Steel box girder incremental launching construction method based on walking type three-dimensional hydraulic incremental launching equipment

A technology of jacking equipment and jacking construction, which is applied in the erection/assembly of bridges, bridges, and bridge construction, etc., can solve the problems of labor and time-consuming, no automatic digital control, and difficulty in controlling the accuracy of jacking and closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

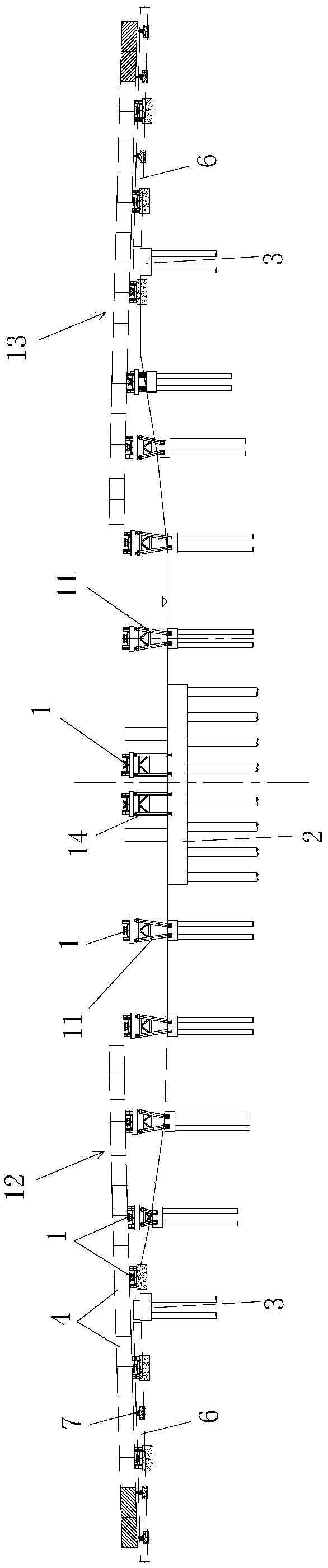

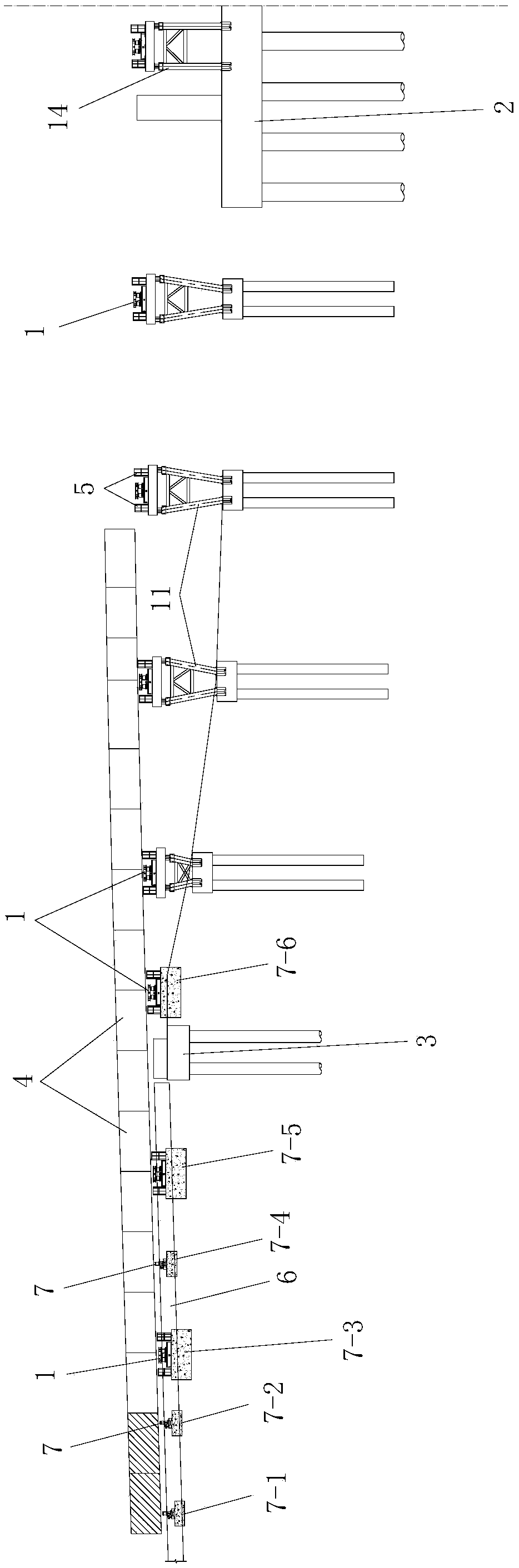

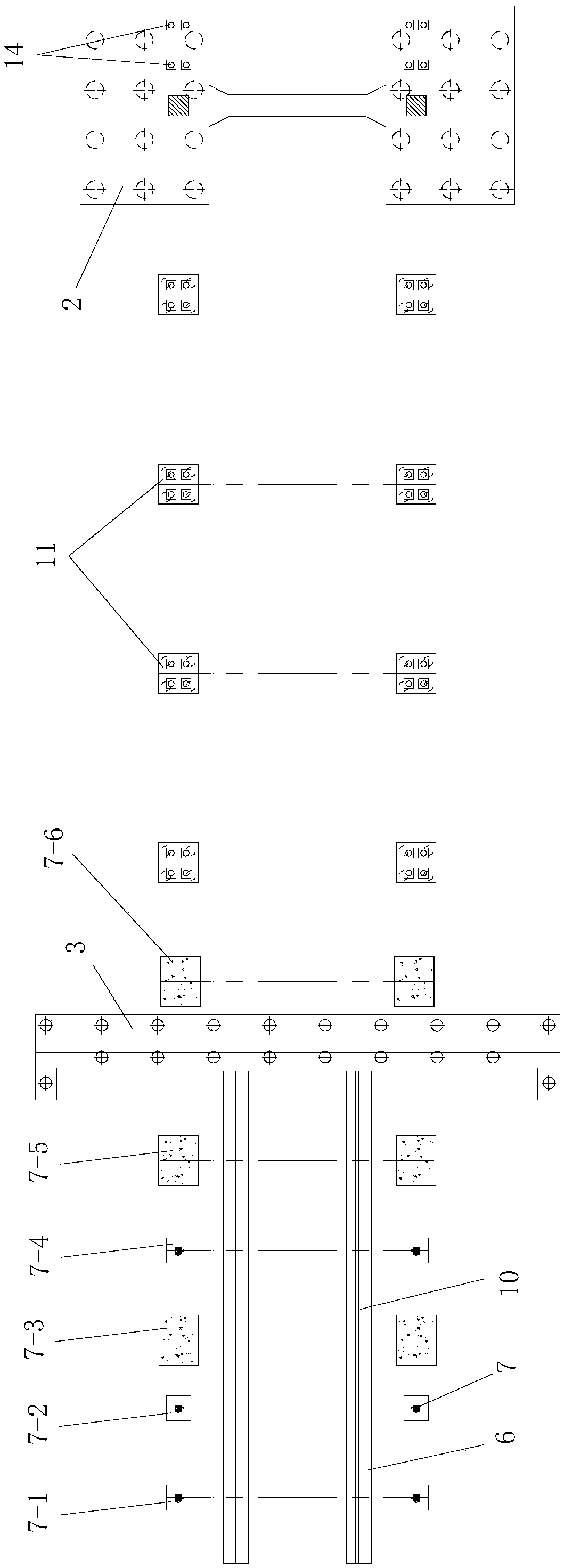

[0108] Such as Figure 19 Shown is a steel box girder jacking construction method based on walking-type three-dimensional hydraulic jacking equipment. There is a mid-span pier 2 between them, and the two beam end piers 3 are arranged symmetrically on both sides of the mid-span pier 2; the constructed steel box girder is divided into the first beam body with the mid-span pier 2 12 and the second beam body 13, the first beam body 12 and the second beam body 13 are arranged symmetrically and both have the same structure and size; the first beam body 12 and the second beam body 13 are made of A steel box girder formed by splicing a plurality of steel box girder segments 4 from front to back, the mid-span pier 2 and the beam end pier 3 are both vertically arranged permanent piers and both are reinforced concrete Support pier, the front ends of the first beam body 12 and the second beam body 13 are supported on the mid-span support pier 2 and the rear ends of the two are supported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com