Steel arch frame mounting trolley used for operation tunnel disease treatment and steel arch frame mechanical mounting method used for operation tunnel disease treatment

A tunnel disease and steel arch technology is applied in the field of operating a steel arch installation trolley for tunnel disease remediation. Problems such as poor application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

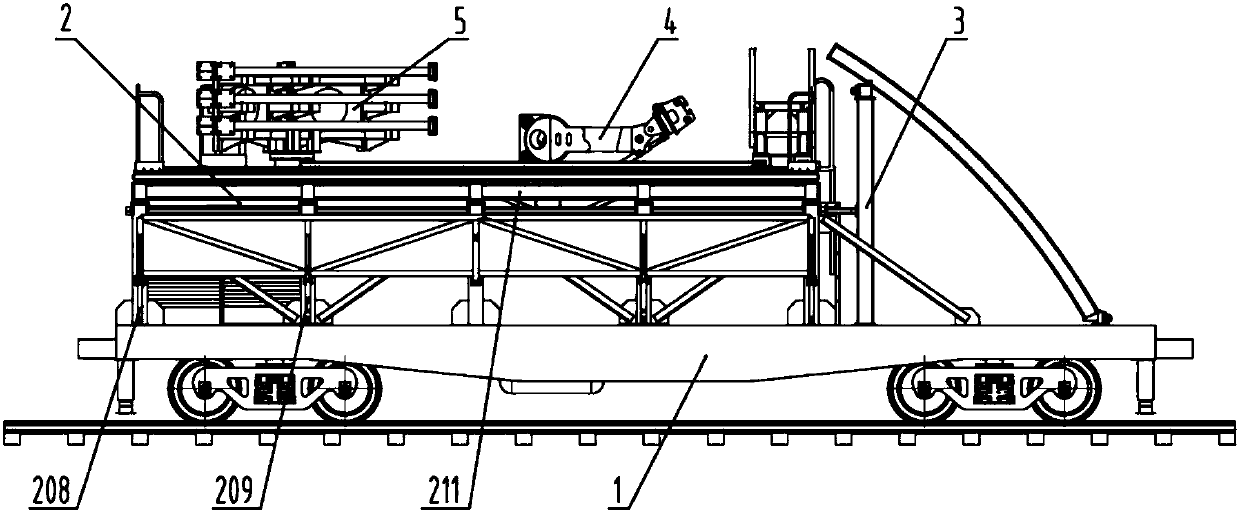

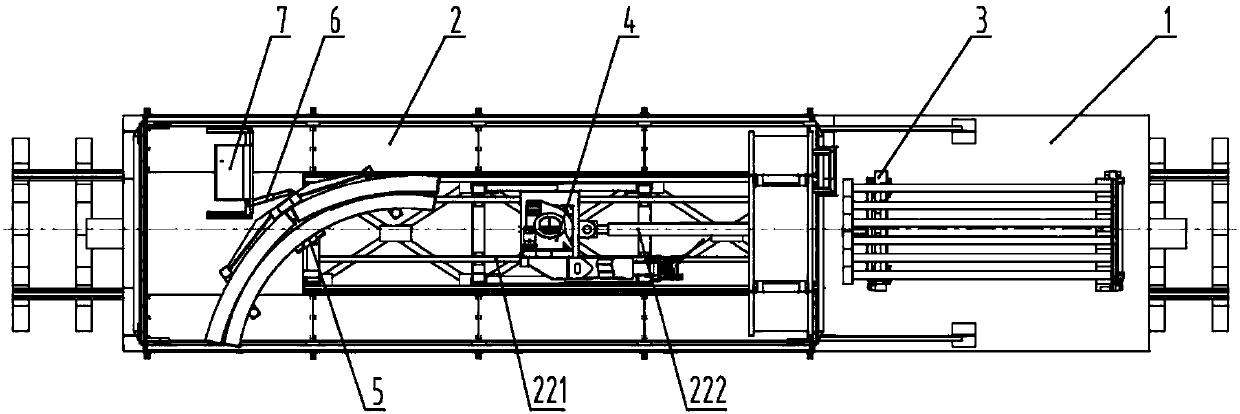

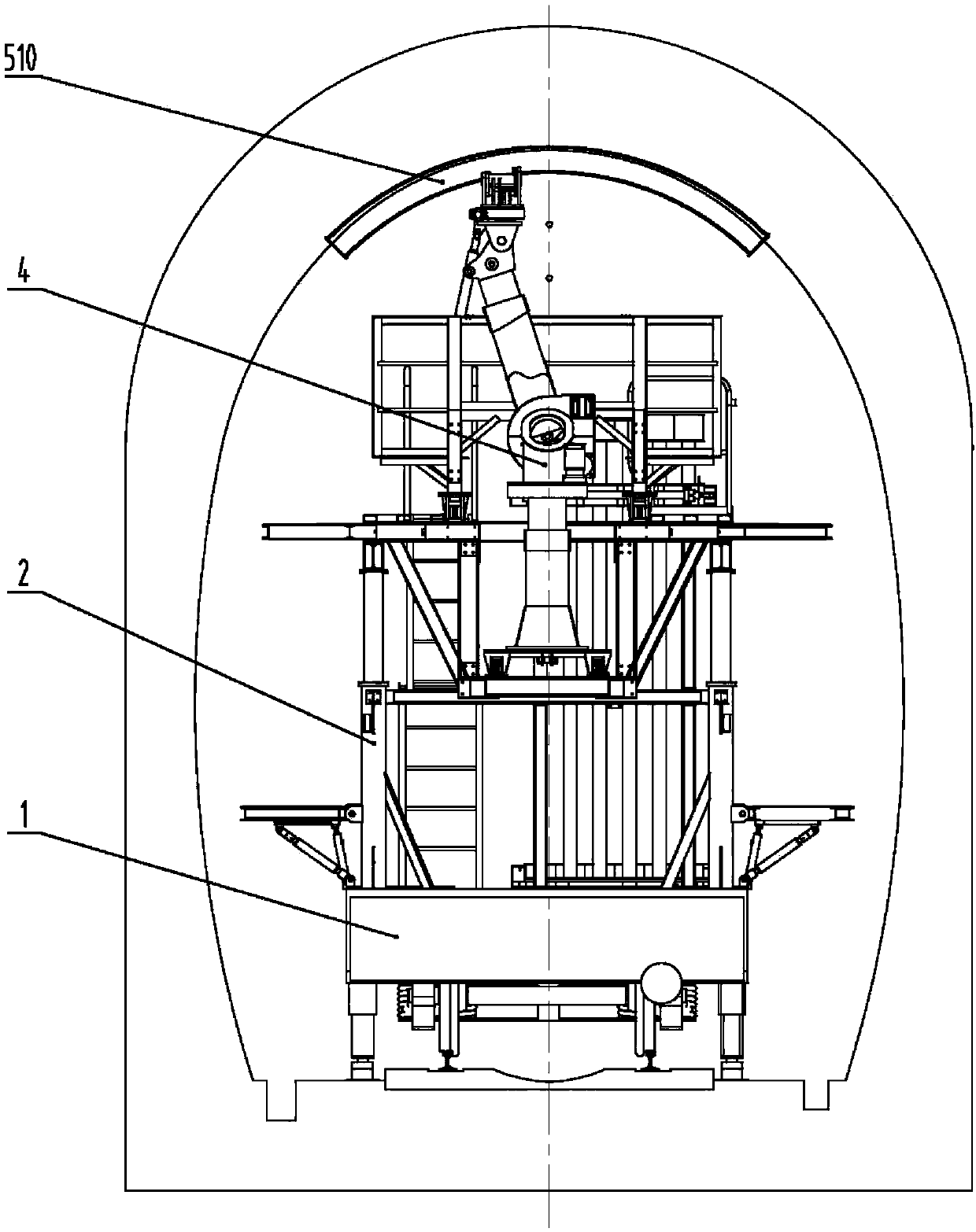

[0069] Such as Figure 1-13 As shown in Fig. 1, a steel arch installation trolley for repairing tunnel defects in operation includes a steel arch installation and operating mechanism, an electrical control part, and a hydraulic control part. The electrical control part and the hydraulic control part are conventional technologies, so they are not shown in the figure. out. The installation and operation mechanism of the steel arch includes a railway flat car 1, a lifting trolley 2, a side wall steel arch feeding mechanism 3, a steel arch installation machine 4, a vault and an arch waist steel arch feeding mechanism 5, The first hydraulic cylinder 6, the console 7; wherein:

[0070] Lifting trolley 2 comprises fixed platform and lifting platform, and fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com