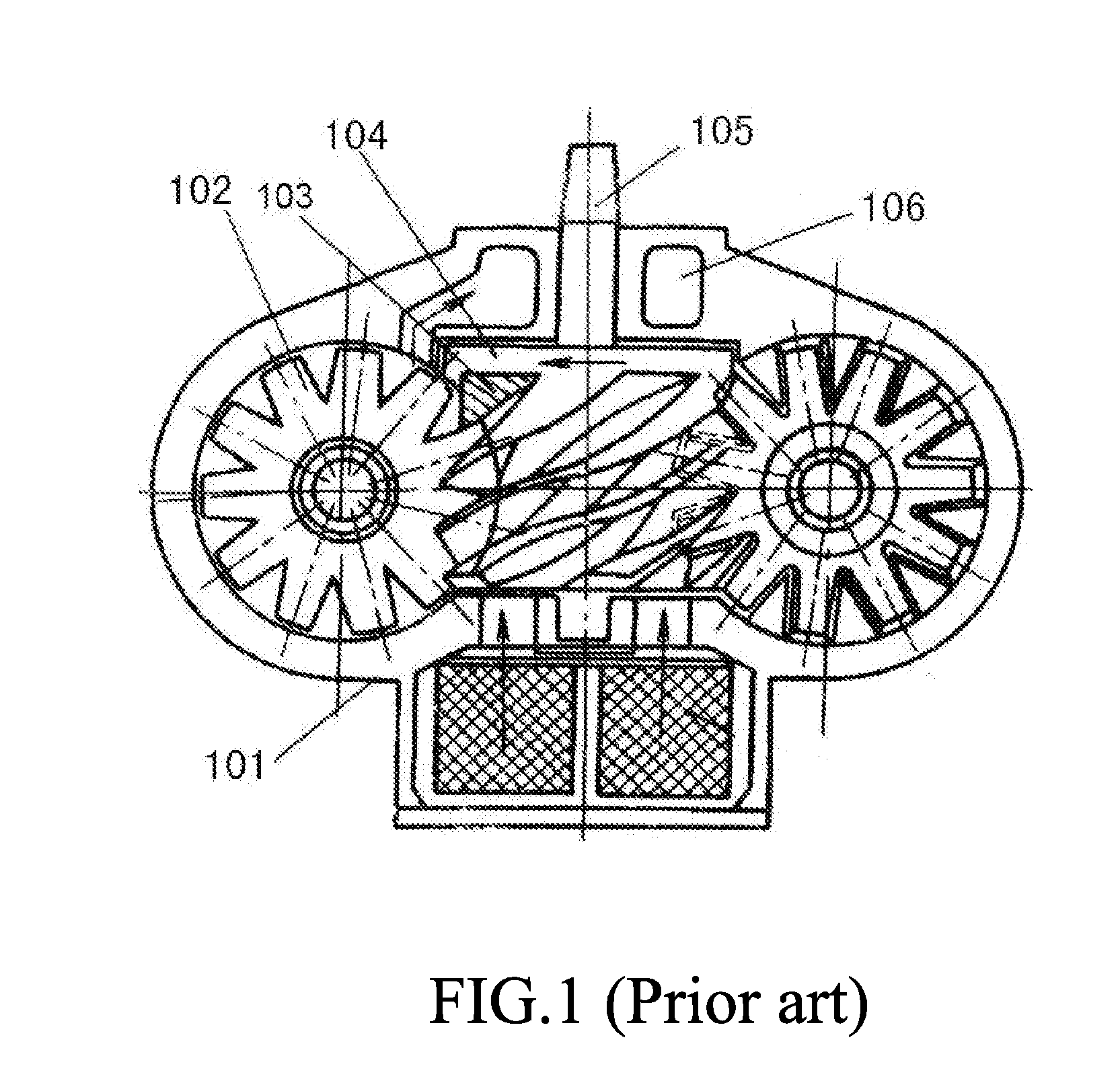

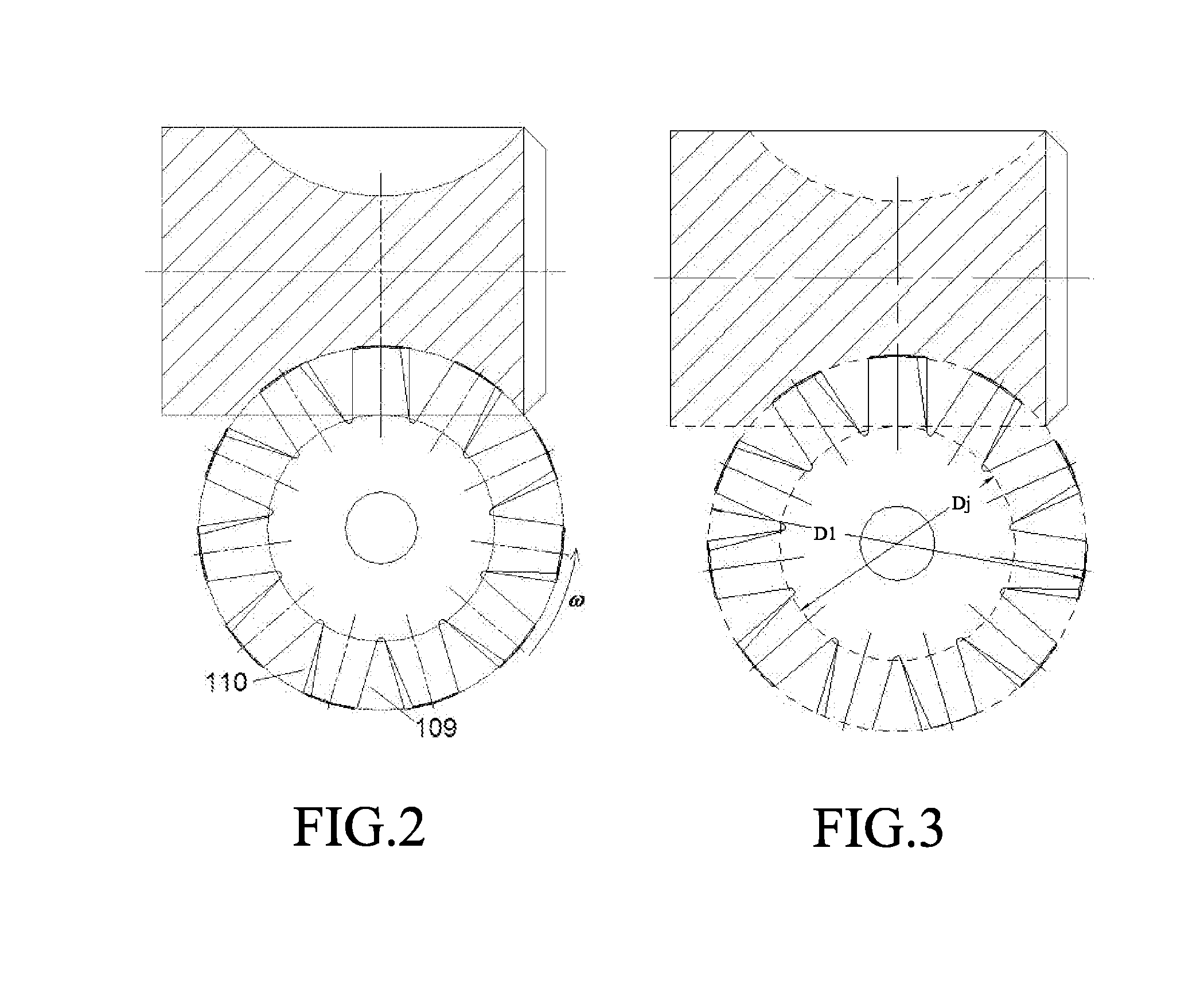

Method for collaboratively constructing column envelope profile of two flanks of star wheel tooth

ActiveUS20160230869A1Reduce abnormal wearExtended service lifeToothed gearingsPortable liftingEngineeringIncenter

A method for collaboratively constructing a column envelope profile of two flanks of a star wheel tooth includes steps of: determining a tooth width B of a star wheel according to a diameter of the star wheel and a dimension of a root circle; thereafter, geometrically representing positions and shapes of the two flanks of each star wheel tooth of the star wheel by two base columns having parallel axes and the same diameter; wherein: the axes of the base columns are parallel with a center line of the star wheel tooth; on a section of a tooth top of the star wheel tooth, a local projection of a first base column close to a front flank of the star wheel tooth is projected on a lowermost part of a projection of the front flank of the star wheel tooth; and a local projection of a second base column close to a back flank of the star wheel tooth is projected on an uppermost part of a projection of the back flank of the star wheel tooth. A center distance L between the two base columns, a diameter d0 of the base columns, the tooth width B of the star wheel tooth and an inclined angle λ of the flanks of the star wheel tooth at a pitch circle have a quantitative mathematic relationship.

