Patents

Literature

49results about How to "Stable lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

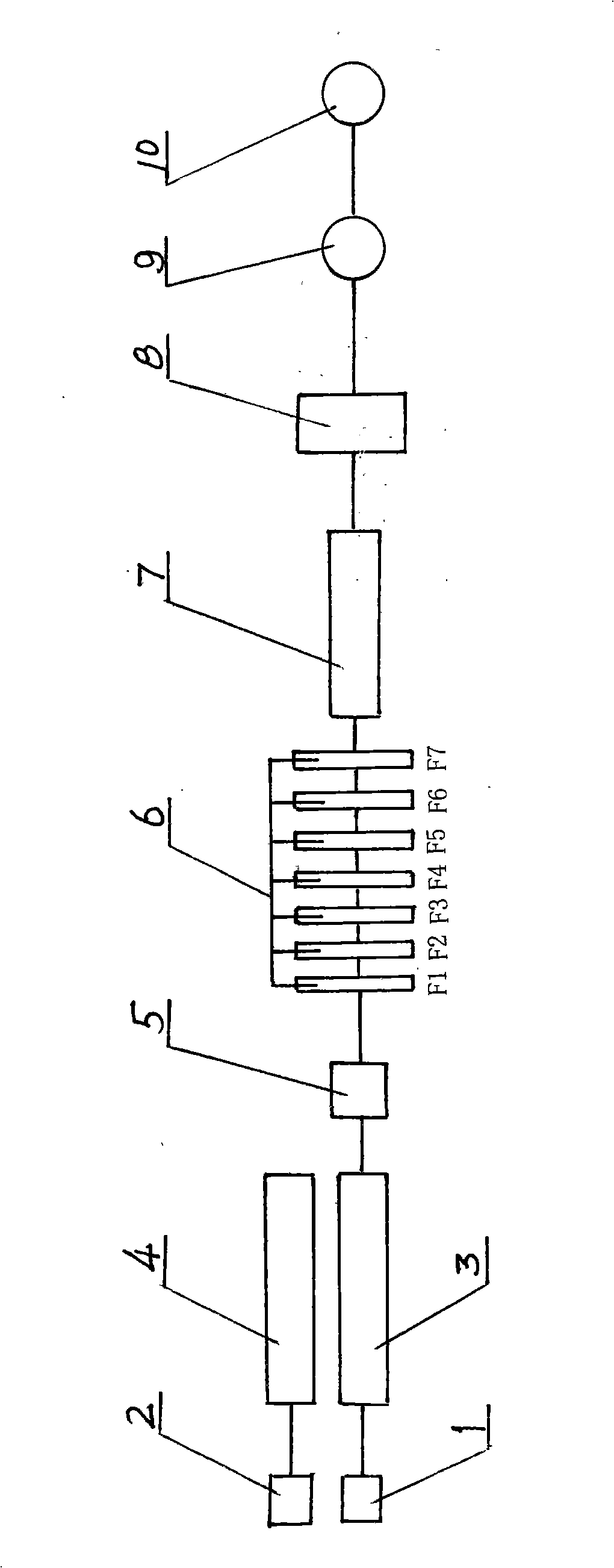

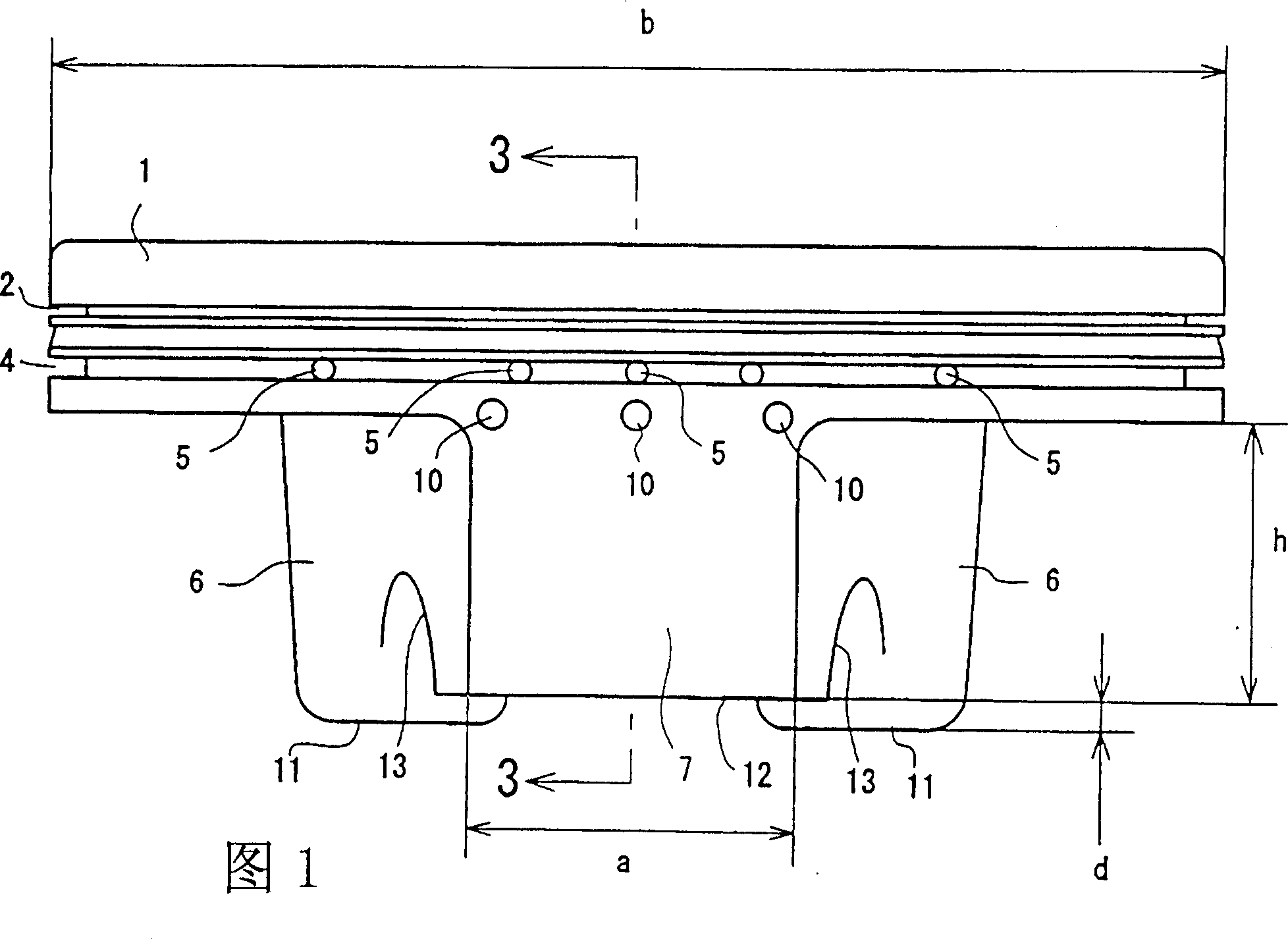

Method for producing variational format/constant format ultra-thin hot-rolled strip steel by using semi-headless technique

InactiveCN101293259AHigh elongationNormal structureRoll force/gap control deviceTemperature control deviceStrip millStrip steel

The invention discloses a method for producing ultra-thin hot rolling strip steel with variable / constant specification by adopting a semi-endless technology; qualified molten steel after refining is sent to a first continuous caster and a second continuous caster to be cast into a flat blank; the semi-endless flat blank cast by the first continuous caster enters a first roller-hearth type soaking furnace for being heated at the temperature of 1050-1150 DEG C, which is sent to a high pressure water descaler at a rolling mill area for the removal of iron scale on the surface of the flat blank and is rolled into the ultra-thin hot rolling strip steel with the thickness being 0.8-1.8mm and the width being 1229-1265mm by F1-F7 rolling mills of a fine continuous rolling mill group; the hot rolling strip steel within the final rolling temperature rang of 860 DEG C to 880 DEG C enters a laminar flow cooler for cooling and is quickly cut by a high-speed flying shear according to the weight of each steel coil; the cut strip steel is alternately coiled by a first coiling machine or a second coiling machine into a finished coil with three or four variable / constant specifications. The ultra-thin hot rolling strip steel produced by the method can expand the products of the strip steel, stabilize rolling condition, lower abrasion of rollers, reduce the times of band penetration and whipping, decrease the loss of waste head and crop end of the products and enhance the yield of the products and productivity.

Owner:湖南华菱涟源钢铁有限公司

Self-lubricating ceramic composite material with biomimetic structure and preparation method thereof

ActiveCN102092164AStable lubricationAvoid adverse effectsCeramic layered productsMolybdenum disulfideGraphite

The invention discloses a self-lubricating ceramic composite material with a biomimetic structure and a preparation method thereof. The composite material has a structure which is alternately laminated by ceramic layers and lubricating layers, wherein the ceramic layer is ZrO2, Al2O3, or ZrO2-Al2O3, and the lubricating layer is made of graphite, molybdenum disulfide, or hexagonal boron nitride. The composite material has excellent friction and abrasion performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

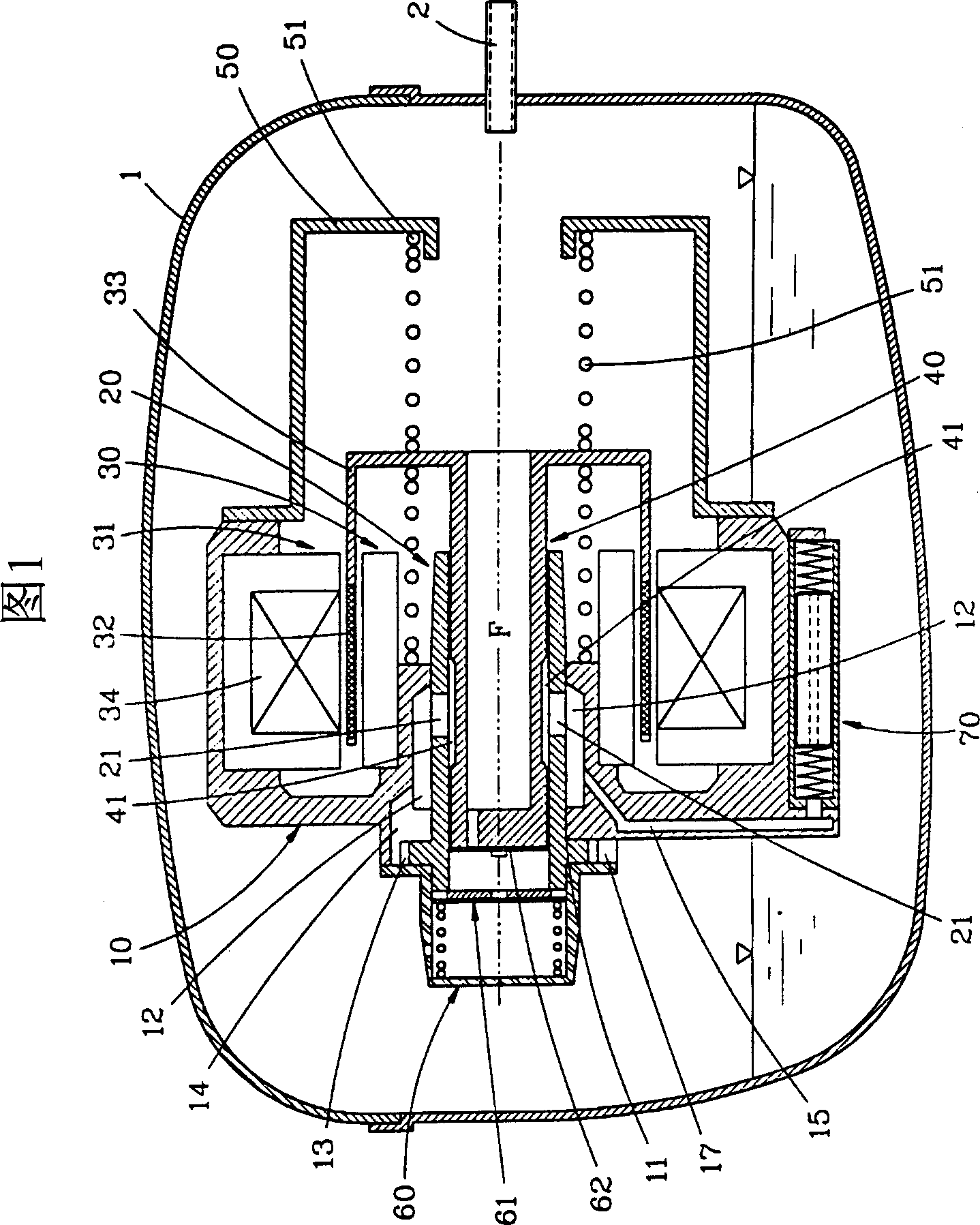

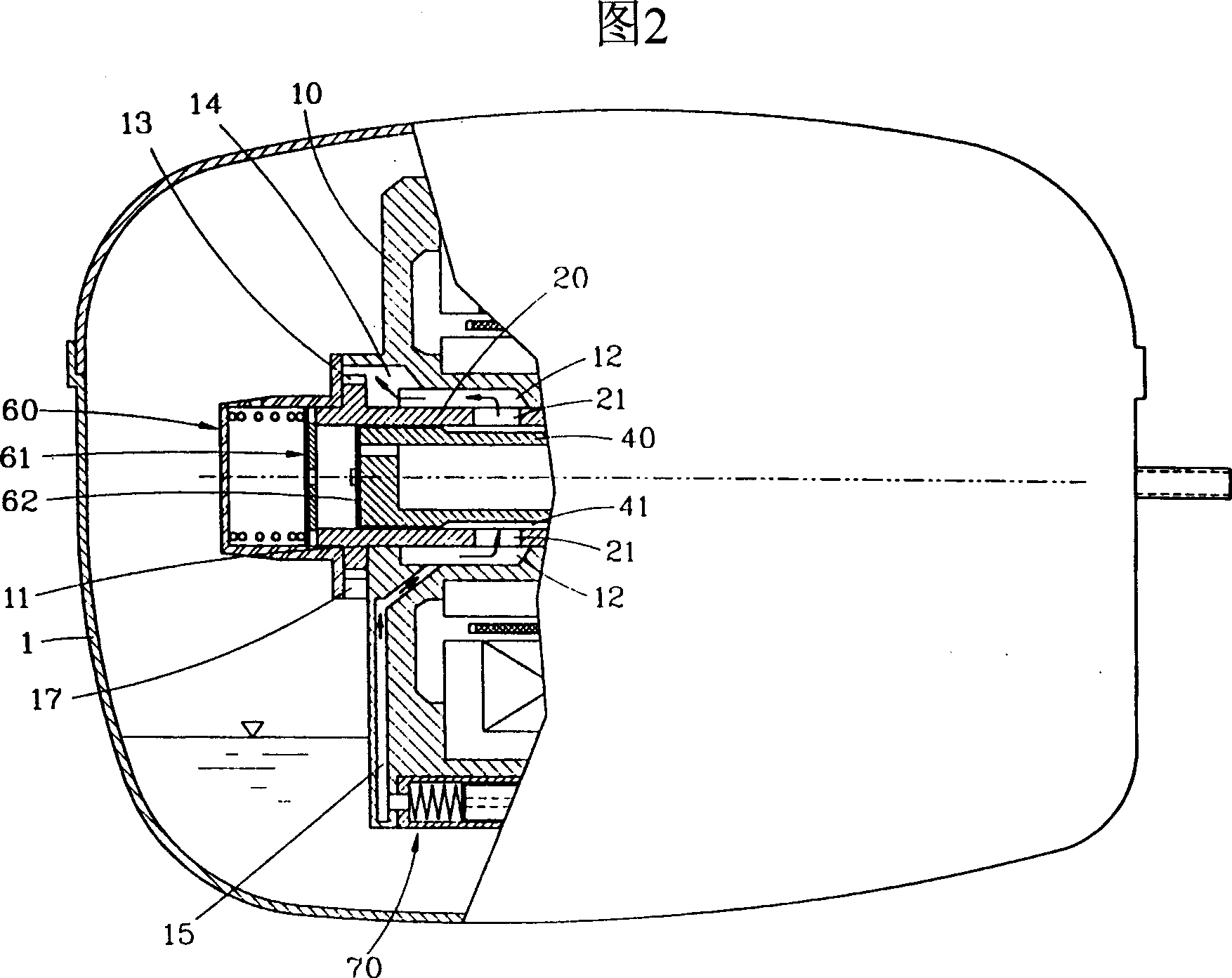

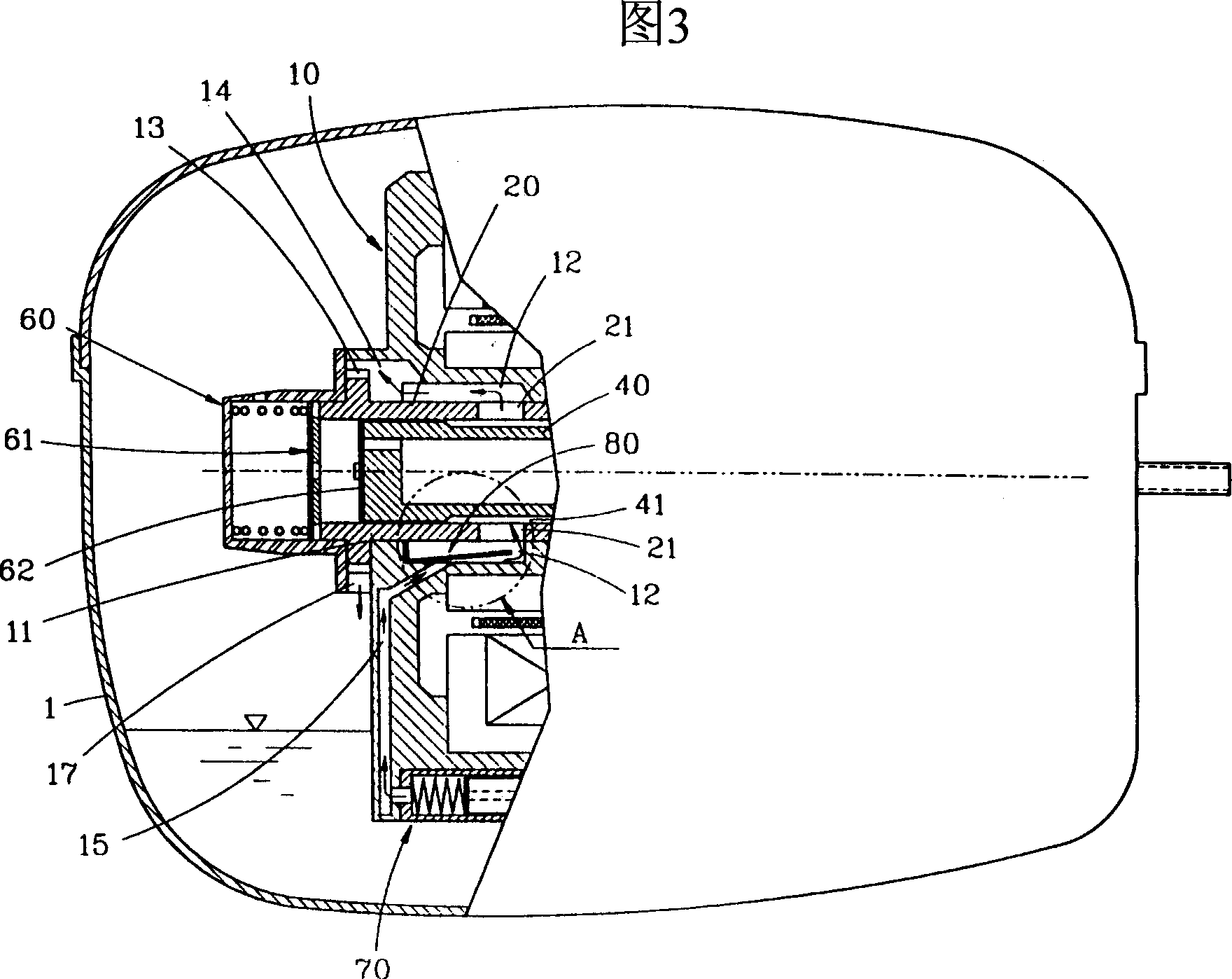

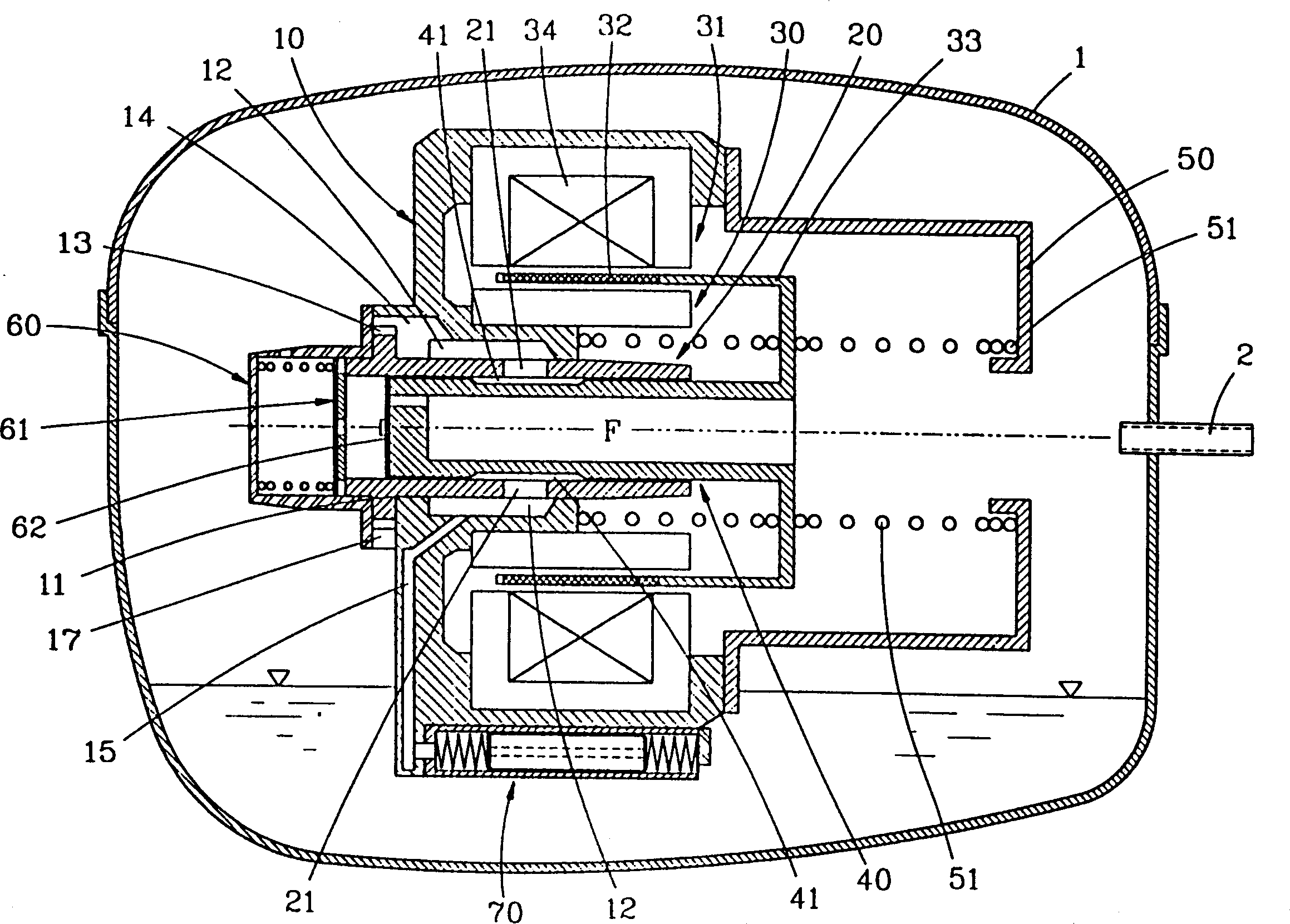

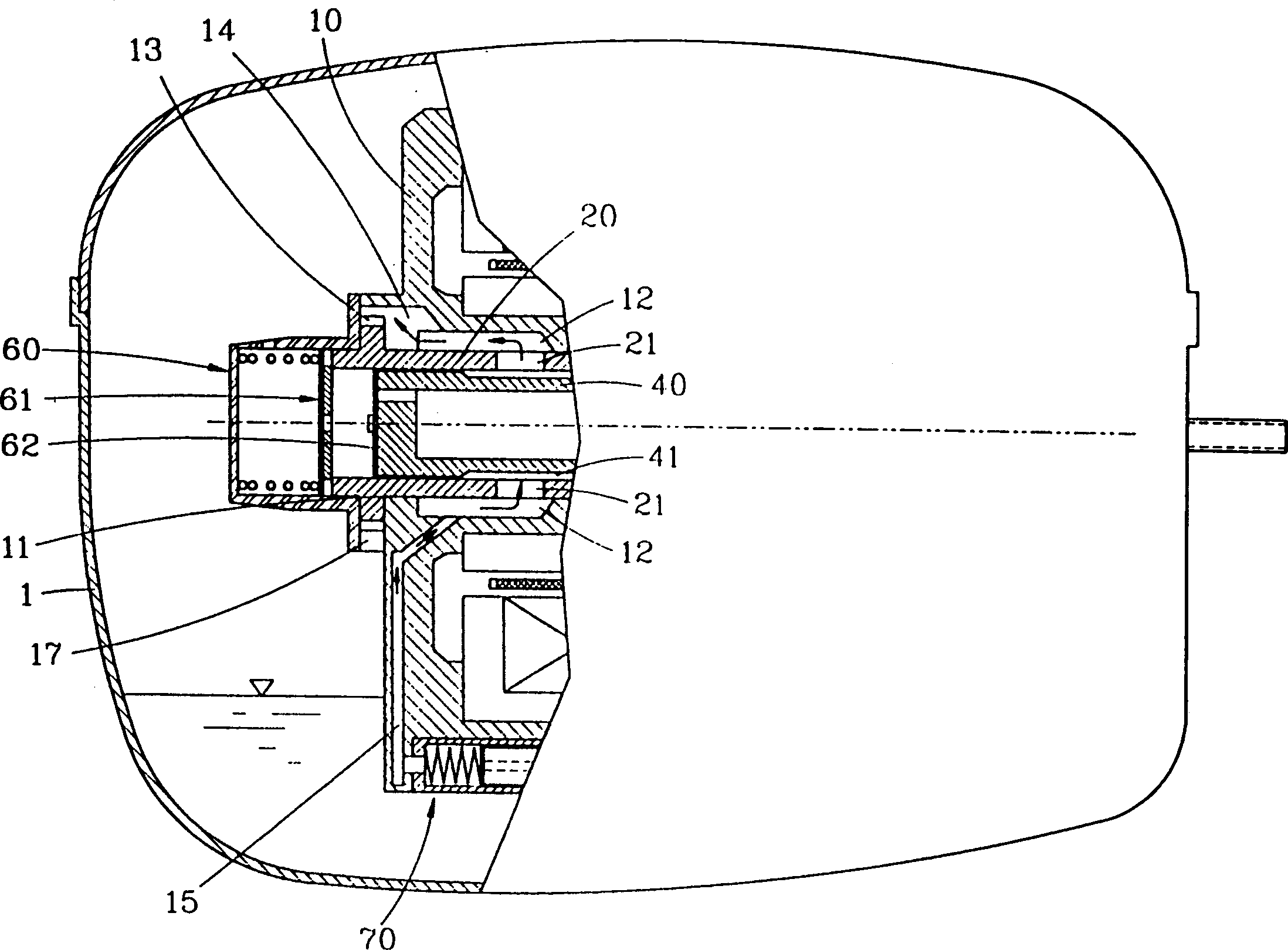

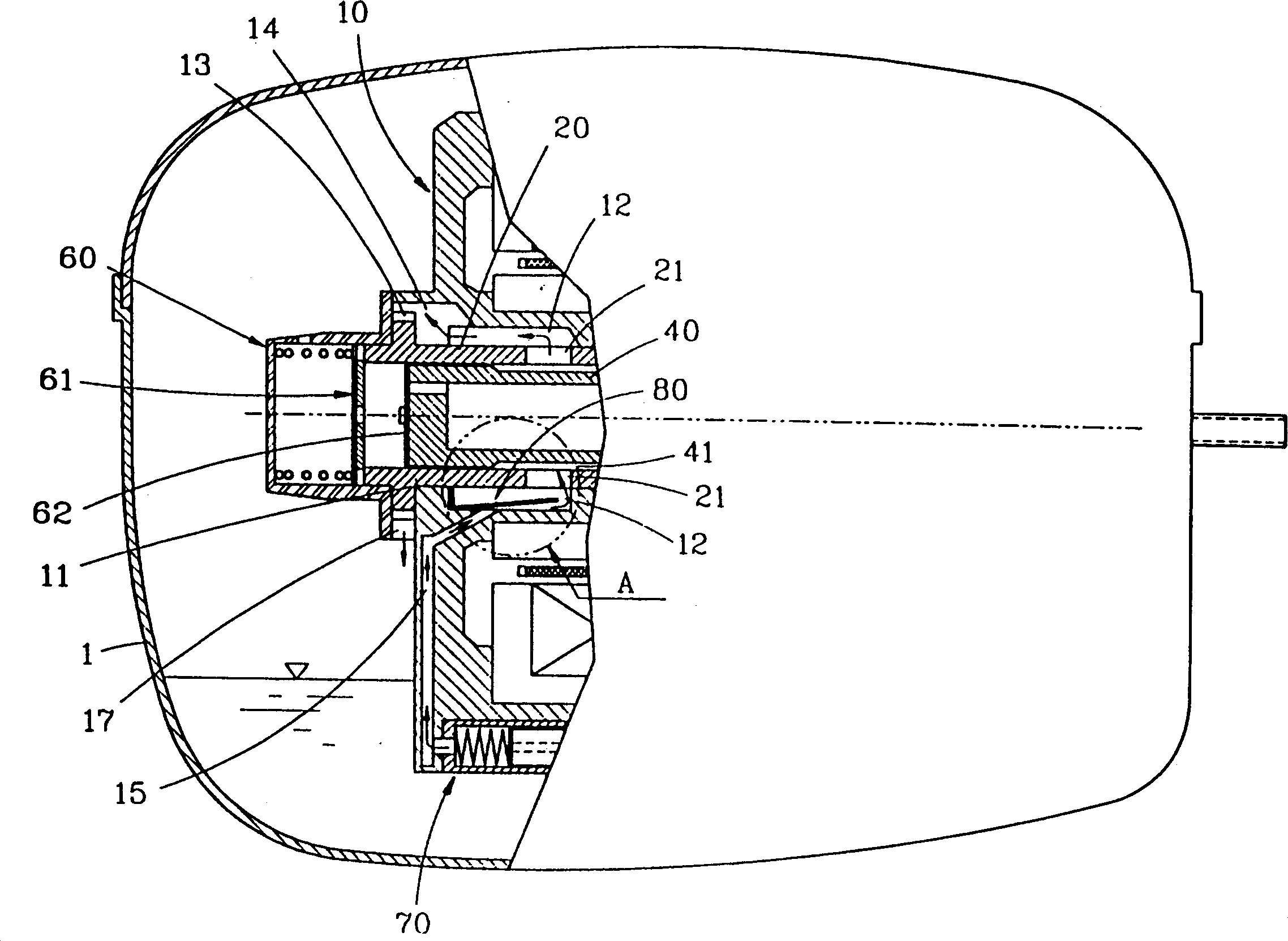

Opening and closing system for oil path of linear compressor

InactiveCN1285897AStable lubricationPositive displacement pump componentsPumpsMarine engineeringLinear compressor

An opening and closing system for an oil path of a linear compressor that facilitates smooth oil supply during the operation of the compressor and has the oil which has been supplied to the compressor partly remained therein when suspending the operation of the compressor for smooth lubrication when reoperating the compressor includes a hermetic vessel in which oil is filled in a bottom part thereof, a frame disposed in the hermetic vessel and communicating with a first oil groove and a second oil groove, a cylinder, a piston linearly reciprocating, the second oil groove being formed on a portion of an outer circumferential surface of the piston, an exhaust cover coupled to one side of the cylinder, an oil supplier communicating with the first oil groove, and a switching means formed between the first oil groove and the oil inflow path for opening and closing the oil inflow path.

