Equipment with overrun clutch

An overrunning clutch and equipment technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of switching failure, low lubricity, reduced clutch service life, etc., to achieve stable lubrication, improve parts life, and facilitate needle withdrawal and rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

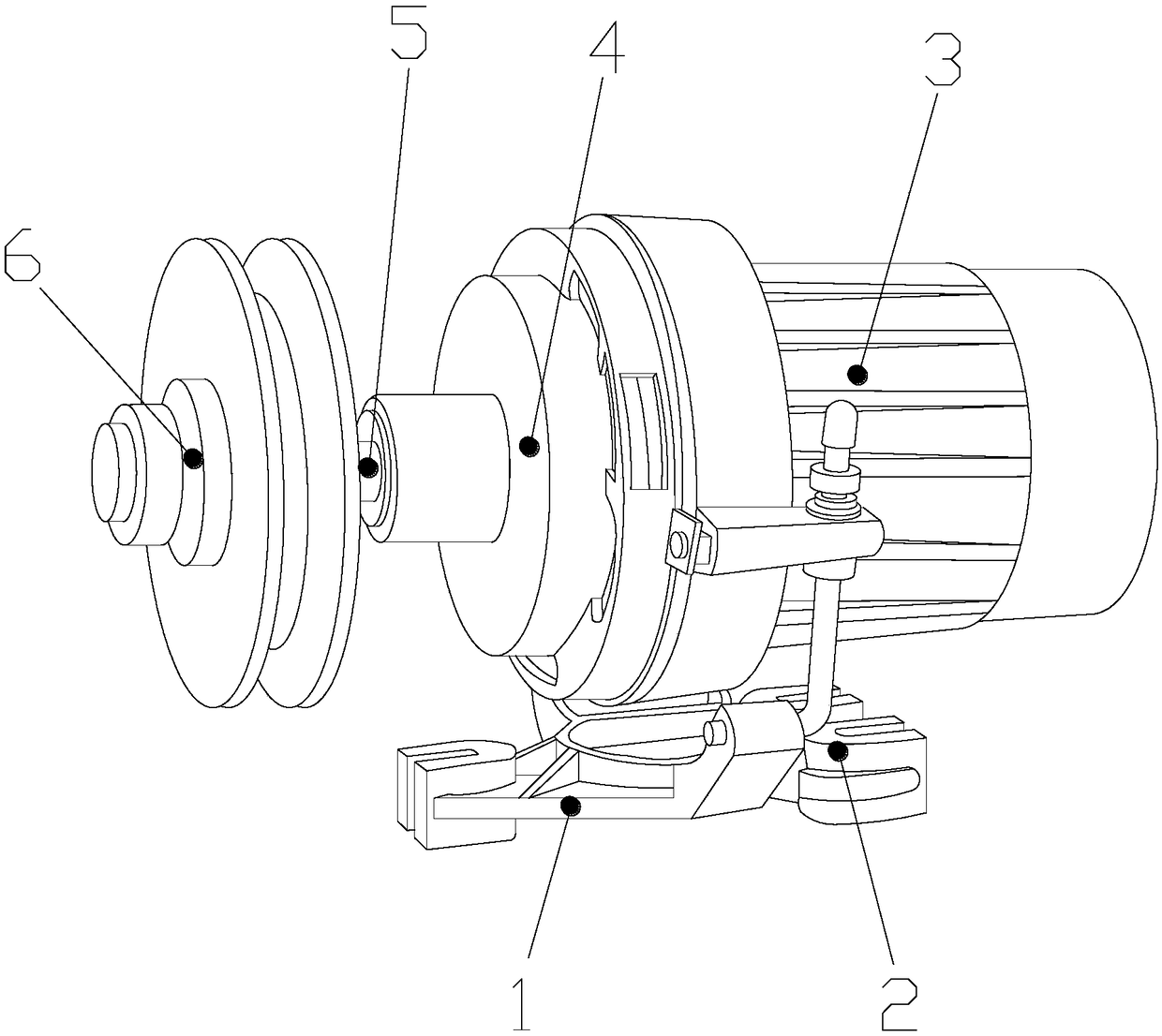

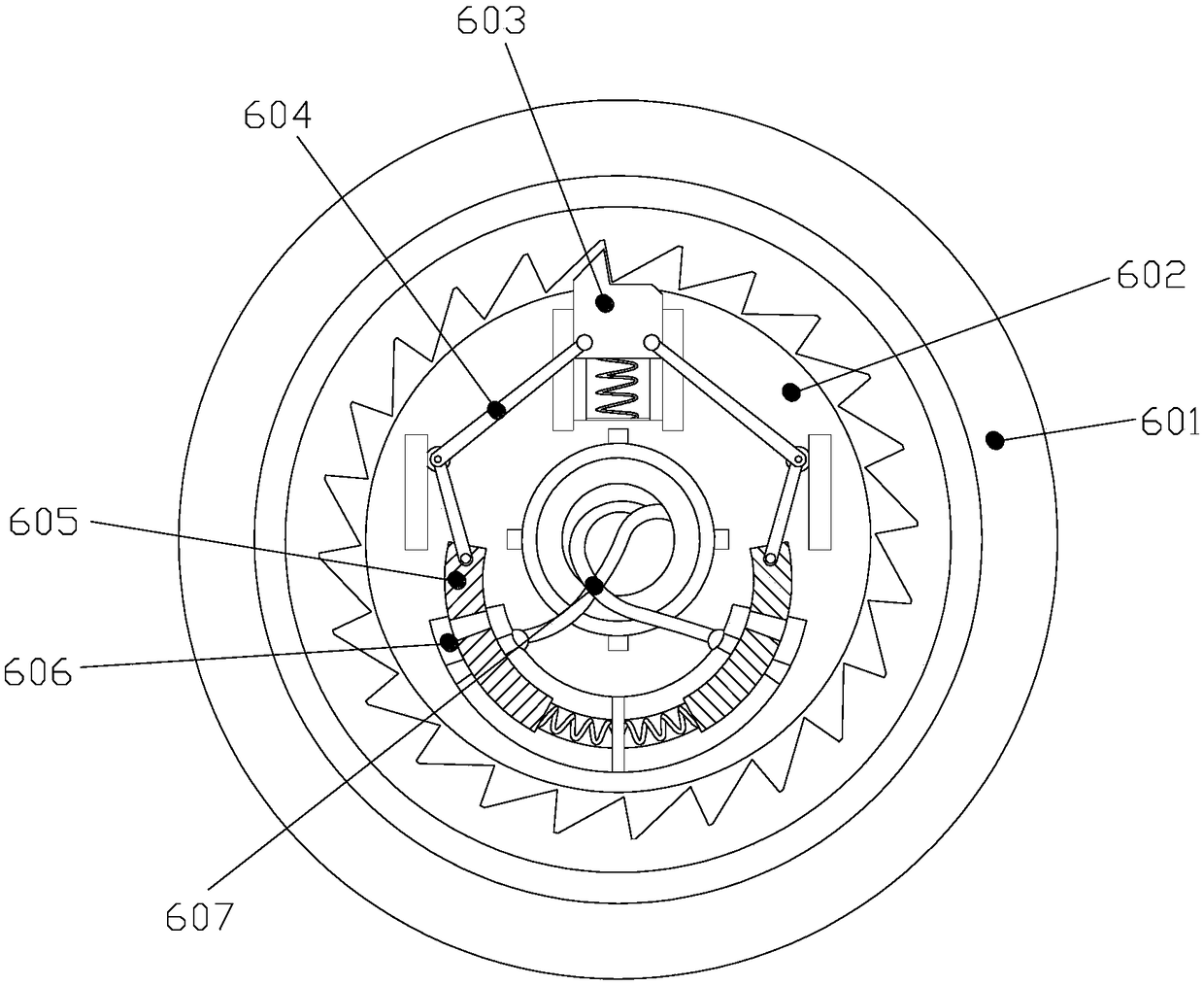

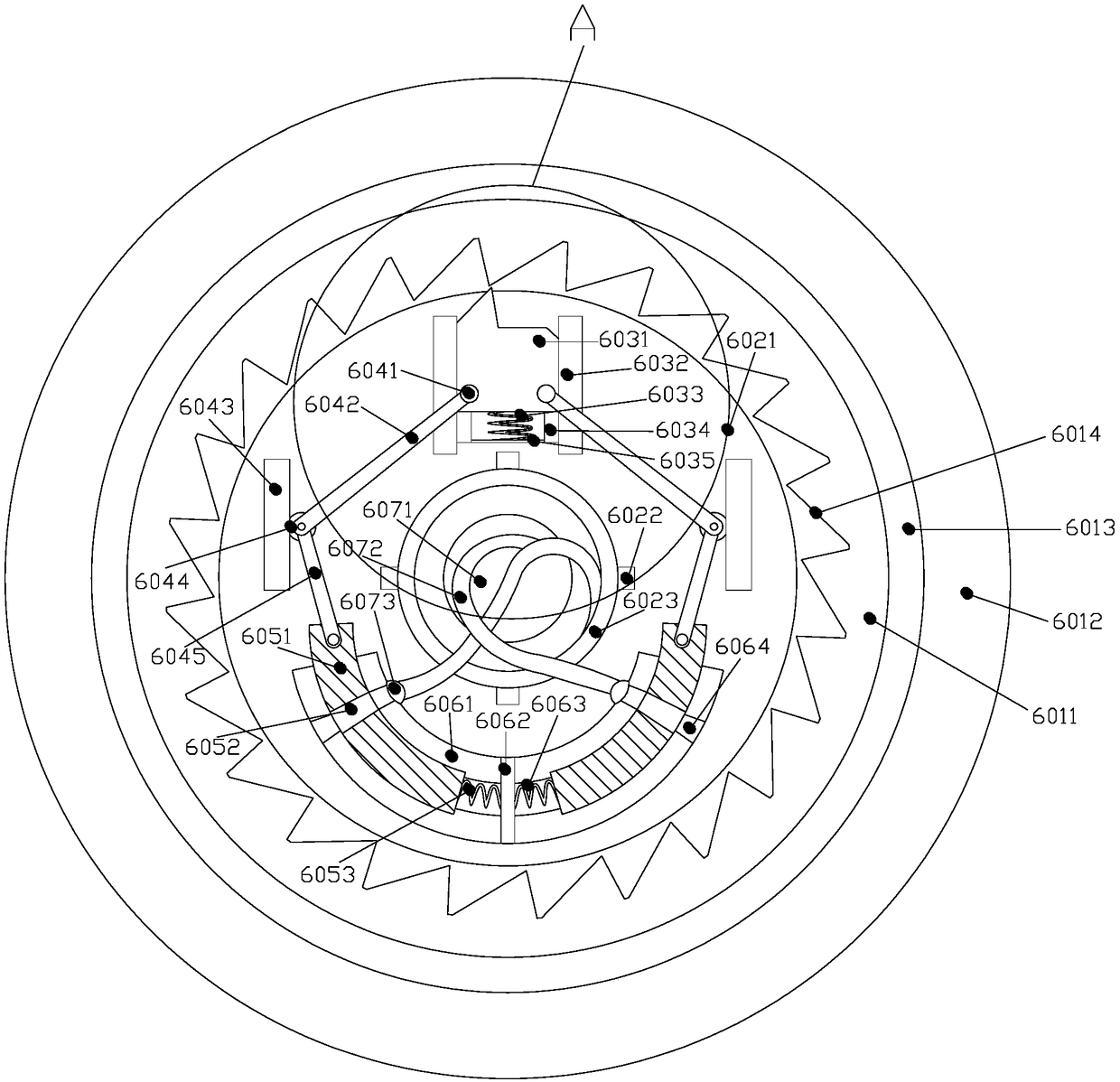

[0022] see Figure 1-Figure 4, the present invention provides equipment with an overrunning clutch, the structure of which includes a fixed support 1, a fixed foot 2, a motor 3, a fixed bushing 4, a transmission main shaft 5, and an overrunning clutch 6. The middle part of the upper end of the fixed support 1 is welded Installed on the bottom of the fixed shaft sleeve 4, the fixed shaft sleeve 4 has a circular structure, and is connected to the left end of the motor 3 by fitting, and the fixed feet 2 are provided with more than two, and are evenly and equidistantly distributed on the fixed The two ends of the support 1, the right end of the transmission main shaft 5 runs through the fixed sleeve 4 and is connected to the inside of the motor 3, and the overrunning clutch 6 is installed on the left end of the transmission main shaft 5 by fitting, and the overrunning clutch 6 includes a clutch housing 601 , a driven plate 602, a driven mechanism 603, a transmission mechanism 604,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com