Owner:XI AN JIAOTONG UNIV

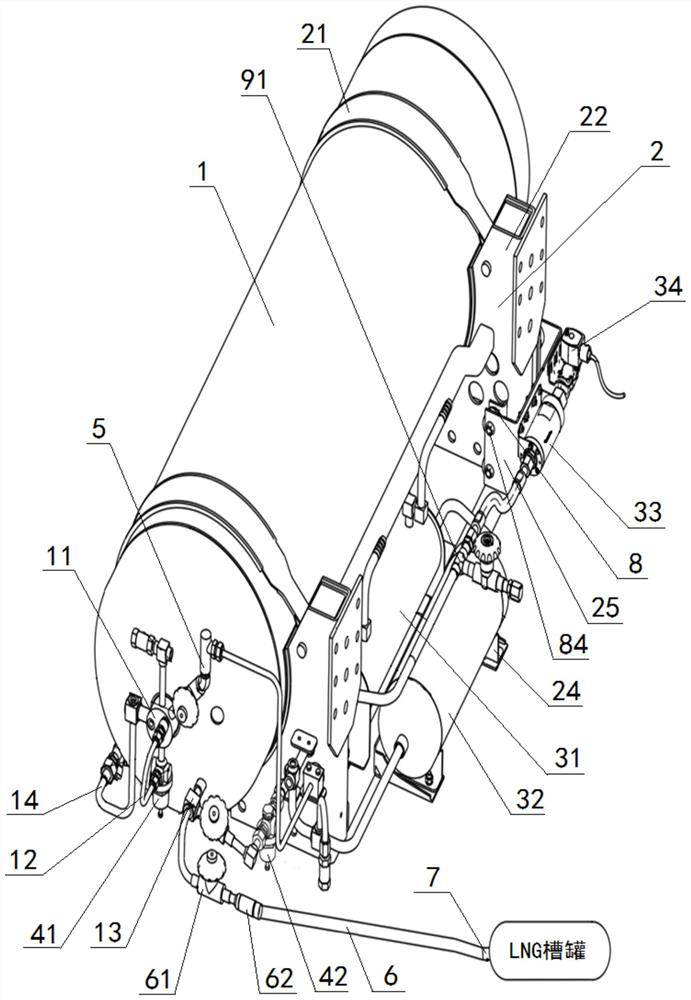

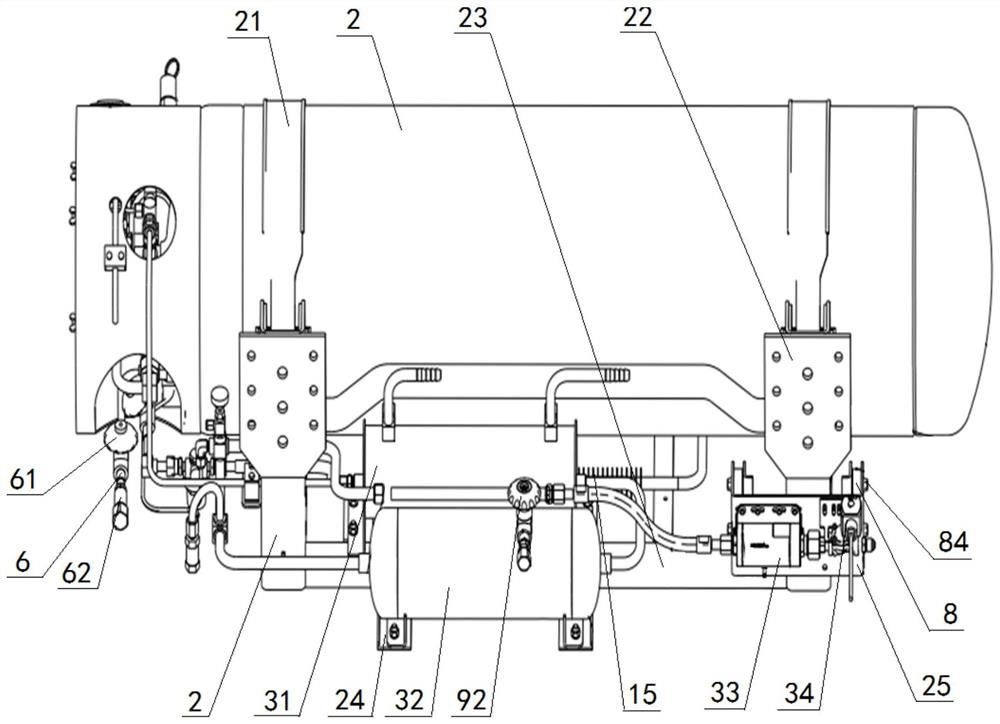

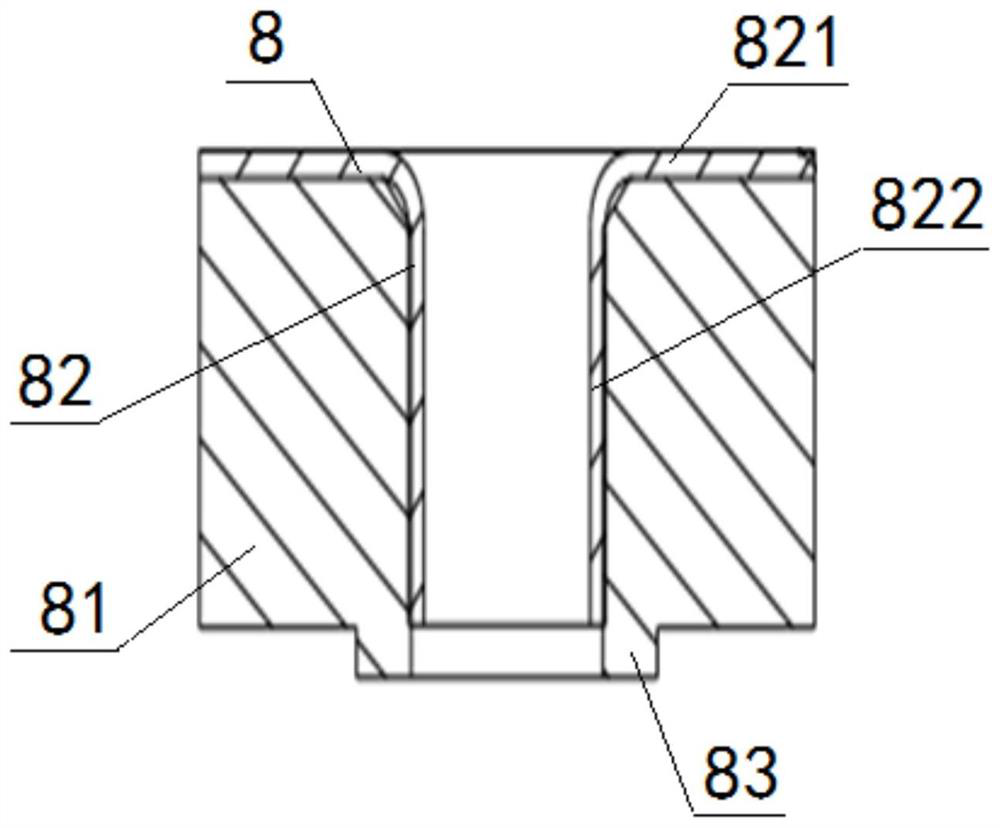

Integrated fuel supply device of light LNG commercial vehicle

An integrated fuel supply device of a light LNG commercial vehicle comprises an installation frame and an LNG vehicle-mounted bottle installed on the installation frame. A distribution head is arranged at one end of the LNG vehicle-mounted bottle, a first economic valve is arranged below the distribution head, one end of the first economic valve is connected with the interior of the LNG vehicle-mounted bottle through the distribution head, and the other end of the first economic valve is connected with one end of a bypass pipeline. The other end of the bypass pipeline is simultaneously connected with the interior of the LNG vehicle-mounted bottle and one end of a gas bottle liquid outlet pipe through the distribution head, and the other end of the gas bottle liquid outlet pipe is connected with a gas supply system; a pressurization pipeline three-way connector is arranged on the lower portion of the LNG vehicle-mounted bottle, a first port of the pressurization pipeline three-way connector is connected with the interior of the LNG vehicle-mounted bottle, and a second port of the pressurization pipeline three-way connector is connected with the interior of the LNG vehicle-mounted bottle sequentially through a second economic valve, a pressurizer, a self-pressurization pipeline and the distribution head; and a third port of the pressurization pipeline three-way connector is connected with a tank car tank safety valve. The design is compact in arrangement, environment-friendly and better in economical efficiency.