Owner:LG ELECTRONICS INC

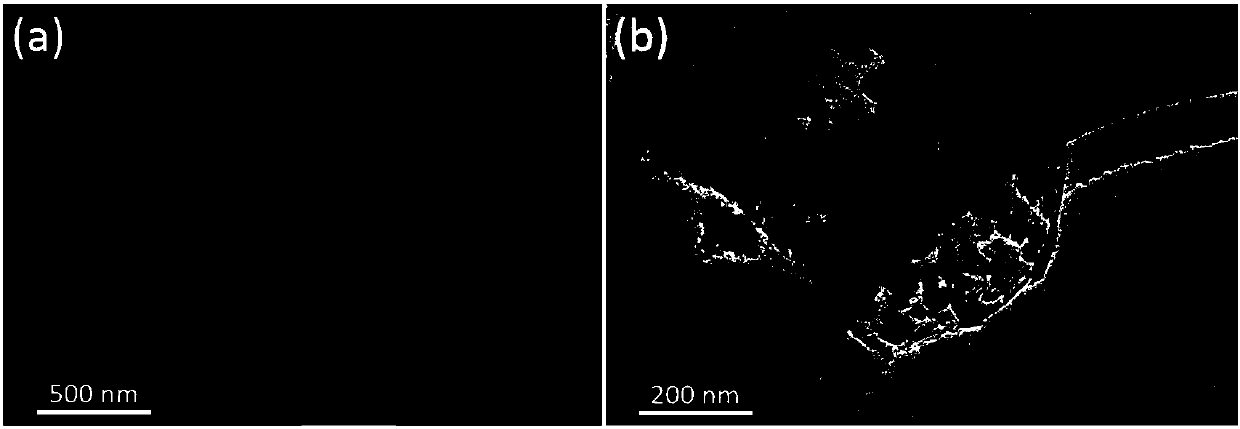

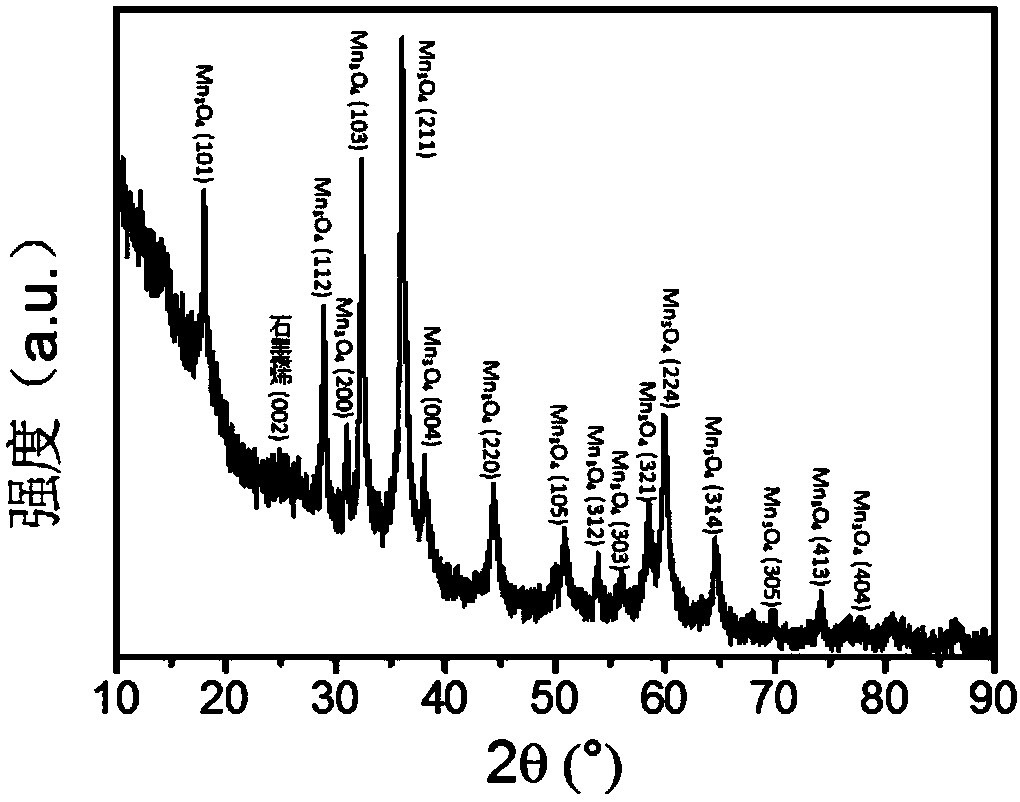

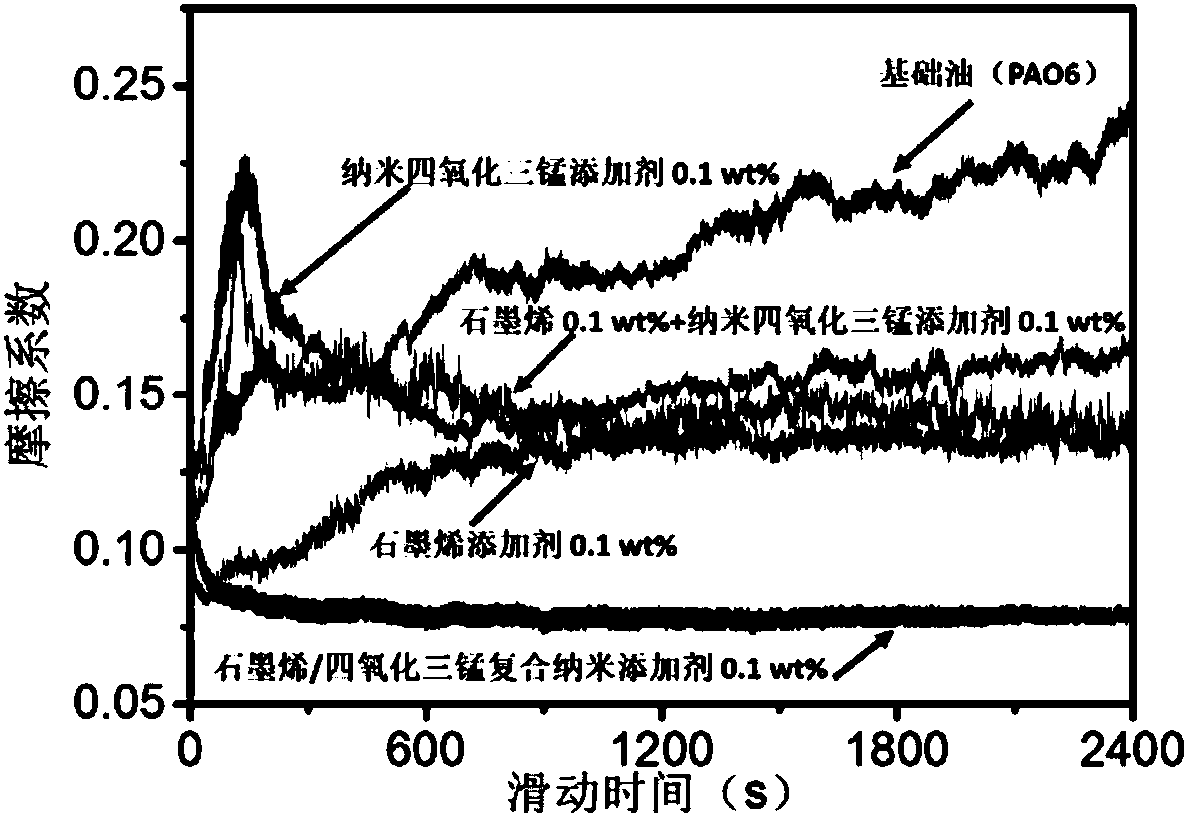

Graphene/trimanganese tetraoxide composite nano lubricating additive and synthesis method thereof

The invention discloses a graphene / trimanganese tetraoxide composite nano lubricating additive and a synthesis method thereof. Specifically, the synthesis method includes: mixing graphite with concentrated sulfuric acid and potassium permanganate in a high mass ratio, and carrying out oxidation reaction to obtain a mixed solution containing graphite oxide and / or graphene oxide; adding hydrogen peroxide into the mixed solution to reduce unreacted potassium permanganate, and adding water for dilution, and conducting ultrasonic treatment for a predetermined period of time to obtain a graphene oxide mixed solution; adjusting the pH of the graphene oxide mixed solution to alkaline, and carrying out reaction to obtain trimanganese tetraoxide and loading it to graphene oxide, and evaporating or filtering the mixture to obtain a solid product; subjecting the solid product to reduction treatment at high temperature to obtain a graphene / trimanganese tetraoxide composite product; and cleaning thegraphene / trimanganese tetraoxide composite product, and then performing ball milling treatment, thus obtaining the graphene / trimanganese tetraoxide composite nano lubricating additive. The method issimple and efficient, and the prepared additive has excellent dispersibility and lubricity.

