Patents

Literature

178results about How to "Easy to move vertically" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

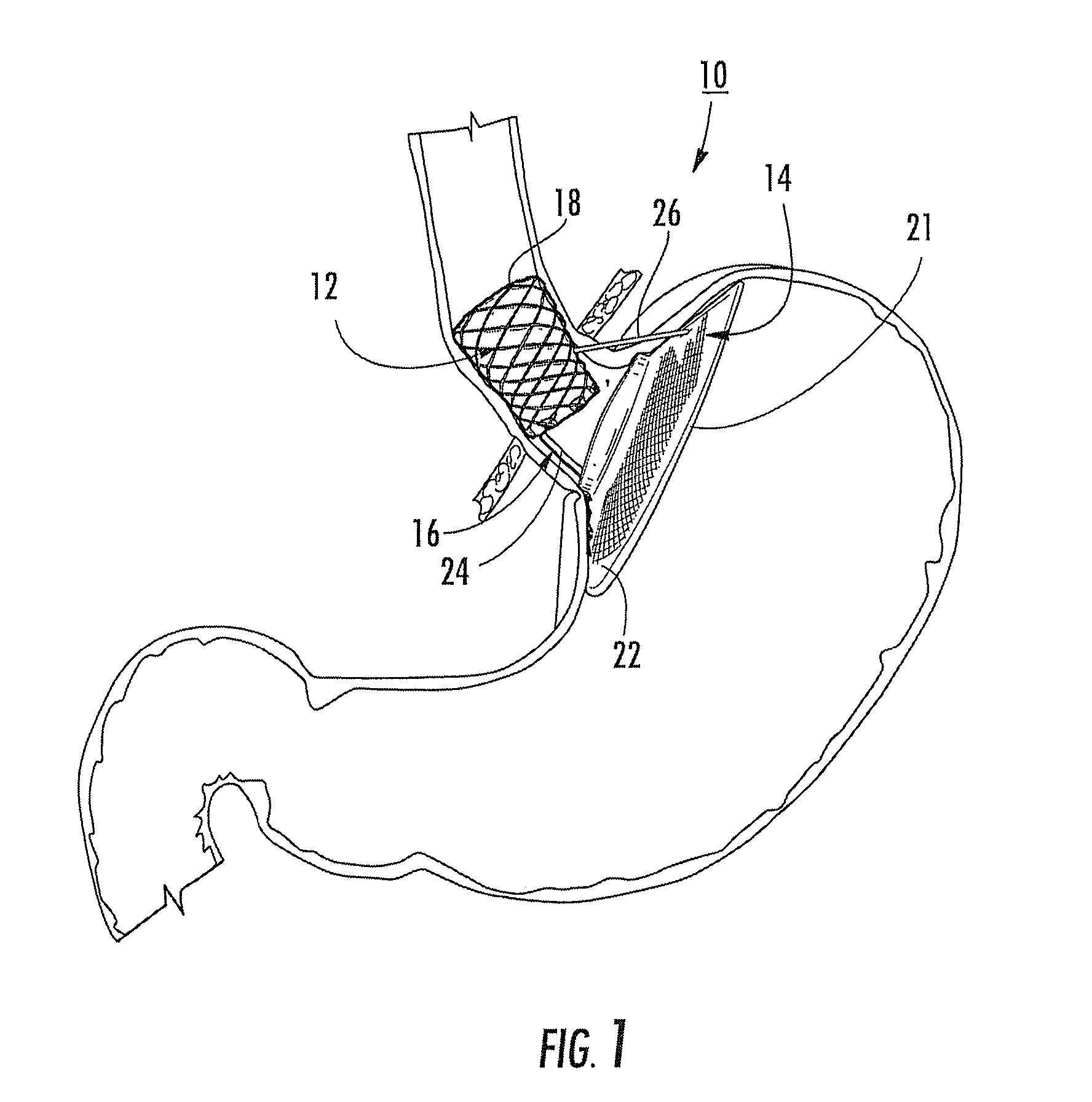

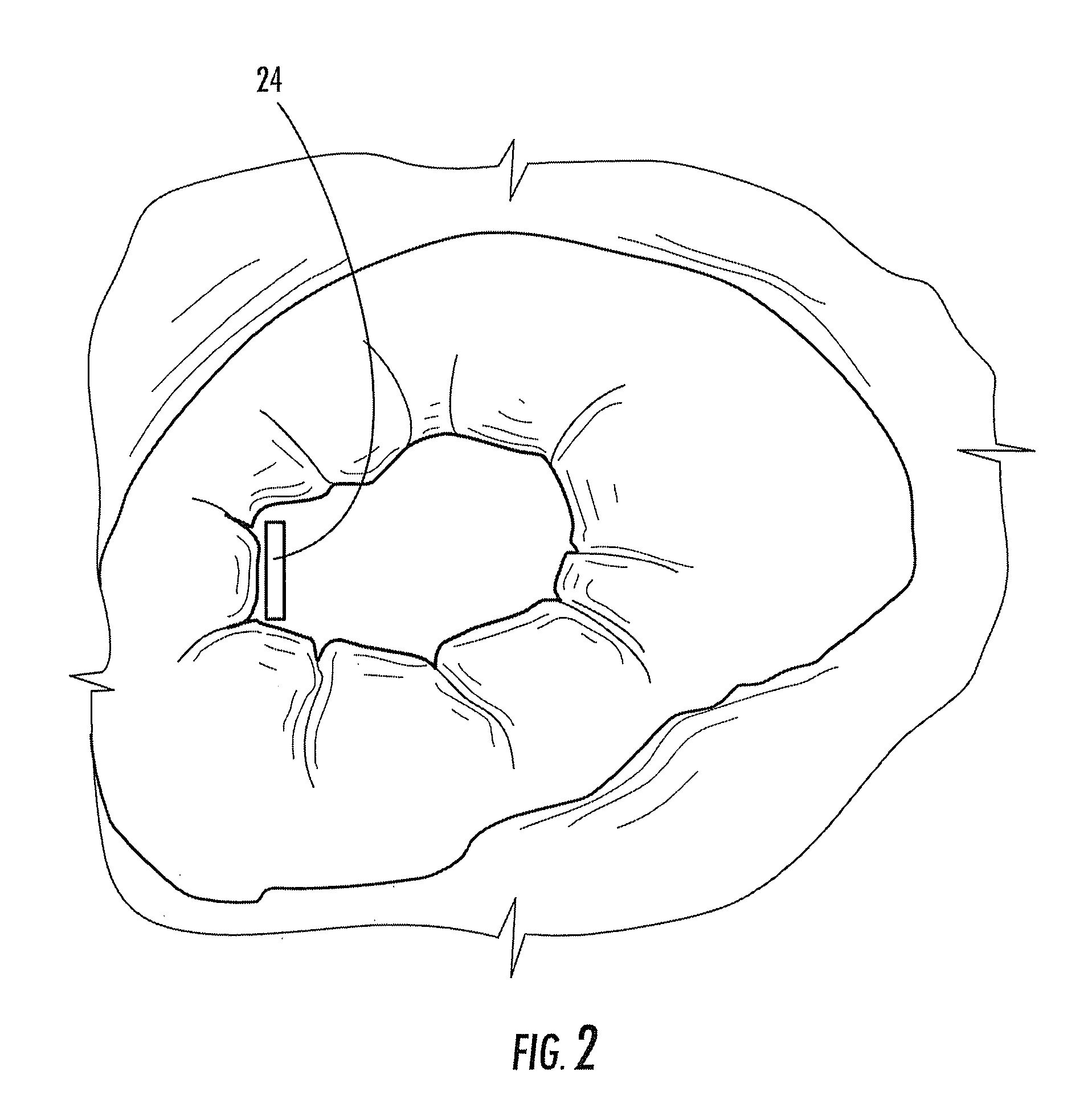

Bariatric device and method

ActiveUS20100030017A1Effective and invasive mannerEffective and minimally invasiveSuture equipmentsDilatorsCardiac surfaceHeart Part

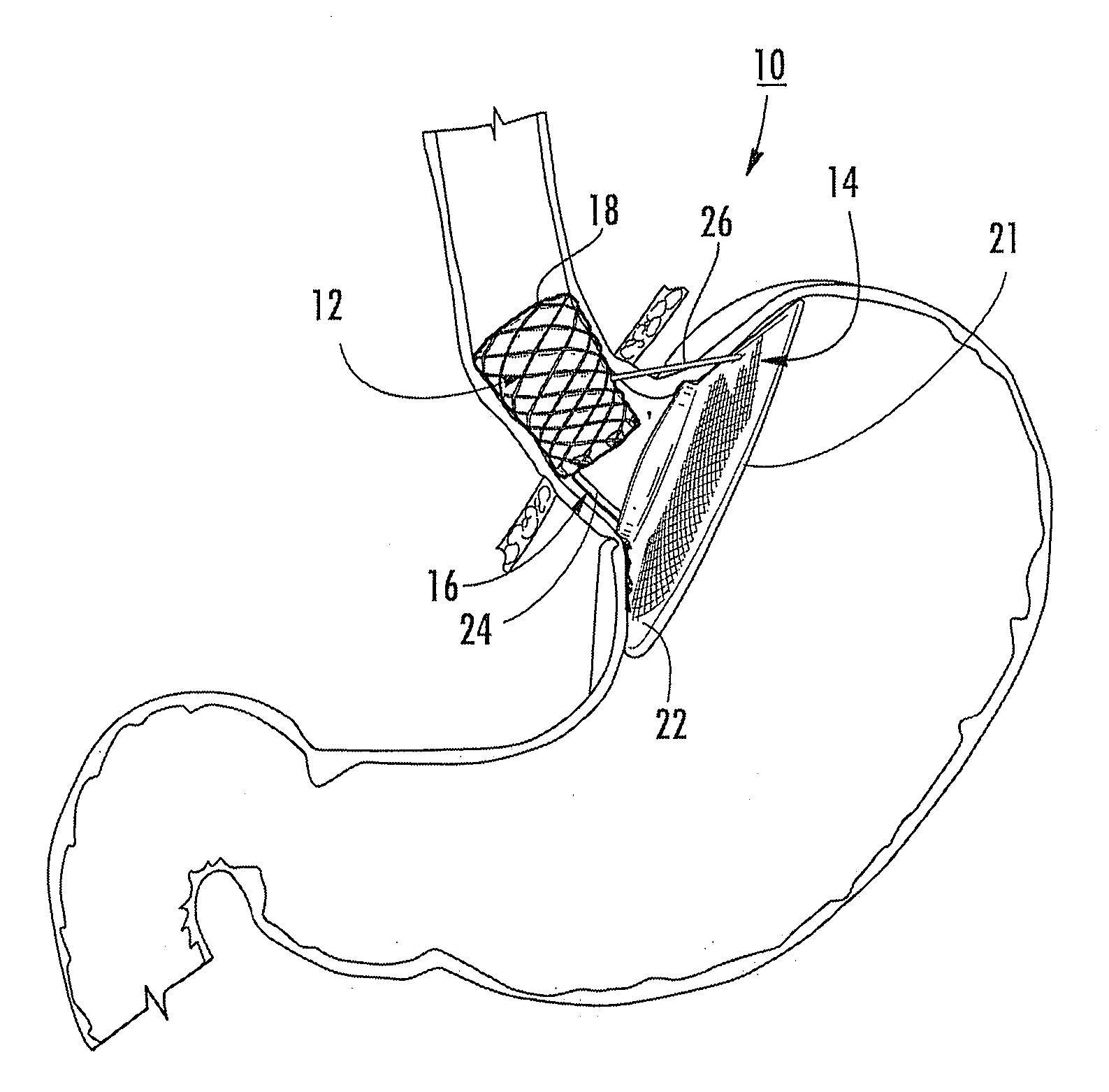

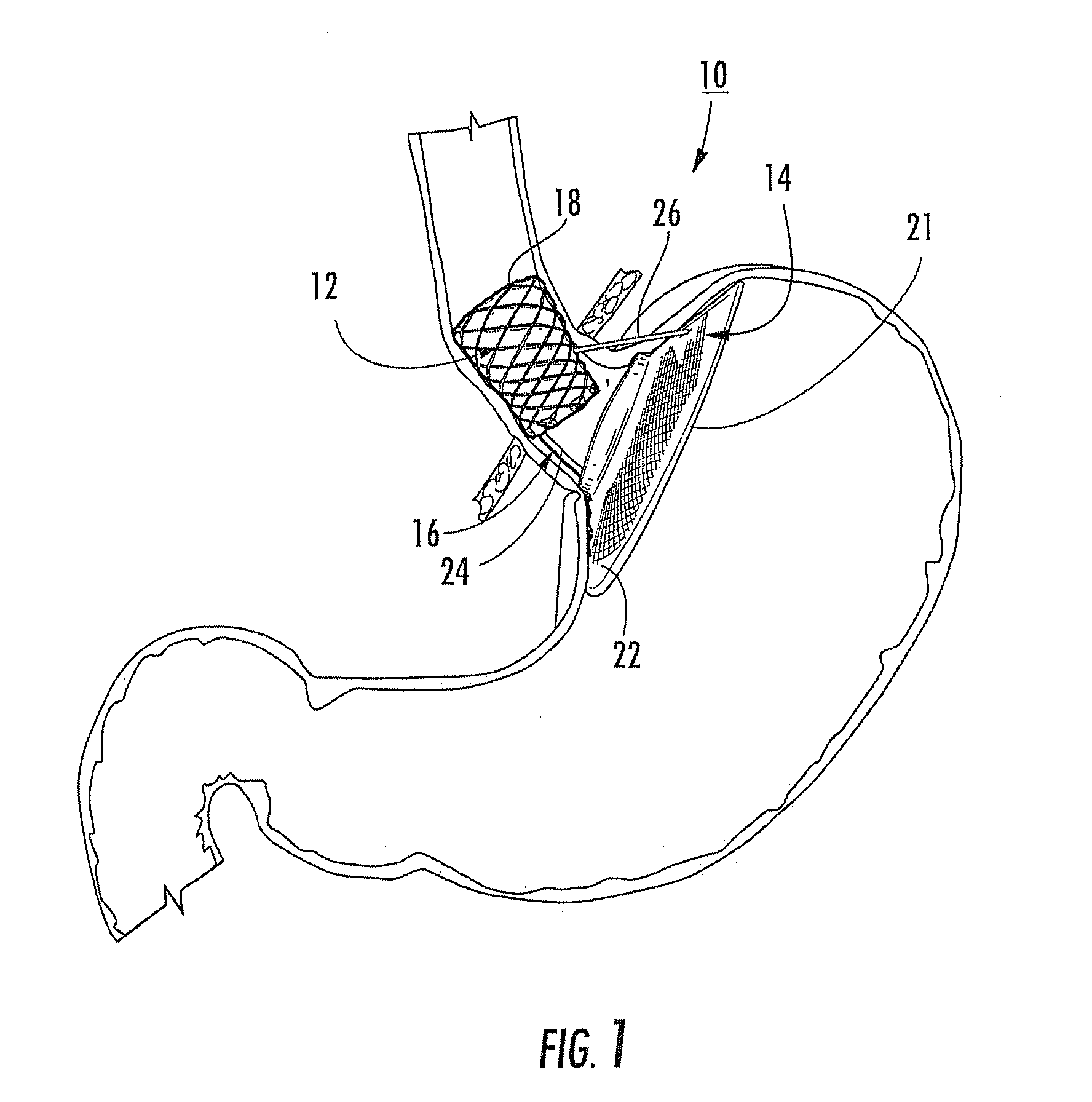

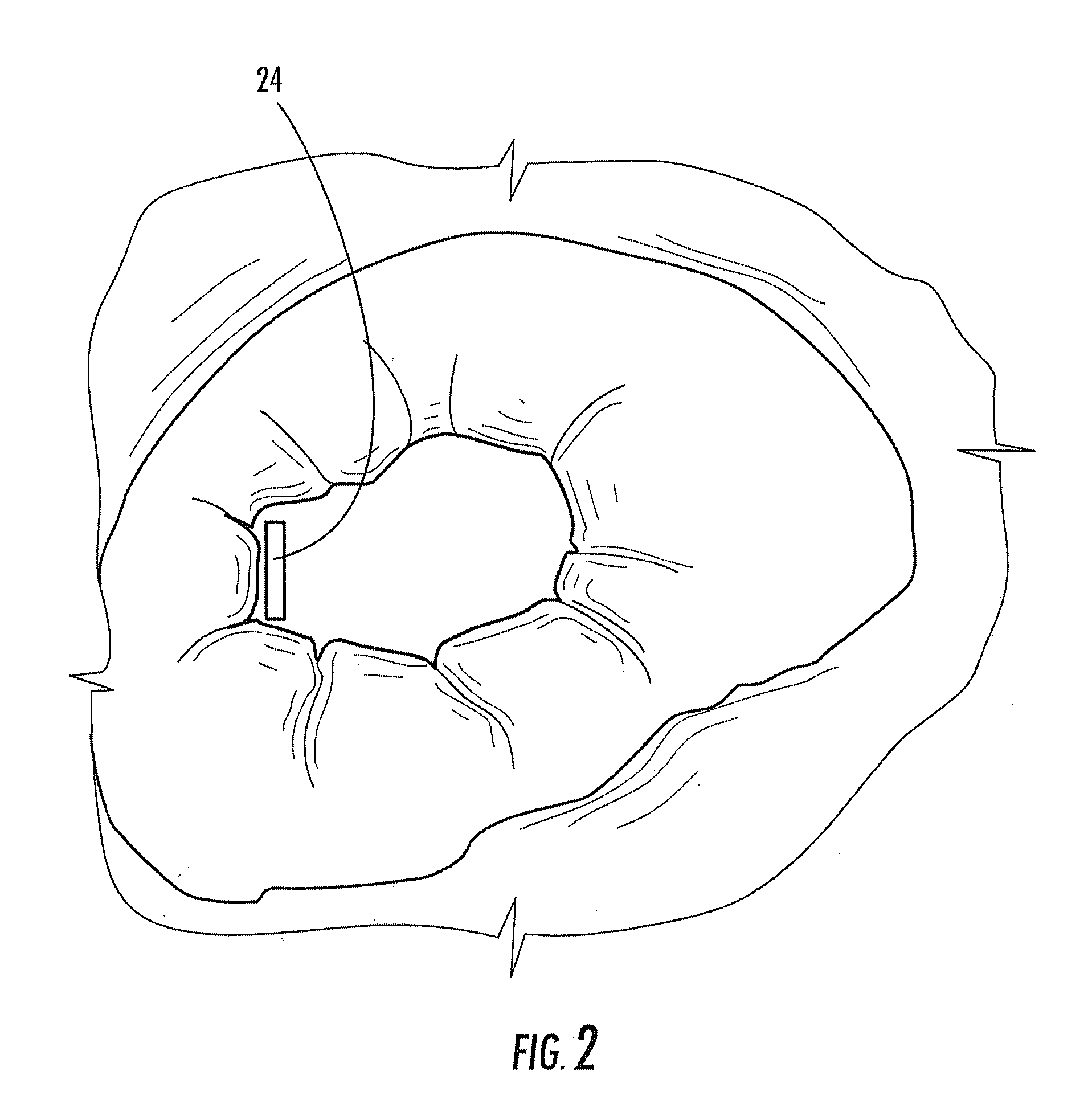

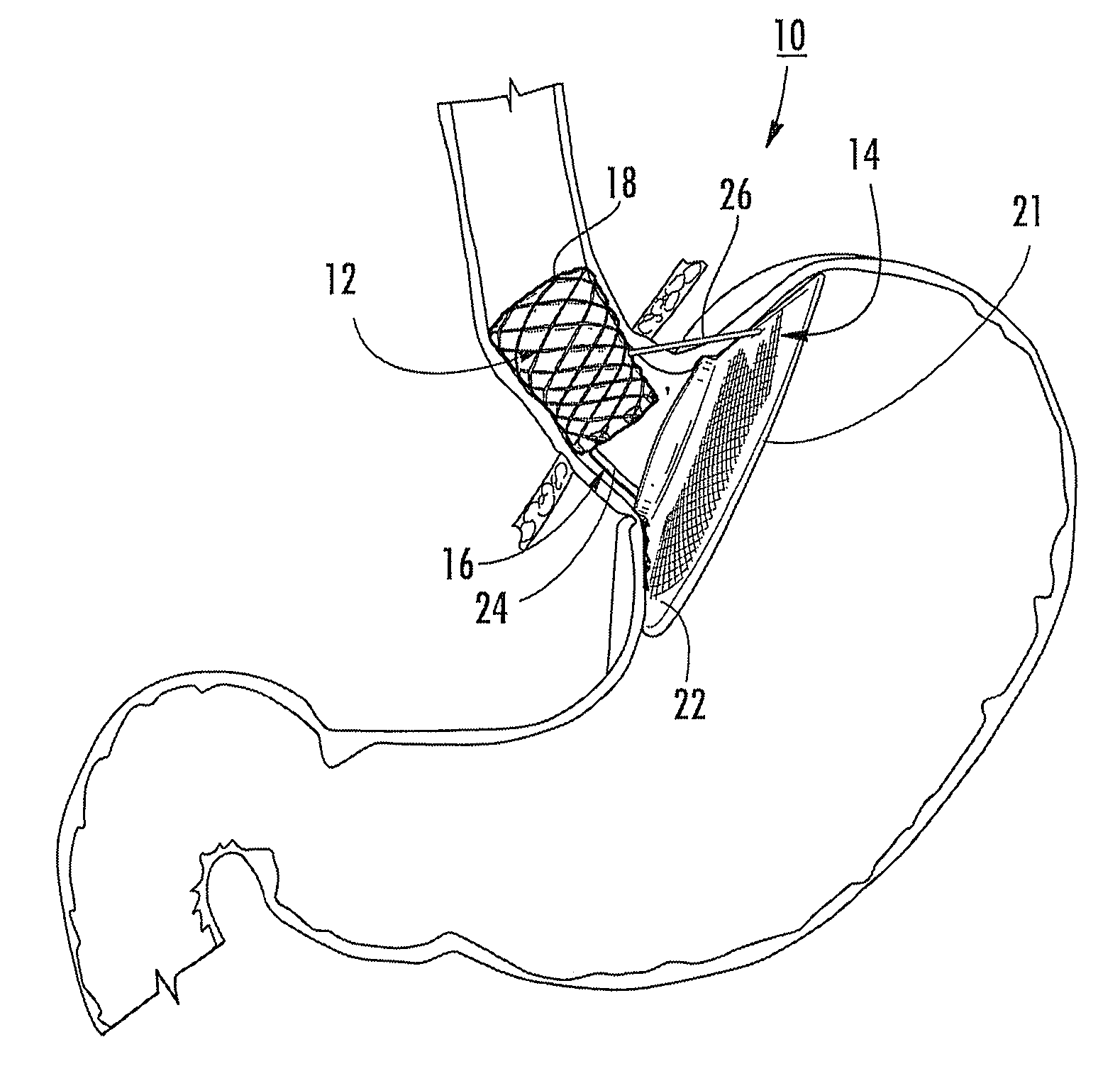

A bariatric device and method of causing weight loss in a recipient includes providing a bariatric device having an esophageal member, a cardiac member and a connector connected with the esophageal member and the cardiac member. The esophageal member has an esophageal surface that is configured to generally conform to the shape and size of a portion of the esophagus. The cardiac member has a cardiac surface that is configured to generally conform to the shape and size of a portion of the cardiac portion of the stomach. The esophageal surface is positioned at the esophagus. The cardiac surface is positioned at the cardiac portion of the stomach. The bariatric device stimulates receptors in order to influence a neurohormonal mechanism in the recipient.

Owner:BFKW

Bariatric device and method

ActiveUS8529431B2Effective and minimally invasiveEasy to move verticallySuture equipmentsDilatorsDecreased body weightNeurohormones

A bariatric device and method of causing weight loss in a recipient includes providing a bariatric device having an esophageal member, a cardiac member and a connector connected with the esophageal member and the cardiac member. The esophageal member has an esophageal surface that is configured to generally conform to the shape and size of a portion of the esophagus. The cardiac member has a cardiac surface that is configured to generally conform to the shape and size of a portion of the cardiac portion of the stomach. The esophageal surface is positioned at the esophagus. The cardiac surface is positioned at the cardiac portion of the stomach. The bariatric device stimulates receptors in order to influence a neurohormonal mechanism in the recipient.