Owner:DONGFENG AUTOMOBILE COMPANY

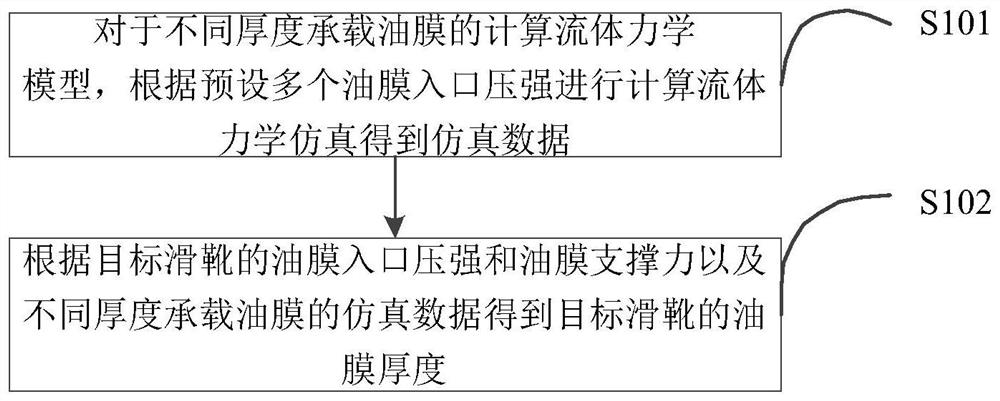

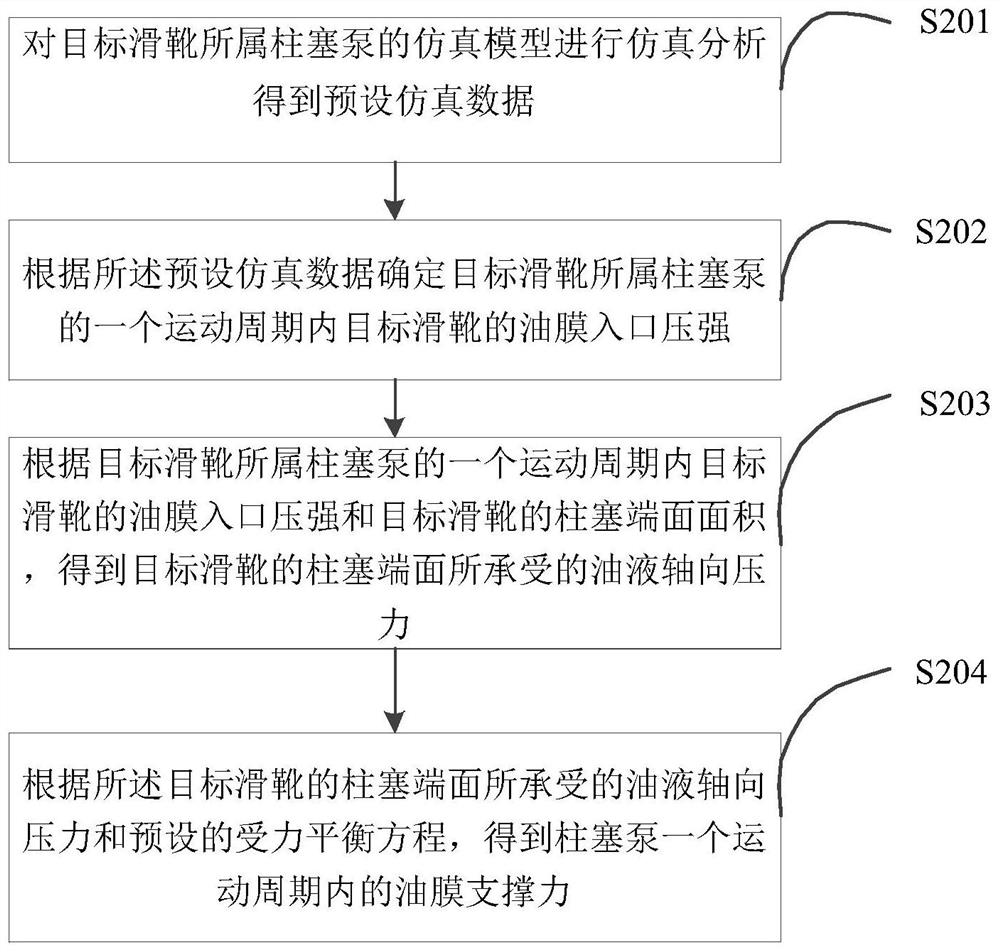

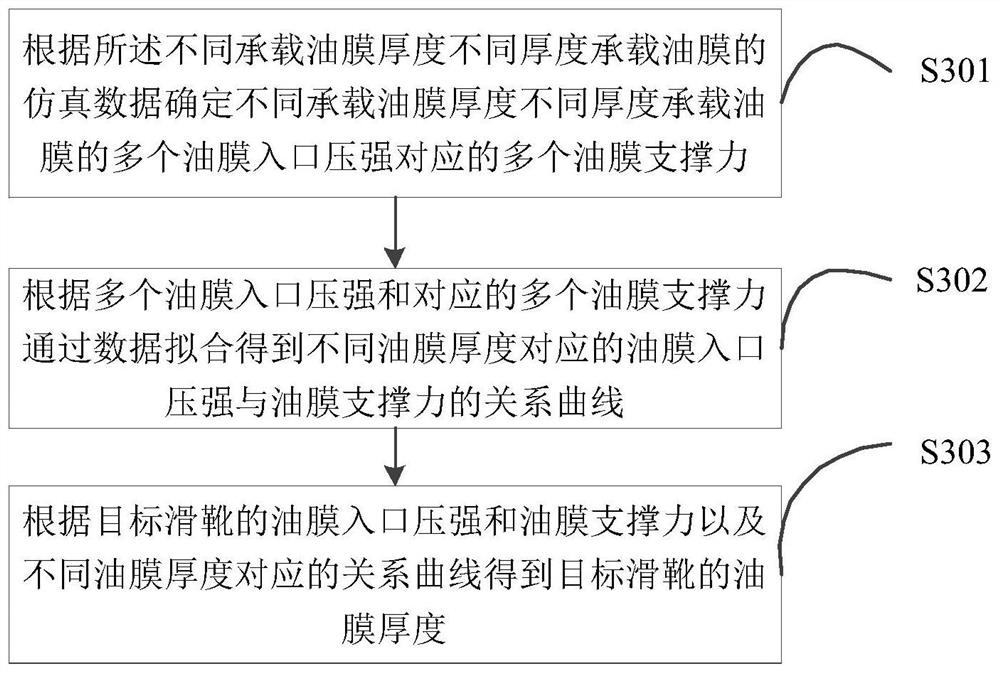

Method and device for determining thickness of bearing oil film of piston shoe of plunger pump