Owner:TSINGHUA UNIV +1

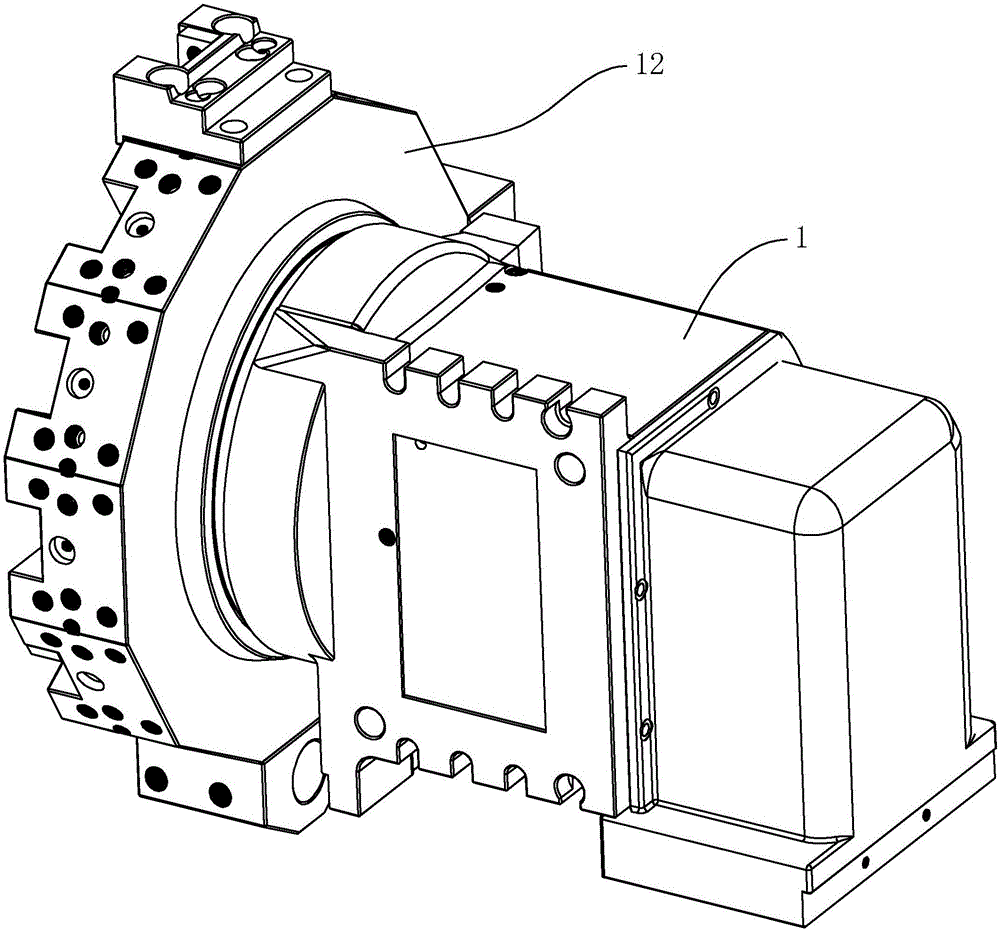

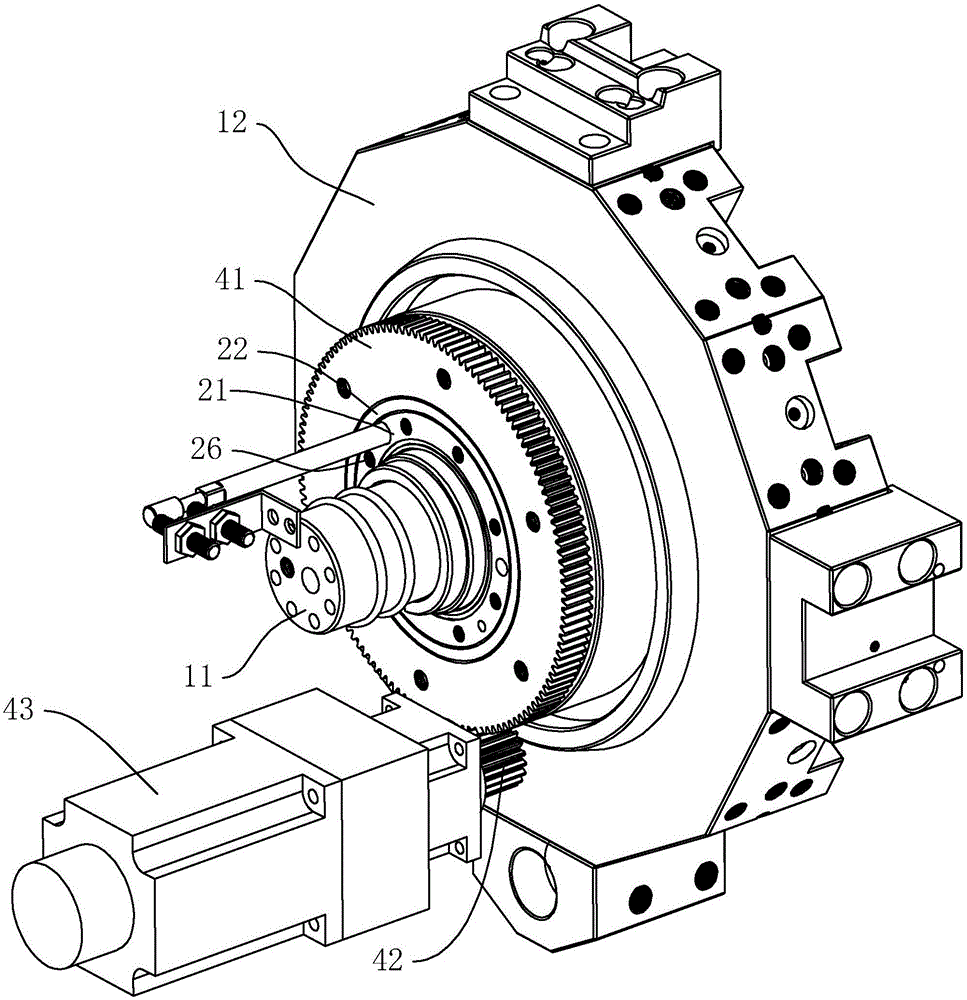

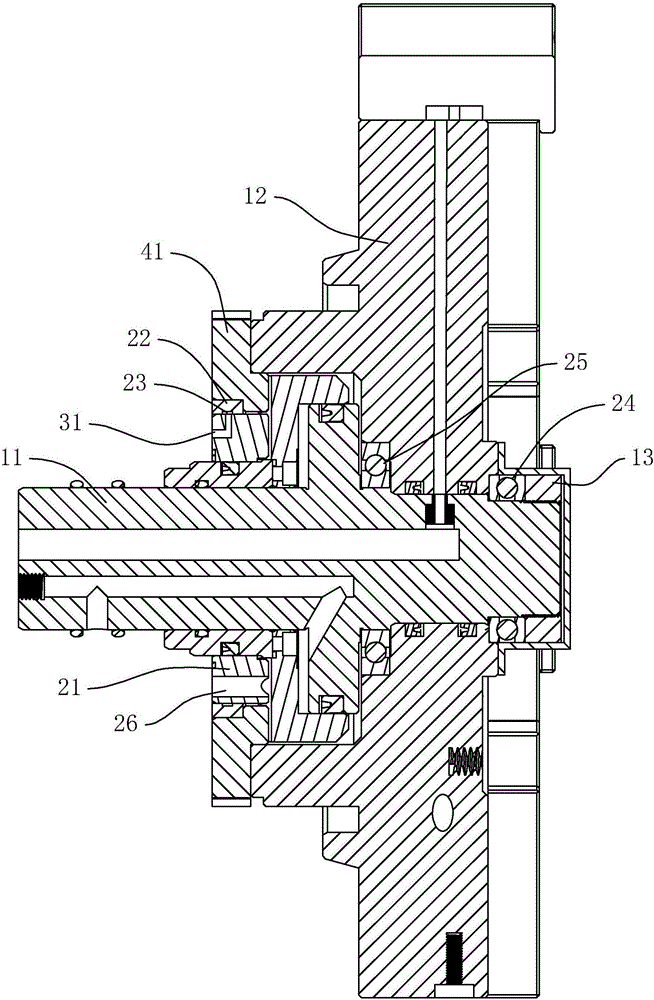

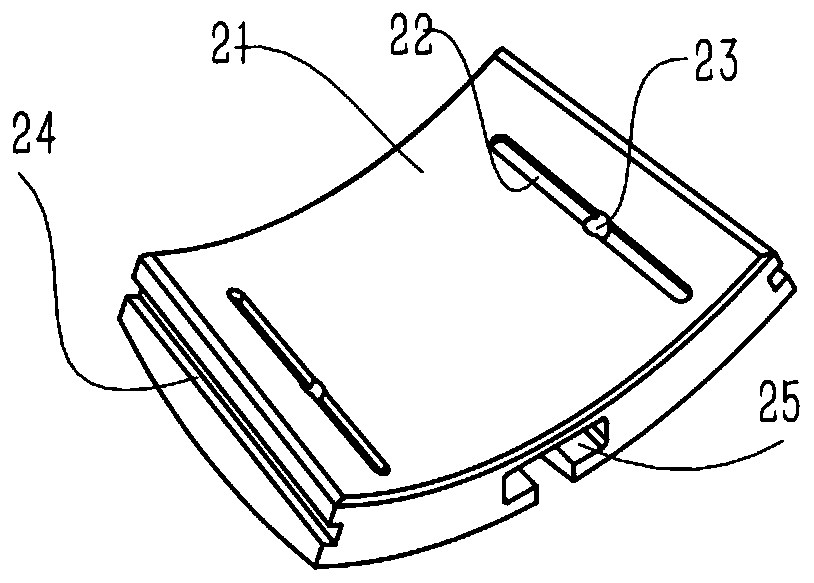

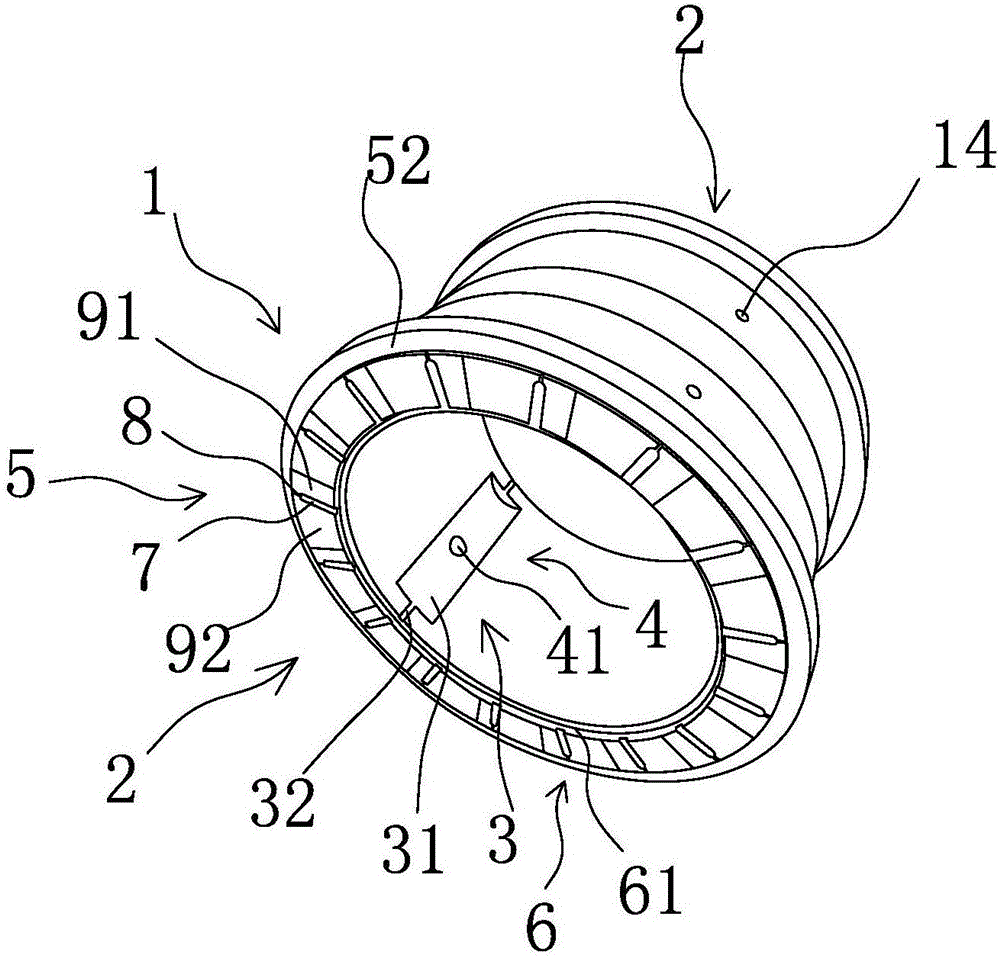

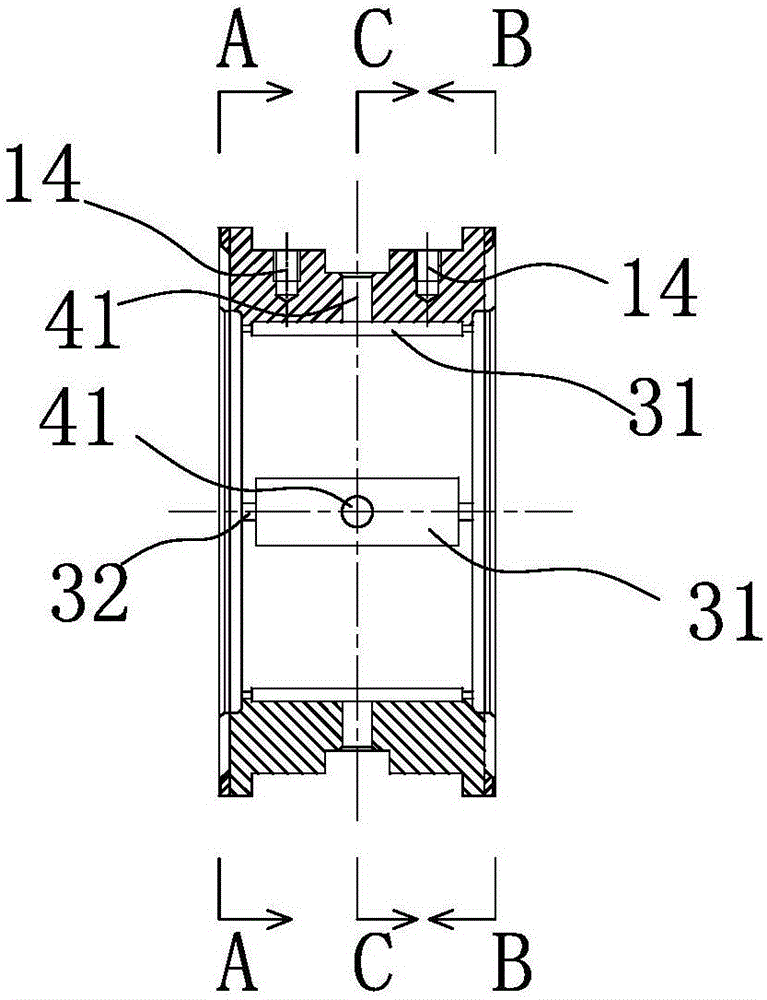

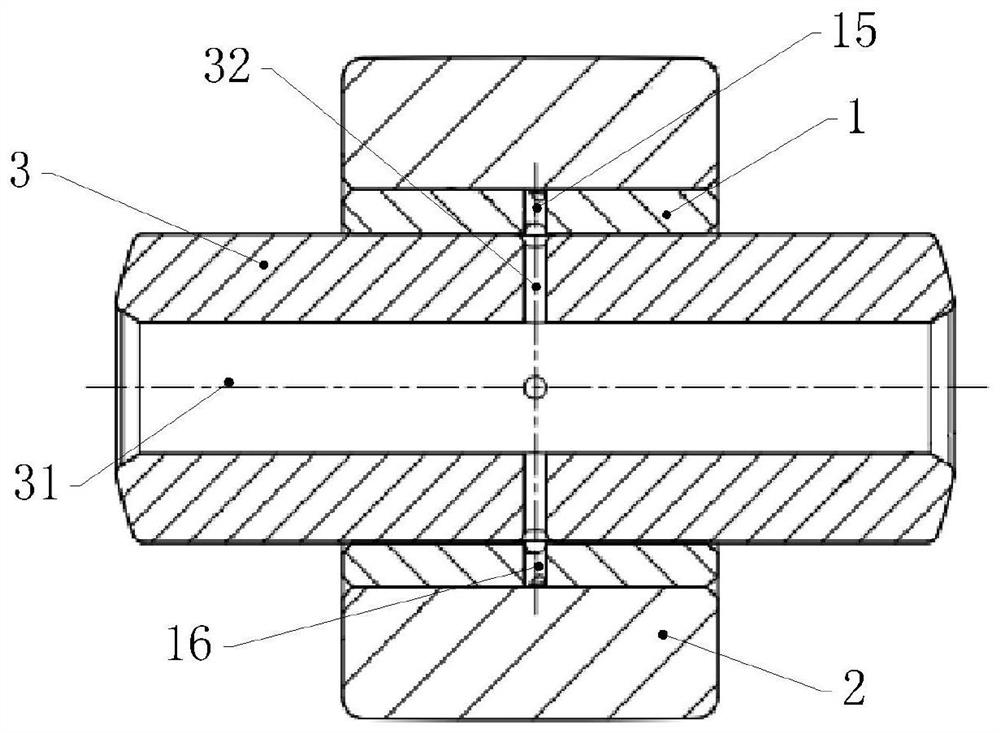

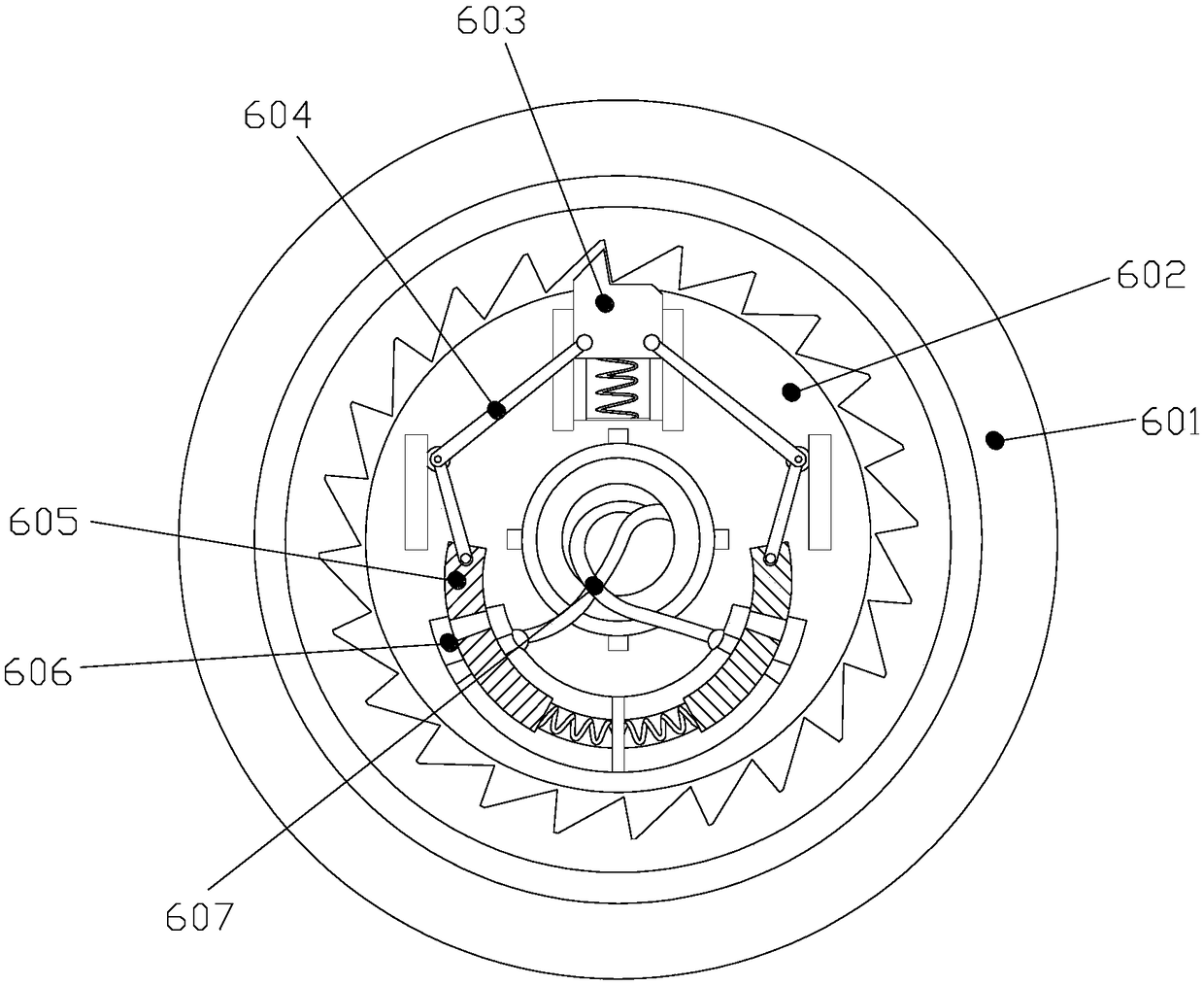

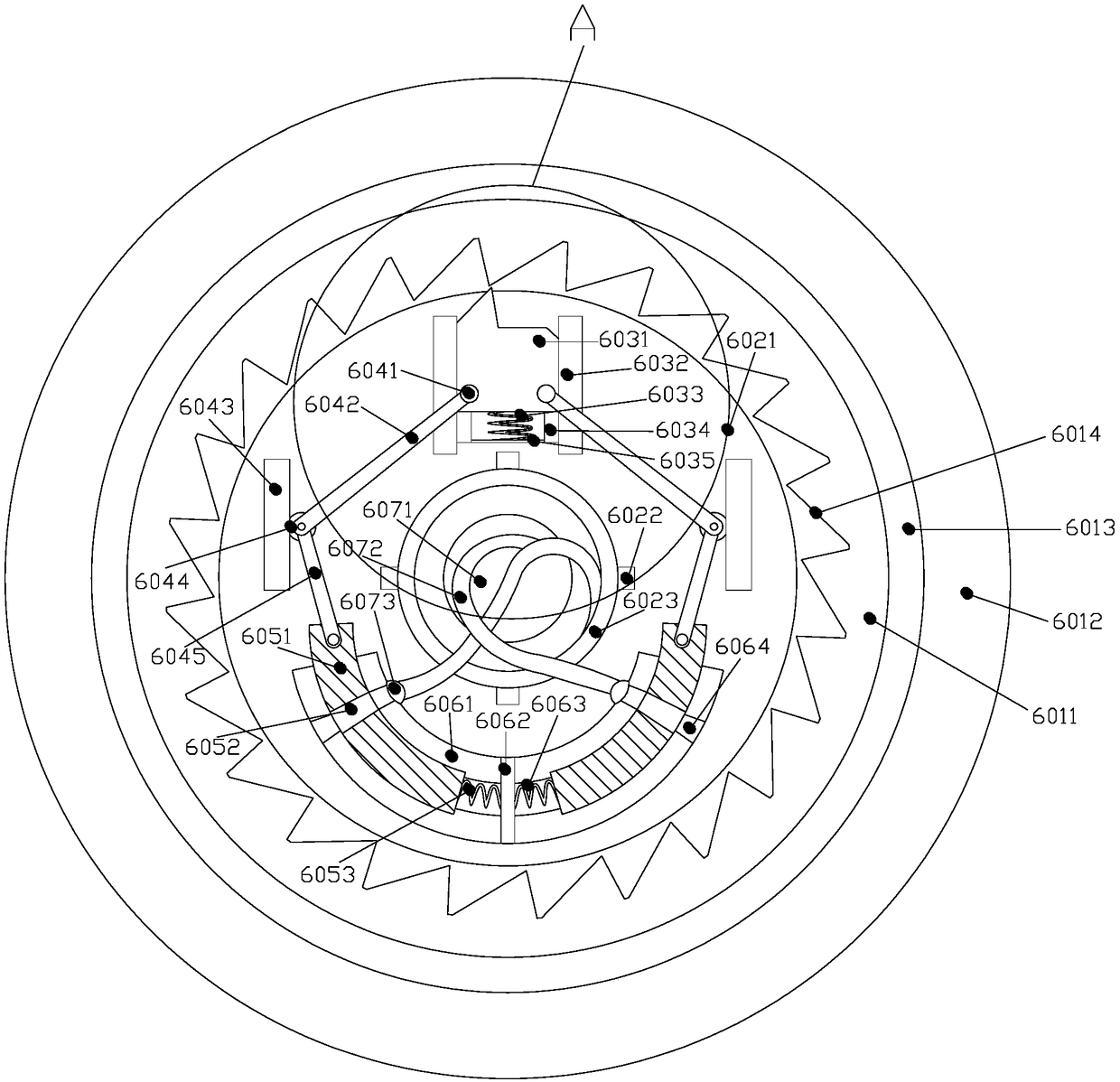

Stably-running lathe tool turret assembly

The invention discloses a stably-running lathe tool turret assembly. According to the technical scheme, the stably-running lathe tool turret assembly is characterized in that a machine shell is included and provided with a fixed shaft; an annular tool disc capable of rotating around the fixed shaft is arranged on the outer portion of the fixed shaft in a sleeving manner; a gear disc is coaxially and fixedly arranged on the tool disc; a drive motor used for driving the gear disc is arranged in the machine shell; a mounting ring is fixedly arranged on the machine shell; the gear disc is arranged on the outer wall of the mounting ring in a sleeving manner; and a sliding bearing is arranged between the mounting ring and the gear disc. In the rotating process, the tool disc is high in stability, and tool disc pressure dispersion is uniform.