Owner:BFKW

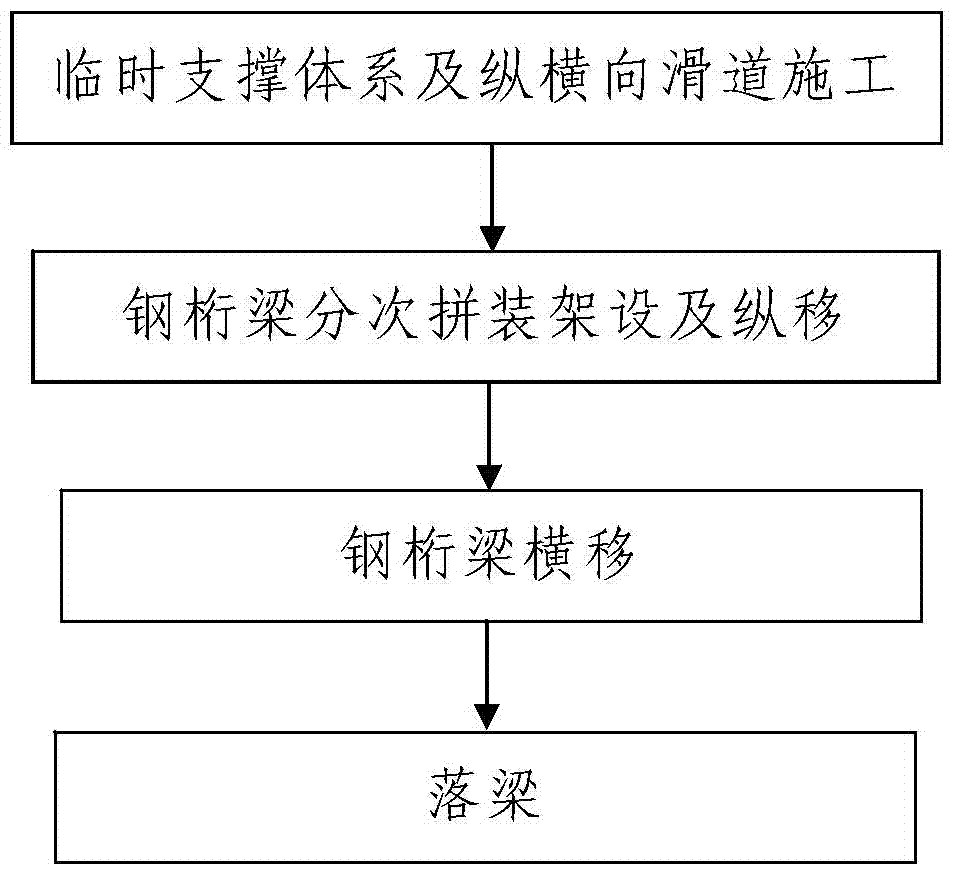

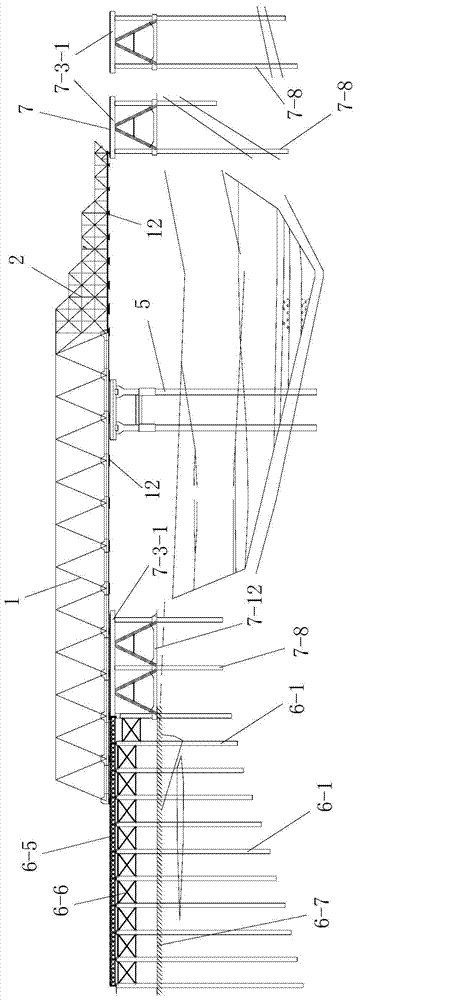

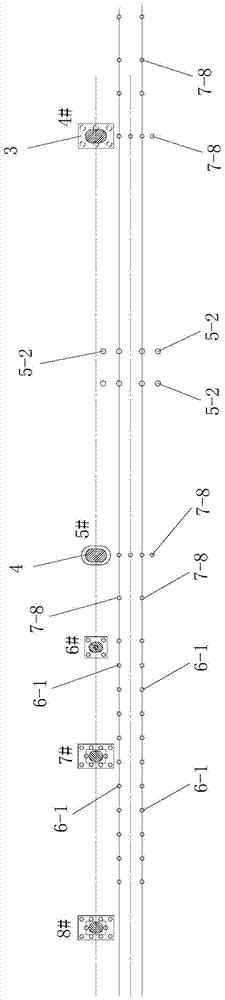

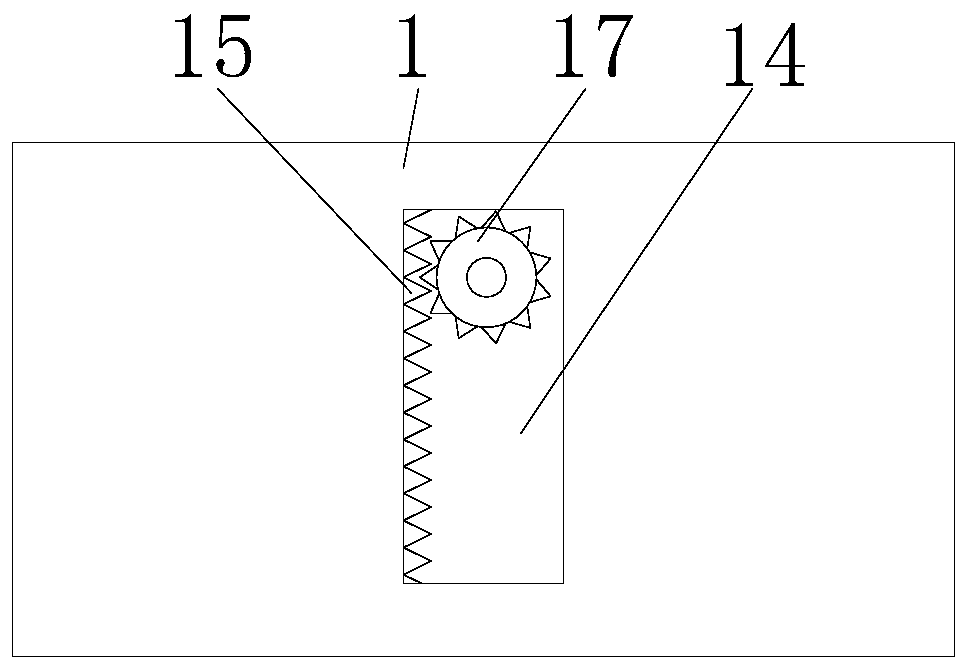

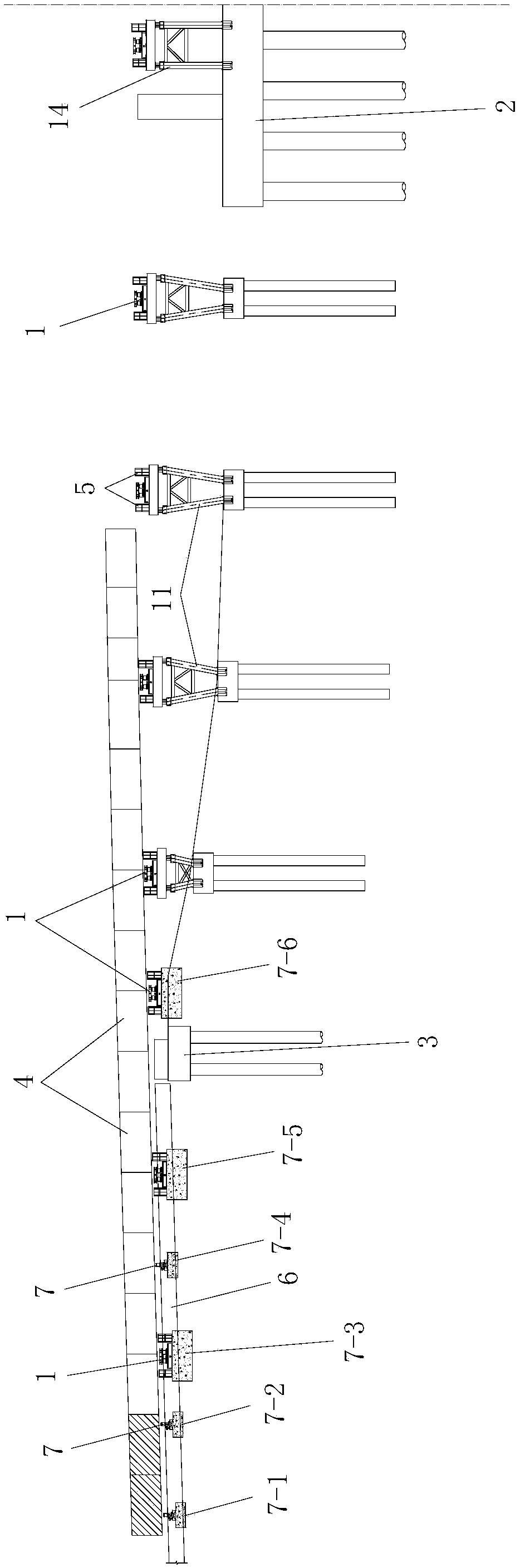

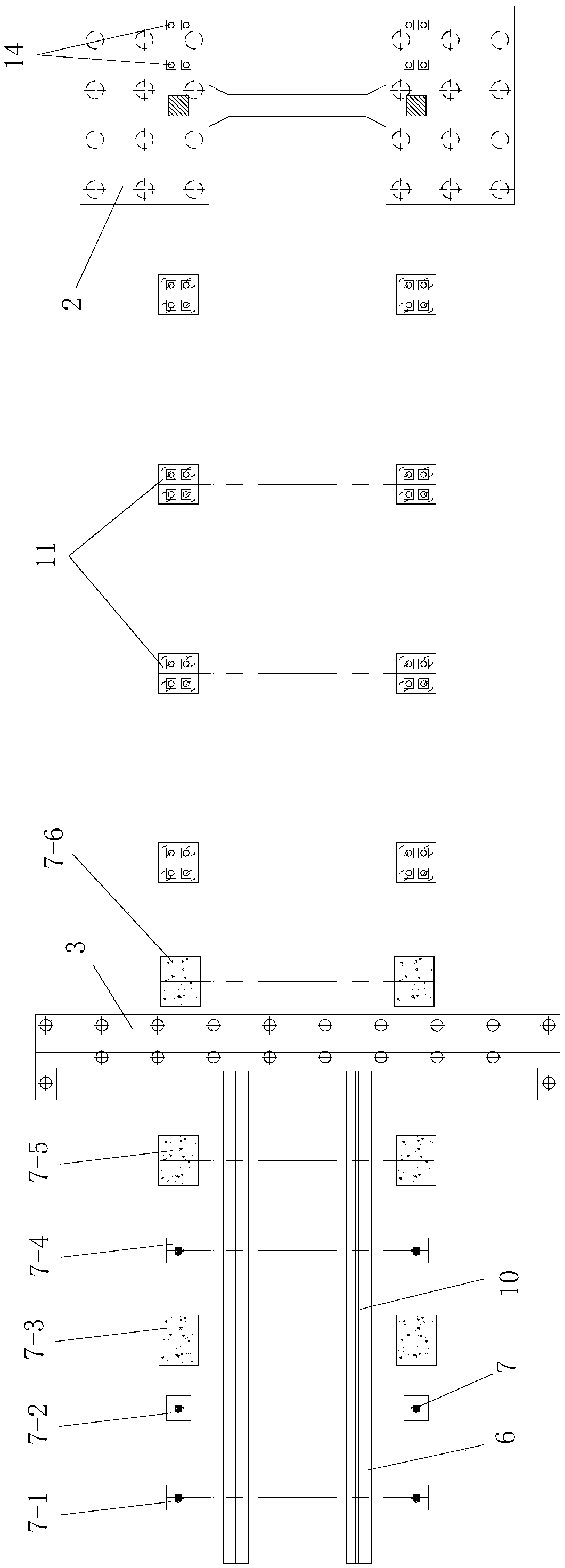

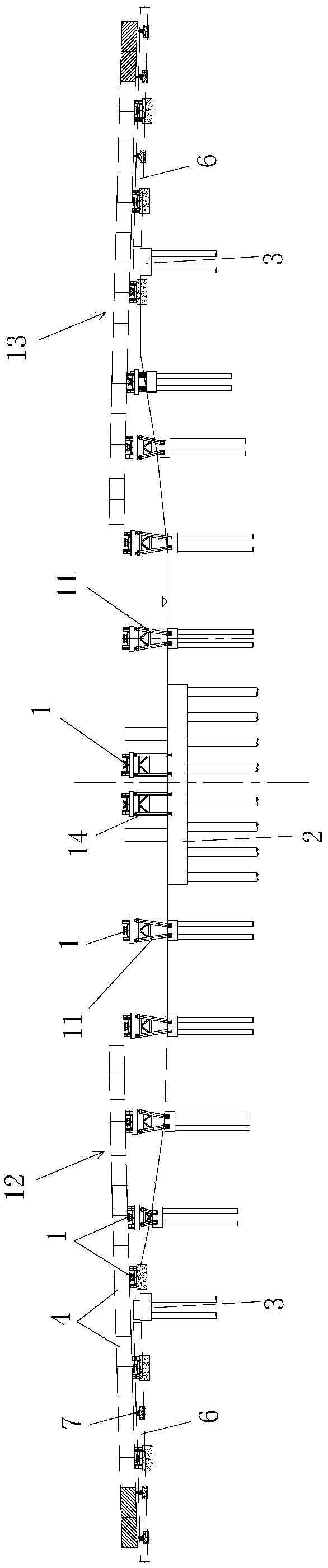

Steel truss girder assembling, erecting and construction process

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

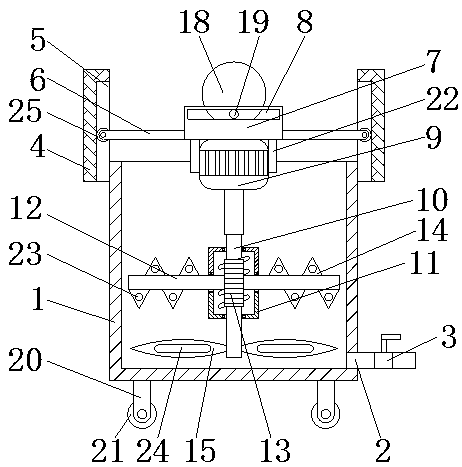

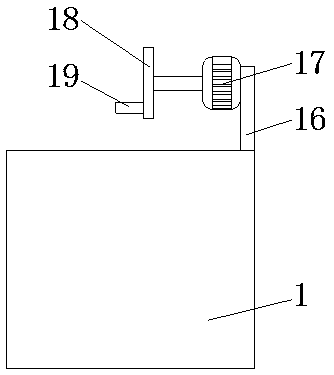

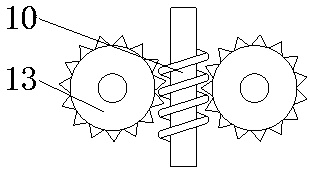

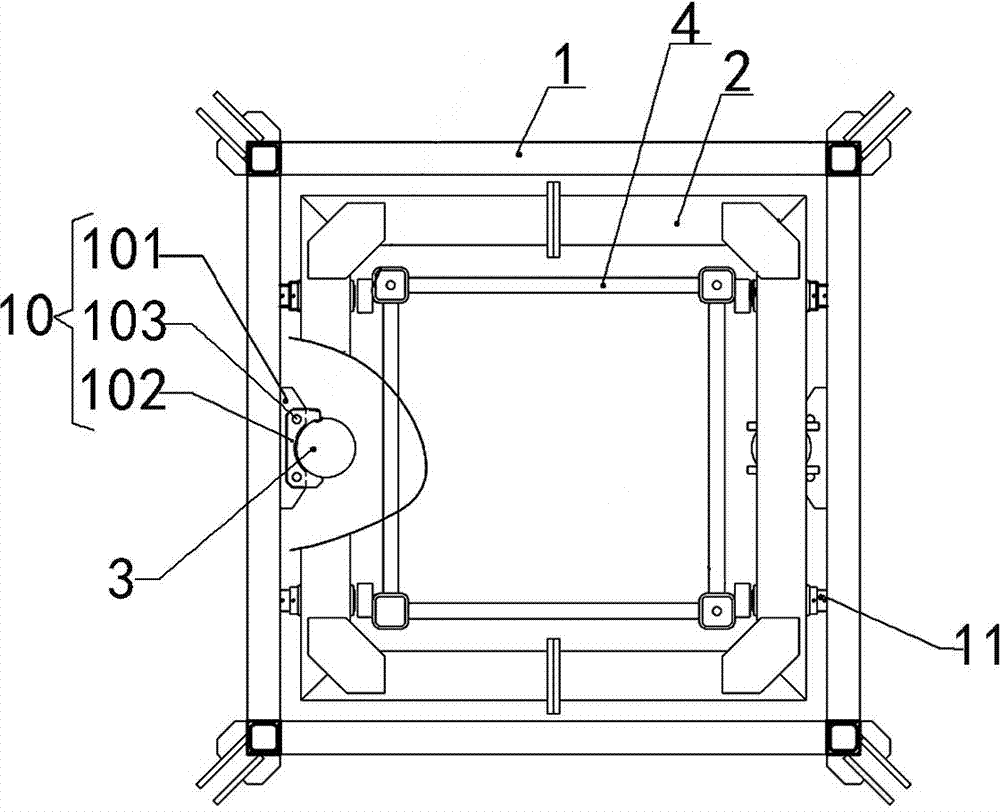

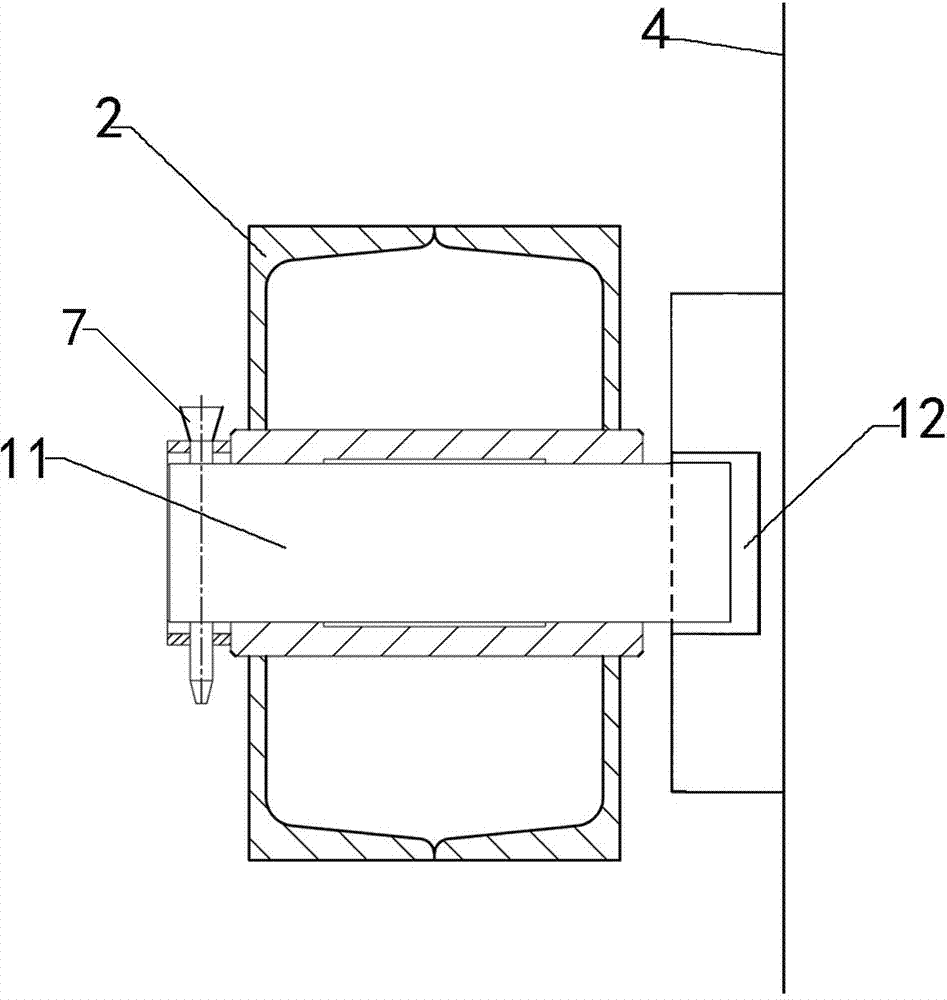

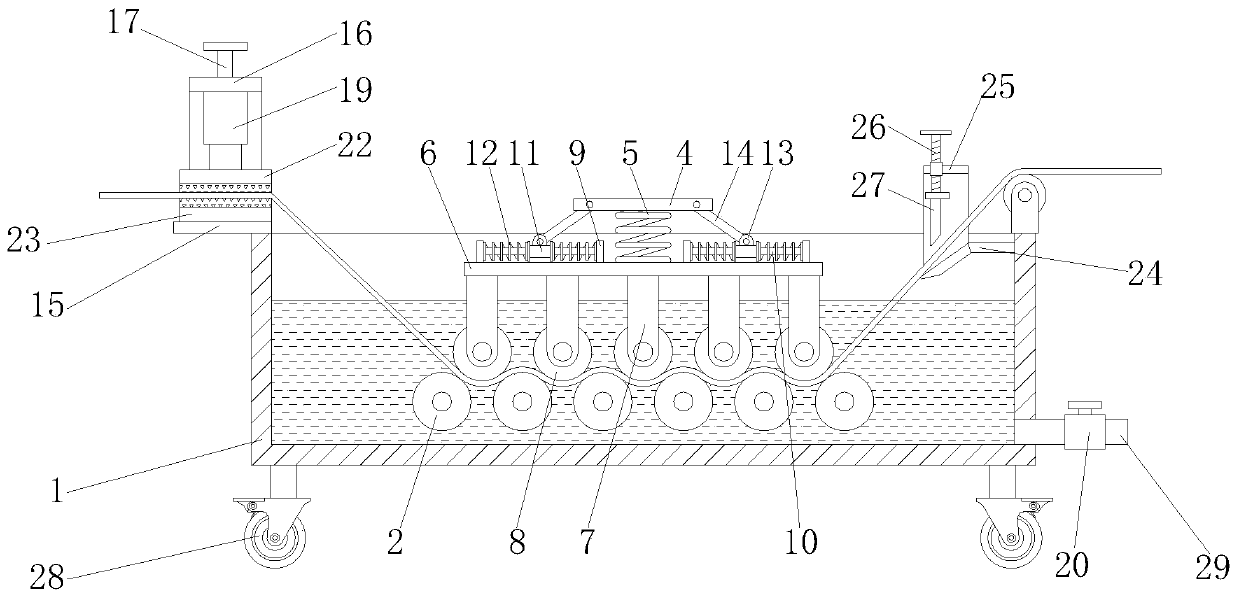

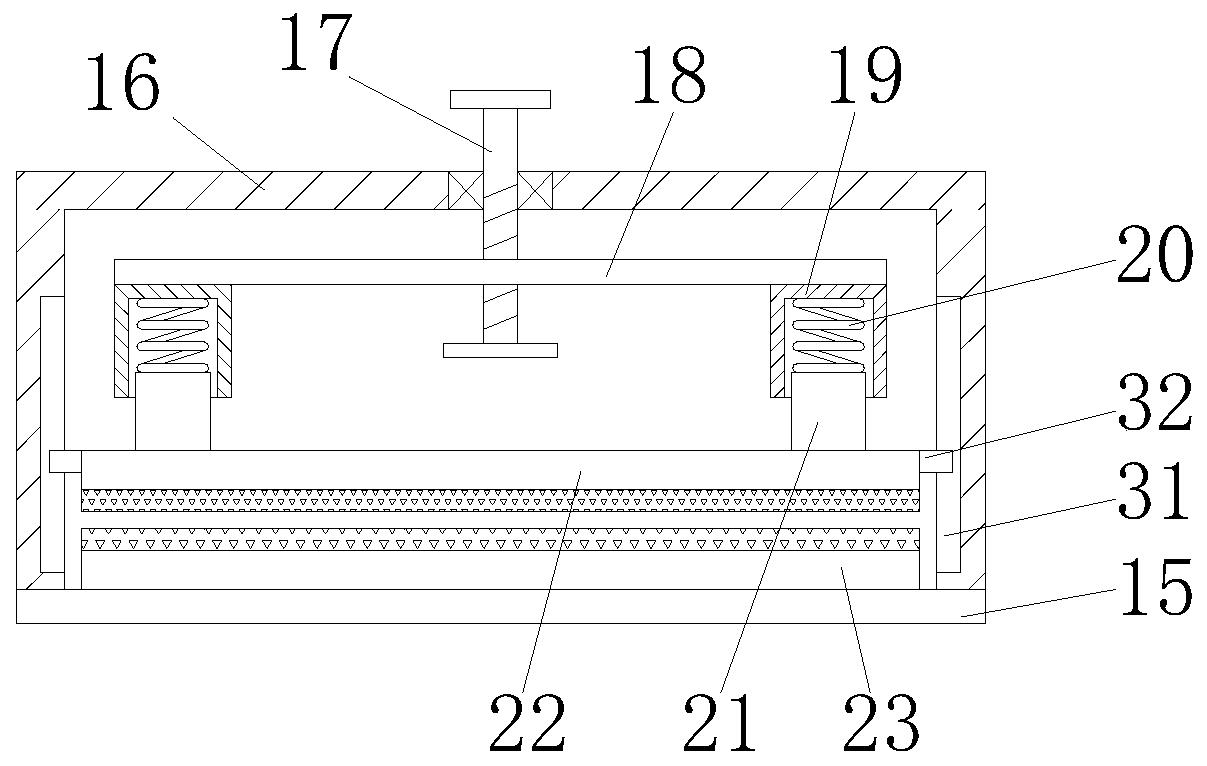

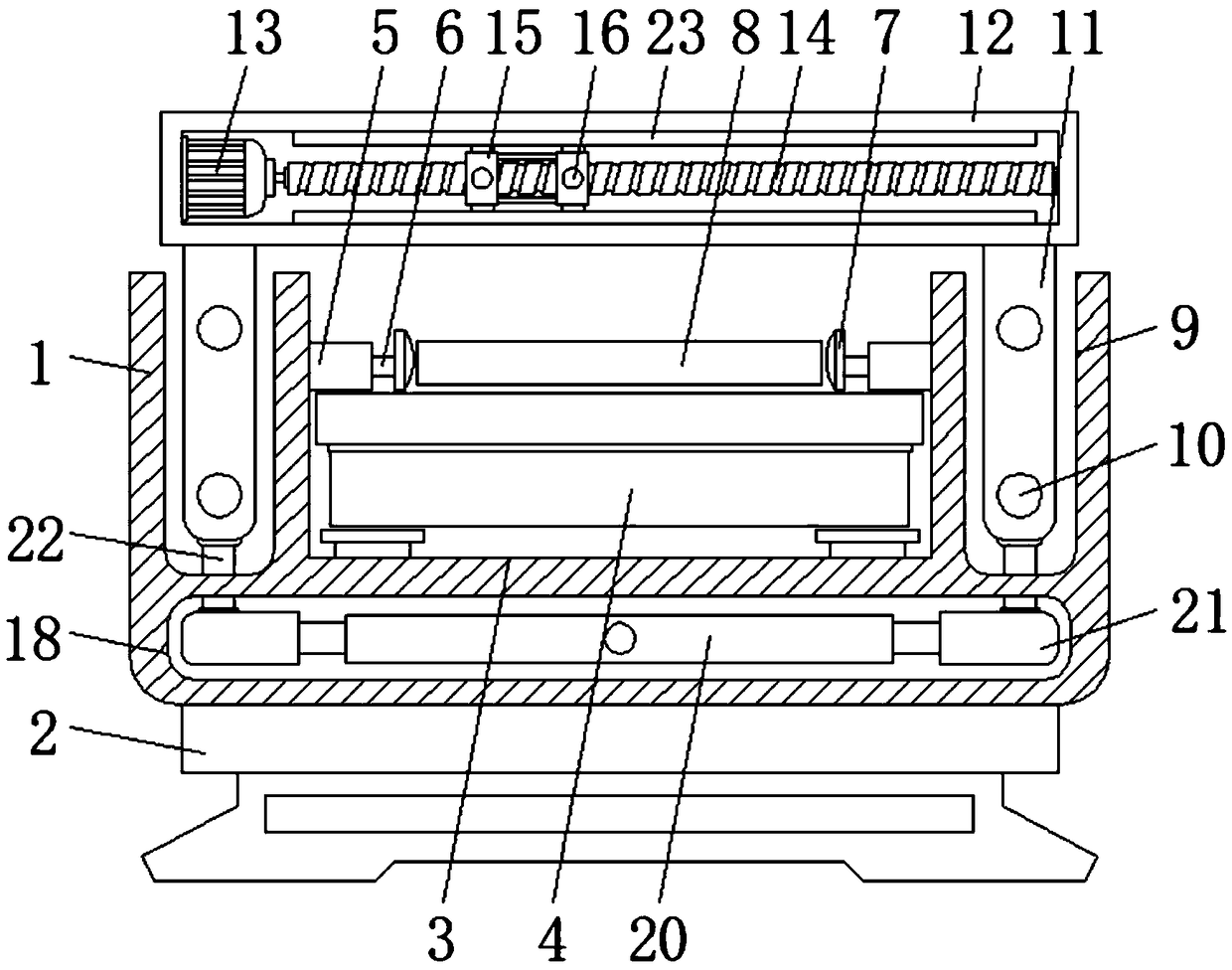

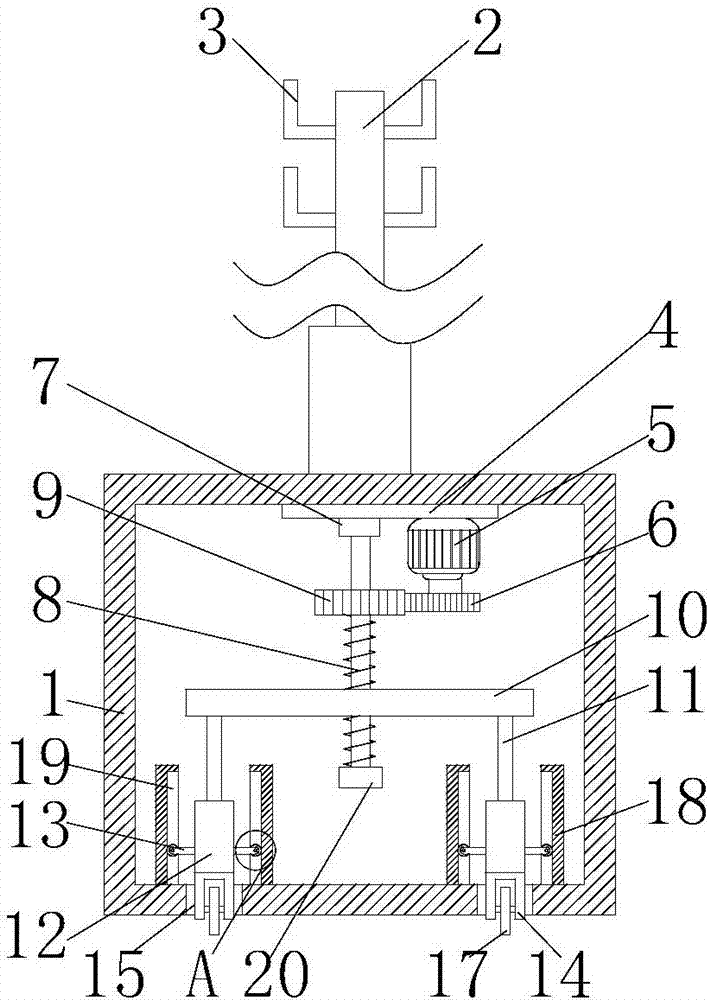

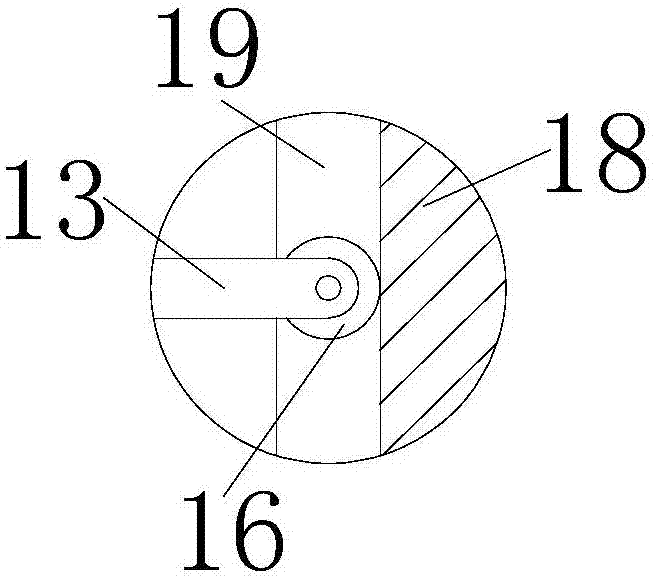

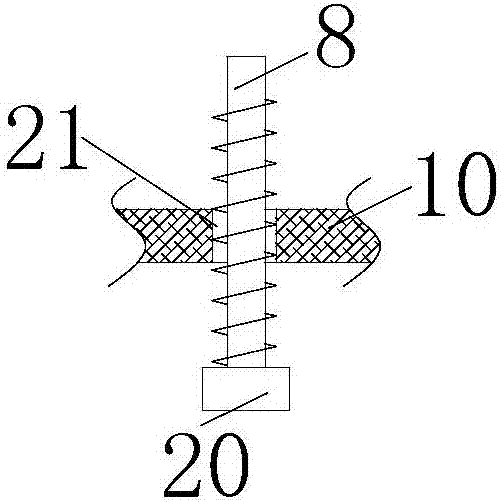

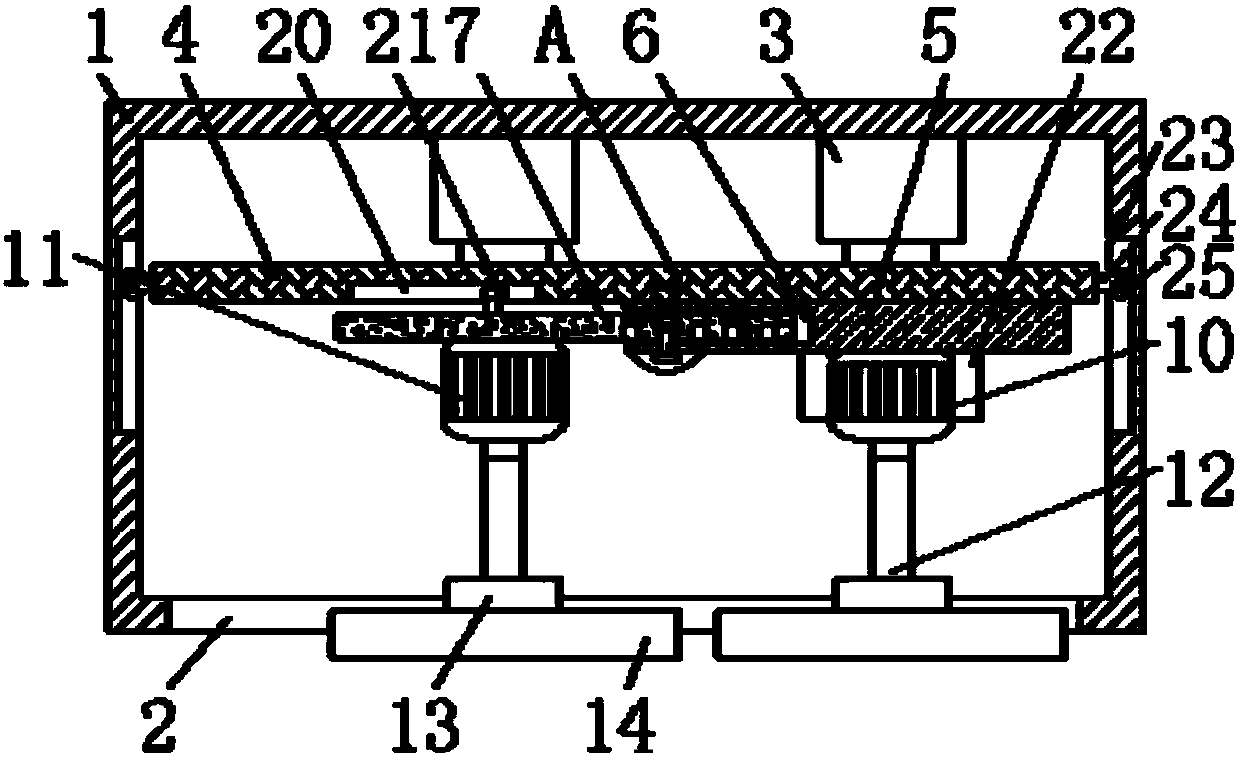

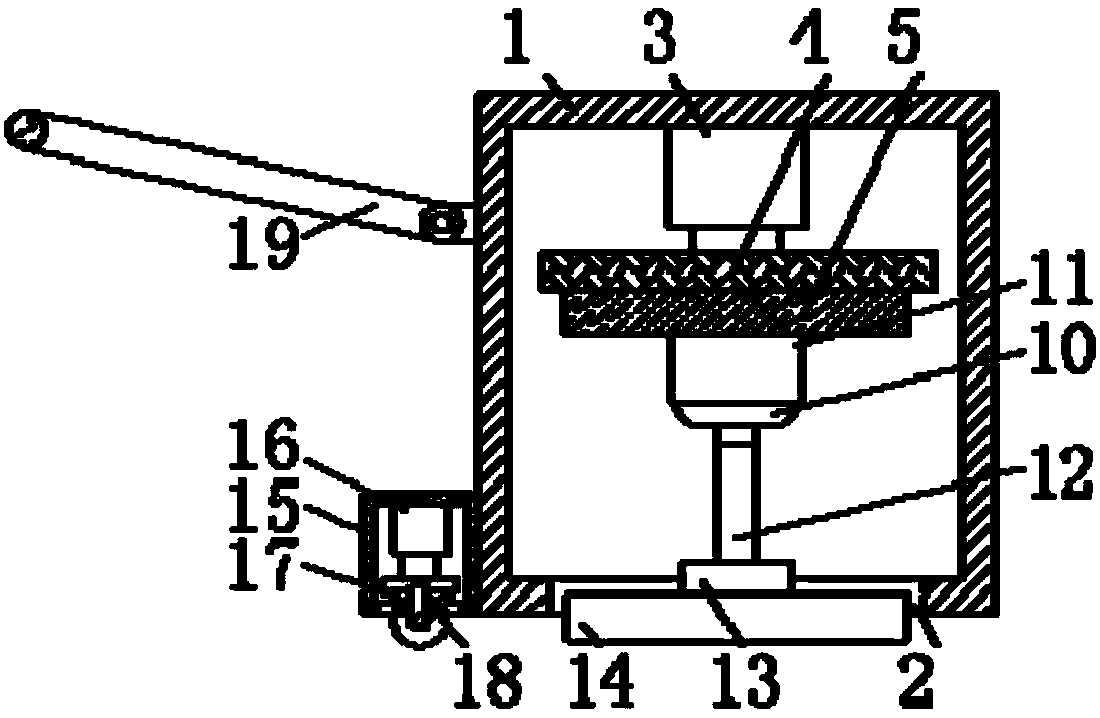

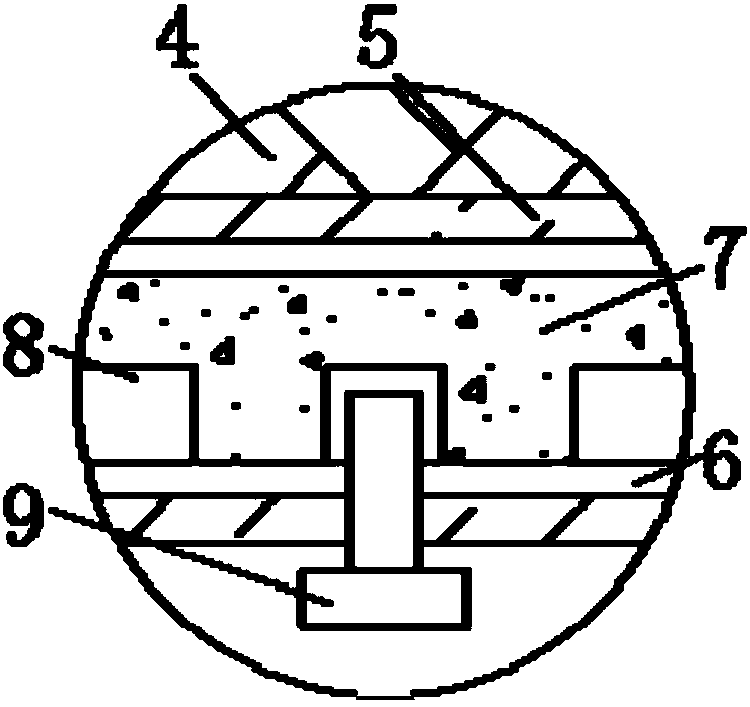

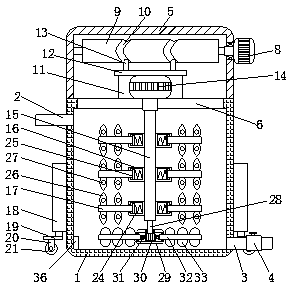

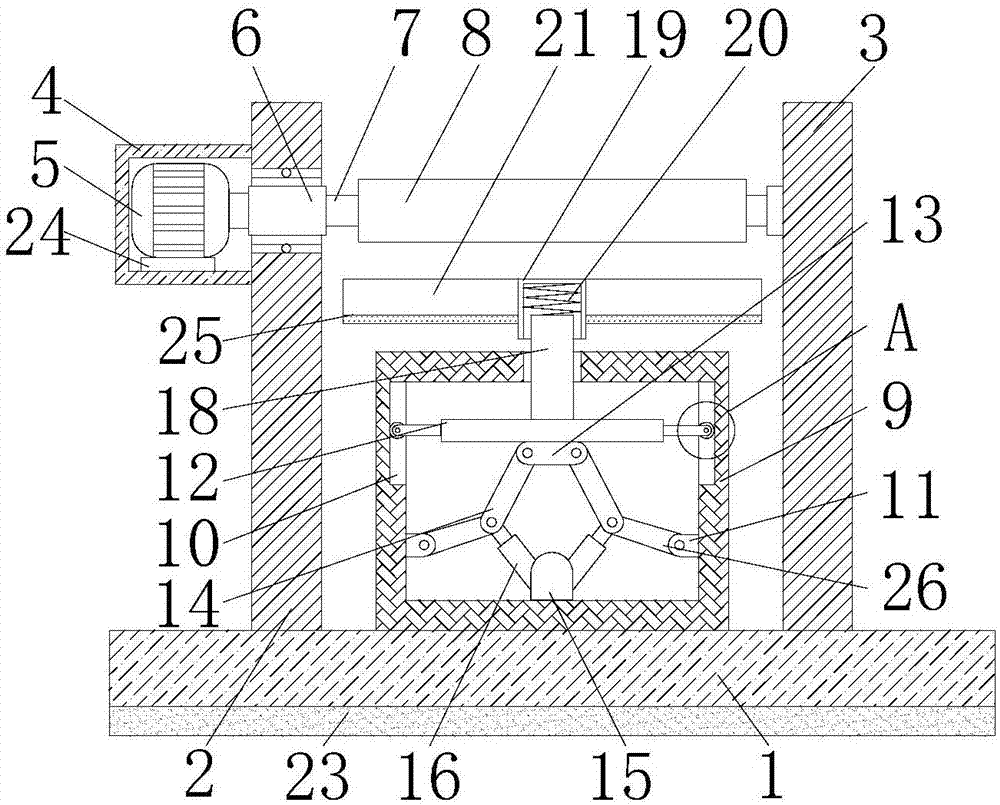

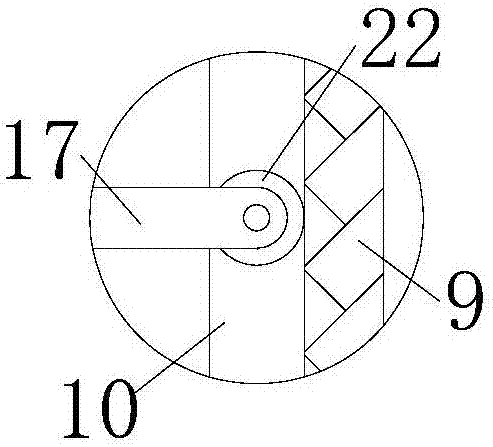

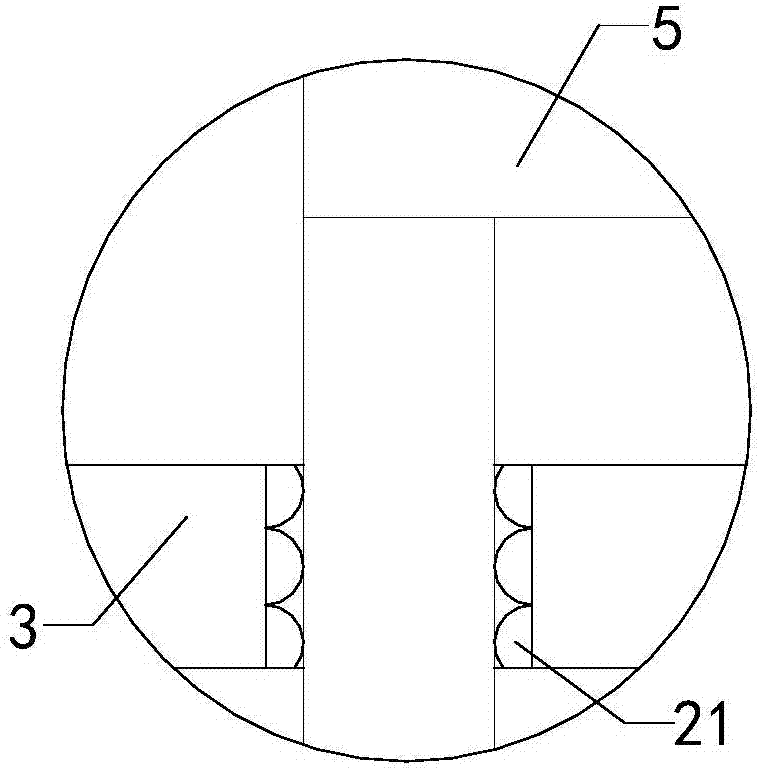

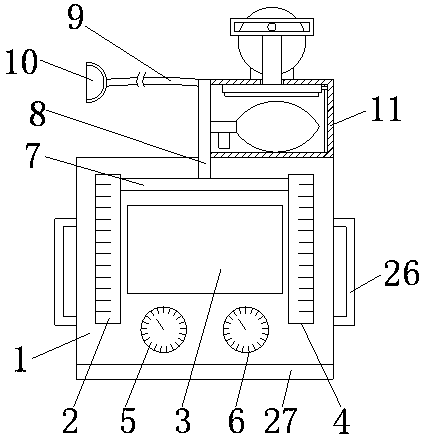

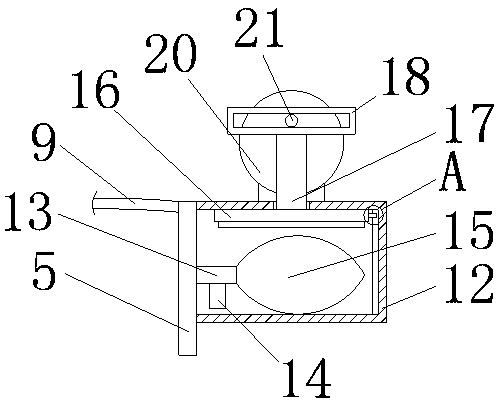

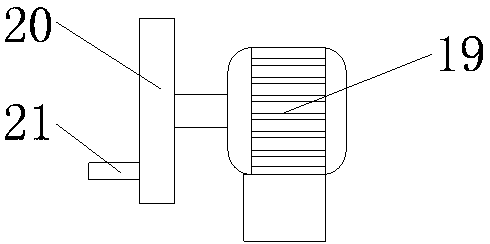

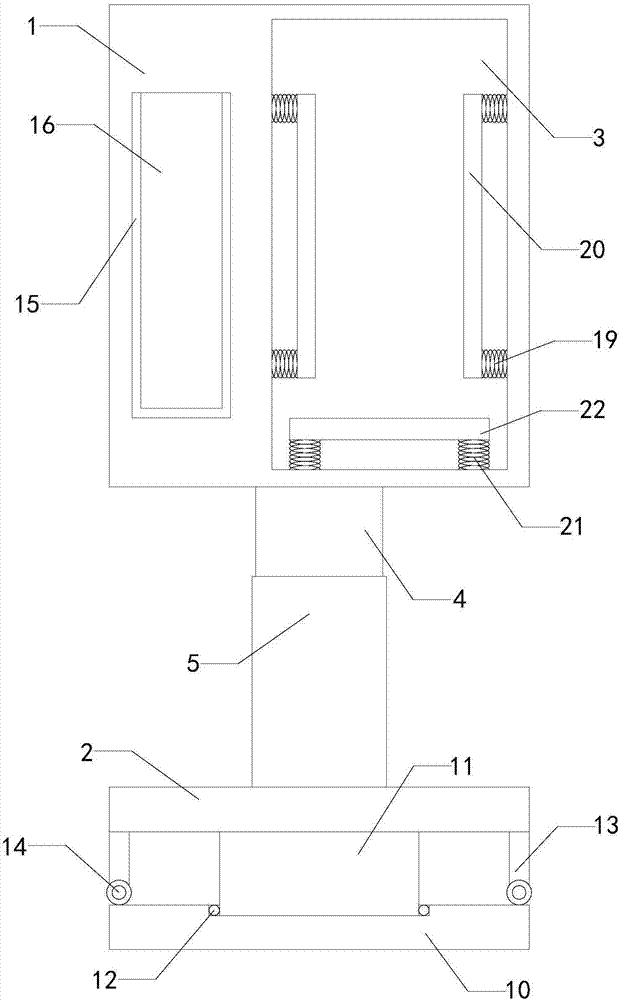

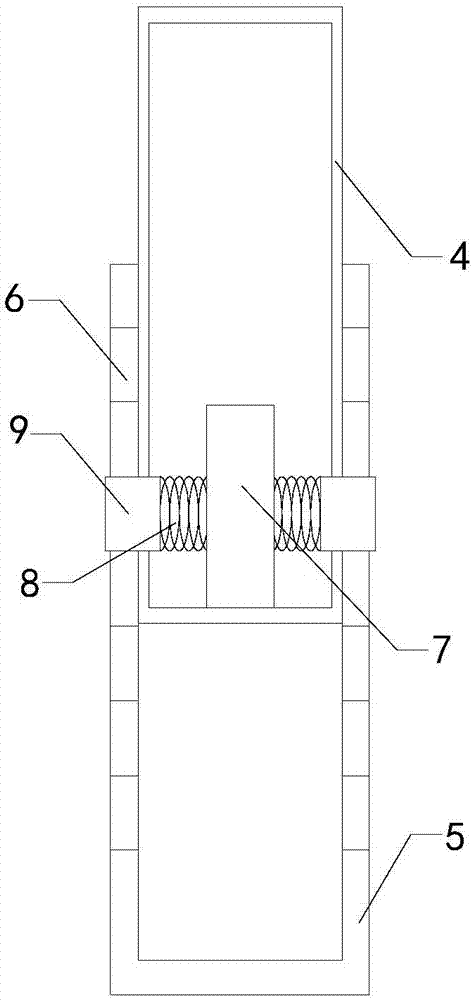

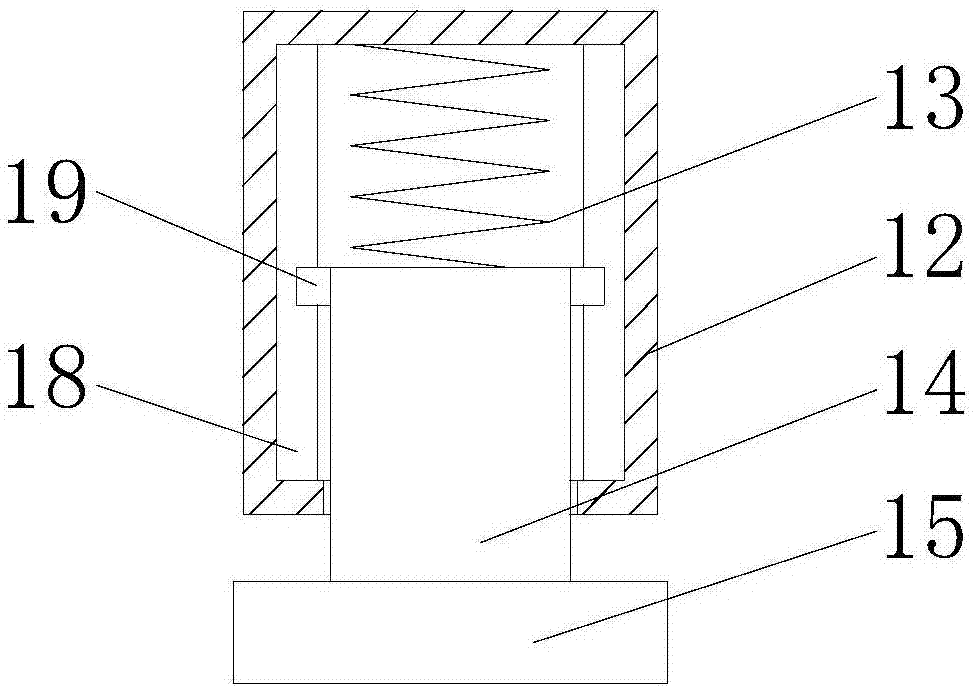

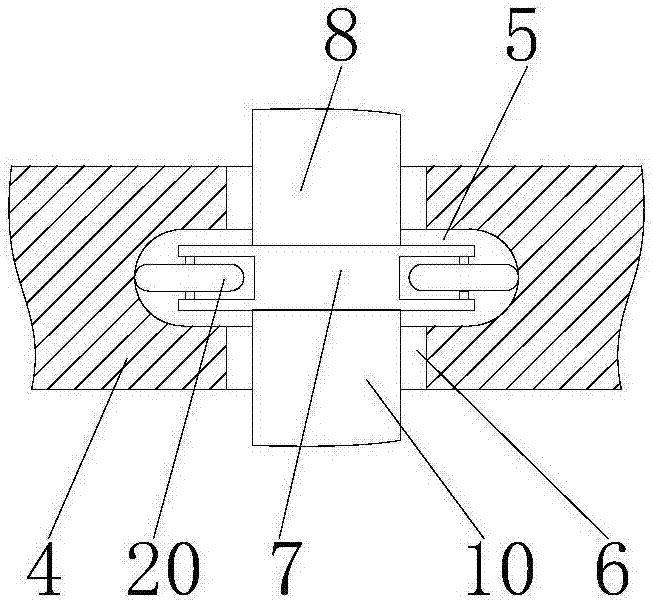

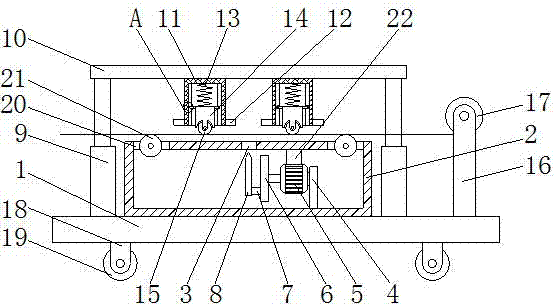

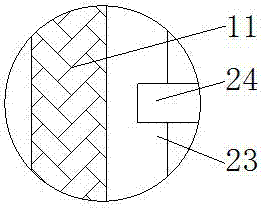

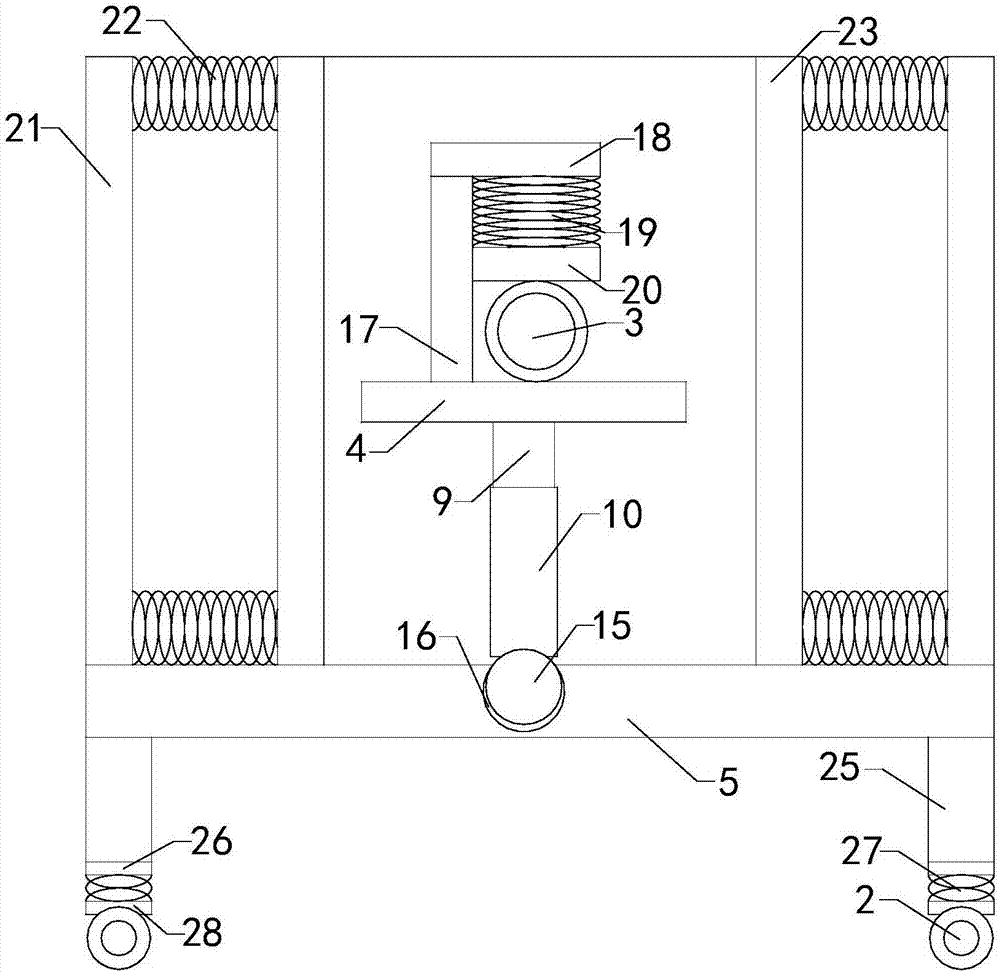

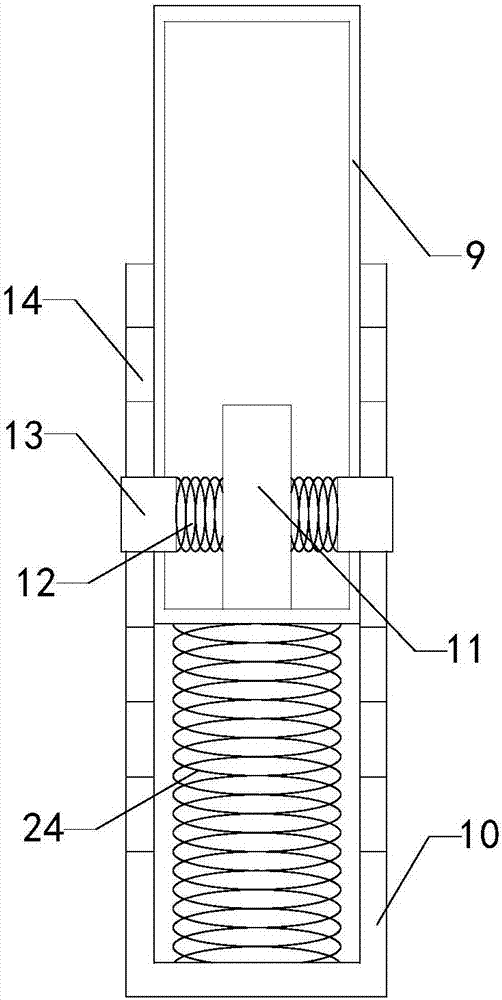

Stirring equipment for production of potassium chlorate

PendingCN107670535AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingReciprocating motionEngineering

The invention discloses stirring equipment for production of potassium chlorate. The stirring equipment for production of potassium chlorate comprises a box, wherein the bottom of the right side of the box communicates with a discharging tube; a valve is arranged on the surface of the discharging tube; tops of two sides of the box are fixedly connected with supporting plates separately; chutes