PendingCN114297956AReduce abnormal wearEasy to determineDesign optimisation/simulationThermodynamicsEngineering

The invention provides a plunger pump sliding shoe bearing oil film thickness determination method and device, and relates to the field of plunger pump sliding shoe lubrication.The method comprises the steps that for computational fluid mechanics models of bearing oil films with different thicknesses, computational fluid mechanics simulation is conducted according to multiple preset oil film inlet pressure intensities, and simulation data are obtained; the simulation data comprises oil film supporting forces corresponding to a plurality of oil film inlet pressures; and obtaining the oil film thickness of the target sliding shoe according to the oil film inlet pressure intensity and the oil film supporting force of the target sliding shoe and the simulation data of the bearing oil films with different thicknesses. According to the method, the thickness of the oil film borne by the piston shoe of the plunger pump can be determined more efficiently and conveniently, so that the abnormal wear condition of the designed plunger pump is reduced while the design cost of the plunger pump is saved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

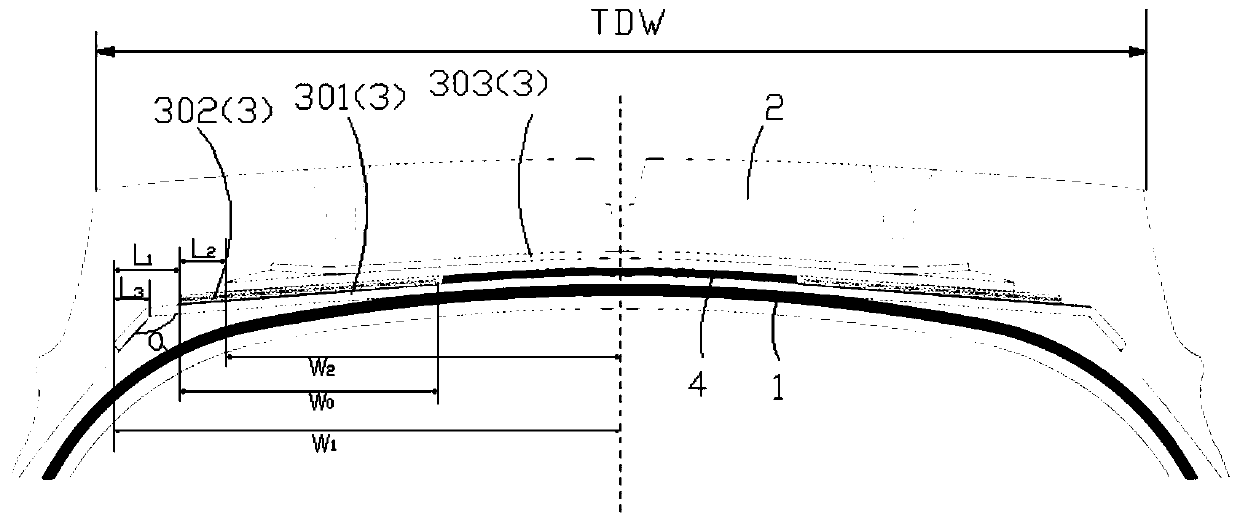

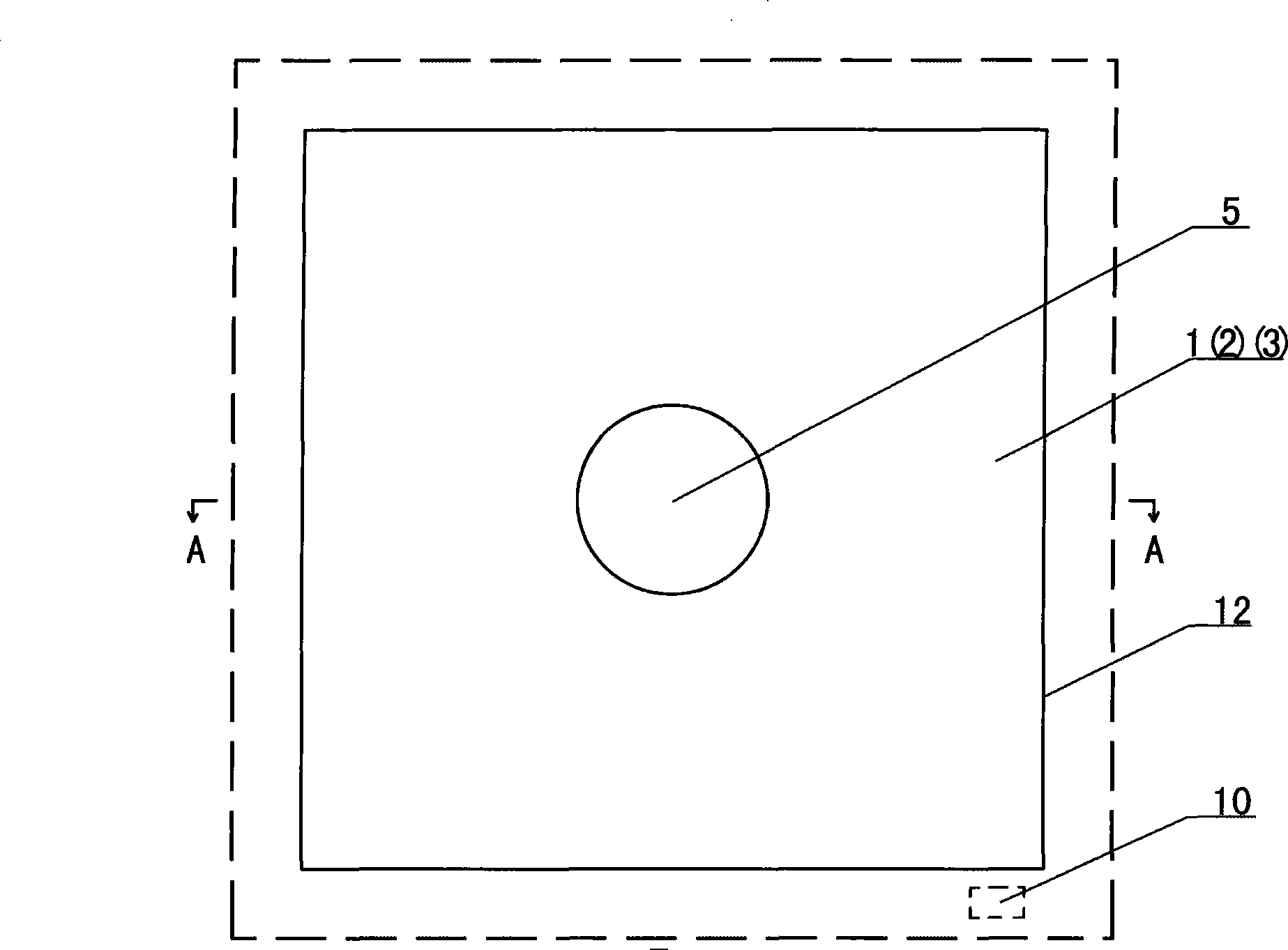

All-steel truck radical tire structure

ActiveCN110978893AImprove high-speed performanceExtend your lifePneumatic tyre reinforcementsRubber materialStructural engineering

The invention provides an all-steel truck radical tire structure. The all-steel radial tire structure comprises a tire body, a tire tread coating the radial outermost periphery of the tire body, and abelt ply arranged between the tire body and the tire tread, the belt ply comprises a first belt ply, a 0-degree winding belt ply and a second belt ply which are sequentially distributed from the tirebody to the tire tread, and the first belt ply, the second belt ply and the 0-degree winding belt ply are arranged in a trapezoid shape, wherein the length 2W1 of