Owner:台州开启精密机械有限公司

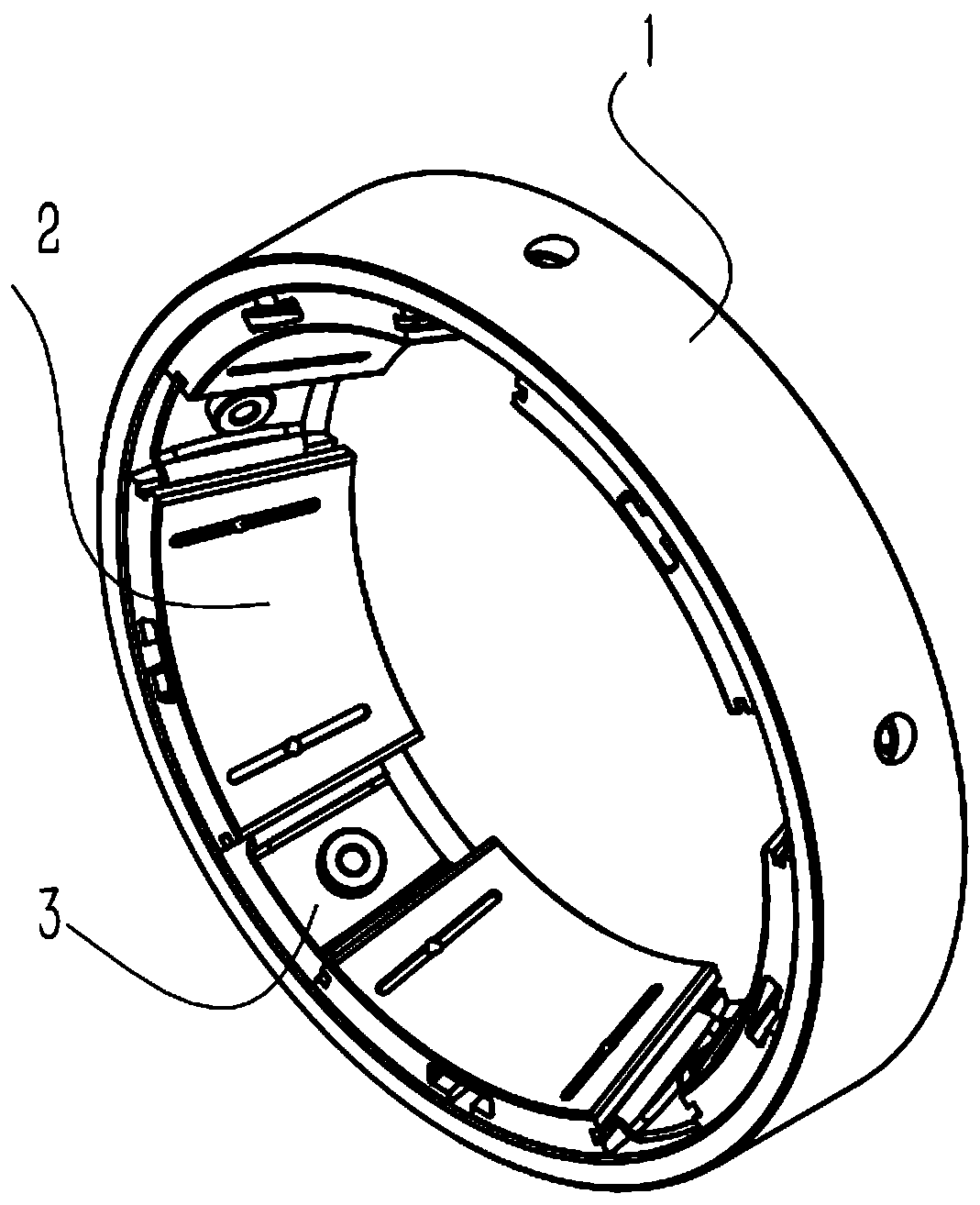

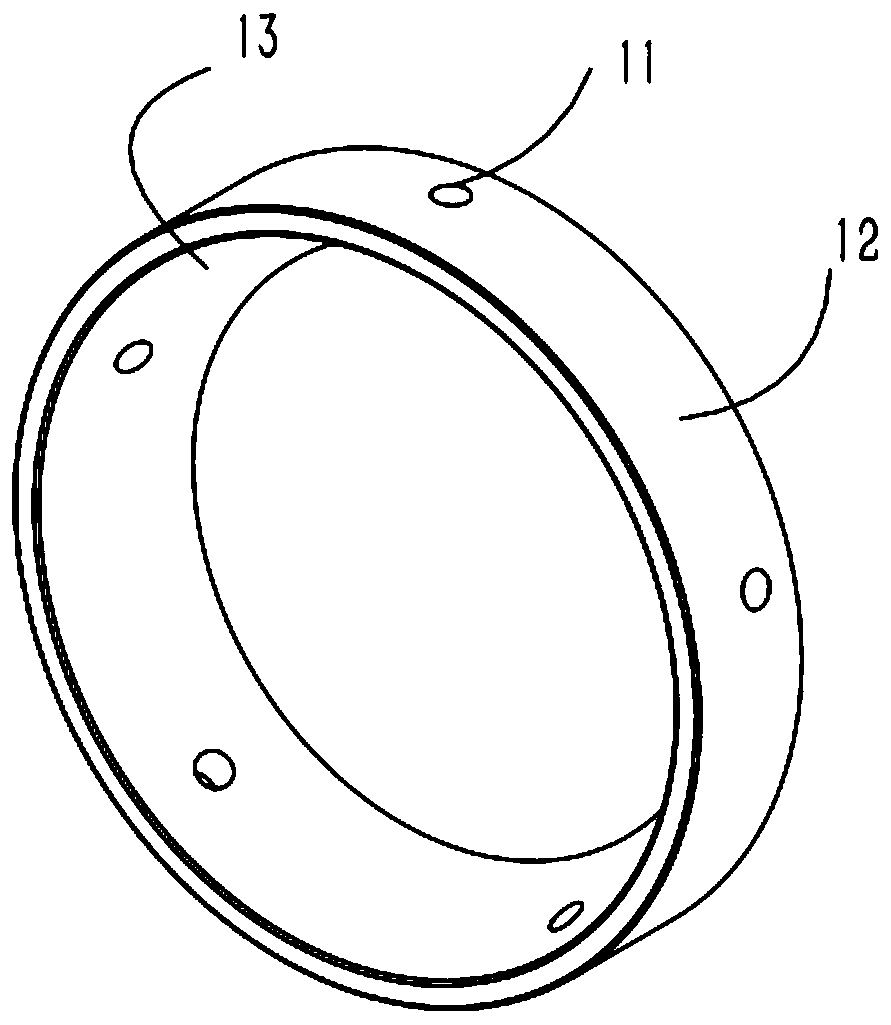

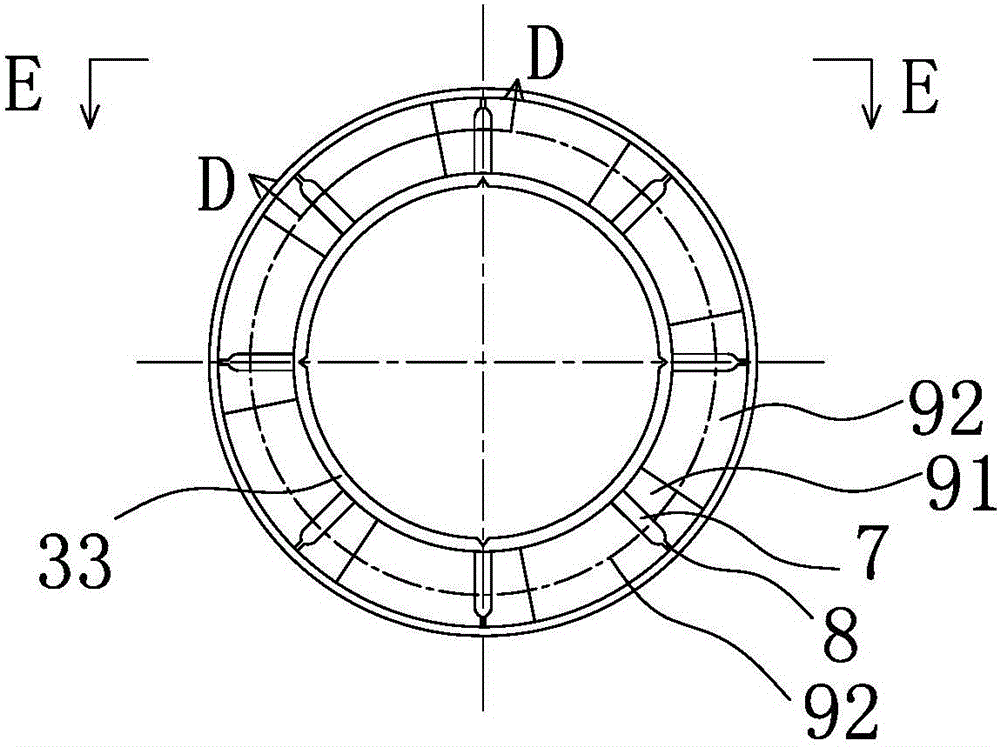

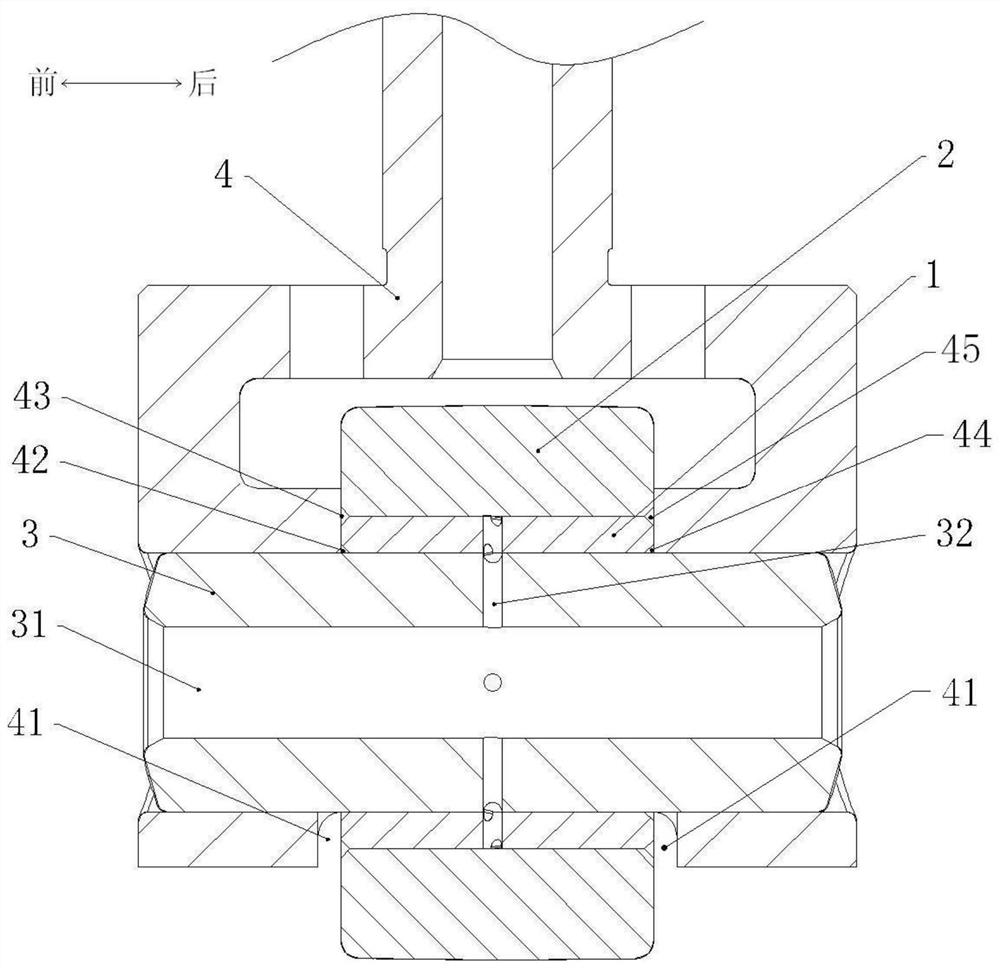

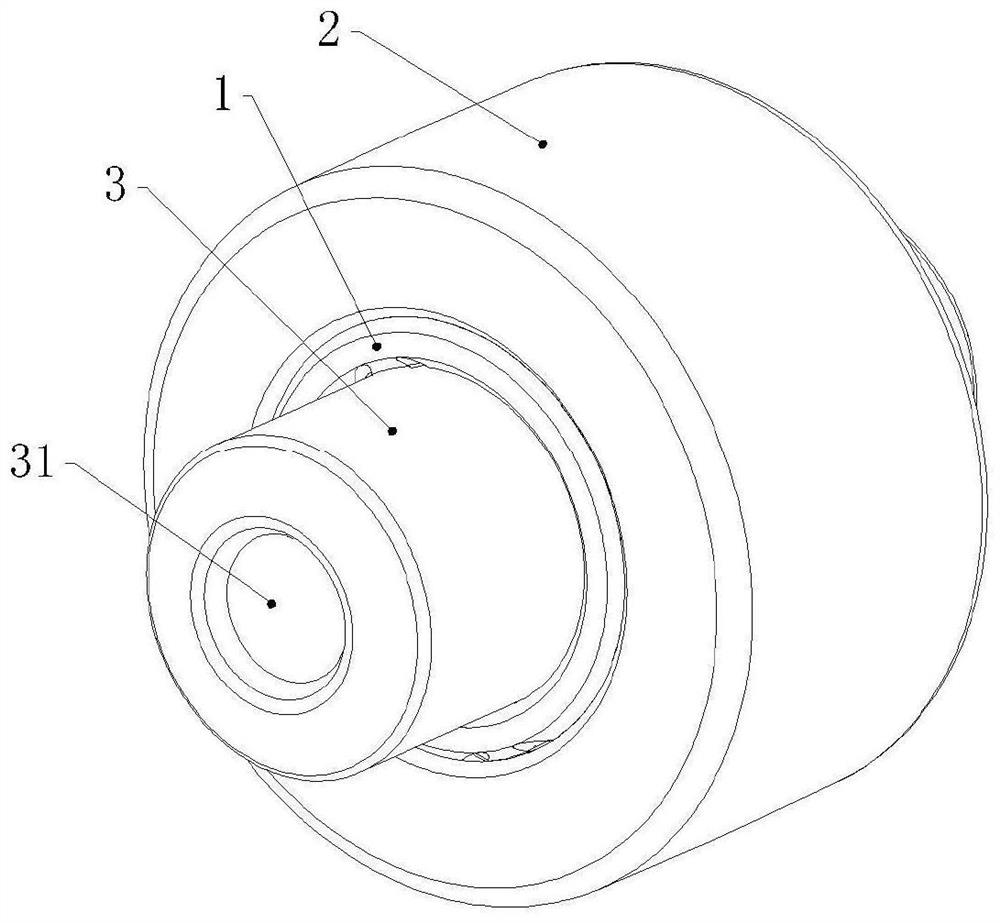

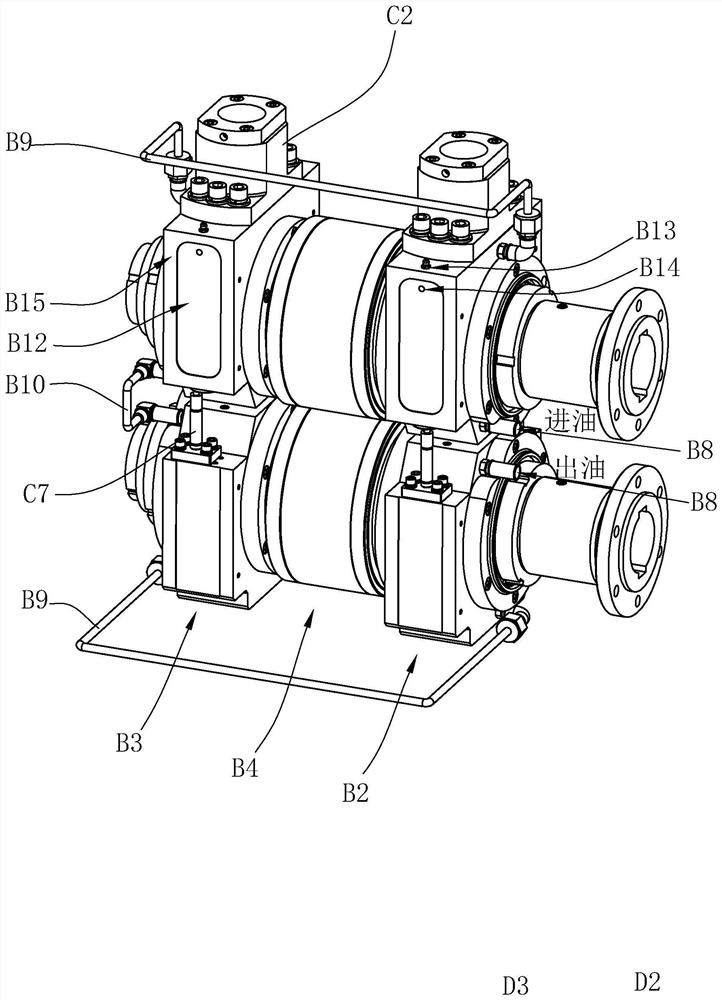

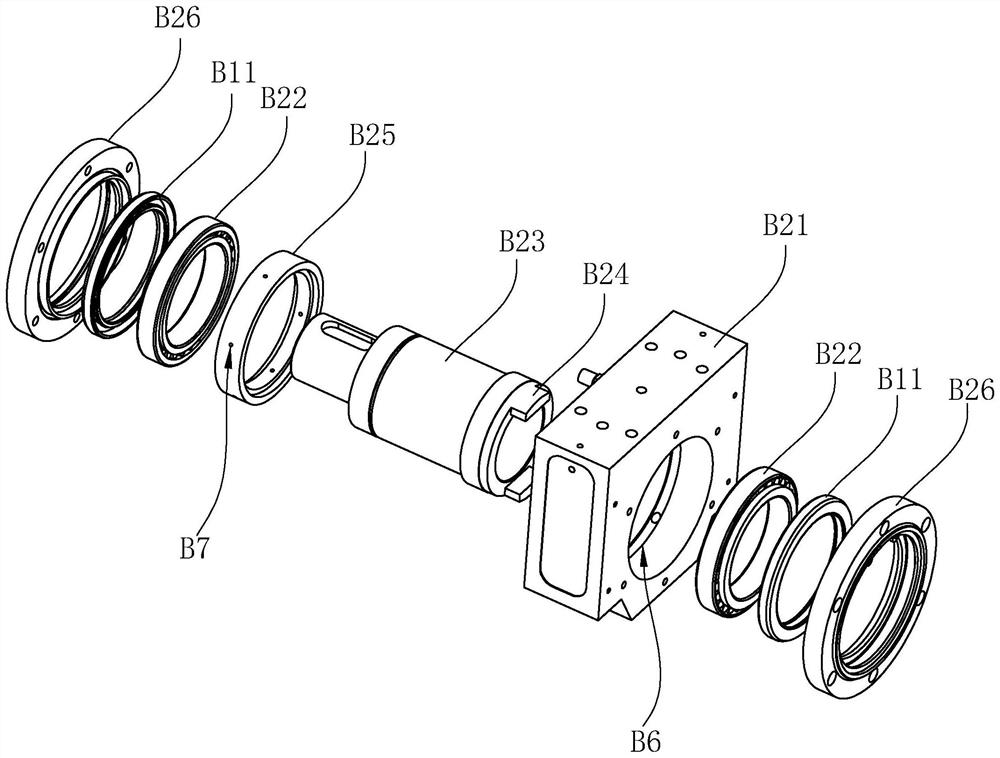

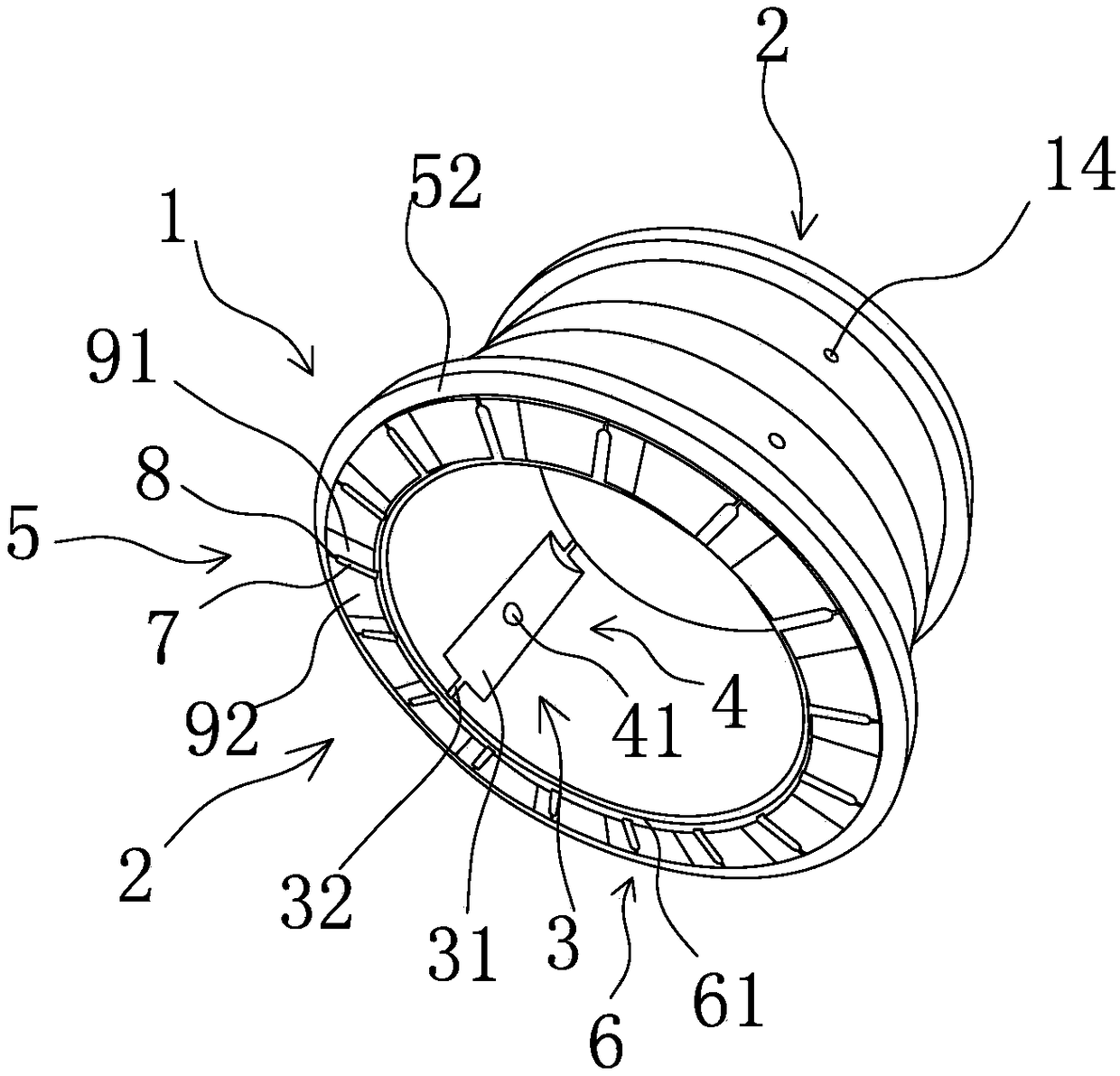

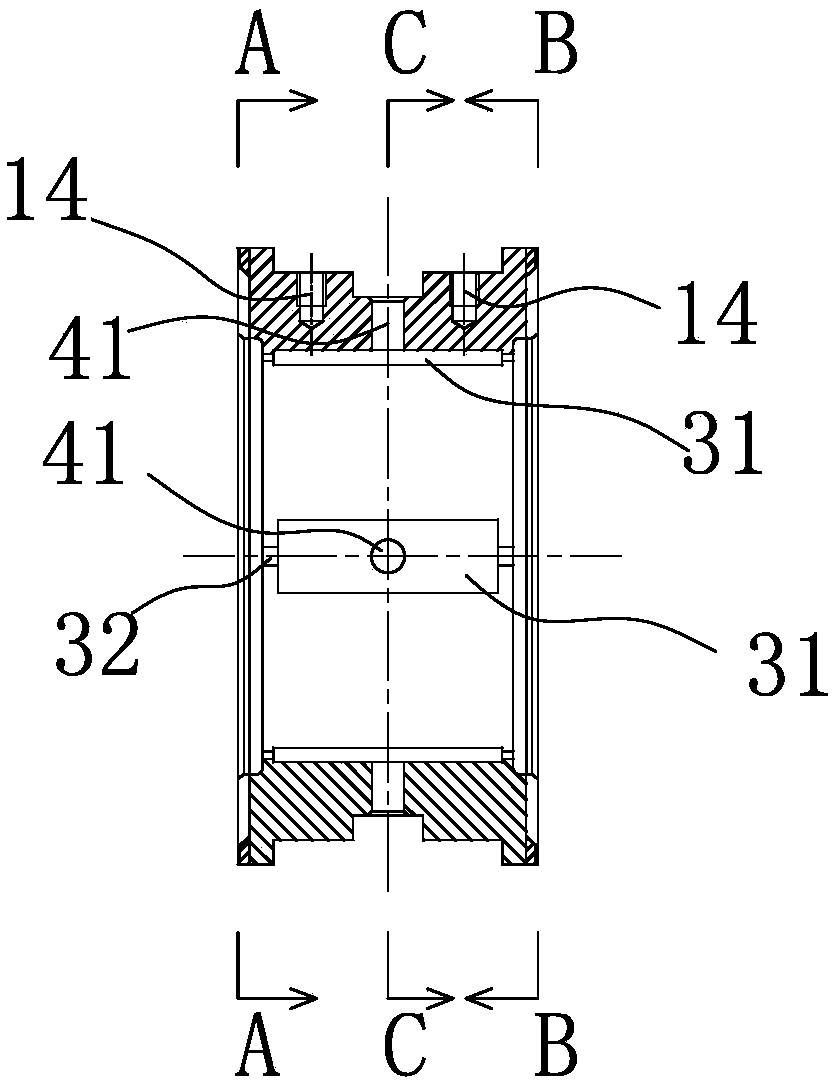

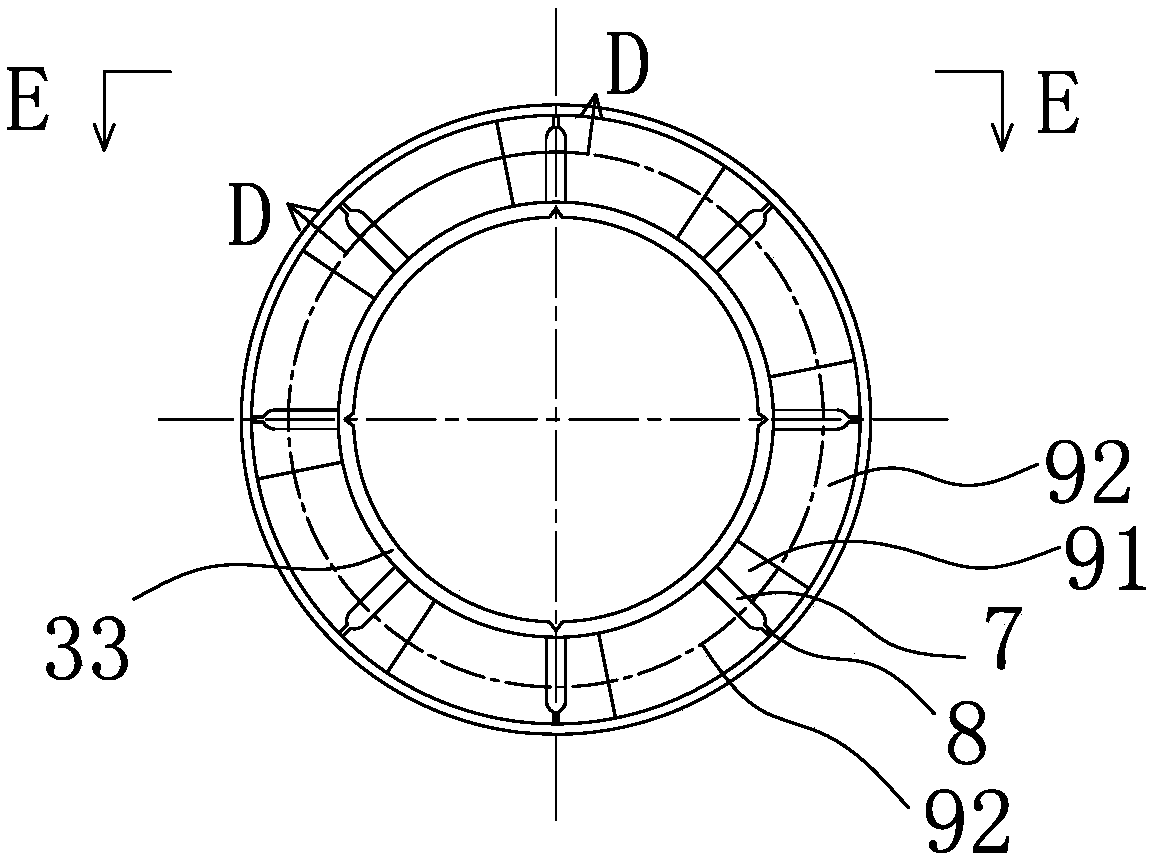

Bush-tilting dynamic pressure bearing

PendingCN111365364AGood lubricating bearing effectAccording to the principle of lubricationSliding contact bearingsBearing coolingSlider bearingEngineering

The invention relates to the technical field of sliding bearings, in particular to a bush-tilting dynamic pressure bearing implementing pressure fluid inner feedback supporting on a bush back. The bush-tilting dynamic pressure bearing specifically comprises a bearing outer ring, a bush and a mounting assembly; and an oil gathering tank is arranged on the sliding face of the bush, gathers a pressure lubrication fluid on the sliding face and feeds back and guides the pressure lubrication fluid into an oil cavity formed in the back face of the bush through an oil hole to form supporting force forthe bush. A deformation structure is arranged in the middle of the bush to divide the bush into two blocks, and the mounting assembly applies radial elastic compressing force to the bush. When the bearing works, under the effect of the supporting force of the oil cavity in the back face of the bush, the corresponding block of the bush overcomes the radial elastic compressing force and spindle load force to be upwarped with the deformation structure as a supporting point to achieve bearing bush tilting, and a convergent gap is formed to enable the bearing to achieve the good lubrication bearing effect; the back face of the bush and the inner surface of the bearing outer ring achieve full-contact supporting, and thus supporting stability is facilitated; and the working flow of the bearing can be additionally increased through the generated inner feedback lubrication flow, and thus cooling of the bearing is greatly facilitated.

Owner:WINTOP DONGGUAN INDAL TECH

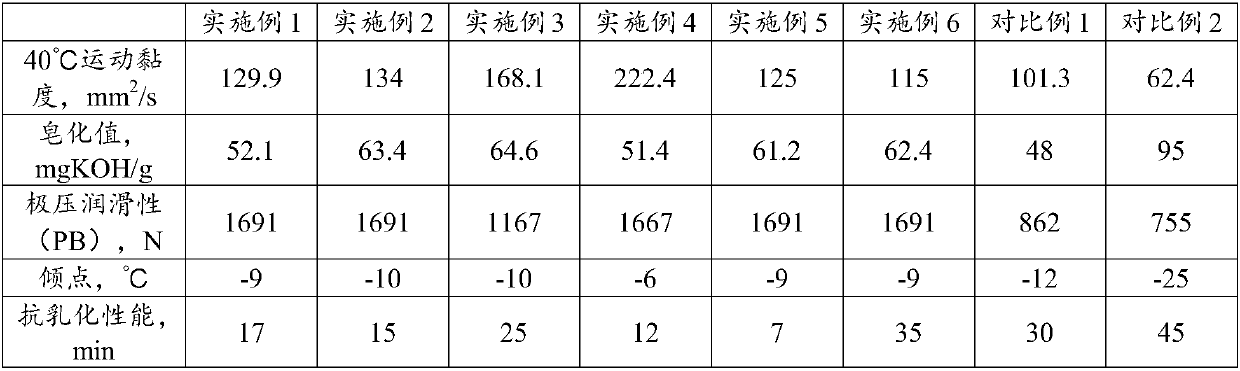

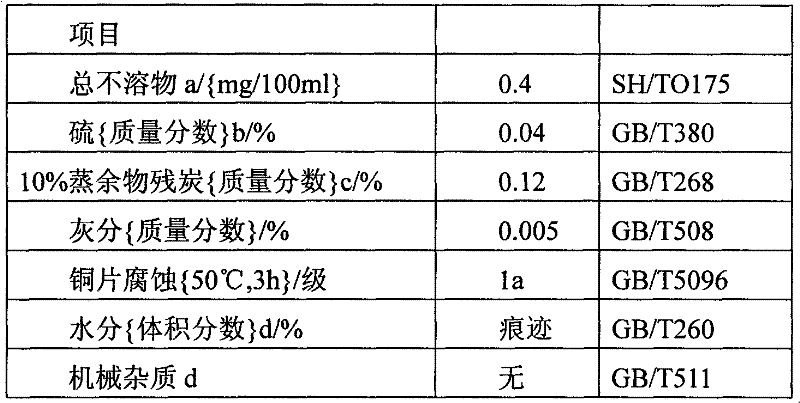

Hot rolling oil composition and application thereof

InactiveCN107629848AImprove the lubrication effectImprove wettabilityWork treatment devicesMetal rolling arrangementsLubricationMetallurgy

The invention relates to a hot rolled oil composition and application thereof. The hot rolled oil composition is composed of the following components in parts by weight: a) 40-80 parts of base oil; b)1-50 parts of an oily agent; c) 0.1-15 parts of an extreme pressure agent; and d) 0.01-1 part of a demulsifying agent. The hot rolled oil composition provided by the invention can better meet lubrication requirement of a hot rolling technology and can be used for lubrication during hot rolling of stainless steel.

Owner:CHINA PETROLEUM & CHEM CORP

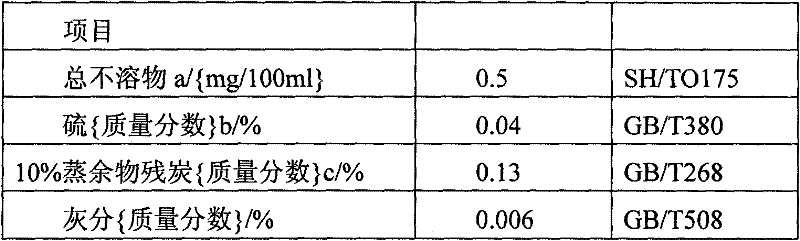

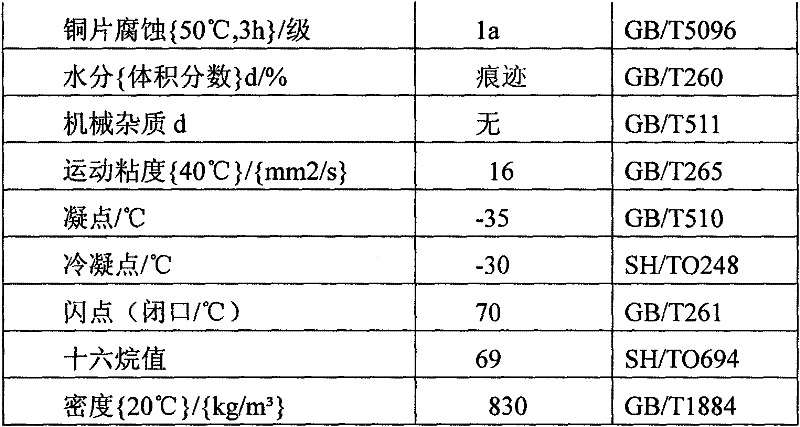

Compound-type environmentally-friendly fuel oil solution and preparation method thereof

InactiveCN102643686ARapid miscibilityLow priceLiquid carbonaceous fuelsFuel additivesHazardous substanceOil additive

The invention discloses a compound-type environmentally-friendly fuel oil solution and a preparation method thereof and relates to a fuel oil solution and a preparation method thereof, which can be used for solving the problems that only a fuel oil additive with a single function can be produced in our country; the manufacturing process is not environmentally friendly; a high-quality fuel oil additive mainly depends on import to be obtained; the high-quality fuel oil additive product at abroad is synthesized by adopting a process method of blending, emulsification and sulfonation; the productive process is complex; the operation is not safe; the produced product performance is not stable; and poisonous and harmful substances such as sulfide, acid and the like are generated in the production and use processes. The compound-type environmentally-friendly fuel is prepared by the following step: 1. carrying out catalyzed oxidation; 2. complexing; 3. refining; and 4. filtering and standing. The invention relates to the production field of fuel oil and product oil.

Owner:HARBIN HONGLI SHENGDA TECH DEV

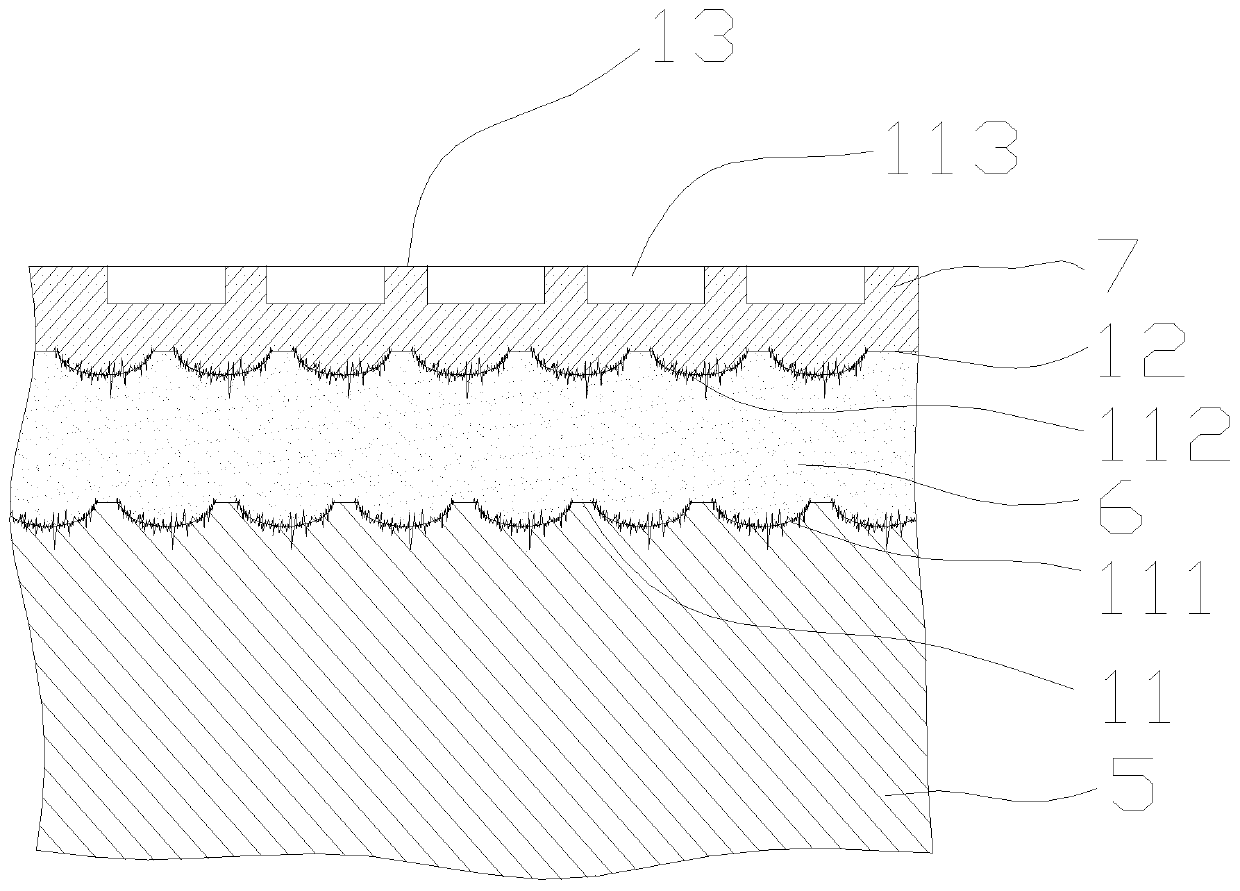

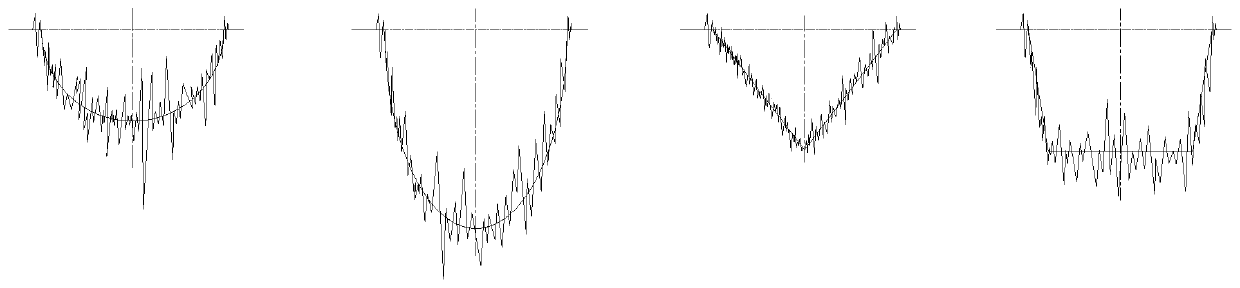

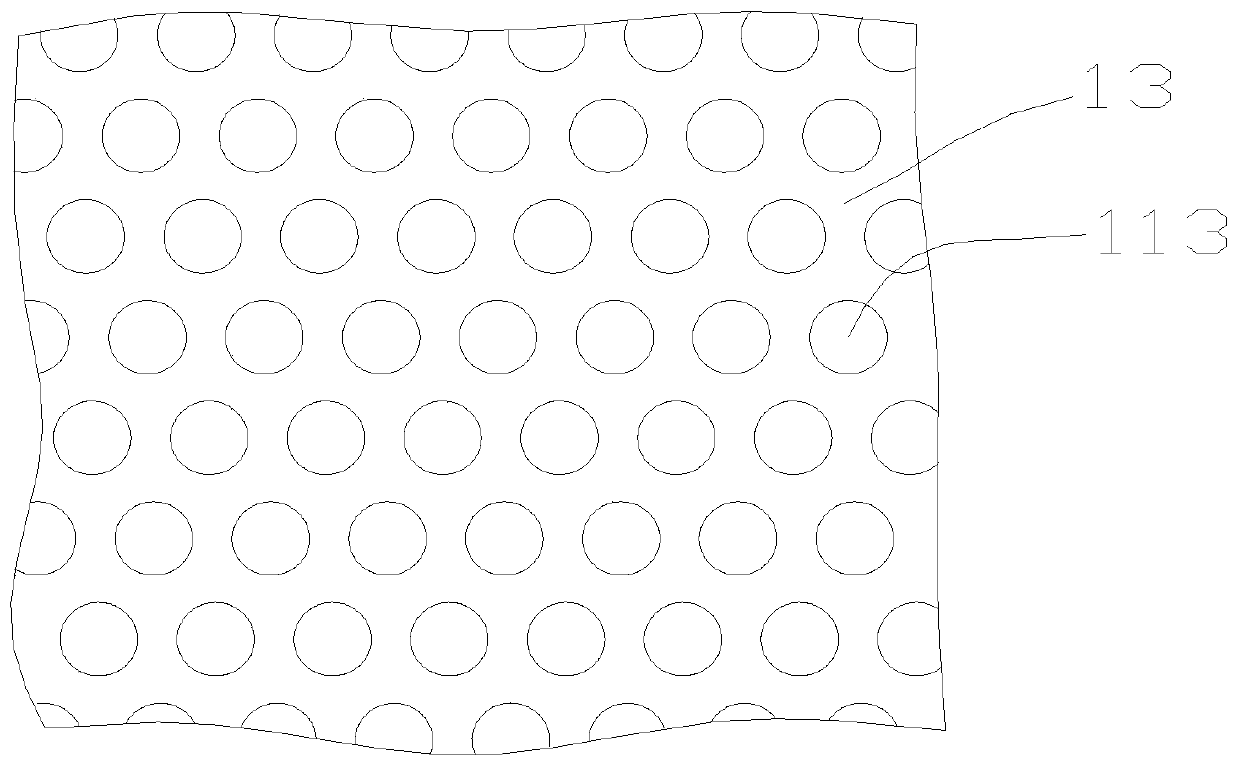

Friction structure, friction part and compressor

InactiveCN110374881AImprove bindingStable lubricationRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringBinding force

The invention provides a friction structure, a friction part and a compressor. The friction structure comprises a base and multiple coatings combined on the base in sequence. A first contact face between the base and the adjacent coating, a second contact face between the two adjacent coatings and the outer surface of the coating on the outermost layer are arranged to be of surface texture structures. The base, the coating and the two adjacent coatings combined with the outer surface are arranged to be of the surface texture structures, the binding force is high, lubrication is stable, and abnormal wear is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

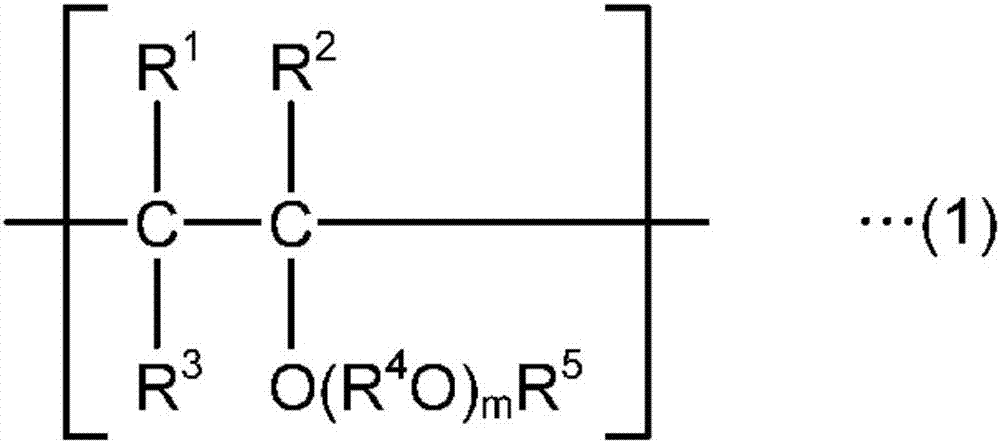

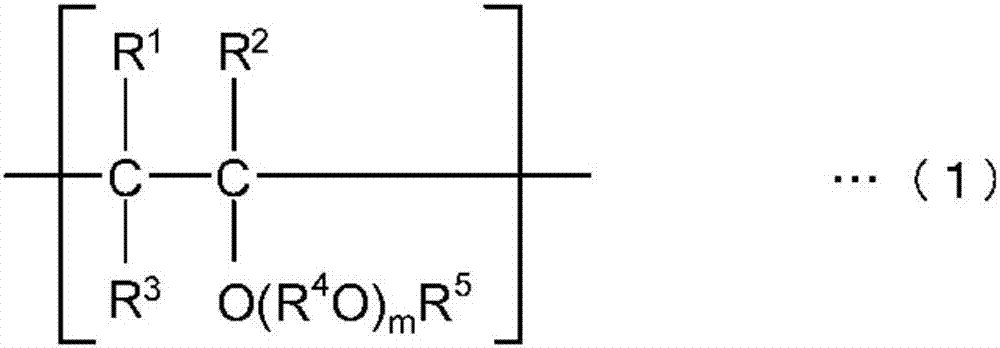

Hydrophilic coating and a method for the preparation thereof

ActiveUS8728508B2High boiling pointSmall to medium hydrogen bonding abilityImpression capsSurgeryCross-linkHydrophilic coating

The present invention provides a method for the preparation of a cross-linked hydrophilic coating of a hydrophilic polymer on a substrate polymer surface of a medical device, involving the use of a polymer solution comprising 1-20% by weight of a hydrophilic polymer, 0-5% by weight of additive(s), and the balance of a vehicle with plasticizing effect on the hydrophilic polymer, wherein the vehicle comprises at least one plasticizer having a solubility in water of at least 6 g / L, a boiling point above 210° C. at 760 mmHg, and Hansen δH parameter of less than 20. Furthermore, the invention provides a medical device, e.g. a catheter or guide wire, provided with such a hydrophilic coating. The invention also provides the use of specific polymer solution for the preparation of a cross-linked hydrophilic coating.