areformed in opposite sides of the supporting plates; a cavity of each chute is slidably connected with a sliding rod; the end, which is away from the cavity of the corresponding chute, of each slidingrod extends to the outside of the corresponding chute and is fixedly connected with a movable plate; an elongated hole is formed in the top of the front surface of each movable plate; and the bottom of each movable plate is fixedly connected with a first motor. By cooperation of the movable plates, the elongated holes, a second motor, a rotating plate and a guiding rod, the movable plates can vertically move in a reciprocating manner, and drive worms, cross rods, stirring teeth and stirring blades to move vertically, materials in the cavity of the box can be fully stirred, the material stirring efficiency is improved, and the material reaction speed is increased.

Owner:LEIYANG JINYUE SCI & TECH DEV

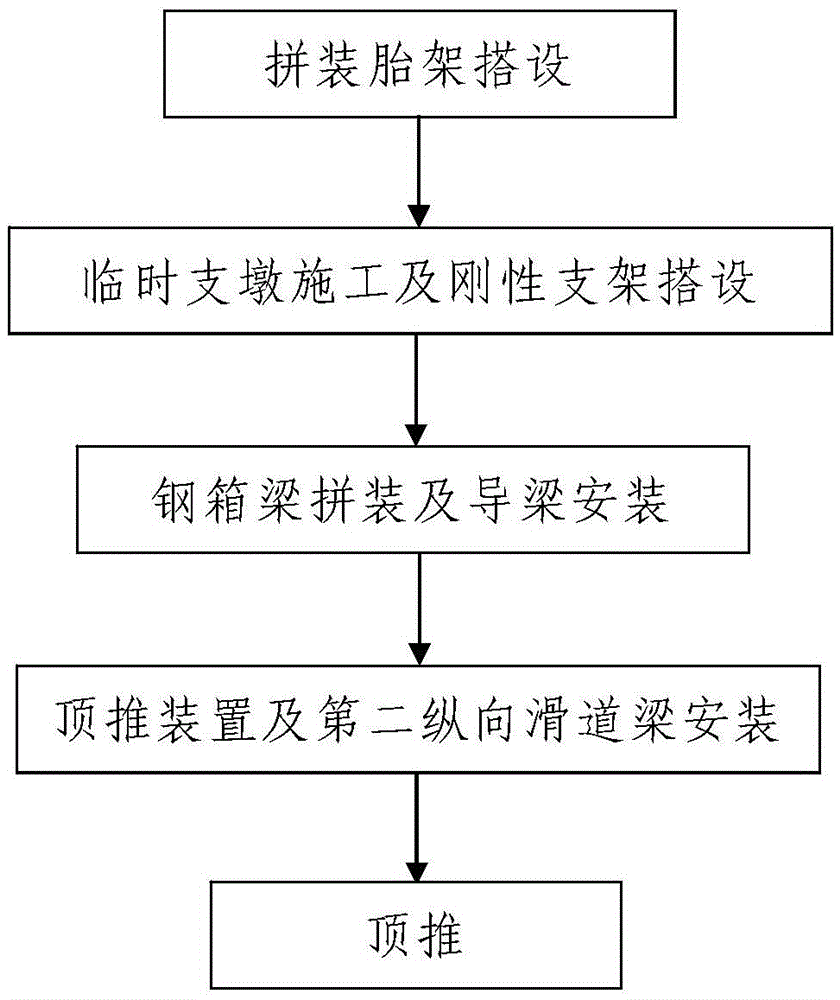

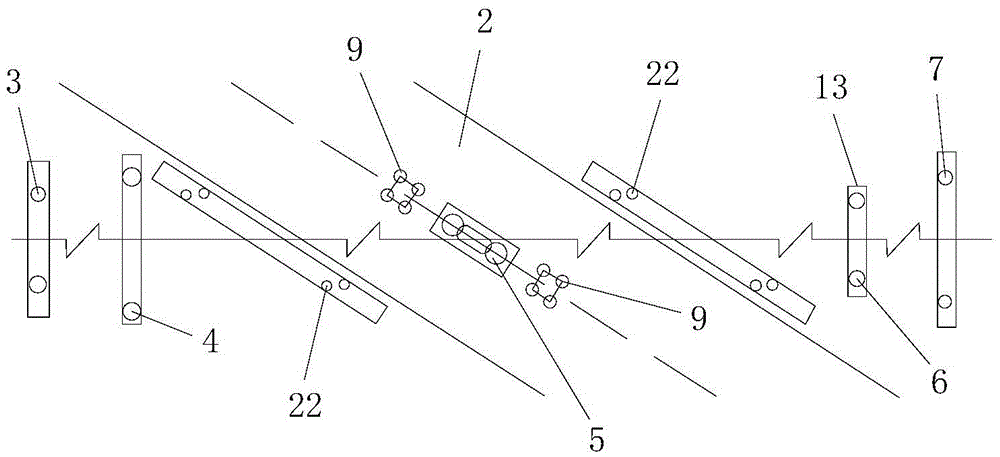

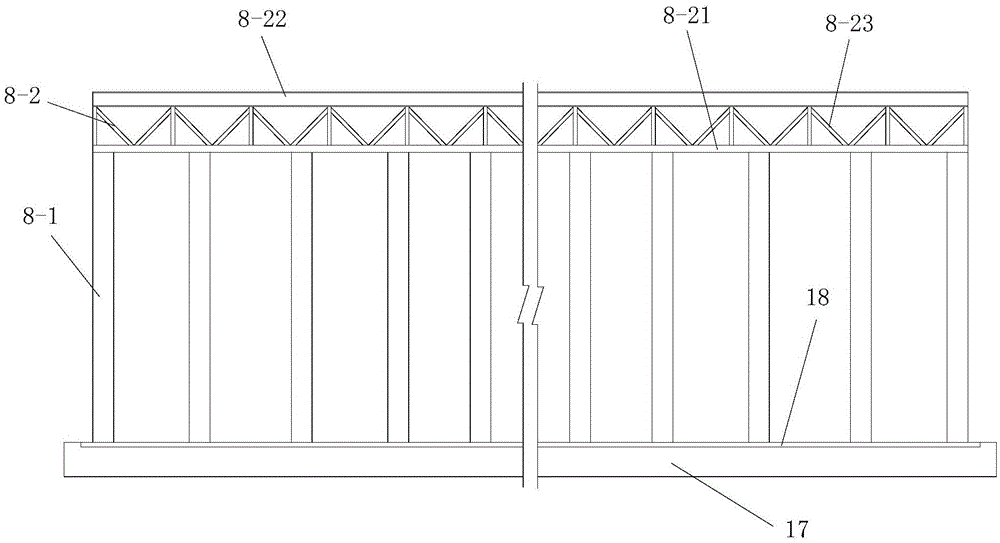

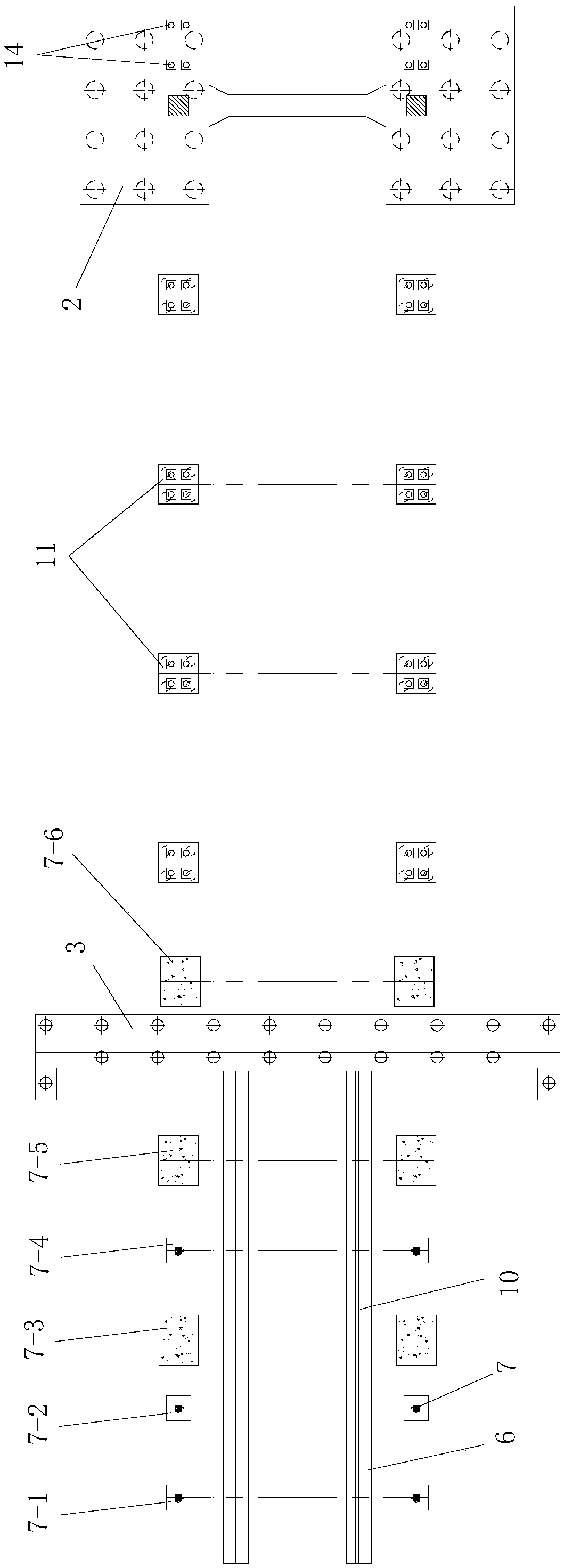

Incremental launching construction method for large-span steel box girder spanning constructed road

ActiveCN105568866AThe method steps are simpleSimple and fast operationBridge erection/assemblyButtressSteel box girder

The invention discloses an incremental launching construction method for a large-span steel box girder spanning a constructed road. An incremental launching steel box girder spans the constructed road, is supported by five permanent buttresses, and is formed by a plurality of steel box girder segments which are spliced back to front; the five permanent buttresses are all uncovered girder double-cylinder pillars; the uncovered girder double-cylinder pillars respectively consist of two cylindrical buttresses which are supported below the left side and the right side of the steel box girder; the incremental launching construction method for the incremental launching steel box girder comprises the following steps: I, splicing jig frames; II, constructing temporary buttresses and rigid brackets; III, splicing the steel box girder and mounting guide beams; IV, mounting an incremental launching device and a second longitudinal slideway beam; V, performing incremental launching. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient to construct and good in use effect, and by constructing the rigid brackets on the outer sides of the buttresses and mounting a longitudinal slideway and a transverse deviation correcting device, the incremental launching construction of the large-span steel box girder can be easily, conveniently and rapidly completed.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

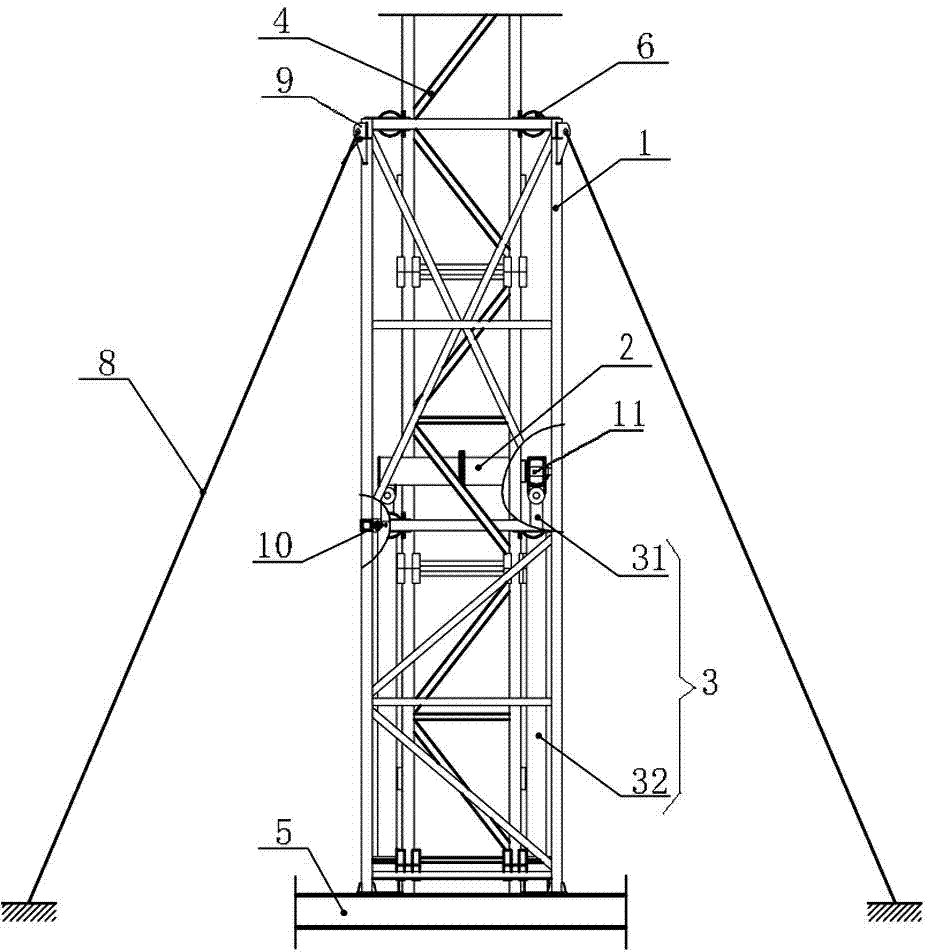

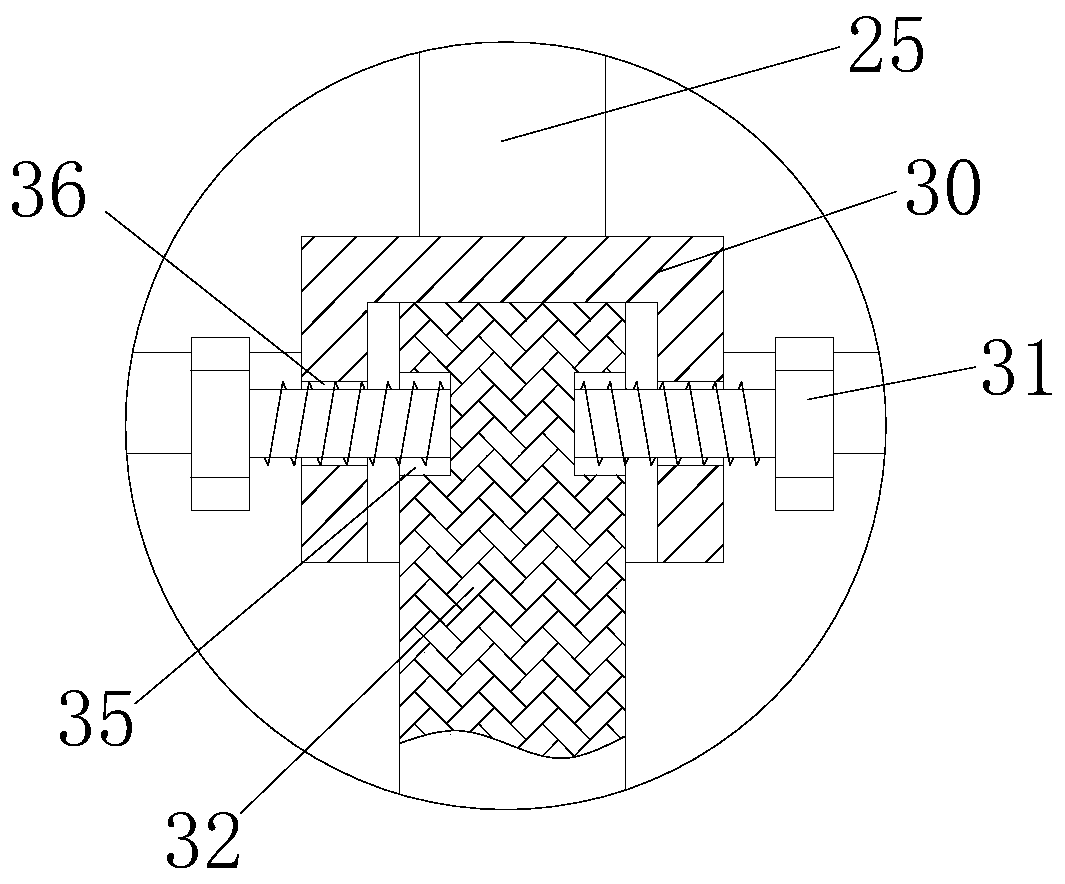

Double-oil-cylinder down jacking system and jacking construction method thereof

The invention provides a double-oil-cylinder down jacking system and a jacking construction method thereof. Double oil cylinders are adopted as jacking oil cylinders, the bottoms of oil cylinder barrels are fixed on a bottom frame, the heads of the oil cylinder barrels are connected with a jacking framework through additional supporting structures, and rod ends of piston rods are connected with a jacking frame. The jacking frame vertically ascends and descends between an upper guide wheel layer and a lower guide wheel layer of the jacking framework and is connected with or disconnected from a main chord of a tower body through axial movement of pin shafts. The bottom of the jacking framework is fixed on the bottom frame, and the top of the jacking framework is fixed on the ground through a cable rope. The double-oil-cylinder down jacking system is simple in structure, convenient to construct, high in safety and good in operating stability in a large stroke, one standard joint is jacked in each step, the number of step changing procedures is reduced, and efficiency is high. The step changing pin shafts are matched with step holes, and the danger that descending of the whole structure does not synchronize with descending of the jacking frame is avoided effectively. The jacking framework and the oil cylinders are all directly fixed on the bottom frame and matched with the cable rope to constitute the stable system, the structure of the system is simplified, and structure self-weight is reduced.