the first belt ply in the tire widthdirection and the length 2W2 of the second belt ply in the tire width direction meets a relationship that W1>W2, and the length 2W1 of the first belt ply in the tire width direction and the horizontal width TDW of a crown meets a relationship that 0.81 <= 2W1 / TDW <= 0.96. The paving mode of the 0-degree winding belt ply, the first belt ply and the second belt ply is optimally designed, so the problem that the end parts of the belt plies cannot be fully bonded with rubber materials is solved, thereby cracks at the end parts of the belt plies are reduced, the high-speed performance of the tireis improved, and the mileage service life of the tire is prolonged.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

Manufacturing method for embedding heat radiating fin on printed circuit board

InactiveCN101257770BGood embedding effectSolve the problem of sagMultilayer circuit manufactureCooling/ventilation/heating modificationsHeat sinkPrinted circuit board

A making method for embedding fins on a printed circuit board includes following steps: 1) opening a tool hole on the position to be embedded with fins in a circuit board and a prepreg forming region, and drilling a pre-positioning hole outside of the forming region; 2) arranging the prepreg between two adjacent circuit board, pre-positioning the circuit boards and the prepreg through the pre-positioning hole; 3) arranging fins in the tool hole in a stitching pre-lamination process; 4) stitching the circuit boards and the prepreg to fill the gap between the tool hole and fins by flowing latex, the prepreg cures automatically during stitching, combining the fins and the circuit boards; 5) mechanical brushing and grinding board elements, cleaning residual prepreg material on surfaces of circuit boards. The invention avoids the inanition phenomenon, solves depression or protrusion of circuit board surfaces, reduces abnormal wear of grinding brush wheels in following process, thereby theembedding effect of fins is good.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