Owner:COLOPLAST AS

Gap-controllable mechanical sealing device based on hinge structure

PendingCN113944756AStable lubricationImprove intelligenceEngine sealsPiezoelectric actuatorsSignal conditioning

The invention discloses a gap-controllable mechanical sealing device based on a hinge structure. The gap-controllable mechanical sealing device comprises a mechanical sealing device body and an end face gap adjusting and controlling device, the mechanical sealing device body comprises a shell assembly, a static ring assembly, a movable ring assembly and a rotating shaft, the shell assembly sleeves the rotating shaft in a clearance manner, the static ring assembly comprises a static ring seat and a static ring, the static ring seat sleeves the rotating shaft in a clearance manner, the static ring is provided with a static ring sealing surface facing the movable ring assembly, the hinge structure is formed between the static ring sealing surface and the rear end part of the static ring, the movable ring assembly comprises a spring seat, a push ring and a movable ring which are sequentially and coaxially arranged on the rotating shaft in a sleeving mode from the high-pressure side to the low-pressure side, the movable ring is provided with a movable ring sealing face facing the static ring, a sealing gap is formed between the movable ring sealing face and the static ring sealing face, the end face gap adjusting and controlling device comprises a monitoring mechanism and a control mechanism, the monitoring mechanism comprises an ultrasonic transducer and a flow meter, and the control mechanism comprises a piezoelectric actuator, a signal conditioner and a microprocessor. The gap-controllable mechanical sealing device has the beneficial effects that the size of the sealing gap can be controlled, and a sealing end face is stably lubricated.

Owner:ZHEJIANG UNIV OF TECH

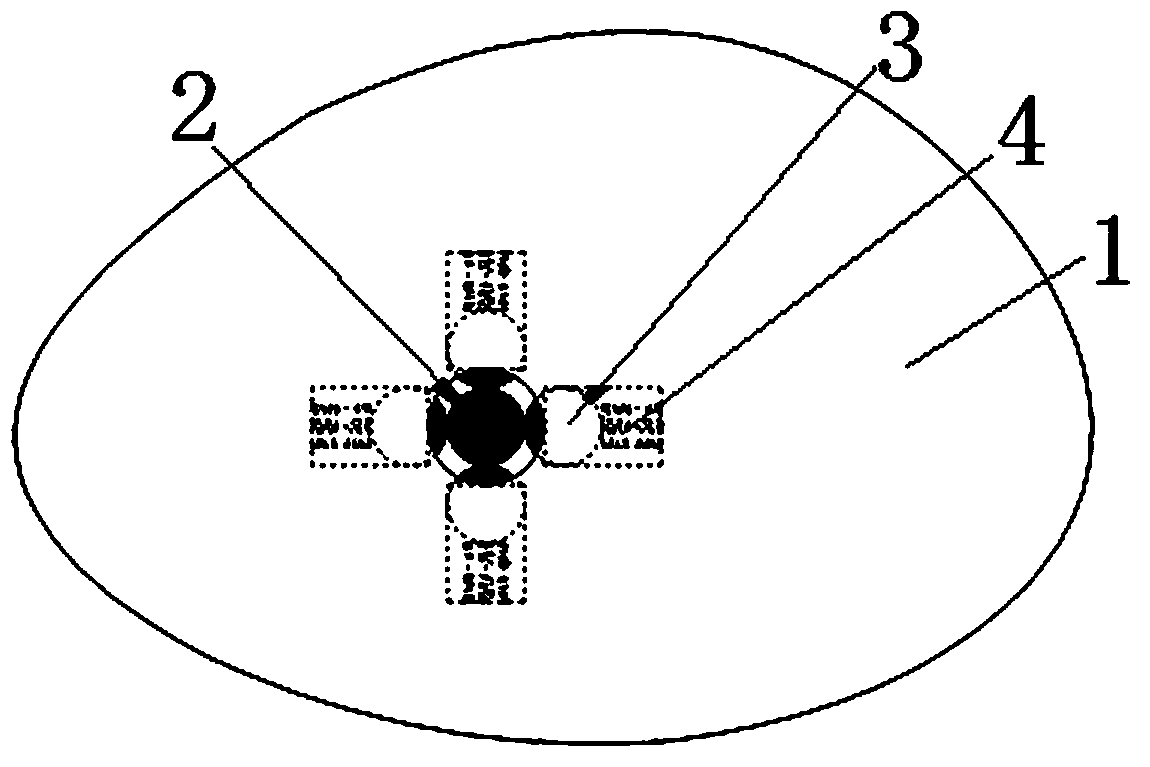

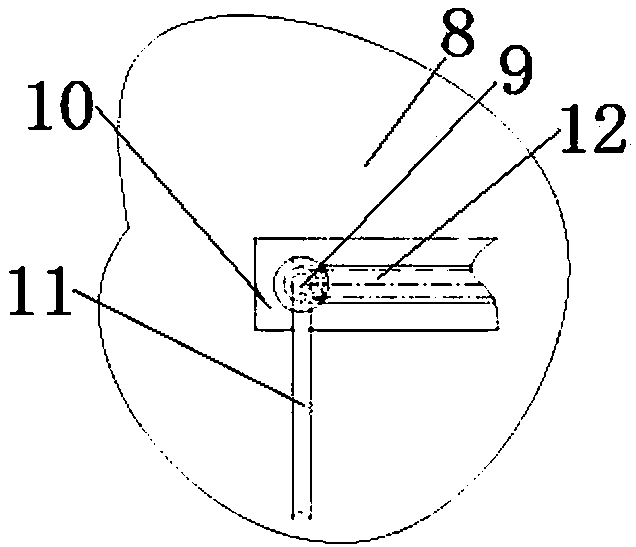

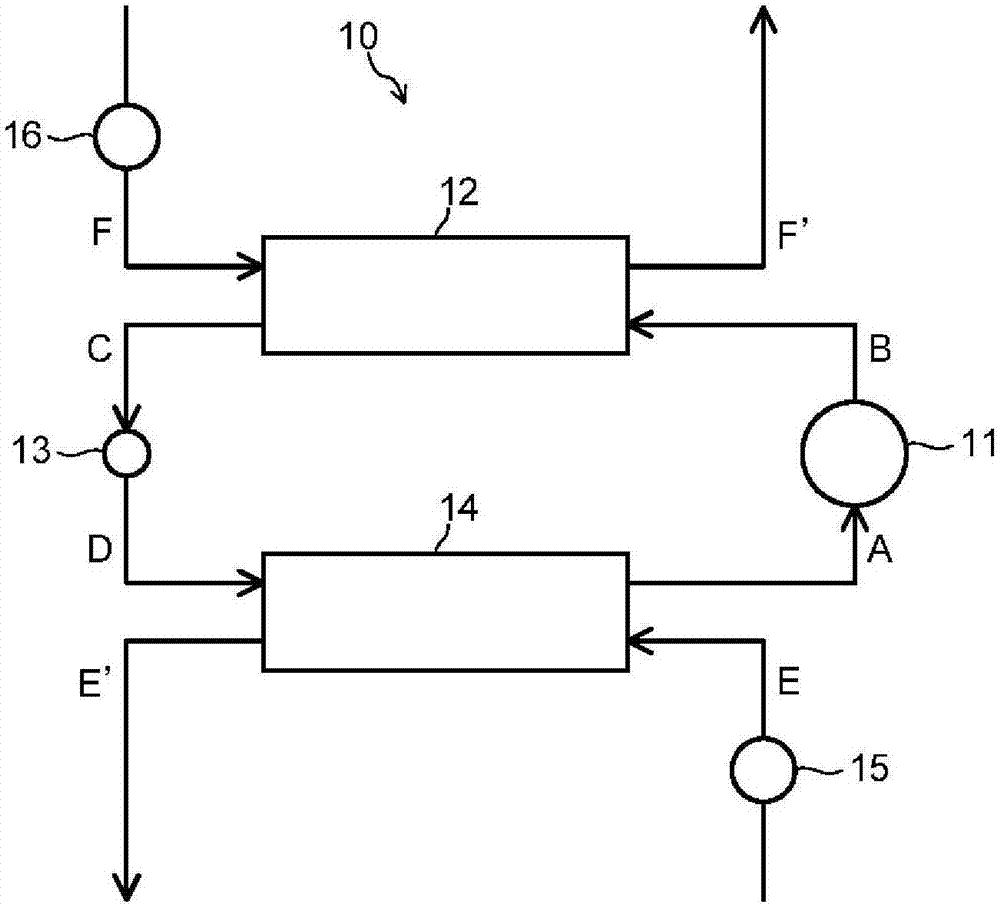

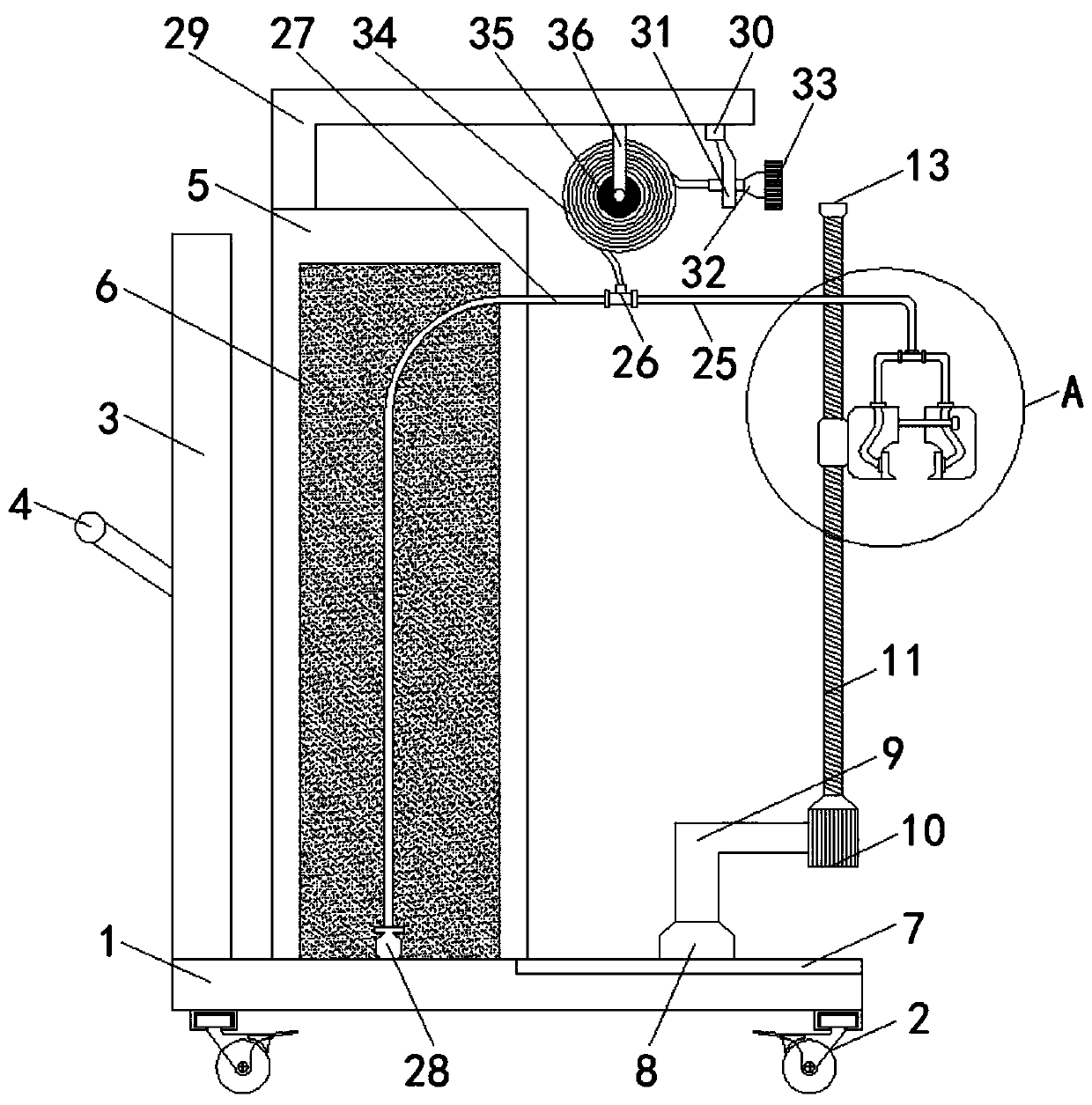

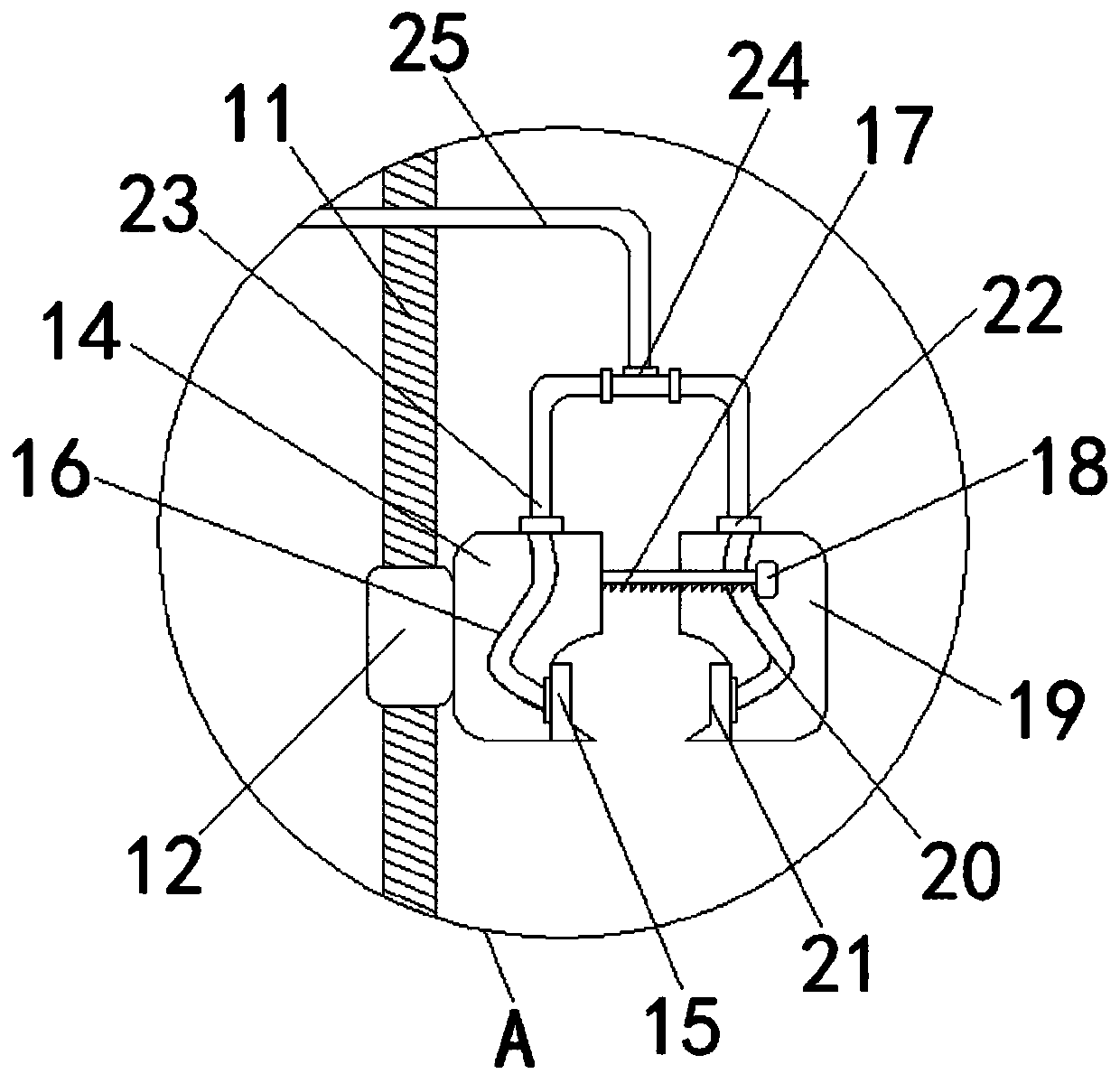

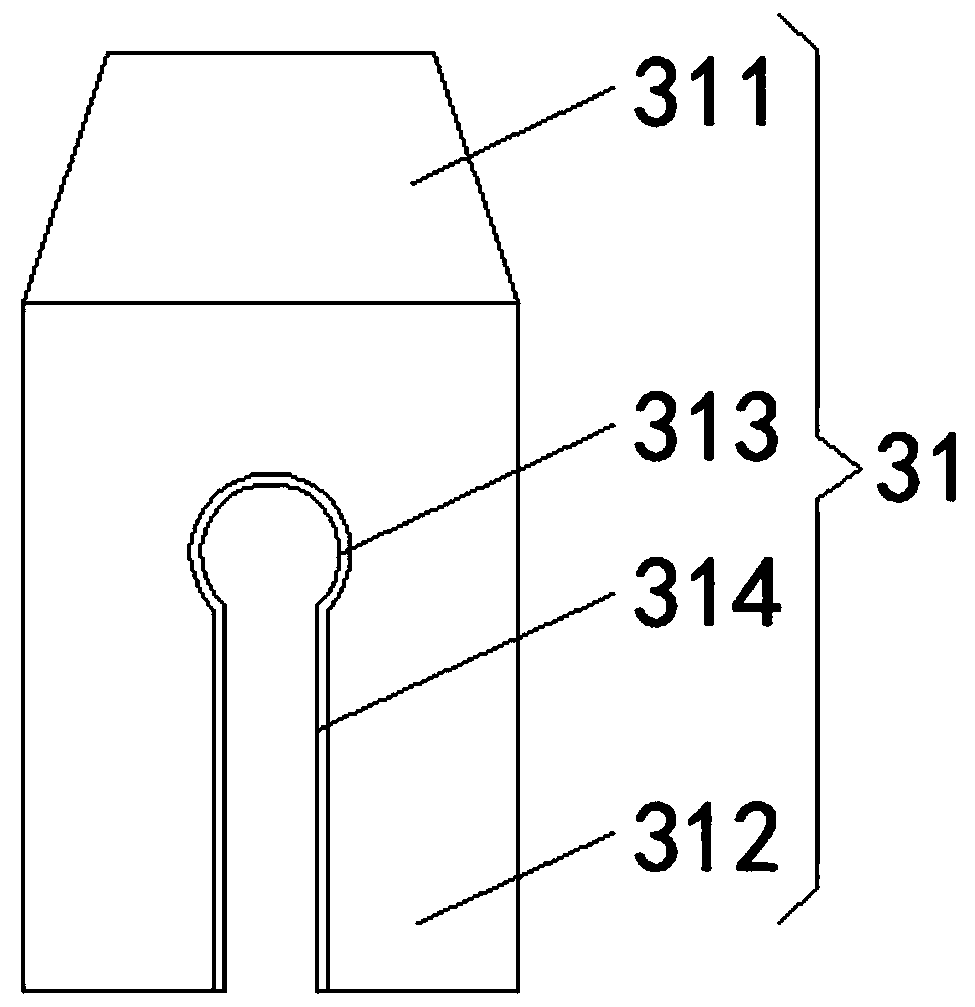

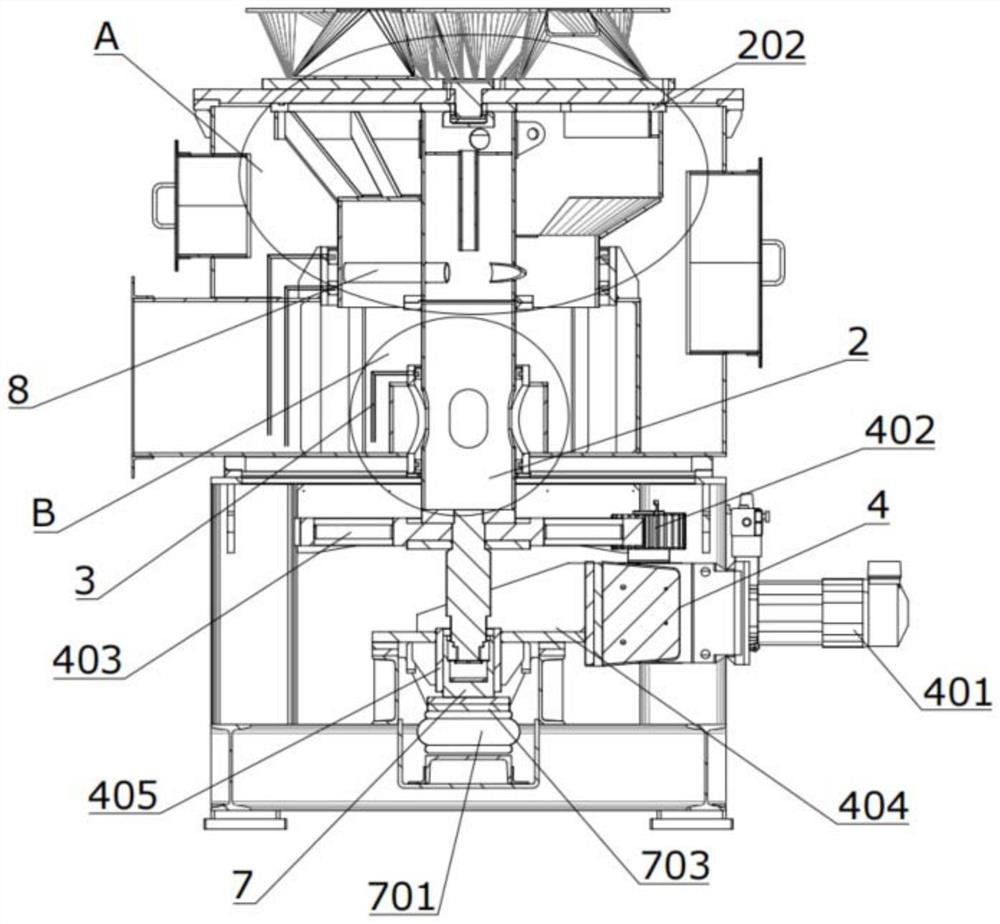

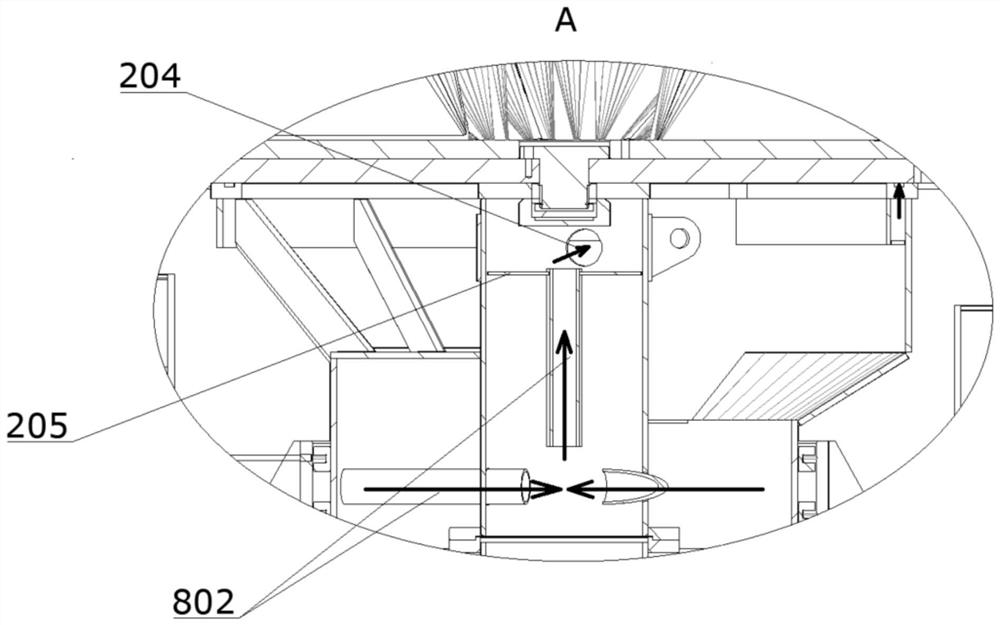

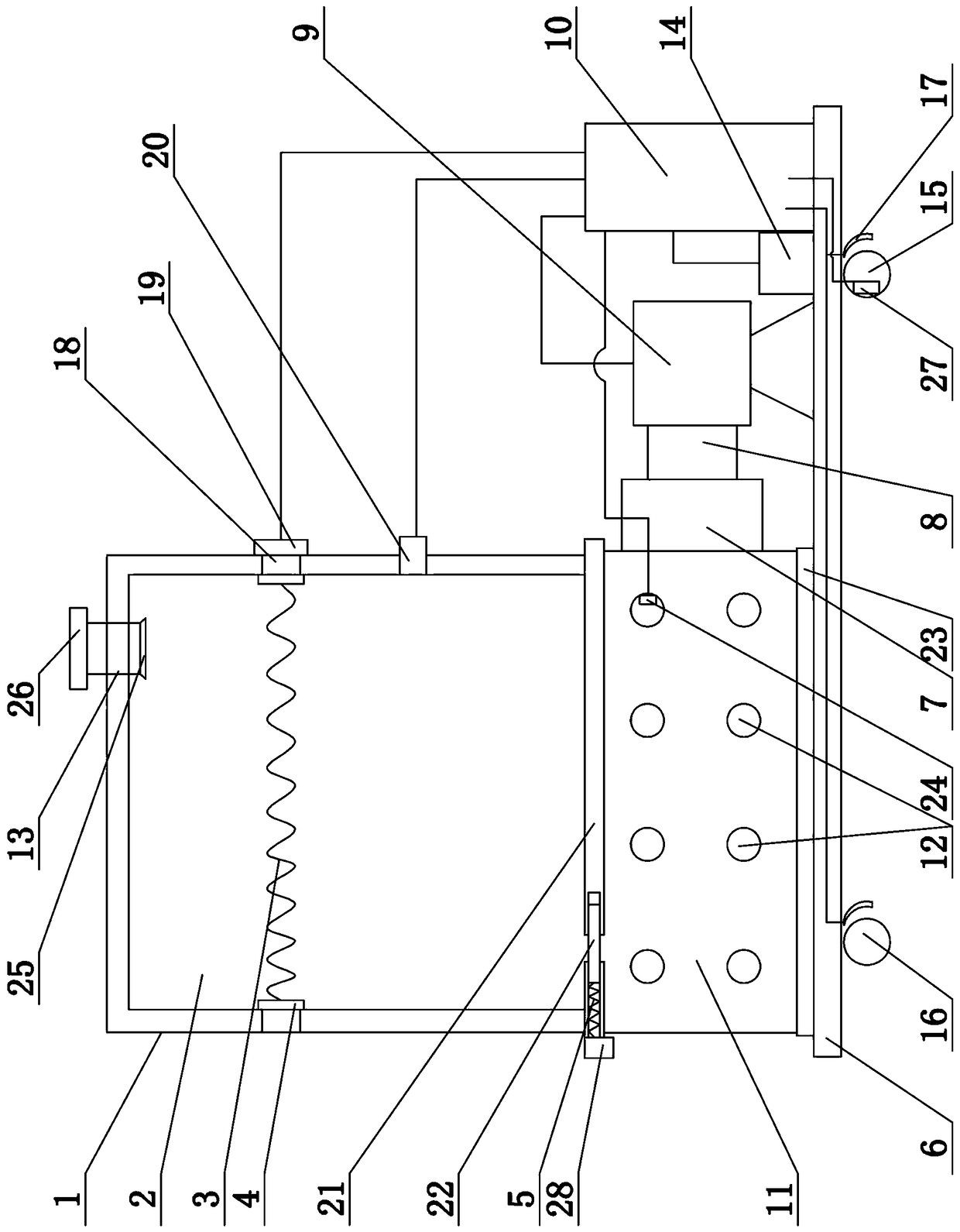

Automatic lubricating device for steel wire rope for swabbing truck

PendingCN108626558AStable lubricationGuaranteed adequate lubricationWinding mechanismsEngine lubricationTruckEngineering

The invention discloses an automatic lubricating device for a steel wire rope for a swabbing truck. The device comprises a shell, oil cavities, a trigger mechanism and a switching connecting rod, wherein the oil cavities, the trigger mechanism and the switching connecting rod are arranged in the shell; the shell is fixed on a running track of the steel wire rope of the swabbing truck, and a passing channel which allows the steel wire rope to penetrate through the shell is formed in the shell through sliding mechanisms; the oil cavities are distributed on the periphery of the steel wire rope ina surrounding mode, first oil outlet holes are formed in the bottom of the wall surface, facing the steel wire rope, of the oil cavities, and a spigot structure for limiting a switching joint is arranged on the outer sides of the first oil outlet holes; the trigger mechanism is clamped on the steel wire rope, and generates displacement / idling due to friction force in the operation of the steel wire rope; and the switching connecting rod is connected between the parts, at the trigger mechanism and the first oil outlet holes, of the spigot structure, and cooperates with the displacement / idlingstate of the trigger mechanism on the steel wire rope so as to enable the switching joint to be capable of achieving switching between two kinds of stations which allow the first oil outlet holes inthe oil cavities to be opened or plugged. According to the device, the steel wire rope of the swabbing truck can be conveniently, efficiently, timely, fully and stably lubricated.

