Friction structure, friction part and compressor

A technology of friction parts and surface texture, which is applied in the field of compressors, can solve the problems of unable to maintain the fluid lubrication state of the end face, the surface does not have dynamic pressure lubrication characteristics, coating damage and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

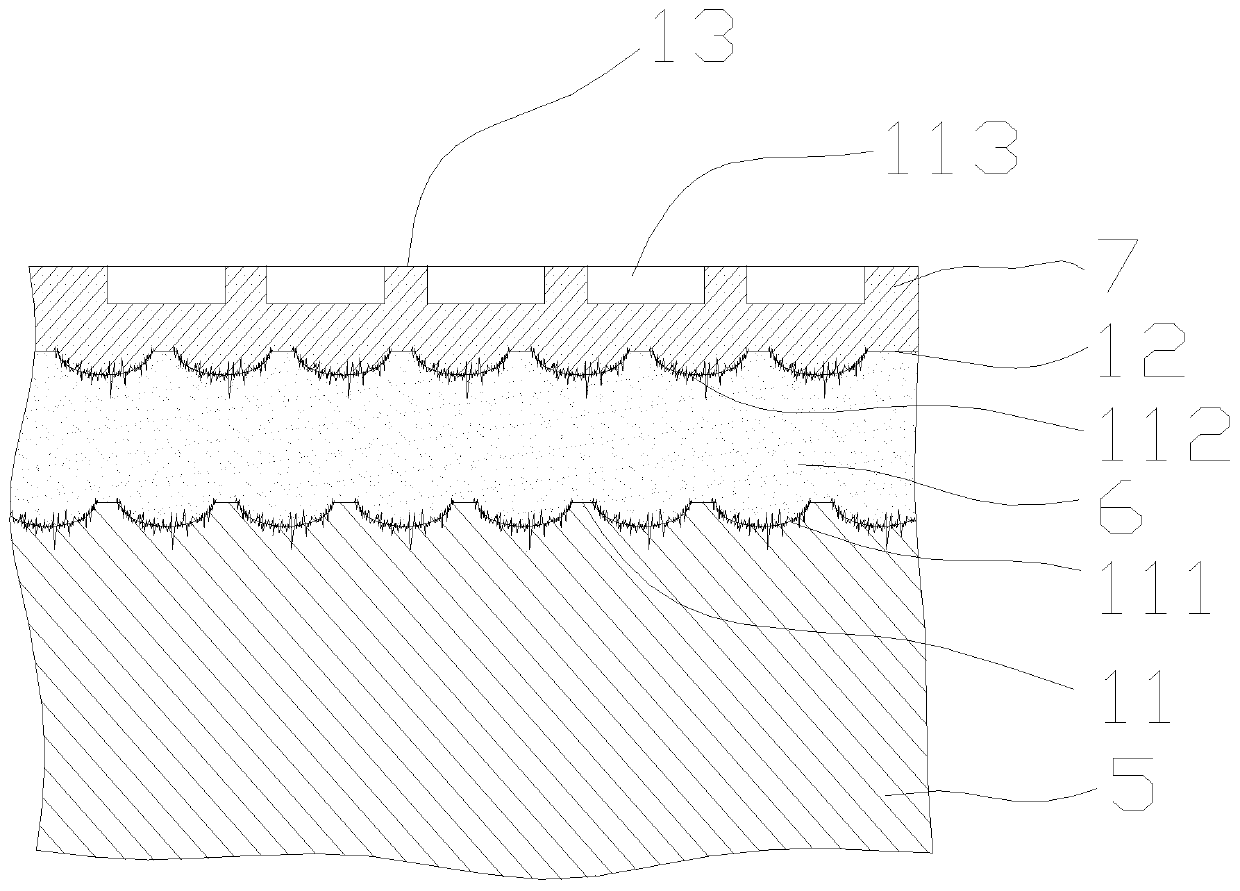

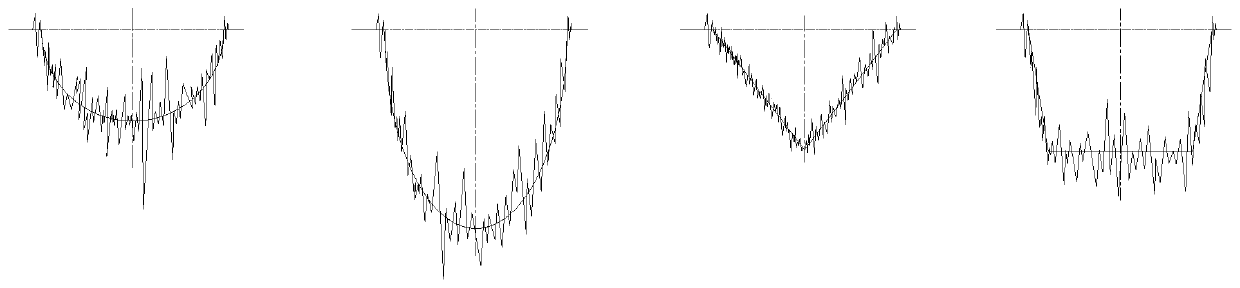

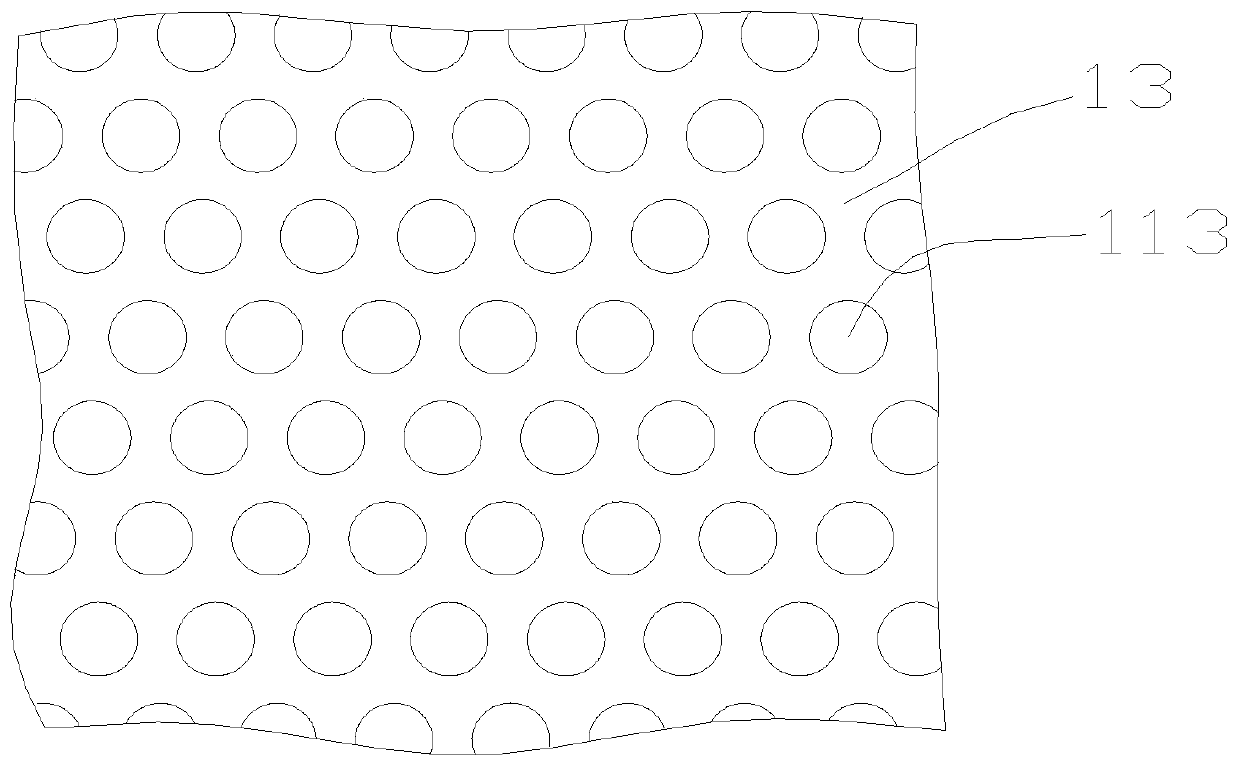

[0034] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a friction structure includes a substrate 5 and multiple layers of coatings sequentially bonded on the substrate 5; the first contact surface between the substrate 5 and the adjacent coatings , the second contact surface between two adjacent coatings and the outer surface of the outermost coating are all set as surface texture structures.

[0035] By setting the bonding surface of the substrate 5 and the coating, the bonding surface of two adjacent coatings, and the outer surface of the outermost coating, all the surface texture structures are set. The bonding strength of adjacent parts in the friction structure is increased, and the phenomenon of coating peeling is not easy to occur, and the surface texture structure can be used to achieve dynamic pressure lubrication characteristics, so that the outer surface has a lower friction coefficient and maintains the fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com