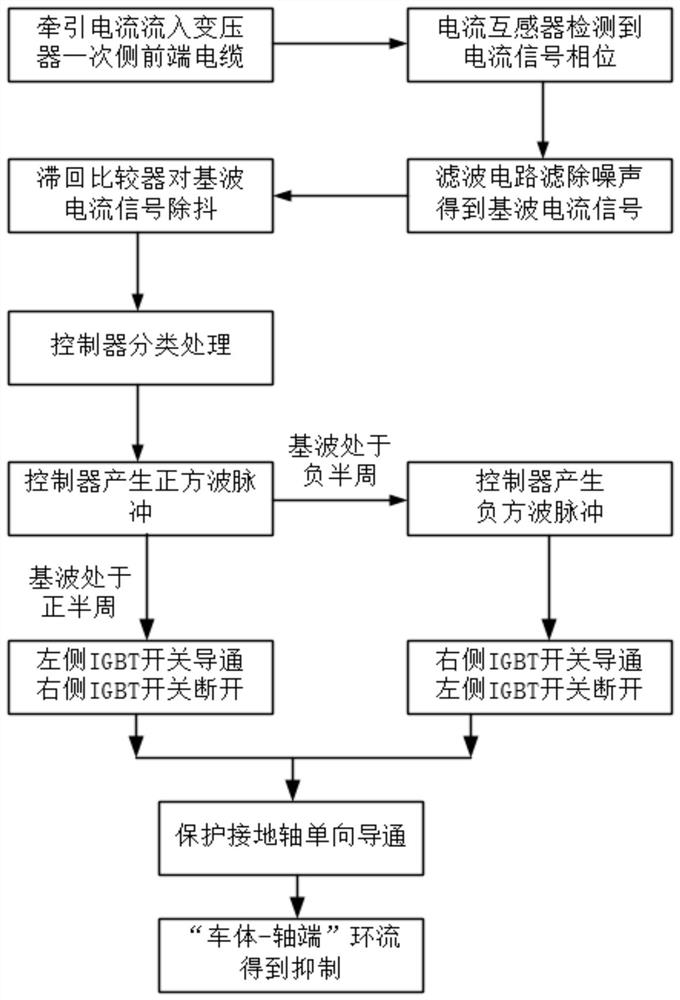

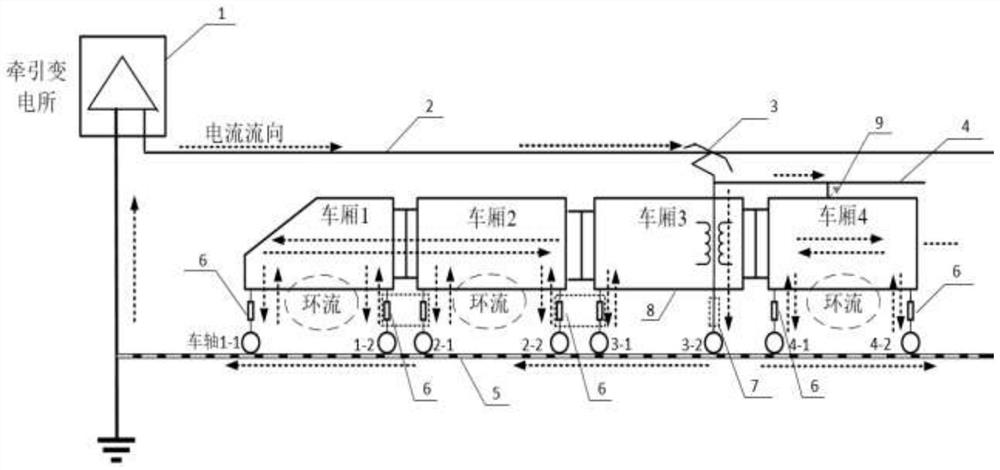

Train body-shaft end circulating current suppression method suitable for high-speed train grounding system

ActiveCN113078627AReduce distractionsAvoid insulation aging damageEmergency protective arrangements for limiting excess voltage/currentAutomotive engineeringCirculating current

The invention discloses a train body-shaft end ring current suppression method for a high-speed train grounding system, which specifically comprises the following steps of: detecting positive and negative phases of traction current through an IGBT (Insulated Gate Bipolar Translator) driving signal generation system, and generating positive and negative square wave pulses to control the on-off of a right channel IGBT switch and a left channel IGBT switch in a current direction measurement and control device; and changing the protection grounding shaft into a one-way conduction path, so that traction backflow on the steel rail is completely isolated from the carriage. According to the invention, the harm caused by'car body-shaft end 'circulation is greatly reduced, the car body is always connected with the steel rail, and the car body is always kept at zero potential.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com