Owner:SINOPEC SSC +1

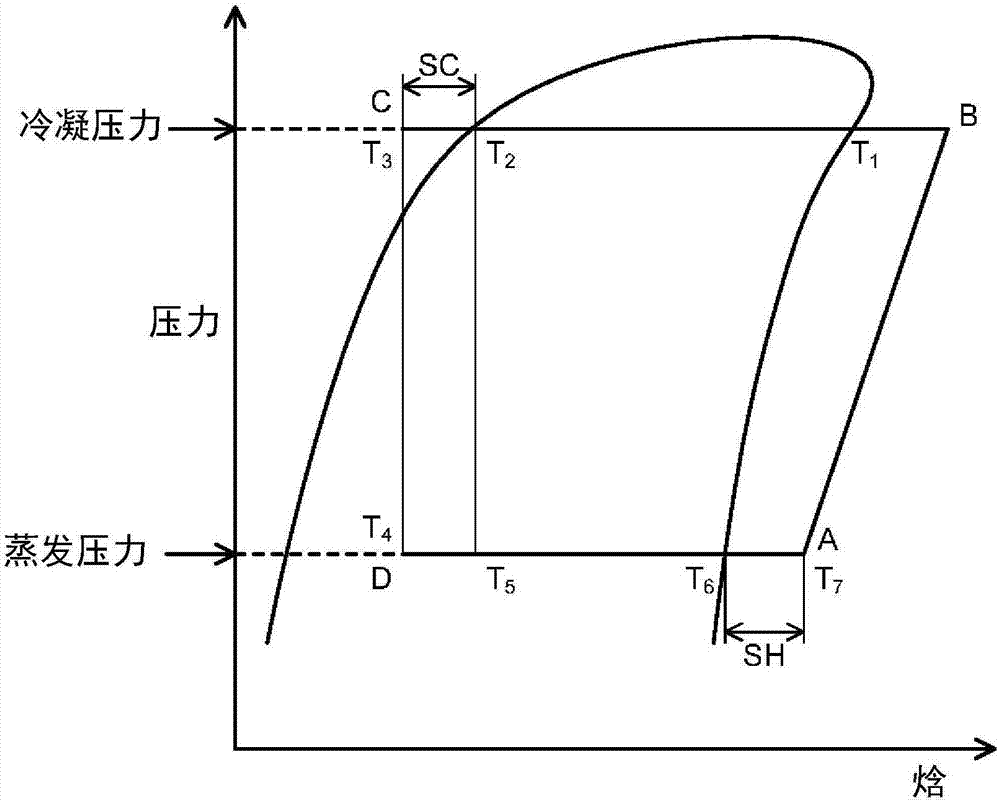

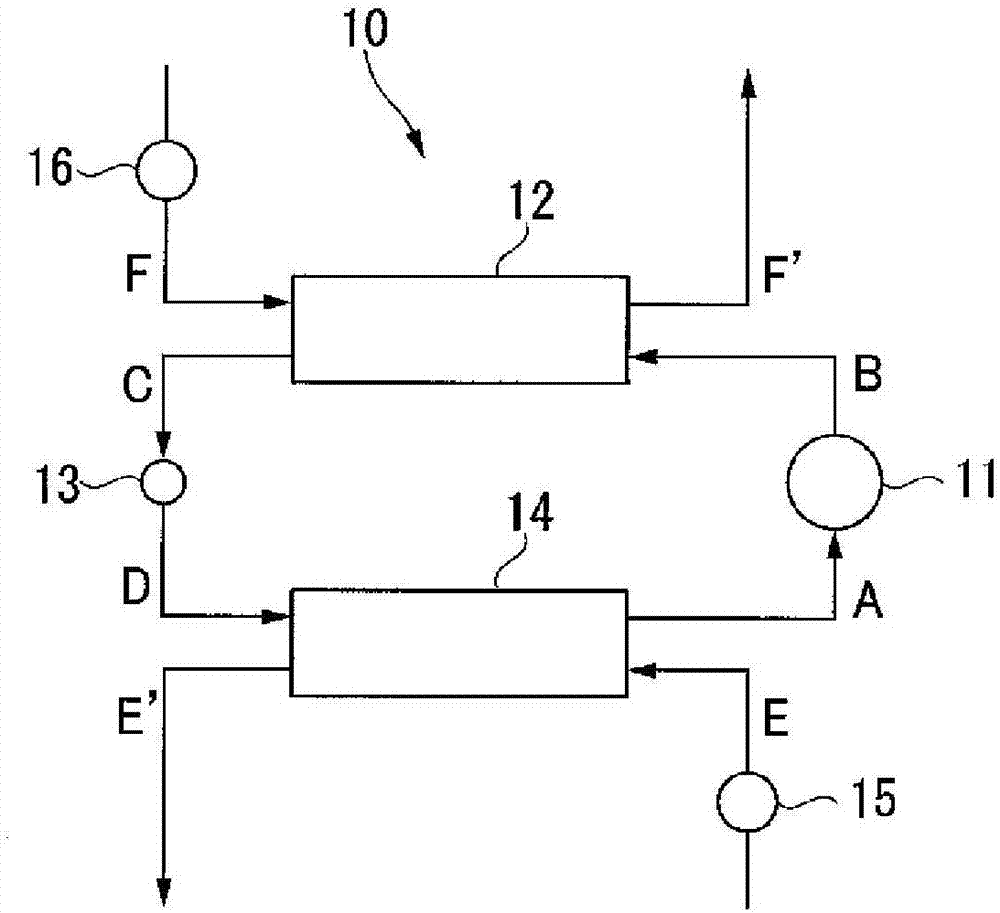

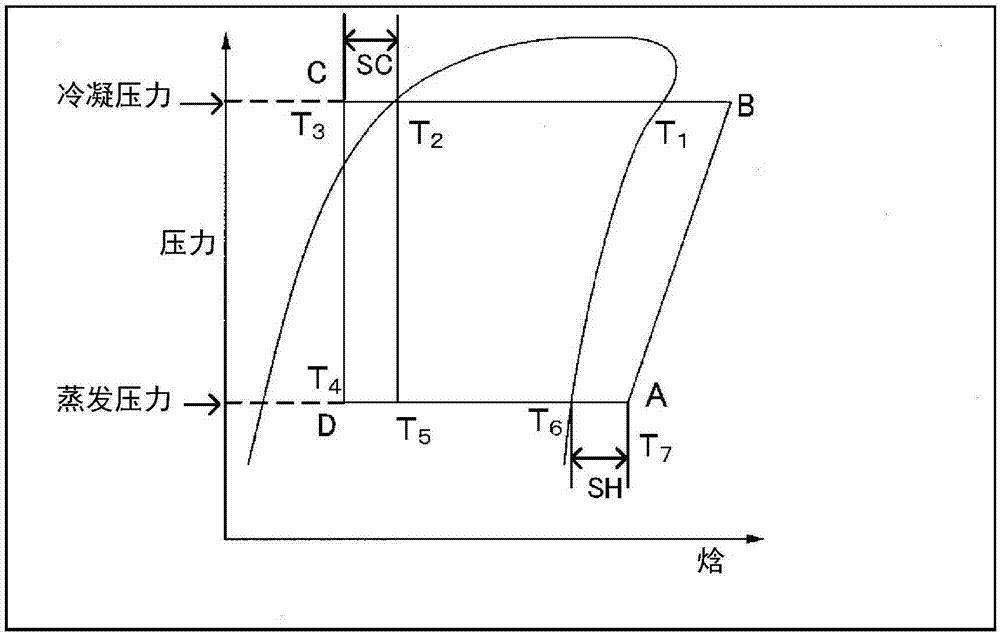

Composition for use in heat cycle system, and heat cycle system

InactiveCN107532071AStable lubricationMake full use of the low greenhouse effect coefficientCompressorCompression machines with non-reversible cycleProcess engineeringThermodynamics

This composition for use in heat cycle system contains a refrigerant oil and a heat cycle working medium that contains 1-chloro-2,3,3,3-tetrafluoropropene.

Owner:ASAHI GLASS CO LTD

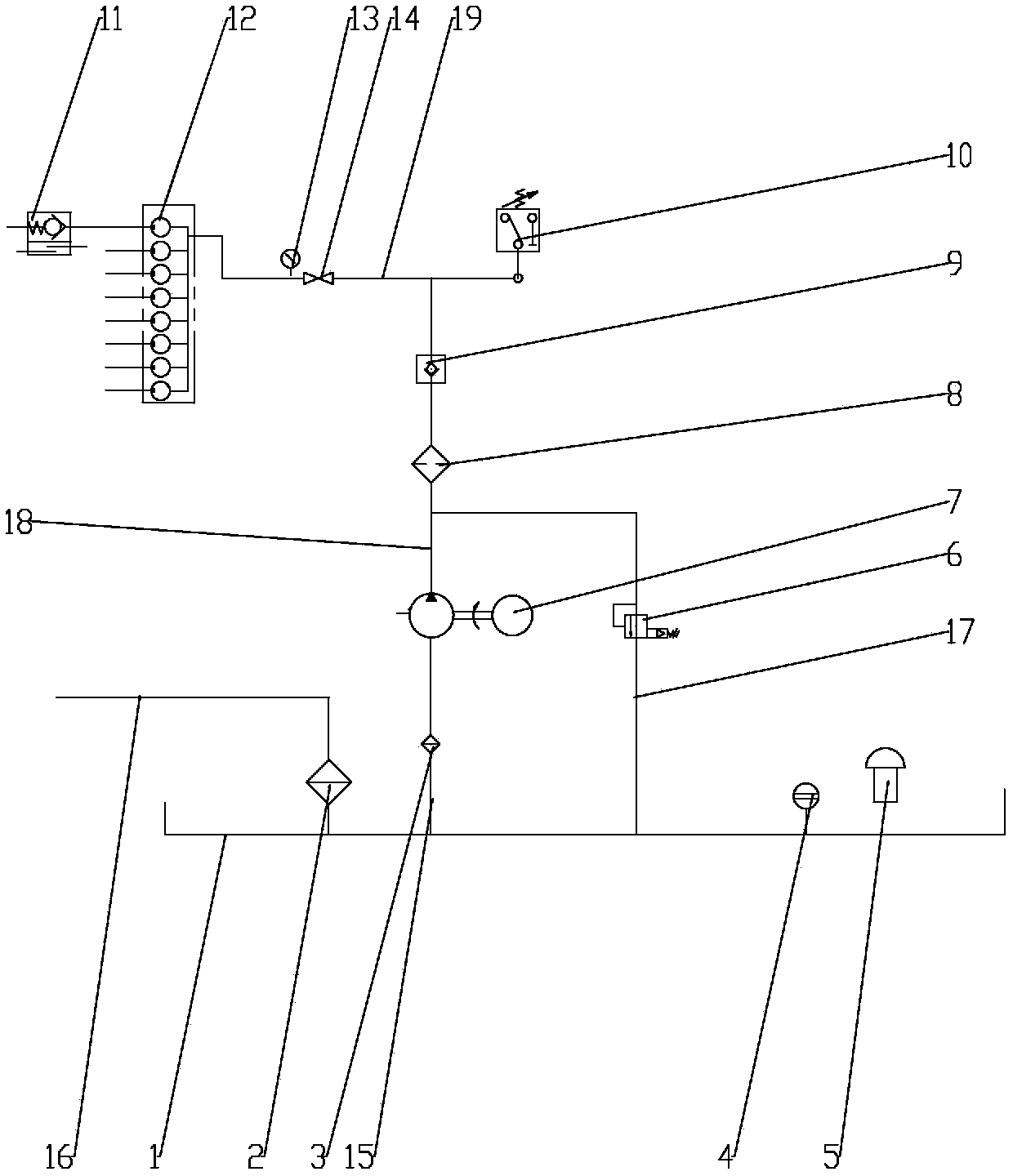

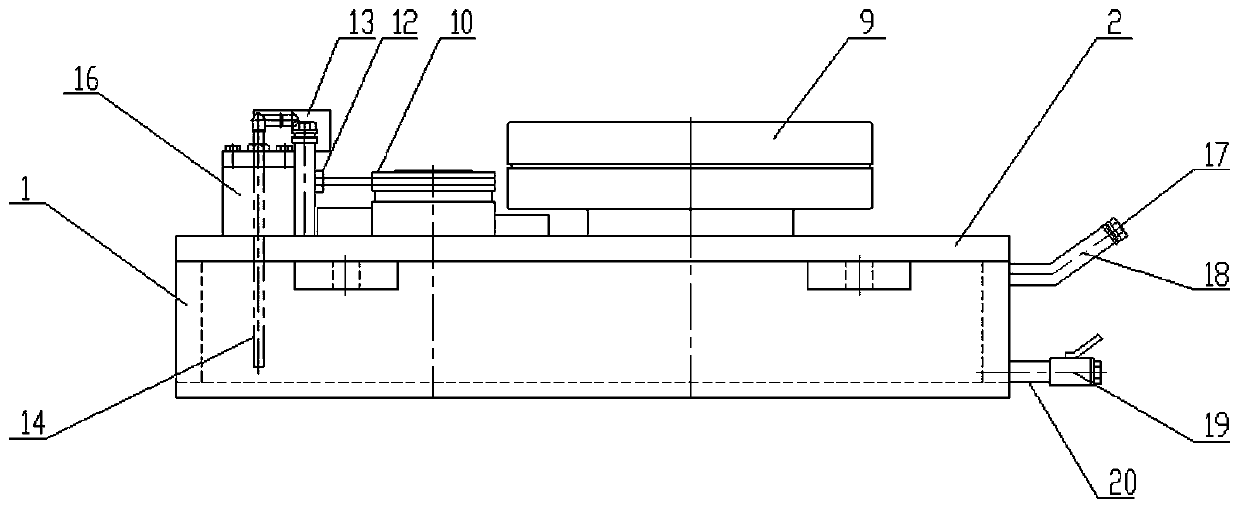

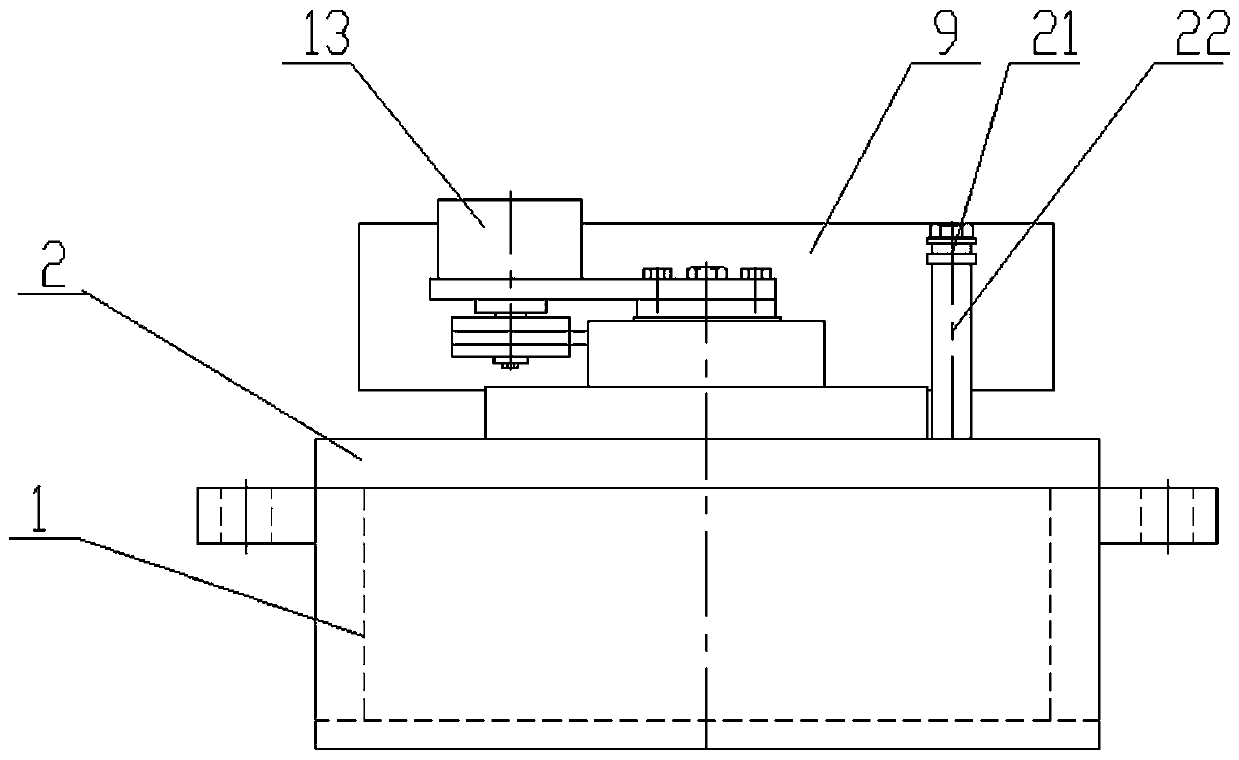

Workbench guide rail lubricating system of vertical lathe

InactiveCN103722448AStable lubricationSmooth motionMaintainance and safety accessoriesFuel tankHydraulic pump

The invention relates to a lubricating system, in particular to a workbench guide rail lubricating system of a vertical lathe, and belongs to the technical field of vertical lathes. The system comprises an oil tank, wherein the oil tank is connected with a motor pump through an oil suction pipe, a motor pump overflow valve is arranged on the motor pump and is connected with the oil tank through an overflow pipe, the motor pump is connected with a one-way valve through a first hydraulic pipe, the one-way valve is connected with a multi-point gear oil distributor through a second hydraulic pipe, the output ends of the multi-point gear oil distributor are connected with static pressure oil cavities of the workbench through the hydraulic pipes respectively, the static pressure oil cavities of the workbench are connected with the oil tank through oil return pipes, a flow pinger is connected to the multi-point gear oil distributor, and a pressure controller is connected to the second hydraulic pipe. The workbench guide rail lubricating system of the vertical lathe is simple, compact and reasonable in structure, and capable of achieving stable lubrication of a workbench, making the workbench move steadily, and improving the work stability of the vertical lathe.