Owner:STATE GRID CORP OF CHINA +3

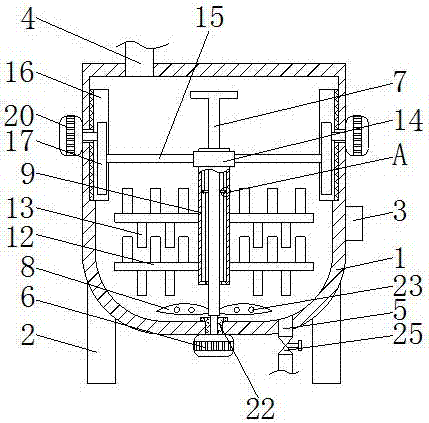

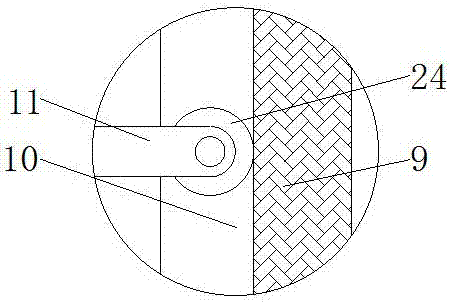

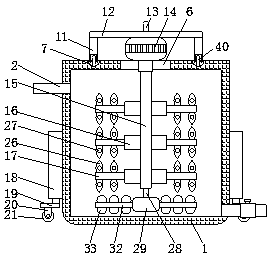

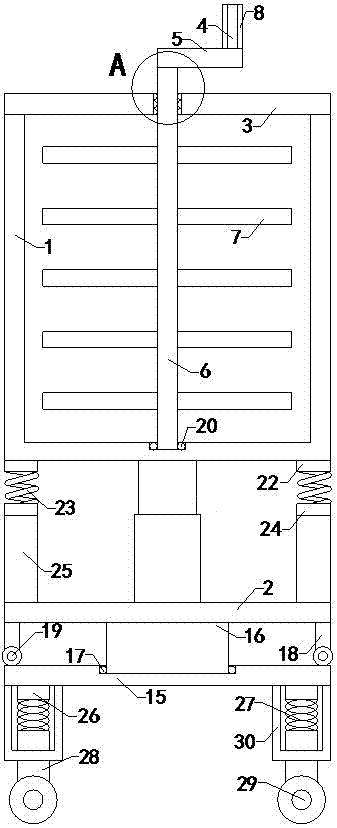

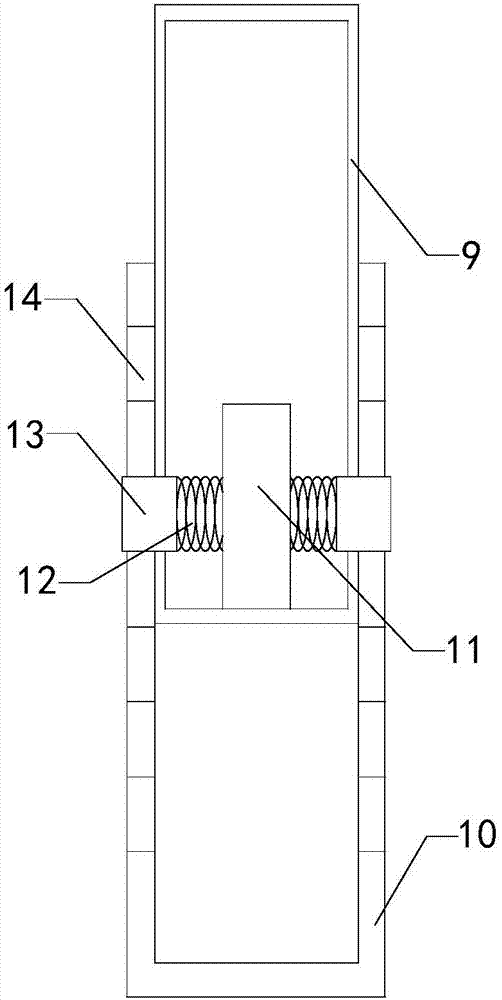

Agitating device for efficient sweet potato wine processing

InactiveCN107096422AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingReciprocating motionSlide plate

The invention discloses an agitating device for efficient sweet potato wine processing. The agitating device comprises a box body. Support legs are fixedly connected to both sides of the bottom of the box body. A controller is fixedly connected to the bottom of the right side of the box body. The left side of the top of the box body is communicated with a feeding pipe. The right side of the bottom of the box body between the support legs is communicated with a discharge pipe. The middle shaft at the bottom of the box body is fixedly connected to a motor. A rotation shaft of the motor extends into the inner cavity of the box body and is fixedly connected to a vertical rod. Stirring blades are fixedly connected to the bottom at two sides of the vertical rod. The surface of the vertical rod above the stirring blades is sleeved by a casing pipe. The sliding plate can move up and down and respectively drives a cross rod, a bearing, the casing pipe, a stirring rod and a stirring block to carry out vertical reciprocating motion so that the materials in the inner cavity are uniformly stirred and thus material stirring efficiency is improved and sweet potato wine production efficiency is improved.

Owner:耒阳市耒兴薯业发展有限公司

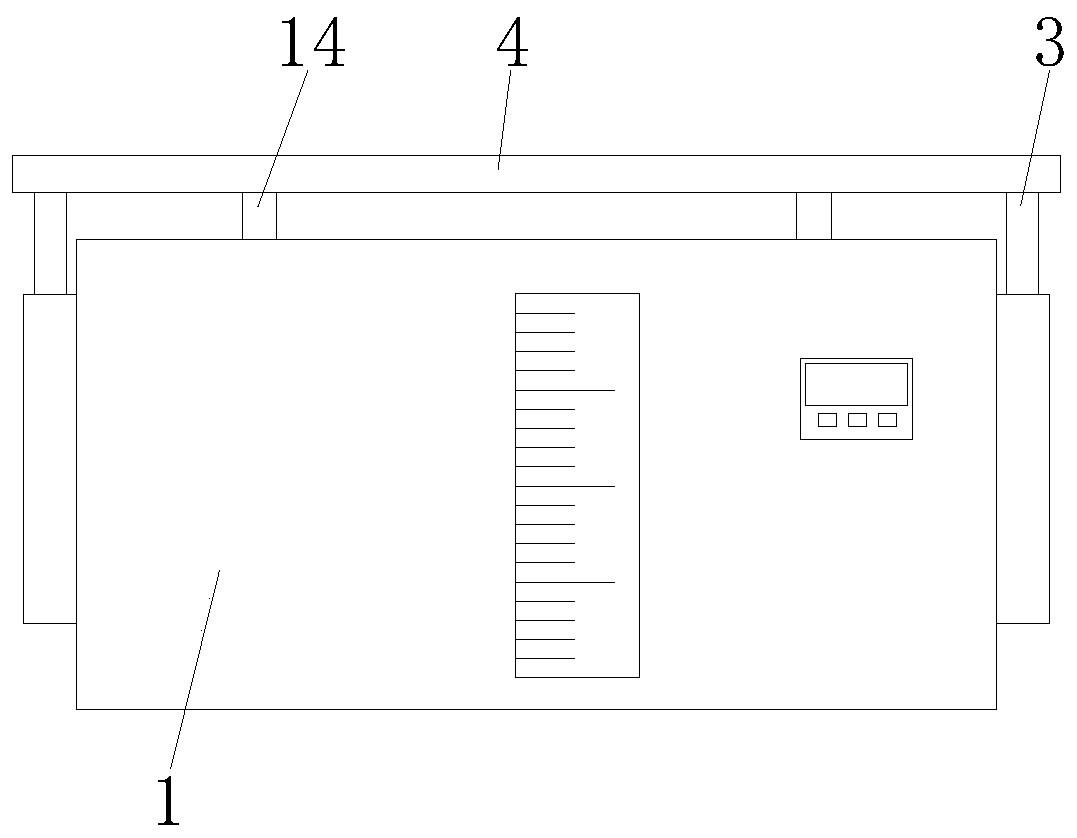

Textile fabric printing and dyeing equipment and printing and dyeing principle

InactiveCN110924015AImprove printing and dyeing qualityEasy to moveMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention discloses textile fabric printing and dyeing equipment and a printing and dyeing principle. The textile fabric printing and dyeing equipment comprises a box body, wherein an inner cavityof the box body is movably connected with a supporting shaft through a rotating shaft; an electric telescopic rod is fixedly connected to each of the front face and the back face of the box body separately; a flat plate is fixedly connected to the tops of the electric telescopic rods; a first spring is fixedly connected to the center of the bottom of the flat plate; the bottom of the first springextends to the inner cavity of the box body and is fixedly connected with a pressing plate; a vertical plate is fixedly connected to each of the front side and the rear side of the bottom of the pressing plate separately; and an extrusion shaft is movably connected to opposite sides of the vertical plates through a rotating shaft. The textile fabric printing and dyeing equipment has the advantages of carrying out pre-dedusting on cloth firstly and then rolling dye on the surface of the cloth, achieving high printing and dyeing quality and capability of scraping and collecting excess dye on the cloth, and solving the problems that the dye and the cloth are not tight in contact, the printing and dyeing quality is poor, scraping and collecting of excess dye on the cloth after printing and dyeing cannot be realized, the dye drips on the ground, and the waste of the dye is caused.

Owner:陈美和

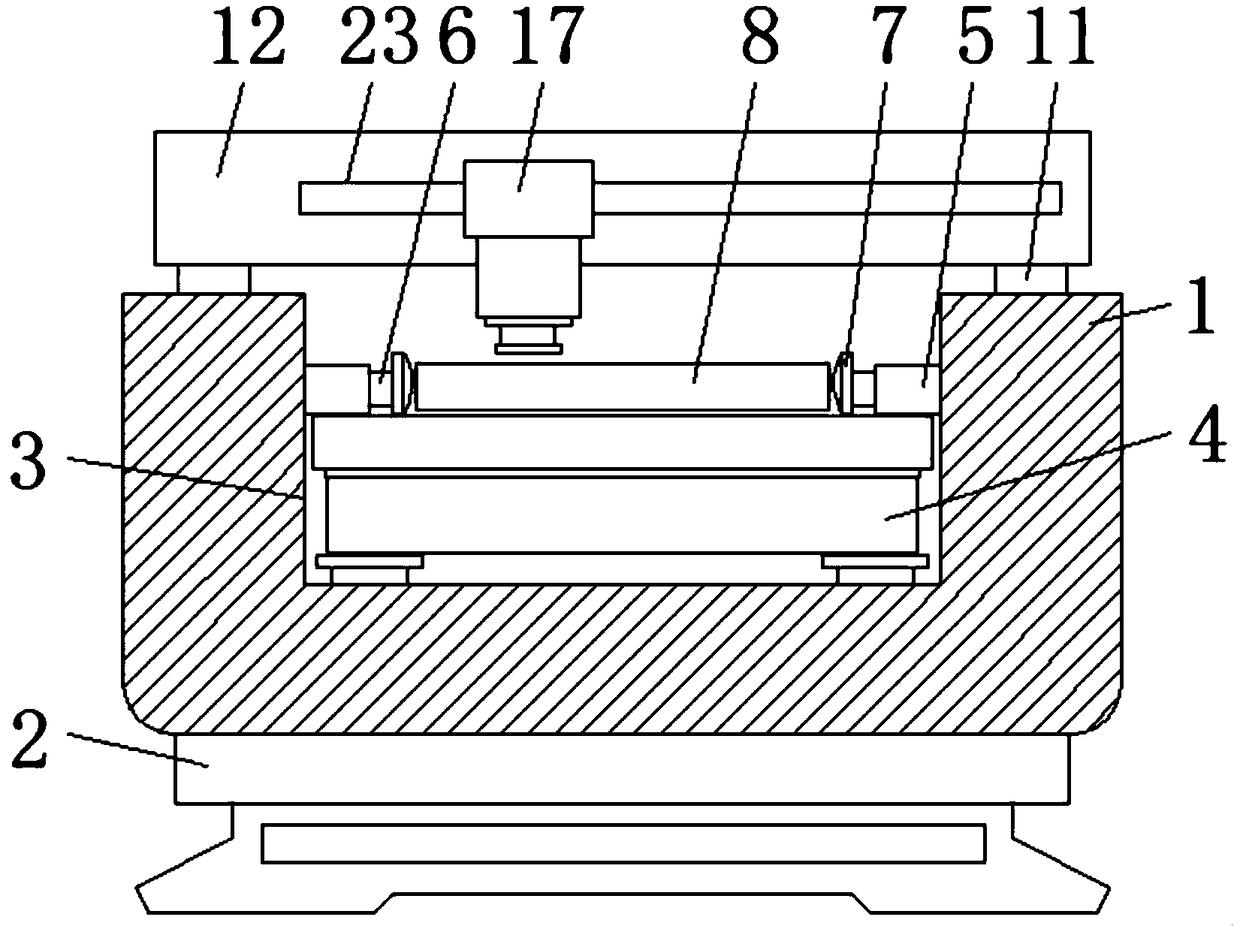

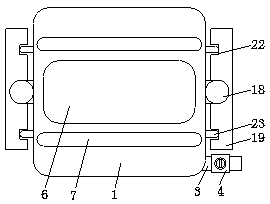

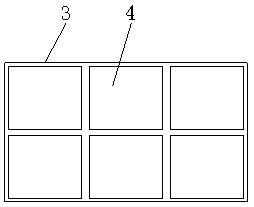

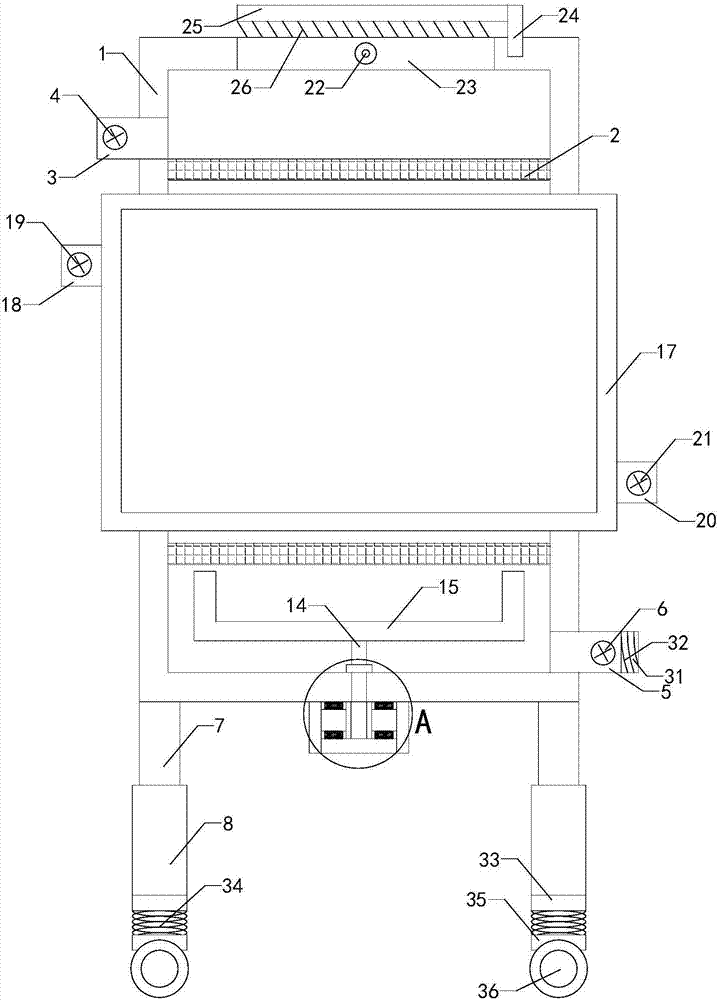

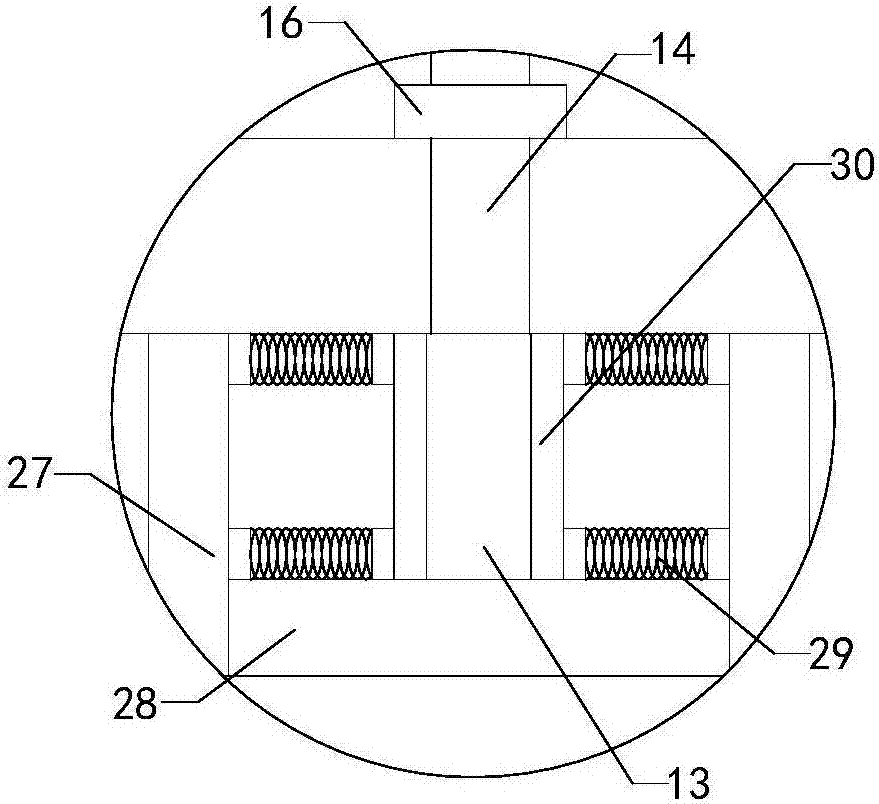

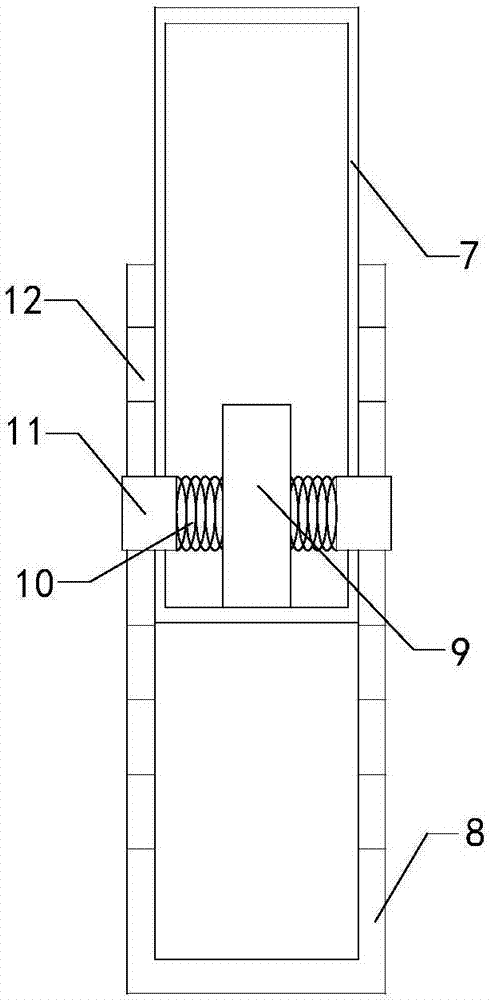

Liquid crystal display module detecting device

ActiveCN108828802ASolve the imperfect functionReduce manufacturing costNon-linear opticsMotor driveLiquid-crystal display

The invention relates to the technical field of liquid crystal display detecting devices, and discloses a liquid crystal display module detecting device. The device comprises a detecting table, the bottom of the detecting table is fixedly provided with a base, a sleeve groove is formed in the middle of the top end of the detecting table, the bottom surface of the sleeve groove is fixedly providedwith a lighting fixture, and sleeves located above the lighting fixture are fixedly mounted on the inner walls of both sides of the sleeve groove. A motor drives a screw to rotate, so that a movable block slides horizontally along a stable groove, the transverse movement of a detecting objective lens is achieved, convenience is provided for the detecting objective lens to detect a liquid crystal display screen transversely, a cover plate is pushed through an electro-hydraulic rod, a support rod drives a slide plate to slide along a fixed rod, the longitudinal movement of the detecting objective lens is achieved, convenience is provided for the longitudinal detection of the liquid crystal display screen by the detecting objective lens, a combination mechanism is used for achieving the lighting detection of the liquid crystal display screen quickly and effectively, convenience is provided for improving the detection efficiency, and detection errors are reduced.