Owner:WUXI JINGHUA HEAVY IND EQUIP MFG

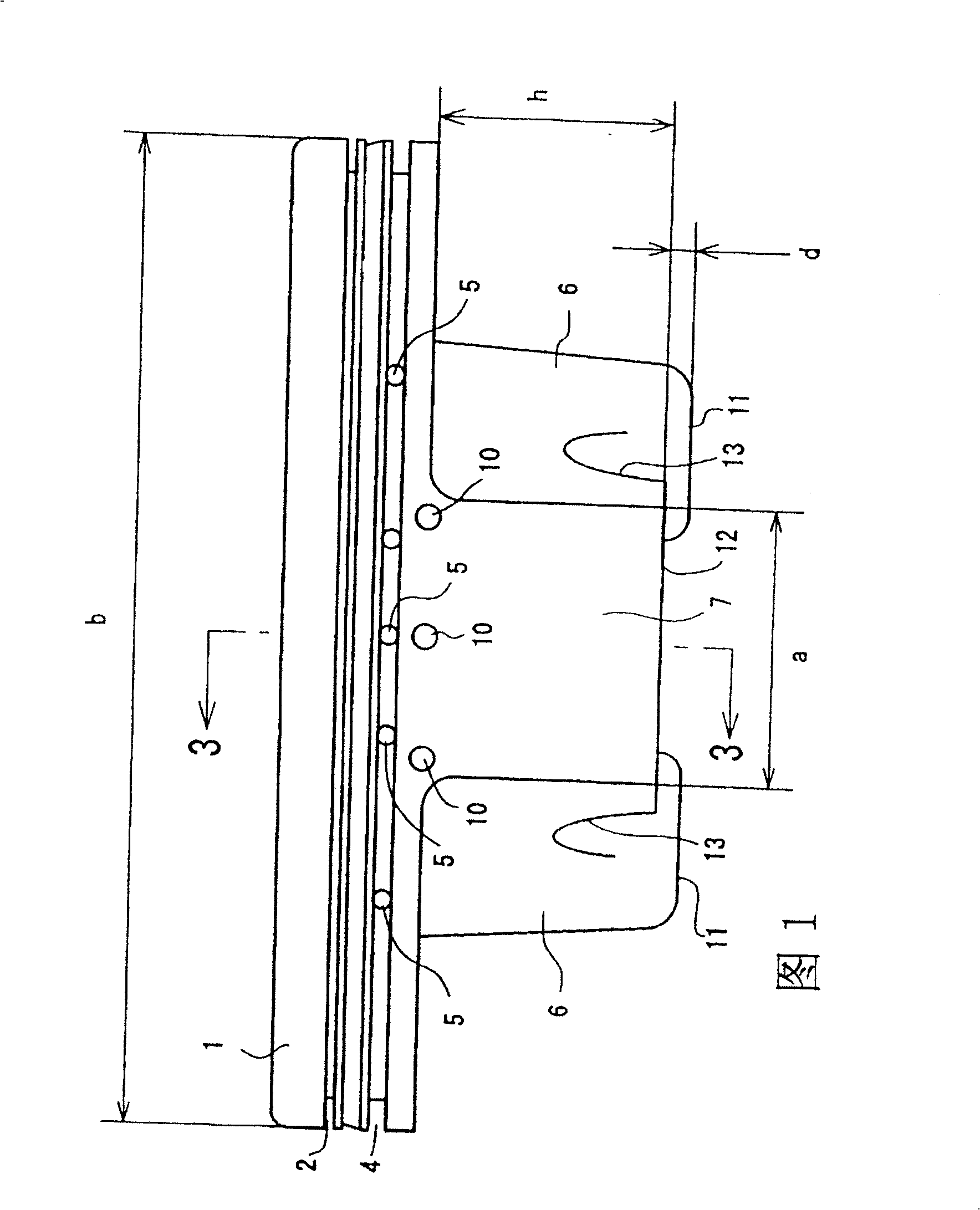

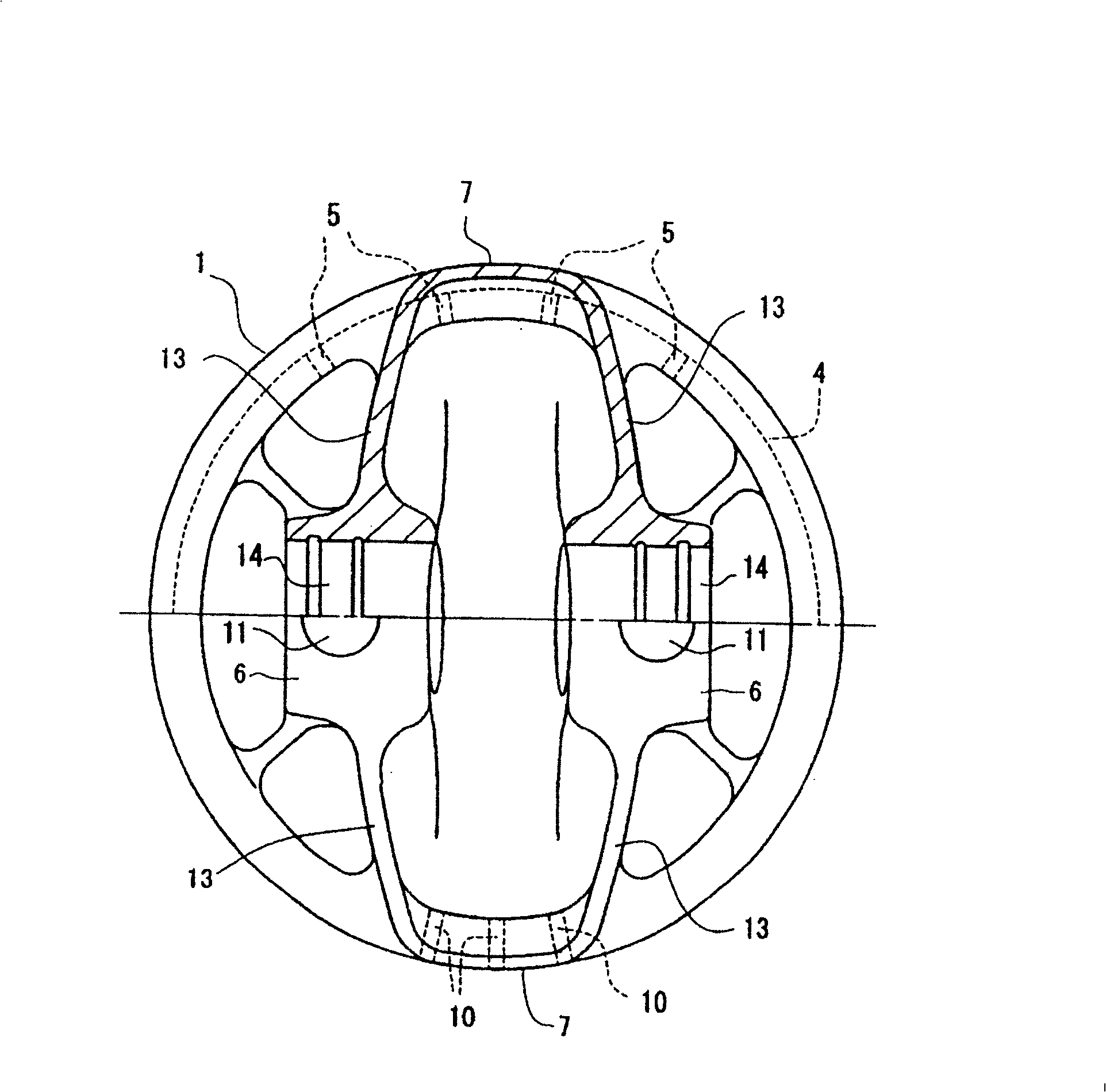

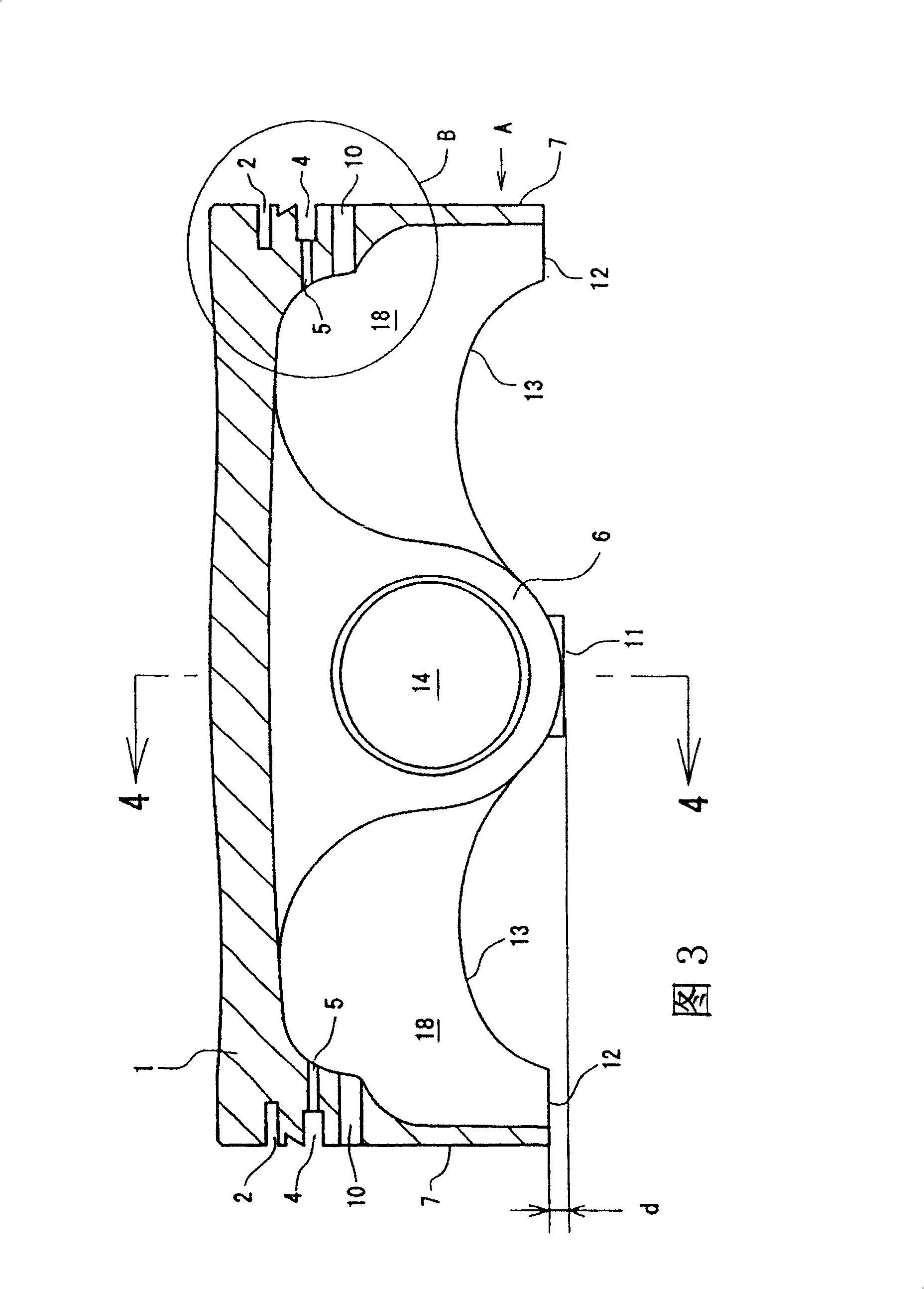

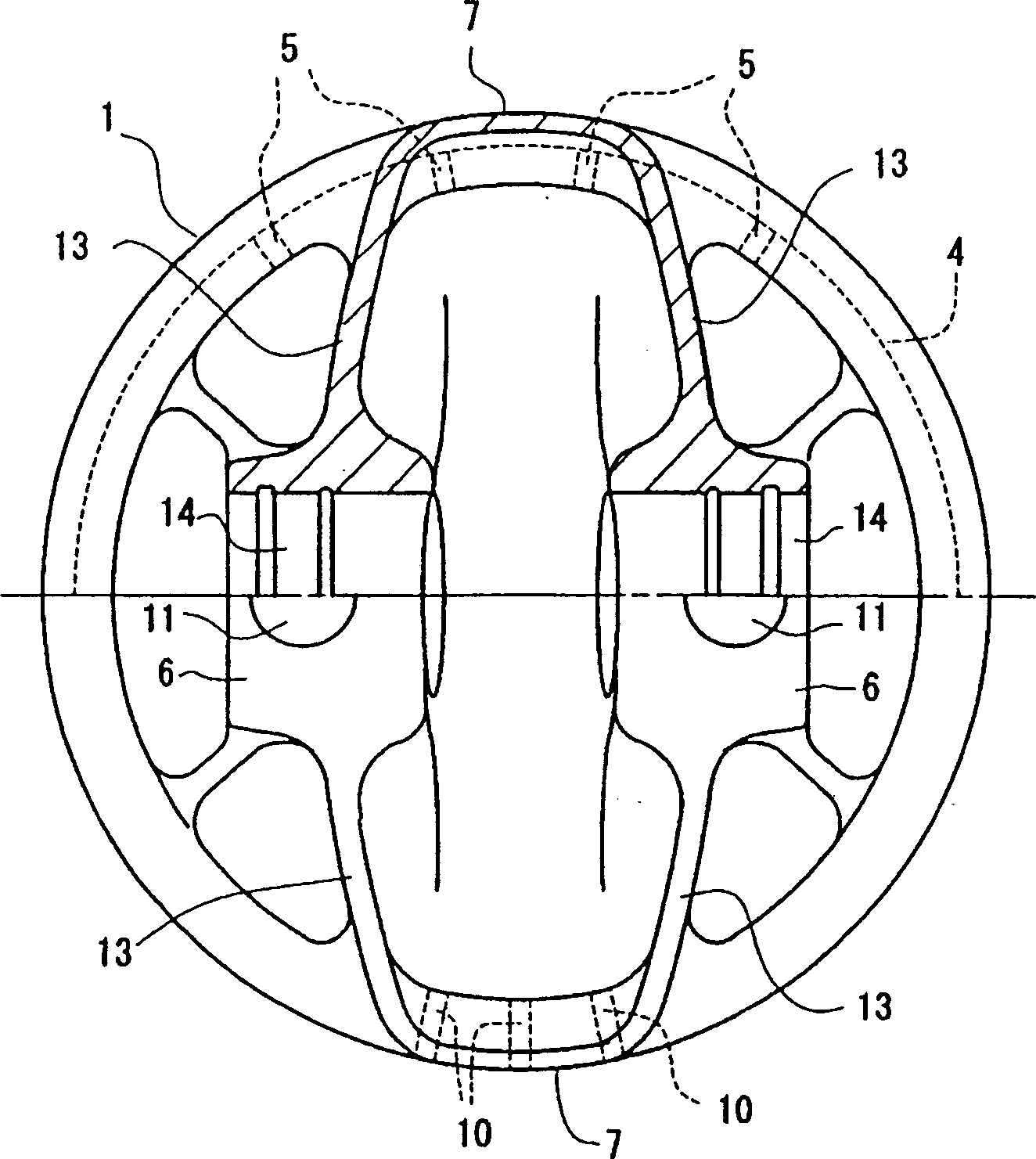

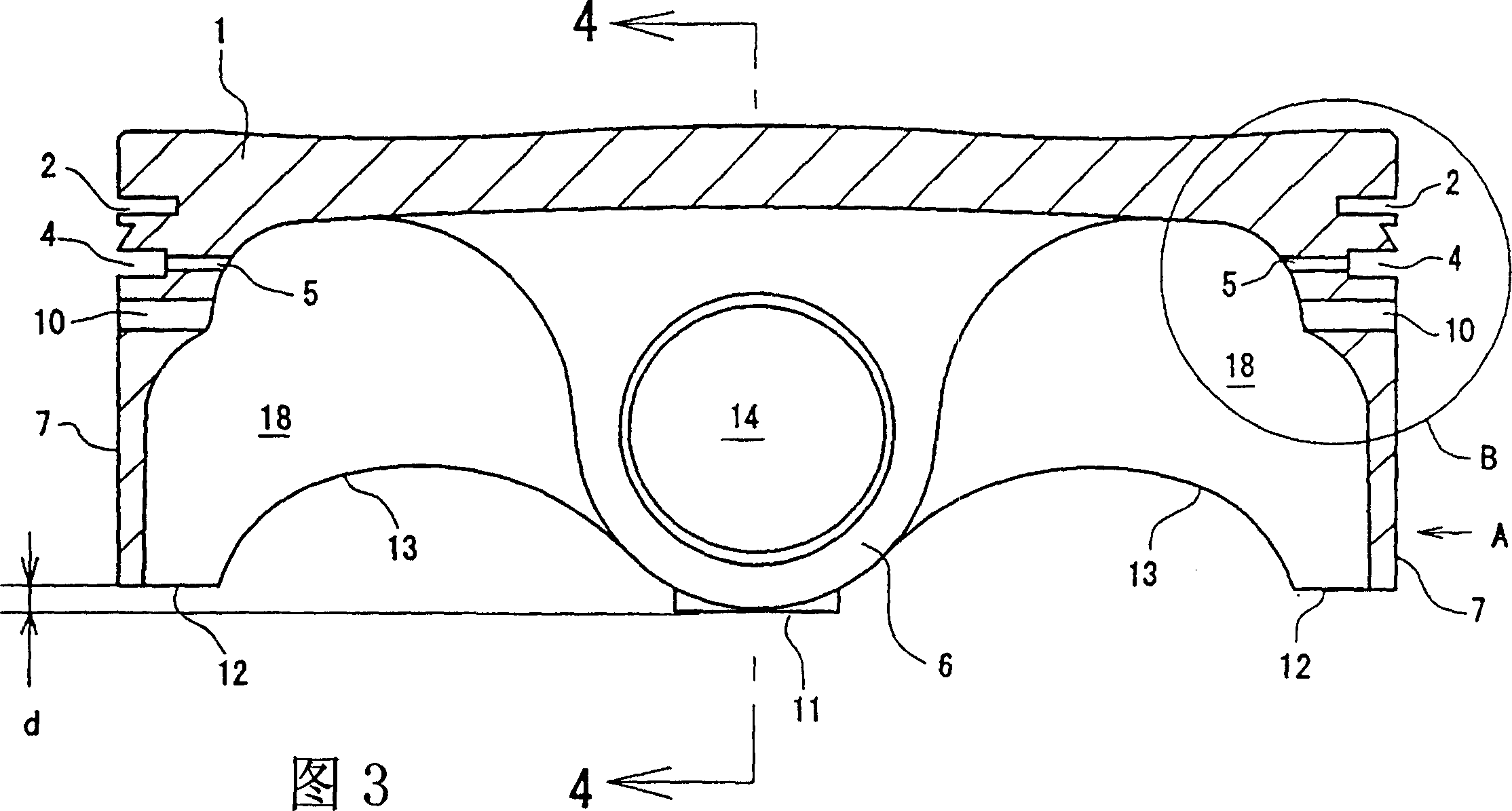

Piston for internal combustion engine

InactiveCN100476185CAvoid weight gainAchieve high rotationPlungersLubricant conduit arrangementsInternal combustion enginePiston

Owner:HONDA MOTOR CO LTD

Steam turbine bearing

InactiveCN106438679AImprove the lubrication effectEasy to useBearing componentsSliding contact bearingsOil separationLubrication

The invention belongs to the technical field of machinery, in particular, relates to a steam turbine bearing, and solves such technical problems as unreasonable design in the prior art. The steam turbine bearing comprises two bearing pads capable of splicing as a cylindrical body; annular thrust surfaces are respectively arranged at two ends of the cylindrical body; an inner lubricating structure is arranged on the inner side of the cylindrical body, and is connected with an oil supply structure arranged on the cylindrical body and capable of supplying oil to the inner lubricating structure; a thrust surface lubricating structure is arranged on the annular thrust surface; and the inner lubricating structure and the thrust surface lubricating structure are connected through an oil separation structure arranged on the cylindrical body. The steam turbine bearing has the following advantages: (1) the design is more reasonable; an oil film is formed between the bearing and a shaft body; the thrust surfaces always can be stably lubricated to effectively prevent wear thereof; and the use performance is improved; and (2) lubricating oil is used for circular lubrication, and a lubricating agent can be cooled, so that the heat dissipation can be further accelerated, meanwhile, the resource is saved, and the cost is reduced.

Owner:ZHEJIANG ZHENGSHENG BEARING

Composition for heat cycle system, and heat cycle system

InactiveCN107532072AReduce the impactStable lubricationCompression machines with non-reversible cycleChemical industryProcess engineeringFour component

Provided is a composition for heat cycle system containing a compound that contains an unsaturated bond, said composition being incombustible, and even in the event of a leakage has minimal impact onthe ozone layer and on global warming, has excellent cycle performance, and excellent safety, in addition to enabling more stable lubrication. Also provided is a heat cycle system using said composition. This composition for heat cycle system contains: a heat cycle operating medium containing trifluoroethylene, 1,1,1,2-tetrafluoroethane, pentafluoroethane and 2,3,3,3-tetrafluoropropene; and refrigeration oil. The composition for heat cycle system contains, in predetermined proportions, the four components that make up the operating medium. The heat cycle system provided uses this composition for heat cycle system.

Owner:ASAHI GLASS CO LTD

Piston for internal combustion engine

InactiveCN1384279AAvoid weight gainAchieve high rotationPlungersLubricant conduit arrangementsEngineeringInternal combustion engine

The invention discloses a piston for an internal combustion engine. The piston for high rotation is formed through lighter weight and compactness. A first air ring groove 2 and an oil ring groove 4 are formed around the crown 1, and an oil supply hole 5 is provided inside the oil ring groove 4, and a pair of air ring grooves 5 are arranged at positions opposite to the bottom of the crown 1 continuously. The piston pin seat 6 is provided with a skirt 7 staggered by 90 degrees from the piston pin seat 6, the lower end 12 of the skirt 7 is located above the lower end 11 of the piston pin 6, and on the upper part of the skirt 7, the oil An oil supply hole 10 is provided below and near the ring groove 4 .

Owner:HONDA MOTOR CO LTD

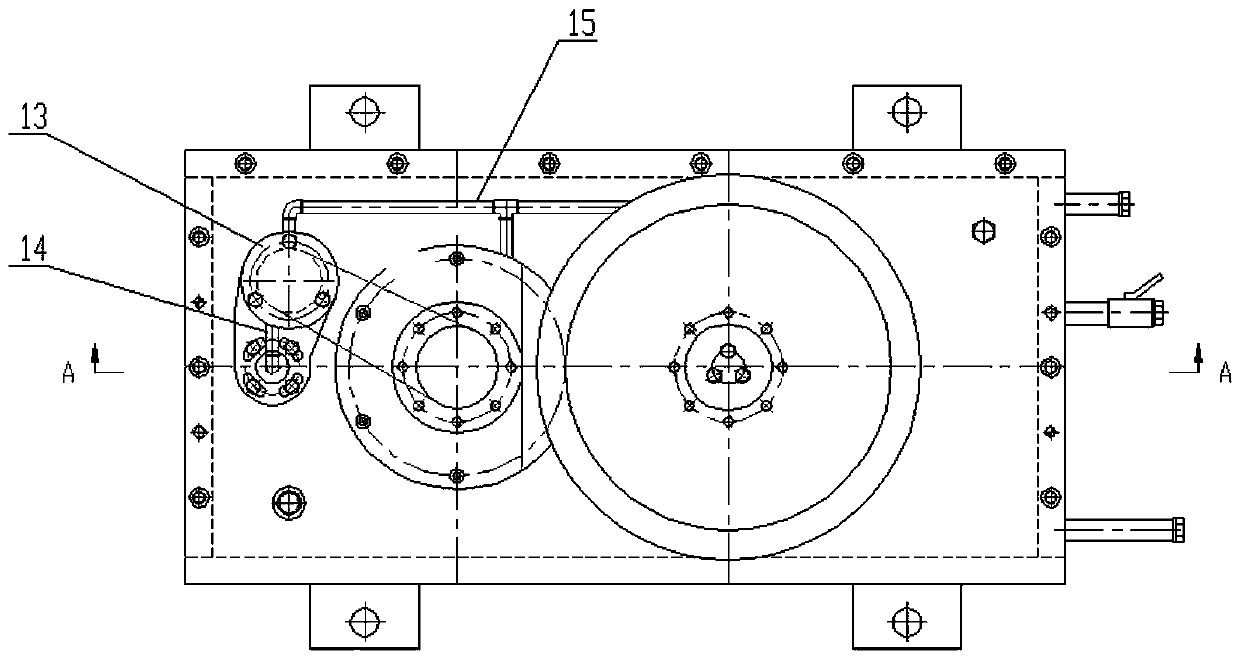

Reducer for copper tube machining

The invention relates to a reducer for copper tube machining. An input shaft and an output shaft are parallel to each other, and are vertically connected with a box cover in a penetrating mode througha penetrating cover by an upper bearing and a lower bearing to be arranged in a box body in a supported mode. The input shaft and the output shaft are driven by a gear set. The upper end of the inputshaft protrudes from the box cover and is in key connection with an input belt wheel driven by a motor through a belt pulley. The upper end of the output shaft protrudes from the box cover, and a shaft section of the extended part of the output shaft is connected with a lubrication driving wheel in a penetrating mode. A multi-plate two-way lubricating pump is arranged on the box cover through a supporting seat. A pump shaft of the multi-plate two-way lubrication pump is provided with a lubrication driven wheel driven by the lubrication driving wheel through a belt. An inlet of the multi-platetwo-way lubrication pump extends to the lower part of the box body through an oil inlet pipe, an outlet of the multi-plate two-way lubrication pump is connected to the corresponding gear set in the box body through a high-pressure oil pipe and / or connected to the upper bearing communicating with the penetrating box. The structure is simple, the lubrication is sufficient, and effect is good.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

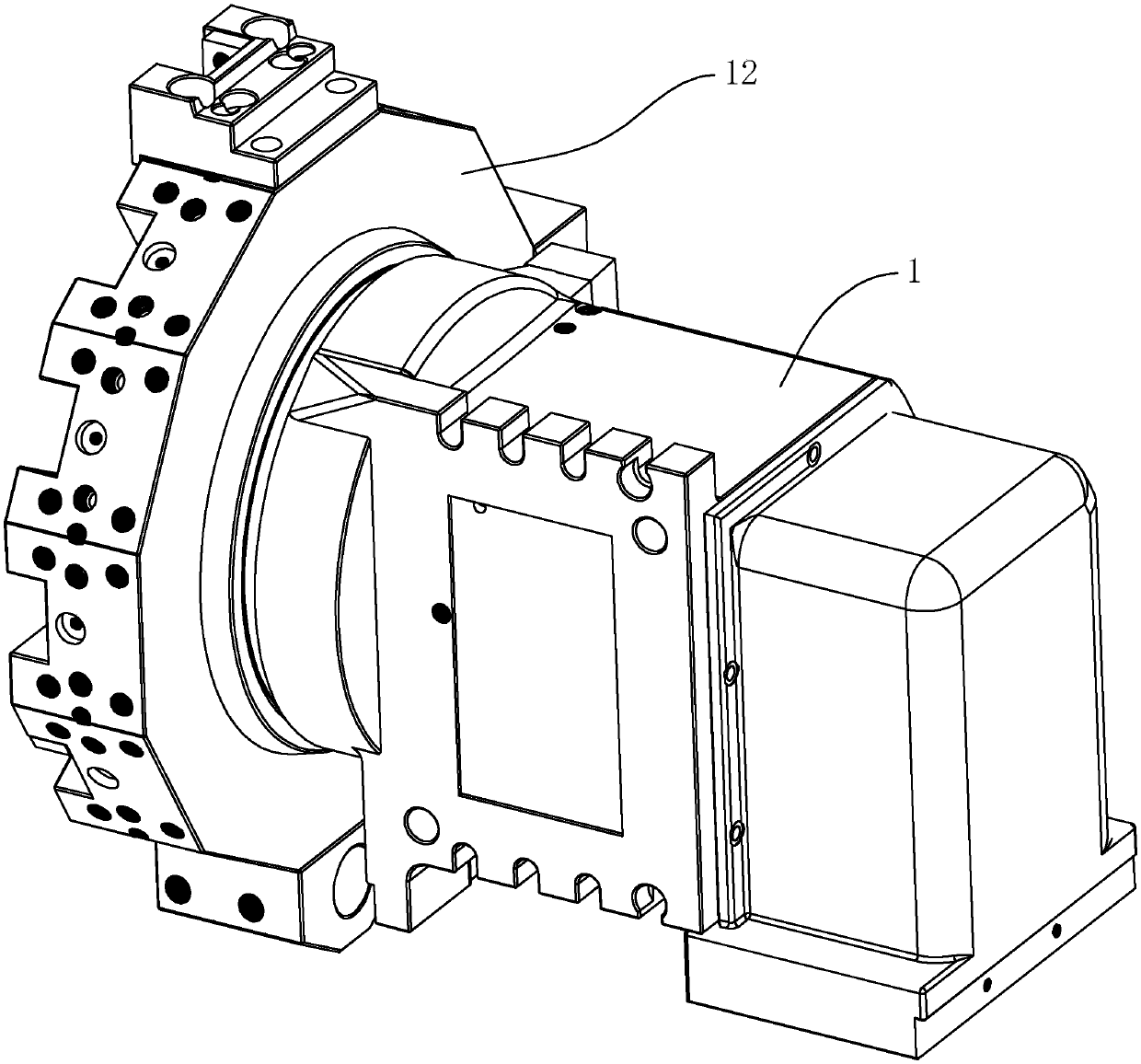

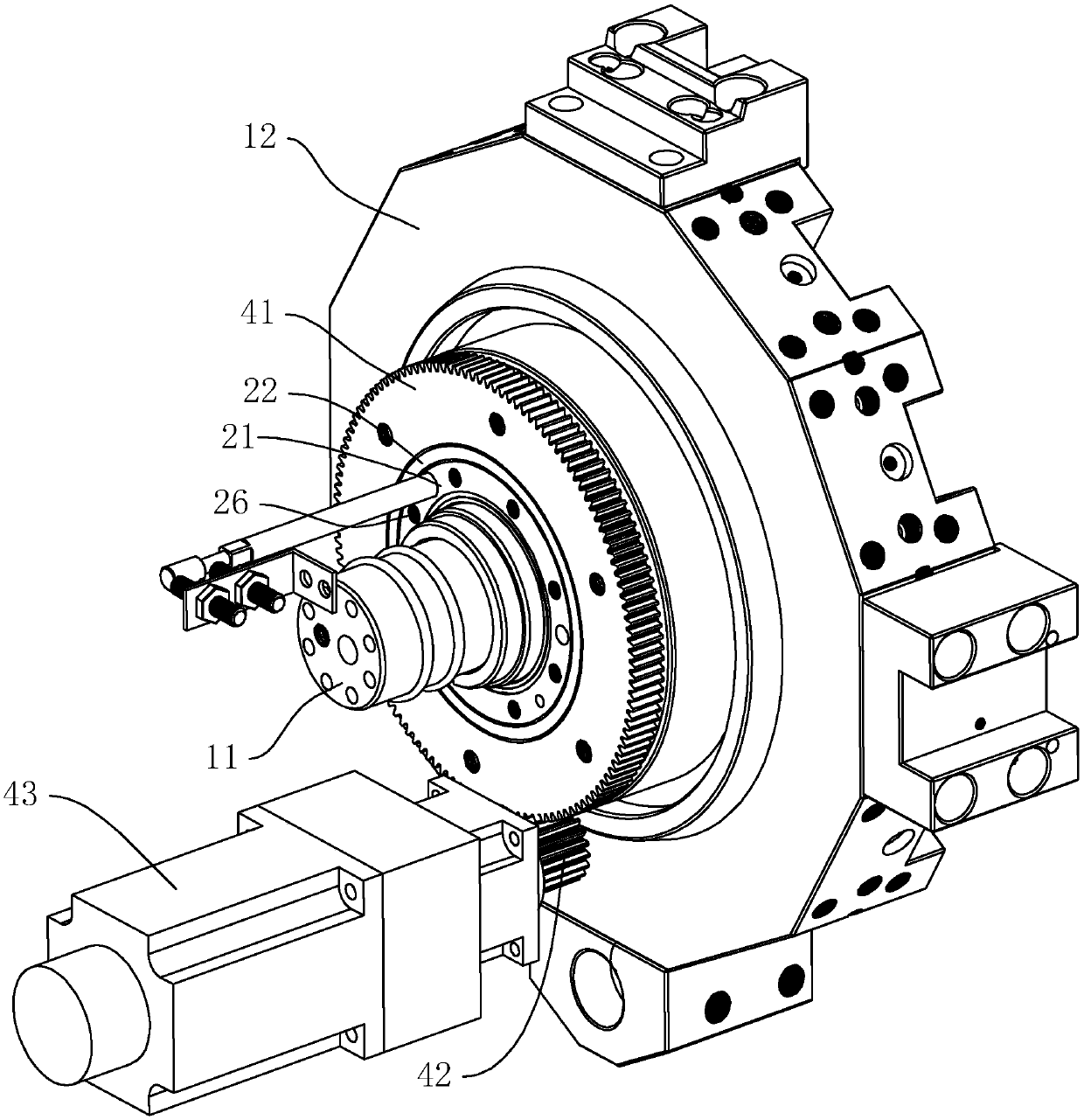

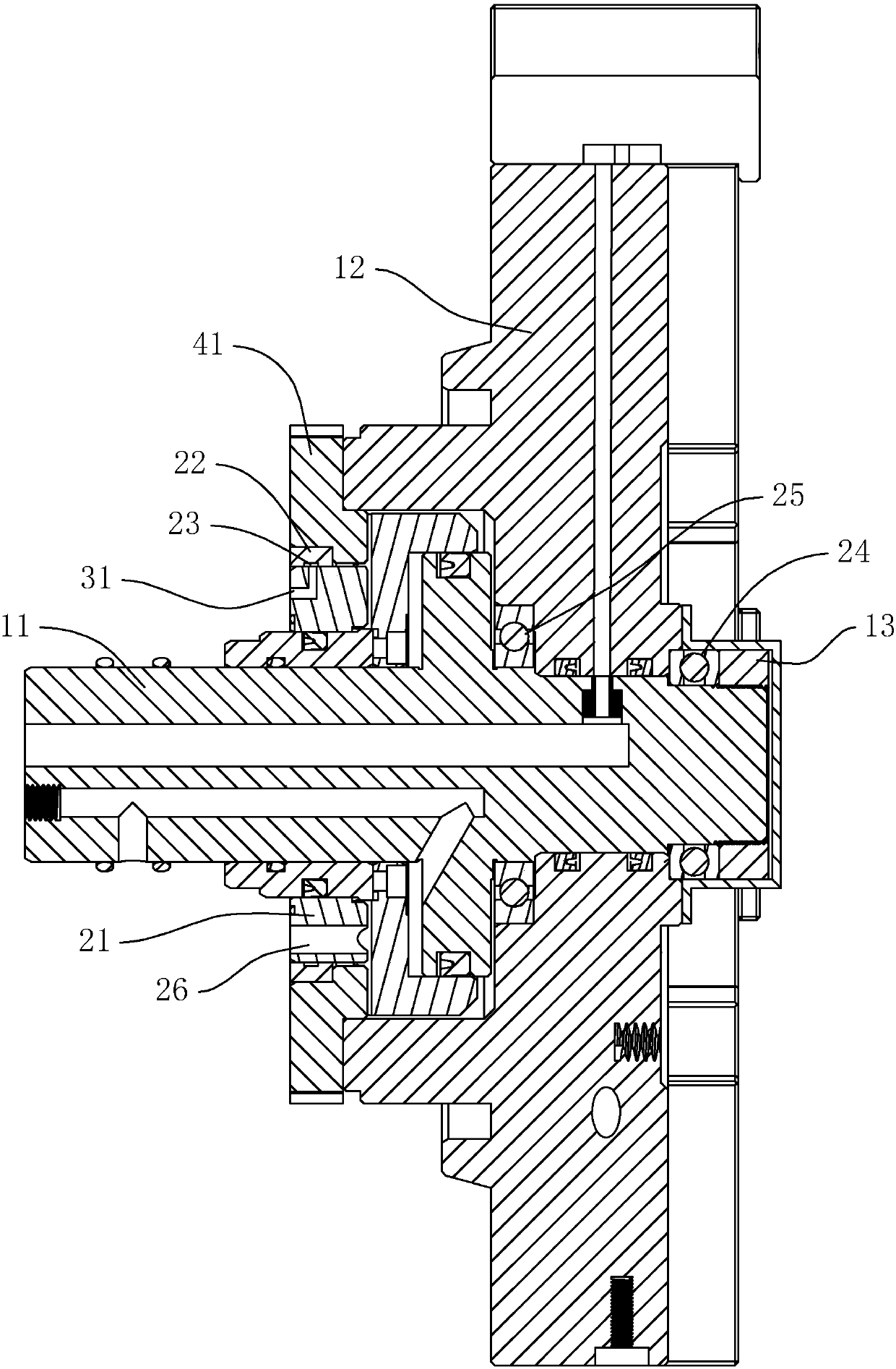

Stable-running lathe turret assembly

The invention discloses a stably-running lathe tool turret assembly. According to the technical scheme, the stably-running lathe tool turret assembly is characterized in that a machine shell is included and provided with a fixed shaft; an annular tool disc capable of rotating around the fixed shaft is arranged on the outer portion of the fixed shaft in a sleeving manner; a gear disc is coaxially and fixedly arranged on the tool disc; a drive motor used for driving the gear disc is arranged in the machine shell; a mounting ring is fixedly arranged on the machine shell; the gear disc is arranged on the outer wall of the mounting ring in a sleeving manner; and a sliding bearing is arranged between the mounting ring and the gear disc. In the rotating process, the tool disc is high in stability, and tool disc pressure dispersion is uniform.

Owner:台州开启精密机械有限公司

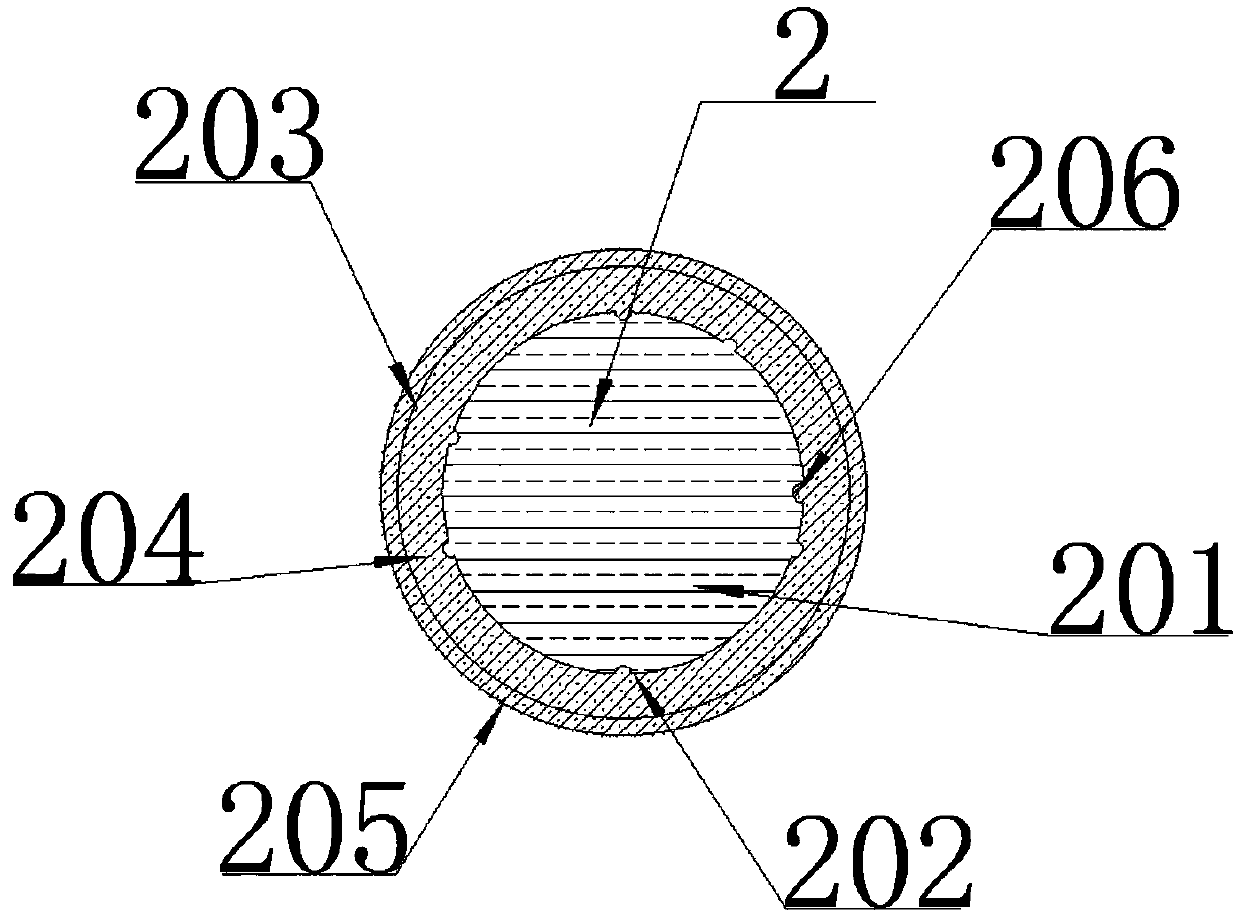

Bushing, roller pin assembly and guide piston assembly

InactiveCN112253616APrevent oxidative deteriorationGuaranteed Lubrication FunctionPositive displacement pump componentsBearing componentsEngineeringStructural engineering

The invention discloses a bushing, a roller pin assembly and a guide piston assembly, the bushing comprises a cylindrical bushing body, the inner wall of the bushing body is provided with an inner lubricating oil groove, and the outer wall of the bushing body is provided with an outer lubricating oil groove. A lubricating oil hole used for communicating the inner lubricating oil groove with the outer lubricating oil groove is further formed in the bushing body, and the inner lubricating oil groove and the outer lubricating oil groove are both grooves which are through front and back in the axial direction. The roller pin assembly and the guide piston assembly each comprise one bushing. The bushing, the roller pin assembly and the guide piston assembly provided by the invention have the advantages of being high in reliability, good in lubricating performance, long in service life, simple in structure and convenient to produce and machine.

Owner:CHONGQING HONGJIANG MACHINERY

Self-lubricating bearing copper mesh and manufacturing method thereof

PendingCN109253166AGood lubrication effectLong-lasting and reliable workBearing componentsLubricationCopper wire

The invention relates to a self-lubricating bearing copper mesh and a manufacturing method thereof. The self-lubricating bearing copper mesh is formed by carrying out warp and weft cross weaving on aplurality of copper wires, wherein the copper wire comprises a copper wire body, the outer surface of the copper wire body is pressed by external force to form a concavo-convex attached surface, and the attached surface is covered with a wear-resistant lubricating graphite layer. According to the present invention, the graphite layer can be firmly wrapped on the copper wire body due to the presence of the attached surface, the graphite layer forms graphite powder during the rotational friction due to the presence of the graphite layer, and the graphite powder lubricates the rotational friction, such that the lubrication effect is good.

Owner:江苏新风网业有限公司

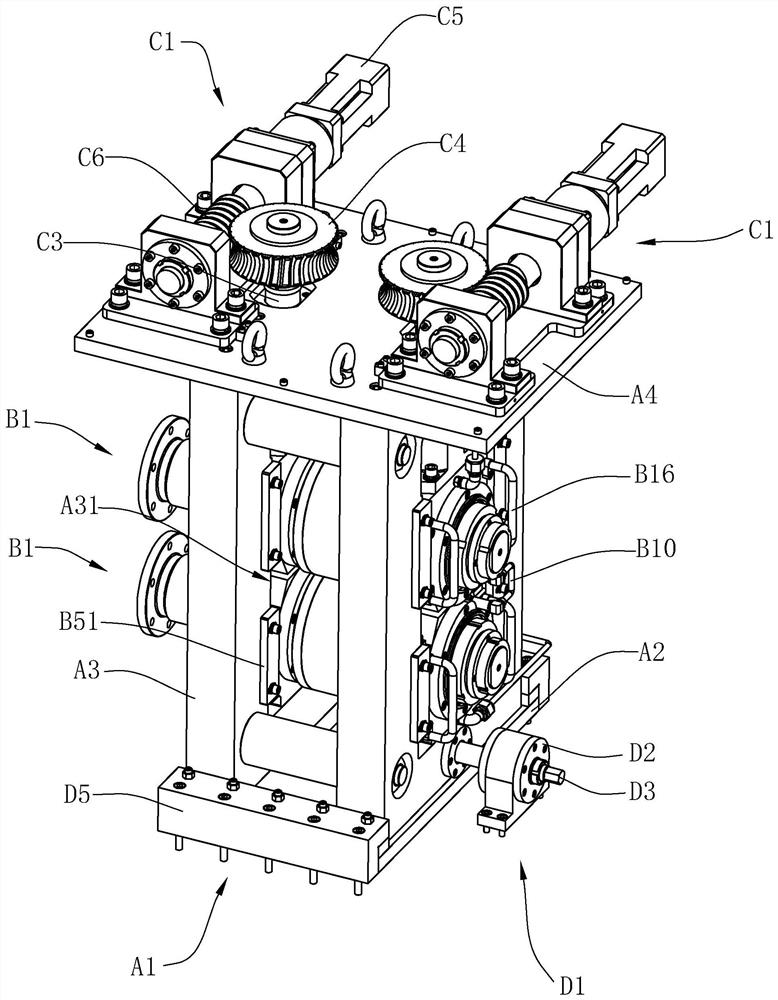

Horizontal type two-roller rolling mill with rapid roller changing function

PendingCN111774420AImprove stabilityHigh precisionMetal rolling stand detailsMetal rolling arrangementsClassical mechanicsStructural engineering

The invention relates to a horizontal type two-roller rolling mill with a rapid roller changing function. The horizontal type two-roller rolling mill comprises a rack and rolling units, wherein each rolling unit comprises a left roller support assembly, a roller assembly and a right roller support assembly which are sequentially arranged in the horizontal direction, each left roller support mechanism comprises a left roller seat, a left bearing and a left shaft sleeve which are sequentially arranged from outside to inside, the left shaft sleeve is hollow inside, the end, facing the roller assembly, of the left shaft sleeve extends to form an inserting block, and the left roller seat is embedded into a mounting groove in a sliding manner; each roller support assembly comprises a right roller seat, a right bearing and a right shaft sleeve which are sequentially arranged from outside to inside, the right shaft sleeve is hollow in side, and the right roller seat is embedded into the mounting groove in a sliding manner; and two ends of each roller assembly are coaxially inserted into the corresponding left shaft sleeve and right shaft sleeve in a sliding manner, the roller assemblies are provided with inserting grooves matched with the inserting blocks, and therefore, the roller assemblies can be rapidly disassembled and can be changed.

Owner:南通瑞格精密机械有限公司

Cleaning solution for aqueous grinding

The invention discloses a cleaning solution for aqueous grinding, which takes sodium ethylenediamine tetraacetate as a main agent, an alcohol ether surfactant and oleylamine as grinding activating agents, liquid alkane as lubrication and protection synergist, and alcohols and de-ionized water as solvents. The cleaning solution provided by the invention has the advantages of low cost, no toxin, no harm, no corrosion on the skin, no stimulation, no danger on human body and no pollution on the environment; the cleaning solution can provide stable lubrication in the process of electromagnetically grinding and has good washing capability and contamination resistance on oil for processing; the cleaning solution is good for protecting magnetic grinding materials and work pieces, prolonging the service life of the grinding materials and shortening the grinding time; by utilizing the cleaning solution, the grinding time of the same work piece is 20% of that of the cleaning solution in the prior art, so that the use cost is reduced and the service life of the cleaning solution is longer.

Owner:AMER TECH CO LTD

Surface lubrication and maintenance device for mechanical equipment

ActiveCN110873274ASimple and quick way to adjust the positionStable lubricationEngine lubricationBall screwEngineering

The invention relates to the technical field of lubricating maintenance devices, and discloses a surface lubrication and maintenance device for mechanical equipment. The surface lubrication and maintenance device comprises a base; the bottom of the base is fixedly provided with universal wheels, the top of the base is fixedly provided with a back plate, the left side of the back plate is fixedly provided with a handle, the right side of the back plate is fixedly provided with a protective box located at the top of the base, an inner fixed mounting head of the protective box is located at an oil tank at the top of the base, the top of the base is provided with a sliding groove located on the right side of the protective box, a sliding block is movably mounted in the groove of the sliding groove, and the top of the sliding block is fixedly provided with a top block. According to the surface lubrication and maintenance device for the mechanical equipment, the sliding groove, the sliding block and the top block are arranged at the top of the base, the position can be adjusted by effectively ensuring that a driver, a ball screw, a screw rod sleeve, an anti-falling block and the like onthe top block can move left and right laterally, the lubrication effect can be improved to a great extent, and the mode of adjusting the position is simple and rapid.

Owner:WENZHOU UNIV OUJIANG COLLEGE

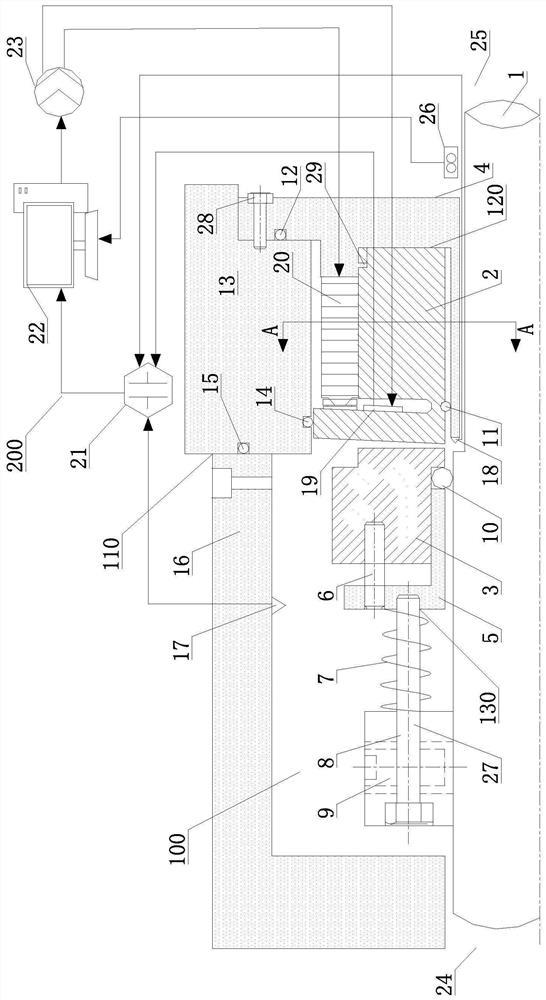

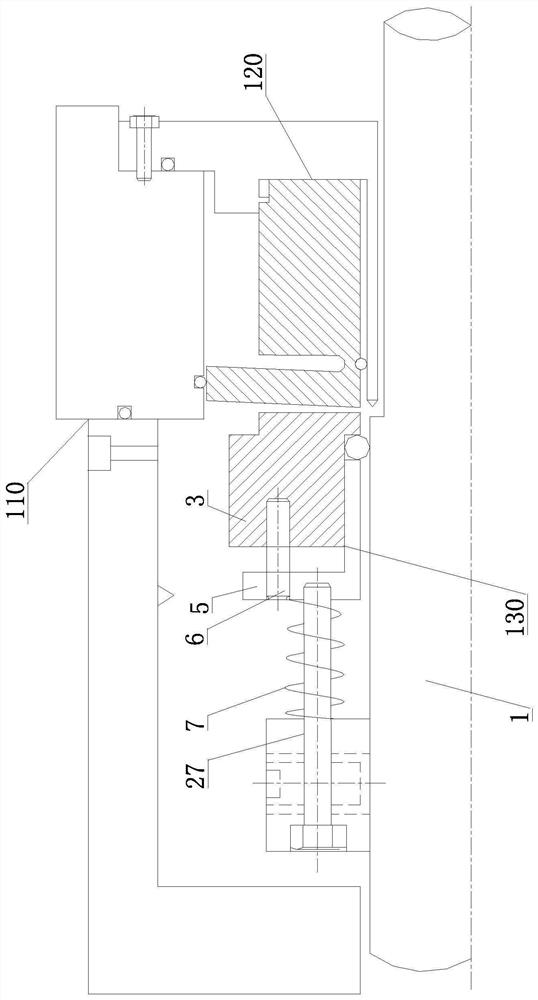

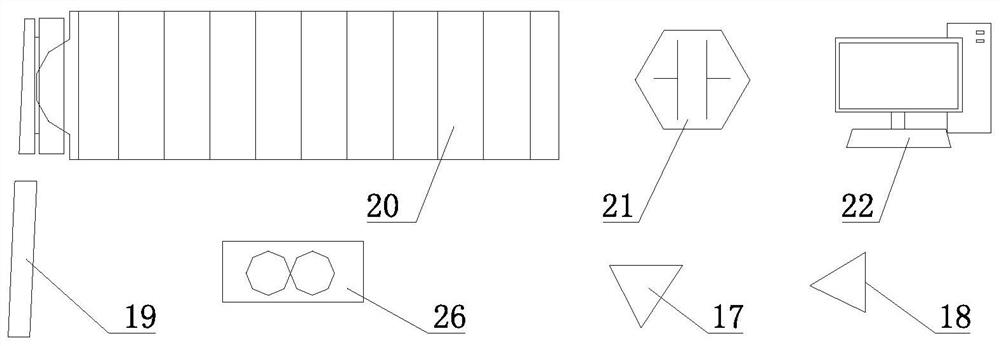

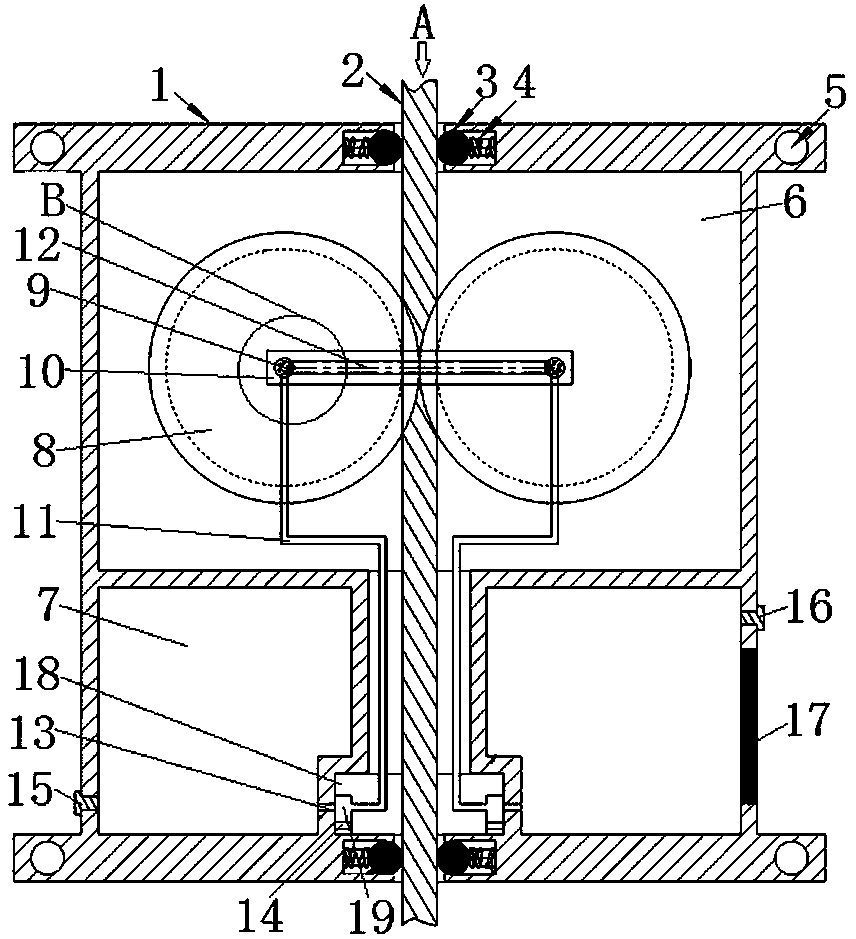

Thermal oxidation rotary valve for waste gas treatment

PendingCN114719047AAir bufferStable lubricationDiaphragm valvesEngine diaphragmsRotary valveEngineering

The invention discloses a thermal oxidation rotary valve for waste gas treatment. The thermal oxidation rotary valve comprises a stator part; a rotor portion; the sealing mechanism is arranged between the stator part and the rotor part and is used for sealing when the stator part and the rotor part move relatively; the transmission mechanism is in transmission connection with the rotor part and used for driving the rotor part to move; the air distribution plate is mounted at the upper ends of the stator part and the rotor part and is used for sealing the rotary valve; the air distribution barrel is mounted above the air distribution plate and is used for discharging waste gas and feeding clean gas; the air bag adjusting mechanism is connected with the rotor part and used for adjusting the gap and friction force between the rotor part and the air distribution plate. According to the rotary valve, the air bag adjusting mechanism is arranged, due to soft adjustment, the relative position of the rotor part and the air distribution plate can be automatically adjusted, automatic alignment and leveling can be achieved, and the pressure and the gap between the rotor part and the air distribution plate can be adjusted by controlling the pressure of compressed air through the air bag adjusting mechanism.

Owner:青岛光华环保科技有限公司

Turbine Bearings

InactiveCN106438679BImprove the lubrication effectEasy to useBearing componentsSliding contact bearingsOil separationEngineering

The invention belongs to the technical field of machinery, in particular, relates to a steam turbine bearing, and solves such technical problems as unreasonable design in the prior art. The steam turbine bearing comprises two bearing pads capable of splicing as a cylindrical body; annular thrust surfaces are respectively arranged at two ends of the cylindrical body; an inner lubricating structure is arranged on the inner side of the cylindrical body, and is connected with an oil supply structure arranged on the cylindrical body and capable of supplying oil to the inner lubricating structure; a thrust surface lubricating structure is arranged on the annular thrust surface; and the inner lubricating structure and the thrust surface lubricating structure are connected through an oil separation structure arranged on the cylindrical body. The steam turbine bearing has the following advantages: (1) the design is more reasonable; an oil film is formed between the bearing and a shaft body; the thrust surfaces always can be stably lubricated to effectively prevent wear thereof; and the use performance is improved; and (2) lubricating oil is used for circular lubrication, and a lubricating agent can be cooled, so that the heat dissipation can be further accelerated, meanwhile, the resource is saved, and the cost is reduced.

Owner:ZHEJIANG ZHENGSHENG BEARING

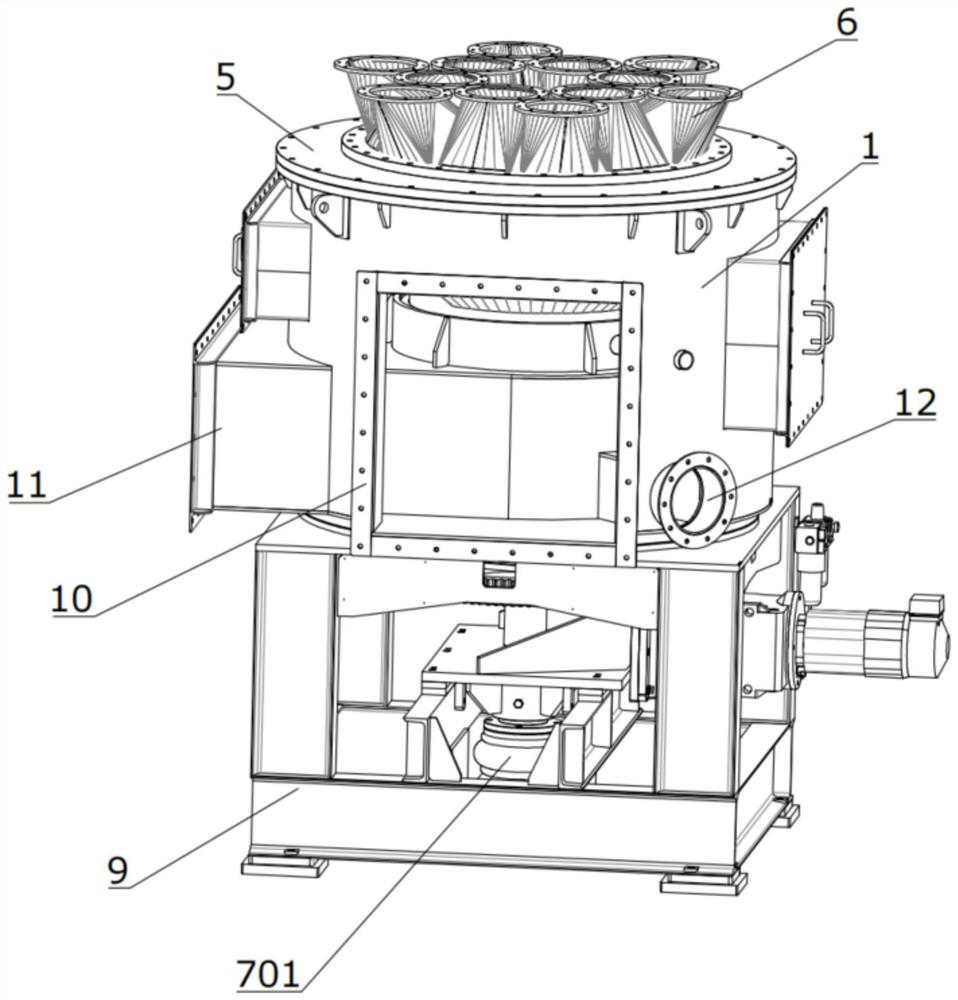

Mobile Intelligent Lubricating Device for Fixed Belt Conveyor

The invention provides a movable intelligent lubricating device for a fixed belt conveyor. The device comprises a vehicle frame, a plunger pump is fixed to the vehicle frame, the power input end of the plunger pump is connected with a plunger motor through a speed reducer, the plunger motor is connected with an intelligent controller through a control wire, the pump body of the plunger pump is provided with an oil drum, an oil inlet of the pump body is made communicated with an oil outlet of the oil drum and provided with an oil inlet valve, the pump body is provided with multiple oil outlets, the top end of the oil drum is provided with an oil injection opening, the vehicle frame is provided with a walking motor, the walking motor drives a driving wheel to rotate through a transmission mechanism, and the driving wheel and a driven wheel are each provided with a brake device. According to the movable intelligent lubricating device, the two motors are arranged, the two motors are controlled by the intelligent controller to drive the plunger pump and the walking wheel to work, the plunger pump can inject oil to the belt conveyor as needed for lubrication, the walking wheel drives the plunger pump and the oil drum to move in the length direction of the belt conveyor, and different portions of the belt conveyor are regularly, quantitatively and reasonably lubricated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Opening and closing system for oil path of linear compressor

InactiveCN1093918CStable lubricationPositive displacement pump componentsPumpsReciprocating motionLinear compressor

An oil circuit opening and closing system of a linear compressor, which can help to supply oil smoothly during the operation of the compressor, and when the compressor is suspended, part of the oil that has been supplied to the compressor is retained in it, so that Helps with smooth lubrication during compressor restart. It includes: a sealed container filled with oil at the bottom; a frame communicated with first and second oil grooves; a cylinder; a linearly reciprocating piston with the second oil groove formed on a part of the outer peripheral surface of the piston; an exhaust cover; an oil supply communicated with the first oil tank; and a switch device for opening and closing the oil inflow passage.

Owner:LG ELECTRONICS INC

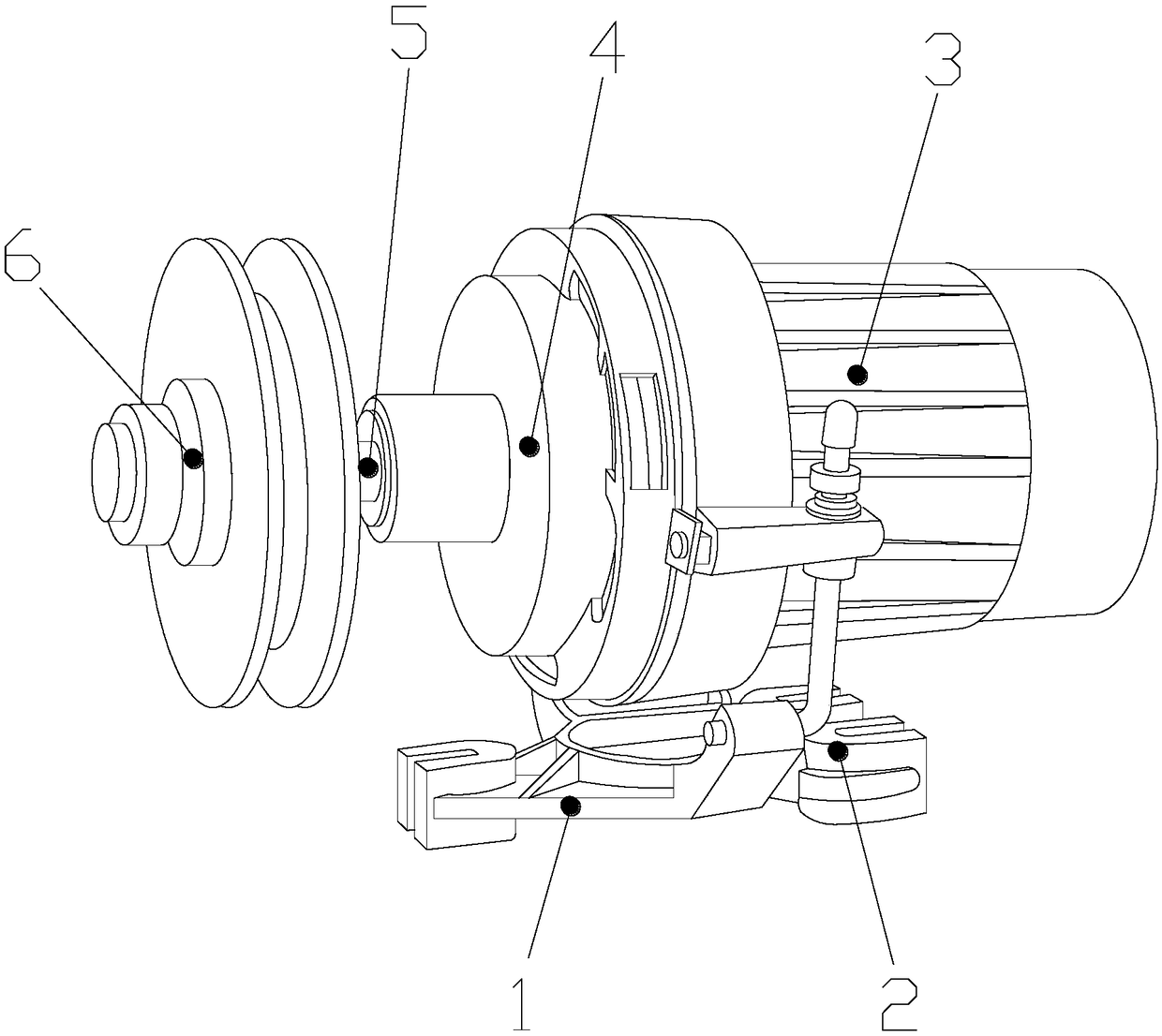

Equipment with overrun clutch

ActiveCN109099074AEasy to move verticallyAvoid deformationGear lubrication/coolingFreewheel clutchesEngineeringClutch

The invention discloses equipment with an overrun clutch. The equipment structurally comprises a fixing support, two or more fixing feet, a motor, a fixing shaft sleeve, a transmission spindle and theoverrun clutch. The middle of the upper end of the fixing support is mounted at the bottom of the fixing shaft sleeve in a welded mode, and the fixing shaft sleeve is of a circular structure and is connected with the left end of the motor in a sleeve-fit mode. The two or more fixing feet are evenly distributed at the two ends of the fixing support at equal distances. According to the overrun clutch arranged on the equipment, when a sewing machine needs to withdraw a needle, a clutch shell rotates clockwise and makes contact with a bevel face of a driven block in a driven mechanism directly topress downwards, and then needle withdrawing rotating can be conducted smoothly; and the driven mechanism transfers power into an oil seal mechanism through a transmission mechanism while being in transmission, and then an oil conveying pipe is connected for lubricating. During overall using, needle withdrawing rotating is convenient and rapid, the interior of the overrun clutch is stably lubricated, and thus the part life of clutch is prolonged.

Owner:JIANGSU TONGWEI MOTOR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com