Owner:深圳市百乐奇科技有限公司

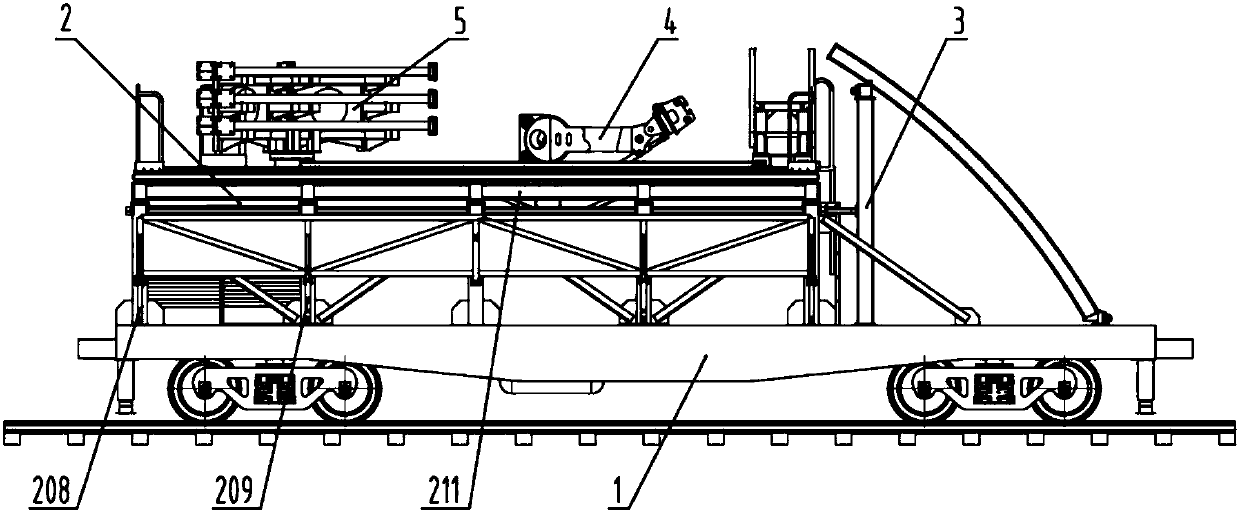

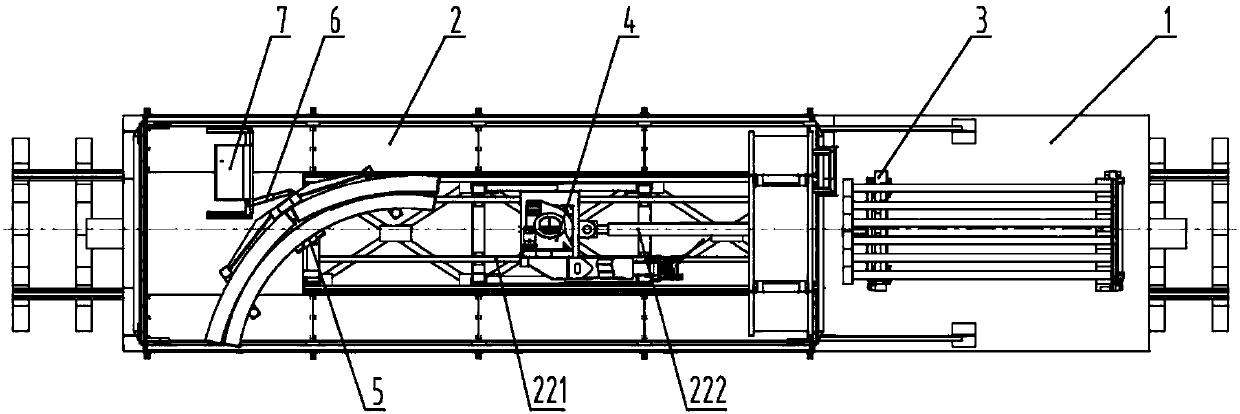

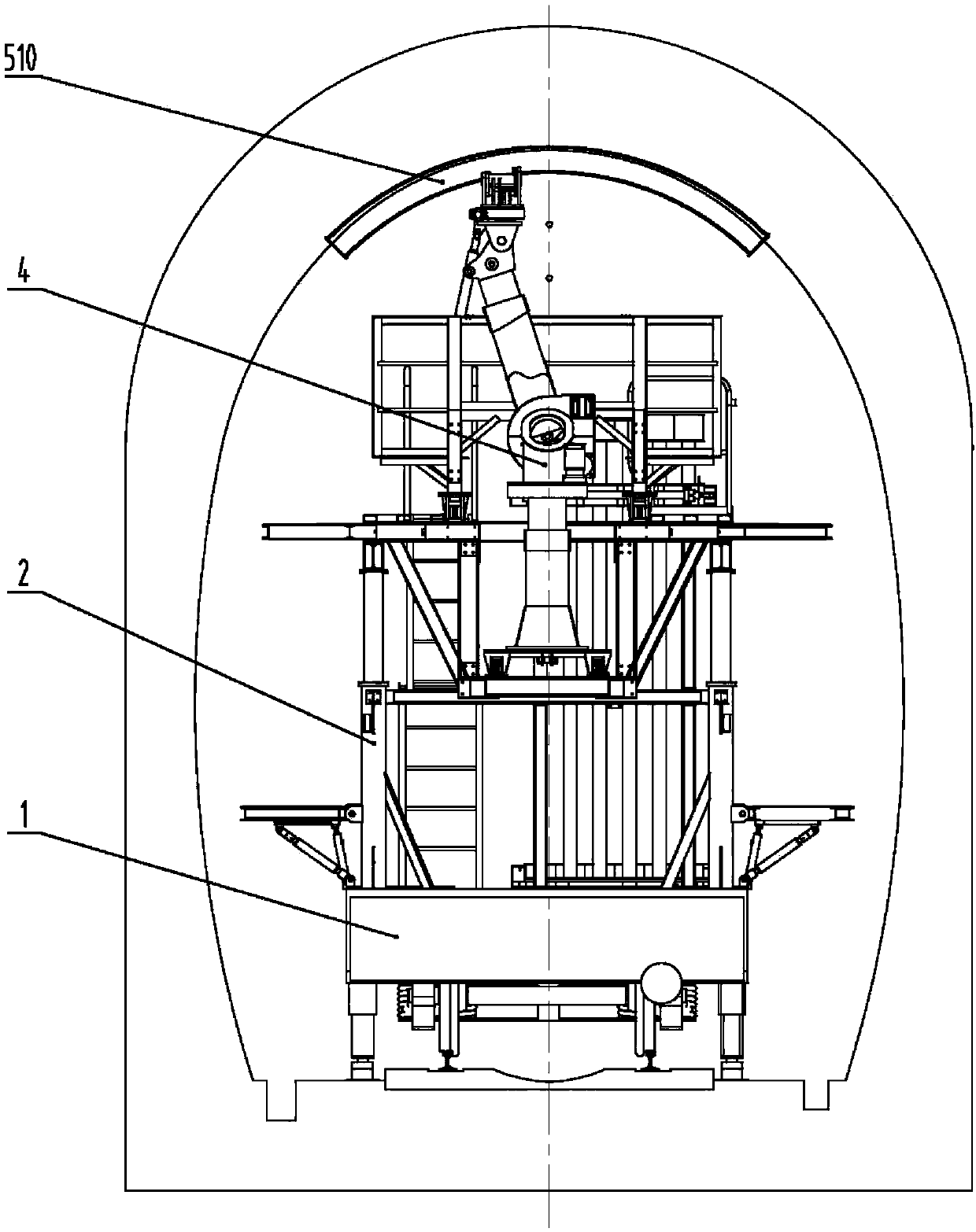

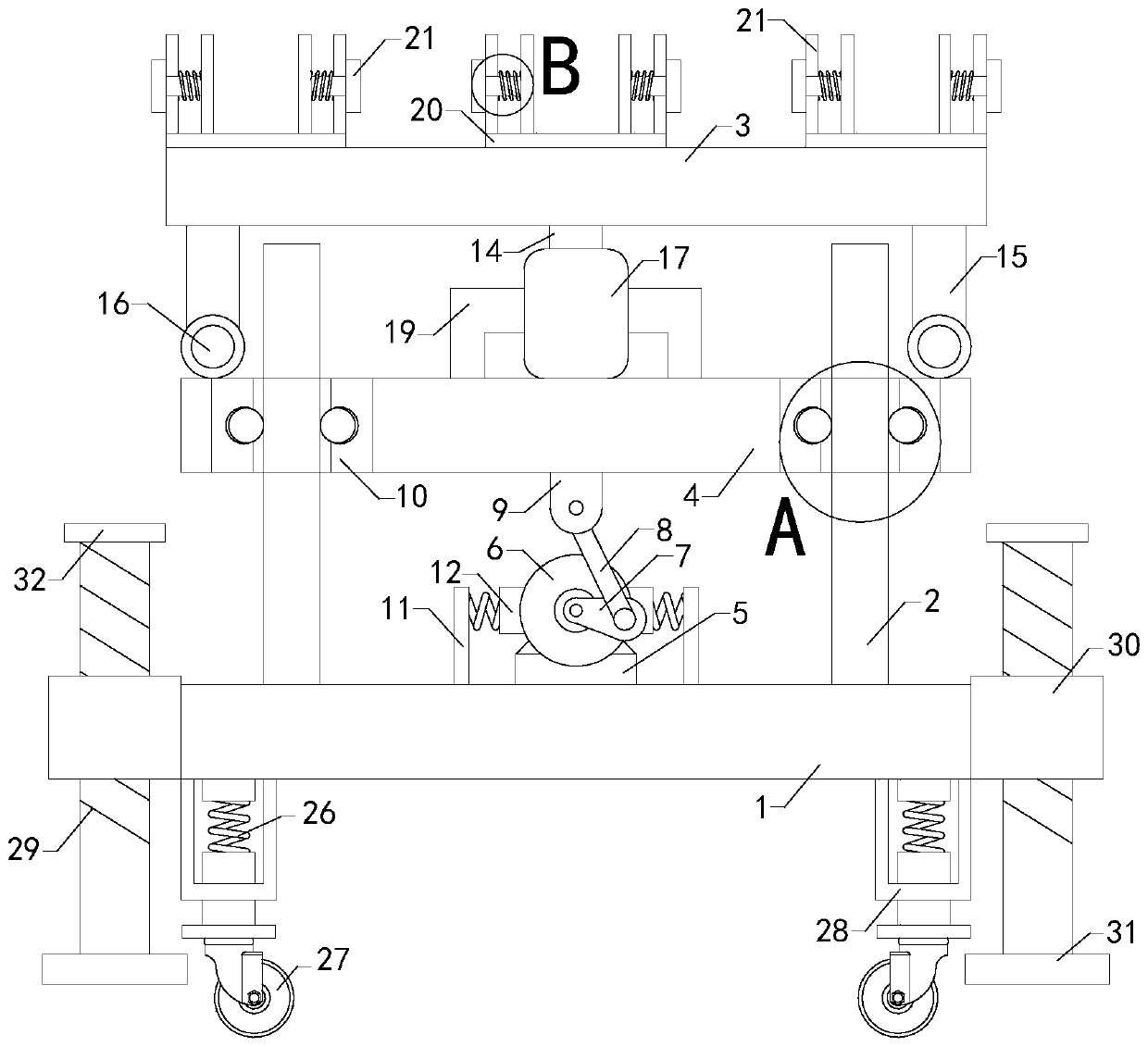

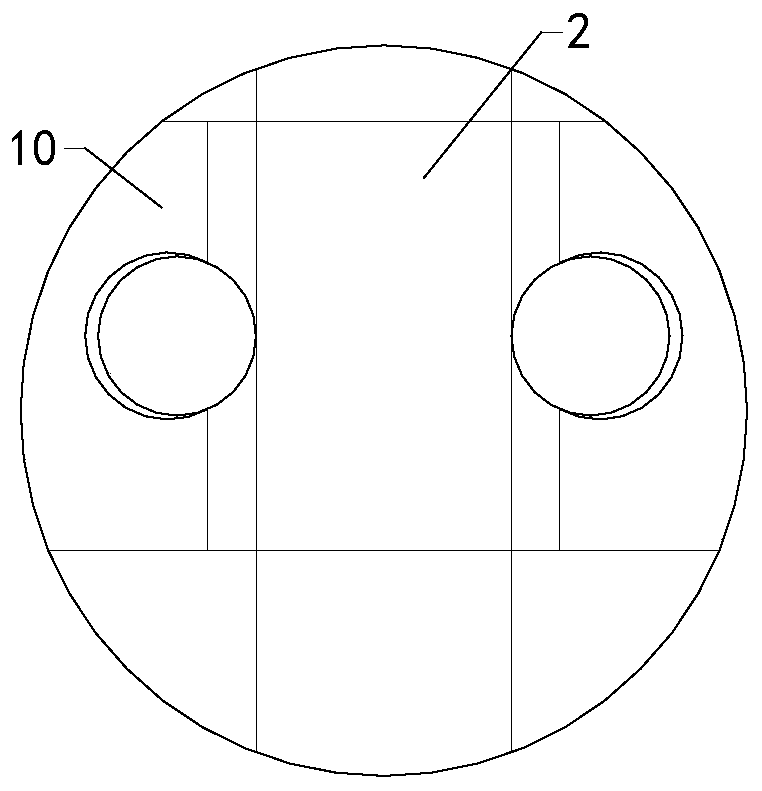

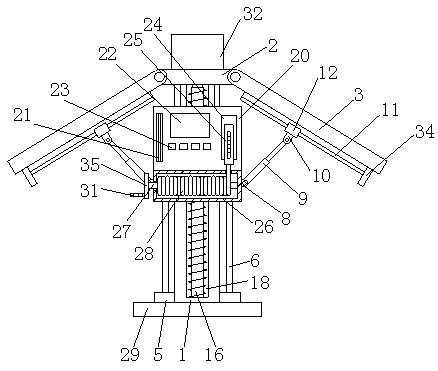

Steel arch frame mounting trolley used for operation tunnel disease treatment and steel arch frame mechanical mounting method used for operation tunnel disease treatment

PendingCN107654245AEasy to moveEasy and quick to reachUnderground chambersTunnel liningElectrical controlDisease treatment

The invention discloses a steel arch frame mounting trolley used for operation tunnel disease treatment. The steel arch frame mounting trolley comprises a steel arch frame mounting operating mechanism, an electrical control part and a hydraulic control part. The steel arch frame mounting operating mechanism comprises a railroad flatbed vehicle, a lift trolley, a side wall steel arch frame feedingmechanism, a steel arch frame mounting machine and an arch top and arch waist steel arch frame feeding mechanism, wherein the lift trolley and the side wall steel arch frame feeding mechanism are installed on the railroad flatbed vehicle, and the steel arch frame mounting machine and the arch top and arch waist steel arch frame feeding mechanism are mounted on the lift trolley. The invention further provides a steel arch frame mechanical mounting method used for the operation tunnel disease treatment. According to the steel arch frame mounting trolley, by arranging the railroad flatbed vehicle, the lift trolley, the side wall steel arch frame feeding mechanism, the steel arch frame mounting machine, the arch top and arch waist steel arch frame feeding mechanism, the electrical control partand the hydraulic control part, side walls and arch top and arch waist steel arch frames can be automatically mounted during tunnel disease treatment, the manpower input is reduced, the mechanizationand automation degrees are high, and the mounting efficiency, quality and operation safety of the steel arch frames of the tunnel disease treatment are sharply improved.

Owner:中铁西南科学研究院有限公司

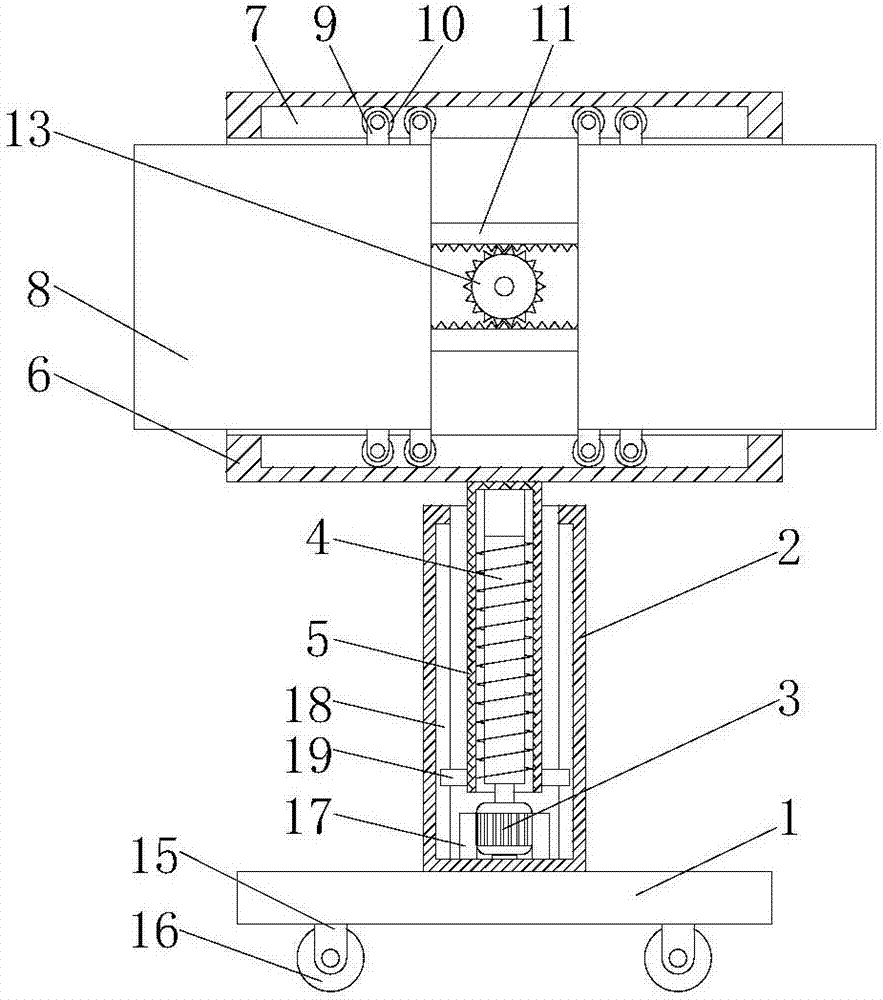

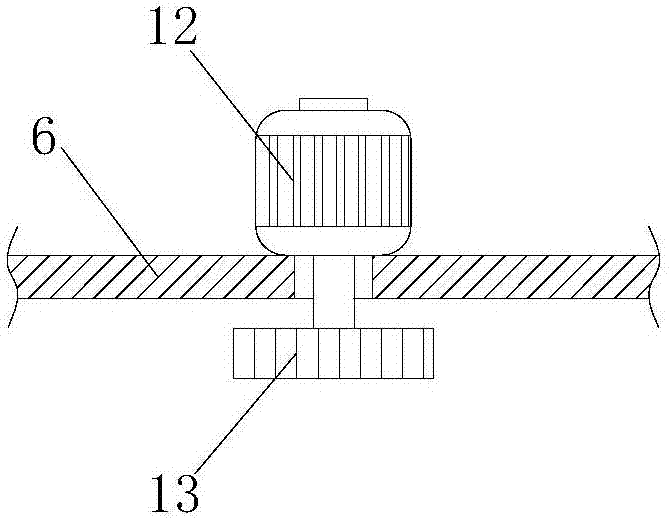

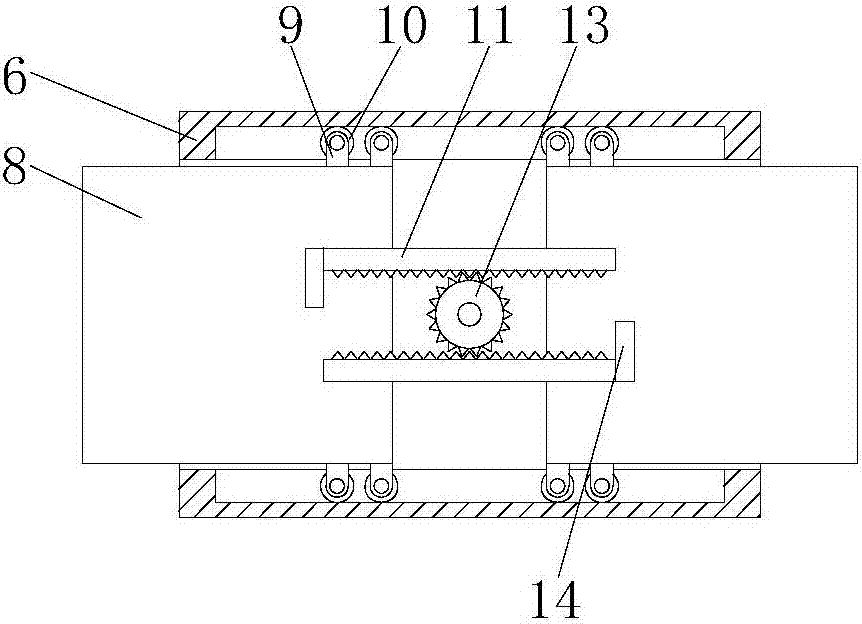

Medical infusion support moving conveniently

The invention discloses a mobile medical infusion stand, which comprises a box body, the top of the box body is fixedly connected with an electric telescopic rod, both sides of the electric telescopic rod are fixedly connected with hooks, and the top of the inner wall of the box body A fixed plate is fixedly connected, the right side of the bottom of the fixed plate is fixedly connected with a motor, the output end of the motor is fixedly connected with a first gear, the left side of the bottom of the fixed plate is fixedly connected with a bearing, and the bottom of the bearing A threaded rod is movably connected, and the surface of the threaded rod is sheathed with a second gear. In the present invention, a box body, an electric telescopic rod, a hook, a fixed plate, a motor, a first gear, a bearing, a threaded rod, a second gear, a threaded plate, a connecting frame, a vertical plate, a sliding rod, a support, a through hole, a first The cooperating use of the rollers, the support plate, the chute and the threaded hole achieves the effect of being easy to move, and is convenient for patients to use when transferring wards or going out on a wheelchair.

Owner:罗金明

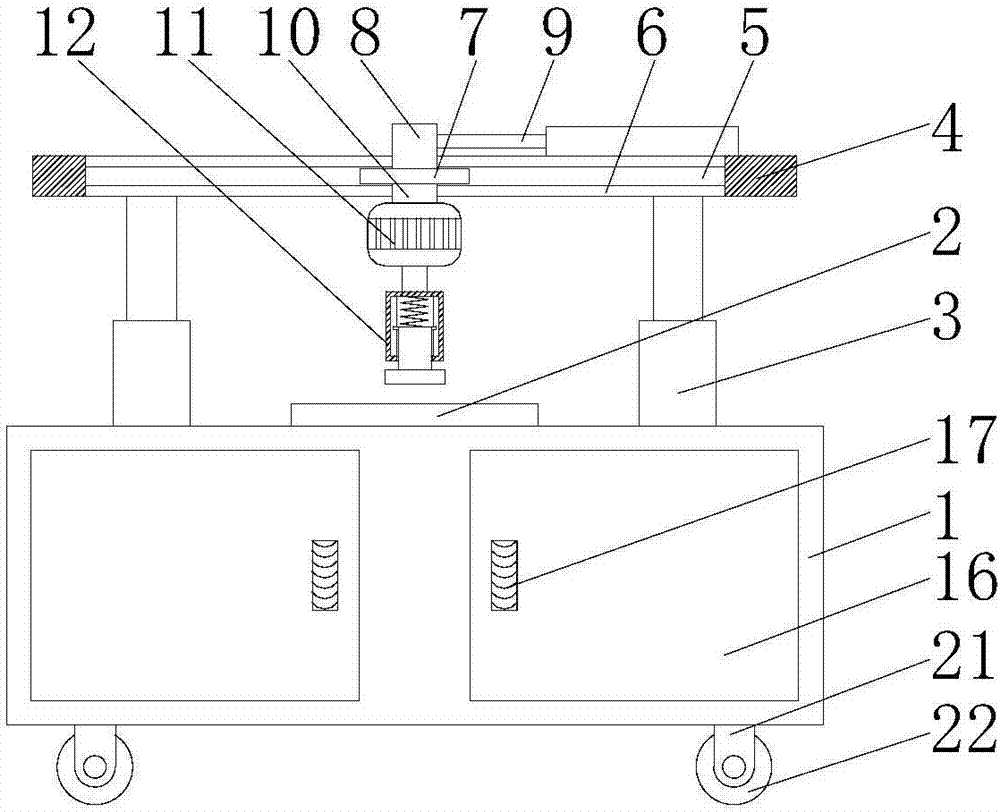

Concrete trowelling machine for construction

InactiveCN107718233AAdjustable distanceAdjust the troweling areaCeramic shaping apparatusStaff timeCombined use

The invention discloses a concrete trowelling machine for construction. The concrete trowelling machine for construction includes a box body, the bottom of the box body is provided with a long hole, the two sides of the top of an inner cavity of the box body are fixedly connected with first electric telescopic rods, and the bottoms of the first electric telescopic rods are fixedly connected with transverse plates. Through the arrangement of the first electric telescopic rods, the transverse plates can be lifted, so that the height of a trowelling plate used is adjusted. Through the matching ofgrooves, moving rods, grooves and threaded rods in use, the distance between a first motor and a second motor can be adjusted, so that a trowelling area of the trowelling machine is adjusted. Throughthe arrangement of second electric telescopic rods, rollers can be lifted; through the arrangement of the rollers, the trowelling machine is moved conveniently, and thus the concrete trowelling machine for construction has the advantages of being capable of adjusting the distance between the trowelling plates and adjusting the trowelling height, the time of repeated operation by workers is saved,and the concrete trowelling machine improves working efficiency and facilitates use by users.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

New energy battery electrolyte mixing processing device

InactiveCN109621798AIncrease the mixing areaImprove stirring efficiencyShaking/oscillating/vibrating mixersAssembling battery machinesElectrical batteryNew energy

The invention discloses a new energy battery electrolyte mixing processing device. The device comprises a box body, the top of the left side of the box body is communicated with a feeding pipe, the bottom of the right side of the box body is communicated with a discharging pipe, and a valve is arranged on the surface of the discharging pipe; a sealing box is fixedly connected to the top of the boxbody, and a square hole is formed in the top of the box body; long grooves are formed in the portions, on the front side and the rear side of the square hole, on the top of the box body respectively;the top of the right side of the sealing box is fixedly connected with a first motor. A stirring rod can transversely move in the process of electrolyte stirring, and the position of the stirring rodcan be adjusted, so that the stirring area of the stirring rod is increased, the electrolyte stirring efficiency is improved, and the production efficiency is improved. The problems that an existingstirring device for a new energy battery is relatively monotonous in stirring mode, the stirring area of the stirring rod is fixed, the position of the stirring rod cannot be adjusted, the electrolytestirring efficiency is reduced and the production efficiency is reduced are solved.

Owner:邵新祥

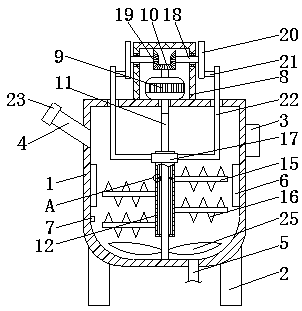

Extraction device for extracting rose flower extract

InactiveCN109107216AStir wellStir to refine and homogenizeShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionArchitectural engineering

The invention discloses an extraction device for extracting a rose flower extract. The extraction device comprises a tank body, support legs are fixedly connected to both sides of the bottom of the tank body, a controller is fixedly connected to the top of the right side of the tank body, a feed pipe is connected to the top of the left side of the tank body, the left side of the bottom of the tankbody is connected with a discharge pipe, a heating block is fixedly connected to both sides of the tank body, a temperature sensor is fixedly connected to the bottom of the left side of the tank body, a motor box is fixedly connected to the top of the tank body, a motor is fixedly connected to the top of the tank body and located in the inner cavity of the motor box, and the top of the motor shaft is sleeved with a first bevel gear. The extraction device can make the sleeve reciprocate up and down, so that a stirring rod and a stirring block can be driven to reciprocate, a fusion object in the inner cavity of the tank body can be fully stirred, the stirring of the fusion object can be more refined and uniform, so that the mixing efficiency of the fusion object is increased.

Owner:张俊铭

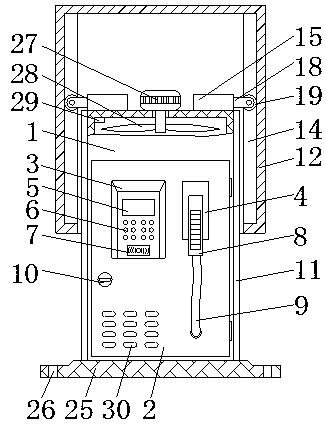

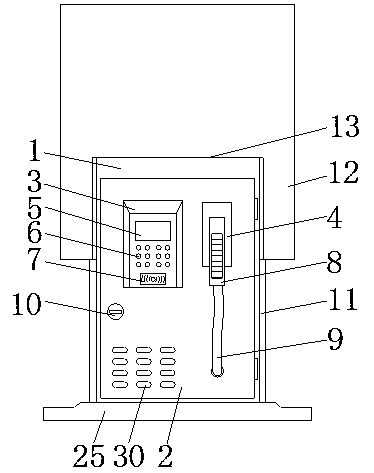

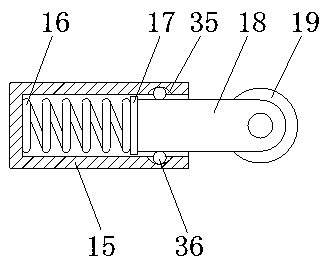

Publicity board adjustable in width

The invention discloses a publicity board with adjustable width, which comprises a base, the top of the base is fixedly connected with a vertical pipe, the top of the inner cavity of the vertical pipe is fixedly connected with a first motor, and the rotating shaft of the first motor is fixedly connected with There is a threaded rod, the top of the threaded rod is covered with a threaded pipe, the top of the threaded pipe extends to the outside of the vertical pipe, the top of the threaded pipe is fixedly connected with a fixing plate, and the top and bottom of the fixing plate are both A first chute is opened, movable plates are arranged on both sides of the inner cavity of the fixed plate, and the top and bottom of the movable plate are fixedly connected with a first slide bar, and the end of the first slide bar is far away from the movable plate Extends to the lumen of the first chute. The invention can make the rack move laterally, and the rack drives the movable plate to move laterally, so that the movable plate extends out of the inner cavity of the fixed plate, and information can be posted on the movable plate, which increases the publicity area of the publicity board and is convenient for people to use.

Owner:SUZHOU MOCHOU CULTURE TECH CO LTD

Sample showing stand for medical instrument sales

InactiveCN110384373AEasy to limitSmooth slidingNon-rotating vibration suppressionShow shelvesDrive shaftEngineering

The invention relates to the technical field of sample display accessory devices, in particular to a sample showing stand for medical instrument sales. The overall use height of the sample showing stand can be conveniently adjusted according to the display environment requirements, so that the adaptability of the sample showing stand is improved, and the use limitation is reduced; the sample showing stand comprises a bottom plate, four groups of brackets and a display panel, and further comprises a placement block, a base, a first motor, a first transmission shaft, a driving shaft and a driving block, wherein the first motor is arranged at the top end of the base; one end of the first transmission shaft is fixedly connected to the output end of the front side of the first motor, and the other end of the first transmission shaft is rotatably connected with one end of the driving shaft; the other end of the driving shaft is rotatably connected with the driving block; the driving block isinstalled in the middle of the bottom end of the placement block; fixed blocks are arranged on the left side and the right side of the front side wall of the placemen block and the left side and theright side of the rear side wall of the placement block respectively, and through grooves are longitudinally formed in the four sets of fixed blocks in the longitudinal direction; ball sets are rotationally fixed on the inner side walls of the four sets of through grooves; and the sample showing stand also comprises two groups of cushioning plates, two groups of cushioning springs and two groups of cushioning blocks.

Owner:盐城盐西幸福产业发展有限公司

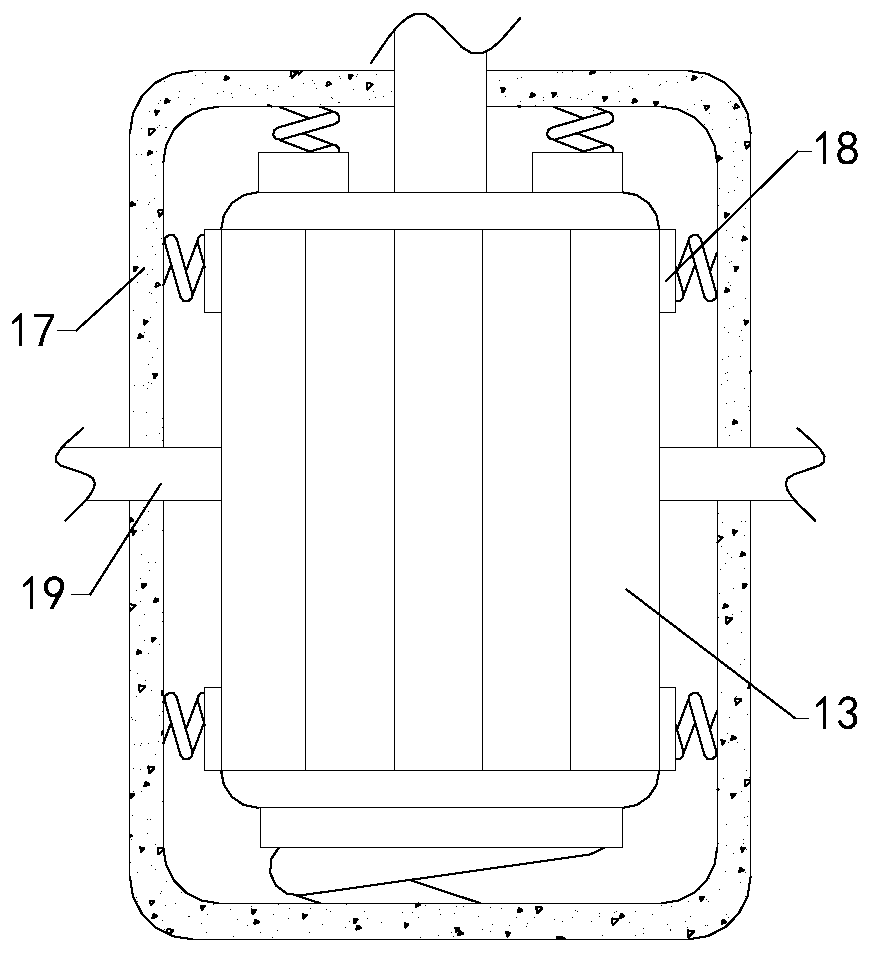

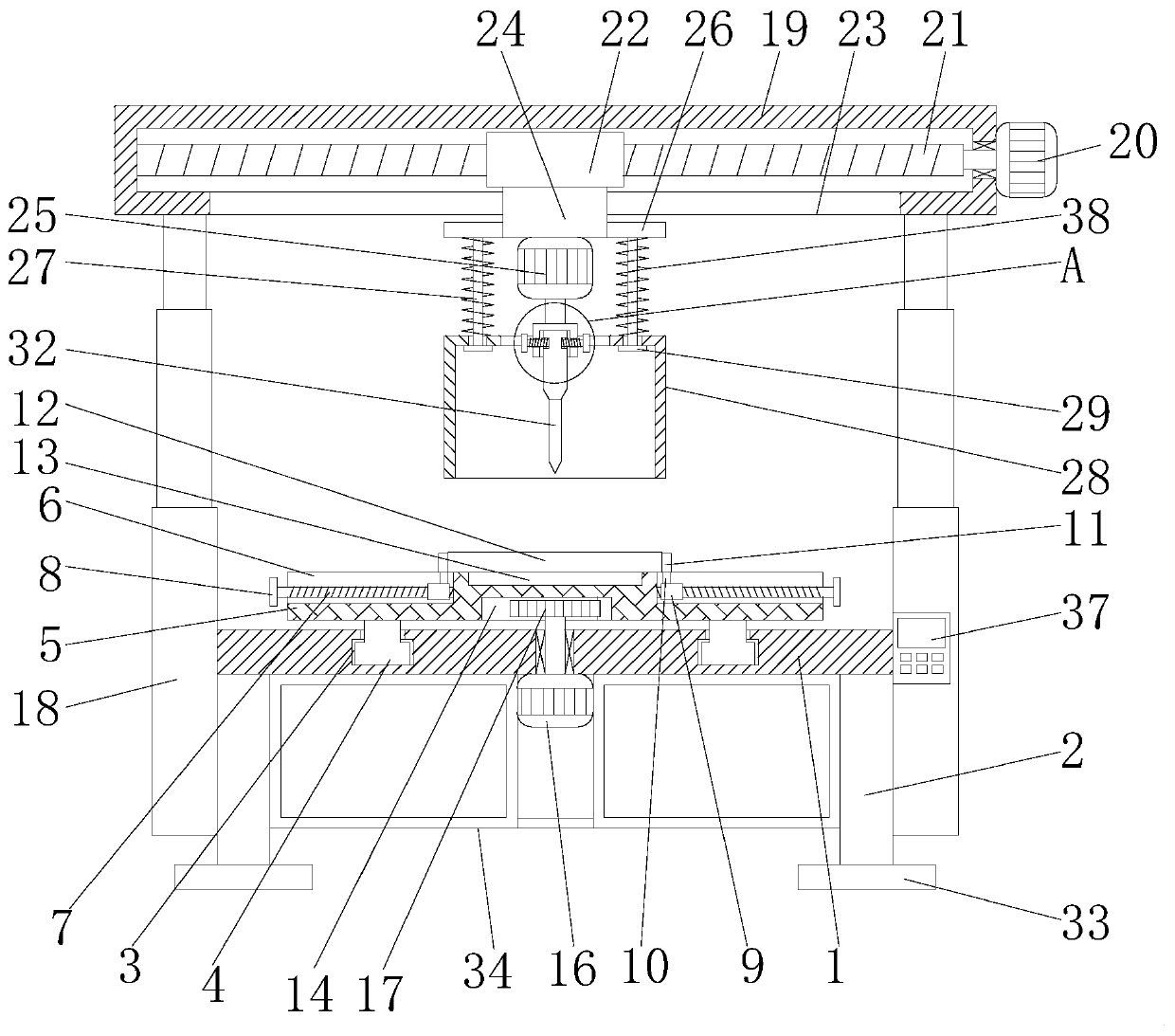

Lamp manufacturing and punching device

InactiveCN111069652AAdjustable lateral positionIncrease flexibilityFeeding apparatusPositioning apparatusStructural engineeringThreaded rod

The invention discloses a lamp manufacturing and punching device. The lamp manufacturing and punching device comprises a flat plate and bolts, wherein supporting legs are fixedly connected to the twosides of the bottom of the flat plate; sliding grooves are formed in the two sides of the top of the flat plate; sliding blocks are in sliding connection with inner cavities of the sliding grooves; the tops of the sliding blocks extend to the outer parts of the sliding grooves and are fixedly connected with a moving table; transverse grooves are formed in the two sides of the top of the moving table; and first threaded rods are movably connected to the inner walls of the transverse grooves. The lamp manufacturing and punching device has the beneficial effects that the longitudinal position ofa lamp panel can be adjusted, the transverse position of a drill rod can be adjusted, the drilling flexibility is improved, and chippings generated in the drilling process are shielded; and the problems that after an existing lamp panel drilling device fixes the lamp panel, the position of the lamp panel cannot be adjusted, the position of the drill rod cannot be conveniently adjusted, the drilling flexibility is reduced, the chippings cannot be shielded in the drilling process, the chippings are likely to fly to the periphery, and injuries are likely to be brought to operators are solved.

Owner:南京雷仕光电科技有限公司

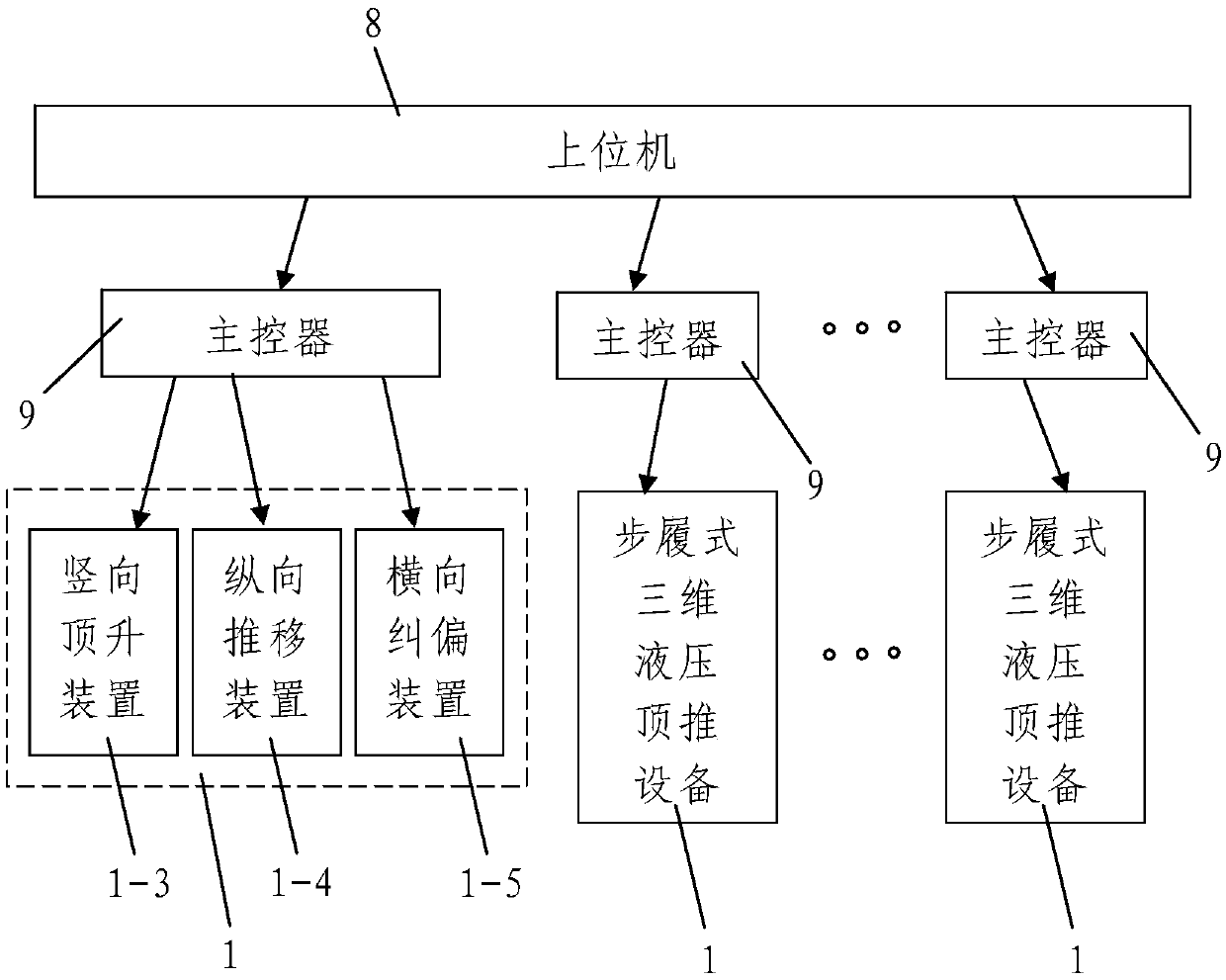

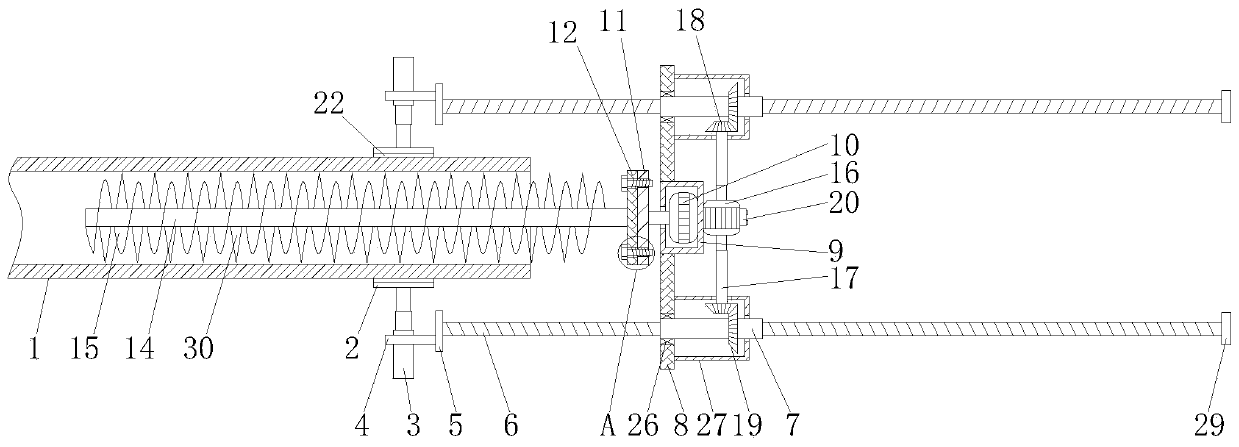

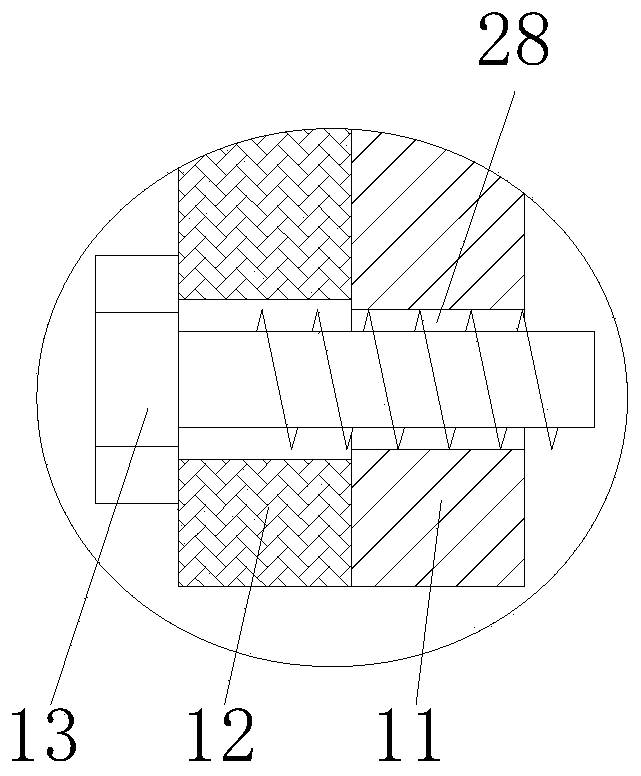

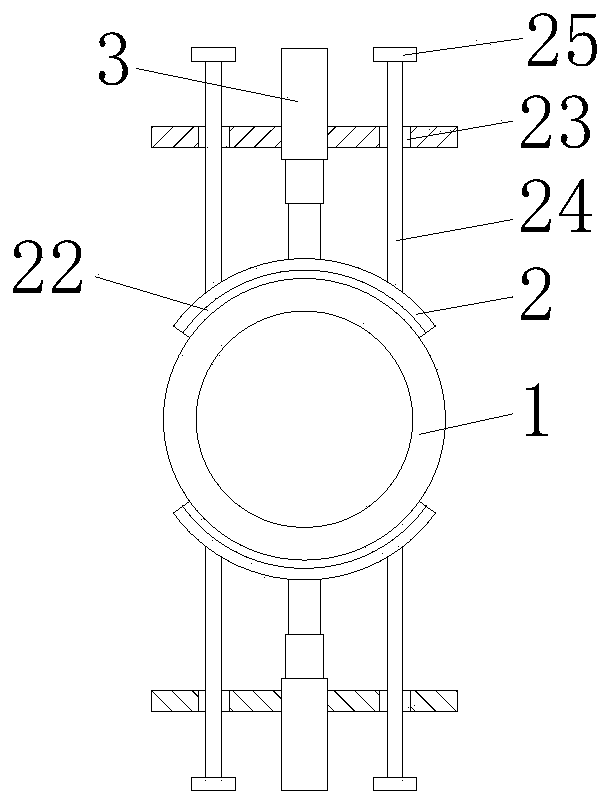

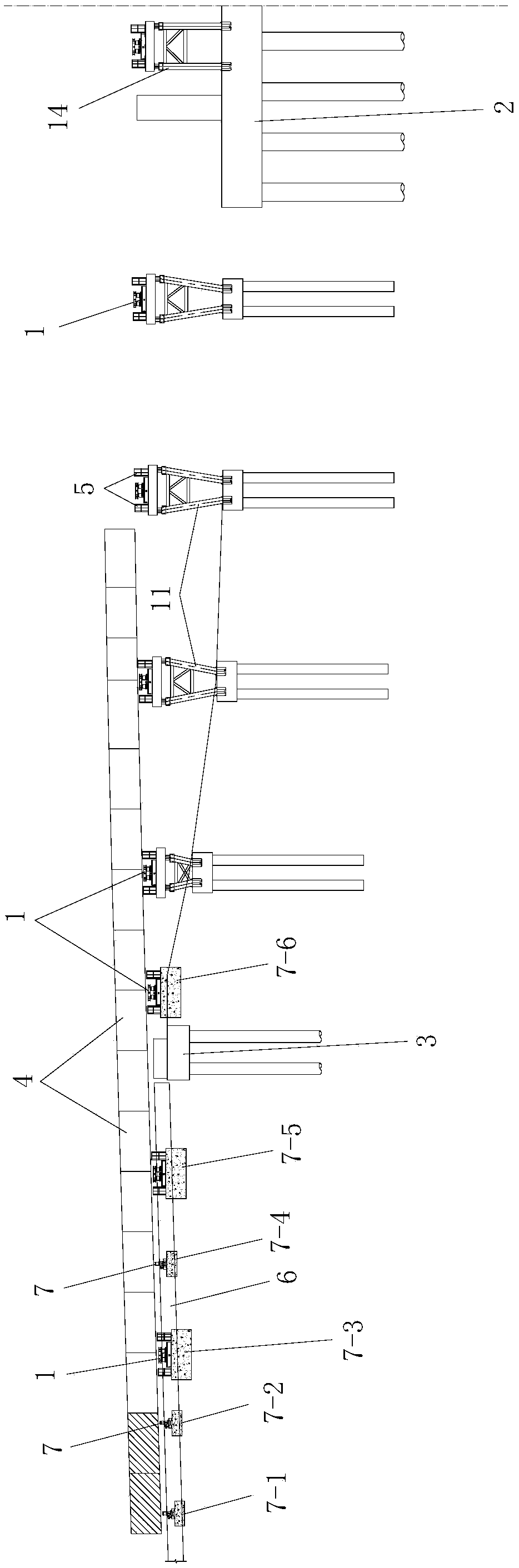

Pushing system and method for PLC multipoint synchronous three-dimensional hydraulic bridge

ActiveCN109629441AReasonable structural designEasy to operateBridge erection/assemblyButtressMonitoring system

The invention discloses a pushing system and method for a PLC multipoint synchronous three-dimensional hydraulic bridge. The pushing system comprises a pushing monitoring system and multiple groups ofwalking-type three-dimensional hydraulic pushing devices for pushing pushed steel box beams, and each pushing buttress is provided with a left temporary supporting base and a right temporary supporting base which are symmetrically distributed. The pushing method includes the steps of 1, constructing assembly jig frames and temporary buttresses; 2, constructing a three-dimensional adjusting device, the pushing devices and the temporary supporting bases; 3, carrying out steel-box-beam assembling and synchronous pushing; 4, carrying out steel-box-beam pushing. According to the pushing system andmethod for the PLC multipoint synchronous three-dimensional hydraulic bridge, steel box beams are synchronously pushed forwards multiple times through the multiple groups of walking-type three-dimensional hydraulic pushing devices, pushing controlling is easy and convenient, synchronous action of the multiple groups of walking-type three-dimensional hydraulic pushing devices can be easily and conveniently achieved, pushing positions are flexibly distributed, guide beams and sliding rail beams for longitudinal pushing are not required, self-balancing pushing is really achieved, and the pushingprocess is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Positioned pipeline dredging equipment and using method

InactiveCN111282927AIncrease laborResolve functions that don't have positioningHollow article cleaningGrain treatmentsMarine engineeringThreaded pipe

The invention discloses positioned pipeline dredging equipment and a using method. The positioning pipeline dredging equipment comprises a pipe body and a bolt, wherein clamping rings are arranged atthe top and the bottom of the pipe body; an electric telescopic rod is fixedly connected with the side, far away from the pipe body, of the clamping rings; a fixed plate is fixedly arranged on the surface of the electric telescopic rod in a sleeving manner; a connecting plate is fixedly connected with the right side of the fixed plate; a threaded rod is movably connected with the right side of theconnecting plate; a threaded pipe is in threaded connection with the surface of the threaded rod in a sleeving manner; and a sleeving plate is arranged on the surface of the threaded pipe in a sleeving manner. The positioned pipeline dredging equipment has the advantages of being positioned and fixed on the pipeline and automatically dredging the pipeline to discharge impurities in the pipeline out, and solves the problems that the existing pipeline dredging equipment does not has the positioning function, needs manual lifting operation during the conveying process, wastes time and labor, increases the labor amount of an operator, cannot automatically control to dredge the pipeline, cannot discharge impurities in the pipeline out and impurities are inconvenient to clean.

Owner:重庆百重泉环保科技有限公司

Cloth clamping device for spinning

The invention discloses a cloth clamping device for weaving, which comprises a base, the left side of the top of the base is fixedly connected with a left support plate, the right side of the top of the base is fixedly connected with a right support plate, and the top of the left side of the left support plate is An electric box is fixedly connected, and the inner cavity of the electric box is provided with a motor. The present invention uses a base, a left support plate, a right support plate, a motor, a rotating rod, a cross bar, a reel, a box body, a connecting block, a moving plate, a connecting frame, a first connecting rod, a fixed block, an electric telescopic rod, and a moving rod. , casing, spring, support plate and the second connecting rod have the advantages of stabilizing the curled fabric, and solve the problem that the existing textile winding device cannot clamp the textile when winding the textile, and it needs to be wound manually. When the cloth is wound by driving the reel to rotate, the operation is cumbersome, which reduces the work efficiency, causes the textiles to be easily crumpled after being rolled up, and reduces the quality of the textiles.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

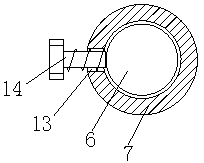

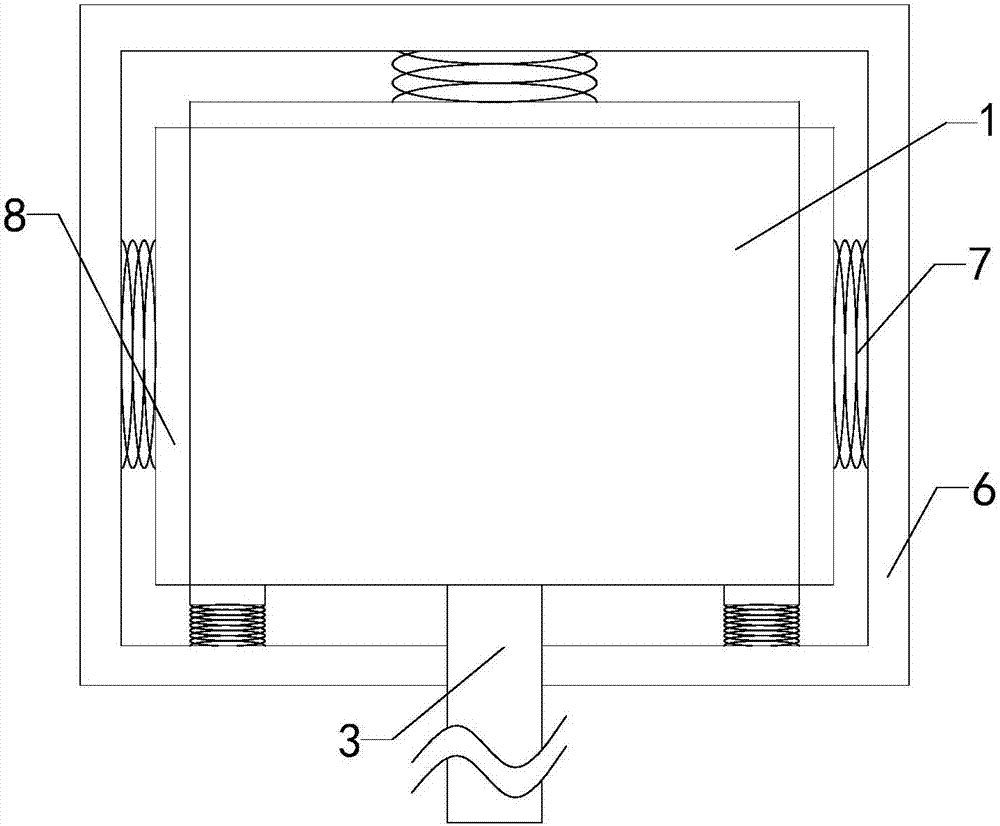

Cloth cleaning box for fiber cloth processing

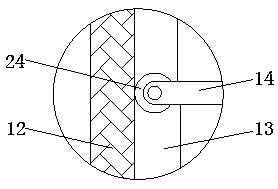

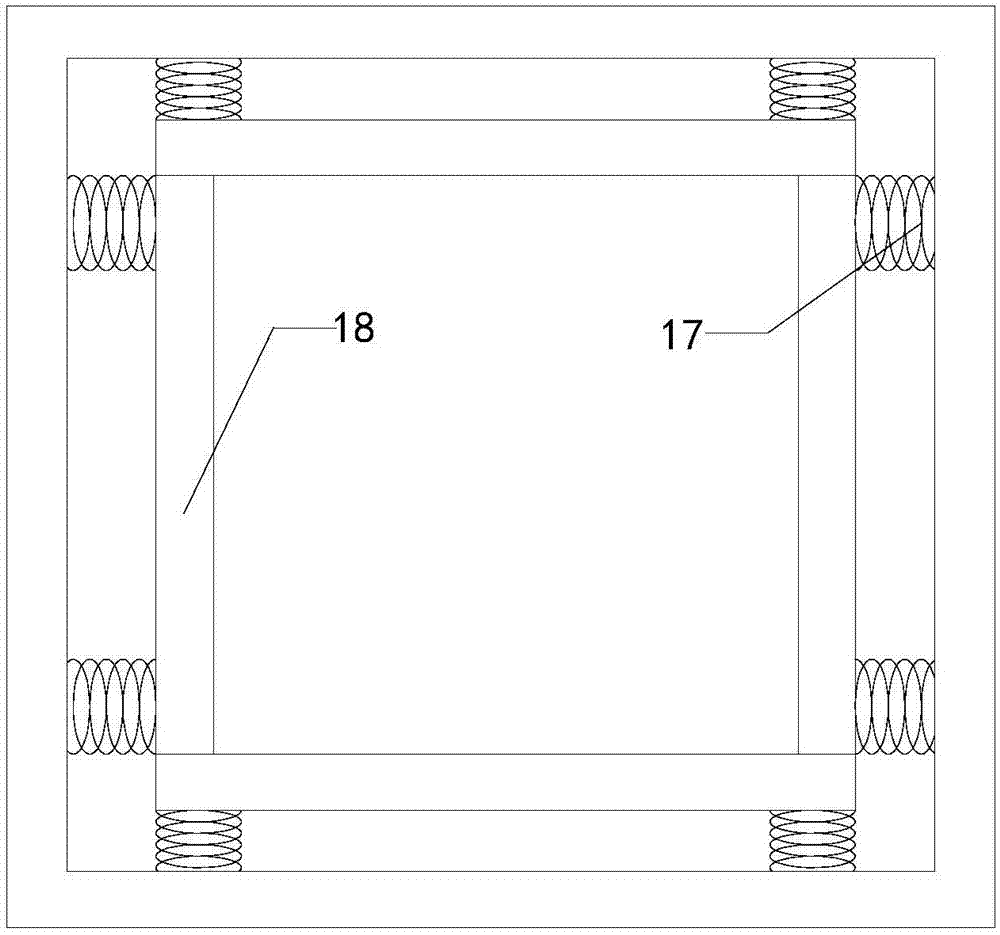

InactiveCN107345348AEasy to cleanEasy to move verticallyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentFiberBall bearing

The invention relates to the technical field of cloth cleaning accessory devices and in particular relates to a cloth cleaning box for fiber cloth processing. The cloth cleaning box for fiber cloth processing is relatively great in fiber cloth cleaning force and the cleaning degree is improved; moreover, the height of a working box can be adjusted according to the height of a user, so that the adaptability of the cloth cleaning box for fiber cloth processing is improved; the working box can rotate, so that the limitation of the cloth cleaning box for fiber cloth processing is reduced; the cloth cleaning box for fiber cloth processing comprises the working box, a bottom plate and a bracket, and also comprises a handle, a connecting shaft, a rotating shaft and a cleaning blade; an anti-skid cover is arranged on the outer side of the handle; the bracket comprises an insertion column, an insertion tube, a limiting column, two limiting springs and two limiting blocks; a left through hole and a right through hole are separately formed in the left side wall and the right side wall of the insertion column; a plurality of left limiting holes and a plurality of right limiting holes are longitudinally formed in the left side wall and the right side wall of the insertion tube, separately; the cloth cleaning box for fiber cloth processing also comprises a supporting plate and a rotating column, a lower placing tank is formed in the top end of the supporting plate, and a lower ball bearing is arranged in the lower placing tank; and the cloth cleaning box for fiber cloth processing also comprises two supporting columns and two pulleys.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

Automatic pressure-regulating anesthesia machine for anesthesia department

InactiveCN109260556AReduce laborGuaranteed ventilationRespiratorsMedical devicesVertical tubeAnesthetic gases

The invention discloses an automatic pressure regulating anesthesia machine for anesthesia department, including an anesthetic machine body, and the front surface of the anesthetic machine body is sequentially provided with an anesthetic gas flow meter, a display screen and an oxygen flow meter from the left to the right; the anesthetic gas pressure gauge and the oxygen pressure wheel gauge are fixedly connected from the left to the right at the bottom of the front face of the anesthetic machine body; a horizontal tube is communicated between the anesthetic gas flow meter and the oxygen flow meter; a vertical tube is communicated at the top of the horizontal tube; and an end of the vertical tube away from the horizontal tube is communicated with a hose. The anesthetic machine body, the anesthetic gas flow meter, the display screen, the oxygen flow meter, the anesthetic gas pressure gauge, the oxygen pressure wheel gauge, the horizontal tube, the vertical tube, the hose, a face mask anda pressure regulating device are cooperated, so that the oxygen pressure can be automatically regulated, the regulating precision is improved, the labor of an operator is reduced, the help of an assistant is not needed, the operation is convenient, the normal ventilation of a patient is fully ensured, and the use of the pressure regulating device is convenient.

Owner:邓磊

Steel box girder incremental launching construction method based on walking type three-dimensional hydraulic incremental launching equipment

ActiveCN109629440AThe method steps are simpleReasonable designBridge erection/assemblySteel box girderBuilding construction

The invention discloses a steel box girder incremental launching construction method based on walking type three-dimensional hydraulic incremental launching equipment. The two ends of a construction steel box girder are each supported on a girder end pier, and the construction steel box girder is divided into a first girder body and a second girder body with a midspan pier being the boundary; incremental launching construction includes the steps that 1, temporary piers and midspan temporary piers are constructed; 2, incremental launching is conducted on the girder bodies synchronously throughthe walking type three-dimensional hydraulic incremental launching equipment; 3, midspan closing is conducted. The walking type three-dimensional hydraulic incremental launching equipment is adopted for conducting incremental launching on the two girder bodies synchronously until the two girder bodies of the constructed steel box girder are closed from two sides to the midspand; incremental launching of the walking type three-dimensional hydraulic incremental launching equipment is easy and convenient to control, multiple sets of walking type three-dimensional hydraulic incremental launching equipment can easily and conveniently act synchronously, incremental launching positions are arranged flexibility, a guide beam and a slideway beam used for longitudinal incremental launching are not needed, self-balance incremental launching is really realized, and the process of incremental launching is safe and reliable.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Solar charging pile convenient to adjust

InactiveCN110154807AAdjust the tilt angleTake advantage ofPhotovoltaic supportsCharging stationsSolar cellOperations management

The invention discloses a solar charging pile convenient to adjust. A supporting box is included, and the top of the supporting box is fixedly connected with a connection plate; the two sides of the connection plate are each movably connected with a supporting plate through a rotating shaft; the tops of the supporting plates are fixedly connected with solar cell panels, and the number of the solarcell panels is twelve; the bottoms of the two sides of the supporting box are each fixedly connected with a fixed block; vertical rods are fixedly connected to the tops of the fixed blocks; the surfaces of the vertical rods are sleeved with slide sleeves; and the ends, away from the supporting box, of the slide sleeves are fixedly connected with first connection blocks. The solar charging pile convenient to adjust avoids that an outer automobile collides with a charging box, the charging box can be protected, and the problems that the height of an existing charging pile cannot be adjusted, the height of the charging pile is too low, collision with an automobile is easy, the charging pile cannot be protected very well, and therefore the huge economic loss is caused, the charging pile cannot fully utilize solar energy, and resource waste is caused are solved.

Owner:浙江国正安全技术有限公司

Electronic product showing shelf

InactiveCN107374193AEasy to move verticallyEasy to placeShow cabinetsShow shelvesBusiness cardBall bearing

The present invention relates to the technical field of electronic product display attachments, in particular to an electronic product display rack, the height of which can be adjusted according to the display needs to improve its adaptability; and the display box can be rotated to reduce its use limitations ; and it can carry out detailed written introductions to electronic products, thereby improving its practicability; including display boxes, brackets and bottom plates, and the first transparent baffles are arranged at the four groups of first observation holes; , limit column, two sets of limit springs and two sets of limit blocks, a limit cavity is set in the insert column, and a plurality of left limit holes and a plurality of right limit holes are respectively arranged longitudinally on the left side wall and the right side wall of the intubation tube hole; also includes a support plate and a rotating column, the top of the support plate is provided with a placement groove, and a ball bearing is arranged in the placement groove; it also includes two sets of pillars and two sets of pulleys; it also includes four sets of business card boxes, and the second observation hole is provided with Second transparent baffle.

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

Sewage recovery and reuse apparatus

InactiveCN107185298AEasy to move verticallyFunction increaseTreatment involving filtrationMultistage water/sewage treatmentDrive shaftCooling chamber

The invention relates to the technical field of a sewage treatment attachment device and particularly relates to a sewage recovery and reuse apparatus. The height of a working box can be adjusted according to the actual situation so that adaptability is improved and use limitation is reduced. The working box has multiple functions and practicality is improved. When the sewage temperature is too high, the device can cool the sewage and improves reliability. The sewage recovery and reuse apparatus comprises the working box, four supports and multiple filters. A working chamber is arranged in the working box. Each one of the four supports comprises insert columns, insert pipes, limited posts, two limiting springs and two limiting blocks. The left and right side walls of the insert column are respectively provided with a left through hole and a right through hole. The left and right side walls of the insert pipe are respectively provided with multiple left limiting holes and multiple right limiting holes along a longitudinal direction. A motor is arranged below the working box. An output end at the top of the motor is provided with a transmission shaft. The transmission shaft is provided with stirring blades. The outer side wall of the transmission shaft is provided with a seal ring. The sewage recovery and reuse apparatus comprises a jacket. A cooling chamber is arranged in the jacket.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

Automobile charging pile with protective function

InactiveCN110027429AConvenient charging operationAvoid damageCharging stationsElectric vehicle charging technologyKey pressingElectrical equipment

The invention discloses an automobile charging pile with a protective function. The automobile charging pile comprises a charging pile body, wherein a pile door is movably connected to the front surface of the charging pile body through hinges, a concave groove is formed in the top of the front surface of the pile door, a placing groove is formed in the top of the front surface of the pile door and located in the right side of the concave groove, a display screen is fixedly connected to the rear side of the inner cavity of the concave groove, and a key is fixedly connected to the rear side ofthe inner cavity of the concave groove and located under the display screen. When the automobile charging pile is not charged, a movable box can be moved downwards, so that the display screen, the key, a magnetic card induction area, a plug and a charging cable are sealing-protected, damage cause by direct collision between the charging pile body and an external object is avoided, and the problemthat huge economic losses are caused due to the fact that the charging pile body is not provided with a protective structure, a large number of electrical components are installed in the inner cavityof the charging pile, once the charging pile is collided by an external object, the electrical components inside the charging pile are prone to being damaged is solved.

Owner:浙江国正安全技术有限公司

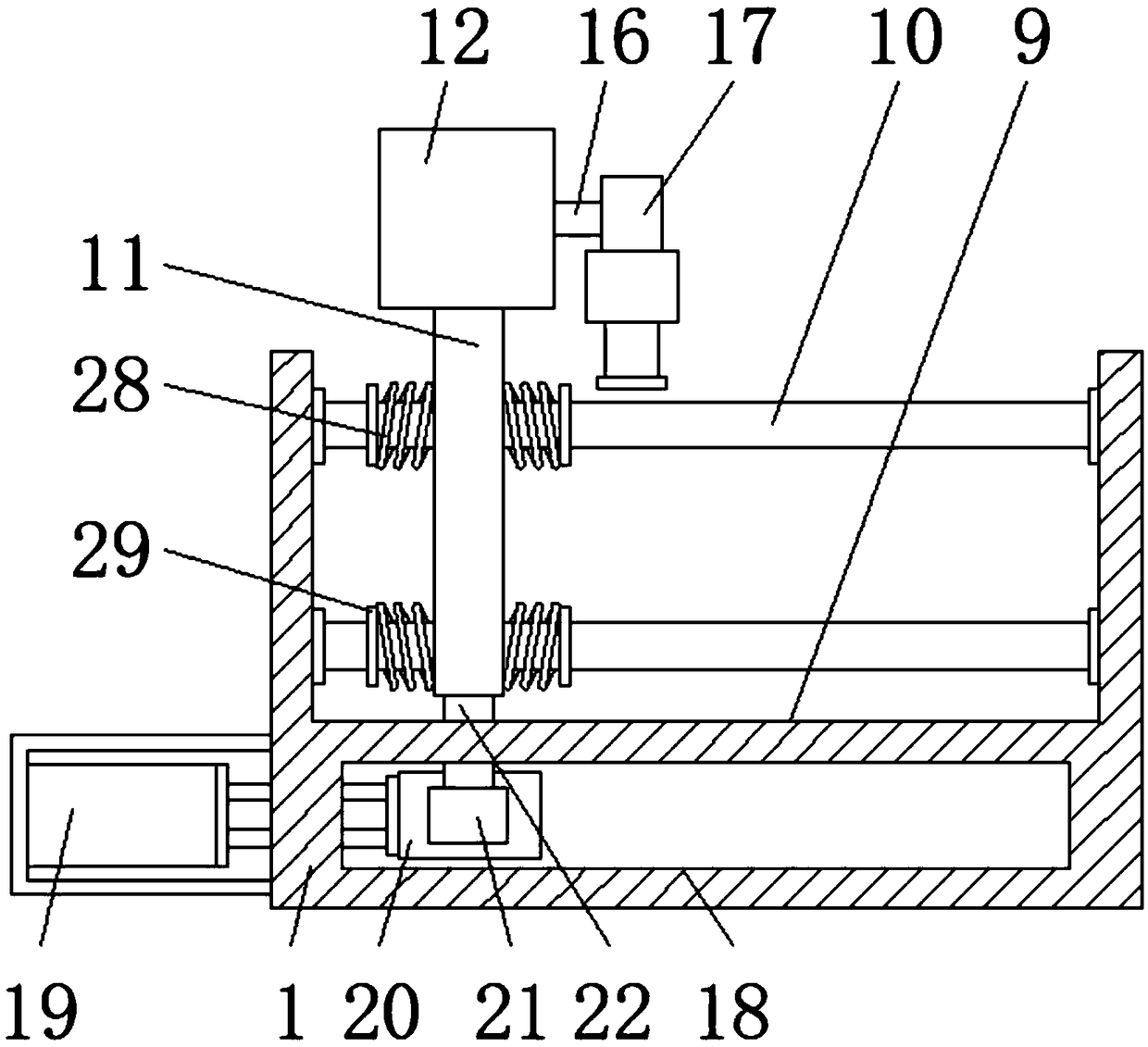

Plastic processing device

InactiveCN107877286AClose contactAdjust the preloadPlane surface grinding machinesSpring forceArchitectural engineering

The invention discloses a plastic processing device. The plastic processing device comprises a box. A clamp is arranged on the top of the box. First electric telescopic rods are fixedly connected to the two sides of the back face of the box. The tops of the first electric telescopic rods are fixedly connected with a transverse plate. A transverse groove is formed in the transverse plate. Long holes communicating with the transverse groove are formed in the top and the bottom of the transverse plate. An inner cavity of the transverse groove is in sliding connection with a sliding plate. The bottom of the transverse plate is fixedly connected with a first connecting plate. The top of the first connecting plate penetrates the long holes and extends out of the long holes. A second electric telescopic rod is fixedly connected to the right side of the top of the transverse plate. A spring is used for generating force to a vertical rod, the vertical rod generates a force to a grinding disc, the grinding disc is promoted to make close contact with a plastic plate, the pre-tightening force between the grinding disc and the plastic plate can be adjusted, the phenomenon of excessive grindingis avoided, and the grinding quality of finished products is improved.

Owner:叶青

Textile cloth cutting device

The invention discloses a textile cloth cutting device, which comprises a bottom plate, a box body is fixedly connected to the top of the bottom plate, a long hole is opened on the top of the box body, and a vertical hole is fixedly connected to the right side of the bottom of the box inner cavity. The left side of the vertical plate is fixedly connected with a motor, the rotating shaft of the motor is fixedly connected with a turntable, the bottom of the left side of the turntable is fixedly connected with a short rod, and the end of the short rod far away from the turntable is fixedly connected with a cutter The front end and the rear end of the top of the bottom plate are fixedly connected with electric extension rods, the electric extension rods are located on both sides of the box body, and the top of the electric extension rods is fixedly connected with a horizontal plate. The contraction of the electric extension rod of the present invention drives the cover plate and the pressing plate to move downward, which can clamp the cloth, make the cloth easier to cut, and can cut the cloth in an electric manner, with simple operation, high cutting quality, and improved work efficiency.

Owner:SUZHOU BONUQI TEXTILE CO LTD

Automatic air blowing and slag removal device for workpiece machining of numerically-controlled machine tool

InactiveCN107309706AEasy to move verticallyAdjustable blowing angleMaintainance and safety accessoriesNumerical controlSlag

The present invention relates to the technical field of waste slag cleaning attachments, in particular to an automatic air blowing and slag removal device for CNC machine tool workpiece processing, which can buffer the shaking generated when the fan is working, thereby improving its reliability; and connected to the hose output The height of the end can be adjusted according to the blowing needs to improve its adaptability; and the blowing angle of the output end of the connecting hose can be adjusted, thereby reducing its use limitations; it includes a fan, a bracket, a connecting hose, a placement frame and a bottom plate; it also includes Buffer sleeves, multiple sets of buffer springs and multiple sets of buffer plates, the buffer sleeves are provided with communication ports; the brackets all include inserts, intubations, limit posts, two sets of limit springs and two sets of limit blocks, and the inserts are set There are limited spacers, left through holes and right through holes are respectively arranged on the left side wall and right side wall of the inserting post, and multiple left spaced holes and multiple right spaced holes are respectively arranged longitudinally on the left side wall and right side wall of the intubation tube hole; the front side of the top of the bottom plate is provided with a spherical groove, and the bottom end of the intubation tube is provided with a universal ball.

Owner:JIANGSU HENGLI MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com